T1/E1 Line Interface

CS61577

Features

Provides Analog Transmission Line

•

Interface for T1 and E1 Applications

Drop-in Replacement for CS61574 with

•

the Following Enhancements:

- Lower Power Consumption

- Transmitter Short-Circuit

Current Limiting

- Greater Transmitter Immunity

to Line Reflections

- Software Selection Between 75Ω and

120Ω E1 Output Options

- Internally Controlled E1 Pulse Width

- B8ZS/HDB3/AMI Encoder/Decoder

General Description

The CS61577 is a drop-in replacement for the

CS61574, and combines the complete analog transmit

and receive line interface for T1 or E1 applications in a

low power, 28-pin device operating from a +5V supply.

The CS61577 supports processor-based or standalone operation and interfaces with industry standard

T1 and E1 framers.

The receiver uses a digital Delay-Locked-Loop which is

continuously calibrated from a crystal reference to provide excellent stability and jitt er tolerance. The receiver

includes a jitter attenuator optimized for minimum delay

in switching and transmission applications. The transmitter provides internal pulse shaping to insure

compliance with T1 and E1 pulse template specifications.

Applications

• Interfacing Network Equipment such as DACS and

Channel Banks to a DSX-1 Cross Connect

• Building Channel Service Units

ORDERING INFORMATION

CS61577-IP1 28 Pin Plastic DIP

CS61577-IL1 28 Pin Plastic PLCC

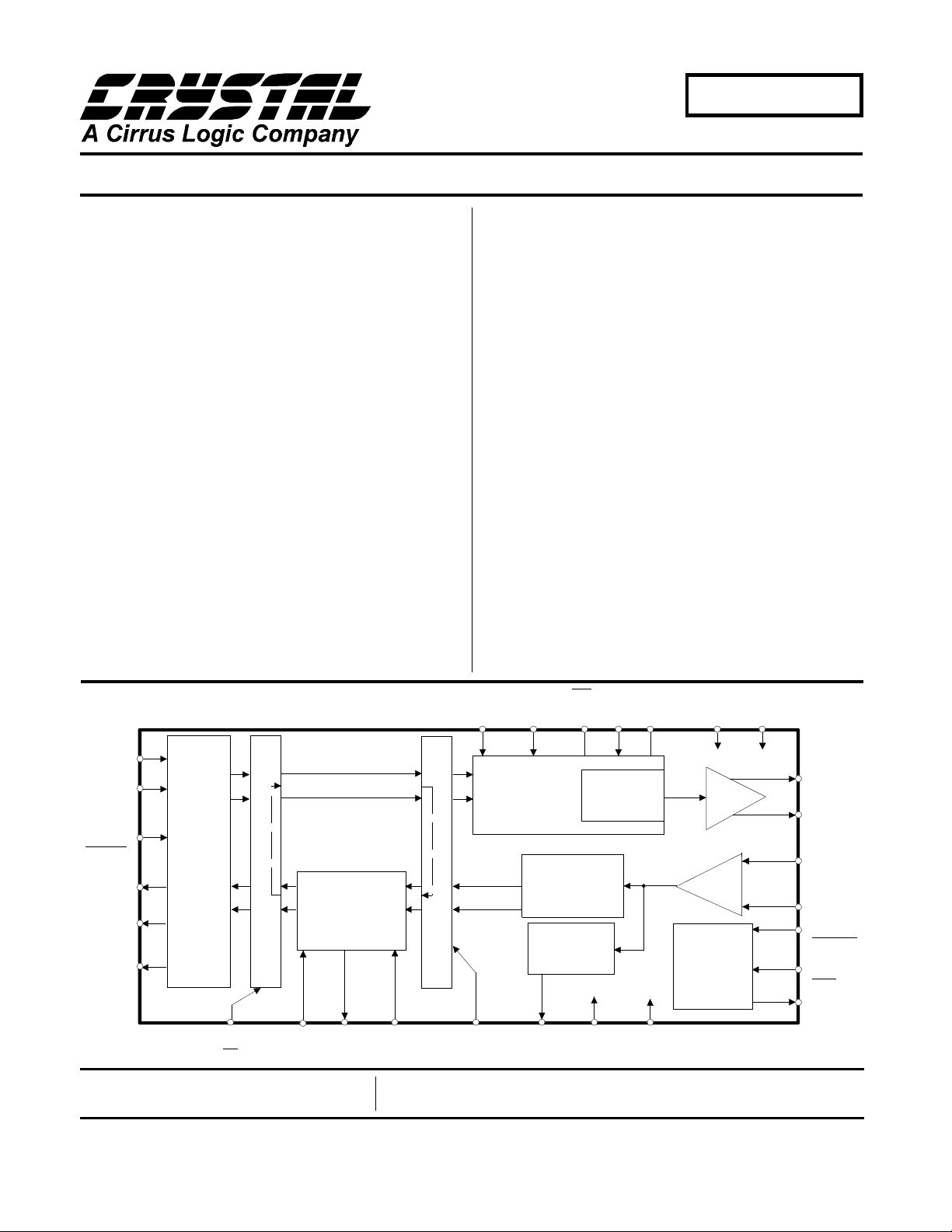

TCLK

TPOS

[TDATA]

TNEG

[TCODE]

RCLK

RPOS

[RDATA]

RNEG

[BPV]

( ) = Pin Function in

[ ] = Pin Function in

2

3

4

AMI,

B8ZS,

HDB3,

8

CODER

7

6

RLOOP

(CS)

Host Mode

Extended Hardware Mode

R

E

M

O

T

E

L

O

O

P

B

A

C

K

26

XTALIN

JITTER

ATTENUATOR

9

XTALOUT10ACLKI

Preliminary Product Information

Crystal Semiconductor Corporation

P. O. Box 17847, Austin, Texas, 78760

(512) 445-7222 FAX:(512) 445-7581

MODE

L

O

C

A

L

L

O

O

P

B

A

C

K

1

LLOOP

(SCLK)

(CLKE)

TAOS

5

CONTROL

27

(INT)

LEN0

28 23

CLOCK &

DATA

RECOVERY

SIGNAL

QUALITY

MONITOR

12 21

LOS

(SDI)

(SDO)

LEN1

LEN2

2524

PULSE

SHAPER

LINE RECEIVER

RV+22RGND

TGND

14

LINE DRIVER

DRIVER

MONITOR

TV+

15

13

16

19

20

17

18

11

TTIP

TRING

RTIP

RRING

MTIP

[RCODE]

MRING

[PCS]

DPM

[AIS]

This document contains information for a new product. Crystal

Semiconductor re ser ve s th e rig ht to modify this product wit hout n otic e.

Copyright Crystal Semiconductor Corporation 1996

(All Rights Reserved)

MAY ’96

DS155PP2

1

CS61577

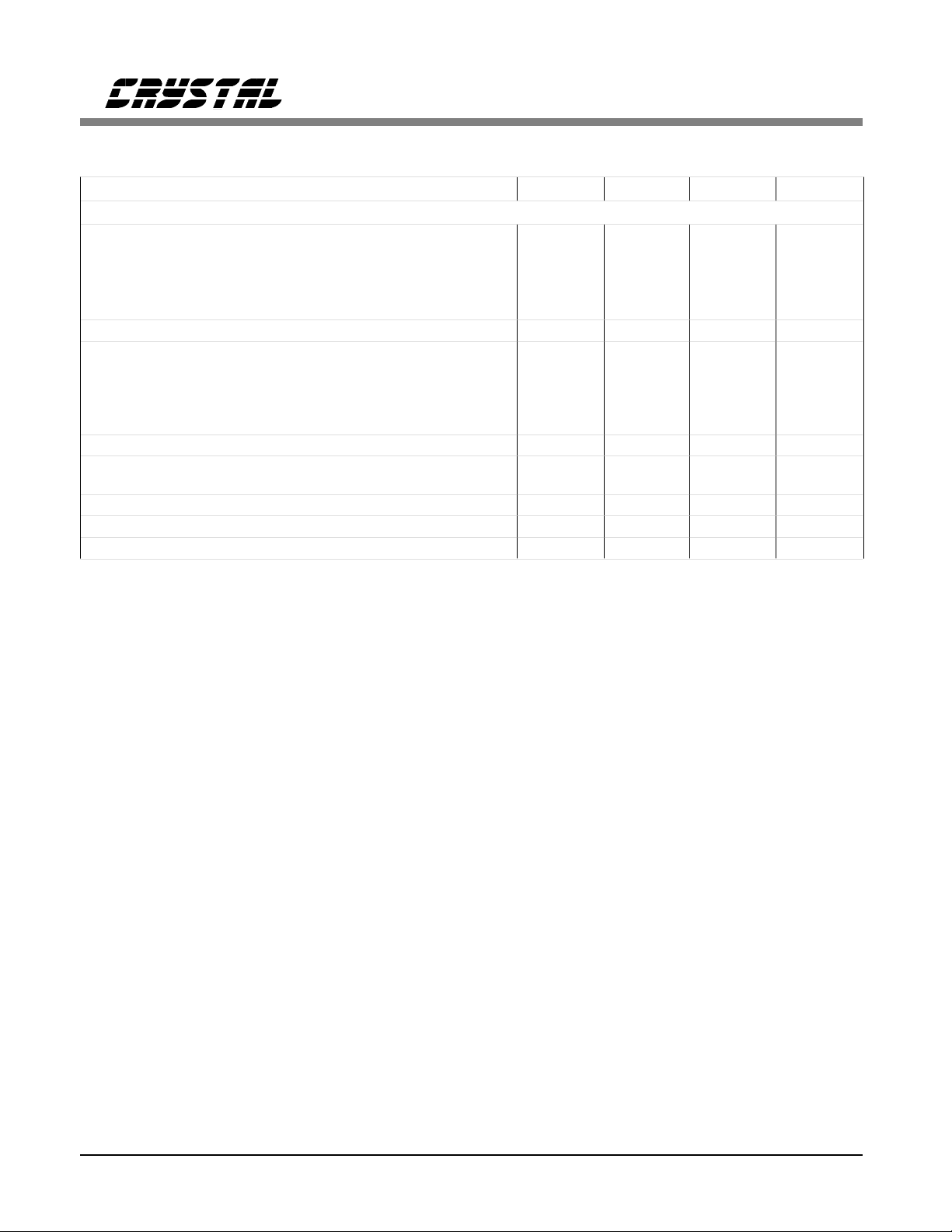

ABSOLUTE MAXIMUM RATINGS

Parameter Symbol Min Max Units

DC Supply (referenced to RGND=TGND=0V) RV+

TV+

Input Voltage, Any Pin (Note 1) V

Input Current, Any Pin (Note 2) I

Ambient Operating Temperature T

Storage Temperature T

in

in

A

stg

-

-

6.0

(RV+) + 0.3

RGND-0.3 (RV+) + 0.3 V

-10 10 mA

-40 85

-65 150

WARNIN G: O perat ions at or beyond these l imits may resul t in perma nent da mage to t he devi ce.

Normal operation is not guaranteed at these extremes.

Notes: 1. Excluding RTIP, RRING, whic h must stay wit hin -6V to (RV+ ) + 0.3V.

2. Transient currents of up to 1 00 mA will not cause SCR la tch-up. Also TTIP, TRING, TV+ and TGND

can withstand a continuous current of 100 mA.

RECOMMENDED OPERATING CONDITIONS

Parameter Symbol Min Typ Max Units

DC Supply (Note 3) RV+, TV+ 4.75 5.0 5.25 V

Ambient Operating Temperature T

Power Consumption (Notes 4,5) P

Power Consumption (Notes 4,6) P

Notes: 3. TV+ must not exceed RV+ by more than 0.3V.

4. Power consumption while driving line load over operating temperature range. Includes IC and load.

Digital input levels are within 10% of the supply rails and digital outputs are driving a 50 pF

capacitive load.

5. Assumes 100% ones density and maximum line length at 5.25V.

6. Assumes 50% ones density and 300ft. line length at 5.0V.

A

C

C

-40 25 85

-400500mW

-230-mW

V

V

°C

°C

°C

DIGITAL CHARACTERISTICS (TA = -4 0°C to 85°C; T V+, RV+ = 5.0V ± 5%; GND = 0V)

Parameter Symbol Min Typ Ma x Units

High-Level Input Voltage (Notes 7, 8)

V

IH

PINS 1-4 , 17, 18 , 23-28

Low-Level Input Voltage (Notes 7, 8)

V

IL

PINS 1-4 , 17, 18 , 23-28

High-Level Output Voltage (Notes 7, 8, 9)

I

= -40 µA PINS 6-8, 11, 12, 25

OUT

Low-Level Output Voltage (Notes 7, 8, 9)

I

= 1.6 mA PINS 6-8, 11, 12, 23, 25

OUT

V

OH

V

OL

Input Leakage Current (Except Pin 5) - Low-Level Input Voltage, PIN 5 V

High-Level Input Voltage, PIN 5 V

Mid-Level Input Voltage, PIN 5 (Note 10) V

IL

IH

IM

Notes: 7. In Extended Hardware Mode, pins 17 and 18 are digital inputs. In Host Mode, pin 23 is

an open drain output and pin 25 is a tristate output.

8. This specification guarantees TTL compatibility (V

= 2.4V @ I

OH

9. Output drivers will drive CMOS logic levels into a CMOS load.

10. As a n a lter nat ive t o suppl yin g a 2.3- to -2.7 V in put, th is pin may b e le ft flo ati ng.

2 DS155PP2

2.0 - - V

--0.8V

4.0 - - V

--0.4V

±10 µA

--0.2V

(RV+) - 0.2 - - V

2.3 - 2.7 V

= -40µA).

OUT

CS61577

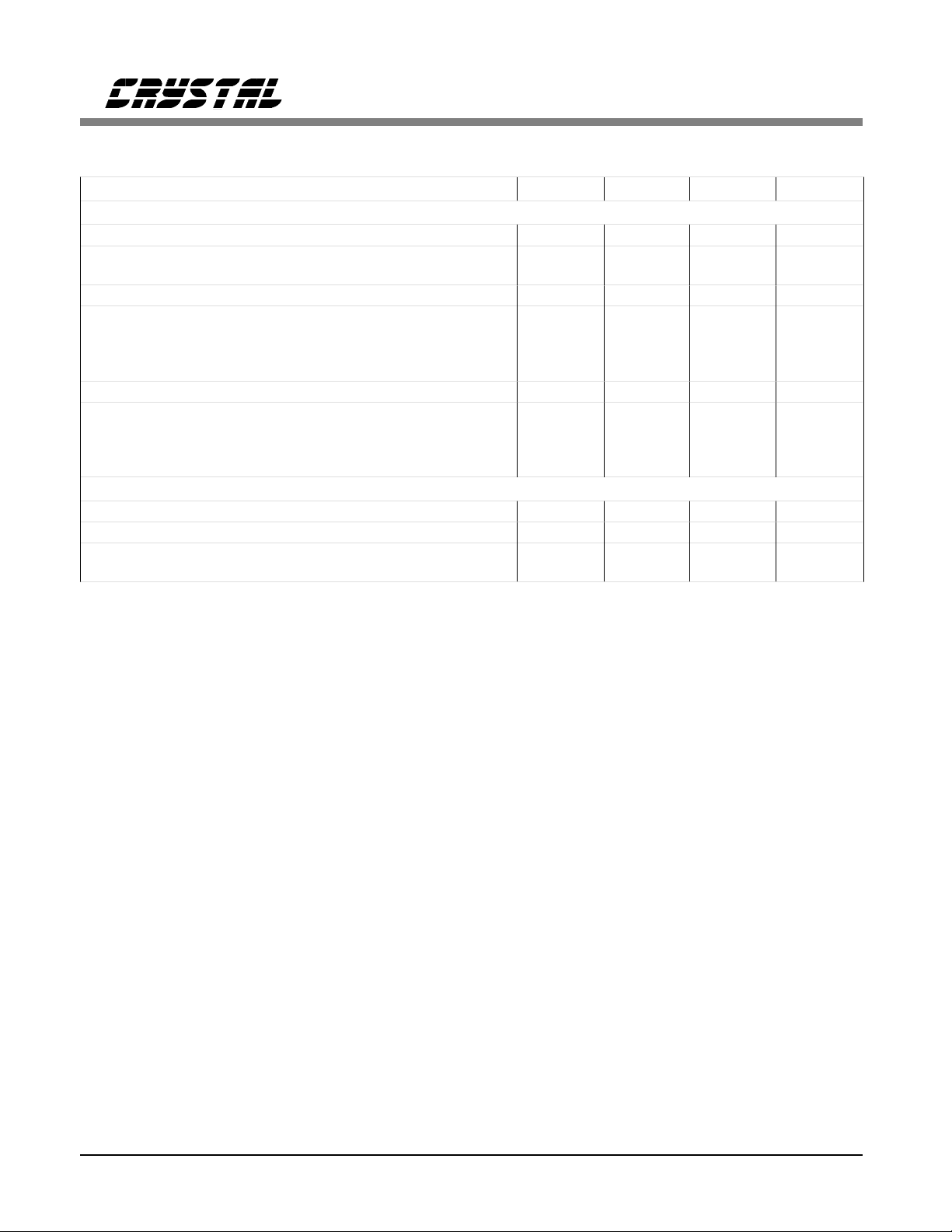

ANALOG SPECIFICATIONS (TA = -40°C to 85°C; TV+, RV+ = 5. 0V ±5%; GND = 0V)

Parameter Min Typ Max Units

Transmitter

AMI Output Pulse Amplitudes (Note 11)

E1, 75 Ω (Note 12)

E1, 120 Ω (Note 13)

T1, (FCC Part 68) (Note 14)

T1, DSX-1 (Note 15)

Load Presented To Transmitter Output (Note 11) - 25 Jitter Added During Remote Loopback (Note 16)

10Hz - 8kHz

8kHz - 40k Hz

10Hz - 40k Hz

Broad Band

Power in 2kHz band about 772kHz (Notes 11, 17) 12.6 15 17.9 dBm

Power in 2kHz band about 1.544MHz (Notes 11, 17)

(referenced to power in 2kHz band at 772kHz)

Positive to Negative Pulse Imbalance (Notes 11, 17) - 0.2 0.5 dB

Transmitter Output Impedance (Notes 17, 18) - - 10

Transmitter Short Circuit Current (Notes 11, 19) - - 50 mA RMS

Notes: 11. Usi ng a 0.47 µF capacitor in series with the primary of a transformer recommended

in the Applications Section.

12. Pulse amplitude measured at the output of the transformer across a 75 Ω load for line length

settings LEN2/1/0 = 0/0/1 and 0/0/0. For LEN2/1/0 = 0/0/0 only, a 4.4 Ω resistor is required

in series with the transformer primary.

13. Pulse amplitude measured at the output of the transformer across a 120 Ω load for line length

setting LEN2/1/0 = 0/0/0.

14. Pulse amplitude measured at the output of the transformer across a 100 Ω load for line length

setting LEN2/1/0 = 0/1/0.

15. Pulse amplitude measured at the DSX-1 Cross-Connect for all line length settings from

LEN2/1/0 = 0/1/1 to LEN2/1/0 = 1/1/1.

16. Input signal to RTIP/RRING is jitter free. Values will reduce slightly if jitter free clock is input to TCLK.

17. Not production tested. Parameters guaranteed by design and characterization.

18. Measured between the TTIP and TRING pins at 772 kHz during marks and spaces.

19. Measured broadband through a 0.5 Ω resistor across the secondary of the transmitter transformer

during the transmission of an all ones data pattern with LEN2/1/0 = 0/0/0 or 0/0/1.

2.14

2.7

2.7

2.4

-

-

-

-

-29 -38 - dB

2.37

3.0

3.0

3.0

0.005

0.008

0.010

0.015

2.6

3.3

3.3

3.6

-

-

-

-

V

V

V

V

Ω

UI

UI

UI

UI

Ω

DS155PP2 3

CS61577

ANALOG SPECIFICATIONS (TA = -40°C to 85°C; TV+, RV+ = 5. 0V ±5%; GND = 0V)

Parameter Min Typ Max Units

Receiver

RTIP/RRING Input Impedance - 50k Sensitivity Below DSX (0dB = 2.4V) -13.6

500

Loss of Signal Threshold - 0.30 - V

Data Decision Threshold

T1, DSX-1 (Note 20)

T1, DSX-1 (Note 21)

T1, (FCC Part 68) and E1 (Note 22)

60

53

45

Allowable Consecutive Zeros before LOS 160 175 190 bits

Receiver Input Jitter Tolerance (Note 23)

10kHz - 100kHz

2kHz

10Hz and below

0.4

6.0

300

Jitter Attenuator

Jitter Attenuation Curve Corner Frequency (Notes 17, 24) - 6 - Hz

Attenuation at 10kHz Jitter Frequency (Notes 17, 24) - 50 - dB

Attenuator Input Jitter Tolerance (Before Onset

12 23 - UI

of FIFO Overflow or Underflow Protection) (Notes 17, 24)

Notes: 20. For input amplitude of 1.2 V

21. For input amplitude of 0.5 V

22. For input amplitude of 1.05 V

to 4. 14 Vpk.

pk

to 1.2 Vpk and from 4. 14 Vpk to RV+.

pk

to 3.3 Vpk.

pk

23. Jitter tolerance increases at lower frequencies. See Figure 11.

24. Attenuation measured with input jitter equal to 3/4 of measured jitter tolerance. Circuit attenuates

jitter at 20 dB/decade above the corner frequency. See Figure 12. Output jitter can increase

significantly when more than 12 UI’s are input to the attenuator. See discussion in the text section.

65

65

50

-

-

-

-

-

70

77

55

-

-

dB

mV

% of peak

% of peak

% of peak

-

-

-

UI

UI

UI

Ω

4 DS155PP2

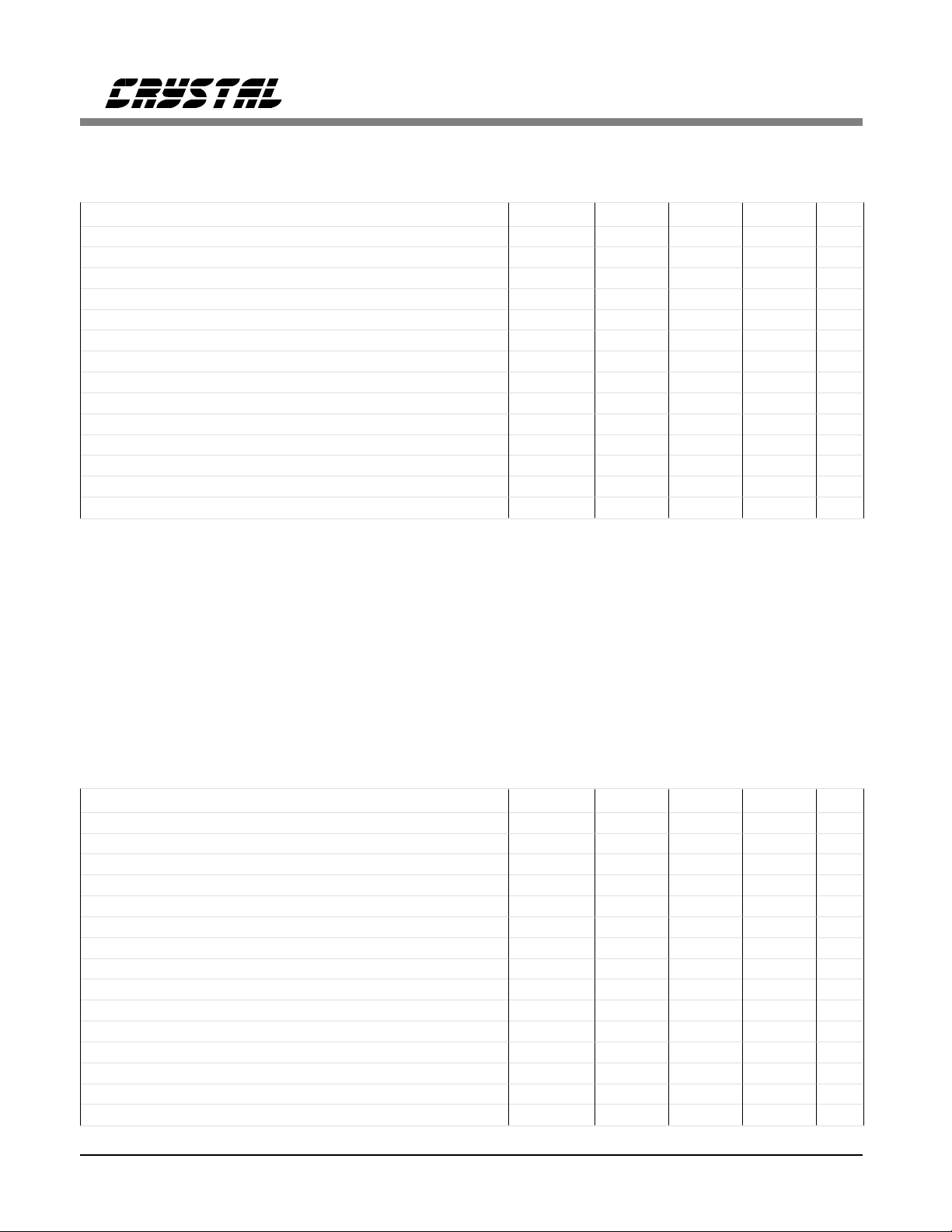

CS61577

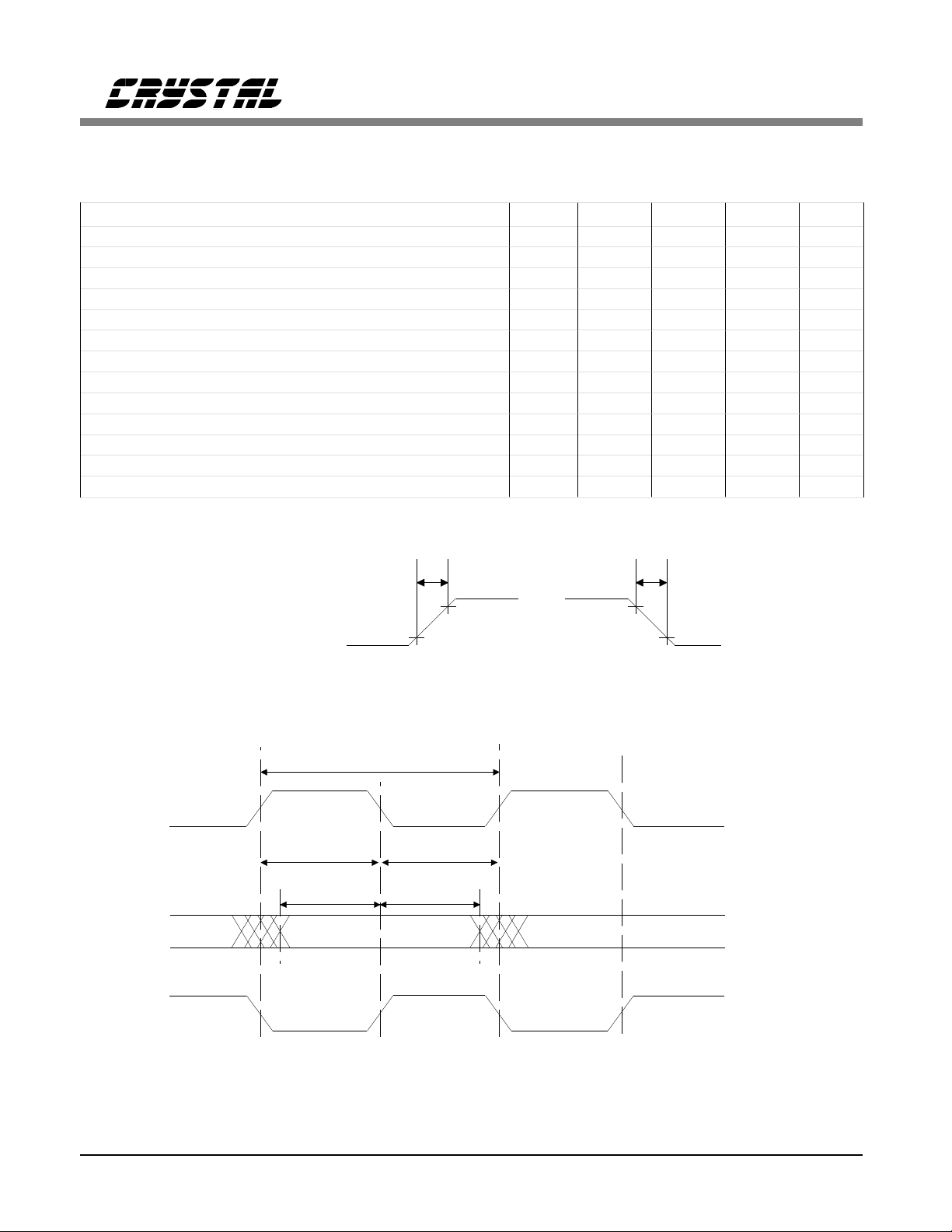

T1 SWITCHING CHARACTERISTICS (TA = -40°C to 85°C; TV+, RV+ = 5.0V ±5%;

GND = 0V; Inputs: Logic 0 = 0V, Logic 1 = RV+; See Figures 1, 2, & 3)

Parameter Symbol Min Typ Max Units

Crystal Frequency (Note 25) f

TCLK Frequency f

ACLKI Frequency (Note 26) f

RCLK Duty Cycle (Note 27) t

Rise Time, All Digital Outputs (Note 28) t

Fall Time, All Digital Outputs (Note 28) t

TPOS/TNEG (TDATA) to TCLK Falling Setup Time t

TCLK Falling to TPOS/TNEG (TDATA) Hold Time t

RPOS/RNEG Valid Before RCLK Falling (Note 29) t

RDATA Valid Before RCLK Falling (Note 30) t

RPOS/RNEG Valid Before RCLK Rising (Note 31) t

RPOS/RNEG Valid After RCLK Falling (Note 29) t

RDATA Valid After RCLK Falling (Note 30) t

RPOS/RNEG Valid After RCLK Rising (Note 31) t

c

tclk

aclki

pwh1/tpw1

r

f

su2

h2

su1

su1

su1

h1

h1

h1

Notes: 25. Crystal must meet specifications described in CXT6176/CXT8192 data sheet.

26. ACLKI provided by an external source or TCLK.

27. RCLK duty cycle will be 62.5% o r 37.5% when jitte r attenuator limit s are reach ed.

28. At max load of 1.6 mA and 50 pF.

29. Host Mode (CLKE = 1).

30. Extended Hardware Mode.

31. Hardware Mode, or Host Mode (CLKE = 0)

32. The transmitted pulse width does not depend on the TCLK duty cycle.

- 6.176000 - MHz

-1.544-MHz

-1.544-MHz

45 50 55 %

- - 85 ns

- - 85 ns

25 - - ns

25 - - ns

150 274 - n s

150 274 - n s

150 274 - n s

150 274 - n s

150 274 - n s

150 274 - n s

E1 SWITCHING CHARACTERISTICS (TA = -4 0°C to 85 °C; TV+, RV+ = 5.0V ±5%;

GND = 0V; Inputs: Logic 0 = 0V, Logic 1 = RV+; See Figures 1, 2, & 3)

Parameter Symbol Min Typ Max Units

Crystal Frequency (Note 25) f

TCLK Frequency f

TCLK Duty Cycle for LEN2/1/0 = 0/0/0 (Note 32) t

ACLKI Frequency (Note 26) f

RCLK Duty Cycle (Note 27) t

Rise Time, All Digital Outputs (Note 28) t

Fall Time, All Digital Outputs (Note 28) t

TPOS/TNEG (TDATA) to TCLK Falling Setup Time t

TCLK Falling to TPOS/TNEG (TDATA) Hold Time t

RPOS/RNEG Valid Before RCLK Falling (Note 29) t

RDATA Valid Before RCLK Falling (Note 30) t

RPOS/RNEG Valid Before RCLK Rising (Note 31) t

RPOS/RNEG Valid After RCLK Falling (Note 29) t

RDATA Valid After RCLK Falling (Note 30) t

RPOS/RNEG Valid After RCLK Rising (Note 31) t

c

tclk

pwh2/tpw2

aclki

pwh1/tpw1

r

f

su2

h2

su1

su1

su1

h1

h1

h1

DS155PP2 5

- 8.192000 - MHz

-2.048-MHz

40 50 60 %

-2.048-MHz

45 50 55 %

- - 85 ns

- - 85 ns

25 - - ns

25 - - ns

100 194 - n s

100 194 - n s

100 194 - n s

100 194 - n s

100 194 - n s

100 194 - n s

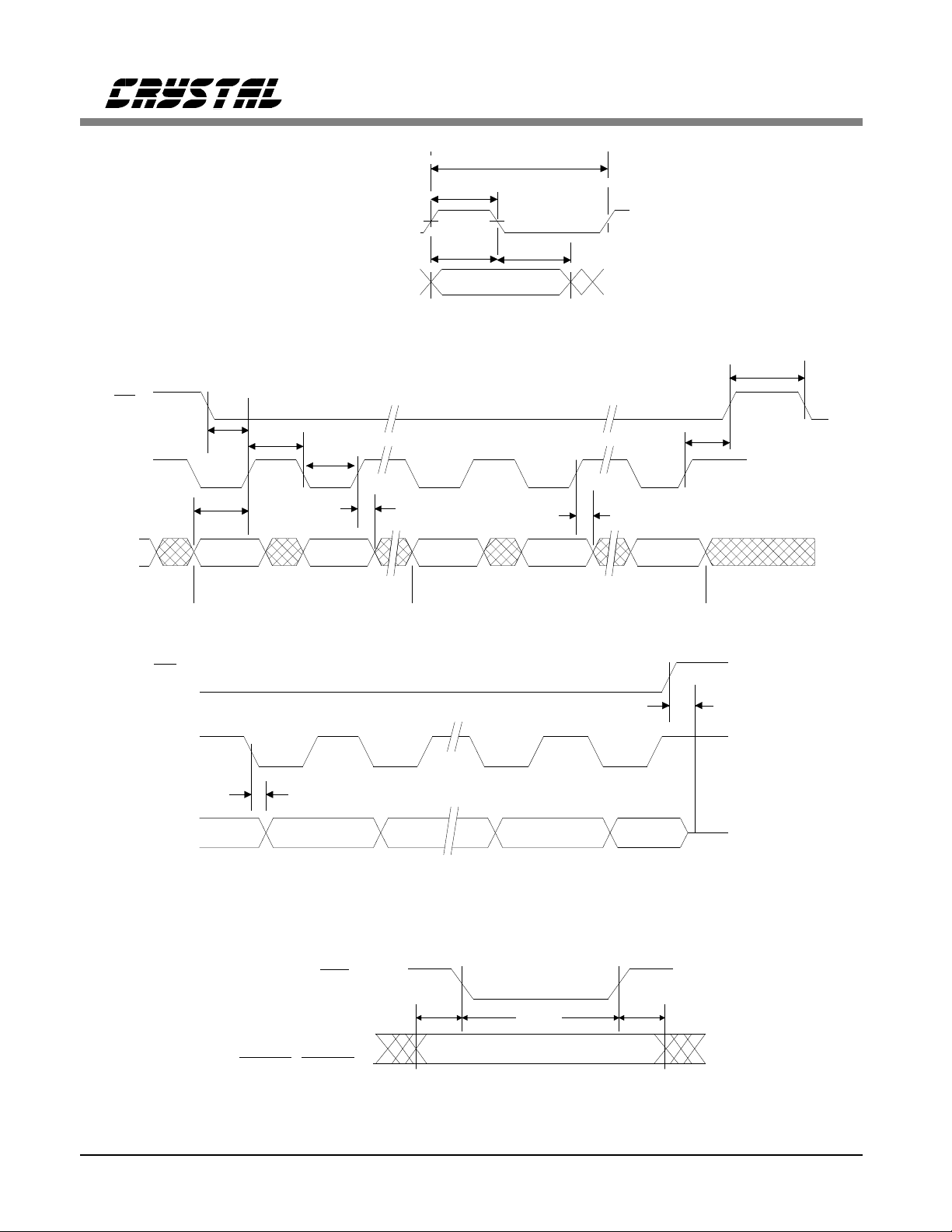

SWITCHING CHARACTERISTICS (TA = -40 ° to 85°C; TV +, RV+ = ±5% ;

Inputs: Logic 0 = 0V, Logic 1 = RV+)

Parameter Symbol Min Typ Max Un its

SDI to SCLK Setup Time t

SCLK to SDI Hold Time t

SCLK Low Time t

SCLK High Time t

SCLK Rise and Fall Time t

CS to SCLK Setup Time t

SCLK to CS Hold Time t

CS Inactive Time t

SCLK to SDO Valid (Note 33) t

CS to SDO High Z t

Input Valid To PCS Falling Setup Time t

PCS Rising to Input Invalid Hold Time t

PCS Active Low Time t

Notes: 33. Output load capacitance = 50pF

dc

cdh

cl

ch

, t

r

cc

cch

cwh

cdv

cdz

su4

h4

pcsl

f

50 - - ns

50 - - ns

240 - - ns

240 - - ns

- - 50 ns

50 - - ns

50 - - ns

250 - - ns

- - 200 ns

- 100 - ns

50 - - ns

50 - - ns

250 - - ns

CS61577

RCLK

RPOS

RNEG

RDATA

BPV

RCLK

Any Digital Output

Figure 1. Signal Rise and Fall Characteristics

t

t

pwl1

tt

su1

pw1

t

r

90% 90%

10%

t

pwh1

h1

10%

t

f

EXTENDED

HARDWARE

MODE OR

HOST MODE

(CLKE = 1)

HARDWARE

MODE OR

HOST MODE

(CLKE = 0)

Figure 2. Recovered Clock and Data Switching Characteristics

6 DS155PP2

t

pwh2

t

pw2

CS61577

CS

SCLK

SDI

TCLK

t

su2

t

h2

TPOS/TNEG

Figure 3. Transmit Clock and Data Switching Characteristics

t

t

cc

t

dc

LSB LSB

ch

CONTROL BYTE DATA BYTE

t

cl

t

cdh

Figure 4. Serial Port Write Timing Diagram

t

cdh

MSB

t

cch

t

cwh

CS

SCLK

SDO

CLKE = 1

t

cdv

Figure 5. Seria l Port R ead Timi ng Di agra m

PCS

t

h4

LEN0/1/2 , T A OS,

RLOOP, LLOOP,

RLOOP, LLOOP,

t

su4

t

pcsl

VALID INPUT DATA

RCODE, TCODE

Figure 6. Exte nded Ha rdwa re Mo de Par allel Chip Select Timin g Dia gram

t

cdz

HIGH Z

DS155PP2 7

CS61577

THEORY OF OPERATION

CS61577 Enhancement s Relative to CS61 574

Existing design s using the CS61574 can be converted to th e higher perform ance, pin-co mpatible

CS61577 with no changes to the PCB, external

component or system software.

The CS61577 provides higher performance and

more features than the CS61574 including:

• Selection of 75 Ω or 120 Ω E1 outpu t op-

tions under software or hardware control,

• 50 mA

transmitter short-ci rcuit current

RMS

limiting for E1 (per OFTEL OTR-001),

• internally co ntrolled puls e width for E1

output options,

• 35% lower power consumption,

• Increased transmit ter immunity to signal re-

flections for improved signal qu ality,

• Optional AMI, B8ZS, HDB3 enc oder/de-

coder or external line coding support,

• Receiver AIS (unframed all on es) detect ion,

• Improved receiver Loss of Signal handling

(LOS set at power-up, reset upon receipt of

3 ones in 32 bit pe riods with no more t han

15 consecutive zeros),

• Transmitter TTIP and TRING ou tputs are

forced low when TCLK is static,

• The Driver Performan ce Monitor op erates

over a wider range of input signal levels.

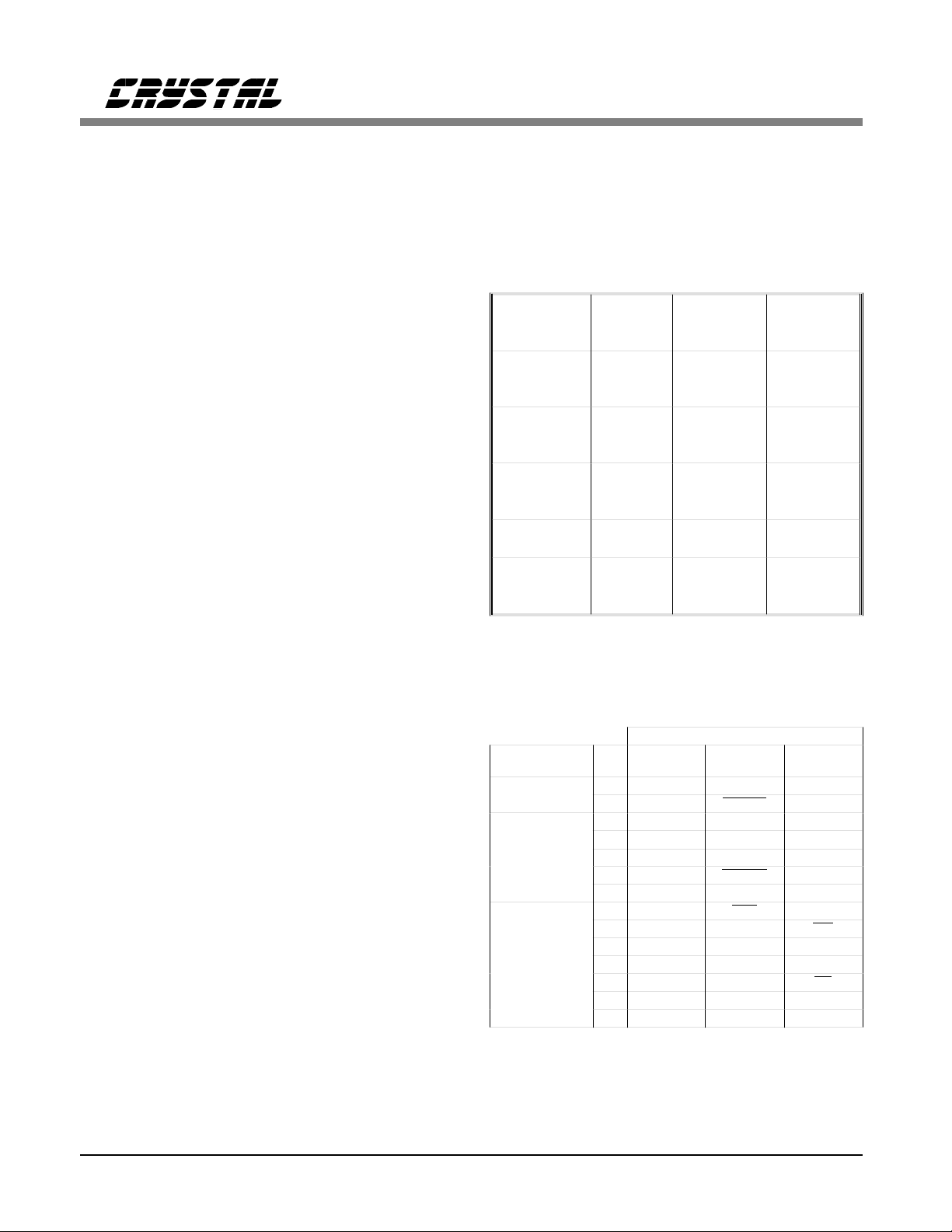

Introduction to Op erating Modes

The CS61577 supports three operating modes

which are selected by the level of the MODE pin

as shown in Tables 1 and 2, Figure 7, and Figures

A1-A3 of the Applications section.

The modes are Har dware Mode, Extended Hardware Mode, and Host Mode. In Hardware and

Extended Hardware Modes, discret e pins are used

to configure and monitor the device. The Extended Hardware Mode provides a parallel chip

select input which latches the control inputs al-

lowing individual ICs to be configured using a

common set of control lines. In the Host Mode,

an external processor monito rs and configures the

device through a serial interface. There are thirteen multi-function pins whose functionality is

determined by the operating mode. (see Table 2).

Hardware

Mode

Control

Method

MODE

Pin

Level

Line

Coding

AIS

Detection

Driver

Performance

Monitor

Table 1. Diff erences Betwe en Operati ng Modes

FUNCTION PIN HARDWARE

TRANSMITTER

RECEIVER/DPM

CONTROL

Control

Pins

<0.2 V Floating or

External Internal-

No Yes No

Yes No Yes

3TPOS TDATA TPOS

4TNEG

6 RNEG B PV RNEG

7RPOS RDATA RPOS

11 DPM AIS DPM

17 MTIP

18 MRING - MRING

18 23 LEN0 LEN0

24 LEN1 LEN1 SDI

25 LEN2 LEN2 SDO

26 RLOOP RLOOP

27 LLOOP LLOOP SCLK

28 TAOS TAOS CLKE

Table 2. Pin Definitions

Extended

Hardware

Mode

Control Pins

with Parallel

Chip Select

2.5 V

AMI, B8ZS,

or HDB3

MODE

EXTENDED

HARDWARE HOST

TCODE TNEG

RCODE MTIP

PCS -

Host

Mode

Serial

Interface

>(R V+)-0.2 V

External

INT

CS

8 DS155PP2

CS62180B

FRAMER

CIRCUIT

TNEG

RPOS

RNEG

CS61577

JITTER

ATTENUATOR

EXTENDED HARDWARE MODE

HARDWARE MODE

RLOOP LEN0/1/2LLOOPTAOS

CONTROL

LINE DRIVER

DRIVER MONITOR

LINE RECEIVER

MRING

MTIP

TTIPTPOS

TRING

DPM

RTIP

RRING

CS61577

TRANSMIT

TRANSFORMER

RECEIVE

TRANSFORMER

T1 or E1

REPEATER

OR

MUX

CONTROL

CS62180B

FRAMER

CIRCUIT

TDATA

CODER

RDATA

BPV AIS

µ

P SERIAL POR T

5

TPOS

TNEG

RPOS

RNEG

RCODETCODE

AMI

B8ZS,

HDB3,

CS61577

JITTER

ATTENUATOR

CS61577

AIS

DETECT

CLKE

CONTROL

RLOOP PCS LEN0/1/2LLOOPTAOS

CONTROL

JITTER

ATTENUATOR

HOST MODE

LINE DRIVER

DRIVER MONITOR

LINE RECEIVER

LINE DRIVER

RECEIVER

LINE

MRING

MTIP

TTIP

TRING

RTIP

RRING

TTIP

TRING

DPM

RTIP

RRING

TRANSMIT

TRANSFORMER

RECEIVE

TRANSFORMER

TRANSMIT

TRANSFORMER

RECEIVE

TRANSFORMER

Figure 7. Overv iew of Op eratin g Mode s

DS155PP2 9

CS61577

Transmitter

The transmitter takes digita l T1 or E1 input data

and drives appropriately shaped bipolar pulses

onto a transmission line through a 1:2 transformer. The transmit data (TPOS & TNEG or

TDATA) is supplied synchronously and sampled

on the falling edge of the input clock, TCLK.

Either T1 (DSX-1 or Network Interface) or E1

CCITT G.703 pulse shapes may be selected.

Pulse shaping and signal level are controlled by

"line length selec t" inputs as shown in Table 3.

For T1 DSX-1 applications, line lengths from 0 to

655 feet (a s measured from t he transmitter to the

DSX-1 cross conne ct) may be selected. The five

partition arrangement in Table 3 meets ANSI

T1.102 and AT&T CB-119 requirements when

using #22 ABAM cable. A typica l outpu t pulse is

shown in Figure 8. The se pulse settings can also

be used to meet CCITT pul se shape require ments

for 1.544 MHz operation.

For T1 Network In terface applicat ions, two add itional opti ons are provided. Not e that the o ptimal

pulse width for Part 68 (324 ns) is narrower than

the optimal pu lse width for DSX-1 (350 ns ). The

CS61577 automatically adjusts the pulse width

based upon the "line length" selection made.

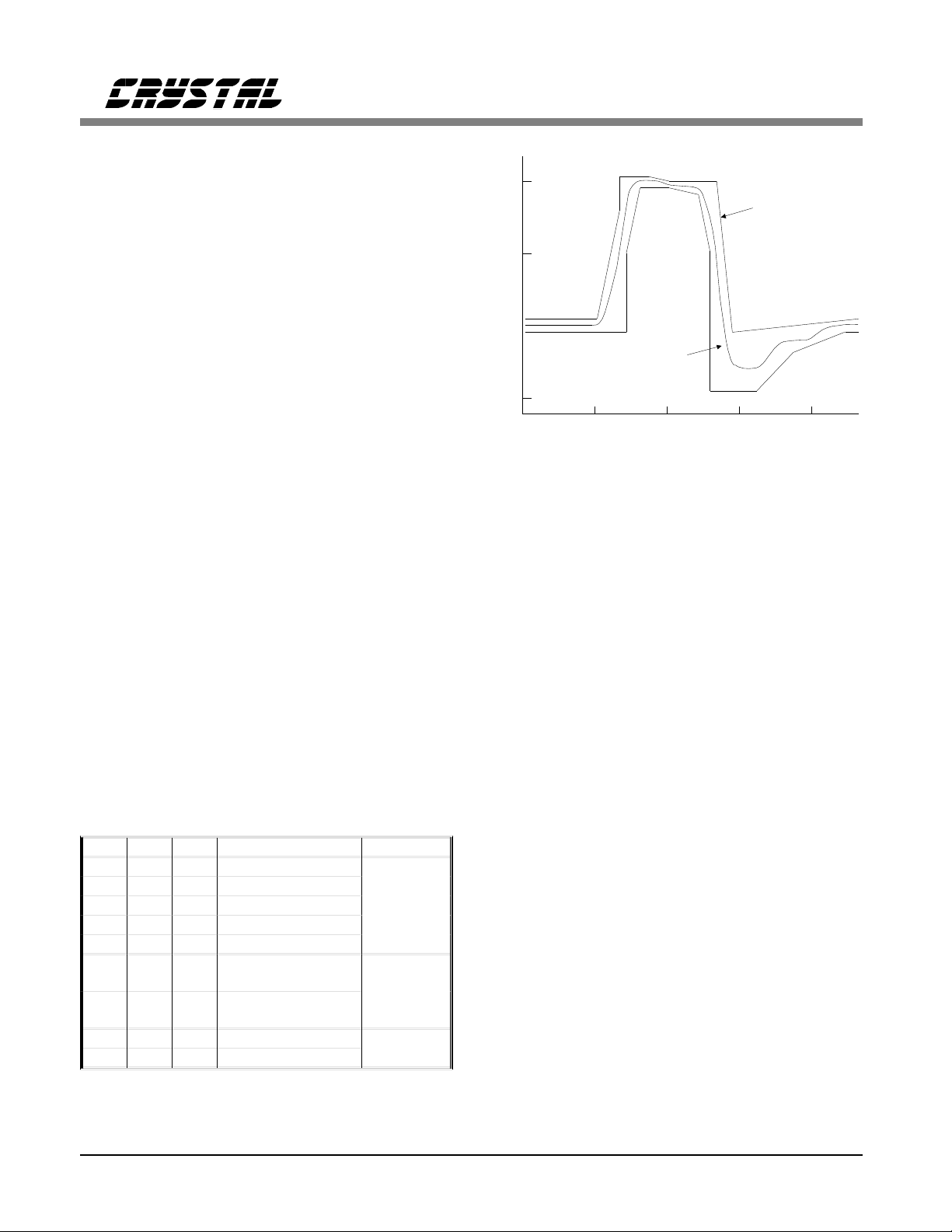

NORMALIZED

AMPLITUDE

1.0

0.5

0

OUTPUT

PULSE SHAPE

-0.5

0

Figure 8. Typical Pulse Shape at DSX-1 Cross Connect

250 750 1000

500

TIME (nanoseconds)

ANSI T1.102,

AT&T CB 119

SPECIFICATIONS

The E1 G.703 p ulse shape is supported wi th line

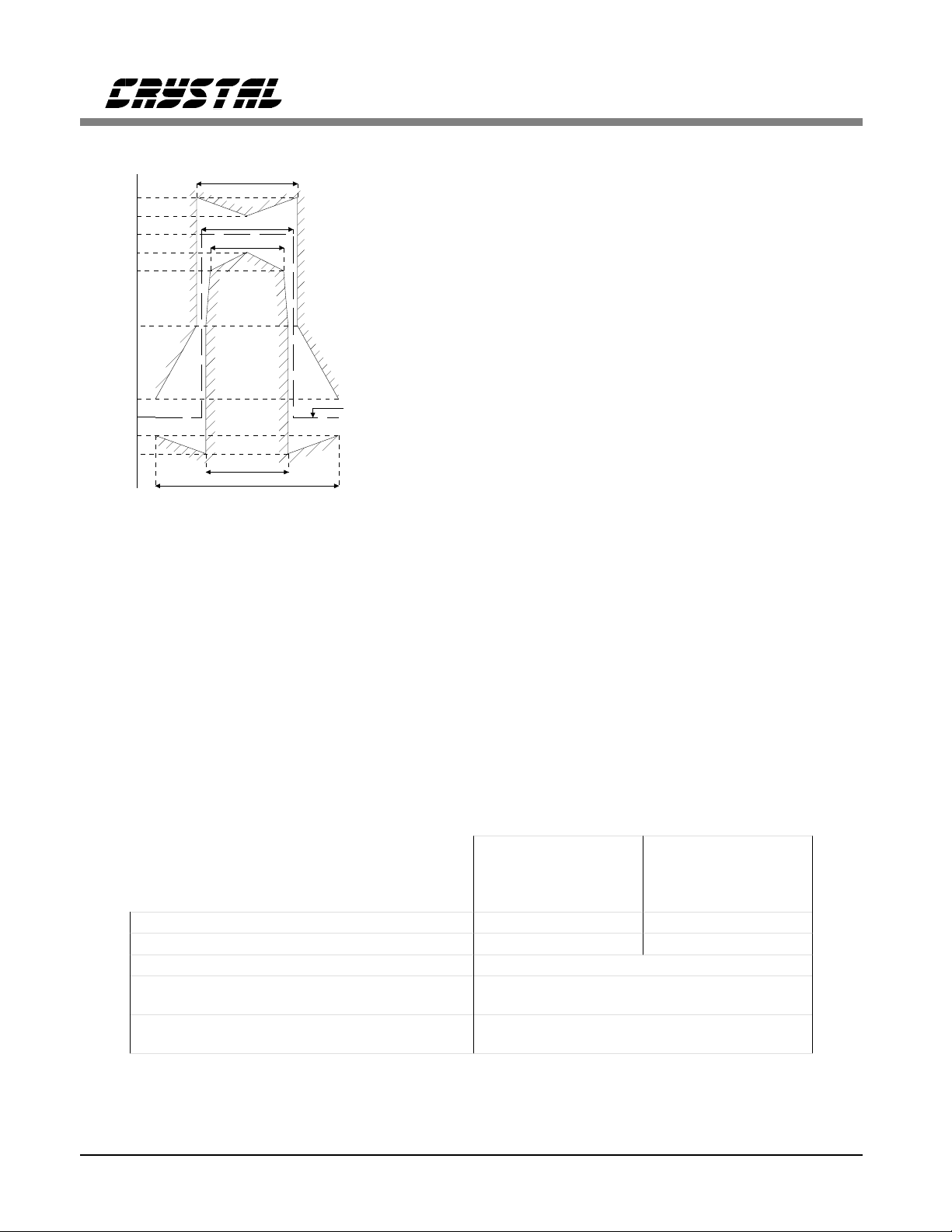

length selections LEN2/1/0=0/0/0 or

LEN2/1/0=0/0/1. As with the CS61574,

LEN2/1/0=0/0 /0 supports the 120 Ω, 3 V o utput

option without external series resistors, but will

also support the 75 Ω, 2.37 V output optio n with

an external 4.4 Ω resistor in series with TTIP or

TRING. The new LEN2/1/0=0/0 /1 code supports

the 75 Ω, 2.37 V outpu t option without external

series resistors allowing for software selection between the two E1 output opti ons. The pulse width

will meet th e G.703 pulse shape template shown

in Figure 9, and specified in Table 4.

The CS61577 wi ll detect a static TCL K, and will

force TTIP and TRING low to prevent trans mis-

LEN2 LEN1 LEN0 Option Selected Application

0 1 1 0-133 FEET

100 133-266 FEET

101 266-399 FEET

110 399-533 FEET

111 533-655 FEET

000

001

0 1 0 FCC PART 68, OPT. A NETWORK

011 ANSI T1.403

Table 3. Line Length Selection

10 DS155PP2

75 Ω (with 4.4 Ω

resistor) & 120 Ω

75 Ω (without

4.4 Ω resistor)

DSX-1

ABAM

(AT&T 600B

or 600C)

E1

CCITT G.703

INTERFACE

sion when data is not present. When any transmit

control pin (TAOS, LEN0-2 or LLOOP) is toggled, the transmitter outputs will require

approximately 22 bit periods to stabilize. The

transmitter will take longer to stabilize when

RLOOP is selected because the timing circuitry

must adjust to the new frequency.

CS61577

Percent of

nominal

peak

voltage

120

110

100

90

80

50

10

0

-10

-20

Figure 9. Mask of the Pulse at the 2048 kbps Interface

269 ns

244 ns

194 ns

Nominal Pulse

219 ns

488 ns

Transmit All Ones Select

The transmitter provides for all ones insertion at

the frequency of TCLK. Transmit all ones is selected when TAOS goes high, and causes

continuous ones to be transmitted on the line

(TTIP and T RING). In this mode , the TPOS and

TNEG (or TDATA) inputs are ignore d. If Remote

Loopback is in effect, any TAOS request will be

ignored.

Receiver

The receiver extracts dat a an d cl ock fro m an AMI

(Alternate Mark Inversion) coded signal and outputs clock an d synchronized data. The receiver is

sensitive to signals over the entire range of

ABAM cable lengths and requires no equalizati on

or ALBO (Automatic Line Build Out) circuits.

The signal is received on both ends of a centertapped, center-grounded transformer. The

transformer is center tapped on the IC side. The

clock and dat a recovery circuit exceeds the jitter

tolerance specifications of Publications 43802,

43801, AT&T 62411, TR-TSY-000170, and

CCITT REC. G.823.

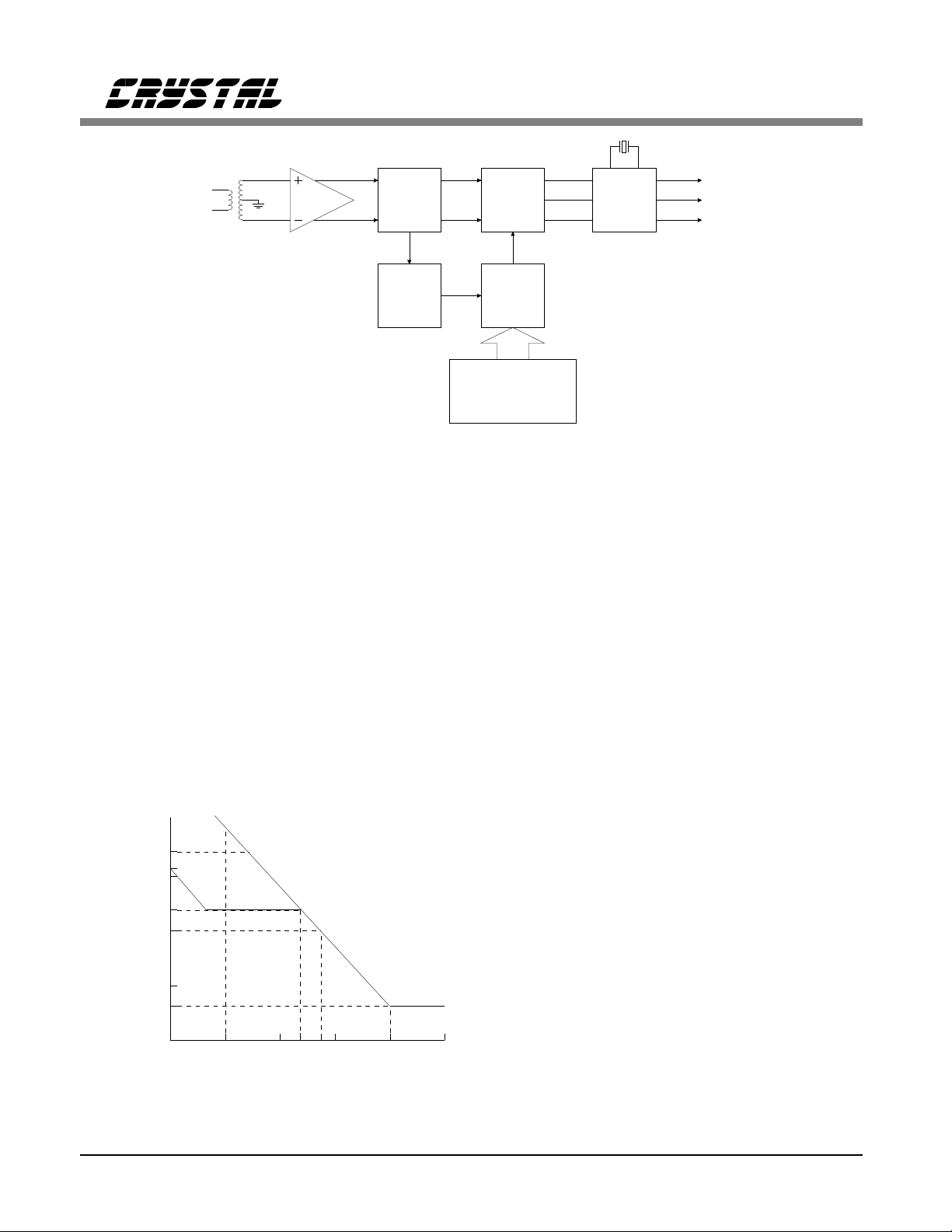

A block diagram of the rec eiver is shown in Figure 10. The two leads of the transformer (RTIP

and RRING) have oppos ite polarity allowing the

receiver to treat RTIP and RRING as unipolar signals. Comparators are used to detect pulses on

RTIP and RRING. The co mparator th resholds are

dynamically established a t a percent of the peak

level (50% of peak for E1, 65% of peak for T1;

with the slicing level selected by LEN2/1/0 inputs).

The leading ed ge of an incoming data pul se triggers the clo ck phase selector. The phase selector

chooses o ne of the 13 available ph ases which the

delay line pr oduces for each bit period. T he out-

For coaxial cable,

75Ω load and

transformer specified

in Application Section.

Nominal peak voltage of a mark (pulse) 2.37 V 3 V

Pea k voltage of a space (no pulse)

Nominal puls e wi dt h 244 ns

Ratio of the amplitudes of positive and negative

pulses at the center of the pulse interval

Ratio of the widths of positive and negative

pulses at the nomi nal half amplitude

* When configured with a 0.47 µF nonpolarized capacitor in series with the TX transformer

primary as shown in Figures A1, A2 and A3.

Table 4. CCITT G.703 S pecificati ons

DS155PP2 11

0 ±0.237 V 0 ±0.30 V

0.95 to 1.05*

0.95 to 1.05*

For shielded twisted

pair, 120Ω load and

transformer specified

in Application Section.

CS61577

RTIP

1 : 2

RRING

Data

Level

Slicer

Edge

Detector

Figure 1 0. Re cei ver Bl oc k Di agr am

put from the phase selector feeds the clock and

data recovery circuits which generate the recovered clock and sample the incoming signal at

appropriate intervals to recover the data.

Data sampling will continue at the periods selected by the phase selector until an incoming

pulse deviates enou gh to cause a new phase to be

selected for da ta sampling. The phases of the d elay line are selected and updated to allow as much

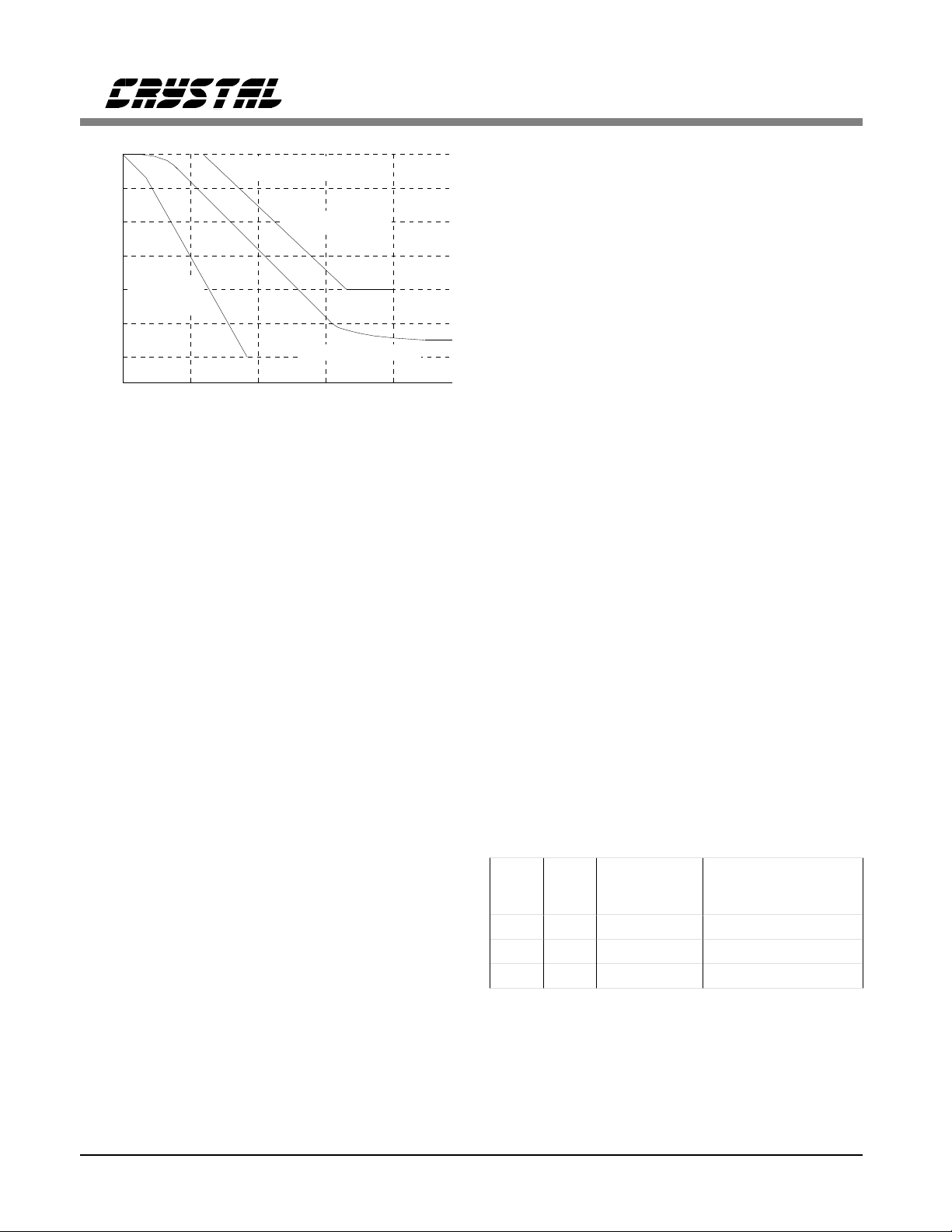

as 0.4 UI of jitter from 10 kHz to 100 kHz, without error. The jitter tolerance of the receiver

exceeds that shown in Figure 11. Additionally,

this method o f clock and d ata recovery is tol erant

of long strings of consecutive zeros. The data

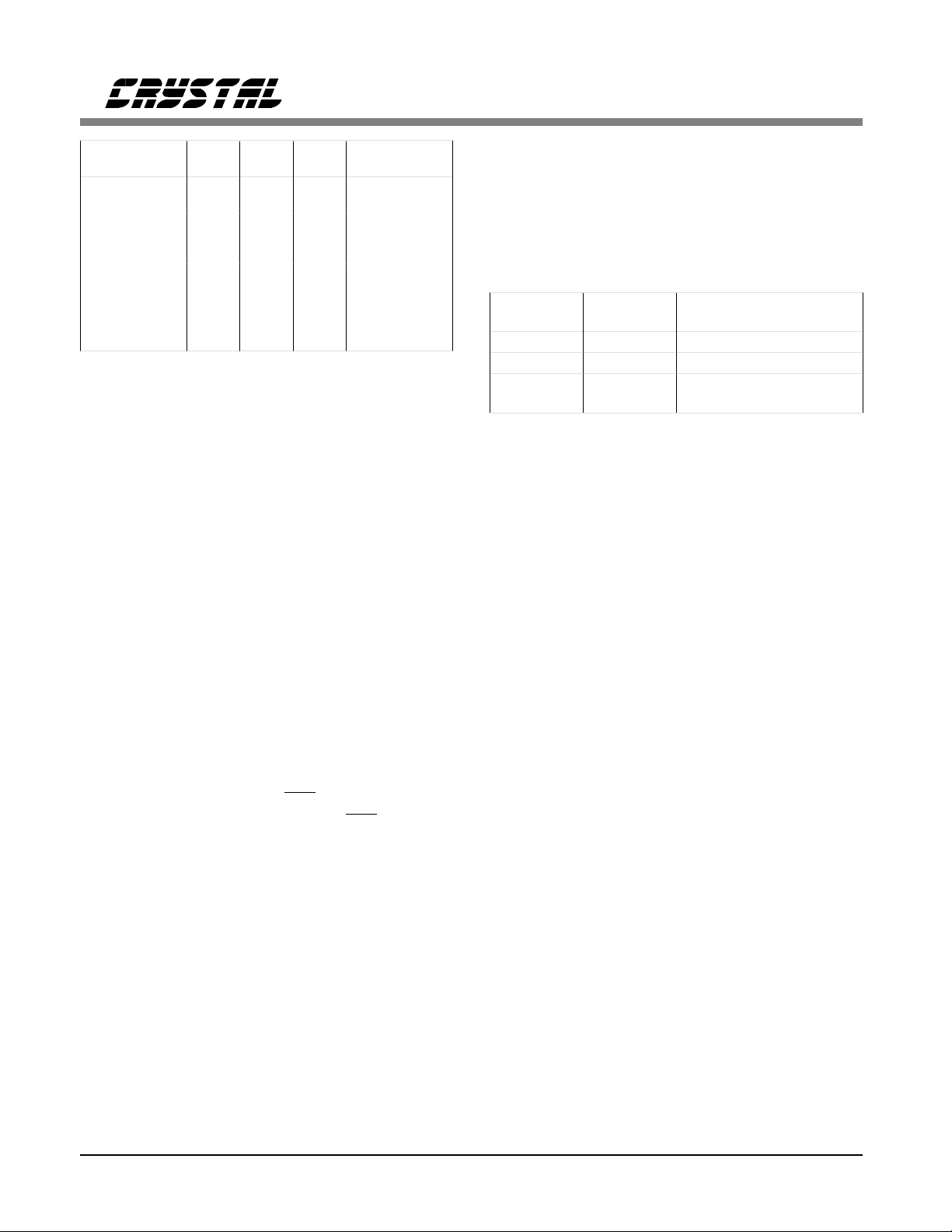

Minimum

Performance

PEAK-TO-PEAK

JITTER

(unit intervals)

300

138

100

AT&T 62411

28

10

Data

Sampling

& Clock

Extraction

Clock

Phase

Selector

Continuously

Calibrated

Delay Line

Jitter

Attenuator

RPOS

RNEG

RCLK

sampler will continuously sample data based on

its last input until a new pulse arrives to update

the clock phase selector.

The delay line is continuously calibrated using

the crystal oscillator reference clock. The delay

line produces 13 phases for eac h cycle of the reference clock. In effect, the 13 phases are

analogous to a 20 MHz clock when the reference

clock is 1.544 MHz. This implementation utilizes

the benefits of a 2 0 MHz clo ck for cl ock recovery

without actually having the clock present to impede analog circuit performance.

In the Hardware Mode, d ata at RPOS and RNEG

should be sampled on th e rising edge of RCLK,

the recovered clock. In the Extended Hardware

Mode, data at RDATA shou ld be sampled on the

falling edge of RCLK. In the Host Mode, CLKE

determines the clock polarity for which output

data should be sampled as s hown in Table 5.

1

.4

.1

1

10 1k 10k

100 100k700

300

JITTER FREQUENCY (Hz)

Figure 11. Minimum Input Jitter Tolerance of Receiver

(Clock Reco very C ircui t and Jitt er Atte nua tor)

12 DS155PP2

CS61577

MODE

(pin 5)

LOW

(<0.2V)

HIGH

(>(V+) - 0.2V)

HIGH

(>(V+) - 0.2V)

MIDDLE

(2.5V)

X = Don’t Care

Table 5. Data Ou tput/Clock Relatio nship

CLKE

(pin 28) DATA CLOCK

RPOS

X

RNEG

LOW

HIGH

RPOS

RNEG

SDO

RPOS

RNEG

SDO

X RDATA RCLK Falling

RCLK

RCLK

RCLK

RCLK

SCLK

RCLK

RCLK

SCLK

Clock Edge for

Valid Data

Rising

Rising

Rising

Rising

Falli ng

Falli ng

Falli ng

Rising

Loss of Signal

The receiver will indicate loss of signal after

power-up, reset or upon receiving 175 consecutive zeros. A digital counter counts received

zeros, base d on RCLK cycles. A zero is received

when the RTIP and RRING inputs are below the

input comparator slicing threshold level established by the peak detector. After the signal is

removed for a period of time the data slicing

threshold level decays to approximately

300 mV

peak

.

The receiver reports loss of s ignal by setting the

Loss of Signal p in, LOS, high. If the serial interface is used, the LOS bit will be set and an

interrupt will be issued on

LOS will return low (asserting the

INT (unless disabled).

INT pin again

in Host Mode) upon receipt of 3 ones in 32 bit

periods with no more t han 15 consecutive zeros.

Note that in the Host Mode, LOS is simultaneously available from both the register and pin 12.

RPOS/RNEG or RDATA are forced low during

LOS unless the jitter attenuator is dis abled. (See

"Jitter Attenuator" section)

If ACLKI is present during the LOS st ate, ACLKI

is switched int o the input of the jitter attenua tor,

resulting in RCLK matching the frequency of

ACLKI. The jitter attenuator buffers any inst antaneous changes in phase between the last

recovered clock and the ACLKI reference clock.

This means that RCLK will smoothly transition

to the new frequency. If ACLKI is not present,

then the crysta l osci lla tor of the jit ter atte nua tor is

forced t o its center frequ ency. Table 6 shows the

status of RCLK upon LOS.

Crystal

present?

No Yes ACLKI

Yes No Center ed Crysta l

Yes Yes

ACLKI

present?

Table 6. RC LK Stat us at L OS

Source of RCLK

ACLKI via t he

Jitter Attenuator

Jitter Attenuator

The jitter at tenuator reduces wander and jitte r in

the recovered cl ock signal. It consists of a 32-bit

FIFO, a crystal os cillator, a set o f load ca pacitors

for the crystal, and control log ic. The jitter attenuator exceeds the jit ter attenu ation requi rements of

Publication s 43802 and REC. G.742.

The jitter attenu ator works in the following manner. The recovered clock and data are in put to t he

FIFO with the recovered clock controlling the

FIFO’s write pointer. The crystal oscillator controls the FIFO’s read pointer which reads data out

of the FIFO and presents it at RPOS and RNEG

(or RDATA). The u pdate rate of the read p ointer

is analogous to RCLK. By chang ing the load capacitance that the IC presents to the crystal, the

oscillation frequency is adjusted to the average

frequency of the recovered signal. Logic determines the phase relationship between the read and

write pointe rs and decid es how to adjust the lo ad

capacitance of the crystal. Thus th e jitter attenuator behaves as a first-order phase lock loop. Jitter

is absorbed in the FIFO according to the jitter

transfer ch ar acteristic s h own in Figure 12.

DS155PP2 13

CS61577

0

a) Minimum Attenuati on Limit

10

20

30

b) Maximum

40

Attenuation in dB

Attenuation

Limit

50

60

110

Figure 12. Typ ical Jitte r Tr ansf er Fun ction

62411 Requirements

Measured Performance

100

Frequency in Hz

1 k 10 k

The FIFO in the jitter attenuator is designed to

prevent overflow and underflow. If the jitter amplitude becomes very large, the read and write

pointers may get very clos e together. Should they

attempt to cross, the oscillator’s divide by four

circuit adjusts by performing a divide by 3 1/2 or

divide by 4 1/2 to prevent the overflow or underflow. During this activity, data will never be lost.

Local Loopback

Local loopbac k is selected by taking LLOOP, pin

27, high or by setting the LLOOP register bit via

the serial interface.

The local loopback mode takes clock and data

presented on TCLK, TPOS, and TNEG (or

TDATA), sends it through the j itter a tte nuator a nd

outputs it at RCLK, RPOS and RNEG (or

RDATA). If the jitter attenuator is disabled, it is

bypassed. Inputs to the tr ansmitter are still transmitted on TTIP and TRING, unless TAOS has

been selec ted in which case, AMI-coded conti nuous ones are tra nsmitted at the TCLK freq uency.

The receiver RT IP and RRING inp uts are igno red

when local loopback is in effect.

Remote Loopback

Remote loopback is selected by taking RLOOP,

pin 26, high o r by settin g the RLOOP register bit

via the serial interface.

The 32-bit FIFO in the CS61577 attenuator allows it to absorb jitter with minimum dat a d elay

in T1 and E1 switching or transmission applications. Like the CS61574, the CS61577 will

tolerate large amplitude jitter (>23 UIpp) by

tracking rather than attenuating it, preventing data

errors so that the jitter may be absorbed in external frame buffers.

The jitter at tenuator may be bypass ed by pulling

XTALIN to RV+ through a 1 kΩ resistor and pro-

viding a 1.544 MHz (or 2.048 MHz) clock on

ACLKI. RCLK may exhibit quantiza tion jitter of

approximately 1/13 UIpp and a duty cycle of approximately 30% (70%) when the attenuator is

disabled.

In remote loopbac k, the re covered clock and da ta

input on RTIP and RRING are sent through the

jitter attenuato r and back ou t on the lin e via TTIP

and TRING. Selecting remote loo pback overrides

any TAOS request (see Table 6). The recovered

incoming signals are also sent to RCLK, RPOS

and RNEG (or RDATA). A remote loopbac k occurs in response to RLOOP going high.

RLOOP

Input

Signal

Notes: 1. X = Don’t Care. The identified All Ones Select

TAOS

Input

Signal

00 TDATA TCLK

0 1 all 1s TCLK

1 X RTIP & RRING RTIP & RRING (RCLK)

input is ignored when the indicated loopback is

in effect.

2. Logic 1 indicates that Loopback or All Ones

option i s sele ct ed.

Table 7. Interaction of RLOOP wi th TAOS

Source of

Data for

TTIP & TRING

Source of

Clock for

TTIP & TRING

14 DS155PP2

CS61577

Simultaneou s selection of local and remote loopback modes is not valid (see Reset).

In the Extended Hardware Mode the transmitted

data is looped before the AMI/B8ZS/HDB3 encoder/decoder du ring remot e loopbac k so that th e

transmitted signal matches the received signal,

even in the presence of received bipolar violations. Data output on RDATA is decoded,

however, if

RCODE is low.

Alarm Indication Signal

In the Extended Hardware Mode, the receiver sets

the output pin AIS high when less than 3 zeros

are detected out of 2048 bit periods.

Line Code Encoder/De coder

In the Extend ed Hardware Mode , three line codes

are available: AMI, B8ZS a nd HDB3. The input

to the encoder is TDATA. The outputs from the

decoder are RDATA and BPV (Bipol ar Violatio n

Strobe). The encoder and decoder are selected

using the LEN2, LEN1, LEN0,

TCODE and

RCODE pins as shown in T a ble 8.

LEN 2/1/0

000 010-111

TCODE

(Transmit

Encoder

Selection)

RCODE

(Receiver

Decoder

Selection)

Table 8. Encoder/Decoder Selection

LOW

HIGH AMI Encoder

LOW

HIGH AMI Decoder

HDB3

Encoder

HDB3

Decoder

B8ZS

Encoder

B8ZS

Decoder

Parallel Chip Select

In the Extended Hardware Mode,

used to gate the digital control inputs:

PCS can be

TCODE,

RCODE, LEN0, LE N1, LEN2, RLOOP, LLOOP

and TAOS. Inputs are ac cepted on th ese p ins only

when

PCS is low and will immediately change

the opera ting stat e of th e device. The refore , when

cycling

PCS to update the operating state, the

digital con trol inputs should be s table for the entire

PCS low period. The digital control inputs are

ignored when

PCS is high

Driver Perfo rmance Moni tor

To aid in early detection and easy isolation of

non-functioning links, the IC is able to monitor

transmit drive performance and report when the

driver is no longer operational. This feature can

be used to monitor either the device’s performance or t he performance of a neig hboring driver.

The driver performan ce monitor indicator is normally low, and goes high upon de tecting a driver

failure.

The driver performance monitor consists of an activity detector th at mo nito rs t he t ransm itt ed sign al

when MTIP is connected to TT IP and MRING is

connected to TRING. DPM will go high if the

absolute difference between MTIP and MRING

does not transition above or below a threshold

level within a time-out period. In the Host Mode,

DPM is available from the register and pin 11.

Whenever more than on e line interface IC res ides

on the sa me ci rcuit bo ard, th e effectiveness of the

driver performance monitor can be maxi mized by

having each IC monitor perfo rmance of a neighboring IC, rather than having it monitor its own

performance. Note that a CS61577 can not be

used to monitor a CS61574 due to output stage

differences.

DS155PP2 15

CS

SCLK

CS61577

SDI

SDO

R/W

0

0

Address/Command Byte

00 01 0

Figure 13. Input/Output Timing

Serial Interface

In the Host Mode, pins 23 th rough 28 serve as a

microprocessor/microcontroller interface. One

on-board register can be written to via the SDI

pin or read from v ia the S DO pin a t th e clo ck rate

determined by SCLK. Through this register, a

host controlle r can be used t o control operati onal

characteri stics and monitor device status. T he serial port read/write timing is independent of the

system transmit and receive timing.

Data transfers are initiated by taking the chip select input,

CS, low (CS must initially be high).

Address and in put data bit s are clocked in o n the

rising edge of SCLK. The clock edge on which

output data is stable and valid is determined by

CLKE as shown in Table 5. Data tran sf e rs ar e ter minated by setting

CS high. CS may go hig h no

sooner than 50 ns after the rising edge of the

SCLK cycle corresponding to the last write bit.

For a serial data read,

CS may go high any time

to terminate the output.

D7D6D5D4D3D2D1D0

Data Inpu t/ Ou tput

D6D5D4D3D2D1D0 D7

LSB, first bit 0 R/W Read/Write Select; 0 = write, 1 = read

1 ADD0 LSB of address, Must be 0

2 ADD1 Must be 0

3 ADD2 Must be 0

4 ADD3 Must be 0

5 ADD4 Must be 1

6 - Reserved - Must be 0

Table 9. Address/Command Byte

An address/command byte, shown in Table 9, precedes a data register. The first bit of the

address/comma nd byt e d ete rmines wh ether a read

or a write is requested. The next six bits contain

the address. The line interface responds to address

16 (0010000). The last bit is ignored.

The data register, shown in Table 10, can be written to the serial port. Data is input on the eight

clock cycles immediately following the address/command byte. Bits 0 and 1 are used to

clear an interrupt issued from the

INT pin, which

occurs in r esponse to a loss of signal or a problem

with the output driver.

Figure 13 shows the timing relationships for dat a

transfers when CLKE = 1. When CLKE = 1, dat a

bit D7 is held until the falling edge of the 16th

clock cycle. When CLKE = 0, dat a bit D7 is held

until the risin g edge of t he 17th c loc k cycle. SDO

goes High-Z after

CS goes high or at the end of

the hold period of data bit D7.

16 DS155PP2

LSB: first bit in 0 clr LOS Clear Loss of Signal

1 clr DPM Clear Driver Performance Monitor

2 LEN0 Bit 0 - Line Lengt h Select

3 LEN1 Bit 1 - Line Lengt h Select

4 LEN2 Bit 2 - Line Lenght Select

5 RLOOP Remote Loopback

6 LLOOP Local Loopback

MSB: last bit in 7 TAOS Transmit All Ones Select

NOTE: Setting 5, 6, & 7 to 101 or 111 puts the CS61577 into a

factory test mode.

Table 10. Input Data Register

CS61577

Writing a "1" to either "Clear LOS" or "Clear

DPM" over the serial interface has three effects:

1) The current inte rrupt on the seri al interface

will be cleared . (Note t hat simply r eading

the register b its will not cl ear the i nterrupt).

2) Output data b its 5, 6 and 7 will be reset as

appropriate.

3) Future interrupts for the correspon ding LOS

or DPM will be prevented from occurring.

Writing a "0" to either "Clear LOS" or "Clear

DPM" enables the corresponding interrupt for

LOS or DPM.

Input bits 5/6/ 7=111 and 5/6/7=1 01 are the same

request, an d cause the line interface to enter into

the factory test mode. In other words, when

RLOOP=1 (Bit 5) and TAOS=1 (Bit 7), LOOP

(Bit 6) is a don’t care. For normal operation,

RLOOP and TAOS should not be simultaneously

selected via the serial interface.

Output data from the serial interface is pre sented

as shown in Table s 11 and 12. Bits 2, 3 and 4 ca n

be read to verify line length selection. Bits 5, 6

and 7 must be decoded. Codes 101, 1 10 and 111

(Bits 5, 6 and 7) indicate intermittent losses of

signal and/or driver problems.

SDO goes to a hig h impedance state wh en not in

use. SDO and SDI may be tied togethe r in applications where the host processor has a

bi-directional I/O port .

LSB: first bit in 0 LOS Loss of Signal

1 DPM Driver Performance Monitor

2 LEN0 Bit 0 - Line Length Select

3 LEN1 Bit 1 - Line Length Select

4 LEN2 Bit 2 - Line Lenght Select

Table 11. Output Data Bits 0 - 4

Bits

567

0 0 0 Reset has occurred or no program input.

001TAOS in effect.

0 1 0 LLOOP in effect.

0 1 1 TAOS/LLOOP in effect.

1 0 0 RLOOP in effect

1 0 1 DPM changed stat e si nce last "clear DPM "

occured.

1 1 0 LOS changed state since last "clear LOS"

occured.

1 1 1 LOS and DPM have changed state since

last "clear LOS" and "clear DPM".

Table 12. Coding for Serial Output bits 5,6,7

Stat us

Power On Reset / Reset

Upon power-up, the IC is held in a static state

until the supply crosses a threshold of approximately 3 Volts. When this threshold is crossed,

the device will del ay for about 10 ms to allow the

power supply to reach operating voltage. After

this delay, calibration of the delay lines used in

the transmit and receive sections commences. The

delay lines can be calibrated only if a reference

clock is present. The reference clock for the receiver is provided by the crystal oscillator, or

ACLKI if the oscillator is disabled. The reference

clock for the transmitter is provided by TCLK.

The initial calibration should take less than

20 ms.

In operation, the delay lin es are continuously calibrated, making the performance of the device

independen t of power suppl y or tempe rature variations. The continuous calibration function

forgoes any requirement t o reset the lin e interface

when in operation. However, a reset function is

available which will clear all registers.

In the Hardware and Extended Hardware Modes,

a reset request is ma de by simultaneously se tting

both the RLOOP and LLOOP pins high for at

least 200 ns. Reset will initiate on the falling edge

of the reset reque st (falling edge of RLOOP and

LLOOP). In the Host Mo de, a res et is initia ted by

simultaneously writing RLOOP and LLOOP to

DS155PP2 17

the register. In either mode, a reset will set all registers to 0 and force the oscillator to its center

frequency before initiating calibration. A reset

will also set LOS high.

Power Supply

CS61577

Schematic & Layout Review Service

Confirm Optimum

Schematic & Layout

Before Building Your Board.

The device operates from a si ngle +5 Volt suppl y.

Separate pins for transmit and receive supplies

provide internal isolation. These pins should be

connected externally near the device and decoupled to their respective grounds. TV+ must not

exceed R V+ by more than 0.3V.

Decoupling an d filtering of the power supplies is

crucial for the proper opera tion of the analog circuits in both th e transmit and rece ive paths. A 1.0

µF capacitor should be connected between TV+

and TGND, and a 0.1 µF capacitor should be con-

nected between RV+ and RGND. Use mylar or

ceramic capacitors and place them as closely as

possible to the ir respective power supply pins. A

68 µF tantalum capacitor should be added close

to the RV+/RGND supply. Wire-wrap breadboarding o f the line interface is n o t recommended

because lead resistance and inductance serve to

defeat the function of the decoupling capacitors.

For Our Free Review Service

Call Applications Engineering.

Call:(512) 445-7222

18 DS155PP2

PIN DESCRIPTIONS

CS61577

Hardware Mode

ACLKI TAOS

TCLK LLOOP

TPOS RLOOP

TNEG L EN 2

MODE LEN1

RNEG LEN0

RPOS RGND

RCLK RV+

XTALIN RRING

XTALOUT RTIP

DPM MRING

LOS MT IP

TTIP TRING

TGND T V+

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Extended Hardware M ode

ACLKI

28

27

26

25

24

23

22

21

20

19

18

17

16

15

TCLK TAOS

TPOS LLOOP

TNEG RLOOP

MODE LEN2

327242628

RNEG LEN1

RPOS LEN0

RCLK RGND

XTALIN RV+

XTALOUT RRING

5

6

7

8

9

10

11

12 14 16 18

1

top

view

13 15

25

24

23

22

21

20

19

17

DPM RTIP

LOS MRING

TTIP MTIP

TGND T RI NG

TV+

DS155PP2 19

Host Mode

CS61577

ACLKI CLKE

TCLK SCLK

TPOS

TNEG SDO

MODE SDI

RNEG

RPOS RGND

RCLK RV+

XTALIN RRING

XTALOUT RTIP

DPM MRING

LOS MT IP

TTIP TRING

TGND T V+

1

2

3

4

5

6

7

8

9

10

11

12

13

14

ACLKI

28

27

26

25

24

23

22

21

20

19

18

17

16

15

CS

INT

TCLK CLKE

TPOS S CL K

TNEG

CS

MODE SDO

327242628

RNEG SDI

RPOS

RCLK RGND

XTALIN RV+

XTALOUT RRING

5

6

7

8

9

10

11

12 14 16 18

1

top

view

13 15

17

25

24

23

22

21

20

19

INT

DPM RTIP

LOS MRING

TTIP MTIP

TGND T RI NG

TV+

20 DS155PP2

Power Supplies

RGND - Ground, Pin 22.

Power supply ground for all subcircuits except the transmit driver; typically 0 Volts.

RV+ - Power Supply, Pin 21.

Power supply for all subcircuits except the transmit driver; typically +5 Volts.

TGND - Ground, Transmit Driver, Pin 14.

Power supply ground for the transmit driver; typically 0 Volts.

TV+ - Power Supply, Transmit Driver, Pin 15.

Power supply for the transmit driver; typically +5 Volts . TV+ mus t n ot exceed RV+ by more than

0.3 V.

Oscillator

XTALIN, XTALOUT - Cr ystal Connections, Pins 9 a nd 10.

A 6.176 MHz (o r 8.19 2 MHz ) cry stal shoul d be c onn ected acro ss t hese pin s. If a 1.5 44 MHz (or

2.048 MHz) clock is provided on ACLKI (pin 1), the jitter att enuator may be disabled by tyin g

XTALIN, Pin 9 to RV+ through a 1 kΩ resistor, and floating XTALOUT, Pin 10.

Overdriving the oscillator with an external clock is not supported.

CS61577

Control

ACLKI - Alternate External Clock Input, Pin 1.

A 1.544 MHz (or 2.048 MHz) clock may be input to ACLKI, or this pin must be tied to ground.

During LOS, the ACLKI input signal, if present, is output on RCLK through the jitter attenuator.

CLKE - Clock Edge, Pin 28 . (Host Mode)

Setting CLKE to logic 1 causes RPOS and RNE G to be valid on t he falling e dge of RCLK, and

SDO to be valid on the risin g edge of SCL K. Conversely, setting CLKE to lo gic 0 causes RPOS

and RNEG to be valid on the rising edge of RCLK, and SDO to be valid on the falling edge of

SCLK.

CS - Chip Select, Pin 26. (Host Mode)

This pin must transition from high to low to read or write the seria l port.

INT - Receive Alarm Interrupt, Pin 23. (Host Mode)

Goes low when LOS or DPM change s tate to flag the host proces sor.

"clear LOS" or " clea r DP M" t o t he regist er.

INT is an open drain out put and s hou ld be ti ed t o the

power supply through a resistor.

INT is cleared by writing

DS155PP2 21

CS61577

LEN0, LEN1, LEN2 - Line Length Selection, Pins 23, 24 and 25. (Hardware and Extended

Hardware Modes)

Determines the shape and amplitu de of the tran smitted pulse to acco mmodate several cable types

and lengths. See Table 3 for information on line length selection. Also controls the receiver

slicing level and the line code in Extended Hardware Mode.

LLOOP - Local Loopback, Pin 27. (Hardware and Extended Hardware Modes)

Setting LL OOP to a logic 1 rou tes the transmit clock and d ata throug h the jitter attenu ator to the

receive clock and data pins. TCLK and TPOS/TNEG (or TDATA) are still transmitted unless

overridden by a TAOS request. Inputs on RTIP and RRING are ignored.

MODE - Mode Select, Pin 5.

Driving the MODE pin hi gh puts the lin e interface in the Ho st Mode. In the host mod e, a serial

control por t is used to co ntrol the line i nterface and determi ne its status. Grou nding the MODE

pin puts the line inte rface in the Hardware Mode, where configurati on and status are controlled

by discrete pi ns. Floating the MODE pin or driving i t to +2.5 Vselects the Ext ended Hardware

Mode, where configuration and status are controlled by discrete pins. When floating MODE,

there should be no externa l load on the pin. MODE defines the status of 13 pins (see Table 2).

PCS - Parallel Chip Select, Pin 18. (Extended Hardware Mode)

Setting

PCS high causes the l ine interface to ig nore th e TCODE, RCODE, LEN0, LEN1, LEN2,

RLOOP, LLOOP and TAOS inputs.

RCODE - Receiver Decoder Select, Pin 17. (Extended Hardware Mode)

Setting

RCODE low enables B8ZS or HDB3 zero substitution in the receiver decoder. Setting

RCODE high enables the AMI receiver decoder (see Table 8).

RLOOP - Remote Loopback, Pin 26. (Hardware and Extended Hardware Modes)

Setting RLOOP to a logic 1 causes the recovered clock and data to be sent through the jitter

attenuator ( if active) and through the driver back to the line. The recovered sign al is also sent to

RCLK and RPOS/RNEG (or RDATA). Any TAOS request is ignored. In the Host Mode,

simultaneous selection of RLOOP & T AOS enables a factory test mode.

Simultaneously taking RLOOP and LLOOP high for at least 200 ns initiates a device reset.

SCLK - Serial Clock, Pin 27. (Host Mode)

Clock used to read or write the serial port registers. SCLK can be either high or low when the line

interface is selected using the

CS pin.

SDI - Serial Data Input, Pin 24. (Host Mode)

Data for the on-chip register. Sampled on the rising edge of SCLK.

SDO - Serial Data Output, Pin 25. (Host Mode)

Status and contro l information from the on-chip register. If CLKE is high SDO is valid on the

rising edge of SCLK. If CLKE is low SDO is valid on the falling edge of SCLK. This pin goes to

a high-impedance sta te when the serial port is bein g written to or after bit D7 is output.

22 DS155PP2

TAOS - Transmit All Ones Select, Pin 28. (Hardware and Extended Hardware Modes)

Setting TAOS to a logic 1 caus es continuous ones to be transmitted at the frequ ency determined

by TCLK. In t he Host Mode, simul taneous selection of RLOOP & TAOS enables a factory test

mode.

TCODE - Transmitter Encoder Select, Pin 4. (Extended Hardware Mode)

Setting

TCODE low enables B8ZS or HDB3 zero substi tution in the transmitter encode r. Setting

TCODE high enables the AMI transmitter encoder .

Data

RDATA - Receive Data - Pin 7. (Extended Hardware Mode)

Data recovered from the RTIP and RRING inputs is outpu t at this p in, afte r bein g decode d by th e

line code decoder. RDAT A is NRZ. RDATA is stable and valid on the falling edge of RCLK.

RCLK - Recovered Clock, Pin 8.

The receiver recovered clock ge nerated by the j itter attenua tor is output o n this pin.When i n the

loss of signal state ACLKI (if present) is output on RCLK via the jitter attenuator. If ACLKI is

not present during LOS, RCLK is forced to the center fr equency of the crysta l oscillator..

CS61577

RPOS, RNEG - Receive Positive Data, Receive Negative Data, Pins 6 and 7 . (Hardware and Host

Modes)

The receiver recovered NRZ digital data is output on these pins. In the Hardware Mode, RPOS

and RNEG are stable and valid on the rising edge of RCLK. In the Host Mode, CLKE determines

the clock edge for which RPOS and RNEG are stable and valid. See Table 5. A positive pulse

(with respect to gro und) received on the RT IP pin generates a logic 1 on RPOS, an d a positive

pulse received on the RRING pin generates a logic 1 on RNEG.

RTIP, RRING - Receive Tip, Receive Ring, Pins 19 and 20.

The AMI receive signal is input to these pins. A center-tapped, center-grounded, 2:1, step-up

transformer is require d on these inputs, as shown in Figure A1 in the Appl ications secti on. Data

and clock are recovered and output on RCLK and RPOS/RNEG or RDTA.

TCLK - Transmit Clock, Pin 2.

The1.544 MHz (o r 2.048 MHz) trans mit clock is input on this pin. TPOS/TNEG or TDATA are

sampled on the falling edge of TCLK.

TDATA - Transmit Data, Pin 3. (Extended Hardware Mode)

Transmitter NRZ input d ata which passes th rough the li ne code encoder, and is then driven on to

the line through TTIP and TRING. TDATA is sampled on the falling edge of TCLK.

TPOS, TNEG - Transmit Positive Data, Transmit Negative Data, Pins 3 and 4. (Hardware and

Host Modes)

Inputs for clock and data to be transmi tted. The signal is driven on to the l ine through TT IP and

TRING. TPOS and TNEG are sampled on the falling edge of TCLK. A TPOS input causes a

positive pulse to be transmitted, while a TNEG input causes a negative pulse to be transmitted.

DS155PP2 23

TTIP, TRING - Transmit Tip, Tr ansmit Ring, Pins 13 and 16.

The AMI signal is driven to the lin e through these pins. The transmitter output is designed to

drive a 25 Ω load between TTIP and TRING. A transformer is required as shown in Table A1.

Status

AIS - Alarm Indication Signal, Pin 11. (Extended Hardware Mode)

AIS goes high when unframed all-ones condition (blue alarm) is detected, using the detection

criteria of less than three zeros out of 2048 bit periods.

BPV- Bipolar Violation Strobe, Pin 6. (Extended Hardware Mode)

BPV strobes high when a bipolar violation is detected in the received signal. B8ZS ( or HDB3)

zero substitutions are not flagged as bipol ar violations if the B8Z S (or HDB3) decoder has been

enabled.

DPM - Driver Perfor mance Monitor, Pin 11. (Hardware and Host Modes)

DPM goes high if no activity is detected on MTIP and MRING.

LOS - Loss of Signal, Pin 12.

LOS goes high when 175 consecutive zeros have been received. LOS returns low when 3 o nes

are received within 32 bit periods wit h no more than 15 consecutive zeros. When in the loss of

signal state RPOS /RNEG or RDATA are forced low, and ACLKI (if present) is output on RCLK

via the jitter attenuator. If ACLKI is not present during LOS, RCLK is forced to the center

frequency of the crys tal oscillator.

CS61577

MTIP, MRING - Monitor Tip, Monitor Ring, Pins 17 and 18. (Hardware and Host Modes)

These pins are normally connecte d to TTIP and TRING and monitor the output of a line interface

IC. If the

INT pin in the hos t mode is used, and the moni tor is not used, writing "clear DPM" to

the serial interface will prevent an interrupt from the driver performance monitor.

24 DS155PP2

CS61577

14

15

E1

28 pin

Plastic DIP

A

L

A1

B

∝

eA

SEATING

PLANE

B1

28

1

D

e1

NOTES:

1. POSITIONAL TOLERANCE OF LEADS SHALL BE WITHIN

0.25mm (0.010") AT MAXIMUM MATERIAL CONDITION, IN

RELATION TO SEATING PLANE AND EACH OTHER.

2. DIMENSI O N e A TO CE N T ER O F LEADS WHEN FORMED PARALLE L .

3. DIMENSION E1 DOES NOT INCLUDE MOLD FLASH.

MILLIMETERS

DIM

MINMAXMINMAX

NOM

3.94

0.51

0.36

1.02

0.20

36.45

13.72

2.41

15.24

3.18

0°

4.32

5.08

0.76

1.02

0.46

0.56

1.27

1.65

0.25

0.38

36.83

37.21

13.97

14.22 0.540

2.54

2.67 0.095

15.87 0.625

-

-

3.81

-

15°

A

A1

B

B1

C

D

E1

e1

C

eA

L

∝

0.155

0.020

0.014

0.040

0.008

1.435

0.600

0.125

0°

INCHES

NOM

0.170

0.030

0.018

0.050

0.010

1.450

0.550

0.100

-

-

-

0.200

0.040

0.022

0.065

0.015

1.465

0.560

0.105

0.150

15°

28-pin PLCC

28

E

E1

D1

D

B

e

A1

D2/E2

DIM

A1

D/E

D1/E1

D2/E2

A

MILLIMETERS INCHES

NOM

A

B

e

4.45

2.29 0.090

2.79

0.41

12.45

12.32 12.57 0.485 0.495

11.43 11.58 0.450 0.456

11.51

9.91 10.92 0.390 0.430

10.41

1.19 1.35 0.047 0.053

1.27

MIN

MAXMIN MAX

4.574.20 0.1800.165

3.04 0.120

0.530.33 0.0210.013

NOM

0.175

0.110

0.016

0.490

0.453

0.410

0.050

DS155PP2 25

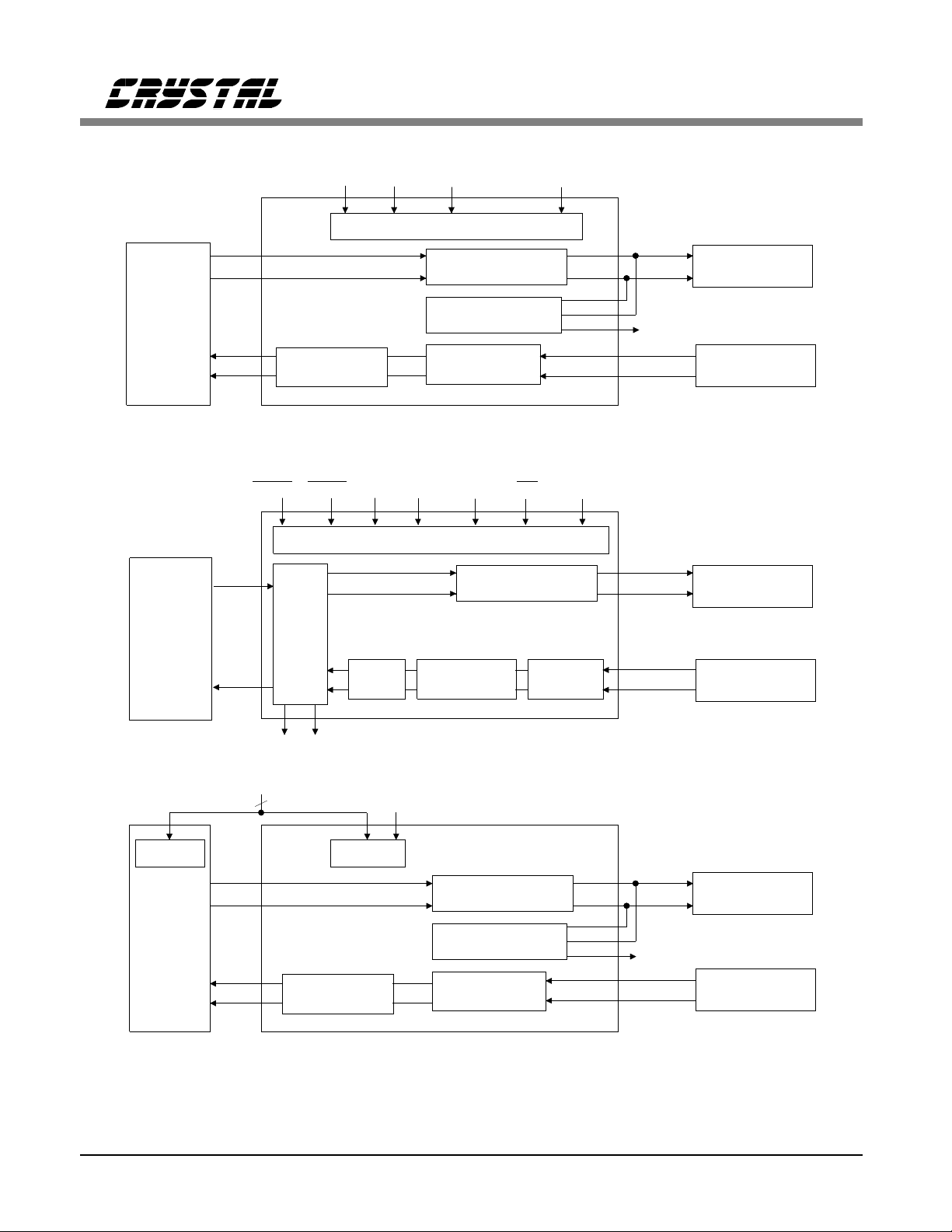

APPLICATIONS

Control

&

Monitor

Frame

Format

Encoder/

Decoder

XTL

+

RV+

68 µF

RGND

28

1

12

11

5

7

6

8

3

4

2

9

10

CLKE

ACLKI

LOS

DPM

MODE

RPOS

RNEG

RCLK

TPOS

TNEG

TCLK

XTALIN

XTALOUT

+5V

0.1 µF

21 15

RV+ TV+

CS61577

IN

HOST

MODE

RGND TGND

22 14

+

1.0 µF

TGND

SCLK

CS

INT

SDI

SDO

RTIP

RRING

MTIP

MRING

TRING

TTIP

27

26

23

24

25

19

20

17

18

16

13

+5V

100 k

0.47

R1

R2

Serial

F

µ

Ω

P

µ

Port

1

3

5

2CT:1

PE-65351

2

6

1:2CT

PE-65351

2

RECEIVE

LINE

6

1

TRANSMIT

LINE

5

CS61577

Figure A 1. T1 Ho st Mo de Conf ig urat io n

Frequency

MHz

Crystal

XTL

Cable

Ω

1.544 (T1) CXT6176 100 0/1/1 - 1/1/1

2.048 (E1) CXT8192 120 0/0/0

75 0/0/0

Table A1. External Component Values

Line Interface

Figures A1-A3 show typical T1 and E 1 line int erface application circuits. Table A1 shows the

external components which are specific to each

application . Fig ur e A1 illus tra tes a T1 in ter face in

the Host Mode. Fig ure A2 illustrates a 12 0 Ω E1

interface in the Hardware Mode . Figure A3 illus-

trates a 75 Ω E1 interface in the Extended

Hardware Mode.

LEN2/1/0 R3

Ω

not used

not used

4.4

0/0/1

not used

R1 and R2

Ω

200

240

150

The 1:2 receiver transformer has a grounded center tap on the IC side. Resistors R1 and R2

between the RTIP and RRING pins to ground

provide the termination for the receive line. The

transmitter als o uses a 1:2 transformer. A 0.47 µF

capacitor is required in series with the transmit

transformer primary. This capacitor is needed to

prevent any output stage imbalance from resulting

in a DC current through the transf ormer primary.

This current might saturate the transformer producing an output offset level shift.

26 DS155PP2

CS61577

+5V

+

µ

F

68

0.1 µF

+

1.0 µF

Control

&

Monitor

Frame

Format

Encoder/

Decoder

XTL

RGND

28

1

26

27

12

11

5

7

6

8

3

4

2

9

10

TAOS

ACLKI

RLOOP

LLOOP

LOS

DPM

MODE

RPOS

RNEG

RCLK

TPOS

TNEG

TCLK

XTALIN

XTALOUT

21 15

RV+ TV+

CS61577

IN

HARDWARE

MODE

RGND TGND

22 14

TGND

LEN0

LEN1

LEN2

RTIP

RRING

MTIP

MRING

TRING

TTIP

23

24

25

19

20

17

18

16

13

0.47

Line

Length

Setting

1

R1

3

R2

5

µ

F

2

6

2CT:1

PE-65351

1:2CT

PE-65351

Figure A 2. 120 Ω, E1 Hardware Mode Configuration

+5V

+

68

µ

F

0.1 µF

+

1.0

µ

F

2

RECEIVE

LINE

6

1

TRANSMIT

LINE

5

Control

&

Monitor

Frame

Format

Encoder/

Decoder

XTL

RGND

17

18

6

28

1

26

27

12

11

5

4

7

8

3

2

9

10

RCODE

PCS

BPV

TAOS

ACLKI

RLOOP

LLOOP

LOS

AIS

MODE

TCODE

RDATA

RCLK

TDATA

TCLK

XTALIN

XTALOUT

21 15

RV+ TV+

CS6157 7

IN

EXTENDED

HARDWARE

MODE

RGND TGND

22 14

LEN0

LEN1

LEN2

RTIP

RRING

TRING

TTIP

TGND

23

24

25

19

20

0.47

16

13

Note:

R3 is used for LEN2/1/0 = 0/0/0, but

not required with LEN2/1/0 = 0/0/1.

Figure A 3. 75 Ω, E1 E xtend ed Ha rdwa re Mode Co nfig urat ion

Line

Length

Setting

R1

R2

F

µ

R3

1

3

5

2CT:1

PE-65351

2

6

1:2CT

PE-65351

2

RECEIVE

LINE

6

1

TRANSMIT

5

LINE

DS155PP2 27

CS61577

Transformers

Recommended transmitter and receiver transformer specificati ons are shown in Table A2. The

transformers in Table A3 have been tested and

recommended for use with th e C S615 77. R efer to

the "Telecom Transformer Selection Guide" for

detailed schematics which show how to connect

the line interfa ce I C with a particu lar tr ansformer.

Turns Ratio

Primary

1:2 CT ± 5%

600 µH min. @ 772 kHz

Inductance

Primary Leakage

1.3 µH max. @ 772 kHz

Inductance

Secondary Leakage

0.4 µH max. @ 772 kHz

Inductance

Interwinding

23 pF max.

Capacitance

ET-constant

16 V -µs min. for T1

12 V-µs min. for E1

Table A2. Transformer Specifications

Selecting an Oscil lator Crystal

Specific crystal parameters are required for

proper operati on of the jitter attenuator. It is recommended that the Crystal Semiconductor

CXT6176 crystal be used for T1 applicati ons and

the CXT8192 crystal be used for E1 applications.

Transmit Side Jitter A ttenuation

In some applications it is desirable to attenuate

jitter from the signal to be transmitted. A

CS61577 in local loopback mode can be used as a

jitter attenua tor. The inputs to the jit ter attenuator

are TPOS, TNEG, TCLK. The outputs from the

jitter attenuator are RPOS, RNEG and RCLK.

Line Protection

Secondary protection components can be added

to provide lightning surge and AC power-cross

immunity. Refer to the "Telecom Line Protection

Application Note" fo r detailed information on the

different electrical safety standards and specific

application circuit recommendations.

Turns

Manufacturer Part Number Package Type

Ratio(s)

1:2CT Pulse Engineering PE-65351 1.5 kV through-hole, single

Schott 67129300

Bel Fuse 0553-0013-HC

dual

1:2CT

dual

1:2CT

Pulse Engineering PE-64951 1.5 kV through-hole, dual

Bel Fuse 0553-0013-1J

Pulse Engineering PE-65761 1.5 kVsurface-mount, dual

Bel Fuse S553-0013-03

1:2CT Pulse Engineering PE-65835 3 kV through-hole, single

EN60950, EN4100 3 approved

Table A3 . Rec ommend ed Tr ansf ormers

28 DS155PP2

Interfacing The CS615 77 With the CS62 180B

T1 Transceiver

To in terface with the CS62180B, connect the devices as shown in Figure A5. In thi s case, the lin e

interface and CS62180B are in host mode controlled by a m icroproc essor serial interface. If the

line interface is used in Hardware Mode, then the

line interface RCLK o utput must be inverted before being input to the CS62180B. If the

CS61577 is used in Extended Hardware Mode,

the RCLK outp ut d oes no t have to be i nverted before being input to the CS62180B.

TO HOST CONTROLLER

CS61577

1.544 MHz

SCLK

SDO

SDI

CS

RNEG

CS62180B

TCLK

TPOS

TNEG

RPOS

RCLK

CLOCK

SIGNAL

ACLK

TCLK

TPOS

TNEG

RNEG

RPOS

RCLK

CS61577

SCLK

SDO

SDI

CS

INT

CLKE

MODE

V+

V+22k

Figure A4. Interfacing the CS61577 with a CS62180B

(Host Mode)

100k

DS155PP2 29

• Notes •

CDB61534, CDB61535, CDB61535A, CDB6158,

CDB6158A, CDB61574, CDB61574A, CDB61575,

CDB61577, CDB615304A, & CDB61305A

Line Interface Evaluation Board

Features

Socketed Line Interface Device

••

All Required Components for Complete

••

Line Interface Evaluation

Configuration by DIP Switch or Serial

••

Interface

LED Status Indicators for Alarm

••

Conditions

Support for Host, Hardware, and

••

Extended Hardware Modes

Mode Select

Circuit

General Description

The evaluation board includes a socketed line interface

device and all support components necessary for

evaluation. The board is powered by an external 5 Volt

supply.

The board may be configured for 100 Ω twisted-pair

T1, 75 Ω coax E1, or 120 Ω twisted-pair E1 operation.

Binding posts are provided for line connections. Several BNC connectors are available to provide system

clocks and data I/O. Two LED indicators monitor device alarm conditions. The board supports all line

interface operating modes.

ORDERING INFORMATION:

CDB61534, CDB61535. CDB61535A,

CDB6158, CDB6158A, CDB61574,

CDB61574A, CDB61575, CDB61577,

CDB61304A, CDB61305A

+5V 0V

Control Circuit

ACLKI

TCLK

TPOS

(TDATA)

TNEG

(TCODE)

RCLK

RPOS

(RDATA)

RNEG

(BPV)

Reset

Circuit

Serial Interface

Control Circuit

Hardware

LED Status

Indicators

CS61534,

CS61535,

CS61535A,

CS6158,

CS6158A,

CS61574,

CS61574A,

CS61575,

CS61577,

CS61304A

or

CS61305A

TTIP

TRING

RTIP

RRING

XTL

Crystal Semiconductor Corporation

P.O. Box 17847, Austin, TX 78760

(512) 445-7222 FAX: (512) 445-7581

SEP ’95

DS40DB3

31

LINE INTERFACE EVALUATION BOARD

POWER SUPPLY

As shown on the evaluation board schematic in

Figure 1, power is supplied to the evaluation

board from an external +5 Volt supply connected

to the two binding posts labeled +5V and GND.

Transient suppressor D10 protects the components on the board from over-voltage damage and

reversed supply connections. The recommended

power supply decoupling is provided by C1, C2

and C3. Ceramic capacitor C1 and electrolyt ic capacitor C2 are used to decouple RV+ to RGND.

Capacitor C3 decouples TV+ to TGND. The TV+

and RV+ power supply traces are connected at the

device socket U1. A ground plane on the component side of the evaluation board insures optimum

performance.

BOARD CONFIGURATION

Pins on line interface device U1 with more than

one pin name have different functions depending

on the operating mode selected. Pin names not

enclosed in parenthesis or square brackets describe the Hardware mode pin function. Pin

names enclosed in parenthesis describe the Extended Hardware mode pin function. Pin names

enclosed in square brackets describe the Host

mode pin function.

Table 1 explains how to configure the evaluation

board jumpers depending on the device installed

and the desired operating mode. Mode selection

is accomplished with slide switch SW1 and jumpers JP2, JP6, and JP7. The CS61535A,

CS61574A, CS61575, CS61577, CS61304A, and

CS61305A support the Hardware, Extended

Hardware, and Host operating modes. The

CS61534, CS61535, and CS61574 support the

Hardware and Host operating modes. The

CS6158 and CS6158A only support the Hardware

operating mode.

Hardware Mode

In the Hardware operating mode, the line interface is configured using DIP switch S2. The digital control inputs to the device selected by S2 include: transmit all ones (TAOS), local loopback

(LLOOP), remote loopback (RLOOP), and transmit line length selection (LEN2,LEN1,LEN0).

Closing a DIP switch on S2 towards the label sets

the device control pin of the same name to logic 1

(+5 Volts). Note that S2 switch positions TCODE

and RCODE have no function in Hardware mode.

In addition, the host processor interface connector

JP1 should not be used in the Hardware mode.

Two LED status indicators are provided in Hardware mode. The LED labeled DPM (AIS) illuminates when the line interface asserts the Driver

JUMPER POSITION FUNCTION SELECTED

JP1 - Connector for external processor in Host operating mode.

JP2, JP6, JP7

JP3

JP4

JP5

JP8

32 DS40DB3

A-A Extended Hardware operating mode.

B-B Hardware or Host operating modes.

IN Hardware or Extended Hardware operating modes.

OUT Host operating mode.

C-C Connects the ACLKI BNC input to pin 1 of device.

D-D

E-E Transmit line connection for all applications except those listed for "F-F" on the next line.

F-F

IN Shorts resistor R2 for all applications except those listed for "OUT" on the next line.

OUT

Grounds the ACLKI BNC input through 51Ω resistor R1.

75Ω coax E1 applications using the Schott 12932/12532 or PE-65389/65566 at transformer T1.

Inserts resistor R2 for 75Ω coax E1 applications using the CS61534, 35, 58, 74, or 77.

Table 1. Evaluation Board Jumper Settings

LINE INTERFACE EVALUATION BOARD

100

R15

RV+

+5V

D10

CC

Pin 4

ACLKI

JP3

R17

10k

P6KE

6

8

2

3

7

1

4

23

24

25

26

27

28

R14

4.7k

SIP

MODE

MODE

SW1

W

RNEG (BPV)

RCLK

TCLK

TPOS (TDATA)

RPOS (RDATA)

ACLKI

TNEG (TCODE)

LEN0 [INT]

LEN1 [SDI]

LEN2 [SD0]

RLOOP [CS]

LLOOP [SCLK]

TAOS [CKLE]

511 12

W

GND

(0V)

R1 51. 1

Ω

JP2

BB

D8

C4 0.047mF

6

R16

1k

Ω

Pin 6

RCLK

TCLK

Pin 3

Pin 7

JP4

DD

AA

3

R18

W

10k

RNEG

(BPV)

RCLK

TCLK

TPOS

(TDATA)

RPOS

(RDATA)

RV+

ACLKI

Ω

TNEG

S2

RCODE

TCODE

LEN0/INT

LEN1/SDI

LEN2/SD0

RLOOP/CS

LLOOP/SCLK

TAOS/CLKE

INT

SDI

SDO

CS

SCLK

D9

JP1

1N914

S1

RESET

R4

W

221k

875124

RV+

C2

0.1mF

C3

1 mF

TGND RGND

{CS6158/58A: RT}

{CS6158/58A: NC}

U1

RV+

DPM

(AIS)

HOST:3-1,6-8

EXT HW: 3-2, 6-7

HW: 3-4, 6-5

C1

68mF

+

21

221415

RV+TV+

XTALIN

XTALOUT

RTIP

RRING

TTIP

MRING (PCS)

TRING

MTIP (RCODE)

LOSDPM (AIS)MODE

LOS

Q2

2N2222

LED

D2

R5

470

Ω

Prototyping

Area

RV+

R13 (only included for CS6158/58A)

W

1k

9

E1: CXT8192

T1: CXT6176

(not included for CS6158/58A)

10

19

20

13

18

16

17

RV+

RTIP

RRING

Pin 18

TRING

Pin 17

Q1

2N2222

LED

D3

R6

470

Change R9 and R10 for E1 operation

R10

W

200

R9

W

200

TTIP

JP6

BB

AA

JP7

BB

AA

Ω

0.47 mF

4.4

(Used only for E1 75

applications with the CS61534,

CS61535, CS6158, CS61574,

OR CS61577)

U1:

(see Table 2)

C5

JP8

R2

W

CS61534, CS61535,

CS61535A, CS6158,

CS6158A, CS61574,

CS61574A, CS61575,

CS61577, CS61304A,