CS5531/32/33/34

16-bit and 24-bit ADCs with Ultra-low-noise PGIA

Features

z Chopper-stabilized PGIA (Programmable

Gain Instrumentation Amplifier, 1x to 64x)

6 nV/√Hz @ 0.1 Hz (No 1/f noise) at 64x

500 pA Input Current with Gains >1

Delta-sigma Analog-to-digital Converter

z

Linearity Error: 0.0007% FS

Noise Free Resolution: Up to 23 bits

Two- or Four-channel Differential MUX

z

z Scalable Input Span via Calibration

±5 mV to differential ±2.5V

Scalable V

z

z Simple Three-wire Serial Interface

SPI™ and Microwire™ Compatible

Schmitt Trigger on Serial Clock (SCLK)

R/W Calibration Registers Per Channel

z

z Selectable Word Rates: 6.25 to 3,840 Sps

z Selectable 50 or 60 Hz Rejection

z Power Supply Configurations

VA+ = +5 V; VA- = 0 V; VD+ = +3 V to +5 V

VA+ = +2.5 V; VA- = -2.5 V; VD+ = +3 V to +5 V

VA+ = +3 V; VA- = -3 V; VD+ = +3 V

Input: Up to Analog Supply

REF

General Description

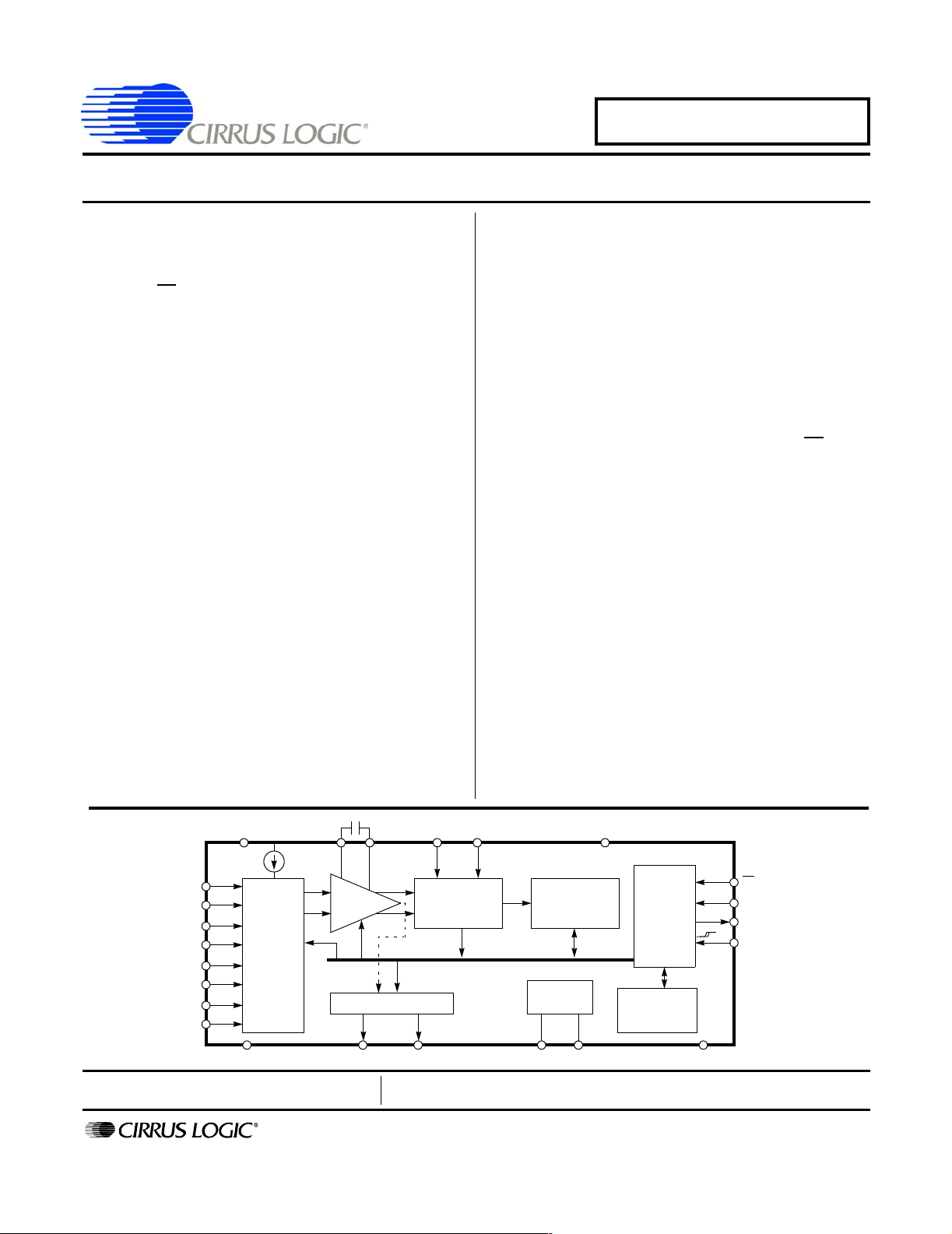

The CS5531/32/33/34 are highly integrated ∆Σ Analogto-Digital Converters (ADCs) which use charge-balance

techniques to achieve 16-bit (CS5531/33) and 24-bit

(CS5532/34) performance. The ADCs are optimized for

measuring low-level unipolar or bipolar signals in weigh

scale, process control, scientific, and medical

applications.

To accommodate these applications, the ADCs

either two-channel (CS5531/32) or four-channel

(CS5533/34) devices and include a very low noise chopper-stabilized instrumentation amplifier (6 nV/√Hz

Hz) with selectable gains of 1×, 2×, 4×, 8×, 16×, 32×, and

64×. These ADCs also include a fourth order ∆Σ modulator followed by a digital filter

which provides twenty

selectable output word rates of 6.25, 7.5, 12.5, 15, 25, 30,

50, 60, 100, 120, 200, 240, 400, 480, 800, 960, 1600,

1920, 3200, and 3840 Sps (MCLK = 4.9152 MHz).

To ease communication between the ADCs and a microcontroller, the converters include a simple three-wire serial interface which is SPI and Microwire compatible with

a Schmitt Trigger input on the serial clock (SCLK).

High dynamic range, programmable output rates, and

flexible power supply options makes these ADCs ideal

solutions for weigh scale and process control

applications.

ORDERING INFORMATION

See page 48

come as

@ 0.1

VA+ C1 C2 VREF+ VREF- VD+

AIN1+

AIN1-

AIN2+

AIN2-

AIN3+

AIN3-

AIN4+

AIN4-

MUX

(CS5533/34

SHOWN)

PGIA

1,2,4,8,16

32,64

Preliminary Product Information

http://www.cirrus.com

CS

SDI

SDO

SCLK

LATCH

DIFFERENTIAL

TH

ORDER

4

MODULATOR

∆Σ

PROGRAMMABLE

SINC FIR FILTER

CLOCK

GENERATOR

OSC2OSC1A1A0/GUARDVA-

SERIAL

INTERFACE

CALIBRATION

SRAM/CONTROL

LOGIC

DGND

This document contains information for a new product.

Cirrus Logic reserves the right to modify this product without notice.

Copyright © Cirrus Logic, Inc. 2005

(All Rights Reserved)

JUL ‘05

DS289F1

1

TABLE OF CONTENTS

1. CHARACTERISTICS AND SPECIFICATIONS ..........................................................4

ANALOG CHARACTERISTICS..........................................................................4

TYPICAL RMS NOISE (NV), CS5531/32/33/34-AS ...........................................7

TYPICAL NOISE FREE RESOLUTION(BITS), CS5532/34-AS .........................7

TYPICAL RMS NOISE (NV), CS5532/34-BS .....................................................8

TYPICAL NOISE FREE RESOLUTION(BITS), CS5532/34-BS .........................8

5 V DIGITAL CHARACTERISTICS ....................................................................9

3 V DIGITAL CHARACTERISTICS ....................................................................9

DYNAMIC CHARACTERISTICS ......................................................................10

ABSOLUTE MAXIMUM RATINGS ...................................................................10

SWITCHING CHARACTERISTICS ..................................................................11

2. GENERAL DESCRIPTION .......................................................................................13

2.1. Analog Input ....................................................................................................13

2.1.1. Analog Input Span .................................................................................... 14

2.1.2. Multiplexed Settling Limitations ............................................................14

2.1.3. Voltage Noise Density Performance .....................................................14

2.1.4. No Offset DAC ......................................................................................14

2.2. Overview of ADC Register Structure and Operating Modes ............................15

2.2.1. System Initialization ..............................................................................16

2.2.2. Command Register Quick Reference ..................................................18

2.2.3. Command Register Descriptions ..........................................................19

2.2.4. Serial Port Interface ..............................................................................23

2.2.5. Reading/Writing On-Chip Registers ......................................................24

2.3. Configuration Register .....................................................................................24

2.3.1. Power Consumption .............................................................................24

2.3.2. System Reset Sequence ......................................................................24

2.3.3. Input Short ............................................................................................25

2.3.4. Guard Signal .........................................................................................25

2.3.5. Voltage Reference Select .....................................................................25

2.3.6. Output Latch Pins .................................................................................25

2.3.7. Offset and Gain Select ..........................................................................26

2.3.8. Filter Rate Select ..................................................................................26

2.3.9. Configuration Register Descriptions .....................................................27

2.4. Setting up the CSRs for a Measurement .........................................................28

2.4.1. Channel-Setup Register Descriptions ..................................................29

2.5. Calibration ........................................................................................................31

2.5.1. Calibration Registers ............................................................................31

2.5.2. Gain Register .......................................................................................31

2.5.3. Offset Register .....................................................................................31

2.5.4. Performing Calibrations ........................................................................32

2.5.5. Self Calibration .....................................................................................32

2.5.6. System Calibration ................................................................................33

2.5.7. Calibration Tips .....................................................................................33

2.5.8. Limitations in Calibration Range ...........................................................34

2.6. Performing Conversions ..................................................................................34

2.6.1. Single Conversion Mode .......................................................................34

2.6.2. Continuous Conversion Mode ..............................................................35

2.6.3. Examples of Using CSRs to Perform Conversions and Calibrations ....36

2.7. Using Multiple ADCs Synchronously ...............................................................37

2.8. Conversion Output Coding ..............................................................................37

2.8.1. Conversion Data Output Descriptions ..................................................38

2.9. Digital Filter ......................................................................................................39

2.10. Clock Generator ...............................................................................................40

2.11. Power Supply Arrangements ...........................................................................40

CS5531/32/33/34

2 DS289F1

2.12. Getting Started ................................................................................................ 44

2.13. PCB Layout ..................................................................................................... 44

3. PIN DESCRIPTIONS ............................................................................................... 45

Clock Generator .............................................................................................. 45

Control Pins and Serial Data I/O ..................................................................... 45

Measurement and Reference Inputs ............................................................... 46

Power Supply Connections ............................................................................. 46

4. SPECIFICATION DEFINITIONS ............................................................................... 47

5. ORDERING GUIDE .................................................................................................. 48

6. PACKAGE DRAWINGS ........................................................................................... 49

LIST OF FIGURES

Figure 1. SDI Write Timing (Not to Scale)............................................................................... 12

Figure 2. SDO Read Timing (Not to Scale)............................................................................. 12

Figure 3. Multiplexer Configuration ......................................................................................... 13

Figure 4. Input models for AIN+ and AIN- pins ....................................................................... 14

Figure 5. Measured Voltage Noise Density............................................................................. 14

Figure 6. CS5531/32/33/34 Register Diagram ........................................................................ 15

Figure 7. Command and Data Word Timing ........................................................................... 23

Figure 8. Guard Signal Shielding Scheme .............................................................................. 25

Figure 9. Input Reference Model when VRS = 1 .................................................................... 26

Figure 10. Input Reference Model when VRS = 0 .................................................................. 26

Figure 11. Self Calibration of Offset ........................................................................................ 33

Figure 12. Self Calibration of Gain .......................................................................................... 33

Figure 13. System Calibration of Offset .................................................................................. 33

Figure 14. System Calibration of Gain .................................................................................... 33

Figure 15. Synchronizing Multiple ADCs................................................................................. 37

Figure 16. Digital Filter Response (Word Rate = 60 Sps) ....................................................... 39

Figure 17. 120 Sps Filter Magnitude Plot to 120 Hz ............................................................... 39

Figure 18. 120 Sps Filter Phase Plot to 120 Hz ......................................................................39

Figure 19. Z-Transforms of Digital Filters................................................................................ 39

Figure 20. On-chip Oscillator Model........................................................................................ 40

Figure 21. CS5532 Configured with a Single +5 V Supply ..................................................... 41

Figure 22. CS5532 Configured with ±2.5 V Analog Supplies..................................................42

Figure 23. CS5532 Configured with ±3 V Analog Supplies..................................................... 42

Figure 24. CS5532 Configured for Thermocouple Measurement ........................................... 43

Figure 25. Bridge with Series Resistors .................................................................................. 43

CS5531/32/33/34

LIST OF TABLES

Table 1. Conversion Timing for Single Mode .......................................................................... 35

Table 2. Conversion Timing for Continuous Mode..................................................................36

Table 3. Command Byte Pointer ............................................................................................. 36

Table 4. Output Coding for 16-bit CS5531 and CS5533......................................................... 37

Table 5. Output Coding for 24-bit CS5532 and CS5534......................................................... 38

DS289F1 3

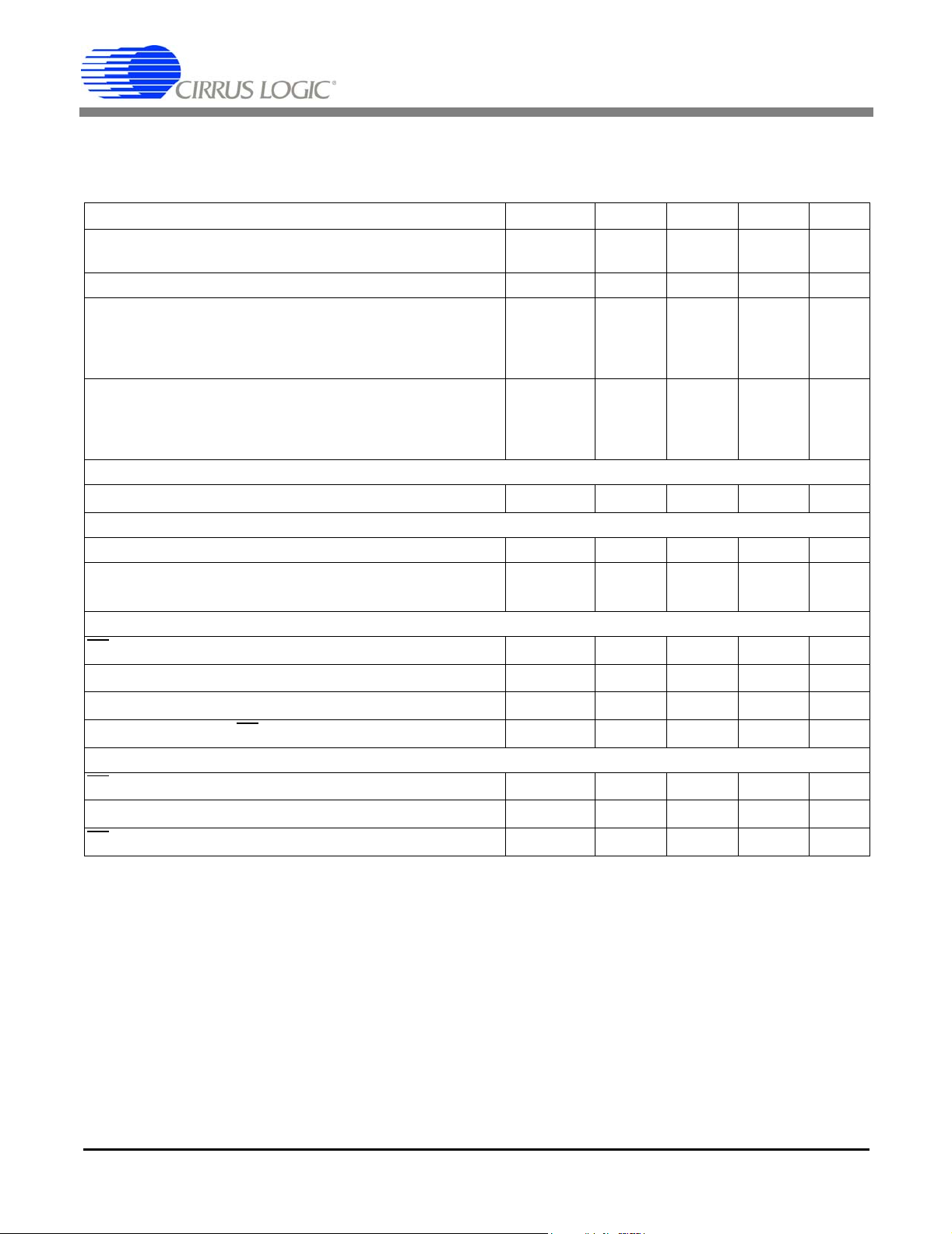

CS5531/32/33/34

1. CHARACTERISTICS AND SPECIFICATIONS

ANALOG CHARACTERISTICS (

VA+, VD+ = 5 V ±5%; VREF+ = 5 V; VA-, VREF-, DGND = 0 V; MCLK = 4.9152 MHz; OWR (Output Word Rate) =

60 Sps; Bipolar Mode; Gain = 32)

(See Notes 1 and 2.)

CS5531-AS/CS5533-AS

Parameter

Accuracy

Linearity Error - ±0.0015 ±0.003 %FS

No Missing Codes 16 - - Bits

Bipolar Offset - ±1±2LSB

Unipolar Offset - ±2 ±4LSB

Offset Drift (Notes 3 and 4) - 640/G + 5 - nV/°C

Bipolar Full Scale Error - ±8 ±31 ppm

Unipolar Full Scale Error - ±16 ±62 ppm

Full Scale Drift (Note 4) - 2 - ppm/°C

UnitMin Typ Max

16

16

CS5532-AS/CS5534-AS CS5532-BS/CS5534-BS

Parameter

Accuracy

Linearity Error - ±0.0015 ±0.003 - ±0.0007 ±0.0015 %FS

No Missing Codes 24 - - 24 - - Bits

Bipolar Offset - ±16 ±32 - ±16 ±32 LSB

Unipolar Offset - ±32 ±64 - ±32 ±64 LSB

Offset Drift (Notes 3 and 4) - 640/G + 5 - - 640/G + 5 - nV/°C

Bipolar Full Scale Error - ±8 ±31 - ±8 ±31 ppm

Unipolar Full Scale Error - ±16 ±62 - ±16 ±62 ppm

Full Scale Drift (Note 4) - 2 - - 2 - ppm/°C

Notes: 1. Applies after system calibration at any temperature within -40 °C ~ +85 °C.

2. Specifications guaranteed by design, characterization, and/or test. LSB is 16 bits for the CS5531/33 and

LSB is 24 bits for the CS5532/34.

3. This specification applies to the device only and does not include any effects by external parasitic

thermocouples. The PGIA contributes 5 nV of offset drift, and the modulator contributes 640/G nV of

offset drift, where G is the amplifier gain setting.

4. Drift over specified temperature range after calibration at power-up at 25 °C.

UnitMin Typ Max Min Typ Max

24

24

4 DS289F1

CS5531/32/33/34

ANALOG CHARACTERISTICS (Continued)

(See Notes 1 and 2.)

Parameter Min Typ Max Unit

Analog Input

Common Mode + Signal on AIN+ or AIN-Bipolar/Unipolar Mode

Gain = 1

Gain = 2, 4, 8, 16, 32, 64 (Note 5)

CVF Current on AIN+ or AIN- Gain = 1 (Note 6, 7)

Gain = 2, 4, 8, 16, 32, 64

Input Current Noise Gain = 1

Gain = 2, 4, 8, 16, 32, 64

Input Leakage for Mux when Off (at 25 °C) - 10 - pA

Off-Channel Mux Isolation - 120 - dB

Open Circuit Detect Current 100 300 - nA

Common Mode Rejection dc, Gain = 1

dc, Gain = 64

50, 60 Hz

Input Capacitance - 60 - pF

Guard Drive Output - 20 - µA

Voltage Reference Input

Range (VREF+) - (VREF-) 1 2.5 (VA+)-(VA-) V

CVF Current (Note 6, 7) - 50 - nA

Common Mode Rejection dc

50, 60 Hz

Input Capacitance 11 - 22 pF

System Calibration Specifications

Full Scale Calibration Range Bipolar/Unipolar Mode 3 - 110 %FS

Offset Calibration Range Bipolar Mode -100 - 100 %FS

Offset Calibration Range Unipolar Mode -90 - 90 %FS

VA-

VA- + 0. 7--

-

-

-

-

-

-

-

-

-

1200

200

130

120

120

120

50

1

90

VA+

VA+ - 1 . 7

-

-

-

-

-

-

-

-

-

V

V

nA

pA

pA/√Hz

pA/√Hz

dB

dB

dB

dB

dB

Notes: 5. The voltage on the analog inputs is amplified by the PGIA, and becomes V

the differential outputs of the amplifier. In addition to the input common mode + signal requirements for

the analog input pins, the differential outputs of the amplifier must remain between (VA- + 0.1 V) and

(VA+ - 0.1 V) to avoid saturation of the output stage.

6. See the section of the data sheet which discusses input models.

7. Input current on AIN+ or AIN- (with Gain = 1), or VREF+ or VREF- may increase to 250 nA if operated

within 50 mV of VA+ or VA-. This is due to the rough charge buffer being saturated under these

conditions.

DS289F1 5

± Gain*(AIN+ - AIN-)/2 at

CM

ANALOG CHARACTERISTICS (Continued)

(See Notes 1 and 2.)

Parameter

Power Supplies

DC Power Supply Currents (Normal Mode) I

Power Consumption Normal Mode (Notes 8 and 9)

Standby

Sleep

Power Supply Rejection (Note 10)

dc Positive Supplies

dc Negative Supply

8. All outputs unloaded. All input CMOS levels.

9. Power is specified when the instrumentation amplifier (Gain ≥ 2) is on. Analog supply current is reduced

by approximately 1/2 when the instrumentation amplifier is off (Gain = 1).

10. Tested with 100 mV change on VA+ or VA-.

A+, IA-

I

D+

CS5531/32/33/34

CS5531/32/33/34-AS CS5532/34-BS

Min Typ

-

-

-

-

-

-

-

7

0.5

40

5

500

115

115

Max

9

1

50

-

-

-

-

Min Typ

-

-

-

13

0.5

70

-

-

500

-

115

-

115

Max

4

15

1

80

Unit

mA

mA

mW

-

mW

-

µW

-

-

dB

dB

6 DS289F1

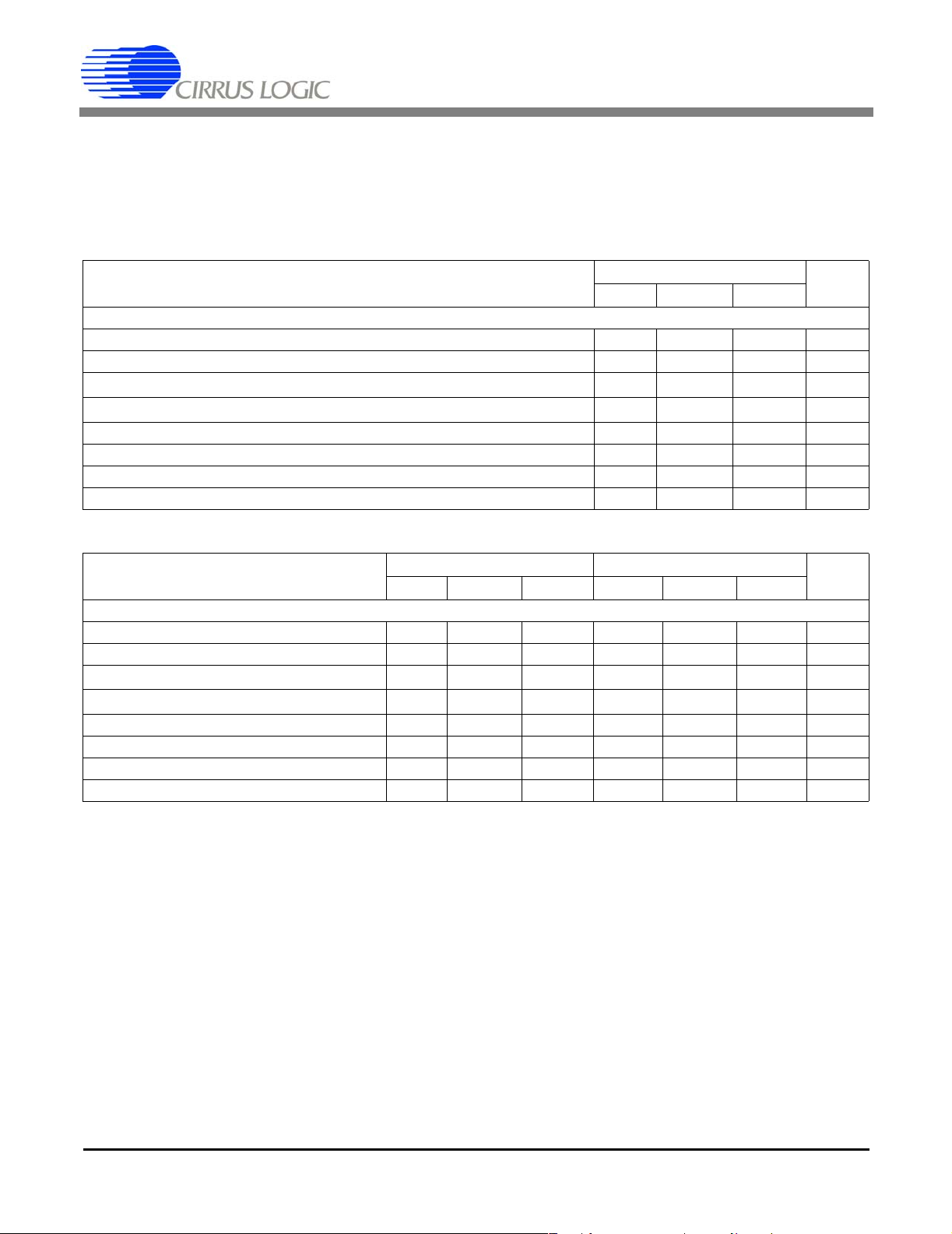

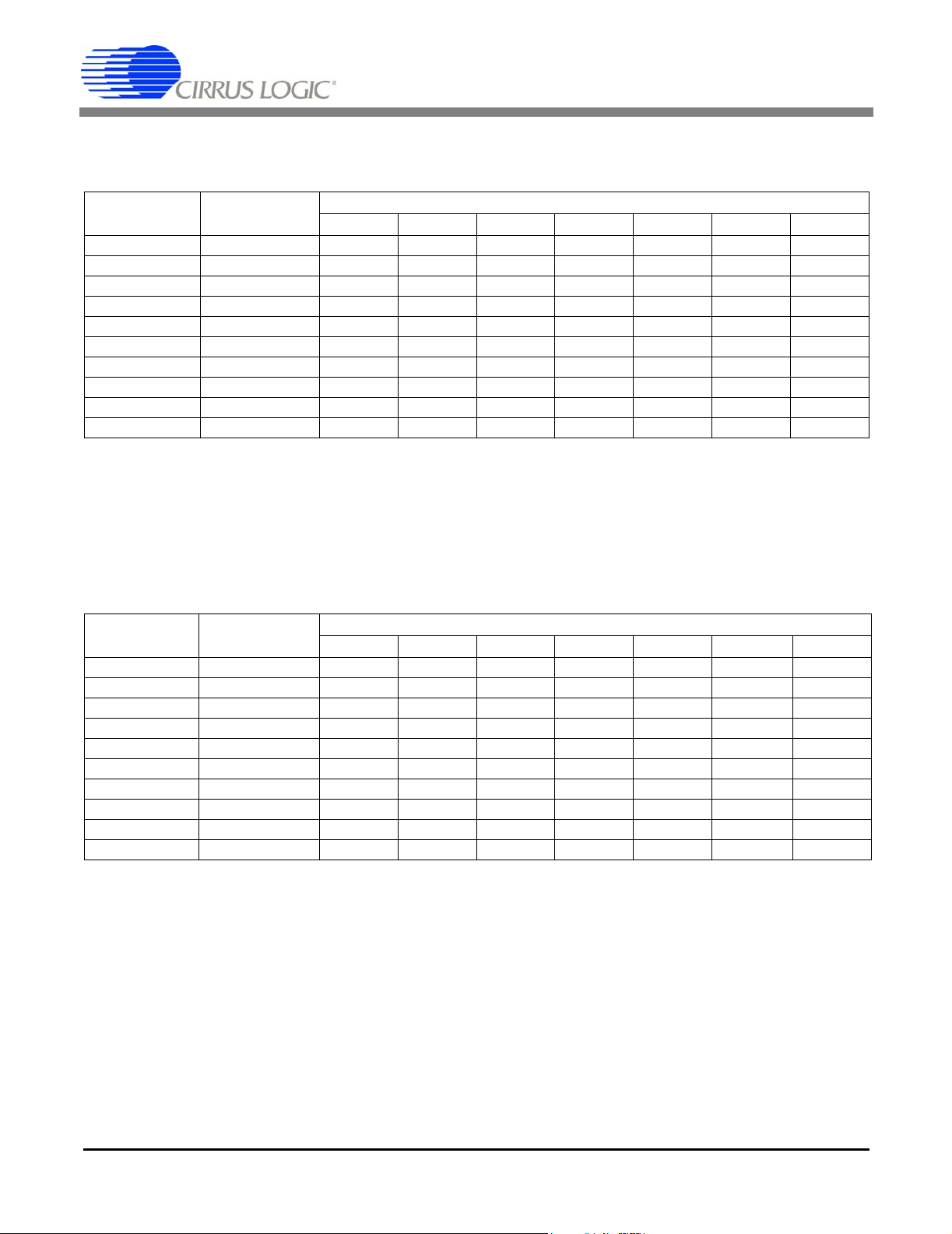

TYPICAL RMS NOISE (nV), CS5531/32/33/34-AS

(See notes 11, 12 and 13)

CS5531/32/33/34

Output Word

Rate (Sps)

7.5 1.94 171719264279155

15 3.88 24 25 27 36 59 111 218

30 7.75 34 35 39 51 84 157 308

60 15.5 48 49 54 72 118 222 436

120 31 68 70 77 102 167 314 616

240 62 115 160 276 527 1040 2070 4150

480 122 163 230 392 748 1480 2950 5890

960 230 229 321 554 1060 2090 4170 8340

1,920 390 344 523 946 1840 3650 7290 14600

3,840 780 1390 2710 5390 10800 21500 43000 86100

Notes: 11. Wideband noise aliased into the baseband. Referred to the input. Typical values shown for 25 °C.

12. For Peak-to-Peak Noise multiply by 6.6 for all ranges and output rates.

13. Word rates and -3dB points with FRS = 0. When FRS = 1, word rates and -3dB points scale by 5/6.

-3 dB Filter

Frequency (Hz)

x64 x32 x16 x8 x4 x2 x1

Instrumentation Amplifier Gain

TYPICAL NOISE FREE RESOLUTION(BITS), CS5532/34-AS (See Notes 14 and 15)

Output Word

Rate (Sps)

7.5 1.94 1920212222 22 22

15 3.88 19 20 21 21 21 22 22

30 7.75 18 19 20 21 21 21 21

60 15.5 18 19 20 20 20 21 21

120 31 17181920202020

240 62 16171717171717

480 122 16 17 17 17 17 17 17

960 230 15 16 16 16 16 16 16

1,920 390 151515151515 15

3,840 780 131313131313 13

-3 dB Filter

Frequency (Hz)

x64 x32 x16 x8 x4 x2 x1

Instrumentation Amplifier Gain

14. Noise Free Resolution listed is for Bipolar operation, and is calculated as LOG((Input Span)/(6.6xRMS

Noise))/LOG(2) rounded to the nearest bit. For Unipolar operation, the input span is 1/2 as large, so one

bit is lost. The input span is calculated in the analog input span section of the data sheet. The Noise

Free Resolution table is computed with a value of 1.0 in the gain register. Values other than 1.0 will

scale the noise, and change the Noise Free Resolution accordingly.

15. “Noise Free Resolution” is not the same as “Effective Resolution”. Effective Resolution is based on the

RMS noise value, while Noise Free Resolution is based on a peak-to-peak noise value specified as 6.6

times the RMS noise value. Effective Resolution is calculated as LOG((Input Span)/(RMS

Noise))/LOG(2).

Specifications are subject to change without notice.

DS289F1 7

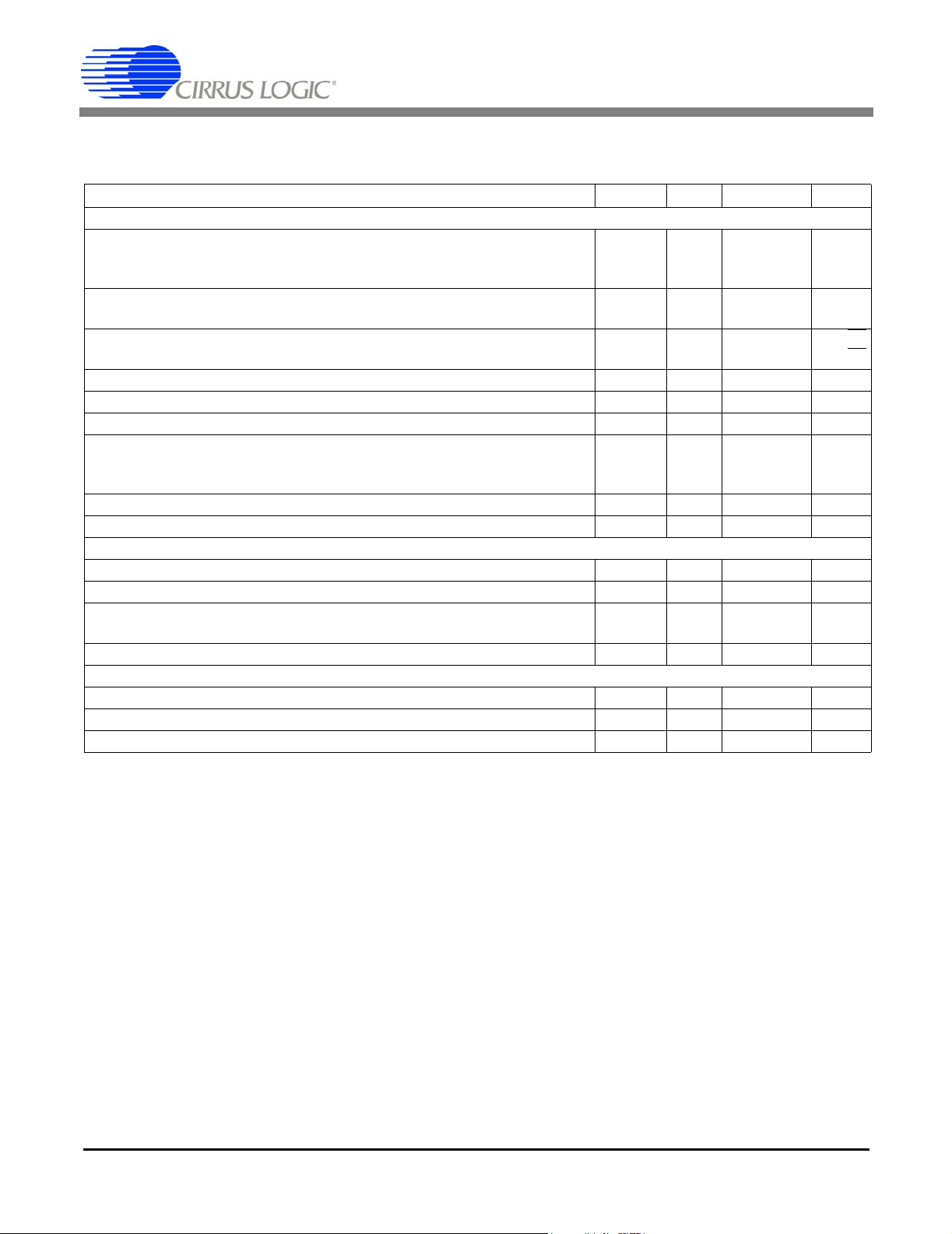

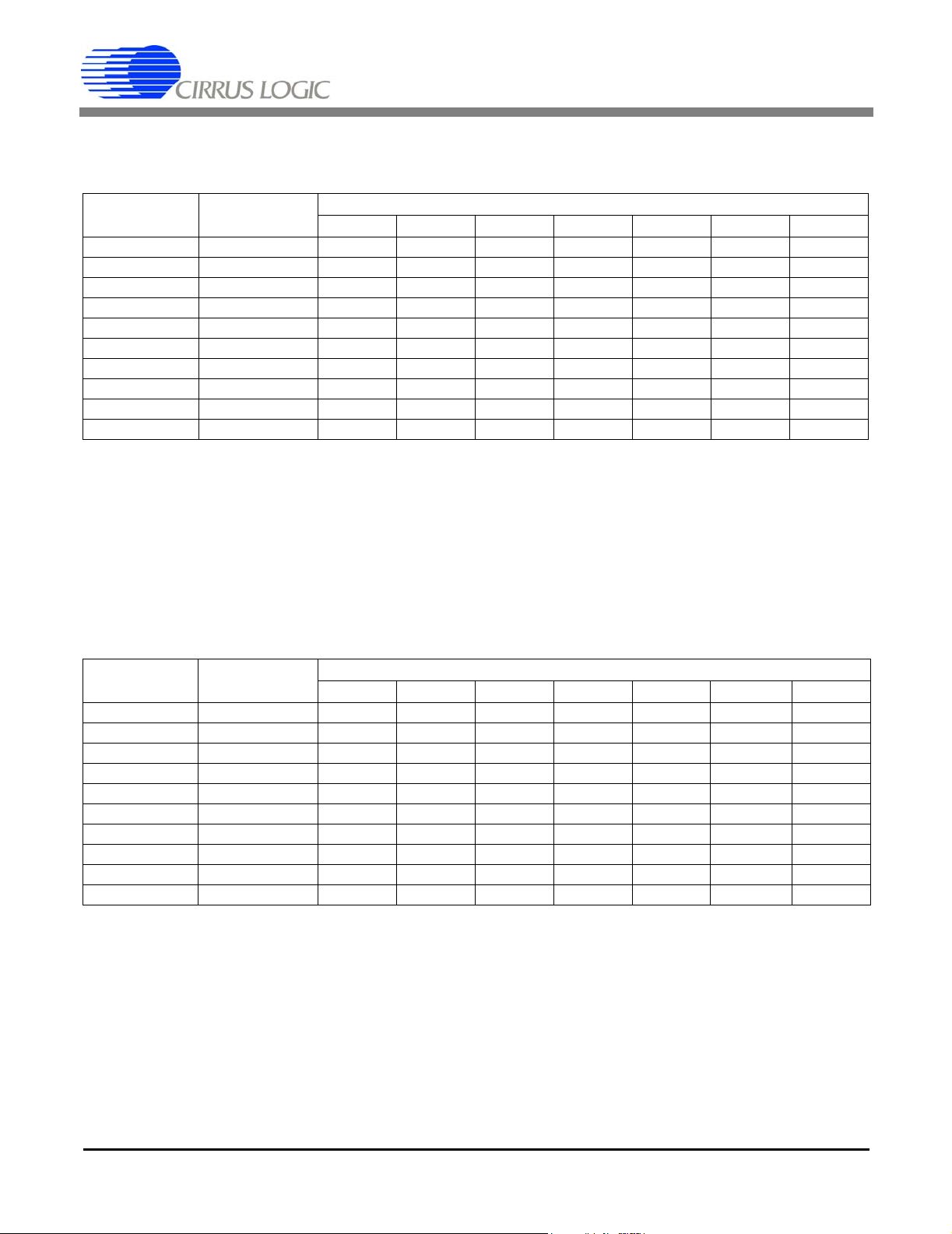

TYPICAL RMS NOISE (nV), CS5532/34-BS

(See notes 16, 17, 18 and 19)

CS5531/32/33/34

Output Word

Rate (Sps)

7.5 1.94 8.5 9 1015265099

15 3.88 12 13 15 21 37 70 139

30 7.75 17 18 21 30 52 99 196

60 15.5 24 25 29 42 73 140 277

120 31 34 36 42 59 103 198 392

240 62 80 136 260 514 1020 2050 4090

480 122 113 194 369 730 1450 2900 5810

960 230 159 274 523 1030 2060 4110 8230

1,920 390 260 470 912 1810 3620 7230 14500

3,840 780 1360 2690 5380 10800 21500 43000 86000

Notes: 16. The -B devices provide the best noise specifications.

17. Wideband noise aliased into the baseband. Referred to the input. Typical values shown for 25 °C.

18. For Peak-to-Peak Noise multiply by 6.6 for all ranges and output rates.

19. Word rates and -3dB points with FRS = 0. When FRS = 1, word rates and -3dB points scale by 5/6.

-3 dB Filter

Frequency (Hz)

x64 x32 x16 x8 x4 x2 x1

Instrumentation Amplifier Gain

TYPICAL NOISE FREE RESOLUTION(BITS), CS5532/34-BS

(See Notes 20 and 21)

Output Word

Rate (Sps)

7.5 1.94 2021222323 23 23

15 3.88 20 21 22 22 22 22 22

30 7.75 19 20 21 22 22 22 22

60 15.5 19 20 21 21 21 21 21

120 31 1819202121 21 21

240 62 1717181818 18 18

480 122 17 17 17 17 17 17 17

960 230 16 16 17 17 17 17 17

1,920 390 16161616161616

3,840 780 13131313131313

20. Noise Free Resolution listed is for Bipolar operation, and is calculated as LOG((Input Span)/(6.6xRMS

Noise))/LOG(2) rounded to the nearest bit. For Unipolar operation, the input span is 1/2 as large, so one

bit is lost. The input span is calculated in the analog input span section of the data sheet. The Noise

Free Resolution table is computed with a value of 1.0 in the gain register. Values other than 1.0 will scale

the noise, and change the Noise Free Resolution accordingly.

21. “Noise Free Resolution” is not the same as “Effective Resolution”. Effective Resolution is based on the

RMS noise value, while Noise Free Resolution is based on a peak-to-peak noise value specified as 6.6

times the RMS noise value. Effective Resolution is calculated as LOG((Input Span)/(RMS

Noise))/LOG(2).

-3 dB Filter

Frequency (Hz)

Specifications are subject to change without notice.

x64 x32 x16 x8 x4 x2 x1

Instrumentation Amplifier Gain

8 DS289F1

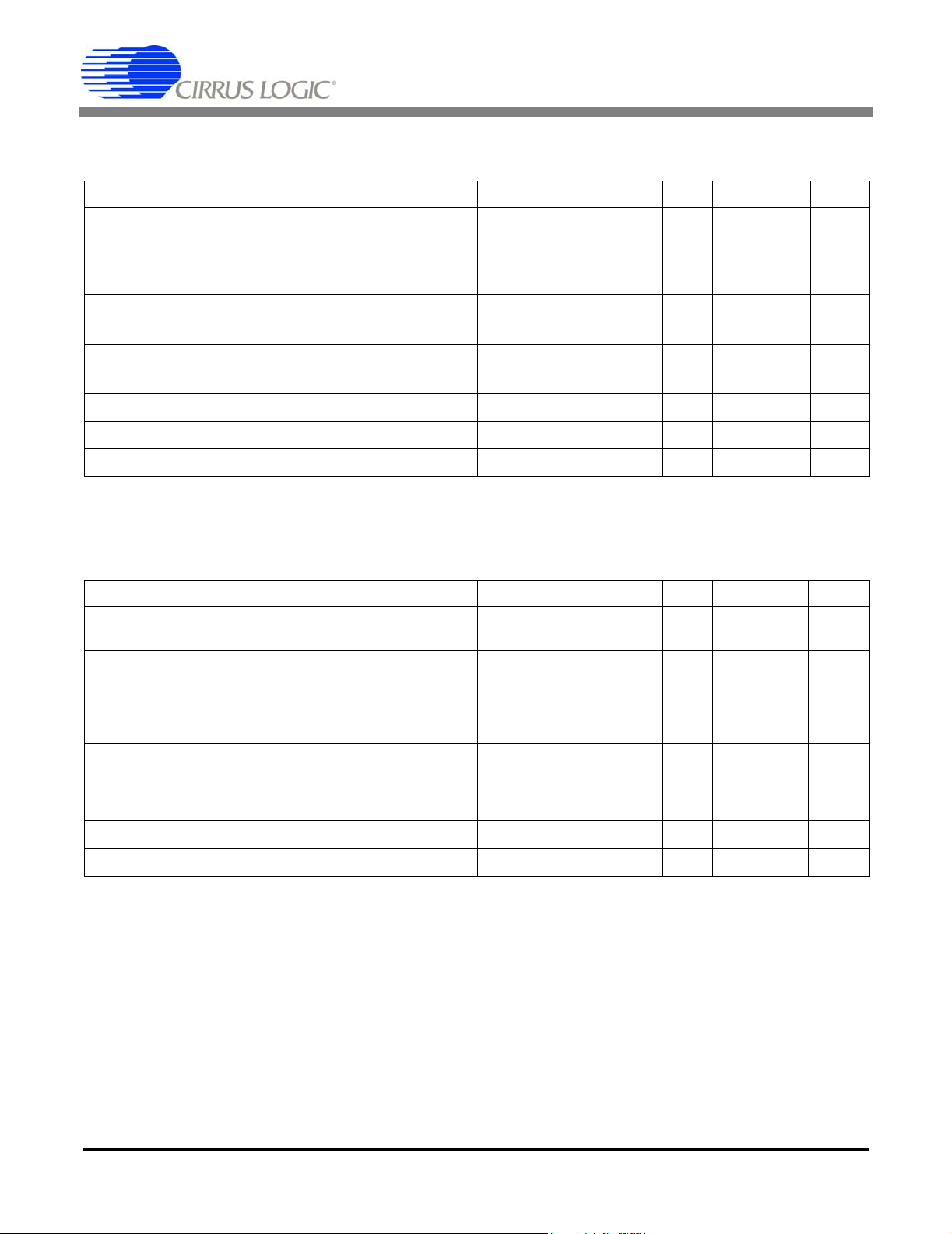

CS5531/32/33/34

5 V DIGITAL CHARACTERISTICS (VA+, VD+ = 5 V ±5%; VA-, DGND = 0 V;

See Notes 2 and 22.)

Parameter Symbol Min Typ Max Unit

High-Level Input Voltage All Pins Except SCLK

SCLK

Low-Level Input Voltage All Pins Except SCLK

SCLK

High-Level Output Voltage A0 and A1, I

SDO, I

Low-Level Output Voltage A0 and A1, I

SDO, I

= -1.0 mA

out

= -5.0 mA

out

= 1.0 mA

out

= 5.0 mA

out

Input Leakage Current I

SDO 3-State Leakage Current I

Digital Output Pin Capacitance C

V

IH

V

IL

V

OH

V

OL

in

OZ

out

0.6 VD+

(VD+) - 0.45--

0.0

-0.8

0.0

(VA+) - 1.0

--V

(VD+) - 1.0

- - (VA-) + 0.4

-±1±10µA

--±10µA

-9-pF

VD+

VD+

0.6

0.4

V

V

V

3 V DIGITAL CHARACTERISTICS (T

= 25 °C; VA+ = 5V ±5%; VD+ = 3.0V±10%; VA-, DGND =

A

0V; See Notes 2 and 22.)

Parameter Symbol Min Typ Max Unit

High-Level Input Voltage All Pins Except SCLK

SCLK

Low-Level Input Voltage All Pins Except SCLK

SCLK

High-Level Output Voltage A0 and A1, I

SDO, I

Low-Level Output Voltage A0 and A1, I

SDO, I

= -1.0 mA

out

= -5.0 mA

out

= 1.0 mA

out

= 5.0 mA

out

Input Leakage Current I

SDO 3-State Leakage Current I

Digital Output Pin Capacitance C

22. All measurements performed under static conditions.

V

IH

0.6 VD+

(VD+) - 0.45

V

IL

0.0

0.0

V

OH

(VA+) - 1.0

-VD+

V

VD+

-0.8

V

0.6

-- V

(VD+) - 1.0

V

OL

- - (VA-) + 0.4

V

0.4

in

OZ

out

-±1±10µA

--±10µA

-9-pF

DS289F1 9

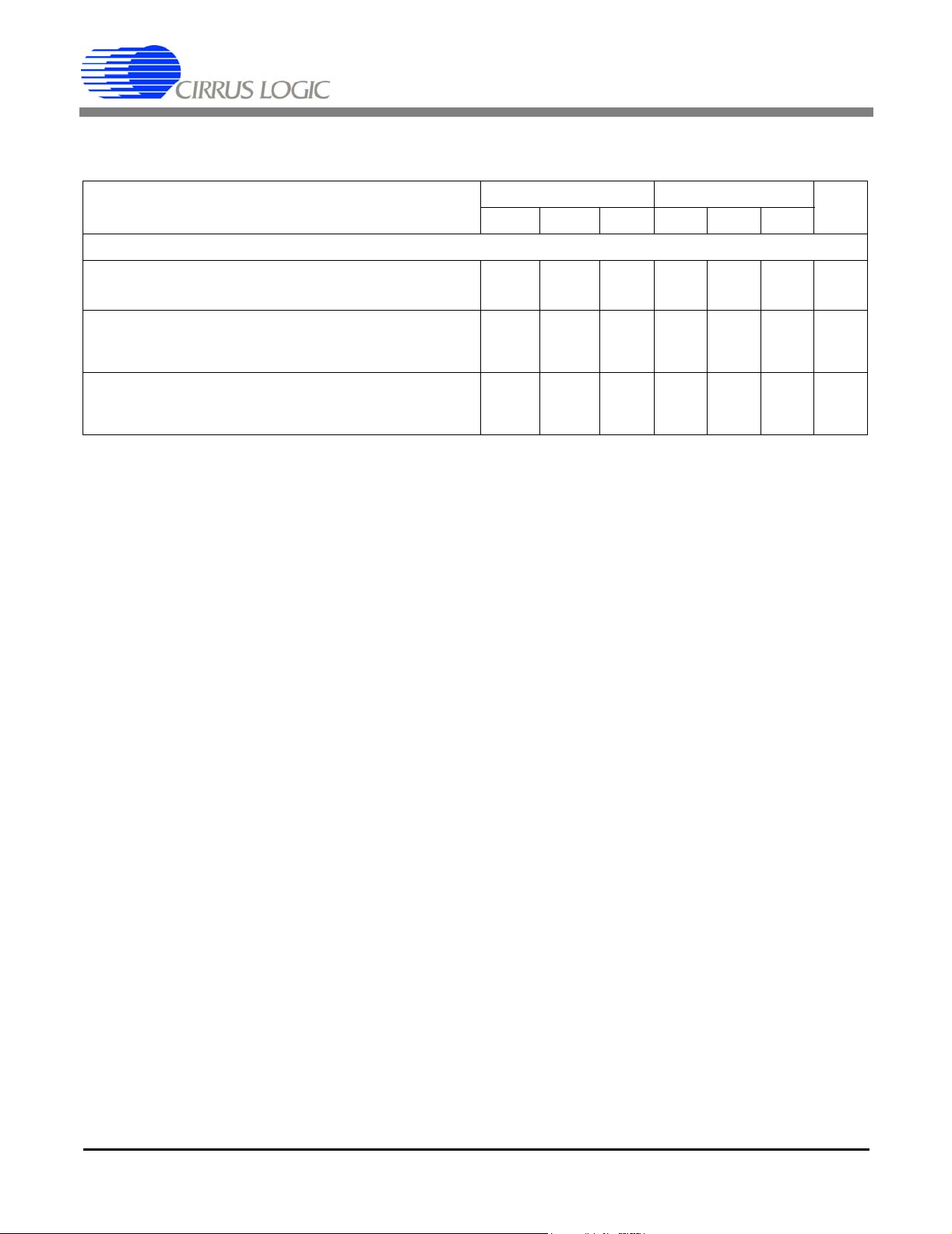

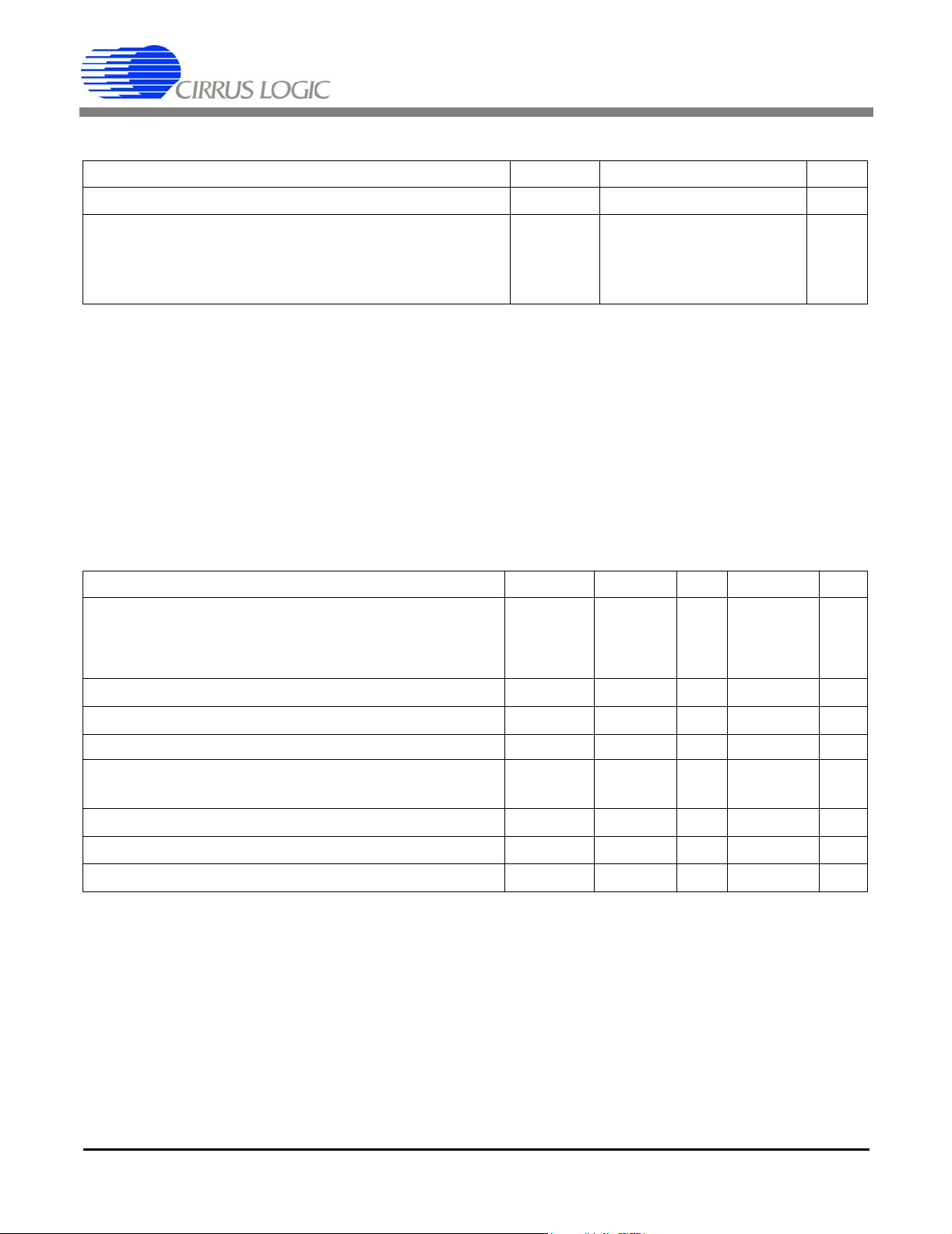

DYNAMIC CHARACTERISTICS

Parameter Symbol Ratio Unit

Modulator Sampling Rate f

Filter Settling Time to 1/2 LSB (Full Scale Step Input)

Single Conversion mode (Notes 23, 24, and 25)

Continuous Conversion mode, OWR < 3200 Sps

Continuous Conversion mode, OWR ≥ 3200 Sps

CS5531/32/33/34

s

t

s

t

s

t

s

MCLK/16 Sps

1/OWR

5/OWR

sinc5

SC

+ 3/OWR

5/OWR

s

s

s

23. The ADCs use a Sinc5 filter for the 3200 Sps and 3840 Sps output word rate (OWR) and a Sinc5 filter

followed by a Sinc

(FRS = 0) word rate associated with the Sinc

3

filter for the other OWRs. OWR

5

filter.

refers to the 3200 Sps (FRS = 1) or 3840 Sps

sinc5

24. The single conversion mode only outputs fully settled conversions. See Table 1 for more details about

single conversion mode timing. OWR

is used here to designate the different conversion time

SC

associated with single conversions.

25. The continuous conversion mode outputs every conversion. This means that the filter’s settling time

with a full scale step input in the continuous conversion mode is dictated by the OWR.

ABSOLUTE MAXIMUM RATINGS

(DGND = 0 V; See Note 26.)

Parameter Symbol Min Typ Max Unit

DC Power Supplies (Notes 27 and 28)

Positive Digital

Positive Analog

Negative Analog

Input Current, Any Pin Except Supplies (Notes 29 and 30) I

Output Current I

Power Dissipation (Note 31) PDN - - 500 mW

Analog Input Voltage VREF pins

AIN Pins

Digital Input Voltage V

Ambient Operating Temperature T

Storage Temperature T

VD+

VA+

VA-

IN

OUT

V

INR

V

INA

IND

A

stg

-0.3

-0.3

+0.3

-

-

-

+6.0

+6.0

-3.75

V

V

V

--±10mA

--±25mA

(VA-) -0.3

(VA-) -0.3--

(VA+) + 0.3

(VA+) + 0.3VV

-0.3 - (VD+) + 0.3 V

-40 - 85 °C

-65 - 150 °C

Notes: 26. All voltages with respect to ground.

27. VA+ and VA- must satisfy {(VA+) - (VA-)} ≤ +6.6 V.

28. VD+ and VA- must satisfy {(VD+) - (VA-)} ≤ +7.5 V.

29. Applies to all pins including continuous overvoltage conditions at the analog input (AIN) pins.

30. Transient current of up to 100 mA will not cause SCR latch-up. Maximum input current for a power

supply pin is ±50 mA.

31. Total power dissipation, including all input currents and output currents.

WARNING: Operation at or beyond these limits may result in permanent damage to the device.

Normal operation is not guaranteed at these extremes.

10 DS289F1

CS5531/32/33/34

SWITCHING CHARACTERISTICS

(VA+ = 2.5 V or 5 V ±5%; VA- = -2.5V±5% or 0 V; VD+ = 3.0 V ±10% or 5 V ±5%;DGND = 0 V; Levels: Logic 0 = 0

V, Logic 1 = VD+; C

Master Clock Frequency (Note 32)

Master Clock Duty Cycle 40 - 60 %

Rise Times (Note 33)

Fall Times (Note 33)

Start-up

Oscillator Start-up Time XTAL = 4.9152 MHz (Note 34) t

Serial Port Timing

Serial Clock Frequency SCLK 0 - 2 MHz

Serial Clock Pulse Width High

SDI Write Timing

CS

Enable to Valid Latch Clock t

Data Set-up Time prior to SCLK rising t

Data Hold Time After SCLK Rising t

SCLK Falling Prior to CS

SDO Read Timing

to Data Valid t

CS

SCLK Falling to New Data Bit t

Rising to SDO Hi-Z t

CS

= 50 pF; See Figures 1 and 2.)

L

Parameter Symbol Min Typ Max Unit

MCLK

External Clock or Crystal Oscillator

Any Digital Input Except SCLK

SCLK

Any Digital Output

Any Digital Input Except SCLK

SCLK

Any Digital Output

Pulse Width Low

Disable t

t

rise

t

fall

ost

t

t

1

2

3

4

5

6

7

8

9

1 4.9152 5 MHz

-

-

-

-

-

-

50

50

-

-

1.0

100

-

-

-

1.0

100

-

-20-ms

250

250

-

-

-

-

50 - - ns

50 - - ns

100 - - ns

100 - - ns

--150ns

--150ns

--150ns

µs

µs

ns

µs

µs

ns

ns

ns

Notes: 32. Device parameters are specified with a 4.9152 MHz clock.

33. Specified using 10% and 90% points on waveform of interest. Output loaded with 50 pF.

34. Oscillator start-up time varies with crystal parameters. This specification does not apply when using an

external clock source.

DS289F1 11

CS

CS5531/32/33/34

t3

CS

SDO

SDI

SCLK

t7

MSB

MSB-1

Figure 1. SDI Write Timing (Not to Scale)

MSB MSB-1

LSB

t6t4 t5 t1

t2

t9

LSB

t8

SCLK

t2

t1

Figure 2. SDO Read Timing (Not to Scale)

12 DS289F1

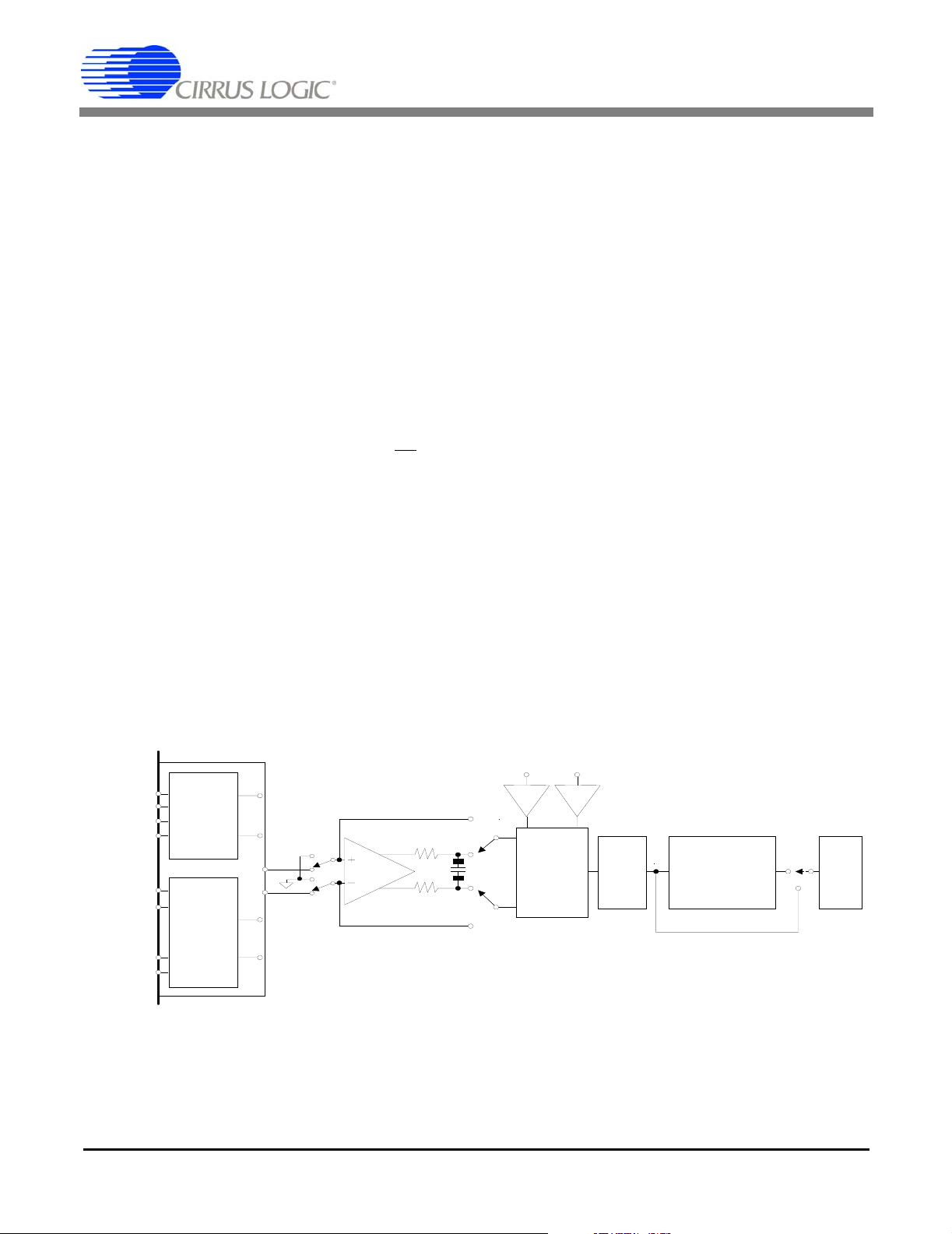

2. GENERAL DESCRIPTION

CS5531/32/33/34

The CS5531/32/33/34 are highly integrated ∆Σ

Analog-to-Digital Converters (ADCs) which use

charge-balance techniques to achieve 16-bit

(CS5531/33) and 24-bit (CS5532/34) performance. The ADCs are optimized for measuring

low-level unipolar or bipolar signals in weigh

scale, process control, scientific, and medical applications.

To accommodate these applications, the ADCs

come as either two-channel (CS5531/32) or fourchannel (CS5533/34) devices and include a very

low noise chopper-stabilized programmable gain

instrumentation amplifier (PGIA, 6 nV/√Hz @ 0.1

Hz) with selectable gains of 1×, 2×, 4×, 8×, 16×,

32×, and 64×. These ADCs also include a fourth

order ∆Σ modulator followed by a digital filter

which provides twenty selectable output word rat es

of 6.25, 7.5, 12.5, 15, 25, 30, 50, 60, 100, 120, 200,

240, 400, 480, 800, 960, 1600, 1920, 3200, and 3840

Samples per second (MCLK = 4.9152 MHz).

To ease communication between the ADCs and a

micro-controller, the converters include a simple

three-wire serial interface which is SPI and Microwire compatible with a Schmitt Trigger input

on the serial clock (SCLK).

2.1. Analog Input

Figure 3 illustrates a block diagram of the

CS5531/32/33/34. The front end consists of a multiplexer, a unity gain coarse/fine charge input buffer,

and a programmable gain chopper-stabilized instrumentation amplifier. The unity gain buffer is activated any time conversions are performed with a

gain of one and the instrumentation amplifier is activated any time conversions are performed with

gain settings greater than one.

The unity gain buffer is designed to accommodate

rail to rail input signals. The common-mode plus

signal range for the unity gain buffer amplifier is

VA- to VA+. Typical CVF (sampling) current for

the unity gain buffer amplifier is about 50 nA

(MCLK = 4.9152 MHz, see Figure 4).

The instrumentation amplifier is chopper stabilized and operates with a chop clock frequency of

AIN2+

AIN2-

AIN1+

AIN1-

AIN4+

AIN4-

AIN1+

AIN1-

*

*

*

CS5531/32

M

U

X

CS5533/34

M

U

X

VREF+

IN+

1000 Ω

22 nF

1000 Ω

X1

C1 PIN

C2 PIN

X1

IN-

IN+

IN-

IN+

IN-

GAIN is the gain setting of the PGIA (i.e. 2, 4, 8, 16, 32, 64)

X1

XGAIN

X1

VREF-

X1

Differential

th

4 Order

∆Σ

Modulator

X1

Sinc

Digital

Filter

5

Programmable

Digita l Filte r

Sinc

3

Serial

Port

Figure 3. Multiplexer Configuration

DS289F1 13

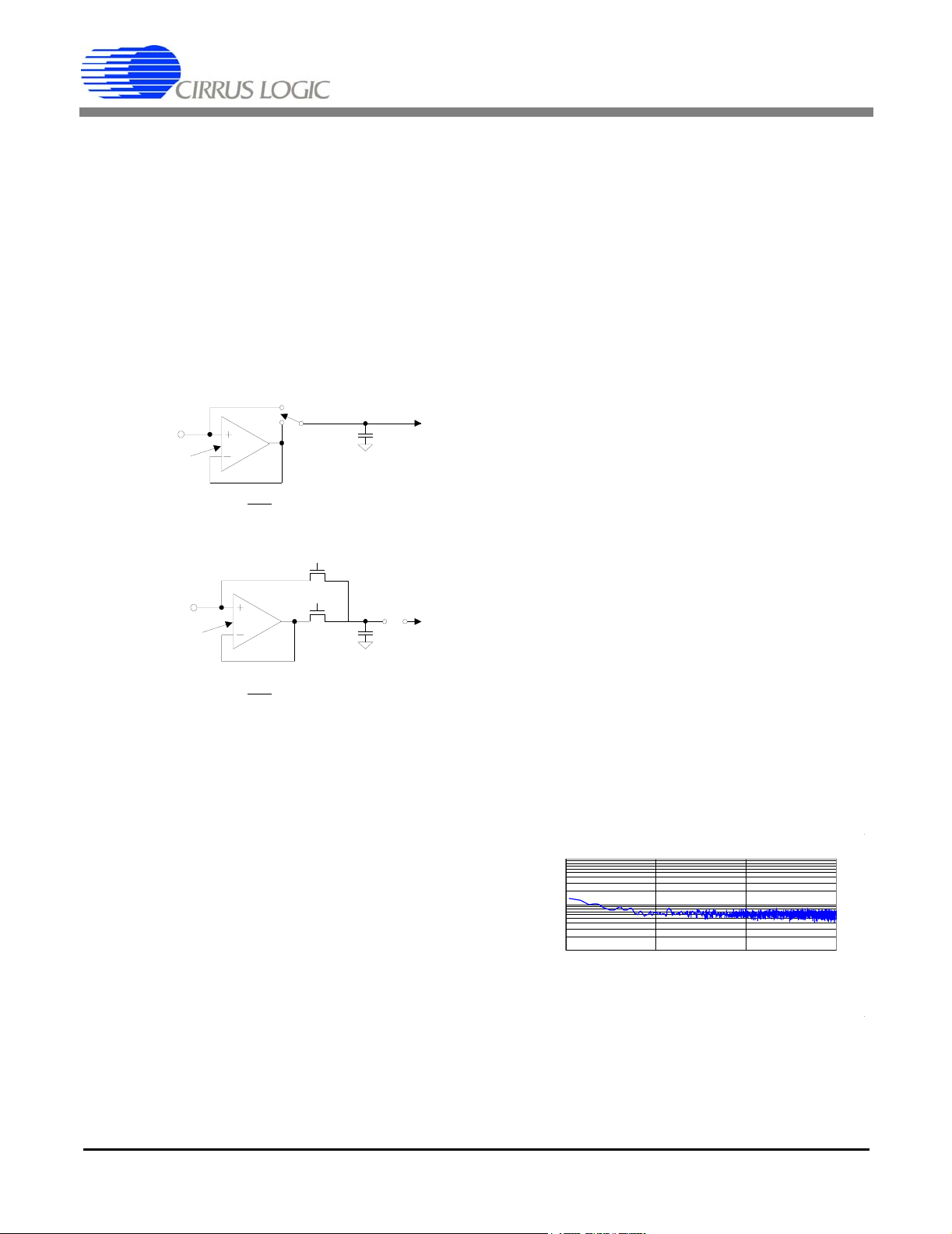

CS5531/32/33/34

MCLK/128. The CVF (sampling) current into the

instrumentation amplifier is typically 1200 pA over

-40°C to +85°C (MCLK=4.9152 MHz). The common-mode plus signal range of the instrumentation

amplifier is (VA-) + 0.7 V to (VA+) - 1.7 V.

Figure 4 illustrates the input models for the amplifiers. The dynamic input current for each of the

pins can be determined from the models shown.

Gain=2,4,8,16,32,64

AIN

V≤8mV

os

i=fV C

n

os

AIN

V≤12 mV

os

i=fV C

osn

Figure 4. Input models for AIN+ and AIN- pins

MCLK

f=

Gain = 1

MCLK

f=

128

16

=3.9pF

C

φ

Fine

1

φ

Coarse

1

C=14pF

age applied to the VREF+ and VREF- pins on the

part. See section 2.3.5 for more details.

After reset, the unity gain buffer is engaged. With a

2.5V reference this would make the full scale input

range default to 2.5 V. By activating the instrumentation amplifier (i.e. a gain setting other than 1) and

using a gain setting of 32, the full scale input range

can quickly be set to 2.5/32 or about 78 mV. Note

that these input ranges assume the calibration registers are set to their default values (i.e. Gain = 1.0 and

Offset = 0.0).

2.1.2. Multiplexed Settling Limitations

The settling performance of the CS5531/32/33/34

in multiplexed applications is affected by the single-pole low-pass filter which follows the instrumentation amplifier (see Figur e 3). To achieve data

sheet settling and linearity specifications, it is recommended that a 22 nF C0G capacitor be used. Capacitors as low as 10 nF or X7R type capacitors can

also be used with some minor increase in distortion

for AC signals.

2.1.3. Voltage Noise Density Performance

Figure 5 illustrates the measured voltage noise density versus frequency from 0.01 Hz to 10 Hz of a

CS5532-BS. The device was powered with ±2.5 V

supplies, using 120 Sps OWR, the 64x gain range,

bipolar mode, and with the input short bit enabled.

Note: The C=3.9pF and C = 14pF capacitors are for

input current modeling only. For physical

input capacitance see ‘Input Capacitance’

specification under Analog Characteristics.

2.1.1. Analog Input Span

The full scale input signal that the converter can digitize is a function of the gain setting and the reference voltage connected between the VREF+ and

100

Hz

√

10

nV/

1

0.01 0.1 1 10

Freque ncy (Hz)

Gain = 64

VREF- pins. The full scale input span of the converter is ((VREF+) - (VREF-))/(GxA), where G is the

gain of the amplifier and A is 2 for VRS = 0, or A is

1 for VRS = 1. VRS is the Voltage Reference Select

bit, and must be set according to the differential volt-

Figure 5. Measured Voltage Noise Density

2.1.4. No Offset DAC

An offset DAC was not included in the CS553X

family because the high dynamic range of the con-

14 DS289F1

CS5531/32/33/34

verter eliminates the need for one. The offset register can be manipulated by the user to mimic the

function of a DAC if desired.

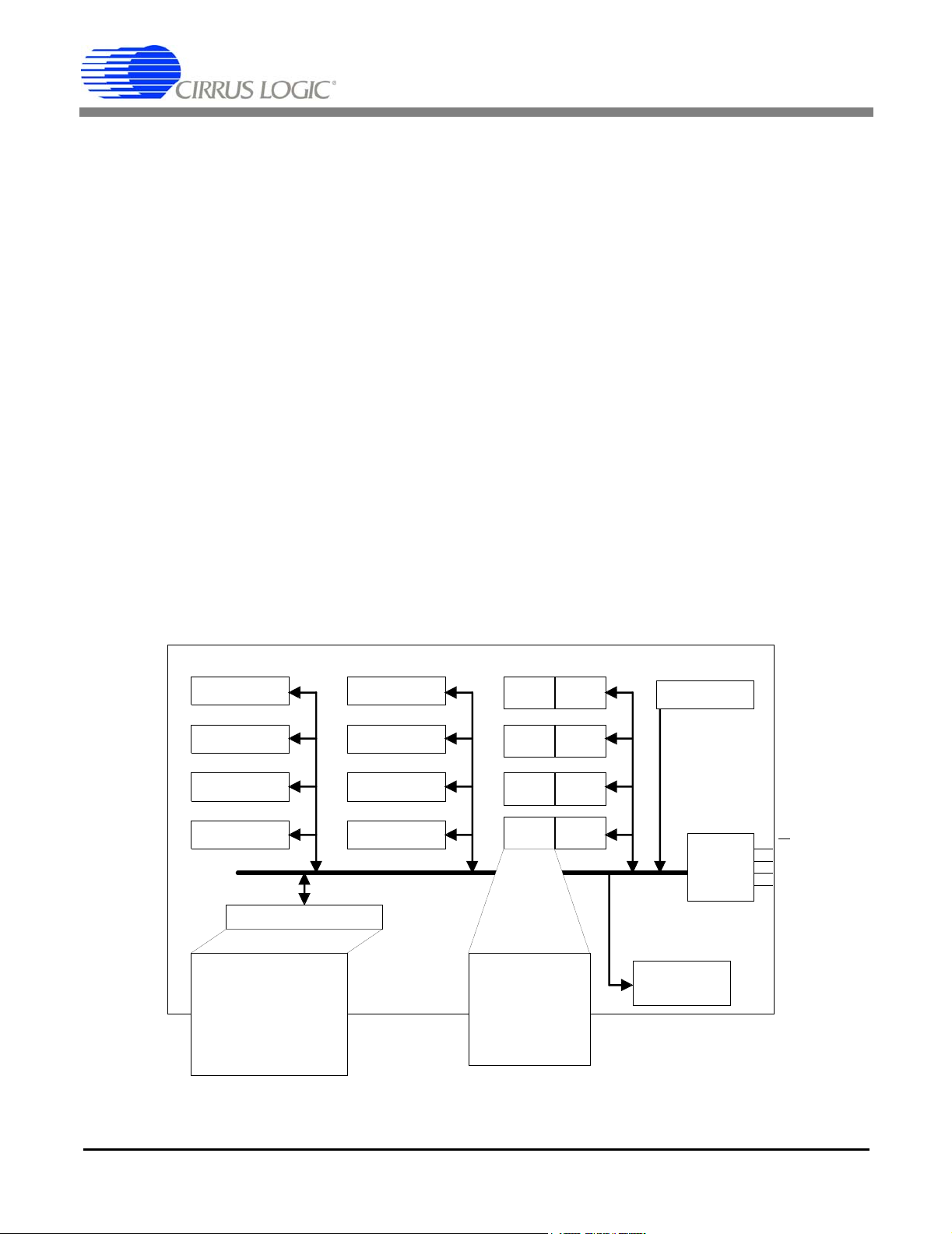

2.2. Overview of ADC Register Structure and Operating Modes

The CS5531/32/33/34 ADCs have an on-chip controller, which includes a number of user-accessible

registers. The registers are used to hold offset and

gain calibration results, configure the chip's operating modes, hold conversion instructions, and to

store conversion data words. Figure 6 depicts a

block diagram of the on-chip controller’s internal

registers.

Each of the converters has 32-bit registers to function as offset and gain calibration registers for each

channel. The converters with two channels have

two offset and two gain calibration registers, the

converters with four channels have four offset and

four gain calibration registers. These registers hold

calibration results. The contents of these registers

can be read or written by the user. This allows calibration data to be off-loaded into an external EEPROM. The user can also manipulate the contents

of these registers to modify the offset or the gain

slope of the converter.

The converters include a 32-bit configuration register which is used for setting options such as the

power down modes, resetting the converter, shorting the analog inputs, and enabling diagnostic test

bits like the guard signal.

A group of registers, called Channel Setup Registers, are used to hold pre-loaded conversion instructions. Each channel setup register is 32 bits

long, and holds two 16-bit conversion instructions

referred to as Setups. Upon power up, these registers can be initialized by the system microcontroller with conversion instructions. The user can then

instruct the converter to perform single or multiple

conversions or calibrations with the converter in

the mode defined by one of these Setups.

Offset Registers (4 x 32) Gain Registers (4 x 32)

Offset1(1x32)

Offset 2 (1 x 32)

Offset 3 (1 x 32)

Offset 4 (1 x 32)

Configuration Register (1 x 32)

Power Save Select

Reset System

Input Short

Guard Signal

Voltage Reference Select

Output Latch

Output Latch Select

Offset/Gain Se lect

Filter Rate Select

Gain 1 (1 x 32)

Gain 2 (1 x 32)

Gain 3 (1 x 32)

Gain 4 (1 x 32)

Figure 6. CS5531/32/33/34 Register Diagram

Channel Setup

Registers (4 x 32)

Setup 1

(1 x 16)

Setup 3

(1 x 16)

Setup 5

(1 x 16)

Setup 7

(1 x 16)

Channel Select

Gain

Word Rate

Unipolar/Bipo lar

Output Latch

Delay T ime

Open Circuit Detect

Offset/Gain Pointer

Setup 2

(1 x 16)

Setup 4

(1 x 16)

Setup 6

(1 x 16)

Setup 8

(1 x 16)

Write Only

Command

Register (1 × 8)

Conversion Data

Register (1 x 32)

Data (1 x 32)

Read Only

Serial

Interface

CS

SDI

SDO

SCLK

DS289F1 15

CS5531/32/33/34

Using the single conversion mode, an 8-bit command word can be written into the serial port. The

command includes pointer bits which ‘point’ to a

16-bit command in one of the Channel Setup Registers which is to be executed. The 16-bit Setups

can be programmed to perform a conversion on any

of the input channels of the converter. More than

one of the 16-bit Setups can be used for the same

analog input channel. This allows the user to convert on the same signal with either a different conversion speed, a different gain range, or any of the

other options available in the channel setup registers. Alternately, the user can set up the registers to

perform different conversion conditions on each of

the input channels.

The ADCs also include continuous conversion capability. The ADCs can be instructed to continuously convert, referencing one 16-bit command

Setup. In the continuous conversions mode, the

conversion data words are loaded into a shift register. The converter issues a flag on the SDO pin

when a conversion cycle is completed so the user

can read the register, if need be. See the section on

Performing Conversions for more details.

The following pages document how to initialize the

converter, perform offset and gain calibrations, and

how to configure the converter for the various conversion modes. Each of the bits of the configuration

register and of the Channel Setup Registers is described. A list of examples follows the description

section. Also the Command Register Quick Refer-

ence can be used to decode all valid commands (the

first 8-bits into the serial port).

2.2.1. System Initialization

The CS5531/32/33/34 provide no power-on-reset

function. To initialize the ADCs, the user must perform a software reset by resetting the ADC’s serial

port with the Serial Port Initialization sequence.

This sequence resets the serial port to the command

mode and is accomplished by transmitting at least

15 SYNC1 command bytes (0xFF hexadecimal),

followed by one SYNC0 command (0xFE hexadecimal). Note that this sequence can be initiated at

anytime to reinitialize the serial port. To complete

the system initialization sequence, the user must

also perform a system reset sequence which is as

follows: Write a logic 1 into the RS bit of the configuration register. This will reset the calibration

registers and other logic (but not the serial port). A

valid reset will set the RV bit in the configuration

register to a logic 1. After writing the RS bit to a

logic 1, wait 20 microseconds, then write the RS bit

back to logic 0. While this involves writing an entire word into the configuration register, the RV bit

is a read only bit, therefore a write to the configuration register will not overwrite the RV bit. After

clearing the RS bit back to logic 0, read the configuration register to check the state of the RV bit as

this indicates that a valid reset occurred. Reading

the configuration register clears the RV bit back to

logic 0.

Completing the reset cycle initializes the on-chip

registers to the following states:

Configuration Register: 00000000(H)

Offset Registers: 00000000(H)

Gain Registers: 01000000(H)

Channel Setup Registers: 00000000(H)

Note: Previous datasheets stated that the RS bit

would clear itself back to logic 0 and therefore

the user was not required to write the RS bit

back to logic 0. The current data sheet

instruction that requires the user to write into

the configuration register to clear the RS bit

has been added to insure that the RS bit is

cleared. Characterization across multiple lots

of silicon has indicated some chips do not

automatically reset the RS bit to logic 0 in the

configuration register, although the reset

function is completed. This occurs only on

small number of chips when the VA- supply is

negative with respect to DGND. This has not

caused an operational issue for customers

because their start-up sequence includes

writing a word (with RS=0) into the

configuration register after performing a

16 DS289F1

CS5531/32/33/34

reset. The change in the reset sequence to

include writing the RS bit back to 0 insures

the clearing of the RS bit in the event that a

user does not write into the configuration

register after the RS bit has been set.

The RV bit in the Configuration Register is set to

indicate a valid reset has occurred. The RS bit

should be written back to logic “0” to complete the

reset cycle. After a system initialization or reset,

the on-chip controller is initialized into command

mode where it waits for a valid command (the first

8-bits written into the serial port are shifted into the

command register). Once a valid command is received and decoded, the byte instructs the converter

to either acquire data from or transfer data to an internal register(s), or perform a conversion or a calibration. The Command Register Descriptions

section can be used to decode all valid commands.

DS289F1 17

CS5531/32/33/34

2.2.2. Command Register Quick Reference

D7(MSB) D6 D5 D4 D3 D2 D1 D0

0 ARA CS1 CS0 R/W

BIT NAME VALUE FUNCTION

D7 Command Bit, C 01Must be logic 0 for these commands.

These commands are invalid if this bit is logic 1.

RSB2 RSB1 RSB0

D6 Access Registers as

Arrays, ARA

D5-D4 Channel Select Bits,

CS1-CS0

D3 Read/Write

D2-D0 Register Select Bit,

RSB3-RSB0

D7(MSB) D6 D5 D4 D3 D2 D1 D0

1 MC CSRP2 CSRP1 CSRP0 CC2 CC1 CC0

, R/W 01Write to selected register.

01Ignore this function.

Access the respective registers, offset, gain, or channel-setup, as an array of registers. The particular registers accessed are determined by the RS bits. The registers

are accessed MSB first with physical channel 0 accessed first followed by physical

channel 1 next and so forth.

00

CS1-CS0 provide the address of one of the two (four for CS5533/34) physical input

01

channels. These bits are also used to access the calibration registers associated

10

with the respective physical input channel. Note that these bits are ignored when

11

reading data register.

Read from selected register.

000

Reserved

001

Offset Register

010

Gain Register

011

Configuration Register

101

Channel-Setup Registers

110

Reserved

111

Reserved

BIT NAME VALUE FUNCTION

D7 Command Bit, C 01These commands are invalid if this bit is logic 0.

Must be logic 1 for these commands.

D6 Multiple Conver-

sions, MC

D5-D3 Channel-Setup Reg-

ister Pointer Bits,

CSRP

D2-D0 Conversion/Calibra-

tion Bits, CC2-CC0

01Perform fully settled single conversions.

Perform conversions continuously.

000

These bits are used as pointers to the Channel-Setup registers. Either a single con-

...

version or continuous conversions are performed on the channel setup register

111

pointed to by these bits.

000

Normal Conversion

001

Self-Offset Calibration

010

Self-Gain Calibration

011

Reserved

100

Reserved

101

System-Offset Calibration

110

System-Gain Calibration

111

Reserved

18 DS289F1

CS5531/32/33/34

2.2.3. Command Register Descriptions

READ/WRITE ALL OFFSET CALIBRATION REGISTERS

D7(MSB) D6 D5 D4 D3 D2 D1 D0

0100R/W

Function: These commands are used to access the offset registers as arrays.

R/W

(Read/Write)

0 Write to selected registers.

1 Read from selected registers.

READ/WRITE ALL GAIN CALIBRATION REGISTERS

D7(MSB) D6 D5 D4 D3 D2 D1 D0

0100R/W

Function: These commands are used to access the gain registers as arrays.

R/W

(Read/Write)

0 Write to selected registers.

1 Read from selected registers.

001

010

READ/WRITE ALL CHANNEL-SETUP REGISTERS

D7(MSB) D6 D5 D4 D3 D2 D1 D0

0100R/W101

Function: These commands are used to access the channel-setup registers as arrays.

R/W

(Read/Write)

0 Write to selected registers.

1 Read from selected registers.

READ/WRITE INDIVIDUAL OFFSET REGISTER

D7(MSB) D6 D5 D4 D3 D2 D1 D0

0 0 CS1 CS0 R/W 001

Function

: These commands are used to access each offset register separately. CS1 - CS0 decode the

registers accessed.

R/W

(Read/Write)

0 Write to selected register.

1 Read from selected register.

CS[1:0] (Channel Select Bits)

00 Offset Register 1 (All devices)

01 Offset Register 2 (All devices)

10 Offset Register 3 (CS5533/34 only)

11 Offset Register 4 (CS5533/34 only)

DS289F1 19

CS5531/32/33/34

READ/WRITE

D7(MSB) D6 D5 D4 D3 D2 D1 D0

0 0 CS1 CS0 R/W

Function

INDIVIDUAL GAIN REGISTER

010

: These commands are used to access each gain register separately. CS1 - CS0 decode the reg-

isters accessed.

R/W

(Read/Write)

0 Write to selected register.

1 Read from selected register.

CS[1:0] (Channel Select Bits)

00 Gain Register 1 (All devices)

01 Gain Register 2 (All devices)

10 Gain Register 3 (CS5533/34 only)

11 Gain Register 4 (CS5533/34 only)

READ/WRITE INDIVIDUAL CHANNEL-SETUP REGISTER

D7(MSB) D6 D5 D4 D3 D2 D1 D0

0 0 CS1 CS0 R/W

Function

: These commands are used to access each channel-setup register separately. CS1 - CS0 de-

101

code the registers accessed.

R/W

(Read/Write)

0 Write to selected register.

1 Read from selected register.

CS[1:0] (Channel Select Bits)

00 Channel-Setup Register 1 (All devices)

01 Channel-Setup Register 2 (All devices)

10 Channel-Setup Register 3 (All devices)

11 Channel-Setup Register 4 (All devices)

READ/WRITE CONFIGURATION REGISTER

D7(MSB) D6 D5 D4 D3 D2 D1 D0

0000R/W

011

Function: These commands are used to read from or write to the configuration register.

R/W

(Read/Write)

0 Write to selected register.

1 Read from selected register.

20 DS289F1

CS5531/32/33/34

PERFORM CONVERSION

D7(MSB) D6 D5 D4 D3 D2 D1 D0

1 MC CSRP2 CSRP1 CSRP0 0 0 0

Function: These commands instruct the ADC to perform either a single, fully-settled conversion or con-

tinuous conversions on the physical input channel pointed to by the pointer bits (CSRP2 CRSP0) in the channel-setup register.

MC (Multiple Conversions)

0 Perform a single conversion.

1 Perform continuous conversions.

CSRP [2:0] (Channel Setup Register Pointer Bits)

000 Setup 1 (All devices)

001 Setup 2 (All devices)

010 Setup 3 (All devices)

011 Setup 4 (All devices)

100 Setup 5 (All devices)

101 Setup 6 (All devices)

110 Setup 7 (All devices)

111 Setup 8 (All devices)

DS289F1 21

CS5531/32/33/34

PERFORM CALIBRATION

D7(MSB) D6 D5 D4 D3 D2 D1 D0

1 0 CSRP2 CSRP1 CSRP0 CC2 CC1 CC0

Function: These commands instruct the ADC to perform a calibration on the physical input channel se-

lected by the setup register which is chosen by the command byte pointer bits (CSRP2 CSRP0).

CSRP [2:0] (Channel Setup Register Pointer Bits)

000 Setup 1 (All devices)

001 Setup 2 (All devices)

010 Setup 3 (All devices)

011 Setup 4 (All devices)

100 Setup 5 (All devices)

101 Setup 6 (All devices)

110 Setup 7 (All devices)

111 Setup 8 (All devices)

CC [2:0] (Calibration Control Bits)

000 Reserved

001 Self-Offset Calibration

010 Self-Gain Calibration

011 Reserved

100 Reserved

101 System-Offset Calibration

110 System-Gain Calibration

111 Reserved

SYNC1

D7(MSB) D6 D5 D4 D3 D2 D1 D0

11111111

Function: Part of the serial port re-initialization sequence.

SYNC0

D7(MSB) D6 D5 D4 D3 D2 D1 D0

11111110

Function: End of the serial port re-initialization sequence.

NULL

D7(MSB) D6 D5 D4 D3 D2 D1 D0

00000000

Function:

This command is used to clear a port flag and keep the converter in the continuous conversion mode.

22 DS289F1

CS5531/32/33/34

2.2.4. Serial Port Interface

The CS5531/32/33/34’s serial interface consists of

four control lines: CS, SDI, SDO, SCLK. Figure 7

details the command and data word timing.

CS, Chip Select, is the control line which enables

access to the serial port. If the CS pin is tied low,

the port can function as a three wire interface.

SDI, Serial Data In, is the data signal used to transfer data to the converters.

SDO, Serial Data Out, is the data signal used to

transfer output data from the converters. The SDO

output will be held at high impedance any time CS

is at logic 1.

CS

SCLK

SDI

Command Time

8SCLKs

MSB

SCLK, Serial Clock, is the serial bit-clock which

controls the shifting of data to or from the ADC’s

serial port. The CS pin must be held low (logic 0)

before SCLK transitions can be recognized by the

port logic. To accommodate optoisolators SCLK is

designed with a Schmitt-trigger input to allow an

optoisolator with slower rise and fall times to directly drive the pin. Additionally, SDO is capable

of sinking or sourcing up to 5 mA to directly drive

an optoisolator LED. SDO will have less than a 400

mV loss in the drive voltage when sinking or sourcing 5 mA.

LSB

Data T ime 32 SCLKs

Write Cycle

CS

SCLK

SDI

Command Time

8SCLKs

t*

d

MSB

8 SCLKs Clear SDO Flag

Data Conversion Cycle

SDO

CS

SCLK

SDI

Command Time

8SCLKs

SDO

* td is the time it takes the ADC to perform a conversion. See the Single

Conversion and Continuous Conversion sections of the data sheet for more

details about conversion timing.

Read Cycle

Data Time 32 SCLKs

MSB

Data T ime 32 SCLKs

/OWR

MCLK

Clock Cycles

LSB

LSB

Figure 7. Command and Data Word Timing

DS289F1 23

CS5531/32/33/34

2.2.5. Reading/Writing On-Chip Registers

The CS5531/32/33/34’s offset, gain, configuration,

and channel-setup registers are readable and writable while the conversion data register is read only.

As shown in Figure 7, to write to a particular register the user must transmit the appropriate write

command and then follow that command by 32 bits

of data. For example, to write 0x80000000 (hexadecimal) to physical channel one’s gain register,

the user would first transmit the command byte

0x02 (hexadecimal) followed by the data

0x80000000 (hexadecimal). Similarly, to read a

particular register the user must transmit the appropriate read command and then acquire the 32 bits of

data. Once a register is written to or read from, the

serial port returns to the command mode.

In addition to accessing the internal registers one at

a time, the gain and offset registers as well as the

channel setup registers can be accessed as arrays

(i.e. the entire register set can be accessed with one

command). In the CS5531/32, there are two gain

and offset registers, and in the CS5533/34, there are

four gain and offset registers. There are four channel setup registers in all parts. As an example, to

write 0x80000000 (hexadecimal) to all four gain

registers in the CS5533, the user would transmit the

command 0x42 (hexadecimal) followed by four iterations of 0x80000000 (hexadecimal), (i.e. 0x42

followed by 0x80000000, 0x80000000,

0x80000000, 0x80000000). The registers are written to or read from in sequential order (i.e, 1, followed by 2, 3, and 4). Once the registers are written

to or read from, the serial port returns to the command mode.

2.3. Configuration Register

To ease the architectural design and simplify the

serial interface, the configuration register is thirtytwo bits long, however, only eleven of the thirty

two bits are used. The following sections detail the

bits in the configuration register.

2.3.1. Power Consumption

The CS5531/32/33/34 accommodate three power

consumption modes: normal, standby, and sleep.

The default mode, “normal mode”, is entered after

power is applied. In this mode, the

CS5531/32/33/34-AS versions typically consume

35 mW. The CS5532/34-BS versions typically

consume 70 mW. The other two modes are referred

to as the power save modes. They power down

most of the analog portion of the chip and stop filter

convolutions. The power save modes are entered

whenever the power down (PDW) bit of the configuration register is set to logic 1. The particular power save mode entered depends on state of the PSS

(Power Save Select) bit. If PSS is logic 0, the converter enters the standby mode reducing the power

consumption to 4 mW. The standby mode leaves

the oscillator and the on-chip bias generator for the

analog portion of the chip active. This allows the

converter to quickly return to the normal mode

once PDW is set back to a logic 1. If PSS and PDW

are both set to logic 1, the sleep mode is entered reducing the consumed power to around 500 µW.

Since this sleep mode disables the oscillator, approximately a 20 ms oscillator start-up delay period

is required before returning to the normal mode. If

an external clock is used, there will be no delay.

Further note that when the chips are used in the

Gain = 1 mode, the PGIA is powered down. With

the PGIA powered down, the power consumed in

the normal power mode is reduced by approximately 1/2. Power consumption in the sleep and standby

modes is not affected by the amplifier setting.

2.3.2. System Reset Sequence

The reset system (RS) bit permits the user to perform a system reset. A system reset can be initiated

at any time by writing a logic 1 to the RS bit in the

configuration register. After the RS bit has been

set, the internal logic of the chip will be initialized

to a reset state. The reset valid (RV) bit is set indicating that the internal logic was properly reset.

The RV bit is cleared after the configuration regis-

24 DS289F1

CS5531/32/33/34

ter is read. The on-chip registers are initialized to

the following default states:

Configuration Register: 00000000(H)

Offset Registers: 00000000(H)

Gain Registers: 01000000(H)

Channel Setup Registers: 00000000(H)

After reset, the RS bit should be written back to

logic 0 to complete the reset cycle. The ADC will

return to the command mode where it waits for a

valid command. Also, the RS bit is the only bit in

the configuration register that can be set when initiating a reset (i.e. a second write command is needed to set other bits in the Configuration Register

after the RS bit has been cleared).

2.3.3. Input Short

The input short bit allows the user to internally

ground all the inputs of the multiplexer. This is a

useful function because it allows the user to easily

test the grounded input performance of the ADC

and eliminate the noise effects due to the external

system components.

2.3.4. Guard Signal

The guard signal bit is a bit that modifies the function of A0. When set, this bit outputs the common

mode voltage of the instrumentation amplifier on

A0. This feature is useful when the user wants to

connect an external shield to the common mode potential of the instrumentation amplifier to protect

against leakage. Figure 8 illustrates a typical connection diagram for the guard signal.

2.3.5. Voltage Reference Select

buffer which reduces the dynamic current demand

of the external reference.

The reference’s input buffer is designed to accommodate rail-to-rail (common-mode plus signal) input voltages. The differential voltage between the

VREF+ and VREF- can be any voltage from 1.0 V

up to the analog supply (depending on how VRS is

configured), however, the VREF+ cannot go above

VA+ and the VREF- pin can not go below VA-.

Note that the power supplies to the chip should be

established before the reference voltage.

2.3.6. Output Latch Pins

The A1-A0 pins of the ADCs mimic the D21D20/D5-D4 bits of the channel-setup registers if

the output latch select (OLS) bit is logic 0 (default).

If the OLS bit is logic 1, A1-A0 mimic the output

latch bit settings in the configuration register.

These two options give the user a choice of allowing the latch outputs to change anytime a different

CSR is selected for a conversion, or to allow the

latch bits to remain latched to a fixed state (determined by the configuration register bit) for all CSR

selections. In either case, A1-A0 can be used to

control external multiplexers and other logic functions outside the converter. The A1-A0 outputs can

sink or source at least 1 mA, but it is recommended

to limit drive currents to less than 20 µA to reduce

self-heating of the chip. These outputs are powered

AIN+

CS5531/32/33/34

+5 VA +

out p

A0/GUARD

The voltage reference select (VRS) bit selects the

size of the sampling capacitor used to sample the

voltage reference. The bit should be set based upon

V+

IN

Comm on Mode = 2.5 V

V-

IN

AIN-

center

out m

x1

the magnitude of the reference voltage to achieve

optimal performance. Figures 9 and 10 model the

effects on the reference’s input impedance and input current for each VRS setting. As the models

Figure 8. Guard Signal Shielding Scheme

show, the reference includes a coarse/fine charge

DS289F1 25

VREF

V≤8mV

os

i=fV C

os

n

φ

Fine

1

φ

Coarse

2

C=14pF

MCLK

f=

16

VRS = 1; 1 V≤V ≤2.5 V

REF

VREF

V≤16 mV

os

i=fV C

osn

CS5531/32/33/34

φ

Fine

1

φ

Coarse

2

C= 7pF

MCLK

f=

16

VRS = 0; 2.5 V < V

REF

≤

VA+

Figure 9. Input Reference Model when VRS = 1

from VA+ and VA-. Their output voltage will be

limited to the VA+ voltage for a logic 1 and VAfor a logic 0.

2.3.7. Offset and Gain Select

The Offset and Gain Select bit (OGS) is used to select the source of the calibration registers to use

when performing conversions and calibrations.

When the OGS bit is set to ‘0’, the offset and gain

registers corresponding to the desired physical

channel (CS1-CS0 in the selected Setup) will be accessed. When the OGS bit is set to ‘1’, the offset

and gain registers pointed to by the OG1-OG0 bits

in the selected Setup will be accessed. This feature

allows multiple calibration values (e.g. for different

gain settings) to be used on a single physical channel without having to re-calibrate or manipulate the

calibration registers.

Figure 10. Input Reference Model when VRS = 0

2.3.8. Filter Rate Select

The Filter Rate Select bit (FRS) modifies the output

word rates of the converter to allow either 50 Hz or

60 Hz rejection when operating from a 4.9152

MHz crystal. If FRS is cleared to logic 0, the word

rates and corresponding filter characteristics can be

selected (using the Channel Setup Registers) from

7.5, 15, 30, 60, 120, 240, 480, 960, 1920, or 3840

Sps when using a 4.9152 MHz clock. If FRS is set

to logic 1, the word rates and corresponding filter

characteristics scale by a factor of 5/6, making the

selectable word rates 6.25, 12.5, 25, 50, 100, 200,

400, 800, 1600, and 3200 Sps when using a 4.9152

MHz clock. When using other clock frequencies,

these selectable word rates will scale linearly with

the clock frequency that is used.

26 DS289F1

CS5531/32/33/34

2.3.9. Configuration Register Descriptions

D31(MSB) D30 D29 D28 D27 D26 D25 D24 D23 D22 D21 D20 D19 D18 D17 D16

PSS PDW RS RV IS GB VRS A1 A0 OLS NU OGS FRS NU NU NU

D15 D14D13D12D11D10D9 D8D7D6D5D4D3D2D1D0

NU NU NU NU NU NU NU NU NU NU NU NU NU NU NU NU

PSS (Power Save Select)[31]

0 Standby Mode (Oscillator active, allows quick power-up).

1 Sleep Mode (Oscillator inactive).

PDW (Power Down Mode)[30]

0 Normal Mode

1 Activate the power save select mode.

RS (Reset System)[29]

0 Normal Operation.

1 Activate a Reset cycle. See System Reset Sequence in the datasheet text.

RV (Reset Valid)[28]

0 Normal Operation

1 System was reset. This bit is read only. Bit is cleared to logic zero after the configuration register is read.

IS (Input Short)[27]

0 Normal Input

1 All signal input pairs for each channel are disconnected from the pins and shorted internally.

GB (Guard Signal Bit)[26]

0 Normal Operation of A0 as an output latch.

1 A0’s output is modified to output the common mode output voltage of the instrumentation amplifier (typically

2.5 V). The output latch select bit is ignored when the guard buffer is activated.

VRS (Voltage Reference Select)[25]

0 2.5 V < V

11 V ≤ V

A1-A0 (Output Latch bits)[24:23]

The latch bits (A0 and A1) will be set to the logic state of these bits upon command word execution if the output

latch select bit (OLS) is set. Note that these logic outputs are powered from VA+ and VA-.

00 A0 = 0, A1 = 0

01 A0 = 0, A1 = 1

10 A0 = 1, A1 = 0

11 A0 = 1, A1 = 1

Output Latch Select, OLS[22]

0 When low, uses the Channel-Setup Register as the source of A1 and A0.

1 When set, uses the Configuration Register as the source of A1 and A0.

NU (Not Used)[21]

0 Must always be logic 0. Reserved for future upgrades.

Offset and Gain Select OGS[20]

0 Calibration registers used are based on the CS1-CS0 bits of the referenced Setup.

1 Calibration registers used are based on the OG1-OG0 bits of the referenced Setup.

≤ [(VA+) - (VA-)]

REF

≤ 2.5V

REF

DS289F1 27

Filter Rate Select, FRS[19]

0 Use the default output word rates.

1 Scale all output word rates and their corresponding filter characteristics by a factor of 5/6.

NU (Not Used)[18:0]

0 Must always be logic 0. Reserved for future upgrades.

2.4. Setting up the CSRs for a Measurement

CS5531/32/33/34

The CS5531/32/33/34 have four Channel-Setup

Registers (CSRs). Each CSR contains two 16-bit

Setups which are programmed by the user to contain

data conversion information such as: 1) which physical channel will be converted, 2) at what gain will

the channel be converted, 3) at what word rate will

the channel be converted, 4) will the output conversion be unipolar or bipolar, 5) what will be the state

of the output latch during the conversion, 6) will the

converter delay the start of a conversion to allow

time for the output latch to settle before the conversion is begun, and 7) will the open circuit detect current source be activated for that Setup. In addition,

when the OGS bit in the Configuration Register is

set, the Setup selects which set of offset and gain

registers to use when performing conversions or calibrati ons. Note that a particular physical input channel can be represented in more than one Setup with

different output rates, gain ranges, etc. (i.e. each

Setup is independently defined). Refer to section

2.4.1 for more details about the Channel Setup

Registers.

Each 32-bit CSR is individually accessible and

contains two 16-bit Setups. As an example, to configure Setup 1 in the CS5531/32/33/34 with the

write individual channel-setup register command

(0x05 hexadecimal), bits 31 to 16 of CSR 1 contains the information for Setup 1 and bits 15 to 0

contain the information for Setup 2. Note that while

reading/writing CSRs, two Setups are accessed in

pairs as a single 32-bit CSR register. Even if one of

the Setups isn’t used, it must be written to or read.

Examples detailing the power of the CSRs are provided in section 2.6.3.

28 DS289F1

2.4.1. Channel-Setup Register Descriptions

CSR

#1 Setup 1

Bits <127:112>

Setup 2

Bits < 111 : 9 6 >

CS5531/32/33/34

#4 Setup 7

Bits <31:16>

D31(MSB) D30 D29 D28 D27 D26 D25 D24 D23 D22 D21 D20 D19 D18 D17 D16

CS1 CS0 G2 G1 G0 WR3 WR2 WR1 WR0 U/B

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

CS1 CS0 G2 G1 G0 WR3 WR2 WR1 WR0 U/B

Setup 8

Bits <15:0>

OL1 OL0 DT OCD OG1 OG0

OL1 OL0 DT OCD OG1 OG0

CS1-CS0 (Channel Select Bits) [31:30] [15:14]

00 Select physical channel 1 (All devices)

01 Select physical channel 2 (All devices)

10 Select physical channel 3 (CS5533/34 only)

11 Select physical channel 4 (CS5533/34 only)

G2-G0 (Gain Bits) [29:27] [13:11]

For VRS = 0, A = 2; For VRS = 1, A = 1; Bipolar input span is twice the unipolar input span.

000 Gain = 1, (Input Span = [(VREF+)-(VREF-)]/1*A for unipolar).

001 Gain = 2, (Input Span = [(VREF+)-(VREF-)]/2*A for unipolar).

010 Gain = 4, (Input Span = [(VREF+)-(VREF-)]/4*A for unipolar).

011 Gain = 8, (Input Span = [(VREF+)-(VREF-)]/8*A for unipolar).

100 Gain = 16, (Input Span = [(VREF+)-(VREF-)]/16*A for unipolar).

101 Gain = 32, (Input Span = [(VREF+)-(VREF-)]/32*A for unipolar).

110 Gain = 64, (Input Span = [(VREF+)-(VREF-)]/64*A for unipolar).

WR3-WR0 (Word Rate) [26:23] [10:7]

The listed Word Rates are for continuous conversion mode using a 4.9152 MHz clock. All word rates will

scale linearly with the clock frequency used. The very first conversion using continuous conversion mode

will last longer, as will conversions done with the single conversion mode. See the section on Performing

Conversions and Tables 1 and 2 for more details.

Bit WR (FRS = 0) WR (FRS = 1)

0000 120 Sps 100 Sps

0001 60 Sps 50 Sps

0010 30 Sps 25 Sps

0011 15 Sps 12.5 Sps

0100 7.5 Sps 6.25 Sps

1000 3840 Sps 3200 Sps

1001 1920 Sps 1600 Sps

1010 960 Sps 800 Sps

1011 480 Sps 400 Sps

1100 240 Sps 200 Sps

All other combinations are not used.

DS289F1 29

CS5531/32/33/34

U/B

(Unipolar / Bipolar) [22] [6]

0 Select Bipolar mode.

1 Select Unipolar mode.

OL1-OL0 (Output Latch Bits) [21:20] [5:4]

The latch bits will be set to the logic state of these bits upon command word execution when the output

latch select bit (OLS) in the configuration register is logic 0. Note that the logic outputs on the chip are

powered from VA+ and VA-.

00 A0 = 0, A1 = 0

01 A0 = 0, A1 = 1

10 A0 = 1, A1 = 0

11 A0 = 1, A1 = 1

DT (Delay Time Bit) [19] [3]

When set, the converter will wait for a delay time before starting a conversion. This allows settling time for

A0 and A1 outputs before a conversion begins. The delay time will be 1280 MCLK cycles when FRS = 0,

and 1536 MCLK cycles when FRS = 1.

0 Begin Conversions Immediately.

1 Wait 1280 MCLK cycles (FRS = 0) or 1536 MCLK cycles (FRS = 1) before starting conversion.

OCD (Open Circuit Detect Bit) [18] [2]

When set, this bit activates a 300 nA current source on the input channel (AIN+) selected by the channel

select bits. Note that the 300nA current source is rated at 25°C. At -55°C, the current source doubles to

approximately 600nA. This feature is particularly useful in thermocouple applications when the user wants

to drive a suspected open thermocouple lead to a supply rail.

0 Normal mode.

1 Activate current source.

OG1-OG0 (Offset / Gain Register Pointer Bits) [17:16] [1:0]

These bits are only used when OGS in the Configuration Register is set to ‘1’. They allow the user to select

the offset and gain register to use while performing a conversion or calibration. When the OGS bit in the

Configuration Register is set to ‘0’, the offset and gain register for the referenced physical channel (CS1CS0 bits of the Setup) will be used.

00 Use offset and gain register from physical channel 1

01 Use offset and gain register from physical channel 2

10 Use offset and gain register from physical channel 3

11 Use offset and gain register from physical channel 4

30 DS289F1

CS5531/32/33/34

2.5. Calibration

Calibration is used to set the zero and gain slope of

the ADC’s transfer function. The CS5531/32/33/34

offer both self calibration and system calibration.

Note: After the ADCs are reset, they are functional

and can perform measurements without

being calibrated (remember that the VRS bit

in the configuration register must be properly

configured). In this case, the converter will

utilize the initialized values of the on-chip

registers (Gain = 1.0, Offset = 0.0) to

calculate output words. Any initial offset and

gain errors in the internal circuitry of the chip

will remain.

2.5.1. Calibration Registers

The CS5531/32/33/34 converters have an individual offset and gain register for each channel input.

The gain and offset registers, which are used during

both self and system calibration, are used to set the

zero and gain slope of the converter’s transfer function. As shown in Offset Register section, one LSB

in the offset register is 1.835007966 X 2

-24

propor-

tion of the input span (bipolar span is 2 times the

unipolar span, gain register = 1.000...000 decimal).

The MSB in the offset register determines if the

offset to be trimmed is positive or negative (0 positive, 1 negative). Note that the magnitude of the

offset that is trimmed from the input is mapped

through the gain register. The converter can typically trim ±100 percent of the input span. As shown

in the Gain Register section, the gain register spans

from 0 to (64 - 2

-24

). The decimal equivalent mean-

ing of the gain register is

29

Db

25b

==

D29

D28

24b

23… bD02

D27

24–

)++++ bDi2

∑

i 0=

24– i+()

where the binary numbers have a value of either

zero or one (b

While gain register settings of up to 64 - 2

is the binary value of bit D29).

D29

-24

are

available, the gain register should never be set to

values above 40.

2.5.2. Gain Register

MSB D30 D29 D28 D27 D26 D25 D24 D23 D22 D21 D20 D19 D18 D17 D16

NU NU

0000000100000000

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 LSB

-9

-10

2

2

0000000000000000

5

2

-11

2

The gain register span is from 0 to (64-2

4

2

-12

2

3

2

-13

2

2

2

-14

2

1

2

-15

2

-24

). After Reset D24 is 1, all other bits are ‘0’.

0

2

-16

2

-1

2

-17

2

-2

2

-18

2

2

-3

2

-19

-4

2

-20

2

-5

2

-21

2

-6

2

22

2

-7

2

2

-23

2

2

2.5.3. Offset Register

MSB D30 D29 D28 D27 D26 D25 D24 D23 D22 D21 D20 D19 D18 D17 D16

Sign

0000000000000000

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 LSB

-17

2

0000000000000000

-2

2

-18

2

One LSB represents 1.835007966 X 2

Offset and data word bits align by MSB. After reset, all bits are ‘0’.

The offset register is stored as a 32-bit, two’s complement number, where the last 8 bits are all 0.

-3

2

-19

2

-4

2

-20

2

-5

2

-21

2

-6

2

-22

2

-24

-7

2

-23

2

-8

2

-24

2

-9

2