CS5460

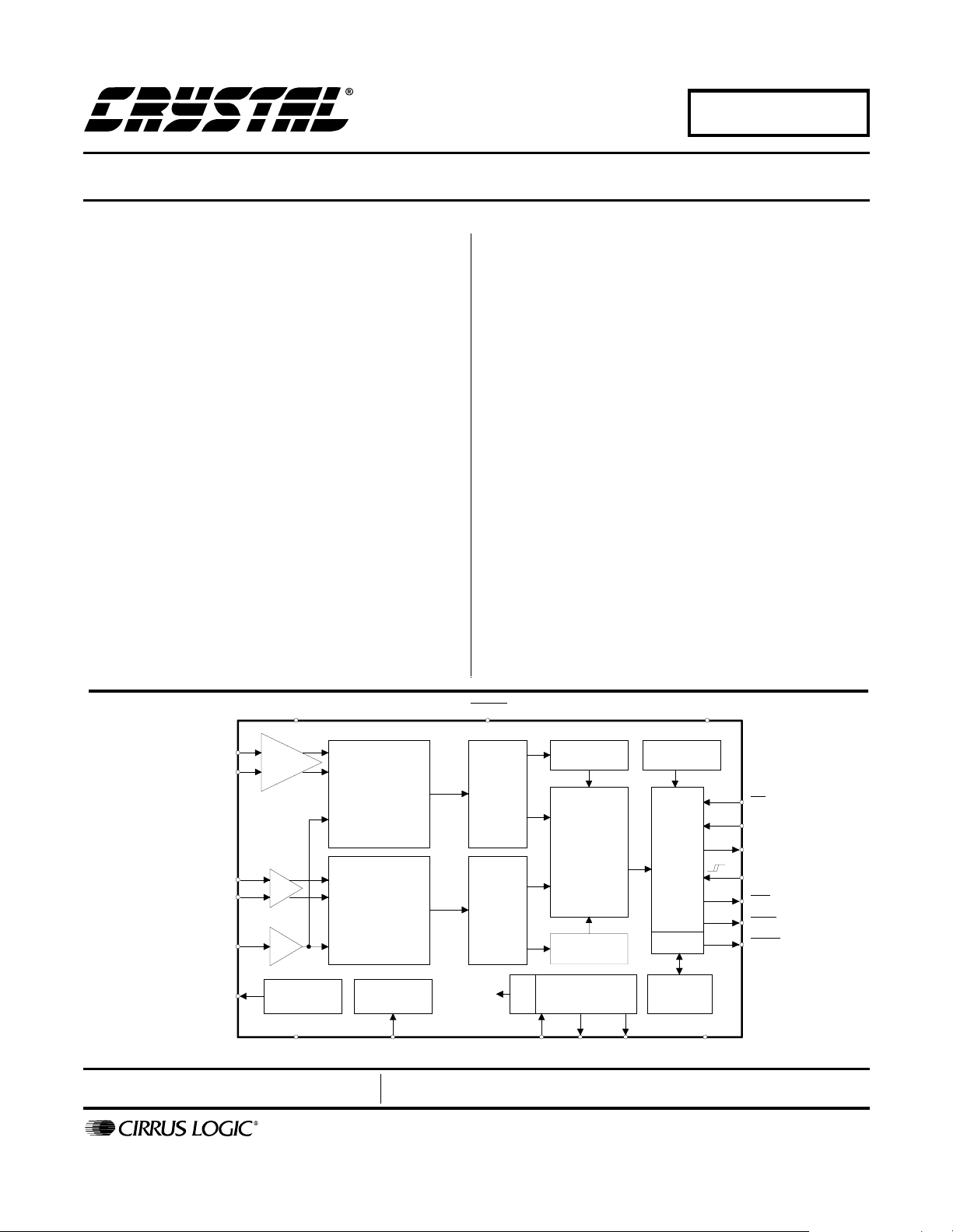

Single Phase Bi-Directional Power/Energy IC

Features

l Energy Data Linearity: 0.1% of Reading over

1000:1 Dynamic Range

l On-Chip Functions: Energy, I ∗ V,

I

and V

RMS

Conversion

l Complies with IEC 687/1036, JIS

l Power Consumption <12 mW

l Interface Optimized for Shunt Sensor

l Phase Compensation

l Ground-Referenced Signals wi th Single

Supply

l System Calibration

l On-chip 2.5 V Reference (60 ppm/°C drift)

l Simple Three-wire Serial Interface

l Watch Dog Timer

l Power Supply Monitor

l Power Supply Configurations

- VA+ = +5 V; VA- = 0V; VD+ = +3 V to +5 V

- VA+ = +2.5 V; VA- = -2.5 V; VD+ = +3 V

, Energy to Pulse-Rate

RMS

Description

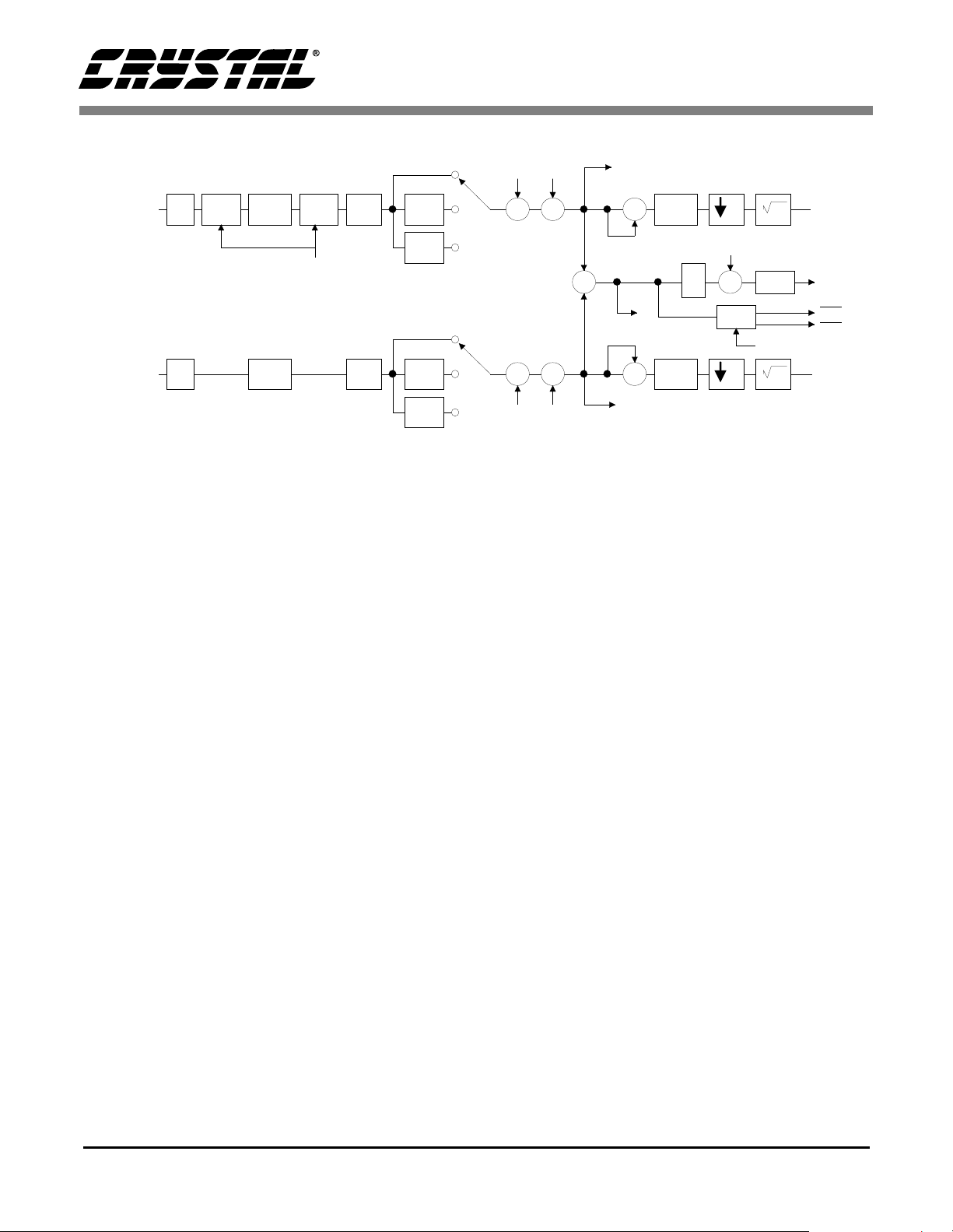

The CS5460 is a h ighly integrated ∆Σ Analog-to -Digital

Converter (ADC) which combines two ∆Σ ADCs, high

speed power calculation functions, and a serial interface

on a single chip. It is desi gned to accurately measure

and calculate: Energ y, Instantaneous Power, I

for single phase 2 or 3-wire po wer meter a pplica-

V

RMS

tions. The CS5460 interfaces to a low cost shunt or

transformer to measure c urrent, and r esistive divid er or

transformer to measure voltage. The CS5460 features a

bi-directional serial interface for communication with a

micro-controller and a fixed-width programmable frequency output that is proportional to energy. The product

is initialized and ful ly functional upon power-u p, and includes facilities for system-level calibration under control

of the user program.

ORDERING INFORMATION:

CS5460-BS -40°C to +85°C 24-pin SSOP

RMS

, and

VA+ VD+

IIN+

IIN-

VIN+

VIN-

VREFIN

VREFOUT

PGA

x10,x50

x10

x1

Voltage

Reference

VA-

4 Order

Modulator

2 Order

Modulator

Preliminary Product Information

P.O. Box 17847, Austin, Texas 78760

(512) 445 7222 FAX: (512) 445 7581

http://www.cirrus.com

RESET

Watch Dog

Timer

Serial

Interface

E-to-F

Calibration

SRAM

DGND

th

∆Σ

nd

∆Σ

Power

Monitor

PFMON

System

Clock

Digital

Filter

Digital

Filter

/K

High Pass

Calculation

I ,V )

RMS RMS

High Pass

Generator

XIN

XOUT

Filter

Power

Engine

(Energy

I * V

Filter

Clock

CPUCLK

This document contains information for a new product.

Cirrus Logic reserves the right to modify this product without notice.

Copyright Cirrus Logic, Inc. 2000

(All Rights Reserved)

CS

SDI

SDO

SCLK

INT

EDIR

EOUT

JUL ‘00

DS279PP6

1

TABLE OF CONTENTS

1. CHARACTERISTICS AND SPECIFICATIONS............................. ...... ....... ...... ....... ..... 4

ANALOG CHARACTERISTICS ...............................................................................4

5 V DIGITAL CHARACTERISTICS ......................................................................... 5

3 V DIGITAL CHARACTERISTICS ......................................................................... 6

ABSOLUTE MAXIMUM RATINGS ..........................................................................6

SWITCHING CHARACTERISTICS ... ....... ...... ............................................. ....... ..... 7

2. GENERAL DESCRIPTION ........................................................................................... 9

2.1 Theory of Operation........................................................................................... 9

2.2 Performing Measurements ................................................................................9

2.2.1 Single Computation Cycle (C = 0).......................................................... 11

2.2.2 Multiple Computation Cycles (C = 1)......................................................11

2.3 High Rate Digital Filters...................................................................................11

2.4 Pulse-Rate Output ...........................................................................................12

3. SERIAL PORT OVERVIEW........................................................................................15

3.1 Command Word (Write Only) ..........................................................................16

3.1.1 Start Conversions...................................................................................16

3.1.2 SYNC0 Command..................................................................................16

3.1.3 SYNC1 Command..................................................................................16

3.1.4 Power-up/Halt Control............................................................................ 16

3.1.5 Power-down Control...............................................................................17

3.1.6 Calibration Control .................................................................................17

3.1.7 Register Read/Write Command ............................................................. 18

3.2 Serial Port Interface.........................................................................................19

3.3 Serial Port Initialization....................................................................................19

3.4 System Initialization......................................................................................... 21

CS5460

4. REGISTER DESCRIPTION ........................... ...... ...... ....... .......................................... 2 2

4.1 Configuration Register ....................................................................................22

4.2 Current Offset Register and Voltage Offset Register ...................................... 23

4.3 Current Gain Register and Voltage Gain Register .......................................... 24

4.4 Cycle Count Register ...................................................................................... 24

4.5 Pulse-Rate Register ........................................................................................24

4.6 I,V,P,E Signed Output Register Results .........................................................24

4.7 IRMS, VRMS Unsigned Output Register Results ...........................................25

4.8 Timebase Calibration ...................................................................................... 25

4.9 Status Register and Mask Register ................................................................25

Contacting Cirrus Logic Support

For a complete listing of Direct Sales, Distributor, and Sales Representative contacts, visit the Cirrus Logic web site at:

http://www.cirrus.com/corporate/contacts/

Microwire is a trademark of National Semiconductor Corporation.

Preliminary product inf o rmation describes products whi ch are in production, but f or wh i ch ful l characterization data is not yet available. Advance produ ct i nf or -

mation describes products which are in development and subject to development changes. Cirrus Logic, Inc. has made best efforts to ensure that the information

contained in this document i s accurat e and reli able. However , t he infor mation is subje ct to chang e without noti ce and is provi d ed “AS IS” without warrant y of

any kind (express or implied). No responsibility is assumed by Cirrus Logic, Inc. for the use of this information, nor for infringements of patents or other ri g ht s

of third parties. This document is the pro perty of Cirrus Logi c, Inc. and i mplie s no licen se under patents, copyrights, tr ademarks, or trade secre ts. No part of

this publication may be copied, reproduced , stored in a retrieval system, or transmitted, in any form or by any means (electronic, mechanical, photographic, or

otherwise) without the pr i or writ ten consent of Cirrus Logic, Inc. Ite ms f rom any Ci rrus L ogi c websi t e or disk may be printed for use by the user. However, no

part of the printout or electronic files may be copied, reproduced, stored in a retrieval system, or transmitted, in any form or by any means (electronic, mechanical,

photographic, or otherwise) without the prior written consent of Cirrus Logic, Inc. Furthermore, no part of this publication ma y be used as a basis for manufacture

or sale of any items without the prior written consent of Cirrus Logic, Inc. The names of products of Cirrus Logic, Inc. or other vendors and suppliers appearing

in this document may be trademarks or service marks of their respective owners which may be registered in some jurisdictions. A list of Cirrus Logic, Inc. trademarks and service marks can be found at http://www.cirrus.com.

2 DS279PP6

CS5460

5. FUNCTIONAL DESCRIPTION ................................................................................... 28

5.1 Interrupt and Watchdog Timer......................................................................... 28

5.1.1 Interrupt.................................................................................................. 28

5.1.1.1 Clearing the Status Register ........................................................ 28

5.1.1.2 Typical use of the INT pin............................................................. 28

5.1.1.3 INT Active State ........................................................................... 28

5.1.1.4 Exceptions.................................................................................... 28

5.1.2 Watch Dog Timer................................................................................... 28

5.2 Oscillator Characteristics................................................................................. 29

5.3 Analog Inputs .................................................................................................. 29

5.4 Voltage Reference........................................................................................... 30

5.5 Performing Calibrations................................................................................... 30

5.5.1 System Calibration................................................................................. 30

5.5.2 Calibration Tips...................................................................................... 31

5.6 Phase Compensation ...................................................................................... 31

5.7 Input Current Protection.................................................................................. 31

5.8 PCB Layout ..................................................................................................... 32

6. PIN DESCRIPTION.................................................... ....... ...... ....... ...... ....... ................ 33

7. SPECIFICATION DEFINITIONS................................................................................. 34

8. PACKAGE DIMENSIONS .......................................................................................... 35

LIST OF FIGURES

Figure 1. SDI Write Timing (Not to Scale).......................................................................................8

Figure 2. SDO Read Timing (Not to Scale)..................................................................................... 8

Figure 3. Typical Connection Diagram (One-Phase 2-Wire)......................................................... 10

Figure 4. Typical Connection Diagram (One-Phase 3-Wire)......................................................... 10

Figure 5. Data Flow....................................................................................................................... 11

Figure 6. Voltage Input Filter Roll-off ............................................................................................ 12

Figure 7. Current Input Filter Roll-off............................................................................................. 12

Figure 8. Multi-Phase System....................................................................................................... 14

Figure 9. CS5460 Register Diagram............................................................................................. 15

Figure 10. Command and Data Word Timing ............................................................................... 20

Figure 11. Oscillator Connection................................................................................................... 29

Figure 12. System Calibration of Offset........................................................................................ 30

Figure 13. System Calibration of Gain.......................................................................................... 30

LIST OF TABLES

Table 1. Specification with MCLK = 4.096 MHz, K = 1, and N = 4000............................................ 9

Table 2. Internal Registers Default Value ..................................................................................... 21

Table 3. CPU Clock (and K) Restrictions...................................................................................... 29

DS279PP6 3

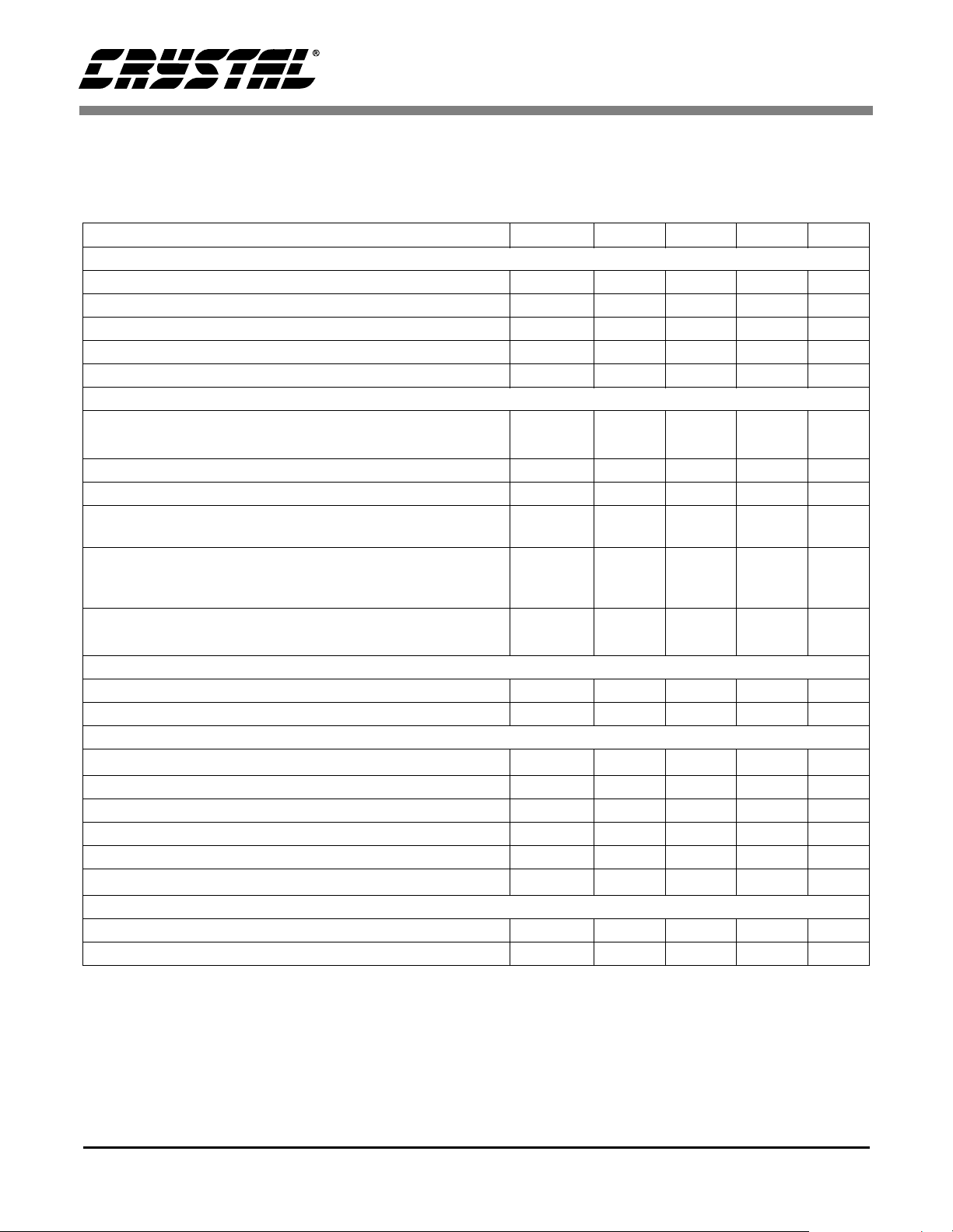

1. CHARACTERISTICS AND SPECIFICATIONS

CS5460

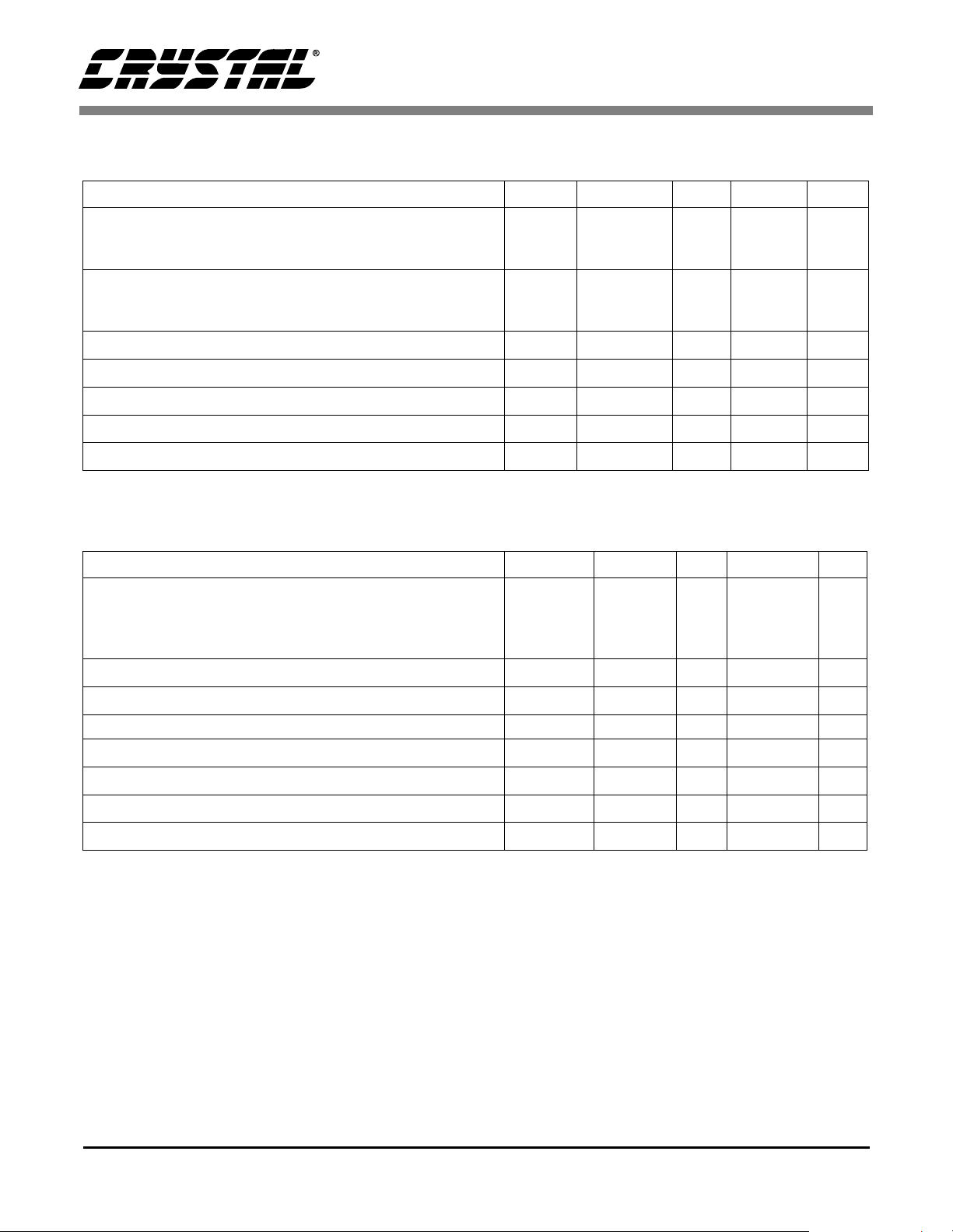

ANALOG CHARACTERISTICS (T

VA- = AGND; MCLK = 4.096 MHz, K = 1; N = 4000, OWR = 4.0 kHz.)(See Notes 1, 2, and 3)

Parameter Symbol Min Typ Max Unit

= -40 °C to +85 °C; VA+, VD+ = +5 V ±10%; VREFIN = 2.5 V;

A

Accuracy (Both Channels)

Total Harmonic Distortion THD 74 - - dB

Common Mode Rejection (DC, 50, 60 Hz) CMRR 80 - - dB

Offset Drift (Without the High Pass Filter) - 5 - nV/°C

Full Scale DC Calibration Range (Note 4) FSCR 25 - 100 %F.S.

Input Sampling Rate DCLK = MCLK/K - DCLK/4 - Hz

Analog Inputs (Current Channel)

Differential Input Voltage Range {(IIN+) - (IIN-)} (Gain = 10)

(Gain = 50)

Common Mode + Signal on IIN+ or IIN- (Gain = 10 or 50) -0.25 - VA+ V

Crosstalk with Voltage Channel at Full Scale (50, 60 Hz) - - -115 dB

Input Capacitance (Gain = 10)

(Gain = 50)

Effective Input Impedance (Note 5)

(Gain = 10)

(Gain = 50)

Noise (Referred to Input) (Gain = 10)

(Gain = 50)

IIN 0

IC -

EII

30

30

-

0

-

-

-

-

5

25

-

-

-

-

±250

±50

-

-

-

-

20

4

mV(dc)

mV(dc)

pF

pF

kΩ

kΩ

µV

rms

µV

rms

Accuracy (Current Channel)

Bipolar Offset Error (Note 1) VOS - - ±0.001 %F.S.

Full-Scale Error (Note 1) FSE - - ±0.001 %F.S.

Analog Inputs (Voltage Channel)

Differential Input Voltage Range {(VIN+) - (VIN-)} VIN 0 - ±250 mV(dc)

Common Mode + Signal on VIN+ or VIN- -0.25 - VA+ V

Crosstalk with Current Channel at Full Scale (50, 60 Hz) - - -70 dB

Input Capacitance IC - 0.2 - pF

Effective Input Impedance (Note 5) EII 5 - - MΩ

Noise (Referred to Input) - - 250 µV

rms

Accuracy (Voltage Channel)

Bipolar Offset Error (Note 1) VOS - - ±0.01 %F.S.

Full-Scale Error (Note 1) FSE - - ±0.01 %F.S.

Notes: 1. Applies after system calibration

2. Specifications guaranteed by design, characterization, and/or test.

3. Analog signals are relative to VA- and digital signals to DGND unless otherwise noted.

4. The minimum FSCR is limited by the maximum allowed gain register value.

5. Effective Input Impedance (EII) varies with clock frequency (DCLK) and Input Capacitance (IC)

EII = 1/(IC*DCLK/4)

4 DS279PP6

CS5460

ANALOG CHARACTERISTICS (Continued)

Parameter Symbol Min Typ Max Unit

Dynamic Characteristics

Phase Compensation (Voltage Channel at 60 Hz) -2.4 - +2.5 °

High Rate Filter Output Word Rate (Both Channels) OWR - DCLK/1024 - Hz

High Pass Filter Pole Frequency -3 dB - 0.5 - Hz

Reference Output

Output Voltage REFOUT 2.4 - 2.6 V

Temperature Coefficient - 25 60 ppm/°C

Load Regulation (Output Current 1 µA Source or Sink) ∆V

R

Output Noise Voltage (0.1 Hz to 512 kHz) eN - 100 - µV

Reference Input

Input Voltage Range VREFIN 2.4 2.5 2.6 V

Input Capacitance - 4 - pF

Input CVF Current - 25 - nA

Power Supplies

Power Supply Currents (Normal Mode) I

I

(VD+ = 5 V)

D+

(VD+ = 3 V)

I

D+

Power Consumption Normal Mode (VD+ = 5 V)

A+

PSCA

PSCD

PSCD

PC -

(Note 6) Normal Mode (VD+ = 3 V)

Standby

Sleep

Power Supply Rejection (50, 60 Hz)

(Gain = 10)

(Gain = 50)

PSRR

PSRR

Power Monitor Thresholds PM 2.3 2.7 V

-610mV

rms

-

-

-

-

-

-

1.3

2.9

1.7

21

11.6

6.75

10

25

-

-

-

mA

mA

mA

mW

-

-

-

mW

mW

µW

-56

70

dB

dB

Notes: 6. All outputs unloaded. All inputs CMOS level.

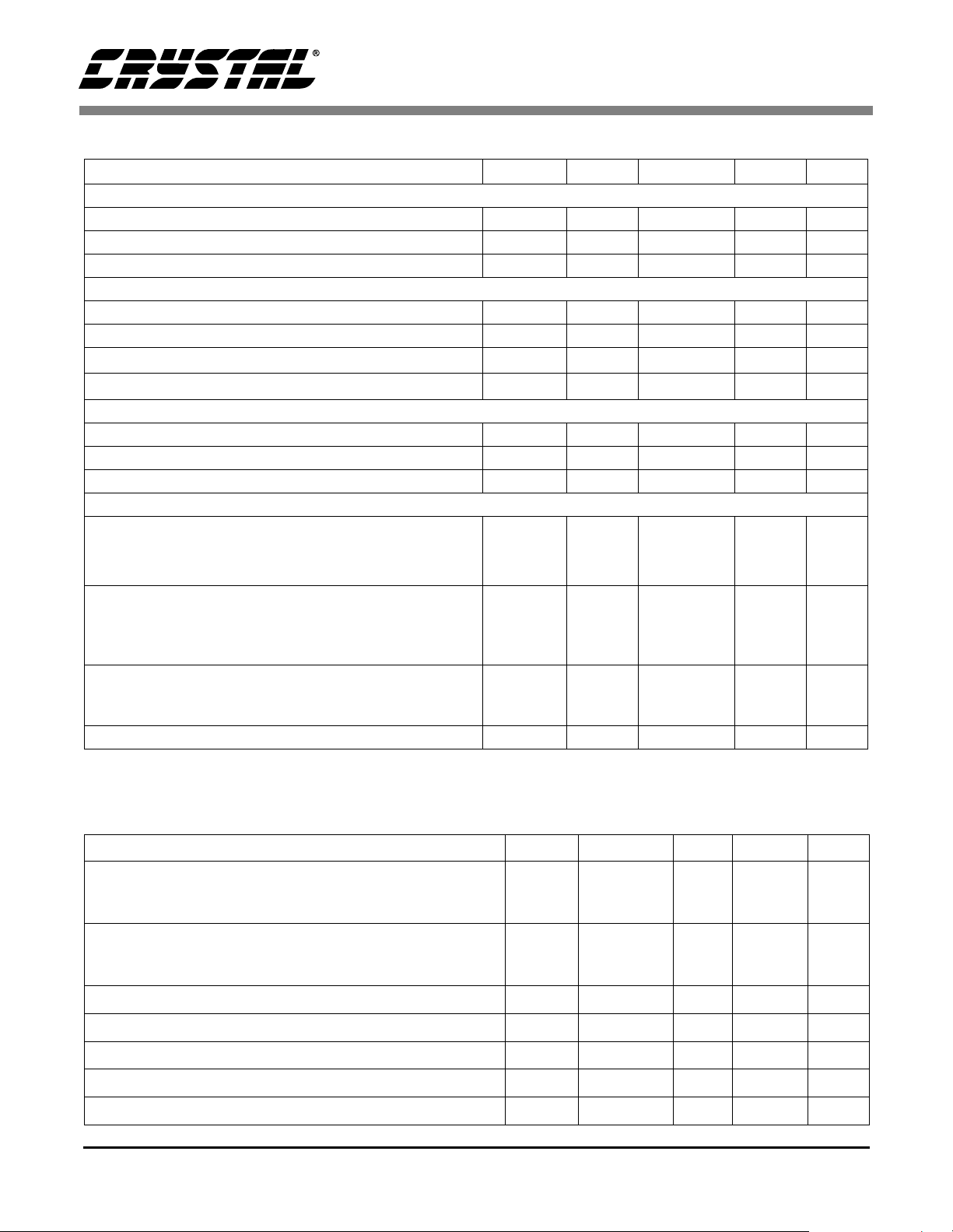

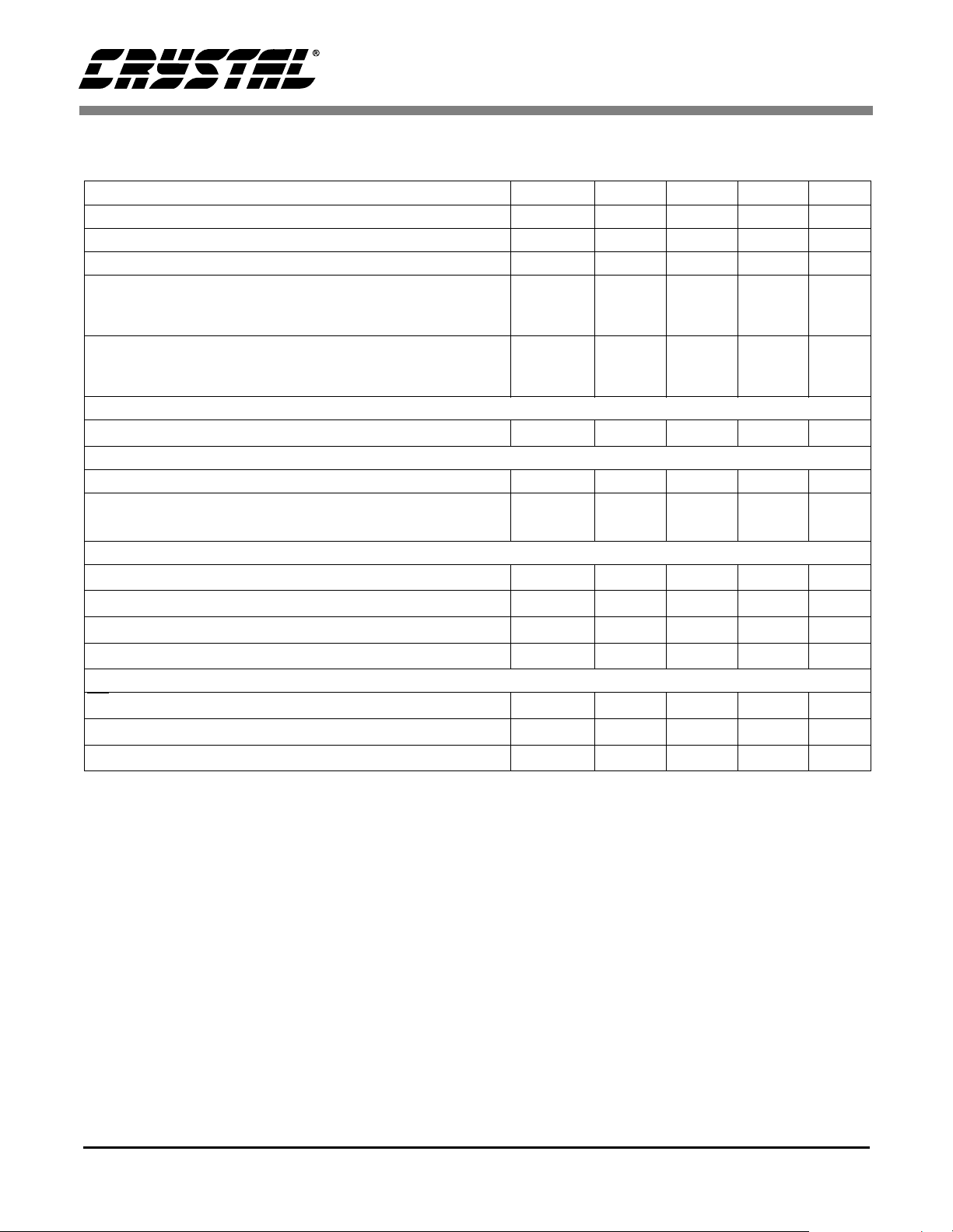

5 V DIGITAL CHARACTERISTICS (T

= -40 °C to +85 °C; VA+, VD+ = 5 V ±10% VA-, DGND = 0

A

V) (See Notes 2 and 7)

Parameter Symbol Min Typ Max Unit

High-Level Input Voltage All Pins Except XIN and SCLK

XIN

SCLK

Low-Level Input Voltage All Pins Except XIN and SCLK

XIN

SCLK

High-Level Output Voltage I

Low-Level Output Voltage I

= +5 mA V

out

= -5 mA V

out

Input Leakage Current I

3-State Leakage Current I

Digital Output Pin Capacitance C

V

V

OH

OL

in

OZ

out

IH

0.6 VD+

(VD+) - 0.5

0.8 VD+

IL

-

-

-

(VD+) - 1.0 - - V

--0.4V

-±1±10µA

--±10µA

-5-pF

-

-

-

-

-

-

-

-

-

0.8

1.5

0.2 VD+

V

V

V

V

DS279PP6 5

CS5460

3 V DIGITAL CHARACTERISTICS (T

= -40 °C to +85 °C; VA+ = 5 V ±10%, VD+ = 3 V ±10%; VA-,

A

DGND = 0 V) (See Notes 2 and 7)

Parameter Symbol Min Typ Max Unit

High-Level Input Voltage All Pins Except XIN and SCLK

XIN

SCLK

Low-Level Input Voltage All Pins Except XIN and SCLK

XIN

SCLK

High-Level Output Voltage I

Low-Level Output Voltage I

= +5 mA V

out

= -5 mA V

out

Input Leakage Current I

3-State Leakage Current I

Digital Output Pin Capacitance C

V

V

OH

OL

in

OZ

out

IH

IL

0.6 VD+

(VD+) - 0.5

0.8 VD+

-

-

-

-

-

-

-

-

-

(VD+) - 1.0 - - V

--0.4V

-±1±10µA

--±10µA

-5-pF

-

-

-

0.48

0.3

0.2 VD+

V

V

V

V

Notes: 7. All measurements performed under static conditions.

ABSOLUTE MAXIMUM RATINGS (DGND = 0 V; See Note 8)

Parameter Symbol Min Typ Max Unit

DC Power Supplies (Notes 9 and 10)

Positive Digital

Positive Analog

Negative Analog

Input Current, Any Pin Except Supplies (Note 11 and 12) I

Output Current I

Power Dissipation (Note 13) PDN - - 500 mW

Analog Inpu t Voltage All Analog Pins V

Digital Input Voltage All Digital Pins V

Ambient Operating Temperature T

Storage Temperature T

VD+

VA+

VA-

IN

OUT

INA

IND

A

stg

-0.3

-0.3

+0.3

-

-

-

+6.0

+6.0

-6.0

--±10mA

--±25mA

- 0.3 - (VA+) + 0.3 V

-0.3 - (VD+) + 0.3 V

-40 - 85 °C

-65 - 150 °C

V

V

V

Notes: 8. All voltages with respect to ground.

9. VA+ and VA- must satisfy {(VA+) - (VA-)} < +6.0 V.

10. VD+ and VA- must satisfy {(VD+) - (VA-)} < +6.0 V.

11. Applies to all pins including continuous over-voltage conditions at the analog input (AIN) pins.

12. Transient current of up to 100 mA will not cause SCR latch-up. Maximum input current for a power

supply pin is ±50 mA.

13. Total power dissipation, including all input currents and output currents.

WARNING: Operation at or beyond these limits may result in permanent damage to the device.

Normal operation is not guaranteed at these extremes.

6 DS279PP6

CS5460

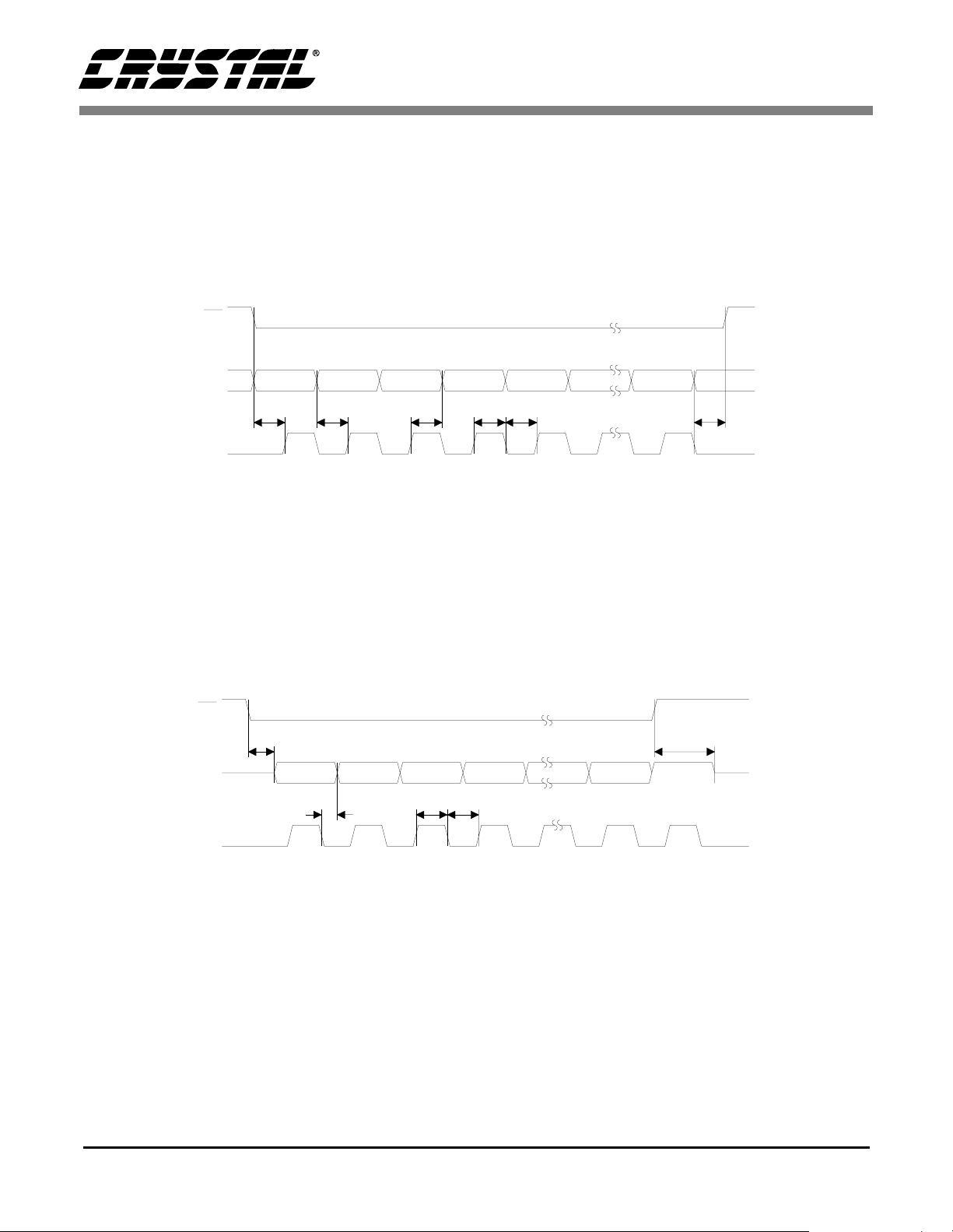

SWITCHING CHARACTERISTICS (T

= -40 °C to +85 °C; VA+ = 5.0 V ±10%; VD+ = 3.0 V ±10%

A

or 5.0 V ±10%; VA- = 0.0 V; Logic Levels: Logic 0 = 0.0 V, Logic 1 = VD+; CL = 50pF))

Parameter Symbol Min Typ Max Unit

Master Clock Frequency Internal Gate Oscillator (Note 14) MCLK 2.5 4.096 20 MHz

Master Clock Duty Cycle 40 - 60 %

CPUCLK Duty Cycle (Note 15) 40 60 %

Rise Times Any Digital Input Except SCLK (Note 16)

SCLK

Any Digital Output

Fall Times Any Digital Input Except SCLK (Note 16)

SCLK

Any Digital Output

t

t

rise

fall

-

-

-

-

-

-

50

50

-

-

-

-

1.0

100

-

1.0

100

-

µs

µs

ns

µs

µs

ns

Start-up

Oscillator Start-up Time XTAL = 4.096 MHz (Note 17) t

ost

-60-ms

Serial Port Timing

Serial Clock Frequency SCLK - - 2 MHz

Serial Clock Pulse Width High

Pulse Width Low

t

1

t

2

200

200

-

-

-

-

ns

ns

SDI Write Timing

CS Enable to Valid Latch Clock t

Data Set-up Time Prior to SCLK Rising t

Data Hold Time After SCLK Rising t

SCLK Falling Prior to CS

Disable t

3

4

5

6

50 - - ns

50 - - ns

100 - - ns

100 - - ns

SDO Read Timing

CS Enable to Valid Latch Clock t

SCLK Falling to New Data Bit t

Rising to SDO Hi-Z t

CS

7

8

9

--150ns

--150ns

--150ns

Notes: 14. Device parameters are specified with a 4.096 MHz clock, however, clocks between 3MHz to 20 MHz

can be used.

15. If external MCLK is used, then its duty cycle must be between 45% and 55% to maintain this spec.

16. Specified using 10% and 90% points on wave-form of interest. Output loaded with 50 pF.

17. Oscillator start-up time varies with crystal parameters. This specification does not apply when using an

external clock source.

DS279PP6 7

CS

CS5460

SDI

SCLK

CS

SDO

SCLK

MSB MSB - 1

t

3

t

7

t

MSB MSB - 1

t

8

t

t

4

5

t

2

1

Figure 1. SDI Write Timing (Not to Scale)

t

t

2

1

LSB

LSB

t

6

t

9

Figure 2. SDO Read Timing (Not to Scale)

8 DS279PP6

CS5460

2. GENERAL DESCRIPTION

The CS5460 is a CMOS monolithic power measurement device with an energy computation engine. The CS5460 combines a programmable gain

amplifier, two ∆Σ modulators, two high rate filters,

system calibration, and power calculation functions to compute Energy, V

RMS

, I

, and Instan-

RMS

taneous Power.

The CS5460 is designed for power meter applica-

tions and is optimized to interface to shunts or current transformers to measure current, and a

resistive divider or transformer to measure voltage.

To accommodate various input voltage levels due

to shunts, the current channel includes a programmable gain amplifier (PGA) which allows the user

to measure either 150 mV

or 30 mV

RMS

RMS

sig-

nals.

The CS5460 includes two high-rate digital filters

which output data at a (MCLK/K)/1024 output word

rate (OWR). A high-pass filter in both channels can

be enabled to remove the DC content from the input

signal before the energy calculations are made.

To ease communication between the CS5460 and a

micro-controller, the converter includes a simple

three-wire serial interface which is SPI™ and Microwire™ compatible. The serial port also contains

a Schmitt Trigger input on its serial clock (SCLK)

to allow for slow rise time signals.

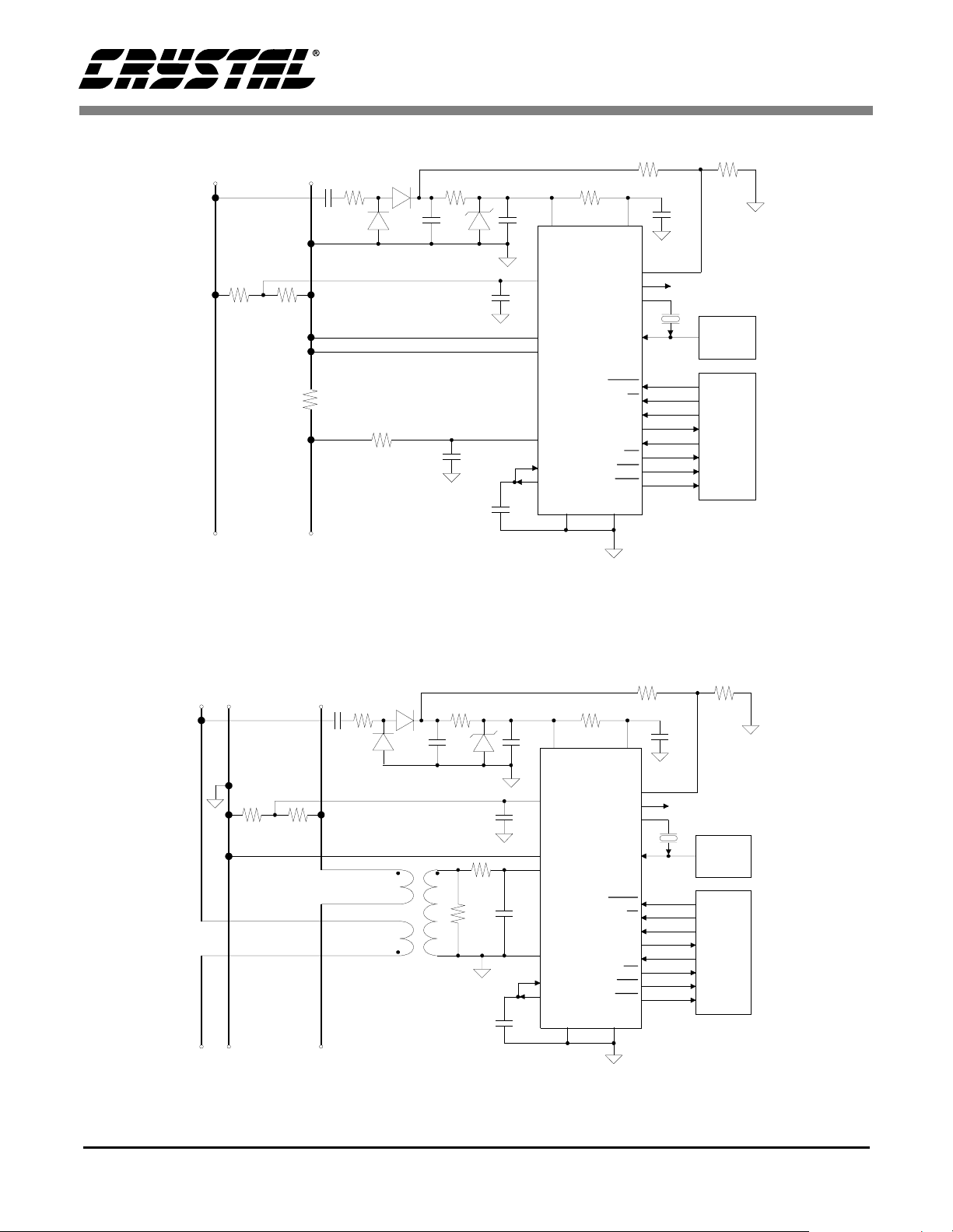

2.1 Theory of Operation

The CS5460 is designed to operate from a single

+5 V supply or dual ±2.5 V supplies, to provide a

30mV

channel and to provide a 150 mV

voltage channel. With single supply, the CS5460 is

designed to accommodate common mode signals

of -0.25 V to VA+.

Figure 3 illustrates the CS5460 connected to a service to measure power in a single-phase 2-wire system while operating in a single supply

configuration. Figure 4 illustrates the CS5460 con-

or 150 mV

RMS

range for the current

RMS

range for the

RMS

figured to measure power in a single-phase 3-wire

system.

2.2 Performing Measurements

The CS5460 performs measurements of instantaneous current, instantaneous voltage, instantaneous

power, energy, RMS current, and RMS voltage.

These measurements are output as 24-bit signed

and unsigned data formats as a percentage of full

scale. The flow of data to per form these calculations is shown in Figure 5. All of these measurements begin when a start conversion command is

given. The energy and RMS registers are then updated every N conversions (or 1 computation cycle) where N is the content of the Cycle Count

register. After the computation cycle has finished,

the DRDY bit in the Status and Mask register is set.

The INT pin will also become active if the DRDY

bit is unmasked.

Table 1 provides an example detailing the output

linearity. A computation cycle is derived from the

master clock and its frequency is

(MCLK/K)/(1024*N). Instantaneous calculations

are performed at a 4000 Hz rate where as, I

V

, and energy, are performed at a 1 Hz rate.

RMS

Also, DRDY is set only after computation cycles

are complete (i.e. there is no indicator flag to indicate when the instantaneous conversions are read;

however, if the Cycle Count register were set to 1,

all output calculations would be instantaneous and

DRDY would indicate when instantaneous calculations were finished).

Energy Vrms Irms

Range

Max Input

Linearity

(After

Calibration)

Output word

Table 1. Specificati o n wi t h MC LK = 4.0 9 6 MH z, K = 1 ,

1000:1 2:1 500:1

See

Analog Characteristics

0.1% of

reading

and N = 4000.

0.1% of

reading

24-bits

RMS

0.1% of

reading

,

DS279PP6 9

N

R

2

To Service

CS5460

5k

Ω

L

470 nF

500

Ω

500

Ω

0.1 µF100 µF

Ω

10

0.1 µF

14

3

VA+ VD+

CS5460

17

9

VIN+

*

CP

V

R

1

10

VIN-

15

IIN-

R

S

*

RP

I

CP

0.1 µF

16

12

11

IIN+

VREFIN

VREFOUT

*

I

VA- DGND

PFMON

CPUCLK

XOUT

XIN

RESET

CS

SDI

SDO

SCLK

INT

EDIR

EOUT

2

1

24

19

7

23

6

5

20

22

21

13 4

* Refer to Input Current Protection

2.5 MHz to

20 MHz

10 k

Ω

Optional

Clock

Source

Serial

Data

Interface

Figure 3. Typical Connection Diagram (One-Phase 2-Wire)

5k

Ω

N

L

1

R

1

To Service

L

2

R

2

Ω

500

470 nF

* Refer to Input Current Protection

500

Ω

R

RP

S

0.1 µF

Ω

10

XIN

CS

SDI

SDO

INT

EDIR

0.1 µF

3

17

2

1

24

19

7

23

6

5

20

22

21

0.1 µF100 µF

14

VA+ VD+

CS5460

VA-

13 4

PFMON

CPUCLK

XOUT

RESET

SCLK

EOUT

DGND

9

VIN+

*

CP

V

10

VIN-

16

CP

*

I

15

12

11

IIN+

IIN-

VREFIN

VREFOUT

*

I

2.5 MHz to

20 MHz

Interface

10 k

Ω

Optional

Clock

Source

Serial

Data

Figure 4. Typical Connection Diagram (One-Phase 3-Wire)

10 DS279PP6

V *

off

V *

gn

CS5460

V*

VOLTAGE

CURRENT

∆Σ

∆Σ

DELAY

REG

SINC

SINC

DELAY

2

REG

Config uration R egiste r *

PC[3:0] Bits

4

FIR

FIR

HPF

APF

HPF

APF

Figure 5. Data Flow.

2.2.1 Single Computation Cycle (C = 0)

Based on the information provided in the Cycle

Count register, a single computation cycle is performed after the user transmits the single conversion cycle command. After the computations are

complete, DRDY is set. Thirty-two SCLKs are

then needed to acquire a calculation result. The first

8 SCLKs are used to clock in the command to determine which result register is to be read. The last

24 SCLKs are needed to read the desired calculation result register. After reading the data, the serial

port returns to the command mode, where it waits

for a new command to be issued.

2.2.2 Multiple Computation Cycles (C = 1)

Based on the information provided in the Cycle

Count register, continuous computation cycles are

repeatedly performed on the voltage and current

cycles. Computation cycles cannot be started/stopped on a per channel basis. After each computation cycle is completed, DRDY is set.

Thirty-two SCLKs are then needed to read a register. The first 8 SCLKs are used to clock in the command to determine which results register is to be

read. The last 24 SCLKs ar e needed to re ad the calculation result. While in this mode, the user may

V *

RMS

E *

E

out

E

dir

I *

RMS

I *

off

N

+

x

x x

x

+

I *

gn

x

x

I *

* DENOTES REGISTER NAME

2

SINC

TBC *

N

Σ

P *

2

SINC

E to F

N

÷

4096

PULSE-RATE*

choose to acquire only the calculations required for

the application as DRDY rises and falls to indicate

the availability of a new data.

The RMS calculations require a Sinc2 operation

prior to their square root operation. Therefore, the

first output for each channel will be invalid (i.e. all

RMS calculations are invalid in the single computation cycle routine and the first RMS calculations

will be invalid in the continuous computation cycle). All energy calculations will be valid since en-

ergy calculations don’t require this Sinc2 operation.

2.3 High Rate Digital Filters

The high rate filter on the voltage channel is imp lemented as a fixed sinc2 filter, compensated by a

short length FIR. When the converter is driven with

a 4.096 MHz clock (K=1), the filter has a magnitude response similar to that shown in Figure 6.

Note that the filter’s response scales with MCLK

frequency and K.

The current channel contains a sinc4 filter, com pensated by a short length FIR. When the converter is

driven with a 4.096 MHz clock (K=1) the composite filter response is given in Figure 7.

DS279PP6 11

CS5460

Figure 6. Voltage Input Filter Roll-off

-2.5

-2

-1.5

-1

-0.5

0

0.5

0 200 400 600 800 1000 1200 1400 1600 1800 2000

Gain (dB)

Frequenc y (Hertz)

Figure 7. Current Input Filter Roll-off

0.5

0.0

-0.5

-1.0

Gain (dB)

-1.5

-2.0

-2.5

0 200 400 600 800 1000 1200 1400 1600 1800 2000

Frequency (Hertz)

15 A respectively, noting that the maximum rated

levels on the power line are 250 V and 20 A. We

also assume that we have calibrated the CS5460

voltage/current channel inputs such that a DC voltage level of 250 mV wi ll cause full -scale readings

of 1.0 in the CS5460A Instantaneous Voltage and

Current Registers as well as in the RMS-Voltage

and RMS-Current Registers. We want to find out

what frequency value we should put into the

CS5460’s pulse-rate register (call this value ‘PR’)

in order to satisfy this re quirement. Our first step is

to set the voltage and current sensor gain constants,

KV and KI, such that there will be acceptable input

voltage levels on the inputs when the power line

voltage and current levels are at the maximum values of 250 V and 20 A, respectively. We need to

calculate KV and KI in order to determine the appropriate ratios of the voltage/current transformers

and/or shunt resistor values to use in the front-end

voltage/current sensor networks.

We assume here that we are dealing with a sinusoidal AC power signal. For a sinewave, the la rgest

RMS value that can be accurately measured (without over-driving the inputs) will register at ~0.7071

of the maximum DC input level. Since power signals are often not perfectly sinusoidal in real-world

situations, and to provide for some over-range capability, we will set the RMS-Voltage and

2.4 Pulse-Rate Output

As an alternative to reading the energy through the

serial port, the EOUT and EDIR pins provide a

simple interface with which signed energy can be

accumulated. Each EOUT pulse represents a predetermined magnitude of energy. The accompanying

EDIR level represents the sign of the energy. With

MCLK = 4.096 MHz, K = 1, and both ADC inputs

at their maximum DC values, the pulses will have

a frequency equal to that in the pulse rate register.

EXAMPLE #1: Suppose that we want the

pulse-frequency on the EOUT pin to be ‘IR’ = 100

pulses per second (100 Hz) when the RMS-voltage/-current levels on the power line are 220 V and

RMS-Current Registers to measure at 0.6 when the

RMS-values of the line-voltage and line-current

levels are at 250 V and 20 A. Therefore, when the

RMS registers measure 0.6, the voltage level at the

inputs will be 0.6 x 250 mV = 150 mV. We now

find our sensor gain constants, KV and KI, by demanding that the voltage and current channel inputs should be at 150 mV RMS when the power

line voltage and current are at the maximum va lues

of 250 V and 20 A.

KV = 150 mV / 250 V = 0.0006

KI = 150 mV / 20 A = 0.0075 Ohms

These sensor gain constants can help determine the

12 DS279PP6

CS5460

PulseRate IR PR

V

Vnom

250 m V

------------------

V

Inom

250mV

------------------

⋅⋅==

PR

IR

V

Vnom

250 m V

------------------

V

Inom

250 m V

------------------

×

------------------------------------------- -

100 H z

132mV

250mV

------------------

112.5 mV

250 m V

-----------------------

×

------------------------------------------------

==

PR

IR

V

Vnom

250 m V

------------------

V

Inom

50mV

---------------

×

---------------------------------------- -

=

ratios of the transformer or resistor-divider sensor

networks. We now use these sensor gain constants

to calculate what the input voltage levels will be on

the CS5460 inputs when the line-voltage and

line-current are at 220 V and 15 A. We call these

values VVnom and VInom.

VVnom = KV * 220 V = 132 mV

VInom = KI * 15 A = 112.5 mV

The pulse rate on EOUT will be at ‘PR’ pulses per

second (Hz) when the RMS-levels of voltage/current inputs are at 250 mV. When the voltage/current inputs are set at VVnom and VInom, we want the

pulse rate to be at ‘IR’ = 100 pulses per second. IR

will be some percentage of PR. The percentage is

defined by the ratios of VVnom/250 mV and

VInom/250 mV with the following formula:

We can rearrange the above equation and solve for

PR. This is the value that we put into the pul se-rate

register.

EXAMPLE #2: Suppose that instead of being given a desired frequency of pulses per second to be issued at a specific voltage/current level, we are

given a desired number of pulses per unit energy to

be present at EOUT, given that the maximum

line-voltage is at 250 V (RMS) and the maximum

line-current is at 20 A (RMS). For example, suppose that the required number of pulses per kW-hr

is specified to be 500 pulses/kW-hr. In such a situation, the nominal line voltage and current do not

determine the appropriate pulse-rate setting. Instead, the maximum line-voltage and line-current

levels must be considered. We use the given maximum line-voltage and line-current levels to determine KV and KI as previously described to get:

KV = 150 mV / 250 V = 0.0006

KI = 150 mV / 20 A = 0.0075 Ohms

where we again have calculated our sensor gains

such that the maximum line-voltage and line-current levels will measure as 0.6 in the RMS-voltage

and RMS-current registers.

We can now calculate the required Pulse-Rate Register setting by using the following equation:

Therefore we set the Pulse-Rate Register to

~420.875 Hz. Therefore, the Pulse-Rate Register

would be set to 0x00349C.

The above equation is valid when current channel

is set to x10 gain. If current channel gain is set to

x50, then the equation becomes:

where it is assumed that the current channel has

been calibrated such th at the current-register will

read at full-scale when the input voltage across the

IIN+ and IIN- inputs is 50 mV (DC).

DS279PP6 13

PR 500

pulses

-----------------kW hr⋅

1hr

--------------

⋅⋅ ⋅ ⋅=

3600 s

1kW

------------ ----- 1000W

250mV

------------------

250m V

------------------

K

K

V

I

Therefore PR = ~1.929 Hz.

Note that the Pulse-Rate Register cannot be set to a

frequency of exactly 1.929 Hz. The closest setting

that the Pulse-Rate register can obtain is 0x00003E

= 1.9375. To improve the accuracy, either gain register can be programmed to correct for the

round-off error in PR. This value would be calculated as

PR

Ign or Vgn

-------------

1.00441≅ 0 x404830==

1.929

To allow for a simpler interface in a multi-phase

system, the EOUT and EDIR pins can be connected

together and used in a wired-or configuration. The

parts must be driven with the same clock and pro-

grammed with different phases (PH[1:0] in the

Phase - 00

Phase - 01

Phase - 10

Phase - 11

t

≅

Pulse-Rate Register Period

8

N

MCLK/K

=

for Integer N

t

t

Figure 8. Multi-Phase System

Configuration register). The pulse width and the

pulse separation is an integer multiple of system

clocks (approximately equal to 1/8 of the period of

the contents of the pulse-rate register). The maximum frequency is therefore MCLK/K/8. A timing

diagram for a multi-phase system is shown in

Figure 8.

CS5460

14 DS279PP6

CS5460

3. SERIAL PORT OVERVIEW

The CS5460’s serial port incorporates a state machine with transmit/re ceive buffers. The state machine interprets 8 bit command words on the rising

edge of SCLK. Upon decoding of the command

word the state machine performs the requested

command or prepares for a data transfer of the a ddressed register. Request for a rea d requires an internal register transfer to the transmit buffer, while

a write waits until the completion of 24 SCLKs before performing a transfer. The internal registers

are used to control the ADC’s functions. All registers are 24-bits in length. Figure 9 depicts the internal registers available to the user.

After system initialization or reset, the serial port

state machine is initialized into command mode

where it waits to receive a valid command (the first

8-bits clocked into the serial port). Upon receiving

and decoding a valid command word the state machine instructs the converter to either perform a

system operation, or transfer data to or from an internal register. The Command Word section can be

used to decode all valid commands.

The state machine decodes the command word as it

is received. The serial port enters data transfer

mode if the MSB of the command word is logic 0

(B7 = 0). In data transfer mode, the internal registers are read from or written to. Command words

instructing a register write must be followed by 24

bits of data. For instance, to write the configuration

register, the user would transmit the command

(0x40) to initiate the write. The ADC would then

acquire the serial data input from the (SDI) pin

when the user pulses the serial clock (SCLK) 24

times. Once the data is received the state machine

would write the data to the configuration register

and return to the command mode. Command words

instructing a register read may be terminated at

8-bit boundaries (e.g., read transfers may be 8, 16,

or 24 bits in length). Also data register reads allow

“command chaining”. For example, a command

word instructs the state machine to read a signed

output register. After the user pulses SCLK for

16-bits of data, a write command word (e.g., to

clear the status register) may be pulsed on to the

SDI line at the same time the remaining 8-bits of

data are pulsed from the SDO line.

Current

Channel

Voltage

Channel

DS279PP6 15

Offset Regi ster (1 × 24)

Offset Register (1 × 24)

Pulse-Rate Register (1 × 24)

Timebase Register (1 × 24)

Configuration Regi ster (1 × 24)

Gain Regi ster (1 × 24)

Gain Reg ister (1 × 24)

Cycle-Counter Register (1 × 24)

Status Register (1 × 24)

Mask Re gister (1 × 24 )

Figure 9. CS5 460 Register Di agram

Signed Output Registers (4 × 24)

(I, V, P, E)

Unsigned Out put Registe rs (2 × 24)

(I , V )

RMS RMS

Receive Buffer

24-Bit

Seri al Interfac e

Transmit Buffer

Command Word

State Mach ine

SDI

CS

SDO

SCLK

INT

CS5460

3.1 Command Word (Write Only)

All command words are always 1 byte in length. Commands that write to a register initiate 3 bytes of register data.

Commands that read from registers must be followed by 1, 2, or 3 bytes of register read data. Commands that read

data can be chained with other commands (e.g., while reading data, a new command can be sent to SDI which can

execute before the original read is completed). This allows for “chaining” commands.

3.1.1 Start Conversions

B7 B6 B5 B4 B3 B2 B1 B0

1110C000

This command indicates to the state machine to begin acquiring measurements and calculating results. The device

has two modes of acquisition.

C Modes of measurement

0 = Perform a single computation cycle

1 = Perform continuous computation cycles

3.1.2 SYNC0 Command

B7 B6 B5 B4 B3 B2 B1 B0

11111110

This command is the end of the serial port re-initialization sequence. The command can also be used as a NOP

command. The serial port is resynchronized to byte boundaries by sending three or more consecutive SYNC1 commands followed by a SYNC0 command.

3.1.3 SYNC1 Command

B7 B6 B5 B4 B3 B2 B1 B0

11111111

This command is part of the serial port re-initialization sequence. The command can also serve as a NOP command,

but no more than three consecutive bytes should be transmitted.

3.1.4 Power-up/Halt Control

B7 B6 B5 B4 B3 B2 B1 B0

10100000

If the device is powered-down, this command will power-up the device. When powered-on, no computations will be

running. If the part is already powered-on, all computations will be halted.

16 DS279PP6

CS5460

3.1.5 Power-down Control

B7 B6 B5 B4 B3 B2 B1 B0

1 0 0S1S00 0 0

The device has two power-down modes to conserve power. If the chip is put in stand-by mode all circuitry except

the clock generator is turned off.

S1,S0 Power-down mode

00 = Reserved

01 = Halt and enter stand-by power saving mode. This mode allows quick power-on time

10 = Halt and enter sleep power saving mode. This mode requires a slow power-on time

11 = Reserved

3.1.6 Calibration Control

B7 B6 B5 B4 B3 B2 B1 B0

110CvCi0GCOC

The device has the capability of performing a system offset and gain calibration. The user must supply the proper

inputs to the device before proceeding with the calibration cycle.

Cv,Ci Designates calibrati on channel

00 = Not allowed

01 = Calibrate the current channel

10 = Calibrate the voltage channel

11 = Calibrate voltage and current channel simultaneously

GC Designates gain calibration

0 = Normal operation

1 = Perform gain calibration

OC Designates offset calibration

0 = Normal operation

1 = Perform offset calibration

DS279PP6 17

CS5460

3.1.7 Register Read/Write Command

B7 B6 B5 B4 B3 B2 B1 B0

0W/R

This command informs the state machine that a register access is required. On reads the addressed register is loaded into the output buffer and clocked out by SCLK. On writes the data is clocked into the input buffer and transferred

to the addressed register on the 24

RA4 RA3 RA2 RA1 RA0 0

th

SCLK.

W/R

Write/Read control

0 = Read register

1 = Write register

RA[4:0] Register address bits. Binary encoded 0 to 31. All registers are 24 bits in length.

Address Name Description

00000 Config Configuration Register

00001 Ioff Current offset calibration

00010 Ign Current gain calibration

00011 Voff Voltage offset calibration

00100 Vgn Voltage gain calibration

00101 Cycle Count Number of conversions to integrate over (N)

00110 Pulse-Rate Used to calibrate/scale the energy to frequency output

00111 I Last current value

01000 V Last voltage value

01001 P Last Power value

01010 E Total energy value of last cycle

01011 I

01100 V

RMS

RMS

RMS current value of last cycle

RMS voltage value of last cycle

01101 TBC Timebase Calibration

01110 Test Internal Use only †

01111 Status Status register

10000 Res Reserved

.

.

10111 Res Reserved

11000 Test Internal Use only †

11001 Test Internal Use Only †

11010 Mask Interrupt mask register

11011 Test Internal Use Only †

11100 Res Reserved

.

.

11111 Res Reserved

† These Registers are for Internal Use only and should not be written to. Accessing these

registers will NOT generate an “Invalid Command” (IC

) bit in the Status Register.

18 DS279PP6

CS5460

3.2 Serial Port Interface

The CS5460’s serial interface consists of four control lines: CS, SDI, SDO, and SCLK.

CS, Chip Select, is the control line which enables

access to the serial port. If the C S pin is tied to logic

0, the port can function as a three wire interf ace.

SDI, Serial Data In, is the data signal used to transfer data to the converters.

SDO, Serial Data Out, is the data signal used to

transfer output data from the converters. The SDO

output will be held at high impedance any time CS

is at logic 1. Figure 10 illustrates the serial sequence necessary to write to, or read from the serial

port’s buffers.

SCLK, Serial Clock, is the serial bit-clock which

controls the shifting of data to or from the ADC’s

serial port. The CS pin must be held at logic 0 before SCLK transitions can be recognized by the

port logic. To accommodate opto-isolators SCLK

is designed with a Schmitt-trigger input to allow an

opto-isolator with slower rise and fall times to directly drive the pin. Additionally, SDO is capable

of sinking or sourcing up to 5 mA to directly drive

an opto-isolator LED. SDO will have less than a

400 mV loss in the drive voltage when sinking or

sourcing 5 mA.

As shown in Figure 10 a transfer of data is always

initiated by sending the appropriate 8-bit command

(MSB first) to the serial port (SDI pin). It is impor-

tant to note that some commands use information

from the cycle-counter and configuration registers

to perform the function. For those commands it is

important that the correct information is written to

those registers first.

When a command involves a write operation the

serial port will continue to clock in the data bits

(MSB first) on the SDI pin for the next 24 SCLK

cycles. When a read command is initiated the serial

port will start transferring register content bit serial

(MSB first) on the SDO pin for the next 8, 16, or 24

SCLK cycles depending on the command issued.

The micro-controller is allowed to send a new command while reading register data. The new command will be acted upon immediately and could

possibly terminate the register read. During the

read cycle, the SYNC0 command (NOP) should be

strobed on the SDI port while clocking the data

from the SDO port.

3.3 Serial Port Initialization

The serial port is initialized to the command mode

whenever a reset is performed o r when the port initialization sequence is completed. The port initialization sequence involves clocking 3 (or more)

SYNC1 command bytes (0xFF) followed by

SYNC0 command byte (0xFE). This sequence

places the chip in the command mode where it

waits until a valid command is received.

DS279PP6 19

CS

SCLK

CS5460

CS

SCLK

SDI

SDO

SDI

MSB MSBLSB

Command Time 8 SCLKs Data Time 24 SCLKs

Write Cycle

MSB

Command Time 8 SC LKs

LSB

LSB

MSB LSB

Data Time 24 SCLKs

Read Cycle

Figure 10. Command and Data Word Timing

20 DS279PP6

3.4 System Initialization

A software or hardware reset can be initiated at any

time. The software reset is initiated by writing a

logic 1 to the RS (Reset System) bit in the configuration register, which automatically returns to logi c

0 after reset. At the end of the 32nd SCLK (i.e., 8 bit

command word and 24 bit data word) internal synchronization delays the loading of the configuration register by 3 or 4 DCLK (MCLK/K). Then the

reset circuit initiates the reset routine on the 1st falling edge of MCLK. A hardware reset is initiated

when the RESET pin is forced low with a minimum

pulse width of 50 ns. The RESET signal is asynchronous requiring no MCLKs for the part to detect

and store a reset event. Once the RESET pin is inactive the internal reset c ircuitry re mains ac tive for

5 MCLK cycles to insure resetting the synchronous

circuitry in the device. The modulators are held in

reset for 12 MCLK cycles after RES ET becomes

CS5460

in

active. The internal registers (some of which drive

output pins) will be reset to their default values on

the first MCLK re ceived after detecting a reset event

(see Table 2). After a reset, the on-chip registers are

initialized to the following states and the converter

is placed in the command mode where it waits for a

valid

command.

Configuration Registe r: 0x000001

Offset Register: 0x000000

Gain Registers 0x400000

Pulse-Rate Register: 0 x0FA000

Cycle-Counter Register: 0x000FA0

Timebase Register: 0x800000

Status Register: 0x000001

Mask Register 0x000000

Signed Registers 0x000000

Unsigned Registers 0x000000

Table 2. Internal Registers Default Value

DS279PP6 21

4. REGISTER DESCRIPTION

CS5460

Notes: * “

** “default” => bit status after reset

RA[4:0]

” => register address bits in the Register Read/Write Command word

4.1 Configuration Register

Address: RA[4:0]* = 0x00

23 22 21 20 19 18 17 16

PC3 PC2 PC1 PC0 0 0 0 Gi

15 14 13 12 11 10 9 8

EWA PH1 PH0 SI1 SI0 EOD DL1 DL0

76543210

RS VHPF IHPF iCPU K3 K2 K1 K0

Default** = 0x000001

K[3:0] Clock divider. A 4 bit binary number ranging from 0 to 15 used to divide the value of MCLK to

generate the internal clock DCLK. The internal clock frequency of DCLK = MCLK/K. Valid values are 1,2, and 4.

0001 = divide by 1 (default)

0010 = divide by 2

0100 = divide by 4

iCPU Inverts the CPUCLK clock. In order to reduce the level of noise present when analog signals

are sampled, the logic driven by CPUCLK should not be active during the sample edge.

0 = normal operation (default)

1 = minimize noise when CPUCLK is driving rising edge logic

IHPF Control the use of the High Pass Filter on the Current Channel.

0 = High-pass filter is disabled. If VHPF is set, use all-pass filter. Otherwise, no filter is used.

(default)

1 = High-pass filter is enabled.

VHPF Control the use of the High Pass Filter on the voltage Channel.

0 = High-pass filter is disabled. If IHPF is set, use all-pass filter. Otherwise, no filter is used.

(default)

1 = High-pass filter enabled

RS Start a chip reset cycle when se t 1. The re set cyc le last s for le ss than 1 0 XIN cycl es. The bit is

automatically returned to 0 by the reset cycle.

DL0 When EOD = 1, EDIR

Default = '0'

DL1 When EOD = 1, EOUT

Default = '0'

EOD Allows the EOUT

also be accessed using the status register.

0 = Normal operation of the EOUT

1 = DL0 and DL1 bits control the EOUT

becomes a user defined pin. DL0 sets the value of the EDIR pin.

becomes a user defined pin. DL1 sets the value of the EOUT pin .

and EDIR pins to be controlled by the DL0 and DL1 bits. EOUT and EDIR can

and EDIR pins. (default)

and EDIR pins.

22 DS279PP6

CS5460

SI[1:0] Soft interrupt configuration. Select the desired pin behavior for indication of an interrupt.

00 = active low level (default)

01 = active high level

10 = falling edge (INT is normally high)

11 = rising edge (INT is normally low)

PH[1:0] Set the phase of the EOUT and EDIR output pin pulse. The EOUT and EDIR pins, on different

phases, can be wire-ORed together as a simple way of summing the frequency of different

parts.

00 = phase 0 (default)

01 = phase 1

10 = phase 2

11 = phase 3

EWA Allows the output pins of EOUT and EDIR of multiple chips to be connected in a wire-AND, us-

ing an external pull-up device.

0 = normal outputs (default)

1 = only the pull-down device of the EOUT and EDIR pins are active

Gi Sets the gain of the current PGA

0 = gain is 10 (default)

1 = gain is 50

Res Reserved. These bits must be set to zero.

PC[3:0] Phase compensation. A 2’s complement number used to set the delay in the voltage channel.

The bigger the number, the greater the delay in the voltage. The phase adjustment range is

about -2.4 to +2.5 degrees at 60 Hz. Each step is about 0.34 degrees at 60 Hz.

0000 = Zero degrees phase delay (default)

4.2 Current Offset Register and Voltage Offset Register

Address: RA[4:0]* = 0x01 (Current Offset Register)

RA[4:0]* = 0x03 (Voltage Offset Register)

MSB LSB

-(20)2-12

-2

Default** = 0.000

The Offset Registers are initialized to zero on reset, allowing the device to function and perform measurements.

The register is loaded after one computation cycle with the system current or voltage offset when the proper

input is applied and the Calibration Command is received. The register may be read and stored so the register

may be restored with the desired system offset compensation. The offset range is ± full scale. Format of the

register value is two’s complement notation.

-3

2

-4

2

-5

2

-6

2

-7

2

.....

-17

2

-18

2

-19

2

-20

2

-21

2

-22

2

-23

2

DS279PP6 23

CS5460

4.3 Current Gain Register and Voltage Gain Register

Address: RA[4:0]* = 0x02 (Current Gain Register)

RA[4:0]* = 0x04 (Voltage Gain Register)

MSB LSB

1

2

4.4 Cycle Count Register

MSB LSB

23

2

0

2

-1

2

-2

2

-3

2

-4

2

-5

2

-6

2

.....

-16

2

-17

2

-18

2

-19

2

-20

2

-21

2

Default** = 1.000

The Gain Registers are initialized to 1.0 on reset, allowing the device to function and perform measurements.

The register is loaded after one cycle with the system gain when the proper input is applied and the Calibration

Command is received. The register may be read and stored so the register may be restored with the desired

system offset compensation. The value is in the range 0.0 ≤ Gain < 4.0.

Address: RA[4:0]* = 0x05

22

2

21

2

20

2

19

2

18

2

17

2

16

2

.....

6

2

5

2

4

2

3

2

2

2

1

2

Default** = 4000

-22

2

0

2

The Cycle Count Register determines the length of an energy and RMS conversion. A conversion cycle is derived from (MCLK/K)/(1024∗N) where MCLK is master clock, K is clock divider, and N is cycle count. N must be

, V

greater than 10 for I

RMS

and energy calculations to be performed.

RMS

4.5 Pulse-Rate Register

Address: RA[4:0]* = 0x06

MSB LSB

18

2

17

2

16

2

15

2

14

2

13

2

12

2

11

2

.....

1

2

0

2

-1

2

-2

2

-3

2

-4

2

Default** = 32000.00 Hz

The Pulse-Rate Register determines the frequency of the train of pulses output on the EOUT

pulse represents a predetermined magnitude of energy.The register’s smallest valid value is 2

-5

increments.

2

pin. Each EOUT

-4

but can be in

4.6 I,V,P,E Signed Output Register Results

Address: RA[4:0]* = 0x07 - 0x0A

MSB LSB

-(20)2-12

Access: Read Only

-2

-3

2

-4

2

-5

2

-6

2

-7

2

.....

-17

2

-18

2

-19

2

-20

2

-21

2

-22

2

-5

2

-23

2

The Signed Registers contain the last value of the measured results of I, V, P, and E. The results are in the

range of -1.0 ≤ I, V, P, E < 1.0. The value is represented in two's complement notation, with the binary point

place to the right of the MSB (which is the sign bit). I, V, P, and E are output results registers which contain

signed values. Note that the I, V, and P registers are updated every conversion cycle, while the E register is

only updated after each computation cycle. The numeric format of this register is two’s complement notation.

24 DS279PP6

CS5460

4.7 I

RMS

, V

Unsigned Output Register Results

RMS

Address: RA[4:0]* = 0x0B - 0x0C

MSB LSB

-1

2

-2

2

-3

2

-4

2

-5

2

-6

2

-7

2

-8

2

.....

-18

2

-19

2

-20

2

-21

2

-22

2

-23

2

Access: Read Only

The Unsigned Registers contain the last value of the calculated results of I

range of 0.0 ≤ I

left of the MSB. I

RMS,VRMS

RMS

< 1.0. The value is represented in binary notation, with the binary point place to the

and V

are output result registers which contain unsigned values.

RMS

RMS

and V

. The results are in the

RMS

4.8 Timebase Calibration

Address: RA[4:0]* = 0x0D

MSB LSB

0

2

-1

2

-2

2

-3

2

-4

2

-5

2

-6

2

-7

2

.....

-17

2

-18

2

-19

2

-20

2

-21

2

-22

2

Default** = 1.000

The Timebase Register is initialized to 1.0 on reset, allowing the device to function and perform computations.

The register is user loaded with the clock frequency error to compensate for a gain error caused by the crystal/oscillator tolerance. The value is in the range 0.0 ≤ TBC < 2.0.

-24

2

-23

2

4.9 Status Register and Mask Register

Address:

23 22 21 20 19 18 17 16

DRDY EOUT EDIR Res MATH Res IOR VOR

15 14 13 12 11 10 9 8

PWOR IROR VROR EOR EOOR Res Res Res

Res Res WDT VOD IOD LSD 0

Default** = 0x000001 (Status Register)

The Status Register indicates the condition of the chip. In normal operation writing a ’1’ to a bit will cause the bit

to go to the ’0’ state. Writing a ’0’ to a bit will maintain the status bit in its current state. With this feature the user

can simply write back the status register to clear the bits that have been seen, without concern of clearing any

newly set bits. Even if a status bit is masked to prevent the interrupt, the status bit will still be set in the status

register so the user can poll the status.

The Mask Register is used to control the activation of the INT

allow the corresponding bit in the status register to activate the INT

IC

RA[4:0]* = 0x0F

RA[4:0]* = 0x1A (Mask Register)

(Status Register)

76543210

0x000000 (Mask Register)

pin. Placing a logic ’1’ in the mask register will

pin when the status bit becomes active.

Invalid Command. Normally logic 1. Set to logic 0 when the part is given an invalid command.

Can be deactivated only by sending a port initialization sequence to the serial port. When writing

to Status Register this bit is ignored.

IC

DS279PP6 25

CS5460

LSD Low Supply Detect. Set when the voltage at the PFMON pin falls below the low-voltage thresh-

old (with respect to VA- pin). For a given part, this threshold can anywhere between 2.3 V to

2.7 V.

IOD Modulator oscillation detect on the current channel. Set when the modulator oscillates due to

an input above Full Scale. Note that the level at which the modulator oscillates is significantly

higher than the current channel’s Differential Input Voltage Range.

VOD Modulator oscillation detect on the voltage channel. Set when the modulator oscillates due to

an input above Full Scale. Note that the level at which the modulator oscillates is significantly

higher than the current channel’s Differential Input Voltage Range.

NOTE: This IOD and VOD bits may be ‘falsely’ triggered by very brief voltage spikes from the

power line. This event should not be confused with a DC overload situation at the inputs, when

the IOD and VOD bits will re-assert themselves even after being cleared, multiple times.

WDT Watch-Dog Timer. Set when there has been no reading of the Energy register for more than 5

seconds. (MCLK = 4.096 MHz, K = 1) To clear this bit, first read the Energy register, then write

to the Status Register with this bit set to logic '1'.

EOOR /EOUT Energy Summation Register went out of range. Note that the /EOUT Energy Summing

Register is different than the Energy Register available through the serial port. This register

cannot be read by the user. Assertion of the this bit can be caused by having an output rate

that is too small for the power being measured. The problem can be corrected by specifying a

higher frequency in the Pulse-Rate Register.

EOR Energy Out of Range. Set when the calibrated energy value is too large or too small to fit in the

Energy Register, which can be read via the serial port.

VROR RMS Voltage Out of Range. Set when the calibrated RMS voltage value is too large to fit in the

RMS-Voltage Register.

IROR RMS Current Out of Range. Set when the calibrated RMS current value is too large to fit in the

RMS-Current Register.

PWOR Power Calculation Out of Range. Set when the

to fit in the Instantaneous Power Register.

VOR Voltage Out of Range.

IOR Current Out of Range. Set when the

too small to fit in the Instantaneous Current Register.

MATH General computation Indicates that a divide operation overflowed. This can happen normally

in the course of computation. If this bit is asserted but no other bits are asserted, then there is

no error, and this bit should be ignored.

EDIR Set whenever the EOUT bit asserted (see below) as long as the energy result is negative.

EOUT Indicates that the energy limit has been reached for the /EOUT Energy Summation Register,

and so this register will be cleared, and one pulse will be generated on the /EOUT pin (if en-

abled). The energy flow may indicate negative energy or positive energy. This must be deter-

mined by looking at the EDIR bit (above). This EOUT bit is cleared automatically when the

energy rate drops below the level that produces a 4 KHz EOUT pin rate. The bit can also be

cleared by writing to the Status Register. This status bit is set with a maximum frequency of

4 KHz (when MCLK/K is 4.096 MHz).

magnitude

magnitude

of the calibrated current value is too large or

of the calculated power is too large

26 DS279PP6

CS5460

DRDY Data Ready. When running in single or continuous conversion mode, this bit will indicate the

end of computation cycles. When running calibrations, this bit indicates that the calibration se-

quence has completed, and the results have been stored in the offset or gain registers.

DS279PP6 27

CS5460

5. FUNCTIONAL DESCRIPTION

5.1 Interrupt and Watchdog Timer

5.1.1 Interrupt

The INT pin is used to indicate that an event has

taken place in the converter that needs attention.

These events inform the system about operation

conditions and internal error conditions. The INT

signal is created by combini ng the Status register

with the Mask register. Whenev er a bit in the Status

register becomes active, and the corresponding bit

in the Mask register is a logic 1, the INT signal becomes active. The interrupt condition is cleared

when the bits of the status regist er are returned to

their inactive state.

5.1.1.1 Clearing the Status Register

Unlike the other registers, the bits in the Status register can only be cleared (set to logic 0). When a

word is written to the Status register, any 1s in the

word will cause the corresponding bits in the Status

register to be cleared. The other bits of the status

register remain unchanged. This allows the clearing of particular bits in the register without having

to know the state of the other bits. This mechanism

is designed to facilitate handshaking and to mini-

mize the risk of losing events that haven’t been processed yet.

5.1.1.2 Typical use of the INT pin

The steps below show how interrupts can be handled.

Initialization:

Step I0 - All Status bits are cleared by writing

FFFFFF (Hex) into the Status register.

Step I1 - The conditional bits which will be

used to generate interrupts are then written to

logic 1 in the Mask register.

Step I3 - Enable interrupts.

Interrupt Handler Routine:

Step H0 - Read the Status register.

Step H1 - Disable all interrupts.

Step H2 - Branch to the proper interrupt service

routine.

Step H3 - Clear the Status register by writing

back the value read in step H0.

Step H4 - Re-enable interrupts.

Step H5 - Return from interrupt service routine.

This handshaking procedure insures that any

new interrupts activated between ste ps H0 and

H3 are not lost (cleared) by step H3.

5.1.1.3 INT Active State

The behavior of the INT pin is controlled by the SI1

and SI0 bits of the configuration register. The pin

can be active low (default), active high, active on a

return to logic 0 (rising edge), or activate on a return to logic 1 (falling edge).

5.1.1.4 Exceptions

The IC (Invalid Command) bit of the Status register

can only be cleared by performing the port initialization sequence. This is also the only Status register bit that is active low.

To properly clear the WDT (WatchDog Timer ) bit

of the Status register, one must first read the Energy

register, then clear the bit in the status register.

5.1.2 Watch Dog Timer

The Watch Dog Timer (WDT) is provided as

means of alerting the system that there is a potential

breakdown in communication with the micro-controller. By allowing the WDT to c ause a n interrupt,

a controller can be brought back, from some unknown code space, into the proper code for processing the data created by the converter. The

time-out is preprogrammed to approximately 5 seconds. The countdown restarts each time the Energy

register is read. Under typical situations, the Energy register is read every second. As a result, the

28 DS279PP6

CS5460

WDT will not time out. Other applications, that

want to use the watchdog timer, will need to ensure

that the Energy register is read at least once in every 5 second span.

5.2 Oscillator Characteristics

XIN and XOUT are the input and output, respectively, of an inverting amplifier to provide oscillation and can be configured as an on-chip oscillator,

as shown in Figure 11. The oscillator circuit is designed to work with a quartz crystal or a ceramic

resonator. To reduce circuit cost two load capaci tors C1 are integrated in the device, one between

XIN and DGND, one between XOUT and DGND.

Lead lengths should be minimized to reduce stray

capacitance. With these load capacitors the oscillator circuit is capable of oscillation up to 20 MHz.

To drive the device from an external clock source,

XOUT should be left unconnected while XIN is

driven by the external circuit ry. Ther e is a n am plifier between XIN and the digital section which provides CMOS level signals. This amplifier works

with sinusoidal inputs so there are no problems

with slow edge times.

The CS5460 can be driven by a clock ranging from

2.5 to 20 MHz Table 3 shows the clock divide value K (default = 1) that the CS5460 needs to be programmed with for normal operation.

K CLK (min)

MHz

12.5 5

25 10

410 20

Table 3. CPU Clock (and K) Restrictions

CLK (max)

MHz

5.3 Analog Inputs

The CS5460 accommodates a full scale range of

150 mV

bration can be used to increase or decrease the full

scale span of the converter as long as the calibra tion register values stay withi n the li mits specified.

See the Calibration section for more details.

The current input channel has an input range of 30

mV

RMS

abled. This signal range is designed to handle low

level signals from a shunt sensor.

on both input channels. System cali-

RMS

when the internal x50 gain stage is en-

XOUT

C1

XIN

C1

DGND

Figure 11. Oscillator Connection

DS279PP6 29

C1 = 22 pF

Oscillator

Circuit

CS5460

5.4 Voltage Reference

The CS5460 is specified for operation with a

+2.5 V reference between the VREFIN and VApins. The converter includes an internal 2.5 V ref-

erence (60 ppm/°C drift) that can be used by connecting the VREFOUT pin to the VREFIN pin of

the device. If higher accuracy/stability is required,

an external reference can be used.

5.5 Performing Calibrations

The CS5460 offers two DC calibration modes: system offset and system gain. For system calibration

the user must supply the converter calibration signals which represent ground and full scale. The

user must provide the positive full scale point to

perform a system gain calibration and a ground

referenced signal when a system offset is performed. The offset and gain signals must be within

the specified calibration limits for each specific

calibration step and channel. Since each converter

channel has its own offset and gain register associated with it, system offset, or system gain can be

performed on either channel without the calibration results from one channel corrupting the other.

The Cycle Count register N, determines the number

of conversions averaged to obtain the calibration

results. The larger N, the higher the accuracy of the

calibration results. Once a calibration cycle is complete, DRDY is set and the results ar e stored in e ither the gain or offset register. Note that if

additional calibrations are performed, the latest calibration results will replace the effects from the

previous calibration. In any event, offset and gain

calibration steps take one cycle each to complete.

After the part is reset, the device is functional and

can perform measurements without being calibrated. The converters will utilize the initialized values

of the on-chip registers (Gain = 1.0, Offset = 0.0) to

calculate power information. Although the device

can be used without performing an offset or gain

calibration, any initial offset and gain errors in the

internal circuitry of the chip will remain.

5.5.1 System Calibration

For the system calibration functions, the user must

supply the converters calibration signals which represent ground and full scale. When a system offset calibration is performed, a ground reference signal must

be applied to the converters. Figure 12 illustrates system offset calibration.

As shown in Figure 13, the user must input a signal

representing the positive full scale point to perform

a system gain calibration. In either case, the calibration signals must be within the specified calibration limits for each specific calibration step (refer

to Full Scale DC Calibration Range).

External

Connections

0V

CM

Full Scale

CM

AIN+

+

-

AIN-

+

-

Figure 12. System Calibration of Offset.

External

Connections

AIN+

+

-

AIN-

+

-

Figure 13. System Calibration of Gain.

+

XGAIN

-

+

XGAIN

-

+

-

+

-

30 DS279PP6

CS5460

5.5.2 Calibration Tips

To minimize digital noise near the device, the user

should wait for each calibration step to be completed before reading or writing to the serial port.

After a calibration is performed, the offset and gain

register contents can be read by the system micro-controller and recorded in memory. The same

calibration words can be uploaded into the offset

and gain registers of the converters when power is

first applied to the system, or when the gain range

on the current channel is changed.

An offset calibration must be performed before a

gain calibration. Each gain calibration depends on