Page 1

Copyright Cirrus Logic, Inc. 2005

(All Rights Reserved)

http://www.cirrus.com

CS61584A

Dual T1/E1 Line Interface

SEP ‘05

DS261F1

Dual T1/E1 Line Interface

CS61584A

Features

l Dual T1/E1 Line Interface

l 3.3 Volt and 5 Volt Versions

l Crystal-less Jitter Attenuator Meets

European CTR 12 and ETSI ETS 300 011

Specifications

l Matched Impedance Transmit Drivers

l Transmitter Tri-state Capability

l Common Transmit and

ReceiveTransformers for all Modes

l Serial and Parallel Host Mo de Operation

l User-customizable Pulse Shapes

l Supports JTAG Boundary Scan

l Compliant with:

– ITU-T Recommendations: G.703, G.704,

G.706, G.732, G.775 and I.431

– American National Standards (ANSI): T1.102,

T1.105, T1.403, T1.408, and T1.231

– FCC Rules and Regulations: Part 68 and Part

15

– AT&T Publication 62411

– ETSI ETS 300 011, 300 233, CTR 12, TBR 13

l TR-NET-00499

Description

The CS61584A is a dual li ne interface for T1/E 1 applications, designed for high-volume cards where low

power and high density are requ ired. The device is optimized for flexible microprocessor control through a

serial or paralle l Host mode interface. Ha rdware mode

operation is also available.

Matched impedance drivers reduce power consumption

and provide substantial transmitter return loss. The

transmitter pulse shapes are customizable to allow nonstandard line loads . Crystalless jitter a ttenuation complies with most stringent standards. Support of JTAG

boundary scan enhances system testability and

reliability.

ORDERING INFORMATION

See

page 53.

CS61584A-IQ3:3.3V, 64-pin TQFP, -40 to +85° C

CS61584A-IL5:5.0V, 68-pin PLCC, -40 to +85° C

CS61584A-IQ5:5.0V, 64-pin TQFP, -40 to +85° C

Preliminary Product Information

P.O. Box 17847, Austin, Texas 78760

(512) 445 7222 FAX: (512) 445 7581

http://www.cirrus.com

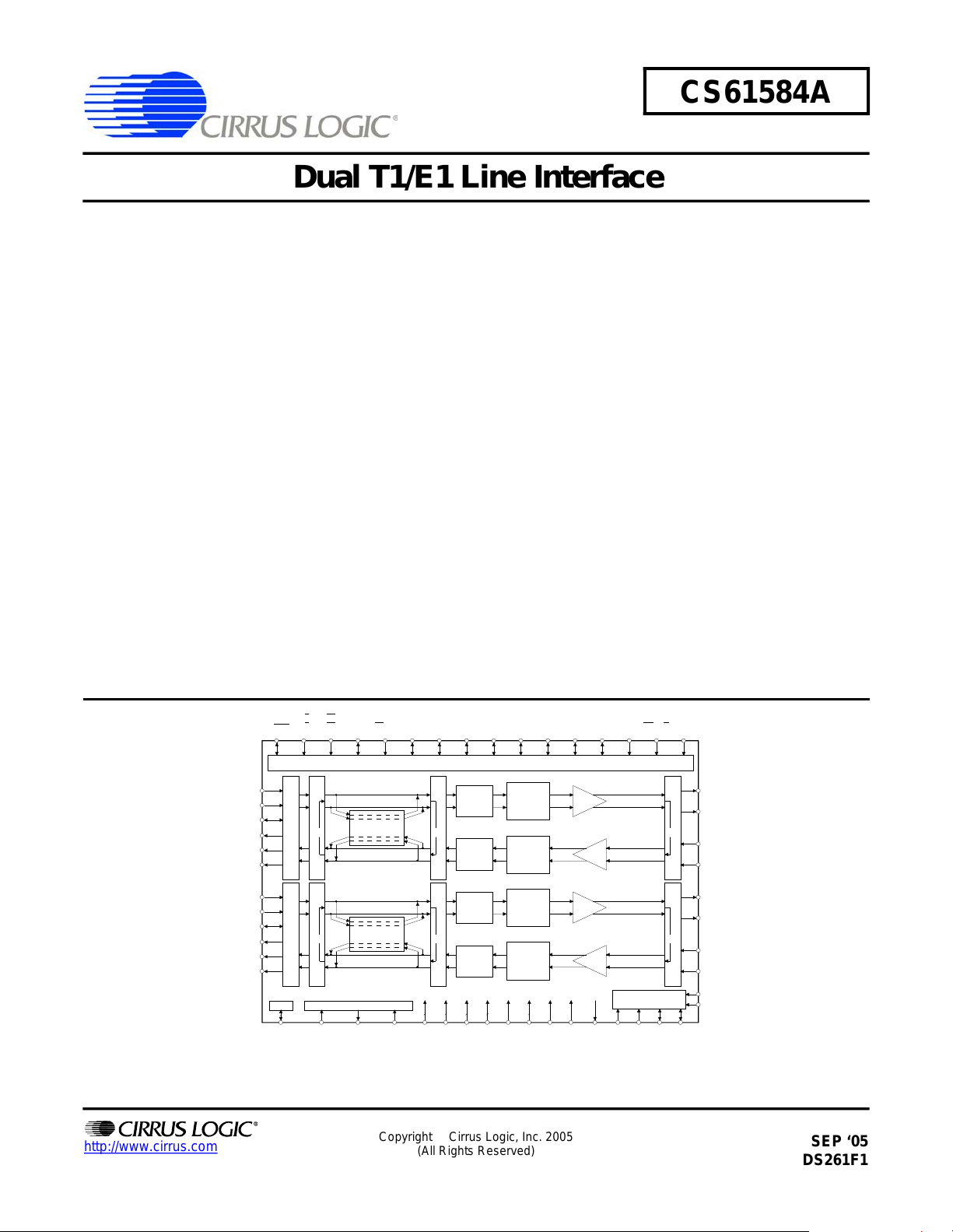

Serial Port

Parallel Port

Hardware Mode

TCLK1

(TDATA1) TPOS1

(AIS1) TNEG1

RCLK1

(RDATA1) RPOS1

(BPV1) RNEG1

TCLK2

(TDATA2) TPOS2

(AIS2) TNEG2

RCLK2

(RDATA2) RPOS2

(BPV2) RNEG2

IPOL

IPOL (DTACK)

CLKE

JTAG

INT

SCLK

SDO

SDI

CS

4

P/S

P/S

ATTEN0

E

N

C

O

D

E

R

D

E

C

O

D

E

R

E

N

C

O

D

E

R

D

E

C

O

D

E

R

INT

RD(DS)

RLOOP2

JITTER

JITTER

AD0

LLOOP

CS

RLOOP1

ATTEN1

R

E

M

O

T

E

L

ATTENUATOR

O

O

P

B

A

C

K

R

E

M

O

T

E

L

ATTENUATOR

O

O

P

B

A

C

K

CLOCK GENERATOR

REFCLK XTALOUT 1XCLK TV+ TGND RV+ RGND DV+ DGND

SPOL

AD1

AD2

TAOS1

TAOS2

CONTROL

L

O

C

A

TAOS

L

L

O

O

P

LOS &

B

A

AIS

C

DETECT

K

1

L

O

C

A

TAOS

L

L

O

O

P

LOS &

B

A

AIS

C

DETECT

K

1

2 2 2 2 3

This document contains information for a new product.

Cirrus Logic reserves the right to modify this product without notice.

Copyright Cirrus Logic, Inc. 2000

AD3

AD4

CON02

PULSE

SHAPING

CIRCUITRY

CLOCK &

DATA

RECOVERY

PULSE

SHAPING

CIRCUITRY

CLOCK &

DATA

RECOVERY

AD5

CON11

AV+ AGND

CON12

CON01

(All Rights Reserved)

AD6

DRIVER

DRIVER

CON21

RECEIVER

RECEIVER

BGREF

AD7

PD1

SAD4

ZTX1

ALE(AS)

CON22

WR(R/W)

CON31

CONTROL

PD2

SAD5

ZTX2

LOS1

SAD6

LOS1

BTS

CON32

L

O

C

A

L

L

O

O

P

B

A

C

K

2

L

O

C

A

L

L

O

O

P

B

A

C

K

2

LOS2

SAD7

LOS2

TTIP1

TRING1

RTIP1

RRING1

TTIP2

TRING2

RTIP2

RRING2

RESET

MODE

Hardware Mode

Parallel Port

Serial Port

JAN ‘01

DS261PP5

1

Page 2

TABLE OF CONTENTS

1. CHARACTERISTICS AND SPECIFICATIONS .................................. ....... ...... ....... ...... ....... ..... 5

ABSOLUTE MAXIMUM RATINGS ...........................................................................................5

RECOMMENDED OPERATING CONDITIONS.......................................................................5

ANALOG CHARACTERISTICS................................................................................................ 6

ANALOG CHARACTERISTICS................................................................................................ 7

DIGITAL CHARACTERISTICS................................................................................................. 8

SWITCHING CHARACTERISTICS . ...... ....... ...... ......................................................................8

SWITCHING CHARACTERISTICS - SERIAL PORT .............................................................10

SWITCHING CHARACTERISTICS - PARALLEL PORT........................................................11

SWITCHING CHARACTERISTICS - JTAG............................................................................ 14

2. OVERVIEW ............................................................................................................................. 15

2.1 AT&T 62411 Customer Premises Application .................................................................. 16

2.2 Asynchronous Multiplexer Application ............................................................................. 16

2.3 Synchronous Application ................................................................................................. 16

3. TRANSMITTER .......................................................................................................................16

4. RECEIVER .............................................................................................................................. 18

5. JITTER ATTENUATOR ................... ...... ....... ...... ....... ...... .......................................................19

6. REFERENCE CLOCK ............................................................................................................20

7. POWER-UP RESET ................................................................................................................20

8. LINE CONTROL AND MONITORING .................................................................................... 20

8.1 Line Code Encoder/Decoder ............................................................................................20

8.2 Alarm Indication Signal ....................................................................................................20

8.3 Bipolar Violation Detection ...............................................................................................21

8.4 Excessive Zeros Detection ..............................................................................................21

8.5 Loss of Signal .................................................................................................................. 21

8.6 Transmit All Ones ............................................................................................................21

8.7 Receive All Ones ............................................................................................................. 21

8.8 Local Loopback ................................................................................................................22

8.9 Remote Loopback ............................................................................................................22

8.10 Driver Tristate ................................................................................................................ 22

8.11 Power Down ................................................................................................................... 22

8.12 Reset Pin ....................................................................................................................... 23

9. HOST MODE ...........................................................................................................................23

9.1 Register Set ..................................................................................................................... 23

9.1.1 Status Registers ..................................................................................................23

DS261PP5

CS61584A

CS61584A

Contacting Cirrus Logic Support

For a complete listing of Direct Sales, Distributor, and Sales Representative contacts, visit the Cirrus Logic web site at:

http://www.cirrus.com/corporate/contacts/sales.cfm

Preliminary product inf o rmation describes products whi c h are i n production, but for whi ch f ul l char act erization data is not yet avai l ab le . Ad vance p roduct infor-

mation describes products which are in development and subject to development changes. Cirrus Logic, Inc. has made best efforts to ensure that the information

contained in this document i s accurat e and reli able. However , t he infor mation is subje ct to chang e without noti ce and is provi d ed “AS IS” without warrant y of

any kind (express or implied). Customers are advised to obtain the latest version of relevant information to verify, before placing orders, that information being

relied on is current and complete. All products are sold subject to the terms and conditions of sale supplied at the time of order acknowledgment, including those

pertaining to warran t y , pa tent infringement, and limitation of liability. N o responsibility is ass umed by Cirrus Logic, In c . for the use of this information, including

use of this inf orma t i on as the basis for manufacture or sale o f any items, nor for i nf ringements of pat en t s or other rights o f thir d parti es. This document i s the

property of Cirrus Logic, Inc. a nd by furni shing th is i nformati on, Cir rus L ogic, In c. grant s no l icense, express or i mpli ed under any patent s, mask work righ ts,

copyrights, trademarks, trad e secrets o r ot her i ntellect ual pro pert y right s of Cirrus L ogic, I nc. Ci rrus L ogic, In c., cop yright owner of the in forma tion co ntaine d

herein, gives consent for copies to be made of the information only for use within your organization with respect to Cirrus Logic integrated circuits or other parts

of Cirrus Logic, Inc. The same consent is gi ven for simi lar inf ormat ion con tai ned on a ny Cirru s Logic we bsite or disk. T his consent does not extend to othe r

copying such as copying for general distribution, advertising or promotional purposes, or for creating any work for resale. The names of products of Cirrus Logic,

Inc. or other vendors and suppliers appearing in this document may be trademarks or service marks of their respective owners which may be registered in some

jurisdictions. A list of Cirrus Logic, Inc. trademarks and service marks can be found at http://www.cirrus.com

2 DS261PP5

2 DS261F1

.

Page 3

DS261PP5

CS61584A

CS61584A

9.1.2 Mask Registers ................................................................................................... 25

9.1.3 Control A Registers ............................................................................................. 26

9.1.4 Control B Registers ............................................................................................. 27

9.1.5 Arbitrary Waveform Registers ............................................................................. 27

9.2 Serial Port Operation ....................................................................................................... 30

9.3 Parallel Port Operation ....................................................................................................31

10. JTAG BOUNDARY SCAN .................................................................................................... 31

10.1 JTAG Data Registers (DR) ............................................................................................ 32

10.2 JTAG Instructions and Instruction Register (IR) ............................................................ 33

10.3 JTAG TAP Controller ..................................................................................................... 33

10.4 Test-Logic-Reset State .................................................................................................. 33

10.5 Run-Test/Idle State ........................................................................................................ 34

10.6 Select-DR-Scan State ................................................................................................... 34

10.7 Capture-DR State ..........................................................................................................34

10.8 Shift-DR State ................................................................................................................ 34

10.9 Exit1-DR State ............................................................................................................... 34

10.10 Pause-DR State ...........................................................................................................35

10.11 Exit2-DR State ............................................................................................................. 35

10.12 Update-DR State ......................................................................................................... 35

10.13 Select-IR-Scan State ................................................................................................... 35

10.14 Capture-IR State .......................................................................................................... 35

10.15 Shift-IR State ............................................................................................................... 35

10.16 Exit1-IR State .............................................................................................................. 36

10.17 Pause-IR State ............................................................................................................ 36

10.18 Exit2-IR State .............................................................................................................. 36

10.19 Update-IR State ........................................................................................................... 36

10.20 JTAG Application Examples ........................................................................................ 36

11. PIN DESCRIPTIONS ............................................................................................................ 39

12. PACKAGE DIMENSIONS .................................................................................................... 46

13. APPLICATIONS ................................................................................................................... 48

13.1 Line Interface ................................................................................................................. 48

13.2 Power Supply ................................................................................................................ 50

13.3 Quartz Crystal Specifications ........................................................................................ 50

13.4 Crystal Oscillator Specifications .................................................................................... 50

13.5 Transformers ................................................................................................................. 51

13.6 Designing for AT&T 62411 ............................................................................................ 51

13.7 Line Protection ............................................................................................................... 51

13.8 Loop Selection Equations .............................................................................................. 51

LIST OF TABLES

Table 1. Line Configuration Selections............................................................................................. 17

Table 3. Jitter Attenuation Control.................................................................................................... 19

Table 4. CS61584A Register Set..................................................................................................... 23

Table 5. Status Registers................................................................................................................. 24

Table 6. Mask Registers................................................................................................................... 25

Table 7. Control A Registers............................................................................................................ 26

Table 8. Control B Registers............................................................................................................ 27

Table 9. Arbitrary Waveform Registers............................................................................................ 28

Table 10. Boundary Scan Register .................................................................................................. 32

Table 11. Device Identifcation Register............................................................................................ 33

Table 12. ......................................................................................................................................... 33

DS261PP5 3

DS261F1 3

Page 4

DS261PP5

Table 13. CS61584A External Components.....................................................................................48

Table 14. Quartz Crystal Specifications ...........................................................................................50

Table 15. Suggested Quartz Crystals...............................................................................................50

Table 16. Suggested Crystal Oscillators ..........................................................................................50

Table 17. Transformer Specifications...............................................................................................51

Table 18. Recommended Transformers........................................................................................... 52

LIST OF FIGURES

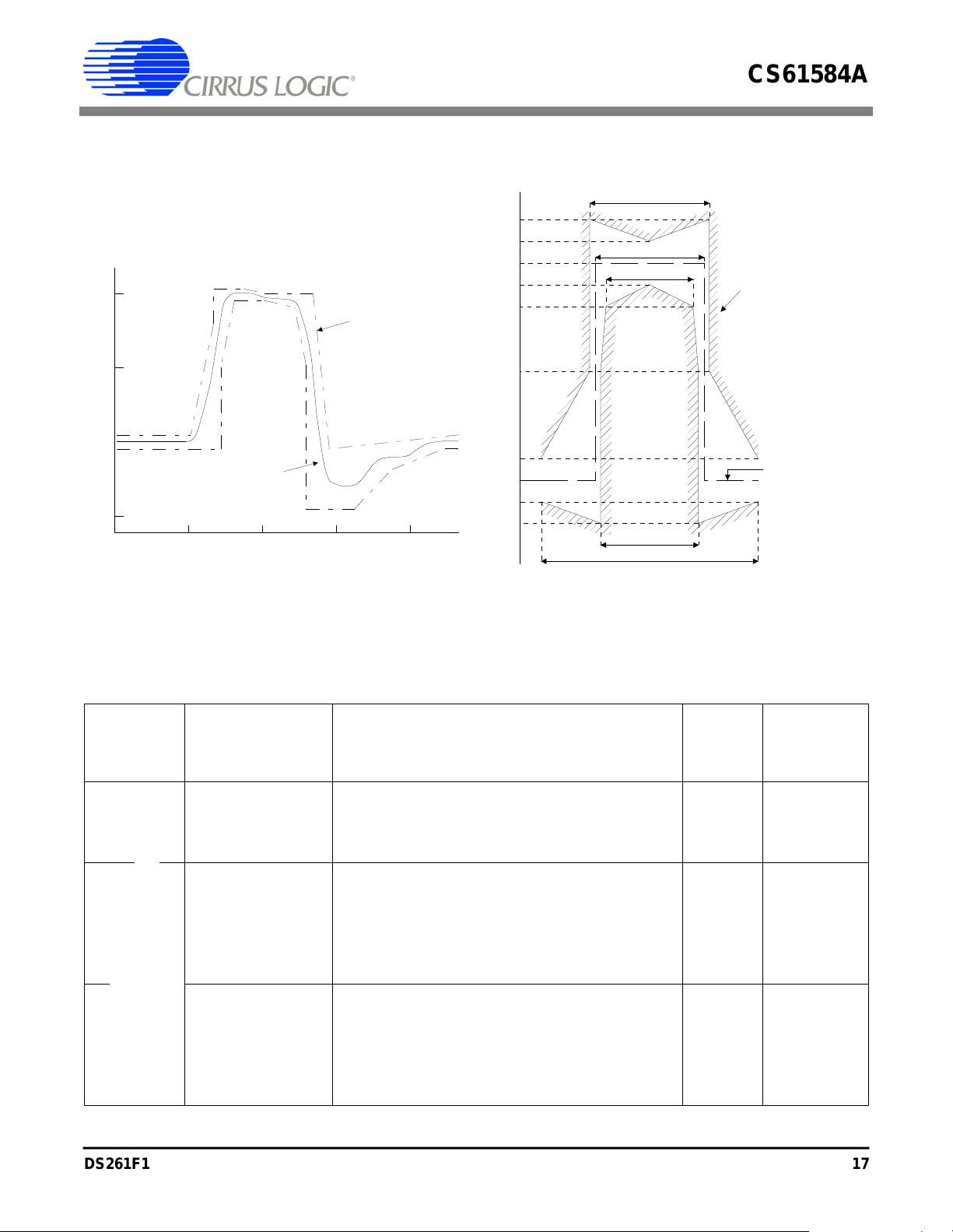

Figure 1. Signal Rise And Fall Characteristics ..............................................................................9

Figure 2. Recovered Clock and Data Switching Characteristics ...................................................9

Figure 3. Transmit Clock and Data Switching Characteristics ......................................................9

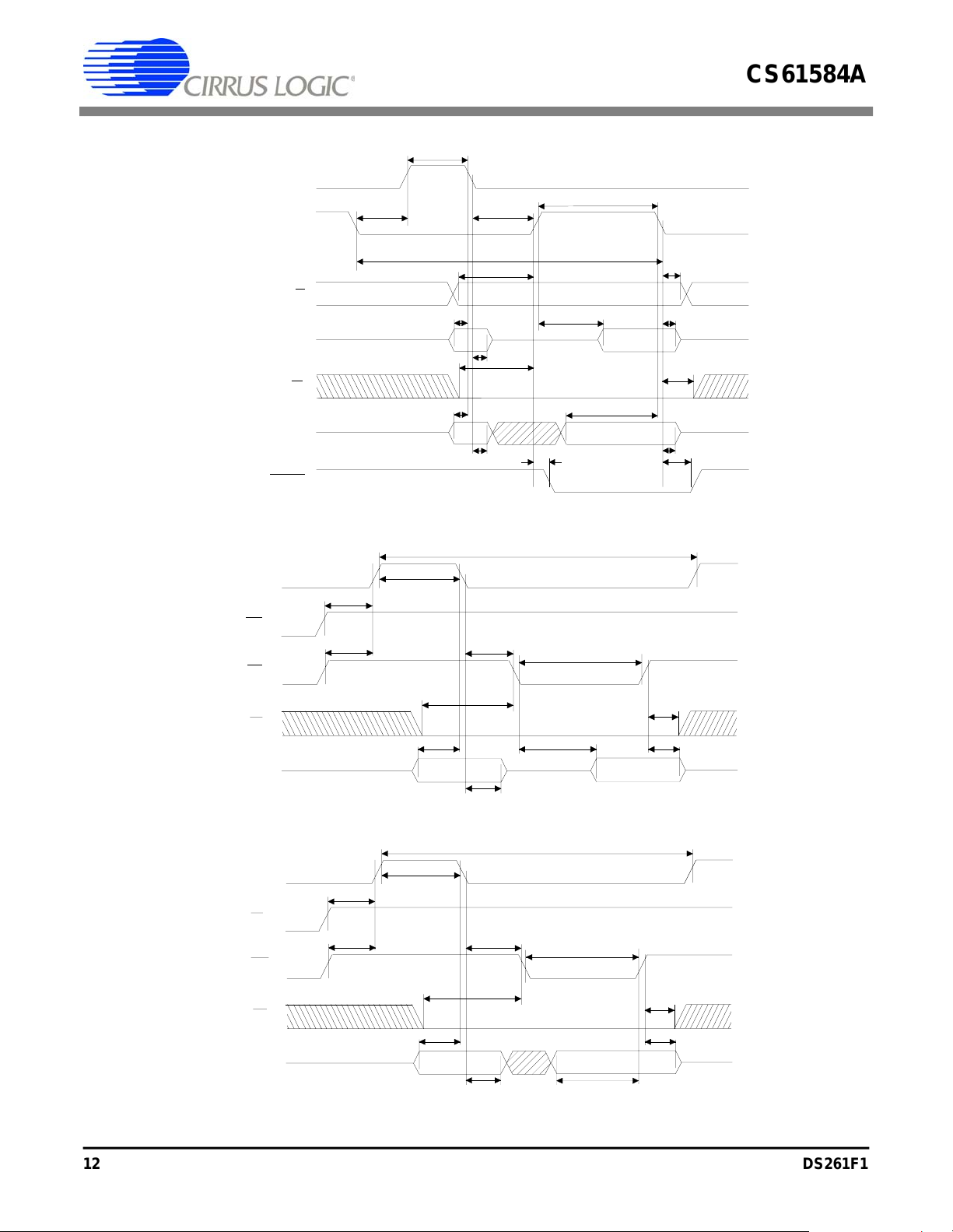

Figure 4. Serial Port Write Timing Diagram ................................................................................. 10

Figure 5. Serial Port Read Timing Diagram ................................................................................10

Figure 6. Parallel Port Timing - Motorola Mode . ...... ....................................................................12

Figure 7. Parallel Port Timing - Intel Read Mode ........................................................................12

Figure 8. Parallel Port Timing - Intel Write Mode ........... ...... ...... ....... ...... ....... .............................12

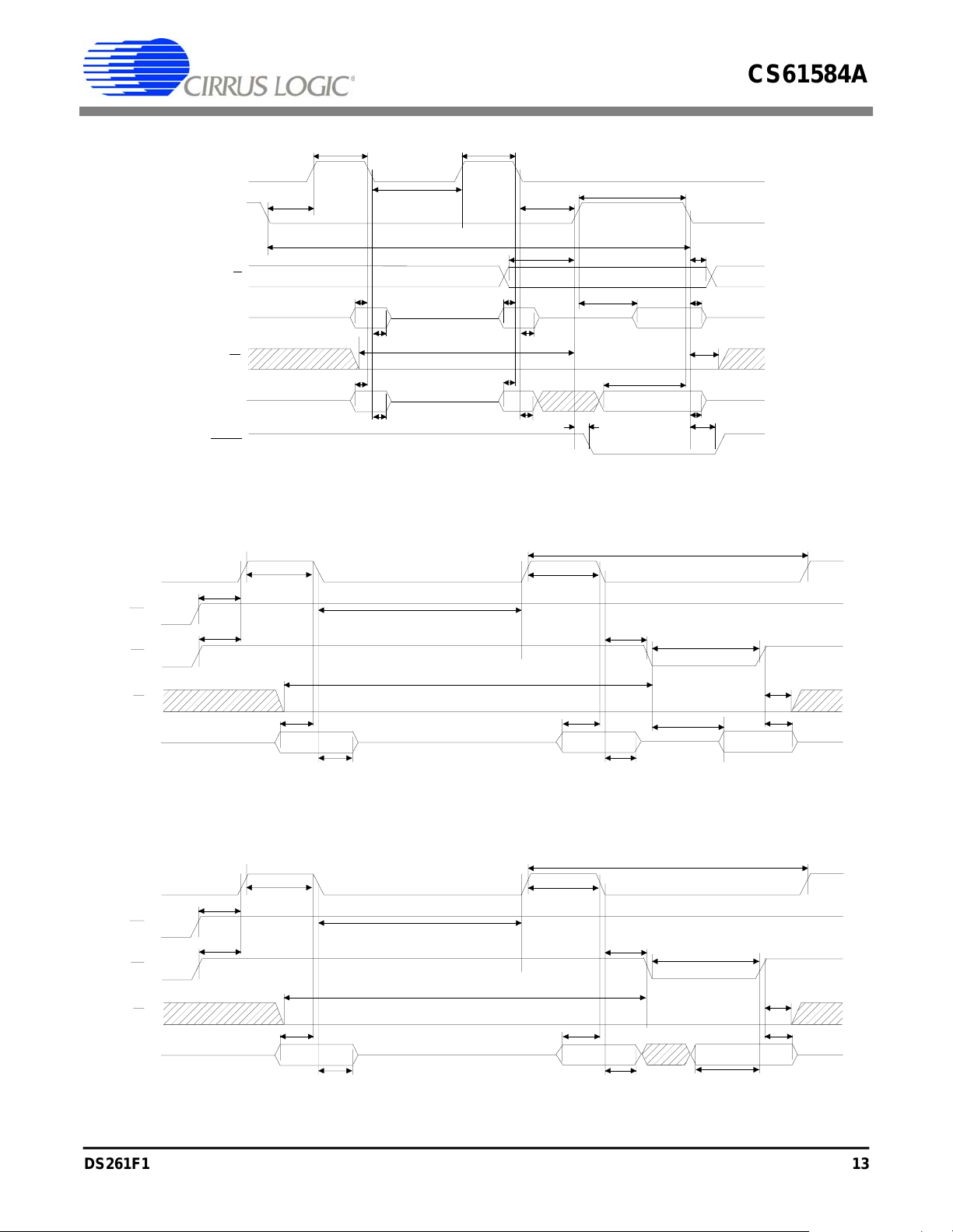

Figure 9. Parallel Port Timing - Motorola Mode to RAM . ...... ...... ....... .......................................... 1 3

Figure 10. Parallel Port Timing - Intel Read Mode from RAM or ROM ......................................... 13

Figure 11. Parallel Port Timing - Intel Write Mode to RAM .......... ....... ....................................... ... 13

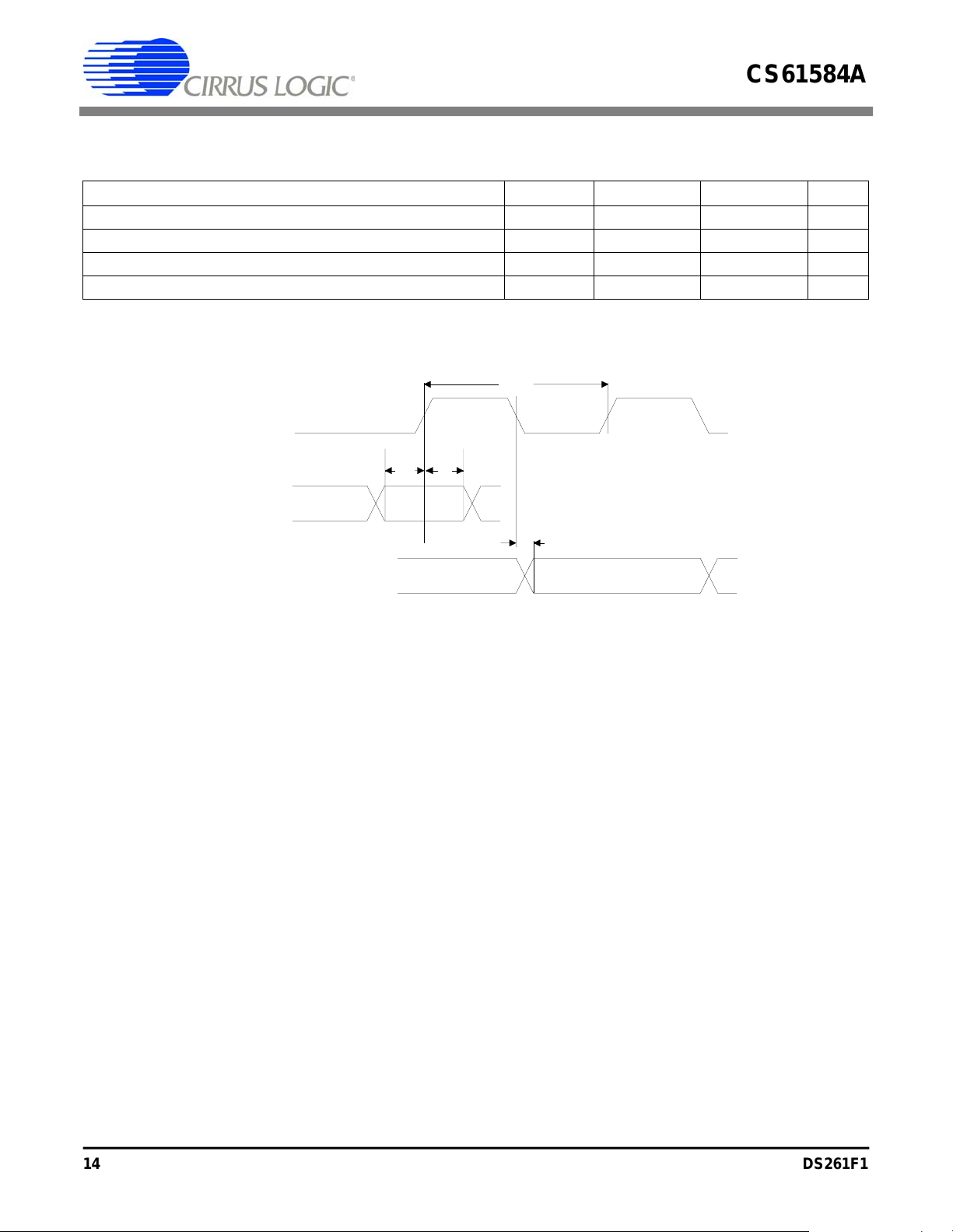

Figure 12. JTAG Switching Characteristics ................................................................................... 14

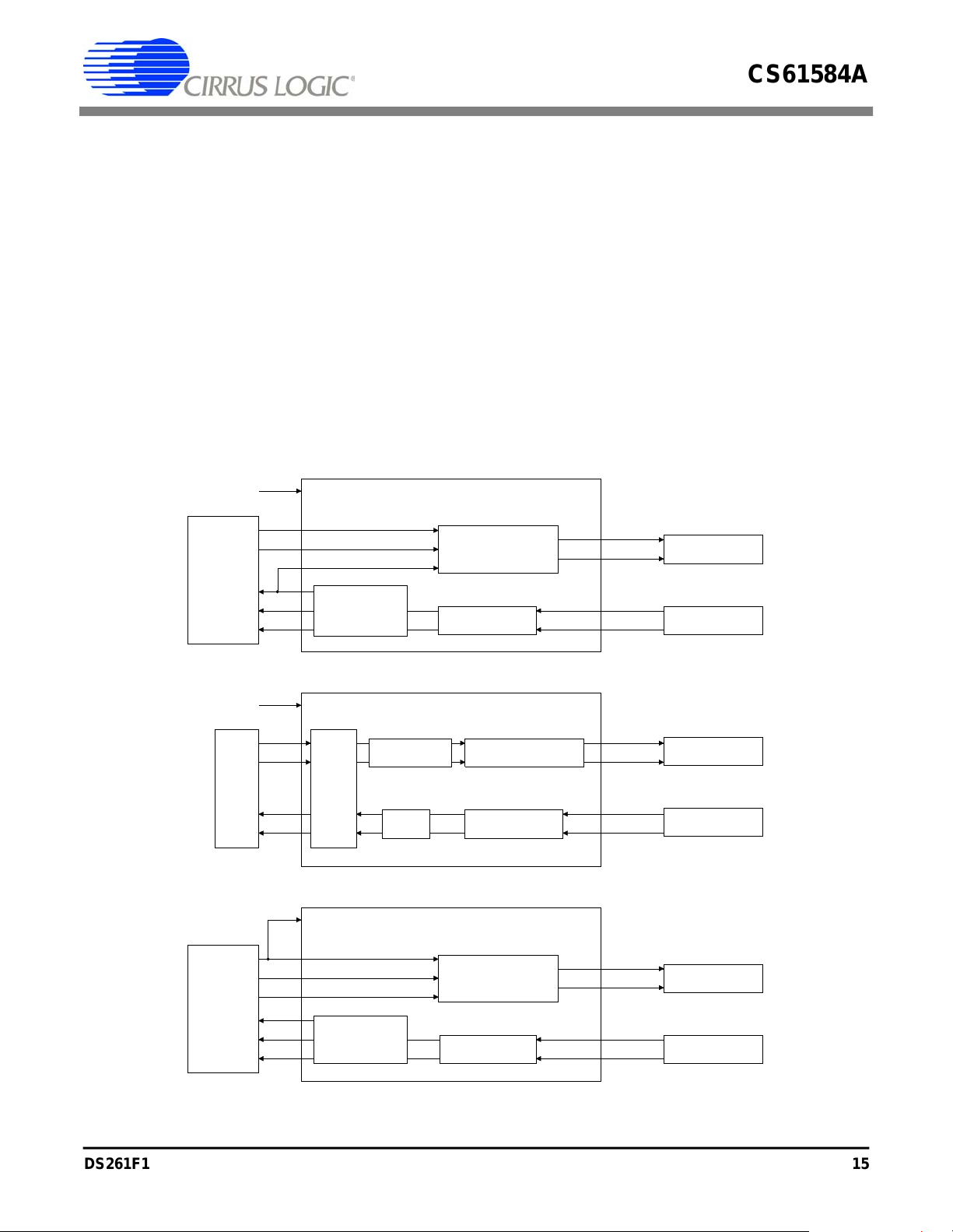

Figure 13. Examples of CS61584A Applications ...........................................................................15

Figure 14. Typical Pulse Shape at DSX-1 Cross Connect ............................................................17

Figure 15. Mask of the Pulse at the 2048 kbps Interface ..............................................................17

Figure 16. Minimum Input Jitter Tolerance of Receiver (Clock Recovery Circuit and

jitter Attenuator) ............................................................................................................ 18

Figure 17. Typical Jitter Transfer Function .................................................................................... 19

Figure 18. Alarm Indication Event Relationships ...........................................................................24

Figure 19. Phase Definition of Arbitrary Waveforms .....................................................................29

Figure 20. Example of Summing of Waveforms ............................................................................ 29

Figure 21. Serial Read/Write Format (SPOL = 0) ..........................................................................30

Figure 22. Address Command byte ............................................................................................... 30

Figure 23. JTAG Circuitry Block Diagram ..................................................................................... 31

Figure 24. TAP Controller State Diagram ...................................................................................... 34

Figure 25. JTAG Instruction Register update ................................................................................37

Figure 26. JTAG Data Register update .........................................................................................38

Figure 27. Hardware Mode Configuration ..................................................................................... 48

Figure 28. Host Mode Serial Port Configuration ............................................................................49

Figure 29. Host Mode Parallel Port Configuration ......................................................................... 49

CS61584A

CS61584A

4 DS261PP5

4 DS261F1

Page 5

DS261PP5

CS61584A

CS61584A

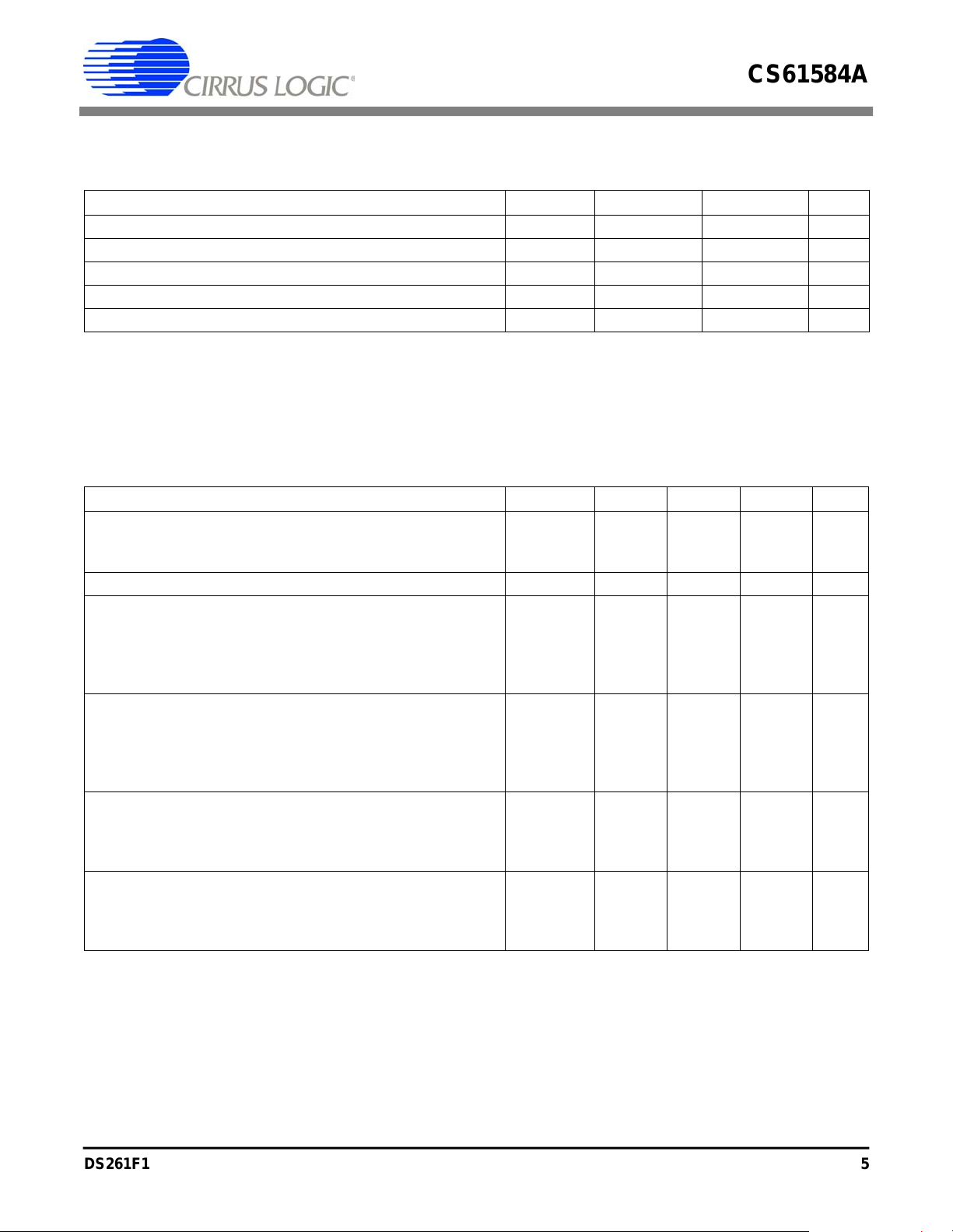

1. CHARACTERISTICS AND SPECIFICATIONS

ABSOLUTE MAXIMUM RATINGS

Parameter Symbol Min Max Unit

DC Supply (TV+1, TV+2, RV+1, RV+2, AV+, DV+) (Note 1) - 6.0 V

Input Voltage (Any Pin) V

Input Current (Any Pin) (Note 2) I

Ambient Operating Temperature T

Storage Temperature T

Notes: 1. Referenced to RGND1, RGND2, TGND1, TGND2, AGND, DGND at 0 V.

2. Transient currents of up to 100 mA will not cause SCR latch-up.

WARNING: Operation at or beyond these limits may result in permanent damage to the device.

Normal operation is not guaranteed at these extremes.

in

in

A

stg

RECOMMENDED OPERATING CONDITIONS

Parameter Symbol Min Typ Max Unit

DC Supply (TV+1, TV+2, RV+1, RV+2, AV+, DV+) (Note 3)

3.3 V

5.0 V

Ambient Operating Temperature T

Power Consumption Per Channel (3.3 V) (Note 4)

T1 (Note 5)

T1 (Note 6)

E1, 75 Ω (Note 5)

E1, 120 Ω (Note 5)

Power Consumption Per Channel (5.0 V) (Note 4)

T1 (Note 5)

T1 (Note 6)

E1, 75 Ω (Note 5)

E1, 120 Ω (Note 5)

REFCLK Frequency T1 1XCLK = 1

T1 1XCLK = 0

REFCLK Frequency E1 1XCLK = 1

E1 1XCLK = 0

A

P

C

P

C

RGND - 0.3 (RV+) + 0.3 V

-10 10 mA

-40 85 °C

-65 150 °C

3.135

4.75

-40 25 85 °C

-

-

-

-

-

-

-

-

(1.544 -

100 ppm)

(12.352 -

100 ppm)

(2.048 -

100 ppm)

(16.384 -

100 ppm)

3.3

5.0

310

190

250

230

350

250

320

310

1.544

12.352

2.048

16.384

3.465

5.25

-

-

-

-

-

-

-

-

(1.544 +

100 ppm)

(12.352 +

100 ppm)

(2.048 +

100 ppm)

(16.384 +

100 ppm)

MHz

MHz

MHz

MHz

V

mW

mW

Notes: 3. TV+1, TV+2, AV+, DV+, RV+1, RV+2 should be connected together. TGND1, TGND2, RGND1, GND2,

DGND1, DGND2, DGND3 should be connected together.

4. Per channel power consumption while driving line load over operating temperature range. Includes

device and load. Digital input levels are within 10% of the supply rails and digital outputs are driving a

50 pF capacitive load.

5. Assumes 100% ones density and maximum line length at maximum supply voltage (3.465 V or 5.25 V).

6. Assumes 50% ones density and 300 ft. line length at typical supply voltage (3.3 V or 5.0 V).

Specifications are subject to change without notice

DS261PP5 5

DS261F1 5

Page 6

DS261PP5

CS61584A

CS61584A

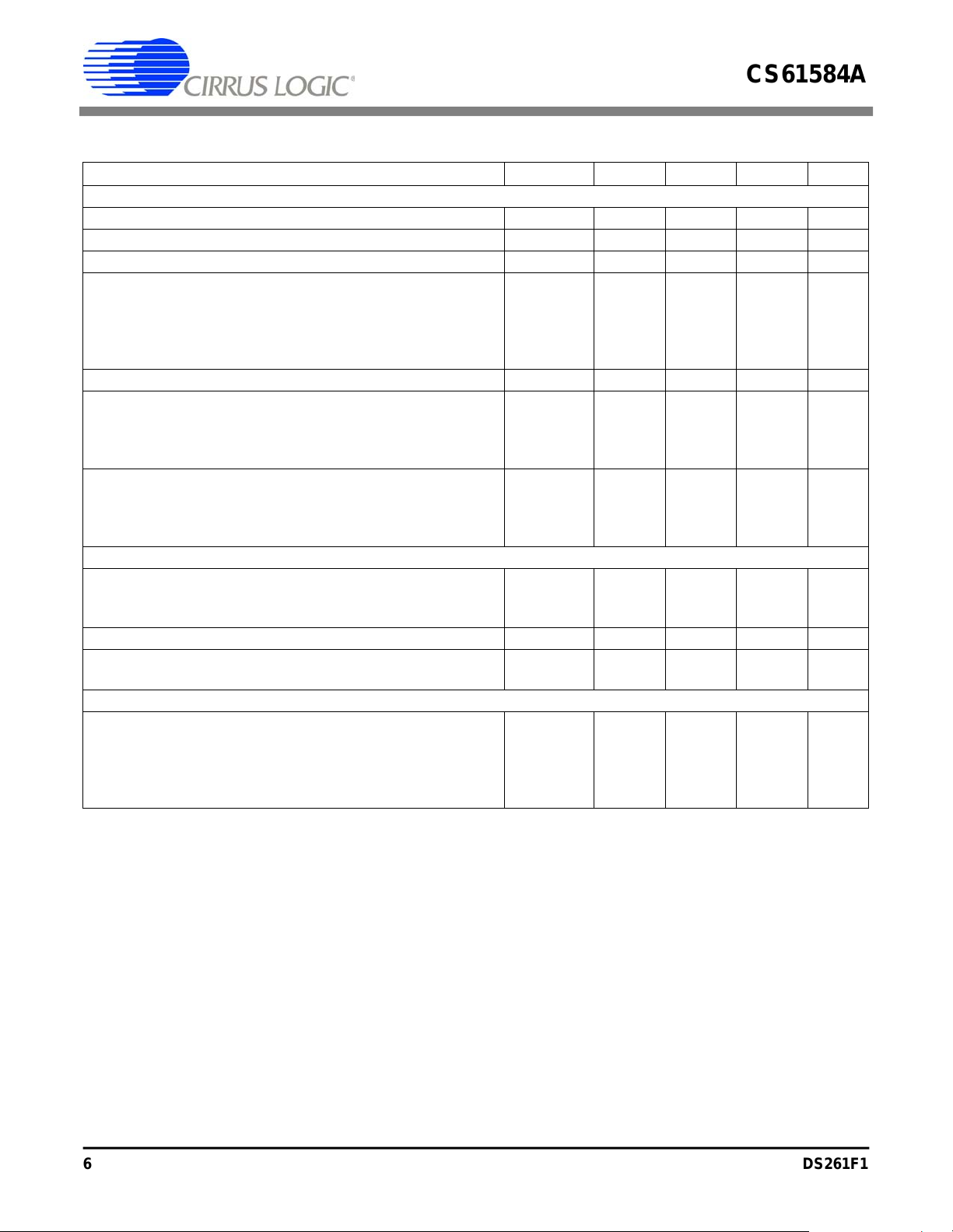

ANALOG CHARACTERISTICS (T

Parameter Symbol Min Typ Max Unit

= -40 to 85 °C; power supply pins within ±5% of nominal.)

A

Receiver

RTIP/RRING Differential Input Impedance - 20 - kΩ

Sensitivity Below DSX-1 (0 dB = 2.4 V) - -13.6 - dB

Loss of Signal Threshold - 0.3 - V

Data Decision Threshold T1, DSX-1 (Note 7)

(Note 8)

T1, FCC Part 68 and E1 (Note

9)

(Note 10)

Allowable Consecutive Zeros before LOS 160 175 190 bits

Receiver Input Jitter Tolerance (DSX-1, E1)

10 Hz and bel ow (N ot e 11)

2kHz

10 kHz - 100 kHz

Receiver Return Loss (Notes 12, 13, and 14)

51 kHz - 102 kHz

102 kHz - 2.048 MHz

2.048 MHz - 3.072 MHz

60

55

45

40

300

6.0

0.4

12

18

14

65

50

22

24

22

70

-

-

-

-

-

75

55

60

-

-

-

-

-

-

% of

Peak

UI

dB

Jitter Attenuator

Jitter Attenuator Corner Frequency

T1 (Notes 12 and 15)

E1

Attenuation at 10 kHz Jitter Frequency (Notes 12 and 15) - 60 - dB

Attenuator Input Jitter Tolerance (Note 12)

(Before Onset of FIFO Overflow or Underflow Protection)

1.25

-

28 43 - UI

4.0

1.25

-

-

Hz

pk-pk

Transmitter

Arbitrary Pulse Amplitude at Transformer Secondary

T1, DSX-1

T1, DS1

E1, 75 Ω

E1, 120 Ω

-

-

-

-

73

52

43

52

mV/LS

-

-

-

-

B

Notes: 7. For input amplitude of 1.2 V

8. For input amplitude of 0.5 V

9. For input amplitude of 1.07 V

10. For input amplitude of 4.14 V

11. Jitter tolerance increases at lower frequencies. Refer to the Receiver section.

12. Not production tested. Parameters guaranteed by design and characterization.

13. Typical performance using the line interface circuitry recommended in the Applications section.

14. Return loss = 20 log

= cable impedance.

z

0

15. Attenuation measured with sinusoidal input jitter equal to 3/4 of measured jitter tolerance. Circuit

attenuates jitter at 20 dB/decade above the corner frequency. Output jitter can increase significantly

when more than 28 UI's are input to the attenuator. The jitter attenuator -3 dB knee in T1 mode is

selectable for 4.0 Hz or 1.25 Hz. Refer to the Jitter Attenuator section.

6 DS261PP5

6 DS261F1

ABS((z1 + z0) / (z1 - z0)) where z1 = impedance of the transmitter or receiver, and

10

to 4.14 Vpk.

pk

to 1.2 Vpk, and 4.14 Vpk to 5.0 Vpk.

pk

to 4.14 Vpk.

pk

to 5.0 Vpk.

pk

Page 7

DS261PP5

CS61584A

CS61584A

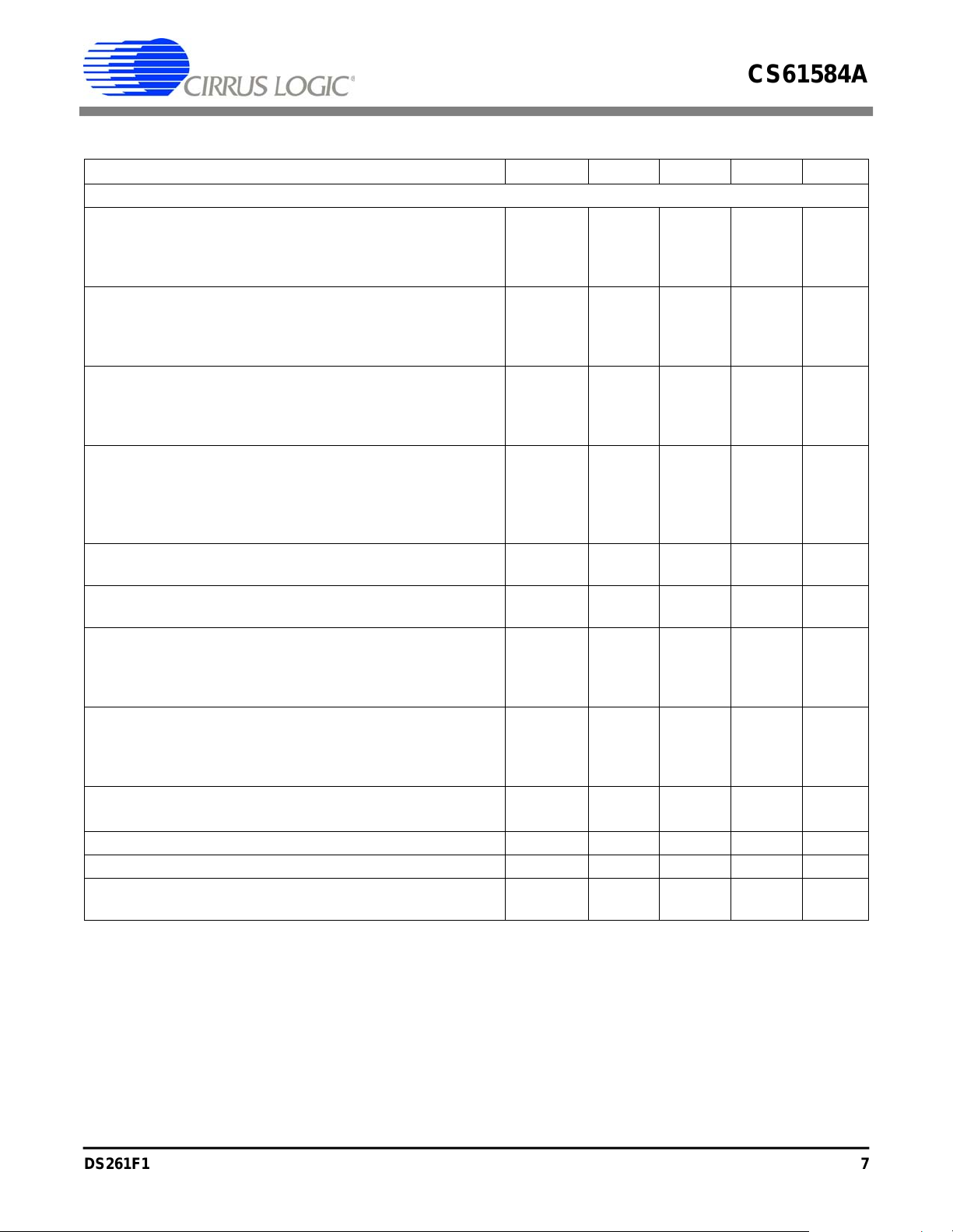

ANALOG CHARACTERISTICS (Continued)

Parameter Symbol Min Typ Max Unit

Transmitter (Continued)

AMI Output Pulse Amplitudes (Note 16)

E1, 75 Ω (Note 17)

E1, 120 Ω (Note 18)

T1, DSX-1 (Note 19)

Recommended Transmitter Output Load (3.3 V) (Note 16)

T1

E1, 75 Ω

E1, 120 Ω

Recommended Transmitter Output Load (5.0 V) (Note 16)

T1

E1, 75 Ω

E1, 120 Ω

Jitter Added During Remote Loopback

10 Hz - 8 kHz

8kHz - 40kHz

10 Hz - 40 kHz

Broad Band (Note 20)

Power in 2 kHz band about 772 kHz (Notes 12 and 13)

(DSX-1 only)

Power in 2 kHz band about 1.544 MHz (Note 12 and 13)

(referenced to power in 2 kHz band at 772 kHz, DSX-1 only)

Positive to Negative Pulse Imbalance (Notes 12 and 13)

T1, DSX-1

E1, amplitude at center fo pulse interval

E1, width at 50% of nominal amplitude

Transmitter Return Loss (Notes 12, 13, and 14)

51 kHz - 102 kHz

102 kHz - 2.048 MHz

2.048 MHz - 3.072 MHz

E1 Short Circuit Current 5.0 V

3.3 V

E1 and DSX-1 Output Pulse Rise/Fall Times (Note 22) - 50 - ns

E1 Pulse Width (at 50% of peak amplitude) - 244 - ns

E1 Pulse Amplitude for a space E1, 75 Ω

(Note 21)

E1, 120 Ω

2.14

2.7

2.4

-

-

-

-

-

-

-

-

-

-

12.6 15 17.9 dBm

-29 -38 - dB

-

-5

-5

8

14

10

-

-

-0.237

-0.3

2.37

3.0

3.0

24.8

18.6

30.0

76.6

57.4

90.6

0.020

0.015

0.015

0.045

0.2

-

-

25

18

12

-

70

-

-

2.6

3.3

3.6

-

-

-

-

-

-

-

-

-

-

0.5

5

5

-

-

-

50

-

0.237

0.3

mA

mA

V

Ω

Ω

UI

dB

%

%

dB

rms

rms

V

V

Notes: 16. Using a transformer that meets the specifications in the Applications section.

17. Measured across 75 Ω at the output of the transmit transformer for CON3/2/1/0 = 0/0/0/0.

18. Measured across 120 Ω at the output of the transmit transformer for CON3/2/1/0 = 0/0/0/1.

19. Measured at the DSX-1 Cross-Connect for line length settings CON3/2/1/0 = 0/0/1/0, 0/0/1/1, 0/1/0/0,

0/1/0/1, and 0/1/1/0 after the length of #22 ABAM cable specified in Table 1.

20. Input signal to RTIP/RRING is jitter free. Values will reduce slightly if jitter free clock is input to TCLK.

21. Transformer secondary shorted with 0.5 Ω resistor during the transmission of 100% ones.

22. At transformer secondary and measured from 10% to 90% of amplitude.

DS261PP5 7

DS261F1 7

Page 8

DS261PP5

CS61584A

CS61584A

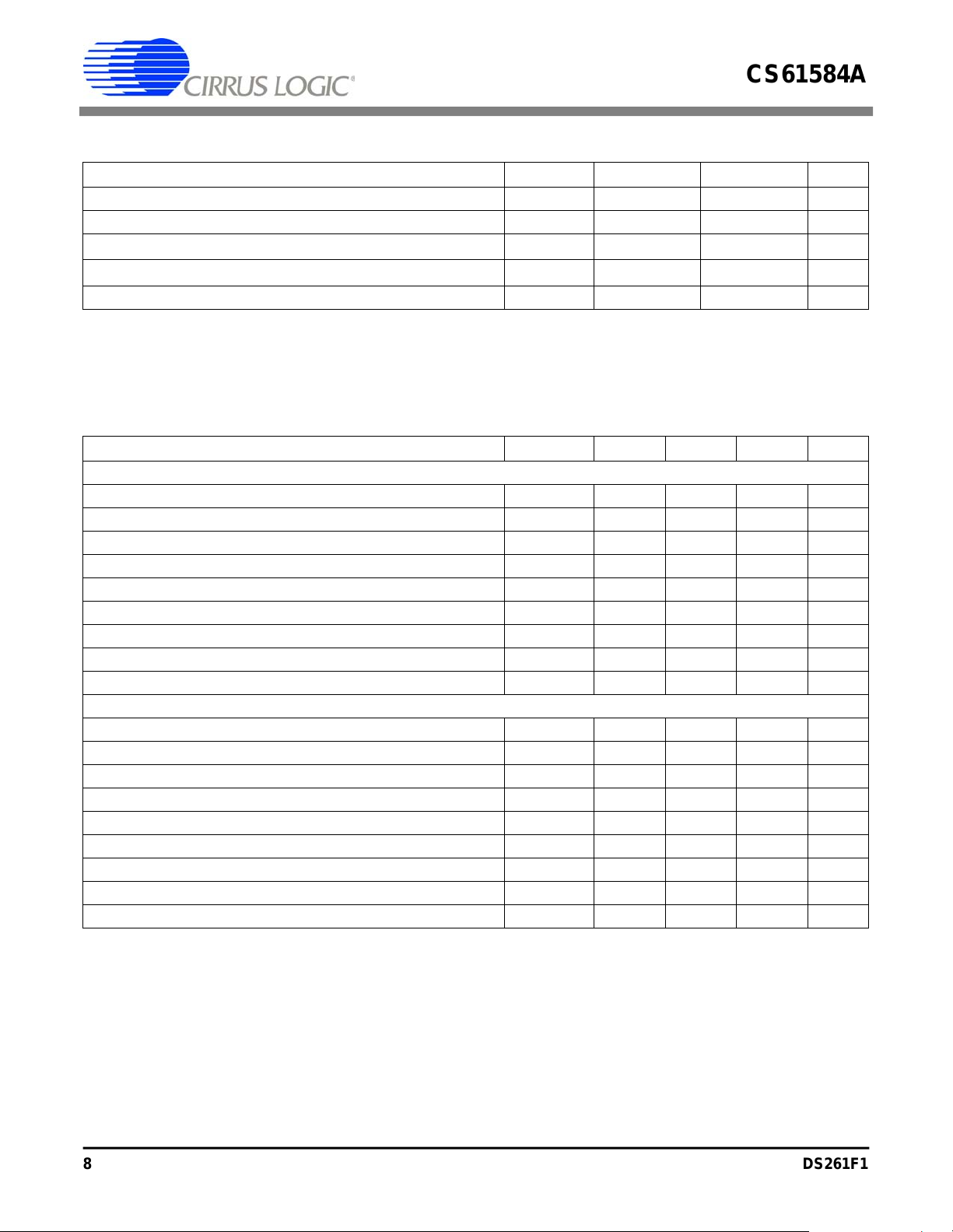

DIGITAL CHARACTERISTICS (T

= -40 to 85 °C; power supply pins within ±5% of nominal.)

A

Parameter Symbol Min Max Unit

High-Level Input Voltage (Note 23) V

Low-Level Input Voltage (Note 23) V

High-Level Output Voltage (I

Low-Level Output Voltage (I

= -40 µA) (Note 24) V

out

= 1.6 mA) (Note 24) V

out

IH

IL

OH

OL

(DV+) - 0.5 - V

-0.5V

(DV+) - 0.3 - V

-0.3V

Input Leakage Current (Digital pins except J-TMS and J-TDI) - ±10 µA

Notes: 23. Digital inputs are designed for CMOS logic levels.

24. Digital outputs are TTL compatible and drive CMOS levels into a CMOS load.

SWITCHING CHARACTERISTICS (T

= -40 to 85 °C; power supply pins within ±5% of nominal;

A

Inputs: Logic 0 = 0 V, Logic 1 = DV+.)

Parameter Symbol Min Typ Max Unit

T1 Clock/Data

TCLK Frequency (Note 25) f

TCLK Duty Cycle t

RCLK Duty Cycle (Note 26) t

pwh2/tpw2

pwh1/tpw1

Rise Time (All Digital Outputs) (Note 27) t

Fall Time (All Digital Outputs) (Note 27) t

RPOS/RNEG (RDATA) to RCLK Rising Setup Time t

RCLK Rising to RPOS/RNEG (RDATA) Hold Time t

TPOS/TNEG (TDATA) to TCLK Falling Setup Time t

TCLK Falling to TPOS/TNEG (TDATA) Hold Time t

tclk

r

f

su1

h1

su2

h2

-1.544-MHz

20 50 80 %

45 50 55 %

- - 65 ns

- - 65 ns

-274-ns

-274-ns

25 - - ns

25 - - ns

E1 Clock/Data

TCLK Frequency (Note 25) f

TCLK Duty Cycle t

RCLK Duty Cycle (Note 26) t

pwh2/tpw2

pwh1/tpw1

Rise Time (All Digital Outputs) (Note 27) t

Fall Time (All Digital Outputs) (Note 27) t

RPOS/RNEG (RDATA) to RCLK Rising Setup Time t

RCLK Rising to RPOS/RNEG (RDATA) Hold Time t

TPOS/TNEG (TDATA) to TCLK Falling Setup Time t

TCLK Falling to TPOS/TNEG (TDATA) Hold Time t

tclk

r

f

su1

h1

su2

h2

-2.048-MHz

20 50 80 %

45 50 55 %

- - 65 ns

- - 65 ns

-194-ns

-194-ns

25 - - ns

25 - - ns

Notes: 25. The maximum burst rate of a gapped TCLK input clock is 8.192 MHz. For the gapped clock to be

tolerated by the CS61584A, the jitter attenuator must be switched to the transmit path of the line

interface. The maximum gap size that can be tolerated on TCLK is 28 UIp-p.

26. RCLK duty cycle may be outside the specified limits when the jitter attenuator is in the transmit path

and when the jitter attenuator is employing the overflow/underflow protection mechanism.

27. At max load of 50 pF.

8 DS261PP5

8 DS261F1

Page 9

DS261PP5

CS61584A

CS61584A

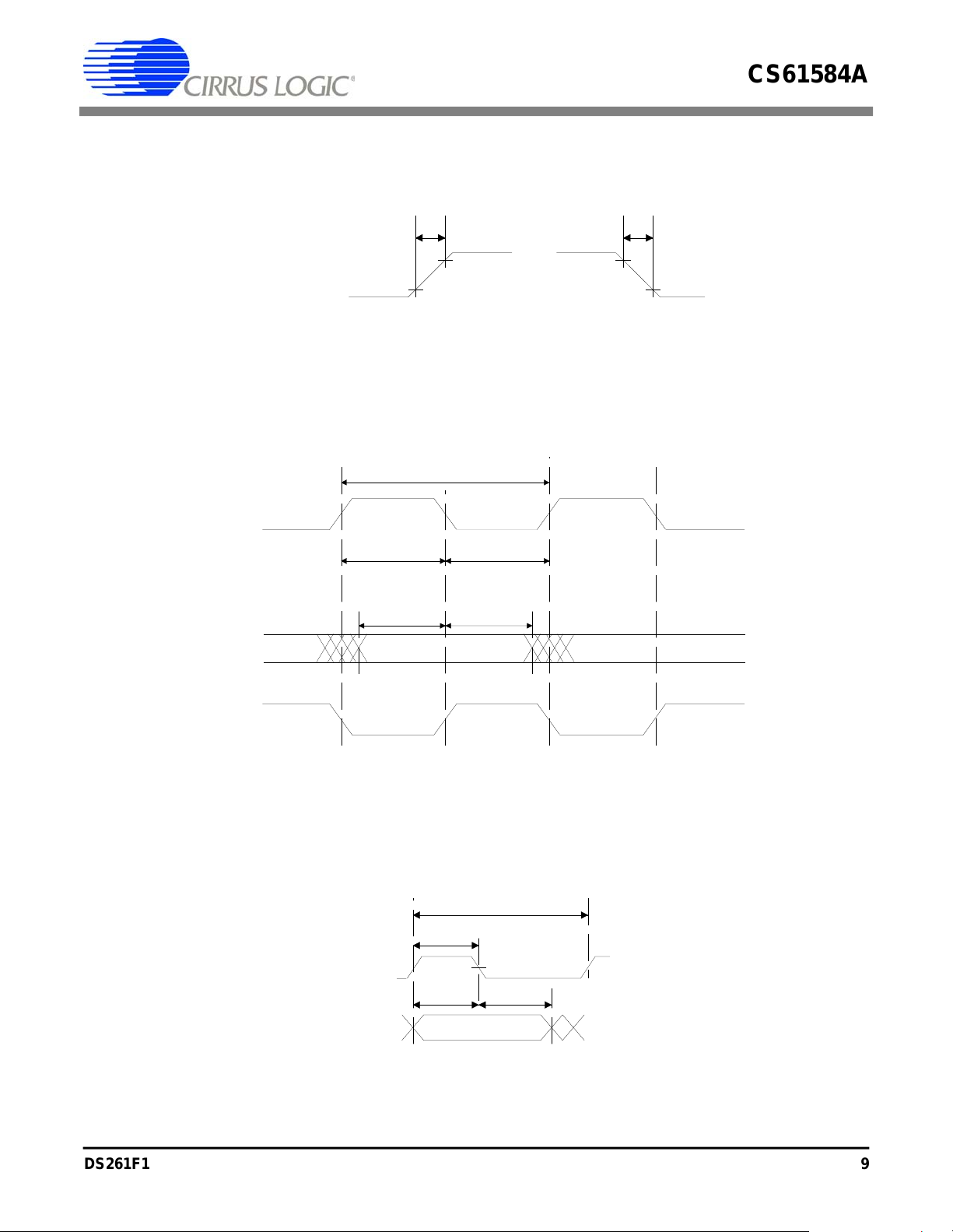

Any Digital Output

RCLK

(for CLKE = high)

RPOS

RNEG

RDATA

BPV

t

r

90% 90%

10% 10%

Figure 1. Signal Rise And Fall Characteristics

t

pw1

t

pwl1

t

su1

t

pwh1

t

h1

t

f

RCLK

(for CLKE = low)

Figure 2. Recovered Clock and Data Switching Characteristics

Figure 3. Transmit Clock and Data Switching Characteristics

TCLK

TPOS

TNEG

TDATA

t

pwh2

t

su2

t

pw2

t

h2

DS261PP5 9

DS261F1 9

Page 10

DS261PP5

CS61584A

CS61584A

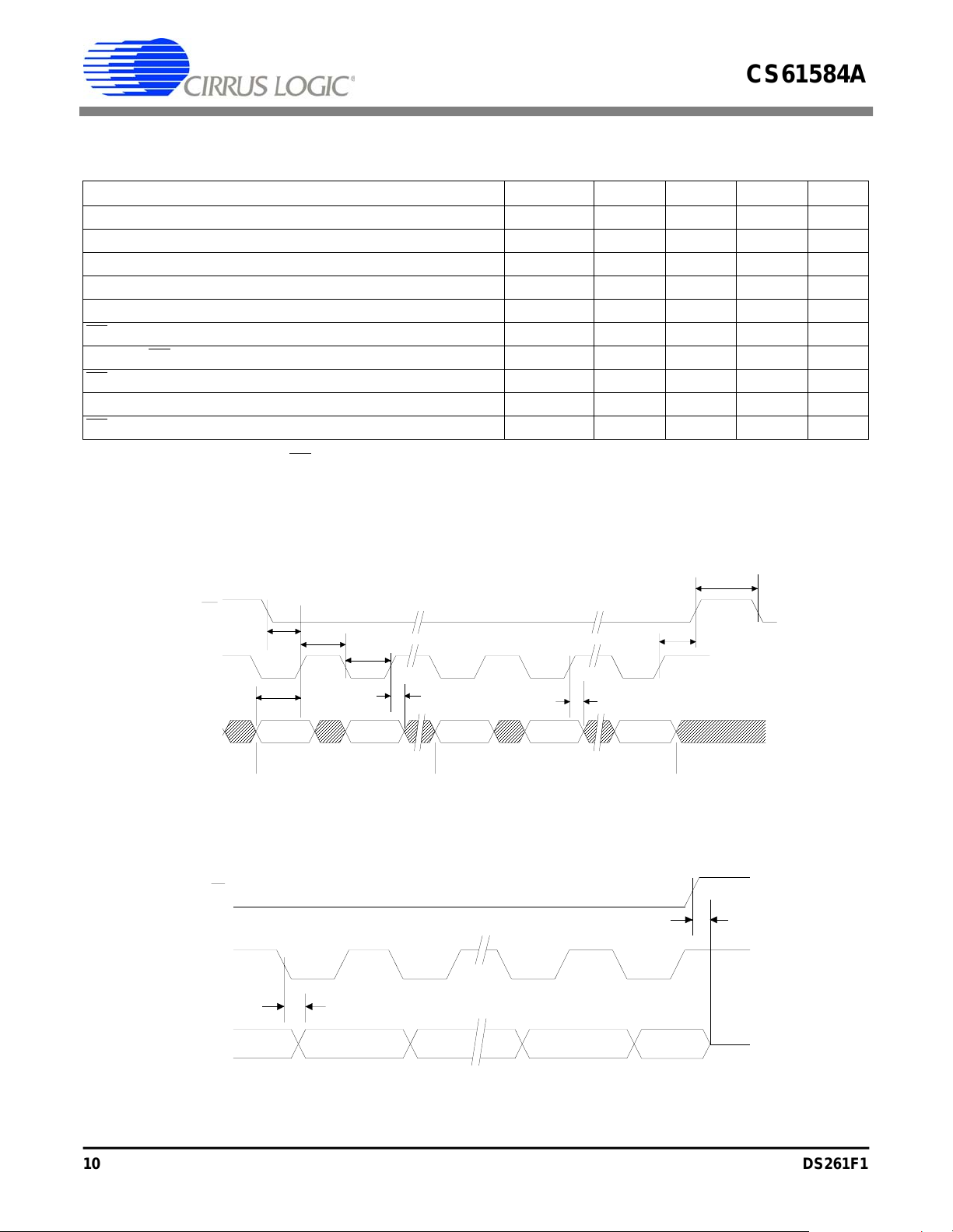

SWITCHING CHARACTERISTICS - SERIAL PORT (T

nominal ± 0.3 V; Inputs: Logic 0 = 0 V, Logic 1 = RV+)

Parameter Symbol Min Typ Max Unit

SDI to SCLK Setup Time t

SCLK to SDI Hold Time t

SCLK Low Time t

SCLK High Time t

SCLK Rise and Fall Time t

CS

to SCLK Setup Time t

SCLK to CS

CS

Inactive Time t

Hold Time (Note 28) t

SDO Valid to SCLK (Note 29) t

CS

to SDO High Z t

Notes: 28. If SPOL = 0, then CS

should return high no sooner than 20 ns after the 16th rising edge of SCLK during

a serial port read.

29. Output load capacitance = 50 pF.

dc

cdh

cl

ch

, t

r

cc

cch

cwh

cdv

cdz

f

= -40 to 85 °C; DV+, TV+, RV+ =

A

25 - - ns

25 - - ns

50 - - ns

50 - - ns

- - 15 ns

20 - - ns

20 - - ns

100 - - ns

- - 50 ns

-50-ns

t

cwh

CS

SCLK

SDI

SCLK

SDO

CS

t

ch

t

cc

t

dc

LSB LSB MSB

CONTROL BYTE DATA BYTE

t

cl

t

cdh

t

cdh

Figure 4. Serial Port Write Timing Diagram

t

cdv

t

cch

t

cdz

HIGH

SPOL = 0

Figure 5. Serial Port Read Timing Diagram

10 DS261PP5

10 DS261F1

Page 11

DS261PP5

CS61584A

CS61584A

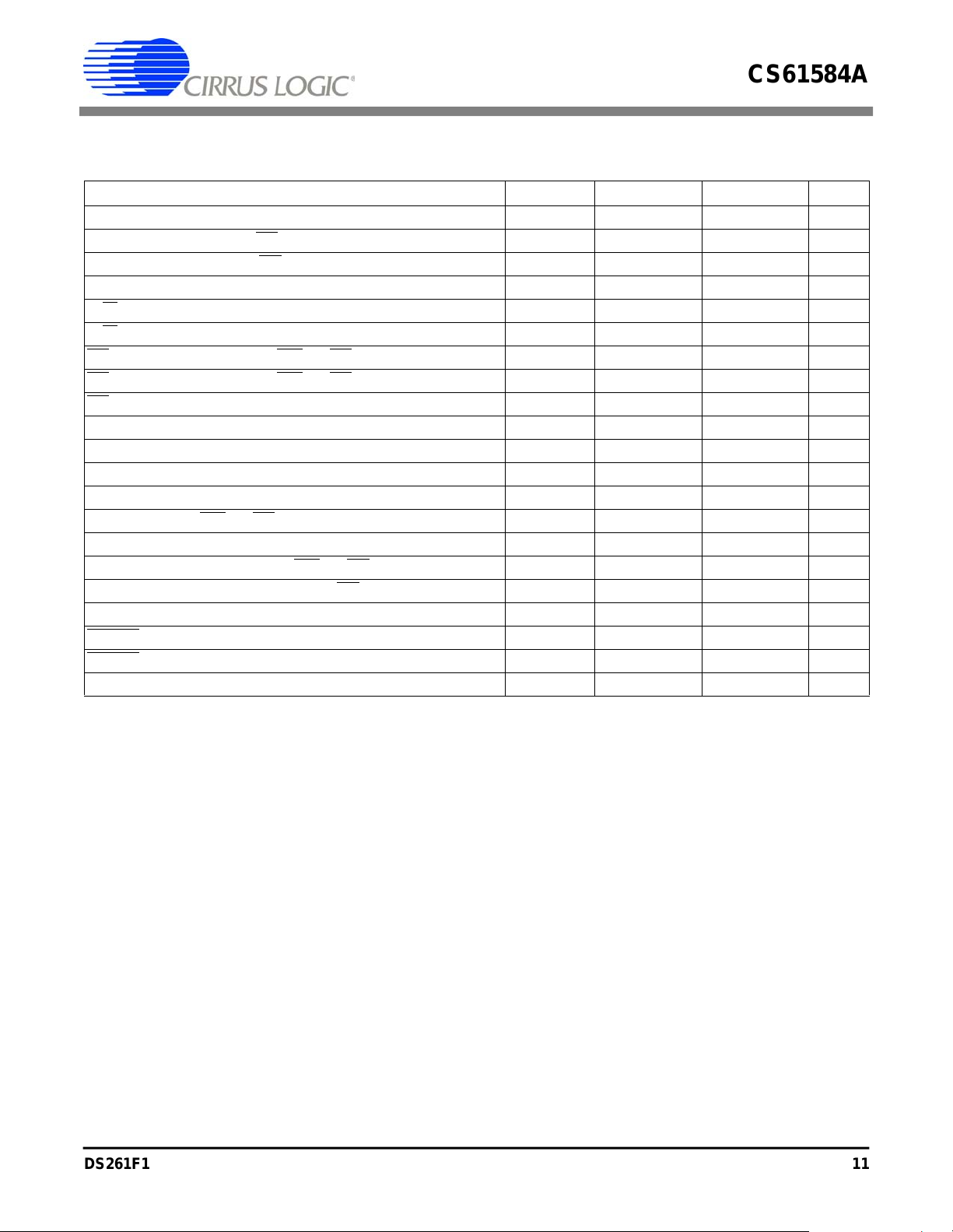

SWITCHING CHARACTERISTICS - PARALLEL PORT (T

= -40 to 85 °C;

A

TV+, RV+ = nominal ± 0.3 V; Inputs: Logic 0 = 0 V, Logic 1 = RV+)

Parameter Symbol Min Max Unit

Cycle Time t

Pulse Width, DS Low or RD

Pulse Width, DS High or RD

High PW

Low PW

Input Rise/Fall Times t

R/W

Hold Time t

R/W

Setup Time Before DS High t

CS

Setup Time Before DS, WR, or RD Active t

CS

Setup Time Before DS, WR, or RD Active for RAM/ROM t

CS

Hold Time t

Read Data Hold Time t

Write Data Hold Time t

Muxed Address Valid to AS or ALE Fall t

Muxed Address Hold Time t

Delay Time DS, WR

, or RD to AS or ALE Rise t

cyc

, t

r

rwh

rws

cs

csr

ch

dhr

dhw

asl

ahl

asd

el

eh

f

250 - ns

150 - ns

150 - ns

-30ns

10 - ns

50 - ns

50 - ns

130 - ns

20 - ns

10 80 ns

5-ns

15 - ns

10 - ns

25 - ns

Pulse Width AS or ALE High 40 - ns

Delay Time AS or ALE to DS, WR

Output Data Delay Time from DS or RD

Data Setup Time t

DTACK

DTACK

Delay t

Hold Time t

AS/ALE Min Low Interval for RAM/ROM t

, or RD t

ased

t

ddr

dsw

dkd

dkh

aamir

40 - ns

20 120 ns

80 - ns

5-ns

5-ns

50 - ns

DS261PP5 11

DS261F1 11

Page 12

AS

DS

R/W

AD0-AD7

(READ)

CS

AD0-AD7

(WRITE)

(READ and WRITE)

DTACK

DS261PP5

PW

ash

PW

t

asd

t

asl

t

asl

t

ased

t

rws

t

ahl

t

cs

t

ahl

t

dkd

Figure 6. Parallel Port Timing - Motorola Mode

eh

t

cyc

t

ddr

t

dsw

t

dhw

CS61584A

CS61584A

t

rwh

t

dhr

t

ch

t

dkh

ALE

WR

RD

CS

AD0-AD7

ALE

RD

AD0-AD7

WR

CS

t

cyc

PW

t

asd

t

asd

ash

t

ased

t

cs

t

asl

t

ahl

PW

el

t

ddr

Figure 7. Parallel Port Timing - Intel Read Mode

t

cyc

PW

t

asd

t

asd

ash

t

ased

t

cs

t

asl

PW

el

t

ch

t

dhr

t

ch

t

dhw

t

ahl

t

dsw

Figure 8. Parallel Port Timing - Intel Write Mode

12 DS261PP5

12 DS261F1

Page 13

DS261PP5

CS61584A

CS61584A

ALE

WR

RD

CS

AD0-AD7

AS

DS

R/W

AD0-AD7

(READ)

CS

AD0-AD7

(WRITE)

(READ and WRITE)

DTACK

t

asd

t

asd

PW

ash

t

t

asd

t

asl

t

asl

t

ahl

aamir

t

ahl

PW

ash

PW

t

ased

t

rws

t

asl

t

t

csr

t

asl

ahl

t

ahl

eh

t

cyc

t

ddr

t

dsw

t

dkd

t

t

ch

t

dhw

Figure 9. Parallel Port Timing - Motorola Mode to RAM

t

cyc

PW

ash

t

aamir

t

csr

t

asl

t

ahl

PW

ash

t

ased

t

asl

t

ahl

PW

t

ddr

Figure 10. Parallel Port Timing - Intel Read Mode from RAM or ROM

t

rwh

dhr

t

dkh

el

t

ch

t

dhr

t

cyc

ALE

WR

t

asd

t

asd

PW

ash

t

aamir

PW

ash

t

ased

PW

el

RD

t

csr

t

ch

CS

t

asl

t

asl

t

dhr

AD0-AD7

t

t

ahl

t

ahl

dsw

Figure 11. Parallel Port Timing - Intel Write Mode to RAM

DS261PP5 13

DS261F1 13

Page 14

DS261PP5

CS61584A

CS61584A

SWITCHING CHARACTERISTICS - JTAG (T

= -40 to 85 °C; TV+, RV+ = nominal ± 0.3 V;

A

Inputs: Logic 0 = 0 V, Logic 1 = RV+)

Parameter Symbol Min Max Unit

Cycle Time t

J-TMS/J-TDI to J-TCK Rising Setup Time t

J-TCK Rising to J-TMS/J-TDI Hold Time t

J-TCK Falling to J-TDO Valid t

t

cyc

J-TCK

t

t

su

J-TMS

J-TDI

J-TDO

h

cyc

su

h

dv

t

200 - ns

50 - ns

50 - ns

-60ns

dv

Figure 12. JTAG Switching Characteristics

14 DS261PP5

14 DS261F1

Page 15

DS261PP5

CS61584A

CS61584A

2. OVERVIEW

The CS61584A is a dual line interface for T1/E1

applications, designed for high-volume cards

where low power and high density are required.

The device can be operated in either Hardware

mode using control pins or in Host mode using an

internal register set. One board design can support

all T1/E1 short-haul modes by only changing component values in the receive and transmit paths (if

REFCLK and TCLK are connected externally).

Figure 13 illustrates applications of the CS61584A

in various environments.

LOOP TIMED APPLICATION

CS62180B

FRAMER

TPOS

TNEG

TCLK

RCLK

RPOS

RNEG

REFCLK

ATTENUATOR

JITTER

CS61584A

The line driver generates waveforms compatible

with E1 (CCITT G.703), T1 short haul (DSX-1)

and T1 FCC Part 68 Option A (DS1). A single

transformer turns ratio is used for all waveform

types. The driver internally match es the impedance

of the load, providing excellent return loss to insure

superior T1/E1 pulse quality. An additional benefit

of the internal impedance matching is a 50 percent

reduction in power consumption compared to implementing return loss using external resistors that

causes the transmitter to drive the equivalent of two

line loads.

LINE DRIVER

LINE RECEIVER

TTIP

TRING

RTIP

RRING

TRANSMIT

CIRCUITRY

RECEIVE

CIRCUITRY

MUX

CS62180B

FRAMER

TDATA

TCLK

(gapped)

RCLK

RDATA

TCLK

TPOS

TNEG

RCLK

RPOS

RNEG

ASYNCHRONOUS MUX APPLICATION

(i.e., VT1.5 card for SONET or SDH mux)

REFCLK

AMI

B8ZS,

HDB3,

CODER

(Including 62411 systems with multiple T1 lines)

REFCLK

JITTER

ATTENUATOR

CS61584A

JITTER

ATTENUATOR

AIS

DETECT

SYNCHRONOUS APPLICATION

LINE DRIVER

LINE RECEIVER

CS61584A

LINE DRIVER

LINE RECEIVER

Figure 13. Examples of CS61584A Applications

TTIP

TRING

RTIP

RRING

TTIP

TRING

RTIP

RRING

TRANSMIT

CIRCUITRY

RECEIVE

CIRCUITRY

TRANSMIT

CIRCUITRY

RECEIVE

CIRCUITRY

DS261PP5 15

DS261F1 15

Page 16

DS261PP5

CS61584A

CS61584A

The line receiver contains all the necessary clock

and data recovery circuits.

The jitter attenuator meets AT&T 62411 requirements when using either a 1X or 8X reference

clock supplied by either a quartz crystal, crystal oscillator, or external reference at the REFCLK input

pin.

2.1 AT&T 62411 Customer Premises Application

The AT&T 62411 specification applies to the T1

interface between the customer premises and the

carrier, and must be implemented by the customer

premises equipment in order to connect to the

AT&T network.

In 62411 applications, the management of jitter is a

very important design consideration. Typically, the

jitter attenuator is placed in the receive path of the

CS61584A to reduce the jitter input to the system

synchronizer. The jitter attenuated recovered clock

is used as the input to the transmit clock to imple-

ment a loop-timed system. A Stratum 4 (±32 ppm)

quality clock or better should be input to R EFCLK.

Note that any jitter present on the reference clock

will not be filtered by the jitter attenuator.

2.2 Asynchronous Multiplexer Application

Asynchronous multiplexers accept multiple T1/E1

lines (which are asynchronous to each other ), and

combine them into a higher speed tran smission rate

(e.g. M13 muxes and SONET muxes). In these systems, the jitter attenuator is placed in the transmit

path of the CS61584A to remove the gapped clock

jitter input by the multiplexer to TCLK. Because

the transmit clock is jittered, the reference clock to

the CS61584A is provided by an external source

operating at 1X or 8X the data rate. Because T1/E1

framers are not usually required in asynchronous

multiplexers, the B8ZS/AMI/HDB3 coders in the

CS61584A are activated to provide data interfaces

on TDATA and RDATA.

2.3 Synchronous Application

A typical example of a synchronous application is

a T1 card in a central office switch or a 0/1 digital

cross-connect system. These systems place the jitter attenuator in the receive path to reduce the jit ter

presented to the system. A Stratum 3 or better system clock is input to the CS61584A transmit and

reference clocks.

3. TRANSMITTER

The transmitter accepts data from a T1 or E1 system and outputs pulses of appropriate shape to the

line. The transmit clock (TCLK) and transmit data

(TPOS and TNEG, or TDATA) are supplied synchronously. Data is sampled on the falling edge of

the TCLK input.

During Hardware mode operation, the configuration pins (CON[3:0]) control transmitted pulse

shapes, transmitter source impedance, receiver

slicing level, and driver tristate as shown in

Table 1. During Host mode operation, the configuration is established by the CON[3:0] bits in the

Control B registers. Typical output pulses are

shown in Figures 14 and 15. These pulse shapes are

fully pre-defined by circuitry in the CS61584A,

and are fully compliant with appropriate standards

when used with our application guidelines in standard installations. Both channels must be operated

at the same line rate (both T1 or both E1).

Host mode operation permits arbitrary transmit

pulse shapes to be created and downloaded to the

CS61584A. These custom pulse shapes can be used

to compensate for waveform degradation caused by

non-standard cables, transformers, or protection

circuitry (refer to the Arbitrary Wavefor m Registers section).

Note that the pulse width for Part 68 Option A

(324 ns) is narrower than the optimal pulse width

for DSX-1 (350 ns). The CS61584A automatically

adjusts the pulse width based on the configuration

selection.

16 DS261PP5

16 DS261F1

Page 17

DS261PP5

500

1.0

0.5

0

-0.5

0 250 750 1000

NORMALIZED

AMPLITUDE

ANSI T1.102

SPECIFICATION

CS61584A

OUTPUT

PULSE SHAPE

TIME (nanoseconds)

e

Percent of

nominal

peak

voltage

120

110

100

90

80

50

269 ns

244 ns

194 ns

CS61584A

CS61584A

G.703

Specification

Figure 14. Typical Pulse Shape at DSX-1 Cross Connect

C

C

C

C

Transmit Pulse

O

O

O

O

Width at 50%

N

N

N

N

3

2

1

0

Amplitude

0000 244ns (50%) E1: square, 2.37 V into 75Ω 50% AMI/HDB3

1000 244ns (50%) Arbitrary E1 Wave into 75Ω 50% AMI/HDB3

0001 244ns (50%) E1: square, 2.37 V into 75Ω 50% AMI/HDB3

1001 244ns (50%) Arbitrary E1 Wave into 120Ω 50% AMI/HDB3

0010 350ns (54%) DSX-1: 0-133 ft. 65% AMI/B8ZS

0011 350ns (54%) DSX-1: 133-266 ft. 65% AMI/B8ZS

0100 350ns (54%) DSX-1: 266-399 ft. 65% AMI/B8ZS

0101 350ns (54%) DSX-1: 399-533 ft. 65% AMI/B8ZS

0110 350ns (54%) DSX-1: 533-655 ft. 65% AMI/B8ZS

1010 350ns (54%) Arbitrary DSX-1 Waveform 65% AMI/B8ZS

0111 324ns (50%) DS1: FCC Part 68 Option A with undershoot 65% AMI/B8ZS

1100 324ns (50%) DS1: FCC Part 68 Option A (0 dB) 65% AMI/B8ZS

1011 324ns (50%) Arbitrary DS1 Waveform 65% AMI/B8ZS

1101 Reserved

1110 Transmit Hi Z Tristate TTIP/TRING Driver Outputs 50% AMI/HDB3

1111 Transmit Hi Z Tristate TTIP/TRING Driver Outputs 65% AMI/B8ZS

DS261PP5 17

DS261F1 17

10

0

-10

-20

Figure 15. Mask of the Pulse at the 2048 kbps Interface

Transmit Pulse Shape Receiver

Table 1. Line Configuration Selections

219 ns

488 ns

Slicing

Level

Nominal Puls

Line Code

Encoder /

Decoder

Page 18

DS261PP5

CS61584A

CS61584A

The transmitter impedance changes with the line

length options in order to match the load impedance (75 Ω for E1 coax, 100 Ω for T1, 120 Ω for

E1 shielded twisted pair), providing a minimum of

14 dB return loss for T1 and E1 frequencies during

the transmission of both marks and spaces. This

improves signal quality by minimizing reflections

from the transmitter. Impedance matching also reduces load power consumption by a factor of two

when compared to the return loss achieved by using

external resistors.

The CS61584A driver will automatically detect an

inactive TLCK (i.e., no data clocked to the driver)

or REFCLK input. When either of these conditions

are detected the driver is forced t o the tristate (highimpedance) condition. If the jitter attenuator is in

the transmit path, the driver will tristate after 170 to

182 TCLK clock cycles. If the attenuator is not in

the transmit path, the driver will tristate after 4 to

12 TCLK clock cycles. During Host mode operation, the CLKLOST bit in the Status register goes

high to indicate when the driver is tristated due to

the absence of TCLK or REFCLK. The driver exits

the tristate condition when four clock cycles are input to TCLK. On power-up or reset, the driver is

tristated until REFCLK is present and four clock

cycles are input to TCLK. In Host mode the driver

will have to be taken out of the tristate condition by

writing the CON[3:0]. The driver is not forced to

the tristate condition during remote loopback if

TCLK is absent.

When the transmit configuration established by

CON[3:0], TAOS, or LLOOP changes state, the

transmitter stabilizes within 22 TCLK bit periods.

The transmitter takes longer to stabilize when

RLOOP1 or RLOOP2 is selected because the timing circuitry must adjust to the new frequency from

RCLK.

When the transmitter transformer secondaries are

shorted through a 0.5 Ω resistor, the transmitter

will output a maximum of 50 mA-rms, as required

by the European specification BS6450. This spec is

met for 5.0 V operation only.

4. RECEIVER

The input signal is connected to the receiver

through a step down transformer (1.15:1 for 5 V

and 2:1 for 3.3 V). Data and clock are extracted

from the T1/E1 signal input to the line interface and

to the system. The signal is detected differentially

across the receive transformer and can be recovered over the entire range of short haul cable

lengths. The transmit and receive transformer specifications are identical and are presented in the Applications section. As shown in Table 1, the

receiver slicing level is set at 65% for DS1/DSX-1

short-haul and at 50% for all other applications.

The clock recovery circuit is a second-order phase

locked loop that can tolerate up to 0.4 UI of jitter

from 10 kHz to 100 kHz without generating er rors

(Figure 13). The clock and data recovery circuit is

tolerant of long strings of consecutive zeros and

will successfully recover a 1-in-175 jitter-free line

input signal.

Recovered data at RPOS and RNEG (or RDATA)

is stable and may be sampled using the recovered

clock RCLK. During Hardware mode operation,

CS61584A

300

138

100

PEAK-TO-PEAK

JITTER

(unit intervals)

Figure 16. Minimum Input Jitter Tolerance of Receiver

28

10

.4

.1

(Clock Recovery Circuit and jitter Attenuator)

1

1

AT&T 62411

(1990 Version)

Performance

10 1k 10k

100 100k700

300

JITTER FREQUENCY (Hz)

18 DS261PP5

18 DS261F1

Page 19

DS261PP5

Figure 17. Typical Jitter Transfer Function

CS61584A

CS61584A

the CLKE pin determines the clock polarity where

the output data is stable and valid as shown in

Table 2. During Host mode operation, the polarity

is established by the CLKE bit in the Control A register. When CLKE is low, RPOS and RNEG (or

RDATA) are valid on the rising edge of RCLK.

When CLKE is high, RPOS and RNEG (or RDATA) are valid on the falling edge of RCLK

During Host mode operation, the data at RPOS and

RNEG (or RDATA) may be forced to output an unframed all-ones pattern by setting both the

LLOOP1 and LLOOP2 bits in the Control B register to "1".

CLKE DATA CLOCK Clock edge for

valid data

LOW RPOS, RNEG

or RDATA

HIGH RP OS, RNEG

or RDATA

Table 2. Recovered Data/Clock Options

RCLK

RCLK

RCLK

RCLK

Rising

Rising

Falling

Falling

During Hardware mode operation, the location of

the jitter attenuators for both channels is controlled

by the ATTEN0 and ATTEN1 pins. During Host

mode operation, the location of the jitter attenuators are independent and are controlled by the ATTEN[1:0] bits in the Control A registers. Table 3

shows how these pins are decoded.

The attenuator consists of a 64-bit FIFO, a narrowband monolithic PLL, and control logic. Signal jitter is absorbed in the FIFO which is designed to

neither overflow nor underflow. If overflow or underflow is imminent, the jitter transfer function is

altered to ensure that no bit-errors occur. Under this

condition, jitter gain may occur and exte rnal provisions may be required. The jitter attenuator will

typically tolerate 43 UIs before the overflow/underflow mechanism occurs. If the jitter attenuator

has not had time to "lock" to the average incoming

frequency (e.g. following a device reset) the a ttenuator will tolerate a minimum of 22 UIs before the

overflow/underflow mechanism occurs.

0

10

20

30

40

Maximum

Attenuation

Attenuation in dB

Limit

50

60

1 10 100 1 k 10 k

E1 Mode

Minimum Attenuation Limit

62411 Requirements

T1 Mode

Measured Performance

Frequency in Hz

5. JITTER ATTENUATOR

The jitter attenuator can be switched into ei ther t he

receive or transmit paths. Alternatively, it can also

be removed from both paths to reduce the propagation delay. Figure 14 illustrates the typical jitter attenuation curves.

The jitter attenuator -3 dB knee frequency is 4.0 Hz

for T1 mode and 1.25 Hz for E1 mode as selected

by the CON[3:0] pins or register bits. A 1.25 Hz

knee for the E1 mode guarantees jitter attenuation

compliance to European specifications CTR 12 and

ETSI ETS 300 011. Setting ATTEN[1:0] = 11 will

place the jitter attenuator in the receive path with a

1.25 Hz knee for both T1 and E1 modes of operation.

For T1/E1 line cards used in high-speed mutiplexers (e.g., SONET and SDH), the jitter attenuator is

typically used in the transmit path. The attenuator

can accept a transmit clock with gaps ≤ 28 UIs and

a transmit clock burst rate of ≤ 8 MHz.

ATTEN1 ATTEN0 Location of Jitter Attenuator

00 Receiver

0 1 Disabled

1 0 Transmitter

1 1 Receiver w/ 1.25 Hz knee

Table 3. Jitter Attenuation Control

DS261PP5 19

DS261F1 19

Page 20

DS261PP5

CS61584A

CS61584A

6. REFERENCE CLOCK

The CS61584A requires a reference clock with a

minimum accuracy of ±100 ppm for T1 and E1 applications. This clock can be either a 1X clock (i.e.,

1.544 MHz or 2.048 MHz), or can be a 8X clock

(i.e., 12.352 MHz or 16.384 MHz) as selected by

the 1XCLK pin. This clock may be supplied from

internal system timing or a CMOS crystal oscillator

and input to the REFCLK pin. An 8X quartz crystal

may be connected across the REFCLK and XTALOUT pins and the 1XCLK pin set low. The quartz

crystal and CMOS crystal oscillator specifications

and are presented in the Applications section.

In systems with a jittered transmit clock, the reference clock should not be tied to the transmit clock

and a separate external quartz crystal or crystal oscillator should drive the reference clock input. Any

jitter present on the reference clock will not be filtered by the jitter attenuator.

7. POWER-UP RESET

On power-up, the device is held in a static state until the power supply achieves approximately 60%

of the power supply voltage. When this threshold is

crossed, the device waits another 10 ms to allow the

power supply to reach operating voltage and then

calibrates the transmit and receive circuitry. This

initial calibration takes less than 20 ms but can occur only if REFCLK and TCLK are present.

Power-up reset initializes the control logic and register set and performs the same functions as the RESET pin. During Host mode operation, a reset event

is indicated by the Latched-Reset bit in the Status

register.

8. LINE CONTROL AND MONITORING

Line control and monitoring of the CS61584A may

be implemented in either Hardware or Host mode.

Hardware mode is selected when the MODE pin is

set low and allows the device to be configured and

monitored using control pins. Host mode is selected when the MODE pin is set high and allows the

device to be configured and monitored using an internal register set.

The following controls and indications are available in Hardware mode: line length selection, receive clock edge, jitter attenuator location, loss of

signal, transmit all ones, local loopback, remote

loopback, and power down. Host mode operation

offers several additional control options (refer to

the Host Mode section).

Note: Please refer to the Loop Selection Equations in

the Applications section.

8.1 Line Code Encoder/Decoder

Hardware mode supports only transparent operation to permit the line code to be encoded and decoded by an external T1/E1 framing device.

Recovered data is output on the RNEG and RPOS

pins in NRZ format and transmitted data is input on

the TNEG and TPOS pins.

Host mode supports transparent, AMI, B8ZS, or

HDB3 line encoding and decoding for applications

not using an external T1/E1 framer (i.e. multiplexers). The CODER, AMI-T, and AMI-R bits in the

Control A registers select the coder mode for a given channel. The selection of the transmit encoder is

independent from the selection of the receive decoder. When CODER = 1, the transmit data is input

to the encoder on TDATA and the receive data is

output from the decoder on RDATA in NRZ format.

8.2 Alarm Indication Signal

During Host mode operation, the alarm indication

signal (AIS) is detected by the receiver and reported using the AIS and Latched-AIS bits in the Status

registers. The receiver detects the AIS condition on

observation of 99.9% ones density in a 5.3 ms period (< 9 zeros in 8192 bits). If CODER = 1 in the

Control A registers, the TNEG pin becomes the

AIS output pin that is set high on detection of AIS.

The AIS condition is exited when ≥ 9 zeros are detected in 8192 bits.

20 DS261PP5

20 DS261F1

Page 21

DS261PP5

CS61584A

CS61584A

8.3 Bipolar Violation Detection

During Host mode operation, a bipolar violation

(BPV) is detected by the receiver and reported using the Latched-BPV bit in the Status registers. If

CODER = 1 in the Control A registers, the RNEG

pin becomes the BPV output strobe pin that is set

high for one bit period on detection of a BPV. Note

that B8ZS (or HDB3) zero substitutions are not

flagged as bipolar violations if the B8ZS (or

HDB3) decoder has been enabled (CODER = 1 and

AMI-R = 0 in the Control A registers).

8.4 Excessive Zeros Detection

During Host mode operation if CODER = 1 and

EXZ = 1 in the Control A register, the BPV output

pin is OR’ed with receive excessive zero events. In

AMI mode when AMI-Rx = 1, the BPV pin is set

high for one bit period when 16 or more consecutive zeros are received. In B8ZS mode when AMIRx = 0, the BPV pin is set high for one bit period

when 8 or more consecutive zeros are received.

This is in accordance with the ANSI T1.231 specification. For E1 operation with HDB3 disabled, the

excessive zeros detection is also disabled. For E1

with HDB3 enabled the BPV pin goes high for every set of 4 consecutively received zeros.

8.5 Loss of Signal

During Hardware mode and Host mode operation,

the loss of signal (LOS) condition is detected by the

receiver and reported when the LOS pin is set high.

Loss of signal is indicated when 175 ±15 consecutive zeros are received, or when the receive

(R TIP/RRING) signal level drops below the receiver sensitivity of the device. The LOS condition is

exited according to the ANSI T1.231-1993 criteria

that requires a minimum 12.5% ones density signal

over 175 ±75 bit periods with no more than 100

consecutive zeros. During LOS, recovered data is

squelched and zeroes are output on RPOS/RNEG

(RDATA).

During Host mode operation, LOS is reported using the LOS and Latched-LOS bits in the Status

registers. Note that both the LOS pin and register

indications are available in Host mode operation.

The LOS pin and/or bit is set high when the device

is reset, in power-up, or a channel is powered-down

and returns low when data is recovered by the receiver.

During LOS condition the RPOS (RDATA),

RNEG pins are forced low, except when LLOOP1

(digital loopback) is enabled, or when the AAO

(Automatic All Ones) bit is set in the channel 1

mask register. Setting the AAO bit high forces unframed all ones pattern out on the RPOS (RDATA), RNEG pins when LOS condition occurs.

When the jitter attenuator is in th e rece ive path and

LOS occurs, the frequency of the last valid recovered signal is held at RCLK. When the jitter attenuator is not in the receive path, the output

frequency becomes the frequency of the reference

clock.

8.6 Transmit All Ones

During Hardware mode operation, transmit all ones

(TAOS) is selected by setting the TAOS pin high.

During Host mode, TAOS is controlled using the

TAOS bit in the Control B registers.

Selecting TAOS causes continuous ones to be

transmitted to the line on TTIP and TRING at the

frequency of REFCLK. In this mode, the transmit

data inputs TPOS and TNEG (or TDATA) are ignored. A TAOS request overrides the data tran smitted to the line interface during local and remote

loopbacks. Note that the CLKLOST interrupt is

not available for TCLK in the TAOS mode.

8.7 Receive All Ones

During Host mode operation, the data at RPOS and

RNEG (or RDATA) may be forced to output an unframed all-ones pattern by setting both the

LLOOP1 and LLOOP2 bits in the Control B register to "1". An automatic Receive All Ones (AAO)

DS261PP5 21

DS261F1 21

Page 22

DS261PP5

CS61584A

CS61584A

response to a Loss of Signal condition for either

channel is activated by setting bit 1 of the channel

1 Mask register to 1.

8.8 Local Loopback

Selecting LLOOP causes the TCLK, TPOS, and

TNEG (or TDATA) inputs to be looped back

through the jitter attenuator (if enabled) to the

RCLK, RPOS, and RNEG (or RDATA) outputs.

The receive line interface is ignored, but data at

TPOS and TNEG (or TDATA) continues to be

transmitted to the line interface at TTIP and

TRING. During Hardware mode operation, simultaneous local loopback 2 of both channels is selected by setting the LLOOP pin high. During Host

mode operation, local loopback 1 on a per channel

basis is controlled using the LLOOP1 bit in the

Control B registers.

During Hardware mode operation, a per channel local loopback 1 is performed when both the RLOOP

and TAOS pins are high. The data at TPOS and

TNEG is overridden with an all-ones pattern (TAOS)

and the receive input at RTIP and RRING is ignored.

During Host mode operation, local loopback 2 can

also be selected using the LLOOP2 bit in the Control

B registers. Selecting LLOOP2 causes the TCLK,

TPOS, and TNEG (or TDATA) inputs to be looped

back to the RCLK, RPOS, and RNEG (or RDATA)

outputs. The line driver, line receiver, and jitter attenuator (if enabled) are also included. The receive

line interface is ignored, but data at TPOS and

TNEG (or TDATA) continues to be transmitted to

the line interface at TTIP and TRING.

A TAOS request overrides the data transmitted to

the line interface during both local loopbacks. A

TAOS request also overrides the data received at

RPOS and RNEG (or RDATA) during local loopback 2. Note that simultaneous selection of local

and remote loopback modes is not valid.

8.9 Remote Loopback

During Hardware mode operation, remote loopbacks of either channel is selected by setting the

RLOOP pin high. During Host mode operation, remote loopback of each channel is controlled using

the RLOOP bit in the Control B registers.

Selecting RLOOP causes the data received from

the line interface at RTIP and RRING to be looped

back through the jitter attenuator (if enabled) and

retransmitted on TTIP and TRING. Data input to

TPOS and TNEG (or TDATA) is ignored, but data

recovered from RTIP and RRING continues to be

output on RPOS and RNEG (or RDATA).

Remote loopback is functional if TCLK is absent.

A TAOS request overrides the data transmitted to

the line interface during a remote loopback. Note

that simultaneous selection of local and remote

loopback modes is not valid.

8.10 Driver Tristate

The drivers may be independently tristated in all

modes of oper ation. During Hardware mode operation, setting the CON[3:0] pins of a channel to

"111X" will tristate the driver. During Host mode serial port operation, t he ZTX1 and ZTX2 pins perform

the driver tristate function and setting the CON[3:0]

bits in the Control B registers to "111X" will also

tristate the driver. During Host mode parallel port operation, setting the CON[3:0] bits in the Control B

register to "111X" tristates the driver. In host mode,

the CS61584A powers up with CON[3:0] set to

1110, which tristates the transmitter.

8.11 Power Down

During Hardware mode operation, channel power

down is selected by setting the PD1 or PD2 pin

high. During Host mode operation, channel power

down is controlled using the PD bit in the Control

A registers. Power down places the transmitter, receiver, and jitter attenuator in reset. The RCLK,

RPOS, RNEG, RDATA, AIS, BPV, TTIP, and

TRING output pins are placed in a high-impedance

22 DS261PP5

22 DS261F1

Page 23

DS261PP5

CS61584A

CS61584A

state. LOS will go high, and the status register will

be reset, but the Control, Mask, and Arbitrary

Waveform registers remain unchanged. The channel not in power down and the processor port will

still to operate normally.

Simultaneously selecting PD1 and PD2 will place

all the above-mentioned pins in high impedance

state and power down additional analog circuitry

that is shared by both channels. The status registers

are reset. In the hardware mode all output pins are

tri-stated and internally pulled up to the positive

supply rail. After exiting the power down state, the

channel will be fully operational in less than 20 ms.

8.12 Reset Pin

The CS61584A is continuously calibrated during

operation to insure the performance of the device

over power supply and temperature. This continuous calibration function eliminates the need to reset

the line interface during operation.

During Hardware and Host modes of opera tion, a

device reset is selected by setting the RESET pin

high for a minimum of 200 ns. The reset function

initiates on the falling edge of RESET and requires

less than 20 ms to complete. The control logic and

register set are initialized and the transmit and receive circuitry is calibrated if REFCLK and TCLK

are present. During Host mode operation, a reset

event is indicated by the Latched-Reset bit in the

Status register.

9. HOST MODE

Host mode allows the CS61584A to be configured

and monitored using an internal register set. This

option is selected when the MODE pin is set high.

Using the P/S pin, serial or 8-bit para llel interface

ports are available in Host mode. During serial port

operation, the registers are specified by a 6-bit address in the range of 0x10 to 0x19. During parallel

port operation, the registers are specified by an 8bit address. The four most significant bits of the address selects one of 16 devices on the board, estab-

lished by the SAD[7:4] pins. The four least

significant bits of the address specify the register

address in the range of 0x00 to 0x09 for the selected

device. Parallel port option is compatible with Motorola and Intel 8-bit, multiplexed address/data bus.

9.1 Register Set

The register set available during Host mode operation is presented in Table 4.

Serial Po rt

Address

0x10 0xY0 Ch 1 Status

0x11 0xY1 Ch 2 Status

0x12 0xY2 Ch 1 Mask

0x13 0xY3 Ch 2 Mask

0x14 0xY4 Ch 1 Control A

0x15 0xY5 Ch 2 Control A

0x16 0xY6 Ch 1 Control B

0x17 0xY7 Ch 2 Control B

0x18 0xY8 Ch 1 Arbitrary Pulse Shape

0x19 0xY9 Ch 2 Arbitrary Pulse Shape

*Y denote s the SAD[7:4] addre ss of the CS61584A device.

Parallel Port

Address*

Table 4. CS61584A Register Set

Description

9.1.1 Status Registers

The Status registers are read-only registers and are

shown in Table 5. The CS61584A generates an interrupt on the INT pin any time an unmasked Status

register bit changes. When BTS is low (Intel

mode), the IPOL pin determines the polarity of the

pin. When BTS is high (Motorola mode), INT

INT

polarity is active low (IPOL becomes DTACK).

Reading both Status register clears the interrupt

and deactivates the INT pin.

LOS: Set high while the loss of signal condition is

detected. Reading the Status register does not clear

the LOS bit. A LOS interrupt is generated only on

the falling edge of the LOS alarm condition. The

Latched-LOS bit generates an interrupt on the rising edge of LOS. Refer to the timing diagram in

Figure 18.

DS261PP5 23

DS261F1 23

Page 24

DS261PP5

CS61584A

CS61584A

Latched-LOS: Set high on the rising edge of the

loss of signal condition. Reading the Status register

clears the Latched-LOS bit and deactivates the INT

pin. Refer to the timing diagram in Figure 18.

AIS: Set high while the alarm indication signal is

the AIS bit. An AIS interrupt is generated only on

the falling edge of the AIS alarm condition. The

Latched-AIS bit generates an interrupt on the rising

edge of AIS. Refer to the timing diagram in

Figure 18.

detected. Reading the Status register does not clear

Status Register (Channel 1)

Serial Port Address: 0x10; Parallel Port Address: 0xY0

Bit Description Definition Reset

10

7 LOS1 LOS currently detected no LOS 1

6 Latched-LOS1 LOS event since last read no LOS 1

5 AIS1 AIS currently detected no AIS 0

4 Latched-AIS1 AIS event since last read no AIS 0

3 Latched-BPV1 BPV event since last read no BPV 0

2 Latched-Overflow1 Pulse overflow since last read no overflow 0

1 Latched-Reset Reset event since last read no reset 1

0 Interrupt1 Interrupt event since last read no interrupt 1

Status Register (Channel 2)

Serial Port Address: 0x11; Parallel Port Address: 0xY1

Bit Description Definition Reset

10

7 LOS2 LOS currently detected no LOS 1

6 Latched-LOS2 LOS event since last read no LOS 1

5 AIS2 AIS currently detected no AIS 0

4 Latched-AIS2 AIS event since last read no AIS 0

3 Latched-BPV2 BPV event since last read no BPV 0

2 Latched-Overflow2 Pulse overflow since last read no overflow 0

1 Latched-CLKLOST TCLK or REFCLK absent TCLK and REFCLK present 0

0 Interrupt2 Interrupt event since last read no interrupt 1

Table 5. Status Registers

Value

Value

AIS/LOS Currently Active

(AIS/LOS bit & AIS/LOS pi n)

Latched LOS

(Latch AIS/LOS bit)

Interrupt

(INT)

Read AIS/LOS bits

Figure 18. Alarm Indication Event Relationships

24 DS261PP5

24 DS261F1

"Short" AIS/LOS event

Set by start

of AIS/LOS

Set by Change

of AIS/LOS

"Long" AIS/LOS event

Cleared by read

Cleared by read

Page 25

DS261PP5

CS61584A

CS61584A

Latched-AIS: Set high on the rising edge of the

alarm indication signal condition. Reading the Status register clears the Latched-AIS bit and deactivates the INT pin. Refer to the timing diagram in

Figure 18.

Latched-BPV: Indicates a bipolar violation has

been received since the last read of the Status register. Reading the Status register clears the

Latched-BPV bit and deactivates the INT

pin. This

bit is set only when the line code decoder is enabled

in the Control A register.

Latched-Overflow: Indicates a waveform generated using the Arbitrary Waveform register has exceeded full scale since the last read of t he Status

register. Reading the Status register clears the

Latched-Overflow bit and deactivates the INT pin.

Latched-Reset: Indicates a reset event (power-up or

RESET pin) has occurred since the last read of the

Status register. Reading the Status register clears

the Latched-Reset bit and deactivates the INT pin.

This bit is not maskable.

Latched-CLKLOST: Set high when TCLK or REFCLK are absent. Reading the Status register clears

the Latched-CLKLOST bit and deactivates the INT

pin.

Interrupt: Indicates a cha nge in the Status registe r

since the last read. Reading the Status register

clears the Interrupt bit and deactivates the INT

pin.

9.1.2 Mask Registers

The Mask registers are read-write registers and are

shown in Table 6. The Mask registers disables the

interrupts in the corresponding Status register on a

per-bit basis. Masking a Status register bit forces it

to remain at zero and prevents the INT pin from activating on the condition.