Page 1

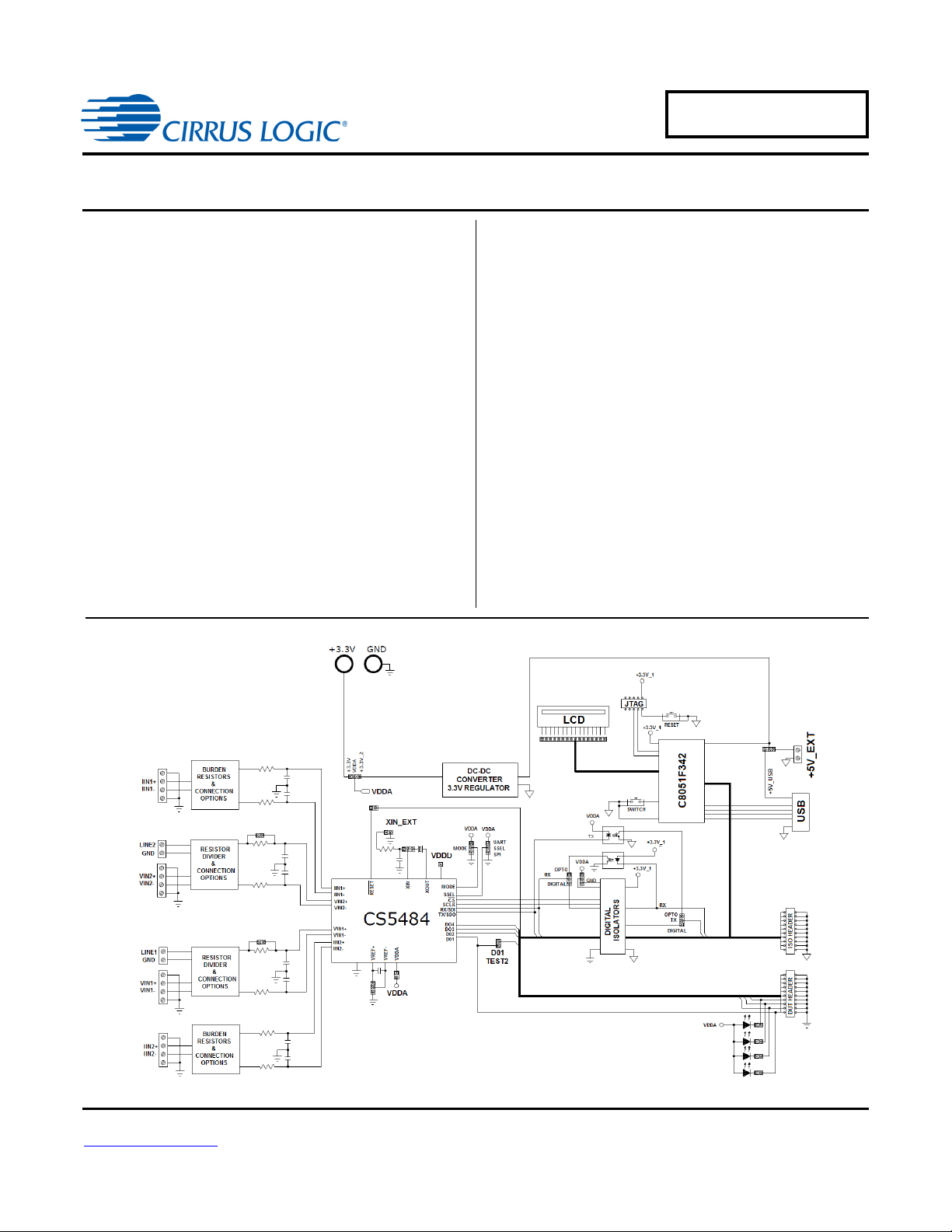

CDB5484U

CDB5484U Engineering Board and GUI Software

Features

• Standalone Power Meter Application

• Voltage and Current Interfaces

• Low- and High-voltage Sensor Connections

• Adaptable Sensor Filters Onboard

• USB Communication with PC

• UART/SPI Isolated Communication

• Onboard C8051F342 Microcontroller

• Single Supply Operation from USB or an External +5 V DC

Supply

• Onboard DC-DC Converter and Regulator

• LCD Power Monitor Display

• LabWindows

– Full Register Setup and Chip Control

– Simplified Register

– Quick Calibration Control

– FFT Analysis

– Time Domain Analysis

– Noise Histogram Analysis

• Voltage Reference Access

®

/CVI® GUI Software

General Description

The CDB5484U is an extensive tool designed to evaluate the

functionality and performance of Cirrus Logic’s CS5484 power/energy measurement device.

Multiple analog input connection options, configuration input filters, direct and isolated digital interfaces, multiple power supply

options, an onboard programmable microcontroller, and visual

LEDs with an LCD panel make the board a flexible and powerful

customer development tool for various power/energy measurement applications.

The GUI software provides easy and complete access and control to the onboard CS5484 device. It also includes the function

of raw ADC data collection with time domain, frequency domain,

and histogram analysis.

Schematics in the PADS™ PowerLogic™ format are available

on request.

ORDERING INFORMATION

CDB5484U-Z Evaluation Board

Cirrus Logic, Inc.

http://www.cirrus.com

Copyright Cirrus Logic, Inc. 2012

(All Rights Reserved)

APR’12

DS919DB5

Page 2

CDB5484U

IMPORTANT SAFETY INSTRUCTIONS

Read and follow all safety instructions prior to using this demonstration board.

This Engineering Evaluation Unit or Demonstration Board must only be used for assessing IC performance in a

laboratory setting. This product is not intended for any other use or incorporation into products for sale.

This product must only be used by qualified technicians or professionals who are trained in the safety procedures

associated with the use of demonstration boards.

Risk of Electric Shock

• The direct connection to the AC power line and the open and unprotected boards present a serious risk of electric

shock and can cause serious injury or death. Extreme caution needs to be exercised while handling this board.

• Avoid contact with the exposed conductor or terminals of components on the board. High voltage is present on

exposed conductor and it may be present on terminals of any components directly or indirectly connected to the AC

line.

• Dangerous voltages and/or currents may be internally generated and accessible at various points across the board.

• Charged capacitors store high voltage, even after the circuit has been disconnected from the AC line.

• Make sure that the power source is off before wiring any connection. Make sure that all connectors are well

connected before the power source is on.

• Follow all laboratory safety procedures established by your employer and relevant safety regulations and guidelines,

such as the ones listed under, OSHA General Industry Regulations - Subpart S and NFPA 70E.

Suitable eye protection must be worn when working with or around demonstration boards. Always

comply with your employer’s policies regarding the use of personal protective equipment.

All components and metallic parts may be extremely hot to touch when electrically active.

Contacting Cirrus Logic Support

For all product questions and inquiries contact a Cirrus Logic Sales Representative. To find the one nearest to you

go to www.cirrus.com

IMPORTANT NOTICE

Cirrus Logic, Inc. and its subsidiaries ("Cirrus") believe that the information contained in this document is accurate and reliable. However, the information is subject

to change without notice and is provided "AS IS" without warranty of any kind (express or implied). Customers are advised to obtain the latest version of relevant

information to verify, before placing orders, that information being relied on is current and complete. All products are sold subject to the terms and conditions of sale

supplied at the time of order acknowledgment, including those pertaining to warranty, indemnification, and limitation of liability. No responsibility is assumed by Cirrus

for the use of this information, including use of this information as the basis for manufacture or sale of any items, or for infringement of patents or other rights of third

parties. This document is the property of Cirrus and by furnishing this information, Cirrus grants no license, express or implied under any patents, mask work rights,

copyrights, trademarks, trade secrets or other intellectual property rights. Cirrus owns the copyrights associated with the information contained herein and gives

consent for copies to be made of the information only for use within your organization with respect to Cirrus integrated circuits or other products of Cirrus. This consent does not extend to other copying such as copying for general distribution, advertising or promotional purposes, or for creating any work for resale.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE ("CRITICAL APPLICATIONS"). CIRRUS PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARRANTED FOR

USE IN AIRCRAFT SYSTEMS, MILITARY APPLICATIONS, PRODUCTS SURGICALLY IMPLANTED INTO THE BODY, AUTOMOTIVE SAFETY OR SECURITY

DEVICES, LIFE SUPPORT PRODUCTS OR OTHER CRITICAL APPLICATIONS. INCLUSION OF CIRRUS PRODUCTS IN SUCH APPLICATIONS IS UNDERSTOOD TO BE FULLY AT THE CUSTOMER'S RISK AND CIRRUS DISCLAIMS AND MAKES NO WARRANTY, EXPRESS, STATUTORY OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSE, WITH REGARD TO ANY CIRRUS PRODUCT THAT

IS USED IN SUCH A MANNER. IF THE CUSTOMER OR CUSTOMER'S CUSTOMER USES OR PERMITS THE USE OF CIRRUS PRODUCTS IN CRITICAL

APPLICATIONS, CUSTOMER AGREES, BY SUCH USE, TO FULLY INDEMNIFY CIRRUS, ITS OFFICERS, DIRECTORS, EMPLOYEES, DISTRIBUTORS AND

OTHER AGENTS FROM ANY AND ALL LIABILITY, INCLUDING ATTORNEYS' FEES AND COSTS, THAT MAY RESULT FROM OR ARISE IN CONNECTION

WITH THESE USES.

Cirrus Logic, Cirrus, the Cirrus Logic logo designs, EXL Core, and the EXL Core logo design are trademarks of Cirrus Logic, Inc. All other brand and product names

in this document may be trademarks or service marks of their respective owners.

SPI is a trademark of Motorola, Inc.

LabWindows and CVI are registered trademarks of National Instruments, Inc.

Windows, Windows 2000, Windows XP, and Windows 7 are trademarks or registered trademarks of Microsoft Corporation.

PADS and PowerLogic are trademarks of Mentor Graphics Corporation.

2 DS919DB5

Page 3

CDB5484U

TABLE OF CONTENTS

1. HARDWARE .............................................................................................................................................. 5

1.1 Introduction ........................................................................................................................................ 5

1.2 Evaluation Board Overview ................................................................................................................ 5

1.3 Analog Section ................................................................................................................................... 6

1.4 Digital Section .................................................................................................................................... 9

1.5 Power Supply Section ...................................................................................................................... 11

1.6 Typical Sensor Connections ............................................................................................................ 12

1.7 Standalone Meter Application .......................................................................................................... 15

2. SOFTWARE ............................................................................................................................................. 16

2.1 Installation Procedure ...................................................................................................................... 16

2.2 Using the Software ........................................................................................................................... 16

2.3 Start-up Window ............................................................................................................................... 17

2.4 Connect Menu .................................................................................................................................. 17

2.5 System Menu ................................................................................................................................... 21

2.6 Calibration Window .......................................................................................................................... 25

2.7 Conversion Window ......................................................................................................................... 27

2.8 Cirrus Test Window .......................................................................................................................... 29

Appendix A. Bill of Materials...................................................................................................................... 38

Appendix B. Schematics............................................................................................................................. 40

Appendix C. Layer Plots ............................................................................................................................. 43

DS919DB5 3

Page 4

CDB5484U

LIST OF FIGURES

Figure 1. CDB5484U Assembly Drawing and Default Configuration ................................................................ 5

Figure 2. Voltage Channel — Low-voltage Input .............................................................................................. 6

Figure 3. Voltage Channel — High-voltage Input ............................................................................................. 7

Figure 4. Current Channel — Low-voltage Input .............................................................................................. 8

Figure 5. MCU Connection Window ................................................................................................................. 9

Figure 6. Shunt Sensor Power Meter ............................................................................................................. 12

Figure 7. Current Transformer Power Meter................................................................................................... 13

Figure 8. Rogowski Coil Power Meter ............................................................................................................14

Figure 9. Standalone Power Meter Measurements ........................................................................................ 15

Figure 10. GUI Start-up Window..................................................................................................................... 17

Figure 11. Connect to the CDB board Window............................................................................................... 18

Figure 12. Connect Menu Showing Successful USB Connection .................................................................. 18

Figure 13. USB Error Message....................................................................................................................... 18

Figure 14. Connect Menu Showing Serial Connection Options...................................................................... 19

Figure 15. UART Serial Port Selection Window, UART Selected................................................................... 19

Figure 16. SPI Serial Port Selection Window, SPI Selected........................................................................... 19

Figure 17. Unknown Chip ID Error Message .................................................................................................. 20

Figure 18. System Pull-down Options ............................................................................................................ 21

Figure 19. Setup Window ............................................................................................................................... 22

Figure 20. Calibration Window........................................................................................................................ 25

Figure 21. Conversion Window.......................................................................................................................27

Figure 22. Cirrus Test Pull-down Options....................................................................................................... 29

Figure 23. Data Collection Window ................................................................................................................ 29

Figure 24. Data Collection UART Error Message...........................................................................................30

Figure 25. Data Collection Output Window..................................................................................................... 31

Figure 26. Data Collection Configuration Window .......................................................................................... 31

Figure 27. Histogram Analysis........................................................................................................................ 34

Figure 28. FFT Analysis.................................................................................................................................. 34

Figure 29. Time Domain Analysis...................................................................................................................35

Figure 30. Data Collection to File Window...................................................................................................... 36

Figure 31. Setup and Test Window ................................................................................................................ 37

Figure 32. Bill of Materials (Page 1 of 2) ........................................................................................................ 38

Figure 33. Bill of Materials (Page 2 of 2) ........................................................................................................ 39

Figure 34. Schematic - Analog Inputs............................................................................................................. 40

Figure 35. Schematic - CS5484 and Socket................................................................................................... 41

Figure 36. Schematic - Microcontroller and USB Interface............................................................................. 42

Figure 37. Top Silkscreen............................................................................................................................... 43

Figure 38. Top Routing ................................................................................................................................... 45

Figure 39. Bottom Routing.............................................................................................................................. 46

Figure 40. Solder Paste Mask ........................................................................................................................ 47

4 DS919DB5

Page 5

CDB5484U

1. HARDWARE

1.1 Introduction

The CDB5484U evaluation board provides a convenient means of evaluating the CS5484 energy measurement IC. The CDB5484U evaluation board operates from a single USB or 5V power supply. An optional 3.3V power supply input is available for powering the CS5484 directly. The evaluation board

interfaces the CS5484 to a PC via a USB cable. To accomplish this, the board comes equipped with a

C8051F342 microcontroller and a USB interface. Additionally, the CDB5484U GUI software provides

easy access to the internal registers of the CS5484. The software also provides a means to display the

on-chip ADC performance in the time domain or frequency domain.

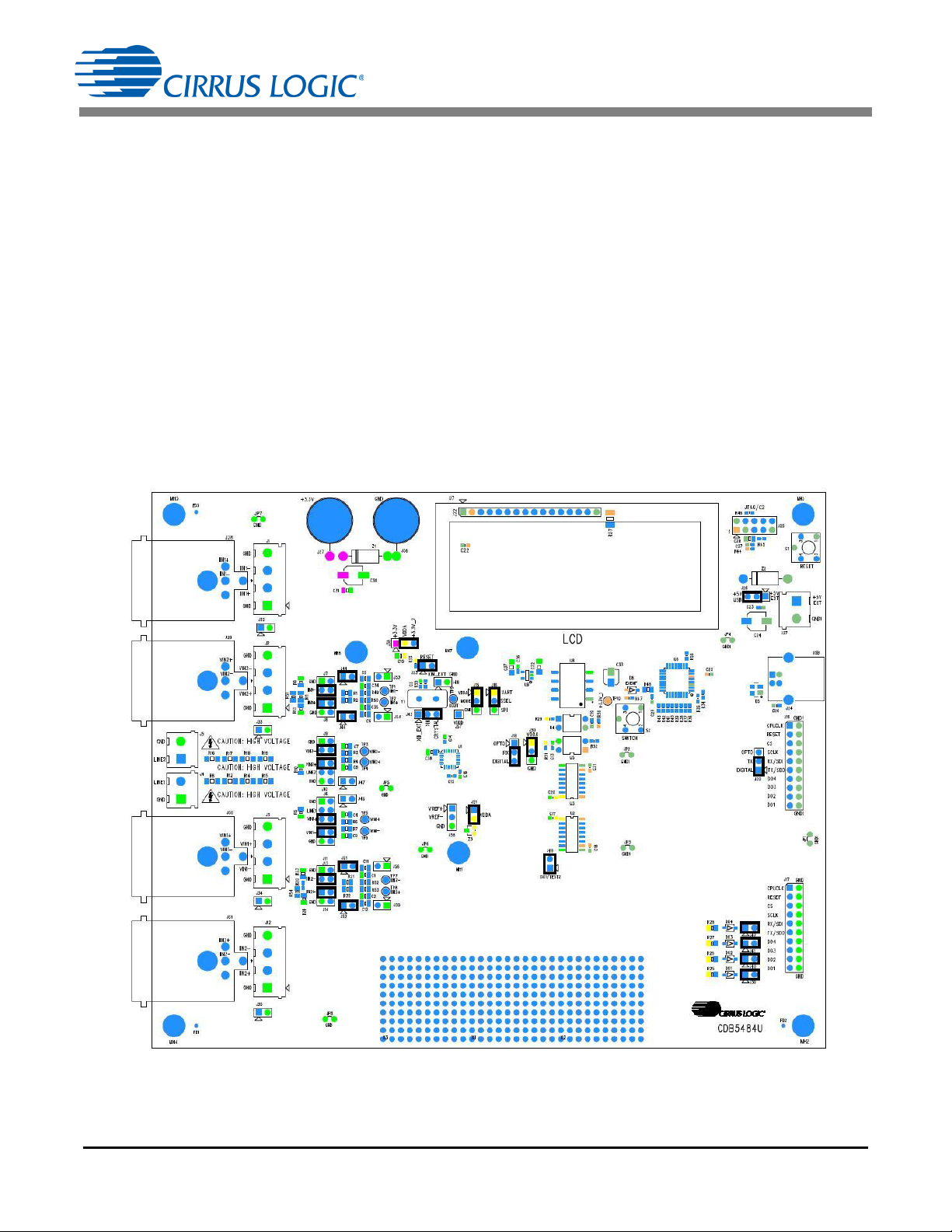

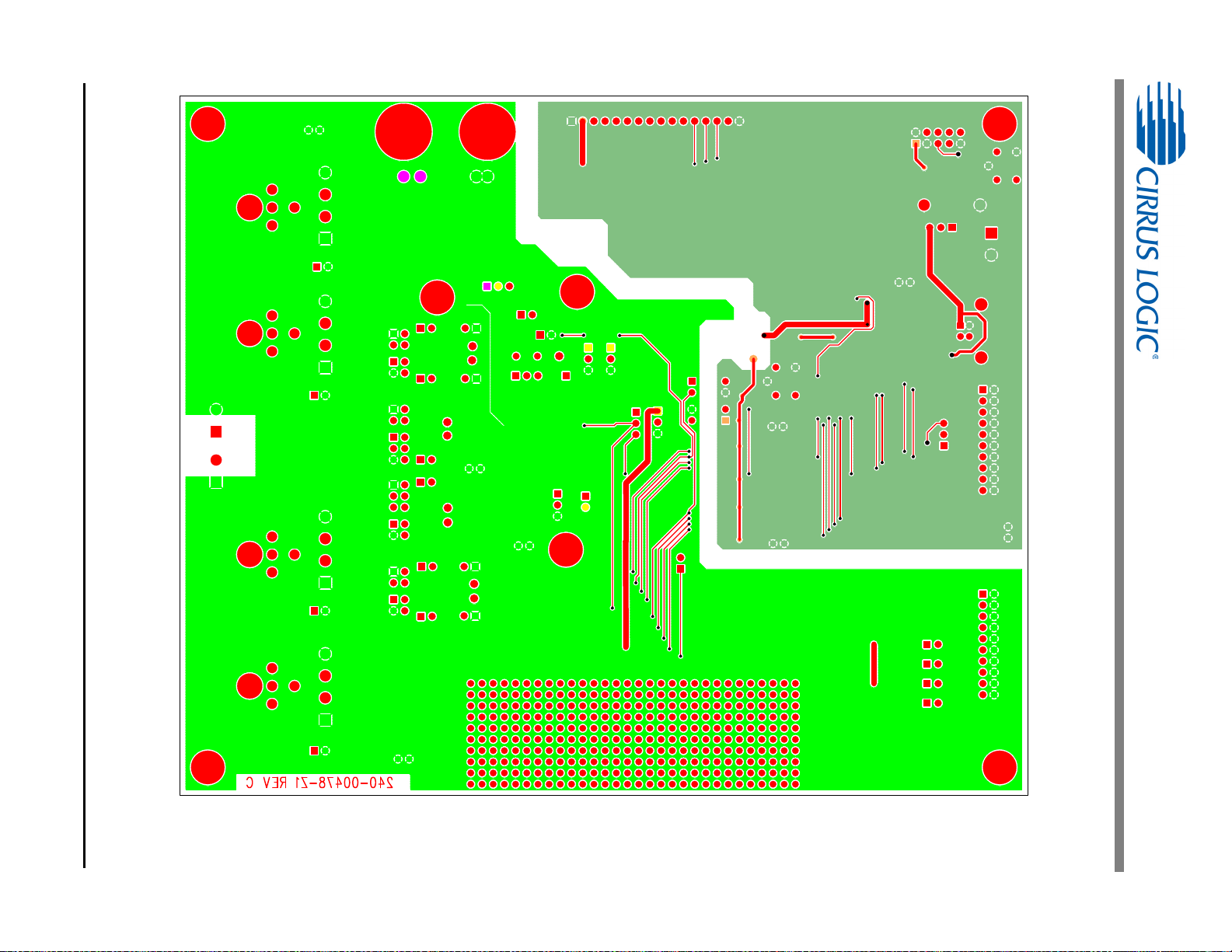

1.2 Evaluation Board Overview

The board is partitioned into two main sections: analog and digital. The analog section consists of the

CS5484, passive anti-aliasing filters, and a high-voltage section with attenuation resistor networks. The

digital section consists of the C8051F342 microcontroller, LCD, test switches, reset circuitry, and USB interface. The board also has a user-friendly power supply connection. The assembly information and default configurations for jumpers are shown below.

Figure 1. CDB5484U Assembly Drawing and Default Configuration

DS919DB5 5

Page 6

CDB5484U

O VIN1-

O O VIN1-

GND

VIN1-

(Default)

O VIN1+

O O VIN1+

O O VIN1+

GND

Line1

VIN1+

(Default)

O VIN2-

O O VIN2-

VIN2-

GND

(Default)

O VIN2+

O O VIN2+

O O VIN2+

VIN2+

Line2

GND

(Default)

O VIN1-

O O VIN1-

GND

VIN1-

O VIN1+

O O VIN1+

O O VIN1+

GND

Line1

VIN1+

O VIN2-

O O VIN2-

VIN2-

GND

O VIN2+

O O VIN2+

O O VIN2+

VIN2+

Line2

GND

O VIN1-

O O VIN1-

GND

VIN1-

O VIN1+

O O VIN1+

O O VIN1+

GND

Line1

VIN1+

O VIN2-

O O VIN2-

VIN2-

GND

O VIN2+

O O VIN2+

O O VIN2+

VIN2+

Line2

GND

O VIN1-

O O VIN1-

GND

VIN1-

O VIN1+

O O VIN1+

O O VIN1+

GND

Line1

VIN1+

O VIN2-

O O VIN2-

VIN2-

GND

O VIN2+

O O VIN2+

O O VIN2+

VIN2+

Line2

GND

VIN1+/VIN2+

VIN1-/VIN2-

250 mVp

CDB5484U

CS5484

J3/J2

J6/J10

J11/J9

C4/C8

0.027UF

C9/C7

0.027UF

R6/R4

1K

R7/R3

1K

J45/J47

VIN1+/VIN2+

VIN1-/VIN2-

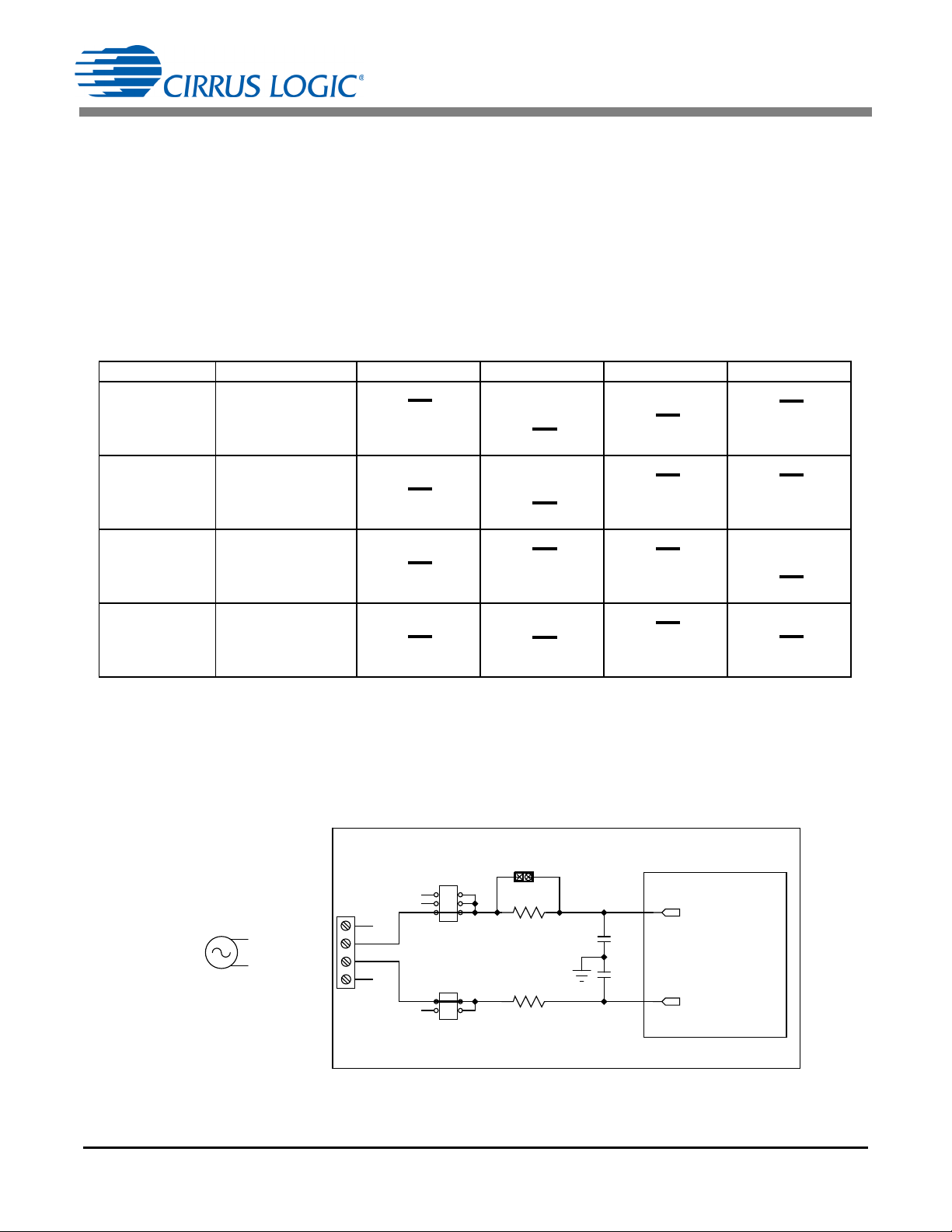

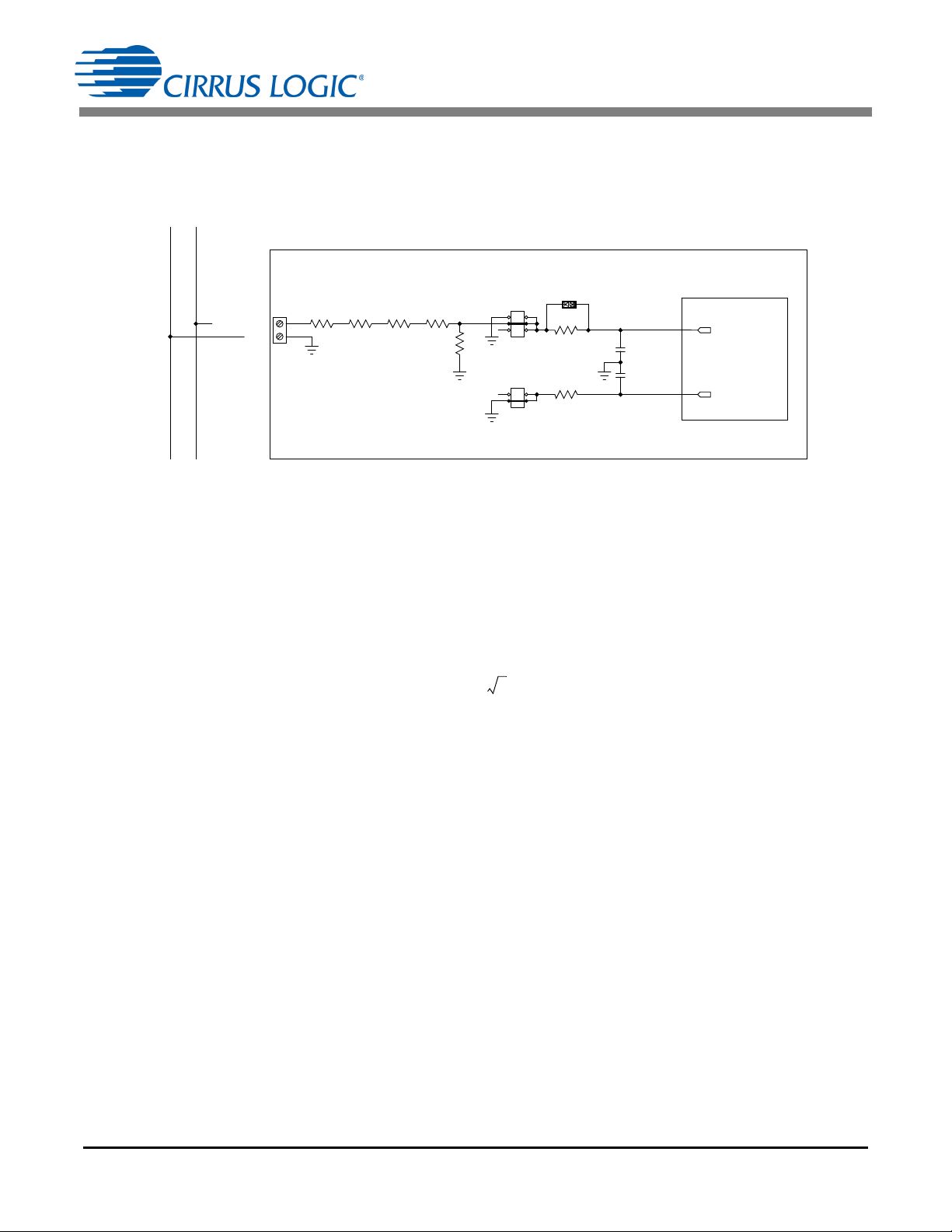

1.3 Analog Section

The analog section of the CDB5484U is highly configurable. Onboard signal conditioning options for the

voltage and current channels enable most applications to interface directly to the sensors. The following

two sections define the voltage and current channel configurations.

1.3.1 Voltage Sensor Connection

There are three input signal options for the voltage channel inputs (VIN1±, VIN2±) which include an external low-voltage signal (via screw terminals or XLR connections), high-voltage line inputs, or GND.

Table 1 illustrates the options available.

Table 1. Voltage Channel Input Signal Selection

INPUT Description J11 J6 J9 J10

Selects External

VIN1± or VIN2±

VIN1± or VIN2±

Low-voltage Fully

Differential Signal

Selects External

Low-voltage Single-ended Signal

GND

High Voltage

Line1 or Line2

Selects Grounding

the Input

Selects External

High-voltage AC

Line Signal

The CDB5484U evaluation board provides screw-type terminals (J3 and J2) or XLR connectors (J30 and

J29) to connect low-voltage input signals to the voltage channels (see Figure 2). The screw terminals are

labeled as VIN1+ / VIN1- and VIN2+ / VIN2-. An R-C network at each channel input provides a simple

configurable anti-alias filter. By installing jumpers on J6 to position VIN1+, J11 to position VIN1-, J10 to

position VIN2+, and J9 to position VIN2-, the input voltage signal is supplied from the screw terminals or

XLR connections.

6 DS919DB5

Figure 2. Voltage Channel — Low-voltage Input

Page 7

CDB5484U

GND

LINE1/LINE2

CS5484

CDB5484U

NEUTRAL

LINE

J4/J5

J11/J9

J6/J10

R5/R10

1K

C9/C7

0.027UF

C4/C8

0.027UF

R7/R3

1K

R6/R4

1K

R8/R16

422K

R12/R17

422K

R14/R18

422K

R15/R19

422K

J45/J47

VIN1-/VIN2-

VIN1+/VIN2+

1k

4422k1k+

------------------------- ---------------

1

1689

-------------

=

300Vrms

250mVp

2

-----------------------

1689=

The CDB5484U evaluation board provides screw-type terminals (J4 and J5) to connect high-voltage line

inputs. By installing jumpers on J6 to position LINE1, J10 to position LINE2, J11 to position GND, and J9

to position GND, the input voltage signal is supplied from the high-voltage inputs. Extreme care should be

used when connecting high-voltage signals to the CDB5484U evaluation board (see Figure 3).

Figure 3. Voltage Channel — High-voltage Input

The default attenuation networks provide the following attenuation:

With the CS5484 input range of 250mVp at a maximum AC line input of:

is acceptable. It is recommended to apply a 10% margin for the AC line input (270Vrms).

The CDB5484U evaluation board provides input shorting options for calibration and noise performance

measurements. With a jumper on J6, J11, J10, and J9 in the GND position, the inputs are connected to

analog ground (GND).

DS919DB5 7

Page 8

CDB5484U

O IIN1+

O O IIN1+

IIN1+

GND

(Default)

O IIN1-

O O IIN1-

GND

IIN1-

(Default)

O IIN2+

O O IIN2+

IIN2+

GND

(Default)

O IIN2-

O O IIN2-

GND

IIN2-

(Default)

O IIN1+

O O IIN1+

IIN1+

GND

O IIN1-

O O IIN1-

GND

IIN1-

O IIN2+

O O IIN2+

IIN2+

GND

O IIN2-

O O IIN2-

GND

IIN2-

O IIN1+

O O IIN1+

IIN1+

GND

O IIN1-

O O IIN1-

GND

IIN1-

O IIN2+

O O IIN2+

IIN2+

GND

O IIN2-

O O IIN2-

GND

IIN2-

IIN1-/IIN2-

IIN1+/IIN2+

GND

GND

CS5484

CDB5484U

250 mV

J1/J12

J7/J13

J8/J14

C5/C11

0.033UF

C6/C12

0.033UF

R11/R22

NO POP

R1/R21

100

R2/R22

100

R9/R23

NO POP

R13/R24

NO POP

R49/R52 1K

R50/R53 1K

C34/C1

0.033UF

C35/C2

0.033UF

J44/J51

J46/J52

R51/R54

0

J53/J56

J54/J55

IIN1+/IIN2+

IIN1-/IIN2-

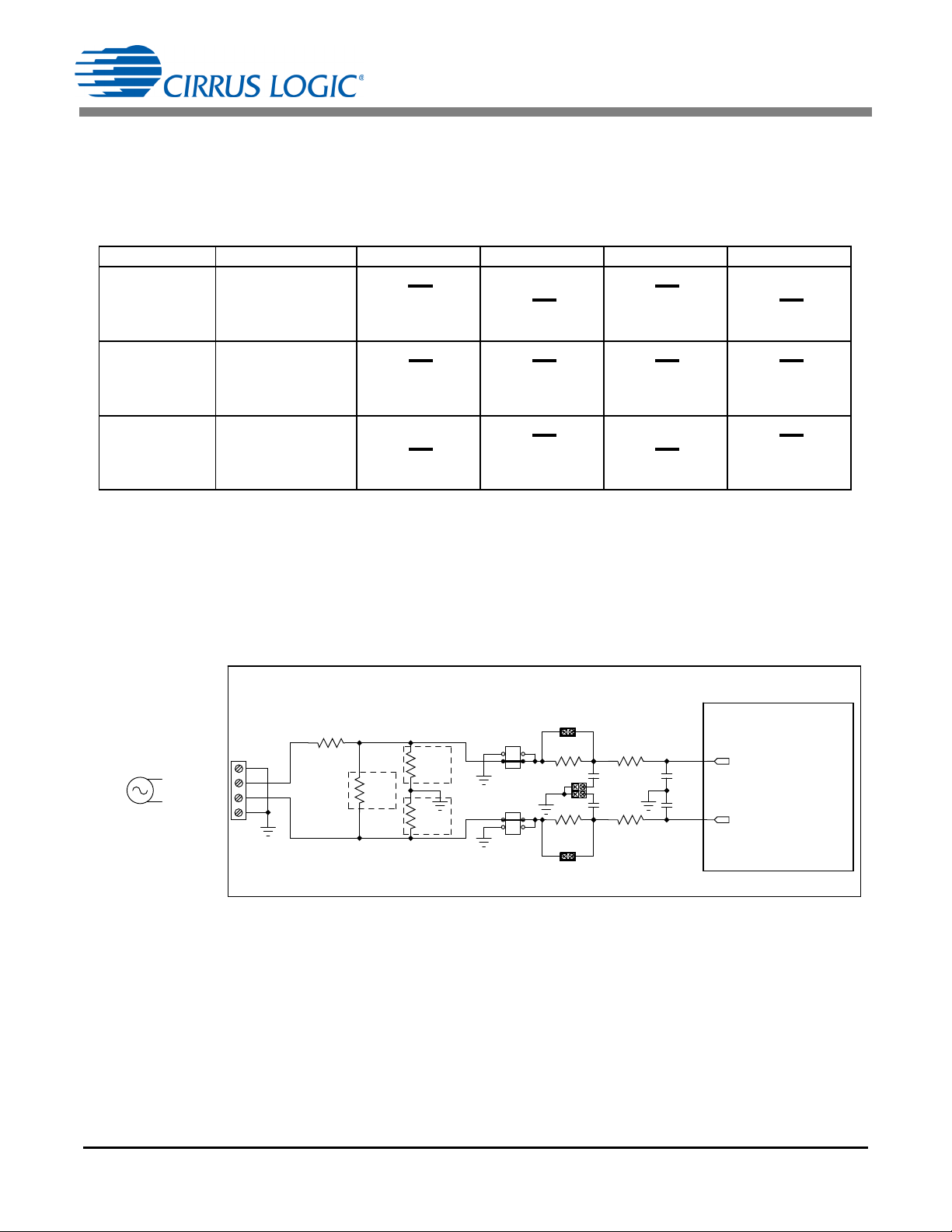

1.3.2 Current Sensor Connection

Current input options include an external signal (via screw terminals or XLR connectors) or GND. Table 2

illustrates the options available.

Table 2. Current Channel Input Signal Selection

INPUT Description J8 J7 J14 J13

Selects External

IIN1± or IIN2±

IIN1± or IIN2±

Low-voltage,

Fully Differential

Signal

Selects External

Low-voltage,

Single-ended

Signal

GND

Selects Grounding

the Input

The CDB5484U evaluation board provides two input signal options for current channels (IIN1±, IIN2±):

screw-type terminals (J1 and J2) or XLR connectors (J28 and J31) to connect input signals to the current

channels. The screw terminals are labeled as IIN1+ / IIN1-, and IIN2+ / IIN2-. An R-C network at each

channel input provides a simple configurable anti-alias filter.

By installing jumpers on J8 to position IIN1+, J7 to position IIN1-, J14 to position IIN2+, and J13 to position

IIN2-, the input current signal is supplied from the screw terminals or XLR connectors.

Figure 4. Current Channel — Low-voltage Input

The CDB5484U evaluation board provides input shorting options for calibration and noise performance

measurements. With a jumper on J8, J7, J14, and J13 in the GND position, the inputs are connected to

analog ground (GND).

8 DS919DB5

Page 9

CDB5484U

U

A

S

P

Low

s

U

A

(4800 B

a

RT

I

peed

RT

ud Max)

J16

Ƒ UART

ż SSEL

ż SPI

(default)

Ƒ UART

ż SSEL

ż SPI

Ƒ UART

ż SSEL

ż SPI

Ƒ

ż

ż

(

d

Ƒ

ż

ż

Ƒ

ż

ż

J18

OPTO

RX

DIGITAL

efault)

OPTO

RX

DIGITAL

OPTO

RX

DIGITAL

J

Ƒ

O

ż

T

ż

D

(def

a

Ƒ

O

ż

T

ż

D

Ƒ

O

ż

T

ż

D

20

PTO

X

IGITAL

ult)

PTO

X

IGITAL

PTO

X

IGITAL

J50

Ƒ VDD

A

ż EN2

ż GND

(default

)

Ƒ VDD

A

ż EN2

ż GND

Ƒ VDD

A

ż EN2

ż GND

1.4 Digital Section

The digital section contains the microcontroller, USB interface, LCD, optical isolation, JTAG header, reset

circuitry, and external interface headers (J17 and J19). The microcontroller interfaces the UART or SPI of

the CS5484 with the USB connection to the PC, enabling the GUI software to access all of the CS5484

registers and functions.

1.4.1 Serial Port Selection

Communication to the CS5484 is provided through two serial port options: UART or SPI. It is necessary

to establish communication with the MCU before establishing a serial port communication protocol with

the CS5484 (see Figure 5).

Figure 5. MCU Connection Window

For UART communication, place the SSEL jumper to the UART position via J16, and select UART in the

serial port selection window. To enable SPI communications, place the SSEL jumper to the SPI position

via J16, and select SPI in the serial port selection window. Table 3 provides the serial communication options on the CDB5484U board.

Table 3. Serial Communication Options

DS919DB5 9

Page 10

CDB5484U

1.4.2 Interface to Microcontroller

Interface headers J17 and J19 are provided to allow the CDB5484U to be connected to an external energy

registration device or an external microcontroller. Interface header J17 provides direct access to the

CS5484 pins while interface header J19 provides an isolated connection. It is imperative to use the isolated connection (J19) when high-voltage signals are used. Failure to use isolation can result in damage

to components or electrical shock. Refer to “Digital Isolation” on page 10 for details on signal isolation.

Interface header J19 can be used to connect to the external microcontroller. To connect the CS5484 to

an external microcontroller, R34, R35, R36, R37, R38, R39, R40, R41, R42, and R43 must be removed

from the board.

1.4.3 Digital Isolation

Two types of isolation are provided, including a low-speed optical coupler for UART-only and high-speed

digital isolation for UART and SPI communication. Default jumper settings provide high-speed digital isolators. To enable high-speed digital isolators, place jumpers (J18 and J20) in the RX to DIGITAL position

and TX to DIGITAL position. To enable the high-speed digital isolators, it is also necessary to install jump-

er (J50) in the VDDA position. To enable low-speed optical UART communication, place jumpers (J18 and

J20) in the RX to OPTICAL position and TX to OPTICAL position.

The high-speed digital isolators operate from DC to 150Mbps. The low-speed optical couplers operate to

a maximum speed of about 4.8kHz. All the signals supplied to the isolators are available to the MCU except CPUCLK.

1.4.4 Additional Device Pin Access

The CS5484’s digital output pins (DO1, DO2, DO3, and DO4) are routed to LEDs, which provide a simple

visual check of the digital output. Jumpers J39, J40, J41, and J42 are equipped at the factory with jumpers

to enable the LEDs. The DO1 digital output pin is supplied to the digital isolation using jumper J49.

The MODE pin jumper (J15) should be installed in the VDDA to MODE position.

The CS5484 system clock can be connected to an onboard quartz crystal, or an external clock can be

supplied to the CS5484 XIN pin though jumper J48. To connect the onboard quartz crystal, install jumper

J43 in the XIN to CRYSTAL position. To connect XIN to an external clock, install jumper J43 in the XIN to

XIN_EXT position.

10 DS919DB5

Page 11

CDB5484U

Sup

p

Sou

r

US

B

Externa

l

&

US

B

Extern

a

ly

ce

C

S

S

o

O

n

3

R

e

+3.3V

B

l +5V

O

n

3

re

g

5484

urce

Bi

p

J3

-board

.3 V

gulator

inding

Post

+

-board

.3V

ulator

nding

ost

6&J37

U

S

u

J

NC

+

3.3 V

+

NC

N

SB

pply

24

5

Ter

m

J

5V

N

5V

N

C

+

V

inals

27

J

C

Ƒ

V

ż

V

(d

e

C

Ƒ

V

ż

V

5V

Ƒ

V

ż

V

VDDA

J21

DDA

DDA

fault)

Ƒ

+

ż

V

ż

+

(d

DDA

DDA

Ƒ

+

ż

V

ż

+

DDA

DDA

Ƒ

+

ż

V

ż

+

J38

+

3.3V

DDA

3.3V_2

efault)

Ƒ

ż

ż

(

3.3V

DDA

3.3V_2

Ƒ

ż

ż

3.3V

DDA

3.3V_2

Ƒ

ż

ż

3.3V_1

J26

+5V EXT

+5V

+5V USB

default)

+5V EXT

+5V

+5V USB

+5V EXT

+5V

+5V USB

1.5 Power Supply Section

Table 4 illustrates the power supply connections on the evaluation board. The positive analog (VDDA) for

the CS5484 can be supplied using the +3.3V binding post (J36 and J37) or the onboard +3.3V regulator.

Jumper J38 allows the VDDA supply to be sourced from the +3.3V binding post (J37) or the regulated

+3.3V supply. The DC-DC converter (U8) powers the onboard +3.3V regulator. Jumper J26 allows the

+5V supply to be sourced from either the +5V EXT screw connector (J27) or the +5V USB supply. The

+5V supplies the power for the microcontroller (8051_REGIN) and the DC-DC converter (U8). Jumper J21

is used to measure the CS5484 analog supply current and must be installed.

When connecting the CDB5484U board to the AC line through non-isolated sensors, it is strongly recommended that the CS5484 GND reference is connected to the neutral, the non-isolated current sensor is

connected to the neutral, and the CS5484 is supplied by +3.3V isolated from AC line. The DC-DC converter (U8) provides 1kVDC isolation, while no isolation is provided for the 3.3V binding post connections.

If +3.3V is used from the binding post, then the external 3.3VDC power supply must be isolated from the

AC line. To prevent electric shock and damages, always use an isolated power source.

Table 4. Power Supply Selection

DS919DB5 11

Page 12

CDB5484U

IIN1-/IIN2-

IIN1+/IIN2+

GND

GND

GND

LINE1/LINE2

CS5484

CDB5484U

PHASE

NEUTRAL

J1/J12

J4/J5

J7/J13

J8/J14

J11/J9

J6/J10

R5/R10

1K

C5/C11

0.033UF

C6/C12

0.033UF

C9/C7

0.027UF

C4/C8

0.027UF

R11/R22

NO POP

R1/R21

100

R2/R22

100

R7/R3

1K

R6/R4

1K

R9/R23

NO POP

R13/R24

NO POP

R8/R16

422K

R12/R17

422K

R14/R18

422K

R15/R19

422K

R49/R52 1K

R50/R53 1K

C34/C1

0.033UF

C35/C2

0.033UF

J44/J51

J46/J52

R51/R54

0

J45/J47

J53/J56

J54/J55

SHUNT

IIN1+/IIN2+

IIN1-/IIN2-

VIN1-/VIN2-

VIN1+/VIN2+

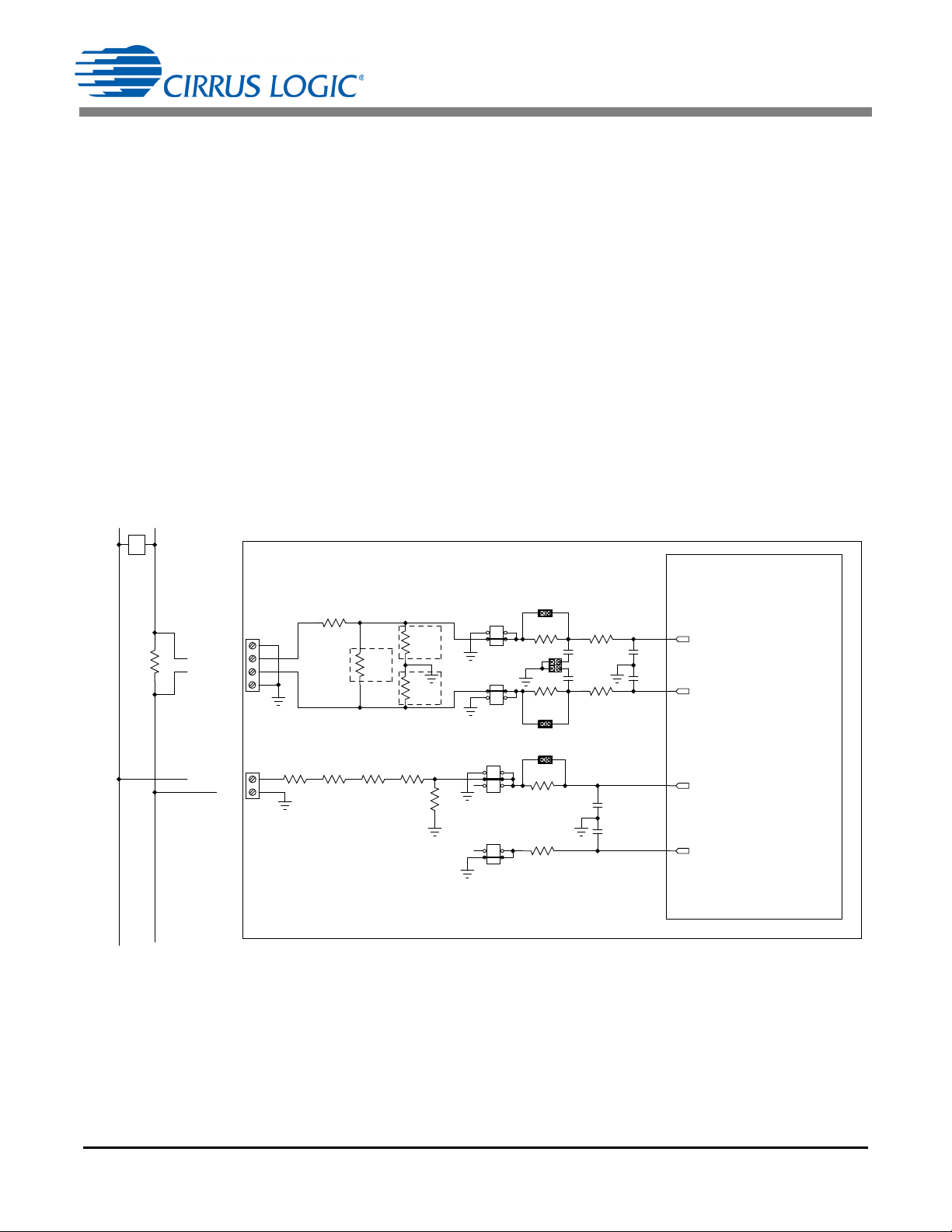

1.6 Typical Sensor Connections

The CDB5484U evaluation board provides connections directly to different types of sensors. Flexible onboard filter networks provide a convenient configuration for three common transducers: current shunt, current transformer (CT), or Rogowski coil.

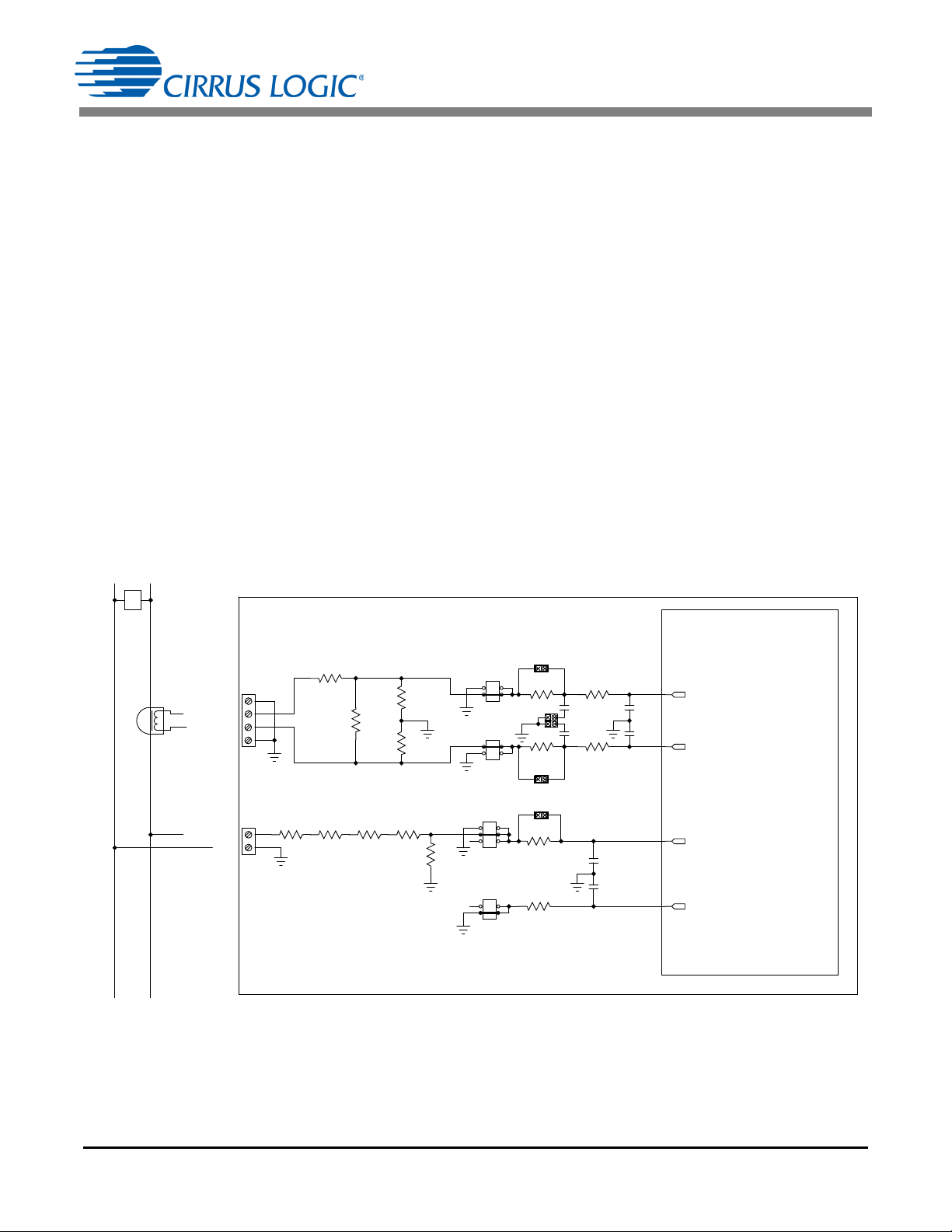

1.6.1 Shunt Power Meter Example

An inexpensive current shunt configuration is easily achievable with the CDB5484U evaluation board.

Figure 6 depicts the voltage and current connections for a shunt sensor and its associated filter configurations.

It is strongly recommended that a low-side (neutral path) current shunt is used, especially in high-voltage

situations. Make sure that all signals are well connected before the power source is turned on. Extreme

care should be taken when connecting high-voltage signals to the CDB5484U evaluation board.

In this configuration it is unnecessary to use a burden resistor. A single anti-alias filter is all that is required

for the current channel. Below the filter corner frequency, the CS5484 inputs will see the same voltage

that is across the shunt. Therefore the shunt voltage should be kept below the maximum of 50mVp with

I-Channel PGA = 50x. A 10% margin is recommended for the shunt voltage (45mVp).

Figure 6. Shunt Sensor Power Meter

12 DS919DB5

Page 13

CDB5484U

V

burden

I

burden

R

burden

I

primary

N

------------------

R

burden

==

IIN1-/IIN2-

IIN1+/IIN2+

GND

GND

GND

LINE1/LINE2

CS5484

CDB5484U

PHASE

NEUTRAL

J1/J12

J4/J5

J7/J13

J8/J14

J11/J9

J6/J10

R5/R10

1K

C5/C11

0.033UF

C6/C12

0.033UF

C9/C7

0.027UF

C4/C8

0.027UF

R11/R22

2.2

R1/R21

100

R2/R22

100

R7/R3

1K

R6/R4

1K

R9/R23

1K

R13/R24

1K

R8/R16

422K

R12/R17

422K

R14/R18

422K

R15/R19

422K

R49/R52 1K

R50/R53 1K

C34/C1

0.033UF

C35/C2

0.033UF

J44/J51

J46/J52

R51/R54

0

J45/J47

J53/J56

J54/J55

IIN1+/IIN2+

IIN1-/IIN2-

VIN1-/VIN2-

VIN1+/VIN2+

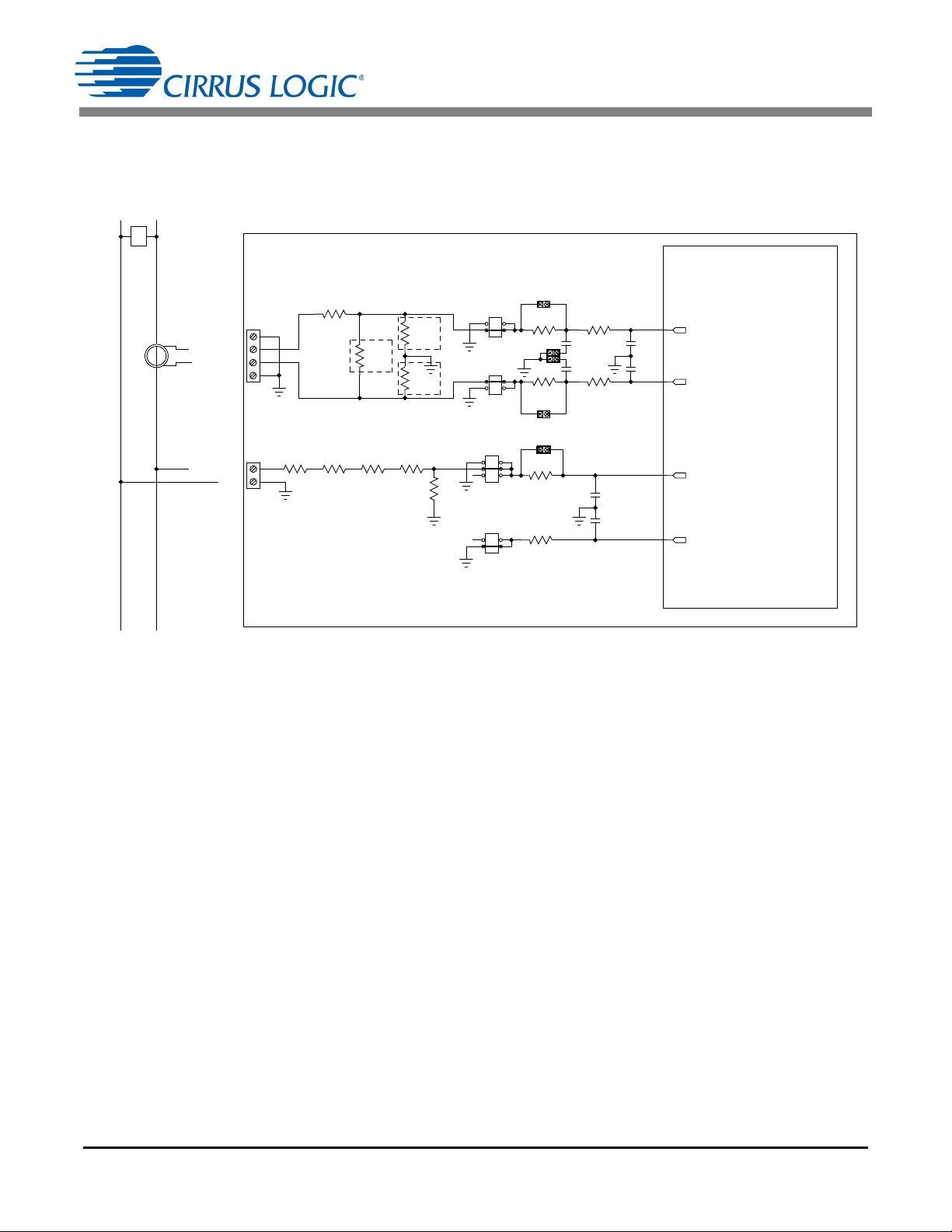

1.6.2 Current Transformer Power Meter Example

A slightly more expensive option is to use a current transformer (CT) to connect the AC current to the

CDB5484U evaluation board. Figure 7 depicts the voltage and current connections for a CT sensor and

its associated filter configurations.

NEVER “open circuit” a CT. Make sure that all signals are well connected before the power source is

turned on. Extreme care should be taken when connecting high-voltage signals to the CDB5484U evaluation board.

The burden resistor (R11/R22) is necessary in a CT application to convert the secondary current into voltage. Knowledge of the current transformers turns ratio (N) is key to determining the proper CS5484 input

voltage (V

maximum current input should be 10% less than the maximum channel voltage of 250mVp with I-channel

PGA = 10x. The secondary voltage (V

ondary current. Then the secondary current (I

) that the meter places on the system. The optimum secondary voltage (V

burden

) is determined by converting the primary current to the sec-

burden

) can be converted into a voltage by Ohm's Law.

burden

burden

) at the

The secondary voltage (V

) is sourced to the CS5484 through a simple low-pass, anti-alias filter, and

burden

this voltage should not exceed the 250mVp.

Figure 7. Current Transformer Power Meter

DS919DB5 13

Page 14

CDB5484U

IIN1-/IIN2-

IIN1+/IIN2+

GND

GND

GND

LINE1/LINE2

CS5484

CDB5484U

PHASE

NEUTRAL

J1/J12

J4/J5

J7/J13

J8/J14

J11/J9

J6/J10

R5/R10

1K

C5/C11

0.033UF

C6/C12

0.033UF

C9/C7

0.027UF

C4/C8

0.027UF

R11/R22

NO POP

R1/R21

100

R2/R22

100

R7/R3

1K

R6/R4

1K

R9/R23

NO POP

R13/R24

NO POP

R8/R16

422K

R12/R17

422K

R14/R18

422K

R15/R19

422K

R49/R52 1K

R50/R53 1K

C34/C1

0.033UF

C35/C2

0.033UF

J44/J51

J46/J52

R51/R54

0

J45/J47

J53/J56

J54/J55

IIN1+/IIN2+

IIN1-/IIN2-

VIN1-/VIN2-

VIN1+/VIN2+

1.6.3 Rogowski Coil Power Meter Example

Rogowski coil power meter can be connected to the CDB5484U evaluation board. Figure 8 shows the

voltage and current connections for the Rogowski sensor and its associated filter configurations.

Figure 8. Rogowski Coil Power Meter

For more information, see AN365: Using the CS5480/84/90 Energy Measurement IC with Rogowski Coil

Current Sensors.

14 DS919DB5

Page 15

CDB5484U

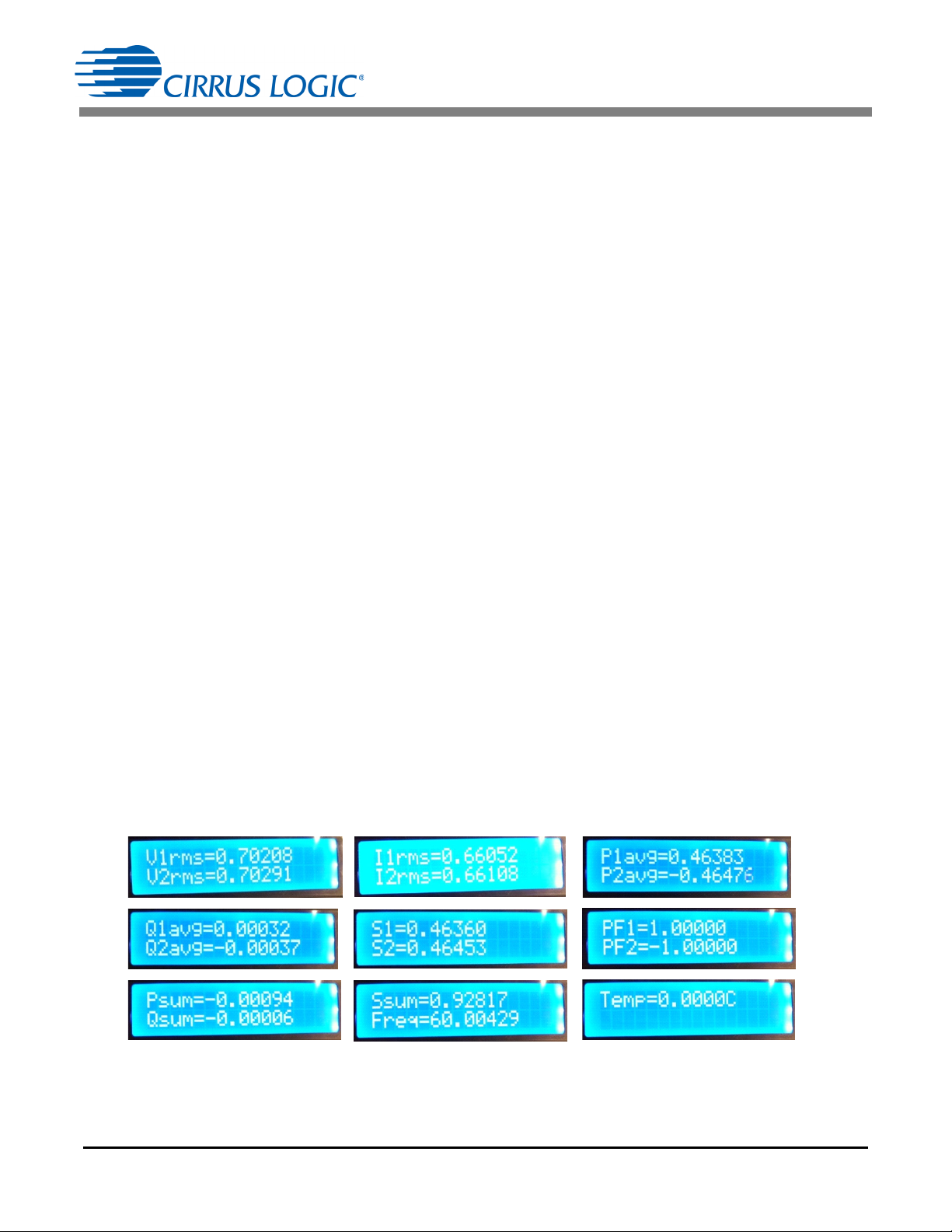

1.7 Standalone Meter Application

The CDB5484U evaluation board provides a standalone power meter using the CS5484, MCU, and LCD.

The user can enable the power meter by connecting the sensors to the analog inputs, providing power to

the board, and resetting the MCU by pressing the RESET switch. Refer to “Typical Sensor Connections”

on page 12 for details on the sensor connections and “Power Supply Section” on page 11 for details on

supply options.

The user should not use the GUI to connect the CDB5484U board. Once the GUI is connected to the

CDB5484U board the standalone power meter function is disabled and the LCD on the CDB5484U will

read "Cirrus Logic CS5484 Eval GUI". To re-enable the standalone power meter feature, close the GUI

software. The standalone power meter feature will initially show the voltage channels’ RMS register values:

V1rms = N.NNNNN and V2rms = N.NNNNN.

By clicking the onboard switch S2, the standalone power meter will display the following measurement

results:

1. RMS Voltage

2. RMS Current

3. Average Active Power

4. Average Reactive Power

5. Average Apparent Power

6. Power Factors

7. Total Active Power

8. Total Reactive Power

9. Total Apparent Power

10. Fundamental Frequency

11. CS5484 Die Temperature

Figure 9. Standalone Power Meter Measurements

DS919DB5 15

Page 16

2. SOFTWARE

CDB5484U

The evaluation board comes with software and a USB cable to link the evaluation board to the PC. The

evaluation software was developed with LabWindows

tional Instruments. The evaluation software is designed to run with Windows XP™ and Windows 7™. The

following procedure is based on Windows XP.

®

/CVI®, a software development package from Na-

2.1 Installation Procedure

Follow the steps below to install the GUI:

1. Access the following web site: http://www.cirrus.com/en/support

2. Navigate to the CDB5484U software link under Energy Measurement. The Software License web

page is displayed.

3. To agree with the terms and conditions, click the Agree button. The File Download window is displayed.

4. Click the Save button. The Save As window is displayed.

5. Select a location to store the compressed folder.

6. Click the Save button. The Download complete window is displayed.

7. Click the Open Folder button. The location where the compressed folder is stored is displayed.

8. Right-click on the compressed folder, and click Extract All.

9. Select a location to extract the files.

.

10. Navigate to the location where the extracted files are stored and double-click on the setup.exe file.

11. Click the Install button, and follow the installation instructions.

12. Execute the GUI using Section 2.1.1 Executing the GUI.

2.1.1 Executing the GUI

1. From the Start menu, click All Programs.

2. Click Cirrus Energy Measurement Evaluation (CDB5484U).

3. Click CDB5484U. The GUI is launched.

2.2 Using the Software

Before launching the software, check all jumper settings on the CDB5484U evaluation board, as described in “Evaluation Board Overview” on page 5, and connect the board to an open USB port on the PC

using the provided cable. Once the board is powered on, the software program can be launched.

16 DS919DB5

Page 17

CDB5484U

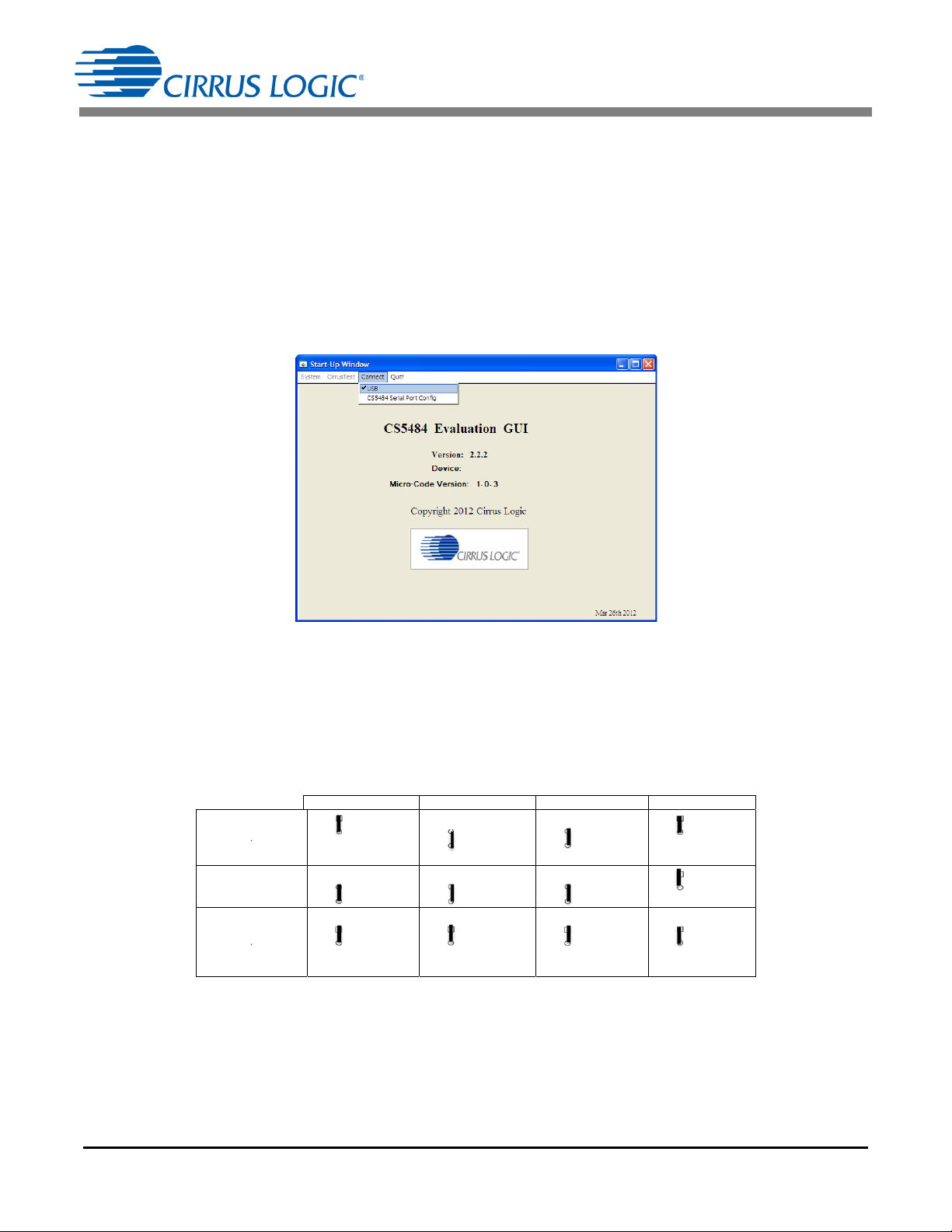

2.3 Start-up Window

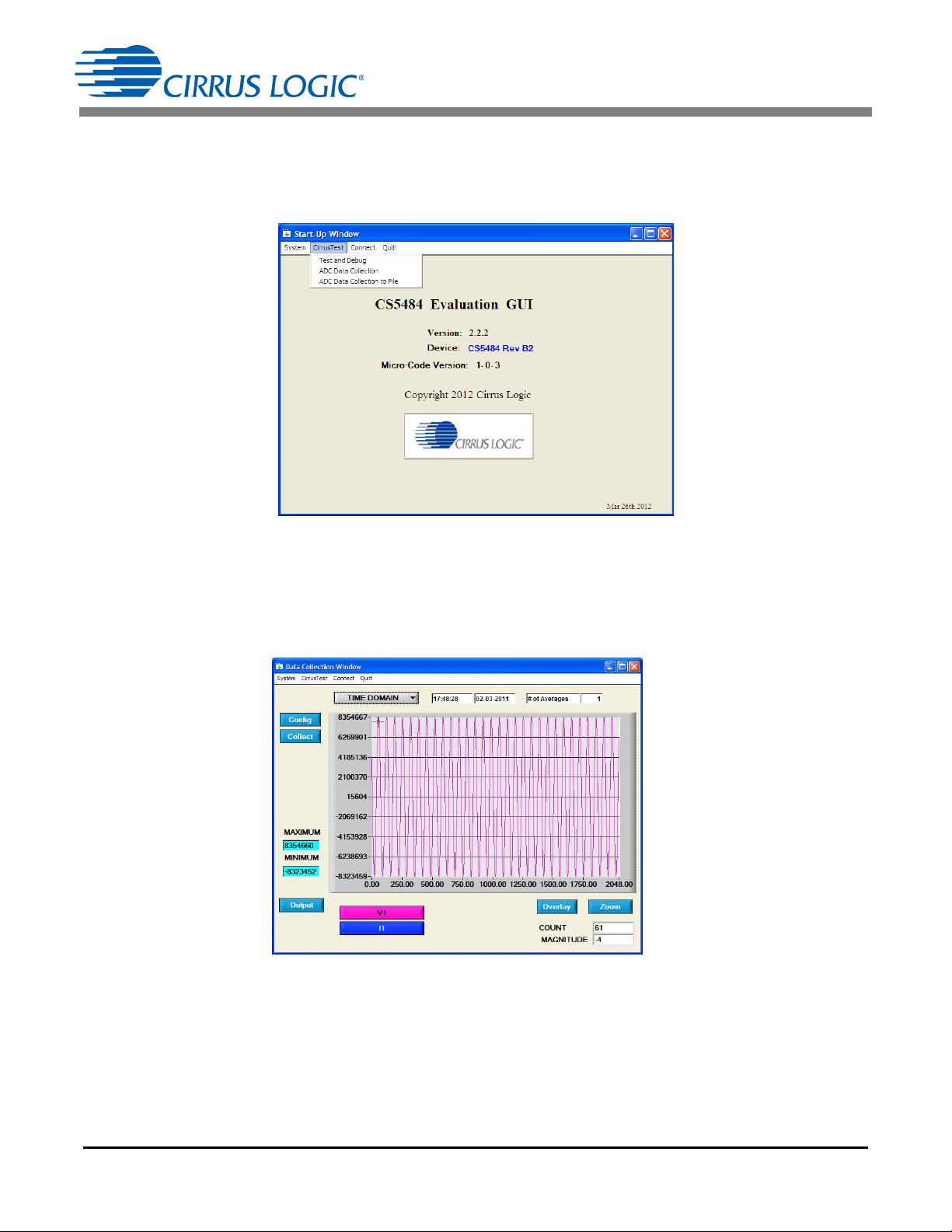

When the software is launched, the Start-Up Window is displayed. This window contains information

about the software, including its title, revision number, and copyright date. The Start-Up Window is displayed in Figure 10.

Figure 10. GUI Start-up Window

A menu bar at the top displays four items: System, Cirrus Test, Connect, and Quit. Initially System and

Cirrus Test are disabled. After establishing a link to a data source, the System and Cirrus Test items will

become available.

2.4 Connect Menu

The Connect menu allows the user to establish a USB communication link with the CDB5484U board.

After the USB communication has been established, the CS5484 serial port configuration needs to be

entered according to the position of jumper J16. Connecting to the CDB5484 is a two-step process:

1. Use the “USB Item” to connect to the MCU.

2. Use the “CS5484 Serial Port Config Item” to connect the MCU to the CS5484.

2.4.1 USB Item

In the Connect menu, the USB item allows the user to establish USB communication. If the USB item in

the Connect menu is selected, the evaluation software will poll the C8051F342 microcontroller, verifying

the serial communication link is ready. When the Connect to the CDB board window is displayed (see

Figure 11), the user should reset the CDB5484 using switch (S1) on the board, wait for Windows to rec-

DS919DB5 17

Page 18

CDB5484U

Figure 11. Connect to the CDB board Window

ognize the MCU (typically 3 seconds), and then select "OK."

At this point, the USB menu item is checked, indicating that the PC has successfully communicated with

the CDB5484U evaluation board. The micro-code version information are read from the board and displayed on the screen (see Figure 12). Due to improvements to the software or new features being added,

the version displayed may be different than the image shown here.

Figure 12. Connect Menu Showing Successful USB Connection

If the evaluation software is unable to establish a communication link with the CDB5484U board, a message is displayed, indicating that the initial communication has failed (see Figure 13).

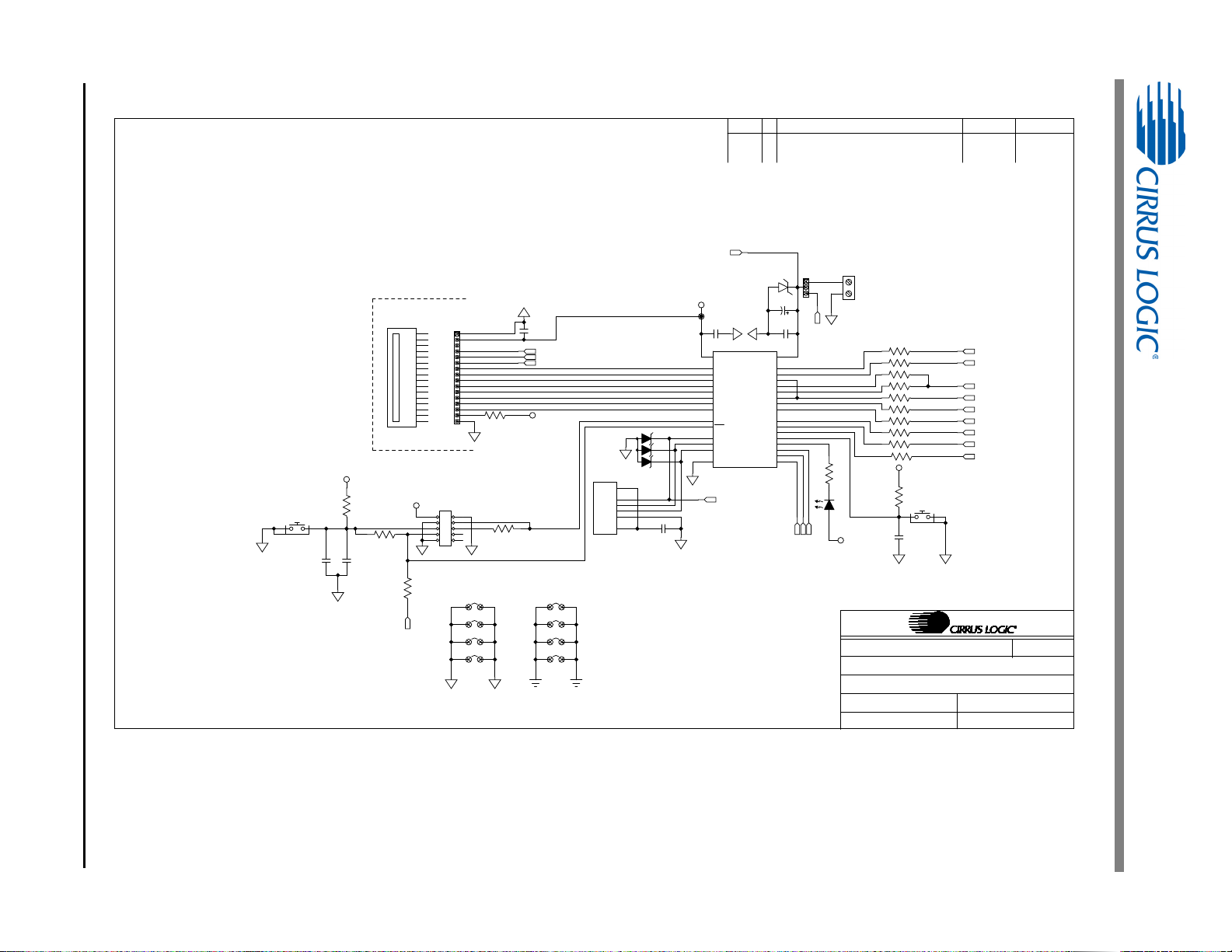

Figure 13. USB Error Message

Check to verify that the USB cable is connected properly and the power supply is on and connected properly to the CDB5484U. Reset the board (press the RESET button on the board) and try to set up the USB

connection again.

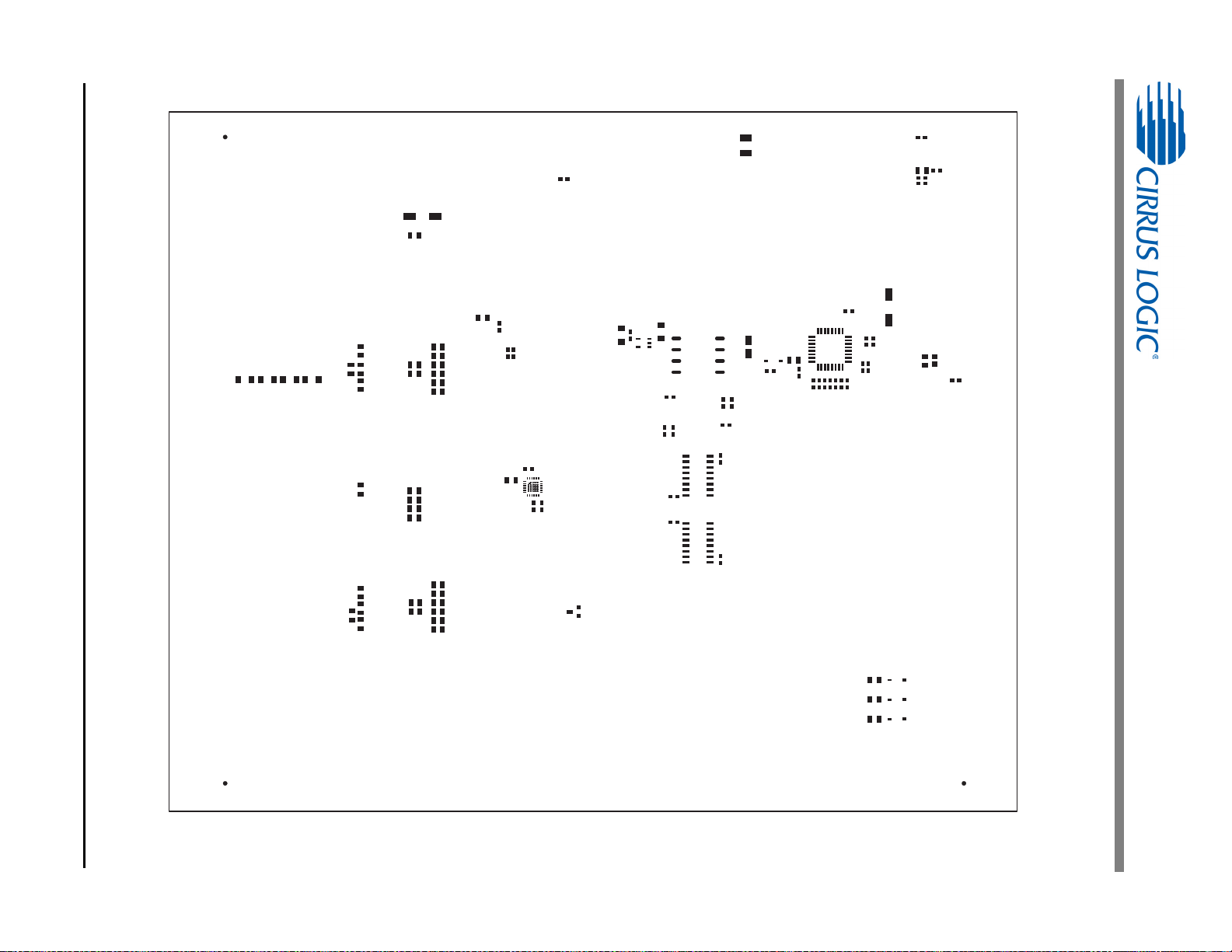

18 DS919DB5

Page 19

CDB5484U

2.4.2 CS5484 Serial Port Config Item

In the Connect menu, the CS5484 Serial Port Config item allows the user to select different types of serial

communication — UART or SPI (see Figure 14).

Figure 14. Connect Menu Showing Serial Connection Options

Before the software is configured, it is necessary to set jumper J16 on the CDB5464U board to either the

UART or SPI communication. To select UART communication, install jumper J16 in the SSEL to UART

position. To select SPI communication install jumper J16 in the SSEL to SPI position.

To select UART communications, position jumper J16 to the SSEL to UART position, and select UART in

the Serial Port Selection window (see Figure 15).

Figure 15. UART Serial Port Selection Window, UART Selected

To select SPI communications, position jumper J16 to the SSEL to SPI position, and select SPI in the Serial Port Selection window (see Figure 16).

Figure 16. SPI Serial Port Selection Window, SPI Selected

DS919DB5 19

Page 20

CDB5484U

After the serial port has been selected, press the OK button. The MCU will try to read the chip ID from the

CS5484. The chip revision number will be displayed in the Device field in the Start-Up Window. If the De-

vice field is populated with "Unknown CHIP ID", the user should check the power supply and clock to the

CS5484, MODE jumper J15, SSEL jumper J16, and the isolation jumpers J18, J51, and J20, click the RE-

SET button, and go back to the USB connection process.

Figure 17. Unknown Chip ID Error Message

20 DS919DB5

Page 21

CDB5484U

2.5 System Menu

The System pull-down provides three options: Setup CS5484, Calibration, and Conversion. Each window

provides a means to evaluate the different functions and performance of the CS5484 (see Figure 18).

Figure 18. System Pull-down Options

DS919DB5 21

Page 22

CDB5484U

2.5.1 Setup Window

The evaluation software provides access to the common CS5484's internal registers through the Setup

Window (see Figure 19). The user can access the Setup Window by selecting the Setup CS5484 item

from the System menu.

Figure 19. Setup Window

The Setup Window displays all of the common CS5484 registers in hexadecimal notation and are decoded to provide easier readability. Refer to the CS5484 data sheet for information on register functionality

and definitions. The Setup Window is segmented by function. Each subsection may contain more than

one CS5484 register in order to configure a particular function. Updating the hexadecimal value of a register will change the definitions display according to the new hexadecimal value of the register(s). Likewise, updating the definitions displayed from the list boxes will update the hexadecimal value(s) of the

associated register(s).

22 DS919DB5

Page 23

CDB5484U

2.5.1.1 Refresh Screen Button

Clicking the Refresh Screen button will update the contents of the screen by reading all the register values

from the CS5484. It is recommended to click the Refresh Screen button when entering the Setup Window,

or after modifying any registers, to reflect the current status of the CS5484.

2.5.1.2 Reset DUT Button

Clicking the Reset DUT button will software-reset the CS5484. The CS5484 will perform a software-reset,

as discussed in the CS5484 data sheet. After the software-reset, the screen contents will be automatically

refreshed with the updated status of the CS5484.

2.5.1.3 Save Config and Load Config Buttons

Clicking the Save Config button will save the current setup widow's configuration to a .txt file. Clicking the

Load Config button will recall a saved configuration and store values into the CS5484.

2.5.1.4 CS5484 MCLK Frequency

The CS5484 accepts a wide range of MCLK input frequencies and can therefore run at many different

sample rates. The frequency being used on the CS5484 should be entered in this box to provide accurate

frequency calculation in the FFT window. This will also help the software decide which functions the evaluation system can perform reliably.

2.5.1.5 Configuration Registers

In the Config0, Config1, and Config2 register boxes, the contents of the CS5484's configuration registers

can be modified by typing a hexadecimal value in the HEX field, or by changing any of the values below

the HEX field to the desired settings. Although the CDB5484U software allows the user to modify any of

the bits in the configuration registers, changing certain reserved bits, such as the NO_OSC bit of Config0,

may cause the software and board to behave erratically. This applies only to the CDB5484U evaluation

system, and not to the CS5484 chip itself.

2.5.1.6 Pulse Control Register

The Pulse Control Register section is used to make changes to, and display the contents of, the CS5484's

PulseCtrl register. The PulseCtrl register contains various bits used to select the input to each energy

pulse generation block within the CS5484. Refer to the CS5484 data sheet for descriptions of the bits.

The value of the PulseCtrl register is displayed in hexadecimal format. Most of the PulseCtrl register bits

are reserved or unused. Only the usable bits are displayed in the Setup Window.

2.5.1.7 Pulse Width and Pulse Rate Registers

The Pulse Width Register section is used to make changes to and display the contents of the CS5484's

PulseWidth register. The PulseWidth register is used to define the frequency range and pulse width of the

energy pulses generated by the CS5484. The PulseWidth register should be configured before setting the

PulseRate register. The Pulse Rate Register section is used to make changes to and display the contents

of the CS5484's PulseRate register. The PulseRate register defines the full-scale frequency of the energy

pulses generated by the CS5484.

DS919DB5 23

Page 24

CDB5484U

2.5.1.8 Phase Compensation

The Phase Comp Register section is used to make changes to, and display the contents of, the CS5484's

PC (Phase Compensation Control) register. The PC register allows coarse- and fine-phase adjustment

on each channel of the CS5484 data path. Refer to the CS5484 data sheet for descriptions of the PC reg-

ister bits.

2.5.1.9 Integrator Gain, System Gain

The Integrator Gain and System Gain sections display the signal path gain in both hexadecimal and decimal format. Each register can be modified by typing a value in the corresponding Decimal or HEX field.

2.5.1.10 Sample Count, Cycle Count, Settle Time

The Sample Count Register, Cycle Count Register, and Settle Time sections provide fields to display the

values of registers associated with low-rate calculations. The SampleCount and CycleCount registers are

entered or displayed in decimal format by default. The user may select to enter or view other number formats of the register by selecting the "d" within the field. The value of the T

hexadecimal and decimal format. Each register can be modified by typing a value in the corresponding

field.

2.5.1.11 Epsilon

register is displayed in both

Settle

The Epsilon section is used to display and adjust the Epsilon register (the ratio of the AC line frequency

to the output word rate). The Epsilon register can be updated either through entering the AC line frequency in the Line Freq field or by entering the direct register value in the HEX field.

2.5.1.12 ZX

When Automatic Frequency Update is enabled, the ZX

NUM

section is used to adjust the number of zero

NUM

crossings used in the Epsilon calculation. The update rate of Epsilon is increased by reducing the zero

crossings. The register can be modified by typing the number of zero crossings.

2.5.1.13 Mask Register

The Mask Register box displays the value for the Mask register in hexadecimal and decodes them to indicate each bit's function. The Mask register can be modified by typing a value in the HEX field, or by

checking the appropriate boxes for the bits that are to be masked. The value present in the Mask register

may be changed by the GUI software during certain operations to provide correct functionality of the

CDB5484U board.

2.5.1.14 Temperature Registers

The Temperature Registers box is used to adjust the temperature offset register (T

gain register (T

) to convert the temperature register (T) from the Celsius scale to the Fahrenheit scale,

GAIN

) and temperature

OFF

or vice versa, and to improve temperature measurement accuracy. Refer to the CS5484 data sheet for

the details of the on-chip temperature sensor.

2.5.1.15 V/I Zero-crossing Level and No Load Threshold

The V/ I Zero-crossing Level and No Load Threshold boxes display the values for these registers in hexadecimal and decimal. Each register can be modified by typing a value in the corresponding Decimal or

HEX field.

24 DS919DB5

Page 25

CDB5484U

2.5.1.16 V1/V2 Sag, V1/ V2 Swell, and I1/I2 Overcurrent Registers

The registers for voltage sag, voltage swell, and overcurrent are displayed in the V1 Sag, V2 Sag, V1

Swell, V2 Swell, I1 Overcurrent, and I2 Overcurrent Register sections. These sections display the level

and duration values of the corresponding registers in both hexadecimal and decimal format. Each register

can be modified by typing a value in the corresponding decimal or HEX field. Refer to the CS5484 data

sheet for detailed descriptions of these registers.

2.5.1.17 Register Checksum, SerialCtrl Registers

The Register Checksum and SerialCtrl Register boxes provide control and status of critical serial port

communication parameters and the register checksum. The SerialCtrl Register section provides control

over RX pin, baud rate, and enabling checksum protection for serial communication. The Register Check-

sum section provides the calculated checksum of the critical registers inside the CS5484. The register

checksum updates automatically after single or continuous conversion has been performed. The RegChk

and SerialCtrl registers are displayed in hexadecimal form. Note that if the opto-couplers are selected as

the isolation (J18, J20), the maximum baud rate is 2400.

The baud rate field applies only to UART serial communication and can be changed by the pull-down field.

It is recommended to set the baud rate to the highest setting possible. The default setting of 600 baud will

cause some GUI functions to overflow the communication buffer and not function correctly.

2.6 Calibration Window

The Calibration Window is used to display and write to the CS5484 offset and gain calibration registers.

The user is also able to initiate the CS5484's calibration sequences that are used to set the calibration

values. AC offset, DC offset, and gain calibrations can be performed on the voltage channel, the current

channel, or both simultaneously. The user should refer to the CS5484 data sheet for more details on calibration (see Figure 20).

Figure 20. Calibration Window

DS919DB5 25

Page 26

CDB5484U

The Refresh Screen button will update the contents of the screen by reading all the register values from

the part. It is recommended to click the Refresh Screen button when entering the Calibration Window, or

after modifying any registers to reflect the current status of the CS5484.

2.6.1 Save Cal and Load Cal Buttons

Clicking the Save Cal button will save the calibration widow's configuration to a .txt file. Clicking the Load

Cal button will recall a saved configuration and store values into the CS5484.

2.6.2 Offset/Gain Register

In the Offset and Gain Calibration boxes, the offset and gain registers for all channels are displayed in

hexadecimal and decimal formats. These registers can be modified directly by typing the desired value in

the display boxes. There are three types of offset registers: DC offset, AC offset, and power offset. The

AC offset registers only affect the RMS register values. The active and reactive power offset registers only

affect the active and reactive power register values, respectively. The DC, AC, and power offset registers

are two's complement numbers whose values range from -1 to +1. The gain register value ranges from 0

to 4.

2.6.3 Performing Calibrations

AC/DC offset and gain calibrations can be performed on both the voltage and current channels of the

CS5484. It is recommended to software-reset the CS5484 before running calibrations because the initial

values in the calibration registers will affect the results of the calibration. A software-reset will reset these

registers back to the default values of zero offset and unity gain. AC/DC offset calibration should be performed before gain calibration to ensure accurate results.

2.6.3.1 Offset Calibrations

1. Ground the channel(s) that need to be calibrated directly at the channel header(s), J6, J10, J11, and

J9 for the voltage channels and J7, J8, J13, and J14 for the current channels. The channel(s) could

also be grounded directly at the screw-type terminals.

2. Press the corresponding AC or DC offset calibrate button (Cal V, Cal I, or Calibrate All Channels) in

the corresponding Offset Calibration box(es).

3. The offset register value(s) will automatically update when the calibration is completed.

2.6.3.2 Gain Calibrations

1. Attach an AC or DC calibration signal to the screw-type terminals, and make sure the corresponding

channel headers (J6, J7, J8, J9, J10, J11, J13, and J14) are set to the desired input position.

2. Press the corresponding gain calibrate button (Cal V, Cal I, or Calibrate All Channels) in the corre-

sponding Gain Calibration box(es).

3. The gain register value(s) will automatically update when the calibration is completed.

The Calibration window also contains the Active and Reactive Power Offset Register 1 and Register 2

display and adjustment. The user can read and write the values in the CS5484 active and reactive power

offset registers (P1

OFF

, P2

OFF

, Q1

OFF

, and Q2

OFF

).

26 DS919DB5

Page 27

CDB5484U

2.7 Conversion Window

The Conversion Window allows the user to see the results of single and continuous conversions and the

CS5484 status, perform data averaging, and use the power-saving modes of the CS5484. The Conversion Window can be accessed from the System pull-down menu, Conversion menu item. The Conversion

Window provides the active, apparent, and reactive energy calculation register results for each channel.

In addition, the RMS, power factor, and peak signal amplitudes for each analog-to-digital converter channel, chip temperature (when temperature measurement function is enabled), AC line frequency (converted from the Epsilon register), and the values of each status register (Status0, 1, 2) are also displayed. The

Conversion Window also provides the total active, apparent, and reactive power register results.

Figure 21. Conversion Window

2.7.1 Single Conversion Button

Clicking the Single Conversion button will cause a single conversion to be performed. After a single conversion is complete, the Result column will be updated with the values present in each data register.

2.7.2 Continuous Conversion Button

Clicking this button will cause continuous conversions to be performed until the user clicks the Stop button. After each conversion is complete, the Result column will be updated with the values present in each

data register. The Mean and STD. DEV columns will be updated every N cycle, where N is the number in

the Samples to Average field. The user should stop continuous conversion before navigating away from

DS919DB5 27

Page 28

CDB5484U

this window. The Continuous Conversion button should not be used with BAUD rates less than 1200Hz

in UART mode. Using lower BAUD rates (including the default 600 baud) will result in overflowing the

communication buffer and cause other window errors, communication failure, or both.

Data logging can be enabled using the DATALOG On/Off check box and Filename field.

2.7.3 Standby Mode Button

When this button is pressed, the CS5484 will enter a standby power-saving mode. To return to normal

mode, press the Power Up button. The user should power up the device before leaving this window.

2.7.4 Power Up Button

The Power Up button is used to send the wake-up command to the CS5484. The CS5484 will return to

normal operating mode.

2.7.5 Line Frequency Result

When the AFC bit in the Config2 register is set, the Epsilon register will be calculated automatically by the

CS5484, and the Line Frequency fields will be updated automatically in continuous conversion mode. If

the AFC bit in the Config2 register is not set and the line frequency is other than the default value (50Hz),

the line frequency must be set manually here to make Epsilon be the ratio of line frequency to the output

word rate (OWR). This ensures the accuracy of the quadrature power (Q1, Q2) and the reactive power

(Q1

AVG

and Q2

) calculations. Refer to the CS5484 data sheet for more details.

AVG

2.7.6 Temperature Result

When the on-chip temperature sensor is enabled, the Temperature fields will display in the top right corner

of the Conversion Window.

2.7.7 Samples to Average

The Samples to Average field allows the user to average a number of measurement results.

28 DS919DB5

Page 29

CDB5484U

2.8 Cirrus Test Window

The Cirrus Test pull-down menu provides three options: Test and Debug, ADC Data Collection, and ADC

Data Collection to File. Each window provides a means to evaluate the different functions and perfor-

mance of the CS5484 (see Figure 22).

Figure 22. Cirrus Test Pull-down Options

2.8.1 Data Collection Window

The Data Collection window allows the user to collect sample sets of data from the CS5484 and analyze

them using time domain, FFT, and histogram plots. The Data Collection window can be accessed by pulling down the CirrusTest menu, and selecting the ADC Data Collection item (see Figure 23).

Figure 23. Data Collection Window

DS919DB5 29

Page 30

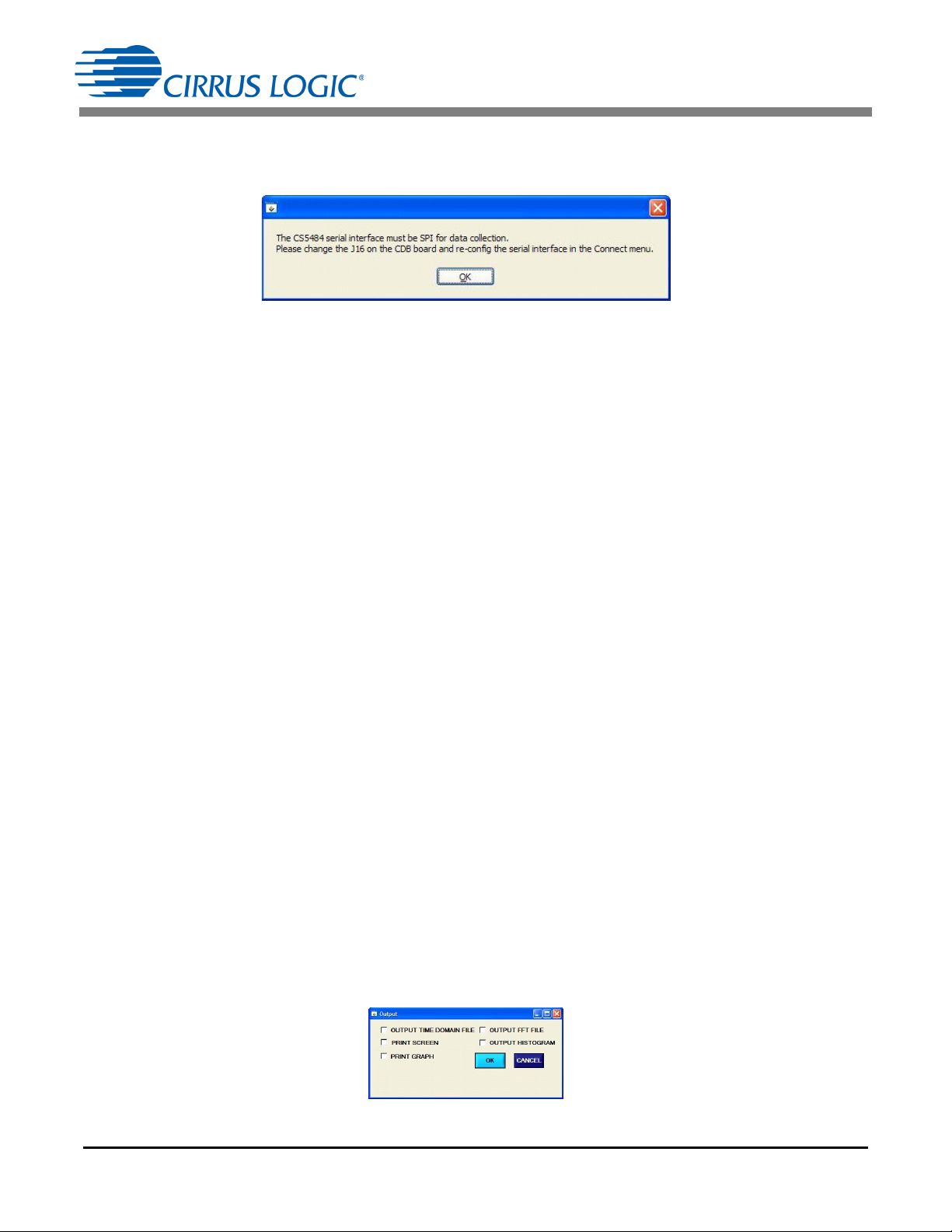

CDB5484U

The Data Collection Window can only be accessed when operating in SPI mode. When UART serial communication is enabled, an error window will be displayed (see Figure 24). To enable SPI, refer to “Serial

Port Selection” on page 9.

Figure 24. Data Collection UART Error Message

2.8.1.1 Time Domain/FFT /Histogram Selector

The Time Domain/FFT /Histogram selector selects the type of data processing to perform on the collected

data and displays the results in the plot area. Refer to “Analyzing Data” on page 32 for more information.

2.8.1.2 Config Button

The Config button will bring up the Configuration window, which allows the user to modify the data collection specifications. Refer to “Configuration Window” on page 31 for more information.

2.8.1.3 Collect Button

The Collect button will collect data from the part to be analyzed in the plot area (see “Collecting Data Sets”

on page 32 for more information).

2.8.1.4 Output Button

The Output button will bring up a window in which the user can output the data to a file for later use, print

out a plot, or print out the entire screen. When saving data, only the data channel being displayed on the

plot will be saved to a file.

2.8.1.5 Zoom Button

The Zoom button allows the user to zoom in on the plot by selecting two points in the plot area. Press the

Restore button to return to the normal data plot, or press the Zoom button again to zoom in further.

2.8.1.6 Channel Select Button

After data collection, the two buttons labeled as “No Data" will be replaced with Current and Voltage but-

tons, allowing the user to choose the appropriate channel for display. In the time domain mode, an additional Overlay button will be present, which allows the user to display all the channels on the same plot.

2.8.1.7 Output Button and Window

The Output button allows the user to:

1. Output Time Domain File

2. Output FFT File

3. Output Histogram

4. Print Screen

5. Print Graph

Figure 25. Data Collection Output Window

30 DS919DB5

Page 31

CDB5484U

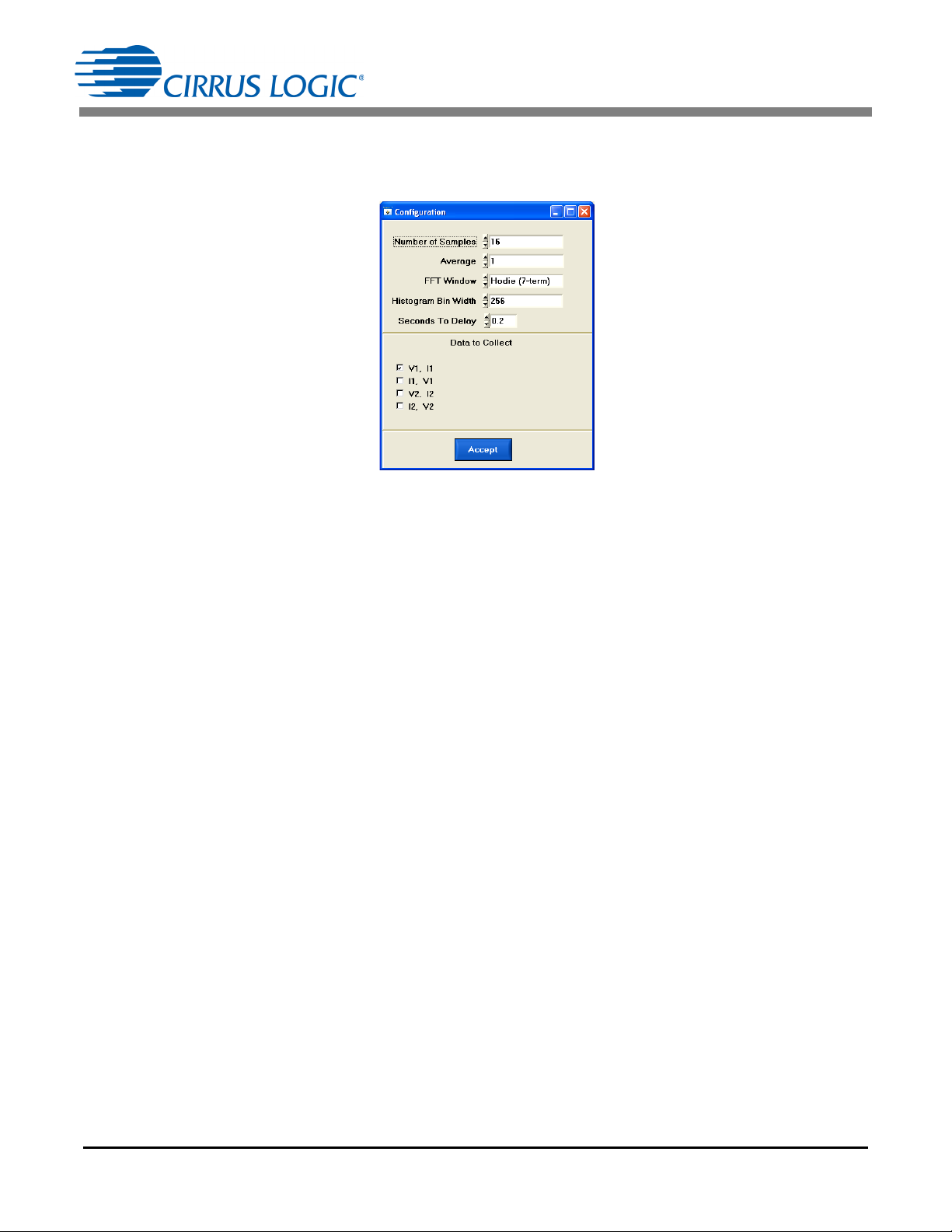

2.8.1.8 Configuration Window

The Configuration window allows the user to set up the data collection and analysis parameters (see

Figure 26).

Figure 26. Data Collection Configuration Window

2.8.1.8.1 Number of Samples

The Number of Samples field allows the user to select the number of samples to collect, between 16 and

524,288.

2.8.1.8.2 Average

When performing FFT analyses, the Average field determines the number of FFTs to average. FFTs will

be collected and averaged when the Collect button is clicked.

2.8.1.8.3 FFT Window

The FFT Window box allows the user to select the type of windowing algorithm for FFT processing. Windowing algorithms include the Blackman, Blackman-Harris, Hanning, 5-term Hodie, and 7-term Hodie.

The 5-term Hodie and 7-term Hodie are windowing algorithms developed at Crystal Semiconductor, now

called Cirrus Logic.

2.8.1.8.4 Histogram Bin Width

This field determines the "bin width" when plotting histograms of the collected data. Each vertical bar in

the histogram plot will contain the number of output codes entered in this field. Increasing this number

may allow the user to view histograms with larger input ranges.

2.8.1.8.5 Seconds to Delay

This field specifies the amount of time the system waits to begin data collection after the CS5484 starts

continuous conversions.

2.8.1.8.6 Data to Collect

The Data to Collect check boxes allow the user to select the data types that will be collected and returned

to the PC for processing.

2.8.1.8.7 Accept Button

When the Accept button is clicked, the current settings will be saved, and the user will return to the Data

Collection window.

DS919DB5 31

Page 32

CDB5484U

2.8.1.9 Collecting Data Sets

To collect a sample data set:

1. In the Data Collection window, click the Config button to bring up the Configuration window and view

the current settings.

2. Select the appropriate settings from the available options (see “Configuration Window” on page 31)

and press the Accept button.

3. The Data Collection window should still be visible. Press the Collect button to begin collecting data.

4. Once the data has been collected, it can be analyzed, printed, or saved to disk.

2.8.1.10 Analyzing Data

The evaluation software provides three types of analysis tests: Time Domain, Frequency Domain, and

Histogram. The time domain analysis processes acquired conversions to produce a plot of magnitude versus conversion sample number. The frequency domain analysis processes acquired conversions to produce a plot of magnitude versus frequency using the Fast-Fourier transform (results up to Fs/2 are

calculated and plotted). Also statistical noise calculations are calculated and displayed. The histogram

analysis processes acquired conversions to produce a histogram plot. Statistical noise calculations are

also calculated and displayed.

32 DS919DB5

Page 33

CDB5484U

Mean

X

i

i0=

n1–

n

----------------------

=

STDDEV

XiMean–

i0=

n1–

n

------------------------------------------------------

2

=

Variance

XiMean–

i0=

n1–

n

------------------------------------------------------

2

=

2.8.1.11 Histogram Information

The following is a description of the indicators associated with histogram analysis. Histograms can be plotted in the Data Collection window by setting the analysis type pull-down menu to Histogram. See

Figure 27. The histogram plot information includes:

• BIN: Displays the x-axis value of the cursor on the histogram.

• MAGNITUDE: Displays the y-axis value of the cursor on the histogram.

• MEAN: Indicates the mean of the data sample set. The mean is calculated using the following

formula:

• STD_DEV: Indicates the standard deviation of the collected data set. The standard deviation is

calculated using the following formula:

• VARIANCE: Indicates the variance of the current data set. The variance is calculated using the

following formula:

• MAXIMUM: Indicates the maximum value of the collected data set.

• MINIMUM: Indicates the minimum value of the collected data set.

DS919DB5 33

Page 34

Figure 27. Histogram Analysis

Figure 28. FFT Analysis

2.8.1.12 Frequency Domain Information

CDB5484U

The following describes the indicators associated with FFT (Fast-Fourier Transform) analysis. FFT data

can be plotted in the Data Collection window by setting the analysis type selector to FFT. See Figure 28.

The FFT information includes:

• FREQUENCY: Displays the x-axis value of the cursor on the FFT display.

• MAGNITUDE: Displays the y-axis value of the cursor on the FFT display.

• S/PN: Indicates the signal-to-peak noise ratio (decibels).

• SINAD: Indicates the signal-plus-noise-plus-distortion to noise-plus-distortion ratio (decibels).

• S/D: Indicates the signal-to-distortion ratio, 4 harmonics are used in the calculations (decibels).

• SNR: Indicates the signal-to-noise ratio, first 4 harmonics are not included (decibels).

• FS-PdB: Indicates the full-scale to signal Ratio (decibels).

34 DS919DB5

Page 35

CDB5484U

2.8.1.13 Time Domain Information

The following controls and indicators are associated with time domain analysis. Time domain data can be

plotted in the Data Collection window by setting the analysis type selector to Time Domain (see

Figure 29). The time domain plot includes:

• COUNT: Displays current x-position of the cursor on the time domain display.

• MAGNITUDE: Displays current y-position of the cursor on the time domain display.

• MAXIMUM: Indicates the maximum value of the collected data set.

• MINIMUM: Indicates the minimum value of the collected data set.

Figure 29. Time Domain Analysis

DS919DB5 35

Page 36

CDB5484U

2.8.2 Data Collection to File Window

The Data Collection to File window allows the user to collect instantaneous voltage and current register

data over an extended period of time to a data file (see Figure 30). The following steps are necessary for

data collection to a file:

1. Provide the Time to Collect in seconds.

2. If a delay before data collection is needed, enter the time in seconds for the Delay.

3. Select the voltage and current channel 1 (V1,I1) or voltage and current channel 2 (V2,I2).

4. Browse to a directory and enter the file name of the desired file to save.

5. Start the data collection by pressing the START button.

6. The data collection status will be provided in Samples Collected and Time Remaining.

7. The collection will complete without any further interaction by the user, or the user may stop the data

collection at any time by pressing the STOP button.

Figure 30. Data Collection to File Window

36 DS919DB5

Page 37

CDB5484U

2.8.3 Setup and Test Window

The Setup and Test window allows the user a way to access CS5484 registers and send commands to

the CS5484 directly (see Figure 31).

Figure 31. Setup and Test Window

There are three types of transactions: Write, Read, and Send. The CS5484 memory is organized by pages. In order to properly write a register it is necessary to set the Page, Address, and Value to Write field

and then press the Write button. To read a register it is necessary to set the Page and Address and then

press the Read button. The register result will be displayed in the Value Read field. To send a command

to the CS5484, enter the command in the Command field and press the SEND button. Refer to the

CS5484 data sheet for more details on registers and commands.

DS919DB5 37

Page 38

38 DS919DB5

CIRRUS LOGIC

CDB5484U_REV_C.PL

BILL OF MATERIAL

Item Cirrus P/N Rev

Description Qty Reference Designator MFG MFG P/N Notes

Status

1 001-04187-Z1 A

CAP 0.027uF ±5% 50V X7R NPb 0805 12 C1 C 2 C4 C5 C6 C7 C8 C9 C11 C12 C34 C35 KEMET C0805C273J5RAC

A

2 001-10064-Z1 A

CAP 15pF ±5% 50V C0G NPb 0603 1 C3 KEMET C0603C150J5GAC

A

3 001-04345-Z1 A

CAP 0.1uF ±10% 50V X7R NPb 0805 2 C10 C31 KEMET C0805C104K5RAC

A

4 001-01994-Z1 A

CAP 0.01uF ±10% 16V X7R NPb 0603 2 C13 C19 MURATA GRM188R71C 103KA01D

A

5 001-02194-Z1 A

CAP 0.1uF ±10% 25V X7R NPb 0603 3 C14 C15 C16 MURATA GRM188R71E104KA01D

A

6 001-10226-Z1 A

CAP 1uF ±10% 25V X5R NPb 0603 4 C17 C18 C20 C21 MURATA GRM188R61E105KA12

A

7 001-02189-Z1 A

CAP 0.1uF ±10% 16V X7R NPb 0603 5 C22 C23 C25 C27 C29 KEMET C 0603C104K4RAC

A

8 012-00010-Z1 A

CAP 47uF ±20% 16V NPb ELEC CASE C 2 C24 C30 PANASONIC EEE1CA470WR

A

9 001-10127-Z1 A

CAP 22pF ±10% 50V C0G NPb 0603 1 C26 KEMET C0603C220K5GAC

A

10 001-04523-Z1 A

CAP 1uF ±10% 16V X7R NPb 0805 2 C28 C38 KEMET C0805C105K4RAC

A

11 001-10233-Z1 A

CAP 4.7uF ±20% 25V X7R NPb 1206 2 C32 C37 TDK C3216X7R1E475M

A

12 012-00013-Z1 A

CAP 4.7uF ±20% 25V ELEC NPb CASE B 1 C33 PANASONIC EEE1EA4R7SR

A

13 001-02194-Z1 A

CAP 0.1uF ±10% 25V X7R NPb 0603 1 C36 KEMET C0603C104K3RAC

A

14 070-00055-Z1 A

DIODE ARRAY 5V (TVS) ESD NPb SOT143 1 D5 LITTELFUSE SP0503BAHTG

A

15 165-00004-Z2 A

LED SUP RED 100mcd NPb SMD 5 D6 DO1 DO2 DO3 DO4 EVERLIGHT 28-21SRC/TR8

A

16 110-00055-Z1 A

CON TERM BLCK 4 POS 5mm NPb BLU TH 4 J1 J2 J3 J12 ON-SHORE TECHNOLOGY ED 100/4DS

A

17 110-00056-Z1 A

CON TERM BLOCK 2POS 5mm NPb BLU TH 3 J4 J5 J27 ON-SHORE TECHNOLOGY ED 100/2DS

A

18 115-00016-Z1 A

HDR 3x2 ML .1"CTR 062 S GLD NP b 2 J6 J10 SAMTEC TSW-103-07-G-D

A

19 115-00257-Z1 A

HDR 2x2 ML .1" 093BD ST GLD NPb TH 6 J7 J8 J9 J11 J13 J14 SAMTEC TSW-102-08-G-D

A

20 115-00009-Z1 A

HDR 3x1 ML .1" 062 ST GLD NPb TH 9 J15 J16 J18 J20 J26 J38 J43 J50 J58 SAMTEC TSW-103-07-G-S

A

21 115-00011-Z1 A

HDR 10x2 ML .1" 062BD ST GLD NPb TH 2 J17 J19 SAMTEC TSW-110-07-G-D

A

22 115-00014-Z1 A

HDR 2x1 ML .1" 062BD ST GLD NPb TH 18

J21 J23 J39 J40 J41 J42 J44 J45 J46 J47 J48 J49 J51

J52 J53 J54 J55 J56

SAMTEC TSW-102-07-G-S

A

23 115-00276-Z1 A

HDR 16X1 ML .1" 062 S GLD NPb TH 1 J22 SAMTEC TSW-116-07-G-S SOLDER J22 TO PCB AND LCD(U7)

A

24 110-00041-Z1 A

CON RA USB BLK NPb TH 1 J24 AMP 292304-1

A

25 115-00003-Z1 A

HDR 5x2 ML .1"CTR S GLD NP b 1 J25 SAMTEC TSW-105-07-G-D

A

26 110-00014-Z1 A

CON XLR CHASSIS 3P FML SILV NPb 0 J28 J29 J30 J31 NEUTRIK NC3FD-H NO POP

A

27 115-00014-Z1 A

HDR 2x1 ML .1" 062BD ST GLD NPb TH 0 J32 J33 J34 J35 SAMTEC TSW-102-07-G-S NO POP

A

28 110-00008-Z1 A

CON BPOST 2" SILV NYLON INS BLK NPb 1 J36 JOHNSON COMPONENTS 111-0103-001

REQUIRES WIRE, 1.5L X 0.25T X 0.25T

TYPE E 24/19 BLU SQUIRES ELEC. INC.

A

29 110-00010-Z1 A

CON BPOST 2" SILV NYLON INS RED NPb 1 J37 JOHNSON COMPONENTS 111-0102-001

REQUIRES WIRE, 1.5L X 0.25T X 0.25T

TYPE E 24/19 BLU SQUIRES ELEC. INC.

A

30 115-00024-Z1 A

HDR 1x1 ML .1"CTR S NPb GL D 1 J57 SAMTEC TSW-101-07-G-S

A

31 080-00004-Z1 A

WIRE JUMPER 2P 0.1" BRASS NPb TH 8 JP1 JP2 JP3 JP4 JP5 JP6 JP7 JP8

COMPONENTS

CORPORATION

TP-101-10

A

32 304-00022-Z1 A

SPCR STANDOFF NYL HEX 1.0/4-40 NPb 7 MH1 MH2 MH3 MH4 MH5 MH6 MH7 KEYSTONE 1902E

REQUIRES SCREW 4-40X5X16" PH

STEEL 300-00025-Z1

A

33 020-01702-Z1 A

RES 100 OHM 1/8W ±1% NPb 0805 FILM 4 R1 R2 R21 R22 DALE CRCW0805100RFKEA

A

34 020-01816-Z1 A

RES 1k OHM 1/8W ±1% NPb 0805 FILM 10 R3 R4 R5 R6 R7 R10 R49 R50 R52 R53 D ALE CRCW08051K00FKEA

A

35 020-06362-Z1 A

RES 422k OHM 1/4W ±1% NPb 1206 8 R8 R12 R14 R15 R16 R17 R18 R19 DALE CRCW1206422KFKEA

A

Figure 32. Bill of Materials (Page 1 of 2)

APPENDIX A. BILL OF MATERIALS

CDB5484U

Page 39

DS919DB5 39

CIRRUS LOGIC

CDB5484U_REV_C.PL

BILL OF MATERIAL

Item Cirrus P/N Rev

Description Qty Reference Designator MFG MFG P/N Notes

Status

36 020-01816-Z1 A