Page 1

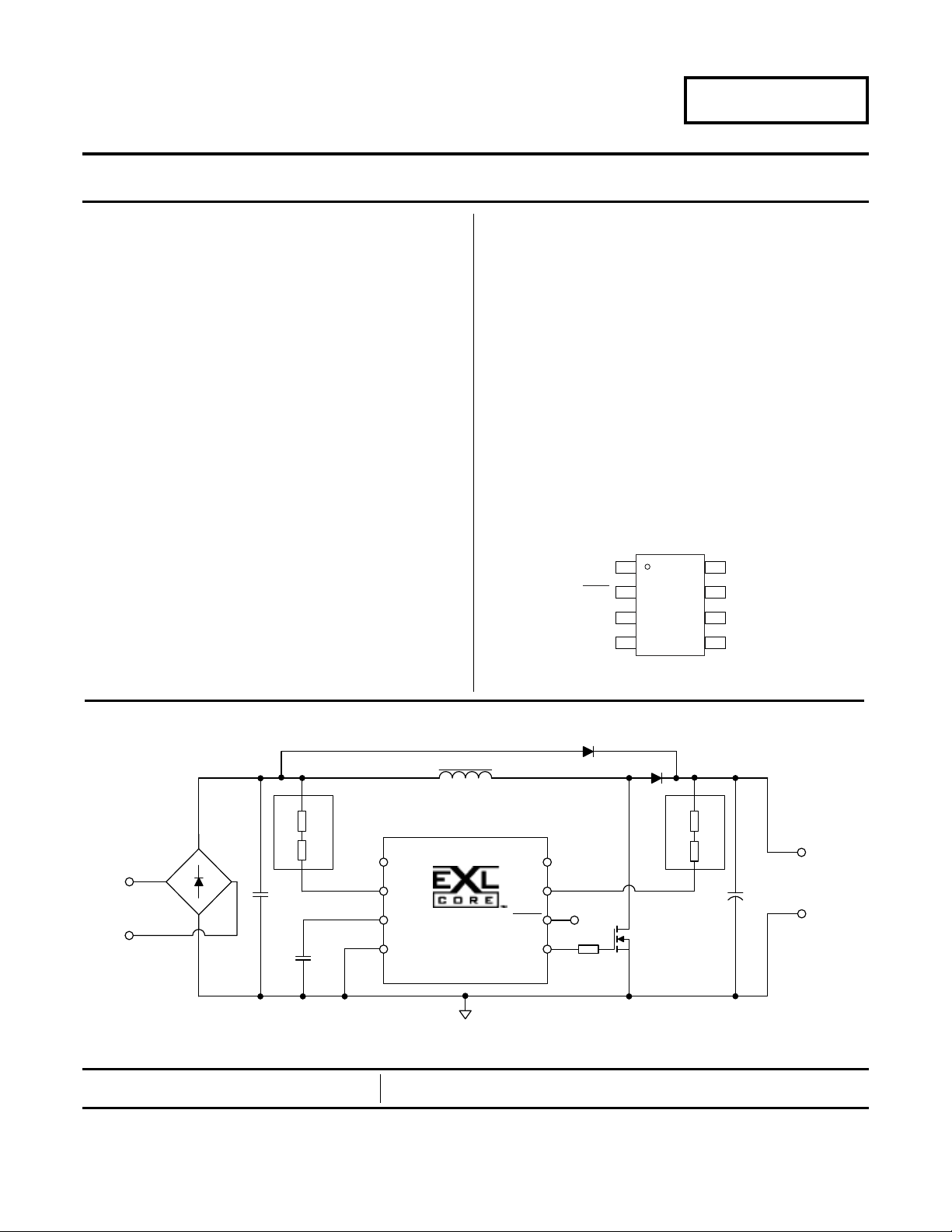

NC

STBY

IAC

FB

NC

VDD

GD

GND

1

2

3

4

8

7

6

5

8-lead SOIC

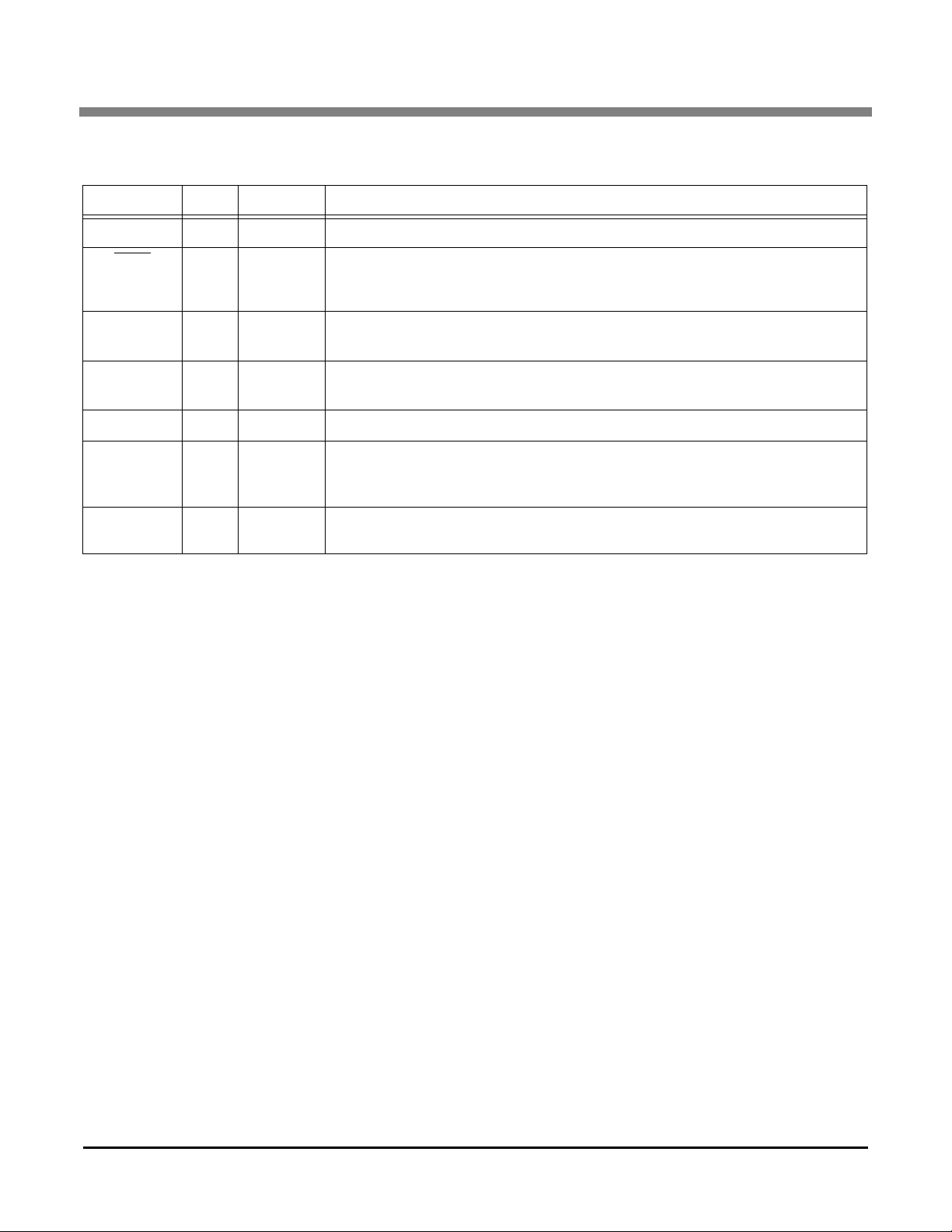

D2

C1

D1

CS1500

C2

L

B

C3

Q1

6

2

8

5

7

3

1

R1a

R1b

R2a

R2b

R3

FB

GD

NC

STBY

GND

VDD

IAC

NC

R

AC

R

FB

BR1

AC

Mains

Regulated

DC Outp u t

4

May ?$shortyear>

CONFIDENTIAL

Digital Power Factor Correction IC

CS1500

Features & Description

Digital EMI Noise Shaping

Excellent Efficiency Under All Load Conditions

Minimal External Devices Required

Optimized Digital Loop Compensation

Comprehensive Safety Features

• Undervoltage Lockout (UVLO)

• Output Overvoltage Protection

• Input Current Limiting

• Output Overpower Protection

• Input Brownout Protection

• Open/short Loop Protection for IAC & FB Pins

• Thermal Shutdown

Description

The CS1500 is a high-performance power factor correction (PFC)

controller for universal AC input, which uses a proprietary digital

algorithm for discontinuous conduction mode (DCM) with variable

on-time and variable frequency control, ensuring unity power factor.

The CS1500 incorporates all the safety features necessary for

robust and compact PFC stages. In addition, it has burst mode

control to lower the light-load/standby losses to a minimum.

Protection features such as overvoltage, overcurrent, overpower,

open- and short-circuit protection, overtemperature, and brownout

help protect the device during abnormal transient conditions.

The digital controller optimizes the system stability and transient

performance, simplifies the PFC design, reduces the external

component count and BOM costs. The simple design and

minimum cost makes CS1500 the ideal choice for PFC up to 300

watts.

Pin Assignments

Advance Product Information

Cirrus Logic, Inc.

http://www.cirrus.com

This document contains information for a product under development.

Cirrus Logic reserves the right to modify this product without notice.

Copyright Cirrus Logic, Inc. 2010

(All Rights Reserved)

MAY ‘10

DS849A6

Page 2

May ?$shortyear>

CONFIDENTIAL

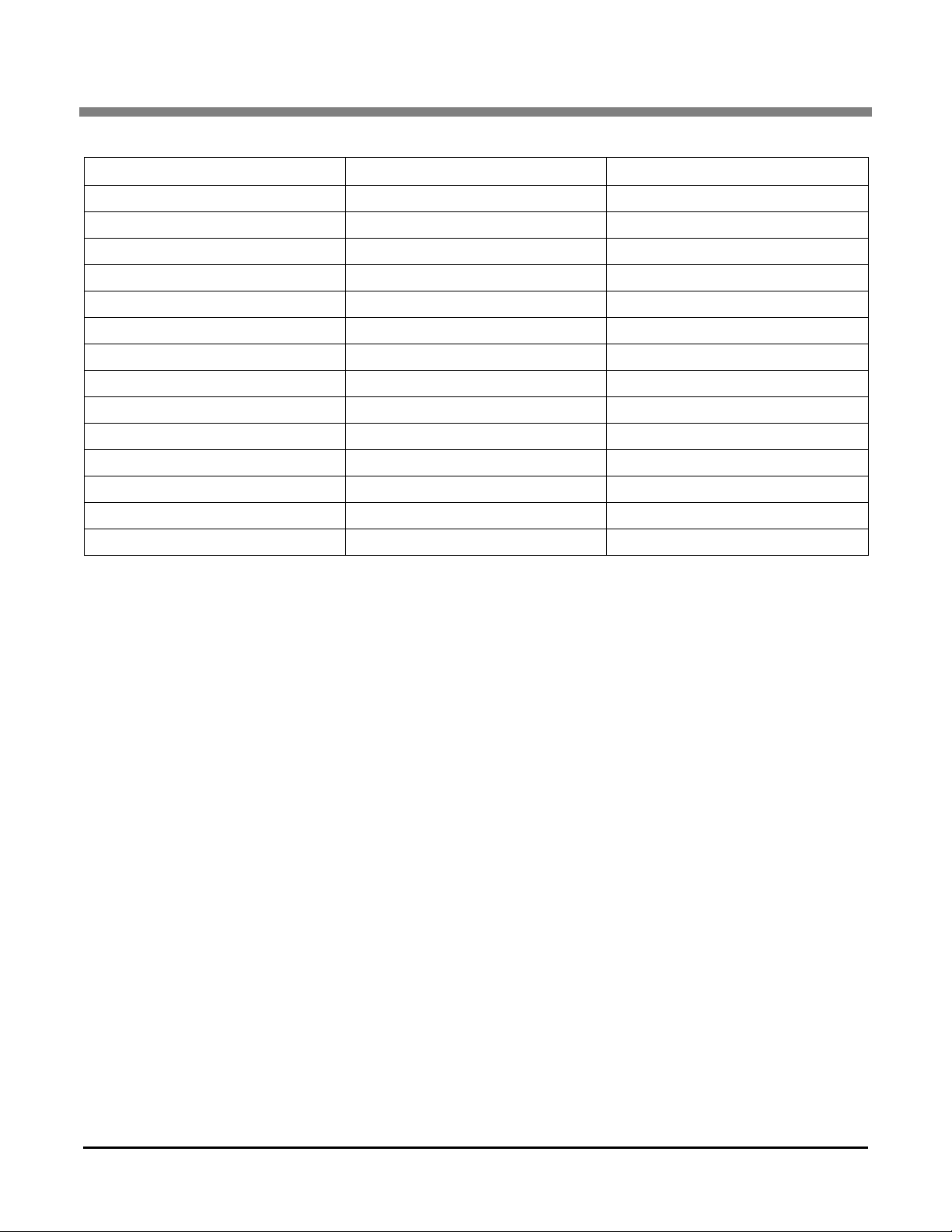

Table 1. Pin Descriptions

CS1500

Pin Name Pin # I/O

NC

STBY

1, 8 -

2IN

IAC

FB

GND

GD

3IN

4IN

5-

6OUT

VDD

7IN

Description

NC — No connections

Remote On/Off Control — A voltage below 0.8 V shuts down the IC (not latched) and

brings the device into low power consumption mode. The input has an internal 600 kΩ

pull-up resistor to the VDD pin and should be driven with an open-collector device.

Rectifier Voltage Sense — A current proportional to the rectified line voltage (V

fed into this pin. The current is measured with an A/D converter.

Link Voltage Sense — A current proportional to the output link voltage (V

PFC is fed into this pin. The current is measured with an A/D converter.

Ground — Current return for both the input signal portion of the IC and the gate driver.

Gate Driver Output — The totem pole stage is able to drive the power MOSFET with a

peak current of 0.5 A source and 1.0 A sink. The high-level voltage of this pin is

clamped at V

IC Supply Voltage — Supply voltage of both the input signal portion of the IC and the

gate driver.

to avoid excessive gate voltages.

Z

link

rect

) of the

) is

2 DS849A6

Page 3

May ?$shortyear>

CONFIDENTIAL

1. CHARACTERISTICS AND SPECIFICATIONS

1.1 Absolute Maximum Ratings

Pin Symbol Parameter Value Unit

7V

DD

1,2,3,4,8 - Analog Input Maximum Voltage -0.5 to V

3,4 - Analog Input Maximum Current 50 mA

6V

GD

6IGDGate Drive Output Current -1.0 / +0.5 A

-P

- θ

T

-T

-T

Stg

IC Supply Voltage V

Z

Gate Drive Output Voltage -0.3 to V

Total Power Dissipation @ TA=50° C 600 mW

D

Junction-to-Ambient Thermal Impedance 107 ºC / W

JA

A

Operating Ambient Temperature Range

Junction Temperature Operating Range -40 to +125 ºC

J

1

-40 to +125 ºC

Storage Temperature Range -65 to +150 ºC

CS1500

Z

Z

V

V

V

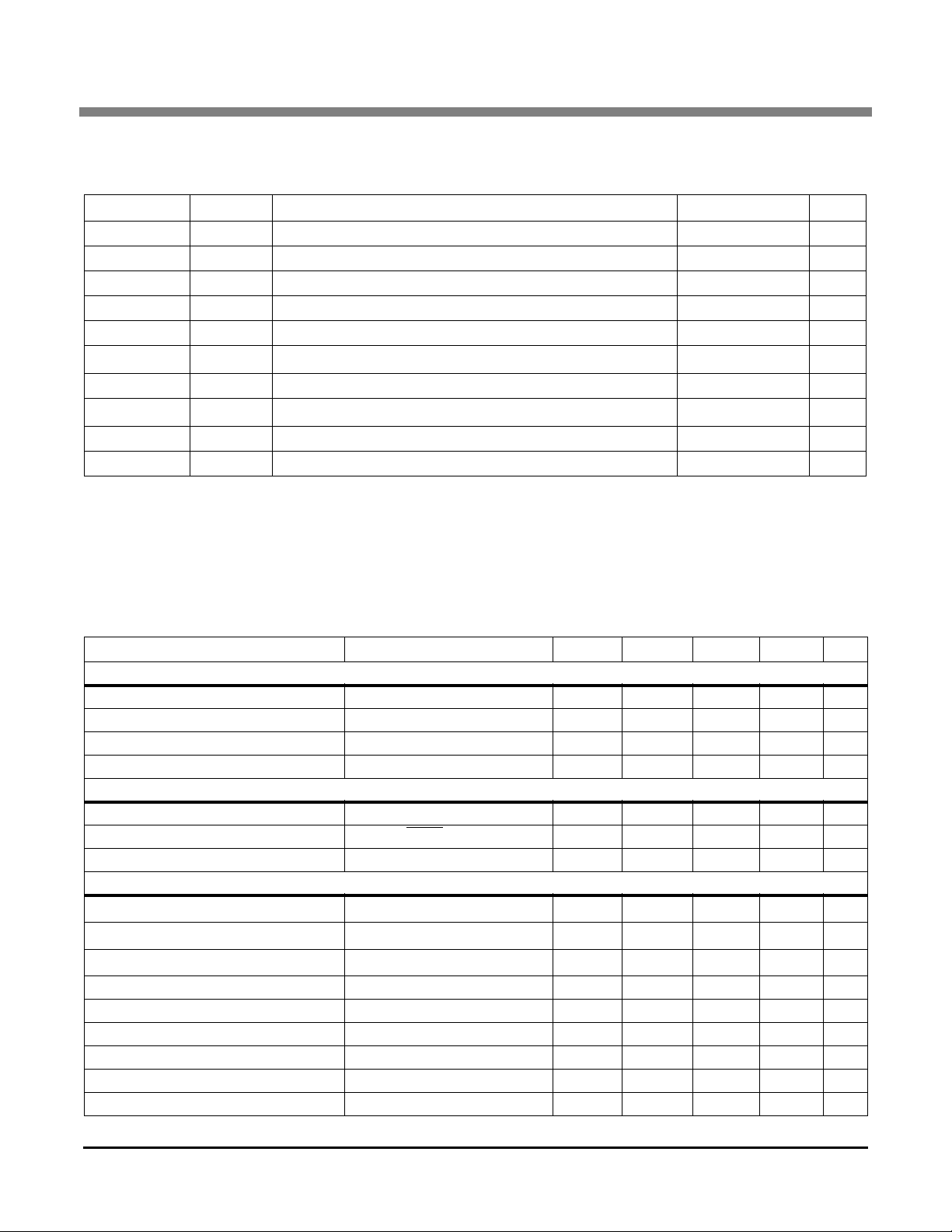

1.2 Electrical Characteristics

(TA = 25º C, VDD = 13V, -40º < TJ < +125º C, CL=1nF between pin GD and GND, all voltages are measured with respect to

GND; all current are positive when flowing into the IC; unless otherwise specified). Recommended V

Parameter Condition Symbol Min Typ Max Unit

VDD Supply Voltage

Turn-on Threshold Voltage V

Turn-off Threshold Voltage (UVLO) V

Increasing V

DD

Decreasing V

DD

UVLO Hysteresis V

Zener Voltage I

=20mA V

DD

DD(on)

DD(off)

Hys

Z

8.4 8.8 9.3 V

7.1 7.4 7.9 V

-1.3-V

17.0 17.9 18.5 V

VDD Supply Current

Start-up Supply Current V

DD=VDD(on)

Standby Supply Current STBY

Operating Supply Current C

=1nF, fsw=70kHz I

L

<0.8V I

I

ST

SB

DD

-6880μA

-80112μA

-1.71.9mA

PFC Gate Drive

Maximum Operating Frequency

Minimum Operating Frequency

Maximum Duty Cycle

6

6

6

Output Source Resistance I

Output Sink Resistance I

Rising Time C

Falling Time C

Output Voltage Low State I

Output Voltage High State I

VDD = 13V f

VDD = 13V f

VDD = 13V D

=100mA,VDD = 13V R

GD

= -200mA,VDD = 13V R

GD

=1nF,VDD = 13V t

L

=1nF,VDD = 13V t

L

= -200mA,VDD = 13V Vol - 0.9 1.3 V

GD

=100mA,VDD = 13V Voh 11.3 11.8 - V

GD

SW(max)

SW(min)

max

OH

OL

r

f

62 66 70 kHz

20 22 23 kHz

64 66 68 %

-9-Ω

-6-Ω

-3245ns

-1525ns

= 10 – 15 V.

DD

DS849A6 3

Page 4

May ?$shortyear>

CONFIDENTIAL

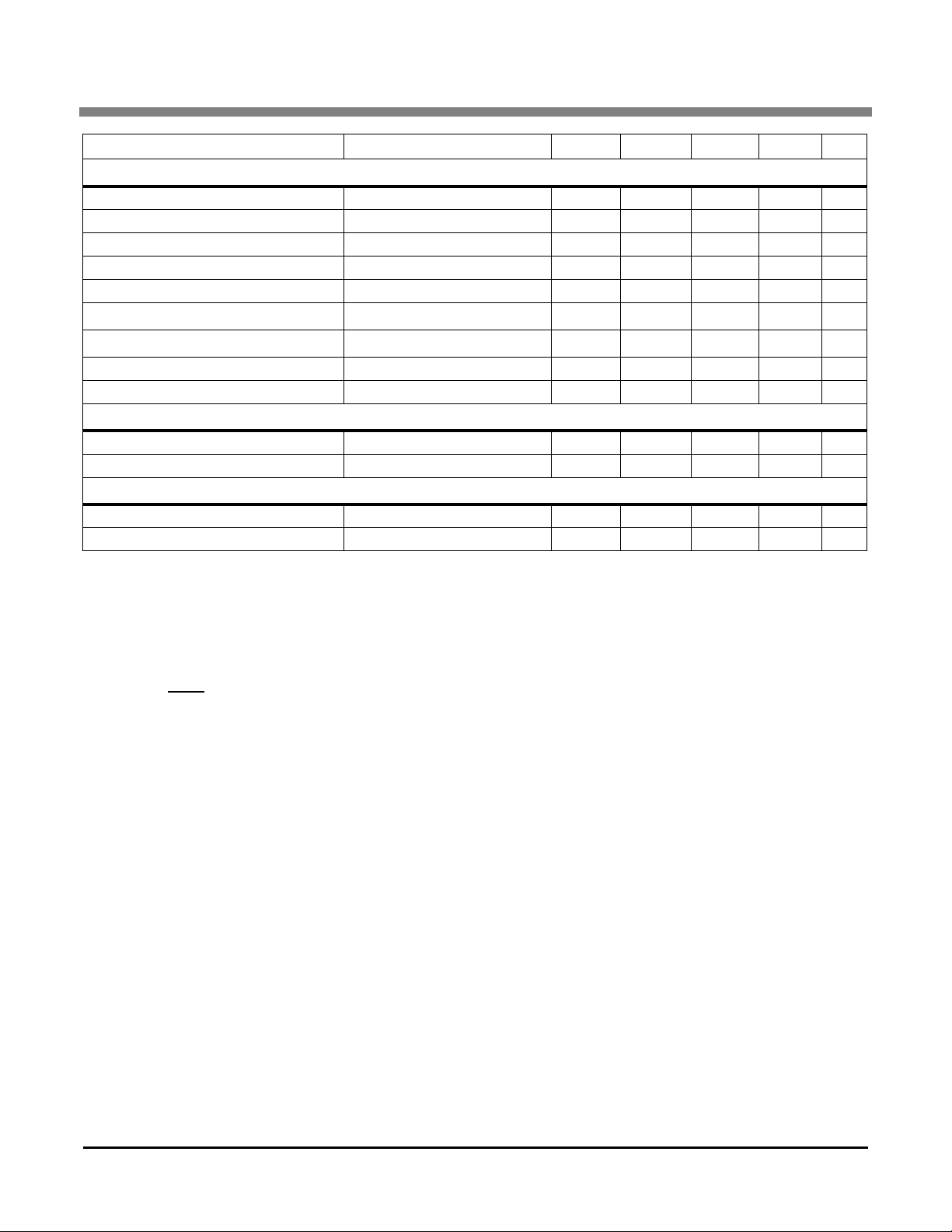

Parameter Condition Symbol Min Typ Max Unit

Feedback & Protection

Reference Current I

Output Voltage at Startup Mode 25º C, 115 VAC V

Output Voltage at Normal Mode V

Overvoltage Protection Threshold 25º C, 115 VAC V

Overvoltage Protection Hysteresis V

Overpower Protection Threshold

Overpower Protection Recovery

Input Brownout Protection Threshold 25º C, GDRV turns off V

Input Brownout Recovery Threshold 25º C, GDRV turns on V

Thermal Protection

Thermal Shutdown Threshold T

Thermal Shutdown Hysteresis T

STBY Input

5

Logic Threshold Low - - 0.8 V

Logic Threshold High Vdd-0.8 - - V

2,3

REF

O(startup)

O(nom)

OVP

OVP(Hy)

2,4

2,4

1

25º C, 115 VAC - 125 - %

25º C, 115 VAC - 100 - %

BP(th)

BR

SD

SD(Hy)

-129-μA

-360-V

-400-V

415 418 421 V

-4-V

62 65 68 Vrms

77 80 83 Vrms

130 143 155 ºC

-9-ºC

CS1500

NOTES:

1. Specifications guaranteed by design & characterization and correlation with statistical process controls.

2. Specification are based upon a PFC system configured for AC input of 90-265 VAC (Sine), 45/65 Hz, V

R

=3x1.0 MΩ, RFB=3x1.0 MΩ, C3 = 180 μF, LB= 360 μH, 90 W. For othe r V

AC

Application Example.

3. Detailed Calculation See Section 4 Application Example.

4. Overpower protection is scaled to rated power.

5. STBY

is designed to be driven by an open collector. The input is internally pulled up with a 600 kΩ resistor.

6. Normal operation mode, see Section 3.2.

voltages, refer to Section 4

link

=400V,

link

4 DS849A6

Page 5

May ?$shortyear>

0

0.5

1

1.5

2

2.5

3

3.5

0 1 2 3 4 5 6 7 8 9 10111213 141516

VDD (V)

I

DD

(mA)

CL = 1 nF

f

SW

= 70 kHz

T

A

= 25 °C

Falling

Rising

7

8

9

10

11

12

13

-50 0 50 100 150

TEMP (oC)

V

DD

(V)

Startup

UVLO

0

0.5

1

1.5

2

-50 0 50 100 150

TEMP (oC)

UVLO Hysteresis (V)

17

17.5

18

18.5

19

-50 0 50 100 150

TEMP (oC)

V

Z

(V)

IDD = 20 mA

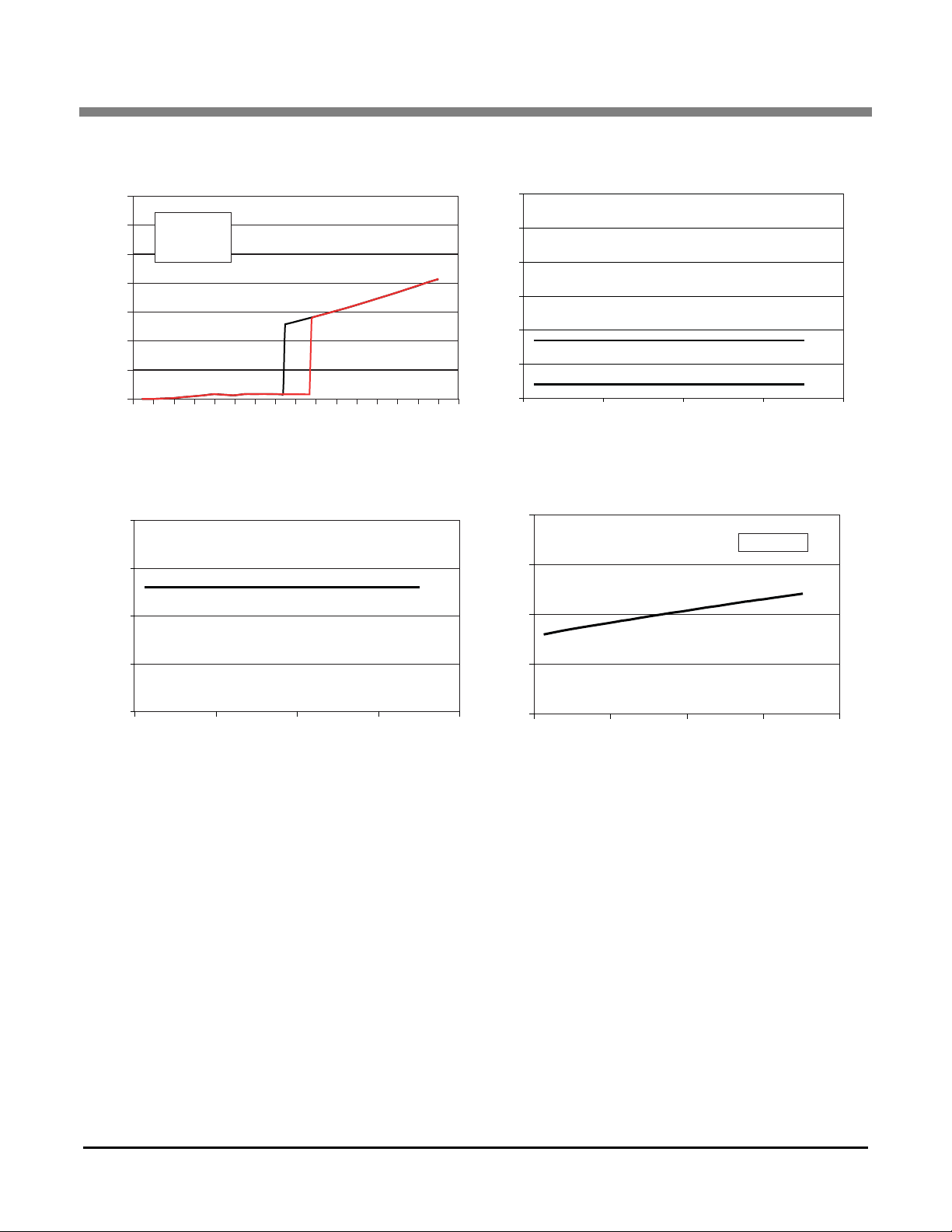

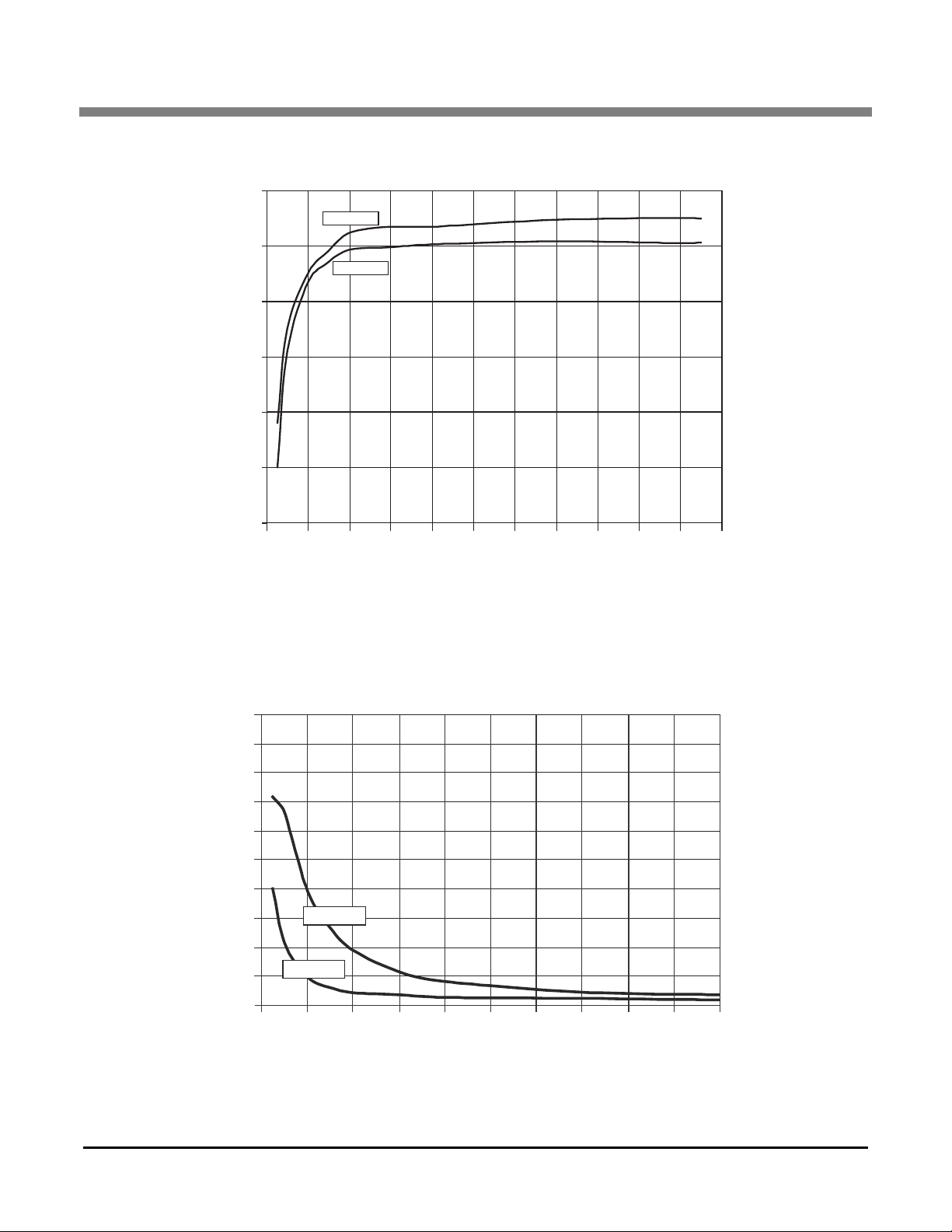

Figure 1. Supply Current vs. Supply Voltage Figure 2. Start-up & UVLO vs. Temp

Figure 3. UVLO Hysteresis vs. Temp Figure 4. VDD Zener Voltage vs. Temp

CONFIDENTIAL

2. TYPICAL ELECTRICAL PERFORMANCE

CS1500

DS849A6 5

Page 6

May ?$shortyear>

385

390

395

400

405

410

415

420

425

-50 0 50 100 150

Temperature (°C)

V

link

(V)

OVP

Normal

Frequency (kHz)

Min Freq

Max Freq

TEMP (oC)

0

10

20

30

40

50

60

70

80

90

100

-60 -40 -20 0 20 40 60 80 100 120 140

0

2

4

6

8

10

12

14

-60 -40 -20 0 40 100 120 140

Gate Resistor (ROH, ROL) Temp (oC)

Z

out

(Ohm)

Source

Sink

VDD = 13 V

I

source

= 100 mA

I

sink

= 200 mA

20 60 80

-50 0 50 100 150

TEM P (oC)

Supply Current (mA)

Start-up

Standby

0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

Operating

VDD = 13 V

C

L

= 1 nF

f

SW

= 70 kHz

Start-up

Standby

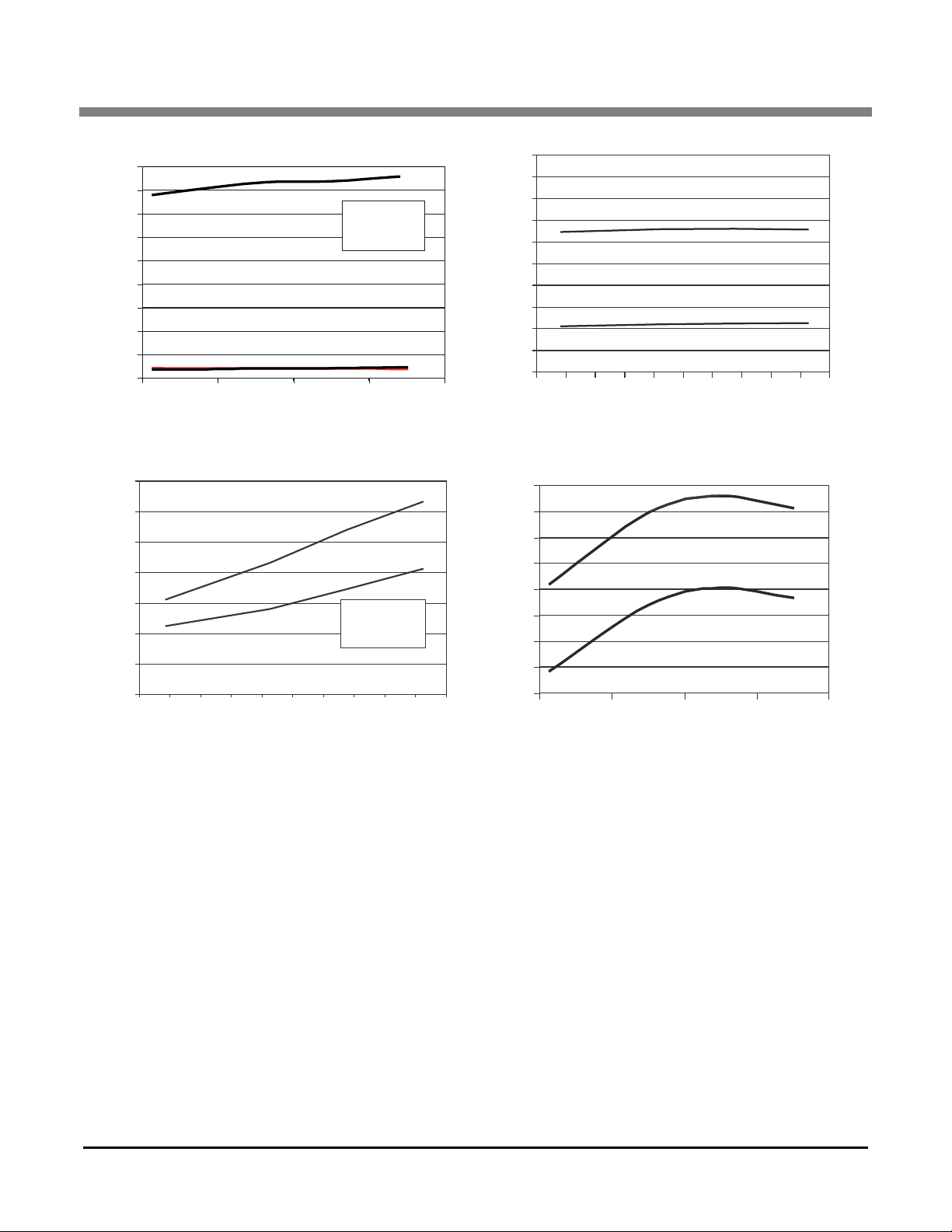

Figure 5. Supply Current (ISB, IST, IDD) vs. Temp Figure 6. Min/Max Operating Frequency vs. Temp

Figu r e 7 . Gate Resistance (R

OH

, ROL) vs. Temp Figure 8. OVP vs. Temp

CONFIDENTIAL

CS1500

6 DS849A6

Page 7

IAC

FB

STBY

3

4

2

CS1500

GD

6

VDD

7

NC

8

GND

5

Processor

Logic

NC

1

PWM

Driver

Oscillator

Protection

ADC

T

on

0.001126

V

rect

------------------------ -

≤

May ?$shortyear>

CONFIDENTIAL

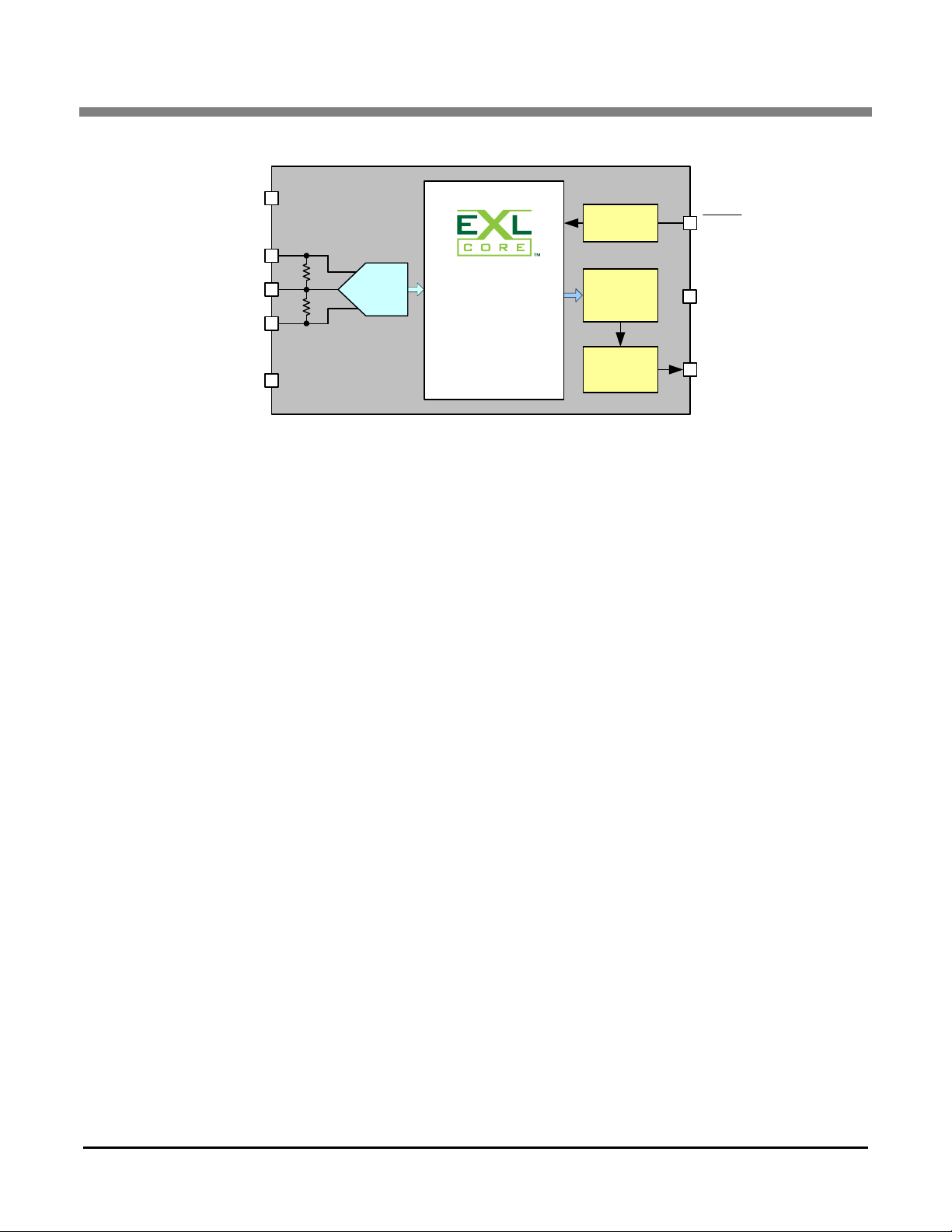

3. INTRODUCTION

Figure 9. CS1500 Block Diagram

The CS1500 digital power factor controller operates in variable

on-time, variable frequency, discontinuous conduction mode

(DCM). The CS1500 uses a proprietary digital algorithm to

maximize the efficiency and reduce the conductive EMI.

The analog-to-digital converter (ADC) shown in the CS1500

block diagram in Figure 9 is used to sense the PFC output

voltage ( V

) and the rectified AC line voltage ( V

link

rect

) by

measuring currents through their respective resistors. The

magnitudes of these currents are measured as a proportion of a

reference current (I

) that functions as the reference for the

REF

ADCs. The digital signal is then processed in a control algorithm

which determines the behavior of the CS1500 during start-up,

normal operation, and under fault conditions, such as brownout,

overvoltage, overcurrent, overpower, and over-temperature

conditions.

• DCM with Variable On-Time, Variable Switching Frequency

The CS1500 PFC switching frequency varies with the

on a cycle-by-cycle basis, and its digital algorithm

V

rect

calculates the on-time accordingly for unity power factor.

Unlike traditional Critical Conduction Mode (CRM) PFC

controller, CS1500 operates at its low switching frequency near the zero-crossing point of the AC input voltage,

even no switching at all, and it operates at its high switching frequency at the peak of its AC input voltage (this is

the opposite of the switching frequency profile for a CRM

PFC controller), thus CS1500 reduces switching losses

especially under light-load conditions, spreads conducted

EMI energy peaks over a wide frequency band and increases overall system efficiency.

• Optimized Digital Loop Compensation

The proprietary digital control engine optimizes the feedback error signal using an adaptive control algorithm, im-

DS849A6 7

proves system stability and transient response. No

external feedback error signal compensation components

are required.

• Overcurrent Mitigation

The CS1500s digital controller algorithm limits the ON

time of the Power MOSFET by the following equation:

Where T

turned on and V

is the max time that the power MOSFET is

on

is the rectified line voltage. In the

rect

event of a sudden line surge or sporadic, high dv/dt line

voltages, this equation may not limit the ON time appropriately. For this type of line disturbance, additional protection mechanisms such as fusible resistors, fast-blow

fuses, or other current-limiting devices are recommended.

• Over Voltage Protection

Under steady-state conditions, the voltage loop keeps

PFC output voltage close to its nominal value. Under light

load startup or feedback loop open conditions, the output

voltage may pass the overvoltage protection threshold.

The digital control engine initiates a fast response loop to

shut down gate driving signal to reduce the energy delivered to the output for PFC capacitor protection. When the

link voltage drop below V

normal operation.

OVP-VOVP(Hy)

, PFC resumes

CS1500

Page 8

May ?$shortyear>

0

20

40

60

80

100

120

04590135180

Rectified Line Voltage Phase (Deg.)

% of Max

Switching Freq. (% of Max.)

Line Voltage (% of Max.)

% P

O max

F

SW max

(kHz)

Vin < 150 VAC

20

70

50

60

40

405

Burst Mode

20

0

60 80 100

Vin > 150 VAC

46

56

DCM Quasi CRM DCM Quasi CRM DCM

I

LB

t [ms]

I

AC

Inductor Current

t [ms]

V

link

[V]

100%

90%

Startup Mode

Normal

Mode

Startup Mode

Normal

Mode

CONFIDENTIAL

CS1500

3.1 PFC Operating Frequency

One key feature of the CS1500 is its operating frequency

profile. Figure 10 illustrates how the frequency varies over half

cycle of the line voltage in steady-state operation. When

power is first applied to the CS1500, it first examines the line

voltage and adapts its operating frequency to the exposed line

voltage as shown in Figure 11. The operating frequency is

varied in about a 2-to-1 ratio from the peak to the trough.

During start-up the control algorithm limits the maximum ontime, provides nearly square-wave envelop current within

every half line cycle by adjusting the operating frequency for

fast startup behavior.

Figure 10. Switching Frequency vs. Phase Angle

The CS1500 is designed to function as a DCM (discontinuous

conduction mode) controller, however it may operate in a

quasi-CRM operation mode near the peak periods. For

90~265VAC main input applications, PFC can be also

designed in quasi-CRM at a peak of 90VAC and full load as

shown in Figure 12.

Figure 12. DCM and quasi-CRM Operation with CS1500

3.2 Start-up vs. Normal Operation Mode

CS1500 has two discrete operation modes: Start-up and

Normal. Start-up mode will be activated when V

90% of nominal value and remains active until V

100% of nominal value, as shown in Figure 13. Startup mode

is activated during initial system power-up. Any V

less than 90% of nominal value, such as load change, can

cause the system to enter Start-up Mode until V

back into regulation.

is less than

link

reaches

link

drop to

link

is brought

link

Figure 11. Switching Frequency vs. Output Power

Figure 11 illustrates how the operating frequency (as a

percentage of maximum frequency) changes with output

power and the peak of the line voltage. Burst mode (when P

below 5%) will be discussed in a later section.

8 DS849A6

Figure 13. Start-up and Normal Modes

3.3 Burst Mode

Burst mode is utilized to improve system efficiency when the

system output power (P

implemented by intermittently disabling the PFC over a full

half-line period cycle under light load conditions, a s shown in

o

Figure 14.

) is < 5% of nominal. Burst mode is

o

Page 9

May ?$shortyear>

V

in

[V]

t [ms]

FET

V

gs

Burst Mode

Active

V

in

P

o

[W]

t [ms]

PFC

Disable

Burst Thres h o ld

P

o

αη

V

in min()

()×2×

V

link

V

in min()

2×()–

2f

maxLBVlink

×××

---------------------------------------------------------

×=

[Eq.1]

L

B

αη

V

in min()

()×

2

×

V

link

V

in min()

2×()–

2f

max

PoV

link

×××

---------------------------------------------------------

×=

[Eq.2]

R

FB

V

linkVdd

–

I

ref

--------------------------- -

=

[Eq.3]

R

FB

I

FB

VDD

ADC

V

link

7

FB

4

R

AC

I

AC

IAC

VDD

ADC

7

3

V

rect

R

AC

RFB=

[Eq.4]

CONFIDENTIAL

CS1500

Figure 14. Burst Modes

3.4 Output Power and PFC Boost Inductor

Maximum output power in normal mode is defined by the

following equation:

where, V

application requirements and maximum operating switching

frequency f

rated power (Po) against tolerances and transients. α is

typically set to 0.9.

The PFC Boost Inductor (LB in Figure 21) value can be

calculated using Equation 1 as follows:

, V

in(min)

max

, and LB are user defined based on

link

= 70kHz. α is a margin factor to guarantee

Resistor R

(shown as R2a & R2b in Figure 21) sets the

FB

feedback current and is calculated as follows:

Figure 15. Feedback Input Pin Model

The ADC is used to measure the magnitude of the I

current

FB

through resistor RFB. The magnitude of the IFB current is then

compared to an internal reference current, I

ref

.

By using digital loop compensation, the voltage feedback

signal does not require an external compensation network.

It is recommended that a ceramic capacitor of up to 2.2 nF be

placed between the FB pin and the VDD pin to filter noise in

the layout.

3.7 IAC Signal

where V

is volts RMS, V

in(min)

is volts DC, and α is set to

link

0.9.

3.5 PFC Output Capacitor

The value of the PFC output capacitor should be chosen

based upon voltage ripple and hold-up requirements. This is

described in more detail in the application section 4.1.6 PFC

Output Capacitor on page 13. To ensure system stability with

the digital controller, the recommended value of the capacitor

is within the range of 0.5 μF / watt to 2.0 μF/watt.

3.6 Output Feedback & Regulation

A current proportional to the PFC output voltage, V

supplied to the IC on pin FB and is used as a feedback control

signal. This current is compared against a fixed-value internal

reference current, I

DS849A6 9

.

ref

, is

link

A current proportional to the AC input voltage is supplied to the

IC on pin IAC and is used by the PFC control algorithm.

Resistor R

current and is calculated as follows:

For optimal performance, resistor RAC, RFB should use less

than 1% tolerance resistor. Resistors can be separated in two

Figure 16. IAC Input Pin Model

(shown as R1a & R1b in Figure 21) sets the IAC

AC

Page 10

May ?$shortyear>

116.8 ms=

[Eq.5]

T

Brownout

8ms

8ms

5V

------------

128V V

BP th()

–()56ms++=

8=

8

5

-- -

128 95–()56++

56 ms

56 ms

Start

Timer

Enter Standby Exit Standby

Upper

Lower

Brownout

Thresholds

Start Timer

T

Brownout

t [ms]

V

link

[V]

100%

90%

t

0

t0 + t

ovrpwr

Overpower

Startup Mode

Normal Mode

Startup Mode

Startup Mode

Normal Mode

Normal Mode

V

AC(rms )

90 265

P

o

P

o(max)

P

o

/ α

L = L

B

/ α

L = L

B

L < L

B

CONFIDENTIAL

CS1500

or more series elements if voltage breakdown or regulatory

compliance is of concern.

It is recommended that a ceramic capacitor of up to 2.2 nF be

placed between the IAC pin and the VDD pin to filter noise in

the layout.

3.8 Brownout Protection

Figure 17 illustrates the brownout protection mechanism

whereby the CS1500 enters standby, and upon recovery from

brownout, enters normal operation mode. In order to avoid the

fault trigger, a digital filter is added for line voltage detection.

The measured peak of the line voltage will be clamped to a

threshold (128 V) set by the IC within half of a line cycle if it is

higher than the threshold. It then decreases the voltage with a

slew rate of 5 V / trough (8 ms). The CS1500 initiates a timer

when the measured voltage falls below the lower brownout

threshold. The IC asserts the brownout protection and stops

the gate drive only if the timer reaches more than 56 ms,

which is set by the algorithm based on minimum line

frequency.

During the brownout state, the device continues monitoring

the input line voltage. The device exits the brownout state

when the input voltage peak value exceeds the brownout

upper threshold for at least 56 ms.

The maximum response time of the brownout protection

normally happens at light load conditions. It can be calculated

by the following equation:

protection is asserted, the IC stops gate drive, goes into a lowpower state, and restarts every 3 seconds. In the case of an

intermittent or minor fault, the device will continue to regulate the

output voltage (V

) to its nominal value.

link

If the PFC remains in startup mode for longer than a given

time, set by the digital controller, it senses an overload

condition and initiates the overpower protection.

The CS1500 has the ability to ensure nearly constant

overpower constraint over a wide range of line voltages, as

shown in Figure 19.

Figure 18. Overpower Protection Mechanism

In the brownout state, the PFC gate driver will restart every 3

seconds, trying to regulate V

to nominal value.

link

Figure 19. Maximal Output Power vs. Line Voltage

3.10 Overvoltage Protection

The overvoltage protection will trigger immediately and stop

the gate drive when the current into the FB pin (I

105% of the reference current value (I

gate drive switching when the link voltage drops below

Figure 17. Brownout Sequence

3.9 Overpower Protection

During normal operation, if the load is increased beyond the

overpower threshold, the output voltage starts falling. When the

output voltage is below the startup threshold voltage, the CS1500

switches to startup mode and the output voltage will rise back

again to the nominal value and will operate in normal mode if the

load is reduced to a normal level. Otherwise, the PFC oscillates

between startup mode and normal mode and the digital engine

declares the overpower condition. When the overpower

10 DS849A6

V

OVP–VOVP(HY)

3.11 Open/short Loop Protection

If the PFC output sense resistor RFB fails (open or short to

GND), the measured output voltage decreases at a slew rate

of about 2V / μs, which is determined by ADC sampling rate.

The IC stops the gate drive when the measured output voltage

is lower than the measured line voltage. The IC resumes gate

drive switching when the current into the FB pin becomes

larger than or equal to the current into the IAC pin and V

.

). The IC resumes

ref

) exceeds

OVP

link

is

Page 11

May ?$shortyear>

<1 nF

600 kΩ

See Te xt

VDD

STBY

GND

CS1500

CONFIDENTIAL

CS1500

greater than the peak of the line voltage (V

maximum response time of open/short loop protection for R

is about 150 μs in the CS1500.

If the PFC input sense resistor RAC fails (open or short to

GND), the current reference signal supplied to the IC on pin

IAC falls to zero. This failure is equivalent to a brownout

condition and will be handled by the brownout protection

mechanism described in Section 3.8.

rect(pk)

). The

FB

3.12 Overcurrent Limiting

Boost inductor saturation is a fatal condition for a PFC

converter. To prevent inductor current saturation conditions,

the IC utilizes a proprietary digital algorithm that keeps the

boost inductor current away from its saturation current. The

boost inductor should be designed for full load, minimal line

voltage, maximum switching frequency, and with enough

margin to prevent saturation in normal operation mode.

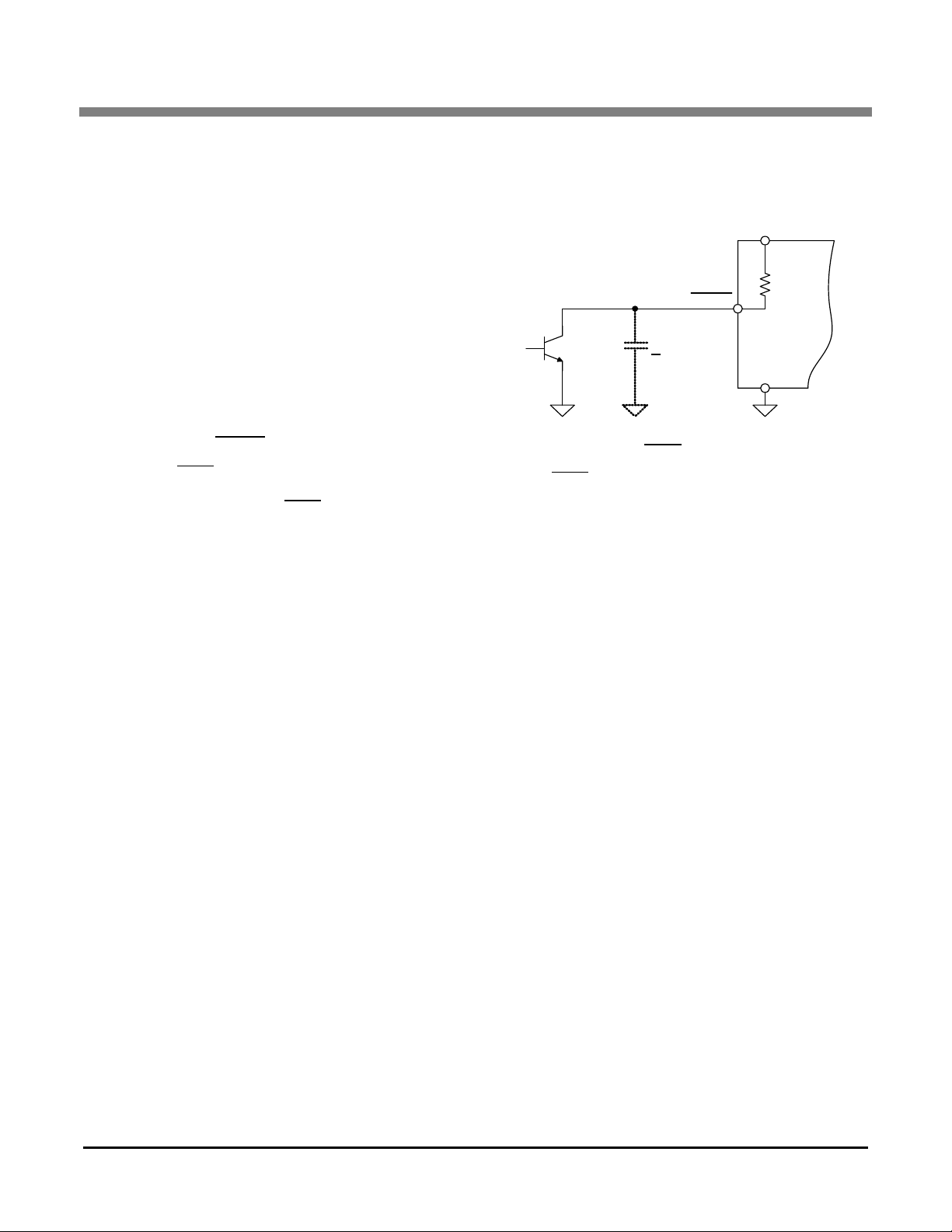

3.13 Standby (STBY) Function

The standby (STBY) pin provides a means by which an

external signal can cause the CS1500 to enter into a nonoperating, low-power state. The STBY

driven by an open-collector/open-drain device. Internal to the

pin, there is a pull-up resistor connected to the VDD pin as

input is intended to be

shown in Figure 20. Since the pull-up resistor has a high

impedance, the user may need to provide a filter capacitor (up

to 1000 p F) on this pin.

Figure 20. STBY Pin Connection

When the STBY

be tied to VDD (pulled high).

pin is not used, it is recommended that the pin

DS849A6 11

Page 12

May ?$shortyear>

D2

C1

D1

CS 1500

C2

L

B

C3

Q1

6

2

8

5

7

3

1

R1a

R1b

R2a

R2b

R3

FB

GD

NC

STBY

GND

VDD

IAC

NC

R

AC

R

FB

BR1

AC

Mains

Regulated

DC Output

4

Figure 21. CS1500 Basic Application Circuit

R

FB

V

linkVdd

–

I

ref

--------------------------- -

=

R

FB

400 12–

129 10

6–

×

--------------------------- -

=

R

FB

3.0MΩ=

[Eq.6]

R

AC

RFB=

R

AC

3.0MΩ=

[Eq.7]

PR

FB

()

V

link

2

R

FB

-------------- -

=

PR

FB

()

400

2

310

6

×

------------------

=

PR

FB

()53.3mW=

[Eq.8]

PRAC()max

265

2

310

6

×

------------------ -

=

PR

AC

()max

V

in max()

[]

2

R

AC

-----------------------------

=

PR

AC

()max 23.4mW=

[Eq.9]

4. APPLICATION EXAMPLE

CONFIDENTIAL

CS1500

The following sections describe an example application. The

example is based upon the typical connection diagram

illustrated in Figure 21.

4.1 PFC for Power Supply Application

The following design example is for a universal main inpu t,

front-end PFC converter with the following parameters:

V

in(min)

V

in(max)

V

P

link

o

90 VAC

265 VAC

400 V

90 W

Equations are provided to demonstrate how a user would

calculate the values for the components shown in the diagram.

Maximum power dissipation in each sense resistor is

calculated as follows (the equation ignores the voltage drop

& R

across R

IAC

IFB

):

4.1.1 IAC and IFB Sensing Inputs

The rectified AC input voltage (V

voltage (V

) are sensed as currents into the IC. The sensing

link

currents are set by resistors R

12 DS849A6

) and boosted PFC output

rect

and RFB, respectively:

AC

Page 13

May ?$shortyear>

C13.3

nF

W

------ -

P

o

×≥

C

1

3.3 120×≥

C

1

390nF≥ 0.39μF=

[Eq.10]

L

B

αη

V

in min()

()×2×

V

link

V

in min()

2×()–

2f

max

PoV

link

×××

---------------------------------------------------------

×=

LB0.9 0.95× 90

2

×

400 90 2×()–

27010

3

×()× 90× 400×

------------------------------------------------------------------ -

×=

LB374μ H=

[Eq.11]

I

LB pk()

4P

o

×

αη× V×

in min()

2×

----------------------------------------------------- -

=

I

LB pk()

3.3A=

I

LB pk()

490×

0.9 0.95× 90×

2

×

---------------------------------------------------- -

=

[Eq.12]

I

sat

0.001126

L

------------------------ -

≤

[Eq.13]

I

FET pk()ILB pk()

=

I

FET pk()

3.3A=

[Eq.14]

I

Dpk()ILB pk()

=

I

Dpk()

3.3A=

[Eq.15]

I

Davg()

P

o

V

link

----------- -

=

I

Davg()

0.225A=

I

Davg()

90

400

--------- -

=

[Eq.16]

[Eq.17]

C

out rip()

P

O

2π f

line min()

× V

link

×ΔV

link rip()

×

-------------------------------------------------------------------------------------- -

=

C

out rip()

90

2π 45× 400× 10×

------------------------------------------------ -

80μ Fu

useu100μF==

CONFIDENTIAL

4.1.2 PFC Input Filter Capacitor

To achieve unity power factor, a DCM PFC circuit needs an

input filtering circuit to bypass the high-frequency current so

that the input current consists of the low-frequency portion

only. There are two main factors on PFC input filter capacitor

selection: its voltage ripple and phase lag, which both will

worsen power factor. The filtering capacitance is proportional

and it is suggested as follows:

to P

o

Use 0.47 μF for tolerance.

If a PI filter used for suppression of conducted EMI is located

on the DC side of the input rectifier, the V

to be moved to the second capacitor.

4.1.3 PFC Boost Inductor

The value of the inductor in normal mode can be calculated by

the following equation, with α = 0.9 as a derating factor to

ensure the inductor is sized to guarantee DCM operation and

provide a slightly higher power than required by the load:

sense point has

rect

CS1500

4.1.4 PFC MOSFET

In normal mode, the PFC MOSFET peak current is equal to

the peak current in the PFC boost inductor:

4.1.5 PFC Diode

The PFC diode peak current in normal mode is the equal to the

inductor peak current:

The PFC Diode average current is calculated as follows:

Choose a 360 μH inductor.

η is the efficiency.

The inductor should be designed so that its saturation current

meets the following requirement, where 0.001126 is a predefined threshold for the current protection algorithm:

where L is the inductance in Henrys.

DS849A6 13

4.1.6 PFC Output Capacitor

The value of the output capacitor is determined by several

requirements. It must meet the voltage ripple and hold-up time

requirements and the RMS current in the capacitor should not

exceed its RMS current rating.

The following equation defines the size of the output capacitor

to meet the output voltage ripple requirements:

is the minimum line frequency the design is required

f

line(min)

to support, V

is the output voltage ripple requirement in volts peak-to-peak.

The equation will provide the value of the output capacitor

needed to meet the ripple requirement.

For 10 V of ripple and minimum line frequency of 45 Hz, the

equation becomes:

A second requirement that the output capacitor may be

required to meet is hold-up time. The value of the ca pacitor

is the output voltage from the PFC, ΔV

link

link(rip)

,

Page 14

May ?$shortyear>

C

out hold()

2P

O

× t×

hold

V

link

ΔV

out rip()

2

------------------------ -

–

2

V

link min()

()

2

–

------------------------------------------------------------------------------------------

=

[Eq.18]

C

out hold()

290× 0.010×

400

10

2

------

–

2

300()

2

–

------------------------------------------------------

27μ F==

V

ovp

V

link

1.05×=

V

ovp

400 1.05×=

V

ovp

420V=

[Eq.19]

CONFIDENTIAL

CS1500

needed to meet the hold-up time required is defined by the

following equation:

t

is the magnitude of the hold-up time in seconds. For

HOLD

10 ms of hold-up time and V

of 300 V, the equation

link(min)

becomes:

Choose a 100 μF capacitor.

4.1.7 Overvoltage Protection

Overvoltage protection is activated when V

of the nominal value:

While in overvoltage protection mode, gate drive output is

disabled. GD output is re-enabled when V

nominal value.

exceeds 105%

link

falls below its

link

14 DS849A6

Page 15

May ?$shortyear>

CONFIDENTIAL

4.1.8 Summary of Component Values

Designator Value Description

R1a 1.5 MΩ SFR25 axial film res - 0.4W-1%

R1b 1.5 MΩ SFR25 axial film res - 0.4W-1%

R2a 1.5 MΩ SFR25 axial film res - 0.4W-1%

R2b 1.5 MΩ SFR25 axial film res - 0.4W-1%

R3 4.7 Ω SFR25 axial film res - 0.4W-1%

C1 0.47 μF ECQ2W474KH

C2 0.47 μF 50V Ceramic cap - X7R

C3 100 μF, 450V LLS2W101MELA

BR1 4A, 600V GBU4J-BP

D1 1 A, 600 V 1N4005

D2 1 A, 600 V STTH1R06

LB 360 μH Premier Magnetics

CS1500

Q1 12 A, 500 V STP12NM50FP

CS1500 PFC Controller CS1500

DS849A6 15

Page 16

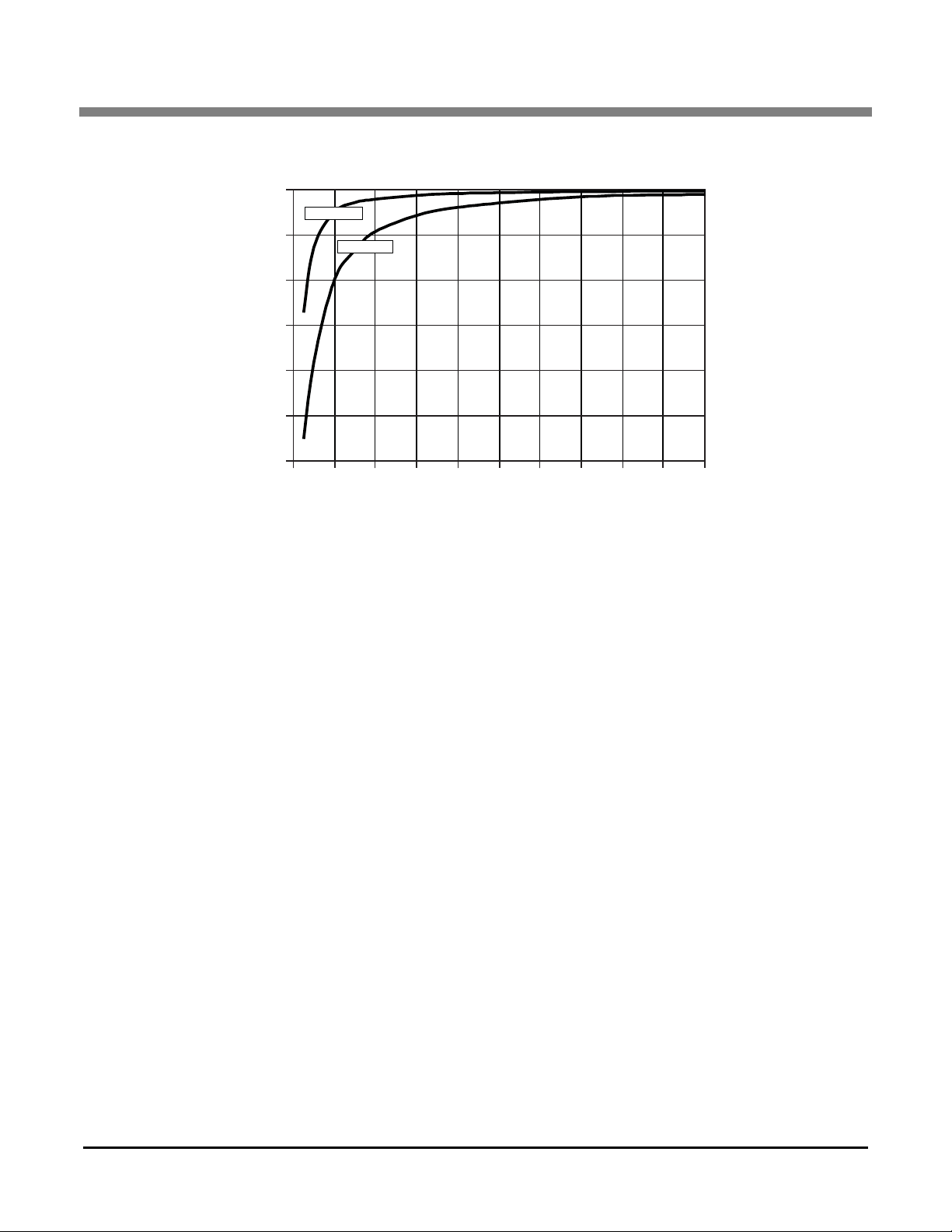

5. PERFORMANCE PLOTS

0

10

20

30

40

50

60

70

80

90

100

0102030405060708090100

Load (%)

THD(%)

Vin = 230

Vin = 115

Load (%)

Efficiency

70

75

80

85

90

95

100

0 102030405060708090100110

Vin=230V

Vin=115V

Figure 22. Efficiency vs. Load, Typi cal

Figure 23. Distortion vs. Load, Typical

May ?$shortyear>

CONFIDENTIAL

CS1500

16 DS849A6

Page 17

May ?$shortyear>

10

0.4

0.5

0.6

0.7

0.8

0.9

1

0 2030405060708090100

Load (%)

Power Factor

Vin = 115

Vin = 230

Figure 24. Power Factor vs. Load, Typica l

CONFIDENTIAL

CS1500

DS849A6 17

Page 18

May ?$shortyear>

Figure 25. Load Transient — 20% to 80% (60 mA to 240 mA), 0.8 A/μsec Slew, 90 VAC

Figure 26. Load Transient — 20% to 80% (60 mA to 240 mA), 0.8 A/μsec Slew, 260 VAC

CONFIDENTIAL

CS1500

18 DS849A6

Page 19

May ?$shortyear>

Figure 27. Overload — 240 mA to 500 mA, 90 VAC

Figure 28. Overload — 240 mA to 500 mA, 265 VAC

CONFIDENTIAL

CS1500

DS849A6 19

Page 20

May ?$shortyear>

CONFIDENTIAL

6. DEFINITIONS

Variable Definition

η The efficiency factor.

α A margin factor to guarantee rated power against tolerances and transient s.

f

line(min)

I

AC

I

FB

I

FET(pk)

I

rms

I

sat

I

st

I

ST

L

P

P

o(max)

R

AC

R

V

in(min)

V

link

V

link(min)

ΔV

link(rip)

V

rect

B

o

FB

The minimum AC line frequency.

The current generated by V

The current generated by V

The PFC MOSFET peak current, which is equal to the peak current in the PFC boost inductor.

that flows into the IAC pin.

rect

that flows into the FB pin.

link

The magnitude of the RMS current.

The boost inductor LB saturation current.

The sum of the current into the IAC and FB pins.

The startup current of the chip.

The PFC boost inductor .

The nominal output power from the CS1500 PFC circuit.

The maximum value of the output power from the CS1500 PFC circuit.

The sense resistor used to measure current into the IAC pin.

The sense resistor used to measure current into the FB pin.

The minimum specified line voltage for proper operation (volts RMS).

The magnitude of the output voltage from the PFC.

The magnitude of the output voltage from the PFC.

ΔV

, is the output voltage ripple requirement in volts peak-to-peak

link(rip)

The instantaneous value of the rectified line voltage (volts).

CS1500

20 DS849A6

Page 21

7. PACKAGE DRAWING

8L SOIC (150 MIL BODY) PACKAGE DRAWING

D

H

E

e

b

A1

A

c

L

∝

SEATING

PLANE

1

May ?$shortyear>

CONFIDENTIAL

CS1500

DIM MIN MAX MIN MAX

A 0.053 0.069 1.35 1.75

A1 0.004 0.010 0.10 0.25

B 0.013 0.020 0.33 0.51

C 0.007 0.010 0.19 0.25

D 0.189 0.197 4.80 5.00

E 0.150 0.157 3.80 4.00

e 0.040 0.060 1.02 1.52

H 0.228 0.244 5.80 6.20

L 0.016 0.050 0.40 1.27

∝

INCHES MILLIMETERS

0° 8° 0° 8°

JEDEC # MS-012

8. ORDERING INFORMATION

Part # Temperature Range Package Description

CS1500-FSZ -40 °C to +125 °C 8-lead SOIC, Lead (Pb) Free

9. ENVIRONMENTAL, MANUFACTURING, & HANDLING INFORMATION

Model Number Peak Reflow Temp MSL Rating

CS1500-FSZ 260 °C 2 365 Days

a. MSL (Moisture Sensitivity Level) as specified by IPC/JEDEC J-STD-020.

b. Stored at 30 °C, 60% relative humidity.

DS849A6 21

a

Max Floor Life

b

Page 22

Jun ?$shortyear>

Contacting Cirrus Logic Support

For all product questions and inquiries contact a Cirrus Logic Sales Representative.

To find one nearest you go to http://www.cirrus.com

IMPORTANT NOTICE

"Advance" product information describes products that are in development and subject to development changes.

Cirrus Logic, Inc. and its subsidiaries ("Cirrus") believe that the information contained in this document is accurate and reliable. However, the information is subject

to change without not ice and is provi ded "AS IS" wi thout warran ty of any kind (express or implied). Customers are advised to obtain the latest version of relevant

information to verify, before placing orders, that information being relied on is current and complete. All products are sold subject to the terms and conditions of sale

supplied at the time of order acknowle dgment, including tho se pertaining to warra nty, indemnification, and l imitation of liability. No responsibility is assumed by Cirrus

for the use of this information, including use of this inform ation as the b asis for ma nufacture or sale of any item s, or for infringement of patents or other rights of third

parties. This document is the property of Cirrus and by furnishing this information, Cirrus grants no license, express or implied under any patents, mask work rights,

copyrights, trademarks, trade secrets or other intellectual p roperty rights. Cirrus owns the copyr ights associated with the information con tained herein and gives consent for copies to be made of the information only for use within your organization with respect to Cirrus inte grated circu its or other products of Cirrus. This consent

does not extend to other copying such as copying for general distribution, advertising or promotional purposes, or for creating any work for resale.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENT IAL RISKS OF DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE ("CRITICAL APPLICATIONS"). CIRRUS PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARRANTED FOR USE

IN PRODUCTS SURGICALLY IMPLANTED INTO THE BODY, AUTOMO TIVE SAFETY OR SECU RITY DEVICES, LIFE SUPPO RT PRODUCTS OR OTHE R CRITICAL APPLICATIONS. INCLUSION OF CIRRUS PRODUCTS IN SUCH APPLICATIONS IS UNDERSTOOD TO BE FULLY AT THE CUSTOMER'S RISK AND

CIRRUS DISCLAIMS AND MAKES NO WARRANTY, EXPRESS, STATUTORY OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR PARTICULAR PURPOSE, WITH REGARD TO ANY CIRRUS PRODUCT THAT IS USED IN SUCH A MANNER. IF THE CUSTOMER OR

CUSTOMER'S CUSTOMER USES OR PERMITS THE USE OF CIRRUS PRODUCTS IN CRITICAL APPLICATIONS, CUSTOMER AGREES, BY SUCH USE, TO

FULLY INDEMNIFY CIRRUS, ITS OFFICERS, DIRECTORS, EMPLOYEES, DISTRIBUTORS AND OTHER AGENTS FROM ANY AND ALL L IAB I LI TY, I NCLUDING ATTORNEYS' FEES AND COSTS, THAT MAY RESULT FROM OR ARISE IN CONNECTION WITH THESE USES.

Cirrus Logic, Cirrus, the Cirrus Logic logo designs, EXL CORE, and the EXL CORE logo designs are trademarks of Cirrus Logic, Inc. All other brand and product

names in this document may be trademarks or service marks of their respective owners.

CONFIDENTIAL

10.REVISION HISTORY

Revision Date Changes

A1 APR 2009 Initial Advance Information release.

A2 JUN 2009 No substantive changes. Document number incremented to avoid

confusion among previous, pre-released versions.

A3 DEC 2009 Revised feature list & product description. Revised electrical charac-

teristics to include brownout & open-loop protection. Modified defini-

tion table. Modified data sheet format.

A4 MAR 2010 Updated to correspond to C1 silicon.

A5 MAY 2010 Updated performance data.

A6 MAY 2010 Updated with additional test bench data for EP leve l.

CS1500

22 DS849A6

Loading...

Loading...