Page 1

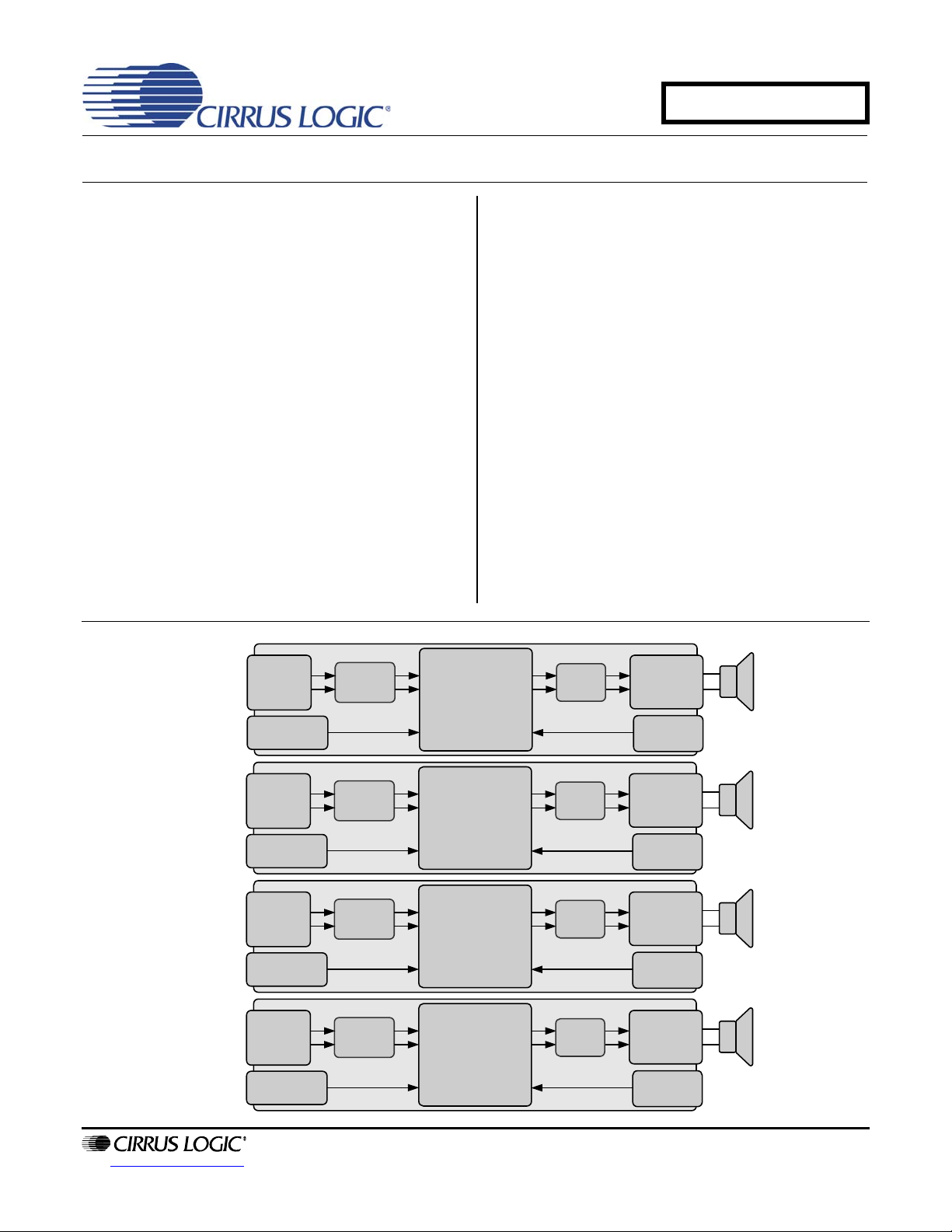

Shutdown

Control (J2)

Speaker

Outpu t ( J 3)

Optional

Gain

Adjustment

Analog

Inpu t ( J 1 )

CS35L01

(SD Mode)

Optional

Output

Filter

VBATT

Power (J4 )

Shutdown

Control (J2)

Speaker

Outpu t ( J 3)

Optional

Gain

Adjustment

Analog

Inpu t ( J 1 )

CS35L01

(FSD Mode)

Optional

Output

Filter

VBATT

Power (J4)

Shutdown

Control (J2)

Speaker

Outpu t ( J 3)

Optional

Gain

Adjustment

Analog

Inpu t ( J 1 )

CS35L01

(HD M ode)

Optional

Output

Filter

VBATT

Power (J4)

Shutdown

Control (J2)

Speaker

Outpu t ( J 3)

Optional

Gain

Adjustment

Analog

Inpu t ( J 1 )

CS35L01

(FHD Mod e)

Optional

Output

Filter

VBATT

Power (J4)

CRD35L01

1 x 1.7 W CS35L01 Amplifier Reference Design Kit

Features

Four boards provided in the CS35L01 Amplifier

Reference Design Kit

Separate boards for each mode configuration

– SD, FSD, HD, and FHD

CS35L01 produces a default +6-dB Gain

Delivers 1.4 W/Ch into 8 at 1% THD+N

Delivers 1.7 W/Ch into 8 at 10% THD+N

Differential mono analog inputs

Demonstrates recommended 4-layer layout

and grounding arrangements

– Optional output filter connections

– Optional gain adjustment resistors

Powered by a single 2.5- to 5.5-V power supply

Device shutdown control

Description

The CRD35L01 demonstrates the CS35L01 high-efficiency Hybrid Class-D audio amplifier. This reference

design implements a single-channel amplifier that delivers 1.7 W per full-bridge channel into 8- loads using a

single +5-V supply.

Differential audio inputs can easily be connected

through the J1 header. If desired, the gain can be adjusted through the optional input resistors.

The -SD, -FSD, -HD, or -FHD suffix designates the

CS35L01’s operational mode. Each of the four boards

is configured to operate in each of the four corresponding modes of the CS35L01 device.

Device shutdown control is available through the J2

header.

ORDERING INFORMATION

CRD35L01 CS35L01 Reference Design

http://www.cirrus.com

Copyright Cirrus Logic, Inc. 2010

(All Rights Reserved)

APR '10

DS914RD2

Page 2

TABLE OF CONTENTS

1. SYSTEM OVERVIEW ............................................................................................................................. 4

1.1 CS35L01 Hybrid Class-D Amplifier .................................................................................................. 4

1.2 Power Supply ................................................................................................................................... 4

1.3 Operational Modes ........................................................................................................................... 4

1.4 Shutdown Control ............................................................................................................................ 4

1.5 Amplifier Gain .................................................................................................................................. 4

1.5.1 Optional Input Gain Adjustment Resistors ...................................................... ... ... .... ... ... ........ 4

1.6 Differential Analog Inputs ................................................................................................................. 5

1.7 Speaker Outputs .............................................................................................................................. 5

1.7.1 Optional Speaker Output EMI Filter Components ........... ........................................................ 5

2. GROUNDING AND POWER SUPPLY DECOUPLING .......................................................................... 6

2.1 Power Supply Decoupling ................................................................................................................ 6

2.2 Electromagnetic Interference (EMI) ................................................................................................. 6

2.2.1 Suppression of EMI at the Source ......................... ... .... ... ... ... ... ....................................... ... ..... 6

3. SYSTEM CONNECTORS AND JUMPERS ....... ... ... ... .... ...................................... .... ... ... ... ... .... ... ... ... .... . 7

4. CRD SCHEMATIC .................................................................................................................................. 8

4.1 Bill of Materials ................................................................................................................................. 9

5. CRD LAYOUT ....................................................................................................................................... 10

6. REVISION HISTORY ............................................................................................................................ 14

CRD35L01

LIST OF FIGURES

Figure 1.Optional Bypass Trace Cut Locations ........................................................................................... 5

Figure 2.CRD35L01-SD Schematic ................... .... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ..................................... 8

Figure 3.CRD35L01-FSD Schematic .................................................. .......................................... ... ........... 8

Figure 4.CRD35L01-HD Schematic .................................................... ... ... ... .... ... ... ... .... ... ... ........................ 8

Figure 5.CRD35L01-FHD Schematic .................................. ... ... ... .... ... ... ... ... .... ........................................... 8

Figure 6.CRD35L01-SD Top Side Component Placement . ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... ... 10

Figure 7.CRD35L01-SD Bottom Side Component Placement .................. ............................................. ... 10

Figure 8.CRD35L01-SD Layer 1 Copper ........................ .... ... ... ... .... ... ... .......................................... ... ...... 10

Figure 9.CRD35L01-SD Layer 2 Copper ........................ .... ... ... ... .... ... ... .......................................... ... ...... 10

Figure 10.CRD35L01-SD Layer 3 Copper ................................................................................................ 10

Figure 11.CRD35L01-SD Layer 4 Copper ................................................................................................ 10

Figure 12.CRD35L01-FSD Top Side Component Placement ................................................................... 11

Figure 13.CRD35L01-FSD Bottom Side Component Placement ........................ ... ... .... ... ... ... ... .... ... ... ... ... 11

Figure 14.CRD35L01-FSD Layer 1 Copper .............................................................................................. 11

Figure 15.CRD35L01-FSD Layer 2 Copper .............................................................................................. 11

Figure 16.CRD35L01-FSD Layer 3 Copper .............................................................................................. 11

Figure 17.CRD35L01-FSD Layer 4 Copper .............................................................................................. 11

Figure 18.CRD35L01-HD Top Side Component Placement ............................ ... ... ... .... ... ... ... ................... 12

Figure 19.CRD35L01-HD Bottom Side Component Placement ............. ................ ................... ................ 12

Figure 20.CRD35L01-HD Layer 1 Copper ................................................................................................ 12

Figure 21.CRD35L01-HD Layer 2 Copper ................................................................................................ 12

Figure 22.CRD35L01-HD Layer 3 Copper ................................................................................................ 12

Figure 23.CRD35L01-HD Layer 4 Copper ................................................................................................ 12

Figure 24.CRD35L01-FHD Top Side Component Placement .......................... ................ ................ ......... 13

Figure 25.CRD35L01-FHD Bottom Side Component Placement ............................................................. 13

Figure 26.CRD35L01-FHD Layer 1 Copper .............................................................................................. 13

Figure 27.CRD35L01-FHD Layer 2 Copper .............................................................................................. 13

Figure 28.CRD35L01-FHD Layer 3 Copper .............................................................................................. 13

Figure 29.CRD35L01-FHD Layer 4 Copper .............................................................................................. 13

2 DS914RD2

Page 3

LIST OF TABLES

Table 1. System Input and Output Connections ......................................................................................... 7

Table 2. J2 Shutdown Control Settings ....................................................................................................... 7

Table 3. Bill of Materials Listing .................................................................................................................. 9

CRD35L01

DS914RD2 3

Page 4

CRD35L01

1. SYSTEM OVERVIEW

The CRD35L01 reference design is a practical means for eva luating the CS35L01 high-efficiency Class-D audio amplifier with idle current consumption. A differential mono analog input signal interface is provided. Option al input gain

and output filtering component placeholders are provided for easy modificatio n to custom tune the CS3 5L01 for the

user’s specific system requirements.

1.1 CS35L01 Hybrid Class-D Amplifier

The CS35L01 Hybrid Class-D amplifier is a mono, full-bridge, closed-loop, +6-dB gain, audio amplifier available in a 9-ball, WLCSP package. A complete description of the CS35 L01 device is included in the CS35L01

product data sheet.

1.2 Power Supply

A single +2.5 to +5.5 VDC power supply is required to power the CRD35L01. The supply must be capable

of delivering sufficient current for the intended power output. The supply provides power to the CS35L01.

The power supply connection to the board is provided by the header J4. The positive terminal is labeled

VBATT. The ground terminal is labeled GND.

1.3 Operational Modes

The CS35L01 device has four operational modes, each of which r equire slightly differ ent hardware connections. Four boards are available to illustrate the hardware design differences between each of the four

modes. More information on the specifics of each operational mode can be found in the CS35L01/03 pro duct datasheet. The CRD names listed below are populated with a CS35L01 device.

• CRD35L01-SD: Standard Class-D Mode

• CRD35L01-FSD: Reduced-Frequency Standard Class-D Mode

• CRD35L01-HD: Hybrid Class-D Mode

• CRD35L01-FHD: Reduced-Frequency Hybrid Class-D Mode

The CRD35L01-SD schematic is shown in Figure 2 on page 8. The CRD35L01-FSD schematic is shown in

Figure 3 on page 8. The CRD35L01-HD schematic is shown in Figure 5 on page 8. The CRD35L01-FHD

schematic is shown in Figure 5 on page 8.

1.4 Shutdown Control

The J2 header contains shutdown control for the CS35L01 device. Placing a jumper across the J2 header

pulls the SD

by the R3 resistor, enabling normal operation.

line LOW and shuts down the amplifier. When no jumper is present, the SD line is pulled HIGH

1.5 Amplifier Gain

The amplifier gain of the CS35L01 device is +6 dB by default. The amplifier gain can be reduced through

the use of the optional input gain adjustment resistors on the CRD35L01.

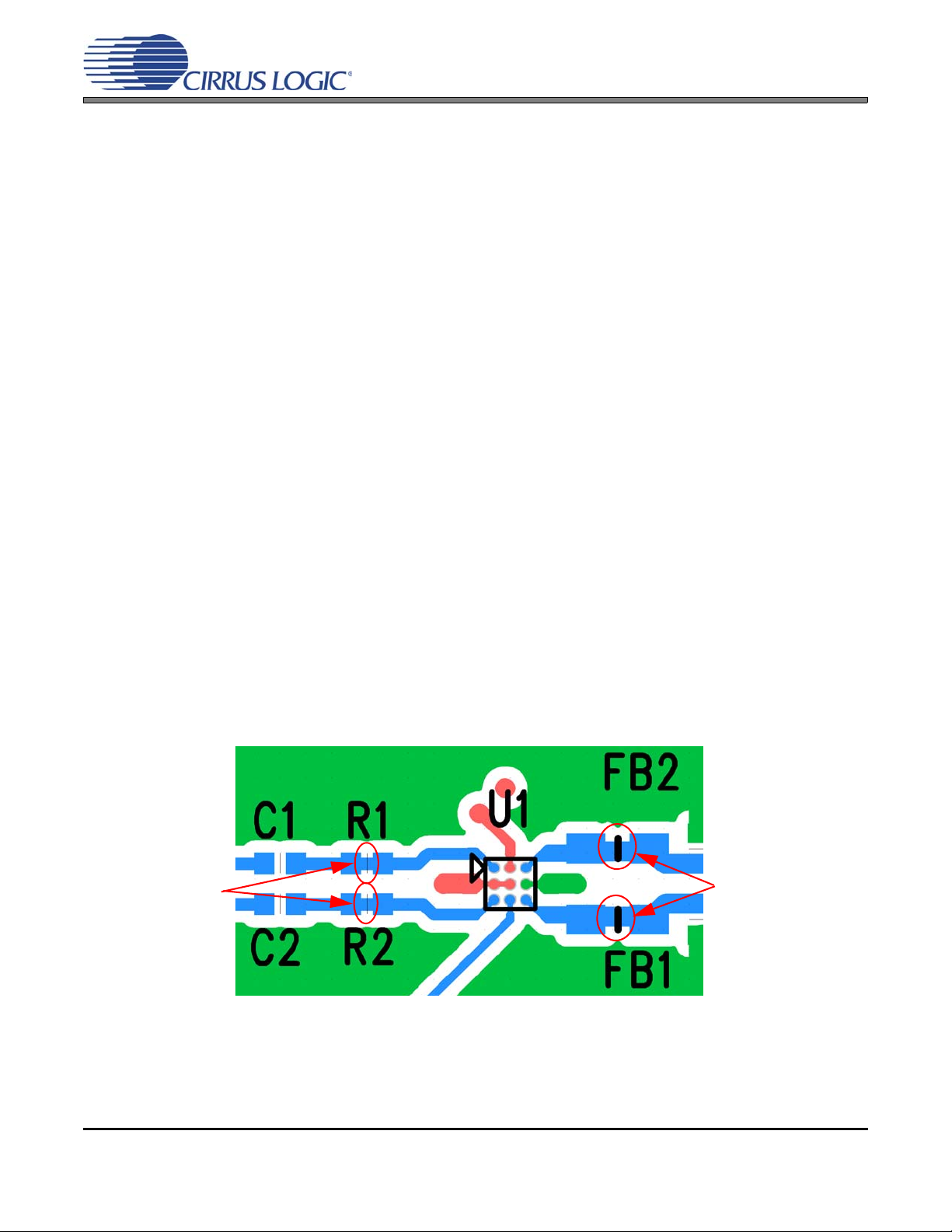

1.5.1 Optional Input Gain Adjustment Resistors

The CRD35L01 contains optional gain adjustment resistor placeholders (R1 and R2). By default, these

placeholders are not populated and are bypassed with a signal trace configuring the CS35 L01 to operate

at its default gain. The gain adjustment resistors are necessary only when a gain of +6 dB is not desired.

4 DS914RD2

Page 5

By adding series resistance to the input, the signal amplitude to the CS35L01 will be reduced, and will

Figure 1. Optional Bypass Trace Cut Locations

Cut the bypass

traces before inserting the optional

input gain adjustment resistors

Cut the bypass

traces before inserting the optional output filter ferrite

beads

reduce the overall system gain. The typical input impedance values of the CS35L01 can be found in the

device datasheet.

In order to use the optional gain adjustment resistors, the traces between the R1 pads and the traces between the R2 pads must be cut to break the bypass circuit, before populatin g R1 and R2 with the desired

resistance values. The location of these required cuts are sho wn in F i gure 1 . After th e trace be twe en th e

pads has been broken, the gain adjustment resistors can be added to the board.

1.6 Differential Analog Inputs

The differential audio inputs into the CS35L01 are provided by the 3-pin header (J1) through DC blocking

capacitors (C1 and C2). The C1 and C2 capacitors allow for an analog source to connect directly to the

CS35L01 regardless of any DC bias that may be present between the analog audio source’s outputs and

CS35L01 inputs.

1.7 Speaker Outputs

The CS35L01 power outputs are configured for a full-bridge, single audio channel. The outputs are routed

through an optional EMI output filter and then presented at the J3 header (OUT- and OUT+).

1.7.1 Optional Speaker Output EMI Filter Components

CRD35L01

As mentioned above, the CS35L01 contains optional placeholders for a series ferrite bead and shunt capacitor output filter. For most applications with very short speaker leads between the CS35L01 and the

speaker, use of these components will not be necessary. However, if there is a long signal path between

the CS35L01 and the speaker or if the system requires connecting to cables off the PCB, it is suggested

that the ferrite bead and capacitor are populated with the recommended values shown in Figure 3 on

page 9.

In order to use the optional output filter ferrite beads, the traces between the L1 pads and the traces between the L2 pads must be cut to break the bypass circuit, before populating L1 and L2 with the desired

component values. The location of these required cuts are shown in Figure 1.

DS914RD2 5

Page 6

CRD35L01

2. GROUNDING AND POWER SUPPLY DECOUPLING

The CS35L01 requires careful attention to power supply and grounding arrangements to optimize p erformance and

minimize radiated emissions. The decoupling capacitors should be located as close to the CS35L01 as possible.

This can be optimized by using both top and bottom side component p opulation as demonstrated by the CRD35L01

boards.

2.1 Power Supply Decoupling

Proper power supply decoupling is one key to maximizing the per formance of a Class-D amp lifier. Figure 6

and Figure 7 on page 10 show the compon en t place ment for the CRD35 L0 1-SD board . Figure 18 and Fig-

ure 19 on page 12 shows the component side placement for the CRD35L01-HD board. Note the addition of

the C8 capacitor connected to the LFILT+ pin. This pin is used as de coupling for th e internal LDO re gulator

when operating in HD or FHD modes.

The small value decoupling capacitors are placed as close as possible to the power pins of the CS35L01

on the CRD35L01 boards. For the WLCSP package it is recommended that the power supply decoupling

capacitors reside on the opposite si de of the board from which the CS35L01 is populated on. This allows

for very close placement of the decoupling capacitors to the power supply pins of the CS35L01 without interfering with the differential audio inputs or differential audio outputs. This placement keeps the high-frequency current loop small to minimize power supply variations and EMI. These capacitor s ar e no t r equir ed

to be expensive low-ESR capacitors.

2.2 Electromagnetic Interference (EMI)

This reference design is a board-level solution that is meant to control emissions by minimizing and suppressing them at the source, in contrast to containing them in an enclosure.

2.2.1 Suppression of EMI at the Source

Several techniques are used in the circuit design and board layout to minimize high-frequency fields in

the immediate vicinity of the high-power components. Specific techniques include the following:

• As mentioned in Section 2.1, effective power supply decoupling of high-frequency currents and minimizing the loop area of the decoupling loop is one aspect of minimizing EMI.

• Differential input and output signals should be routed differentially whenever possible.

• A solid ground plane on the adjacent PCB layer underneath all high-frequency traces to minimize the

loop area of the return path.

• Optional output EMI filter component landings are available as described in Section 1.7.1, if emissions

need to be further reduced.

• Keeping the switching output filter components as close to the amplifier as possible.

6 DS914RD2

Page 7

3. SYSTEM CONNECTORS AND JUMPERS

CRD35L01

Connector

Name

IN+

IN-

GND

SD

GND

OUT+

OUT-

VBATT

GND

Reference

Designator

J1

J1

J1

J2

J2

J3

J3

J4

J4

Pin Signal

Connector Function

Direction

1

2

3

1

2

1

2

1

2

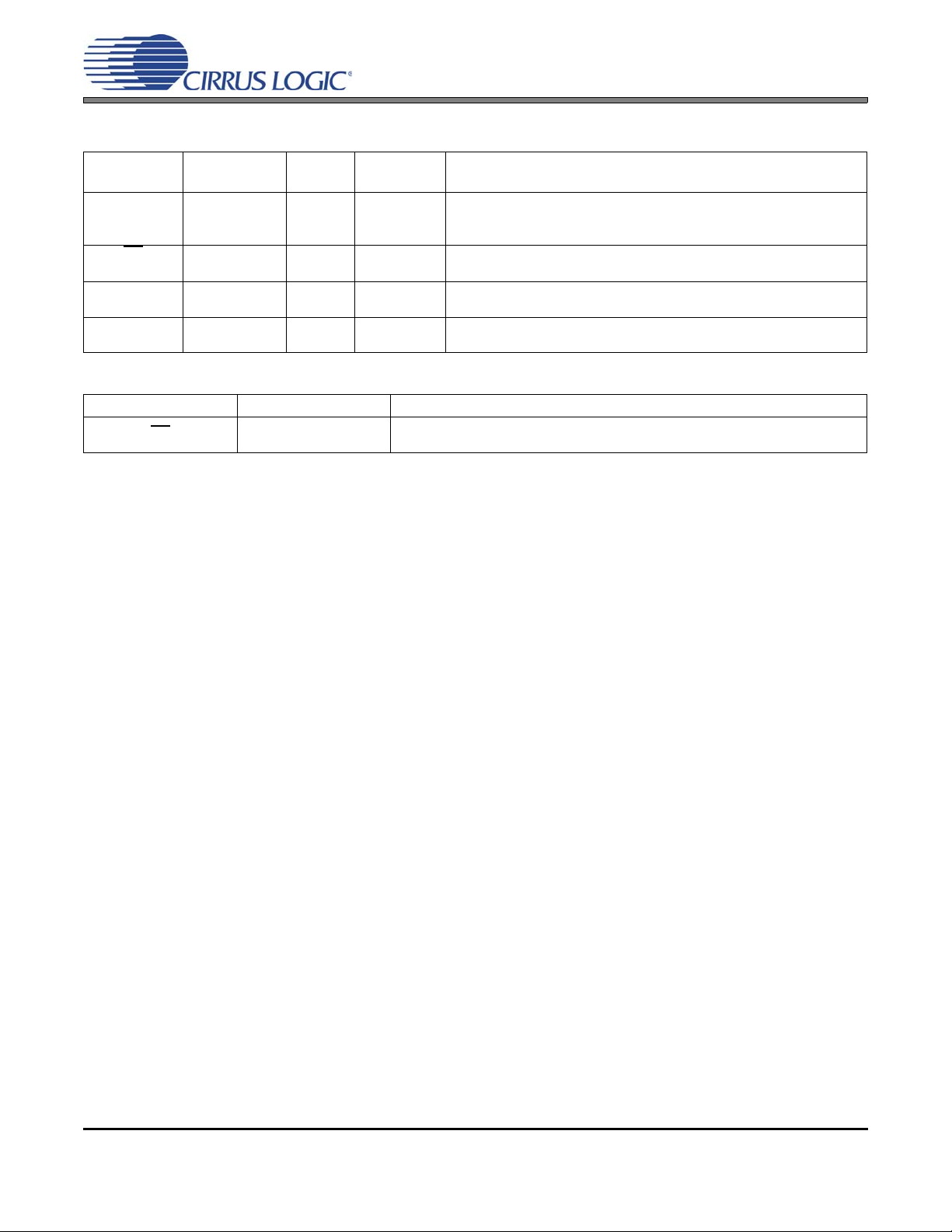

Table 1. System Input and Output Connections

Input

Input

GND

Input

GND

Output

Output

Input

Input

Differential analog input (+) to CS35L01.

Differential analog input (-) to CS35L01.

GND reference connection.

Device shutdown control.

GND reference connection.

Analog output (+) from CS35L01.

Analog output (-) from CS35L01.

Positive connection from power supply, +2.5 to +5.5 VDC.

GND connection from power supply.

Control Name Function Function Selected

SD Shutdown

Low = CS35L01 shutdown enabled

High = CS35L01 shutdown disabled

Table 2. J2 Shutdown Control Settings

DS914RD2 7

Page 8

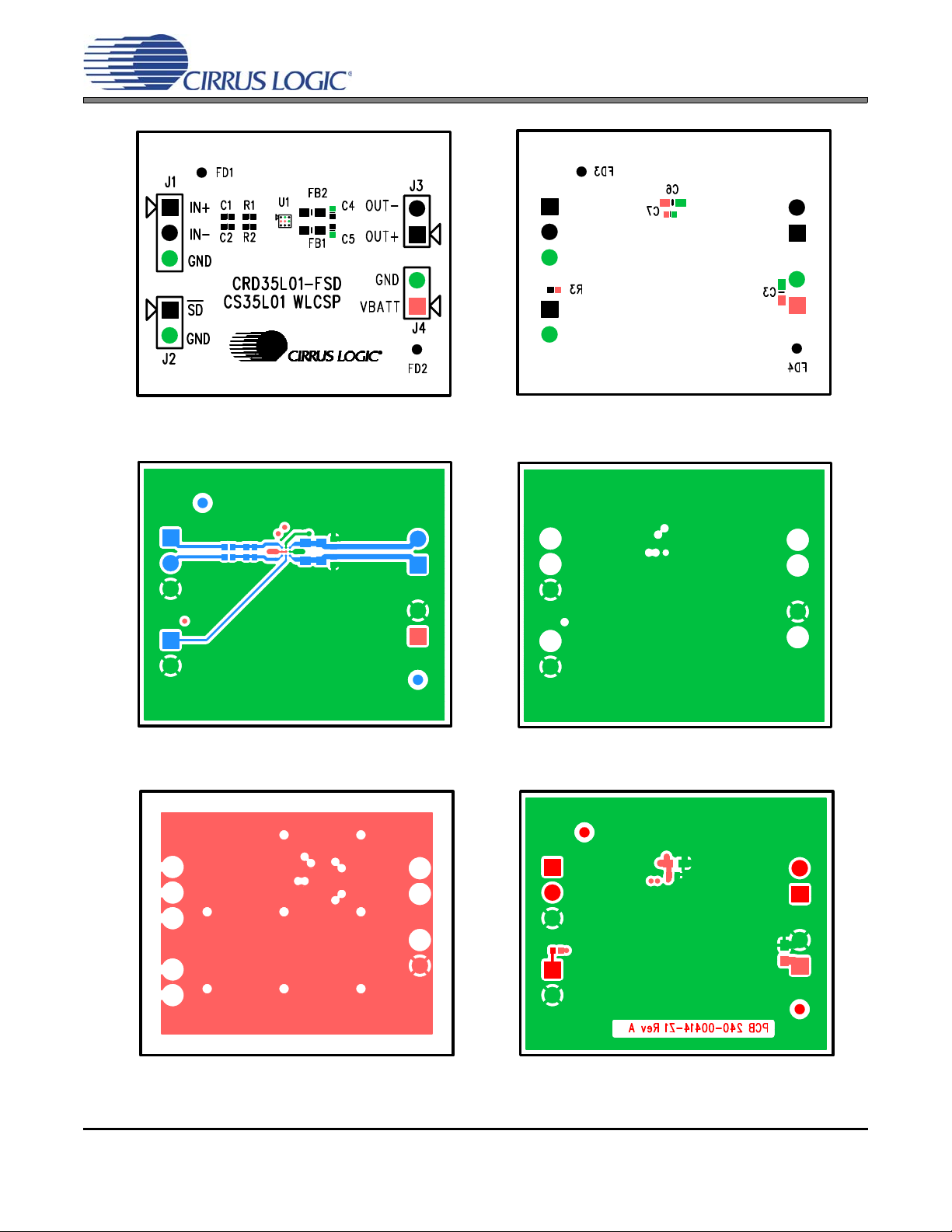

4. CRD SCHEMATIC

Figure 3. CRD35L01-FSD Schematic

Figure 2. CRD35L01-SD Schematic

Figure 4. CRD35L01-HD Schematic Figure 5. CRD35L01-FHD Schematic

CRD35L01

8 DS914RD2

Page 9

CRD35L01

4.1 Bill of Materials

The component listing below is shown for the four CRD35L01 board variations (-SD, -FSD, -HD, and -FHD).

Unpopulated (DNP) components are listed with recommended components for reference purposes.

Reference

Qty

(DNP) C4, C5 -SD, -FSD, -HD, -FHD Capacitor, 1 nF, X7R, 50 V Murata / GRM155R71H102KA01D

(DNP) FB1, FB2 -SD, -FSD, -HD, -FHD Ferrite Bead, 220

(DNP) R1, R2 -SD, -FSD, -HD, -FHD Resistor, 0

Designator(s) CRD35L01 Boards Description MFG / Part Number

2 C1, C2 -SD, -FSD, -HD, -FHD Capacitor, 0.1 F, X7R, 16 V Kemet / C0402C104K4RAC

1 C3 -SD, -FSD, -HD, -FHD Capacitor, 1 F, X5R, 10V Kemet / C0603C105K8PAC

1 C6 -SD, -FSD, -HD, -FHD Capacitor, 10 F, X5R, 6.3 V Kemet / C0603C106M9PAC

1 C7 -SD, -FSD, -HD, -FHD Capacitor, 0.1 F, X7R, 16 V Kemet / C0402C104K4RAC

1 C8 -HD, -FHD (Note 1) Capacitor, 1 F, X5R, 10 V Kemet / C0603C105K8PAC

1 R3 -SD, -FSD, -HD, -FHD Resistor 47k

1 U1 -SD, -FSD, -HD, -FHD Hybrid Class-D WLCSP Amp Cirrus Logic / CS35L01-CWZ

, 1/16 W Dale / CRCW040247K0JNED

@ 100 MHz TDK / MPZ1608S221A

, 1/16 W Yageo / RC0402JR-070RL

Table 3. Bill of Materials Listing

Note:

1. C8 is not present on SD or FSD boards. LFILT+ (B1) is connected directly to VBATT.

DS914RD2 9

Page 10

5. CRD LAYOUT

Figure 6. CRD35L01-SD Top Side Component

Placement

Figure 7. CRD35L01-SD Bottom Side Component

Placement

Figure 8. CRD35L01-SD Layer 1 Copper

Figure 9. CRD35L01-SD Layer 2 Copper

Figure 10. CRD35L01-SD Layer 3 Copper

Figure 11. CRD35L01-SD Layer 4 Copper

CRD35L01

10 DS914RD2

Page 11

CRD35L01

Figure 12. CRD35L01-FSD Top Side Component

Placement

Figure 13. CRD35L01-FSD Bottom Side Component

Placement

Figure 15. CRD35L01-FSD Layer 2 Copper

Figure 14. CRD35L01-FSD Layer 1 Copper

Figure 16. CRD35L01-FSD Layer 3 Copper

Figure 17. CRD35L01-FSD Layer 4 Copper

DS914RD2 11

Page 12

CRD35L01

Figure 18. CRD35L01-HD Top Side Component

Placement

Figure 19. CRD35L01-HD Bottom Side Component

Placement

Figure 20. CRD35L01-HD Layer 1 Copper

Figure 21. CRD35L01-HD Layer 2 Copper

Figure 22. CRD35L01-HD Layer 3 Copper

Figure 23. CRD35L01-HD Layer 4 Copper

12 DS914RD2

Page 13

CRD35L01

Figure 24. CRD35L01-FHD Top Side Component

Placement

Figure 29. CRD35L01-FHD Layer 4 Copper

Figure 25. CRD35L01-FHD Bottom Side Compo-

nent Placement

Figure 26. CRD35L01-FHD Layer 1 Copper

Figure 27. CRD35L01-FHD Layer 2 Copper

Figure 28. CRD35L01-FHD Layer 3 Copper

DS914RD2 13

Page 14

6. REVISION HISTORY

Contacting Cirrus Logic Support

For all product questions and inquiries, contact a Cirrus Logic Sales Representative.

To find the one nearest to you, go to www.cirrus.com.

IMPORTANT NOTICE

Cirrus Logic, Inc. and its subsidiaries (“Cirrus”) believe that the information contai ned in this document is accurate and reliable. However, the information is subject

to change without noti ce and is p rovided “AS IS” wit hout warran ty of any k ind (expr ess or i mplied). Customers are advis ed to ob tain the latest version of relevant

information to verify, before placing orders, that information being relied on is current and complete. All products are sold subject to the terms and conditions of sale

supplied at the time of order acknowledgment, including those pertaining to warranty, indemnification, and limitation of liability. No responsibility is assumed by Cirrus

for the use of this information, including use of this information as the basis for manufacture or sale of any items, or for infringement of patents or other rights of third

parties. This document is the property of Cirrus and by furnishing this information, Cirrus grants no license, express or implied under any patents, mask work rights,

copyrights, trademarks, trade secrets or other inte llectual property rig hts. Cirrus owns the copyrights associated with the information contained herein and gives consent for copies to be made of the information only for use within your organization with respect to Cirrus integrated circuits or other products of Cirrus. This consent

does not extend to other copying such as copying for general distribution, advertising or promotional purposes, or for creating any work for resale.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL APPLICATIONS”). CIRRUS PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARR ANTED FOR USE

IN PRODUCTS SURGICALLY IMPLANTED INTO THE BODY, AUTOMOTIVE SAFETY OR SECURITY DEVICES, LIFE SUPPORT PRODUCTS OR OTHER CRITICAL APPLICATIONS. INCLUSION OF CIRRUS PRODUCTS IN SUCH APPLICATIONS IS UNDERSTOOD TO BE FULLY AT THE CUSTOM ER’S RISK AND CIRRUS DISCLAIMS AND MAKES NO WARRANTY, EXPRESS, STATUTORY OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MER CHANTABILITY AND

FITNESS FOR PARTICULAR PURPOSE, WITH REGARD TO ANY CIRRUS PRODUCT THAT IS USED IN SUCH A MANNER. IF THE CUSTOMER OR CUSTOMER’S CUSTOMER USES OR PERMITS THE USE OF CIRRUS PRODUCTS IN CRITICAL APPLICATIONS, CUSTOMER AGREES, BY SUCH USE, TO FULLY

INDEMNIFY CIRRUS, ITS OFFICERS, DIRECTORS, EMPLOYEES, DISTRIBUTORS AND OT HER AGE NTS FRO M ANY AND AL L LI ABI L IT Y, I NCL UDING ATTORNEYS’ FEES AND COSTS, THAT MAY RESULT FROM OR ARISE IN CONNECTION WITH THESE USES.

Cirrus Logic, Cirrus, and the Cirrus Logic logo design s ar e tra de m a rks of Ci rru s Lo gi c, Inc. All o ther bra nd and product names in this document may be trademarks

or service marks of their respective owners.

Release Changes

RD1 – Initial Release

RD2 – Updated front page 1% and 10% output power numbers to match DS909A2 datasheet.

– Updated Figure 2 on page 8 to match the updated CRD35L01-SD Rev A1 schematic.

– Updated Figure 3 on page 8 to match the updated CRD35L01-FSD Rev A1 schematic.

– Updated Figure 4 on page 8 to match the updated CRD35L01-HD Rev A1 schematic.

– Updated Figure 5 on page 8 to match the updated CRD35L01-FHD Rev A1 schematic.

– Updated BOM values for C6 & C7 in Table 3 on page 9 to match the updated Rev A1 schematics and

the typical connection diagram in the DS909A2 datasheet. All CRD35L01-SD, -FSD, -HD, and -FHD

boards with an assembly date of 02/15/10 or earlier contain components from the Rev A0 BOM.

CRD35L01

14 DS914RD2

Loading...

Loading...