CS5529

16-Bit, Programmable

Features

l Delta-Sigma Analog-to-Digital Converter

- Linearity Error: 0.0015%FS

- Noise Free Resolution: 16-Bits

l 2.5 V Bipolar/Unipolar Buffered Input Range

l 6-Bit Output Latch

l Eight Digital Filters

- Selectable Output Word Rates

- Output Settles in One Conversion Cycle

- 50/60 Hz ±3 Hz Simultaneous Rejection

l Simple three-wire serial interface

- SPI™ and Microwire™ Compatible

- Schmitt Trigger on Serial Clock (SCLK)

l System/Self-Calibration with R/W Registers

l Power Supply Configurations

- VA+ = +5 V; VA- = 0 V; VD+ = +3 V to +5 V

- VA+ = +2.5 V; VA- = -2.5 V; VD+ = +3 V to +5 V

l Low Power Consumption: 2.5 mW

∆Σ

ADC with 6-Bit Latch

General Description

The 16-bit CS5529 is a low-power programmable ∆Σ Analog-to-Digital Converter (ADC) which includes

coarse/fine charg e buf fers, a fou rt h or der ∆Σ modulator,

a calibration microcontroller, a digital filter with programmable decimation rates, a 6-bit output latch, and a threewire serial interface. The ADC is designed to operate

from single or dual analog supplie s and a single digital

supply.

The digital filter is programmable with output update

rates between 1.88 Hz to 101 Hz. These output rates are

specified for XIN = 32.768 kHz . Output word rate s can be

increased by approximately 3X by using XIN = 100 kHz.

The filter is designed to settle to full accuracy for the selected output word rate in one conversion. When

operated at word rates of 1 5 Hz or less, the fi lt er re ject s

both 50 Hz and 60 Hz simultaneously.

Low power, single conversion settling time, programmable output rates, and the ability to handle ne gative inpu t

signals make th is sing le or dual s upp ly pro duct a n ideal

solution for isolated and non-isolated applications.

AIN+

AIN-

VREF+

VREF-

VA+

VA- DGND

1X

1X

Latch

A0 A1 D0 D1 D2 D3

Differential

4th Order

Delta-Sigma

Modulator

Calibration

Memory

ORDERING INFORMATION

See page 27.

Digital Filte r

Clock

Calibration µC

Gen.

XIN XOUT

VD+

Calibration

Register

Control

Register

Output

Register

CS

SCLK

SDI

SDO

Cirrus Logic, Inc.

Crystal Semiconductor Products Division

P.O. Box 17847, Austin, Texas 78760

(512) 445 7222 FAX: (512) 445 7581

http://www.crystal.com

Copyright Cirrus Logic, Inc. 1999

(All Rights Reserved)

MAR ‘99

DS246F1

1

TABLE OF CONTENTS

TABLE OF CONTENTS ................. ....... ...... ....... ...... ...... ....... ...... ....... ...... ............ 2

TABLE OF FIGURES ........................................................... ...... ....... ...... ....... ..... 3

CHARACTERISTICS/SPECIFICATIONS ................................................ ............4

ANALOG CHARACTERISTICS................................................................... 4

5 V DIGITAL CHARACTERISTICS .............................................................6

3 V DIGITAL CHARACTERISTICS .............................................................6

DYNAMIC CHARACTERISTICS ................................................................. 6

ABSOLUTE MAXIMUM RATINGS.............................................................. 7

SWITCHING CHARACTERISTICS ................................................. ....... ..... 8

GENERAL DESCRIPTION ................................................................................10

Analog Input ............................................................................................. 10

Analog Input Model ............................................................................10

Voltage Reference Input Model ..........................................................10

Serial Port ................................................................................................. 11

Command Register Descriptions ........................................................12

Serial Port Interface ...........................................................................13

Serial Port Initialization ....................................................................... 15

System Initialization ................................. ...... ....... ............................. 1 5

Configuration Register ..............................................................................15

Latch Output Pins ...............................................................................15

Power Consumption ...........................................................................15

Output Word Rate ..............................................................................16

Digital Filter ........................................................................................16

Clock Generator ................................................................................. 16

Reset System ................. ....... ...... ....... ...... ...... ....... ............................. 16

Port Flag .............................................................................................17

Calibration .......................................................................................... 17

Configuration Register Descriptions ................................................. 20

Performing Conversions ...........................................................................21

Performing Conversions with PF bit = 0 ............................................. 21

Performing Conversions with PF bit = 1 ............................................. 21

Output Coding .................................................................................... 22

Power Supply Arrangements .................................................................... 23

PCB Layout .............................................................................................. 24

PIN DESCRIPTIONS ......................................................................................... 25

Clock Generator.........................................................................................25

Control Pins and Serial Data I/O................................................................25

Measurement and Reference Inputs ......................................................... 26

Power Supply Connections........................................................................26

SPECIFICATION DEFINITIONS ........................................................................ 27

ORDERING GUIDE ............................................................................................ 27

PACKAGE DIMENSIONS ................................................................................. 28

CS5529

Calibration Registers ................................................................... 17

Offset Register ......................................................................17

Gain Register ........................................................................18

Self Calibration ............................................................................ 18

System Calibration .......................................................................18

Limitations in Calibration Range ..................................................19

Calibration Tips ............................................................................ 19

Single Conversion ........................................................................ 21

Continuous Conversions ..............................................................21

2 DS246F1

TABLE OF FIGURES

Input models for AIN+ and AIN- pins......................................................... 11

Input model for VREF+ and VREF- pins. .................................................. 11

CS5529 Register Diagram. ....................................................................... 11

Command and Data Word Timing............................................................. 14

Filter Response (Normalized to Output Word Rate = 1)............................ 16

Self Calibration of Offset. .......................................................................... 18

Self Calibration of Gain. ............................................................................ 18

System Calibration of Offset...................................................................... 18

System Calibration of Gain........................................................................ 19

CS5529 Configured with a +5.0 V Analog Supply..................................... 23

CS5529 Configured with ±2.5 V Analog Supplies..................................... 23

CS5529

SPI™ is a trademark of Motorola Inc., Microwire™ is a trademark of National Semiconductor Corp.

Preliminary product information describes products which are in production, but for which full characterization data is not yet available. Advance product infor-

mation describes products which are in development and subj ect to development changes. Cirrus Logic, In c. has made best effor ts to ensure that the information contained in thi s document is accura te and reliabl e. However, the i nformation is subje ct to change withou t notice and i s provided “AS IS” witho ut

warranty of any k in d (express or implied ) . No responsibility is ass u med by Cirrus Logic, Inc. for the use of this in f ormation, nor for infringements of patents or

other rights of third parties. This document is the property of Cirrus Logic, Inc. and implies no license under patents, copyrights, trademarks, or trade secrets.

No part of this publication may be copied, reprod uced, stored in a retrieval system, or transmitted, in any form or by any means (electronic, mechanical, photographic, or otherwise) without the prior written consent of Cirrus Logic, Inc. Items from any Cirrus Logic website or disk may be printed for use by the user.

However, no part of the printout or electronic files may be copied, reproduced, stored in a retrieval system, or transmitted, in any form or by any means (electronic, mechanical, photographic, or otherwise) without the prior written consent of Cirrus Logic, Inc.Furthermore, no part of this publication may be used as a

basis for manufacture or sale of any items witho ut the pri or written consent of Cirrus Logic, Inc. The names of pr oducts of Ci rrus Logic, Inc. or other vendors

and suppliers appearing in this document may be trademarks or service marks of their respective owners which may be registered in some jurisdictions. A list

of Cirrus Logic, Inc. trademarks and service marks can be found at http://www.cirrus.com.

DS246F1 3

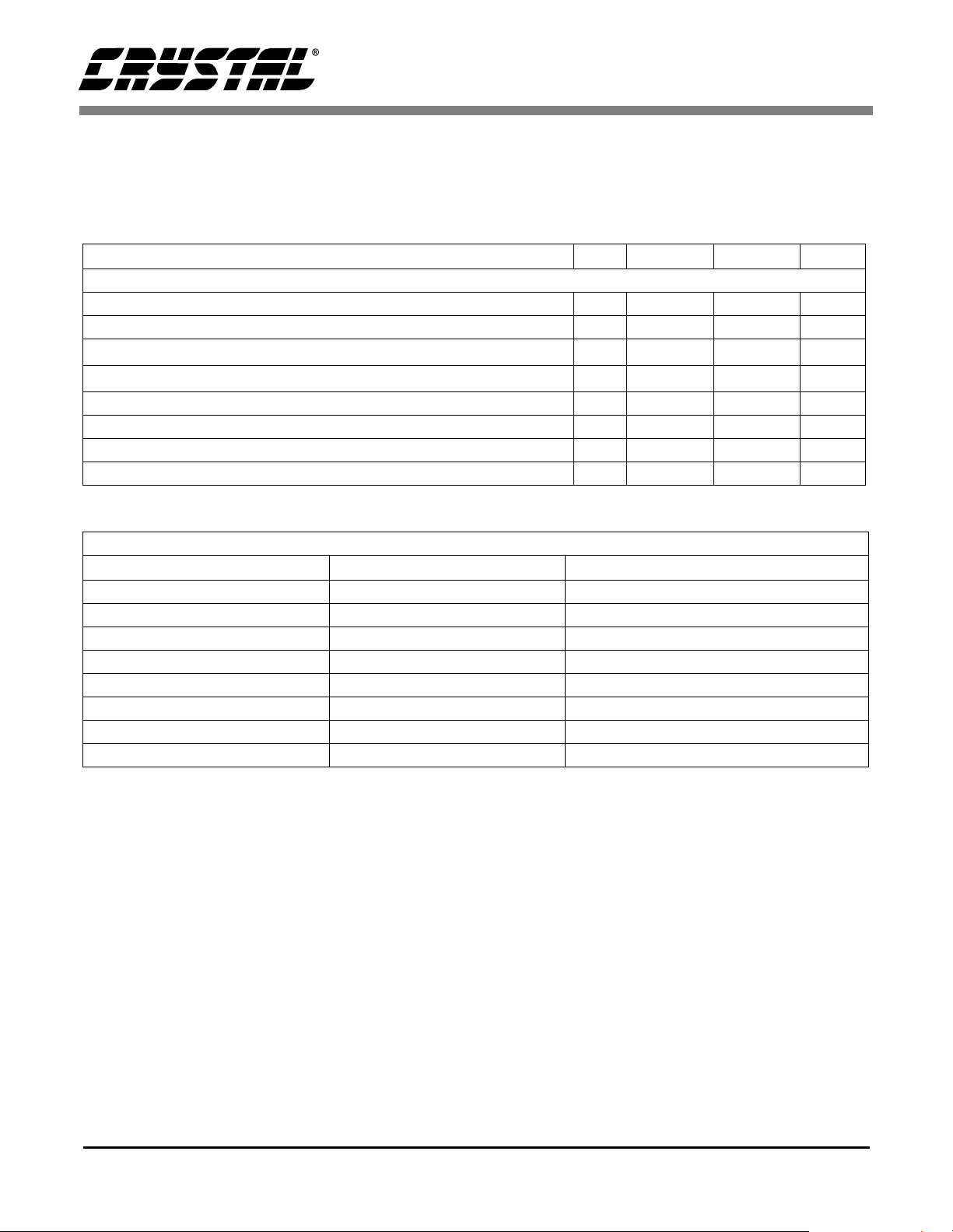

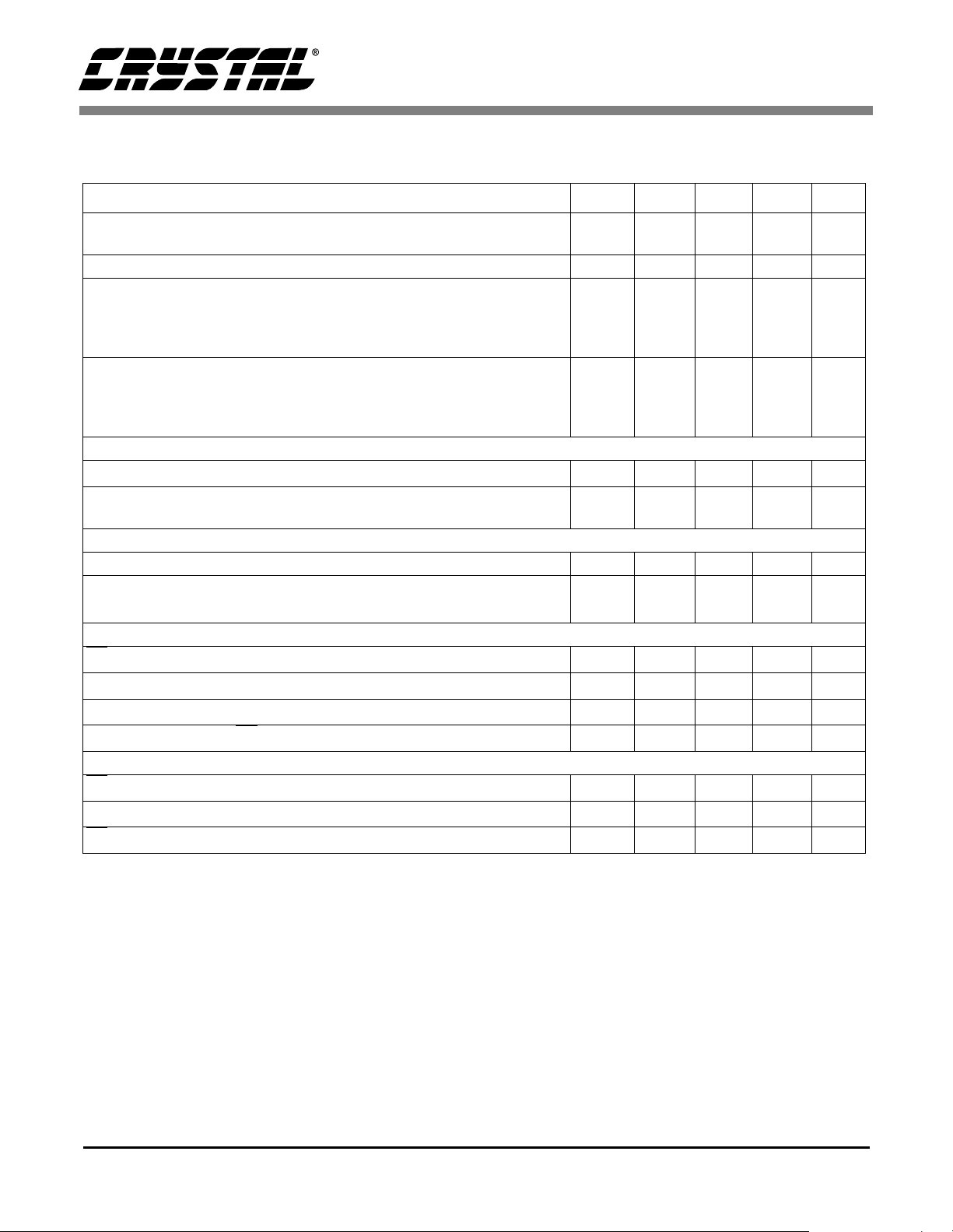

CHARACTERISTICS/SPECIFICATIONS

CS5529

ANALOG CHARACTERISTICS (T

VREF- = 0.0 V, F

(See Notes 1 and 2.)

= 32.768 kHz, OWR (Output Word Rate) = 15 Hz, Bipolar Mode, Input Range = ±2.5 V.)

CLK

Parameter Min Typ Max Unit

= 25 °C; VA± = ±2.5 V ±5%, VD + = 5 V ±5%, VR EF+ = 2.5 V,

A

Accuracy

Linearity Error - ±0.0015 ±0.003 %FS

No Missing Codes 16 - - Bits

Bipolar Offset (Note 3) - ±1 ±2 LSB

Unipolar Offset (Note 3) - ±2 ±4 LSB

Offset Drift (Notes 3 and 4) - 11 - nV/°C

Bipolar Gain Error - ±8 ±31 ppm

Unipolar Gain Error - ±16 ±63 ppm

Gain Drift (Note 4) - 1 - ppm/°C

Noise (Notes 5 and 6)

Output Word Rate (Hz) -3 dB Filter Frequency (Hz) Noise (µV)

1.88 1.64 4.5

3.76 3.27 5.0

7.51 6.55 7.0

15.0 12.7 15

30.0 25.4 45

61.6 50.4 190

84.5 70.7 900

101.1 84.6 3000

16

16

Notes: 1. Applies after system calibration at any temperature within -40 °C ~ +85 °C.

2. Specifications guaranteed by design, characterization, and/or test.

3. Specification applies to the device only and does not include any effects by external parasitic

thermocouples.

4. Drift over specified temperature range after calibration at power-up at 25 °C.

5. Wideband noise aliased into the baseband. Referred to the input. Typical values shown for 25 °C.

6. For peak-to-peak noise multiply by 6.6 for all ranges and output rates.

Specifications are subject to change without notice.

4 DS246F1

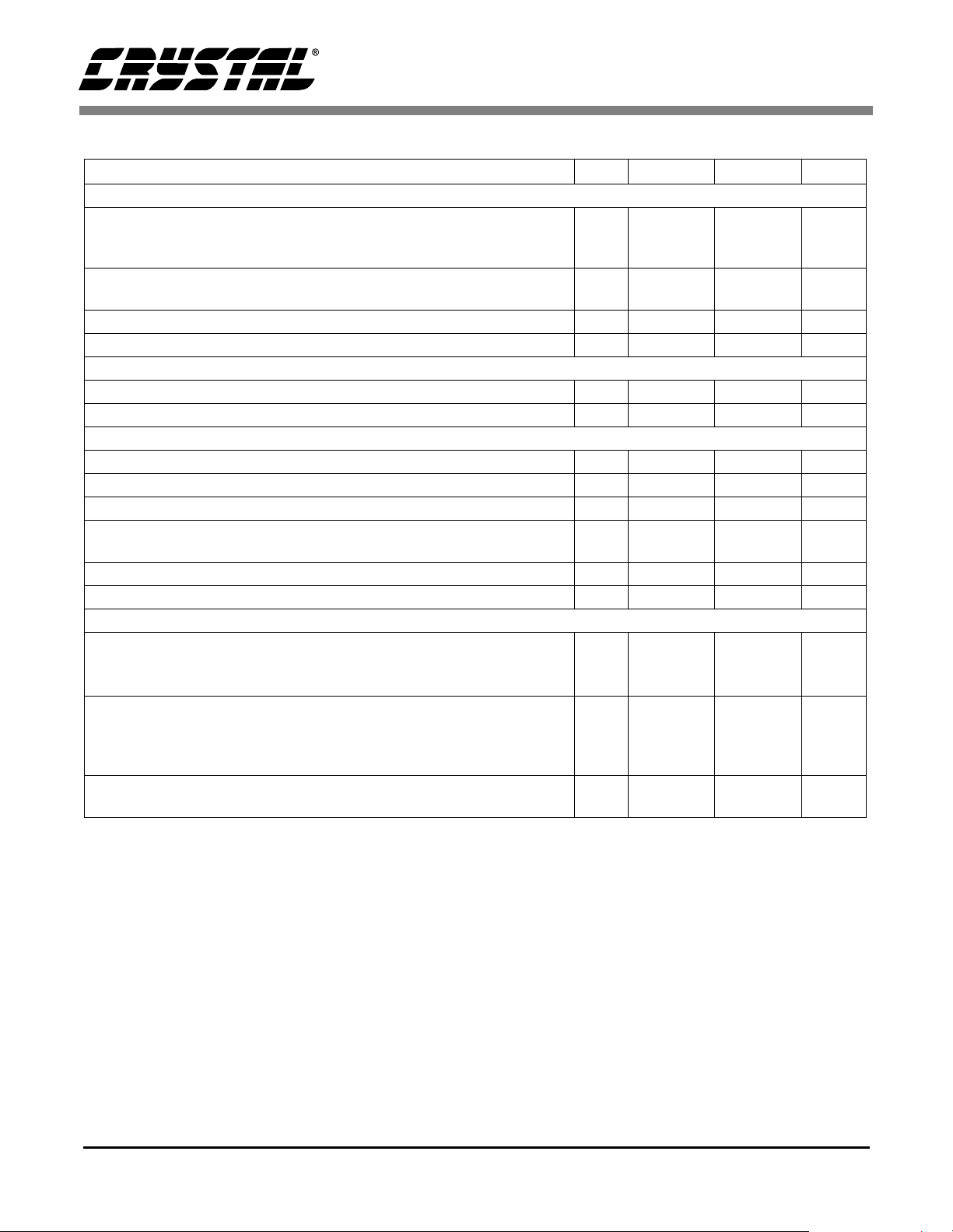

CS5529

ANALOG CHARACTERISTICS (Continued)

Parameter Min Typ Max Unit

Analog Input

Common Mode + Signal on AIN+ or AIN- (Bipolar/Unipolar Mode)

Single Supply

Dual Supply

Common Mode Rejection dc

50, 60Hz

Input Capacitance - 10 - pF

CVF Current AIN+, AIN- (Note 7) - 16 - nA

System Calibration Specifications

Full Scale Calibration Range, with VREF = 2.5 V (Note 8) 1.0 - 3.5 V

Offset Calibration Range (Bipolar/Unipolar Mode) - - ±1.25 V

Voltage Reference Input

Range {(VREF+) - (VREF-)} (Note 9) 1.0 2.5 5 V

REF+ VA- - VA+ V

REF- VA- - VA+ V

Common Mode Rejection dc

50, 60 Hz

Input Capacitance - 16 - pF

CVF Current (Note 7) - 8 - nA

Power Supplies

DC Power Supply Currents (Normal Mode)

I

A+

I

D+

Power Consumption Normal Mode (Note 10)

Low Power Mode

Standby

Sleep

Power Supply Rejection dc Positive Supplies

dc Negative Supply

0.0

VA-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

120

120

110

130

360

95

2.5

1.4

1

500

80

80

VA+

VA+

-

-

-

-

450

150

2.875

2.2

-

-

-

-

dB

dB

dB

dB

µA

µA

mW

mW

mW

µW

dB

dB

V

V

Notes: 7. See the section of the data sheet which discusses Analog Input Models.

8. The minimum Full Scale Calibration Range (FSCR) is limited by the maximum allowed gain register

value (with margin). The maximum FSCR is limited by the

“Analog Input” section for details. Also see “Limitations in Calibration Range”.

9. VREF must be less than or equal to supply voltages.

10. All outputs unloaded. All inputs CMOS levels.

DS246F1 5

∆Σ

modulator’s 1’s density range. See

CS5529

5 V DIGITAL CHARACTERISTICS (T

= 25 °C; VA± = ±2.5V

A

and 11.)

Parameter Symbol Min Typ Max Unit

High-Level Input Voltage: All Pins Except XIN, SCLK

XIN

SCLK

Low-Level Input Voltage: All Pins Except XIN, SCLK

XIN

SCLK

High- L evel O u t put Voltage: All Pins Except SDO (Note 12)

SDO, I

Low-Level Output Voltage: All Pins Except SDO, I

SDO, I

= -5.0mA

out

= 1.6mA

out

= 5.0mA

out

Input Leakage Current I

3-State Leakage Current I

Digital Output Pin Capacitance C

Notes: 11. All measurements performed under static conditions.

12. I

= -100 µA unless stated otherwise. (VOH = 2.4 V @ I

out

out

±

5%, VD+ = 5V ± 5% .)(See Notes 2

V

IH

V

IH

IH

IL

IL

IL

OH

OH

OL

OL

in

OZ

out

(VD+)-0.45

V

V

V

V

V

V

V

V

= -40 µA).

0.6VD+

(VD+)-0.9

-

-

-

(VD+)-1.0

(VD+)-1.0--

-

-

-

-

-

-

-

-

-

-

-

0.8

2.0

0.6

-

-

-

-

0.4

0.4

-±1±10µA

--±10µA

-9-pF

V

V

V

V

V

V

V

V

V

V

3 V DIGITAL CHARACTERISTICS (T

= 25 °C; VA± = ±2.5 V ±5%, VD+ = 3.0 V ±5%.)

A

(See Notes 2 and 11.)

Parameter Symbol Min Typ Max Unit

High-Level Input Voltage: All Pins Except XIN, SCLK

XIN

SCLK

Low-Level Input Voltage: All Pins Except XIN, SCLK

XIN

SCLK

High-Level Output Voltage: All Pins Except SDO, I

SDO, I

Low-Level Output Voltage: All Pins Except SDO, I

SDO, I

= -400 µA

out

= -5.0 mA

out

= 400 µA

out

= 5.0 mA

out

Input Leakage Current I

3-State Leakage Current I

Digital Output Pin Capacitance C

DYNAMIC CHARACTERISTICS

Parameter Symbol Ratio Units

V

IH

V

IH

V

IH

V

IL

V

IL

V

IL

V

OH

V

OH

V

OL

V

OL

in

OZ

out

0.6VD+

(VD+)-0.9

(VD+)-0.45

-

-

-

(VD+)-0.3

(VD+)-1.0--

-

-

-±1±10µA

--±10µA

-9-pF

-

-

-

-

-

-

-

-

-

-

-

0.16 VD+

0.5

0.6

-

-

0.3

0.4

V

V

V

V

V

V

V

V

V

V

Modulator Sampling Frequency f

Filter Settling Time to 1/2 LSB (Full Scale Step) t

s

s

XIN/4 Hz

1/f

out

s

6 DS246F1

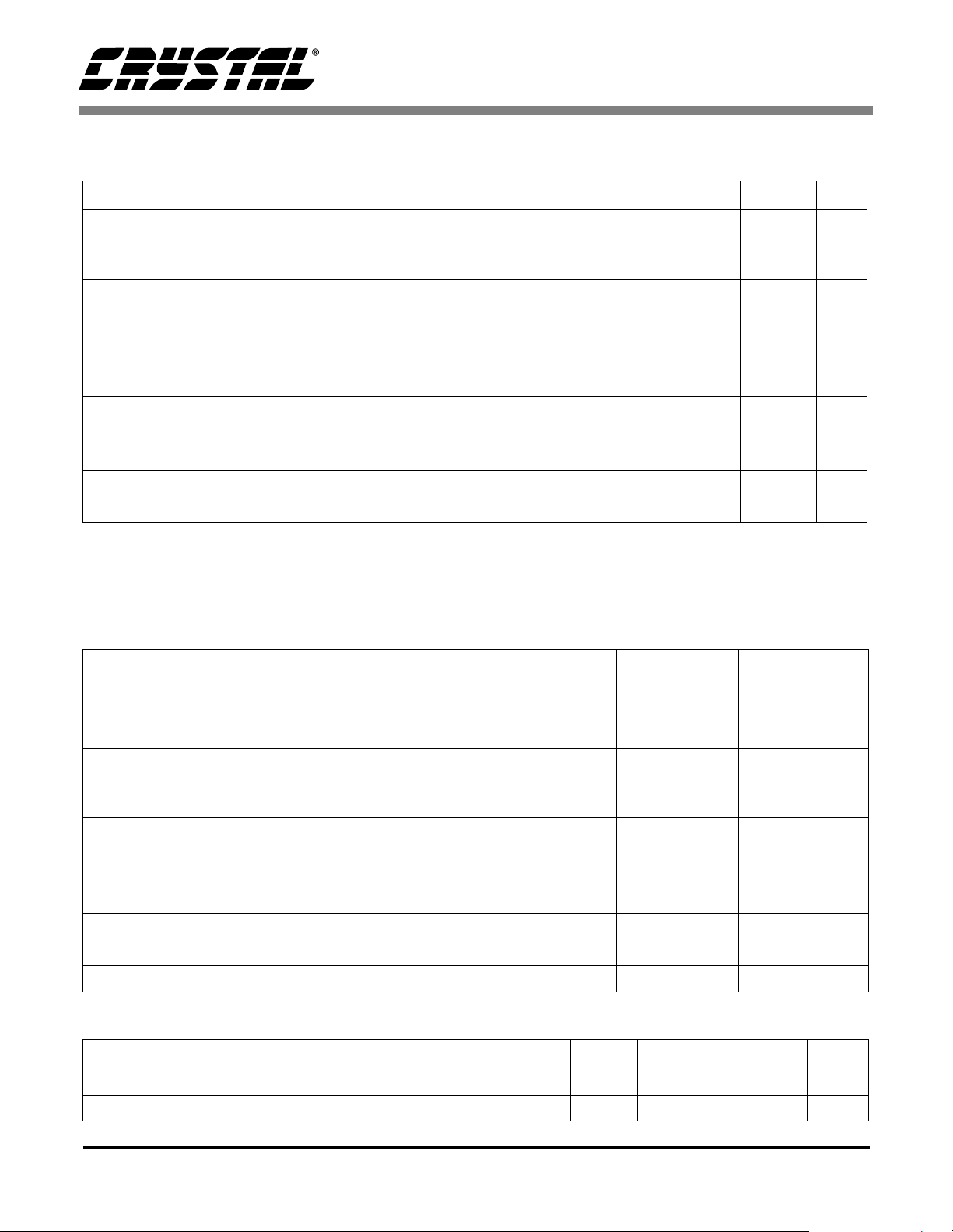

CS5529

ABSOLUTE MAXIMUM RATINGS (DGND = 0 V) (See Note 13.)

Parameter Symbol Min Typ Max Unit

DC Power Supplies (Notes 14 and 15)

Positive Digital

Positive Analog

Negative Analog

Input Current, Any Pin Except Supplies (Notes 16 and 17) I

Output Current I

Power Dissipation (Note 18) PD N - - 8 mW

Analog Input Voltage AIN and VREF pins V

Digital Input Voltage V

Ambient Operating Temperature T

Storage Temperature T

Notes: 13. All voltages with respect to ground.

14. VA+ and VA- must satisfy {(VA+) - (VA-)} ≤ +6.0 V.

15. VD+ and VA- must satisfy {(VD+) - (VA-)} ≤ +7.75 V.

16. Applies to all pins including continuous overvoltage conditions at the analog input (AIN) pins.

17. Transient current of up to 100mA will not cause SCR latch-up. Maximum input current for a power

supply pin is ±50 mA.

18. Total power dissipation, including all input currents and output currents.

VD+

VA+

VA-

IN

OUT

INA

IND

A

stg

-0.3

-0.3

-6.0

-

-

-

+6.0

+6.0

+0.3

--±10mA

--±25mA

(VA-) + (-0.3) - (VA+)+0.3 V

-0.3 - (VD+)+0.3 V

-40 - +85 °C

-65 - +150 °C

V

V

V

WARNING: Operation at or beyond these limits may result in permanent damage to the device.

Normal operation is not guaranteed at these extremes.

DS246F1 7

CS5529

SWITCHING CHARACTERISTICS (T

Input Levels: Logic 0 = 0 V, Logic 1 = VD+; C

= 50pF)

L

= 25 °C; VA ± = ±2.5 V ±5%, VD+ = 3 V ±5% or 5 V ±5%;

A

Parameter Symbol Min Typ Max Unit

Master Clock Frequency: External Clock or Internal Oscillator

XIN 30 32.768 100 kHz

(Note19)

Master Clock Duty Cycle 40 - 60 %

Rise Times (Note 20)

Any Digital Input Except SCLK

SCLK

Any Digital Output

Fall Times (Note 20)

Any Digital Input Except SCLK

SCLK

Any Digital Output

t

t

rise

rise

-

-

-

-

-

-

50

50

-

-

-

-

1.0

100

-

1.0

100

-

µs

µs

ns

µs

µs

ns

Start-up

Oscillator Start-up Time XTAL = 32.768 kHz (Note 21) t

Power-on Reset Period t

ost

por

-500-ms

- 1002 - XIN

cycles

Serial Port Timing

Serial Clock Frequency SCLK 0 - 2 MHz

Serial Clock Pulse Width High

Pulse Width Low

t

1

t

2

250

250

-

-

-

-

ns

ns

SDI Write Timing

CS Enable to Valid Latch Clock t

Data Set-up Time prior to SCLK rising t

Data Hold Time After SCLK Rising t

SCLK Falling Prior to CS

Disable t

3

4

5

6

50 - - ns

50 - - ns

100 - - ns

100 - - ns

SDO Read Timing

CS to Data Valid t

SCLK Falling to New Data Bit t

CS

Rising to SDO Hi-Z t

7

8

9

--150ns

--150ns

--150ns

Notes: 19. Device parameters are specified with 32.768 kHz clock, however, clocks up to 100 kHz can be used for

increased throughput.

20. Specified using 10% and 90% points on waveform of interest. Output loaded with 50 pF.

21. Oscillator start-up time varies with crystal parameters. This specification does not apply when using an

external clock source.

8 DS246F1

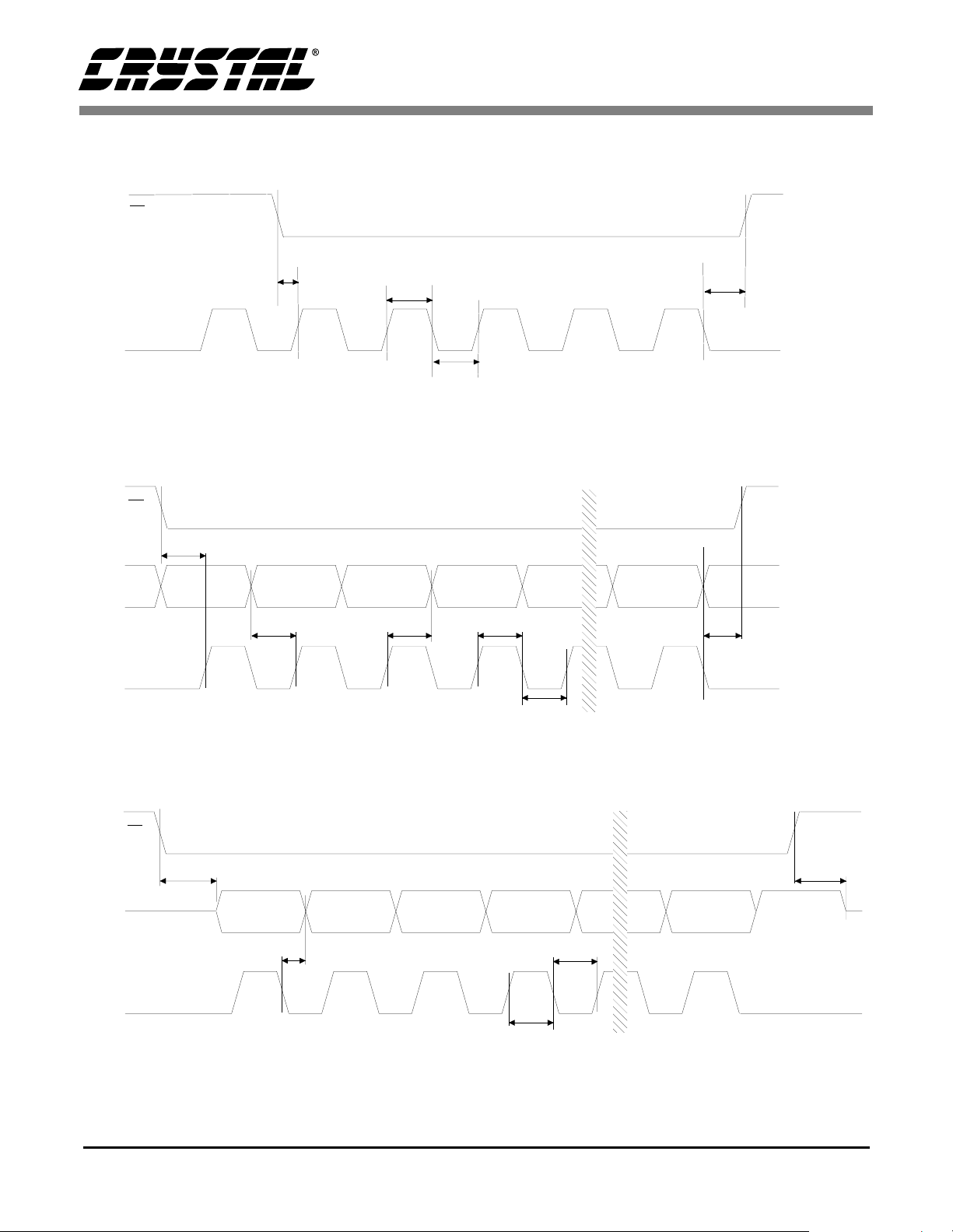

CS

CS5529

SCLK

CS

SDI

SCLK

t3

MSB

t3

t1

t2

Continuous Running SCLK Timing (Not to Scale)

MSB-1

t2

t6

LSB

t6t4 t5 t1

SDI Write Timing (Not to Scale)

CS

SDO

t7

MSB MSB-1

t8

t2

LSB

t9

SCLK

t1

SDO Read Timing (Not to Scale)

DS246F1 9

CS5529

GENERAL DESCRIPTION

The CS5529 is a 16-bit ∆Σ Analog-to-Digital Converter (ADC) which includes coarse/fine charge

buffers, a fourth order ∆Σ modulator, a c alibration

microcontroller, eight digital filters which provide

selectable decimation rates, a 6-bit output latch,

and a three-wire serial inter face. The A DC is opti mized to digitize unipolar or bipolar signals in industrial applications.

The digital filters provide eight selectable output

word rates (OWRs) of 1.88 Hz, 3.76 Hz, 7.51 Hz,

15.0 Hz, 30.0 Hz, 61.6 Hz, 84.5 Hz, 101.1 Hz when

operated from a 32.768 kHz watch crystal or equivalent clock (output word rates can be increased by

approximately 3X by using 100 kHz clock). The

filters are designed to settle to full accuracy for the

selected output word rate in one conversion. When

operated at word rates of 15 Hz or less (XIN =

32.768 kHz), the filter rejects both 50 Hz and 60 Hz

line interference simultaneously.

Analog Input

The CS5529 provides a nominal 2.5 V input span

when the gain register is 1.0 decimal and the differential reference voltage between VREF+ and

VREF- is 2.5 V. The gain registers content is used

during calibration to set the gain slope of the

ADC’s transfer function. The differential reference

voltage magnitude and the gain register are two

factors that can be used to scale the nominal 2.5 V

input span. After reset, the gain register defaults to

1.0 decimal. In this case, the external voltage between the VREF+ pin and the VREF- pin sets the

ADC’s nominal full scale input span to 2.5 V. If a

user want to modify the input span, either the gain

register or the reference voltage’s magnitude needs

to be changed. For example, if a 1.25 V reference is

used in place of the nominal 2.5 V input, the fullscale span is cut in half. To achieve the same 1.25V

input span, the user could simply use a 2.5 V reference and modify the gain register to 2.0 decimal.

Note that to keep from saturating the analog front

end, the input span must stay at or below 1.5 times

the reference voltage. This corresponds to a gain

register of 0.666... when a 2.5 V reference voltage

is used.

Note: When a smaller reference voltage is used,

the resulting code widths are smaller. Since

the output codes exhibit more chang ing

codes for a fixed amount of noise, the

converter appears noisier.

Calibration can also affect the ADC’s full scale

span because system gain calibration can be used to

increase or decrease the full scale span of the

ADC’s transfer functions. At its limit, the input full

scale can be reduced to the point in which the gain

register reaches its upper limit of 3.999... (this will

occur when the ADC is gain calibrated with an input signal less than or equal to approximately 1/4 of

its nominal full scale, if the ADC does not have intrinsic gain error). Calibration and its effects on the

analog input span is detailed in a later section of the

data sheet.

Analog Input Model

Figure 1 illustrates the input models for the AIN

pins. The model includes a coarse/fine charge buffer which reduces the dynamic current demands

from the signal source. The buffer is designed to

accommodate rail to rail (common-mode plus signal) input voltages. Typical CVF (sampling) current is about 16nA (XIN = 32.768 kHz, see Figure

1). Application Note 30, “Switched-Capacitor A/D

Input Structures”, details various input architectures.

Voltage Reference Input Model

Figure 2 illustrates the input models for the VREF

pins. It includes a coarse/fine charge buffer which

reduces the dynamic current demand of the external reference. Typical CVF (sampling) current is

about 8nA (XIN = 32.768 kHz, see Figure 2).

The reference’s buffer is designed to accommodate

rail-to-rail (common-mode plus signal) input volt-

10 DS246F1

AIN

C = 20pF

f = 32.768 kHz

φ

Coarse

1

φ

Fine

1

V ≤ 25mV

i = fV C

os

os

n

Figure 1. Input models for AIN+ and AIN- pins.

VREF

Fine

φ

1

Coarse

φ

2

CS5529

ages. The differential voltage between VREF+ and

VREF- sets the nominal full scal e input spa n of the

converter. For a single-ended reference voltage,

such as the LT1019-2.5, the reference output is

connected to the VREF+ pin of the CS5529 and the

ground reference for the LT1019-2.5 is connec ted

to the VREF- pin.

Serial Port

The CS5529 includes a microcontroller with a

command register, a configuration register, a conversion data register (read only), and a gain and offset register for calibration. All registers, except the

8-bit command register, are 24-bits in length. Fig-

V ≤ 25mV

os

i = fV C

n

os

C = 10pF

f = 32.768 kHz

Figure 2. Input model for VREF+ and V R EF - pins.

ure 3 illustrates a block diagram of all the internal

register.

After a system initialization or reset, the serial port

is set to the command mode. The converter stays in

this mode until a valid 8-bit command is received

(the first 8-bits into the serial port). Once a valid 8bit command is received and interpreted by the

ADC’s command register, the serial port enters the

data mode. In data mode the next 24 serial clock

pulses shift data either into or out of the serial port

(72 serial clock pulses are needed if the setup register command is issued). The Command Register

Descriptions section illustrates all valid commands.

DS246F1 11

Gain Register (1 × 24)Offset Register (1 × 24)

Configuration Register (1 × 24)

Latch Outputs

Low Power Mode

Output Word Rates

Unipolar/Bipolar

Reset System

etc.

Figure 3. CS5 529 Register Diagram.

Conversion Data Register (1x24)

Read Only

Serial

Interface

Write Only

Com ma n d Re g i ster ( 1 × 8)

CS

SDI

SDO

SCLK

Command Register Descriptions

D7(MSB)D6D5D4D3D2D1D0

CS5529

CB SC CC R/W

RSB2 RSB1 RSB0 PS/R

BIT NAME VALUE FUNCTION

D7 Command Bit, CB 0

Null command (no operation). All command bits,

including CB must be 0.

D6 Single Conversion, SC 0

D5 Continuous Conversions,

CC

D4 Read/Write

D3-D1 Register Select Bit, RSB2-

RSB0

, R/W 0

000

001

010

011

100

101

110

111

D0 Power Save/Run

, PS/R 0

1

1

0

1

1

1

Logic 1 for executable commands.

Single Conversion not active.

Perform a conversion.

Continuous Conversions not active.

Perform conversions continuously.

Write to selected register.

Read from selected register.

Offset Register

Gain Register

Configuration Register

Conversion Data Register (read only)

Set-up Registers (Offset, Gain, Configuration)

Reserved

Reserved

Reserved

Run

Power Save

Table 1. Command Set

Perform Single Conversion

76543210

11000000

This command instructs the ADC to perform a single conversion.

Perform Continuous Conversions

76543210

10100000

This command instructs the ADC to perform continuous conversions.

Power Save/Run

76543210

1000000PS/R

If PS/R = 0, normal run mode is entered. If PS/R = 1, power save mode is entered.

Null

76543210

00000000

This command is used to clear the port flag in the continuous conversion mode when the port flag bit in the configuration register

is set to logic 1.

12 DS246F1

CS5529

SYNC1

76543210

11111111

Part of the serial port re-initialization sequence (see text for use of command).

SYNC0

76543210

11111110

End of the serial port re-initialization sequence.

Read/Write Registers

76543210

100R/W

These commands are used to perform a write to or a read from a specific register. The register to be accessed is

selected with the RSB2-RSB0 bits of the command word.

RSB2 RSB1 RSB0 0

R/W

RSB[4:0] Register address binary encoded 0 to 31 as follows. All registers are 24 bits long.

Serial Port Interface

The CS5529’s serial interface consists of four control lines: CS, SDI, SDO, and SCLK.

0 Write Register

1 Read Register

Address

000 Read or Write Offset Register

001 Read or Write Gain Register

010 Read or Write Configuration Register

011 Read Conversion Data Register

100 Read or Write Offset Gain and Configuration Registers in

Description

this sequence (i.e. one 8-bit command is followed by 72-bits of

data to access the Offset, then the Gain, and then the

Configuration register)

port logic. To accommodate opto-isolators SCLK

is designed with a Schmitt-trigger input to allow an

opto-isolator with slower rise and fall times to directly drive the pin. Additionally, SDO is capable

CS, Chip Select, is the control line which enables

access to the serial port. If the C S pin is tied to logic

0, the port can function as a three wire interface.

SDI, Serial Data In, is the data signal used to transfer data to the converters.

SDO, Serial Data Out, is the data signal used to

transfer output data from the converters. The SDO

output will be held at high impedance any time CS

is at logic 1.

SCLK, Serial Clock, is the serial bit-clock which

controls the shifting of data to or from the ADC’s

serial port. The CS pin must be held at logic 0 be fore SCLK transitions can be recognized by the

of sinking or sourcing up to 5 mA to directly drive

an opto-isolator LED. SDO will have less than a

400 mV loss in the drive voltage when sinking or

sourcing 5 mA.

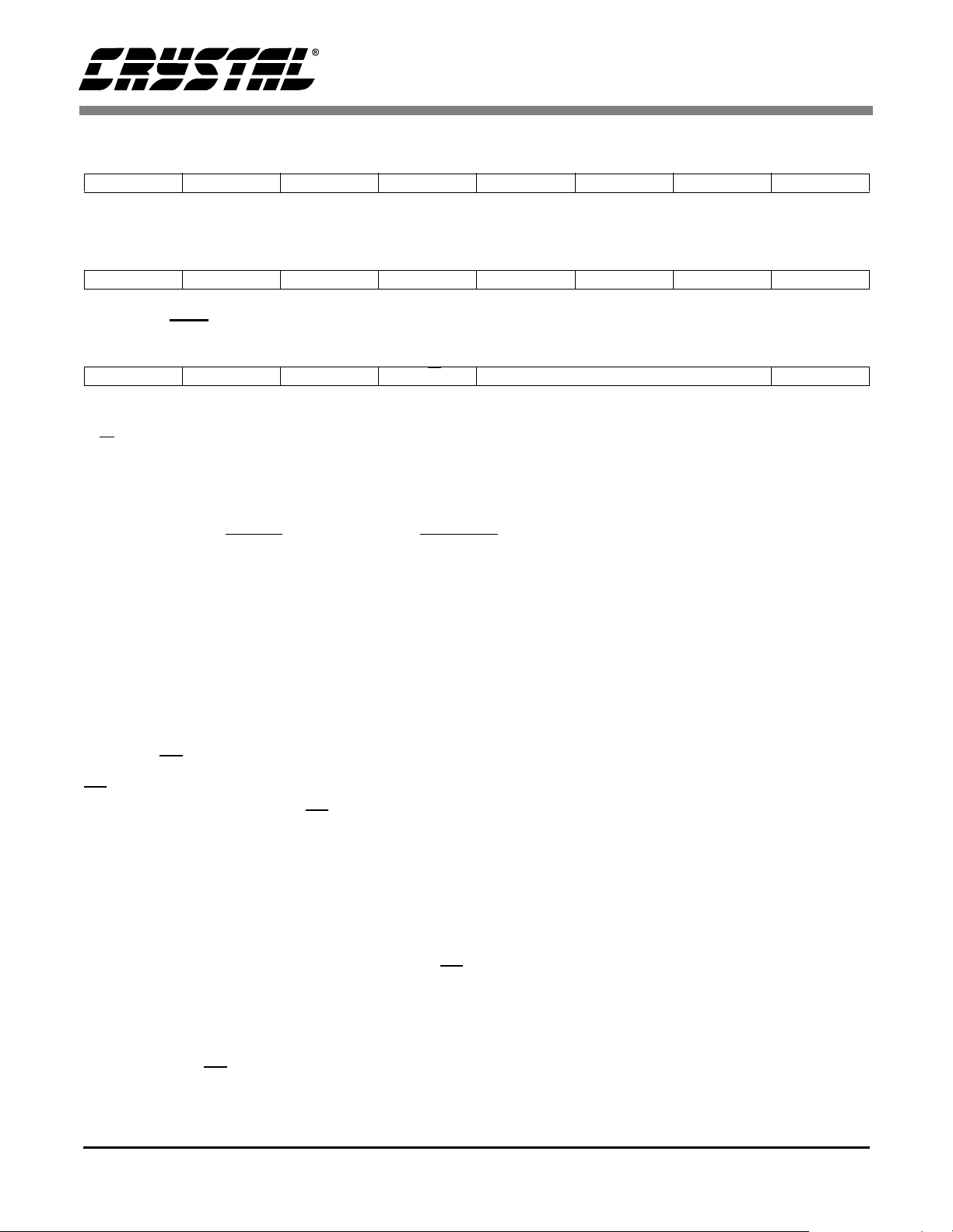

Figure 4 illustrates the serial sequence necessary to

write to, or read from the serial port’s registers. A

transfer of data is always initiated by sending the

appropriate 8-bit command (MSB first) to the serial

port (SDI pin). It is important to note that some

commands use information from the configuration

registers to perform the function. For those commands it is important that the correct information is

written to the configuration register first.

DS246F1 13

CS

SCLK

CS5529

SDI

CS

SCLK

SDI

SDO

Command T im e

8 SCLKs

Command T im e

8 SCLKs

MSB

Write Cycle

MSB

Read Cycle

LSB

Data Time 24 SCLK s

(or 72 SCLKs for Set-up Registers)

LSB

Data Time 24 SCLKs

(or 72 SCLKs for Set-up Registers)

SCLK

SDI

t *

Command Time

8 SCLKs

SDO

* td = XIN/OWR clock cycles for each conversion except the

first conversion which will take XIN/OWR + 7 clock cycles

d

SDO Continuous Conversion Read (PF bit = 1)

8 SCLKs Clear SDO Fla g

MSB

Data Time

24 SCLKs

XIN/OWR

Clock Cycles

LSB

Figure 4. Command and Data Word Ti ming.

14 DS246F1

CS5529

Configuration Registe r: 000040(H)

Offset Register: 000000(H)

Gain Register: 400000(H)

Serial Port Initialization

The serial port is initialized to the command mode

whenever a power-on reset is performed or when

the port initialization sequence is completed. The

port initialization sequence involves clocking fifteen (or more) SYNC1 command bytes (0xFF) followed by one SYNC0 command byte (0xFE). This

sequence places the chip in the command mode

where it waits until a valid command is received.

This function does not reset the internal registers to

their default settings. It only resets the serial port to

the command mode.

System Initialization

When power to the CS5529 is applied, the chip is

held in a reset condition until the 32.768 kHz oscillator has started and a counter-timer elapses. Due to

the high Q of the 32.768 kHz crystal, the oscillator

takes 400-600 ms to start. The counter-timer counts

1002 oscillator clock cycles to make sure the oscillator is fully stable. During thi s ti me -out pe ri od t he

serial port logic is reset and the RV (Reset Valid)

bit in the configuration register is set to indicate

that a valid reset occurred. After a reset, the on-chip

registers are initialized to the following states and

the converter is placed in the command mode

where it waits for a valid command.

Latch Output Pins

The D3-D0 pins of the converter mimic the D21D18 bits of the configuration register. D3-D0 can

be used to control multiplexers and other digital

logic functions outside the converter. The D0-D3

outputs are powered from VD+ and DGND. Their

output voltage will be VD+ for a logic 1 and

DGND for a logic 0. The A1-A0 pins of the converter mimic the D23-D22 bits of the configuration

register and can be used to control analog switches.

These outputs are powered from VA+ and VA-,

hence, their output voltage will be either VA+ for a

logic 1 or VA- for a logic 0.

All outputs can sink or source at least 1 mA, but it

is recommended to limit drive currents to less than

20 µA to reduce self-heating of the chip.

Power Consumption

The CS5529 accommodates four power consumption modes: normal, low power, standby, and sleep.

The normal mode, the default mode, is entered after

a power-on-reset and typically consumes 2.5 mW.

The low power mode is an alte rnate mode that re duces the consumed power to 1.4 mW. It is entered

by setting bit D16 (the low power mode bit) in the

configuration register to logic 1. Since the convert-

er’s noise and linearity performance improves with

increased power consumption, slightly degraded

noise or linearity performance should be expected

in the low power mode.

Note: A system reset can be initiated at any time by

writing a logic 1 to the RS (Reset System) bit

in the configuration register. After a reset, the

RV (Reset Valid) bit is set until the

configuration register is read. The user must

then write a logic 0 to the RS bit to take the

part out of the reset mode.

Configuration Register

The configuration register is a 24 bit register used

to modify the functions of the ADC. The following

sections detail the functions of the bits in the configuration register.

DS246F1 15

The final two modes are the power save modes.

These modes power down most of the analog portion of the chip and stop filter convolutions. The

power save modes are entered whenever the Power

Save (0x81 hexadecimal) command is issued to the

serial port. The particular power save mode entered

depends on state of bit D4 (the power save select

bit) in the configuration register. If D4 is logic 0,

the converter enters the standby mode reducing the

power consumption to 1 mW. The standby mode

leaves the oscillator and the on-chip bias generator

CS5529

Figure 5. Filter Response

(Normalized to Output Word Rate = 1).

running. This allows the converter to quickly return

to the normal or low power mode once the PS/R bit

is set back to a logic 0. If D4 in the configuration

register is logic 1 and Power Save command is issued, the sleep mode is entered reducing the con-

sumed power to less than 10 µ W. Since the sleep

mode disables the oscillator, approximately a 500

ms crystal oscillator start-up delay period is required before returning to the normal or low power

mode. If an external clock is used, the chip should

start within a few microseconds.

Output Word Rate

The WR2-WR0 bits of the configuration register

set the output conversion word rate of the converter

as shown in the Configuration Register Descriptions table. The word rates indicated in the table assume a master clock of 32.768 kHz. Upon reset the

converter is set to operate with an output word rate

of 15.0 Hz.

better than 80 dB rejection for both 50 Hz and

60 Hz with output word rates at or below 15.0 Hz

(XIN = 32.768 kHz).

The converter’s digital filters scale with XIN. For

example with an output word rate of 15 Hz, the filter’s corner frequency is typically 12.7 Hz. If XIN

is increased to 64.536 kHz the OWR doubles and

the filter’s corner frequency moves to 25.4 Hz.

Clock Generator

The CS5529 includes a gate which can be connected with an external crystal to provide the master

clock for the chip. The chip is designed to operate

using a low-cost 32.768 kHz “tuning fork” type

crystal. One lead of the crystal should be connected

to XIN and the other to XOUT. Lead lengths

should be minimized to reduce stray capacitance.

Note that the converter will operate w ith an external (CMOS compatible) clock with frequencies up

to 100 kHz.

Digital Filter

The CS5529 has eight different linear phase digital

filters which set the output word rates (OWRs) as

stated in Configuration Register Descriptions.

These rates assume that XIN is 32.768 kHz. Each

of the filters has a magnitude response similar to

that shown in Figure 5. The fi lters are optimi ze d to

settle to full accuracy every conversion and yield

Reset System

The reset system bit permits the user to perform a

hardware reset. A hardware reset can be initiated at

any time by writing a logic 1 to the RS (Reset System) bit in the configuration register. After a hardware reset cycle is complete, the serial port logic is

reset and the RV (Reset Valid) bit in the configuration register is set to indicate that a valid reset occurred. After a reset, the on-chip registers are

initialized to the following states and the converter

is placed in the command mode where it waits for

a valid command.

Configuration Registe r: 000040(H)

Offset Register: 000000(H)

Gain Register: 400000(H)

Note: A system reset can be initiated at any time by

writing a logic 1 to the RS (Reset System) bit

in the configuration register. After a reset, the

RV (Reset Valid) bit is set until the

configuration register is read. The user must

then write a logic 0 to the RS bit to take the

part out of the reset mode.

16 DS246F1

CS5529

Port Flag

The port flag bit in the configuration register allows

the user to select the mode in which conversions

will be presented to the serial port. With the port

flag bit cleared, the user must read the conversion

data register. With the port flag bit set to logic 1, the

user can read the conversion data from the se rial

port by first issuing the NULL command to clear

the SDO flag and then issuing 24 SCLKs to read

the conversion word.

Calibration

Calibration is used to set the zero and gain slope of

the ADC’s transfer function. The calibration control bits in the configuration register allow the user

to perform either self calibration or system calibration.

The offset and gain calibration steps each take one

conversion cycle to complete. At the end of the calibration step, the calibration control bits will be set

back to logic 0, and the DF (Done Flag) bit will be

set to a logic 1. For the combination self-calibration

(CC2-CC0= 011; offset calibration followed by

gain calibration), the calibration will take two con-

version cycles to complete and will set the DF bit

after the gain calibration is completed.

Note: 1) The DF bit will be cleared any time the data

register, the offset register, the gain register,

or the setup register is read. Reading the

configuration register alone will not clear the

DF bit. 2) After the CS5529 is reset, the

converter is functional and can perform

measurements without being calibrated. In

this case, the converter will utilize the

initialized values of the on-chip registers

(Gain = 1.0, Offset = 0.0) to calculate output

words. Any initial offset and gain errors in the

internal circuitry of the chip will remain.

Calibration Registers

The offset calibration result is stored in the offset

register. The result is used during the conversion

process to nullify offset errors. One LSB in the offset register is 2

polar span is 2 times the unipolar span). The MSB

in the offset register determines if the offset to be

trimmed is positive or negat ive (0 pos itive, 1 ne gative). The converter can typically trim ±50 percent

of the input span. Refer to the following Offset

Register and Gain Register descriptions for details.

-24

proportion of the input span (bi-

Offset Register

23(MSB)2221201918171615141312

Sign

000000000000

11109876543210

-13

2

000000000000

-2

2

-14

2

One LSB represents 2

Offset and data word bits align by MSB (bit MSB-4 of offset register changes bit MSB-4 of data). After reset, all bits

are ‘0’.

DS246F1 17

-3

2

-15

2

-24

proportion of the input span (bipolar span is 2 times unipolar span).

-4

2

-16

2

-5

2

-17

2

-6

2

-18

2

-7

2

-19

2

-8

2

-20

2

-9

2

-21

2

-10

2

-22

2

-11

2

-23

2

-12

2

-24

2

CS5529

Db

MSB

21b(020b121–… bN2N–)++++ b

MSB

2

1

bi2

i–

i 0=

N

∑

+==

Figure 6. Self Calibration of Offset.

Gain Register

23(MSB)2221201918171615141312

1

2

000000000000

11109876543210

-11

2

000000000000

0

2

-12

2

-1

2

-13

2

-2

2

-14

2

-3

2

-15

2

-4

2

-16

2

-5

2

-17

2

-6

2

-18

2

-7

2

-19

2

-8

2

-20

2

-9

2

-21

2

-10

2

-22

2

The gain register span is from 0 to (4-2

-22

). After Reset the (MSB-1) bit is ‘1’, all other bits are ‘0’.

The gain calibration results is stored in the gain

register. The result sets the slope of the ADC’s

transfer function. The gain register spans from 0 to

-22

(4 - 2

). The decimal equivalent meaning of the

gain register is

where the binary numbers have a value of either

zero or one (b0 corresponds to bit MSB-1, N = 22).

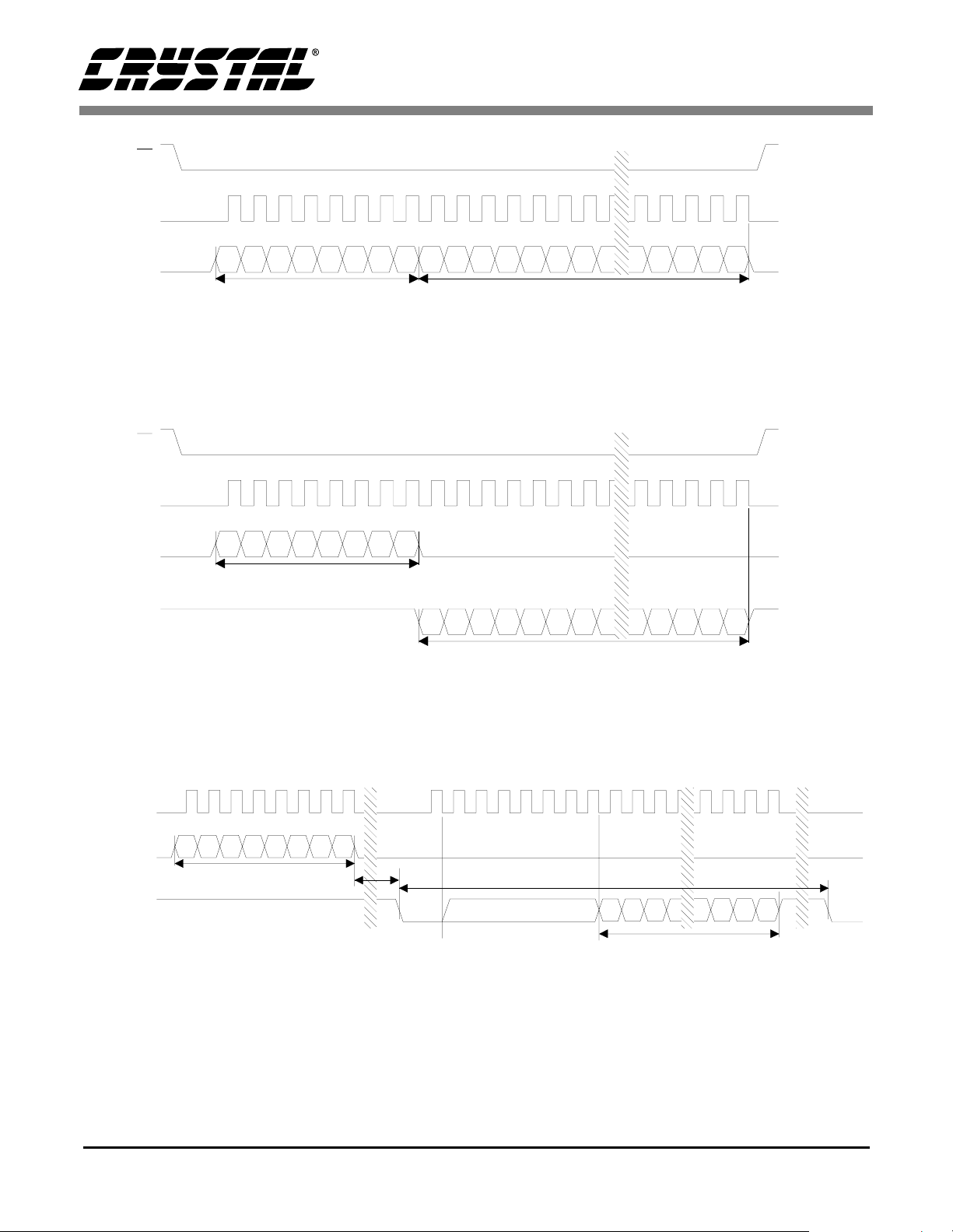

Self Calibration

The CS5529 offers both self offset and self gain

calibrations. For the self-calibration of offset, the

converter internally ties the inputs of the modulator

together and routes them to the VREF- pin as

shown in Figure 6. Also self offset calibration requires that VREF- be tied to a fixed voltage between VA+ and VA-. For self-calibration of gain,

the differential inputs of the modulator are connected to VREF+ and VREF- as shown in Figure7.

OPEN

Reference

+

-

AIN+

AIN-

VREF+

VREF-

OPEN

CLOSED

CLOSED

+

-

Figure 7. Self Calibration of Gain.

System Calibration

For the system calibration functions, the user must

input signals which represent system ground and

system full scale to the converter. When a system

offset calibration is performed a ground reference

signal must be applied to the converter (see Figure

8). When a system gain calibration is performed,

the user must input a signal representing the positive full scale point as shown in Figure 9. In either

case, calibration signals must be within the specified calibration limits for each specific calibration

step (refer to the System Calibration Specifica-

External

Connections

+

0V

-

AIN+

AIN-

+

-

AIN+

AIN-

VREF-

S1

OPEN

S2

OPEN

S4

CLOSED

S3

+

CLOSED

-

Figure 8. System Calibration of Offset.

18 DS246F1

Calibration Tips

Figure 9. System Calibration of Gain.

CS5529

External

Connections

+

-

Full Scale

AIN+

+

-

AIN-

tions). If a system gain calibration is performed, the

calibrated input must not cause the resulting gain

register’s content, decoded in decimal, to exceed

3.9999998. The above condition requires that the

full scale input voltage to be greater than 25 percent

of the differential reference voltage (i.e. a 625mV

input signal must be applied if the differential reference voltage is 2.5V).

Limitations in Calibration Range

System calibration can be limited by signal headroom in the analog signal path inside the chip as

discussed under the Analog Input section of this

data sheet. For gain calibration the full scale input

signal can be reduced to the point in which the gain

register reaches its upper limit of (4-2

or FFFFFF (hexadecimal). Under nominal conditions, this occurs with a full scale input signal equal

to about 1/4 the reference voltage. With the converter’s intrinsic gain error, this full scale input signal may be higher or lower. In defining the

minimum Full Scale Calibration Range (FSCR)

under “Analog Characteristics”, margin is retained

to accommodate the intrinsic gain error. Alternatively the input full scale signal can be increased to

a point which exceeds the operating range of the

analog circuitry. This occurs when the input voltage is approximately 1.5X the differential reference voltage (Gain Register = 1.0).

-22

decimal)

Calibration steps are performed at the output word

rate selected by the WR2-WR0 bits of the configuration register. Since higher word rates result in

conversion words with more peak-to-peak noise,

calibration should be performed at lower output

word rates. Also, to minimize digital noise near the

device, the user should wait for each calibration

step to be completed before reading or writing to

the serial port.

Factory calibration can be performed in a user’s

system by using the system calibration capabilities

of the CS5529. After the ADC is calibrated in the

user’s system, the offset and gain register contents

can be read by the system microcontroller and recorded in EEPROM. These same calibration words

can then be uploaded into the offset and gain registers of the converter when power is first applied to

the system.

A user can scale the input range by modifying the

gain register. For example, if a self or system calibration is performed with a full scale of 2.5 V and

a full scale of 1.25 V is desired, the user can modify

the gain register to double its slope. This can be

done by reading the gain register, shifting the binary word one position to the left (this multiplies the

gain word by 2), and writing this word back into the

gain register. The gain register can be scaled by any

amount as long as it does not exceed a decimal

range of 0.25 to 4.0.

One of two methods can be used to determine when

a calibration is complete: 1) if the PF (Port Flag) bit

of the configuration register is set to logic 1, SDO

falls to logic 0 at the completion of a calibration; or

2) regardless of the PF bit, the DF (Done Flag) bit

in the configuration register is set at completion of

calibration. The user can either monitor the DF bit

or SDO to determine when a calibration is complete. Whichever method is used, the calibration

control bits (CC2-CC0) automatically ret urn to logic 0 upon completion of any calibration.

DS246F1 19

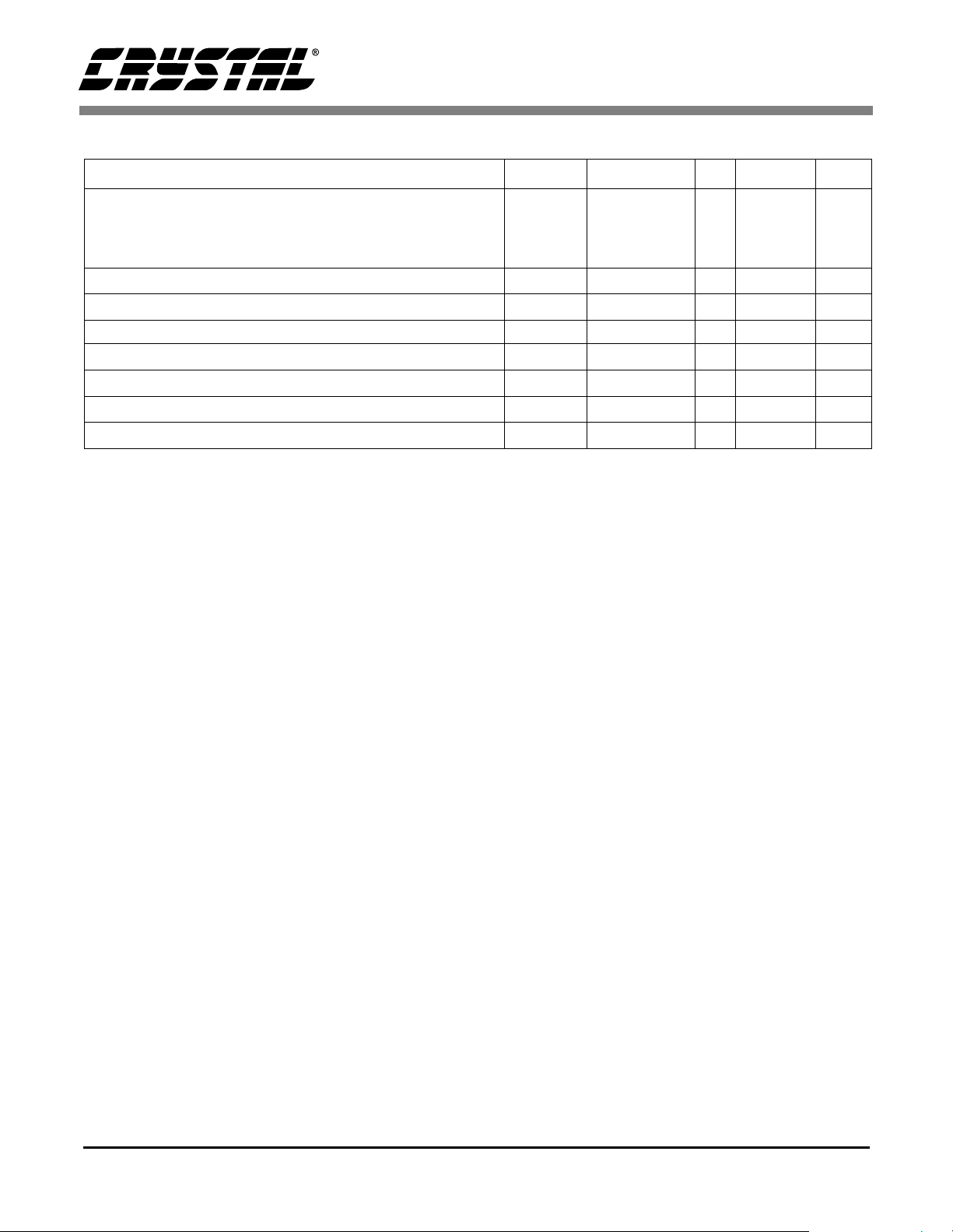

CS5529

Configuration Register Descriptions

D23(MSB) D22 D21 D20 D19 D18 D17 D16 D15 D14 D13 D12

A1 A0 D3 D2 D1 D0 NU LPM WR2 WR1 WR0 U/B

D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

NU NU NU NU RS RV PF PSS DF CC2 CC1 CC0

BIT NAME VALUE FUNCTION

D23-D22 Latch Outputs, A1-A0 00 R* Latch Output Pins A1-A0 mimic the D23-D22 Register bits.

D21-D18 Latch Outputs, D3-D0 0000 R* Latch Output Pins D3-D0 mimic the D21-D18 Register bits.

D17 Not Used, NU 0 R Must always be logic zero.

D16 Low Power Mode,

LPM

D15-D13 Word Rate, WR2-0

(Note: Rates valid for

XIN = 32.768 kHz)

D12 Unipolar/Bipolar

D11-D8 Not Used, NU 0 R Must always be logic 0.

D7 Reset System, RS 0

D6 Reset Valid , RV 0

D5 Port Flag, PF 0

D4 Power Save Select,

PSS

D3 Done Flag, DF 0

D2-D0 Calibration Control

Bits, CC2-CC0

* R indicates the bit value after the part is reset

, U/B 0

0

R Normal Mode (≅ 2.5 mW)

1

000

001

010

011

100

101

110

111

000

001

010

011

100

101

110

111

R 15.0 Hz (2180 XIN cycles)

R B ipolar Measurement mode

1

R Normal Operation

1

1R

R Port Flag mode inactive

1

0

R Standby Mode (Oscillator active, allows quick power-up)

1

R Done Flag bit is cleared (read only).

1

R Normal operation (no calibration)

Reduced Power Mode (≅ 1 mW)

30.0 Hz (1092 XIN cycles)

61.6 Hz (532 XIN cycl es )

84.5 Hz (388 XIN cycl es )

101.1 Hz (324 XIN cycles)

1.88 Hz (17444 XIN cycles)

3.76 Hz (8724 XIN cycles)

7.51 Hz (4364 XIN cycles)

Unipolar Measurement mode

Activate a Reset cycle. To return to normal operation this bit must

be written back to logic zero.

No reset has occurred or bit has been cleared (read only).

Valid Reset has occurred. (Cleared when read.)

Port Flag mode active

Sleep Mode (Oscillator inactive)

Calibration or Conversion cycle completed (read only).

Offset -- Self-Calibration

Gain -- Self-Calibration

Offset self-cal follo w ed by Gai n self -cal ib ratio n

Not Used.

Offset -- System Calibration

Gain -- System Calibration

Not Used.

20 DS246F1

CS5529

Performing Conversions

The CS5529 offers two modes of performing conversions: single conversion and continuous conversions. The sections that follow detail the

differences and provides examples illustrating how

to use the modes. Note that it is assumed that the

configuration register has been initialized before

conversions are performed.

Performing Conversions with PF bit = 0

A single conversion is performed after the user

transmits the single conversion command (0xC0

Hexadecimal). At the completion of the conversion, the DF (Done Flag) bit of the configuration

register will be set to a logic 1. While the conversion is being performed, the user can read the configuration register to determine if the DF bit is set.

Once DF has been set, the read conversion data register command (0x96 Hexadecimal) can be issued

to read the conversion data register to obtain the

conversion data word.

Single Conversion

A single conversion is performed after the user

transmits the single conversion command (0xC0

Hexadecimal). At the completion of the conversion, SDO will fall to logic 0 to indicate that the

conversion is complete. To acquire the conversion,

the user must issue 8 SCLKs with SDI = logic 0

(i.e. the NULL command) to cl ear the SDO flag.

Upon the falling edge of the 8th SCLK, the SDO

pin will present the first bit (MSB) of the conversion word. 24 SCLKs (high, then low) are then required to read the conversion word from the port.

Note: 1) The user must not give an explicit

command (other than the NULL command) to

read the conversion data register when the

PF bit is set to logic 1. 2) The data conversion

word must be read before a new command

can be entered as the converter will remain in

the data mode until the conversion word is

read. 3) Once the conversion is read the

converter returns to the command mode.

Continuous Conversions

Note: 1)The DF bit of the configuration register will

be cleared to logic 0 when the conversion

data register, the gain register, or the offset

register is read. Reading only the

configuration register will not clear the DF flag

bit. 2) If another single conversion command

is issued to the converter while it is

performing a conversion, the filter will

abandon the current conversion and restart a

new convolution cycle.

Performing Conversions with PF bit = 1

The PF (Port Flag) bit in the configuration register

eliminates the need for the user to monitor the DF

(Done Flag) in the configuration register to determine if the conversion is available. When PF is set

to a logic 1, SDO’s output pin behaves as a flag signal indicating when conversions are completed.

SDO will fall to logic 0 once a new conversion is

complete.

Continuous conversions are performed after the

user transmits the continuous conversions command (0xA0 Hexadecimal). At the completion of a

conversion, SDO will fall to logic 0 to indicate that

the conversion is complete. To read the conversion

word, the user must issue 8 SCLKs with SDI = logic 0 (i.e. the NULL command) to clear the SDO

flag. Upon the falling edge of the 8th SCLK, the

SDO pin will present the first bit (MSB) of the conversion word. 24 SCLKs (high, then low) are then

required to re ad the con version w ord fro m the por t.

When operating in the continuous conversion

mode, the user need not read every conversion. I f

the user chooses not to read a conversion after SDO

falls, SDO will rise one XIN clock cycle before the

next conversion word is available and then fall

again to signal that another conversion word is

available. To exit the continuous conversion mode,

the user must issue any valid command, other than

the NULL command, to the SDI input when the

SDO flag falls. For instance , the user can just read

DS246F1 21

CS5529

the conversion data register again to exit the continuous conversion mode.

Note: 1) If the user begins to clear the SDO flag and

read the conversion data, this action must be

finished before the conversion cycle which is

occurring in the background is complete if the

user wants to be able to read the new

conversion data. 2) If a CC command is

issued to the converter while it is performing

a conversion, the filter will stop the current

conversion and start a new convolution cycle

to perform a new conversion. 3) Continuous

conversions aren’t allowed unless the port

flag bit is set in the configuration register. 4)

The converter will remain in data mode and

continually perform conversions until the exit

command is issued (i.e. to exit the user must

read a register).

Output Coding

As shown in the Output Conversion Data Register

Descriptions, the CS5529 presents output conversions as a 24-bit conversion word. The first 16 bits

of the conversion word represent conversion data.

The third byte contains two error flag bits.

In the third byte, D7-D4 are always logic 1; D3-D2

are always logic 0; and bits D1-D0 are the two flag

bits. The OF (Overrange Flag) bit is set to a logic 1

any time the input signal is: 1) more positive than

positive full scale, 2) more negative than zero (unipolar mode), 3) more negative than negative full

scale (bipolar mode). It is cleared back to logic 0

whenever a conversion word occurs which is not

overranged.The OD (Oscillation Detect) bit is set to

a logic 1 any time that an oscillatory condition is detected in the modulator. This does not occur under

normal operating conditions, but may occur whenever the input to the converter is extremely overranged. If the OD bit is set, the conversion data bits

can be completely erroneous. The OD flag bit will be

cleared to logic 0 when the modulator becomes stable.

Table 2 and Table 3 illustrate the out put coding for

the CS5529. Unipolar conversions are output in binary format and bipolar conversions are output

two’s complement.

D23 D22 D21 D20 D19 D18 D17 D16 D15 D14 D13 D12

MSB1413121110987654

D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

3 2 1 LSB 1 1 1 1 0 0 OD OF

Table 2. Output Conversion Data Register Description (16 bits + flags).

Unipolar Input Voltage Offset Binary Bipolar Input Voltage

>(VFS-1.5 LSB) FFFF >(VFS-1.5 LSB) 7FFF

FFFF

VFS-1.5 LSB

VFS/2-0.5 LSB

+0.5 LSB

<(+0.5 LSB) 0000 <(-VFS+0.5 LSB) 8000

Note: VFS in the table equals the voltage between ground and full scale for any of the unipolar gain ranges,

or the voltage between ±full scale for any of the bipolar gain ranges. See text about error flags under

overrange conditions.

-----

FFFE

8000

-----

7FFF

0001

-----

0000

Table 3. CS5529 16-Bit Output Coding.

VFS-1.5 LSB

-0.5 LSB

-VFS+0.5 LSB

Two’s

Complement

7FFF

-----

7FFE

0000

-----

FFFF

8001

-----

8000

22 DS246F1

CS5529

Power Supply Arrangements

The CS5529 is designed to operate from single or

dual analog supplies and a single digital supply.

The following power supply connections are possible:

+5.0 V

Analog

Supply

±5 V Differential Inputs (Gain Registe r = 1.0)

±2.5 V Differential Inputs (Gain Register = 2.0)

±1.25 V Differential Inputs (Gain Register = 4.0)

Common Mode = 0 to VA+

0.1 µF

+

-

VA+ = +5 V; VA- = 0 V; VD+ = +3 V to +5 V

VA+ = +2.5 V; VA- = -2.5 V; VD+ = +3 V to +5 V.

Figure 10 illustrates the CS5529 connected with a

single +5 V supply to measure differential inputs

relative to a common mode of 2.5 V. Figure 11 il-

10

Ω

0.1

µ

213

CS5529

1

VD+

XOUT

XIN

SCLK

SDI

SDO

DGND

12

CS

10

11

8

9

15

14

VA+

20

VREF+

19

VREF-

3

AIN+

4

AIN-

18

D3

17

D2

16

D1

7

D0

6

A1

5

A0

VA-

F

32.768 kHz ~ 100 kHz

Optional Clock

Source

Serial

Data

Interface

Logic Outputs:

A0, A1 Switch from VA+ to VAD0-D3 Switch from VD+ to DGND

Figure 10. CS5529 Configured with a +5.0 V Analog Supply.

+2.5 V

Analog

Supply

±2.5 V Differential Inputs (Gain Register = 1.0)

±1.25 V Differential Inputs (Gain Register = 2.0)

±625 mV Differential Inputs (Gain Register = 4.0)

-2.5 V

Analog

Supply

Logic Outputs:

A0, A1 Switch from VA+ to VAD0-D3 Switch from VD+ to DGND

0.1 µF

Figure 11. CS5529 Configured with ±2.5 V Analog Supplies.

20

19

213

VA+

VREF+

VREF-

CS5529

3

AIN+

4

AIN-

18

D3

17

D2

16

D1

7

D0

6

A1

5

A0

VA-

1

0.1 µF

VD+

XOUT

XIN

SCLK

SDI

SDO

DGND

12

CS

+3 V ~ +5 V

µ

F

0.1

10

32.768 kHz ~ 100 kHz

11

8

9

15

14

Optional Clock

Source

Serial

Data

Interface

Digital

Supply

DS246F1 23

CS5529

lustrates the CS5529 connected with ±2.5 V bipolar

analog supplies and a +3 V to +5 V digital supply

to measure ground referenced bipolar signals.

PCB Layout

The CS5529 should be placed entirely over an analog ground plane with the DGND pin of the device

connected to the analog ground plane. Place the an-

alog-digital plane split immediately adjacent to the

digital portion of the chip

See the CDB5529 data sheet for suggested layout

details and Applications Note 18 for more detailed

layout guidelines. Applications engineering provides a Free and Confidential Schematic Review

Service.

24 DS246F1

PIN DESCRIPTIONS

CS5529

NEGATIVE ANALOG POWER

POSITIVE ANAL OG POWER

DIFFERENTIAL ANALOG INPUT

DIFFERENTIAL ANALOG INPUT

LOGIC OUTPUT (ANALOG)

LOGIC OUTPUT (ANALOG)

LOGIC OUTPUT (DIGITAL)

CHIP SELECT

SERIAL CLOCK INPUT

CRYSTAL OUT

VA-

VA+

AIN+

AIN-

SCLK

1

2

3

4

A0

5

A1

6

7

D0

813

9

10 11

Clock Generator

XIN; XOUT - Crystal In; Crystal Out, Pins 10, 11.

A gate inside the chip is connected to these pins and can be used with a crystal to provide the

master clock for the device. Alternatively, an external (CMOS compatible) clock (powered

relative to VD+) can be supplied into the XIN pin to provide the master clock for the device.

20

19

18

17

16

15

14

12

VREF+

VREFD3

D2

D1

SDI

SDO

VD+CS

DGND

XINXOUT

VOLTAGE REFER ENCE INPUT

VOLTAGE REFER ENCE INPUT

LOGIC OUTPUT (DIGITAL)

LOGIC OUTPUT (DIGITAL)

LOGIC OUTPUT (DIGITAL)

SERIAL DATA INPUT

SERIAL DATA OUT PUT

POSITIVE DIGITAL POWER

DIGITAL GROUND

CRYSTAL IN

Control Pins and Serial Data I/O

CS - Chip Select, Pin 8.

When active low, the port will recognize SCLK. When high the SDO pin will output a high

impedance state. CS should be changed when SCLK = 0.

SDI - Serial D ata Input, Pin 1 5.

SDI is the input pin of the serial input port. Data will be input at a rate determined by SCLK.

SDO - Serial Data Output, Pin 14.

SDO is the serial data output. It will output a high impedance state if CS = 1.

SCLK - Serial Clock Input, Pin 9.

A clock signal on this pin determines the input/output rate of the data for the SDI/SDO pins

respectively. This input is a Schmitt trigger to allow for slow rise time signals. The SCLK pin

will recognize clocks only when CS is low.

DS246F1 25

A0, A1 - Logic Outputs (Analog), Pin 5, 6.

The logic states of A0-A1 mimic the states of the D22-D23 bits of the configuration register.

Logic Output 0 = VA-, and Logic Output 1 = VA+.

D0, D1, D2, D3 - Logic Outputs (Digital), Pin 7, 16, 17, 18.

The logic states of D0-D3 mimic the states of the D18-D21 bits of the configuration register.

Logic Output 0 = DGND, and Logic Output 1 = VD+.

Measurement and Reference Inputs

AIN+, AIN- - Differential Analog Input, Pins 3, 4.

Differential input pins into the device.

VREF+, VREF- - Voltage Reference Input, Pins 20, 19.

Fully differential inputs which establish the voltage reference for the on-chip modulator.

CS5529

Power Supply Connections

VA+ - Positive Analog Power, Pin 2.

Positive analog supply voltage.

VA- - Negative Analog Power, Pin 1.

Negative analog supply voltage.

VD+ - Positive Digital Power, Pin 13.

Positive digital supply voltage (+3.0 V or +5 V).

DGND - Digital Ground, Pin 12.

Digital Ground.

26 DS246F1

SPECIFICATION DEFINITIONS

Linearity Error

The deviation of a code from a straight line which connects the two end points of the A/D

Converter transfer function. One end point is located 1/2 LSB below the first code transition

and the other end point is located 1/2 LSB beyond the code transition to all ones. Units in

percent of full-scale.

Differential Nonlinearity

The deviation of a code’s width from the ideal width. Units in LSBs.

Full Scale Error

The deviation of the last code transition from the ideal [{(VREF+) - (VREF-)} - 3/2 LSB].

Units are in LSBs.

Unipolar Offset

The deviation of the first code transition from the ideal (1/2 LSB above the voltage on the

AIN- pin). When in unipolar mode (U/B bit = 1). Units are in LSBs.

CS5529

Bipolar Offset

The deviation of the mid-scale transition (111...111 to 000...000) from the ideal (1/2 LSB below

the voltage on the AIN- pin). When in bipolar mode (U/B bit = 0). Units are in LSBs.

ORDERING GUIDE

Model Number Linearity Error (Max) Temperature Range Package

CS5529-AP

CS5529-AS

±

0.003% -40°C to +85°C 20-pin 0.3" Plastic DIP

±

0.003% -40°C to +85°C 20-pin 0.2" Plastic SSOP

DS246F1 27

PACKAGE DIMENSIONS

20 PIN PLASTIC (PDIP) PACKAGE DRAWING

CS5529

D

1

TOP VIEW

E1

SEATING

PLANE

b1

e

BOTTOM VIEW

A

A2

A1

b

L

INCHES MILLIMETERS

DIM MIN MAX MIN MAX

A 0.000 0.210 0.00 5.33

A1 0.015 0.025 0.38 0.64

A2 0.115 0.195 2.92 4.95

b 0.014 0.022 0.36 0.56

b1 0.045 0.070 1.14 1.78

c 0.008 0.014 0.20 0.36

D 0.980 1.060 24.89 26.92

E 0.300 0.325 7.62 8.26

E1 0.240 0.280 6.10 7.11

e 0.090 0.110 2.29 2.79

eA 0.280 0.320 7.11 8.13

eB 0.300 0.430 7.62 10.92

eC 0.000 0.060 0.00 1.52

L 0.115 0.150 2.92 3.81

∝

0° 15° 0° 15°

eB

E

∝

eA

SIDE VIEW

eC

c

28 DS246F1

CS5529

20L SSOP PACKAGE DRAWING

N

1

23

TOP VIEW

D

E

e

2

b

SIDE VIEW

A2

A1

A

SEATING

PLANE

L

1

E1

END VIEW

INCHES MILLIMETERS NOTE

DIM MIN MAX MIN MAX

A -- 0.084 -- 2.13

A1 0.002 0.010 0.05 0.25

A2 0.064 0.074 1.62 1.88

b 0.009 0.015 0.22 0.38 2,3

D 0.272 0.295 6.90 7.50 1

E 0.291 0.323 7.40 8.20

E1 0.197 0.220 5.00 5.60 1

e 0.022 0.030 0.55 0.75

L 0.025 0.041 0.63 1.03

∝ 0° 8° 0° 8°

Notes: 1. “D” and “E1” are reference datums and do not included mold flash or protrusions, but do include mold

mismatch and are measured at the parting line, mold flash or protrusions shall not exceed 0.20 mm per

side.

2. Dimension “b” does not include dambar protrusion/intrusion. Allowable dambar protrusion shall be

0.13 mm total in excess of “b” dimension at maximum material condition. Dambar intrusion shall not

reduce dimension “b” by more than 0.07 mm at least material condition.

3. These dimensions apply to the flat section of the lead between 0.10 and 0.25 mm from lead tips.

DS246F1 29

Preliminary product inform ati on describes products which are i n prod ucti on, but for which full characterization data is not yet avai l able. Advance product informat io n

describes products which are in development and subject to development changes. Cirrus Logic, Inc. has made best efforts to ensure that the information contained

in this document is accurate and reliable. However, the information is subject to change without notice and is provided “AS IS” without warranty of any kind (express

or implied). No responsibility i s assumed by Cirrus Logi c, Inc. for the use of this in formation, nor for i nfringements of pat ents or ot her right s of t hird parties. This

document is the property of Cirrus Logic, Inc. and implies no license under patents, copyrights, trademarks, or trade secrets. No part of this publication may be copied,

reproduced, stored in a retr ieval system, or transmitted, i n any form or by any means (electr onic, mechani cal, photogr aphic, or otherwise ) without t he prior wri tten

consent of Cirrus Logic, Inc. Items from any Cirrus Logic website or disk may be printed for use by the user. However, no part of the printout or electronic files may

be copied, reproduced, stored in a retrieval system, or transmitted, in any form or by any means (electronic, mechanical, photographic, or otherwise) without the prior

written consent of Cirrus Logic, Inc.Furthermore, no part of this publication may be used as a basis for manufacture or sale of any items without the prior written consent

of Cirrus Logic, Inc. The names of products of Ci rrus Logic, Inc. or oth er ven dors and suppliers appeari ng i n this document may be trademarks or servi ce marks of

their respective owners which may be registered in some jurisdictions. A list of Cirrus Logic, Inc. trademarks and service marks can be found at http://www.cirrus.com.

Loading...

Loading...