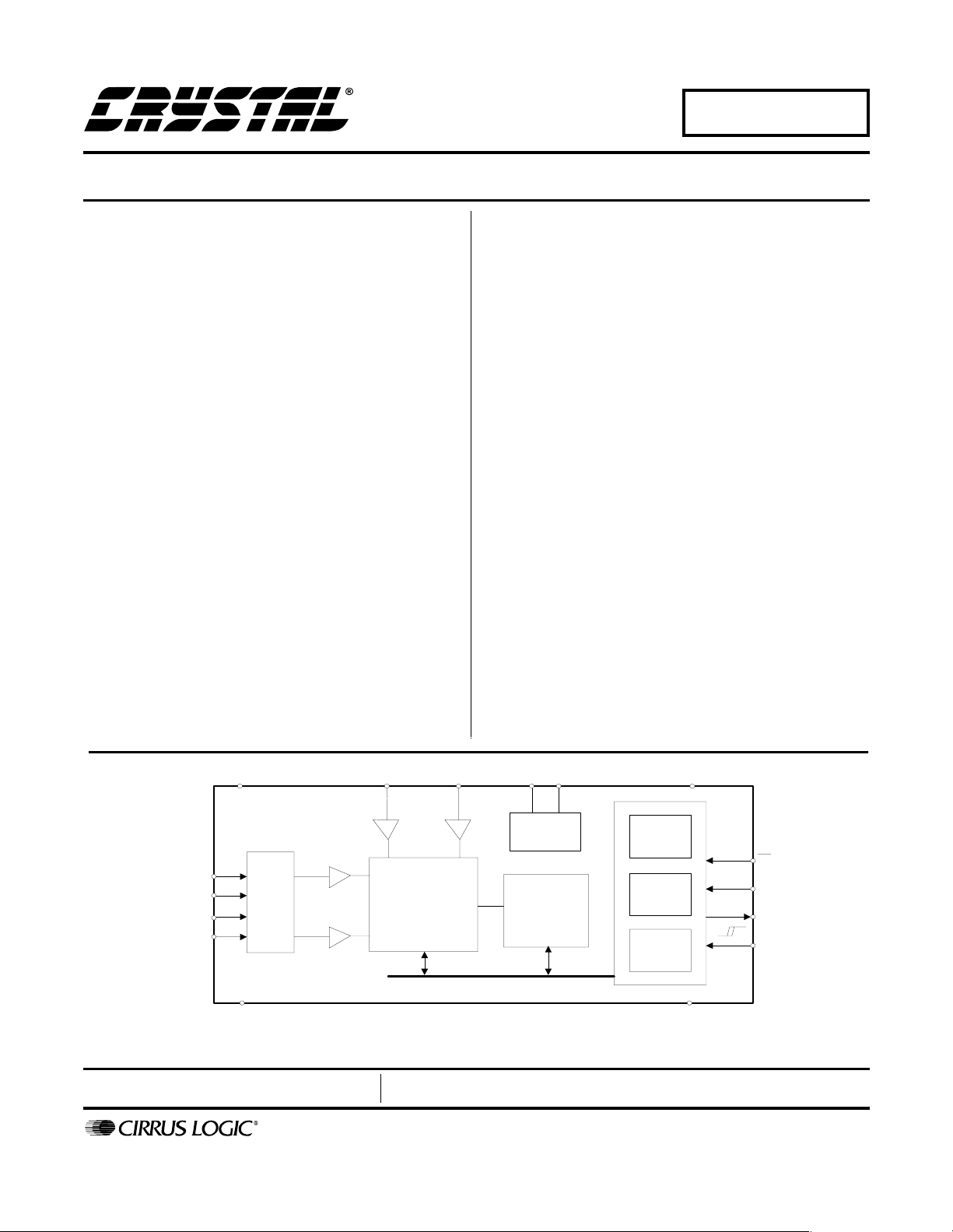

CS5541

Low-Power, Low-Voltage, 24-Bit ∆Σ ADC

Features

l ∆Σ Analog-to-Digital Converter

- Linearity Error: 0.0015% FS

- RMS Noise: 2 µV

l Two Channel Differential MUX

l Buffered, Fully Differential Analog and

Voltage Reference Inputs

l Scalable V

l Absolute Accuracy via Calibration

l Flexible Digital Filters

- Single Conversion Settling at 13.4 SPS or 4

Conversion Settling at 53.7 SPS with

Simultaneous 50/60 Hz Rejection

- Single Conversion Settling at 64.8 SPS or Four

Conversion Settling at 260 SPS with 16-bit

Resolution

l Simple 3-Wire Serial Interface

- SPITM and MicrowireTM Compatible

- Schmitt Trigger on Serial Clock (SCLK)

l Low Power

- Single +3.0 V Supply

- 330 µA Operating; 10 µA Sleep Current

Input: 0.1 V to Analog Supply

REF

Description

The CS5541 is a 24-bit low-power and low-voltage ∆Σ

analog-to-digital converter (ADC). It is optimized to convert analog signals in DC measurement applications,

such as temperature and pressure measurement, and

various portable devices where low-power consumption

is required.

To accommodate these applications, the ADC integrates

analog input and reference buffers for increased input

impedance and includes a two-channel multiplexer. Absolute accuracy is achieved via one-time or continuous

calibration modes. The device draws less than 330µA.

The CS5541 includes two digital filters. The first filter,

which achieves simultaneous rejection of 50/60 Hz, provides single conversion settling at 13.4 SPS throughput

or four conversion settling at 53.7 SPS throughput. The

second filter, which achieves 16-bit performance, provides single conversion settling at 64.8 SPS throughput

or four conversion settling at 260 SPS throughput.

Low-power, low-voltage operation and an easy-to-configure serial interface reduces time-to-market and makes

the CS5541 an ideal device for low-cost, power-conscious DC measurement applications.

ORDERING INFORMATION

CS5541-BS-40 ºC - +85 ºC 16-Pin SSOP

VA+

AIN1+

AIN1-

AIN2+

AIN2-

VA-

Input

Mux

X1

X1

Preliminary Product Information

P.O. Box 17847, Austin, Texas 78760

(512) 445 7222 FAX: (512) 445 7581

http://www.cirrus.com

VREF+ VREF-

X1

Differential

4th Order

Modulator

This document contains information for a new product.

Cirrus Logic reserves the right to modify this product without notice.

X1

∆Σ

OSC1 OSC2

Clock

Generator

Digital

Filter

Copyright Cirrus Logic, Inc. 2000

(All Rights Reserved)

Serial

Interface

Calibration

Register

Output

Register

VD+

DGND

CS

SDI

SDO

SCLK

JUN ‘01

DS500PP1

1

TABLE OF CONTENTS

1. CHARACTERISTICS AND SPECIFICATIONS ........................................................................ 4

2. GENERAL DESCRIPTION ..................................................................................................... 10

2.1 Analog Input ..................................................................................................................... 10

2.1.1 Analog Input Model ............................................................................................. 10

2.2 Voltage Reference Input .................................................................................................. 11

2.2.1 Voltage Reference Input Model ........................................................................... 11

2.3 Power Supply Arrangements ........................................................................................... 12

2.4 Clock Generator ............................................................................................................... 12

2.5 Serial Port Interface ......................................................................................................... 12

2.6 Serial Port ........................................................................................................................ 13

2.7 Serial Port Initialization Sequence ................................................................................... 14

2.8 Command Register Quick Reference ............................................................................. 15

2.9 Performing Conversions/Calibrations .............................................................................. 16

2.9.1 Continuous Calibrations and Conversions (reduced output rate) ....................... 16

2.9.2 One Time Calibration followed by Continuous Conversions ............................... 17

2.9.3 Continuous Conversions with Default Calibration Coefficients ........................... 17

2.9.4 Continuous Conversions with Existing Calibration Coefficients .......................... 17

2.9.5 System Calibration .............................................................................................. 17

2.9.6 Reading Conversions .......................................................................................... 17

2.9.7 Output Coding ..................................................................................................... 18

2.9.8 Digital Filter ......................................................................................................... 18

2.10 Sleep and Standby Modes ............................................................................................. 20

2.11 Power-Up Sequence and Initialization ........................................................................... 20

2.12 PCB Layout .................................................................................................................... 20

3. PIN DESCRIPTIONS .............................................................................................................. 22

4. SPECIFICATION DEFINITIONS ............................................................................................. 24

CS5541

Contacting Cirrus Logic Support

For a complete listing of Direct Sales, Distributor, and Sales Representative contacts, visit the Cirrus Logic web site at:

http://www.cirrus.com/corporate/contacts/

SPI is a trademark of Motorola Inc.

Microwire is a trademark of National Semiconductor Corp.

Preliminary product information describes products which are in production, but for which full characterization data is not yet available. Advance product information describes products which are in development and subject to development changes. Cirrus Logic, Inc. has made best efforts to ensure that the information contained in this document is accurate and reliable. However, the information is subject to change without notice and is provided “AS IS” without warranty

of any kind (express or implied). No responsibility is assumed by Cirrus Logic, Inc. for the use of this information, nor for infringements of patents or other rights

of third parties. This document is the property of Cirrus Logic, Inc. and implies no license under patents, copyrights, trademarks, or trade secrets. No part of

this publication may be copied, reproduced, stored in a retrieval system, or transmitted, in any form or by any means (electronic, mechanical, photographic, or

otherwise) without the prior written consent of Cirrus Logic, Inc. Items from any Cirrus Logic website or disk may be printed for use by the user. However, no

part of the printout or electronic files may be copied, reproduced, stored in a retrieval system, or transmitted, in any form or by any means (electronic, mechanical, photographic, or otherwise) without the prior written consent of Cirrus Logic, Inc.Furthermore, no part of this publication may be used as a basis for manufacture or sale of any items without the prior written consent of Cirrus Logic, Inc. The names of products of Cirrus Logic, Inc. or other vendors and suppliers

appearing in this document may be trademarks or service marks of their respective owners which may be registered in some jurisdictions. A list of Cirrus Logic,

Inc. trademarks and service marks can be found at http://www.cirrus.com.

2 DS500PP1

LIST OF FIGURES

Figure 1. Continuous Running SCLK Timing (Not to Scale) ................................ 9

Figure 2. SDI Write Timing (Not to Scale) ............................................................ 9

Figure 3. SDO Read Timing (Not to Scale) .......................................................... 9

Figure 4. Multiplexer Configuration. ................................................................... 10

Figure 5. Input model for AIN+ and AIN- pins. ................................................... 10

Figure 6. Resolution vs. Voltage Reference ....................................................... 11

Figure 7. Resolution vs. Voltage Reference ....................................................... 11

Figure 8. Input model for VREF+ and VREF- pins. ............................................ 11

Figure 9. CS5541 Configured with +3.0 V Analog Supply. ................................ 12

Figure 10. CS5541 Register Diagram. ............................................................... 13

Figure 11. Command and Data Word Timing. ................................................... 13

Figure 12. Self Calibration of Offset. .................................................................. 16

Figure 13. Self Calibration of Gain. .................................................................... 16

Figure 14. Digital Filter 1 Response ................................................................... 19

Figure 15. Filter 2 Response (MCLK = 32.768 kHz) .......................................... 19

LIST OF TABLES

Table 1. Filter Output Word Rates ................................................................................................ 14

Table 2. Output Conversion Data Register Description (24 bits + flags) ...................................... 18

Table 3. CS5541 24-Bit Output Coding......................................................................................... 19

CS5541

DS500PP1 3

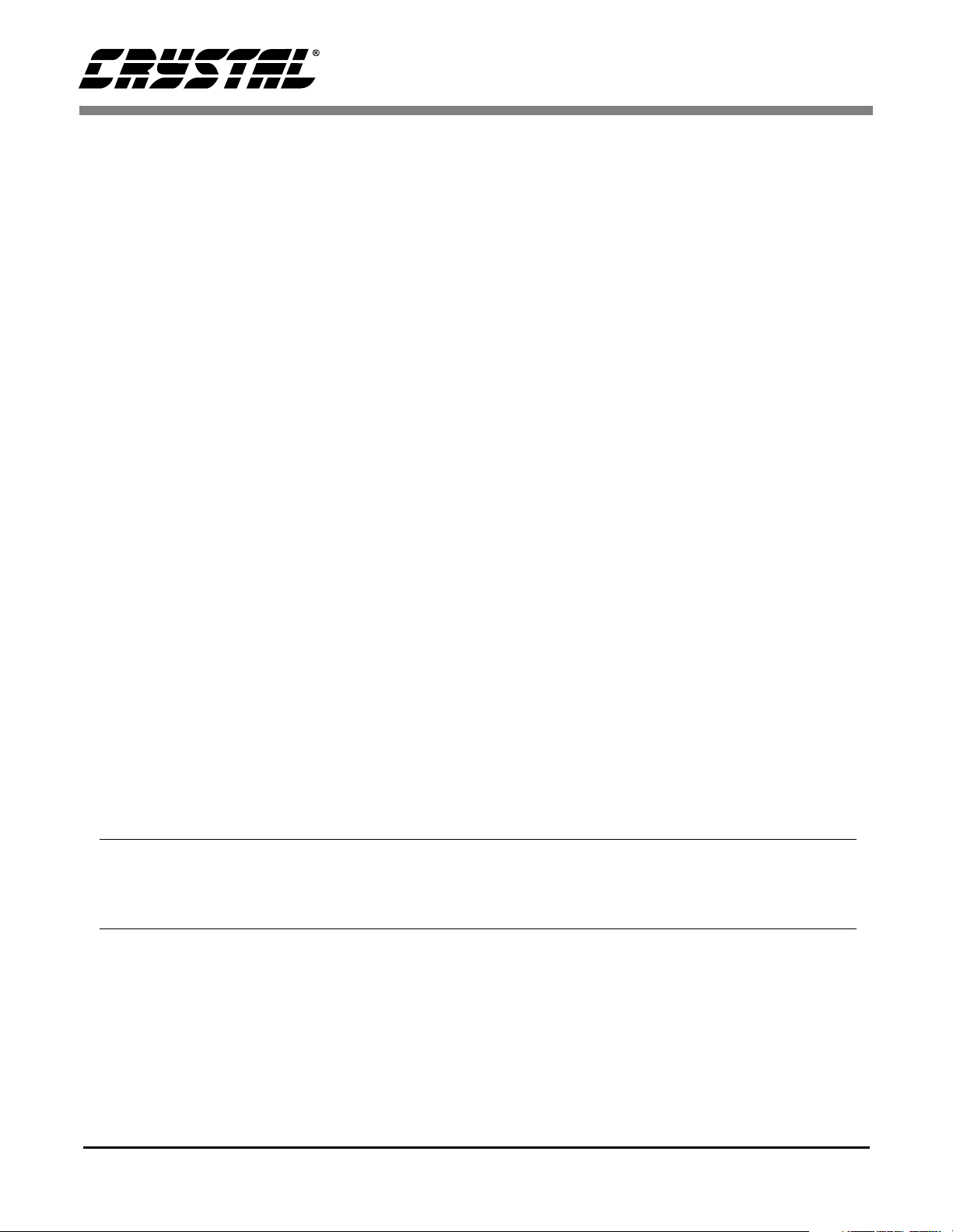

1. CHARACTERISTICS AND SPECIFICATIONS

CS5541

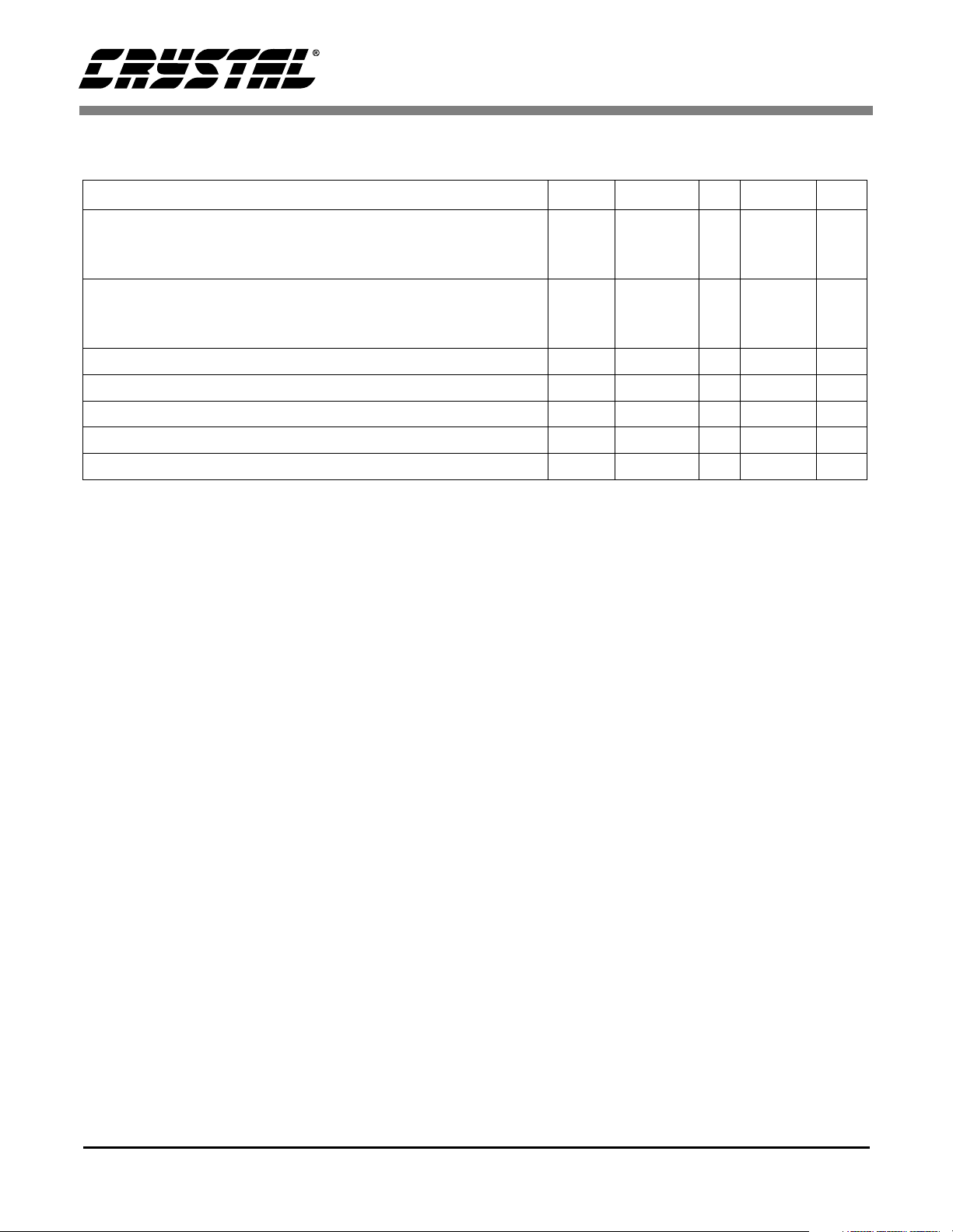

ANALOG CHARACTERISTICS (T

= 0 V, VREF+ = 2.5 V, VREF- = 0 V, MCLK = 32.768 kHz, OWR (Output Word Rate) = 53.7 SPS, Bipolar Mode,

Input Range = ±2.5 V Differential, Vcm=1.25 V.) (See Notes 1 and 2.)

Parameter Min Typ Max Units

Accuracy

Linearity Error - ±0.0015 ±0.003 %FS

No Missing Codes 24 - - Bits

Bipolar Offset (Note 3) - ±16 TBD LSB

Unipolar Offset (Note 3) - ±32 TBD LSB

Offset Drift (Notes 3 and 4) - 20 - nV/°C

Bipolar Full Scale Error - ±8 ±31 ppm

Unipolar Full Scale Error - ±16 ±62 ppm

Full Scale Drift (Note 4) - 1 - ppm/°C

Noise

(Notes 5, 6, and 7)

Filter Type Output Word Rate (SPS) -3 dB Filter Frequency (Hz) RMS Noise (µV)

Single Conversion Settling with

50/60 Hz Rejection

Four Conversion Settling with

50/60 Hz Rejection

Fast Filter with

Single Conversion Settling

Fast Filter with

Four Conversion Settling

= 25 °C; VA+ = +3 V ±5%, VA- = 0 V, VD+ = +3.0 V ±5%, DGND

A

13.4 11.96 2

53.7 11.96 2

64.8 56.91 35

260 56.91 35

24

24

Notes: 1. Applies after a one-time self-calibration at any temperature within -40 °C ~ +85 °C.

2. Specifications guaranteed by design, characterization, and/or test.

3. Specification applies to the device only and does not include any effects by external parasitic

thermocouples.

4. Drift over specified temperature range after calibration at power-up at 25 °C.

5. Wideband noise aliased into the baseband. Referred to the input. Typical values shown for 25 °C.

6. For peak-to-peak noise multiply by 6.6 for all ranges and output rates.

7. RMS noise numbers assume continuous calibration mode is not used. In continuous calibration mode

the noise increases by a factor of two.

* Specifications are subject to change without notice.

4 DS500PP1

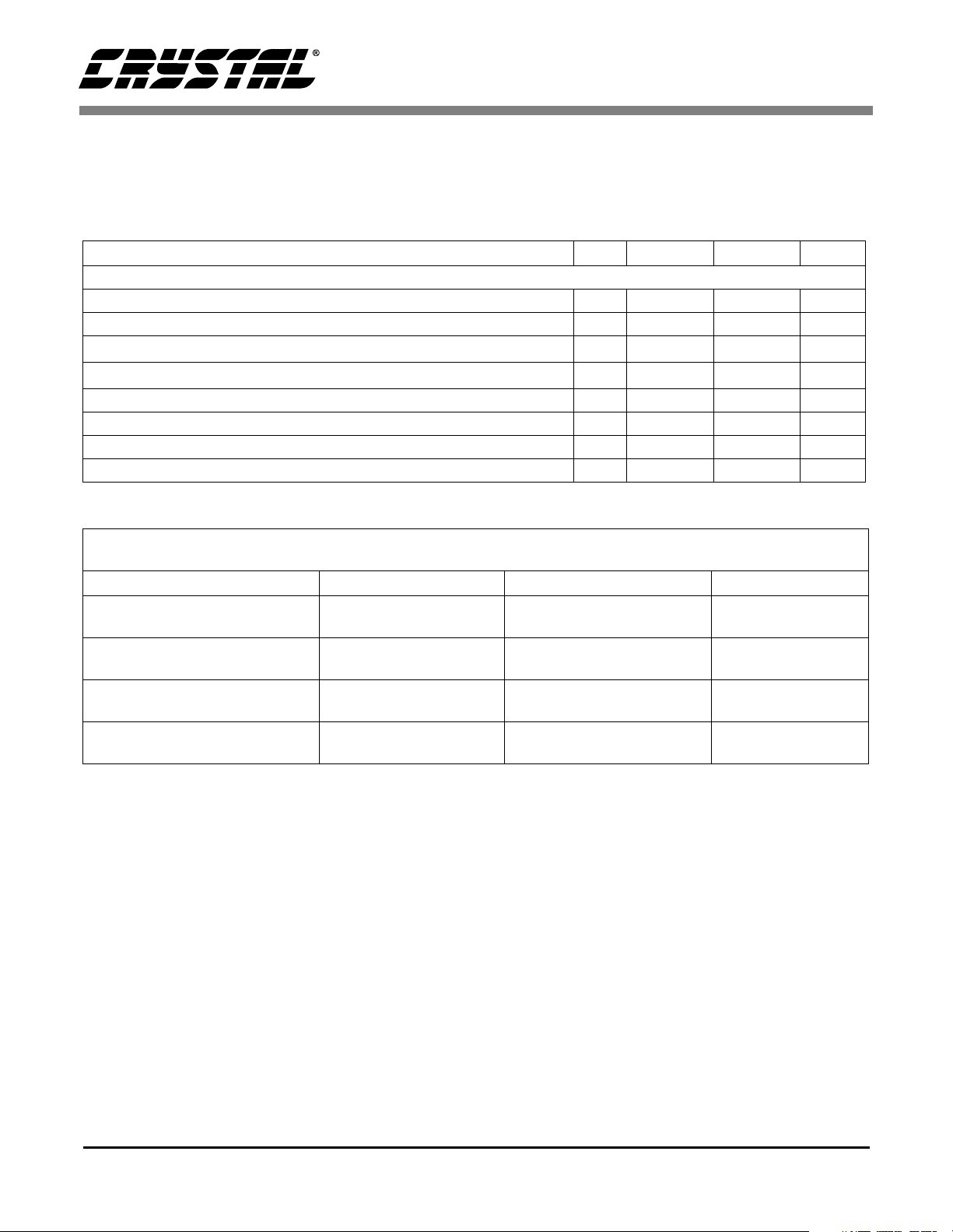

CS5541

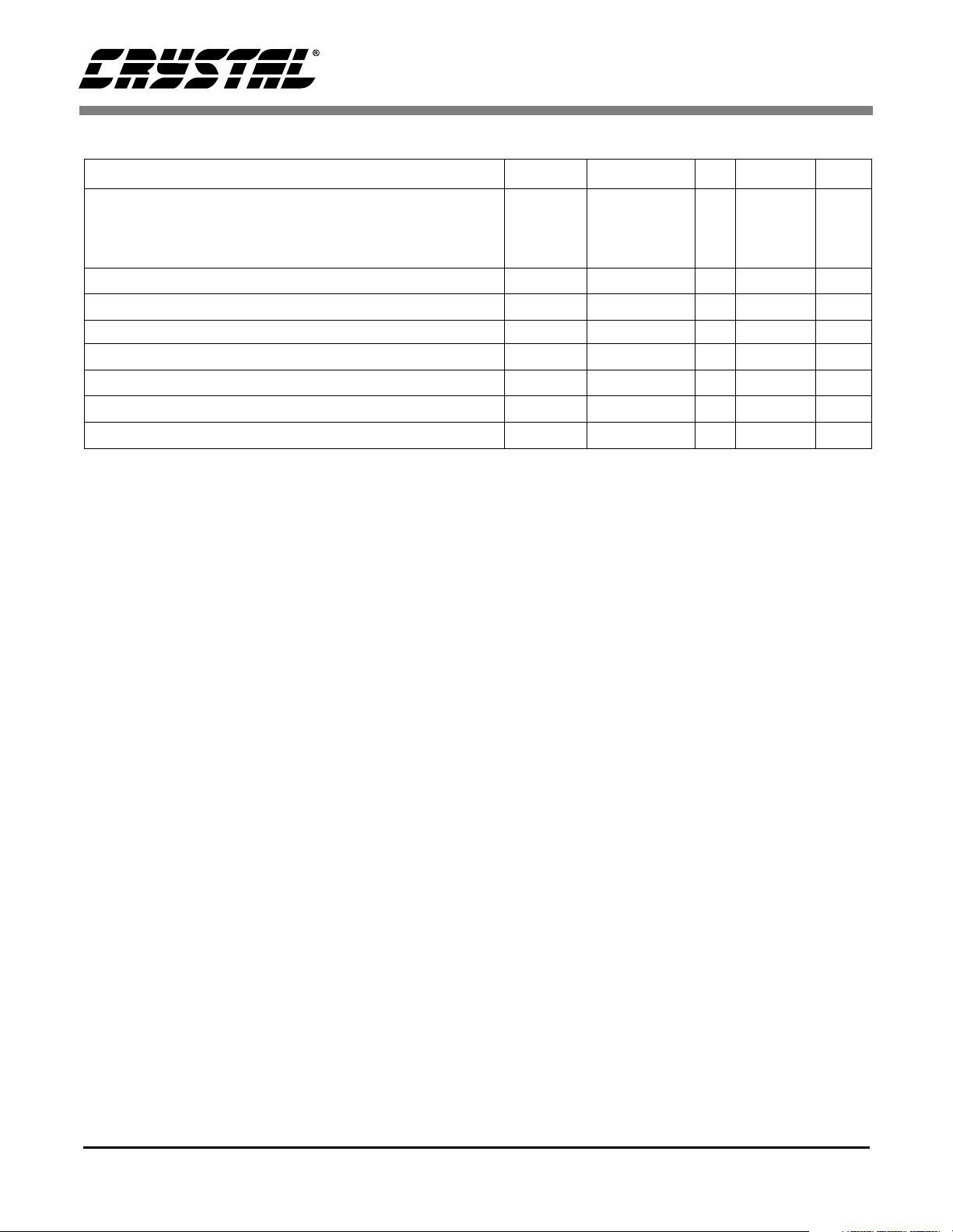

ANALOG CHARACTERISTICS (Continued)

Parameter Min Typ Max Units

Analog Inputs

Common Mode + Signal on AIN+ or AIN- (Bipolar/Unipolar Mode)

Single Supply

Dual Supply

CVF Current on AIN+, AIN- (Note 8) - 12 - nA

Input Leakage for MUX when off - 10 - pA

Common Mode Rejection dc

50, 60Hz

Input Capacitance - 8 - pF

Voltage Reference Inputs

Range (VREF+) - (VREF-) (Note 10) 0.1 2.5 (VA+) -

CVF Current on VREF+ and VREF- (Note 9) - 20 - nA

Common Mode Rejection dc

50, 60 Hz

Input Capacitance - 12 - pF

Dynamic Characteristics

Modulator Sampling Frequency - MCLK/2 - Hz

Filter Settling to 1/2 LSB (Full Scale Step) (Note 11)

13.4 SPS OWR

53.7 SPS OWR

64.8 SPS OWR

260 SPS OWR

Power Supplies

DC Power Supply Currents (Normal Mode)

I

A+

I

D+

Power Consumption Normal Mode (Note 12)

Standby Mode

Sleep Mode

Power Supply Rejection dc Positive Supplies

dc Negative Supply

0.0

VA-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

120

120

120

120

1/OWR

4/OWR

1/OWR

4/OWR

225

25

750

75

30

80

80

VA+

VA+

-

-

(VA-)

-

-

-

-

-

-

280

36

1000

-

-

-

-

dB

dB

dB

dB

µA

µA

µW

µW

µW

dB

dB

V

V

V

s

s

s

s

Notes: 8. See Section

9. See Section

10. VREF must be less than or equal to supply voltages.

11. The CS5541 includes two digital filters. The first filter, which achieves simultaneous rejection of 50/60

Hz, provides single conversion settling at 13.4 SPS throughput or four conversion settling at 53.7 SPS

throughput. The second filter, which achieves 16-bit performance, provides single conversion settling at

64.8 SPS throughput or four conversion settling at 260 SPS throughput.

12. All outputs unloaded. All digital inputs at CMOS levels.

DS500PP1 5

2.1, “Analog Input”.

2.2, “Voltage Reference Input”.

CS5541

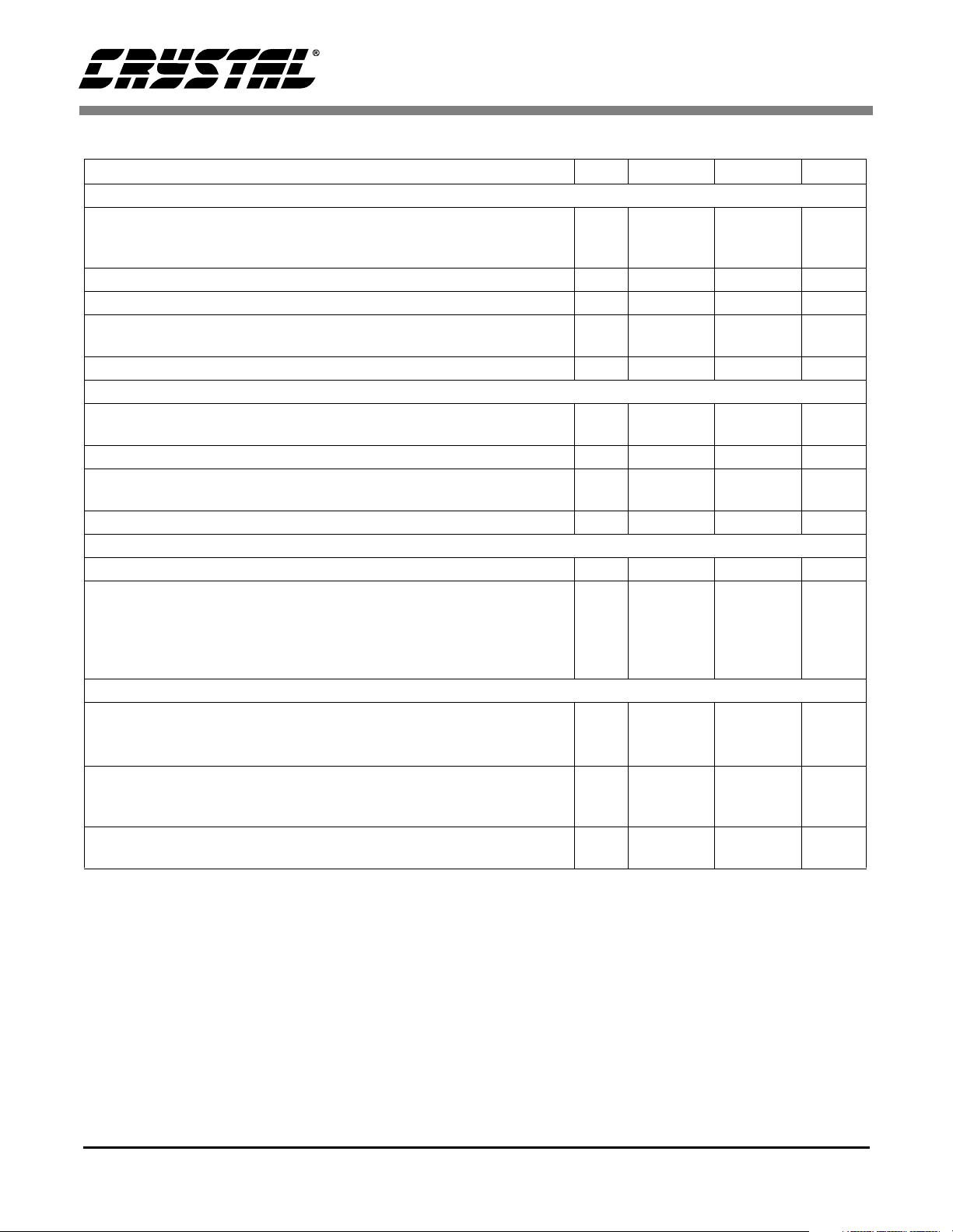

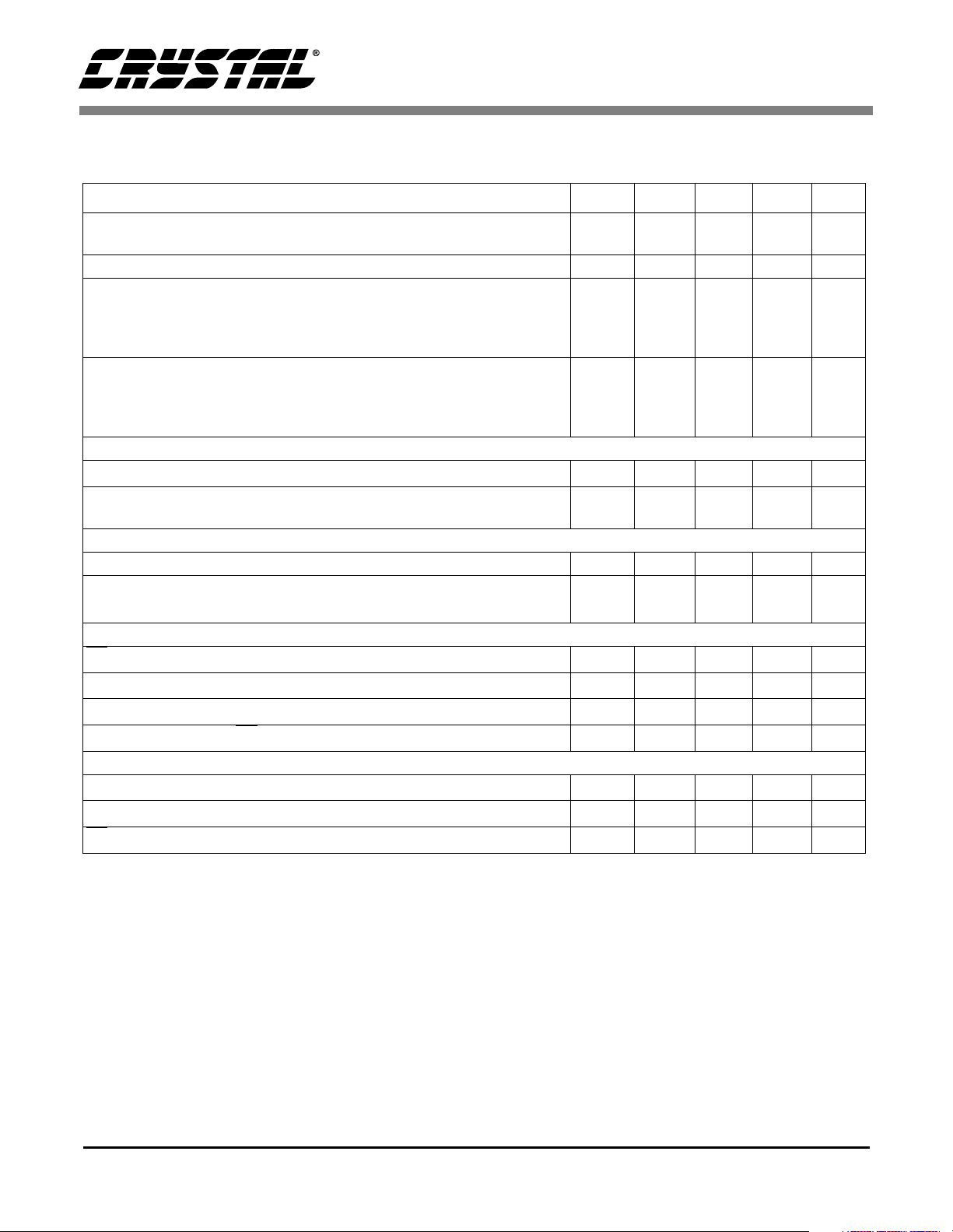

3 V DIGITAL CHARACTERISTICS (T

= 25 °C; VA+ = 3.0 V ±5%, VA- = 0 V, VD+ = 3.0 V ± 5%,

A

DGND = 0 V.)(See Notes 2 and 13.)

Parameter Symbol Min Typ Max Units

High-Level Input Voltage: All Pins Except OSC1, SCLK

OSC1

SCLK

Low-Level Input Voltage: All Pins Except OSC1, SCLK

OSC1

SCLK

High-Level Output Voltage: (SDO pin) I

Low-Level Output Voltage: (SDO pin) I

= -1.0 mA V

out

= 1.0 mA V

out

Input Leakage Current I

3-State Leakage Current I

Digital Output Pin Capacitance C

Notes: 13. All measurements performed under static conditions.

V

V

V

V

V

V

IH

IH

IH

IL

IL

IL

OH

OL

in

OZ

out

0.6VD+

TBD

(VD+)-0.45

-

-

-

(VD+)-0.25 - - V

--0.2V

-±1±10µA

--±10µA

-9-pF

-

-

-

-

-

-

-

-

-

0.16VD+

TBD

0.6

V

V

V

V

V

V

6 DS500PP1

CS5541

ABSOLUTE MAXIMUM RATINGS (DGND = 0 V) (See Note 14.)

Parameter Symbol Min Typ Max Units

DC Power Supplies (Notes 15 and 16)

Positive Digital

Positive Analog

Negative Analog

Input Current, Any Pin Except Supplies (Notes 17 and 18) I

Output Current I

Power Dissipation (Note 19) PDN - - 500 mW

Analog Input Voltage AIN and VREF pins V

Digital Input Voltage V

Ambient Operating Temperature T

Storage Temperature T

Notes: 14. All voltages measured with respect to digital ground (DGND).

15. VA+ and VA- must satisfy {(VA+) - (VA-)} ≤ +4.0 V.

16. VD+ and VA- must satisfy {(VD+) - (VA-)} ≤ +4.0 V.

17. Applies to all pins including continuous overvoltage conditions at the analog input (AIN) pins.

18. Transient currents up to 100 mA will not cause SCR latch-up. Maximum input current for a power

supply pin is ±50 mA.

19. Total power dissipation, including all input currents and output currents.

VD+

VA+

VA-

IN

OUT

INA

IND

A

stg

-0.3

-0.3

-0.3

-

-

-

+4.0

+4.0

+0.3

--±10mA

--±25mA

(VA-) + (-0.3) - (VA+)+0.3 V

-0.3 - (VD+)+0.3 V

-40 - +85 °C

-65 - +150 °C

V

V

V

WARNING: Operation at or beyond these limits may result in permanent damage to the device.

Normal operation is not guaranteed at these extremes.

DS500PP1 7

CS5541

SWITCHING CHARACTERISTICS (T

DGND = 0 V; Input Levels: Logic 0 = 0 V, Logic 1 = VD+; C

= 25 °C; VA+ = +3.0 V ±5% VA- = 0 V, VD+ = 3.0 V ±5%,

A

= 50 pF)

L

Parameter Symbol Min Typ Max Units

Master Clock Frequency: External Clock

Internal Oscillator (Note 20)

MCLK 5

-

-

32.768

40

kHz

-

Master Clock Duty Cycle 40 - 60 %

Rise Times (Note 21)

Any Digital Input Except SCLK

SCLK

Any Digital Output

Fall Times (Note 21)

Any Digital Input Except SCLK

SCLK

Any Digital Output

t

t

rise

rise

-

-

-

-

-

-

50

50

-

-

-

-

1.0

100

-

1.0

100

-

µs

µs

ns

µs

µs

ns

Start-up

Oscillator Start-up Time XTAL = 32.768 kHz (Note 22) t

Power-on-Reset Period t

ost

por

-500-ms

-490-MCLK

cycles

Serial Port Timing

Serial Clock Frequency SCLK 0 - 2 MHz

Serial Clock Pulse Width High

Pulse Width Low

t

1

t

2

250

250

-

-

-

-

ns

ns

SDI Write Timing

CS

Enable to SCLK Rising t

Data Set-up Time prior to SCLK rising t

Data Hold Time After SCLK Rising t

SCLK Falling Prior to CS

Disable t

3

4

5

6

50 - - ns

50 - - ns

100 - - ns

100 - - ns

SDO Read Timing

CS

to Data Valid t

SCLK Falling to New Data Bit t

CS

Rising to SDO Hi-Z t

7

8

9

--150ns

--150ns

--150ns

Notes: 20. Device parameters are specified with 32.768 kHz clock; however, clocks up to 40 kHz can be used for

increased throughput.

21. Specified using 10% and 90% points on waveform of interest. Output loaded with 50 pF.

22. Oscillator start-up time varies with crystal parameters. This specification does not apply when using an

external clock source.

8 DS500PP1

CS

CS5541

SCLK

CS

SCLK

t3

t3

t1

t2

t6

Figure 1. Continuous Running SCLK Timing (Not to Scale)

MSB MSB-1 LSBSDI

t4 t5

t1 t2

t6

Figure 2. SDI Write Timing (Not to Scale)

CS

t9

SDO

SCLK

t7

MSB MSB-1 LSB

t8

t2

t1

Figure 3. SDO Read Timing (Not to Scale)

DS500PP1 9

CS5541

2. GENERAL DESCRIPTION

The CS5541 is a 24-bit, low-power and low-voltage ∆−Σ analog-to-digital converter (ADC). It is

optimized to convert analog signals in DC measurement applications such as temperature and

pressure

es where low power consumption is required.

To accommodate these applications, the ADC integrates analog input and reference buffers for increased input impedance and includes a

two-channel multiplexer. Absolute accuracy is

achieved via one-time or continuous calibration

modes. The device also operates with a variety of

supply configurations while drawing less than 330

µA.

The CS5541 includes two digital filters. The first

filter which achieves simultaneous rejection of

50/60 Hz provides single conversion settling at

13.4 SPS throughput or four conversion settling at

53.7 SPS throughput. The second filter which

achieves 16-bit performance provides single conversion settling at 64.8 SPS throughput or four conversion settling at 260 SPS throughput. (Either

filter’s output word rates can be increased by using

a faster master clock, up to 40 kHz).

To ease communication between the ADCs and a

microcontroller, the converters include a simple

three-wire serial interface which is SPI and Mi-

measurement, and various portable devic-

crowire compatible. A Schmitt Trigger input is provided on the serial clock (SCLK) input.

2.1 Analog Input

Figure 4 illustrates a block diagram of the CS5541.

The device consists of a multiplexer, a unity gain

coarse/fine charge input buffer, a fourth order ∆−Σ

modulator, and a digital filter.

2.1.1 Analog Input Model

Figure 5 illustrates the input models for the AIN

pins. The model includes a coarse/fine charge buffer which reduces the dynamic current demand on

the analog input signal. The buffer is designed to

accommodate rail to rail (common-mode plus signal) input voltages. Typical CVF (sampling) current is about 12 nA (MCLK = 32.768 kHz).

Application Note 30, “Switched-Capacitor A/D Input Structures”, details various input architectures.

φ Fine

1

in = CVosf

φ

Coarse

2

AIN

Vos≤ 25mV

C = 8 pF

f = 2*MCLK = 65.536 kHz

Figure 5. Input model for AIN+ and AIN- pins.

VREF+

AIN1+

AIN1-

AIN2+

AIN2-

10 DS500PP1

M

U

X

X1

X1

Figure 4. Multiplexer Configuration.

VREF-

X1

X1

Differential

th

4 Order

∆Σ

Modulator

Sinc

Digital

Filter

4

Serial

Port

CS

SDI

SDO

SCLK

CS5541

14

15

16

17

18

19

20

00.511.522.53

VREF (V)

Noise-Free Resolution (Bits)

Figure 6. Typical Noise-Free Resolution

vs. Voltage Reference

One-Time Cal, 4 Cycle Settling, 50/60 Hz Reject

Noise-Free Res. = log

2

(Bipolar Span/6.6*RMS Noise)

13

14

15

16

17

18

19

0 0.5 1 1.5 2 2.5 3

VREF ( V)

Noise-Free Resolution (Bits)

Figure 7. Typical Noise-Free Resolution

vs. Voltage Reference

Continuous Cal, 1Cycle Settling, 50/60 Hz Reject

Noise-Free Res. = log

2

(Bipolar Span/6.6*RMS Noise)

2.2 Voltage Reference Input

The differential voltage between VREF+ and

VREF- sets the nominal full scale input range of

the converter. For a single-ended reference voltage,

the reference output is connected to the VREF+ pin

of the CS5541 and the ground reference is connected to the VREF- pin. Note that the differential reference voltage can be from 0.1 V to ((VA+)(VA-)). The noise-free resolution of a single sample from the ADC is directly proportional to the

voltage reference as depicted in Figures 6 and 7.

Note: When a lower reference voltage is used, the

resulting code widths are smaller. Since the

output codes exhibit more changing codes for

a fixed amount of noise, the converter

appears noisier.

2.2.1 Voltage Reference Input Model

Figure 8 illustrates the input models for the VREF

pins. It includes a coarse/fine charge buffer which

reduces the dynamic current demand on the external reference. The reference’s buffer is designed to

accommodate rail-to-rail (common-mode plus signal) input voltages. Typical CVF (sampling) current is about 20 nA (MCLK = 32.768 kHz; see

Figure 8).

φ Fine

1

in = CVosf

φ

Coarse

2

VREF

Vos≤ 25mV

C = 12 pF

f = 2*MCLK = 65.536 kHz

Figure 8. Input model for VREF+ and VREF- pins.

DS500PP1 11

CS5541

2.3 Power Supply Arrangements

The CS5541 is designed to operate with a total supply voltage of 3.0 V ± 5%. For maximum flexibility

separate pins are provided for VA+, VA-, VD+,

and DGND, which is especially useful with ground

referenced input signals.

Figure 9 illustrates the CS5541 connected with a

single +3.0 V supply for both the analog and digital

sections.

2.4 Clock Generator

The CS5541 includes an oscillator circuit which

can be connected with an external crystal to provide the master clock for the chip. The chip is designed to operate using a low-cost 32.768 kHz

“tuning fork” type crystal. One lead of the crystal

should be connected to OSC1 and the other to

OSC2. A 10 Megohm resistor should be connected

in parallel with the crystal. Lead lengths should be

minimized to reduce stray capacitance. The converter will operate with an external (CMOS com-

patible) clock applied at OSC1 with frequencies up

to 40 kHz.

2.5 Serial Port Interface

The CS5541’s serial interface consists of four control lines: CS, SDI, SDO, and SCLK.

CS

, Chip Select, is the control line which enables

access to the serial port. If the CS pin is tied to logic

0, the port will function as a three wire interface.

SDI, Serial Data In, is the data signal used to transfer data to the converters.

SDO, Serial Data Out, is the data signal used to

transfer output data from the converters. The SDO

output will be held at high impedance any time CS

is at logic 1.

SCLK, Serial Clock, is the serial bit-clock which

controls the shifting of data to or from the ADC’s

serial port. The CS pin must be held at logic 0 before SCLK transitions can be recognized by the

port logic. To accommodate opto-isolators SCLK

is designed with a Schmitt-trigger input.

Ω

VA+

VREF+

VREF-

AIN1+

AIN1-

AIN2+

AIN2-

VA-

10

4

CS5541

3

11

VD+

OSC2

OSC1

SDI

SDO

SCLK

DGND

12

CS

0.1µF

9

5 kHz ~ 40 kHz

8

5

7

10

6

10 M

Ω

Optional Clock

Source

Serial

Data

Interface

+3.0 V

Analog

Supply

Reference

Analog

Signal

Sources

Voltage

0.1µF

+

-

14

13

1

2

16

15

Figure 9. CS5541 Configured with +3.0 V Analog Supply.

12 DS500PP1

CS5541

Serial

Interface

CS

SDI

SDO

SCLK

Command Register (1 × 8)

Write Only

Read Only

Conversion Data Register (1x24)

Figure 10. CS5541 Register Diagram.

2.6 Serial Port

The CS5541 includes a state machine with an 8-bit

command register, which instructs the ADC to perform conversions, and a 24-bit conversion data register (read only) to store conversion results. Figure

10 illustrates a block diagram of the internal registers.

After power is applied to the ADC (the ADC includes a power-on reset circuit) or after the user

transmits the serial port initialization sequence, the

serial port is set to the command mode. The converter stays in this mode until a valid 8-bit command is received (the first 8 bits into the serial

port). Once a valid 8-bit data mode command is received and interpreted by the ADC’s command

register, the serial port enters the data mode and

continuous conversions are performed. The SDO

pin falls at the end of a conversion and the user may

read the conversion data by providing 32 serial

clocks (SCLKs), as shown in Figure 11 . The first 8

SCLKs are needed to clear the SDO flag and to

read the status flags. During the next 24 SCLKs,

the conversion data is shifted out of the serial port.

To continue performing the conversions, SDI must

be kept low during the status read time. A new

command can be issued any time other than during

the data read. If the command happens to be a power save command, the serial port goes back to the

command mode. Otherwise, the conversions will

stop in progress and start new conversions based on

the information in the command byte, and the serial

port will remain in the data mode. Section 2.8,

“Command Register Quick Reference”, lists all

valid commands.

2.7 Serial Port Initialization Sequence

To initialize the serial port of the ADC to the command mode, the user can transmit the serial port

initialization sequence. The port initialization sequence involves clocking seven (or more) SYNC1

command bytes (0xFF) followed by one SYNC0

command byte (0xFE). Note that this sequence

places the ADC’s serial port in the command mode

where it waits until a valid command is received.

This sequence does not reset the internal registers

to their default settings. Further note that the sequence can be issued at any time and aids significantly in initial code development.

SCLK

SDI

1st Command Time

SDO

* t

, to - Refer to Table 1. for output timing.

d

DS500PP1 13

8 SCLKs

td *

Figure 11. Command and Data Word Timing.

SDI set low while

reading status & data

to *

1

0

1

1

1

8 SCLKs to read status

CH OD OF

MSB

LSB

Data Time

24 SCLKs

2.8 Command Register Quick Reference

D7(MSB)D6D5D4D3D2D1D0

CS5541

CB CH PS U/B

BIT NAME VALUE FUNCTION

D7 Command Bit, CB 0

D6 Channel Select, CH 0

D5 Power Save, PS

Notes 23, 24

D4 Unipolar/Bipolar, U/B

D3-D2 Filter Select, FS1-FS0

Note 25

D1-D0 Conversion Calibration

Select, C1-C0

Notes: 23. After entering a Power Save Mode, the user must wait a minimum of 2 system clocks before issuing a

convert command.

24. A Power Save Mode cannot be entered by selectively setting the D5 bit.

0xAX must be written to the command register before the Sleep Mode will be enabled.

Similarly, 0xBX must be written to the command register before the Standby Mode will be enabled.

25. If Four Cycle Settling is selected (D3 = ’1’), the part will perform a one-time calibration when continuous

calibration is chosen.

FS1 FS0 C1 C0

Reserved

1

1

0

1

0

1

00

01

10

11

00

01

10

11

Logic 1 for executable commands

Activate AIN1 for conversion

Activate AIN2 for conversion

Data Mode

Power Save Mode (Standby or Sleep)

Bipolar Conversion Mode

Unipolar Conversion Mode

Single Cycle Settling, 50/60 Hz Reject

Single Cycle Settling, No 50/60 Hz Reject

Four Cycle Settling, 50/60 Hz Reject

Four Cycle Settling, No 50/60 Hz Reject

Calibrate prior to each point

Perform a one time calibration

Use default calibration coefficients for conversions

Use existing calibration coefficients for conversion

14 DS500PP1

CS5541

2.9 Performing Conversions/Calibrations

The CS5541 offers four conversion/self-calibration

modes (if a user requires system calibration, this

can be accommodated in the system microcontroller). The first mode allows the user to calibrate continuously between each conversion. The second

mode allows the user to calibrate once after the

command is issued and then continuously convert

on the channel selected using the calibration result.

The third mode allows the user to skip calibration;

however, it performs conversions with the default

calibration coefficients. The final mode allows the

user to use the previous calibration coefficients to

perform continuous conversions on the channel selected. The sections that follow detail the differences between the conversion modes. The sections

also explain how to decode the conversion word

into the respective flag and data bits.

2.9.1 Continuous Calibrations and Conversions (reduced output rate)

This mode performs an offset and gain calibration

prior to each conversion. Note that the effective

throughput in this mode is reduced by two as a calibration is performed prior to each conversion.

Nevertheless, after the first command instructing

the ADC to enter this mode is given, an offset calibration is performed followed by a gain calibration.

Then the first data conversion is performed. Subsequent conversions are offset calibration followed

by data conversion. Then, a gain calibration is performed followed by a data conversion. The ADC

repetitively steps through this sequence until a new

command is issued.

Note: The CS5541 offers self calibration where the

ADC calibrates out offset and gain errors due

to the ADC itself. Calibration in the CS5541 is

used to set the zero and gain slope of the

ADC’s transfer function. For the

self-calibration of offset, the converter

internally ties the inputs of the modulator

together and routes them to the VREF- pin as

shown in Figure 12. VREF- must be tied to a

fixed voltage between VA+ and VA-. For

self-calibration of gain, the differential inputs

of the modulator are connected to VREF+

and VREF- as shown in Figure 13. Further

note that each calibration step (offset or gain)

takes one conversion cycle to complete.

However, after the ADC is reset, it is

functional and can perform measurements

without being calibrated (see Perform

Continuous Conversions with Default

Calibration Coefficients section for details). In

this case, the converter will utilize the

initialized values of the on-chip registers

(Offset = 0, Gain = 1.0) to calculate output

words. Any initial offset and gain errors in the

internal circuitry of the chip will remain.

AIN+

AIN-

VREF-

Figure 12. Self Calibration of Offset.

AIN+

AIN-

VREF+

Reference

Figure 13. Self Calibration of Gain.

+

-

VREF-

+

-

+

-

DS500PP1 15

CS5541

2.9.2 One Time Calibration followed by Continuous Conversions

After the first command instructing the ADC to enter this mode is given, an offset calibration is performed followed by a gain calibration. Then the

first data conversion is performed. Subsequent conversions do not include new calibrations. This allows the ADC to provide maximum throughput for

the filter rate selected.

2.9.3 Continuous Conversions with Default Calibration Coefficients

After the command instructing the ADC to enter

this mode is given, the ADC will utilize the initialized values of the on-chip calibration registers

(Offset = 0, Gain = 1.0) for all conversions. This allows the ADC to provide maximum throughput for

the filter rate selected. This mode is recommended

when the user is performing a system calibration.

2.9.4 Continuous Conversions with Existing Calibration Coefficients

After the command instructing the ADC to enter

this mode is given, the ADC will use the coefficients from the previous calibration to calculate

conversions. If no prior calibration has been performed since power-up, the ADC will use the default calibration coefficients (Offset = 0, Gain = 1).

The ADC performs conversions at the maximum

throughput for the filter rate selected.

2.9.5 Output Word Timing

Table 1 describes the output word timing of the

CS5541. D3-D0 are the last four bits of the command word issued, as described in Section 2.8.

Both td and to are represented graphically in Figure

11. td represents the amount of time for a conversion to be completed, once a valid command is received. to is the time required for all subsequent

conversions, before a new command is received.

“Throughput” is the rate at which those subsequent

conversions are output.

D3-D0

0000 7358 4884 6.7093

0001 7358 2442 13.418

001x 2474 2442 13.418

0100 1550 1012 32.379

0101 1550 506 64.759

011x 538 506 64.759

100x 7358 610 53.718

101x 2474 610 53.718

110x 1550 126 260.06

111x 538 126 260.06

Notes: 26. td can be off by one MCLK cycle if SCLK is asynchronous to MCLK.

td - First Output (cycles)

Note 26

Table 1. Filter Output Word Rates

27. Throughput calculations assume that MCLK = 32.768 kHz.

to - Subsequent Outputs (cycles)

Throughput (SPS)

Note 27

16 DS500PP1

CS5541

2.9.6 System Calibration

If a system level calibration is to be performed using a system microcontroller, it is best to put the

converter in the Continuous Conversions with De-

fault Calibration Coefficients mode. The user

would configure the system with a zero-level input

and store the resulting conversion for system offset

correction. Then the user would configure the system with a full-scale input level and store the resulting conversion for system full-scale correction.

Correction of converter data is then performed using the system microcontroller.

2.9.7 Reading Conversions

At the completion of a conversion, SDO will fall to

logic 0 to indicate that the conversion is complete.

If calibration modes are used they will be transparent to user and only affect the effective throughput

of the ADC. Nevertheless, to read a conversion

word, the user must issue 8 SCLKs (SDI = logic 0

for the NULL command and remain in this mode or

SDI can be used to clock in a new command) to

clear the SDO flag and read the status flags. Upon

the falling edge of the 8th SCLK, the SDO pin will

present the first bit (MSB) of the conversion word.

24 SCLKs (high, then low) are then required to

read the conversion word from the port. Upon the

nd

falling edge of the 32

high, waiting till the next conversion is complete

before it falls again.

When operating in any of the conversion modes,

the user need not read every conversion. If the user

chooses not to read a conversion after SDO falls,

SDO will rise one MCLK clock cycle before the

next conversion is completed and then fall to signal

that another conversion word is available. To exit

the particular conversion mode, the user must issue

any valid command, other than the NULL command, to the SDI input. The new command can be

issued anytime other than during the data read. If

the user wants to read the last conversion data and

issue the new command, the following protocol is

SCLK, SDO will return

required: After SDO falls, read the status flags

(keeping SDI low, 8 SCLKs), followed by the conversion data (24 SCLKs). Then follow it up with

the new command at SDI (8 SCLKs).

If the command happens to be a power save command, the serial port goes back to the command

mode. Otherwise, the conversion will stop in

progress and start new conversions based on the information in the command byte, and the serial port

remains in the data mode.

Note: 1) If the user begins to clear the SDO end-of-

conversion flag and read the conversion data,

this action must be finished before the

conversion cycle which is occurring in the

background is complete if the user wants to

be able to read the new conversion data.

2) If a new conversion command is issued to

the converter while it is performing a

conversion, the filter will stop the current

conversion and start a new convolution cycle

to perform a new conversion.

3) If a new conversion command is issued

when SDO is low, SDO will output 01111,

then CH, OD, and OF. Afterwards, SDO will

remain high until one MCLK cycle before the

new data is ready, then fall to indicate that the

conversion is completed.

2.9.8 Output Coding

The CS5541 outputs 24-bit data conversion words.

To read a conversion word the user must read the

conversion data register. The conversion data register is 24 bits long and outputs the data word MSB

first. Once a conversion is complete, SDO falls and

32 SCLK’s are required to read the results. The first

8 SCLKs are used to clear the SDO flag and clock

out the status flags.

The Channel Indicator (CH) bit keeps track of

which input channel was converted.

The Oscillation Detect (OD) bit is set to a logic 1 any

time that an oscillatory condition is detected in the

modulator. This does not occur under normal operating conditions, but may occur whenever the input

to the converter is extremely overranged. If the OD

bit is set, the conversion data bits can be completely

DS500PP1 17

CS5541

erroneous. The OD flag bit will be cleared to logic 0

when the modulator becomes stable.

The Overrange Flag (OF) bit is set to a logic 1 any

time the input signal is: 1) more positive than positive full scale, 2) more negative than zero (unipolar

mode), 3) more negative than negative full scale

(bipolar mode). It is cleared back to logic 0 whenever a conversion word occurs which is not overranged.

The last 24 SCLKs are used to clock data out of the

conversion data register.

Table 2 and Table 3 illustrate the output coding for

the CS5541. Unipolar conversions are output in binary format and bipolar conversions are output in

two’s complement format.

2.9.9 Digital Filter

The CS5541 includes two digital filters. The first

filter which achieves simultaneous rejection of

50/60 Hz provides single conversion settling at

13.4 SPS throughput or four conversion settling at

53.7 SPS throughput. The second filter which

achieves 16-bit performance provides single conversion settling at 64.8 SPS throughput or four conversion settling at 260 SPS throughput.

The first filter (13.4 SPS and 53.7 SPS throughput)

is optimized to yield better than 80 dB rejection between 47 Hz to 63 Hz (i.e. 80 dB minimum rejection for both 50 Hz and 60 Hz) when the master

clock is 32.768 kHz. The filter has a response as

shown in Figure 14.

The second filter is optimized for higher throughput, and does not provide 50 Hz or 60 Hz rejection.

It has a frequency response that is shown in Figure

15.

To ease code development, each filter (13.4 SPS or

64.8 SPS throughput) has a mode that only outputs

fully settled output conversions (every 4

th

convolu-

tion).

D31 D30 D29 D28 D27 D26 D25 D24

01 1 1 1 CHODOF

D23 D22 D21 D20 D19 D18 D17 D16 D15 D14 D13 D12

MSB 2221201918 17 16 15 14 13 12

D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

11 109876 5 4 3 2 1LSB

Table 2. Output Conversion Data Register Description (24 bits + flags)

Unipolar Input Voltage Offset Binary Bipolar Input Voltage

>(VFS-1.5 LSB) FFFFFF >(VFS-1.5 LSB) 7FFFFF

FFFFFF

VFS-1.5 LSB

VFS/2-0.5 LSB

+0.5 LSB

<(+0.5 LSB) 000000 <(-VFS+0.5 LSB) 800000

Note: VFS in the table equals the voltage between ground and full scale for the unipolar mode, or the voltage

between ± full scale for the bipolar mode. See text about error flags under overrange conditions.

-----

FFFFFE

800000

-----

7FFFFF

000001

-----

000000

Table 3. CS5541 24-Bit Output Coding

VFS-1.5 LSB

-0.5 LSB

-VFS+0.5 LSB

Two ’s

Complement

7FFFFF

-----

7FFFFE

000000

-----

FFFFFF

800001

-----

800000

18 DS500PP1

CS5541

-140

-120

-100

-80

-60

-40

-20

0

0 20 40 60 80 100 120

Frequency (Hz)

Magnitude (dB)

47 Hz

63 Hz

Figure 14. Filter 1 Response (MCLK = 32.768 kHz)

-140

-120

-100

-80

-60

-40

-20

0

0 100 200 300 400 500

Frequency (Hz)

Magnitude (dB)

Figure 15. Filter 2 Response (MCLK = 32.768 kHz)

a data mode command. Since the sleep mode disables the oscillator, approximately a 500 ms crystal

oscillator start-up delay period is required before

the ADC returns to the normal power consumption

mode. Note that if an external clock is used, the

ADC will return to normal power mode within 3

milliseconds.

The Standby Mode is entered by writing 0xBX to

the part. The Standby Mode performs the same

function as the Sleep Mode except that the oscillator is not powered down. This eliminates the crystal

oscillator start-up time, with a return to normal

power within 3 milliseconds. Again, to exit standby

(i.e. to return to normal power consumption mode),

the user must transmit a data mode command. The

power during Standby will be around 75 µW.

To accommodate higher throughput requirements,

each filter has a mode (53.7 SPS or 260 SPS

throughput) that outputs every single convolution.

This allows users to see input signal trends at higher update rates.

Note: The converter’s digital filter characteristics

linearly scale with MCLK.

2.10 Sleep and Standby Modes

The CS5541 accommodates three power consumption modes: normal, sleep, and standby. The normal power consumption mode is entered by default

after a power-on-reset. In this mode, the CS5541

typically consumes 750 µW.

The Sleep Mode is entered whenever the sleep

command, 0xAX, is issued to the serial port. The

ADC immediately enters sleep after the command

is issued, reducing the consumed power to around

30 µW. During sleep, most of the analog portion of

the chip is powered down and filter convolutions

are halted. To exit sleep (i.e. to return to normal

power consumption mode), the user must transmit

DS500PP1 19

2.11 Power-Up Sequence and Initialization

Care must be taken to assure that no pins are ever

taken below the negative analog supply (VA-) potential. The analog and digital supplies should be

applied simultaneously to assure that the power-on

reset circuit will automatically reset the ADC when

both supplies are at acceptable levels.

Commands should not be sent to the ADC until a

stable clock is present. If a 32.768 kHz crystal is

being used, it will take approximately 500 ms for

the oscillator to stabilize after power has been applied to the converter. If a CMOS compatible

source with no start-up delay is used, then the ADC

is immediately ready for a command.

After a valid reset, the ADC is placed into the command state where it waits for a valid command to

execute. Once a valid conversion command has

been received, conversions will begin and data can

be read using the serial port.

Note: The CS5541 includes an on-chip power-on

reset circuit to automatically reset the ADC

shortly after power-up. When power to the

CS5541 is applied, the ADC is held in a reset

condition until the master clock has started

and a counter-timer elapses (i.e. the

counter-timer counts 490 MCLK cycles to

CS5541

make sure the oscillator is fully stable). In

normal start-up conditions, this power on

reset circuit should reset the chip when power

is applied. If your application could

experience abnormal power start-up

conditions, it is recommended that the serial

port reinitialization sequence, followed by a

power save command, be performed to

guarantee that the converter begins proper

operation.

2.12 PCB Layout

The CS5541 should be placed entirely over an analog ground plane with the DGND pin of the device

connected to the analog ground plane. Place the analog-digital plane split immediately adjacent to the

digital portion of the chip

See the CDB5540/41 data sheet for suggested layout details and Applications Note 18 for more detailed layout guidelines.

Applications Engineering provides a free and confidential Schematic Review Service.

20 DS500PP1

3. PIN DESCRIPTIONS

CS5541

Clock Generator

OSC1; OSC2 - Master Clock.

An inverting amplifier inside the chip is connected between these pins and can be used with a

crystal to provide the master clock for the device. Alternatively, an external (CMOS

compatible) clock (powered relative to VD+) can be supplied into the OSC1 pin to provide the

master clock for the device.

AIN1+

AIN1-

VA-

VA+

CS

SCLK

SDI

OSC1

1

2

3

4

5

16

15

14

13

12

AIN2+

AIN2-

VREF+

VREF-

DGND

CS5541

6

7

89

11

10

VD+

SDO

OSC2

Control Pins and Serial Data I/O

CS - Chip Select.

When active low, the port will recognize SCLK. When high the SDO pin will output a high

impedance state. CS

should be changed when SCLK = 0.

SDI - Serial Data Input.

SDI is the input pin of the serial input port. Data will be input at a rate determined by SCLK.

SDO - Serial Data Output.

SDO is the serial data output. It will output a high impedance state if CS = 1.

SCLK - Serial Clock Input.

A clock signal on this pin determines the input/output rate of the data for the SDI/SDO pins

respectively. This input is a Schmitt trigger to allow for slow rise time signals. The SCLK pin

will recognize clocks only when CS is low.

DS500PP1 21

Measurement and Reference Inputs

AIN1+, AIN1-, AIN2+, AIN2- - Differential Analog Input.

Differential input pins into the device.

VREF+, VREF- - Voltage Reference Input.

Fully differential inputs which establish the voltage reference for the on-chip modulator.

Power Supply Connections

VA+ - Positive Analog Power.

Positive analog supply voltage.

VA- - Negative Analog Power.

Negative analog supply voltage.

VD+ - Positive Digital Power.

CS5541

Positive digital supply voltage.

DGND - Digital Ground.

Digital Ground.

22 DS500PP1

4. SPECIFICATION DEFINITIONS

Linearity Error

The deviation of a code from a straight line which connects the two end points of the A/D

Converter transfer function. One end point is located 1/2 LSB below the first code transition

and the other end point is located 1/2 LSB beyond the code transition to all ones. Units in

percent of full-scale.

Differential Nonlinearity

The deviation of a code’s width from the ideal width. Units in LSBs.

Full Scale Error

The deviation of the last code transition from the ideal [{(VREF+) - (VREF-)} - 3/2 LSB].

Units are in LSBs.

Unipolar Offset

The deviation of the first code transition from the ideal (1/2 LSB above the voltage on the

AIN- pin). When in unipolar mode (U/B

CS5541

bit = 1). Units are in LSBs.

Bipolar Offset

The deviation of the mid-scale transition (111...111 to 000...000) from the ideal (1/2 LSB below

the voltage on the AIN- pin). When in bipolar mode (U/B bit = 0). Units are in LSBs.

DS500PP1 23

CS5541

16L SSOP PACKAGE DRAWING

N

D

E

A2

A

E1

1

∝

2

b

SIDE VIEW

1

23

e

TOP VIEW

INCHES MILLIMETERS NOTE

DIM MIN NOM MAX MIN NOM MAX

A -- -- 0.084 -- -- 2.13

A1 0.002 0.005 0.010 0.05 0.13 0.25

A2 0.064 0.069 0.074 1.68 1.75 1.88

b 0.009 0.012 0.015 0.22 -- 0.38 2,3

D 0.232 0.244 0.256 5.90 6.20 6.50 1

E 0.291 0.307 0.323 7.40 7.80 8.20

E1 0.197 0.209 0.220 5.00 5.30 5.60 1

e 0.022 0.026 0.030 0.55 0.65 0.75

L 0.025 0.0295 0.041 0.63 0.75 1.03

∝

0° 4° 8° 0° 4° 8°

JEDEC #: MO-150

A1

SEATING

PLANE

L

END VIEW

Notes: 1. “D” and “E1” are reference datums and do not included mold flash or protrusions, but do include mold

mismatch and are measured at the parting line, mold flash or protrusions shall not exceed 0.20 mm per

side.

2. Dimension “b” does not include dambar protrusion/intrusion. Allowable dambar protrusion shall be

0.13 mm total in excess of “b” dimension at maximum material condition. Dambar intrusion shall not

reduce dimension “b” by more than 0.07 mm at least material condition.

3. These dimensions apply to the flat section of the lead between 0.10 and 0.25 mm from lead tips.

24 DS500PP1

• Notes •

Loading...

Loading...