Page 1

CRD44600-PH-FB

Stereo 100 W PWM Amplifier Reference Design

Features

z Two full-bridge channels, 100 W each

z 106 dB Dynamic Range - both channels

z 0.015% THD+N at 1 W

z Power Supply Rejection (PSR) feedback

allowing amplifier to operate from low cost

linear unregulated power supplies

z Spread Spectrum Modulation - Reduces

Modulation Energy

z Passes CISPR and FCC requirements for

radiated and power line conducted

emissions

z Independent peak signal limiting per channel

z Thermal and over-current protection

z > 85% amplifier efficiency

z Works with GUI to configure the board

z Demonstrates recommended layout and

grounding arrangements

Description

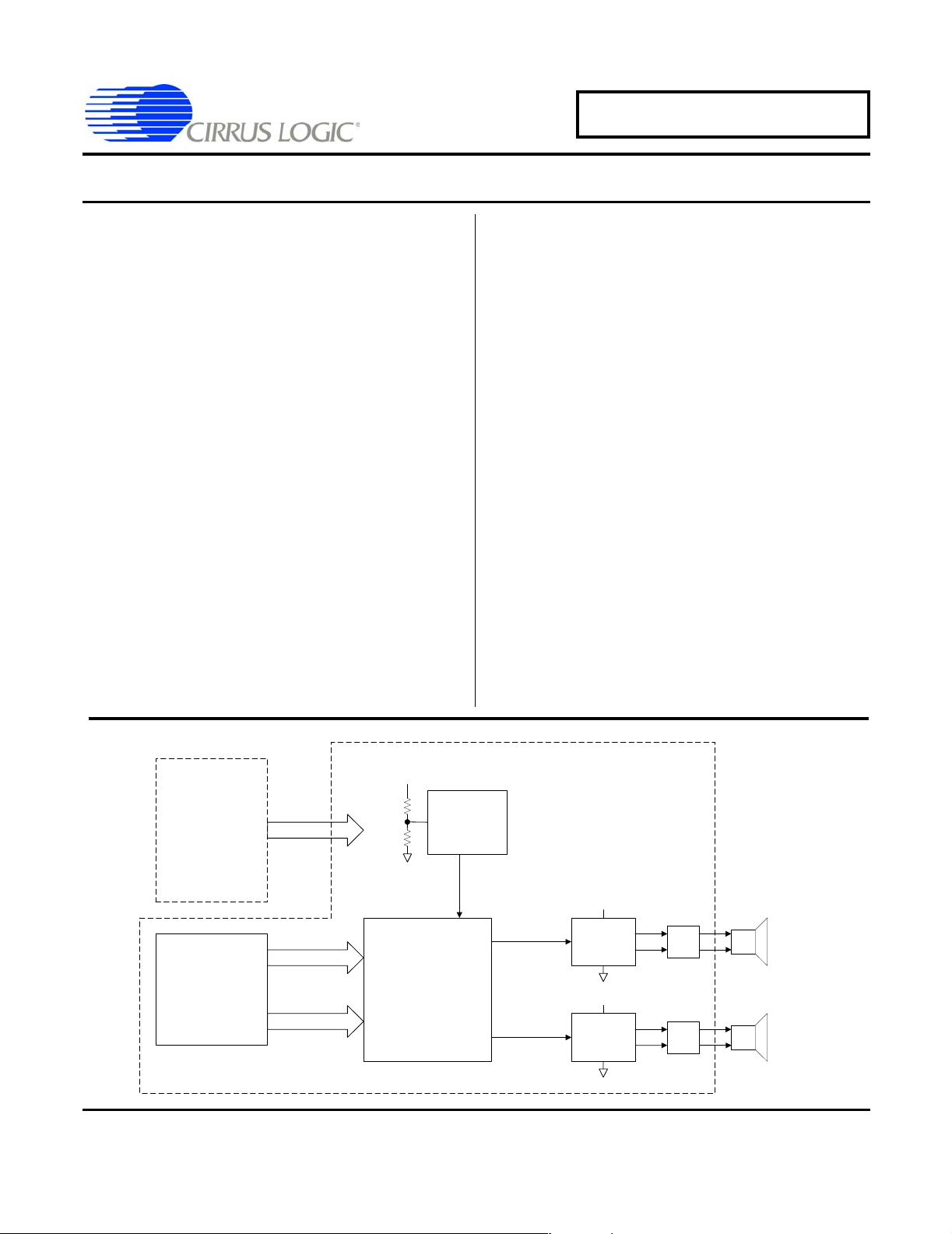

The CRD44600-PH-FB PWM Amplifier demonstrates

the CS44600, Cirrus’ multi-channel pure digital PWM

I

controller. This reference design implements a twochannel amplifier which delivers 100 W per full-bridge

channel into 8 Ω loads using a single +50 V supply (at

1% THD+N). A 155 W unregulated linear power supply

is used to power the CRD44600-PH-FB.

As shown below, the CS44600 IC takes two stereo digital audio PCM inputs and converts them to PWM

outputs. This 64-pin LQFP PWM controller provides an

integrated sample rate converter for 32 kHz-192 kHz input sample rate support, volume up/down, speaker load

compensation, peak limiting to prevent amplifier clipping,

power supply ripple compensation, and AM frequency

interference elimination.

This reference design uses the the Philips TDA8939, an

integrated power stage back end for digital amplifiers

(two TDA8939 parts configured as full-bridges are used

for this two-channel design). Current limiting and thermal protection are provided by the TDA893 9.

The inductor/capacitor 2

nd

order low pass filter (LPF) removes high frequency components from the output

signal effectively converting it from digital to analog.

ORDERING INFORMATION

CRD44600-PH-FB Reference Design

155W Unregulated

Linear Power Supply

Audio Inputs and GUI

Cirrus Logic, Inc.

www.cirrus.com

Interface

+50 V

PCM Clocks & Data

I2C Host Control

PSR Circuitry

+50 V

CS4461 ADC

Channel 1

CS44600

(PWM Controller)

Channel 2

Copyright © Cirrus Logic, Inc. 2005

(All Rights Reserved)

+50 V

Philips

TDA8939

+50 V

Philips

TDA8939

LPF

LPF

8Ω

8Ω

MAR '05

DS633RD1

1

Page 2

TABLE OF CONTENTS

1. SYSTEM OVERVIEW ............................................................................................................... 3

1.1 CS44600 PWM Modulator ................................................................................................. 3

1.2 CS4461 PSR Feedback ADC ................................. ... ... ... .... ... ... ... ... .... ... ... ........................3

1.3 TDA8939 Power Stage ....................... ... .... ... .......................................... ... ... .... ... ... ...........3

1.4 CS8416 Digital Audio Receiver .......................................................................................... 3

1.5 CS5341 Analog to Digital Converter ..................................................................................3

1.6 Control Port Interface and GUI .......................................................................................... 4

1.7 Unregulated Linear Power Supply ..................................................................................... 4

2. GUI CONTROL ......................................................................................................................... 5

2.1 CS44600 Dialog Tab .......................................................................................................... 5

2.2 Advanced Register Debug Tab .. ... ... ... ... .... .......................................... ... ... ... .... ... ... ... ... .... . 6

3. POWER SUPPLY ..................................................................................................................... 8

3.1 Power Supply Ratings ................................... ... ... .... ... ... ... .... ... ... ... .....................................8

3.2 Power Supply Decoupling ...... .... ... ... ... ... .... .......................................... ... ... ... .... ... ... ... ... .... . 8

4. ELECTROMAGNETIC INTERFERENCE (EMI) ....................................................................... 9

4.1 Suppression of EMI at the Source ..................................................................................... 9

4.2 EMI Testing ......... .......................................... ... ... .......................................... .... ... ... ...........9

5. CRD44600-PH-FB SCHEMATICS .........................................................................................14

6. CRD44600-PH-FB POWER SUPPLY SCHEMATICS ........................................................... 19

7. CRD44600-PH-FB LAYOUT ...................................................................................................20

8. CRD44600-PH-FB BILL OF MATERIALS ....................................................................... 23

9. TYPICAL PERFORMANCE PLOTS ....................................................................................... 25

10. REVISION HISTORY ............................................................................................................30

CRD44600-PH-FB

LIST OF FIGURES

Figure 1. CS44600 Dialog Tab........................................................................................................ 5

Figure 2. Advanced Register Debug Tab - CS44600......................................................................6

Figure 3. Advanced Register Debug Tab - CS8416........................................................................7

Figure 4. EMI Testing Setup..........................................................................................................11

Figure 5. EMI Testing Setup, Close-up .........................................................................................11

Figure 6. Radiated EMI Testing Results- 30 MHz to 200 MHz.......................................... ... ... ... ... 12

Figure 7. Radiated EMI Testing Results- 200 MHz to 1 GHz........................................................12

Figure 8. Conducted Power Line Testing Results.........................................................................13

Figure 9. Audio Inputs...................................................................................................................14

Figure 10. CS44600......................................................................................................................15

Figure 11. PSR Feedback.............................................................................................................16

Figure 12. Left/Right Channels......................................................................................................17

Figure 13. Control Port and Power................................................................................................18

Figure 14. Power Supply...............................................................................................................19

Figure 15. Silk Screen Top............................................................................................................ 20

Figure 16. Topside Layer .............................................................................................................. 21

Figure 17. Bottomside Layer .........................................................................................................22

Figure 18. Frequency Response...................................................................................................25

Figure 19. THD+N vs. Frequency at 1 W, 10 W, and 50 W ..........................................................26

Figure 20. THD+N vs. Power at 1 kHz..........................................................................................27

Figure 21. FFT at -60 dBFS and 1 kHz .........................................................................................28

Figure 22. FFT at -1 dBFS and 1 kHz. Red = PSR Feedback Off. Blue = PSR Feedback On .....29

LIST OF TABLES

2 MAR '05 DS633RD1

Page 3

CRD44600-PH-FB

Table 1. Bill of Materials................................................................................................................ 23

Table 2. Revision History.............................................................................................................. 30

MAR '05 DS633RD1 3

Page 4

CRD44600-PH-FB

1. SYSTEM OVERVIEW

The CRD44600-PH-FB reference design is an excellent means for evaluating the CS44600 sixchannel Class-D PWM modulator. It incorporates a digital Class-D PWM modulator, two fullbridge power stages, and power supply rejection (PSR) circuitry, all on a two-layer board.

The CRD44600-PH-FB schematic set is shown in Figures 9 through 13 and the board layout is

shown in Figures 15 through 17.

1.1 CS44600 PWM Modulator

A complete description of the CS44600 is included in the CS44600 product data sheet.

The CS44600 converts linear PCM data to pulse width modulated (PWM) output. It uses a

Sample Rate Converter (SRC) to eliminate serial audio interface jitter effects and maintains

a constant PWM switch rate of 384 kHz, resulting in high-quality sound output.

PCM data and clocks are input from either the CS8416 (S/PDIF Receiver), CS5341 (Stereo

ADC), or J19 (PCM Input Header).

1.2 CS4461 PSR Feedback ADC

A complete description of the CS4461 is included in the CS4461 product data sheet.

The CS4461 is connected to the CS44600 to provide power supply rejection (PSR) for the

VP supply voltage connected to J17. Resistors R41 and R42 are set for VP = +50 V. See the

CS4461 data sheet for equations to determine the resistor values.

1.3 TDA8939 Power Stage

A complete description of the Philips TDA8939 is included in the TDA8939 product data

sheet.

The TDA8939 is a high-voltage PWM amplifier power stage. It integrates two half-bridge drivers and fault protection. For the CRD44600-PH-FB, each of the two TDA8939’s are configured as full-bridges. Care should be taken to not connect the full bridge black speaker

connectors to ground as these outputs are driven.

1.4 CS8416 Digital Audio Receiver

The operation of the CS8416 receiver and a discussion of the digital audio interface are described in the CS8416 data sheet.

The CS8416 converts the input S/PDIF data stream into PCM data for the CS44600. The

CS8416 operates in master mode with RMCK = 256*Fs. The digital Interface format is set to

Left Justified (24-bit).

D20 (RERR) indicates a receiver error, such as loss of lock.

S/PDIF input is through OPT1 or J33.

1.5 CS5341 Analog to Digital Converter

The operation of the CS5341 ADC is described in the CS5341 data sheet.

4 MAR '05 DS633RD1

Page 5

CRD44600-PH-FB

The CS5341 converts analog audio into PCM data for the CS44600. The CS5341 operates

in slave mode and the digital Interface format is set to Left Justified (24-bit).

Analog input is through J5 and J6.

1.6 Control Port Interface and GUI

The CS44600 and CS8416 are controlled through the provided control port interface. Connection to the control port is made through J37 (RS-232 Serial). A Windows based GUI provides control over all the individual registers of the CS44600 and the CS8416.

1.7 Unregulated Linear Power Supply

The power supply used for the CRD44600-PH-FB is a linear 155 W supply. The supply provides an unregulated +50 V for the TDA8939 power stages. The power supply consists of a

transformer, diode bridge rectifier, and bulk capacitor. Schematics are shown in Figure 14.

MAR '05 DS633RD1 5

Page 6

CRD44600-PH-FB

2. GUI CONTROL

The CRD44600-PH-FB is shipped with a Microsoft Windows® based GUI, which allows control

over the CS8416 and CS44600 registers. Interface to the CDB44600 control port is provided using an RS-232 serial cable. The GUI requires no installation and can be run directly from the CD

or copied to a local directory and run from there. Once the serial port cable is connected between

the CRD44600-PH-FB and the host PC, load the FlexLoader.exe from the CRD44600-PH-FB directory. Once loaded, all registers are set to their default reset state. The GUI File menu provides the ability to save and restore (load) register settings. Sample script files are provided for

basic functionality. The GUI serial port interface is setup by default for 115.2 Kbps operation on

COM1. To change these settings, edit the “CRD44600-PH-FBCommunications” section of the

flexconfig.ini file or change the system communications setting in the Windows® control panel.

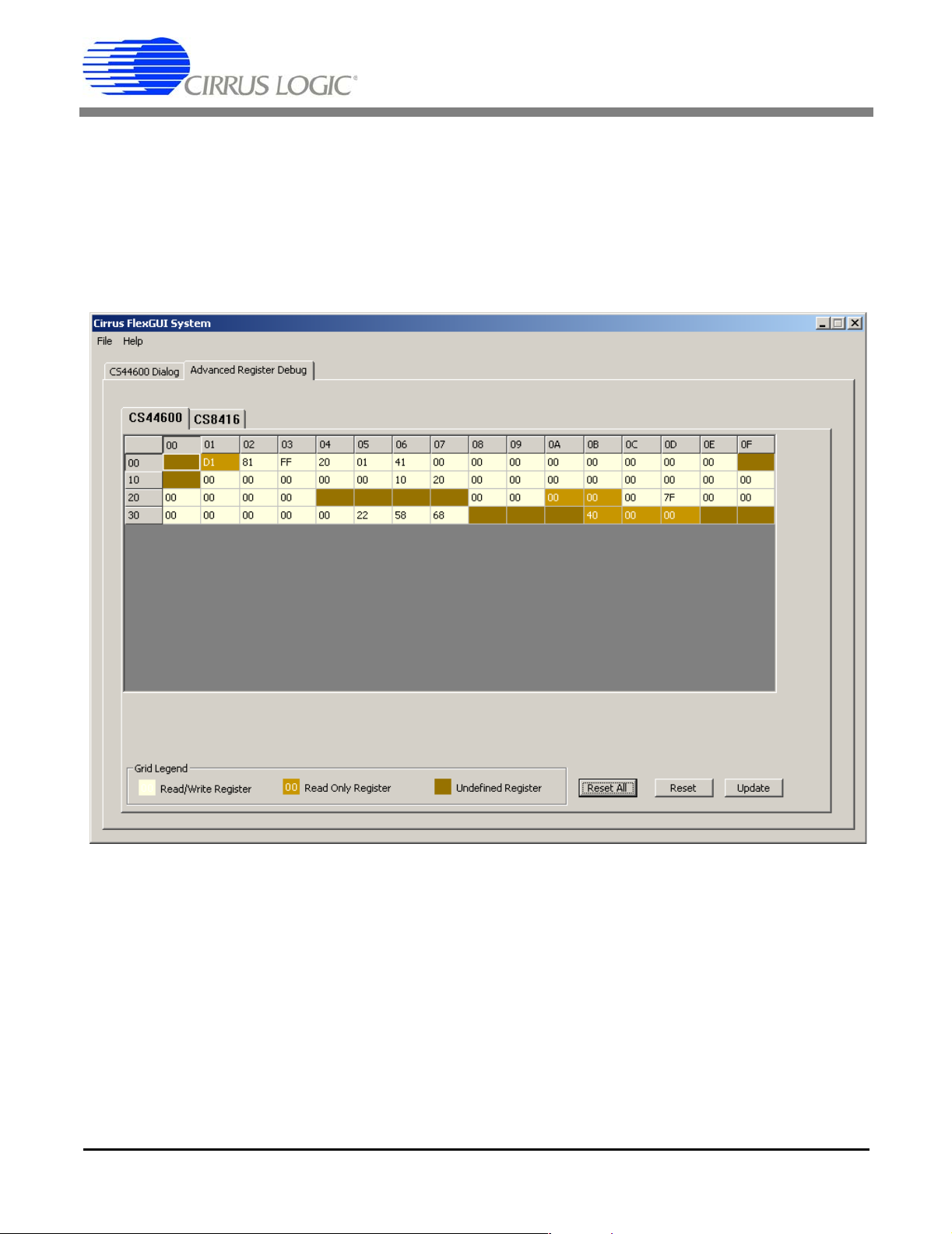

2.1 CS44600 Dialog Tab

The CS44600 Dialog tab provides high level control over the CS44600’s registers. Controls

are provided to change volume, mute, enable PSR, enable the power stages, limiter control.

Figure 1. CS44600 Dialog Tab

6 MAR '05 DS633RD1

Page 7

CRD44600-PH-FB

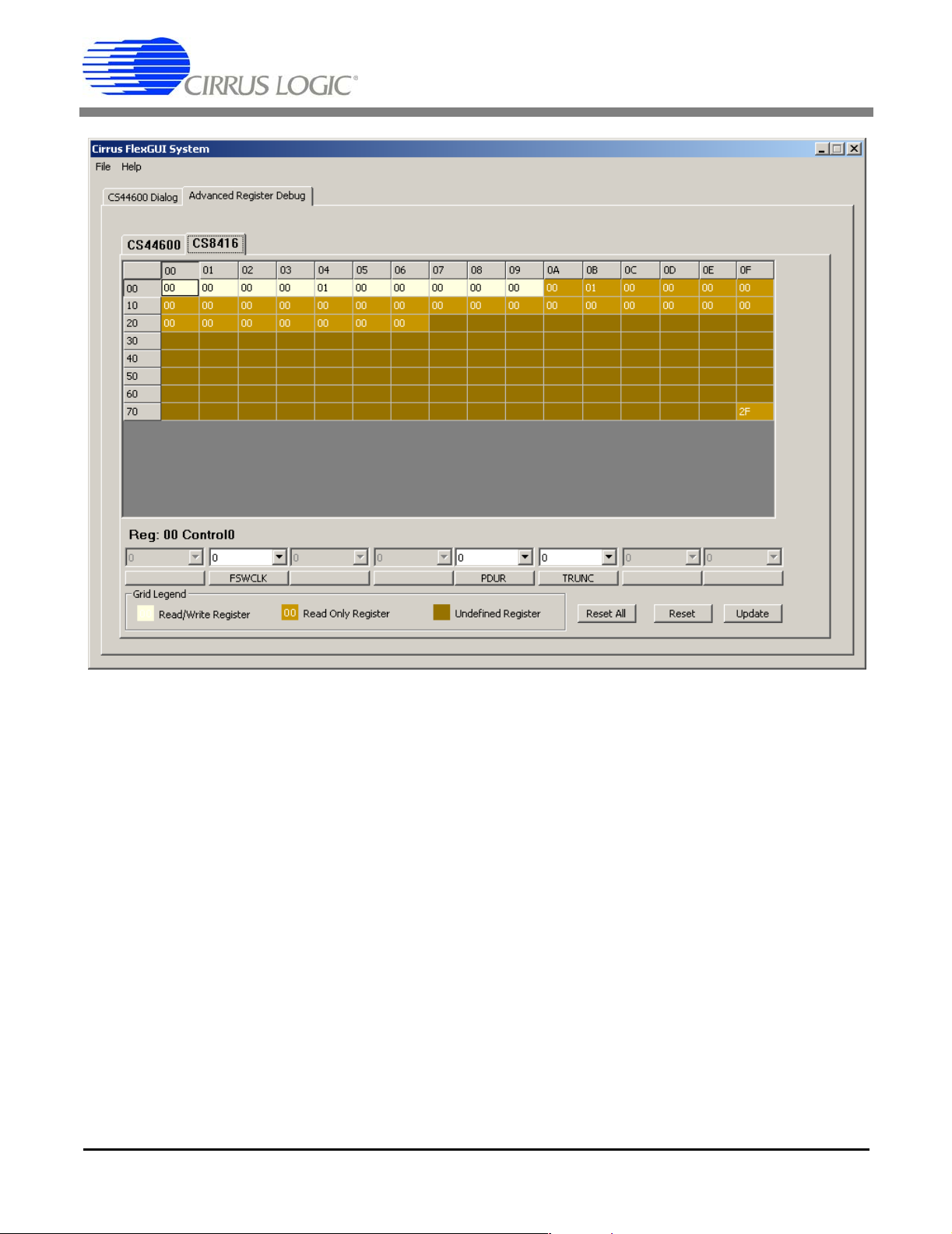

2.2 Advanced Register Debug Tab

The Advanced Register Debug tab provides low level control over the CS44600 and CS8416

individual register settings. Each device is displayed on a separate tab. Register values can

be modified bitwise or bytewise. For bitwise, click the appropriate push button for the desired

bit. For bytewise, the desired hex value can be typed directly in the register address box in

the register map.

Figure 2. Advanced Register Debug Tab - CS44600

MAR '05 DS633RD1 7

Page 8

CRD44600-PH-FB

Figure 3. Advanced Register Debug Tab - CS8416

8 MAR '05 DS633RD1

Page 9

CRD44600-PH-FB

3. POWER SUPPLY

3.1 Power Supply Ratings

The required power supply current rating can be estimated as follows. 95 W is used as the

reference output power per channel because this represents the typical full scale output with

no clipping. Assume the efficiency, η, is approximately 85% (this accounts for power to supply control electronics and overhead), then for 95 W x 2 channels:

WP

190

Total

P

Supply

P

Consequently the supply current is:

Out

224

85.0

W

2

η

Total

P

2

W

224

===

W

112

===

Supply

I

Supply

P

V

Supply

The factor of 2 in the denominator of the P

Supply

W

112

50

===

V

A

24.2

calculation arises from the fact that for typical

consumer applications in A/V or DVD receivers, the power supply should be capable of providing ½ the total requirement for all channels operating at full power. This design guide is

still quite conservative, and gives more than adequate headroom in real applications.

3.2 Power Supply Decoupling

Proper power supply decoupling is one key to maximizing the performance of a Class-D amplifier. Because the design uses an open loop output stage, noise on the power supply rail

will be coupled to the output. While the PSR functionality of the CS44600 helps reduce power

supply noise feedthrough to the output, careful decoupling of the power stage supply rails is

essential. Referring to Figure 15, the top side of the CRD44600-PH-FB PWM amplifier board,

good decoupling practice is shown. Notice that the 0.1 µF ceramic capacitors are as close

as physically possible to the power pins of the TDA8939. The ground side of the capacitors

is connected directly to top side ground plane, which is also used by the power supply return

pins. This keeps the high frequency current loop small to minimize power supply variations

and EMI. 470 µF electrolytic capacitors are also located in close proximity to the power supply pins to supply the current locally for each channel. These are not required to be expensive

low ESR capacitors. General purpose electrolytic capacitors that are specified to handle the

ripple current can be used. The real time PSR feedback of the CS44600/CS4461 can greatly

attenuate the induced voltages due to the power supply ripple current.

MAR '05 DS633RD1 9

Page 10

CRD44600-PH-FB

4. ELECTROMAGNETIC INTERFERENCE (EMI)

This reference design from Cirrus Logic is a board level solution which is meant to control

emissions by minimizing and suppressing them at the source in contrast to containing them

in an enclosure. Utilizing spread spectrum modulation techniques to reduce the overall

switching energy, along with a low internal modulator clock frequency of 24.576 MHz, the radiated emissions are greatly reduced. These features allow for the use of very low cost components to couple the high frequency noise to chassis ground. No common mode chokes,

inductors, or power line filters were required.

The EMI requirements for an amplifier have added dimensions beyond those imposed on

power supplies. Audio amplifiers are usually located in close proximity to radio receivers, particularly AM receivers which are notoriously sensitive to interference. Amplifiers also need to

operate with speaker leads of unpredictable length and construction which make it possible

for any high frequency currents that appear on the outputs to generate nuisance emissions.

4.1 Suppression of EMI at the Source

Several techniques are used in the circuit design and board layout to minimize high frequency fields in the immediate vicinity of the high power components. Specific techniques

include the following:

• As was mentioned in Section 3.2, effective power supply decoupling of high frequency currents, and minimizing the loop area of the decoupling loop is one aspect of minimizing EMI.

• Each output of the TDA8939 includes “snubbing” components. For example, OUT1 of U1 includes snubber components R18/R30 (5.6 Ω) and C34/C46 (560 pF). These components serve

to damp ringing on the switching outputs in the 30-50 MHz range. The snubbing components

should be as close as practical to the output pins to maximize their effectiveness. Again, refer

to Figure 15 for the preferred component layout.

• A separate ground plane with a capacitively coupled electrical connection to the chassis and

which surrounds the speaker output connector should be implemented. This allows the speaker

outputs to be AC coupled to the chassis just before they exit the chassis from the speaker connector. Again, refer to Figure 15 for the preferred component layout.

• Make use of source termination resistors on all digital signals whose traces are longer than approximately 25 mm.

It is extremely critical that the layout of the power amplifier section of the Cirrus Logic

CS44600 Reference Design be copied as exactly as possible to assure best RF/EMI performance.

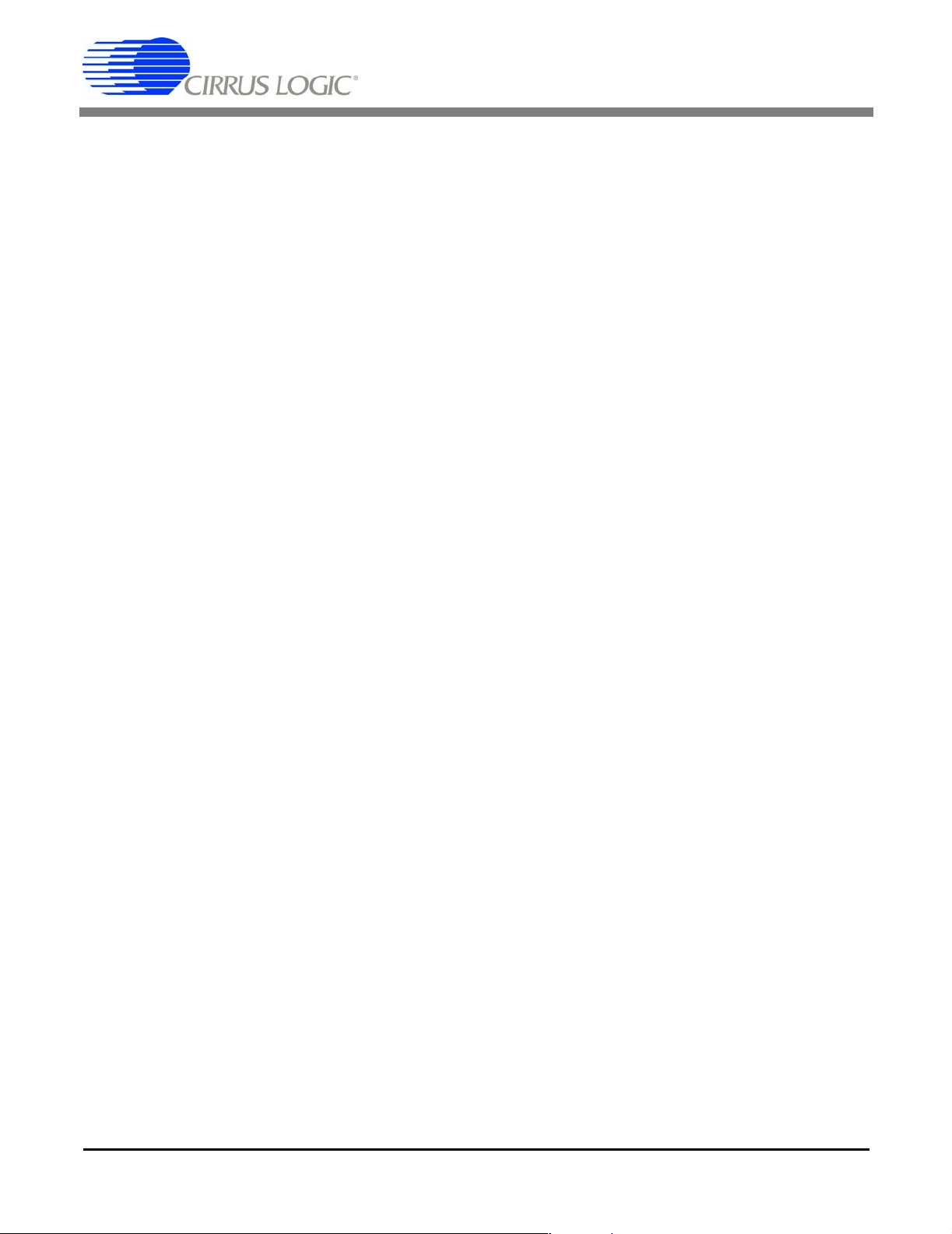

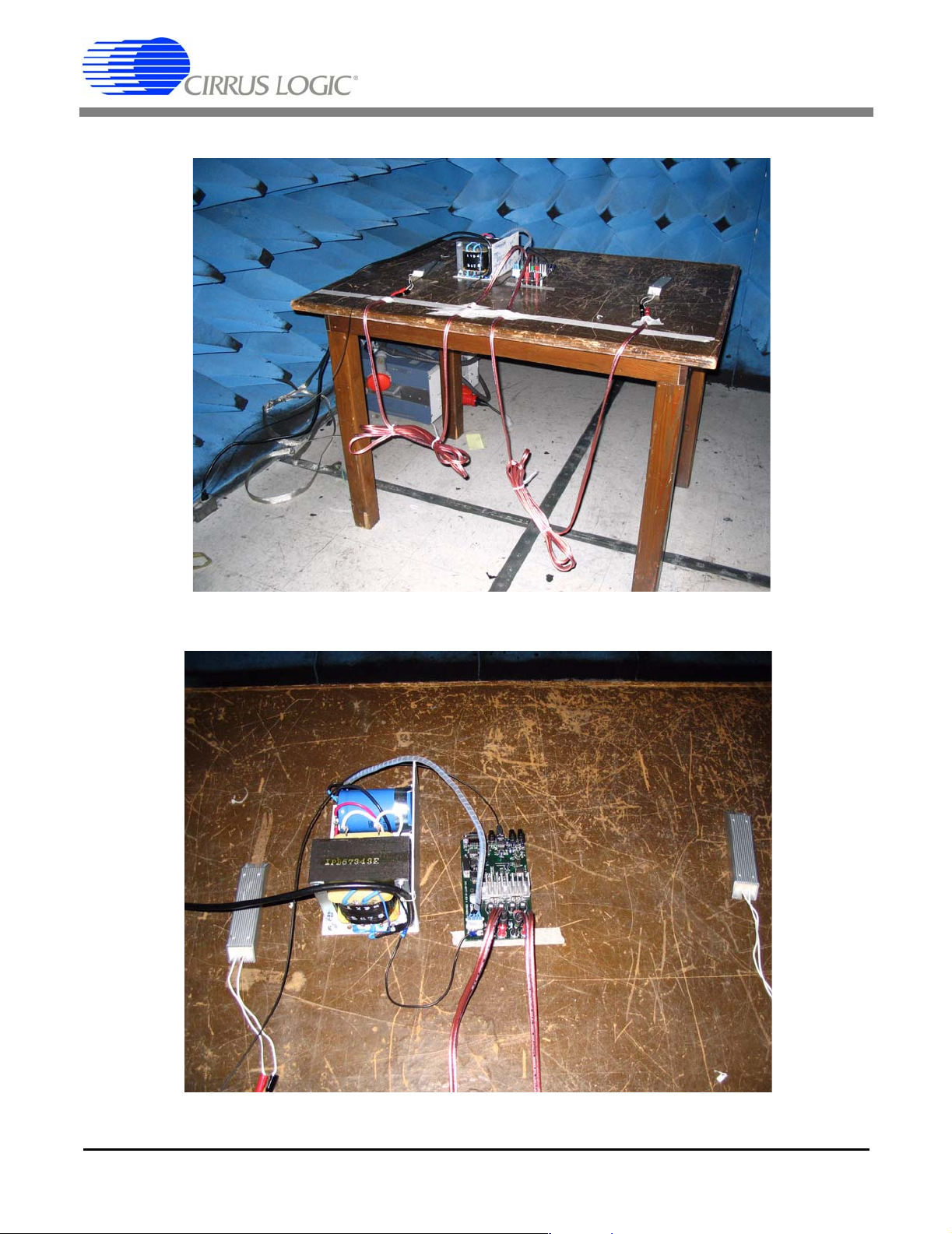

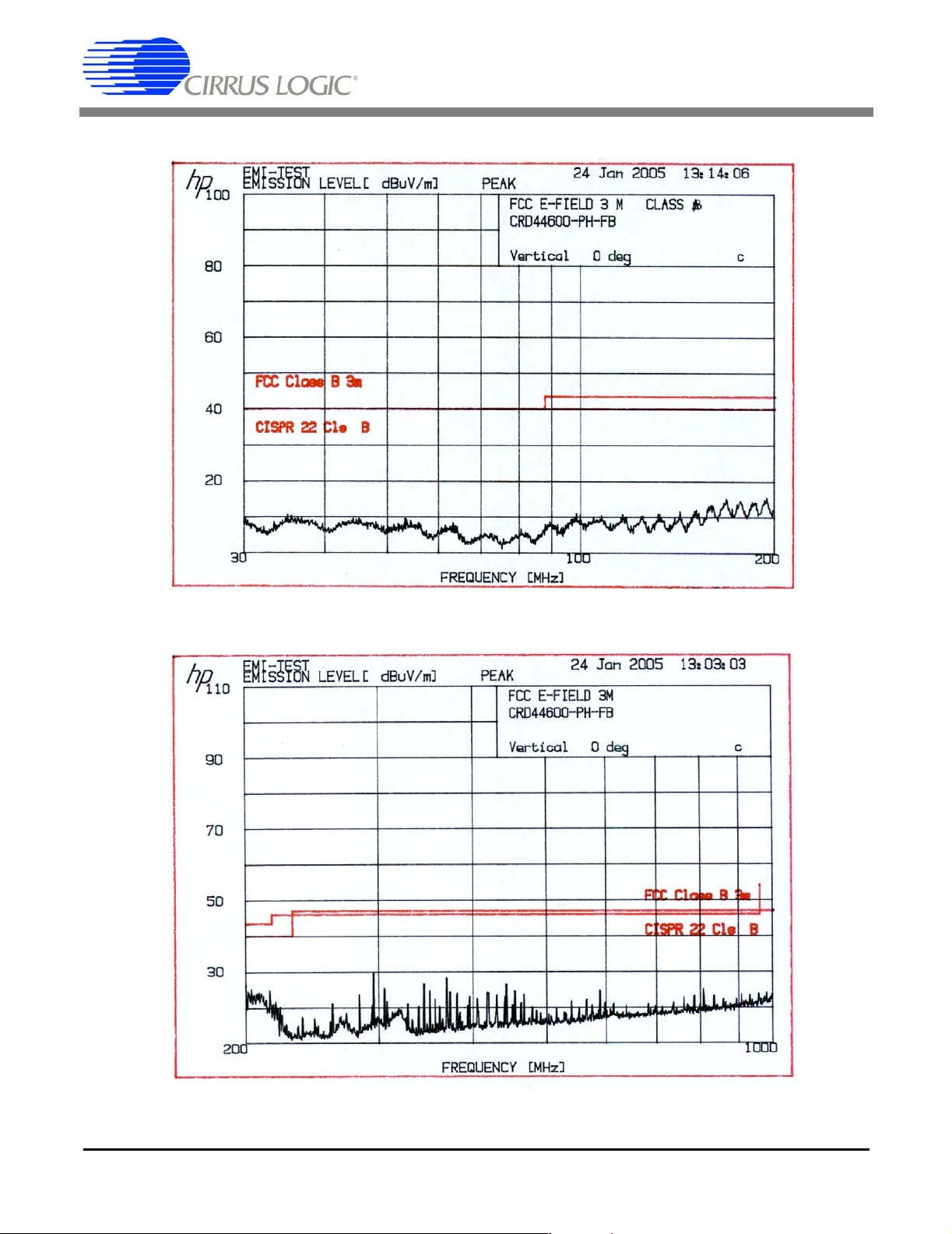

4.2 EMI Testing

The CRD44600-PH-FB has been tested to CISPR and FCC Class B limits for radiated and

power line conducted emissions. The same test setup and test signal were used for all

tests. The setup consisted of an unregulated linear power supply, CRD44600-PH-FB

board, 5m of speaker cable, and two 8-Ω resistive loads. This setup is shown in Figure 4

10 MAR '05 DS633RD1

Page 11

CRD44600-PH-FB

and Figure 5. The power supply earth ground was connected to the board chassis ground

at a single point.

A CD-player with an optical fiber connection was used a signal source. A constant 0dBFS, 1-kHz sine wave was used as the test signal and the board volume was set so that

the output to the resistive loads was 1/8th of the full scale output level, or 12.5 W.

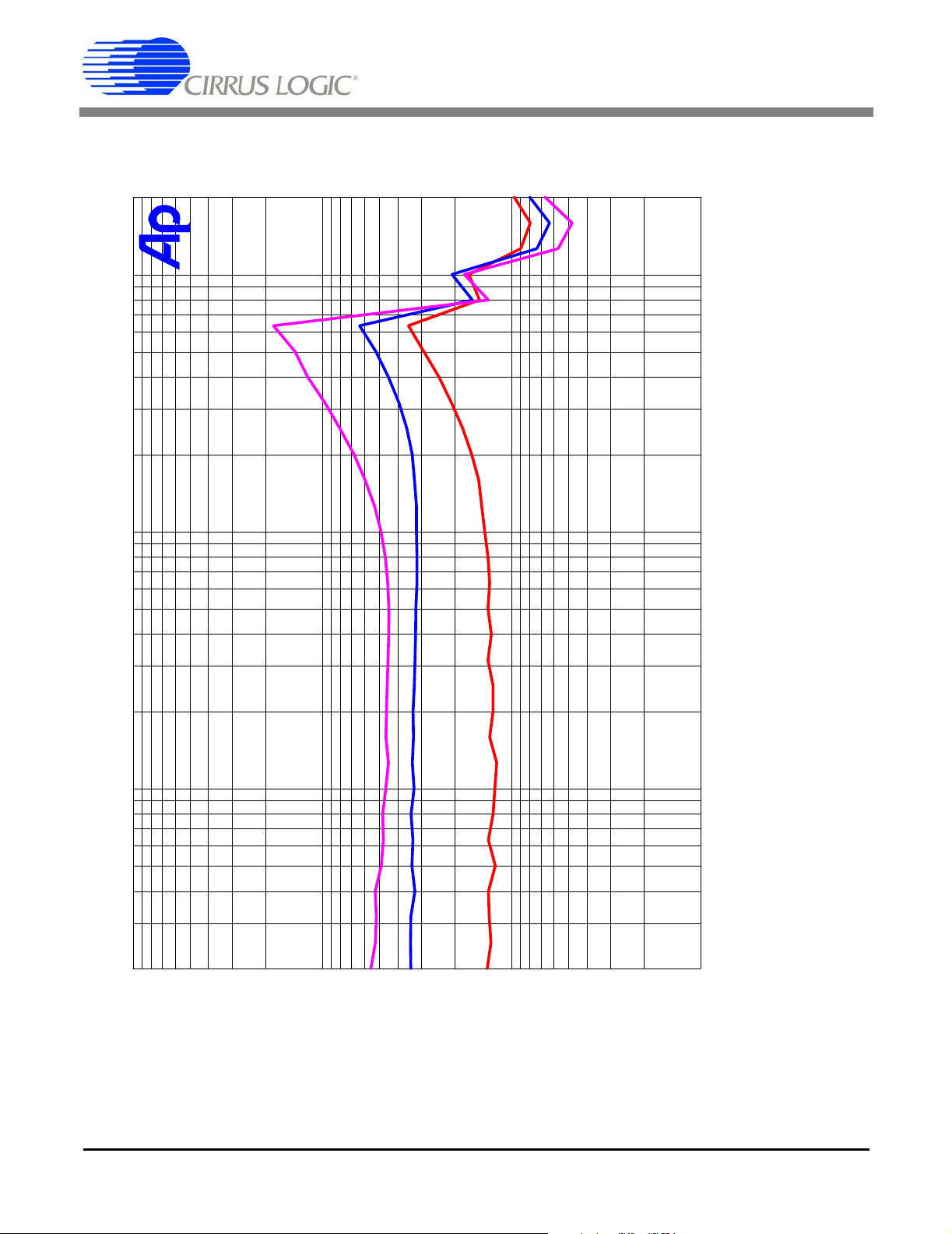

The test results shown in Figure 6 and Figure 7 are pre-screened radiated EMI test results

from an antenna placement of 3 m in an anechoic chamber. The test results shown in Figure 8 are preliminary power line conducted test results.

MAR '05 DS633RD1 11

Page 12

CRD44600-PH-FB

Figure 4. EMI Testing Setup

Figure 5. EMI Testing Setup, Close-up

12 MAR '05 DS633RD1

Page 13

CRD44600-PH-FB

Figure 6. Radiated EMI Testing Results- 30 MHz to 200 MHz

Figure 7. Radiated EMI Testing Results- 200 MHz to 1 GHz

MAR '05 DS633RD1 13

Page 14

CRD44600-PH-FB

Figure 8. Conducted Power Line Testing Results

14 MAR '05 DS633RD1

Page 15

5. CRD44600-PH-FB SCHEMATICS

CRD44600-PH-FB

Figure 9. Audio Inputs

MAR '05 DS633RD1 15

Page 16

CRD44600-PH-FB

Figure 10. CS44600

16 MAR '05 DS633RD1

Page 17

CRD44600-PH-FB

Figure 11. PSR Feedback

MAR '05 DS633RD1 17

Page 18

CRD44600-PH-FB

Figure 12. Left/Right Channels

18 MAR '05 DS633RD1

Page 19

CRD44600-PH-FB

Figure 13. Control Port and Power

MAR '05 DS633RD1 19

Page 20

6. CRD44600-PH-FB POWER SUPPLY SCHEMATICS

CRD44600-PH-FB

Figure 14. Power Supply

20 MAR '05 DS633RD1

Page 21

7. CRD44600-PH-FB LAYOUT

CRD44600-PH-FB

Figure 15. Silk Screen Top

MAR '05 DS633RD1 21

Page 22

CRD44600-PH-FB

Figure 16. Topside Layer

22 MAR '05 DS633RD1

Page 23

CRD44600-PH-FB

Figure 17. Bottomside Layer

MAR '05 DS633RD1 23

Page 24

8. CRD44600-PH-FB BILL OF MATERIALS

p

y

g

r

L

PANASONIC ECJ1VC1H102J

MFG MFG P/N

KEMET C1206C104K1RAC

KEMET C0603C104K4RAC

CRD44600-PH-FB

nato

C167 C173 C174 C205 C208 C210

Refe rence Desi

tion Qt

1 CAP 1000pF ±5% 50V C0G 0603 21 C1 C2 C4 C9 C10 C11 C12 C56 C71 C72 C73 C83 C88 C89 C153

2 NO POP CAP 0603 0 C3 C20 C21 C22 C78 C79 NO POP NP-CAP-0603

3 CAP 0.22uF ±5% 50V X7R 1206 4 C5 C6 C7 C8 KEMET C1206C224J5RAC

Item Descri

4 CAP 0.01uF ±10% 50V X7R 0603 10 C13 C84 C90 C91 C92 C93 C94 C95 C195 C196 KEMET C0603C103K5RAC

C110 C111 C112 C113

5 CAP 0.68µF ±10% 100V POLY RAD 2 C14 C16 PANASONIC ECQE1684KF

6 CAP 0.1uF ±10% 100V X7R 1206 18 C15 C19 C61 C62 C67 C68 C69 C70 C80 C81 C82 C85 C86 C87

7 CAP 100uF ±20% 10V ELEC RAD 5X11 6 C17 C51 C76 C125 C214 C227 PANASONIC ECA1AM101

8 CAP 470pF ±5% 50V C0G 0603 2 C18 C23 KEMET C0603C471J5GAC

9 CAP 1uF ±10% 100V X7R 1210 4 C24 C25 C65 C66 MURATA GRM32ER72A105KA01

C126 C128 C129 C134 C156 C158 C159 C164 C166 C168 C170

C172 C175 C177 C180 C181 C194 C199 C201 C213 C221 C222

C230 C231 C232

10 NO POP CAP 0805 0 C26 C63 C64 C96 NO POP NP-CAP-0805

11 CAP 10uF ±20% 50V ELEC RAD 7 C27 C31 C54 C59 C182 C190 C219 PANASONIC ECA1HM100I

12 CAP 0.1uF ±10% 16V X7R 0603 39 C28 C32 C37 C40 C41 C43 C49 C50 C52 C55 C57 C60 C74 C124

13 CAP 470uF ±20% 63V ELEC RAD 2 C29 C30 PANASONIC ECA1JM471B

14 CAP 560pF ±5% 100V C0G 0805 8 C33 C34 C35 C36 C45 C46 C47 C48 KEMET C0805C561J1GAC

15 CAP 2200pF ±5% 50V C0G 0805 3 C38 C39 C130 KEMET C0805C222J5GAC

16 CAP 1uF ±10% 25V X7R 1206 5 C42 C44 C77 C127 C131 KEMET C1206C105K3RAC

17 CAP 0.01uF ±5% 25V C0G 1206 2 C53 C58 KEMET C1206C103J3GAC

18 CAP 10uF ±20% 63V ELEC RAD 5x11 1 C75 PANASONIC ECA1JM100I

19 CAP 120pF ±5% 50V C0G 0603 2 C122 C123 KEMET C0603C121J5GAC

20 CAP 0.022uF ±5% 50V X7R 0603 1 C215 KEMET C0603C223J5RAC

21 LED CLR SUP RED 1.7V 1mA 1.6MCD SMD 1 D20 CHICAGO MINIATURE CMD28-21SRC/TR8/T1

22 HTSNK 30W DUAL SITE 1 HS1 SUMMIT HEAT SINKS CO LTD 311-00005-01

23 CON BPOST 2" SILV NYLON INS RED 2 J1 J3 JOHNSON COMPONENTS 111-0102-001

24 CON BPOST 2" SILV NYLON INS BLK 2 J2 J4 JOHNSON COMPONENTS 111-0103-001

25 JACK RCA, RA-BLK, PHONO, GLD TABS 3 J5 J6 J33 A/D ELECTRONICS ARJ-2018-NIL-1-NIL

26 HDR 2x1 ML .1"CTR 062BD ST GLD TH 1 J7 SAMTEC TSW-102-07-G-S

27 CON PWR SHIELDED 4PIN 1 J17 MOLEX 15-24-4049

28 HDR 4x3 MLE .1"CTR S GLD 1 J19 SAMTEC TSW-104-07-G-T

29 HDR 5x2 MLE .1"CTR S GLD 1 J26 SAMTEC TSW-105-07-G-D

30 CON DSUB 9P FML .318"W W/ BDLCK RA 1 J37 AMP 747844-6

31 IND 22uH 6A ±10% 400 DIA TH 4 L1 L2 L3 L4 TRANSTEK MAGNETICS TMP50627CT

32 IND 47uH 20% CDRH125 SERIES SMT 1 L9 SUMIDA CDRH125-470MC

33 IND 680uH 20% CDRH125 SERIES SMT 1 L10 SUMIDA CDRH125-681MC

34 IND 47uH ±10% 1210 1 L16 PANASONIC ELJFA470KF

35 IND 4.7uH ±10% 0805 1 L17 PANASONIC ELJFD4R7KF

36 SPCR, STANDOFF 4-40 THR, 0.875"L 6 MH1 MH2 MH3 MH4 MH5 MH6 KEYSTONE 1809

Table 1. Bill of Materials

37 OPTICAL RCVR 6Mb/s 7V 20MA 10M 1 OPT1 TOSHIBA TORX173

38 RES 10k OHM 1/10W ±1% 0603 FILM 10 R1 R2 R3 R14 R15 R38 R74 R157 R169 R179 DALE CRCW06031002F

24 MAR '05 DS633RD1

Page 25

CRD44600-PH-FB

p

y

g

r

MFG MFG P/N

nato

Refe rence Desi

DALE CRCW060390R9F

R135 R140

tion Qt

Item Descri

39 RES 22.1 OHM 1/10W ±1% 0603 FILM 12 R4 R11 R72 R73 R93 R108 R154 R161 R162 R167 R172 R176 DALE CRCW060322R1F

40 RES 22.1 OHM 1W ±1% 2512 FILM 4 R5 R6 R7 R8 DALE CRCW251222R1F

41 RES 90.9 OHM 1/10W ±1% 0603 FILM 15 R12 R13 R26 R27 R62 R63 R94 R95 R96 R97 R131 R133 R134

42 RES 5.6 OHM 1W ±5% 2512 FILM 8 R17 R18 R19 R20 R29 R30 R31 R32 DALE CRCW25125R6J

43 RES 649 OHM 1/10W ±1% 0603 FILM 4 R24 R25 R60 R187 DALE CRCW06036490F

44 RES 100k OHM 1/10W ±1% 0603 FILM 6 R28 R33 R34 R35 R36 R37 DALE CRCW06031003F

45 RES 10 OHM 1/8W ±5% 0805 FILM 10 R39 R45 R46 R47 R48 R68 R106 R170 R180 R182 DALE CRCW0805100J

46 RES 2k OHM 1/10W ±1% 0603 FILM 5 R41 R51 R61 R98 R146 DALE CRCW06032001F

47 RES 54.9k OHM 1/10W ±1% 0603 FILM 1 R42 DALE CRCW06035492F

48 NO POP RES 0805 0 R111 NO POP NP-RES-0805

49 RES 1k OHM 1/10W ±5% 0603 FILM 3 R150 R151 R156 DALE CRCW0603102J

50 RES 75 OHM 1/10W ±1% 0603 FILM 1 R171 DALE CRCW060375R0F

51 RES 3.01k OHM 1/10W ±1% 0603 FILM 1 R178 DALE CRCW06033011F

52 IC LOG CLASS D PWR COMP HSOP24 2 U1 U2 PHILIPS TDA8939TH

53 IC LNR DUAL OP AMP LOW V RRO VSP8 2 U3 U4 NJR NJM2140R

54 IC CRUS, 105dB 192kHz M-BIT AUD ADC 1 U6 CIRRUS LOGIC CS5341-CZZ/E

55 IC LNR VREG µPWR 150mA 3.3V SOT23-5 1 U7 NATIONAL SEMICONDUCTOR LP2985IM5-3.3

56 IC CRUS A/D PSR FEEDBACK TSSOP24 1 U8 CIRRUS LOGIC CS4461-CZZ/D

57 IC LNR VREG µPWR 150MA 2.5V SOT23-5 1 U9 NATIONAL SEMICONDUCTOR LP2985IM5-2.5

58 IC LNR ISO 2W SINGLE OUT DC-DC CONV 1 U10 C&D TECHNOLOGIES NDL4805S

59 IC CRUS 6-CH DIG AMP CTRL LQFP64 1 U14 CIRRUS LOGIC CS44600-CQZ/A

60 IC LOG, UHS 2IN NON INV MUX SC70-6 1 U17 FAIRCHILD SEMICONDUCTOR NC7SZ157P6X

61 IC PGM USB 16kB FLASH MCU LQFP32 1 U20 CYGNAL C8051F320

62 IC CRUS 192kHz DIG AUD RCVR TSSOP28 1 U26 CRYSTAL SEMICONDUCTOR CS8416-CZ/E

63 IC LNR 5V RS-232 DRV/RCVR SO16-300 1 U31 MAXIM MAX232ACWE

64 IC PGM 128 BIT SER EEPROM SOT23-5 1 U32 MICROCHIP 24LC00-I/OT

65 OSC 24.576MHz 50PPM 5V HALF DIP8 1 Y2 CAL CRYSTAL CX21AH-24.576MHZ

65 WIRE, HOOK-UP 12AWG 65/30 RED 100ft 4 XJ1 XJ2 XJ3 XJ4 ALPHA WIRE COMPANY 3080 RD005

66 SCREW 4-40X5/16" PH STEEL 6 XMH1 XMH2 XMH3 XMH4 XMH5 XMH6 BUILDING FASTENERS PMS 440 0031 PH

67 SCREW 4-40X1/4"L PH STEEL 3 XHS1 McMASTER-CARR 90190A106

68 WASHER LOCK INTERNAL #4 3 XHS1 BUILDING FASTENERS INT LWZ 004

MAR '05 DS633RD1 25

Page 26

CRD44600-PH-FB

9. TYPICAL PERFORMANCE PLOTS

These performance plots were taken with the CRD44600-PH-FB powered from the described

+50 V linear unregulated power supply. The PSR circuitry was calibrated to a nominal +50 V rail.

+1

+0.5

-0

-0.5

-1

-1.5

-2

-2.5

-3

-3.5

-4

-4.5

-5

Hz

Figure 18. Frequency Response

20 20k50 100 200 500 1k 2k 5k 10k

B

r

A

d

26 MAR '05 DS633RD1

Page 27

1

CRD44600-PH-FB

0 W

W

0 W

Hz

Figure 19. THD+N vs. Frequency at 1 W, 10 W, and 50 W

1

0.5

0.2

0.1

0.05

0.02

0.01

0.005

0.002

20 20k50 100 200 500 1k 2k 5k 10k

0.001

%

MAR '05 DS633RD1 27

Page 28

CRD44600-PH-FB

10

5

2

1

0.5

0.2

0.1

0.05

0.02

W

Figure 20. THD+N vs. Power at 1 kHz

100m 100200m 500m 1 2 5 10 20 50

0.01

%

28 MAR '05 DS633RD1

Page 29

CRD44600-PH-FB

+0

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

-120

-130

Hz

Figure 21. FFT at -60 dBFS and 1 kHz

20 20k50 100 200 500 1k 2k 5k 10k

-140

B

r

A

d

MAR '05 DS633RD1 29

Page 30

CRD44600-PH-FB

+0

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

-120

-130

Hz

Figure 22. FFT at -1 dBFS and 1 kHz. Red = PSR Feedback Off. Blue = PSR Feedback On

20 20k50 100 200 500 1k 2k 5k 10k

-140

B

r

A

d

30 MAR '05 DS633RD1

Page 31

10. REVISION HISTORY

Release Date Changes

RD1 March 2005 1st Release

CRD44600-PH-FB

Table 2. Revision History

Contacting Cirrus Logic Support

For all product questions and inquiries contact a Cirrus Logic Sales Representative.

To find one nearest you go to <http://www.cirrus.com/corporate/contacts/sales.cfm>

IMPORTANT NOTICE

Cirrus Logic, Inc. and it s su bsi di ar i es ( " Ci r ru s" ) bel i eve that the information conta i ned in t hi s doc ument is accurate and reli able . Howev er , t he in f ormation is subject

to change without not ice and i s provi ded "AS I S" witho ut warrant y of an y kind ( express o r implie d). Cust omers are a dvised t o obtain the latest version of relevant

information to verify, before placing orders, that information being relied on is current and complete. All products are sold subject to the terms and conditions of sale

supplied at the time of order acknowledgment, including those pertaining to warranty, indemnification, and limitation of liability. No responsibility is assumed by Cirrus

for the use of this information, includ ing u se of this i nforma tion a s the basis for m anu facture or sa le of a ny item s, or for in fringement of patents or other rights of third

parties. This document is the property of Cirru s and by furnishing this information, Cirrus grants n o lice nse, express or implied under any patents, mask work rights,

copyrights, trademarks, trade secrets or other intellectual property rights. Cirrus owns the copyrights associated with the information contained herein and gives consent for copies to be made of the information only for use within your organization with respe c t to Cirrus integrated circu its or other products of Cirrus. This consent

does not extend to other copying such as copying for general distribution, advertising or promotiona l purposes, or for creating any work for resale.

CERTAIN APPLICATIONS USING SEMI CONDUCTOR P RODUCT S MAY I NVOL VE PO TENT I AL RI SKS OF DEAT H, PE RS ONAL IN JU RY, OR S EV ERE PRO PERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL APPLICATIONS”). CIRRUS PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARRANTED FOR USE

IN AIRCRAFT SYSTEMS, MILITARY APPLICATIONS, PRODUCTS SURGICALLY IMPLANTED INTO THE BODY, AUTOMOTIVE SAFETY OR SECURITY DEVICES, LIFE SUPPORT PRODUCTS OR OTHER CRITICAL APPLICATIONS. INCLUSION OF CIRRUS PRODUCTS IN SUCH APPLICATIONS IS UNDERSTOOD

TO BE FULLY AT THE CUSTOMER’S RISK AND CIRRUS DISCLAIMS AND MAKES NO WARRANTY, EXPRESS, STATUTORY OR IMPLIED, INCLUDING THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSE, WITH REGARD TO ANY CIRRUS PRODUCT THAT IS USED

IN SUCH A MANNER. IF THE CUSTOMER OR CUSTOMER’S CUSTOMER USES OR PERMITS THE USE OF CIRRUS PRODUCTS IN CRITICAL APPLICATIONS, CUSTOMER AGREES, BY SUCH USE, TO FULLY INDEMNIFY CIRRUS, ITS OFFICERS, DIRECTORS, EMPLOYEES, DISTRIBUTORS AND OTHER

AGENTS FROM ANY AND ALL LIABILITY, INCLUDING ATTORNEYS’ FEES AND COSTS, THAT MAY RESULT FROM OR ARISE IN CONNECTION WITH

THESE USES.

Cirrus Logic, Cirrus, and the Cirrus Log ic lo go d esi gn s ar e trademarks of Cirrus Logic, Inc. All other brand an d pr od uct names in this document may be trademarks

or service marks of their respective owners.

Microsoft Windows is a registered trademark of Microsoft Corporation.

MAR '05 DS633RD1 31

Page 32

CRD44600-PH-FB

32 MAR '05 DS633RD1

Loading...

Loading...