Semiconductor Corporation

PCM Jitter Attenuator

CS61600

Features

Unique Clock-Tracking Circuitry Filters

••

50 Hz or Higher Frequency Jitter for

T1 and PCM-30 Applications

Minimal External Components Required

••

14 Pin DIP

••

Single 5 Volt Supply

••

3 Micron CMOS for High Reliability

••

and Low Power Dissipation: 50 mW

Typical at 25 °C

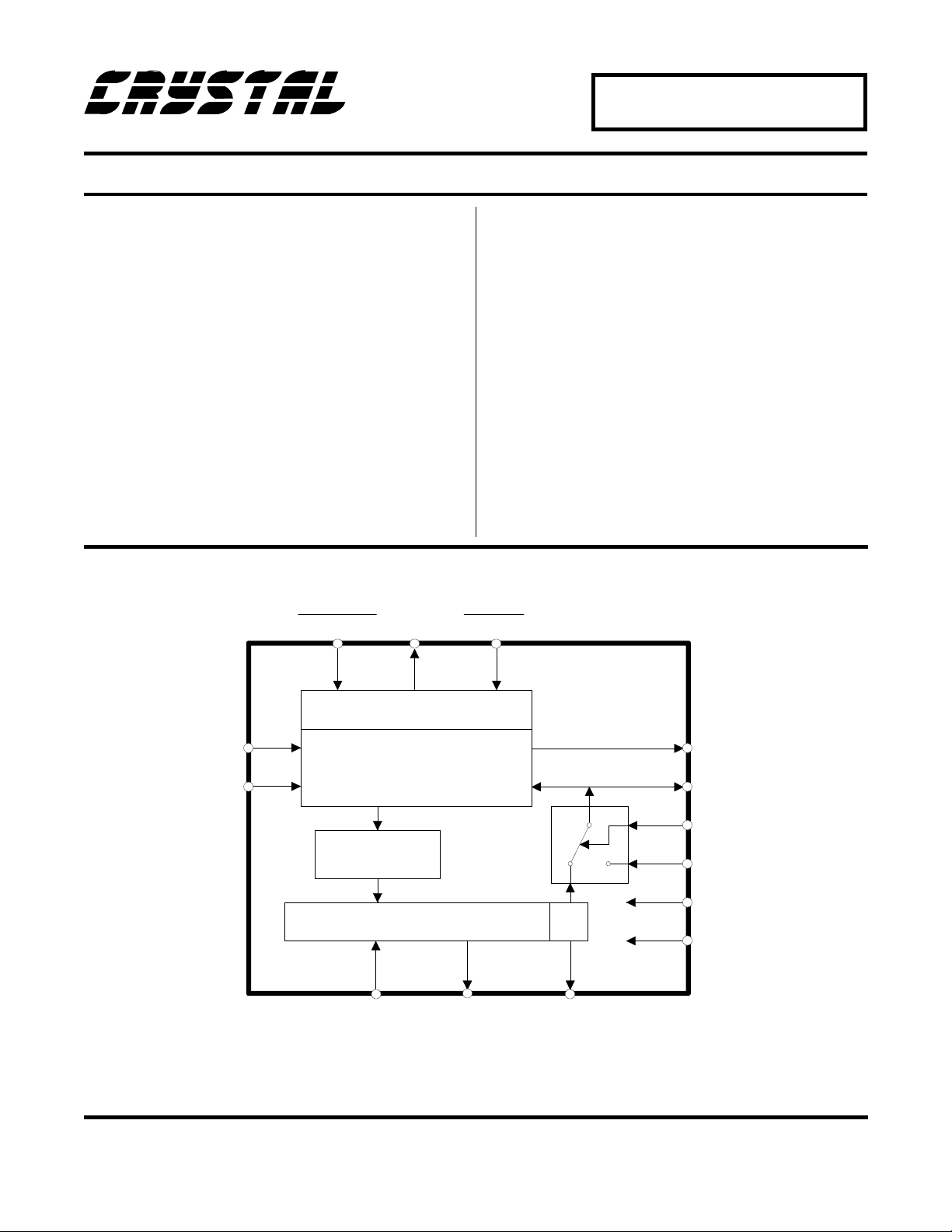

FIFORST OVR RESET

General Description

The CS61600 from Crystal Semiconductor accepts T1

(1.544 Mb/s) or CCITT standard (2.048 Mb/s) data and

clock inputs, and tolerates at least 7 (and up to 14) unit

intervals, peak-to-peak, of jitter. Before outputting data

and clock, jitter is attenuated using an internal clocktracking variable oscillator and a 16 bit FIFO elastic

store.

The jitter attenuation function can be determined by

appropriate specification of the external crystal.

The CS61600 is transparent to data format, and is intended for application in carrier systems, switching

systems, Local Area Network gateways and multiplexers.

ORDERING INFORMATION

CS61600-IP1 - 14 Pin Plastic DIP; T1 and 2.048 MHz

DIN

CLKIN

13

231

FIFO CONTROL

8

VARIABLE OSCILLATOR

16-BIT FIFO

HALF FULL

DETECT

4

XTALIN

5

XTALOUT

÷

4

11

OSCOUT

9

DOUT

10

CLKOUT

6

ARE

12

ARC

14

V+

7

GND

Crystal Semiconductor Corporation

P.O. Box 17847, Austin, TX 78760

(512) 445-7222 FAX: (512) 445-7581

Copyright Crystal Semicondutor Corporation 1994

(All Rights Reserved)

APR ’90

DS9F3

1

CS61600

ABSOLUTE MAXIMUM RATINGS

Parameter Symbol Min Max Units

DC Supply (V+)-GND -0.3 7.0 V

Input Voltage V

Input Current, Any Pin (Note 1) I

Ambient Operating Temperature T

Storage Temperature T

in

in

A

stg

Note: 1. Transient currents of up to 100 mA will not cause SCR latch-up.

WARNING: Operation at or beyond these limits may result in permanent damage to the device.

Normal operation is not guaranteed at these extremes.

GND - 0.3 (V+) + 0.3 V

-10 10 mA

-40 85 °C

-65 150 °C

RECOMMENDED OPERATING CONDITIONS

Parameter Symbol Min Typ Max Units

DC Supply (V+)-GND 4.5 5.0 5.5 V

Ambient Operating Temperature T

DIGITAL CHARACTERISTICS (T

= -40° to 85° C; V+ = 5V ±10%; GND = 0V)

A

Parameter Symbol Min Typ Max Units

High-Level Input Voltage V

Low-Level Input Voltage V

High-Level Output Voltage (Notes 2 and 3) V

Low-Level Output Voltage (Notes 2 and 4) V

Input Leakage Current I

Notes: 2. Outputs will drive CMOS logic levels into a CMOS load.

3. I

= -40 µA

out

= 1.6 mA

4. I

out

A

IH

IL

OH

OL

in

-402585°C

2.0 - - V

--0.8V

2.4 - - V

--0.4V

--

±10.0 µA

Specifications subject to change without notice.

2 DS9F3

CS61600

DIGITAL CHARACTERISTICS (T

= -40° to 85° C; V+ = 5V ±10%; GND = 0V)

A

Parameter Symbol Min Typ Max Units

Power Dissipation P

D

-5085mW

Input Jitter Tolerance 7 - 14* U.I.

* Depends on accuracy of cr ystal with respect to CLK IN frequency. See

SWITCHING CHARACTERISTICS (T

= -40° to 85° C; V+ = 5V ±10%; GND = 0V;

A

Applications

section.

Inputs: Logic 0 = 0V, Logic 1 = V+)

Parameter Symbol Min Typ Max Units

Crystal Frequency T1

CCITT (Note 5)

CLKIN Frequency T1

CCITT (Note 6)

CLKOUT Frequency T1

CCITT (Note 6)

Clock Pulse Width T1

CCITT

(Note 7)

Acceptable CLKIN range (Note 8) -

f

t

pwh

t

t

pwh

t

f

c

f

in

out

pwl

pwl

-

-

-

-

-

-

-

-

-

-

6.176000

8.192000

1.544

2.048

1.544

2.048

324

324

244

244

±130

-

MHz

-

-

MHz

-

-

MHz

-

-

ns

-

-

ns

-

- ppm

Duty Cycle (Note 9) - 50 - %

Rise Time, All Digital Outputs (Note 10) t

Fall Time, All Digital Outputs (Note 10) t

DIN to CLKIN Falling Setup Time t

CLKIN Falling to DIN Hold Time t

CLKOUT Falling to DOUT Propogation Delay t

r

f

su

h

phl

- 36 100 ns

- 17 100 ns

30 - - ns

50 - - ns

- - 200 ns

Note: 5. Crystal should have sufficient pull range when in the oscillator circuit, to meet the system’s frequency

tolerance requirement over the operating temperature range. See

Applications

section for more

information on crystals.

6. Although CLKIN and CLKOUT will vary in instantaneous frequency (jitter) over time, CLKOUT

will have the same average frequency as CLK IN.

7. The sum of the pulse widths must always meet the frequency specifications.

8. Crystal must have at least ±130ppm pull range over operating temperature range.

9. Duty cycle is (t

10. At C

= 50pF.

L

PWH

/ (t

PWH

+ t

)) x 100%.

PWL

DS9F3 3

CS61600

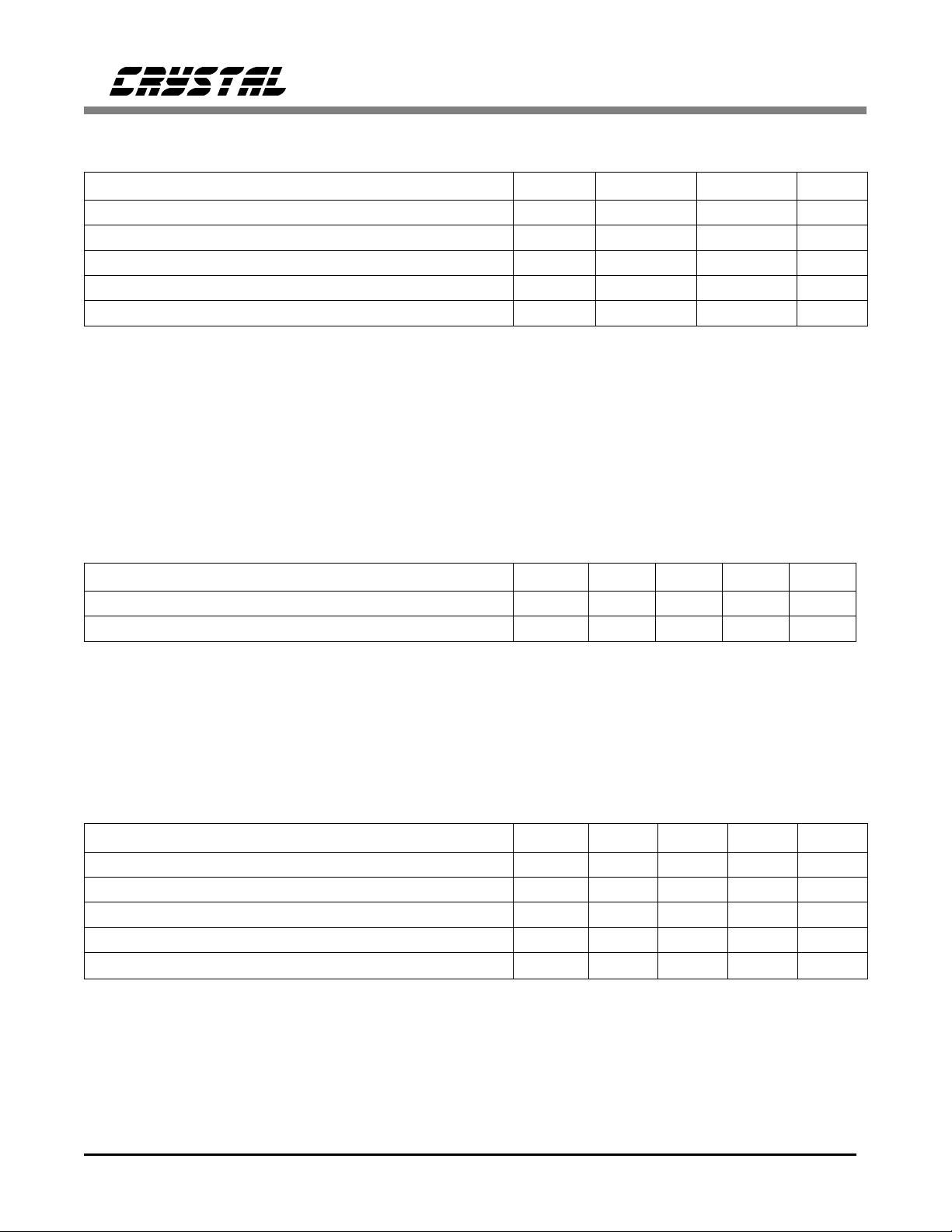

Any Digital Output

Figure 1. Signal Rise and Fall Characteristics

CLKIN, CLKOUT

t

r

90% 90%

10% 10%

t

pwh

Figure 2. Clock Signal Quality

t

pwl

t

f

CLKIN

t

su

t

h

DIN

Figure 3. Switching Characteristics

4 DS9F3

CLKOUT

DOUT

t

phl

PEAK-TO-PEAK

(SINUSOIDAL)

JITTER

AMPLITUDE

IN UNIT

INTERVALS

10.0

7.0

5.0

1.5

1.0

0.2

0.1

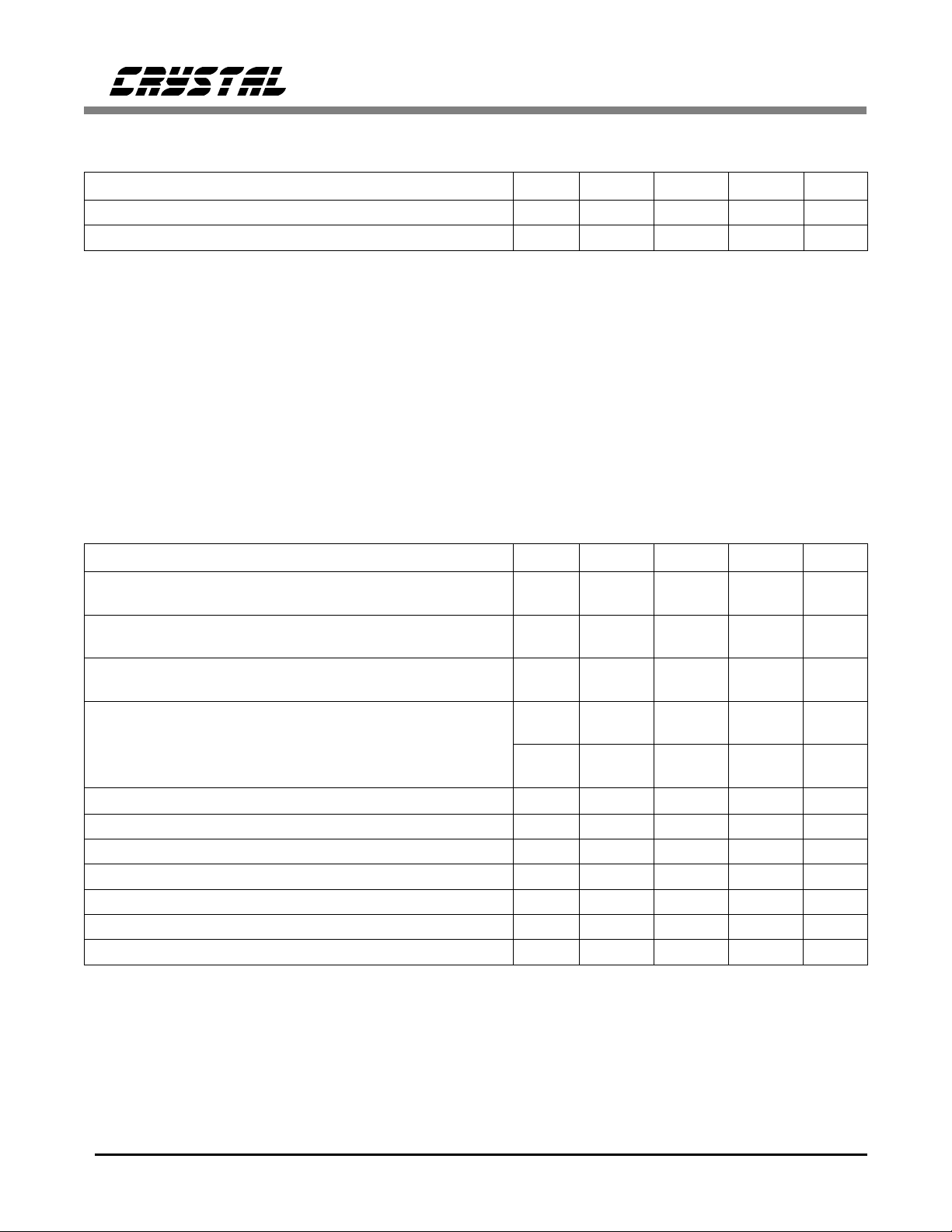

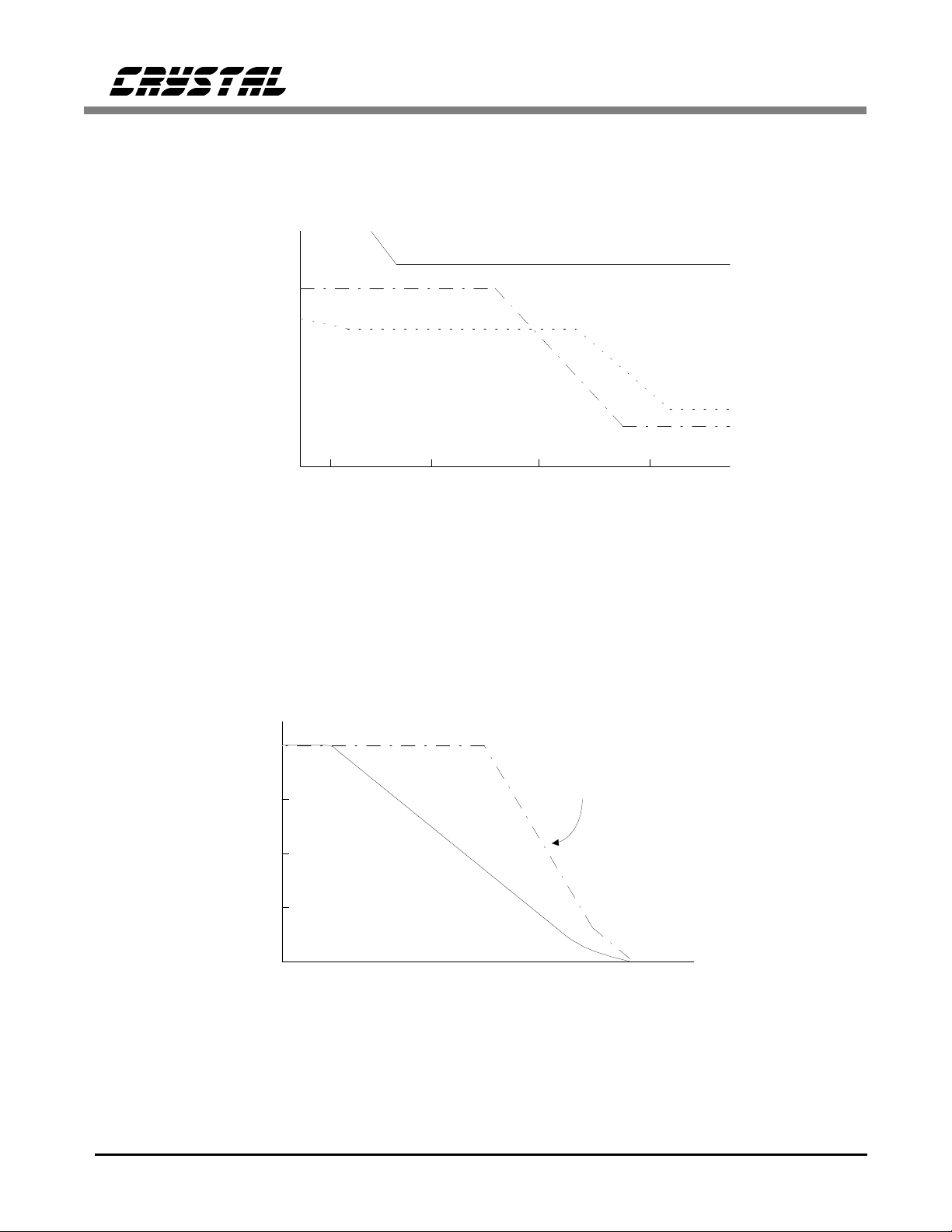

CS61600 PERFORMANCE

AT&T

43802

SPECIFICATION

CS61600

CCITT

G.823

SPECIFICATION

-10

-20

-30

0

10.0

JITTER

GAIN

(dB)

500 8.0k

100.0 1.0k 10.0k

JITTER FREQUENCY (Hz)

Figure 4. Input Jitter Tolerance

BELL SYSTEM

PUB 43802

20 dB/

decade

CS61600

PERFORMANCE

SPECIFICATION

18k2.4k20

Input of five

unit intervals

of jitter at all

frequencies.

-40

10 100 1k 10k

JITTER FREQUENCY

(Hz)

Figure 5. Jitter Attenuat ion Char acteristic

DS9F3 5

CS61600

CIRCUIT DESCRIPTION

Jitter Attenuation

The CS61600 will tolerate and attenuate at least

seven unit intervals of jitter from clock and data

signals of 1.544 MHz and 2.048 MHz. An

external clock divide circuit can be added for

jitter attenuation for lower frequency signals.

Jitter attenuation is accomplished by means of a

FIFO and a variable oscillator. The frequency of

the oscillator is controlled by logic in the

CS61600 to be the same as the average of the

input clock signal, CLKIN. Signal jitter is absorbed in the FIFO.

The FIFO’s write pointer is controlled by the

CLKIN signal. Data present on DIN is written

into the memory location selected by the write

pointer. The CLKOUT signal corresponds to the

FIFO’s read pointer and is controlled by the

crystal oscillator. Internal logic determines the

relationship of the read pointer and the write

pointer, and adjusts the speed of the oscillator.

For example, if the CLKIN signal is at a higher

frequency than the CLKOUT signal, the write

pointer will start to catch up with the read

pointer. When this situation is detected, the capacitive loading the device presents to the crystal

is reduced, resulting in an increase in oscillator

frequency and read pointer (CLKOUT) frequency. The oscillator frequency is periodically

updated and adjusted to maintain the FIFO at

half full. High frequency variations in the phase

of the CLKIN signal (jitter) are absorbed in the

FIFO.

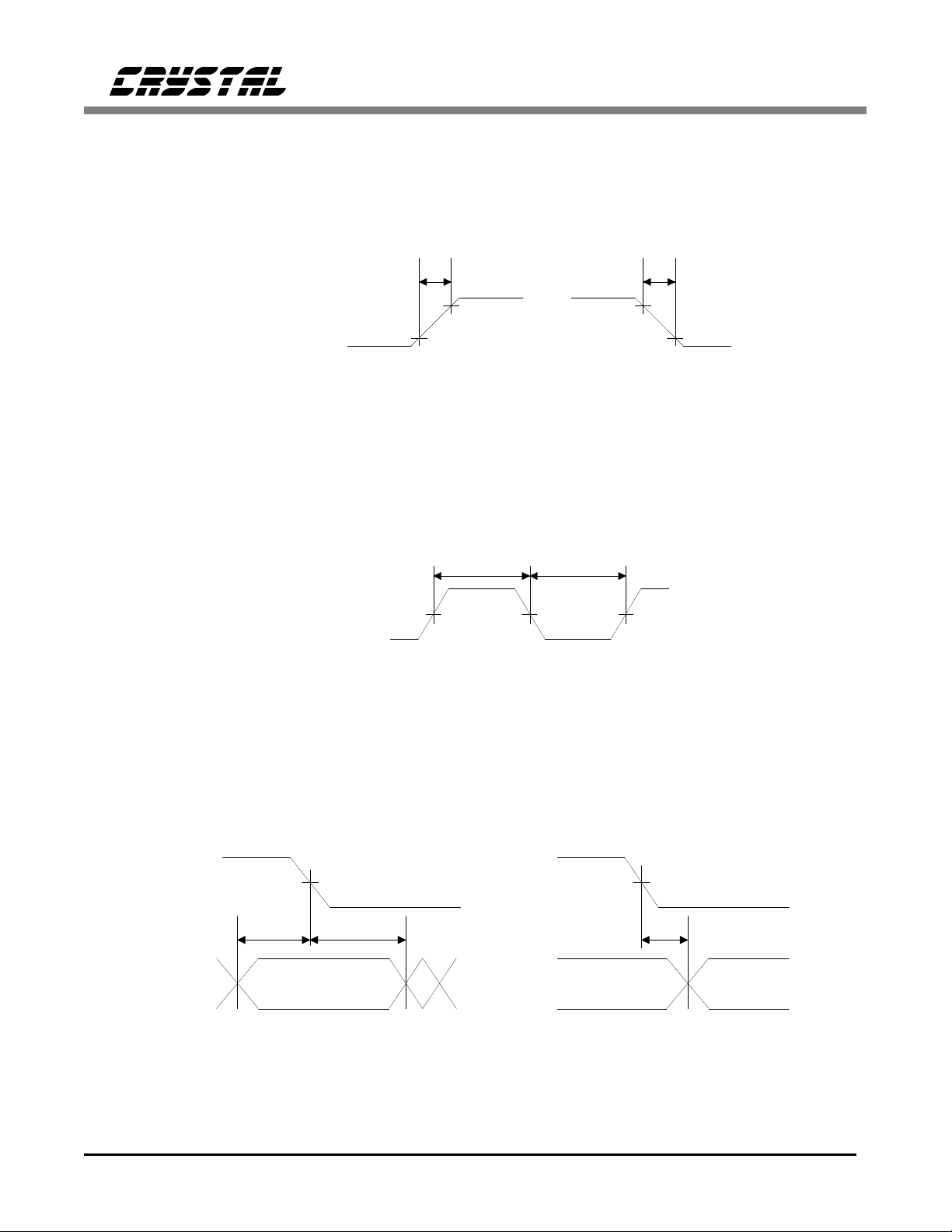

There are some advantages to this method of

jitter attenuation. The device can tolerate large

amplitude jitter at high frequencies. The device

can track slow changes of the input clock frequency (wander) and tolerate input frequencies

ranging over a specified frequency tolerance.

A by product of this method of jitter attenuation

is that the greater the input jitter, the greater the

jitter attenuation, and the lower the frequency at

which the device starts to attenuate jitter.

Conversely, low amplitude jitter receives little

attenuation. This performance characteristic is

shown graphically in Figure 6.

JITTER

GAIN

(dB)

0

UNIT INTERVALS

-10

5

-20

-30

Measurement made at 1.544 MHz

with 6.176 MHz ± 200 pp m cry s tal.

-40

dB

10 100 1k 10k

Figure 6. Jitter Attenuat ion Char acteristics

OF INPUT JITTER

...

3

1

(Hz)

Using the CS61600 in a Slave Configuration

It is possible to use an externally generated clock

signal to clock data out of the CS61600. When

an external clock is used, a crystal is not necessary. The external clock is input to the Alternate

Read Clock input, ARC (pin 12). Holding the

Alternate Read Enable pin, ARE (pin 6), high directs the CS61600 to clock data out of the FIFO

at the rate determined by ARC. Unless the clock

signal on ARC is at exactly the same average

frequency as the clock signal on CLKIN, the

CS61600 will be prone to underflow or overflow,

and data will be lost. See the Applications section of this data sheet for more information on

the use of an alternate clock.

Oscillator and Crystal

The CS61600 requires an external 6.176000

MHz (8.192000 MHz for CCITT) crystal be

connected to pins XTALOUT and XTALIN. The

oscillator circuit divides the crystal frequency by

four, and switches various capacitive loads to

provide a clock that swings in five steps from at

least 1.544 MHz - 130 ppm to at least

1.544 MHz + 130 ppm (2.048 MHz - 50 ppm to

6 DS9F3

CS61600

2.048 MHz + 50 ppm for CCITT). The crystal

oscillator must be able to reach these signal frequency tolerances over the system’s operating

temperature range. The oscillator adjusts to and

holds the average frequency of the signal input

to CLKIN.

Some applications specify a narrower frequency

tolerance. In these cases, it is possible to improve jitter attenuation performance by specifying a crystal with less pull range. A narrow pull

range crystal has the effect of shifting the curves

shown in Figure 6 to the left. Care must be taken

to ensure that the crystal/oscillator wi ll reach the

signal’s frequency extremes over the operating

temperature range of the system. More information on specifying and testing crystals is provided in the Applications section at the back of

this data sheet.

FIFO Overflow/Underflow

eighth locations respectively. The oscillator will

continue to run and CLKOUT will be held low.

Power-Up Reset

Upon power up, the CS61600 goes through an

initialization procedure which requires

approximately 3 ms. During this initialization

procedure, OVR is held high. After initialization

is complete, OVR goes low. When the clock

signal is input to CLKIN, the CS61600 will

immediately try to lock onto the clock signal on

CLKIN. At this point, the FIFO may overflow,

and the RESET pin should be toggled to clear

the overflow/underflow flag, OVR.

Schematic & Layout Review Service

Because the oscillator clock, which is used to

empty the FIFO, has a wider frequency range

than the standard T1 input signal, the FIFO

should never underflow or overflow. However, if

underflow or overflow occurs, the buffer

overflow/underflow flag, OVR (pin 3), goes

high. A RESET (pin 1) resets the overflow flag.

If an overflow occurs, the 16 bits of data in the

FIFO are lost. An underflow condition causes the

next 16 bits read from the FIFO to be invalid. In

either case, the CS61600 will immediately

attempt to relock on to the clock signal. Holding

RESET low disables the overflow flag, OVR.

FIFO Reset

Taking the FIFORST pin low causes most of the

subcircuits of the CS61600 to go into a reset

state. These circuits will remain in a reset

condition until FIFORST is returned to a logic 1

state. However, the outputs of the CS61600 are

undefined if FIFORST is held low for more

than 500 ms. The FIFO reset function will set

the FIFO write and read poi nters to the first and

Confirm Optimum

Schematic & Layout

Before Building Your Board.

For Our Free Review Service

Call Applications Engineering.

Call:(512) 445-7222

DS9F3 7

PIN DESCRIPTIONS

CS61600

RESET

FIFO RESET

BUFFER OVERFLOW/UNDERFLOW

CRYSTAL OUTPUT

CRYSTAL INPUT

ALTERNATE READ ENABLE

GROUND

RESET V+

FIFORST DIN

OVR ARC

XTALIN OSCOUT

XTALOUT CLKOUT

ARE DOUT

GND CLKIN

14

1

13

2

12

3

11

4

10

5

9

6

8

7

Power Supplies

V+ - Positive Power Supply, PIN 14.

Typically +5V volts.

GND - Ground, PIN 7.

Ground reference.

Oscillator

XTALIN, XTALOUT - Crystal Input 1, 2; PINS 4, 5.

6.176 MHz or 8.192 MHz crystal inputs. A 200 kohm resistor should be connected across these

pins. There is no need for external capacitors. The crystal should be connected to XTALIN and

XTALOUT with minimal length traces on the pc board.

POWER SUPPLY

DATA INPUT

ALTERNATE READ CLOCK

OSCILLATOR OUTPUT

OUTPUT CLOCK

DATA OUTPUT

INPUT CLOCK

Control

RESET - Reset, PIN 1.

When RESET is taken low, the OVR signal is reset.

FIFORST - FIFO Reset, PIN 2.

Taking FIFORST low resets the read and write pointers of the FIFO. Resetting the pointers will

cause some data loss. When FIFORST is low, the OSCOUT output is disabled.

ARE - Alternate Read Enable, PIN 6.

For normal operation, ARE is held at logic 0. In this configuration the oscillator controls the

read pointer of the FIFO. When ARE is at logic 1, the read pointer of the FIFO will be

controlled by the clock signal on pin 12, ARC.

8 DS9F3

Inputs

CLKIN - Clock Input, PIN 8.

Clock for the data input. This clock contains the jitter to be removed.

DIN - Data Input, PIN 13.

Input data is sampled on the falling edge of CLKIN.

ARC - Alternate Read Clock, PIN 12.

When ARE, Pin 6, is at logic 1, a clock signal on ARC will control the FIFO’s read pointer.

CLKOUT, pin 10, will be at the same frequency and phase as ARC. Setting ARE to logic 0

results in the device using its oscillator to generate CLKOUT.

Outputs

OVR - Buffer Overflow/Underflow, PIN 3.

Goes high if the FIFO overflows or underflows, and is cleared by RESET.

DOUT - Data Output, PIN 9.

Output data with jitter attenuated. DOUT is stable and valid on the rising edge of CLKOUT.

CS61600

CLKOUT - Output Clock, PIN 10.

Jitter reduced clock output corresponding to the data on DOUT.

OSCOUT - Oscillator Output, Pin 11.

Output of on-chip oscillator, divided by four. This pin should be left floating for normal

operation.

DS9F3 9

CS61600

RESET

V+

200k6.176 MHz

V+

10k

OVR

ARE

GND

1

2

3

4

5

6

7

RESET

10k

FIFORST

XTALIN

XTALOUT

Figure A1. Typical Application Circuit

APPLICATIONS

Selecting an Oscillator Crystal

Specific crystal parameters are required for

proper operation of the CS61600. It is recommended that the Crystal Semiconductor

CXT6176 crystal be used for T1 applications

and the CXT8192 crystal be used for PCM-30

applications.

General Applications

The CS61600 will tolerate and attenuate at least

seven unit intervals of jitter over the specified

range of input clock and oscillator frequencies. If

the oscillator crystal is chosen so that the center

frequency of its pull range is close to the input

frequency, CLKIN, the CS61600 will tolerate

more jitter; up to 14 unit intervals will be tolerated under optimal conditions.

Consider the case where the average clock

frequency at CLKIN approaches the slow end of

the range, 1.544 MHz - 130 ppm. In this case,

the oscillator will be near the bottom of its

pull range, restricting its ability to achieve

frequencies well below the CLKIN frequency.

The result is that the read pointer of the FIFO

will begin to catch up to the write pointer. If

enough jitter is introduced, the read pointer will

overtake the write pointer resulting in an error

(i.e. the device will try to read out data before it

is written in). A similar situation occurs when

+5V

14

V+

13

12

11

10

9

8

DIN

ARC

OSCOUT

CLKOUT

DOUT

CLKIN

JITTERED DATA INPUT

JITTER FREE CLOCK

JITTER FREE DATA

JITTERED CLOCK INPUT

the CLKIN signal approaches the fast end of its

range, 1.544 MHz + 130 ppm.

Taking care in selecting the proper crystal can

result in improved jitter tolerance without degrading the performance of the CS61600. If the

center frequency of the oscillator is precisely

four times the CLKIN frequency, and the crystal

has at least the specified pull range, the CS61600

will tolerate 14 unit intervals of jitter. In this

case, the read and write pointers of the FIFO

will maintain optimal separation w hen the

signal is jitter free, allowing the device to tolerate maximum jitter input.

Master/Slave Configuration

Some T1 applications require separate representations of the positive and negative going

pulses for an AMI signal. Two CS61600s can be

used to remove jitter from a set of signals consisting of POS, NEG and CLK. Figure A2 shows

the master/slave configuration.

This configuration requires one crystal (on the

master). The CLKOUT signal from the master

controls the FIFO read pointer of the slave

CS61600. Setting ARE, pin 6, of the slave to

logic 1 directs the device to use the clock input

to ARC, pin 12, to control the FIFO read pointer.

For this configuration to function properly, the

positions of the FIFO read and write pointers in

both devices must correspond. The FIFO pointer

reset, FIFORST, of both devices must be tied to-

10 DS9F3

OVR

RESET

CLKIN

10k

200k

POINTER

V+

OVR

FIFO

RESET

1

2

3

4

5

6

7

V+

R

Q

V+

10k

CS61600

MASTER

CLKIN

14

13

12

11

10

9

8

V+

NC

D

S

DIN

DOUT

Q

1

CLKOUT

1

10k

10k

V+

ARE

V+

OVR

NC

NC

OVR

RESET

1

2

3

4

5

6

7

CS61600

Figure A2. Master / Slave configuration

SLAVE

14

13

12

11

10

CS61600

V+

DIN

2

ARC

DOUT

multiple

slaves

may be

added

2

NC

NC

9

8

gether. After the power supplies have stabilized,

and the clock has been input at CLKIN, FIFORST should be momentarily pulled low to reset the pointers of both devices. The overflow

flags should then be reset by momentarily pulling RESET, pin 1, low.

Additional slaves may be added. The ARC input

may be derived from either the CLKOUT pin on

the master, or the CLKOUT pin on a preceding

slave. When using the master’s CLKOUT pin,

the fan out must be considered. Attaching several

inputs to the CLKOUT pin increases the load

that the output must drive. The added capacitance will reduce the switching speed of the output driver. Similarly, a configuration which uses

the CLKOUT signal of each CS61600 to drive

the subsequent CS61600 will induce some

propagation delay. These potential timing problems should be considered when cascading

CS61600s.

Maintaining Clock

Many applications require that the clock signal

from CLKOUT be maintained within some

specified range of frequencies when the clock

signal on CLKIN (often generated from a recovered T1 signal clock) goes away. Figure A3

shows one method for maintaining the CLKOUT

signal. The reference clock is a locally generated

clock whose frequency lies within the tolerance

of the applicable specifications which govern the

system’s design. When the CLKIN signal goes

away, the multiplexor should switch in the reference clock. Since this clock goes through the jitter attenuator, phase and frequency integrity at

CLKOUT is maintained.

Jitter Attenuation at Different Clock Rates

The CS61600 can be used to attenuate jitter at

frequencies below 2.048 MHz. For signal frequencies above about 900 kHz, selection of the

appropriate crystal will suffice. For jitter attenu-

LOCALLY

GENERATED

REFERENCE

CLOCK

RECOVERED

1.544 MHz

1.544 MHz

MULTIPLEXER

CLOCK

LOSS OF

CLOCK

DETECTOR

Figure A3. Maintaining Clock Integrity

CLKIN

pin 8

CLKOUT

CS61600

pin 10

DS9F3 11

CS61600

ation of lower frequency signals, an external divider is required. Figure A4 shows how the

CS61600 can be configured for low frequency

jitter attenuation.

Frequency tolerance of the input signal is still

based on the pull range of the crystal in ppm.

For example, a 64 kbps jitter attenuator which

uses an external divide by 32, and a 8.192 MHz

crystal with ± 2 00 ppm pull range will have

+ 200 ppm tolerance at 64 kbps or + 12.8 Hz.

V+

RESET

FIFORST

4.5 MHz to 8.2 MHz

V+

10k

10k

200k

10k

ARE

1

2

3

4

5

6

CS61600

7

14

13

12

11

10

9

8

+5V

DIN

ARC

OSCOUT

CLKOUT

DOUT

CLKIN

1

DIVIDER

1

Figure A4. Low Clock Frequency Jitter Attenuation

12 DS9F3

14 PIN PLASTIC (PDIP) PACKAGE DRAWING

D

1

TOP VIEW

E1

SEATING

PLANE

b1

e

BOTTOM VIEW

A

A2

A1

b

L

INCHES MILLIMETERS

DIM MIN MAX MIN MAX

A 0.000 0.210 0.00 5.33

A1 0.015 0.025 0.38 0.64

A2 0.115 0.195 2.92 4.95

b 0.014 0.022 0.36 0.56

b1 0.045 0.070 1.14 1.78

c 0.008 0.014 0.20 0.36

D 0.735 0.775 18.67 19.69

E 0.300 0.325 7.62 8.26

E1 0.240 0.280 6.10 7.11

e 0.090 0.110 2.29 2.79

eA 0.280 0.320 7.11 8.13

eB 0.300 0.430 7.62 10.92

eC 0.000 0.060 0.00 1.52

L 0.115 0.150 2.92 3.81

∝

0° 15° 0° 15°

eB

E

∝

eA

SIDE VIEW

eC

c

8/24/99 : CIRRUS LOGIC --- CRYSTAL SEMICONDUCTOR : 14 PIN PLASTIC (PDIP) PACKAGE DRAWING

Contacting Cirrus Logic Support

For a complete listing of Direct Sales, Distributor, and Sales Representative contacts, visit the Cirrus Logic web site at:

http://www.cirrus.com/corporate/contacts/

Preliminary product info rmation describes products which are i n production, but for whi ch ful l characterization data is not yet available. Advance produ ct i nf or mation describes products which are in development and subject to development changes. Cirrus Logic, Inc. has made best efforts to ensure that the information

contained in this document is accurate and reli able. However , the i nformati on is sub ject to change with out no tice and i s provi ded “AS IS” withou t warranty of

any kind (express or implied). No responsibility is assumed by Cirrus Logic, Inc. for the use of this information, nor for infringements of patents or other rights

of third parties. This document i s the propert y of Cirru s Logic, Inc. and implie s no licen se under patent s, copyri ghts, trademarks, or tr ade secrets. No part of

this publication may be copied, reproduced , stored in a retrieval system, or transmitted, in any form or by any means (electronic, mechanical, photographic, or

otherwise) without the pri or wri tt en consen t of Ci rrus Logic, Inc. Items from any Cirrus Logi c websit e or disk may be printed for use by the user. However, no

part of the printout or electronic files may be copied, reproduced, stored in a retrieval system, or transmitted, in any form or by any means (electronic, mechanical,

photographic, or otherwise) without the prior written consent of Cirrus Logic, Inc.Furthermore, no part of this publication may be used as a basis for manufacture

or sale of any items without the prior written consent of Cirrus Logic, Inc. The names of products of Cirrus Logic, Inc. or other vendors and suppliers appearing

in this document may be trademarks or service marks of their respective owners which may be registered in some jurisdictions. A list of Cirrus Logic, Inc. trademarks and service marks can be found at http://www.cirrus.com.

Loading...

Loading...