Page 1

T1/E1 Line Interface

CS61305A

Features

Provides Analog Transmission Line

••

Interface for T1 and E1 Applications

Provides Line Driver, Jitter Attenuator

••

and Clock Recovery Functions

Transmit Side Jitter Attenuation

••

Starting at 3 Hz, with > 300 UI of Jitter

Tolerance

B8ZS/HDB3/AMI Encoders/Decoders

••

Compatible with SONET, M13 , CCITT

••

G.742, and Other Asynchronous Muxes

50 mA Transmitter Short-Circuit

••

Current Limiting

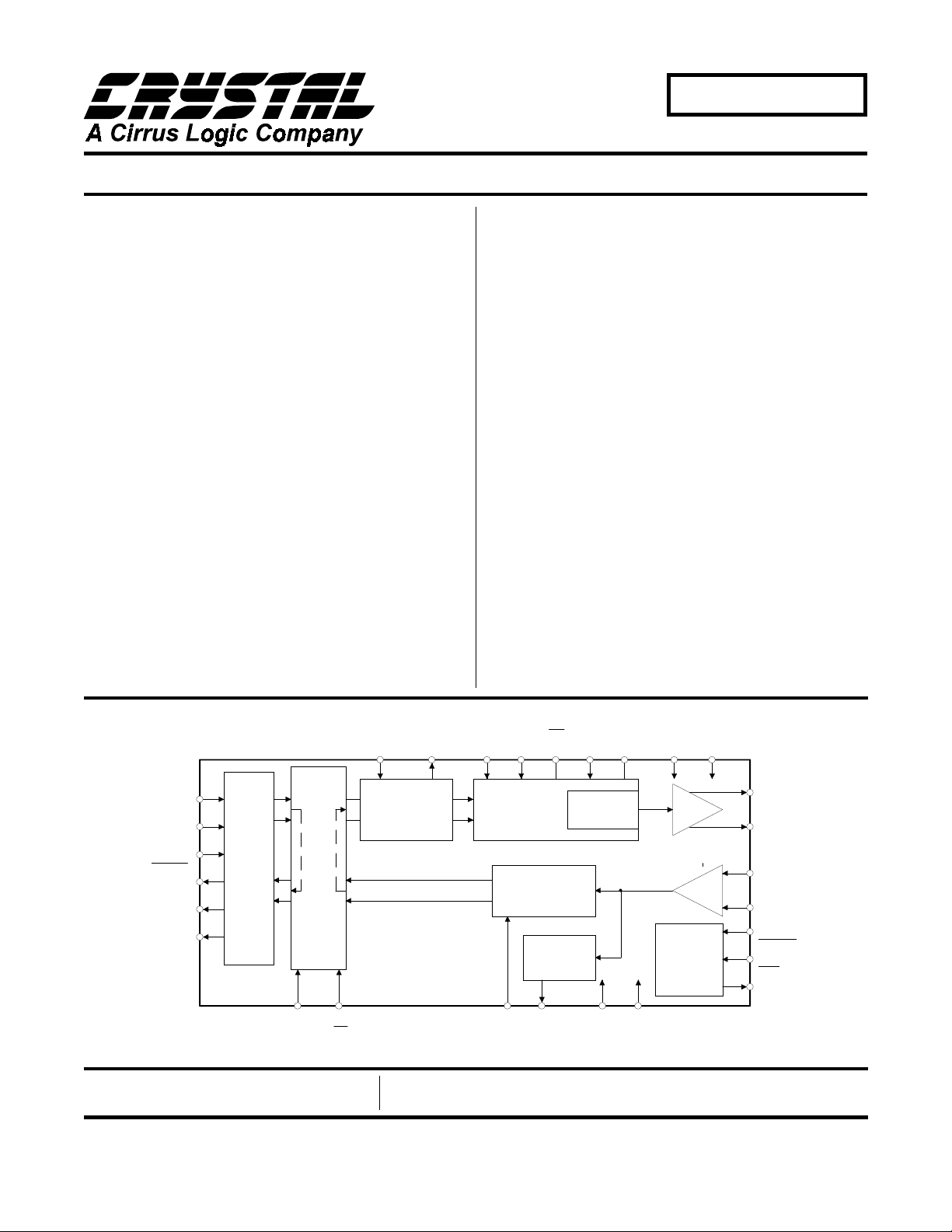

General Description

The CS61305A combines the complete analog transmit

and receive line interface for T1 or E1 applications in a

low power, 28-pin device operating from a +5V supply.

The CS61305A is a pin-compatible replacement for the

LXT305A in most applications.

The CS61305A provides a transmitter jitter attenuator

making it ideal for use in asynchronous multiplexor

systems with gapped transmit clocks. The transmitter

features internal pulse shaping and a low impedance

output stage allowing the use of external resistors for

transmitter impedance matching. The receiver uses a

digital Delay-Locked-Loop clock and data recovery circuit which is continuously calibrated from a crystal

reference to provide excellent stability and jitter tolerance.

Applications

•

Interfacing network transmission equipment such as

SONET multiplexor and M13 to a DSX-1 cross connect.

•

Interfacing customer premises equipment to a CSU.

ORDERING INFORMATION

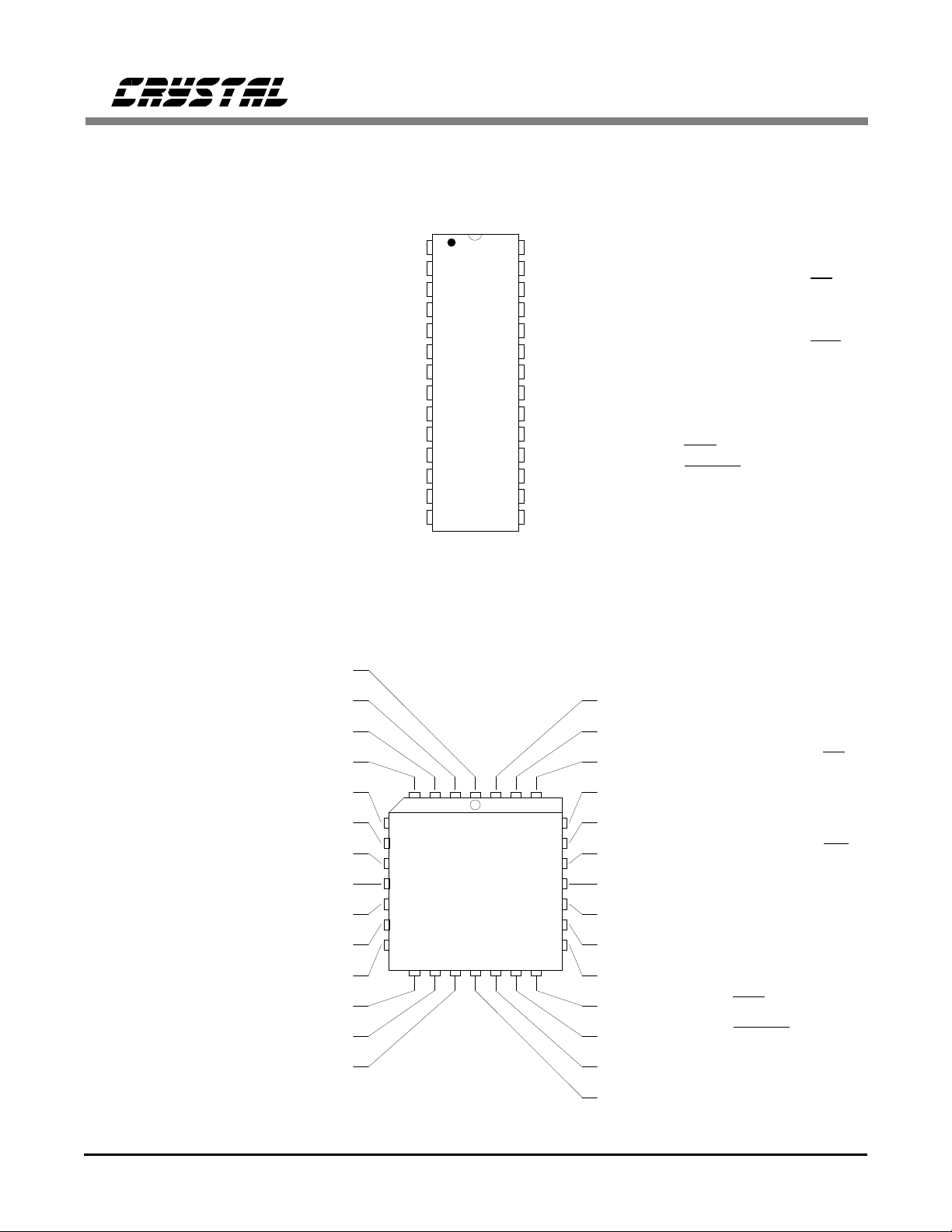

CS61305A-IP1 28 Pin Plastic DIP

CS61305A-IL1 28 Pin Plastic PLCC

[ ] = Pin Function in

( ) = Pin Function in

TCLK

TPOS

[TDATA]

TNEG

[TCODE]

RCLK

RPOS

[RDATA]

RNEG

[BPV]

2

3

4

8

7

6

Extended Hardware Mode

Host Mode

AMI,

B8ZS,

HDB3

CODER

LOOP

BACK

27

LLOOP

(SCLK)

XTALIN

26

RLOOP

(CS)

Preliminary Product Information

Crystal Semiconductor Corporation

P. O. Box 17847, Austin, Texas, 78760

(512) 445 7222 FAX:(512) 445 7581

(INT)

(SDI)

XTALOUT

9

JITTER

ATTENUATOR

(CLKE)

MODE

10

5

CONTROL

ACLKI

LEN0

TAOS

28 23

CLOCK &

DATA

RECOVERY

SIGNAL

QUALITY

MONITOR

12 21

1

LOS

LEN1

PULSE

SHAPER

RV+

(SDO)

LEN2

2524

RGND

TGND

14

LINE DRIVER

LINE RECEIVER

DRIVER

MONITOR

22

TV+

15

13

TTIP

16

TRING

19

RTIP

20

RRING

17

MTIP

[RCODE]

18

MRING

[PCS]

11

DPM

[AIS]

This document contains information for a new product. Crystal

Semiconductor reserves the right to modify this product without notice.

Copyright Crystal Semiconductor Corporation 1996

(All Rights Reserved)

MAY ’96

DS157PP3

1

Page 2

CS61305A

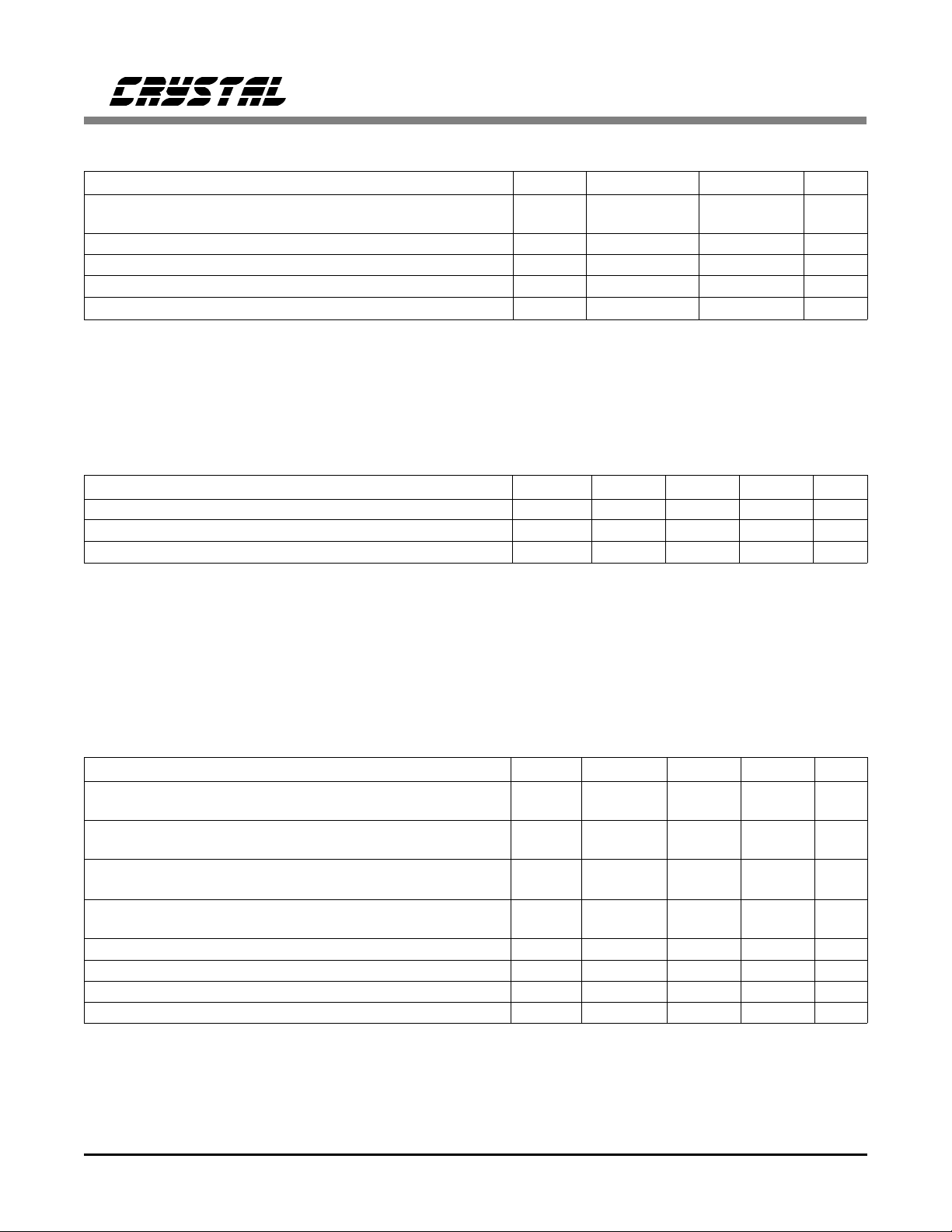

ABSOLUTE MAXIMUM RATINGS

Parameter Symbol Min Max Units

DC Supply (referenced to RGND=TGND=0V) RV+

TV+

Input Voltage, Any Pin (Note 1) V

Input Current, Any Pin (Note 2) I

Ambient Operating Temperature T

Storage Temperature T

in

in

A

stg

-

-

6.0

(RV+) + 0.3

RGND-0.3 (RV+) + 0.3 V

-10 10 mA

-40 85

-65 150

WARNING: Operations at or beyond these limits may result in permanent damage to the device.

Normal operation is not guaranteed at these extremes.

Notes: 1. Excluding RTIP, RRING, which must stay within -6V to (RV+) + 0.3V.

2. Transient currents of up to 100 mA will not cause SCR latch-up. Also TTIP, TRING, TV+ and TGND

can withstand a continuous current of 100 mA.

RECOMMENDED OPERATING CONDITIONS

Parameter Symbol Min Typ Max Units

DC Supply (Note 3) RV+, TV+ 4.75 5.0 5.25 V

Ambient Operating Temperature T

Power Consumption (Notes 4,5) P

Notes: 3. TV+ must not exceed RV+ by mor e than 0.3V.

4. Power consumption while driving line load over oper ating temperature range. Includes IC and load.

Digital input levels are within 10% of the supply rails and digital outputs are driving a 50 pF

capacitive load.

5. Assumes 100% ones density and maximum line length at 5.25V.

A

C

-40 25 85

- - 350 mW

V

V

°C

°C

°C

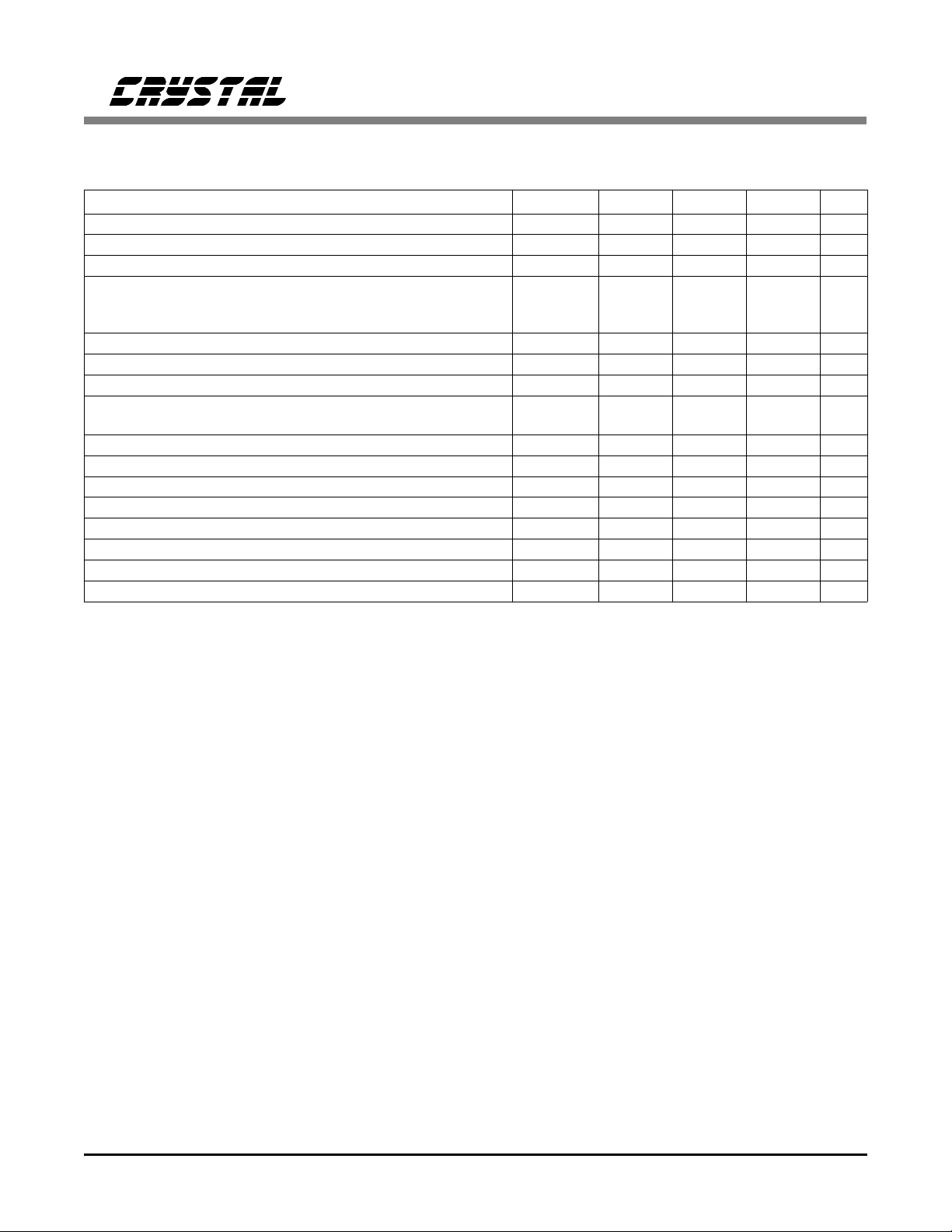

DIGITAL CHARACTERISTICS (TA = -40°C to 85°C; TV+, RV+ = 5.0V ±5%; GND = 0V)

Parameter Symbol Min Typ Max Units

High-Level Input Voltage (Notes 6, 7)

PINS 1-4, 17, 18, 23-28

Low-Level Input Voltage (Notes 6, 7)

PINS 1-4, 17, 18, 23-28

High-Level Output Voltage (Notes 6, 7, 8)

I

= -400 µA PINS 6-8, 11, 12, 25

OUT

Low-Level Output Voltage (Notes 6, 7, 8)

I

= 1.6 mA PINS 6-8, 11, 12, 23, 25

OUT

Input Leakage Current (Except Pin 5) - -

Low-Level Input Voltage, PIN 5 V

High-Level Input Voltage, PIN 5 V

Mid-Level Input Voltage, PIN 5 (Note 9) V

Notes: 6. In Extended Hardware Mode, pins 17 and 18 are digital inputs. In Host Mode, pin 23 is

an open drain output and pin 25 is a tristate digital output.

7. This specification guarantees TTL compatibility (V

8. Output drivers will drive CMOS logic levels into a CMOS load.

9. As an alternative to supplying a 2.3-to-2.7V input, this pin may be left floating.

2 DS157PP3

V

IH

V

IL

V

OH

V

OL

IL

IH

IM

= 2.4V @ I

OH

2.0 - - V

--0.8V

2.4 - - V

--0.4V

±10 µA

--0.2V

(RV+) - 0.2 - - V

2.3 - 2.7 V

= -40µA).

OUT

Page 3

CS61305A

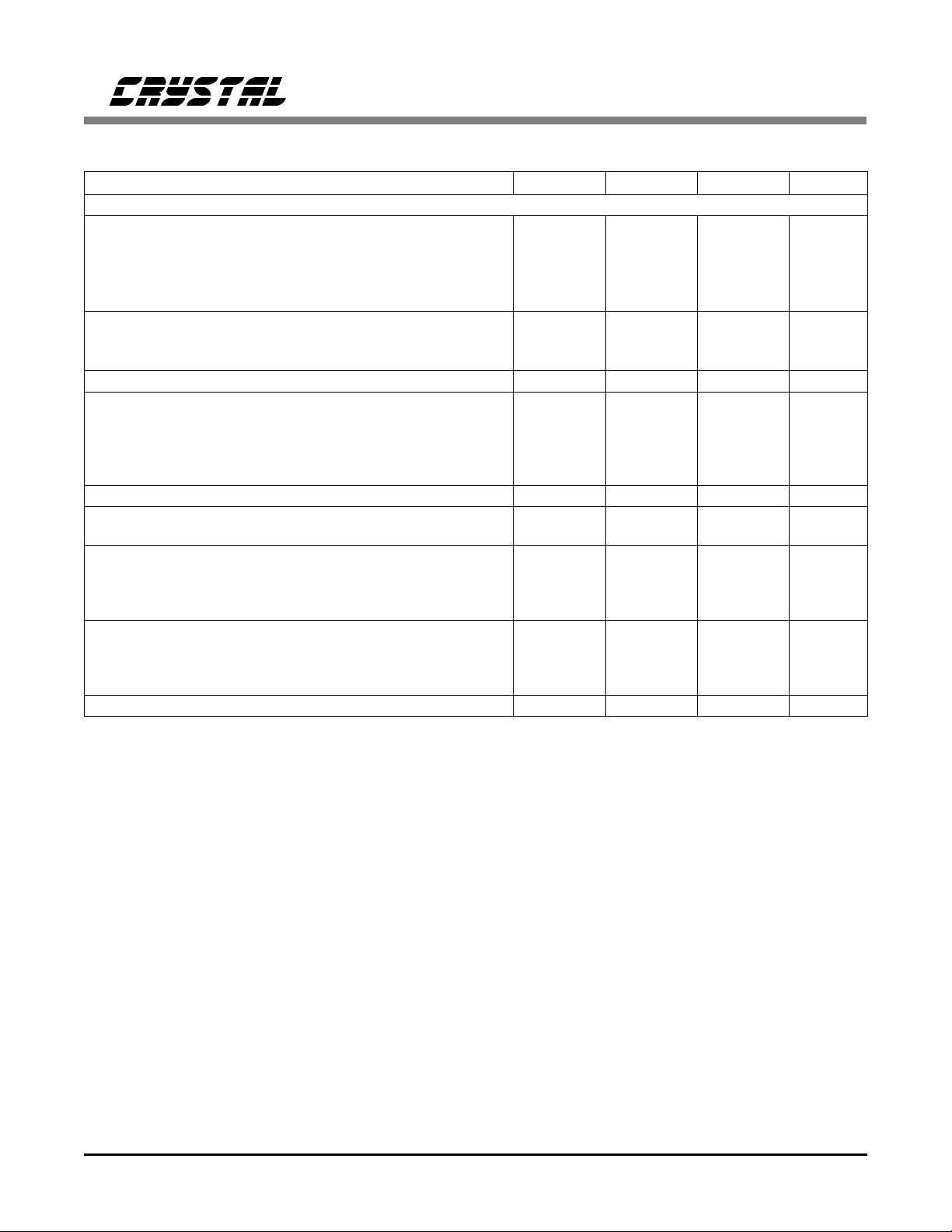

ANALOG SPECIFICATIONS (TA = -40°C to 85°C; TV+, RV+ = 5.0V ±5%; GND = 0V)

Parameter Min Typ Max Units

Transmitter

AMI Output Pulse Amplitudes (Note 10)

E1, 75 Ω (Note 11)

E1, 120 Ω (Note 12)

T1, FCC Part 68 (Note 13)

T1, DSX-1 (Note 14)

E1 Zero (space) level (LEN2/1/0 = 000)

1:1 transformer and 75Ω load

1:1.26 transformer and 120Ω load

Load Presented To Transmitter Output (Note 10) - 75 Jitter Added by the Transmitter (Note 15)

10Hz - 8kHz

8kHz - 40kHz

10Hz - 40kHz

Broad Band

Power in 2kHz band about 772kHz (Notes 10, 16) 12.6 15 17.9 dBm

Power in 2kHz band about 1.544MHz (Notes 10, 16)

(referenced to power in 2kHz band at 772kHz)

Positive to Negative Pulse Imbalance (Notes 10, 16)

T1, DSX-1

E1 amplitude at center of pulse

E1 pulse width at 50% of nominal amplitude

E1 Transmitter Return Loss (Notes 10, 16, 17)

51 kHz to 102 kHz

102 kHz to 2.048 MHz

2.048 MHz to 3.072 MHz

E1 Transmitter Short Circuit Current (Notes 10, 18) - - 50 mA RMS

Notes: 10. Using a 0.47 µF capacitor in series with the primary of a tr ansformer recommended

in the Applications Section.

11. Pulse amplitude measured at the output of a 1:1 tr ansformer across a 75 Ω load for

line length setting LEN2/1/0 = 0/0/0.

12. Pulse amplitude measured at the output of a 1:1.26 tr ansformer across a 120 Ω load for line length

setting LEN2/1/0 = 0/0/0 or at the output of a 1:1 transformer across a 120 Ω load for LEN2/1/0 = 001.

13. Pulse amplitude measured at the output of a 1:1.15 tr ansformer across a 100 Ω load for

line length setting LEN2/1/0 = 0/1/0.

14. Pulse amplitude measured at the DSX-1 Cross -Connect across a 100 Ω load for all line length

settings from LEN2/1/0 = 0/1/1 to LEN2/1/0 = 1/1/1 using a 1:1.5 transformer.

15. Input signal to RTIP/RRING is jitter free. Values will reduce slightly if jitter free clock is input to TCLK.

16. Not production tested. Parameters guaranteed by design and characterization.

17. Return loss = 20 log

= impedance of line load. Measured with a repeating 1010 data pattern with LEN2/1/0 = 0/0/0

z

0

and a 1:2 transformer with two 9.4 Ω series res istors terminated by a 75Ω load,

or for LEN2/1/0 = 0/0/1 with a 1:2 transformer and two 15 Ω ser ies resistors terminated by a

120Ω load.

18. Measured broadband through a 0.5 Ω resistor across the secondary of the transmitter transformer

during the transmission of an all ones data pattern for LEN2/1/0 = 0/0/0 or 0/0/1with a 1:2 transformer

and the series resistors specified in Table A1.

ABS((z1 +z0)/(z1-z0)) where z1 = impedance of the transmitter, and

10

2.14

2.7

2.7

2.4

-0.237

-0.3

-

-

-

-

-29 -38 - dB

-

-5

-5

20

20

20

2.37

3.0

3.0

3.0

-

-

-

-

-

-

0.2

-

-

28

28

24

2.6

3.3

3.3

3.6

0.237

0.3

0.01

0.025

0.025

0.05

0.5

5

5

-

-

-

V

V

V

V

V

V

Ω

UI

UI

UI

UI

dB

%

%

dB

dB

dB

DS157PP3 3

Page 4

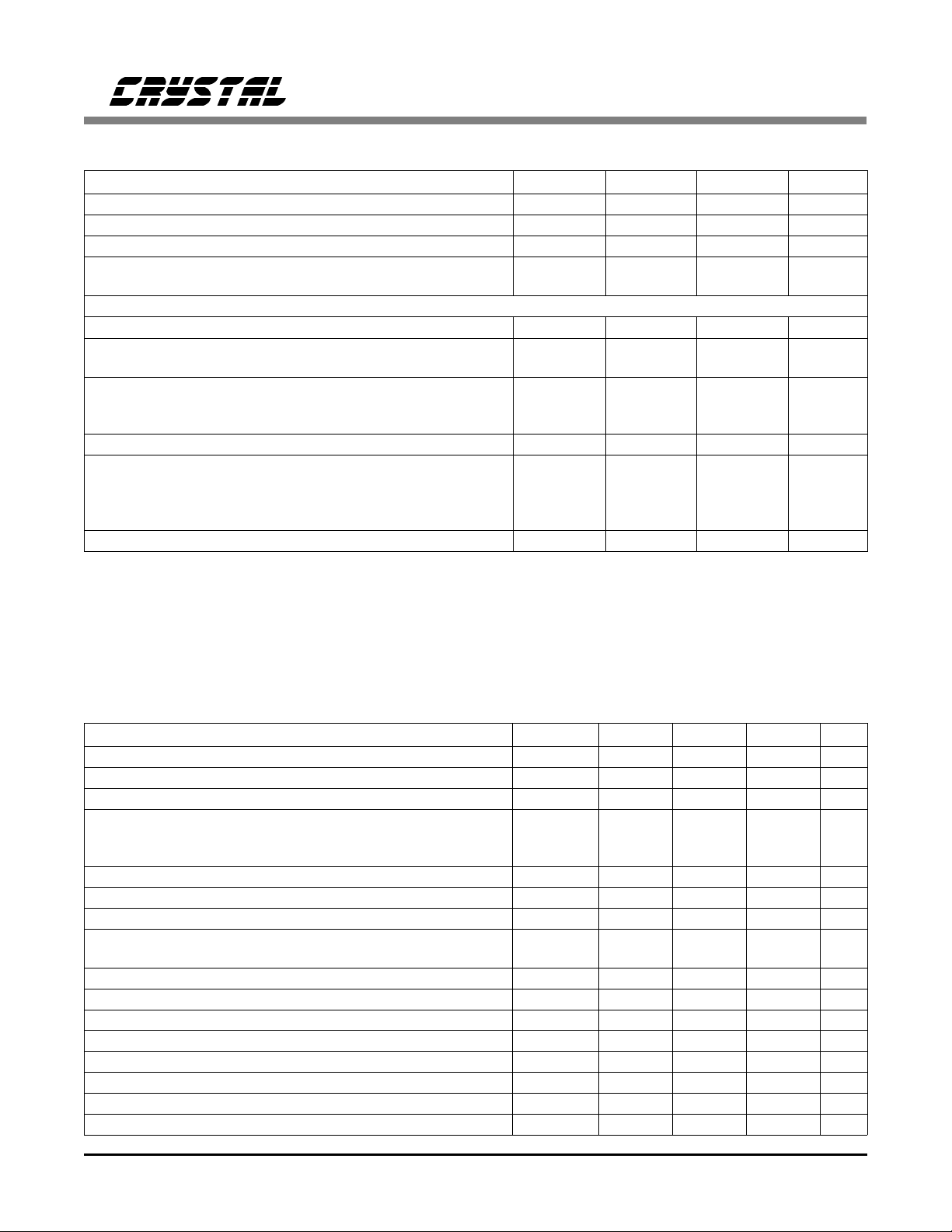

CS61305A

ANALOG SPECIFICATIONS (TA = -40°C to 85°C; TV+, RV+ = 5.0V ±5%; GND = 0V)

Parameter Min Typ Max Units

Transmitter Jitter Attenuator

Jitter Attenuation Curve Corner Frequency (Notes 16, 19) - 3 - Hz

Attenuation at 10kHz Jitter Frequency (Notes 16, 19) - 50 - dB

Attenuator Input Jitter Tolerance (Notes 16, 19)

(Before Onset of FIFO Overflow or Underflow Protection)

Receiver

RTIP/RRING Input Impedance - 50k Sensitivity Below DSX (0dB = 2.4V ) -13.6

Data Decision Threshold

T1, DSX-1 (Note 20)

T1, (FCC Part 68) and E1 (Note 21)

Allowable Consecutive Zeros before LOS 160 175 190 bits

Receiver Input Jitter Tolerance (Note 22)

10kHz - 100kHz

2kHz

10Hz and below

Loss of Signal Threshold - 0.30 - V

Notes: 19. Attenuation measured with input jitter equal to 3/4 of measured jitter tolerance. Circuit attenuates

jitter at 20 dB/decade above the corner frequency. See Figure 10. Output jitter can increase

significantly when more than 12 UI’s are input to the attenuator. See discussion in the text section.

20. For input amplitude of 1.2 V

21. For input amplitude of 1.05 V

to 4.14 Vpk.

pk

to 3.3 Vpk.

pk

22. Jitter tolerance increases at lower frequencies. See Figure 12.

138 - - UI

Ω

500

53

45

0.4

6.0

300

-

-

65

50

-

-

-

77

55

-

-

dB

mV

% of peak

% of peak

-

-

-

UI

UI

UI

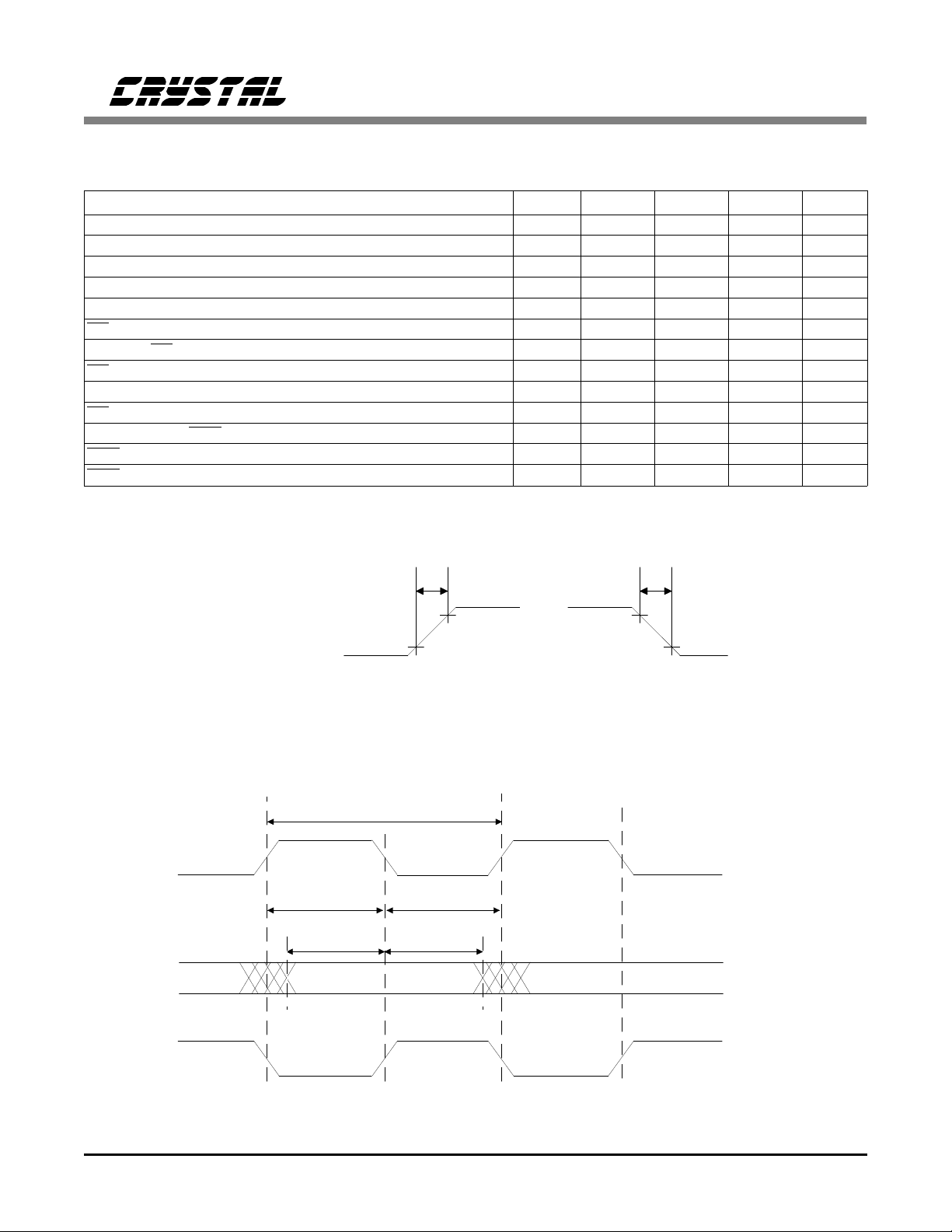

E1 SWITCHING CHARACTERISTICS (TA = -40°C to 85°C; TV+, RV+ = 5.0V ±5%;

GND = 0V; Inputs: Logic 0 = 0V, Logic 1 = RV+; See Figures 1, 2, & 3)

Parameter Symbol Min Typ Max Units

Crystal Frequency (Note 23) f

ACLKI Duty Cycle t

pwh3/tpw3

ACLKI Frequency (Note 24) f

RCLK Cycle Width (Note 25) t

t

t

Rise Time, All Digital Outputs (Note 26) t

Fall Time, All Digital Outputs (Note 26) t

TCLK Frequency f

TCLK Pulse Width (Notes 27, 28)

t

(Notes 29, 30)

TPOS/TNEG (TDATA) to TCLK Falling Setup Time t

TCLK Falling to TPOS/TNEG (TDATA) Hold Time t

RPOS/RNEG Valid Before RCLK Falling (Note 27) t

RDATA Valid Before RCLK Falling (Note 29) t

RPOS/RNEG Valid Before RCLK Rising (Note 28) t

RPOS/RNEG Valid After RCLK Falling (Note 27) t

RDATA Valid After RCLK Falling (Note 29) t

RPOS/RNEG Valid After RCLK Rising (Note 28) t

c

aclki

pw1

pwh1

pwl1

r

f

tclk

pwh2

su2

h2

su1

su1

su1

h1

h1

h1

- 8.192000 - MHz

40 - 60 %

- 2.048 - MHz

310

90

120

488

140

348

620

190

500

- - 85 ns

- - 85 ns

- 2.048 - MHz

80

150

-

-

340

25 - - ns

25 - - ns

100 194 - ns

100 194 - ns

100 194 - ns

100 194 - ns

100 194 - ns

100 194 - ns

ns

ns

ns

-

ns

ns

4 DS157PP3

Page 5

CS61305A

T1 SWITCHING CHARACTERISTICS (TA = -40°C to 85°C; TV+, RV+ = 5.0V ±5%;

GND = 0V; Inputs: Logic 0 = 0V, Logic 1 = RV+; See Figures 1, 2, & 3)

Parameter Symbol Min Typ Max Units

Crystal Frequency (Note 23) f

ACLKI Duty Cycle t

ACLKI Frequency (Note 24) f

RCLK Cycle Width (Note 25) t

Rise Time, All Digital Outputs (Note 26) t

Fall Time, All Digital Outputs (Note 26) t

TCLK Frequency f

TCLK Pulse Width (Notes 16, 27, 28)

c

pwh3/tpw3

aclki

pw1

t

pwh1

t

pwl1

r

f

tclk

t

pwh2

(Notes 29, 30)

TPOS/TNEG (TDATA) to TCLK Falling Setup Time t

TCLK Falling to TPOS/TNEG (TDATA) Hold Time t

RPOS/RNEG Valid Before RCLK Falling (Note 27) t

RDATA Valid Before RCLK Falling (Note 29) t

RPOS/RNEG Valid Before RCLK Rising (Note 28) t

RPOS/RNEG Valid After RCLK Falling (Note 27) t

RDATA Valid After RCLK Falling (Note 29) t

RPOS/RNEG Valid After RCLK Rising (Note 28) t

su2

h2

su1

su1

su1

h1

h1

h1

Notes: 23. Crystal must meet specifications described in CXT6176/CXT8192 data sheet.

24. ACLKI provided by an external source or TCLK but not RCLK.

25. RCLK duty cycle will vary with extent by which pulses are displaced by jitter. Specified under worst

case jitter conditions: 0.4 UI AMI data displacement for T1 and 0.2 UI AMI data displacement for E1.

26. At max load of 1.6 mA and 50 pF.

27. Host Mode (CLKE = 1).

28. Hardware Mode, or Host Mode (CLKE = 0).

29. Extended Hardware Mode.

30. The maximum TCLK burst rate is 5 MHz and t

(min) = 200ns. The maximum gap size that can

pw2

be tolerated on TCLK is 138 VI.

- 6.176000 - MHz

40 - 60 %

- 1.544 - MHz

320

130

100

648

190

458

980

240

850

- - 85 ns

- - 85 ns

- 1.544 - MHz

80

150

-

-

500

25 - - ns

25 - - ns

150 274 - ns

150 274 - ns

150 274 - ns

150 274 - ns

150 274 - ns

150 274 - ns

ns

ns

ns

-

ns

ns

DS157PP3 5

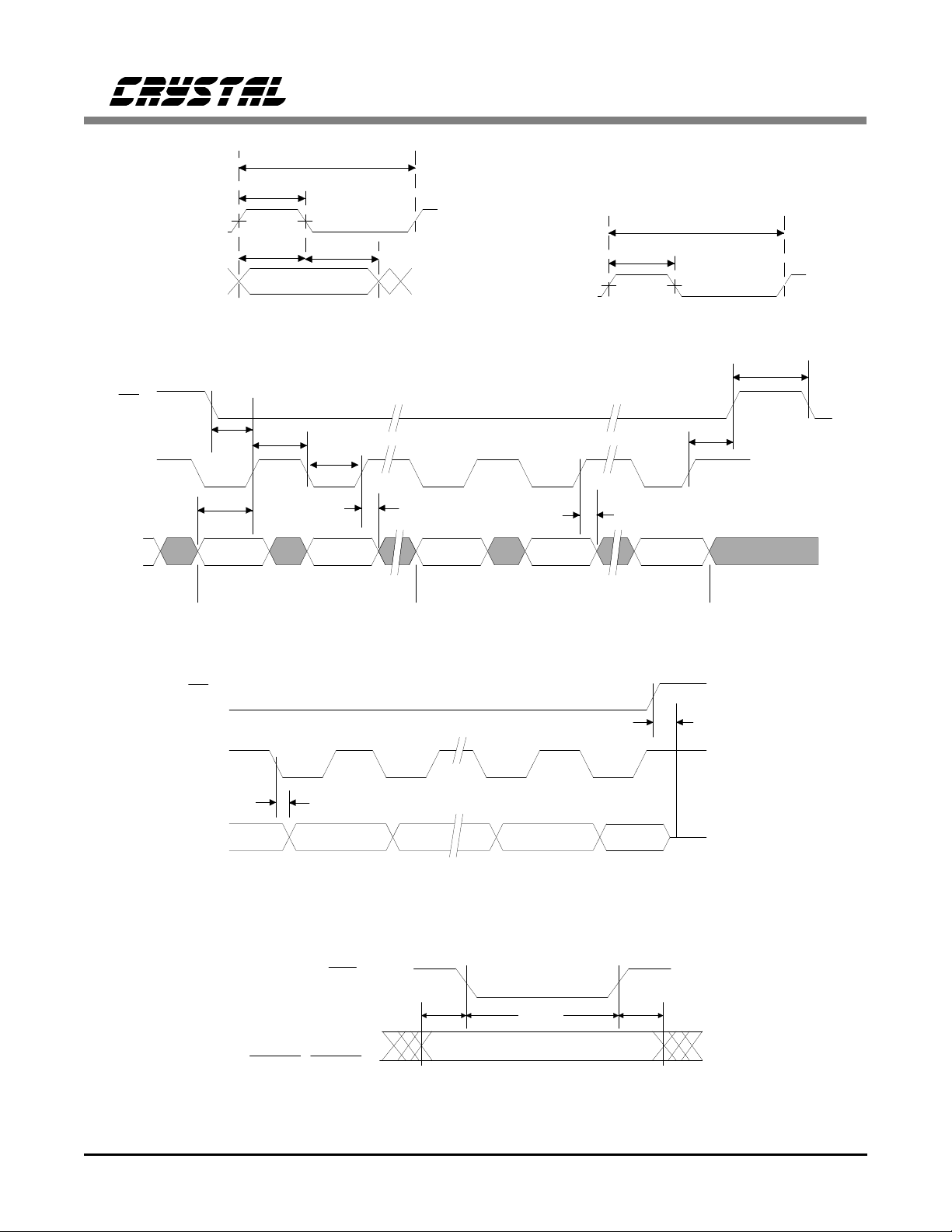

Page 6

CS61305A

SWITCHING CHARACTERISTICS

(TA = -40° to 85°C; TV+, RV+ = ±5%;

Inputs: Logic 0 = 0V, Logic 1 = RV+)

Parameter Symbol Min Typ Max Units

SDI to SCLK Setup Time t

SCLK to SDI Hold Time t

SCLK Low Time t

SCLK High Time t

SCLK Rise and Fall Time t

CS to SCLK Setup Time t

SCLK to

CS Hold Time t

CS Inactive Time t

SCLK to SDO Valid (Note 31) t

CS to SDO High Z t

Input Valid To

PCS Falling Setup Time t

PCS Rising to Input Invalid Hold Time t

PCS Active Low Time t

Notes: 31. Output load capacitance = 50pF.

t

r

dc

cdh

cl

ch

, t

r

cc

cch

cwh

cdv

cdz

su4

h4

pcsl

50 - - ns

50 - - ns

240 - - ns

240 - - ns

f

- - 50 ns

50 - - ns

50 - - ns

250 - - ns

- - 200 ns

- 100 - ns

50 - - ns

50 - - ns

250 - - ns

t

f

RCLK

RPOS

RNEG

RDATA

BPV

RCLK

Any Digital Output

Figure 1. Signal Rise and Fall Characteristics

t

pwl1

tt

su1

t

pw1

90% 90%

10%

t

pwh1

h1

10%

EXTENDED

HARDWARE

MODE OR

HOST MODE

(CLKE = 1)

HARDWARE

MODE OR

HOST MODE

(CLKE = 0)

Figure 2. Recovered Clock and Data Sw itching Characterist ics

6 DS157PP3

Page 7

TCLK

t

pwh2

t

su2

t

pw2

CS61305A

t

pw3

t

h2

t

pwh3

TPOS/TNEG

Figure 3a. Transmit Clock and Data Switching

Characteristics

CS

t

ch

cc

CONTROL BYTE DATA BYTE

t

cl

t

cdh

Figure 4. Serial Port Write Timing Diagram

SCLK

SDI

t

t

dc

LSB LSB MS B

CS

ACLKI

Figure 3b. Alternate External Clock Characteristics

t

cwh

t

cch

t

cdh

t

cdz

SCLK

t

cdv

SDO

CLKE = 1

Figure 5. Serial Port Read Timing Diagram

PCS

t

su4

t

LEN0/1/2, TAOS,

RLOOP, LLOOP,

RCODE, TCODE

Figure 6. Extended Hardware Mode Parallel Chip Select Timing Diagram

DS157PP3 7

VALID INPUT DATA

pcsl

t

h4

HIGH Z

Page 8

CS61305A

THEORY OF OPERATION

Key Enhancements of the CS61305A Relative

to the LXT305A

• 12.5% lower power consumption,

• 50 mA

transmitter short-circuit current

RMS

limiting for E1 (per OFTEL OTR-001),

• Optional AMI, B8ZS, HDB3 encoder/de-

coder or external line coding support,

• Receiver AIS (unframed all ones) detection,

• Improved receiver Loss of Signal handling

(LOS set at power-up, reset upon receipt of

3 ones in 32 bit periods with no more than

15 consecutive zeros),

• Transmitter TTIP and TRING outputs are

forced low when TCLK is static.

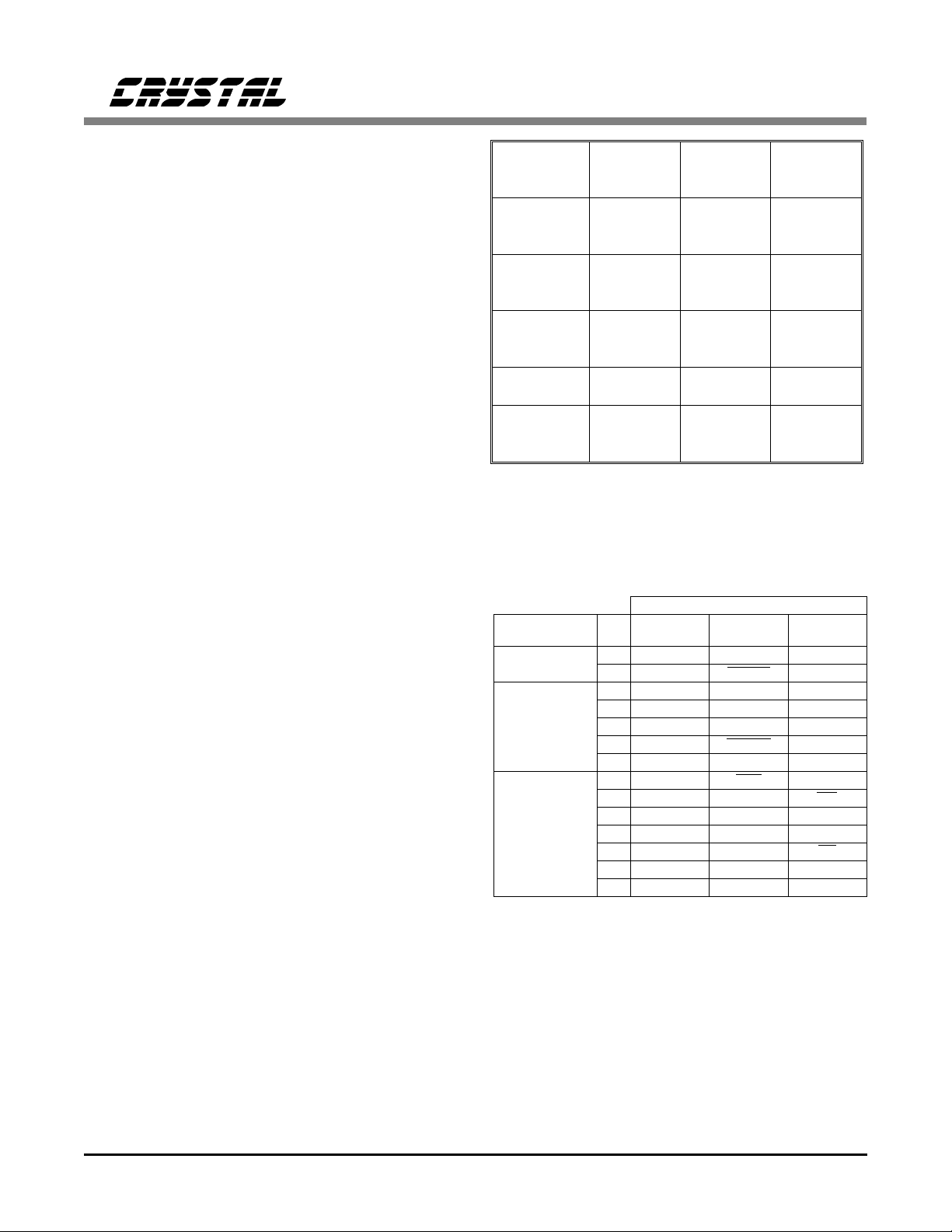

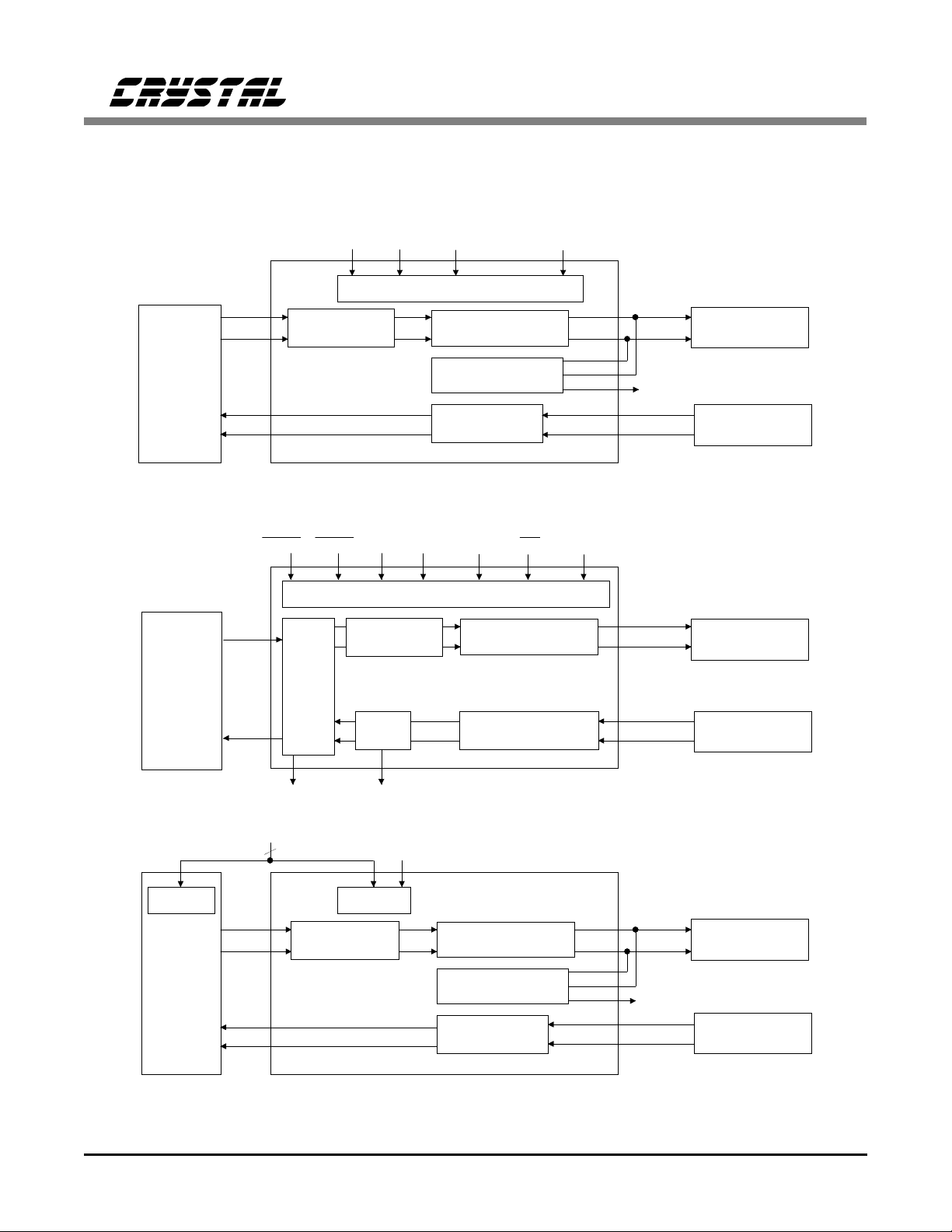

Introduction to Operating Modes

The CS61305A supports three operating modes

which are selected by the level of t he MODE pin

as shown in Tables 1 and 2, Figure 7, and Figures

A1-A3 of the Applications section.

There are thirteen multi-function pins whose

functionality is determined by the operating

mode. (see Table 2). The modes are Hardware

Mode, Extended Hardware Mode, and Host

Mode. In Hardware and Extended Hardware

Modes, discrete pins are used to configure and

monitor the device. The Extended Hardware

Mode provides a parallel chip select input which

latches the control inputs allowing individual ICs

to be configured using a common set of control

lines. In the Host Mode, an external processor

monitors and configures the device through a serial interface.

Hardware

Mode

Control

Method

MODE

Pin

Level

Line

Coding

AIS

Detection

Driver

Performance

Monitor

Table 1. Differences Between Operating Modes

FUNCTION PIN HARDWARE

TRANSMITTER

RECEIVER/DPM

CONTROL

Control

Pins

<0.2 V Floating or

External Internal-

No Yes No

Yes No Yes

3TPOS TDATA TPOS

4TNEG

6 RNEG BPV RNEG

7 RPOS RDATA RPOS

11 DPM AIS DPM

17 MTIP

18 MRIN G - MRING

18 23 LEN0 LEN0

24 LEN1 LEN1 SDI

25 LEN2 LEN2 SDO

26 RLOOP RLOOP

27 LLOOP LLOOP SCLK

28 TAOS TAOS CLKE

Table 2. Pin Definitions

Extended

Hardware

Mode

Control Pins

with Parallel

Chip Select

2.5 V

AMI, B8ZS,

or HDB3

MODE

EXTENDED

HARDWARE HOST

TCODE TNEG

RCODE MTIP

PCS -

Host

Mode

Serial

Interface

>(R V+)-0.2

V

External

INT

CS

8 DS157PP3

Page 9

CS62180B

FRAMER

CIRCUIT

TNEG

RPOS

RNEG

HARDWARE MODE

RLOOP LEN0/1/2LLOOPTAOS

CONTROL

JITTER

ATTENUATOR

CS61305A

LINE DRIVER

DRIVER MONITOR

LINE RECEIVER

EXTENDED HARDWARE MODE

RCODETCODE

RLOOP PCS LEN0/1/2LLOOPTAOS

MRING

MTIP

TTIPTPOS

TRING

DPM

RTIP

RRING

CS61305A

TRANSMIT

TRANSFORMER

RECEIVE

TRANSFORMER

HIGH

SPEED

MUX

(e.g., M13)

CONTROL

CS62180B

FRAMER

CIRCUIT

TDATA

RDATA

BPV

P SERIAL PORT

µ

5

TPOS

TNEG

RPOS

RNEG

AMI

B8ZS,

HDB3,

CODER

JITTER

ATTENUATOR

CS61305A

JITTER

ATTENUATOR

CS61305A

AIS

DETECT

AIS

HOST MODE

CLKE

CONTROL

CONTROL

LINE DRIVER

DRIVER MONITOR

LINE RECEIVER

LINE DRIVER

LINE RECEIVER

MRING

MTIP

TTIP

TRING

RTIP

RRING

TTIP

TRING

DPM

RTIP

RRING

TRANSMIT

TRANSFORMER

RECEIVE

TRANSFORMER

TRANSMIT

TRANSFORMER

RECEIVE

TRANSFORMER

Figure 7. Overview of Operating Modes

DS157PP3 9

Page 10

CS61305A

Transmitter

The transmitter takes digital T1 or E1 input data

and drives appropriately shaped bipolar pulses

onto a transmission line. The transmit data (TPOS

& TNEG or TDATA) is supplied synchronously

and sampled on the falling edge of the input

clock, TCLK.

Either T1 (DSX-1 or Network Interface) or E1

CCITT G.703 pulse shapes may be selected.

Pulse shaping and signal level are controlled by

"line length select" inputs as shown in Table 3.

The output options in Table 3 are specified with a

1:1.15 transmitter transformer turns ratio for T1

and a 1:1 turns ratio for E1 without external series resistors. Other turns ratios may be used if

approriate resistors are placed in series with the

TTIP and TRING pins. Table A1 in the applications section lists other combinations which can

be used to provide transmitter impedance matching.

For T1 DSX-1 applications, line lengths from 0 to

655 feet (as measured from the transmitter to the

DSX-1 cross connect) may be selected. The five

partition arrangement in Table 3 meets ANSI

T1.102-1993 and AT&T CB-119 requirements

when using #22 ABAM cable. A typical output

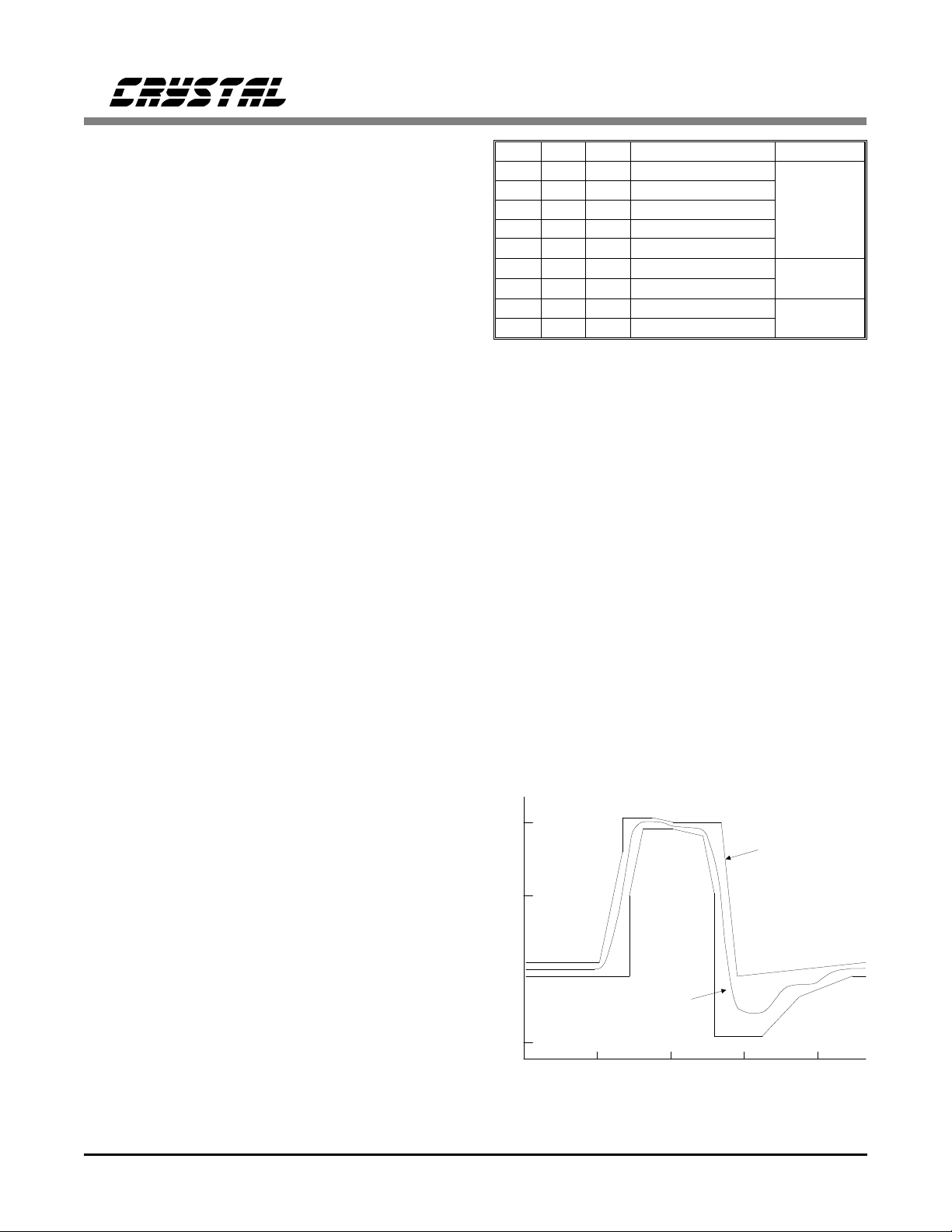

pulse is shown in Figure 8. These pulse settings

can also be used to meet CCITT pulse shape requirements for 1.544 MHz operation.

LEN2 LEN1 LEN0 Option Selected Application

011 0-133 ft

100 133-266 ft

101 266-399 ft

110 399-533 ft

111 533-655 ft

000

001

0 1 0 FCC PART 68, OPT. A Network

0 1 1 ANSI T1.403

Table 3. Line Length Selection

75Ω coax

120Ω twisted-pair

DSX-1

ABAM

(AT&T 600B

or 600C)

E1

CCITT G.703

Interface

The CS61305A transmitter provides short-circuit

current limiting protection and meets OFTEL

OTR-001 short-circuit current limiting requirements for E1 applications.

The CS61305A will detect a static TCLK, and

will force TTIP and TRING low to prevent transmission when data is not present. When any

transmit control pin (TAOS, LEN0-2 or LLOOP)

is toggled, the transmitter outputs will require approximately 22 bit periods to stabilize. The

transmitter will take longer to stabilize when

RLOOP is selected because the timing circuitry

must adjust to the new frequency.

NORMALIZED

AMPLITUDE

1.0

ANSI T1.102,

AT&T CB 119

SPECIFICATIONS

For T1 Network Interface applications, two additional options are provided. Note that the optimal

0.5

pulse width for Part 68 (324 ns) is narrower than

the optimal pulse width for DSX-1 (350 ns). The

CS61305A automatically adjusts the pulse width

based upon the "line length" selection made.

The E1 G.703 pulse shape is supported with line

length selections LEN2/1/0 = 0/0/0 and 0/0/1.

The pulse width will meet the G.703 pulse shape

template shown in Figure 9, and specified in Table 4.

10 DS157PP3

0

OUTPUT

PULSE SHAPE

-0.5

0 250 750 1000

Figure 8. Typical Pulse Shape at DSX-1 Cross Connect

500

TIME (nanoseconds)

Page 11

120

110

100

90

80

50

Percent of

nominal

peak

voltage

269 ns

244 ns

194 ns

Attenuation in dB

0

10

20

30

40

50

CS61305A

a) Minimum Attenuation Limit

AT&T 62411

Requirements

b) Maximum

Attenuation

Limit

-10

-20

10

0

219 ns

488 ns

Nominal Pulse

Figure 9. Mask of the Pulse at the 2048 kbps Interface

Transmit All Ones Select

The transmitter provides for all ones insertion at

the frequency of ACLKI. Transmit all ones is selected when TAOS goes high, and causes

continuous ones to be transmitted on the line

(TTIP and TRING). In this mode, the TPOS and

TNEG (or TDATA) inputs are ignored. A TAOS

request will be ignored if remote loopback is in

effect. ACLKI jitter will be attenuated. TAOS is

not available on the CS61305A when ACLKI is

grounded.

60

1 10 100 1 k 10 k

Frequency in Hz

Measured Performance

Figure 10. Typical Jitter Attenuation Curve

Jitter Attenuator

The jitter attenuator is designed to reduce wander

and jitter in the transmit clock signal. It consists

of a 192 bit FIFO, a crystal oscillator, a set of

load capacitors for the crystal, and control logic.

The jitter attenuator exceeds the jitter attenuation

requirements of Publications 43802 and REC.

G.742. A typical jitter attenuation curve is shown

in Figure 10.

The jitter attenuator works in the following manner. Data on TPOS and TNEG (or TDATA) are

For coaxial cable,

75Ω load and

transformer specified

in Application Section.

For shielded twisted

pair, 120Ω load and

transformer specified

in Application Section.

Nominal peak voltage of a mark (pulse) 2.37 V 3 V

Peak voltage of a space (no pulse)

0 ±0.237 V 0 ±0.30 V

Nominal pulse width 244 ns

Ratio of the amplitudes of positive and negative

pulses at the center of the pulse interval

Ratio of the widths of positive and negative

pulses at the nominal half amplitude

0.95 to 1.05*

0.95 to 1.05*

* When configured with a 0.47 µF nonpolarized capacitor in series with the TX transformer

primary as shown in Figures A1, A2 and A3.

Table 4. CCITT G.703 Specifications

DS157PP3 11

Page 12

CS61305A

written into the ji tt er at tenu at o r’s FIFO by TCLK.

The rate at which data is read out of the FIFO and

transmitted is determined by the oscillator. Logic

circuits adjust the capacitive loading on the crystal to set its oscillation frequency to the average

of the TCLK frequency. Signal jitter is absorbed

in the FIFO.

Jitter Tolerance of Jitter Attenuator

The FIFO in the jitter attenuator is designed to

neither overflow nor underflow. If the jitter amplitude becomes very large, the read and write

pointers may get very close together. Should the

pointers attempt to cross, the oscillator’s divide

by four circuit adjusts by performing a divide by

3 1/2 or divide by 4 1/2 to prevent the overflow

or underflow. When a divide by 3 1/2 or 4 1/2

occurs, the data bit will be driven on to the line

either an eighth bit period early or an eighth bit

period late.

The FIFO of the jitter attenuator in the transmit

path is 192 bits deep. This FIFO will typically be

near the half full point under normal operating

conditions, buffering about 96 bits of data. The

number of bits actually buffered depends on the

relationship of the nominal TCLK frequency to

the center frequency of the crystal oscillator. As

these frequencies deviate, a few bits of FIFO

depth will be lost.

TCLK can have gaps or bursts. As long as the gap

or burst is less than the remaining FIFO depth,

normal operation will continue. For example, if

the nominal TCLK frequency was less than the

oscillator’s center frequency by 40 Hz. The FIFO

will operate 3-4 bits off center or 92 bits full. A

gap in TCLK of 80 cycles would empty the FIFO

by 80 bits but would still not envoke the divide

by 4 1/2 circuitry, as about 12 bits would remain

in the FIFO.

The crystal frequency must be 4 times the nominal signal frequency: 6.176 MHz for 1.544 MHz

operation; 8.192 MHz for 2.048 MHz applica-

tions. Internal capacitors load the crystal, controlling the oscillation frequency. The crystal must be

designed so that over operating temperature, the

oscillator frequency range exceeds the system frequency tolerance. Crystal Semiconductor offers

the CXT6176 & CXT8192 crystals, which yield

optimum performance with the CS61305A.

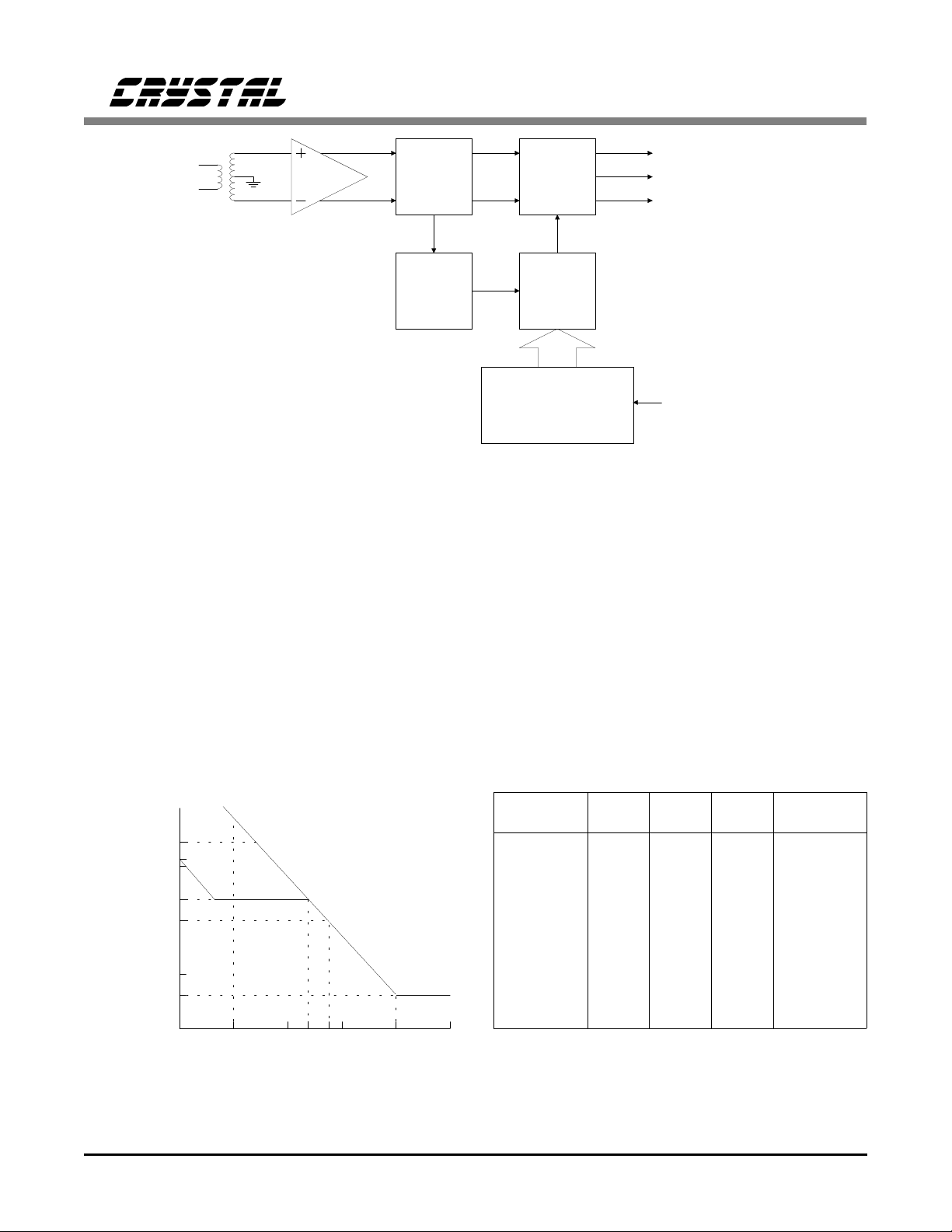

Receiver

The receiver extracts data and clock from an AMI

(Alternate Mark Inversion) coded signal and outputs clock and synchronized data. The receiver is

sensitive to signals over the entire range of cable

lengths and requires no equalization or ALBO

(Automatic Line Build Out) circuits. The signal is

received on both ends of a center-tapped, centergrounded transformer. The transformer is

center-tapped on the IC side. The clock and data

recovery circuit exceeds the jitter tolerance specifications of Publications 43802, 43801, 62411

amended, TR-TSY-000170, and CCITT REC.

G.823.

A block diagram of the receiver is shown in Figure 11. The two leads of the transformer (RTIP

and RRING) have opposite polarity allowing the

receiver to treat RTIP and RRING as unipolar signals. Comparators are used to detect pulses on

RTIP and RRING. The comparator thresholds are

dynamically established at a percent of the peak

level (50% of peak for E1, 65% of peak for T1;

with the slicing level selected by LEN2/1/0).

The receiver uses an edge detector and a continuously calibrated delay line to generate the

recovered clock. The delay line divides its reference clock, ACLKI or the jitter attenuator’s

oscillator, into 13 equal divisions or phases. Continuous calibration assures timing accuracy, even

if temperature or power supply voltage fluctuate.

The leading edge of an incoming data pulse triggers the clock phase selector. The phase selector

chooses one of the 13 available phases which the

delay line produces for each bit period. The out-

12 DS157PP3

Page 13

CS61305A

RTIP

1 : 2

RRING

Data

Level

Slicer

Edge

Detector

Figure 11. Receiver Block Dia gram

put from the phase selector feeds the clock and

data recovery circuits which generate the recovered clock and sample the incoming signal at

appropriate intervals to recover the data. The jitter

tolerance of the receiver exceeds that shown in

Figure 12.

The CS61305A outputs a clock immediately upon

power-up and will lock onto the AMI data input

immediately. If loss of signal occurs, the RCLK

frequency will equal the ACLKI frequency.

Data

Sampling

&

Clock

Extraction

Clock

Phase

Selector

Continuously

Calibrated

Delay Line

RPOS

RNEG

RCLK

ACLKI or

Oscillator in Jitter

Attenuator

In the Hardware Mode, data at RPOS and RNEG

is stable and may be sampled on the rising edge

of the recovered clock. In the Extended Hardware

Mode, data at RDATA is stable and may be sampled on the fallings edge of the recovered clock.

In the Host Mode, CLKE determines the clock

polarity for which output data is stable and valid

as shown in Table 5.

Jitter and Recovered Clock

The CS61305A is designed for error free clock

and data recovery from an AMI encoded data

Minimum

Performance

10 1k 10k1 100 100k700

JITTER FREQUENCY (Hz)

300

PEAK-TO-PEAK

JITTER

(unit intervals)

300

138

100

AT&T 62411

28

10

1

.4

.1

Figure 12. Minimum Input Jitter Tolerance of Receiver

MODE

(pin 5)

LOW

(<0.2V)

HIGH

(>(V+) - 0.2V)

HIGH

(>(V+) - 0.2V)

MIDDLE

(2.5V)

X = Don’t care

Table 5. Data Output/Clock Relationship

CLKE

(pin 28)

X RPOS

LOW RPOS

HIGH RPOS

DATA CLOCK Clock Edge

for Valid Data

RCLK

RNEG

RCLK

RCLK

RNEG

SDO

RCLK

SCLK

RCLK

RNEG

SDO

RCLK

SCLK

X RDATA RCLK Falling

Rising

Rising

Rising

Rising

Falling

Falling

Falling

Rising

DS157PP3 13

Page 14

CS61305A

stream in the presence of more than 0.4 unit intervals of jitter at high frequency. The clock

recovery circuit is also tolerant of long strings of

zeros. The edge of an incoming data bit causes

the circuitry to choose a phase from the delay line

which most closely corresponds with the arrival

time of the data edge, and that clock phase triggers a pulse which is typically 140 ns in duration.

This phase of the delay line will continue to be

selected until a data bit arrives which is closer to

another of the 13 phases, causing a new phase to

be selected. The largest jump allowed along the

delay line is six phases.

When an input signal is jitter free, the phase selection will occasionally jump between two

adjacent phases resulting in RCLK jitter with an

amplitude of 1/13 UIpp. These single phase

jumps are due to differences in frequency of the

incoming data and the calibration clock input to

ACLKI. For T1 operation the instantaneous period can be 14/13 * 648 ns = 698 ns or 12/13 *

648 ns = 598 ns when adjacent clock phases are

chosen. As long as the same phase is chosen, the

period will be 648 ns. Similar calculations hold

for the E1 rate.

The clock recovery circuit is designed to accept at

least 0.4 UI of jitter at the receiver. Since the data

stream contains information only when ones are

transmitted, a clock/data recovery circuit must assume a zero when no signal is measured during a

bit period. Likewise, when zeros are received, no

information is present to update the clock recovery circuit regarding the trend of a signal which is

jittered. The result is that two ones that are separated by a string of zeros can exhibit maximum

deviation in pulse arrival time. For example, one

half of a period of jitter at 100 kHz occurs in 5

µs, which is 7.7 T1 bit periods. If the jitter amplitude is 0.4 UI, then a one preceded by seven zeros

can have maximum displacement in arrival time,

i.e. either 0.4 UI too early or 0.4 UI too late. The

data recovery circuit correctly assigns a received

bit to its proper clock period if i t is displaced by

less than 6/13 of a bit period from its optimal location. Theoretically, this would give a jitter

tolerance of 0.46 UI. The actual jitter tolerance of

the CS61305A is only slightly less than the ideal.

In the event of a maximum jitter hit, the RCLK

clock period immediately adjusts to align itself

with the incoming data and prepare to accurately

place the next one, whether it arrives one period

later, or after another string of zeros and is displaced by jitter. For a maximum early jitter hit,

RCLK will have a period of 7/13 * 648 ns = 349

ns. For a maximum late jitter hit, RCLK will have

a period of 19/13 * 648 ns = 947 ns.

Loss of Signal

Receiver loss of signal is indicated upon receiving 175 consecutive zeros. A digital counter

counts received zeros based on RCLK cycles. A

zero input is determined either when zeros are received, or when the received signal amplitude

drops below a 0.3 V peak threshold.

The receiver reports loss of signal by setting the

Loss of Signal pin, LOS, high. If the serial interface is used, the LOS bit will be set and an

interrupt issued on INT. LOS will go low (and

flag the INT pin again if serial I/O is used) when

a valid signal is detected. Note that in the Host

Mode, LOS is simultaneously available from both

the register and pin 12.

In a loss of signal state, the RCLK frequency will

be equal to the ACLKI frequency since ACLKI is

being used to calibrate the clock recovery circuit.

Received data is output on RPOS/RNEG regardless of LOS status. LOS returns to logic zero

when 3 ones are received out of 32 bit periods

containing no more than 15 consecutive zeros.

Also, a power-up or manual reset will set LOS

high.

14 DS157PP3

Page 15

CS61305A

Local Loopback

Local loopback is selected by taking LLOOP, pin

27, high or by setting the LLOOP register bit via

the serial interface.

The local loopback mode takes clock and data

presented on TCLK, TPOS, and TNEG (or

TDATA), and outputs it at RCLK, RPOS and

RNEG (or RDATA). Inputs to the transmitter are

still transmitted on TTIP and TRING, unless

TAOS has been selected in which case, AMIcoded continuous ones are transmitted at the

TCLK frequency. The receiver RTIP and RRING

inputs are ignored when local loopback is in effect. The jitter attenuator is not in the local loop

back path.

Remote Loopback

Remote loopback is selected by taking RLOOP,

pin 26, high or by setting the RLOOP register bit

via the serial interface.

In remote loopback, the recovered clock and data

input on RTIP and RRING are sent through the

jitter attenuator and back out on the line via TTIP

and TRING. Selecting remote loopback overrides

any TAOS request (see Table 7). The recovered

RLOOP

Input

Signal

Notes: 1. X = Don’t Care. The identified All Ones Select

TA OS

Input

Signal

00 TDATA TCLK

0 1 all 1s TCLK

1 X RTIP & RRING RTIP & RRING (RCLK)

input is ignore d when the indi cated loop back is

in effect.

2. Logic 1 indicates that Loopb ack or All Ones

option is se lected .

Table 7. Interaction of RLOOP with TAOS

Source of

Data for

TTIP & TRING

Source of

Clock for

TTIP & TRING

incoming signals are also sent to RCLK, RPOS

and RNEG (or RDATA). A remote loopback occurs in response to RLOOP going high.

Simultaneous selection of local and remote loopback modes is not valid (see Reset).

In the Extended Hardware Mode the transmitted

data is looped before the AMI/B8ZS/HDB3 encoder/decoder during remote loopback so that the

transmitted signal matches the received signal,

even in the presence of received bipolar violations. Data output on RDATA is decoded,

however, if RCODE is low.

Driver Performance Monitor

To aid in early detection and easy isolation of

non-functioning links, the IC is able to monitor

transmit drive performance and report when the

driver is no longer operational. This feature can

be used to monitor either the device’s performance or the performance of a neighboring driver.

The driver performance monitor indicator is normally low, and goes high upon detecting a driver

failure.

The driver performance monitor consists of an activity detector that monitors the transmitted signal

when MTIP is connected to TTIP and MRING is

connected to TRING. DPM will go high if the

absolute difference between MTIP and MRING

does not transition above or below a threshold

level within a time-out period. In the Host Mode,

DPM is available from both the register and pin

11.

Whenever more than one line interface IC resides

on the same circuit board, the effectiveness of the

driver performance monitor can be maximized by

having each IC monitor performance of a neighboring IC, rather than having it monitor its own

performance.

DS157PP3 15

Page 16

CS61305A

LEN 2/1/0

000 010-111

TCODE

(Transmit

Encoder

Selection)

RCODE

(Receiver

Decoder

Selection)

Table 8. Encoder/Decoder Selection

LOW

HIGH AMI Encoder

LOW

HIGH AMI Decoder

HDB3

Encoder

HDB3

Decoder

B8ZS

Encoder

B8ZS

Decoder

Alarm Indication Signal

In the Extended Hardware Mode, the receiver sets

the output pin AIS high when unframed all-ones

condition (blue alarm) is detected using the criteria of less than 3 zeros out of 2048 bit periods.

Line Code Encoder/Decoder

In the Extended Hardware Mode, three line codes

are available: AMI, B8ZS and HDB3. The input

to the encoder is TDATA. The outputs from the

decoder are RDATA and BPV (Bipolar Violation

Strobe). The encoder and decoder are selected

using the LEN2, LEN1, LEN0, TCODE and

RCODE pins as shown in Table 8.

Parallel Chip Select

In the Extended Hardware Mode, PCS can be

used to gate the digital control inputs: TCODE,

RCODE, LEN0, LEN1, LEN2, RLOOP, LLOOP

and TAOS. Inputs are accepted on these pins only

when PCS is low and will immediately change

the operating state of the device. Therefore, when

cycling PCS to update the operating state, the

digital control inputs should be stable for the entire PCS low period. The digital control inputs are

ignored when PCS is high.

Power On Reset / Res et

Upon power-up, the IC is held in a static state

until the supply crosses a threshold of approximately 3 Volts. When this threshold is crossed,

the device will delay for about 10 ms to allow the

power supply to reach operating voltage. After

this delay, calibration of the delay lines used in

the transmit and receive sections commences. The

delay lines can be calibrated only if a reference

clock is present. The reference clock for the receiver is provided by ACLKI, or the crystal

oscillator. The reference clock for the transmitter

is provided by TCLK. The initial calibration

should take less than 20 ms.

In operation, the delay lines are continuously calibrated, making the performance of the device

independent of power supply or temperature variations. The continuous calibration function

eliminates any requi rement to reset the line in terface when in operation. However, a reset function

is available which will clear all registers.

In the Hardware and Extended Hardware Modes,

a reset request is made by simultaneously setting

both the RLOOP and LLOOP pins high for at

least 200 ns. Reset will initiate on the falling edge

of the reset request (falling edge of RLOOP and

LLOOP). In the Host Mode, a reset is initiated by

simultaneously writing RLOOP and LLOOP to

the register. In either mode, a reset will set all registers to 0 and force the oscillator to its center

frequency before initiating calibration. A reset

will also set LOS high.

Serial Interface

In the Host Mode, pins 23 through 28 serve as a

microprocessor/microcontroller interface. One

on-board register can be written to via the SDI

pin or read from via the SDO pin at the clock rate

determined by SCLK. Through this register, a

16 DS157PP3

Page 17

CS

SCLK

CS61305A

SDI

SDO

R/W

0 D7D6D5D4D3D2D1D0

0

Address/Command Byte

00 01 X

Figure 13. Input/Output Timing

host controller can be used to control operational

characteristics and monitor device status. The serial port read/write timing is independent of the

system transmit and receive timing.

Data transfers are initiated by taking the chip select input, CS, low (CS must initially be high).

Address and input data bits are clocked in on the

rising edge of SCLK. The clock edge on which

output data is stable and valid is determined by

CLKE as shown in Table 5. Data transfers are terminated by setting CS high. CS may go high no

sooner than 50 ns after the rising edge of the

SCLK cycle corresponding to the last write bit.

For a serial data read, CS may go high any time

to terminate the output.

Figure 13 shows the timing relationships for data

transfers when CLKE = 1. When CLKE = 1, data

bit D7 is held until the falling edge of the 16th

clock cycle. When CLKE = 0, data bit D7 is held

until the rising edge of the 17th clock cycle. SDO

goes to the high impedance state when the serial

port is being written (R/W = 0), or if CS goes

high, or at the end of the hold period of data bit

D7.

An address/command byte, shown in Table 9,

precedes the data byte. The first bit of the address/command byte determines whether a read

or a write is requested. The next six bits contain

the address. The line interface responds to address

16 (0010000). The last bit is ignored.

Data Input/Output

D6D5D4D3D2D1D0 D7

Bit D esignation Description

0R/W Read/Write Select; 0 = write, 1 = read

1 ADD0 LSB of address, Must be 0

2 ADD1 Must be 0

3 ADD2 Must be 0

4 ADD3 Must be 0

5 ADD4 Must be 1

6 - Reserved - Must be 0

7 X Don’t Care

Note: Bit 0 is the first bit input (LSB).

Table 9. Address/Command Byte

During a write cycle (R/W = 0), data is written to

the input data register on the eight clock cycles

immediately following the address/command

byte. The input data format over SDI is shown in

Table 10.

Bit Designation Description

D0 clr LOS Clear Loss of Signal

D1 clr DPM Clear Driver Performance Monitor

D2 LEN0 Bit 0 - Line Length Select

D3 LEN1 Bit 1 - Line Length Select

D4 LEN2 Bit 2 - Line Lenght Select

D5 RLOOP Remote Loopback

D6 LLOOP Local Loopback

D7 TAOS T ransm it All O nes Select

Note: Bit D0 is the first bit input (LSB).

Table 10. Input Data Register

Bits D0 and D1 are used to clear an interrupt issued from the INT pin, which occurs in response

to a loss of signal or a problem with the output

driver.

Writing a "1" to either "Clear LOS" or "Clear

DPM" over the serial interface has three effects:

DS157PP3 17

Page 18

CS61305A

1) The current interrupt on the serial interface

will be cleared. (Note that simply reading

the register bits will not clear the interrupt).

2) Output data bits D5, D6 and D7 will be reset as appropriate.

3) Future interrupts for the corresponding LOS

or DPM will be prevented from occurring.

Writing a "0" to either "Clear LOS" or "Clear

DPM" enables the corresponding interrupt for

LOS or DPM.

Bit Designation Description

D0 LOS Loss of Signal

D1 DPM Driver Performance Monitor

D2 LEN0 Bit 0 - Line Length Select

D3 LEN1 Bit 1 - Line Length Select

D4 LEN2 Bit 2 - Line Lenght Select

Note: Bit D0 is the first bit output (LSB)

Table 11. Output Data Register (bits D0-D4)

During a read cycle (R/W = 1), data is read from

the output data register on the eight clock cycles

immediately following the address/ command

byte. The output data format over SDO is shown

in Tables 11 and 12.

Bits D2, D3 and D4 can be read to verify line

length selection. Bits D5, D6 and D7 must be decoded according to Table 12. Codes 101, 110 and

111 (Bits D5, D6 and D7) indicate intermittent

losses of signal and/or driver problems.

Bits

D5D6D7

0 0 0 Reset has occurred or no program input.

0 0 1 TAOS in effect.

0 1 0 LLOOP in effect.

0 1 1 TAOS/LLOOP in effect.

1 0 0 RLOOP in effect

1 0 1 DPM changed state since last "clear DPM"

occured.

1 1 0 LOS changed state since last "clear LOS"

occured.

1 1 1 LOS and DPM have changed state since

last "clear LOS" and "clear DPM".

Table 12. Output Data Register (bits D5-D7)

Status

respective grounds. TV+ must not exceed RV+ by

more than 0.3V.

Decoupling and filtering of the power supplies is

crucial for the proper operation of the analog circuits in both the transmit and receive paths. A 1.0

µF capacitor should be connected between TV+

and TGND, and a 0.1 µF capacitor should be con-

nected between RV+ and RGND. Use mylar or

ceramic capacitors and place them as closely as

possible to their respective power supply pins. A

68 µF tantalum capacitor should be added close

to the RV+/RGND supply. Wire-wrap breadboarding of the line interface is not recom mended

because lead resistance and inductance serve to

defeat the function of the decoupling capacitors.

The SDO pin goes to a high impedance state

when not in use. The SDO and SDI pins may be

Schematic & Layout Review Service

tied together in applications where the host processor has a bi-directional I/O port.

Power Supply

The device operates from a single +5 Volt supply.

Separate pins for transmit (TV+, TGND) and receive (RV+, RGND) supplies provide internal

isolation. These pins should be connected exter-

Confirm Optimum

Schematic & Layout

Before Building Your Board.

For Our Free Review Service

Call Applications Engineering.

Call:(512) 445-7222

nally near the device and decoupled to their

18 DS157PP3

Page 19

CS61305A

PIN DESCRIPTIONS

Extended Hardware Hardware/Host Hardware Extended Hardware Host

ACLKI TAOS CLKE

TCLK LLOOP SCLK

TDATA TPOS RLOOP

TCODE TNEG LEN2 SDO

MODE LEN1 SDI

BPV RNEG

RDATA RPOS

RCLK

XTALIN RRING

XTALOUT RTIP

AIS DPM MRING

LOS MTIP

TTIP TRING

TGND TV+

1

2

3

4

5

6

7

8

9

10

11

12

13

14

DIP

top

view

28

27

26

25

24

LEN0 INT

23

22

RGND

21

RV+

20

19

18

17

16

15

PCS

RCODE

CS

Extended Hardware Hardware/Host Hardware Extended Hardware Host

ACLKI

TCLK TAOS CLKE

TDATA TPOS LLOOP SCLK

TCODE TNEG RLOOP

CS

MODE LEN2 SDO

3

4

BPV RNEG LEN1 SDI

RDATA RPOS

RCLK RGND

XTALIN RV+

XTALOUT RRING

5

6

7

8

9

10

11

12 14 16 1813 15 17

PLCC

1

top

view

272

2628

25

24

23

22

21

20

19

LEN0 INT

AIS DPM RTIP

LOS MRING

TTIP MTIP

PCS

RCODE

TGND TRING

TV+

DS157PP3 19

Page 20

Power Supplies

RGND - Ground, Pin 22.

Power supply ground for all subcircuits except the transmit driver; typically 0 Volts.

RV+ - Power Supply, Pin 21.

Power supply for all subcircuits except the transmit driver; typically +5 Volts.

TGND - Ground, Transmit Driver, Pin 14.

Power supply ground for the transmit driver; typically 0 Volts.

TV+ - Power Supply, Transmit Driver, Pin 15.

Power supply for the transmit driver; typically +5 Volts. TV+ must not exceed RV+ by more than

0.3 V.

Oscillator

XTALIN, XTALOUT - Crystal Connections, Pins 9 and 10.

A 6.176 MHz (T1 operation) or 8.192 MHz (E1 operation) crystal should be connected across

these pins. Overdriving the oscillator with an external clock is not supported.

CS61305A

Control

ACLKI - Alternate External Clock Input, Pin 1.

A 1.544 MHz or 2.048 MHz clock signal may be input on ACLKI to calibrate the clock recovery

circuit and control the transmit clock during TAOS. If a clock is not provided on ACLKI, this

input must be grounded, and the oscillator in the jitter attenuator is used to calibrate the clock

recovery circuit and TAOS is not available. ACLKI may not be provided by RCLK.

CLKE - Clock Edge, Pin 28. (Host Mode)

Setting CLKE to logic 1 causes RPOS and RNEG to be valid on the falling edge of RCLK, and

SDO to be valid on the rising edge of SCLK. Conversely, setting CLKE to logic 0 causes RPOS

and RNEG to be valid on the rising edge of RCLK, and SDO to be valid on the falling edge of

SCLK.

CS - Chip Select, Pin 26. (Host Mode)

This pin must transition from high to low to read or write the serial port.

INT - Receive Alarm Interrupt, Pin 23. (Host Mode)

Goes low when LOS or DPM change state to flag the host processor. INT is cleared by writing

"clear LOS" or "clear DPM" t o the regi ster. INT is an open drain output and should be tied to the

power supply through a resistor (47k - 100k).

20 DS157PP3

Page 21

CS61305A

LEN0, LEN1, LEN2 - Line Length Selection, Pins 23, 24 and 25. (Hardware and Extended

Hardware Modes)

Determines the shape and amplitude of the transmitted pulse to accommodate several cable types

and lengths. See Table 3 for information on line length selection. These pins also control the

receiver slicing level.

LLOOP - Local Loopback, Pin 27. (Hardware and Extended Hardware Modes)

Setting LLOOP to a logic 1 routes the transmit clock and data through to the receive clock and

data pins. TPOS/TNEG (or TDATA) are still transmitted unless overridden by a TAOS request.

Inputs on RTIP and RRING are ignored during LLOOP. The jitter attenuator is bypassed.

Simultaneously taking RLOOP and LLOOP high for at least 200 ns initiates a device reset.

MODE - Mode Select, Pin 5.

Driving the MODE pin high places the line interface in the Host Mode. In the Host mode, a serial

control port is used to control the line interface and determine its status. Grounding the MODE

pin places the line interface in the Hardware Mode, where configuration and status are controlled

by discrete pins. Floating the MODE pin or driving it to +2.5 V places the device in Extended

Hardware Mode, where configuration and status are controlled by discrete pins. When floating

MODE, there should be no external load on the pin. MODE defines the status of 13 pins (see

Table 2).

PCS - Parallel Chip Select, Pin 18. (Extended Hardware Mode)

Setting PCS low causes the line interface t o accept the TCODE, RCODE, LEN0, LEN1, LEN2,

RLOOP, LLOOP and TAOS inputs.

RCODE - Receiver Decoder Select, Pin 17. (Extended Hardware Mode)

Setting RCODE low enables B8ZS or HDB3 zero substitution in the receiver decoder. Setting

RCODE high enables the AMI receiver decoder (see T able 8).

RLOOP - Remote Loopback, Pin 26. (Hardware and Extended Hardware Modes)

Setting RLOOP to a logic 1 causes the recovered clock and data to be sent through the jitter

attenuator and through the driver back to the line. The recovered signal is also sent to RCLK and

RPOS/RNEG (or RDATA). Any T AOS reques t is ignored.

Simultaneously taking RLOOP and LLOOP high for at least 200 ns initiates a device reset.

SCLK - Serial Clock, Pin 27. (Host Mode)

Clock used to read or write the serial port registers. SCLK can be either high or low when the line

interface is selected using the CS pin.

SDI - Serial Data Input, Pin 24. (Host Mode)

Input for the input data register. Sampled on the rising edge of SCLK.

DS157PP3 21

Page 22

CS61305A

SDO - Serial Data Output, Pin 25. (Host Mode)

Status and control output from the output data register. If CLKE is high SDO is valid on the

rising edge of SCLK. If CLKE is low SDO is valid on the falling edge of SCLK. This pin goes to

a high-impedance state when the serial port is being written, or if CS is high, or after bit D7 is

output.

TAOS - Transmit All Ones Select, Pin 28. (Hardware and Extended Hardware Modes)

Setting TAOS to a logic 1 causes continuous ones to be transmitted at the frequency determined

by ACLKI.

TCODE - Transmi tter Encoder Select, Pin 4. (Extended Hardware Mode)

Setting TCOD E low en ables B8ZS or HDB3 zero substi tution in the transmitter en coder. Setting

TCODE high enables the AMI transmitter encoder .

Data

RCLK - Recovered Clock, Pin 8.

The receiver recovered clock is output on this pin.

RDATA - Receive Data - Pin 7. (Extended Hardware Mode)

Data recovered from the RTIP and RRING inputs is output in NRZ format at this pin, after being

decoded by the line code decoder. RDATA is stable and valid on the falling edge of RCLK.

RPOS, RNEG - Receive Positive Data, Receive Negative Data, Pins 6 and 7. (Hardware and

Host Modes)

The receiver recovered NRZ digital data from RTIP and RRING is output on these pins. A

positive pulse (with respect to ground) received on the RTIP pin generates a logic 1 on RPOS,

and a positive pulse (with respect to ground) received on the RRING pin generates a logic 1 on

RNEG. In the Hardware Mode, RPOS and RNEG are stable and valid on the rising edge of

RCLK. In the Host Mode, CLKE determines the clock edge for which RPOS and RNEG are

stable and valid (see Table 5).

RTIP, RRING - Receive Tip, Receive Ring, Pins 19 and 20.

The AMI receive signal is input on these pins. A center-tapped, center-grounded, 2:1, step-up

transformer is required on these inputs, as shown in Figure A1 of the Applications section. Clock

and data are recovered and output on RCLK and RPOS/RNEG or RDATA.

TCLK - Transmit Clock, Pin 2.

The1.544 MHz (T1 operation) or 2.048 MHz (E1 operation) transmit clock is input on this pin.

TPOS/TNEG or TDATA are sampled on the falling edge of TCLK.

TDATA - Transmit Data, Pin 3. (Extended Hardware Mode)

Data to be transmitted by the TTIP and TRING outputs is input in NRZ format at this pin, after

being encoded by the line code encoder. TDATA is sampled on the falling edge of TCLK.

22 DS157PP3

Page 23

CS61305A

TPOS, TNEG - Transmit Positive Data, Transmit Negative Data, Pins 3 and 4. (Hardware and

Host Modes)

The transmit NRZ digital data to TTIP and TRING is input on these pins. A logic 1 on TPOS

causes a positive pulse (with respect to ground) to be transmitted on the TTIP pin, and a logic 1

on TNEG causes a negative pulse (with respect to ground) to be transmitted on the TRING pin.

TPOS and TNEG are sampled on the falling edge of TCLK.

TTIP, TRING - Transmit Tip, Transmit Ring, Pins 13 and 16.

The AMI signal is driven to the line through these pins. This output is designed to drive a 75 Ω

load. A transformer is required as shown in Figure A1 of the Applications section. Clock and data

are sourced on TCLK and TPOS/ TNEG or TDATA.

Status

AIS - Alarm Indication Signal, Pin 11. (Extended Hardware Mode)

AIS goes high when unframed all-ones condition (blue alarm) is detected, using the detection

criteria of less than three zeros out of 2048 bit periods.

BPV- Bipolar Violation Strobe, Pin 6. (Extended Hardware Mode)

BPV strobes high when a bipolar violation is detect ed in the received signal. B8ZS (or HDB3)

zero substitutions are not flagged as bipolar violations if the B8ZS (or HDB3) decoder has been

enabled.

DPM - Driver Performance Monitor, Pin 11. (Hardware and Host Modes)

DPM goes high if no activity is detected on MTIP and MRING.

LOS - Loss of Signal, Pin 12.

LOS goes high when 175 consecutive zeros have been received. LOS returns low when 3 ones

are received within 32 bit periods containing no more than 15 consecutive zeros.

MTIP, MRING - Monitor Tip, Monitor Ring, Pins 17 and 18. (Hardware and Host Modes)

These pins are normally connected to TTIP and TRING and monitor the transmitter output. If the

INT pin in the Host mode is used, and the monitor is not used, writing a "1" to the "clear DPM"

bit will prevent an interrupt from the driver performance monitor.

DS157PP3 23

Page 24

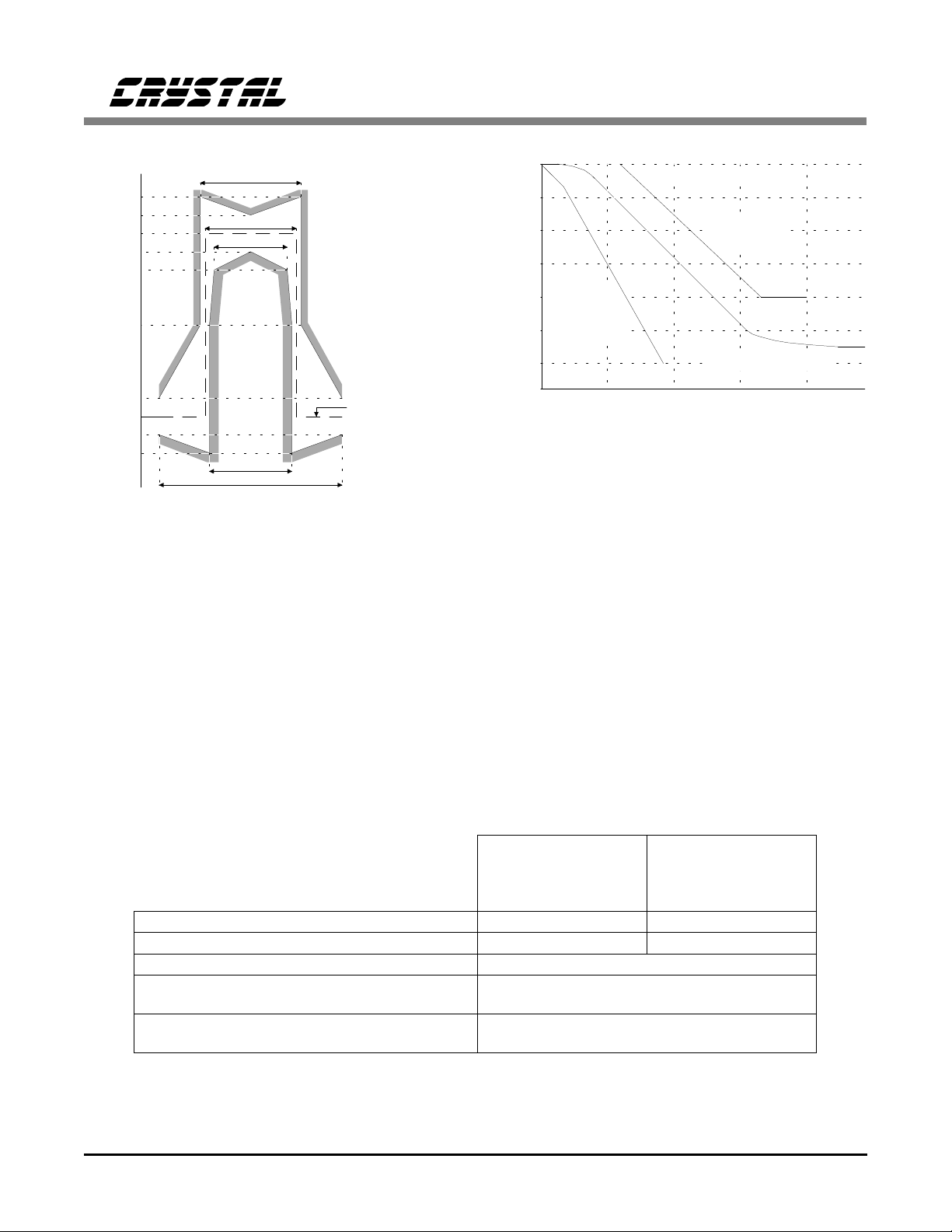

CS61305A

15

14

E1

28 pin

Plastic DIP

A

L

A1

B

∝∝

eA

SEATING

PLANE

B1

28

1

D

e1

NOTES:

1. POSITIONAL TOLERANCE OF LEADS SHALL BE WITHIN

0.25mm (0.010") AT MAXIMUM MATERIAL CONDITION, IN

RELATION TO SEATING PLANE AND EACH OTHER.

2. DIMENSION eA TO CENTER OF LEADS WHEN FORMED PARALLEL.

3. DIMENSION E1 DOES NOT INCLUDE MOLD FLASH.

28-pin PLCC

MILLIMETERS

DIM

MIN

3.94

A

0.51

A1

0.36

B

1.02

B1

0.20

C

36.45

D

E1

13.72

e1

2.41

eA

C

L

∝∝

15.24

3.18

0°

MAX

NOM

4.32

5.08

0.76

1.02

0.46

0.56

1.27

1.65

0.25

0.38

36.83

37.21

13.97

14.22 0.540

2.54

2.67 0.095

15.87 0.625

-

-

3.81

-

15°

INCHES

MIN MAX

NOM

0.170

0.030

0.018

0.050

0.010

1.450

0.550

0.100

-

-

-

0.200

0.040

0.022

0.065

0.015

1.465

0.560

0.105

0.150

15°

0.155

0.020

0.014

0.040

0.008

1.435

0.600

0.125

0°

28

E

E1

DIM

A1

D/E

D1

D

B

e

A1

D2/E2

D1/E1

D2/E2

A

MILLIMETERS INCHES

NOM

MAXMIN MAXMIN

A

B

e

4.45

4.574.20 0.1800.165

2.29 0.090

2.79

3.04 0.120

0.530.33 0.0210.013

0.41

12.32 12.57 0.485 0.495

12.45

11.43 11.58 0.450 0.456

11.51

9.91 10.92 0.390 0.430

10.41

1.19 1.35 0.047 0.053

1.27

NOM

0.175

0.110

0.016

0.490

0.453

0.410

0.050

24 DS157PP3

Page 25

APPLICATIONS

CS61305A

CS61305A

RTIP

RRING

TRING

TTIP

16

13

19

20

R1

R2

0.47 µF

1

3

5

R3

21

R4

65

2

2CT:1

T1

Figure A1. Line Interface Circuitry

Frequency

MHz

Crystal

XTL

CableΩR1 and R2ΩLEN2/1/0 T1 turns

ratio

1.544 (T1) CXT6176 100 200 0/1/1 - 1/1/1 1:1.15

1:2

1:2.3

2.048 (E1) CXT8192 120 240 0/0/0

0/0/0

0/0/1

0/0/1

75 150 0/0/0

0/0/0

0/0/1

0/0/1

1:1.26

1:2

1:1

1:2

1:1

1:2

1:1

1:2

RECEIVE

LINE

6

TRANSMIT

LINE

R3 and R4ΩTypical TX

0

9.4

9.4

0

8.7

0

15

0

9.4

10

14.3

Return Loss

(dB)

0.5

20

28

0.5

12

0.5

30

0.5

24

5

12

Note: Refer to Table A3 for specific transformer recommendations.

Table A1. External Component Values

Line Interface

Mode. Figure A4 illustrates a 75 Ω E1 interface

in the Extended Hardware Mode.

Figure A1 illustrates the external components for

the line interface circuitry and Table A1 shows

the specific components for each application.

Figures A2-A4 show typical T1 and E1 line interface application circuits. Figure A2 illustrates a

The receiver transformer has a grounded center

tap on the IC side. Resistors between the RTIP

and RRING pins to ground provide the termination for the receive line.

T1 interface in the Host Mode. Figure A3 illustrates a 120 Ω E1 interface in the Hardware

DS157PP3 25

Page 26

Control

&

Monitor

Frame

Format

Encoder/

Decoder

XTL

+

RV+

68

RGND

28

1

12

11

5

7

6

8

3

4

2

9

10

F

µ

CLKE

ACLKI

LOS

DPM

MODE

RPOS

RNEG

RCLK

TPOS

TNEG

TCLK

XTALIN

XTALOUT

+5V

0.1 µF

21 15

RV+ TV+

CS61305A

IN

HOST

MODE

RGND TGND

22 14

+

1.0 µF

SCLK

CS

INT

SDI

SDO

RTIP

RRING

MTIP

MRING

TRING

TTIP

TGND

27

26

23

24

25

19

20

17

18

16

13

+5V

100 k

0.47

200

200

Ω

Serial

Port

F

µ

CS61305A

P

µ

1

2CT:1

1:1.15

2

RECEIVE

LINE

6

1

TRANSMIT

LINE

5

Ω

3

Ω

5

PE-65351

2

6

PE-65388

Figure A2. T1 Host Mode Configuration

Figures A2-A4 show a 0.47 µF capacitor in series

with the transmit transformer primary. This capacitor is needed to prevent any output stage

imbalance from resulting in a DC current through

the transformer primary. This current might saturate the transformer producing an output offset

level shift.

Transformers

Recommended transmitter and receiver transformer specifications are shown in Table A2. The

transformers in Table A3 are recommended for

use with the CS61305A. Refer to the "Telecom

Transformer Selection Guide" for detailed schematics which show how to connect the line

interface IC with a particular transformer.

Selecting an Oscillator Crystal

Specific crystal parameters are required for

proper operation of the jitter attenuator. It is recommended that the Crystal Semiconductor

CXT6176 crystal be used for T1 applications and

the CXT8192 crystal be used for E1 applications.

Line Protection

Secondary protection components can be added

to provide lightning surge and AC power-cross

immunity. Refer to the Application Note "Secondary Line Protection for T1 and E1 Line Cards"

for detailed information on the different electrical

safety standards and specific application circuit

recommendations.

26 DS157PP3

Page 27

CS61305A

+5V

+

68 µF

0.1 µF

+

1.0 µF

Control

&

Monitor

Frame

Format

Encoder/

Decoder

XTL

RGND

28

1

26

27

12

11

5

7

6

8

3

4

2

9

10

TAOS

ACLKI

RLOOP

LLOOP

LOS

DPM

MODE

RPOS

RNEG

RCLK

TPOS

TNEG

TCLK

XTALIN

XTALOUT

21 15

RV+ TV+

CS61305A

IN

HARDWARE

MODE

RGND TGND

22 14

TGND

LEN0

LEN1

LEN2

RTIP

RRING

MTIP

MRING

TRING

TTIP

23

24

25

19

20

17

18

16

13

0.47

Line

Length

Setting

Ω

240

Ω

240

µ

F

1

3

5

2CT:1

PE-65351

2

6

1:1.26

PE-65389

Figure A3. 120 Ω, E1 Hardware Mode Configuration

+5V

+

68 µF

0.1 µF

+

1.0 µF

2

RECEIVE

LINE

6

1

TRANSMIT

LINE

5

Control

&

Moni tor

Frame

Format

Encoder/

Decoder

XTL

RGND

17

18

6

28

1

26

27

12

11

5

4

7

8

3

2

9

10

RCODE

PCS

BPV

TAOS

ACLKI

RLOOP

LLOOP

LOS

AIS

MODE

TCODE

RDATA

RCLK

TDATA

TCLK

XTALIN

XTALOUT

21 15

RV+ TV+

CS61305A

IN

EXTENDED

HARDWAR E

MODE

RGND TGND

22 14

TGND

LEN0

LEN1

LEN2

RTIP

RRING

TRING

TTIP

23

24

25

19

20

16

13

0.47

Figure A4. 75 Ω, E1 Extended Hardware Mode Configuration

Line

Length

Setting

150

Ω

Ω

150

µ

F

1

3

5

2CT:1

PE-65351

2

6

1:1

PE-65389

2

RECEIVE

LINE

6

3

TRANSMIT

LINE

5

DS157PP3 27

Page 28

Parameter Receiver Transmitter

Turns Ratio

1:2 CT ± 5% 1:1 ± 1.5 % for 75 Ω E1

1:1.15 ± 5 % for 100 Ω T1

1:1.26 ± 1.5 % for 120 Ω E1

Primary Inductance

Primary Leakage Inductance

Secondary Leakage Inductance

600 µH min. @ 772 kHz

1.3 µH max. @ 772 kHz 0.3 µH max. @ 772 kHz

0.4 µH max. @ 772 kHz 0.4 µH max. @ 772 kHz

1.5 mH min. @ 772 kHz

Interwinding Capacitance 23 pF max. 18 pF max.

ET-constant

Table A2. Transformer Specifications

16 V-µs min. for T1

12 V-µs min. for E1

16 V-µs min. for T1

12 V-µs min. for E1

Interfacing The CS61305A With the

CS62180B T1 Transceiver

CS61305A

To interface with the CS62180B, connect the devices as shown in Figure A5. In this case, the line

interface and CS62180B are in Host mode controlled by a microprocessor serial interface. If the

line interface is used in Hardware mode, then the

line interface RCLK output must be inverted before being input to the CS62180B. If the

CS61305A is used in Extended Hardware Mode,

the RCLK output does not have to be inverted

before being input to the CS62180B.

TO HOST CONTROLLER

1.544 MHz

SCLK

SDO

SDI

CS

CS62180B

TCLK

TPOS

TNEG

RNEG

RPOS

RCLK

CLOCK

SIGNAL

ACLK

TCLK

TPOS

TNEG

RNEG

RPOS

RCLK

SCLK

CLKE

MODE

CS61305A

SDO

SDI

INT

CS

Figure A5. Interfacing the CS61305 A with a

CS62180B (Ho st Mode)

V+

100k

V+22k

28 DS157PP3

Page 29

CS61305A

Application Turns

Ratio(s)

RX:

1:2CT Pulse Engineering PE-65351 1.5 kV through-hole, single

T1 & E1

TX:

1:1.15 Pulse Engineering PE-65388 1.5 kV through-hole, single

T1

TX:

1:1.26

E1 (75 & 120 Ω)

RX &TX:

T1

RX &TX:

E1 (75 & 120 Ω)

RX &TX:

T1

RX &TX:

E1 (75 & 120 Ω)

RX :

1:2CT

1:1.15

1:2CT

1:1.26

1:2CT

1:1.15

1:2CT

1:1.26

1:2CT Pulse Engineering PE-65835 3 kV through-hole, single

T1 & E1

TX:

1:1.26

E1 (75 & 120 Ω)

1:1

1:1

1:1

1:1

Manufacturer Part Number Package Type

Schott 67129300

Bel Fuse 0553-0013-HC

Schott 67129310

Bel Fuse 0553-0013-RC

Pulse Engineering PE-65389 1.5 kV through-hole, single

Schott 67129320

Bel Fuse 0553-0013-SC

Pulse Engineering PE-65565 1.5 kV through-hole, dual

Bel Fuse 0553-0013-7J

Pulse Engineering PE-65566 1.5 kV through-hole, dual

Bel Fuse 0553-0013-8J

Pulse Engineering PE-65765 1.5 kVsurface-mount, dual

Bel Fuse S553-0013-06

Pulse Engineering PE-65766 1.5 kV surface-mount, dual

Bel Fuse S553-0013-07

EN60950, EN41003 approved

Pulse Engineering PE-65839 3 kV through-hole, single

EN60950, EN41003 approved

Table A3. Recommended Transformers

DS157PP3 29

Page 30

• Notes •

Page 31

CDB61534, CDB61535, CDB61535A, CDB6158,

CDB6158A, CDB61574, CDB61574A, CDB61575,

CDB61577, CDB615304A, & CDB61305A

Line Interface Evaluation Board

Features

Socketed Line Interface Device

••

All Required Components for Complete

••

Line Interface Evaluation

Configuration by DIP Switch or Serial

••

Interface

LED Status Indicators for Alarm

••

Conditions

Support for Host, Hardware, and

••

Extended Hardware Modes

Mode Select

Circuit

General Description

The evaluation board includes a socketed line interface

device and all support components necessary for

evaluation. The board is powered by an external 5 Volt

supply.

The board may be configured for 100 Ω twisted-pair

T1, 75 Ω coax E1, or 120 Ω twisted-pair E1 operation.

Binding posts are provided for line connections. Several BNC connectors are available to provide system

clocks and data I/O. Two LED indicators monitor device alarm conditions. The board supports all line

interface operating modes.

ORDERING INFORMATION:

CDB61534, CDB61535. CDB61535A,

CDB6158, CDB6158A, CDB61574,

CDB61574A, CDB61575, CDB61577,

CDB61304A, CDB61305A

+5V 0V

Serial Interface

Control Circuit

Control Circuit

ACLKI

TCLK

TPOS

(TDATA)

TNEG

(TCODE)

RCLK

RPOS

(RDATA)

RNEG

(BPV)

Reset

Circuit

Hardware

LED Status

Indicators

CS61534,

CS61535,

CS61535A,

CS6158,

CS6158A,

CS61574,

CS61574A,

CS61575,

CS61577,

CS61304A

or

CS61305A

TTIP

TRING

RTIP

RRING

XTL

Crystal Semiconductor Corporation

P.O. Box 17847, Austin, TX 78760

(512) 445-7222 FAX: (512) 445-7581

SEP ’95

DS40DB3

31

Page 32

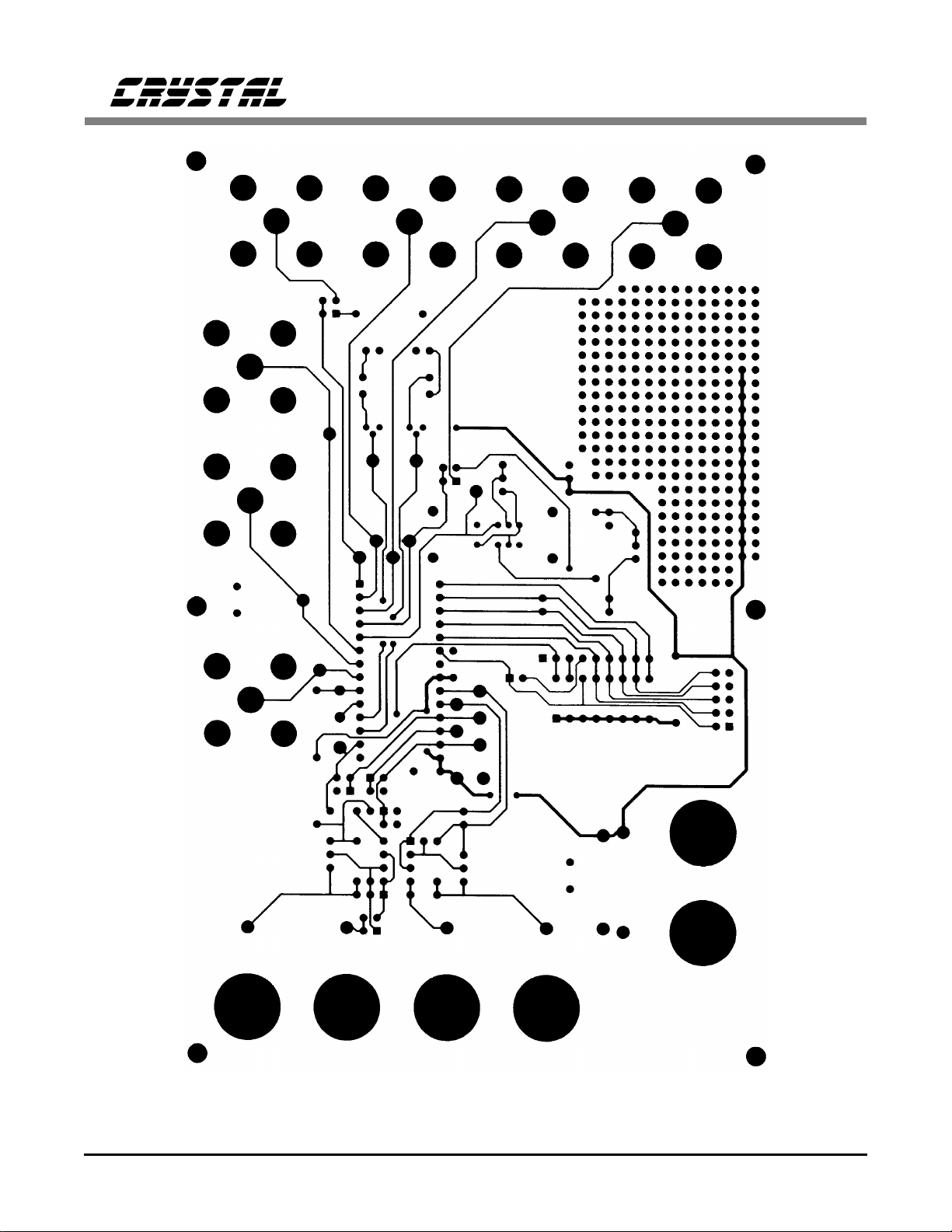

LINE INTERFACE EVALUATION BOARD

POWER SUPPLY

As shown on the evaluation board schematic in

Figure 1, power is supplied to the evaluation

board from an external +5 Volt supply connected

to the two binding posts labeled +5V and GND.

Transient suppressor D10 protects the components on the board from over-voltage damage and

reversed supply connections. The recommended

power supply decoupling is provided by C1, C2

and C3. Ceramic capacitor C1 and electrolyt ic capacitor C2 are used to decouple RV+ to RGND.

Capacitor C3 decouples TV+ to TGND. The TV+

and RV+ power supply traces are connected at the

device socket U1. A ground plane on the component side of the evaluation board insures optimum

performance.

BOARD CONFIGURATION

Pins on line interface device U1 with more than

one pin name have different functions depending

on the operating mode selected. Pin names not

enclosed in parenthesis or square brackets describe the Hardware mode pin function. Pin

names enclosed in parenthesis describe the Extended Hardware mode pin function. Pin names

enclosed in square brackets describe the Host

mode pin function.

Table 1 explains how to configure the evaluation

board jumpers depending on the device installed

and the desired operating mode. Mode selection

is accomplished with slide switch SW1 and jumpers JP2, JP6, and JP7. The CS61535A,

CS61574A, CS61575, CS61577, CS61304A, and

CS61305A support the Hardware, Extended

Hardware, and Host operating modes. The

CS61534, CS61535, and CS61574 support the

Hardware and Host operating modes. The

CS6158 and CS6158A only support the Hardware

operating mode.

Hardware Mode

In the Hardware operating mode, the line interface is configured using DIP switch S2. The digital control inputs to the device selected by S2 include: transmit all ones (TAOS), local loopback

(LLOOP), remote loopback (RLOOP), and transmit line length selection (LEN2,LEN1,LEN0).

Closing a DIP switch on S2 towards the label sets

the device control pin of the same name to logic 1

(+5 Volts). Note that S2 switch positions TCODE