Page 1

CDB5529

CDB5529 Evaluation Board and Software

Features

l

RS-232 Serial Communication with PC

l

On-board 80C51 Microcontroller

l

On-board Voltage Reference

l

Lab Windows/CVITM Evaluation

Software

- Register Setup & Chip Control

- FFT Analysis

- Time Domain Analysis

- Noise Histogram Analysis

l

Integrated RS-232 Test Mode

General Description

The CDB5529 is an inexpensive tool designed to evaluate the performance of the CS5529 16-bit Analog-toDigital Converter (ADC).

The evaluation board includes an LT1019 voltage reference, an 80C51 microcontroller, an RS232

driver/receiver, and firmware. The 8051 controls the serial communication between the evaluation board and

the PC via the firmware, thus, enabling quick and easy

access to all of the CS5529’s registers.

The CDB5529 also includes software for Time Domain

Analysis, Histogram Analysis, and Frequency Domain

Analysis.

ORDERING INFORMATION: CDB5529

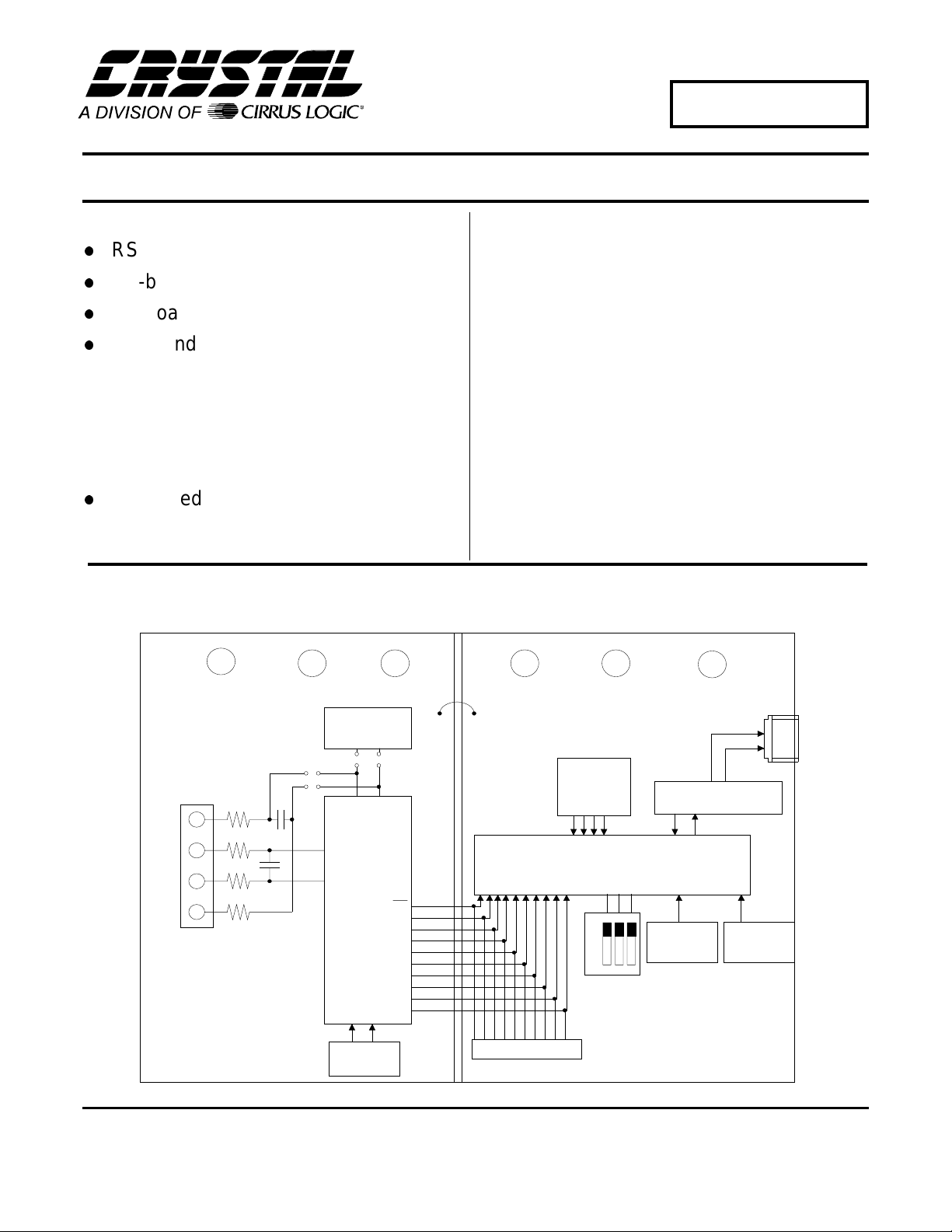

+5/+2.5 ANALOG -2.5 ANALOG AGND DGND +5/3.3 DIGITAL

VOLTAGE

REFERENCE

J1

REF+

AIN+

AIN-

REF-

AIN+

AIN-

CRYSTAL

32768Hz

Cirrus Logic, Inc.

Crystal Semiconductor Products Division

P.O. Box 17847, Austin, Texas 78760

(512) 445 7222 FAX: (512) 445 7581

http://www.crystal.com

CS5529

CS

SDI

SDO

SCLK

D3

D2

D1

D0

A1

A0

XINXOUT

LEDs

80C51

MICROCONTROLLER

123

ON

OFF

TEST

SWITCHES

HDR6

Copyright Cirrus Logic, I nc. 1997

(All Rights Reserv ed)

+5 DIGITAL

RS232

CONNECTOR

RS232

DRIVER/RECEIVER

CRYSTAL

11.0592MHz

RESET

CIRCUITRY

AUG ‘97

DS246DB1

1

Page 2

CDB5529

PART I: HARDWARE

Introduction

The CDB5529 evaluation board provides a quick

means of testing the CS5529 Analog-to-Digital

Converter (ADC). The board interfaces the

TM

CS5529 to an IBM

RS-232 interface while operating from either a sin-

gle +5 V supply or dual ±2.5 volt supplies. To accomplish this, the board comes equipped with an

80C51 microcontroller and a 9-pin RS-232 cable

which physically interfaces the evaluation board to

the PC. Additionally, analysis software provides

easy access to the internal registers of the converter, and provides a means to display the converter’s

time domain, frequency domain, and noise histogram performance. The evaluation board’s software includes debug algorithms to trouble shoot

the evaluation board. Refer to the Trouble Shoot -

ing the Evaluation Board section for more details.

compatible PC via an

The evaluation board provides two voltage reference options, on-board and external. With HDR5’s

jumpers in positions 1 and 4, the LT1019 provides

an absolute voltage level of 2. 5 volts (the LT1019

was chosen for its low drift, typically 5ppm/°C). By

setting HDR5’s jumpers to position 2 and 3, the

user can supply an external voltage reference to

J1’s REF+ and REF- inputs (Application Note 4 on

Crystal Semiconductor’s web site details various

voltage references).

TM

The ADC serial interface is SPI

TM

MICROWIRE

lines (CS

the 80C51 microcontroller via port one. To interface an external microcontroller, these control lines

are also connected to HDR6. However to accomplish this, the evaluation board must be modified in

one of three ways: 1) cut the interface control traces

going to the microcontroller, 2) remove resistors

R1-R8, or 3) remove the microcontroller.

, SDI, SDO, and SCLK) are connected to

compatible. The interface co ntrol

and

Evaluation Board Overview

The board is partitioned into two sections: analog

and digital. The analog section consists of the

CS5529 and a precision voltage reference. The digital section consists of the 80C51 microcontroller,

the hardware test switches, the reset circuitry, and

the RS-232 interface.

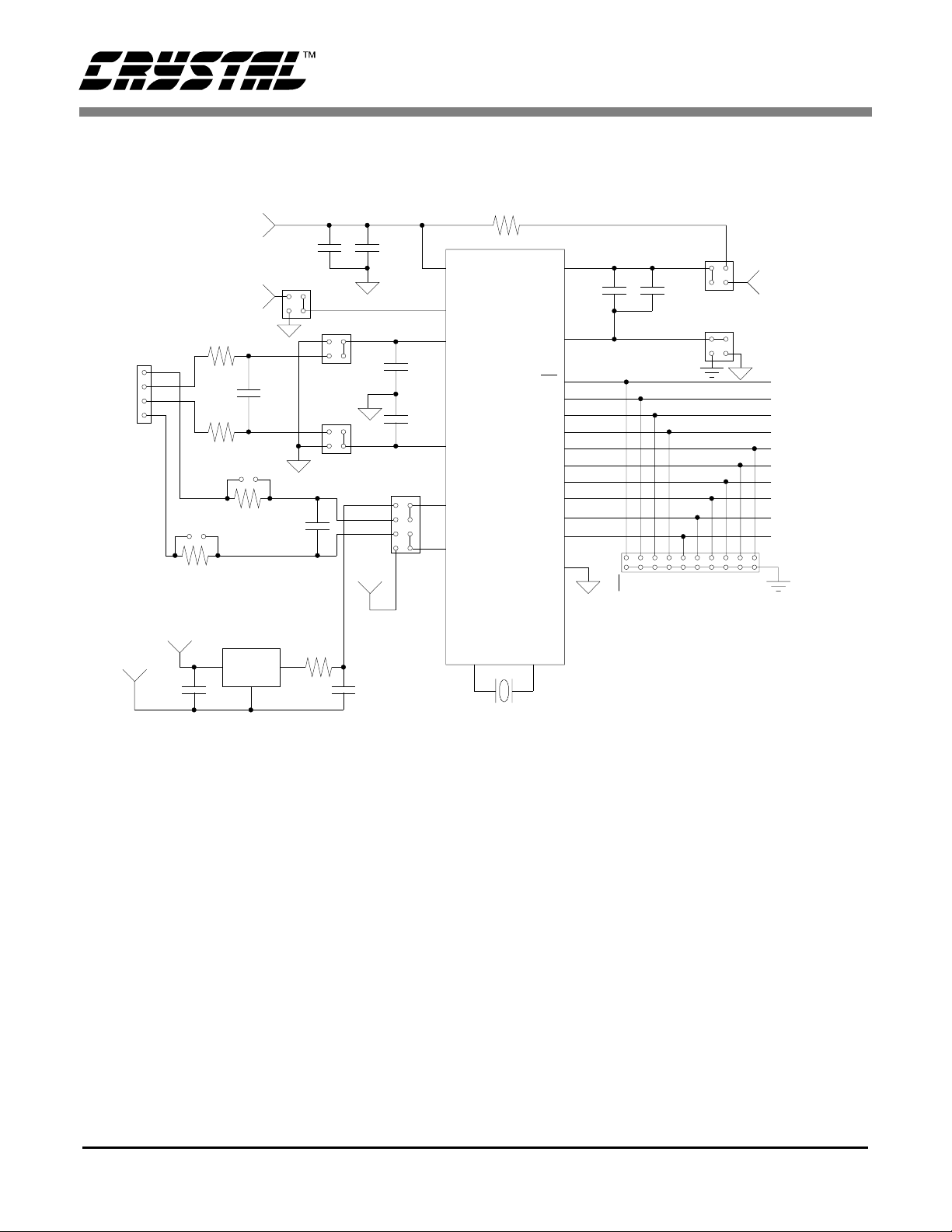

The CS5529 is designed to digitize signals while

operating from a 32.768 KHz crystal. As shown in

Figure 1, a signal can be connected to the converter’s inputs via J1’s AIN+ and AIN- inputs. Note

that a simple RC network filters the input to reduce

broadband noise.

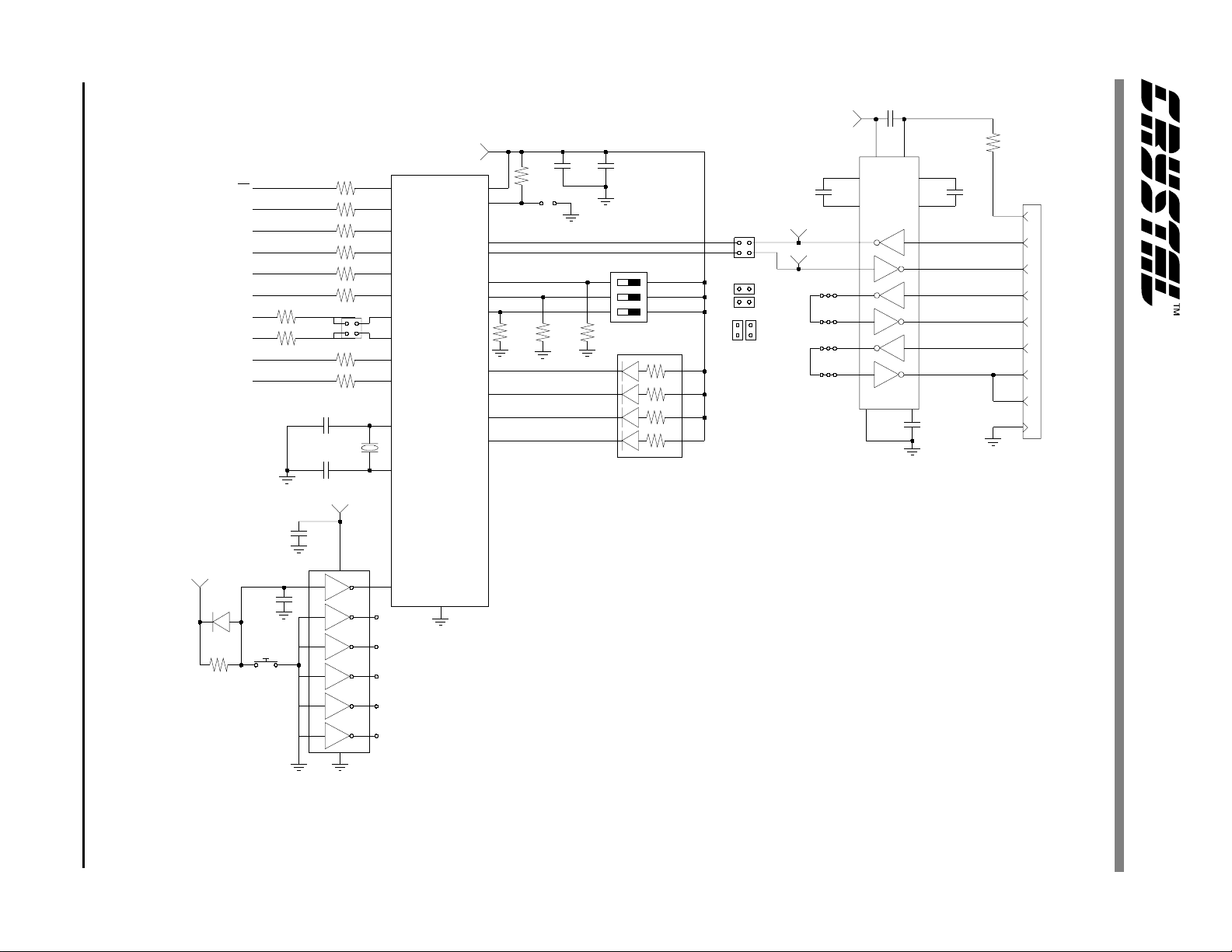

Figure 2 illustrates the schematic of the digital section. It contains the microcontroller, a Motorola

MC145407 interface chip, and test swit ches. The

test switches aid in debugging communication

problems between the CDB5529 and the PC. The

microcontroller derives its clock from an 11.0592

MHz crystal. From this, the controller is configured

to communicate via RS-232 at 9600 baud, no parity, 8-bit data, and 1 stop bit.

2 DS246DB1

Page 3

REF+

AIN+

AIN-

REF-

+5V / 2.5V Analog

-2.5V Analog

J1

JP4

R16

Ω

301

R18

301

R17

301

Ω

Ω

JP3

R15

301

0.1µF

HDR8

C2

4700pF

Ω

4700pF

C16

C1

HDR1

7

HDR2

1, AGND

2, AIN+

1, AIN2, AGND

1,LT1019

2,REF+

3,REF4,VA-

VA-

C30

10µF

0.68µF

HDR5

C3

0.68µF

C4

20

19

2

1

3

4

VA+

VAAIN+

AIN-

REF+

REF-

R21

Ω

10

U4

CS5529

VD+

DGND

CS

SDI

SDO

SCLK

D3

D2

D1

D0

A1

A0

DGND

13

C31

10µF

8

15

14

9

18

17

16

7

6

5

12

CS

CDB5529

HDR3

HDR9

D0D1D2

D3

+5V / 3.3V Digital

To

Figure 2

HDR6

C11

0.1µF

A1

A0

SDI

SDO

SCLK

+5V / 2.5V Analog

VA-

C21

0.1µF

U3

LT1019

2.5V

R22

50

Ω

C15

0.1µF

XOUT

10

Y2

32768Hz

Figure 1. Analog Schematic Section

XIN

11

DS246DB1 3

Page 4

4 DS246DB1

From

Figure 1

+5V Digital

1N4148

750k

C26

10µF

VCC VDD

3

C2-

1

C2+

MC145407

2

+

R14

Ω

C25

10µF

10k

TXD

RXD

RTS

CTS

DTR

DSR

DCD

J2

RI

9

3

2

7

8

4

6

1

5

17

18

C1-

+

20

C1+

5

6

7

8

9

10

U1

4

C28

10µF

+

CDB5529

+5V Digital

+5V Digital

1

HDR10

Ω

Ω

Y1

+5V Digital

C19

1 2

3 4

5

9

11

13

14

17

R1

Ω

200

R2

Ω

200

R3

Ω

200

R4

Ω

200

R5

Ω

200

R6

Ω

200

R19

Ω

200

R20

Ω

200

6

8

10

12

U5

SN74HC14N

2

3

4

5

6

7

8

18

19

9

TP65

TP64

TP63

TP62

TP61

P1.0

P1.1

P1.2

P1.3

P1.4

P1.5

P1.6

P1.7

P3.5

P3.6

XTAL1

XTAL2

RST

UM1

80C51

VSS

20

CS

SDI

SDO

SCLK

D1

D0

Bypass

Cap

C18

R7

200

R8

200

C23

33pF

C0G

11.0592MHz

C24

33pF

C0G

0.1µF

A1

A0

D2

D3

D4

0.1µF

R9

RESET

Ω

VDD

P0.0

P3.0

P3.1

P3.2

P3.3

P3.4

P2.0

P2.1

P2.2

P2.3

40

39

10

11

12

13

14

5.11k

21

22

23

24

R12

10k

Ω

R13

Ω

JP2

+

R11

5.11k

C7

47µF

Ω

C17

0.1µF

R10

Ω

5.11k

6

5

LED_555_5003

S1

Test Switch 1

Test Switch 2

Test Switch 3

+18

+27

+3

+4

D1

HDR7

From RS-232

To RS-232

RESET

COMM

GAINCAL

OFFSETCAL

Normal

Loopback

C27

10µF

RXD

TP71

TXD

TP721615

+

14

13

12

11

Figure 2. Digital Schematic Section

Page 5

Register Read Command Byte Write Command Byte

Offset Register 0x90 (H) 0x80 (H)

Gain Register 0x92 (H) 0x82 (H)

Configuration Register 0x94 (H) 0x84 (H)

Conversion Data Register 0x96 (H) ---

Table 1. Microcontroller Command via RS-232

CDB5529

Table 1 lists the RS-232 commands used to communicate between the PC and the microcontroller.

To develop additional code to communicate to the

evaluation board via RS-232, the following applies: to write to an internal A DC register, choos e

the appropriate write command byte (See Table 1),

and transmit it LSB first. Then, transmit the three

data bytes, lowest order byte (bit s 7-0) first, with

the LSB of each byte transmitted first. These three

data bytes provide the 24-bits of information to be

written to the desired register. To read from an internal register, choose the appropriate read command byte and transmit it LSB first. Then, the

microcontroller automatically acquires the ADC’s

register contents and returns the 24-bits of information. The returned data is transmitted lowest order

byte first with the LSB of each byte transmitted

first.

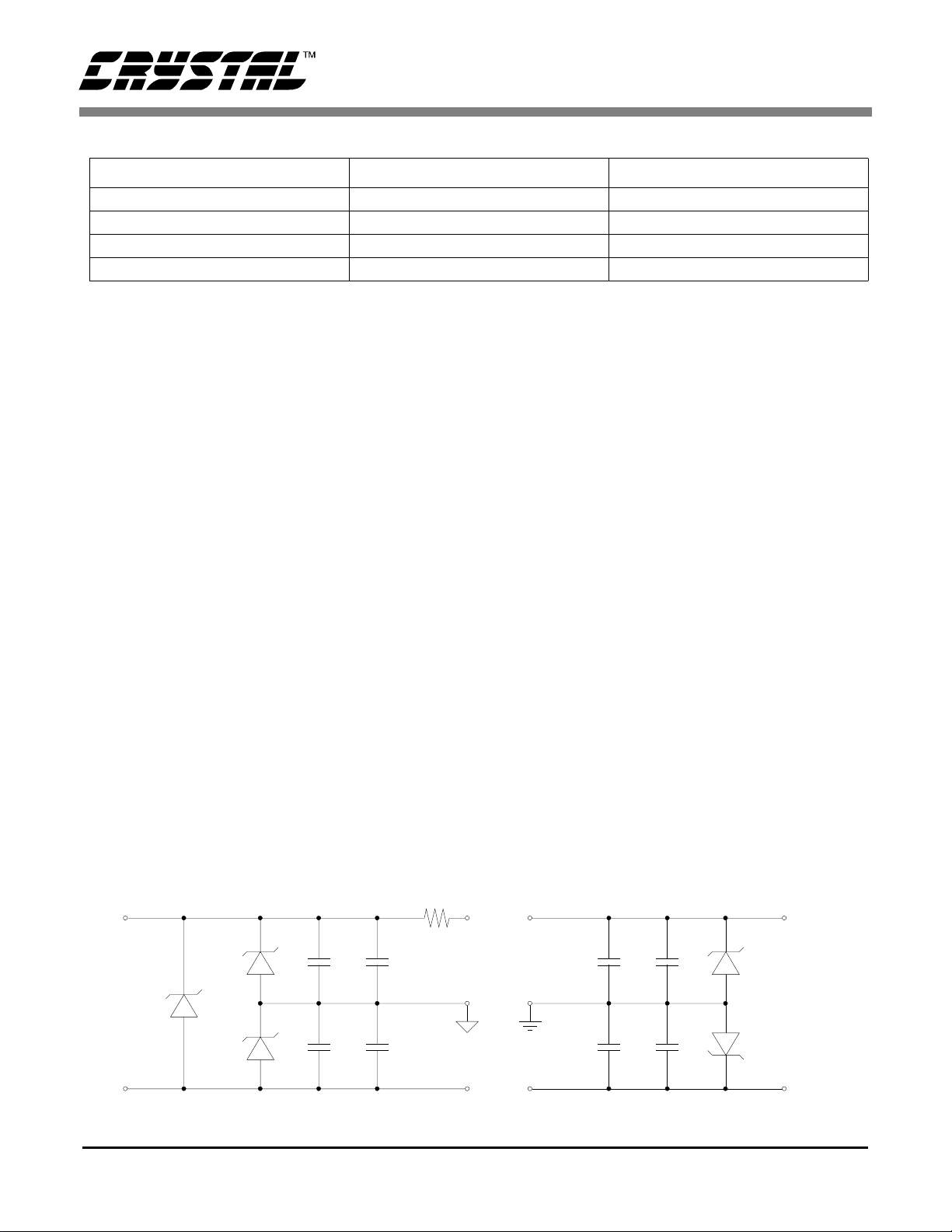

The CS5529 A/D converter is designed t o operate

from a single +5V or a dual ±2. 5V analog supply.

Figure 3 illustrates the power supply connections to

the evaluation board. The +2.5/5V Analog supplies

the positive analog section of the evaluation board,

the LT1019 and the ADC. The -2.5V Analog supplies the negative. HDR8 (see Figure 1) can be used

to bypass VA- to ground. The +5V Digital supplies

the digital section of the evaluation board. It powers the 80C51, the reset circuitry, and the RS-232

interface circuitry.

Using the Evaluation Board

The CS5529 is a highly integrated ADC. It contains

coarse/fine charge buffers and programmable output word rates (OWR). The buffers provide charge

to the modulator reducing the dynamic current demand from the signal being digitized and from the

external reference. The ADC’s digital filter allows

the user to select output word rates (OWR’s) from

1.88 Hz up to 101.1 Hz (assum ing a 32.768 kHz

clock). 303 Hz output word rates can be attained

when a 100kHz clock source is used. Since the

CS5529 has such a high degree of integration and

flexibility, the CS5529 data sheet should be read

thoroughly before and consulted during the use of

the CDB5529.

+2.5V / 5V Analog

Z2

P6KE6V8P

Z5

P6KE6V8P

-2.5V Analog

DS246DB1 5

Z3

P6KE6V8P

C6

47µF

+

C5

47µF

+

C20

0.1µF

C14

0.1µF

Figure 3. Power Supplies

R21

Ω

10

AGND

To HDR8

To HDR3

To µC VD+

DGND

C12

0.1µF

C12

0.1µF

C8

47µF

+

C8

47µF

+

+5V / 3.3V A/D Digital

Z4

P6KE6V8P

Z1

P6KE6V8P

+5V Digital

Page 6

CDB5529

Name Function Description

HDR1 Used to switch AIN+ between J1 input

and AGND.

HDR2 Used to switch AIN- between J1 input

and AGND.

HDR3 Used to switch digital power for the

converter (VD+) from positive analog

supply header (+5V/2.5V Analog) to

the positive digital supply header

(+5V/3.3V Digital).

HDR4 Does not exist.

HDR5 Used to switch VREF+ and VREF-

pins from external J1 connection

header to the on board LT1019 refer-

ence.

HDR6 Used to connect external micro-con-

troller.

HDR7 Used in conjunction with the self test

modes to test the UART communica-

tion between the microcontroller and

the PC.

HDR8 Used to switch the analog compo-

nent’s (LT1019 and converter) nega-

tive potential between the -2.5V

Analog header and AGND.

HDR9 Used in conjunction with HDR3 to

switch the digital ground of the con-

verter (DGND) from the AGND header

to the DGND header.

HDR10 Used to switch the A0 and A1 output

switches of the converter into the

microcontroller. These shunts must be

disconnected when the converter

powered from bipolar supplies.

Software

The evaluation board comes with software and an

RS-232 cable to link the evaluation board to the

PC. The executable software was developed with

TM

Lab Windows/CVI

TM

dows

3.1 or later. After installing the software,

read the readme.txt file for last minute changes in

the software. Additionally, Part II: Software further details how to install and use the software.

IBM, AT and PS/2 are trademarks of International Business Machines Corporation.

Windows is a trademark of Microsoft Corporation.

Lab Windows and CVI are trademarks of National

Instruments.

SPI is a trademark of Motorola.

MICROWIRE is a trademark of National Semiconduc-

tor.

and meant to run under Win-

6 DS246DB1

Page 7

CDB5529

PART II: SOFTWARE

Installation Procedure

To install the software:

1) Turn on the PC.

2) At DOS prompt type WIN to Launch Windows 3.1

3) Insert the Installation Diskette into the PC.

4) From within the Windows Program Manager,

pull down File from the menu bar and select

the Run option.

5) At the prompt

type: A:\SETUP.EXE <enter>.

6) The program will begin installation.

7)After a few seconds, the user will be

prompted to enter the directory in which to

install the CVI Run-Time Engine

Run-Time Engine

created with Lab Windows/CVI

approximately 1.5 megabytes of hard drive

space. If the default directory is acceptable,

select OK and the Run-Time Engine

be installed there.

8) After the Run-Time Engine

user is prompted to enter the directory in

which to install the CDB5529 software.

Select OK to accept the default directory.

9)The program takes a few minutes to install.

After the program is installed, double click on

the Eval5529 icon to launch it. After a few

seconds, the user should be in the graphical

user interface environment.

Note: The software is written to run with 640 x 480

(standard VGA in Windows 3.1

it will work with 1024 x 768 resolution. If the user interface seems to be a little small, the user might consider

setting the display settings to the 640 x 480 standard

(640x480 was chosen to accommodate a variety of

computers).

TM

or later.

TM

. The

TM

manages executables

TM

and takes

TM

TM

is installed, the

TM

) resolution; however,

will

Using the Software

At start-up, the window START-UP CONFIGURATION appears first. This window contains in-

formation concerning the software’s ti tle, revision

number, copyright date, etc. Additionally, at the

top of the screen is a menu bar which displays user

options. Notice, the men u bar item Menu is initially

disabled. This eliminates any conflicts with the

mouse or concurrent use of modems. Before proceeding any further, the user is prompted to select

the serial communication port. To initialize a p ort,

pull down option Setup from the m enu bar and select either COM1 or COM2. Next, select the appropriate part under the Part menu. After a port is

initialized and the part selected, it is a good idea to

test the RS-232 link between the PC and the evaluation board. To do this, pull down th e S etup menu

from the menu bar and select the option

TESTRS232. The user is then prompted to set the

evaluation board’s test switches to 011 and then reset the board. Once this is done, proceed with the

test. If the test fails, check the hardware connection

and repeat again. Otherwise, set the test switches to

000 (normal mode) and reset the board. The option

Menu is now availabl e and performance tests can

be executed.

The evaluation software provides three types of

analysis tests - Time Domain, Frequency Domain,

and Histogram. The Time Domain analysis processes acquired conversions to produce a plot of

Conversion Sample Number versus Magnitude.

The Frequency Domain analysis processes acquired conversions to produce a magnitude versus

frequency plot using the Fast-Fourier transform

(results up to Fs/2 are calculated and plotted). Also,

statistical noise calculations are calculated and displayed. The Histogram analysis processes acquired conversions to produce a histogram plot.

Statistical noise calculations are also calculated and

displayed (see figures 4 through figure 9).

DS246DB1 7

Page 8

CDB5529

The evaluation software was developed with L ab

TM

Windows/CVI

from National Instruments. More sophisticated

analysis software can be developed by purchasing

the development package from National Instruments (512-794-0100).

, a software development package

Menu Bars Overview

The menu bar controls the link bet ween windows

and allows the user to exit the program. It also allows the user to initialize the serial port and load

presaved data conversions from a file. The five

principal windows are the START UP CONFIGURATION (also referred to as the Setup Window),

the Input / Output Window, the Histogram Window, the Power Spectrum Window (also referred to

as the FFT window), and the Time Domain Window.

Specifically, the menu bar has the following control items:

Menu: To select, click on option Menu from the

menu bar, or use associated hot keys . The items associated with MENU are listed and described below.

Setup Window (F1)

Input/Output Window (F2)

Histogram Window (F3)

Power Spectrum Window (F4)

Time Domain Window (F5)

These five menu items allow the user to navigate

between the five windows. They are available at all

times via the menu bar or hot keys.

SETUP: To select, click on option Setup from the

menu bar. The functions available under Setup are:

COM1: When selected, COM1 is initialized to

9600 baud, no parity, 8 data bits, and 1 stop bit.

COM2: When selected, COM2 is initialized to

9600 baud, no parity, 8 data bits, and 1 stop bit.

Load From Disk: Used to load and display previously saved data conversions from a file. The fi le

must comply with the CDBCAPTURE file save

format. The format is: part number, number of bits,

number of conversions, maximum range, and the

data conversions. The user is prompted to enter the

path and file name of previously saved data. To

prevent hardware conflicts, this option is deactivated while in the Input/Output Window.

TESTRS232: This test mode tests the ability of th e

PC to communicate to the evaluation board. It consists of two subt ests: 1) test the link between t he

PC and the RS-232 interface circuitry; and 2) test

the RS-232 link between the PC and the microcontroller. HDR7 distinguishes these two subtests. Set

HDR7 to N ormal to tes t the complete communication link. Or set HDR7 to Loop Back to test the link

between the RS-232 Circuitry and the PC. Then,

set the test switches to 110 and reset the evaluation

board. The LED’s should indicate a binary six signifying that the hardware is ready to initiate the

test. To complete the tes t, the user must initialize

the PC. First, use the SETUP menu to select a communications port and then select the TESTRS232

option. From there, prompts navigate the user

through the test. The PC indicates if the test passes

or fails. Once either test is complete, the LED’s

toggle to indicate that the test mode is complete.

QUIT: Allows user to exit program .

Input/Output Window Overview

The Input/Output Window al lows the user to read

and write to the internal register of the converter in

either binary or hexadecimal, and acquire real-time

conversions. It has quick access control icons that

quickly reset the converter, reset the converter’s serial port, or self-calibrate the converter’s offset and

gain. The following are controls and indicators associated with this window.

Acquire: This is a control icon. When pressed, the

PC transmits the collect single conversion command

8 DS246DB1

Page 9

CDB5529

to the microcontroller. The microcontroller in turn

collects a conversion from the ADC and returns it to

the PC. The PC stores the conversion and collects

additional conversions to form a set. From the sample set collected, the high, the low, peak-to-peak, av erage, and standard deviation, are computed (the

size of the data set is set by the Num To Average input) and then the display icons are updated. This

process continues until the STOP button is pressed,

or until another window is selected. Note: The

quick access control icons are disabled once Acquire

is selected. This eliminates potential hardware conflicts.

BINARY: Input icons set or clear the 24 individual

bits in the gain, configuration, or offset registers.

The bits are first set, then the control icon Write All

Registers is selected to update the registers in the

converter.

CONFIGURATION REGISTER: Text display

box that displays the decoded meaning of each bit

in the configuration register.

DECIMAL: Three display icons that display in

decimal the contents of the gain, configuration, and

offset registers.

DIGITAL OUTPUT: Display icon that displays

the six states of the output latch. A0 and A1 are invalid when the converter is powered from bipolar

supplies.

GAIN REGISTER: Display icon that displays the

decimal equivalent of the bits set in gain register.

HEX: Three input/display icons that allow a user to

set the 24 bits in the gain, configuration, or offset

registers via 6 hexadecimal nibbles. If the upper

nibbles in the registers are zero’s, then leading zero

nibbles need to be entered.

Num To Average: Input icon that sets the size of

the data conversion set referred to when the Acquire button is pressed.

Read All Registers: This is a control icon. When

pressed the gain, offset, and configuration registers

contents are acquired. Then, the configuration text

box and the register content icons are updated.

Reinitialize: This is a control icon. When pressed,

128 logic 1’s followed by a logic ‘0’ are sent to the

ADC’s serial port to reset its port. It does not reset

the RS-232 link.

Reset A/D: This is a control icon. When pres sed,

the microcontroller sends the appropriate commands to return the converter to its initial default

state.

SELF Calibrate: This is a control icon. When

pressed, the appropriate c om m ands a re se nt t o t he

ADC to calibrate its own offset and gain.

STOP: Stops the collection of conversion data.

Write All Registers: This is a control icon. When

pressed, the 72 binary input icons settings are acquired. This data is then transmitted to the ADC’s

gain, offset, and configuration registers. Then, the

PC’s display is updated to reflect the registers

changes.

DS246DB1 9

Page 10

CDB5529

Histogram Window Overview

The following is a description of the controls and indicators associated with the Histogram Window.

Many of the control icons are usable from the Histogram Window, the Frequency Domain Window, and

the Time Domain Window. For brevity, they are

only described in this section.

BIN: Displays the x-axis value of the cursor on the

Histogram.

CANCEL: Once selected, it allow s a user to exit

from the COLLECT algorithm. If data co nversion

sample sets larger than 64 are being collected and

the CANCEL button is selected, it is recommended

that the user reset th e evaluation board. The board

will eventually recover from the continuous collection mode, but the recovery time could be as long

as 10 minutes.

COLLECT: Initiates the data conversion collection process. COLLECT has tw o modes of ope ration: collect from file or collect from converter. To

collect from a file an appropriate file from the SETUP-DISK menu bar option must be selected. Once

a file is selected, its content is displayed in the

graph. If the user is collecting real-time conversions to analyze, the appropriate COM port must be

selected. The user is then free to collect the preset

number of conversions (preset by the CONFIG

pop-up menu discussed below). Notice, there is a

significant acquisition time difference in the two

methods.

ie and 7-term Hodie are windowing algorithms developed at Crystal Semiconductor. If information

concerning these algorithms is needed, call technical support.

AVERAGE: Sets the number of consecutive FFT ’s

to perform and average.

LIMITED NOISE BANDWIDTH: Limits the

amount of noise i n the convert ers bandwidth. Default is 0 Hz.

OK: Accept the change

MAGNITUDE: Displays the y-axis value of the

cursor on the Histogram.

MAXIMUM: Indicator for the maximum value of

the collected data set.

MEAN: Indicator for the mean of the data sample set.

MINIMUM: Indicator for the minimum value of

the collected data set.

OUTPUT: Control that calls a pop-up menu. This

menu controls three options: 1) save current data

set to a file with the CDBCAPTURE format, 2)

print current screen, or 3) print current graph.

RESTORE: Restores the display of the graph after

zoom has been entered.

STD. DEV.: Indicator for the Standard Deviation

of the collected data set.

TEST: Quick access control icon, similar to the hot

keys, to allow user to quickly switch between a time

domain, a frequency domain, or a histogram display.

CONFIG: Opens a pop-up panel to configure how

much data is to be collected, and how to pr ocess the

data once it is collected. The following are controls

and indicators associated with the CONFIG panel.

SAMPLES: User selection of 64, 256, 512, 1024,

2048, 4096, or 8192 conversions.

WINDOW: Used in the Power Spectrum Window

to calculate the FFT. Windowing algorithms include the Blackman, Blackman-Harris, Hanning,

5-term Hodie, and 7-term Hodie. The 5-term Hod-

10 DS246DB1

VARIANCE: Indicates the Variance for the current data set.

ZOOM: Control icon that allows the operator to

zoom in on a specific portion of the current graph.

To zoom, click on the ZOOM icon, then click on the

graph to select the first point (the 1st point is the top

left corner of the zoom box). Then click on the

graph again to select the second point (the 2nd point

is the bottom right corner of the zoom box). Once an

area has been zoomed in to, the OUTPUT functions

Page 11

CDB5529

can be used to print a hard copy of that region. Click

on RESTORE when done with the zoom function.

Frequency Domain Window (i.e. FFT)

The following describe the controls and indicators

associated with the Frequency Domain Window.

CANCEL: See description in Histogram Window

Overview.

COLLECT: See description in Histogram Win-

dow Overview.

CONFIG: See description in Histogram Window

Overview.

FREQUENCY: Displays the x-axis value of the

cursor on the FFT display.

MAGNITUDE: Displays the y-axis value of the

cursor on the FFT display.

OUTPUT: See description in Histogram Window

Overview.

ZOOM: See description in Histogram Window

Overview.

# of AVG: Displays the number of FFT’s averaged

in the current display.

Time Domain Window Overview

The following controls and indicators are associated with the Time Domain Window.

CANCEL: See description i n Histogram Window

Overview.

COLLECT: See description in Histogram Win-

dow Overview.

CONFIG: See description in Histogram Window

Overview.

COUNT: Displays current x-position of the cursor

on the time domain display.

MAGNITUDE: Displays current y-position of the

cursor on the time domain display.

S/D: Indicator for the Signal-to-Distortion Ratio, 4

harmonics are used in the calculations (decibels ) .

S/N+D: Indicator for the Signal-to-Noise + Distortion Ratio (decibels).

SNR: Indicator for the Signal-to-Noise Ratio, first

4 harmonics are not included (decibels).

S/PN: Indicator for the Signal-to-Peak Noise Ratio

(decibels).

TEST: See description in Histogram Window

Overview.

MAXIMUM: Indicator for the maximum value of

the collected data set.

MINIMUM: Indicator for the minimum value of

the collected data set.

OUTPUT: See description in Histogram Window

Overview.

TEST: See description in Histogram Window

Overview.

ZOOM: See description in Histogram Window

Overview.

DS246DB1 11

Page 12

CDB5529

Trouble Shooting the Evaluation Board

This section describes special test modes incorporated

in the microcontroller software to diagnose hardware

problems with the evaluation board.

Note: To enter these modes, set the test switches to the

appropriate positi on an d reset the eval uation board . To re enter t he no rmal opera tion mod e, set t he s wi tches b ack to

binary zero and r eset the boar d aga in.

Test Mode 0, Normal Mode: This is the default

mode of operation. To en ter th is mo d e, set th e test

switches to 000 and reset the board. The evaluation

board allows normal read/writes to the ADC’s registers. All the LED’s toggle on then off after reset,

and then only when communicating with th e PC.

Test Mode 1, Loop Back Test: This test mode

checks the microcontroller’s on-chip UART. To

enter this mode, set test switches to 001, set HDR7

for loop back, and then reset the board. If the communication works, all the LED's toggle. Otherwise, only 1/2 of the LED’s toggle to indicate a

communication problem.

Test Mode 2, Read/Write to ADC: This test mode

tests the microcontroller’s ability to read and write

to the ADC. To enter this mode, set the switches to

010 and reset the board. In this test mode, the

ADC’s configuration, offset, and gain registers are

written to and then read from. If the correct data is

read back, all the LED's toggle. Otherwise, only

half of them toggle to indicate an error.

Test Mode 3, Continuously Acquire Single Conversion: This test mode repetitively acquires a sin-

gle conversion. To enter this mode, set the test

switches to 011 and press reset. A binary three is indicated on the LED’s. By probing HDR6 and using

as a triggering pin, an oscilloscope or logic an-

CS

alyzer will display in real-time how the microcontroller reads conversion data.

Test Mode 4: Reserved for future modifications.

Test Mode 5, Continuously Read Gain Register:

This test mode repetitively acquires the gain registers default contents (0x400000 HEX). To enter

this mode, set the test switches to 101 and press reset. The LED’s should indicate a binary five. By

probing HDR6 and using CS

as a triggering pin, an

oscilloscope or logic analyzer will display in realtime how the microcontroller acquires a conversion.

Test Mode 6, PC to Microcontroller RS-232

Communication Link Test: This test mode tests

the ability of the PC to communicate to the evaluation board. It consists of two subtests: 1) test the

link between the PC and the RS-232 interface circuitry; and 2) test the RS-232 link between the PC

and the microcontroller. HDR7 distinguishes these

two subtests. Set HDR7 to Normal to test the complete communication link. Or set HDR7 to Loop

Back to test the link between the RS-232 Circuitry

and the PC. Then, set the test switches to 110 and

reset the evaluation board. The LED’s should indicate a binary six signifying that the hardware is

ready to initiate the tes t. To complete the test, the

user must initialize the PC. First, use th e SETUP

menu to select a communications port and then select the TESTRS232 option. From there, user

prompts navigate the user through the test. The PC

indicates if the test passes or fails. Once either test

is complete, the LED’s toggle to indicate that the

test mode is complete.

Test Mode 7, Toggle LED’s: This test mode tests

the evaluation board LED’s. To enter this mode,

set the test switches to 111 and reset the board. If

the mode passes, the LED ’s toggle.

Note: Remember, to return to the normal operating

mode, set the test switche s to binar y zero, return HDR7

to Normal, and reset the evaluation board.

12 DS246DB1

Page 13

CDB5529

Figure 4. Main Menu

Figure 5. Input/Output Window

DS246DB1 13

Page 14

CDB5529

Figure 6. Frequency Domain Analysis

Figure 7. Configuration Menu

14 DS246DB1

Page 15

CDB5529

Figure 8. Time Domain Analysis

Figure 9. Histogram Analysis

DS246DB1 15

Page 16

CDB5529

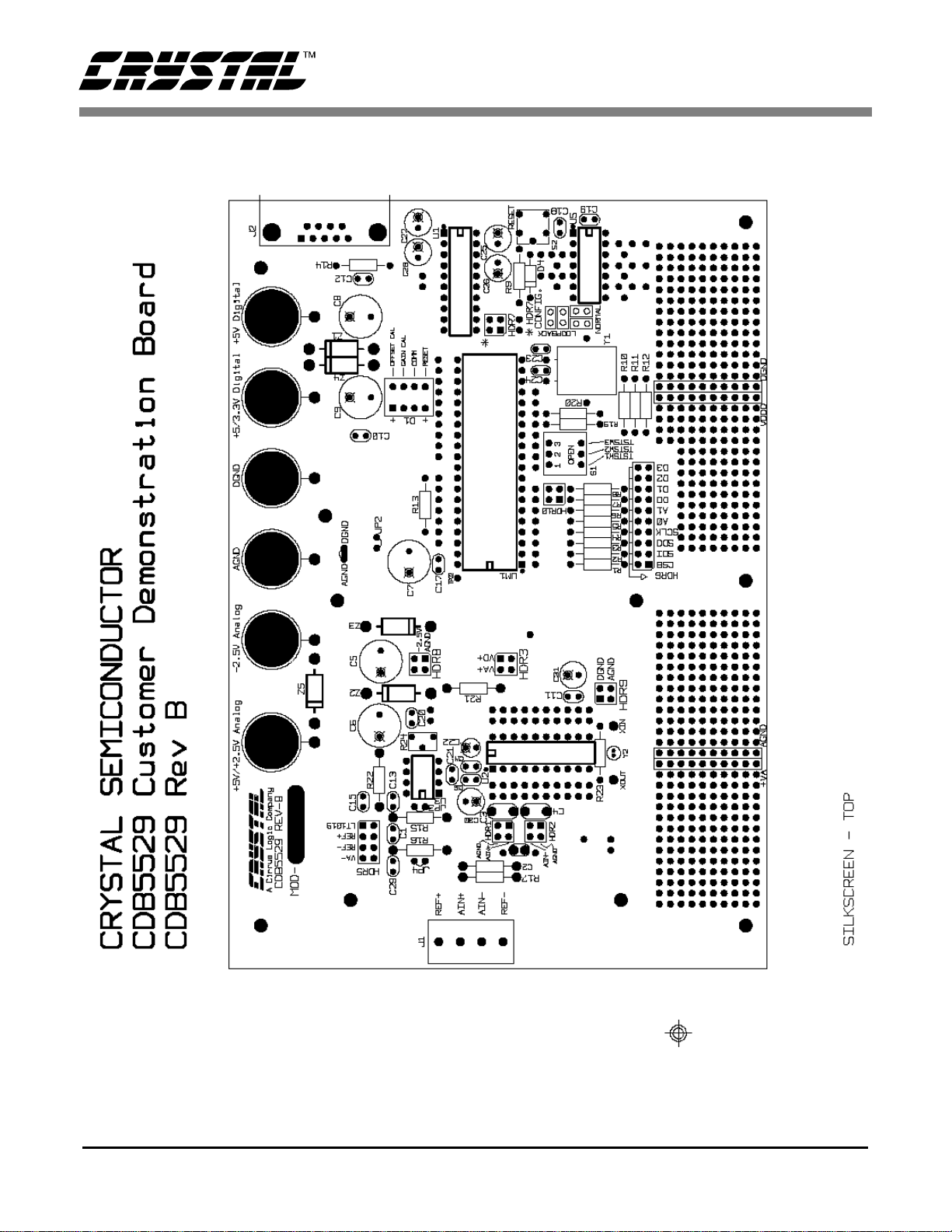

Figure 10. CDB5529 Component Side Silkscreen

16 DS246DB1

Page 17

CDB5529

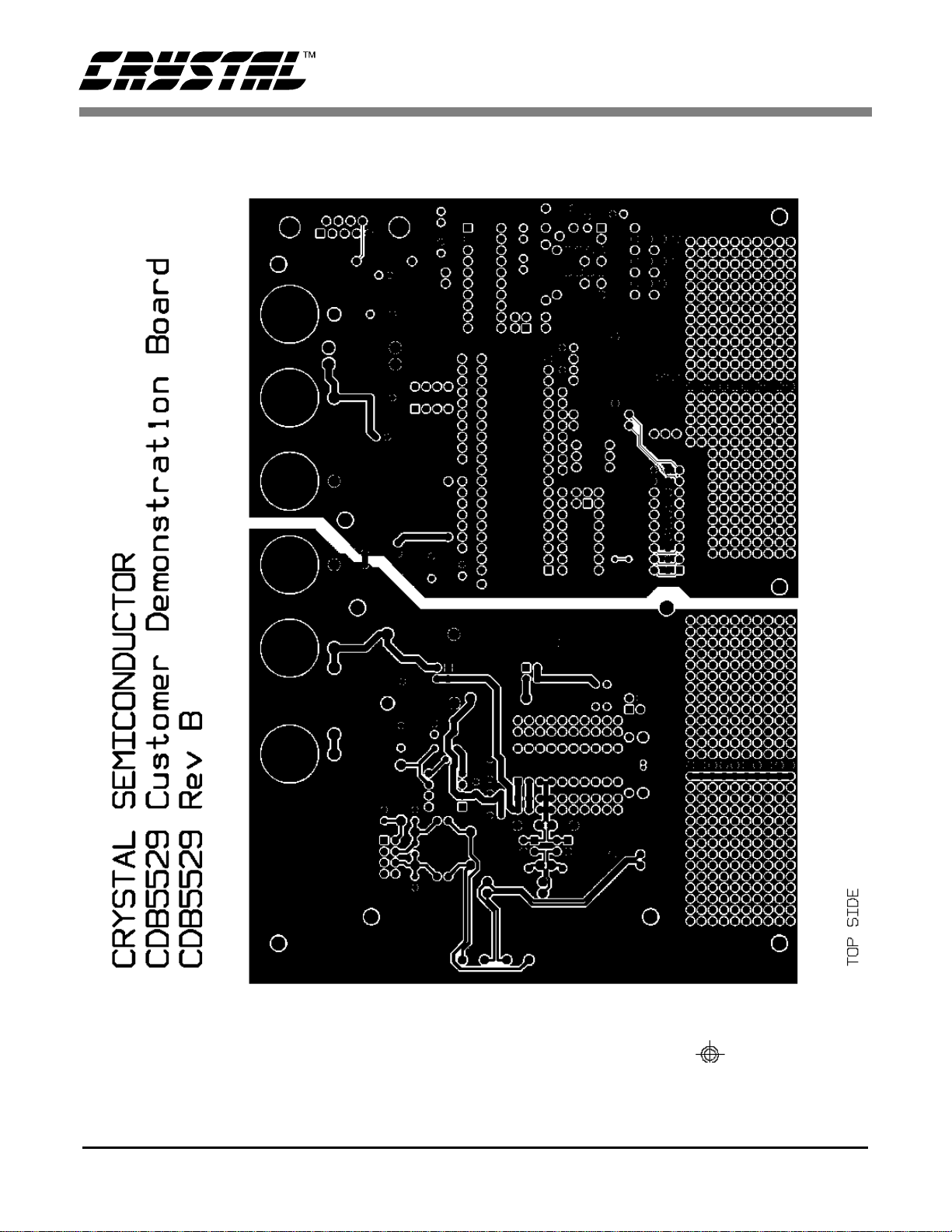

Figure 11. CDB5529 Component Side (top)

DS246DB1 17

Page 18

CDB5529

Figure 12. CDB5529 Solder Side (bottom)

18 DS246DB1

Page 19

• Notes •

Page 20

Loading...

Loading...