Page 1

\

CDB5521/22/23/24/28

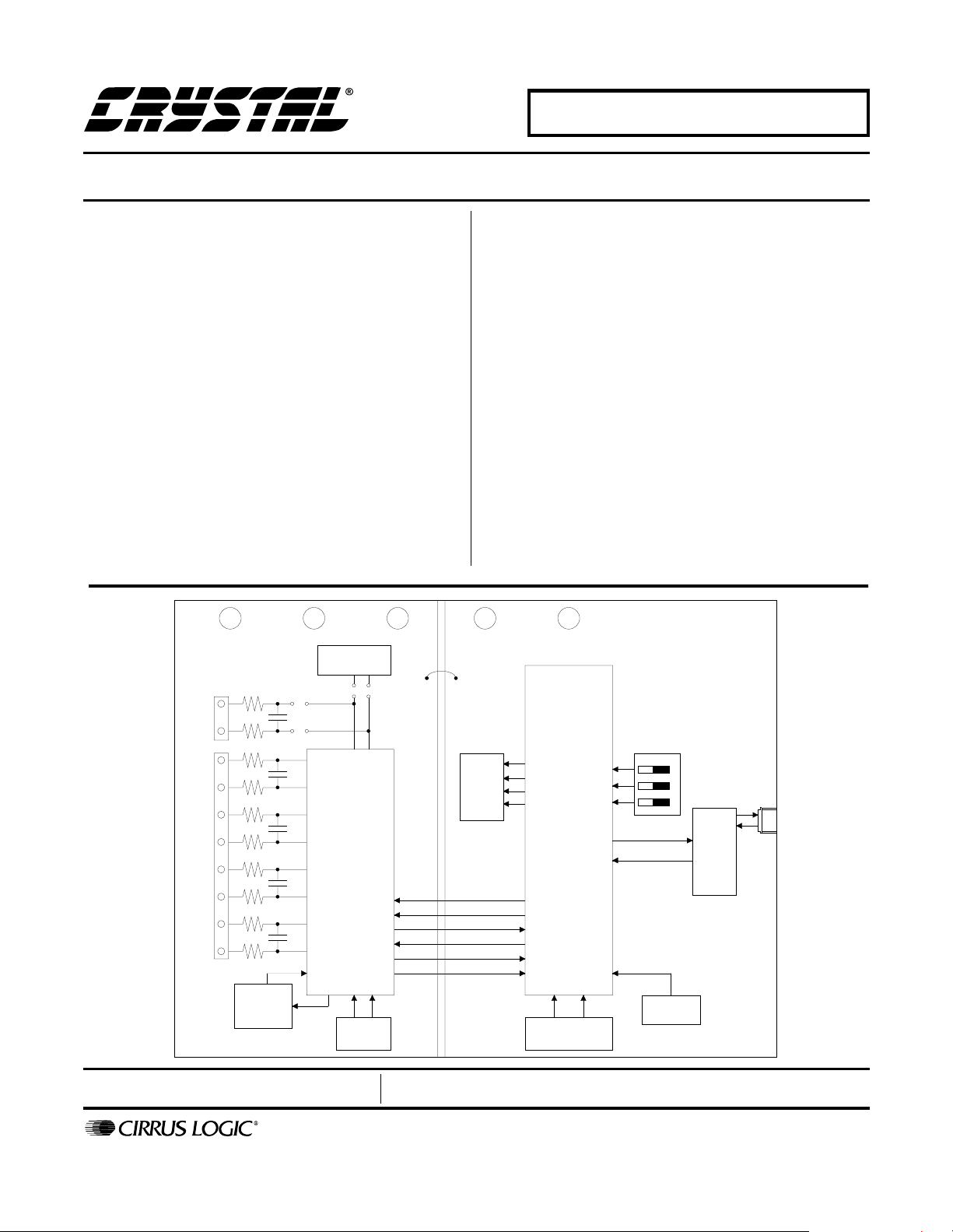

CDB5521/22/23/24/28 Evaluation Board and Software

Features

l Evaluation Board and Software Supports All

Chips: CS5521, CS5522, CS5523, CS5524,

and CS5528

l Direct Thermocouple Interface

l RS-232 to PC With Test Modes

l On-board 80C51 Micr ocontroller

l On-board Voltage Reference

l Lab Windows/CVI

– Register Setup & Chip Control

– Data Capture

– FFT Analysis

– Time Domain Analysis

– Noise Histogram Analysis

l On-board Charge Pump Drive Circuitry

REF+

TM

Evaluation Software

+5 ANALOG-5 ANALOG AGND

VOLTAGE

REFERENCE

J2

General Description

The CDB5521/22/23/24/28 is an inexpensive tool designed to evaluate the performance of the CS5521,

CS5522, CS5523, CS5524, and CS5528 Analog-to-Digital Converters (ADC).

The evaluation board includes a 2.5 V voltage reference,

an 80C51 microcontroller, an RS232 driver/receiver, and

firmware. The 8051 controls the serial communication

between the evaluat ion board and the PC vi a the firmware, thus, enabling qui ck and ea sy ac cess to all of th e

CS5521/22/23/24/28’s registers.

The CDB5521/22/23/24/28 also includes one installed

ADC sample, and software for Dat a Capture, Time Domain Analysis, Histogram Analysis, and Frequency

Domain Analysis.

ORDERING INFORMATION

CDB5521/22/23/24/28 Evaluation Board

DGND

+5 DIGITAL

REF-

J1

AIN1+

AIN1-

AIN2+

AIN2-

AIN3+

AIN3-

AIN4+

AIN4-

NBV DRIVE

CIRCUITRY

NBV

CPD

CS5521

CS5522

CS5523

CS5524

CS5528

CRYSTAL

32.768 kHz

Preliminary Product Information

P.O. Box 17847, Austin, Texas 78760

(512) 445 7222 FAX: (512) 445 7581

http://www.cirrus.com

TEST

SWITCHES

on off

3

2

1

DRIVER/RECEIVER

RESET

CIRCUITRY

CONNECTOR

RS232

CS

SDI

SDO

SCLK

LEDs

A0

A1

80C51

Microcontroller

CRYSTAL

11.0592 MHz

This document contains information for a new product.

Cirrus Logic reserves the right to modify this product without notice.

Copyright Cirrus Logic, Inc. 2000

(All Rights Reserved)

RS232

MAY ‘00

DS317DB2

1

Page 2

TABLE OF CONTENTS

1. PART I: HARDWARE ............................................................................................................... 4

1.1 Introduction ........................................................................................................................4

1.3 Using the Evaluation Board ............................................................................................... 8

1.4. Power Connections ........................................................................................................... 8

1.5 Negative Bias Voltage ........................................................................................................ 8

1.6 Software ............................................................................................................................. 9

1.7. Writing Your Own Interface Software ................................................................................ 9

2. PART II: SOFTWARE ............................................................................................................. 13

2.1 Installation Procedure ......................................................................................................13

2.3 Menu Bars Overview ........................................................................................................ 14

2.4 Setup Window Overview ..................................................................................................15

2.5 Data FIFO Window Overview .......................................................................................... 15

2.6 Histogram Window Overview ...........................................................................................16

2.7 Frequency Domain Window (i.e. FFT) ............................................................................. 17

2.8 Time Domain Window Overview ......................................................................................18

2.9 Calibration Window Overview ..........................................................................................19

2.10 Trouble Shooting the Evaluation Board ......................................................................... 19

LIST OF FIGURES

CDB5521/22/23/24/28

Figure 1. CS5522 Analog Section................................................................................................... 5

Figure 2. CS5524/28 Analog Section..............................................................................................6

Figure 3. Digital Section .................................................................................................................. 7

Figure 4. Power Supplies ................................................................................................................ 8

Figure 5. Main Menu .....................................................................................................................21

Figure 6. Setup Window................................................................................................................ 21

Figure 7. Data FIFO Window.........................................................................................................22

Figure 8. Frequency Domain Analysis ..........................................................................................22

Figure 9. Calibration Menu............................................................................................................ 23

Figure 10. Time Domain Analysis .................................................................................................23

Figure 11. Histogram Analysis (Using the CS5524 with default register settings and

24-bit output words) ...................................................................................................... 24

Figure 12. CDB5521/22/23/24/28 Component Side Silkscreen....................................................25

Contacting Cirrus Logic Support

For a complete listing of Direct Sales, Distributor, and Sales Representative contacts, visit the Cirrus Logic web site at:

http://www.cirrus.com/corporate/contacts/

IBM, AT and PS/2 are trademarks of International Business Machines Corporation.

Windows is a trademark of Microsoft Corporation.

Lab Windows and CVI are trademarks of National Instruments.

TM

SPI

is a trademark of Motorola.

MICROWIRE

TM

is a trademark of National Semiconductor.

Preliminary product inf o rmation describes product s whi ch are in production, b ut f or which full character iza t i on da t a i s not yet available. Advance p rodu ct i nformation describes products which are in development and subject to development changes. Cirrus Logic, Inc. has made best efforts to ensure that the information

contained in this document i s accurat e and reli able. However , t he infor mation is subje ct to chang e without noti ce and is provi d ed “AS IS” without warrant y of

any kind (express or implied). No responsibility is assumed by Cirrus Logic, Inc. for the use of this information, nor for infringements of patents or other ri g ht s

of third parties. This document is the pro perty of Cirrus Logi c, Inc. and i mplie s no licen se under patents, copyrights, tr ademarks, or trade secre ts. No part of

this publication may be copied, reproduced , stored in a retrieval system, or transmitted, in any form or by any means (electro nic, mechanical, photographic, or

otherwise) without the pr i or writ ten consent of Cirrus Logic, Inc. It e ms f rom any Ci rrus Logic website or disk may be printed for use by the user. However, no

part of the printout or electronic files may be copied, reproduced, stored in a retrieval system, or transmitted, in any form or by any means (electronic, mechanical,

photographic, or otherwise) without the prior written consent of Cirrus Logic, Inc.Furthermore, no part of this publication may be used as a basis for manufacture

or sale of any items without the prior written consent of Cirrus Logic, Inc. The names of products of Cirrus Logic, Inc. or other vendors and suppliers appearing

in this document may be trademarks or service marks of their respective owners which may be registered in some jurisdictions. A list of Cirrus Logic, Inc. trademarks and service marks can be found at http://www.cirrus.com.

2 DS317DB2

Page 3

Figure 13. CDB5521/22/23/24/28 Component Side (top) ............................................................. 26

Figure 14. CDB5521/22/23/24/28 Solder Side (bottom) ............................................................... 27

LIST OF TABLES

Table 1. Header Descriptions.......................................................................................................... 9

Table 2. Microcontroller Read/Write Commands via RS-232 ....................................................... 10

Table 3. Microcontroller Conversion Commands via RS-232....................................................... 10

Table 4. Microcontroller Self Calibration Commands via RS-232................................................. 11

Table 5. Microcontroller System Calibration Commands via RS-232 ........................................... 12

CDB5521/22/23/24/28

DS317DB2 3

Page 4

CDB5521/22/23/24/28

1. PART I: HARDWARE

1.1 Introduction

The CDB5521/22/23/24/28 evaluation board provides a means of testing the CS5521/22/23/24/28

Analog-to-Digital Converters (ADCs). The board

interfaces the converters to an IBMTM compatible

PC via an RS-232 interface while operating from a

+5 V and -5 V power supply. To accomplish this,

the board comes equipped with an 80C51 microcontroller and a 9-pin RS-232 cable, which physically interfaces the evaluation board to the PC.

Additionally, analysis software provides easy access to the internal registers of the converters and

provides a means to capture data and display the

converters’ time domain, frequency domain, and

noise histogram performance.

1.2 Evaluation Board Overview

The board is partitioned into two main sections: analog and digital. The analog section consists of the

either the CS5521, CS5522, CS5523, CS5524 or

CS5528, a precision voltage reference, and the circuitry to generate a negative voltage. The digital

section consists of the 80C51 microcontroller, the

hardware test switches, the reset circuitry, and the

RS-232 interface.

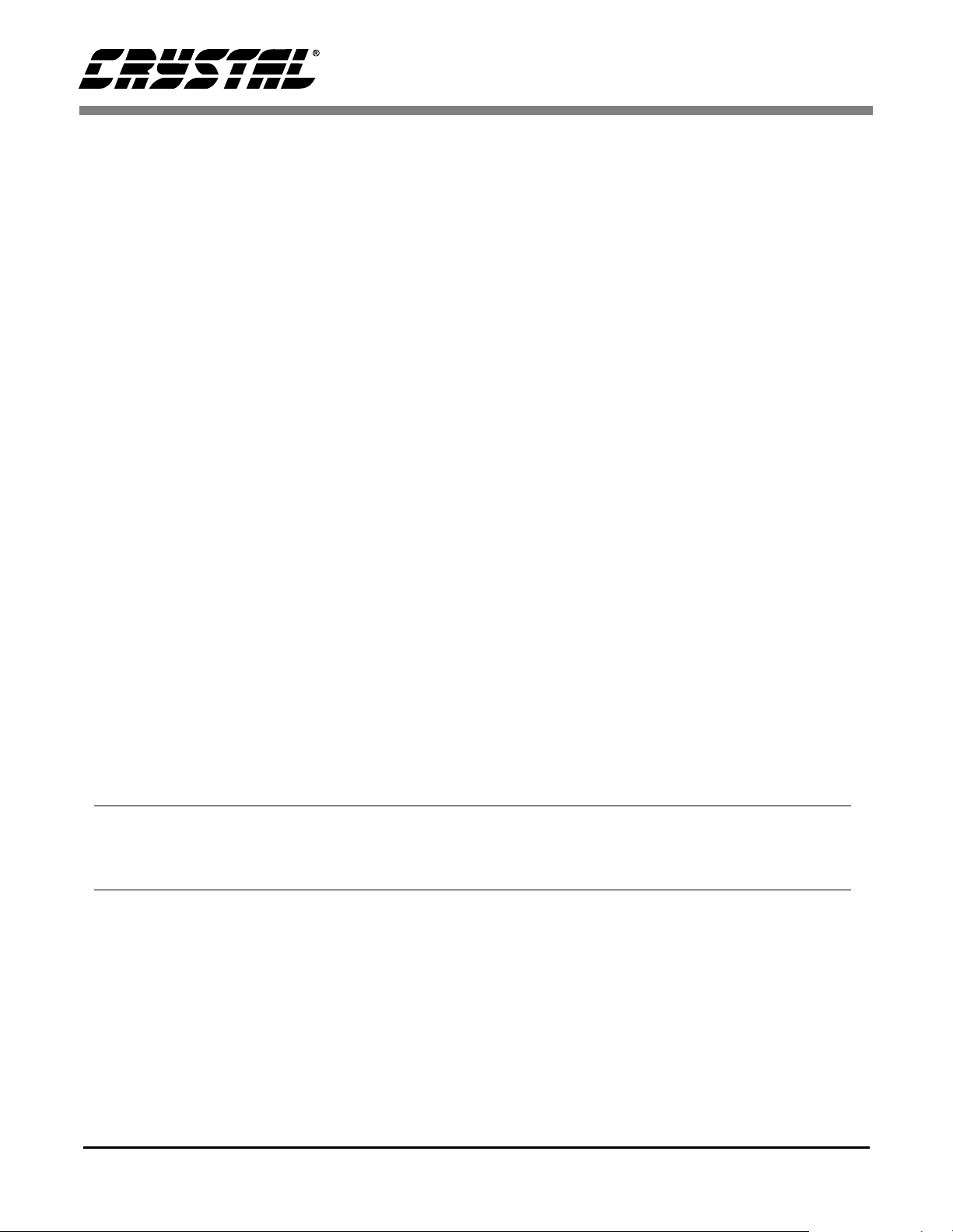

The CS5521/22/23/24/28 is designed to digitize

low level signals while operating from a

32.768 KHz crystal. As shown in Figures 1 and 2,

a thermocouple can be connected to the converter’s

inputs via J1’s AIN+ and AIN- inputs. Note, a simple RC network filters the thermocouple’s output to

reduce any interference picked up by the thermocouple leads.

The evaluation board provides two voltage reference options, on-board and external. With HDR5’s

jumpers in positions 1 and 4, the LT1019 provides

2.5 volts (the LT1019 was chosen for its low drift,

typically 5ppm/°C). By setting HDR5’s j umpers to

position 2 and 3, the user can supply an external

voltage reference to J2’s REF+ and REF- inputs

(Application Note 4 on the web details various

voltage references).

The A/D converters’ serial interfaces are SPI

and MICROWIRETM compatible. The interface

control lines (CS, SDI, SDO, and SCLK) are connected to the 80C51 microcontroller via port one.

To interface a different microcontroller to the ADC

chip, the control lines to the ADC are availa ble at

HDR6 (Header 6). However, to connect an external

microcontroller to the header, the evaluation board

must be modified in one of three ways: 1) cut the

interface control traces going to the on-board

80C51 microcontroller, 2) remove resistors R1-R6,

or 3) remove the 80C51 microcontroller from its

socket on the evaluation board.

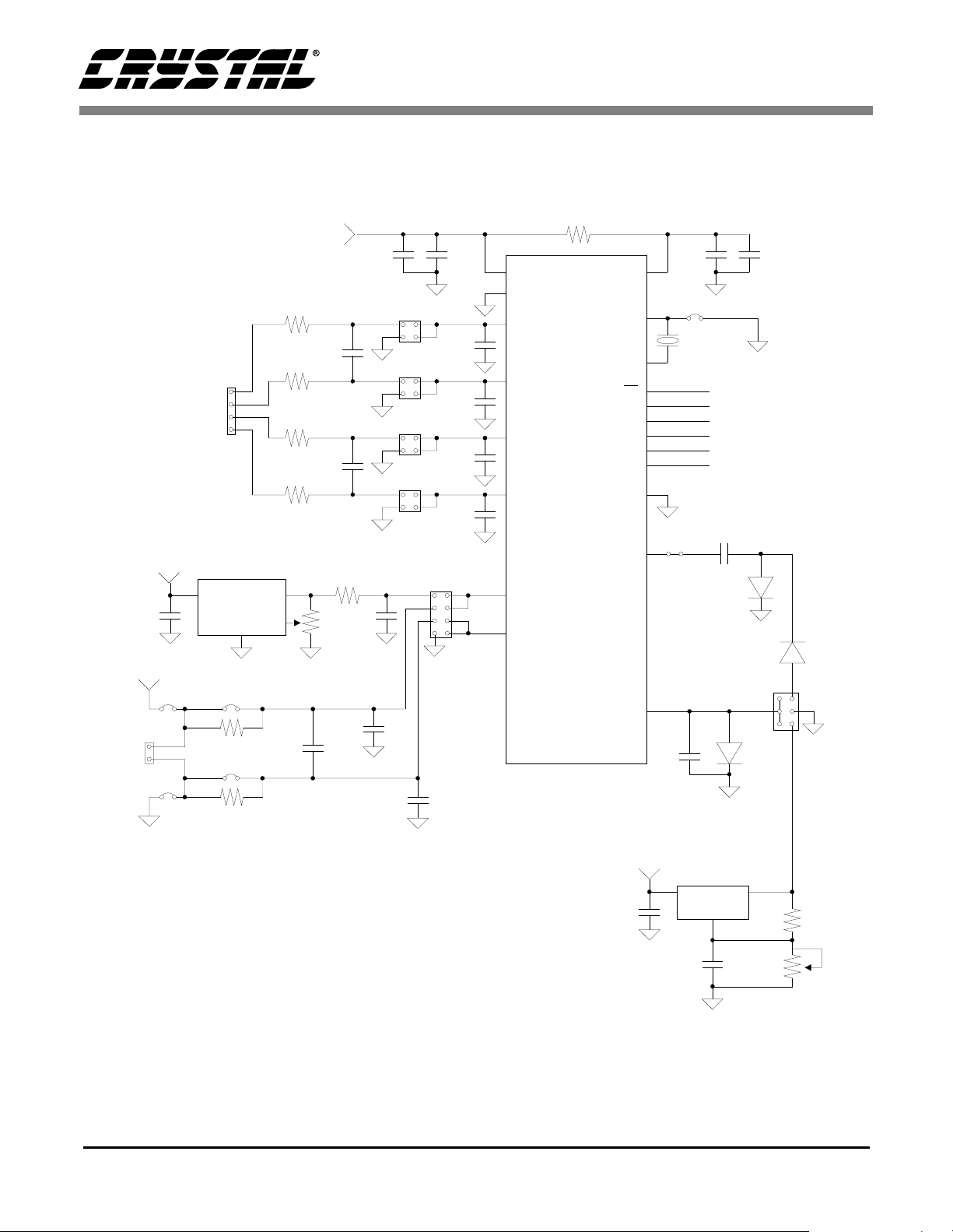

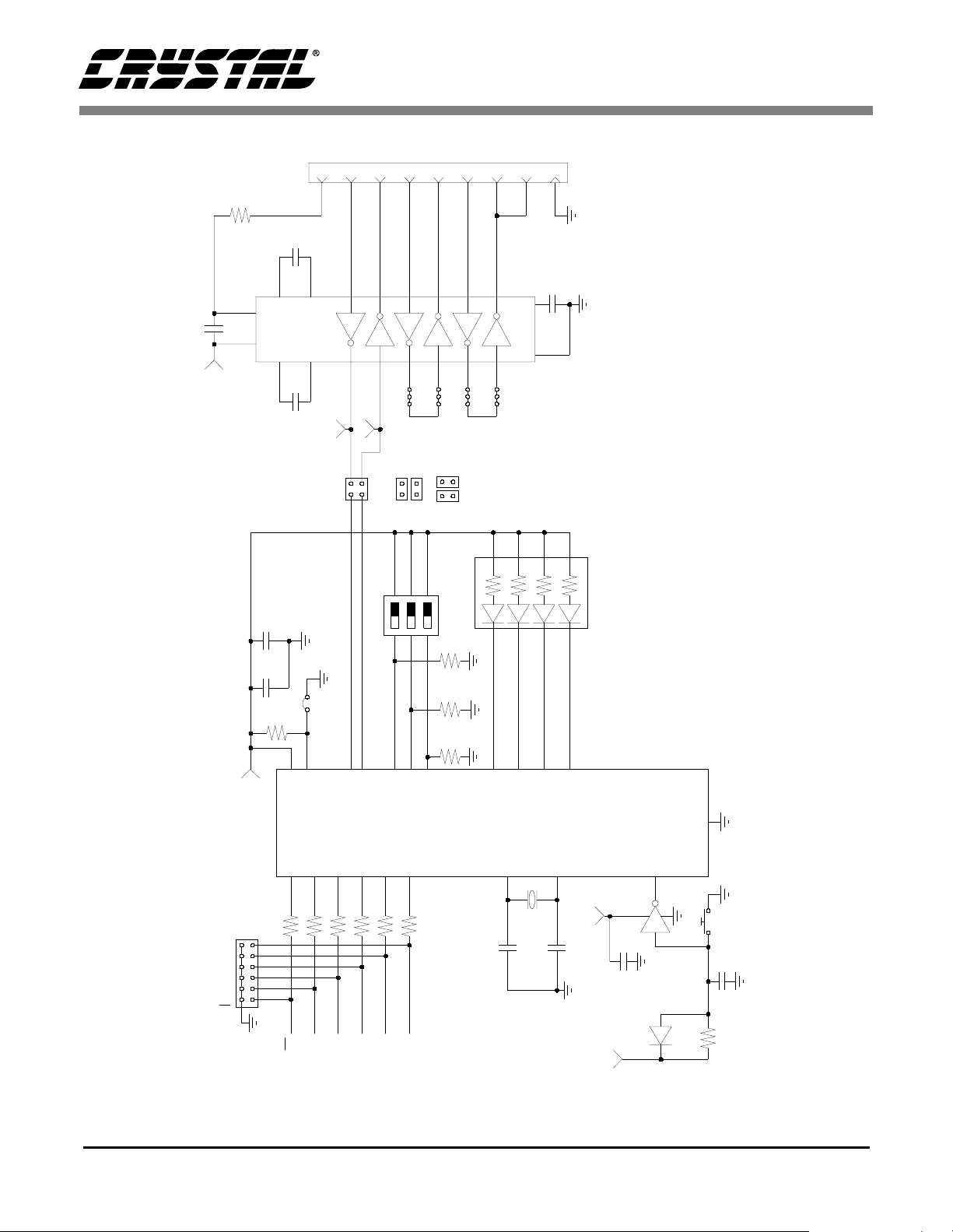

Figure 3 illustrates the schemati c of the digital section. It contains the microcontroller, a Motorola

MC145407 interface chip, and test switches. The

test switches aid in debugging communication

problems between the CDB5521/22/23/24/28 and

the PC. The microcontroller derives its clock from

an 11.0592 MHz crystal. From this, the controller

is configured to communicate via RS-232 at

9600 baud, no parity, 8-bit data, and 1 stop bit.

TM

4 DS317DB2

Page 5

+5V Analog

C20

0.1µF

+5V Analog

J2

REF+

REF-

JP6

JP5

AIN1+

AIN1-

AIN2+

AIN2-

R21

Ω

301

R22

Ω

301

J1

1

2

3

4

U4

LT1019

GND

JP3

JP4

OUTIN

TRIM

4700pF

+5V Analog

R17

C2

Ω

301

4700pF

R18

Ω

301

R25

C3

Ω

301

4700pF

R26

Ω

301

R7

20k

C1

R24

49.9

Ω

C41

0.1µF

0.1µF

Ω

C16

0.1µF

C14

C40

0.1µF

HDR1

HDR2

HDR8

HDR9

R15

10

Ω

C29

2

10µF

C32

0.1µF

C33

0.1µF

C34

0.1µF

C35

0.1µF

HDR5

1

3

4

VA+

AGND

AIN1+

AIN1-

U6

CS5521

VD+

XOUT

CS5522*

18

AIN2+

17

AIN2-

20

VREF+

19

VREF-

* CS5521 and CS5522 are interchangeable

SDO

SCLK

DGND

CPD

CDB5521/22/23/24/28

XIN

CS

SDI

A0

A1

NBV

14

10

11

9

8

12

15

6

16

13

7

5

C22

10µF

C30

10µF

JP7

Y2

32.768kHz

Figure 3

0.033µF

1N4148

+

C9

D2

To

D3

1N4148

CPD

GND

BAT85

C15

0.1µF

HDR4

337

D5

-5V Analog

C21

+

1µF

LM337_LZ

C11

0.1µF

U2

ADJ

VOUTVIN

R23

Ω

1k

+

R16

1k

Ω

Figure 1. CS5522 Analog Section

DS317DB2 5

Page 6

+5V Analog

C20

0.1µF

+5V Analog

REF+

REF-

CDB5521/22/23/24/28

R15

Ω

+5V Analog

C14

0.1µF

R17

C2

Ω

301

4700pF

R18

Ω

301

OUTIN

TRIM

R25

301

R26

301

R27

301

R28

301

R29

301

R30

301

C1

4700pF

Ω

4700pF

Ω

Ω

4700pF

Ω

Ω

4700pF

Ω

C3

C4

C31

20k

R24

49.9

R7

Ω

C41

0.1µF

0.1µF

J1

1

AIN1+

2

AIN1-

3

AIN2+

4

AIN2-

5

AIN3+

6

AIN3-

7

AIN4+

8

AIN4-

U4

LT1019

GND

R21

301

301

JP3

Ω

JP4

R22

Ω

JP6

J2

JP5

HDR1

HDR2

HDR8

HDR9

HDR11

HDR12

HDR13

HDR14

Ω

C16

C40

0.1µF

C29

2

10µF

C32

0.1µF

C33

0.1µF

C34

0.1µF

C35

0.1µF

C36

0.1µF

C37

0.1µF

C38

0.1µF

C39

0.1µF

HDR5

* CS5523, CS5524 and CS5528

are interchangeable

VA+

1

AGND

3

AIN1+/AIN1

4

AIN1-/AIN2

22

AIN2+/AIN3

21

AIN2-/AIN4

5

AIN3+AIN5

6

AIN3-/AIN6

20

AIN4+/AIN7

19

AIN4-/AIN8

24

VREF+

23

VREF-

10

U3

CS5523

CS5524

CS5528*

VD+

XIN

XOUT

CS

SDI

SDO

SCLK

A0

A1

DGND

CPD

NBV

-5V Analog

C21

1µF

+

16

12

13

11

10

14

17

8

18

15

9

7

C22

10µF

C30

10µF

JP7

Y2

32.768kHz

+

LM337_LZ

C11

0.1µF

Figure 3

C9

0.033µF

D2

1N4148

U2

VOUTVIN

ADJ

+

To

D3

1N4148

CPD

GND

337

*

D5

BAT85

C15

0.1µF

R23

1k

R16

1k

HDR4

Ω

Ω

Figure 2. CS5524/28 Analog Section

6 DS317DB2

Page 7

CDB5521/22/23/24/28

7

RTS

7

14

Normal

Test Switch 2

13

8

CTS

8

13

Loopback

Test Switch 3

R10

R11

R12

14

9

3

2

Ω

R14

10k

17

+

C26

10µF

19

VCC VDD

+5V Digital

C17

C7

+

RI

TXD

RXD

C25

10µF

+

18

20

5

6

C1-

C1+

C2+

C2-

3

1

16

15

+

TP71

RXD

From RS-232

TP72

TXD

To RS-232

Test Switch 1

S1

12

11

10

C27

10µF

HDR7

0.1µF

47µF

Ω

R13

JP2

10k

40

39

6

4

DTR

DSR

9

10

12

11

RESET

18+27+36+45

+

Ω

5.11k

Ω

5.11k

Ω

5.11k

21

5

1

DCD

C28

10µF

+

U1

24

MC145407

COMM

GAINCAL

23

22

24

OFFSETCAL

D1

LED_555_5003

Figure 3. Digital Section

P0.0

P3.0

P3.1

P3.2

P3.3

A1

A0

SCLK

SDO

SDI

CS

+5V Digital

HDR6

VDD

P1.0

P1.1

P1.2

1

Ω

R1

R2 2

200

CS

SDI

P1.3

4

Ω

Ω

Ω

R4

R3 3

200

200

SDO

From

R5 5

200

SCLK

Figure 1, 2

P3.4

P1.4

P1.5

Ω

Ω

R6 6

200

200

A0

A1

P2.0

P2.1

P2.2

P2.3

20

UM1

80C51

XTAL1

18

C23

C0G

33pF

XTAL2

19

Y1

11.0592MHz

+5V Digital

C24

C0G

33pF

+5V Digital

RST

9

C19

0.1µF

Cap

Bypass

D4

1N4148

VSS

RESET

C18

0.1µF

Ω

R9

750k

DS317DB2 7

Page 8

CDB5521/22/23/24/28

1.3 Using the Evaluation Board

The CS5521/22/23/24/28 are highly integrated

ADCs. They contain a multiplexer, an instrumentation amplifier (IA), a programmable gain amplifier

(PGA), an on-chip charge pump drive (CPD), and

programmable output word rates (OWR). The IA

provides a set gain of 20 while the PGA sets the input levels of the ADC at either 25 mV, 55 mV,

100 mV, 1 V, 2.5 V, or 5 V (for VREF = 2.5 V).

The CPD provides a square wave output. This output, along with two diodes and two capacitors, is

used to supply the negative supply to the IA, enabling measurements of ground referenced signals.

The ADC’s digital filter allows the user to select

output word rates (OWR’s) from 1.88 Hz up to

101 Hz. higher output word rates ca n be attained

when a faster clock source is used. Since the

CS5521/22/23/24/28 have such a high degree of integration and flexibility, the CS5521/23 or

CS5522/24/28 data sheet should be read thoroughly before and consulted during the use of the

CDB5521/22/23/24/28. Table 1 lists the different

headers on the CDB5521/22/23/24/28 and their

functions. The locations of these headers are

marked on the top of the board, and the silkscreen

and layout of the board can also be found at the end

of this document in Figures 12, 13, and 14 for reference.

1.4. Power Connections

Figure 4 illustrates the power supply connections to

the evaluation board. The +5 V Analog supplies the

analog section of the evaluation board, the LT1019

and the ADC. The -5 V Analog supplies the negative bias voltage circuitry. The +5 V Digital supplies a separate five volts to the digital section of

the evaluation board, the 80C51, the reset circuitry,

and the RS-232 interface circuitry.

1.5 Negative Bias Voltage

The evaluation board provides three means of supplying the Negative Bias Voltage (NBV). HDR4

(Header 4) selects between them. When HRD4 is in

position one, the LM337 supplies NBV with an adjustable voltage. R16 is used to adjust this voltage

between -1.25 V and -5 V. When in position two,

HDR4 grounds NBV. And by setting HDR4 to position three, the converter’s Charge Pump Drive

provides NBV with a dc rectified voltage, nominally -2.1 V.

Note: NBV should not exceed a voltage more

negative than -3.0 V.

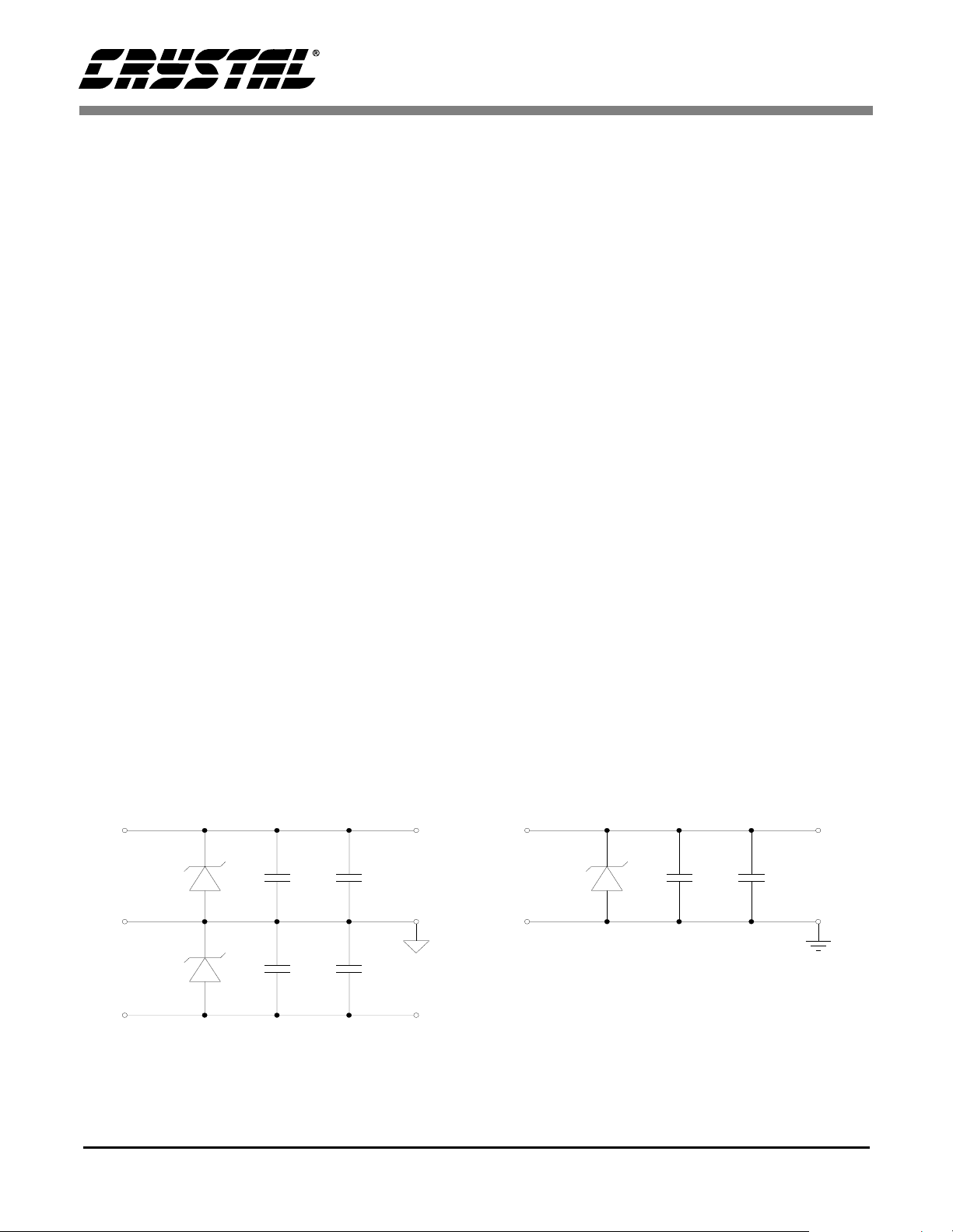

+5V Analog

Z3

P6KE6V8P

AGND DGND

Z1

P6KE6V8P

-5V Analog

8 DS317DB2

+

C8

47µF

+

C5

47µF

+5V Analog

C13

0.1µF

C10

0.1µF

-5V Analog

Figure 4. Power Supplies

+5V Digital

Z2

P6KE6V8P

+5V Digi tal

+

C6

47µF

C12

0.1µF

Page 9

CDB5521/22/23/24/28

1.6 Software

The evaluation board comes with software and an

RS-232 cable to link the evaluation board to the

PC. The executable software was developed with

Lab Windows/CVITM and meant to run under WindowsTM 3.1 or later. After installing the software,

read the readme.txt file for last minute changes in

the software. Additionally, Section 2., Part II: Soft-

ware further details how to install and use the software

Name Function Description

HDR1 Used to switch AIN1+ (AIN1 on

CS5528) between J1 and AGND.

HDR2 Used to switch AIN1- (AIN2 on

CS5528) between J1 and AGND.

HDR3 Does not exist.

HDR4 Used to switch the power for NBV

from the LM337, CPD, or AGND.

HDR5 Used to switch VREF+ and VREF-

pins from external J2 header to the on

board LT1019 reference.

HDR6 Used to connect an external micro-

controller.

HDR7 Used in conjunction with the self test

modes to test the UART/RS232 com-

munication link between the micro-

controller and a PC.

HDR8 Used to switch AIN2 + (AIN3 on

CS5528) between J1 and AGND.

HDR9 Used to switch AIN2- (AIN4 on

CS5528) between J1 and AGND.

HDR10 Does not exist.

HDR11 Used to switch AIN3+ (AIN5 on

CS5528) between J1 and AGND.

HDR12 Used to switch AIN3- (AIN6 on

CS5528) between J1 and AGND.

HDR13 Used to switch AIN4+ (AIN7 on

CS5528) between J1 and AGND.

HDR14 Used to switch AIN4- (AIN8 on

CS5528) between J1 and AGND.

Table 1. Header Descriptions

1.7. Writing Your Own Interface Software

Tables 2 through 5 list the RS-232 commands used

to communicate between the PC and the microcontroller. To develop additional code to communicate to the evaluation board via RS-232, the

following applies: to write to an internal ADC register, choose the appropriate write command byte

(See Table 2), and transmit it LSB first. Then,

transmit the three data byt es lowest order byt e (b its

7-0) first with the LSB of each byte transmitted

first. These three data bytes provide the 24-bits of

information to be written to the desired register.

To read from an internal register, choose the appropriate read command byte and transmit it LSB first.

Then, the microcontroller automatically acquires the

ADC’s register contents and returns the 24-bits of

information. The returned data is transmitted lowest

order byte first with the LSB of each byte transmitted first.

DS317DB2 9

Page 10

CDB5521/22/23/24/28

Register Read Command (HEX) Write Command (HEX)

Offset Register Physical Channel 1 09 01

Offset Register Physical Channel 2 19 11

Offset Register Physical Channel 3 29 21

Offset Register Physical Channel 4 39 31

Offset Register Physical Channel 5 49 41

Offset Register Physical Channel 6 59 51

Offset Register Physical Channel 7 69 61

Offset Register Physical Channel 8 79 71

Gain Register Physical Channel 1 0A 02

Gain Register Physical Channel 2 1A 12

Gain Register Physical Channel 3 2A 22

Gain Register Physical Channel 4 3A 32

Gain Register Physical Channel 5 4A 42

Gain Register Physical Channel 6 5A 52

Gain Register Physical Channel 7 6A 62

Gain Register Physical Channel 8 7A 72

Configuration Register 0B 03

Conversion Data FIFO 0C --Channel Setup Registers 0D 05

Table 2. Microcontroller Read/Write Commands via RS-232

Perform Conversion Conversion Command (HEX)

Normal Conversion on Setup 1 80

Normal Conversion on Setup 2 88

Normal Conversion on Setup 3 90

Normal Conversion on Setup 4 98

Normal Conversion on Setup 5 A0

Normal Conversion on Setup 6 A8

Normal Conversion on Setup 7 B0

Normal Conversion on Setup 8 B8

Normal Conversion on Setup 9 C0

Normal Conversion on Setup 10 C8

Normal Conversion on Setup 11 D0

Normal Conversion on Setup 12 D8

Normal Conversion on Setup 13 E0

Normal Conversion on Setup 14 E8

Normal Conversion on Setup 15 F0

Normal Conversion on Setup 16 F8

Table 3. Microcontroller Conversion Commands via RS-232

10 DS317DB2

Page 11

CDB5521/22/23/24/28

Self-Offset Calibration Calibration Command (HEX)

Self-Offset Calibration on Setup 1 81

Self-Offset Calibration on Setup 2 89

Self-Offset Calibration on Setup 3 91

Self-Offset Calibration on Setup 4 99

Self-Offset Calibration on Setup 5 A1

Self-Offset Calibration on Setup 6 A9

Self-Offset Calibration on Setup 7 B1

Self-Offset Calibration on Setup 8 B9

Self-Offset Calibration on Setup 9 C1

Self-Offset Calibration on Setup 10 C9

Self-Offset Calibration on Setup 11 D1

Self-Offset Calibration on Setup 12 D9

Self-Offset Calibration on Setup 13 E1

Self-Offset Calibration on Setup 14 E9

Self-Offset Calibration on Setup 15 F1

Self-Offset Calibration on Setup 16 F9

Self Gain Calibration Calibration Command (HEX)

Self-Gain Calibration on Setup 1 82

Self-Gain Calibration on Setup 2 8A

Self-Gain Calibration on Setup 3 92

Self-Gain Calibration on Setup 4 9A

Self-Gain Calibration on Setup 5 A2

Self-Gain Calibration on Setup 6 AA

Self-Gain Calibration on Setup 7 B2

Self-Gain Calibration on Setup 8 BA

Self-Gain Calibration on Setup 9 C2

Self-Gain Calibration on Setup 10 CA

Self-Gain Calibration on Setup 11 D2

Self-Gain Calibration on Setup 12 DA

Self-Gain Calibration on Setup 13 E2

Self-Gain Calibration on Setup 14 EA

Self-Gain Calibration on Setup 15 F2

Self-Gain Calibration on Setup 16 FA

Table 4. Microcontroller Self Calibration Commands via RS-232

DS317DB2 11

Page 12

CDB5521/22/23/24/28

System-Offset Calibration Calibration Command (HEX)

System-Offset Calibration on Setup 1 85

System-Offset Calibration on Setup 2 8D

System-Offset Calibration on Setup 3 95

System-Offset Calibration on Setup 4 9D

System-Offset Calibration on Setup 5 A5

System-Offset Calibration on Setup 6 AD

System-Offset Calibration on Setup 7 B5

System-Offset Calibration on Setup 8 BD

System-Offset Calibration on Setup 9 C5

System-Offset Calibration on Setup 10 CD

System-Offset Calibration on Setup 11 D5

System-Offset Calibration on Setup 12 DD

System-Offset Calibration on Setup 13 E5

System-Offset Calibration on Setup 14 ED

System-Offset Calibration on Setup 15 F5

System-Offset Calibration on Setup 16 FD

System Gain Calibration Calibration Command (HEX)

System-Gain Calibration on Setup 1 86

System-Gain Calibration on Setup 2 8E

System-Gain Calibration on Setup 3 96

System-Gain Calibration on Setup 4 9E

System-Gain Calibration on Setup 5 A6

System-Gain Calibration on Setup 6 AE

System-Gain Calibration on Setup 7 B6

System-Gain Calibration on Setup 8 BE

System-Gain Calibration on Setup 9 C6

System-Gain Calibration on Setup 10 CE

System-Gain Calibration on Setup 11 D6

System-Gain Calibration on Setup 12 DE

System-Gain Calibration on Setup 13 E6

System-Gain Calibration on Setup 14 EE

System-Gain Calibration on Setup 15 F6

System-Gain Calibration on Setup 16 FE

Miscellaneous Commands Command

Variable # of Normal Conversions 1F

Serial Port Initialization 3F

Reset Converter 4F

Arbitrary Read SDO EF

Arbitrary Write SDI FF

Table 5. Microcontroller System Calibration Commands via RS-232

12 DS317DB2

Page 13

CDB5521/22/23/24/28

2. PART II: SOFTWARE

2.1 Installation Procedure

To install the software:

1) Turn on the PC, running Windows 95TM or later.

2) Insert the Installation Diskette #1 into the PC.

3) Select the Run option from the Start menu.

4) At the prompt, type: A:\SETUP.EXE <enter>.

5) The program will begin installation.

6) If it has not already been installed on the PC,

the user will be prompted to enter the directory

in which to install the CVI Run-Time EngineTM. The Run-Time EngineTM manages executables created with Lab Windows/CVITM. If

the default directory is acceptable, select OK

and the Run-Time EngineTM will be installed

there.

7) After the Run-Time EngineTM is installed, the

user is prompted to enter the directory in which

to install the CDB55521/22/23/24/28 software.

Select OK to accept the default directory.

8) Once the program is installed, it can be run by

double clicking on the Eval5522 icon, or

through the Start menu.

Note: The software is written to run with 640 x 480 resolution;

however, it will work with 1024 x 768 resolution.

If the user interface seems to be a little small,

the user might consider setting the display

settings to 640 x 480. (640x480 was chosen to

accommodate a variety of computers).

2.2 Using the Software

At start-up, the window Start-Up appears first (Figure 5). This window contains information concern-

ing the software’s title, revision number, copyright

date, etc. Additionally, at the top of the screen is a

menu bar which displays user options. Notice, the

menu bar item Menu is initially disabled. This

eliminates any conflicts with the mouse or concurrent use of modems. Before proceeding any further,

the user is prompted to select the serial communication port. To initialize a port, pull down option

Setup from the menu bar and select either COM1 or

COM2. After a port is initialized, it is a good idea

to test the RS-232 link between the PC and the

evaluation board. To do this, pull down the Setup

menu from the menu bar and select the option

TESTRS232. The user is then prompted to set the

evaluation board’s test switches to 011 and then reset the board. Once this is done, proceed with the

test. If the test fails, c heck the hardware connection

and repeat again. Otherwise, set the test switches to

000 (normal mode) and reset the board. The option

Menu is now available and performance tests can

be executed.

The evaluation software provides three types of

analysis tests - Time Domain, Frequency Domain,

and Histogram. The Time Domain analysis processes acquired conversions to produce a plot of

Conversion Sample Number versus Magnitude.

The Frequency Domain analysis processes acquired conversions to produce a magnitude versus

frequency plot using the Fast-Fourier transform

(results up to Fs/2 are calculated and plotted). Also,

statistical noise calculations are calculated and displayed. The Histogram analysis test processes acquired conversions to produce a histogram plot.

Statistical noise calculations are also calculated and

displayed (see Figures 4 through 9).

The evaluation software was developed w ith Lab

Windows/CVITM, a software development package

from National Instruments. More sophisticated

analysis software can be developed by purchasing

the development package from National Instruments (512-794-0100).

DS317DB2 13

Page 14

CDB5521/22/23/24/28

2.3 Menu Bars Overview

The menu bar controls the link between windows

and allows the user to exit the program. It also allows the user to initialize the serial port and load

presaved data conversions from a file. The six principal windows are the Start-Up, the Setup W indow ,

the Power Spectrum Window (also referred to as

the FFT window), the Histogram Window, the

Time Domain Window, and the Calibrate Window.

Specifically , the menu bar has the following control

items:

•Menu

To select, click on option Menu from the menu

bar, or use associated hot keys. The items associated with MENU are listed and described below.

- Start-Up Window (F1)

- Setup Window (F2)

- Power Spectrum Window (F3)

- Histogram Window (F4)

- Time Domain Window (F5)

- Calibrate Window (F6)

These six menu items allow the use r to navigate

between the windows. They are available at all

times via the menu bar or hot keys.

• Setup

To select, click on option Setup from the menu

bar. The functions available under Setup are:

- COM1 - When selected, COM1 is initialized to 9600 baud, no parity, 8 data bits, and

1 stop bit.

file. The file must comply with the CDBCAPTURE file save format. The format is:

part number, throughput (or sample rate),

number of conversions, maximum range,

and the data conversions. The user is

prompted to enter the path and file name of

previously saved data. To prevent hardware

conflicts, this option is deactivated while in

the Setup Window.

- TESTRS232 - This test mode tests the ability of the PC to communicate to the evaluation board. It consists of two subtests:

1) test the link between the PC and the RS232 interface circuitry; and

2) test the RS-232 link between the PC and

the microcontroller.

- HDR7 distinguishes these two subtests. Set

HDR7 to Normal to test the complete communication link. Or set HDR7 to Loop

Back to test the link between the RS-232

Circuitry and the PC. Then, set the test

switches to 110 and reset the evaluation

board. The LED’s should indicate a binary

six signifying that the hardware is ready to

initiate the test. To complete the test, the

user must initialize the PC. First, use the

SETUP menu to select a communications

port and then select the TESTRS232 option.

From there, user prompts navigate the user

through the test. The PC indicates if the test

passes or fails. Once either test is complete,

the LED’s toggle to indicate that the test

mode is complete.

• Part

- COM2 - When selected, COM2 is initialized to 9600 baud, no parity, 8 data bits, and

1 stop bit.

- Load From Disk - Used to load and display

previously saved data conversions from a

14 DS317DB2

Allows user to select a different converter.

•Quit

Allows user to exit program.

Page 15

CDB5521/22/23/24/28

2.4 Setup Window Overview

The Setup Window (Figure 6) allows the user to

read and write to the internal register of the converter in either binary or hexadecimal, and acquire

real-time conversions. It has quick access control

icons that quickly reset the converter, reset the con-

verter’s serial port, or self-calibrate the converter’s

offset and gain. The following are controls and indicators associated with this window.

•Acquire Data

This is a control icon. When pressed, the PC

transmits the collect single conversion command

to the microcontroller. The microcontroller in

turn collects a conversion from the ADC and returns it to the PC. The PC stores the conversion

and collects additional conversions to form a set.

From the sample set collected, the high, the low,

peak-to-peak, average, and standard deviation,

are computed (the size of the data set is set by the

Num To Average input) and then the display

icons are updated. This process continues until

the STOP button is pressed, or until another window is selected.

Note: The quick access contro l icons are disa bled

once Acquire is selected. This eliminates

potential hardwar e con flicts.

• Binary Icons

Input icons array to set/clear the 24 individual

bits in the configuration or channel-setup registers. The respective registers bit is set/cleared

as soon as the icon is clicked.

• Channel

Selects the Setup that will be accessed to perform conversions when Acquire Data is activated.

down menu above the register decode box to

select between the different registers.

• Hexadecimal Icons

Nine input/display icons that allow a user to

set/clear the 24 bits in the configuration, or

channel setup registers via 6 hexadecimal nibbles. If the upper nibbles in the registers are zero’s, the leading zero nibbles need not be

entered.

• Num To Average

Input icon that sets the size of the data conversion set referred to after the Acquire Icon is activated.

• Reinitialize Port

This is a control icon. When pressed, 128 logic

1’s followed by a logic ‘0’ are sent to the

ADC’s serial port to reset its port. It does n ot reset the RS-232 link.

• Reset A/D

This is a control icon. When pressed, the microcontroller sends the appropriate commands to

return the converter to its initial default state.

• Stop

Stops the collection of conversion data.

• Update Icons

This is a control icon. When pressed the configuration and channel -setup registers contents

are acquired. Then, the configuration text box

and the register content icons are updated.

• Data FIFO Window

This button opens the Data FIFO Window

when pressed.

• Register Decode Box

Text display box that displays the decoded

meaning of each bit in the configuration regis-

2.5 Data FIFO Window Overview

The following describes the controls available in

the Data FIFO Window (Figure 7).

ter and the channel setup registers. Use the pull-

DS317DB2 15

Page 16

CDB5521/22/23/24/28

•Acquire Data

This icon begins a conversion cycle based on

the selection of MC, LP, and RC. Depending

on the status of these bits, the software will instruct the converter to do single conversions or

collect data in the FIFO, and display the information on the screen. Pressing the STOP button will end the conversion cycle. All other

icons are disabled during the conversion cycles

to avoid hardware conflicts.

• MC/LP/RC Selection

This box allows the user to select between the

different types of conversion cycles available

by modifying the MC, LP, and RC bits in the

configuration register (refer to the

CS5521/22/23/24/28 data sheet for more information).

• Channel

Selects the Setup that will be accessed for single conversions (MC = 0). For MC = 1, this

box is ignored.

• Data FIFO Boxes

These boxes display the information returned

from the data FIFO buffer when MC = 1. For

MC = 0, the single conversion will be displayed

in box number 1.

• Channel Data Boxes

When using the CS5521/23, these boxes will

contain the conversion channel information returned with the data word. When using the

CS5522/24/28, these boxes will be inactive.

2.6 Histogram Window Overview

The following is a description of the controls and indicators associated with the Histogram Window

(Figure 11). Many of the control icons are usable

from the Histogram Window, the Frequency Domain Window, and the Time Domain Window. For

brevity, they are only described in this section.

• Bin

Displays the x-axis value of the cursor on the

Histogram.

• Cancel

Once selected, it allows a user to exit from the

COLLECT algorithm. If data conversion sample sets larger than 64 are being collected and

the CANCEL button is selected, it is recommended that the user reset the evaluation board.

The board will eventually recover from the

continuous collection mode, but the recovery

time could be as long as 10 minutes.

• Channel

Selects the Setup that will be accessed to perform conversions when COLLECT is activated.

• Collect

Initiates the data conversion collection process.

COLLECT has two modes of operation: collect

from file or collect from converter. To collect

from a file an appropriate file from the SETUPDISK menu bar option must be selected. Once

a file is selected, its content is displayed in the

graph. If the user is collecting real-time conversions to analyze, the appropriate COM port

must be selected. The user is then free to coll ect

the preset number of conversions (preset by the

CONFIG pop-up menu discussed below). Notice, there is a significant acquisition time difference between the two methods.

• Config

Opens a pop-up panel to configure how much

data is to be collected, and how to process the

data once it is collected. The following are controls and indicators associated with the CONFIG panel.

- Samples - User selection of 16, 32, 64, 128,

256, 512, 1024, 2048, 4096, or 8192 conversions.

16 DS317DB2

Page 17

CDB5521/22/23/24/28

- Window - Used in the Power Spectrum

Window to calculate the FFT. Windowing

algorithms include the Blackman, Blackman-Harris, Hand, 5-term Hodie, and 7term Hodie. The 5-term Hodie and 7-term

Hodie are windowing algorithms developed

at Crystal Semiconductor. If information

concerning these algorithms is needed, call

technical support.

- Average - Sets the number of consecutive

FFT’s to perform and average.

- Limited Noise Bandwidth - Limits the

amount of noise in the converters bandwidth. When set to zero, no limited noise

calculations are done.

- FFT Bandwidth - Used in the Power Spectrum Window to allow user-scalability of

the frequency axis. When set to zero, the

axis is auto-scaled to one-half the output

word rate.

- OK - Accept the changes

• MAGNITUDE

Displays the y-axis value of the cursor on the

Histogram.

• MAXIMUM

Indicator for the maximum value of the collected data set.

2) print current screen, or

3) print current graph.

• RESTORE

Restores the display of the graph after zoom has

been entered.

• STD. DEV.

Indicator for the Standard Deviation of the collected data set.

• VARIANCE

Indicates the Variance for the current data set.

• ZOOM

Control icon that allows the operator to zoom in

on a specific portion of the current graph. To

zoom, click on the ZOOM icon, then click on the

graph to select the firs t p oint (t he 1st point is the

top left corner of the zoom box). Then click on

the graph again to select the second point (the

2nd point is the bottom right corner of the zoom

box). Once an area has been zoomed in to, the

OUTPUT functions can be used to print a hard

copy of that region. Click on RESTORE when

done with the zoom function.

2.7 Frequency Domain Window (i.e. FFT)

The following describe the controls and indicators

associated with the Frequency Domain Analysis

(Figure 8).

•MEAN

Indicator for the mean of the data sample set.

• MINIMUM

Indicator for the minimum value of the collect-

ed data set.

• Output

Control that calls a pop-up menu. This menu

controls three options:

1) save current data set to a file with the CDB-

CAPTURE format

DS317DB2 17

• CANCEL

See description in Section 2.6, Histogram

Window Overview.

• Channel

See description in Section 2.6, Histogram Win-

dow Overview.

• COLLECT

See description in Section 2.6, Histogram Win-

dow Overview.

Page 18

CDB5521/22/23/24/28

• Config

See description in Section 2.6, Histogram Window Overview.

• FREQUENCY

Displays the x-axis value of the cursor on the

FFT display.

• MAGNITUDE

Displays the y-axis value of the cursor on the

FFT display.

• Output

See description in Section 2.6, Histogram Win-

dow Overview.

• S/D

Indicator for the Signal-to-Distortion Ratio, 4

harmonics are used in the calculations (decibels).

• S/N+D

Indicator for the Signal-to-Noise + D istortion

Ratio (decibels).

• SNR

Indicator for the Signal-to-Noise Ratio, first 4

harmonics are not included (decibels).

• S/PN

Indicator for the Signal-to-Peak Noise Ratio

(decibels).

• ZOOM

See description in Section 2.6, Histogram Win-

dow Overview.

• # of AVG

Displays the number of FFT’s averaged in the

current display.

2.8 Time Domain Window Overview

The following controls and indicators are associated with the Time Domain Analysis (Figure 10).

• CANCEL

See description in Section 2.6, Histogram Win-

dow Overview.

• Channel

See description in Section 2.6, Histogram Win-

dow Overview.

• COLLECT

See description in Section 2.6, Histogram Win-

dow Overview.

• Config

See description in Section 2.6, Histogram Window Overview.

• COUNT

Displays current x-position of the cursor on the

time domain display.

• MAGNITUDE

Displays current y-position of the cursor on the

time domain display.

• MAXIMUM

Indicator for the maximum value of the colle cted data set.

• MINIMUM

Indicator for the minimum value of the collected data set.

• Output

See description in Section 2.6, Histogram Win-

dow Overview.

• ZOOM

See description in Section 2.6, Histogram Win-

dow Overview.

18 DS317DB2

Page 19

CDB5521/22/23/24/28

2.9 Calibration Window Overview

The following controls and indicators are associated with the Calibration Menu (Figure 9).

• GAIN DECODE

Eight display boxes that displays the decoded

meaning of each gain register.

• Gain Hexadecimal Icons

Eight input/display icons that allow a user to

set/clear the 24 bits in the eight gain registers

via 6 hexadecimal nibbles. If the upper nibbles

in the registers are zero’s, then leading zero

nibbles need to be entered.

• Offset Hexadecimal Icons

Eight input/display icons that allow a user to

set/clear the 24 bits in the eight offset registers

via 6 hexadecimal nibbles. If the upper nibbles

in the registers are zero’s, then leading zero

nibbles need to be entered.

• Self-Gain

Used to perform a self-gain calibration using

the chosen Setup.

• Self-Offset

Used to perform a self-offset calibration using

the chosen Setup.

• Shift Gain Register

Sixteen input icons used to shift the contents on

the gain registers either 1 bit left or right. Once

shifted the data at the respective gain registers

ends is lost.

• System-Gain

Used to perform a system-gain calibration using the chosen Setup.

• System-Offset

Used to perform a system-offset calibration using the chosen Setup.

• Update Icons

This is a control icon. When pressed the offset

and gain registers are read. Then, the register

content icons are updated.

2.10 Trouble Shooting the Evaluation Board

This section describes special test modes incorporated

in the microcontroller software to diagnose hardware

problems with the evaluation board.

Note: To enter these modes, set the test switches to the

appropriate posi tion a nd rese t th e e valu at ion

board. To re-enter the normal operation mode, set

the switches back to binary zero an d reset the

board again.

• Test Mode 0, Normal Mode

This is the default mode of operation. To enter

this mode, set the test switches to 000 and reset

the board. The evaluation board allows normal

read/writes to the ADC’s registers. All the

LED’s toggle on then off after reset, and then

only when communicating with the PC.

• Test Mode 1, Loop Back Test

This test mode checks the microcontroller’s on-

chip UART. To enter this mode, set test switches to 001, set HDR7 for loop back, and then reset the board. If the communication works, all

the LED's toggle. Otherwise, only 1/2 of the

LED’s toggle to indicate a communication

problem.

• Test Mode 2, Read/Write to ADC

This test mode tests the microcontroller’s abil-

ity to read and write to the ADC. To enter this

mode, set the switches to 010 and reset the

board. In this test mode, the ADC’s configuration, offset, and gain registers are written to and

then read from. If the correct data is read back,

all the LED's toggle. Otherwise, only half of

them toggle to indicate an error.

DS317DB2 19

Page 20

CDB5521/22/23/24/28

• Test Mode 3, Continuously Acquire Single

Conversion

This test mode repetitively acquires a single

conversion. To enter this mode, set the test

switches to 011 and press reset. A binary three

is indicated on the LED’s. By probing HDR6

and using CS as a triggering pin, an oscilloscope or logic analyzer will display in real-time

how the microcontroller reads conversion data.

•Test Mode 4

Reserved for future modifications.

• Test Mode 5, Continuously Read Gain Register

This test mode repetitively acquires the gain

registers default contents (0x800000 HEX). To

enter this mode, set the test switc hes to 101 and

press reset. The LED’s should indicate a binary

five. By probing HDR6 and using CS as a triggering pin, an oscilloscope or logic analyzer

will display in real-time how the microcontroller acquires a conversion.

• Test Mode 6, PC to Microcontroller RS-232

Communication Link Test

This test mode tests the ability of the PC to

communicate to the evaluation board. It consists of two subtests:

2) test the RS-232 link between the PC and the

microcontroller.

HDR7 distinguishes these two subtests. Set

HDR7 to Normal to test the complete communication link. Or set HDR7 to Loop Back to test

the link between the RS-232 Circuitry and the

PC. Then, set the test switches to 110 and reset

the evaluation board. The LED’s should indicate a binary six signifying that the hardware is

ready to initiate the test. To complete the test,

the user must initialize the PC. First, use the

SETUP menu to select a communications port

and then select the TESTRS232 option. From

there, user prompts navigate the user through

the test. The PC indicates if the test passes or

fails. Once either test is complete, the LED’s

toggle to indicate that the test mode is complete.

• Test Mode 7, Toggle LED’s

This test mode tests the evaluation board

LED’s. To enter this mode, set the test switches

to 111 and reset the board. If the mode passes,

the LED’s toggle.

Note: Remember, to return to the normal

operating mode, set the test switches to

binary zero, return HDR7 to Normal, and

reset the evaluation board.

1) test the link between the PC and the RS-232

interface circuitry; and

20 DS317DB2

Page 21

CDB5521/22/23/24/28

Figure 5. Main Menu

Figure 6. Setup Window

DS317DB2 21

Page 22

CDB5521/22/23/24/28

Figure 7. Data FIFO Window

Figure 8. Frequency Domain Analysis

22 DS317DB2

Page 23

CDB5521/22/23/24/28

Figure 9. Calibration Menu

Figure 10. Time Domain Analysis

DS317DB2 23

Page 24

CDB5521/22/23/24/28

Figure 11. Histogram Analysis (Using the CS5524 with default register settings and 24-bit output words)

24 DS317DB2

Page 25

CDB5521/22/23/24/28

Figure 12. CDB5521/22/23/24/28 Component Side Silkscreen

DS317DB2 25

Page 26

CDB5521/22/23/24/28

Figure 13. CDB5521/22/23/24/28 Component Side (top)

26 DS317DB2

Page 27

CDB5521/22/23/24/28

Figure 14. CDB5521/22/23/24/28 Solder Side (bottom)

DS317DB2 27

Page 28

Loading...

Loading...