Page 1

CDB61884

Octal T1/E1/J1 Line Interface Evaluation Board

Features

Socketed CS61884 Octal L ine Interface

Unit

Binding post connectors for power and line

interface connections

Components supplied for all operational

modes E1 75Ω, E1 120 Ω andT1/J1 100 Ω

Socketed termination circuitry for easy

testing

ConnectorforIEEE1149.1JTAGBoundary

Scan

LEDIndicatorsforLossof Signal(LOS) and

power

Supports Hardware, Serial, and Parallel

Host Modes

Easy-to-use evaluation software

On-board socketed reference clock

oscillator

Description

The CS61884 evaluation board is used to demostrate

the functions of a CS61884 Octal Line Interface Unit in

either E1 75 Ω, E1 120 Ω, or T1/J1 100 Ω applications.

The evaluation board can be operated in either Hardware Mode or Host Mode . In Hardware Mode, s witches

and bed stake headers are used to control the line configuration and chann el operations f or all eight channels.

In Host Mode (Serial or Parallel), the evaluation software, switches, and bed stake headers are used to

control the line con figuration and operating mode settings for each channel.

In both Hardware and Host modes, the board may be

configured for E1 75 Ω, E1 120 Ω, or T1/ J 1 100 Ω operating modes. In both modes binding post connectors

provide easy connections between the line interface

connections of the CS61884 and any E1/T1 analyzing

equipment, which ma y be used to evaluate the CS61884

device. Bed stake headers a llow easy access to each

channel’s clock and data I/O digital interface.

Eight LED indictors display the Loss of Signal (LOS)

conditions for each channel during Hardware and Host

modes. An LED indictor is used on the Interrupt pin to

indicate a change of state.

Preliminary Product Information

P.O. Box 17847, Austin, Texas 78760

(512) 445 7222 FAX: (512) 445 7581

http://www.cirrus.com

ORDERING INFORM ATION

CS61884-IQ -40° to 85° C 144-pin LQFP

CDB61884 Evaluation Board

This document contains information for a new product.

Cirrus Logic reserves the right to modify this product withoutnotice.

CopyrightCirrus Logic, Inc. 2002

(All Rights Reserved)

DS485DB1

MAR ‘02

1

Page 2

TABLE OF CONTENTS

1. CDB61884 EVALUATION BOARD LAYOUT ..........................................................................4

2. BOARD COMPONENT DESCRIPTIONS .................................................................................5

2.1 Power Connections ............................................................................................................5

2.2 Master Clock Selection ......................................................................................................5

2.3 Operating Mode Selection .................................................................................................6

2.4 Line Interface Connections ................................................................................................6

2.5 TXOE Selection .................................................................................................................6

2.6 Clock Edge Selection .........................................................................................................7

2.7 Jitte r Attenuator Select ion ..................................................................................................7

2.8 Loopback Mode Selection ..................................................................................................7

2.9 Line Lengt h Selec tion ........................................................................................................7

2.10 Line Impedanc e Selection ................................................................................................8

2.11 Coder/Motorola/Intel Selection .........................................................................................8

2.12 G.772 Monitoring Address Selection ...............................................................................8

2.13 Mux/Non-Mux/BITS Clock Selection ................................................................................8

2.14 Digital Signal Connections ...............................................................................................9

2.15 LOS Indicators .................................................................................................................9

2.16 JT AG Connec tion .............................................................................................................9

2.17 Host Interface Connection ...............................................................................................9

3. HOST SETUP DESCRIPTION ..................................................................................................9

4. HOST SOFTWARE INTERFACE .............................................................................................9

4.1 Starting the Software .......................................................................................................10

4.2 Software Interface Buttons ...............................................................................................10

4.2.1 Bit Indicator Description ......................................................................................10

4.3 Set All Button Description ................................................................................................10

4.3.1 Clear All Button Description ................................................................................11

4.3.2 Write All Button Description ................................................................................11

4.3.3 Read All Button Description ................................................................................11

4.4 Write Button Description ..................................................................................................11

4.5 Read Button De scription ..................................................................................................11

4.6 Program Exit Function .....................................................................................................11

CDB61884

Contacting Cirrus Logic Support

For a complete listing of Direct Sales, Distributor, and Sales Representative contacts, visit the Cirrus Logic web site at:

http://www.cirrus.com/corporate/contacts/sales.cfm

IMPORTANT NOTICE

"Preliminary" product information describes products that are in production, but for which full characterization data is not yet available. "Advance" product infor-

mation describes products that are in development and subject to development changes. Cirrus Logic, Inc. and its subsidiaries ("Cirrus") believe that the information containedinthis document isaccurate and reliable. However, theinformation issubject to changewithoutnotice and is provided "AS IS" without warranty

of any kind (express or implied). Customers are advised to obtain the latest version of relevant information toverify, before placing orders, that information being

reliedon is current and complete. All products are sold subject totheterms and conditions of sale suppliedat the time of order acknowledgment, including those

pertaining to warranty, patent infringement, and limitation of liability. No responsibility is assumed by Cirrus for the use of this information, including use of this

information as the basis for manufacture or sale of any items, or for infringement of patents or other rightsof thirdparties. Thisdocumentis the property of Cirrus

and by furnishing this information, Cirrus grants no license, express or implied under any patents, mask work rights, copyrights, trademarks, trade secrets or

other intellectual property rights. Cirrus owns the copyrights of the informationcontained herein and gives consent for copies to be madeof the information only

for usewithin your organization with respect to Cirrus integrated circuitsor other parts of Cirrus. This consent does not extendto other copying suchas copying

for general distribution, advertising or promotional purposes, or for creating any work for resale.

An export permit needs to be obtained fromthe competent authorities of the Japanese Government if any of the products or technologies described in thismaterial and controlled under the "Foreign Exchange and Foreign Trade Law" is to be exported or taken out of Japan. An export license and/or quota needs to be

obtained fromthecompetentauthorities of the Chinese Governmentif any of the products or technologies describedinthis material is subject to the PRC Foreign

Trade Law and is to be exported or taken out of the PRC.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF DEATH, PERSONAL INJURY, OR SEVERE

PROPERTY OR ENVIRONMENTAL DAMAGE ("CRITICAL APPLICATIONS"). CIRRUS PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR WARRANTED TO BESUITABLE FOR USE IN LIFE-SUPPORT DEVICESOR SYSTEMS OR OTHER CRITICAL APPLICATIONS. INCLUSIONOFCIRRUSPRODUCTS

IN SUCH APPLICATIONS IS UNDERSTOOD TO BE FULLY AT THE CUSTOMER'S RISK.

Cirrus Logic, Cirrus, and the Cirrus Logic logo designs are trademarks of Cirrus Logic, Inc. All other brand and product names in this document may be trademarks or service marks of their respective owners.

2 DS485DB1

Page 3

5. CS61884 CONFIGURATION SCREENS ............................................................................... 12

5.1 Choose Parallel Port Settings ..........................................................................................12

5.2 Access and Configure the Read / Write Registers .......................................................... 12

5.2.1 Access Configurati on Screens ............................................................................ 12

5.2.2 Select Register to Configure ...............................................................................12

5.3 Lo opbac k /Bits Clock Screen ........................................................................................... 13

5.4 LOS/AIS/DFM/JA Register Screen .................................................................................. 14

5.5 Transmitter Re gister Screen ............................................................................................ 15

5.6 AWG Re gister Screen ..................................................................................................... 16

5.7 G lobal Control Register Screen . ...................................................................................... 17

6. BOARD CONFIGURATIONS .................................................................................................18

6.1 E1 75 Ω Mode Setup ....................................................................................................... 18

6.2 E1 120 Ω Mode Setup .....................................................................................................19

6.3 T1/J1 100 Ω Mode Setup ................................................................................................20

7. EVALUATION HINTS .............................................................................................................21

LIST OF FIGURES

Figure 1. CDB61884 Board Layout................................................................................................. 4

Figure 2 . On-board Logic Power Selection.....................................................................................5

Figure 3 . Master Clock Selections .................................................................................................. 5

Figure 4 . Hardware/Host Mode Selection....................................................................................... 6

Figure 5 . Transmitter Enable Selection...........................................................................................7

Figure 6 . Clock Edge Selection....................................................................................................... 7

Figure 7 . Jitter Attenuator Selection................................................................................................7

Figure 8 . Loopba ck Mode Selection................................................................................................7

Figure 9 . Switch S9 Settings ........................................................................................................... 8

Figure 1 0. Digital Signal Control/Access.........................................................................................9

Figure 11. CDB61884 Software Opening Sc reen ......................................................................... 10

Figure 1 2. Register Bit Box........................................................................................................... 10

Figure 1 3. Set All Button............................................................................................................... 10

Figure 1 4. Clear All Button ............................................................................................................11

Figure 1 5. Write All Button............................................................................................................11

Figure 1 6. Read All Button............................................................................................................ 11

Figure 1 7. Write Button.................................................................................................................11

Figure 1 8. Read Button................................................................................................................. 11

Figure 1 9. Opening Screen for Port and Address Selection Screen.............................................12

Figure 2 0. Loopb ac k/G.703 B its Clock Selection Screen ............................................................. 13

Figure 2 1. LOS/AIS/DFM/JAERR Status/Enable Selection Screen.............................................14

Figure 2 2. Transmitter Register Screen........................................................................................15

Figure 2 3. AWG Registers Screen................................................................................................16

Figure 2 4. Global Control Screen..................................................................................................17

CDB61884

LIST OF TABLES

Table 1 . External Impedanc e Res istor Values ...................................................................................... 6

Table 2. ProtectionResistor Selection .................................................................................................6

Table 3. Switch Settings for Host Mode ................................................................................................9

Table4.E175Ω Operational Mode Switch/Jumper Position .............................................................18

Table5.E1120Ω Operational Mode Switch/Jumper Position ........................................................... 19

Table 6. T1/J1 100 Ω Operational Mode Switch/Jum per Position....................................................... 20

DS485DB1 3

Page 4

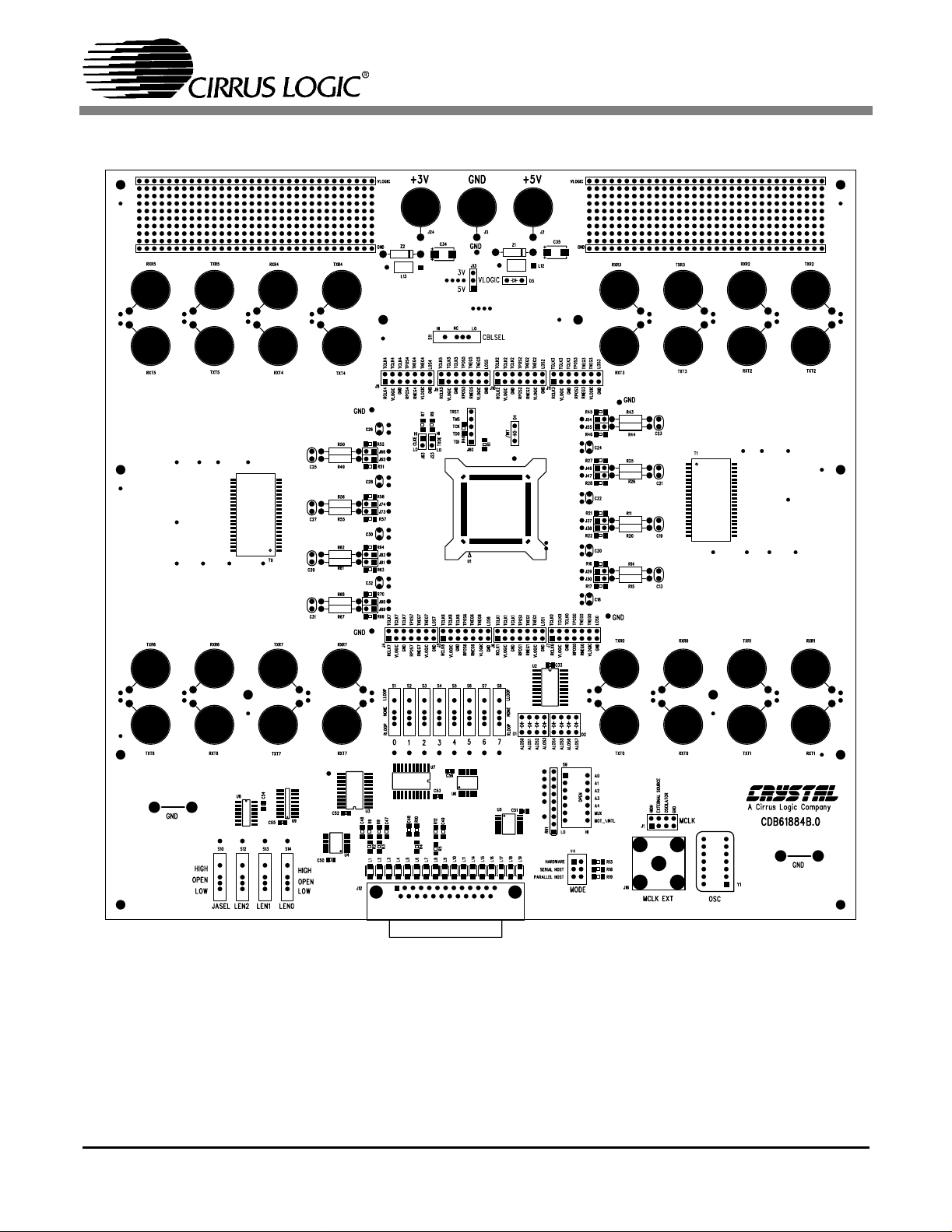

1. CDB61884 EVALUATION BOARD LAYOUT

CDB61884

Figure 1. CDB61884 Board Layout

4 DS485DB1

Page 5

2. BOARD COMPONENT DESCRIPTIONS

CDB61884

2.1 Power Connections

Power for the evaluation board is supplied by an

external +3.3 V DC power supply. A +5 V DC

power supply can also be connected to the on-board

control logic. The LED labeled “D3” will illuminate when power is supplied to the on-board control logic.

– Connectthe +3.3VDC power supply tothe+3V

binding post and the +5 VDC power supply to

the +5 V binding post if 5 Volt logic is required

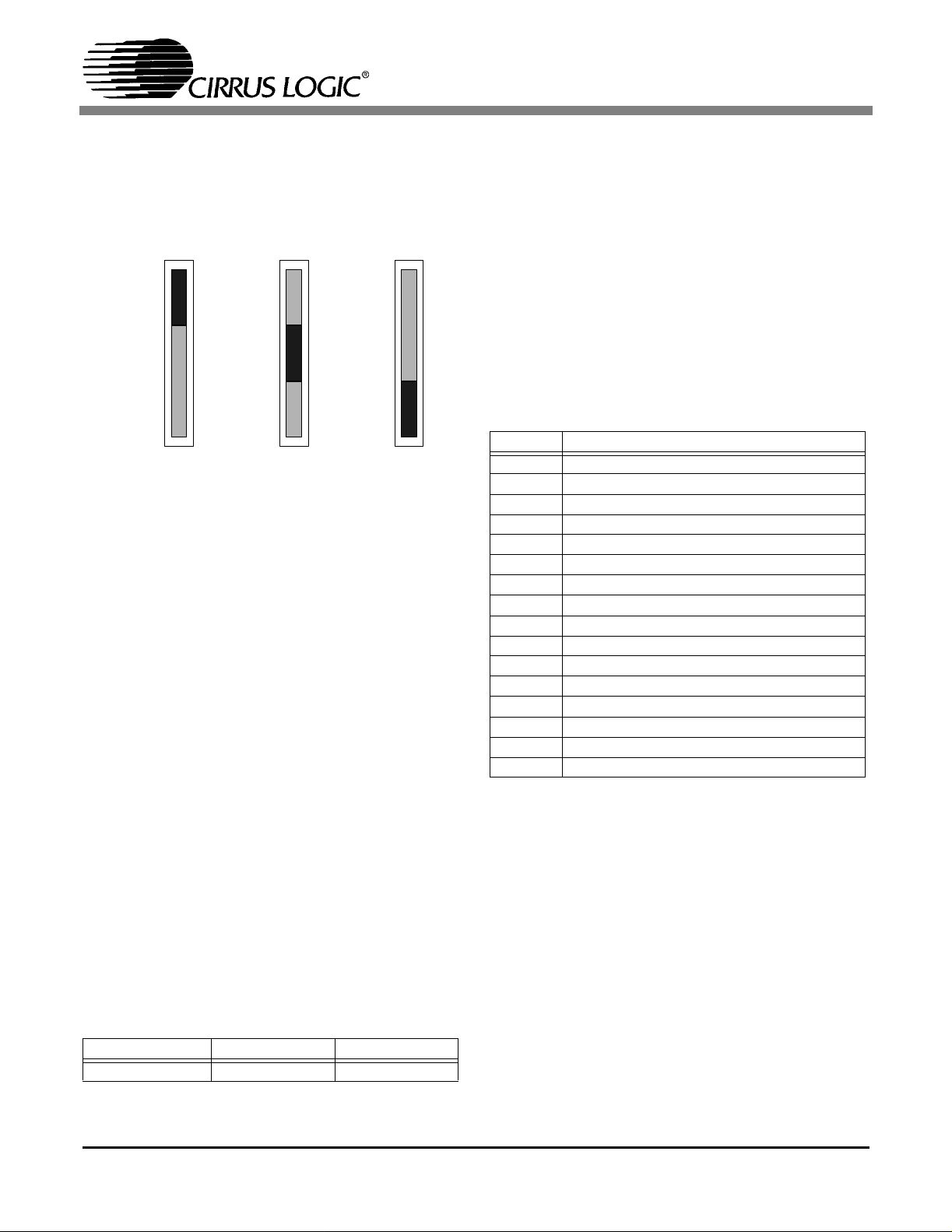

– Jumper J13 shown in Figure 2 allows all the

external logic on the evaluation board to be

connected to either +3 V or +5 V binding post.

J13

3V

VLOGIC

5V

On-board logic connected

to +3 V binding post

2.2 Master Clock Selection

In both hardware and host modes, the MCLK pin is

configured by placing a short block on one of the

positions of bed stake header J1. Figure 3 shows

the different positions of the J1 bed stake header.

HIGH

EXTERNAL SOURCE

OSCILLATOR

GND

J1

Data Recovery Mode

MCLK

HIGH

J1

On-board Oscillator

OSCILLATOR

EXTERNAL SOURCEEXTERNAL SOURCE

GND

MCLK

J13

3V

VLOGIC

5V

On-board logic connected

to +5 V binding post

Figure 2. On-board Logic Power Selection

– To measure the current consumption of only

the CS61884 device,place a shortblock on

Jumper J13 to connect the Vlogic power

supplies to the +5 V binding post. This will

isolate the CS61884 device from all the onboard logic, to allow the current measurement

to be made at the +3 V binding post.

HIGH

J1

External Clock Source

OSCILLATOR

EXTERNAL SOURCE

GND

MCLK

HIGH

J1

Receivers Powered Down

OSCILLATOR

GND

MCLK

Figure 3. Master Clock Selections

– A 2.048 MHz clock oscillator is provided on the

evaluation board for use as the on-board clock

source for a ll E1 modes.

– A 1.544 MHz clock oscillator is also provided

with the e valuation board for use as the onboard clock source for the T1/J1 operation

modes.

– A BNC connector (labeled J16) provides the

connection for an external clock source.

DS485DB1 5

Page 6

CDB61884

2.3 Operating Mode Selection

The operating mode for the CS61884 can be selected by setting switch S15 to one of the positions

shown in Figure 4.

S15

MODE

Selects Serial

Host Mode

S15

Hardware

Serial Host

Parallel Host

Selects Parallel

Host Mode

Hardware

Serial Host

Parallel Host

Hardware Mode

S15

Hardware

Serial Host

Parallel Host

MODE MODE

Selects

Figure 4. Hardware/Host Mode Selection

2.4 Line Interface Connections

In both hardware and host modes, the receive line

signals (RTIP/RRING) are connected to the binding post labeled RXT 0-7 and RXR 0-7. The line

signals from the binding posts are coupled to the

device throughtwo octal transformers (T1andT9).

The receivers of the device use external resistors to

match the line impedance. These resistors are socketed for ease in changing the line impedance,forinternal or external line impedance matching. During

internal line impedance matching mode, the resistor values are the same (15 Ω) for all modes of operation: E1 75 Ω, E1 120 Ω or T1/J1 100 Ω. During

external line impedance matching mode the receiver resistors need to be change to the values shown

in Table 1.

Table 1. ExternalImpedance ResistorValues

T1/J1 100 Ω E1 75 Ω E1 120 Ω

12.5Ω 9.31Ω 15Ω

The jumpers listed in Table 2 areusedtoplaceor

bypass 1 KΩ protection resistors in series with the

receive line signals (RTIP/RRING). These resistors are used for receiver protection while in external line impedance matching mode and should not

be used during internal line impedance matching

mode. To place the 1 KΩ resistors in series with the

receive line signals, remove the short blocks from

each of the jumpers described in Table 2. To bypass the 1 KΩ resistors, place a short block on each

jumper shown in Table 2.

Table 2. Protection Resistor Selection

Jumper Description

J29 Channel 0 RRING signal

J30 Channel 0 RTIP Sig nal

J37 Channel 1 RTIP Sig nal

J38 Channel 1 RRING Signal

J46 Channel 2 RRING Signal

J47 Channel 2 RTIP Sig nal

J54 Channel 3 RTIP Sig nal

J55 Channel 3 RRING Signal

J65 Channel 4 RRING Signal

J66 Channel 4 RTIP Sig nal

J73 Channel 5 RTIP Sig nal

J74 Channel 5 RRING Signal

J81 Channel 6 RRING Signal

J82 Channel 6 RTIP Sig nal

J89 Channel 7 RTIP Sig nal

J90 Channel 7 RRING Signal

The transmit line signals (TTIP/TRING) from the

device are coupled to the line binding post (TXT 07 and TXR 0-7) through two octal transformers (T1

and T 9). External protection circuitry such as diodes or chokes are recommended for protection.

For further information on line protection refer to

Application Note AN34, “Secondary Line Protection for T1 and E1 Line Cards” (AN34REV1 SEP

'94).

2.5 TXOE Selection

Jumper J23 is used to enable or High-Z all eight

transmitters in both hardware and host mode. A

shorting block on Jumper J23 places all the trans-

6 DS485DB1

Page 7

CDB61884

mitters in a high impedance state. Removing the

shorting block, enables the transmitters. See

HI

TXOE

LO

J23

Enable all eight

transmitters

eight transmitters

HI

TXOE

LO

J23

Hi-Z all

Figure 5. Transmitter Enable Selection

Figure 5.

2.6 Clock Edge Selection

In clock/data recovery mode, jumper J93 selects

the edge of RCLK and SCLK on which the

RPOS/RDATA, RNEG, and SDO data signals are

valid. When in data recovery mode, jumper J93 selects the output polarity of RPOS/RNEG.The function of J93 applies to both the hardware and host

mode. Figure 6 shows the settings for jumper J93

and the effect in both clock/data recovery and data

recovery only mode.

HI

CKLE

LO

Clock/Data Recovery -

RPOS/RNEG= falling

edge RCLK SDO =

rising edge SCLK

Data Recovery -

RPOS/RNEG

J93

polarity active high

In host mode, switch S10 has no effect on the

CS61884 device and should be set to the open

(middle) position.

S10

HIGH

OPEN

LOW

JASEL JASEL JASEL

Hardwa reMode

-JAplacedin

transmit path

OPEN

S10

HIGH

LOW

Hardwa reMode

- JA Disabled

S10

HIGH

OPEN

LOW

Hardwa reMode

-JAplacedin

receive path

Figure 7. Jitter Attenuator Selection

2.8 Loopback Mode Selection

In hardware mode, the Loopback modes are configured with switches S1 through S8 (0-7). Figure 8

shows the three different settings for all eight loop

back switches.

In host mode, switches S1 through S8 must be set

to the NONE (middle) position to allow host interface control.

S1 - S8 S1 - S8 S1 - S8

LloopnoneRloop

LloopnoneRloop

LloopnoneRloop

HI

CKLE

LO

Figure 6. Clock Edge Selection

2.7 Jitter Attenuator Selection

In hardware mode, switch S10 (JASEL) controls

the position of the jitter attenuator for all eight

channels. The corner frequency and FIFO length

can not be changed in hardware mode. Figure 7

Clock/Data Recovery -

RPOS/RNEG= rising

edge RCLK SDO =

falling edge SCLK

Data Recovery -

RPOS/RNEG

polarity active low

J93

0-7

Hardware Mode -

Selects Remote

Loopback

0-7

Hardware Mode -

Selects no

Loopback

0-7

Hardware Mode -

Selects local

Loopback

Figure 8. Loopback Mode Selection

2.9 Line Length Selection

In hardware mode, the transmit pulse shapes for E1

75 Ω, E1 120 Ω and T1(J1) 100 Ωare selected with

switches S12 through S14 (LEN 2-0). Refer to the

CS61884 Data Sheet for the correct settings.

shows the settings for switch S10.

DS485DB1 7

Page 8

CDB61884

In host mode, switches S12 through S14 (LEN2-0)

must be set to the open (middle) position to allow

host processor control.

2.10 Line Impedance Selection

In hardware mode, switch S11 (CBLSEL), in combination with the LEN 2-0 switches are used to set

the internal or external line impedance for all eight

channels. Refer to the CS61884 Data Sheet for the

CBLSEL settings.

In host mode, switch S11 has no effect on the

CS61884 device and should be set to the NC (middle) position.

2.11 Coder/Motorola/Intel Selection

In hardware mode, switch 1 (MOT/INTL) inside

switch block S9 (S9 #1) is used to enable AMI or

HDB3/B8ZS line coding. Setting switch S9 #1 to

the open (HIGH) position enables AMI coding and

theclosed (low) position enables HDB3/B8ZS coding.

Inhostmode,switchS9#1isusedtoselecteither

Motorola or Intel parallel host mode. When set to

the open (HIGH) position Intel mode is selected

and the closed (LOW) position enables Motorola

mode. Figure 9 shows the settings for switch S9 #1

in hardware and parallel host mode.

2.12 G.772 Monitoring Address Selection

In hardware mode, the address for the G.772 NonIntrusive monitoringfeature is selected by switches

3 through 7 (A4-A0) inside switch block S9. When

switches 3 through 7 inside switch block S9 are all

set to the closed “LOW” position, the G.772 NonIntrusive monitoring function is disabled. Refer to

the CS61884 Data Sheet for more address settings.

In host mode, switches 3 through 7 inside switch

block S9 must be set to the open (high) position so

that the host interface can have control over the address signals during parallel host modes.

2.13 Mux/Non-Mux/BITS Clock Selection

In hardware mode, switch 2 (MUX) inside switch

block S9 enables or disables the Channel #0 G.703

BITS Clock function. Placing switch S9 #2 in the

open “HIGH” position enables Channel #0 G.703

BITS Clock function and the closed “LOW” position disa bles this function.

In host mode, switch S9 #2 (MUX) is used to select

multiplex or non-multiplex. Placing switch S9 #2

S9

A0

A1

A2

A3

A4

OPEN

MUX

1234567

LO

MOT_\INTL

HI

Hardware Mode - Enables

AMI coding & enables

Channel 0 G.703 Bits

Clock function

8 DS485DB1

S9

A0

A1

A2

A3

A4

OPEN

MUX

1234567

LO

MOT_\INTL

HI

Hardware Mode - Enables

HDB3/B8ZS coding &

disables Channel 0 G.703 Bits

Clock function

Figure 9. Switch S9 Settings

S9

A0

A1

A2

A3

A4

OPEN

MUX

1234567

LO

MOT_\INTL

HI

Parallel Host Mode -

Enables Motorola Non-

Multiplex parallel host mode

Page 9

CDB61884

in the open “HIGH” position selects multiplex and

the closed “LOW” position selects Non-multiplex

2.14 Digital Signal Connections

There are eight fourteen pin bed stake headers (labeled J4 through J11) that provide access to the

digital signals used to interface with back-end devices (framers, mappers, ASIC, etc.) and all eight

LOS signals, in both hardware and host mode.

Figure 10 shows the layout for one of the eight 14-

pin bed stake headers used to access the back-end

digital signals, LOS signals and the different settings for the TCLK/TNEG pins.

Bi-polar Mode

TCLK #

TCLK #

J1

Vlogic

RCLK #

TPOS #

TCLK #

TNEG #

TNEG #

LOS #

GND

RPOS #

GND

Vlogic

RNEG #

Uni-Polar Mode Active

TCLK #

TPOS #

TCLK #

TCLK #

TNEG #

J1

GND

Vlogic

RCLK #

RPOS #

RNEG #

TNEG #

Vlogic

pins.TheALOS 0-7 LEDs will illuminate when the

corresponding receiver has detected a loss of signal

condition. Refer to the CS61884 Data Sheet for

LOS conditions.

2.16 JTAG Connection

A 5-pin bed stake header (J60) is provided to allow

easy access to the IEEE 1149.1 JTAG Boundary

Scan signals from the device.

2.17 Host Interface Connection

Connector J12 is used to connect the CS61884

evaluation board to the host computer, through a

standard 25 pin male to female parallel port cable.

No external µController board is required for host

interface connection. This connector is used for

both serial and parallel interface.

LOS #

3. HOST SETUP DESCRIPTION

Place the switches shown in Table 3 to the stated

configuration before setting the Mode switch (S15)

to Serial or Parallel host mode. Refer to the

GND

Figure 4 on page 6 for switch S15 settings.

Table 3. Switch Settings for Host Mode

TAOS active when

MCLK present

RZ mode active when

MCLK absent

TCLK #

TPOS #

TCLK #

TCLK #

TNEG #

TNEG #

LOS #

Transmitters High-Z

TCLK #

TPOS #

TCLK #

TCLK #

TNEG #

TNEG #

J1

J1

GND

Vlogic

RCLK #

RPOS #

GND

Vlogic

RNEG #

GND

Vlogic

RCLK #

Vlogic

RPOS #

RNEG #

Figure 10. Digital Signal Control/Access

2.15 LOS Indicators

The two 4-LED packs D1 and D2 (labeled ALOS

0-7) represent the LOS signal status for LOS 0-7

Switch Position

S1 through S8 NONE ( middle)

S9 # 3 through # 7 OPEN (low)

S10 OPEN (middle)

LOS #

S11 NC (middle)

S12 through S14 OPEN (middle)

– Switches #1 and #2 inside of switch block S9

are used in parallel host mode to select

Motorola, Intel, multiplex or Non-multiplex

GND

modes. Switch S9 #1 and #2 are not used in

Serial host mode.

4. HOST SOFTWARE INTERFACE

The software provided with the CDB61884 evaluation board is used to control and monitor the

CS61884 device. The program is designed to automatically read back each bit after each write. If the

bit is read back incorrectly an error will occur. The

DS485DB1 9

Page 10

Figure 11. CDB61884 Software Opening Screen

CDB61884

following registers do not have the automatic read

back function:

–AWGPhaseAddress

– AWG Phase Data,

– Software Reset registers.

4.1 Starting the Software

There is no installation procedure associated with

the CS61884 software, simply click on the appropriate CS61884 software icon (95/98 or NT) on the

CD in the CDB61884 kit.

Note: The software can be used with Windows®95

98®,NT®or 2000®.

®

,

Figure 11 shows the opening screen that appears

after you have launched the software.

4.2 Software Interface Buttons

The following subsections explain the functions of

buttons that are common to the register configuration screens in the CS61884 software.

4.2.1 Bit Indicator Description

The Register Bit checkbox shown in Figure 12

shows one bit, each register consists of eight bits (0

through 7). The grayed-out bits in some registers

are bits that can not be accessed. Figure 12 shows a

bit with a check mark and without a check mark. A

check represents a “1” and no check mark equals a

“0”.

Figure 12. Register Bit Box

4.3 Set All Button Description

The Set All button shown in Figure 13 is used to set

all the bits in the c orresponding register to 1s. This

button is placed to the left of each register that has

write access.

Figure 13. Set All Button

10 DS485DB1

Page 11

4.3.1 Clear All Button Description

CDB61884

The CLR All Buttonshown Figure 14 is us ed to set

all the bits in the corresponding register to 0s. This

button is placed to the left of each register that has

write access.

Figure 14. Clear All Button

4.3.2 Write All Button Description

The Write All button shown in Figure 15 writes

every bit of every register on the current register

screen. This button is located in the bottom right

corner of each register screen.

Figure 15. Write All Button

Figure 16. Read All Button

4.4 Write Button Description

The Writebutton shown in Figure Figure 17 writes

the bits of the corresponding register. This button is

located to the right of every register that allows

write access.

Figure 17. Write Button

4.5 Read Button Description

The Read button shown in Figure 18 reads the bits

of the corresponding register. This button is located

to the right of every register.

4.3.3 Read All Button Description

The Read All button shown in Figure 16 reads every bit of every register on the current register

screen. This button is located in the bottom left corner of each register screen.

Figure 18. Read Button

4.6 Program Exit Function

To exit any of the register screens simple press the

X in the top right hand corner of each screen. This

DS485DB1 11

Page 12

5. CS61884 CONFIGURATION SCREENS

CDB61884

5.1 Choose Parallel Port Settings

The opening screen shown before in Figure 11 and

now in Figure 19 is used for the following configuration activities:

– Select the parallel port mode of operation

– Select the parallel port address

Click the appropriate radio button to choose the operational modes you wish to use.

Important N otes:

1. Ifthemode of operation doesno t match the

mode switches on the evaluation board, an

error will occur.

2. If the parallel port address does not match

the ad dres s of the control parallel port,

access to the register bits will not be

permitted.

5.2 Access and Configure the Read / Write Registers

You also use the opening screen to access the

tabbed configuration screens for the Read / Write

Registers.

5.2.1 Access Configuration Screens

Click on the Read/ Write Registers button on the

opening screen to start configuring these registers.

5.2.2 Select Register to Configure

When the next screen appears, select the desired

register screen by clicking on one of the TABs labeled Loopback/Bits Clk, LOS/AIS/DFM,

XMIT, AWG, or GCR at the top of the

Read/Write Register screen.

Figure 19. Opening Screen for Port and Address Selection

12 DS485DB1

Page 13

CDB61884

5.3 Loopback /Bits Clock Screen

The Loopback /Bits Clock Register tabbed screen shown in Figure 20 allows access to the following registers:

–Remoteloopback

–Analogloopback

– DigitalLoopback

– G.703 Bits Clock

Figure 20. Loopback/G.703 Bits Clock Selection Screen

DS485DB1 13

Page 14

CDB61884

5.4 LOS/AIS/DFM/JA Register Screen

The LOS/AIS/DFM/JA Register tabbed screen shown in Figure 21 allows access to the following registers:

–LOSStatus

– LOS Interrupt Enable

– LOS Interrupt Status

– LOS/AIS Mode Enable

–DFMStatus

– DFM interrupt Status

– DFM Interrupt Enable

– AIS Status

– AIS Interrupt Enable

– AIS Interrupt Status

– JA Error Interrupt Enable

– JA Error Interrupt Status

.

Figure 21. LOS/AIS/DFM/JA ERR Status/Enable Selection Screen

14 DS485DB1

Page 15

CDB61884

5.5 Transmitter Register Screen

The Transmitter Register screen shown in Figure 22 consists of the following registers:

– Automatic TAOS

– TAOS Enable

– Performance Monitor

–LineLengthChannelID

– Line Length D ata

– Output Disable.

Note:Some indictor boxes (bits) in the Performance Monitor, Line Length Channel ID, and Line Length Data

registers are grayed out, this means that these bits can not be acc es s ed.

Figure 22. Transmitter Register Screen

DS485DB1 15

Page 16

CDB61884

5.6 AWG Register Screen

The AWG Register screen shown in Figure 23 allows access to the following AWG registers:

– AWG Broadcast

– AWG Enable

– AWG Overflow Interrupt Enable

– AWG Overflow Interrupt Status

– AWG Phase Address

– AWG Phase Data.

The AWG Phase Address Register is broken up into two easy-to-use data input boxes: the Chan Address

(i.e., channel address) and the Sample Address. For example, to access the AWG function for channel 5,

write 05 into the Chan Address input box. This is the same for every channel. The Chan Address, Sam-

ple Address,andPhase Data input boxes use the values discussed in the AWG section of the CS61884

Data Sheet.

Figure 23. AWG Registers Screen

16 DS485DB1

Page 17

CDB61884

5.7 Global Control Register Screen

Figure 24 shows the Global Control Register (GCR) register screen, The GCR register screen consists of

the following registers:

– Software reset

– ID registers.

Each bit in the Global Control Register can be access by writing directly to the bit in the Global Control

Register on the top of this screen or by changing the radio buttons in one of the following windows:

– Jitter Attenuator

– JA FIFO Length

–AWGAutoIncrement

–Raisen

– Coden

– Jitter Corner Freq.

The variables listed above change the corresponding bit in the Global Control Register. The Software Reset Register is a write only register and will clear after the write. The ID Register is a read only register.

Figure 24. Global Control Screen

DS485DB1 17

Page 18

CDB61884

6. BOARD CONFIGURATIONS

6.1 E1 75 Ω Mode Setup

Table 4 shows the position of the different switches and jumpers used to set up the CDB61884 evaluation

board to operate in E1 75 Ω Hardware, Serial Host and Parallel Host operational modes. Before selecting

Host mode, the switches in Table 4 in bold should be set to the position stated.

Table 4. E1 75 Ω Operational Mode Switch/Jumper Position

Switches/Jumpers Hardware Serial Host (Note 3) Parallel Host (Note 3)

S15 (MODE) HARDWARE SERIAL HOST PARALLEL HO ST

S1 (0) LOOP FUNCTION NONE NONE

S2 (1) LOOP FUNCTION NONE NONE

S3 (2) LOOP FUNCTION NONE NONE

S4 (3) LOOP FUNCTION NONE NONE

S5 (4) LOOP FUNCTION NONE NONE

S6 (5) LOOP FUNCTION NONE NONE

S7 (6) LOOP FUNCTION NONE NONE

S8 (7) LOOP FUNCTION NONE NONE

S9 #1 (MOT_\INTL) HIGH HIGH MOTOROLA/INTEL

S9 #2 (MUX) LOW (Note 4) HIGH MUX/NON-MUX

S9 # 3 (A4) LOW (Note 5) HIGH HIGH

S9 # 4 (A3) LOW (Note 5) HIGH HIGH

S9 # 5 (A2) LOW (Note 5) HIGH HIGH

S9 # 6 (A1) LOW (Note 5) HIGH HIGH

S9 # 7 (A0) LOW (Note 5) HIGH HIGH

S10 (JASEL) ANY POSITION OPEN OPEN

S11 (CBLSEL) HIGH (Note 6) NC NC

S12 (LEN 2) LOW OPEN OPEN

S13 (LEN 1) LOW OPEN OPEN

S14 (LEN 0) LOW OPEN OPEN

J13(VLOGIC)3V3V3V

J1 (MCLK) OSCILLATOR OSCILLATOR OSCILLATOR

J93 (CLKE) OPEN OPEN OPEN

J23 (TXOE) OPEN OPEN OPEN

3. Connect a standard 25-pin male to female parallel port cable to connector J12 and the control PC.

4. Set “HIGH” to enable BITS Clock Recovery function for only Channel #0 in Hardware Mode.

5. Other settings may be used to enter G.772 Non-Intrusive Monitoring in Hardware Mode. Refer to the

CS61884 Data Sheet for other settings.

6. Set “LOW” to disable receiver Internal line impedance matching function. The external resistors for all

eight rece ivers must be changed to 9.31 Ω to properly match the i nput line impedance.

18 DS485DB1

Page 19

CDB61884

6.2 E1 120 Ω Mode Setup

Table 5 shows the position of the different switches and jumpers used to set up the CDB61884 evaluation

board to operate in E1 120 Ω Hardware, Serial Host and Parallel Host operational modes. Before selecting

host mode, the switches in Table 5 in bold should be set to the position stated.

Table 5. E1 120 Ω Operational Mode Switch/Jumper Position

Switches/Jumpers Hardware Serial Host (Note 3) Parallel Host (Note 3)

S15 (MODE) HARDWARE SERIAL HOST PARALLEL HO ST

S1 (0) LOOP FUNCTION NONE NONE

S2 (1) LOOP FUNCTION NONE NONE

S3 (2) LOOP FUNCTION NONE NONE

S4 (3) LOOP FUNCTION NONE NONE

S5 (4) LOOP FUNCTION NONE NONE

S6 (5) LOOP FUNCTION NONE NONE

S7 (6) LOOP FUNCTION NONE NONE

S8 (7) LOOP FUNCTION NONE NONE

S9 #1 (MOT_\INTL) HIGH OPEN MOTOROLA/INTEL

S9 #2 (MUX) LOW (Note 4) OPEN MUX/NON-MUX

S9 # 3 (A4) LOW (Note 5) OPEN OPEN

S9 # 4 (A3) LOW (Note 5) OPEN OPEN

S9 # 5 (A2) LOW (Note 5) OPEN OPEN

S9 # 6 (A1) LOW (Note 5) OPEN OPEN

S9 # 7 (A0) LOW (Note 5) OPEN OPEN

S10 (JASEL) ANY POSITION OPEN OPEN

S11 (CBLSEL) NC(Note 7) NC NC

S12 (LEN 2) LOW OPEN OPEN

S13 (LEN 1) LOW OPEN OPEN

S14 (LEN 0) LOW OPEN OPEN

J13(VLOGIC)3V3V3V

J1 (MCLK) OSCILLATOR OSCILLATOR OSCILLATOR

J93 (CLKE) OPEN OPEN OPEN

J23 (TXOE) OPEN OPEN OPEN

7. Set to “NC” to di sab le receiver Internal line impedance matching fun ction . The external resistors for all

eight rece ivers must be changed to 15 Ω to properly match the input line im pedance.

DS485DB1 19

Page 20

CDB61884

6.3 T1/J1 100 Ω Mode Setup

Table 6 shows the position of the different switches and jumpers used to set up the CDB61884 evaluation

board to operate in T1/J1 100 Ω Hardware, Serial Host and Parallel Host operational modes. Before selecting host mode the switches in Table 6 in bold should be set to the position stated.

Table 6. T1/J1 100 Ω Operational Mode Switch/Jumper Position

Switches/Jumpers Hardware Serial Host (Note 3) Parallel Host (Note 3)

S15 (MODE) HARDWARE SERIAL HOST PARALLEL HO ST

S1 (0) LOOP FUNCTION NONE NONE

S2 (1) LOOP FUNCTION NONE NONE

S3 (2) LOOP FUNCTION NONE NONE

S4 (3) LOOP FUNCTION NONE NONE

S5 (4) LOOP FUNCTION NONE NONE

S6 (5) LOOP FUNCTION NONE NONE

S7 (6) LOOP FUNCTION NONE NONE

S8 (7) LOOP FUNCTION NONE NONE

S9 #1 (MOT_\INTL) OPEN (HIGH) HIGH MOTOROLA/INTEL

S9 #2 (MUX) LOW (Note 4) HIGH MUX/NON-MUX

S9 # 3 (A4) LOW (Note 5) HIGH HIGH

S9 # 4 (A3) LOW (Note 5) HIGH HIGH

S9 # 5 (A2) LOW (Note 5) HIGH HIGH

S9 # 6 (A1) LOW (Note 5) HIGH HIGH

S9 # 7 (A0) LOW (Note 5) HIGH HIGH

S10 (JASEL) ANY POSITION OPEN OPEN

S11 (CBLSE L) NC or HIGH (Note 8) NC NC

S12(LEN2) LOW(Note9) OPEN OPEN

S13 (LEN 1) HIGH (Note 9) OPEN OPEN

S14 (LEN 0) HIGH (Note 9) OPEN OPEN

J13(VLOGIC)3V3V3V

J1 (MCLK) OSCILLATOR OSCILLATOR OSCILLATOR

J93 (CLKE) OPEN OPEN OPEN

J23 (TXOE) OPEN OPEN OPEN

8. Set “LOW” to disable receiver Internal line impedance matching function. The external resistors for all

eight rece ivers must be changed to 12.5 Ω to properly match the i nput line impedance.

9. Selects T1/J110 0 Ω 0ft-133ft line length settings. These pins can be changed to select other T1/J1100

Ω l ine length settings. Refer to the CS61884 Data Sheet for other settings.

20 DS485DB1

Page 21

CDB61884

7. EVALUATION HINTS

– Pin #1 of the socket is indicatedby an arrow with U1 below it.

– A short in the desired position must be placed on Jumper J13 to connect the CS61884 to one of the

power supply binding post. LED D3 will illuminate when jumper J13 is connected to a power supply.

– Before selecting any host mode place the CBLSEL, LOOP, ADDRESS, LEN and JASEL switches in

the open or none position.

– When using the CS61884 device in internal match impedance mode, be sure that the 1 KΩ resistors

are not in series with the receivers.

DS485DB1 21

Page 22

Loading...

Loading...