Dual T1/E1 Line Interface

CS61583

Features

Dual T1/E1 Line In terface

•

Low Power Consumption

•

(Typically 220mW per Line Interface)

Matched Impedance Transmit Drivers

•

Common Transmit and Receive Transform-

•

ers for all Modes

Selectable Jitter Attenuation for Transmit

•

or Receive Paths

Supports JTAG Boundary Scan

•

Hardware Mode Derivative of the CS61584

•

TCLK1

TPOS1/

TDATA1

TNEG1/

AIS1

RCLK1

RPOS1/

RDATA1

RNEG1/

BPV1

TCLK2

TPOS2/

TDATA2

TNEG2/

AIS2

RCLK2

RPOS2/

RDATA2

RNEG2/

BPV2

CLKE TAOS1

RESET

E

R

N

E

C

M

O

O

D

T

E

E

R

L

D

O

E

O

C

P

O

B

D

A

E

C

R

K

E

R

N

E

C

M

O

O

D

T

E

E

R

L

D

O

E

O

C

P

O

B

D

A

E

C

R

K

ATTEN2

JITTER

ATTENUATOR

JITTER

ATTENUATOR

CON01

CON11

CON21

L

O

C

A

L

L

O

O

P

B

A

C

K

L

O

C

A

L

L

O

O

P

B

A

C

K

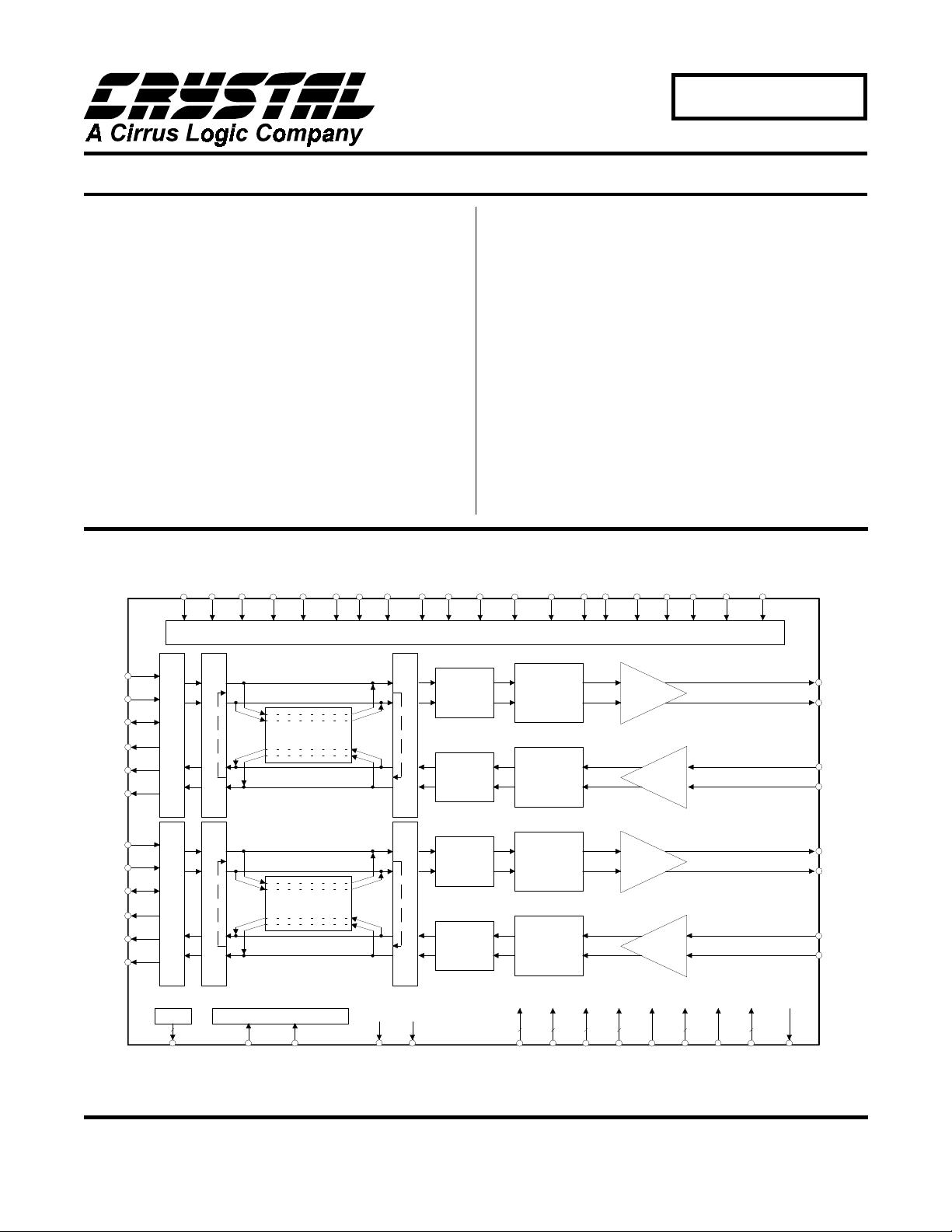

General Description

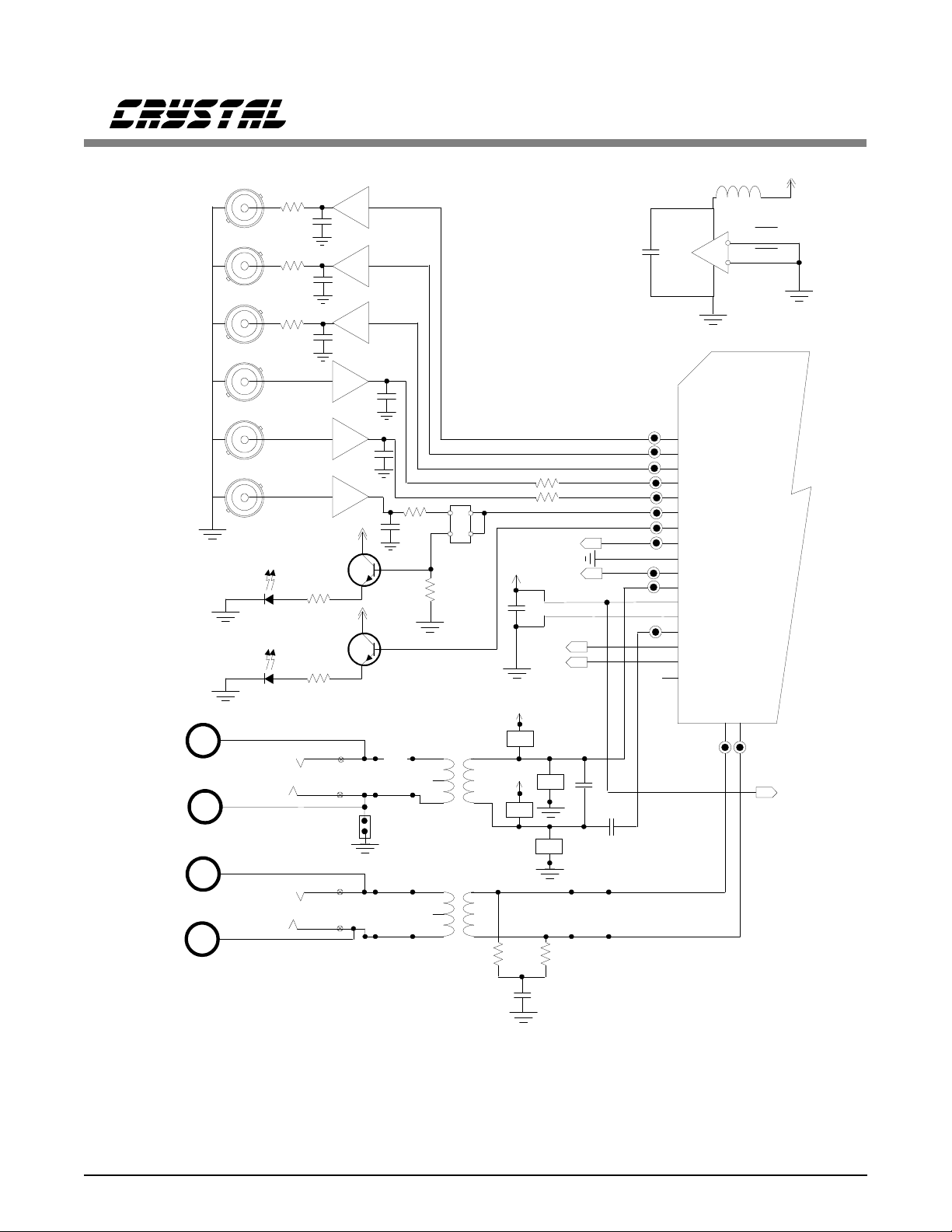

The CS61583 is a dual line interface for T1/E1 applications, designed for high-volume cards where low power

and high density are required. Each channel features

individual control and status pins which eliminates the

need for external microprocessor support. The

matched impedance drivers reduce power consumption

and provide substantial return loss to insure superior

T1/E1 pulse quality.

The CS61583 provides JTAG boundary scan to enhance system testability and reliability. The CS61583 is

a 5 volt device and is a hardware mode derivative of

the CS61584.

ORDERING INFORMATION

CS61583-IL5: 68-pin PLCC, -40 to +85 °C

CS61583-IQ5: 64-pin TQFP, -40 to +85 °C

LLOOP1

CONTROL

TAOS

LOS

DETECT

TAOS

LOS

DETECT

RLOOP1

CIRCUITRY

RECOVERY

CIRCUITRY

RECOVERY

CODER2CODER1ATTEN1

PULSE

SHAPING

CLOCK &

DATA

PULSE

SHAPING

CLOCK &

DATA

CON02

CON12

DRIVE R

DRIVER

AMI2AMI1

CON22

RECEIVER

RECEIVER

TAOS2

LLOOP2

RLOOP2

TTIP1

TRING1

RTIP1

RRING1

TTIP2

TRING2

RTIP2

RRING2

JTAG

4

CLOCK GEN ERAT OR

REFCLK 1XCLK

Crystal Semiconductor Corporation

P. O. Box 17847, Austin, Texas, 78760

(512) 445 7222 FAX:(512) 445 7581

LOS1 LOS2

2 2 2 2 3 2

TV+ TGND RV+ RGND DV+ DGND AV+ AGND

Copyright Crystal Semiconductor Corporation 1996

(All Rights Reserved)

BGREF

JULY ’96

DS172PP5

1

Table of Contents

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications

Absolute Maximum Ratings. . . . . . . . . . . . . . . . . . . . . . . . . 3

Recommended Operating Conditions. . . . . . . . . . . . . . . . . . 3

Digital Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Analog Specifications

Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Jitter Attenuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Switching Characteristics

T1 Clock/Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

E1 Clock/Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

JTAG. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

CS61583

General Description

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Jitter Attenuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Reference Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Power-Up Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Line Control and Monitoring . . . . . . . . . . . . . . . . . . . . . . . . 13

Line Code Encoder/Decoder. . . . . . . . . . . . . . . . . . . 13

Alarm Indication Signal . . . . . . . . . . . . . . . . . . . . . . 14

Bipolar Violation Detection . . . . . . . . . . . . . . . . . . . 14

Loss of Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Transmit All Ones . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Local Loopback . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Remote Loopback. . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Reset Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

JTAG Boundary Scan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pin Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Physical Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2 DS172PP5

CS61583

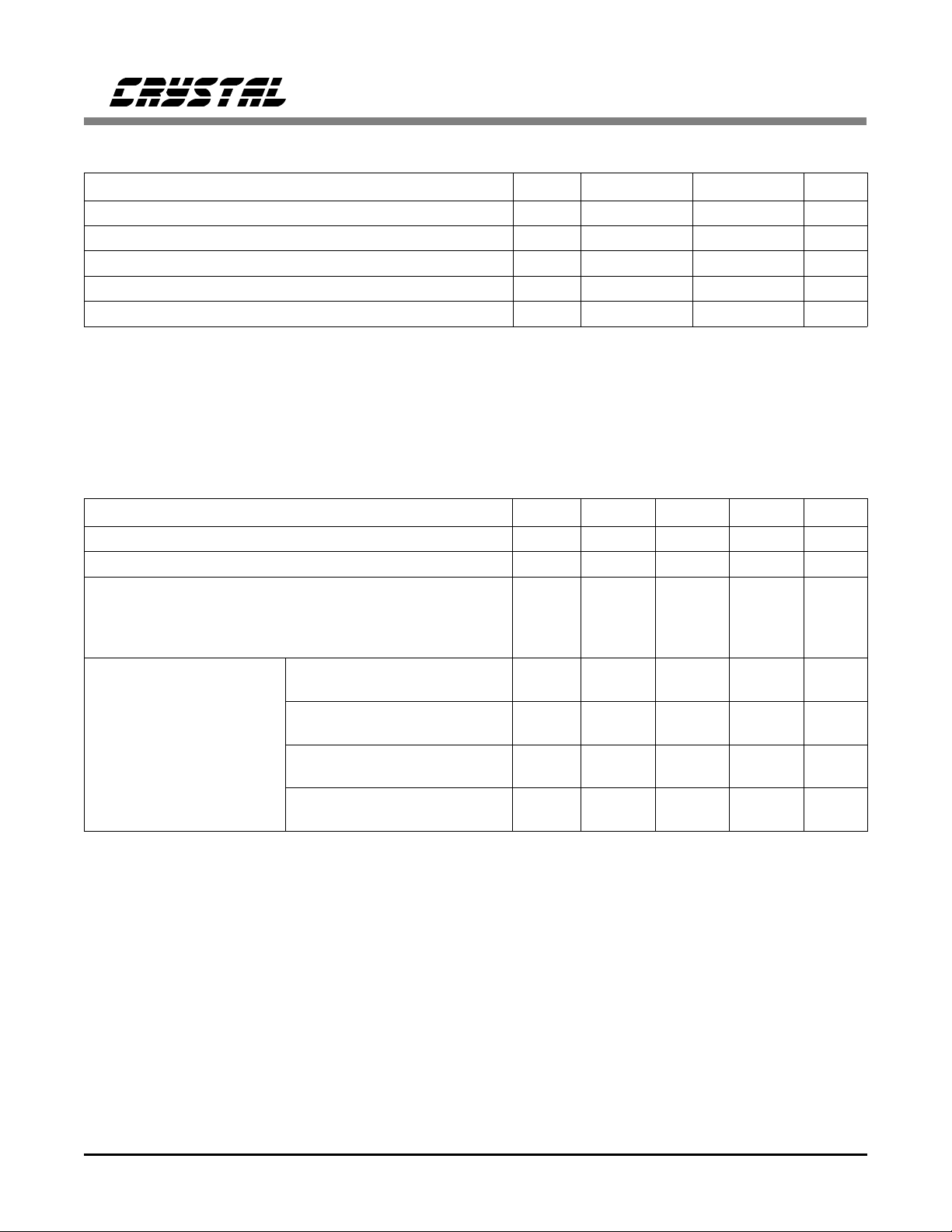

ABSOLUTE MAXIMUM RATINGS

Parameter Symbol Min Max Units

DC Supply (TV+1, TV+2, RV+1, RV+ 2, AV+, DV+) (Note 1) - 6.0 V

Input Voltage (Any Pin) V

Input Current (Any Pin) (Note 2) I

Ambient Operating Temperature T

Storage Temperature T

in

in

A

stg

RGND - 0.3 (RV+) + 0.3 V

-10 10 mA

-40 85 °C

-65 150 °C

WARNING: Operations at or beyond these limits may result in permanent damage to the device.

Normal operation is not guaranteed at these extremes.

Notes: 1. Referenced to RGND1, RGND2, TGND1, TGND2, AGND, DGND at 0V.

2. Transient cur rents of up to 100 mA will not cause SCR latch-up.

RECOMMENDED OPERATING CONDITIONS

Parameter Symbol Min Typ Max Units

DC Supply (TV+1, TV+2, RV+1, RV+ 2, AV+, DV+) (Note 3) 4.75 5.0 5.25 V

Ambient Operating Temperature T

A

Power Consumption T1 (Notes 4 and 5)

(Each Channel) T1 (Notes 4 and 6)

E1, 75Ω (Notes 4 and 5)

P

C

E1, 120Ω (Notes 4 and 5)

REFCLK Frequency

T1 1XCLK = 1

T1 1XCLK = 0

E1 1XCLK = 1

E1 1XCLK = 0

Notes: 3. TV+1, TV+2, AV+, DV+, RV+1, RV+2 should be connected together. TGND1, TGND2, RGND1,

RGND2, DGND1, DGND2, DGND3 should be connected together.

4. Power consumption while driving line load over operating temperature range. Includes IC and load.

Digital input levels are within 10% of the supply rails and digital outputs are driving a 50 pF

capacitive load.

5. As sumes 100% ones density and maximum line length at 5.25V.

6. As sumes 50% ones density and 300ft. line length at 5.0V.

-40 25 85 °C

-

-

-

-

1.544 -

100 ppm

12.352 -

100 ppm

2.048 -

100 ppm

16.384 -

100 ppm

310

220

275

275

1.544

12.352

2.048

16.384

-

-

-

-

1.544 +

100 ppm

12.352 +

100 ppm

2.048 +

100 ppm

16.384 +

100 ppm

MHz

MHz

MHz

MHz

mW

mW

mW

mW

DS172PP5 3

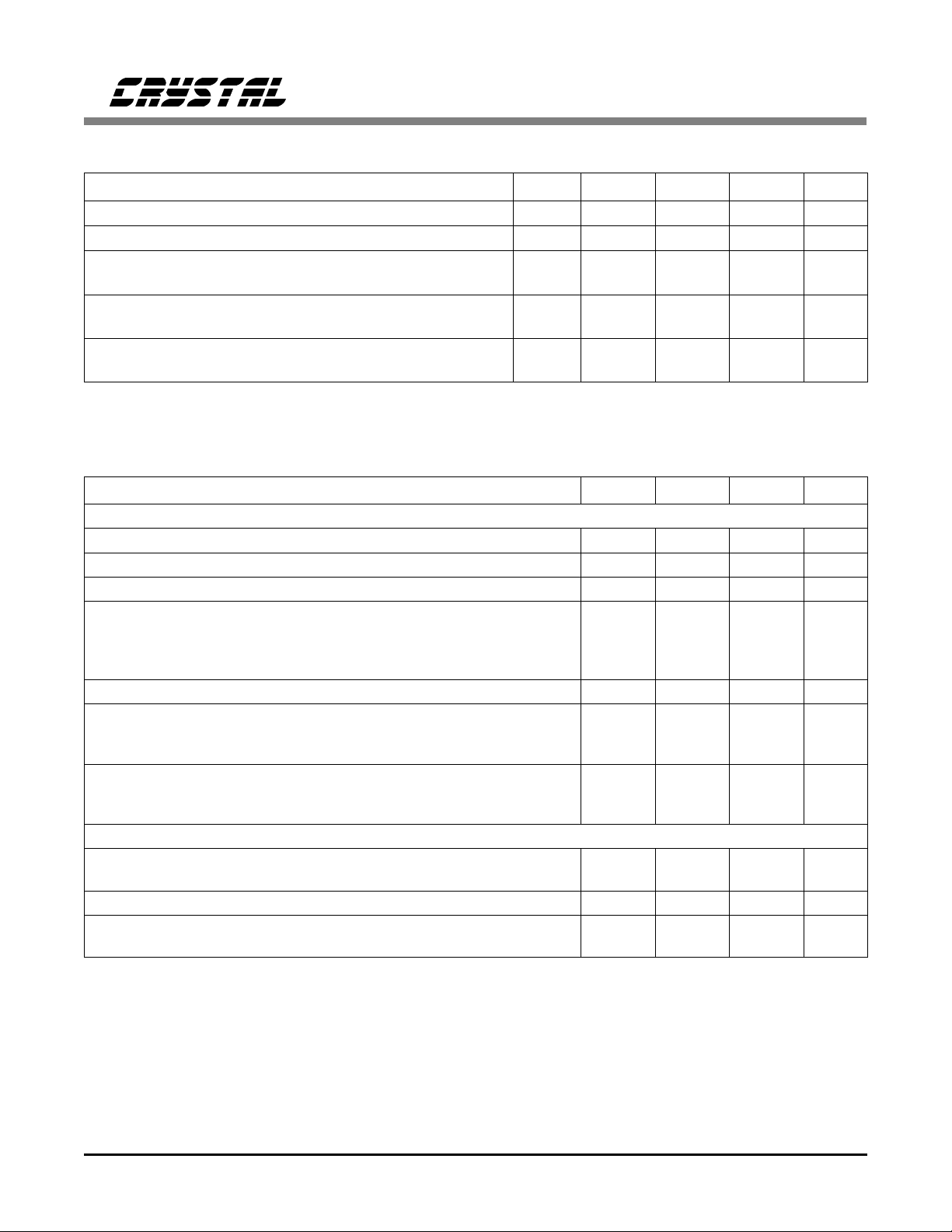

CS61583

DIGITAL CHARACTERISTICS (T

= -40 to 85 °C; power supply pins within ±5% of nominal)

A

Parameter Symbol Min Typ Max Units

High-Level Input Voltage (Note 7) V

Low-Level Input Voltage (Note 7) V

High-Level Output Voltage (Note 8)

(Digital pins) I

OUT

= -40 µA

Low-Level Output Voltage (Note 8)

(Digital pins) I

OUT

= 1.6 mA

V

V

Input Leakage Current

(Digital pins except J-TMS, and J-TDI)

(DV+)-0.5 - - V

IH

IL

OH

OL

--0.5V

(DV+)-0.3 - - V

--0.3V

--

±10 µA

Notes: 7. Digital inputs are designed for CMOS logic levels .

8. Digital outputs are TTL compatible and drive CMOS levels into a CMOS load.

ANALOG SPECIFICATIONS (T

= -40 to 85 °C; power supply pins within ±5% of nominal)

A

Parameter Min Typ Max Units

Receiver

RTIP/RRING Differential Input Impedance

- 20k Sensitivity Below DSX-1 (0 dB = 2.4 V) -13.6 - - dB

Loss of Signal Threshold - 0.3 - V

Data Decision Threshold T1, DSX-1 (Note 9)

(Note 10)

E1 (Note 11)

(Note 12)

60

55

45

40

65

50

70

-

-

75

55

60

% of

Peak

Allowable Consecutive Zeros before LOS 160 175 190 bits

Receiver Input Jitter 10 Hz and below (Note 13)

Tolerance (DSX-1, E1) 2 kHz

10 kHz - 100 kHz

Receiver Return Loss 51 kHz - 102 kHz (Notes 14,

102 kHz - 2.048 MHz 21, and 22)

2.048 MHz - 3.072 MHz

300

6.0

0.4

12

18

14

-

-

-

-

-

-

-

-

-

-

-

-

dB

dB

dB

Jitter Attenuator

Jitter Attenuation Curve T1 (Notes 14 and 15)

Corner Frequency E1

-

-

4

5.5

-

-

Hz

Hz

Attenuation at 10 kHz Jitter Frequency (Notes 14 and 15) - 60 - dB

Attenuator Input Jitter Tolerance (Note 14)

(Before Onset of FIFO Overflow or Underflow Protection)

Notes: 9. For input amplitude of 1.2 Vpk to 4.14 V

pk

10. For input amplitude of 0.5 Vpk to 1.2 Vpk, and 4.14 Vpk to 5.0 V

28 43 - UI

pk

11. For input amplitude of 1.07 Vpk to 4.14 Vpk,

12. For input amplitude of 4.14 V

to 5.0 Vpk,

pk

13. Jitter tolerance increases at lower frequencies. Refer to the Receiver section.

14. Not production tested. Parameters guaranteed by design and characterization.

15. Attenuation measur ed with sinusoidal input jitter equal to 3/4 of measured jitter tolerance.

Circuit attenuates jitter at 20 dB/decade above the corner frequency. Output jitter

can increase significantly when more than 28 UI’s are input to the attenuator. Refer to the

Jitter Attenuator section.

Ω

UI

UI

UI

pk-pk

4 DS172PP5

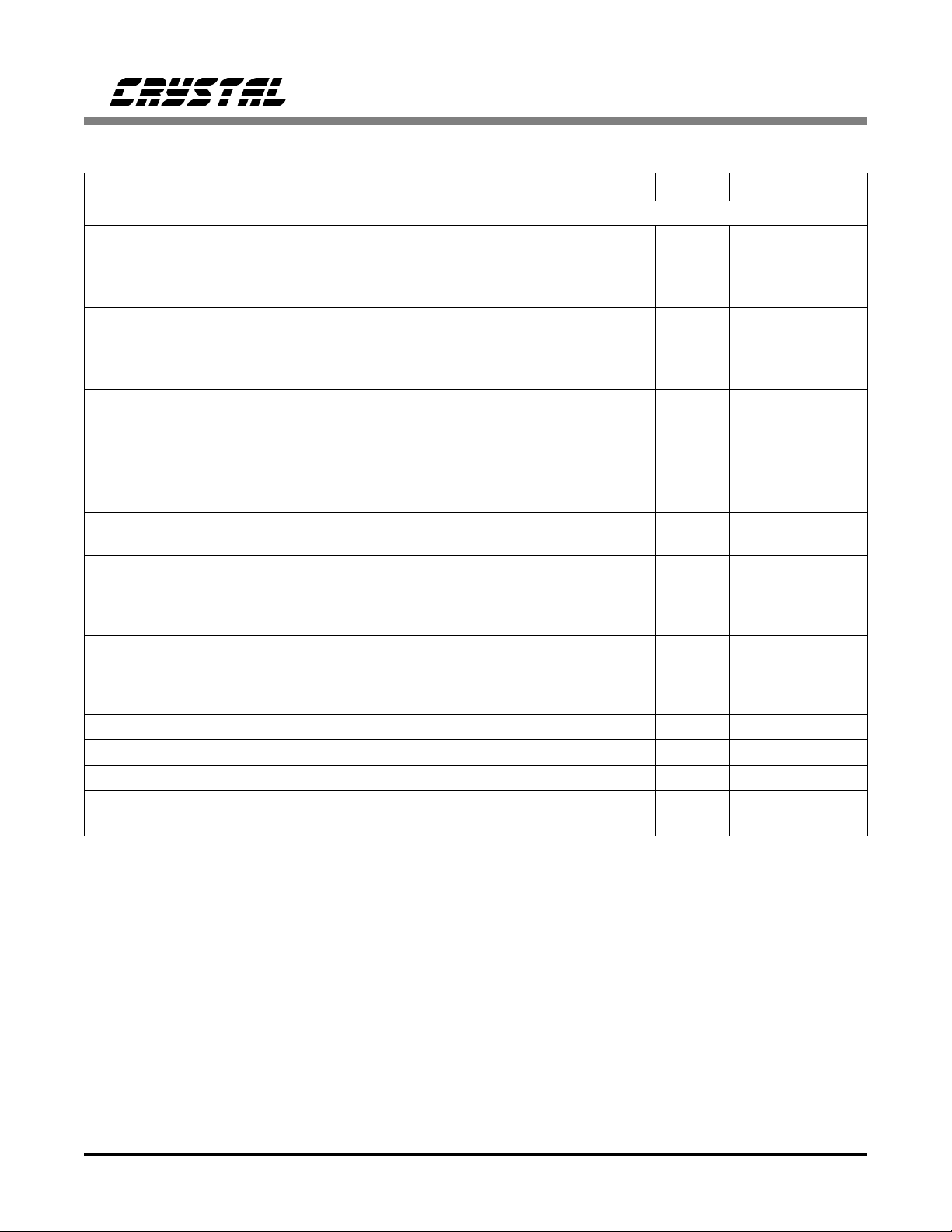

CS61583

ANALOG SPECIFICATIONS (T

= -40 to 85 °C; power supply pins within ±5% of nominal)

A

Parameter Min Typ Max Units

Transmitter

AMI Output Pulse Amplitudes (Note 16)

E1, 75Ω (Note 17)

E1, 120Ω (Note 18)

T1, DSX-1 (Note 19)

2.14

2.7

2.4

2.37

3.0

3.0

2.6

3.3

3.6

Recommended Transmitter Output Load (Note 16)

T1

E1, 75Ω

E1, 120Ω

Jitter Added During 10 Hz - 8 kHz

Remote Loopback 8 kHz - 40 kHz

10 Hz - 40 kHz

Broad Band (Note 20)

Power in 2 kHz band about 772 kHz (Notes 14 and 21)

(DSX-1 only)

Power in 2 kHz band about 1.544 MHz (Notes 14 and 21))

(referenced to power in 2 kHz band at 772 kHz) (DSX-1 only)

-

-

-

-

-

-

-

76.6

57.4

90.6

0.005

0.008

0.010

0.015

-

-

-

-

-

-

-

12.6 15 17.9 dBm

-29 -38 - dB

Positive to Negative Pulse Imbalance (Notes 14 and 21)

T1, DSX-1

E1, amplitude at center of pulse interval

E1, width at 50% of nominal amplitude

-

-5

-5

0.2

-

-

0.5

+5

+5

Transmitter Return Loss (Notes 14, 21, and 22)

51 kHz - 102 kHz

102 kHz - 2.048 MHz

2.048 MHz - 3.072 MHz

18

14

10

25

18

12

-

-

E1 Short Circuit Current (Note 23) - - 50 mA

E1 and DSX-1 Output Pulse Rise/Fall Times (Note 24) - 25 - ns

E1 Pulse Width (at 50% of peak amplitude) - 244 - ns

E1 Pulse Amplitude E1, 75Ω

for a space E1, 120Ω

-0.237

-0.3

-

-

0.237

0.3

Notes: 16. Using a tr ansformer that meets the specifications in the Applications section.

17. Measur ed across 75 Ω at the output of the transmit transformer for CO N2/1/0 = 0/0/0.

18. Measur ed across 120 Ω at the output of the transmit transformer for CO N2/1/0 = 0/0/1.

19. Measur ed at the DSX-1 cross- connect for line length settings CON2/1/0 = 0/1/0, 0/1/1,

1/0/0, 1/0/1, and 1/1/0 after the appropriate length of #22 ABA M cable specified in Table 1.

20. Input s ignal to RTIP/RRING is jitter free. Values will reduc e slightly if jitter free c lock is input to TCLK.

21. Ty pical performance using the line interface circuitry recommended in the Applications section.

22. Return loss = 20 log

=cable impedance.

z

0

ABS((z1+z0)/(z1-z0)) where z1=impedance of the transmitter or receiver, and

10

23. Transfor mer secondary shorted with 0.5 Ω resistor during the transmission of 100% ones.

24. At trans former secondary and measured from 10% to 90% of amplitude.

V

V

V

Ω

Ω

Ω

UI

UI

UI

UI

dB

%

%

dB

dB

dB

rms

V

V

DS172PP5 5

CS61583

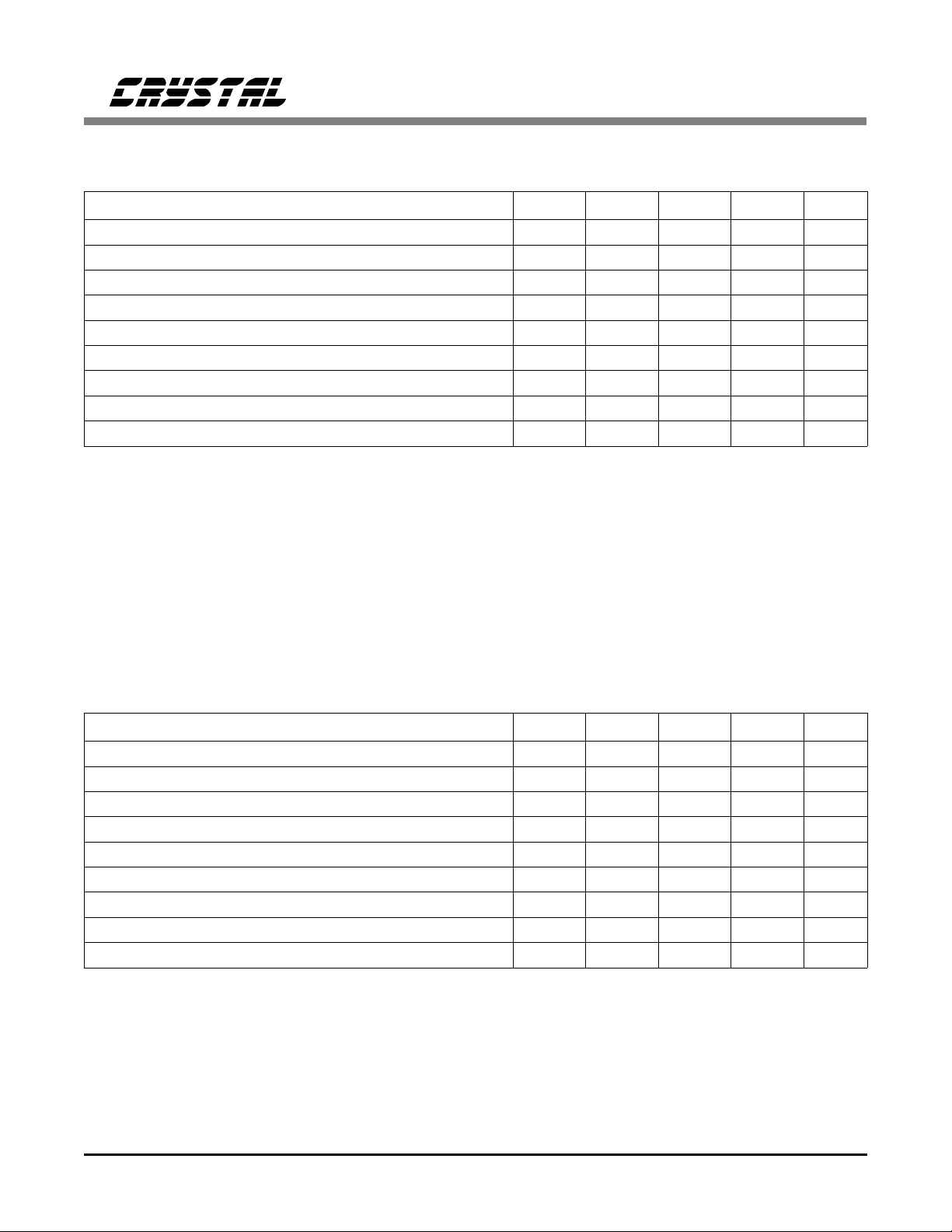

SWITCHING CHARACTERISTICS - T1 CLOCK/DATA (T

= -40 to 85 °C; power supply

A

pins within ±5% of nominal; Inputs: Logic 0 = 0V, Logic 1 = DV+) (See Figures 1, 2, and 3)

Parameter Symbol Min Typ Max Units

TCLK Frequency (Note 25) f

TCLK Duty Cycle t

RCLK Duty Cycle (Note 26) t

pwh2/tpw2

pwh1/tpw1

Rise Time (All Digital Outputs) (Note 27) t

Fall Time (All Digital Outputs) (Note 27) t

RPOS/RNEG (RDATA) to RCLK Rising Setup Time t

RCLK Rising to RPOS/RNEG (RDATA) Hold Time t

TPOS/TNEG (TDATA) to TCLK Falling Setup Time t

TCLK Falling to TPOS/TNEG (TDATA) Hold Time t

tclk

r

f

su1

h1

su2

h2

- 1.544 - MHz

30 50 70 %

45 50 55 %

- - 65 ns

- - 65 ns

- 274 - ns

- 274 - ns

25 - - ns

25 - - ns

Notes: 25. The maximum burst rate of a gapped TCLK input clock is 8.192 MHz. For the gapped clock to be

tolerated by the CS61583, the jitter attenuator must be switched to the transmit path of the line

interface. The maximum gap size that can be tolerated on TCLK is 28 UIp-p.

26. RCLK duty cycle may be outside the specified limits when the jitter attenuator is in the r eceive path,

and when the jitter attenuator is employing the overflow/underflow protection mec hanism.

27. At max load of 50 pF.

SWITCHING CHARACTERISTICS - E1 CLOCK/DATA (T

= -40 to 85 °C; power supply

A

pins within ±5% of nominal; Inputs: Logic 0 = 0V, Logic 1 = DV+) (See Figures 1, 2, and 3)

Parameter Symbol Min Typ Max Units

TCLK Frequency (Note 25) f

TCLK Duty Cycle t

RCLK Duty Cycle (Note 26) t

pwh2/tpw2

pwh1/tpw1

Rise Time (All Digital Outputs) (Note 27) t

Fall Time (All Digital Outputs) (Note 27) t

RPOS/RNEG (RDATA) to RCLK Rising Setup Time t

RCLK Rising to RPOS/RNEG (RDATA) Hold Time t

TPOS/TNEG (TDATA) to TCLK Falling Setup Time t

TCLK Falling to TPOS/TNEG (TDATA) Hold Time t

tclk

r

f

su1

h1

su2

h2

- 2.048 - MHz

30 50 70 %

45 50 55 %

- - 65 ns

- - 65 ns

- 194 - ns

- 194 - ns

25 - - ns

25 - - ns

6 DS172PP5

CS61583

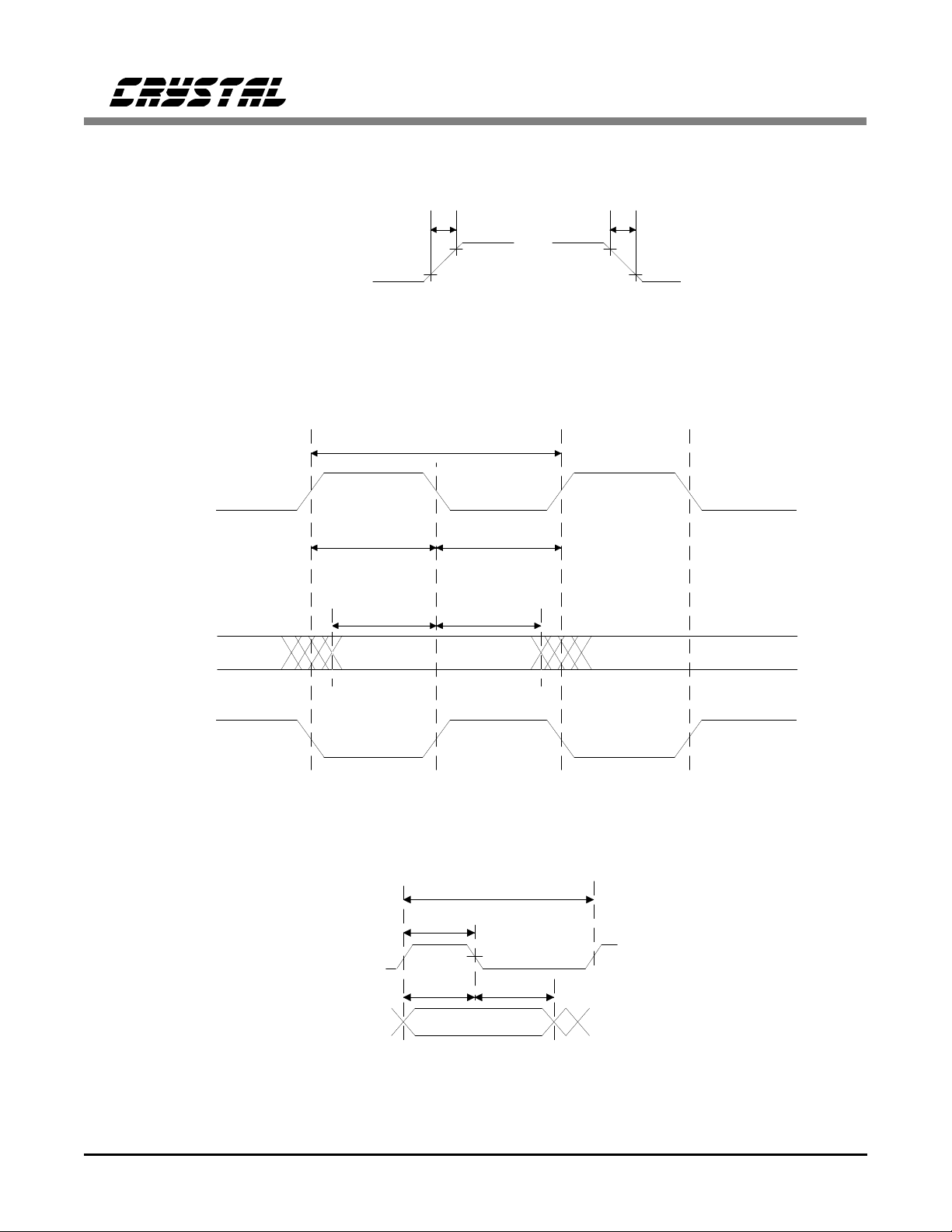

RCLK

(CLKE = 1)

RPOS

RNEG

RDATA

BPV

Any Digital Output

Figure 1. Signal Rise and Fall Characteristics

t

pwl1

t

su1

t

r

90% 90%

10% 10%

t

pw1

t

pwh1

t

h1

t

f

RCLK

(CLKE =0)

Figure 2. Recovered Clock and Data Sw itching Characterist ics

t

pw2

t

pwh2

TCLK

t

TPOS

TNEG

TDATA

Figure 3. Transmit Clock and Data Switching Characteristics

DS172PP5 7

su2

t

h2

CS61583

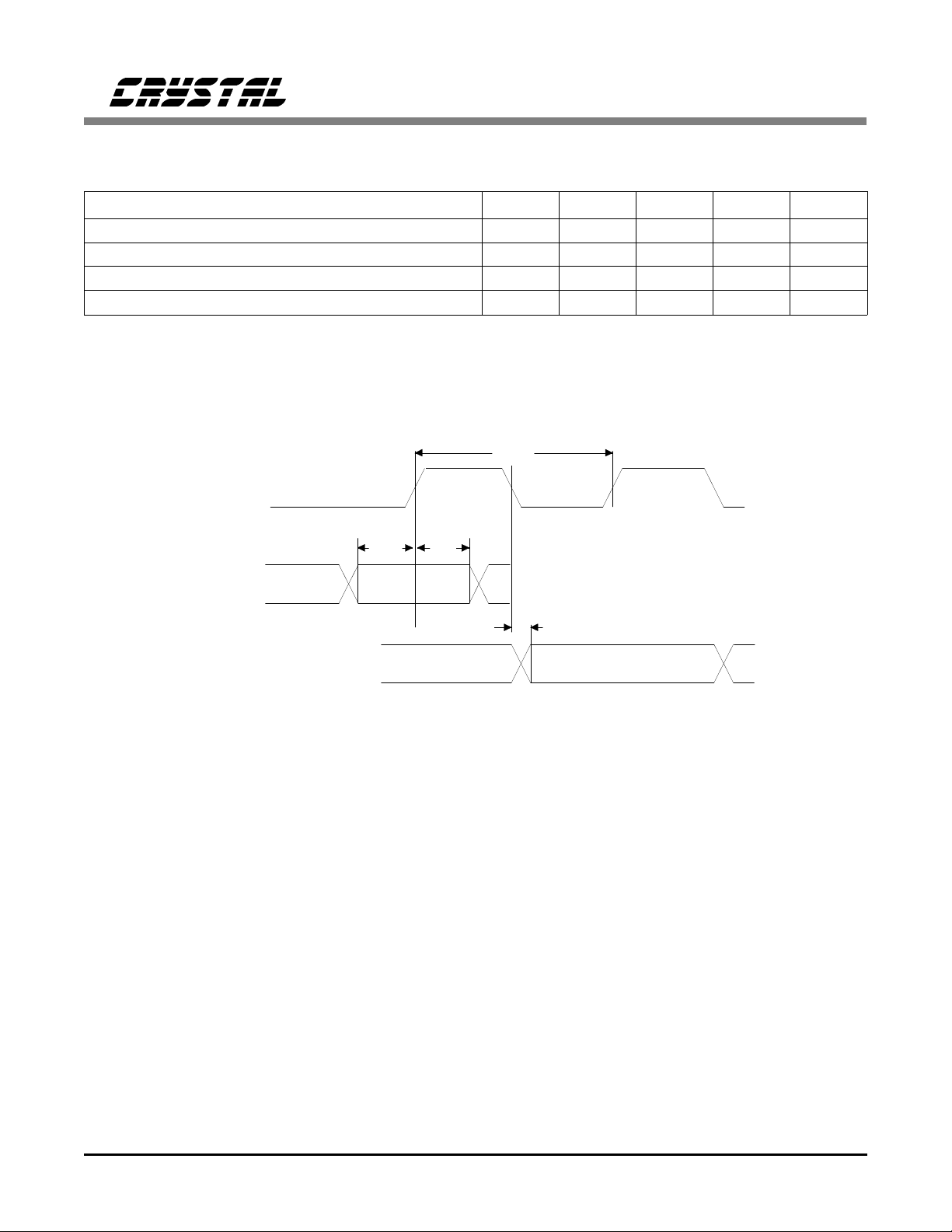

SWITCHING CHARACTERISTICS - JTAG

TV+, RV+ = nominal ±0.3V; Inputs: Logic 0 = 0V, Logic 1 = RV+) (See Figure 4)

Parameter Symbol Min Typ Max Units

Cycle Time t

J-TMS/J-TDI to J-TCK rising setup time t

J-TCK rising to J-TMS/J-TDI hold time t

J-TCK falling to J-TDO valid t

(TA = - 40 ° to 85 ° C;

200 - - ns

50 - - ns

50 - - ns

- - 50 ns

t

cyc

su

h

dv

cyc

J-TCK

t

su

t

h

J-TMS

J-TDI

J-TDO

t

dv

Figure 4. JAG Switching Characte ristics

8 DS172PP5

CS61583

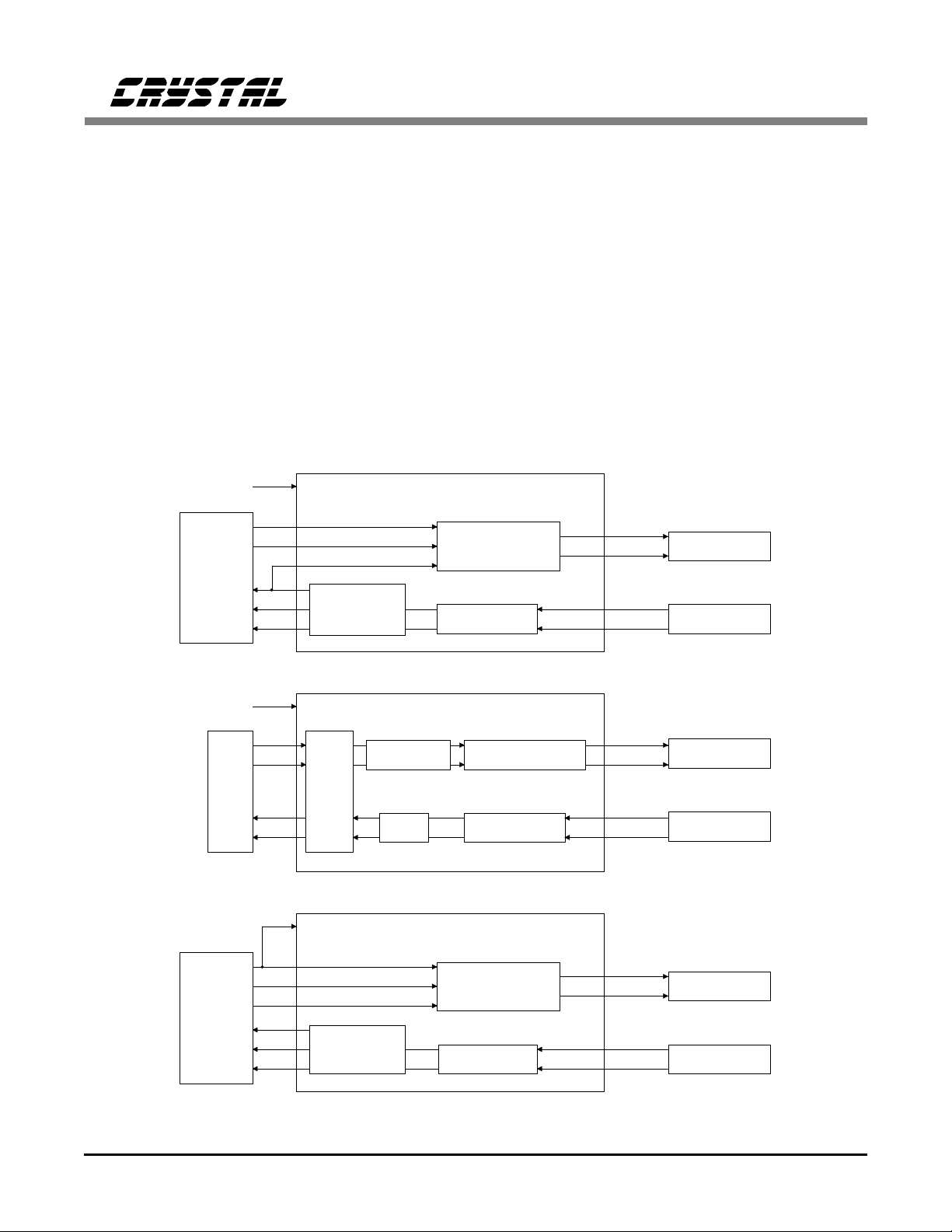

OVERVIEW

The CS61583 is a dual line interface for T1/E1

applications, designed for high-volume cards

where low power and high density are required.

One board design can support all T1/E1 shorthaul modes by only changing component values

in the receive and transmit paths (if REFCLK

and TCLK are externally tied together). Figure 5

illustrates applications of the CS61583 in various

environments.

All control of the device is achieved via external

pins, eliminating the need for microprocessor

LOOP TIMED APPLICATION

CS62180B

FRAMER

TPOS

TNEG

TCLK

RCLK

RPOS

RNEG

REFCLK

JITTER

ATTENUATOR

CS61583

support. The following pin control options are

available on a per channel basis: line length selection, coder mode, jitter attenuator location,

transmit all ones, local loopback, and remote

loopback.

The line driver generates waveforms compatible

with E1 (CCITT G.703), T1 short haul (DSX-1),

and T1 FCC Part 68 Option A (DS1). A single

transformer turns ratio is used for all waveform

types. The driver internally matches the impedance of the load, providing excellent return loss

to insure superior T1/E1 pulse quality. An addi-

LINE D R IV ER

LINE RECEIVER

TTIP

TRING

RTIP

RRING

TRANSMIT

CIRCUITRY

RECEIVE

CIRCUITRY

MUX

CS62180B

FRAMER

TDATA

TCLK

(gapped)

RCLK

RDATA

TCLK

TPOS

TNEG

RCLK

RPOS

RNEG

ASYNCHRONOU S MU X APPLICATION

(i.e., VT1 .5 c ard f or S O NET o r S DH mu x)

REFCLK

AMI

B8ZS,

HDB3,

CODER

REFCLK

ATTENUATOR

ATTENUATOR

(Including 62411 system s w ith m u ltiple T1 lines)

JITTER

CS61583

JITTER

AIS

DETECT

SYNCHRONOUS A PPLICATION

LINE DRIVER

LINE RECEIVER

CS61583

LINE D R IV ER

LINE RECEIVER

Figure 5. Examples of CS61583 A pplications

TTIP

TRING

RTIP

RRING

TTIP

TRING

RTIP

RRING

TRANSMIT

CIRCUITRY

RECEIVE

CIRCUITRY

TRANSMIT

CIRCUITRY

RECEIVE

CIRCUITRY

DS172PP5 9

CS61583

tional benefit of the internal impedance matching

is a 50 percent reduction in power consumption

compared to implementing return loss using external resistors that causes the transmitter to

drive the equivalent of two line loads.

The line receiver contains all the necessary clock

and data recovery circuits.

The jitter attenuator meets AT&T 62411 requirements when using a 1X or 8X reference clock

supplied by either a crystal oscillator or external

reference at the REFCLK input pin.

AT&T 62411 Customer Premises Application

The AT&T 62411 specification applies to the T1

interface between the customer premises and the

carrier, and must be implemented by the customer premises equipment in order to connect to

the AT&T network.

In 62411 applications, the management of jitter

is a very important design consideration. Typically, the jitter attenuator is placed in the receive

path of the CS61583 to reduce the jitter input to

the system synchronizer. The jitter attenuated recovered clock is used as the input to the transmit

clock to implement a loop-timed system. A Stra-

tum 4 (±32 ppm) quality clock or better should

be input to REFCLK. Note that any jitter present

on the reference clock will not be filtered by the

jitter attenuator.

not usually required in asynchronous multiplexers, the B8ZS/AMI/HDB3 coders in the

CS61583 are activated to provide data interfaces

on TDATA and RDATA.

Synchronous Application

A typical example of a synchronous application

is a T1 card in a central office switch or a 0/1

digital cross-connect system. These systems

place the jitter attenuator in the receive path to

reduce the jitter presented to the system. A Stratum 3 or better system clock is input to the

CS61583 transmit and reference clocks.

TRANSMITTER

The transmitter accepts data from a T1 or E1

system and outputs pulses of appropriate shape

to the line. The transmit clock (TCLK) and

transmit data (TPOS & TNEG, or TDATA) are

supplied synchronously. Data is sampled on the

falling edge of the TCLK input.

The configuration pins CON[2:0] control transmitted pulse shapes, transmitter source

impedance, and receiver slicing level as shown in

Table 1. Typical output pulses are shown in Figures

6 and 7. These pulse shapes are fully pre-defined

by circuitry in the CS61583, and are fully compliant with appropriate standards when used with our

application guidelines in standard installations.

Both channels must be operated at the same line rate

(both T1 or both E1).

Asynchronous Multiplexer Application

Note that the pulse width for Part 68 Option A

Asynchronous multiplexers accept multiple

T1/E1 lines (which are asynchronous to each

other), and combine them into a higher speed

transmission rate (e.g. M13 muxes and SONET

(324 ns) is narrower than the optimal pulse

width for DSX-1 (350 ns). The CS61583 automatically adjusts the pulse width based on the

configuration selection.

muxes). In these systems, the jitter attenuator is

placed in the transmit path of the CS61583 to

remove the gapped clock jitter input by the multiplexer to TCLK. Because the transmit clock is

jittered, the reference clock to the CS61583 is

provided by an external source operating at 1X

or 8X the data rate. Because T1/E1 framers are

10 DS172PP5

The transmitter impedance changes with the line

length options in order to match the load imped-

ance (75Ω for E1 coax, 100Ω for T1, 120Ω for

E1 shielded twisted pair), providing a minimum

of 14 dB return loss for T1 and E1 frequencies

CS61583

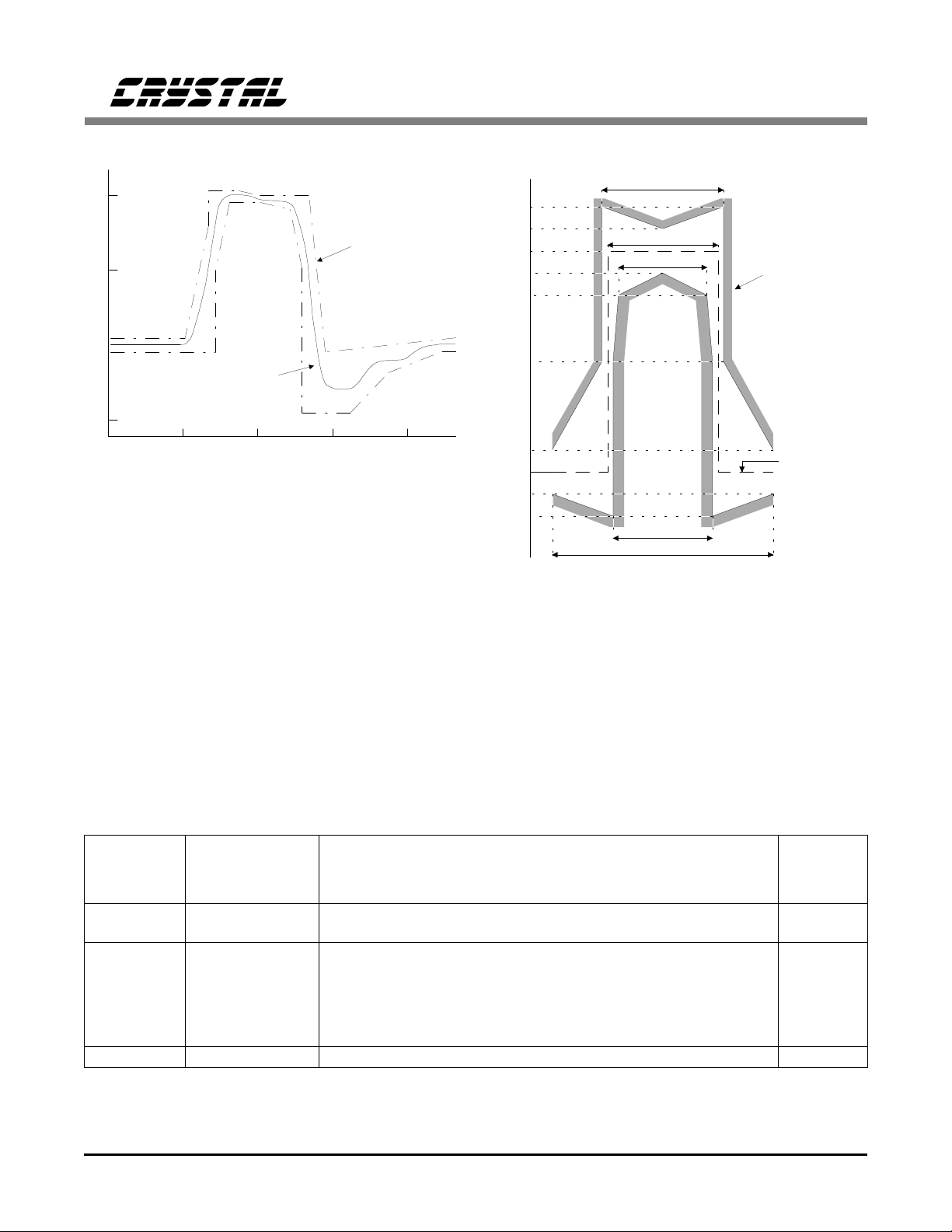

NORMALIZED

AMPLITUDE

1.0

ANSI T1.102

SPECIFICATION

0.5

0

CS61583

OUTPUT

PULSE SHAPE

-0.5

0 250 750 1000

500

TIME (nanoseconds)

Figure 6. Typical Pulse Shape at DSX-1 Cross Connect

during the transmission of both marks and

spaces. This improves signal quality by minimizing reflections from the transmitter. Impedance

matching also reduces load power consumption

by a factor of two when compared to the return

loss achieved by using external resistors.

The CS61583 driver will automatically detect an

inactive TLCK input (i.e., no valid data is being

clocked to the driver). When this condition is detected, the driver is forced low (except during

remote loopback) to output spaces and prevent

TTIP and TRING from entering a constant transmit-mark state.

Percent of

nominal

peak

voltage

120

110

100

90

80

50

10

0

-10

-20

269 ns

244 ns

194 ns

219 ns

488 ns

G.703

Specification

Nominal Pulse

Figure 7. Pulse Mask at the 2048 kbps Interface

When any transmit configuration established by

CON[2:0], TAOS, or LLOOP changed states, the

transmitter stabilizes within 22 TCLK bit periods. The transmitter takes longer to stabilize

when RLOOP1 or RLOOP2 is selected because

the timing circuitry must adjust to the new frequency from RCLK.

When the transmitter transformer secondaries are

shorted through a 0.5 ohm resistor, the transmit-

C

C

C

Transmit Pulse

O

O

O

Width at 50%

N

N

N

2

1

0

Amplitude

000001244 ns (50%)

244 ns (50%)

Transmit Pulse Shape

E1: square, 2.37 Volts into 75

E1: square, 3.00 Volts into 120

Ω

Ω

Receiver

Slicing

Level

50%

50%

0 1 0 350 ns (54%) DSX-1: 0-133 ft. / or DS1 FCC Part 68 Option A with undershoot 65%

0 1 1 350 ns (54%) DSX-1: 133-266 ft. 65%

1 0 0 350 ns (54%) DSX-1: 266-399 ft. 65%

1 0 1 350 ns (54%) DSX-1: 399-533 ft. 65%

1 1 0 350 ns (54%) DSX-1: 533-655 ft. 65%

1 1 1 324 ns (50%) DS1: FCC Part 68 Option A (0 dB) 65%

Table 1. Configuration Selection

DS172PP5 11

CS61583

ter will output a maximum of 50 mA-rms, as required by European specification BS6450.

RECEIVER

The receiver extracts data and clock from the

T1/E1 signal on the line interface and outputs

clock and synchronized data to the system. The

signal is detected differentially across the receive

transformer and can be recovered over the entire

range of short haul cable lengths. The transmit

and receive transfomer specifications are identical

and are presented in the Applications section.

As shown in Table 1, the receiver slicing level is

set at 65% for DS1/DSX-1 short-haul and at

50% for all other applications.

The clock recovery circuit is a second-order

phase locked loop that can tolerate up to 0.4 UI

of jitter from 10 kHz to 100 kHz without generating errors (Figure 8). The clock and data

recovery circuit is tolerant of long strings of consecutive zeros and will successfully recover a

1-in-175 jitter-free line input signal.

Recovered data at RPOS and RNEG (or

RDATA) is stable and may be sampled using the

recovered clock RCLK. The CLKE input determines the clock polarity for which output data is

stable and valid as shown in Table 2. When

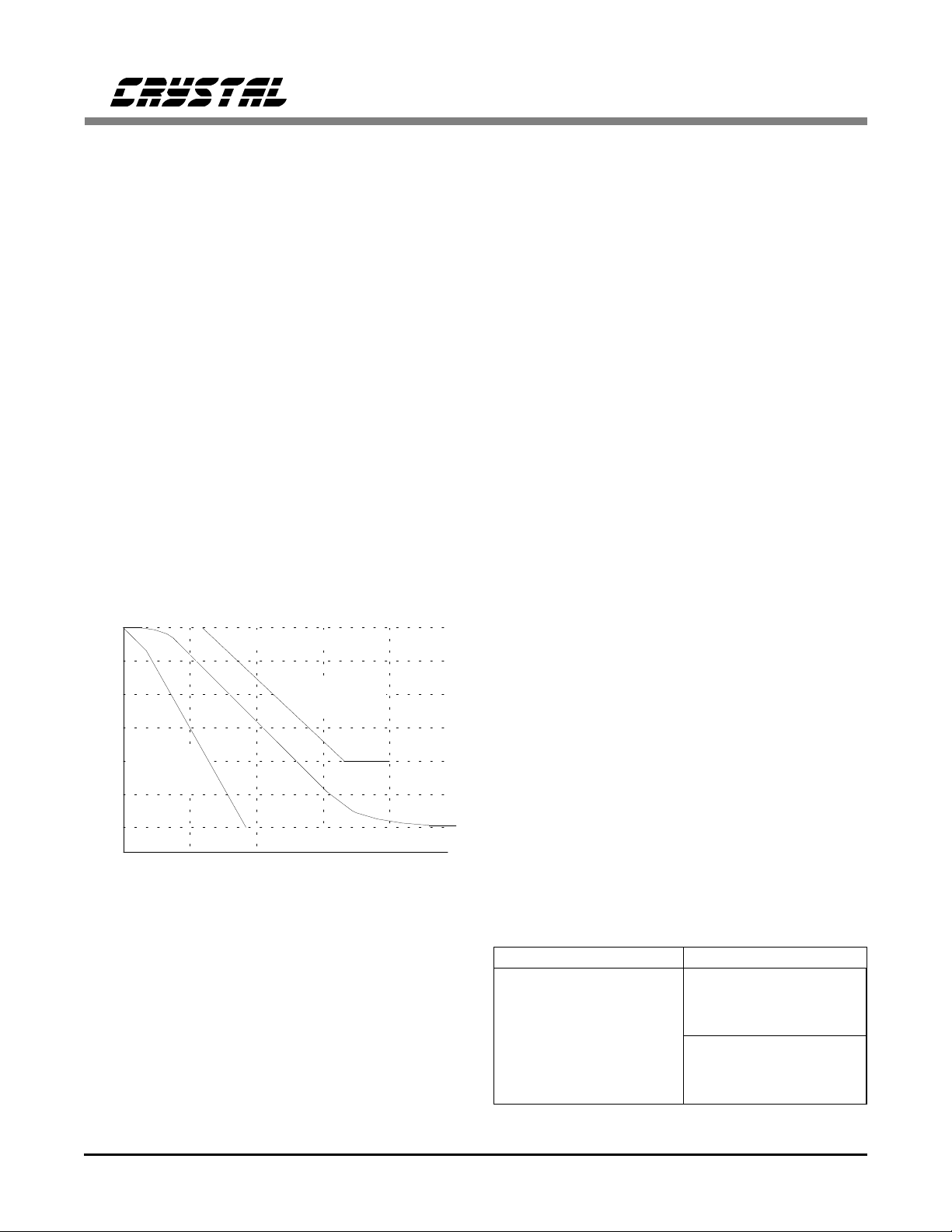

CS61583

300

138

100

PEAK-TO-PEAK

JITTER

(unit intervals)

Figure 8. Minimum Input Jitter Tolerance of Receiver

28

10

.4

.1

(Clock Recovery Circuit and Jitter Attenuator)

1

AT&T 62411

(1990 Version)

Performance

10 1k 10k1 100 100k700

300

JITTER FREQUENCY (Hz)

CLKE is low, RPOS and RNEG (or RDATA) are

valid on the rising edge of RCLK. When CLKE

is high, RPOS and RNEG (or RDATA) are valid

on the falling edge of RCLK.

CLKE DATA CLOCK Clock Edge

for Valid Data

LOW RPOS, RNEG

or RDATA

HIGH RPOS, RNEG

or RDATA

Table 2. Re covere d Data /Cloc k Optio ns

RCLK

RCLK

RCLK

RCLK

Rising

Rising

Falling

Falling

JITTER ATTENUATOR

The jitter attenuator can be switched into either

the receive or transmit paths. Alternatively, it can

also be removed from both paths to reduce the

propagation delay.

The location of the attenuators for both channels

is controlled by the ATTEN0 and ATTEN1 pins.

Table 3 shows how these pins are decoded.

ATTEN1 ATTEN0 Locatio n of

Jitter Attenuator

00 Receiver

0 1 Disabled

1 0 Transmitter

11 Reserved

Table 3. Jitter Attenuation Control

The attenuator consists of a 64-bit FIFO, a narrow-band monolithic PLL, and control logic.

Signal jitter is absorbed in the FIFO which is designed to neither overflow nor underflow. If

overflow or underflow is imminent, the jitter

transfer function is altered to insure that no biterrors occur. Under this condition, jitter gain

may occur and jitter should be attenuated externally in a frame buffer. The jitter attenuator will

typically tolerate 43 UIs before the overflow/underflow mechanism occurs. If the jitter

attenuator has not had time to "lock" to the aver-

12 DS172PP5

CS61583

age incoming frequency (e.g. following a device

reset) the attenuator will tolerate a minimum of

22 UIs before the overflow/underflow mechanism occurs.

For T1/E1 line cards used in high-speed mutiplexers (e.g., SONET and SDH), the jitter

attenuator is typically used in the transmit path.

The attenuator can accept a transmit clock with

gaps ≤ 28 UIs and a transmit clock burst rate of

≤ 8 MHz.

When the jitter attenuator is in th e receive path and

loss of signal occurs, the frequency of the last recovered signal is held. When the jitter attenuator is

not in the receive path, the last recovered frequency

is not held and the output frequency becomes the

frequency of the reference clock.

A typical jitter attenuation curve is shown in Figure 9.

jittered transmit clock, the reference clock

should not be tied to the transmit clock and a

separate external oscillator should drive the reference clock input. Any jitter present on the

reference clock will not be filtered by the jitter

attenuator.

POWER-UP RESET

On power-up, the device is held in a static state

until the power supply achieves approximately

60% of the power supply voltage. When this

threshold is crossed, the device waits another 10

ms to allow the power supply to reach operating

voltage and then calibrates the transmit and receive circuitry. This initial calibration takes less

than 20 ms but can occur only if REFCLK and

TCLK are present. The power-up reset performs

the same functions as the RESET pin.

LINE CONTROL AND MONITORING

0

10

20

30

b) Maximum

40

Attenuation

Attenuation in dB

Limit

50

60

1 10 100 1 k 10 k

Figure 9. Typical Jitter Transfer Function

a) Minimum Attenuation Limit

62411 (1990 Version)

Requirements

CS61583 Performance

Frequency in Hz

REFERENCE CLOCK

The CS61583 requires a reference clock with a

minimum accuracy of ±100 ppm for T1 and E1

applications. This clock can be either a 1X clock

(i.e., 1.544 MHz or 2.048 MHz), or can be a 8X

clock (i.e., 12.352 MHz or 16.384 MHz) as selected by the 1XCLK pin. In systems with a

Line control and monitoring of the CS61583 is

achieved using the control pins. The controls and

indications available on the CS61583 are detailed below.

Line Code Encoder/Decoder

Coding may be transparent, AMI, B8ZS, or

HDB3 and is selected using the CODER1,

CODER2, AMI1, and AMI2 pins. In the coder

mode, AMI, B8ZS, and HDB3 line codes are

available. The input data to the encoder is on

TDATA and the output data from the decoder is

in NRZ format on RDATA. See Table 4.

CODER[2:1]=0 CODER[2:1]=1

AMI[2:1]=0

Transparent Mode

Enabled

and

AMI[2:1] Pin(s)

Disabled

Table 4. Coder Mode Options

B8ZS/HDB3

Encoder/Decoder

Enabled

AMI[2:1]=1

AMI

Encoder/Decoder

Enabled

DS172PP5 13

CS61583

Alarm Indication Signal

In coder mode, the TNEG pin becomes the

alarm indication signal (AIS) output controlled

by the receiver. The receiver detects the AIS

condition on observation of 99.9% ones density

in a 5.3 ms period (< 9 zeros in 8192 bits) and

sets the AIS pin high. The AIS condition is ex-

ited when ≥ 9 zeros are detected in 8192 bits.

Bipolar Violation Detection

In coder mode, the RNEG pin becomes the bipolar violation (BPV) strobe output controlled by

the receiver. The BPV pin goes high for one

RCLK period when a bipolar violation is detected in the received signal. Note that B8ZS or

HDB3 zero substitutions are not flagged as bipolar violations when the decoder is enabled.

Loss of Signal

The loss of signal (LOS) indication is detected

by the receiver and reported when the LOS pin

is high. Loss of signal is indicated when 175±15

consecutive zeros are received. The LOS condition is exited according to the ANSI

T1.231-1993 criteria that requires 12.5% ones

density over 175±75 bit periods with no more

than 100 consecutive zeros. Note that bit errors

may occur at RPOS and RNEG (or RDATA)

prior to the LOS indication if the analog input

level falls below the receiver sensitivity.

The LOS pin is set high when the device is reset

or in powered up and returns low when data is

recovered by the receiver.

Transmit All Ones

Transmit all ones is selected by setting the

TAOS pin high. Selecting TAOS causes continuous ones to be transmitted to the line interface

on TTIP and TRING at the frequency of

REFCLK. In this mode, the transmit data inputs

TPOS and TNEG (or TDATA) are ignored. A

TAOS overrides the data transmitted to the line

interface during local and remote loopbacks.

Local Loopback

A local loopback is selected by setting the

LLOOP pin high. Selecting LLOOP causes the

TCLK, TPOS, and TNEG (or TDATA) inputs to

be looped back through the jitter attenuator (if

enabled) to the RCLK, RPOS, and RNEG (or

RDATA) outputs. Data received at the li ne interface is ignored, but data at TPOS and TNEG (or

TDATA) continues to be transmitted to the line

interface at TTIP and TRING.

A TAOS request overrides the data transmitted to

the line interface during local loopback. Note

that simultaneous selection of local and remote

loopback modes is not valid.

Remote Loopback

A remote loopback is selected by setting the

RLOOP pin high. Selecting RLOOP causes the

data received from the line interface at RTIP and

RRING to be looped back through the jitter attenuator (if enabled) and retransmitted on TTIP

and TRING. Data transmitted at TPOS and

TNEG (or TDATA) is ignored, but data recovered from RTIP and RRING continues to be

transmitted on RPOS and RNEG (or RDATA).

Remote loopback is functional if TCLK is absent. A TAOS request overrides the data

transmitted to the line interface during a remote

loopback. Note that simultaneous selection of local and remote loopback modes is not valid.

Reset Pin

The CS61583 is continuously calibrated during

operation to insure the performance of the device

over power supply and temperature. The continuous calibration function eliminates the need

to reset the line interface during operation.

A device reset may be selected by setting the

RESET pin high for a minimum of 200 ns. The

reset function initiates on the falling edge of RESET and takes less than 20 ms to complete. The

control logic is initialized and the transmit and

14 DS172PP5

CS61583

receive circuitry is calibrated if REFCLK and

TCLK are present.

JTAG BOUNDARY SCAN

Board testing is supported through JTAG boundary scan. Using boundary scan, the integrity of

the digital paths between devices on a circuit

board can be verified. This verification is supported by the ability to externally set the signals

on the digital output pins of the CS61583, and to

externally read the signals present on the input

pins of the CS61583. Additionally, the manufacturer ID, part number and revision of the

CS61583 can be read during board test using

JTAG boundary scan.

As shown in Figure 10, the JTAG hardware consists of data and instruction registers plus a Test

Access Port (TAP ) controller. Control of the TAP

is achieved through signals applied to the Test

Mode Select (J-TMS) and Test Clock ( J-TCK)

input pins. Data is shifted into the registers via

the Test Data Input (J-TDI) pin, and shifted out

of the registers via the Test Data Output (J-TDO)

pin. Both J-TDI and J-TDO are clocked at a rate

determined by J-TCK. The Instruction register

defines which data register is accessed in the

shift operation. Note that if J-TDI is floating,

an internal pull-up resistor forces the pin high.

JTAG Data Registers (DR)

The test data registers are the Boundary-Scan

Register (BSR), the Device Identification Register (DIR), and the Bypass Register (BR).

Boundary Scan Register: The BSR is connected

in parallel to all the digital I/O pins, and provides the mechanism for applying/reading test

patterns to/from the board traces. The BSR is 67

bits long and is initialized and read using the instruction SAMPLE/PRELOAD. The bit ordering

for the BSR is the same as the top-view package

pin out, beginning with the LOS1 pin and moving counter-clockwise to end with the CODER1

pin as shown in Table 5. Note that the analog,

oscillator, power, ground, CLKE, and ATTEN0

pins are not included as part of the boundaryscan register.

The input pins require one bit in the BSR and

only one J-TCK cycle is required to load test

data for each input pin.

The output pins have two bits in the BSR to define output high, output low, or high impedance.

Digital output pins Digital i nput pins

parallel latched

output

Boundary Sc an D at a Reg i st er

Device ID Data Register

J-TDI

Bypass Data Register

J-TCK

J-TMS

Figure 10. Block Diagram of JTAG Circuitry

DS172PP5 15

Instructi on (shift) Register

parallel latched

output

TAP

Controller

JTAG Block

MUX

J-TDO

CS61583

The first bit (shifted in first) selects between an

output-enabled state (bit set to 1) or high-impedance state (bit set to 0). The second bit shifted in

contains the test data that may be output on the

pin. Therefore, two J-TCK cycles are required to

load test data for each output pin.

BSR bits Pin Name Pad Type

0-2 LOS1 bi-direc tional

3-5 TNEG1/AIS1 bi-dir ectional

6 TPOS1/TDATA1 input

7 TCLK1 input

8-9 RNEG1/BP V1 output

10-11 RPOS1/RDATA1 output

12-13 RCLK1 output

14-16 ATTEN1 bi-directional

17-19 RLOOP1 bi-directional

20 LLOOP 1 input

21-23 LLOOP2 bi-directional

24-26 TAOS1 bi-directional

27-29 TAOS2 bi-directional

30-32 CO N01 bi-directional

33-35 CO N02 bi-directional

36-38 CON11 bi-directional

39-41 CO N12 bi-directional

42-44 CO N21 bi-directional

45 CON22 input

46-48 AMI1 bi-directional

49-50 RCLK2 output

51-52 RPOS2/RDATA2 output

53-54 RNEG2/BPV2 output

55 TCLK2 input

56 TPOS2/TDATA2 input

57-59 TNEG2/AIS2 bi-directional

60-62 LOS2 bi-directional

63 AMI2 input

64 CODER2 input

65 RLOOP2 input

66 CODER1 input

1. Configure pad as an input.

2. Configure pad as an output.

2

1

1

1

1

1

1

1

1

1

1

1

2

The bi-directional pins have three bits in the

BSR to define input, output high, output low, or

high impedance. The first bit shifted into the

BSR configures the output driver as high-impedance (bit set to 0) or active (bit set to 1). The

second bit shifted into the BSR sets the output

value when the first bit is 1. The third bit captures the value of the pin. This pin may have its

value set externally as an input (if the first bit is

0) or set internally as an output (if the first bit is

1). To configure a pad as an input, the J-TDI

pattern is 0X0. To configure a pad as an output,

the J-TDI pattern is 1X1. Therefore, three J-TCK

cycles are required to load test data for each bidirectional pin.

Device Identification Register: The DIR provides

the manufacturer, part number, and version of the

CS61583. This information can be used to verify

that the proper version or revision number has

been used in the system under test. The DIR is 32

bits long and is partitioned as shown in figure 11.

MSB LSB

31 28 27 1211 1 0

00000000000000000011000011001001

(4 bits) (16 bits) (11 bits)

BIT #(s) FUNCTION Total Bits

31-28 Version number 4

27-12 Part Number 16

11- 1 Manufacturer Number 11

0 Constant Logic ’1’ 1

Figure 11. Device Identification Register

Data from the DIR is shifted out to J-TDO LSB

first.

Bypass Register: The Bypass register consists of

a single bit, and provides a serial path between

J-TDI and J-TDO, bypassing the BSR. This allows bypassing specific devices during certain

board-level tests. This also reduces test access

times by reducing the total number of shifts required from J-TDI to J-TDO.

Table 5. Boundary Scan Register

16 DS172PP5

CS61583

JTAG Instructions and Instruction Register (IR)

The instruction register (2 bits) allows the instruction to be shifted into the JTAG circuit. The

instruction selects the test to be performed or the

data register to be accessed or both. The valid

instructions are shifted in LS B first and are listed

below:

IR CODE INSTRUCTION

00 EX TEST

01 SA MPLE/PRELOAD

10 IDCODE

11 BYPASS

EXTEST Instruction: The EXTEST instruction

allows testing of off-chip circuitry and boardlevel interconnect. EXTEST connects the BSR to

the J-TDI and J-TDO pins. The normal path between the CS61583 logic and I/O pins is broken.

The signals on the output pins are loaded from

the BSR and the signals on the input pins are

loaded into the BSR.

SAMPLE/PRELOAD Instruction: The SAMPLE/PRELOAD instructions allows scanning of

the boundary-scan register without interfering

with the operation of the CS61583. This instruction connects the BSR to the J-TDI and J-TDO

pins. The normal path between the CS61583

logic and its I/O pins is maintained. The signals

on the I/O pins are loaded into the BSR. Additionally, this instruction can be used to latch

values into the digital output pins.

Internal Testing Considerations

Note that the INTEST instruction is not supported because of the difficulty in performing

significant internal tests using JTAG.

The one test that could be easily performed using an arbitrary clock rate on TCLK and

REFCLK is a local loopback with jitter attenuator disabled. However, this test provides limited

fault coverage and is only useful in determining

if the device had been catastrophically destroyed.

Alternatively, catastrophic destruction of the device and/or surrounding board traces can be

detected using EXTEST. Therefore, the INTEST

instruction provides limited testing capability

and was not included in the CS61583.

JTAG TAP Controller

Figure 12 shows the state diagram for the TAP

state machine. A description of each state follows. Note that the figure contains two main

branches to access either the data or instruction

registers. The value shown next to each state

transition in this figure is the value present at

J-TMS at each rising edge of J-TCK.

Test-Logic-Reset State

In this state, the test logic is disabled to continue

normal operation of the device. During initialization, the CS61583 initializes the instruction

register with the IDCODE instruction.

IDCODE Instruction: The IDCODE instruction

connects the device identification register to the

J-TDO pin. The IDCODE instruction is forced

into the instruction register during the TestLogic-Reset controller state.The default

instruction is IDCODE after a device reset.

Regardless of the original state of the cont roller,

the controller enters the Test-Logic-Reset state

when the J-TMS input is held high for at least

five rising edges of J-TCK. The controller remains in this state while J-TMS is high. The

CS61583 processor automatically enters this

state at power-up.

BYPASS Instruction: The BYPASS instruction

connects the minimum length bypass register between the J-TDI and J-TDO pins and allows data

to be shifted in the Shift-DR controll er state.

Run-Test/Idle State

This is a controller state between scan operations. Once in this state, the controller remains

in the state as long as J-TMS is held low. The

DS172PP5 17

CS61583

instruction register and all test data registers retain their previous state. When J-TMS is high

and a rising edge is applied to J-TCK, the controller moves to the Select-DR state.

Select-DR-Scan State

This is a temporary controller state. The test

data register selected by the current instruction

retains its previous state. If J-TMS is held low

and a rising edge is applied to J-TCK when in

this state, the controller moves into t he CaptureDR state and a scan sequence for the selected

test data register is initiated. If J-TMS is held

high and a rising edge applied to J-TCK, the

controller moves to the Select-IR-Scan state.

The instruction does not change in this state.

Capture-DR State

In this state, the Boundary Scan Register captures input pin data if the current instruction is

EXTEST or SAMPLE/PRELOAD. The other

test data registers, which do not have parallel input, are not changed.

The instruction does not change in this state.

When the TAP controller is in this state and a

rising edge is applied to J-TCK, the controller

enters the Exit1-DR state if J-TMS is high or the

Shift-DR state if J-T MS is low.

Shift-DR State

In this controller state, the test data register connected between J-TDI and J-TDO as a result of

the current instruction shifts data on stage toward its serial output on each rising edge of

J-TCK.

The instruction does not change in this state.

When the TAP controller is in this state and a

rising edge is applied to J-TCK, the controller

enters the Exit1-DR state if J-TMS is high or remains in the Shift-DR state if J-TMS is low.

Exit1-DR State

This is a temporary state. While in t his state, if

J-TMS is held high, a rising edge applied to JTCK causes the controller to enter the

Update-DR state, which terminates the scanning

process. If J-TMS is held low and a rising edge

is applied to J-TCK, the controller enters the

Pause-DR state.

Test-Logic-Reset

1

0

0

Run-Test/Idle

1

Select-DR-Scan

1

0

10

0

Capture-DR

0

Shift-DR

1

Exit1-DR

0

Pause-DR

1

Exit2-DR

1

Update-DR

1

0

1

0

Select-IR-Scan

1

0

10

0

Capture-IR

0

Shift- IR

1

Exit1-IR

0

Pause-IR

1

Exit2-IR

1

Update-IR

1

0

1

0

Figure 12. TAP Controller State Diagram

18 DS172PP5

CS61583

The test data register selected by the current instruction retains its previous value during this

state. The instruction does not change in this

state.

Pause-DR State

The pause state allows the test controller to temporarily halt the shifting of data through the test

data regist er in the serial path between J-TDI and

J-TDO. For example, this state could be used to

allow the tester to reload its pin memory from

disk during application of a long test sequence.

The test data register selected by the current instruction retains its previous value during this

state. The instruction does not change in this

state.

The controller remains in this state as long as

J-TMS is low. When J-TMS goes high and a

rising edge is applied to J-TCK, the controller

moves to the Exit2-DR state.

parallel output of this register from the shift-register path on the falling edge of J-TCK. The

data held at the latched parallel output changes

only in this state.

All shift-register stages in the test data register

selected by the current instruction retains their

previous value during this state. The instructions

does not change in this state.

Select-IR-Scan State

This is a temporary controller state. The test

data register selected by the current instruction

retains its previous state. If J-TMS is held low

and a rising edge is applied to J-TCK when in

this state, the controller moves into t he CaptureIR state, and a scan sequence for the instruction

register is initiated. If J-TMS is held high and a

rising edge is applied to J-TCK, the controller

moves to the Test-Logic-Reset state. The instruction does not change in this state.

Exit2-DR State

This is a temporary state. While in t his state, if

J-TMS is held high, a rising edge applied to JTCK causes the controller to enter the

Update-DR state, which terminates the scanning

process. If J-TMS is held low and a rising edge

is applied to J-TCK, the controller enters the

Shift-DR state.

The test data register selected by the current instruction retains its previous value during this

state. The instruction does not change in this

state.

Update-DR State

The Boundary Scan Register is provided with a

latched parallel output to prevent changes while

data is shifted in response to the EXTEST and

SAMPLE/PRELOAD instructions. When the

TAP controller is in this state and the Boundary

Scan Register is selected, data is latched into the

Capture-IR State

In this controller state, the shift register contained in the instruction register loads a fixed

value of "01" on the rising edge of J-TCK. This

supports fault-isolation of the board-level serial

test data path.

Data registers selected by the current instruction

retain their value during this state. The instructions does not change in this state.

When the controller is in this state and a rising

edge is applied to J-TCK, the controller enters

the Exit1-IR state if J-TMS is held high, or the

Shift-IR state if J-TMS is held low.

Shift-IR State

In this state, the shift register contained in the

instruction register is connected between J-TDI

and J-TDO and shifts data one stage towards its

serial output on each rising edge of J-TCK.

DS172PP5 19

CS61583

The test data register selected by the current instruction retains its previous value during this

state. The instruction does not change in this

state.

When the controller is in this state and a rising

edge is applied to J-TCK, the controller enters

the Exit1-IR state if J-TMS is held high, or remains in the Shift-IR state if J-TMS is held low.

Exit1-IR State

This is a temporary state. While in t his state, if

J-TMS is held high, a rising edge applied to JTCK causes the controller to enter the Updat e-IR

state, which terminates the scanning process. If

J-TMS is held low and a rising edge is applied

to J-TCK, the controller enters the Pause-IR

state.

The test data register selected by the current instruction retains its previous value during this state.

The instruction does not change in this state.

J-TMS is held low and a rising edge is applied

to J-TCK, the controller enters the Shift-IR state.

The test data register selected by the current instruction retains its previous value during this

state. The instruction does not change in this

state.

Update-IR State

The instruction shifted into the instruction register is latched into the parallel output from the

shift-register path on the falling edge of J-TCK.

When the new instruction has been latched, it

becomes the current instruction.

Test data registers selected by the current instruction retain their previous value.

JTAG Application Examples

Figures 13 and 14 illustrate examples of updating the instruction and data registers during

JTAG operation.

Pause-IR State

The pause state allows the test controller to temporarily halt the shifting of data through the

instruction register.

The test data register selected by the current instruction retains its previous value during this

state. The instruction does not change in this

state.

The controller remains in this state as long as

J-TMS is low. When J-TMS goes high and a

rising edge is applied to J-TCK, the controller

moves to the Exit2-IR state.

Exit2-IR State

This is a temporary state. While in t his state, if

J-TMS is held high, a rising edge applied to JTCK causes the controller to enter the Updat e-IR

state, which terminates the scanning process. If

20 DS172PP5

TCK

TMS

Controller state

TDI

Parallel Input to IR

IR shift-register

Test-Logic-Reset

CS61583

Shift-IR

Exit1-IR

Select-DR-Scan

Select-IR-Scan

Capture-IR

Run-Test/Idle

Pouse-IR

Exit2-IR

Shift-IR

Exit1-IR

Update-IR

Run-Test/Idle

Parallel out put of IR

Parallel I n put t o TDR

Parallel output of TDR

TDR shift-register

Register selecte d

TDO enable

TDO

IDCODE New Instruction

Old data

Instruction register

Inactive ActiveInactive Inactive

Act

= Don't care or undef i ned

Figure 13. JTAG Instruction Register Update

DS172PP5 21

TCK

TMS

Controller state

TDI

Parallel Input to IR

IR shift- regi s te r

CS61583

Shift-DR

Exit1-DR

Run-Test/Idle

Select-DR-Scan

Capture-DR

Pouse-DR

Exit2-DR

Shift-DR

Exit1-DR

Update-DR

Run-Test/Idle

Select-DR-Scan

Select-IR-Scan

Test-Logic-Reset

Parallel output of IR

Parallel Input to TDR

TDR shift-register

Parallel output of TDR

Register Selected

TDO enable

TDO

Inactive ActiveInactive InactiveActive

= Don't care or undefined

Figure 14. JTAG Data Register Update

Old data

IDCODEInstruction

New data

Test data register

22 DS172PP5

PIN DESCRIPTIONS

DGND1

CON01

TAOS2

TAOS1

LLOOP2

LLOOP1

RLOOP1

ATTEN1

not used

RCLK1

RPOS1/RDATA1

RNEG1/BPV1

TCLK1

TPOS1/TDATA1

TNEG1/AIS1

LOS1

J-TDO

DGND2

J-TDI

TTIP1

TV+1

TGND1

TRING1

CODER1

ATTEN0

not used

RTIP1

RRING1

RV+1

RGND1

AGND1

BGREF

AGND2

AV+

11

13

15

17

19

21

23

25

13579 67656361

CS61583

68-Pin PLCC

Top View

3533312927 37 39 41 43

59

57

55

53

51

49

47

45

CS61583

DV+

DGND3

CON02

CON11

CON12

CON21

CON22

AMI1

not used

RCLK2

RPOS2/RDATA2

RNEG2/BPV2

TCLK2

TPOS2/TDATA2

TNEG2/AIS2

LOS2

AMI2

J-TCK

J-TMS

TTIP2

TV+2

TGND2

TRING2

CODER2

CLKE

not used

RTIP2

RRING2

RV+2

RGND2

1XCLK

RLOOP2

REFCLK

RESET

Note: Pins labeled as "not used" should be tied to ground.

DS172PP5 23

CS61583

DGND1

CON01

TAOS2

TAOS1

LLOOP2

LLOOP1

RLOOP1

ATTEN1

RCLK1

RPOS1/RDATA1

RNEG1/BPV1

TCLK1

TPOS1/TDATA1

TNEG1/AIS1

LOS1

J-TDO

DGND2

J-TDI

TTIP1

TV+1

TGND1

TRING1

CODER1

ATTEN0

RTIP1

RRING1

RV+1

RGND1

AGND1

BGREF

AGND2

AV+

64 62 60 58 56 54 52 50

1

2

4

6

8

10

12

14

16

18 20 22 24 26 28 30 32

CS61583

64-Pin TQFP

Top View

48

46

44

42

40

38

36

34

DV+

DGND3

CON02

CON11

CON12

CON21

CON22

AMI1

RCLK2

RPOS2/RDATA2

RNEG2/BPV2

TCLK2

TPOS2/TDATA2

TNEG2/AIS2

LOS2

AMI2

J-TCK

J-TMS

TTIP2

TV+2

TGND2

TRING2

CODER2

CLKE

RTIP2

RRING2

RV+2

RGND2

1XCLK

RLOOP2

REFCLK

RESET

24 DS172PP5

CS61583

Power Supplies

AGND1, AGND2 : Analog Ground (PLCC pins 31, 33; TQFP pins 21, 23)

Analog supply ground pins.

AV+ : Analog Power Supply (PLCC pin 34; TQFP pin 24)

Analog supply pin for the internal bandgap reference and timing generation circuits.

BGREF : Bandgap Reference (PLCC pin 32; TQFP pin 22)

This pin is used by the internal bandgap reference and must be connected to ground

by a 4.99kΩ ±1% resistor to provide an internal current reference.

DGND1, DGND2, DGND3 : Digital Ground (PLCC pins 1, 18, 67; TQFP pins 57, 9, 55)

Power supply ground pins for the digital circuitry of both channels.

DV+ : Power Supply (PLCC pin 68; TQFP pin 56)

Power supply pin for the digital circuitry of both channels.

RGND1, RGND2 : Receiver Ground (PLCC pins 30, 39; TQFP pins 20, 29)

Power supply ground pins for the receiver circuitry.

RV+1, RV+2 : Receiver Power Supply (PLCC pins 29, 40; TQFP pins 19, 30)

Power supply pins for the analog receiver circuitry.

TGND1, TGND2 : Transmit Ground (PLCC pins 22, 47; TQFP pins 13, 36)

Power supply ground pins for the transmitter circuitry.

TV+1, TV+2 : Transmit Power Supply (PLCC pins 21, 48; TQFP pins 12, 37)

Power supply pins for the analog transmitter circuitry.

T1/E1 Data

RCLK1, RCLK2 : Receive Clock (PLCC pins 10, 59; TQFP pins 1, 48)

RPOS1, RPOS2 : Receive Positive Data (PLCC pins 11, 58; TQFP pins 2, 47)

RNEG1, RNEG2 : Receive Negative Data (PLCC pins 12, 57; TQFP pins 3, 46)

The receiver recovered clock and NRZ digital data from RTIP and RRING is output on these

pins. The CLKE pin determines the clock edge on which RPOS and RNEG are stable and

valid. A positive pulse (with respect to ground) received on RTIP generates a logic 1 on RPOS,

and a positive pulse received on RRING generates a logic 1 on RNEG.

RDATA1, RDATA2 : Receive Data (PLCC pins 11, 58; TQFP pins 2, 47)

In coder mode (CODER = 1), the decoded digital data stream from RTIP and RRING is output

on RDATA in NRZ format. The CLKE pin determines the clock edge on which RDATA is

stable and valid.

RTIP1, RTIP2 : Receive Tip (PLCC pins 27, 42; TQFP pins 17, 32)

RRING1, RRING2 : Receive Ring (PLCC pins 28, 41; TQFP pins 18, 31)

The receive AMI signal from the line interface is input on these pins. The recovered clock and

data are output on RCLK, RPOS, and RNEG (or RDATA).

DS172PP5 25

TCLK1, TCLK2 : Transmit Clock (PLCC pins 13, 56; TQFP pins 4, 45)

TPOS1, TPOS2 : Transmit Positive Data (PLCC pins 14, 55; TQFP pins 5, 44)

TNEG1, TNEG2 : Transmit Negative Data (PLCC pins 15, 54; TQFP pins 6, 43)

The transmit clock and data are input to these pins. The signal is driven to the line interface at

TTIP and TRING. Data at TPOS and TNEG are sampled on the falling edge of TCLK. An

input at TPOS causes a positive pulse to be transmitted at TTIP and TRING, while an input at

TNEG causes a negative pulse to be transmitted at TTIP and TRING.

TDATA1, TDATA2 : Transmit Positive Data (PLCC pins 14, 55; TQFP pins 5, 44)

In coder mode (CODER = 1), the un-encoded digital data stream is input on TDATA in NRZ

format. Data at TDATA is sampled on the falling edge of TCLK.

TTIP1, TTIP2 : Transmit Tip (PLCC pins 20, 49; TQFP pins 11, 38)

TRING1, TRING2 : Transmit Ring (PLCC pins 23, 46; TQFP pins 14, 35)

The transmit AMI signal to the line interface is output on these pins. The transmit clock and

data are input from TCLK, TPOS, and TNEG (or TDATA).

Oscillator

1XCLK : One-times Clock Frequency Select (PLCC pin 38; TQFP pin 28)

When 1XCLK is set high, REFCLK must be a 1X clock (i.e., 1.544 MHz for T1 or 2.048 MHz

for E1 applications). When 1XCLK is set low, REFCLK must be an 8X clock (i.e., 12.352

MHz for T1 or 16.384 MHz for E1 applications).

CS61583

REFCLK : External Reference Clock Input (PLCC pin 36, TQFP pin 26)

Input reference clock for the receive and jitter attenuator circuits. When 1XCLK is high,

REFCLK must be a 1X clock (i.e., 1.544 MHz ±100 ppm for T1 applications or 2.048 MHz

±100 ppm for E1 applications). When 1XCLK is set low, REFCLK must be an 8X clock (i.e.,

12.352 MHz ±100 ppm for T1 applications or 16.384 MHz ±100 ppm for E1 applications). The

REFCLK input also determines the transmission rate when TAOS is asserted.

Control

AMI1, AMI2 : Encoder/Decoder Select (PLCC pins 61, 52; TQFP pins 49, 41)

Setting AMI low enables the B8ZS or HDB3 zero substitution in the transmitter encoders and

receiver decoders. Setting AMI high enables AMI encoders and decoders. The AMI pins are

enabled by setting the corresponding CODER pin high.

ATTEN0, ATTEN1 : Jitter Attenuator Select (PLCC pins 25, 8; TQFP pins 16, 64)

Selects the jitter attenuation path for both channels (transmi t/receive/neither).

CLKE : Clock Edge (PLCC pin 44; TQFP pin 33)

Controls the polarity of the recovered clock RCLK. When CLKE is high, RPOS and RNEG are

valid on the falling edge of RCLK. When CLKE is low, RPOS and RNEG are valid on the

rising edge of RCLK.

26 DS172PP5

CS61583

CODER1, CODER2 : Coder Mode Configuration (PLCC pins 24, 45; TQFP pins 15, 34)

Setting CODER high causes the Coder Mode to be enabled. In Coder Mode, the transmit and

receive data appears in NRZ format on TDATA and RDATA, respectively. These pins also

enable the corresponding AMI pin.

CON01, CON11, CON21, : Configuration Selection

CON02, CON12, CON22 : (PLCC pins 2, 65, 63, 66, 64, 62; TQFP pins 58, 53, 51, 54, 52, 50)

These pins configure the transmitter (pulse shape, pulse width, pulse amplitude, and driver

impedance) receiver (slicing level), and coder (HDB3 vs B8ZS). The CONx1 pins control

channel 1 and the CONx2 pins control channel 2. Both channels must be configured to operate

at the same data rate on the line interface (both T1 or both E1).

LLOOP1, LLOOP2 : Local Loopback (PLCC pins 6, 5; TQFP pins 62, 61)

A local loopback is enabled when LLOOP is high. During local loopback, the TCLK,

TPOS/TNEG (or TDATA) inputs are looped back through the jitter attenuator (if enabled) to the

RCLK, RPOS/RNEG (or RDATA) outputs. The data at TPOS/TNEG continues to be

transmitted to the line interface unless overridden by a TAOS request. The inputs at RTIP and

RRING are ignored.

RESET : Reset (PLCC pin 35; TQFP pin 25)

A device reset is selected by setting the RESET pin high for a minimum of 200 ns. The reset

function initiates on the falling edge of RESET and requires less than 20 ms to complete. The

control logic is initialized and LOS is set high.

RLOOP1, RLOOP2 : Remote Loopback (PLCC pins 7, 37; TQFP pins 63, 27)

A remote loopback is selected when RLOOP is high. The data received from the line interface

at RTIP and RRING is looped back through the jitter attenuator (if enabled) and retransmitted

on TTIP and TRING. Data recovered from RTIP and RRING continues to be transmitted on

RPOS/RNEG (or RDATA). Data input on TPOS/TNEG (or TDATA) is ignored. A TAOS

request overrides the data transmitted at TTIP and TRING.

TAOS1, TAOS2 : Transmit All Ones Select (PLCC pins 4, 3; TQFP pins 60, 59)

Setting TAOS high causes continuous ones to be transmitted at the line interface on TTIP and

TRING at the frequency determined by REFCLK.

Status

AIS1, AIS2 : Alarm Indication Signal (PLCC pins 15, 54; TQFP pins 6, 43)

The AIS indication goes high when the receiver detects 99.9% ones density in a 5.3 ms period

(< 9 zeros in 8192 bits). The AIS indication returns low when the receiver detects ≥ 9 zeros in

8192 bits.

BPV1, BPV2 : Bipolar Violation (PLCC pins 12, 57; TQFP pins 3, 46)

The BPV indication goes high for one RCLK bit period when a bipolar violation is detected in

the received signal. Bipolar violations caused by B8ZS (or HDB3) zero substitutions are not

flagged by the BPV pin if the coder mode is enabled.

DS172PP5 27

LOS1, LOS2 : Loss of Signal (PLCC pins 16, 53; TQFP pins 7, 42)

The LOS indication goes high when 175 ± 15 consecutive zeros are received on the line

interface. The LOS indication returns low when a minimum 12.5% ones density signal over

175 ± 75 bit periods with no more than 100 consecutive zeros is received.

Test

J-TCK : JTAG Test Clock (PLCC pin 51; TQFP pin 40)

Data on pins J-TDI and J-TDO is valid on the rising edge of J-TCK. When J-TCK is stopped

low, all JTAG registers remain unchanged.

J-TMS : JTAG Test Mode Select (PLCC pin 50; TQFP pin 39)

An active high signal on J-TMS enables the JTAG serial port. This pin has an internal pull-up

resistor.

J-TDI : JTAG Test Data In (PLCC pin 19; TQFP pin 10)

JTAG data is shifted into the device on this pin. This pin has an internal pull-up resistor. Data

must be stable on the rising edge of J-TCK.

J-TDO : JTAG Test Data Out (PLCC pin 17; TQFP pin 8)

JTAG data is shifted out of the device on this pin. This pin is active only when JTAG testing is

in progress. J-TDO will be updated on the falling edge of J-TCK.

CS61583

28 DS172PP5

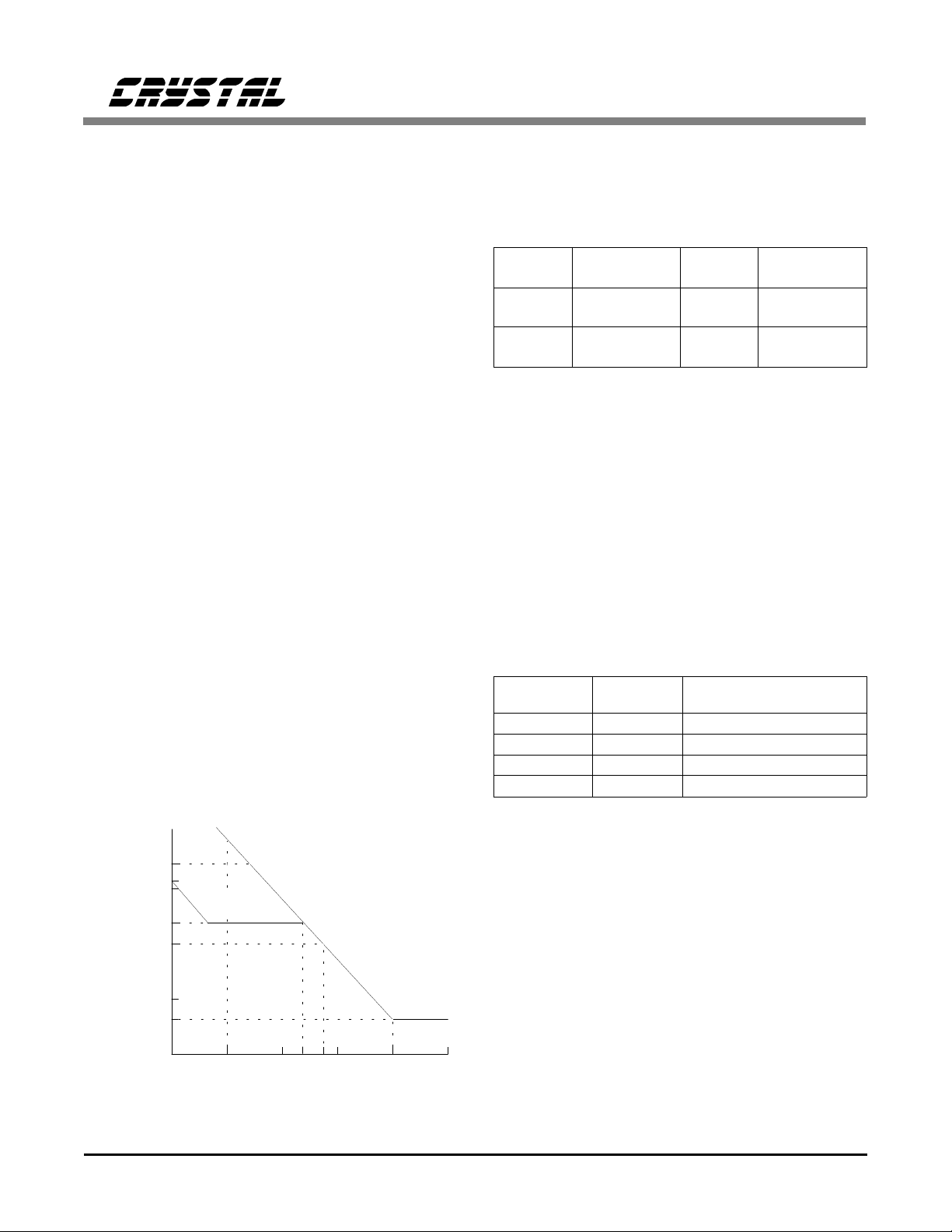

PHYSICAL DIMENSIONS

68 pin PLCC

MILLIMETERS INCHES

DIM

A

A

B

D

D

E

E

e

2.29 .090

1

24.79 25.30 .976 .996

24.13 24.38 .950 .960

1

24.79 25.30 .976 .996

24.13 24.38 .950 .960

1

1.27 .050

MAXMIN MAXMIN

5.084.20 .200.165

3.30 .130

0.530.38 .021.015

68 pin

PLCC

CS61583

1

EE

u

x

y

z

23.37 23.62 .920 .930

1.067 .042

1.219 .048

.51 .020

.51 x 45° x 3 .02 x 45° x 3

x

D

1

D

z

A

y

1

A

e

u

B

DS172PP5 29

CS61583

D

D

1

64-Pin

TQFP

MILLIMETERS INCHES

DIM

E

E

1

64

1

MIN

A

A

B

C

D

D

E

E

e

L

∝∝

-

0.00

1

0.14

0.077

11.70

10.00

1

11.70

10.00

1

0.40

0.35

0° 12° 0° 12°

MAX

1.66

-

0.26

0.177

12.30

10.00

12.30

10.00

0.60

0.70

MIN

-

0.00

0.006

0.003

0.461

0.394

0.461

0.394

0.016

0.014

MAX

0.068

-

0.010

0.007

0.484

0.394

0.484

0.394

0.024

0.028

A

A

C

B

e

1

Terminal

Detail 1

∝∝

L

30 DS172PP5

APPLICATIONS

CS61583

Framer

Framer

CLKE TAOS1

ATTEN2

REFCLK 1XCLK

Clock Generator

TCLK1

TPOS1 (TDATA1)

TNEG1 (AIS1)

RCLK1

RPOS1 (RDATA1)

RNEG1 (BPV1)

TCLK2

TPOS2 (TDATA2)

TNEG2 (AIS2)

RCLK2

RPOS2 (RDATA2)

RNEG2 (BPV2)

AV+ AGND1:2 BGREF TV+1 TGND1 RV+1 RGND1 DV+ DGND1:3

0.1 µF

V

+

CC

1 µF

RESET

TV+2TGND2 RV+2RGND2

2

R3

4.99k

Ω

F 0.1 µF0.1 µF

0.1

µ

CON11

CON01

CON21

Hardware Control

Channel 1

Channel 2

Power Supply

0.1 µF

+

22 µF

Figure A1. Typical Connection Diagram

Data Rate (MHz) REFCLK Frequency (MHz)

1XCLK = 1 1XCLK = 0

1.544 1.544 12.352 100 38.3 220

2.048 2.048 16.384 75 28.7 470

RLOOP1

LLOOP1

AMI2AMI1

CODER2CODER1ATTEN1

CON02

CON12

TAOS2

CON22

Cable (Ω)R1-R4 (

RLOOP2

LLOOP2

TTIP1

TRING1

RTIP1

RRING1

TTIP2

TRING2

RTIP2

RRING2

0.01 µF

0.47µF

R1

0.47

R2

0.47µF

R3

0.47

R4

3

Ω

)

C1

C2

120 45.3 220

1:1.15

T1

T2

1:1.15

F

µ

T3

1:1.15

T4

1:1.15

F

µ

C1-C2 (pF)

transmit

receive

transmit

receive

Table A1. CS61583 External Components

Line Interface

In the receive line interface circuitry, resistors R1-

R4 provide receive impedance matching and

Figure A1 illustrates a typical connection diagram

and Table A1 lists the external components that

are required in T1 and E1 applications.

In the transmit line interface circuitry, capacitors

receiver return loss. The 0.47 µF capacitor to

ground provides the necessary differential input

voltage reference for the receiver.

Power Supply

C1 and C2 provide transmitter return loss. The

0.47 µF capacitor in series with the transformer

primary prevents output stage imbalances from

producing a DC current through the transformer

that might saturate the transformer and result in

an output level offset.

As shown in Figure A1, the CS61583 operates

from a 5.0 Volt supply. Separate analog and digi-

tal power supply and ground pins provide internal

isolation. The TGND, RGND, and DGND ground

pins must not be more negative than AGND. It is

recommended that all of the supply pins be con-

nected together at the device. A 4.99kΩ ±1%

DS172PP5 31

CS61583

resistor must be connected from BGREF to

ground to provide an internal current reference.

De-coupling and filtering of the power supplies is

crucial for the proper operation of the analog circuits. A capacitor should be connected between

each supply and its respective ground. For capaci-

tors smaller than 1 µF, use mylar or ceramic

capacitors and place them as close as possible to

their respective power supply pins. Wire-wrap

bread boarding of the line interface is not recommended because lead resistance and inductance

defeat the function of the de-coupling capacitors.

Crystal Oscillator Specifications

When a reference clock signal is not available, a

CMOS crystal oscillator operating at either the

1X or 8X rate can be connected at the REFCLK

pin. The oscillator must have a minimum symme-

try of 40-60% and minimum stability of ±100

ppm for T1 and E1 applications. Based on these

specifications, some suggested crystal oscillators

for use with the CS61583 are shown in Table A2.

Turns Ratio 1:1.15 step-up transmit

1:1.15 step-down receive

Primary inductance 1.5 mH min at 772 kHz

Primary leakage

inductance

Secondary leakage

0.3 µH max at 772 kHz

with secondary shorted

0.4 µH max at 772 kHz

inductance

Interwinding

capacitance

ET-constant

Table A3. Transformer Specifications

18 pF max, primary to

secondary

16 V-µs min

Designing for AT&T 62411

For additional information on the requirements of

AT&T 62411 and the design of an appropriate

system synchronizer, refer to the Crystal Semiconductor Application Notes "AT&T 62411

Design Considerations - Jitter and Synchronization" and "Jitter Testing Procedures for

Compliance with AT&T 62411."

Manufacturer Part Number Contact Number

Comclok CT31CH (800) 333-9825

CTS CXO-65HG-5-I (815) 786-8411

M-tron MH26TAD (800) 762-8800

SaRonix NTH250A (800) 227-8974

Notes:

Frequency tolerances are ±32 ppm with a -40 to +85 °C

operating tempera ture range.

All are 8-pin DIP packages and can be tristated.

Table A2. Suggested Crystal Oscillators

Transformers

Recommended transformer specifications are

shown in Table A3. Based on these specifications,

the transformers recommended for use with the

CS61583 are listed in Table A4.

Line Protection

Secondary protection components can be added

to the line interface circuitry to provide lightning

surge and AC power-cross immunity. For additional information on the different electrical

safety standards and specific application circuit

recommendations, refer to the Crystal Semiconductor Application Note "Secondary Line

Protection for T1 and E1 Line Cards."

32 DS172PP5

CS61583

Turns Ratio Manufacturer Part Number Package Type

PE-65388 1.5 kV through-hole, single

PE-65770 1.5 kV through-hole, single

extended temperature

PE-65838 3.0 kV through-hole, single

1:1.15 Pulse Engineering

extended temperature

PE-68674 1.5 kV surface-mount, dual

extended temperature

PE-65870 1.5 kV surface-mount, dual

Schott 67124840 1.5 kV through-hole, single

extended temperature

Valor ST5112 2.0 kV surface mount, dual

Schematic & Layout Review Service

Confirm Optimum

Schematic & Layout

Before Building Your Board.

For Our Free Review Service

Call Applications Engineering.

Call:(512)445-7222

DS172PP5 33

CDB61583

Dual Line Interface Evaluat ion Board

Features

Socketed CS61 583 Dual Line In terface

••

All Required Components for CS61583

••

Evaluation

Locations to Evaluate P rotection Circuitry

••

LED Status Indications for Alarm

••

Conditions

Control of Enhanced Hardware Options

••

TCLK1

TPOS1

(TDATA1)

TNEG1

CHANNEL 1

RCLK1

+5V 0V

General Description

The evaluation board includes a socketed CS61583

dual line interface device and all support components

necessary for evaluation. The board is powered by

an external +5 Volt supply.

The board may be configured for 100Ω twisted-pair

T1, 75Ω coax E1, or 120Ω twisted-pair E1 operation.

Binding posts and bantam jacks are provided for line

interface connections. Several BNC connectors provide clock and data I/O at the system interface.

Reference timing may be derived from a crystal osc illator or an external reference clock. Four LED

indicators monitor device alarm conditions.

ORDERING INFORMATION: CDB61583

TTIP1

TRING1

RTIP1

CHANNEL 1

RPOS1

{

(RDATA1)

RNEG1

(BPV1)

+5V

Hardware Control

and Mode Circuit

LED Status

Indicators

TCLK2

TPOS2

(TDATA2)

TNEG2

CHANNEL 2

Crystal Semiconductor Corporation

P.O. Box 17847, Austin, TX 78760

(512) 445-7222 FAX: (512) 445 7581

RCLK2

RPOS2

{

(RDATA2)

RNEG2

(BPV2)

RESET

CIRCUIT

}

RRING1

Circuit

TTIP2

TRING2

RTIP2

REFCLK

CHANNEL 2

CS61583

Oscillator

}

RRING2

Copyright Crystal Semiconductor Corporation 1995