CDB5467U

CDB5467U Engineering Board and GUI Software

Features

Voltage and Current Interface

USB Communication with PC

On-board C8051F320 Microcontroller

On-board Voltage Reference

LabWindows

– Register Setup & Chip Control

– FFT Analysis

– Time Domain Analysis

– Noise Histogram Analysis

"Auto-boot" Demo with Serial EEPROM

®

/CVI® GUI Software

+5V GND

General Description

The CDB5467U is an inexpensive tool designed to evaluate

the functionality and performance of the CS5467 analog-to-digital converter (ADC). The evaluation board includes an LT1019

voltage reference, a C8051F320 microcontroller with a USB interface, and firmware. The microcontroller controls the serial

communication between the evaluation board and the PC via

the firmware, enabling quick and easy access to all of

theCS5467's registers and functions.

The CDB5467U includes software for data capture, time domain analysis, histogram analysis, and frequency domain

analysis.

Schematics in PADS™ PowerLogic™ format are available for

download at www.cirrus.com/IndustrialSoftware

ORDERING INFORMATION

CDB5467U Evaluation Board

VD+_EXT

Vu+_EXT

USB

.

REF

VIN1+

VIN1-

VIN2+

VIN2-

IIN1+

IIN1-

IIN2+

IIN2-

www.cirrus.com

+2.5V

reference

IN OUT

VREF

CS5467

4.096MHz

Crystal

SERIAL

EERPOM

CS

SDI

SDO

SCLK

INT

RESET

E1

E2

E3

MODE

Copyright © Cirrus Logic, Inc. 2007

(All Rights Reserved)

C8051F320

Reset

Circuirty

RESET

BUTTON

OCT ‘07

DS714DB1

CDB5467U

TABLE OF CONTENTS

1. HARDWARE ............................................................................................................................. 3

1.1 Introduction ........................................................................................................................ 3

1.2 Evaluation Board Overview ................................................................................................ 3

1.3 Analog Section ................................................................................................................... 4

1.4 Digital Section .................................................................................................................... 5

1.5 Power Supply Section ........................................................................................................ 5

1.6 Auto-boot Mode ................................................................................................................. 6

2. SOFTWARE .............................................................................................................................. 8

2.1 Installation .......................................................................................................................... 8

2.2 Using the Software ............................................................................................................. 8

2.3 Start-up Window ................................................................................................................ 8

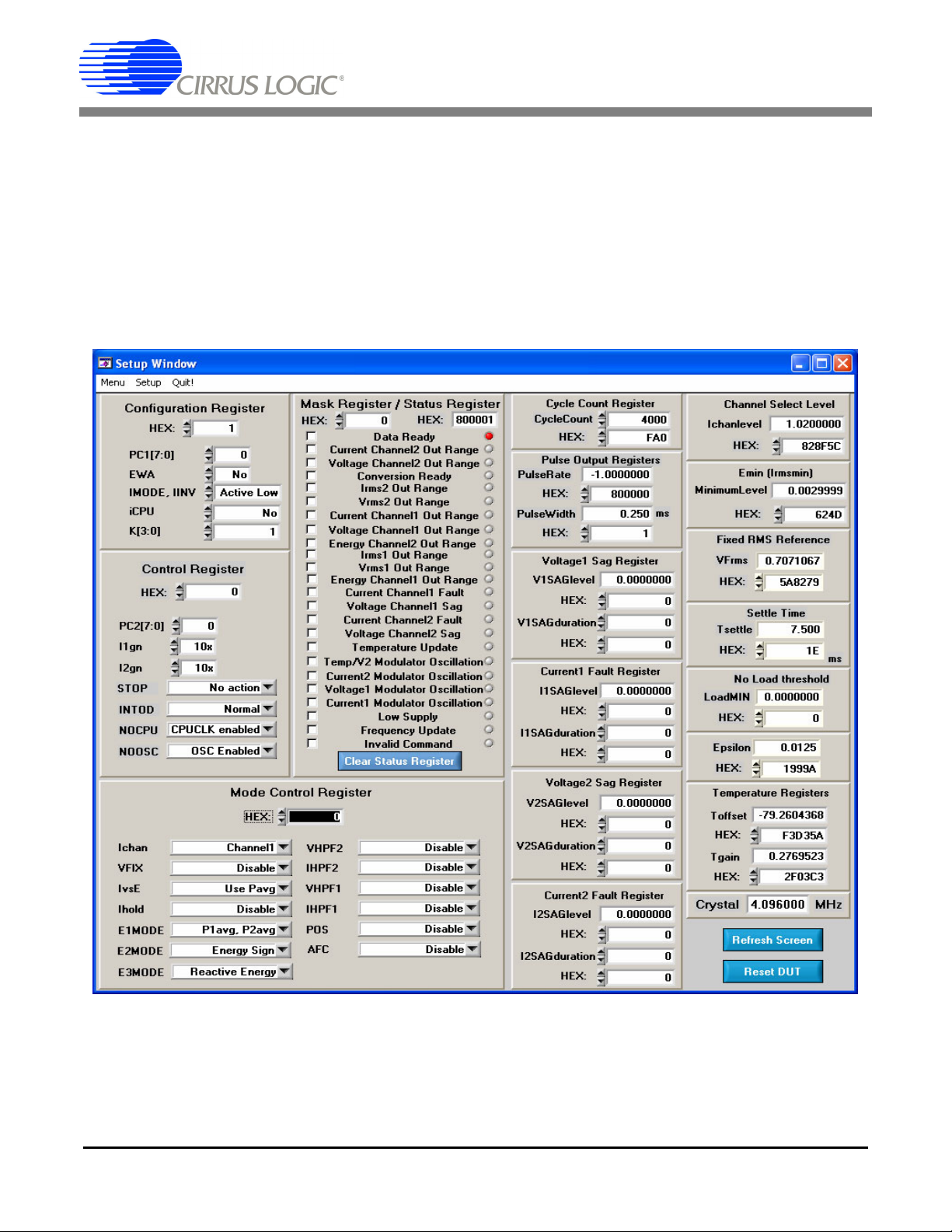

2.4 Setup Window .................................................................................................................. 12

2.5 Calibration Windows ........................................................................................................14

2.6 Conversion Window ......................................................................................................... 16

2.7 Pulse Rate Window ..........................................................................................................18

2.8 Data Collection Window ................................................................................................... 19

2.9 EEPROM Window ............................................................................................................ 26

2.10 Debug Panel .................................................................................................................. 27

Appendix A. Bill Of Materials ................................................................................................... 28

Appendix B. Schematics .......................................................................................................... 30

Appendix C. Layer Plots ........................................................................................................... 34

LIST OF FIGURES

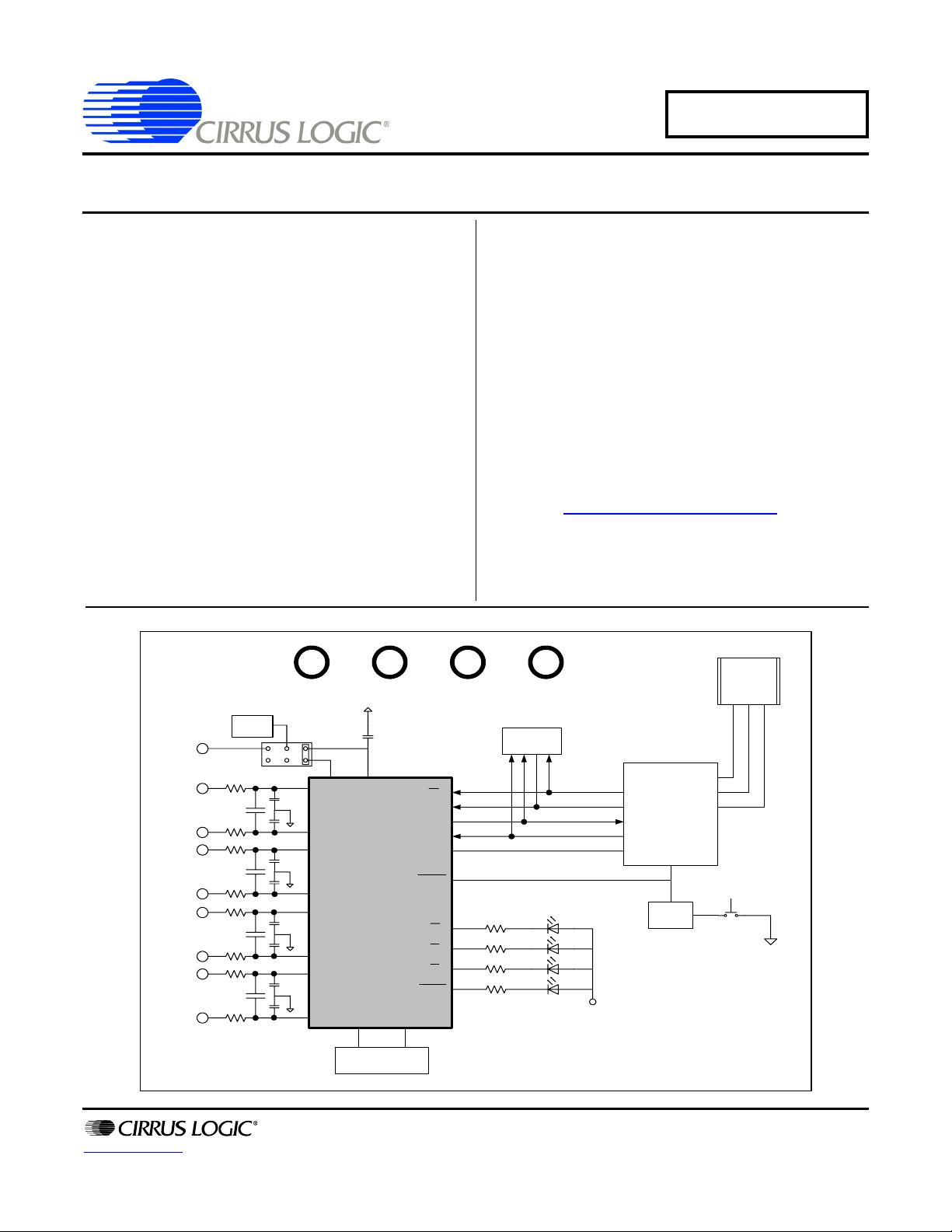

Figure 1. CDB5463U Assembly Drawing ........................................................................................ 3

Figure 2. GUI Start-up Window ....................................................................................................... 8

Figure 3. Setup Menu Showing Successful USB Connection ......................................................... 9

Figure 4. USB Error Message ......................................................................................................... 9

Figure 5. Data from Disc File Selection Window ........................................................................... 10

Figure 6. Data from Disc File Selection Window ........................................................................... 11

Figure 7. Quit Dialog ..................................................................................................................... 11

Figure 8. Setup Window ................................................................................................................ 12

Figure 9. Calibration Window ........................................................................................................ 14

Figure 10. Conversion Window ..................................................................................................... 16

Figure 11. Pulse Rate Output Window .......................................................................................... 18

Figure 12. Data Collection Window ...............................................................................................19

Figure 13. Configuration Window .................................................................................................. 20

Figure 14. Histogram Analysis ...................................................................................................... 22

Figure 15. FFT Analysis ................................................................................................................ 24

Figure 16. Time Domain Analysis .................................................................................................25

Figure 17. EEPROM Window........................................................................................................26

Figure 18. Debug Panel ................................................................................................................ 27

Figure 19. Schematic - Analog Inputs ........................................................................................... 30

Figure 20. Schematic - CS5463 & Socket..................................................................................... 31

Figure 21. Schematic - Microcontroller & USB Interface ............................................................... 32

Figure 22. Schematic - Power Supplies ........................................................................................ 33

Figure 23. Top Silkscreen ............................................................................................................. 34

Figure 24. Top Routing.................................................................................................................. 35

Figure 25. Bottom Routing ............................................................................................................ 36

Figure 26. Bottom Silkscreen ........................................................................................................ 37

2 DS714DB1

CDB5467U

1. HARDWARE

1.1 Introduction

The CDB5467U evaluation board provides a convenient means of evaluating the CS5467 power measurement IC. The CDB5467U evaluation board operates from a single +5V power supply. The evaluation

board interfaces the CS5467 to a PC via a USB cable. To accomplish this, the board comes equipped

with a C8051F320 microcontroller and a USB interface. Additionally, the CDB5467U GUI software provides easy access to the internal registers of the CS5467. The software also provides a means to display

the performance in the time domain or frequency domain.

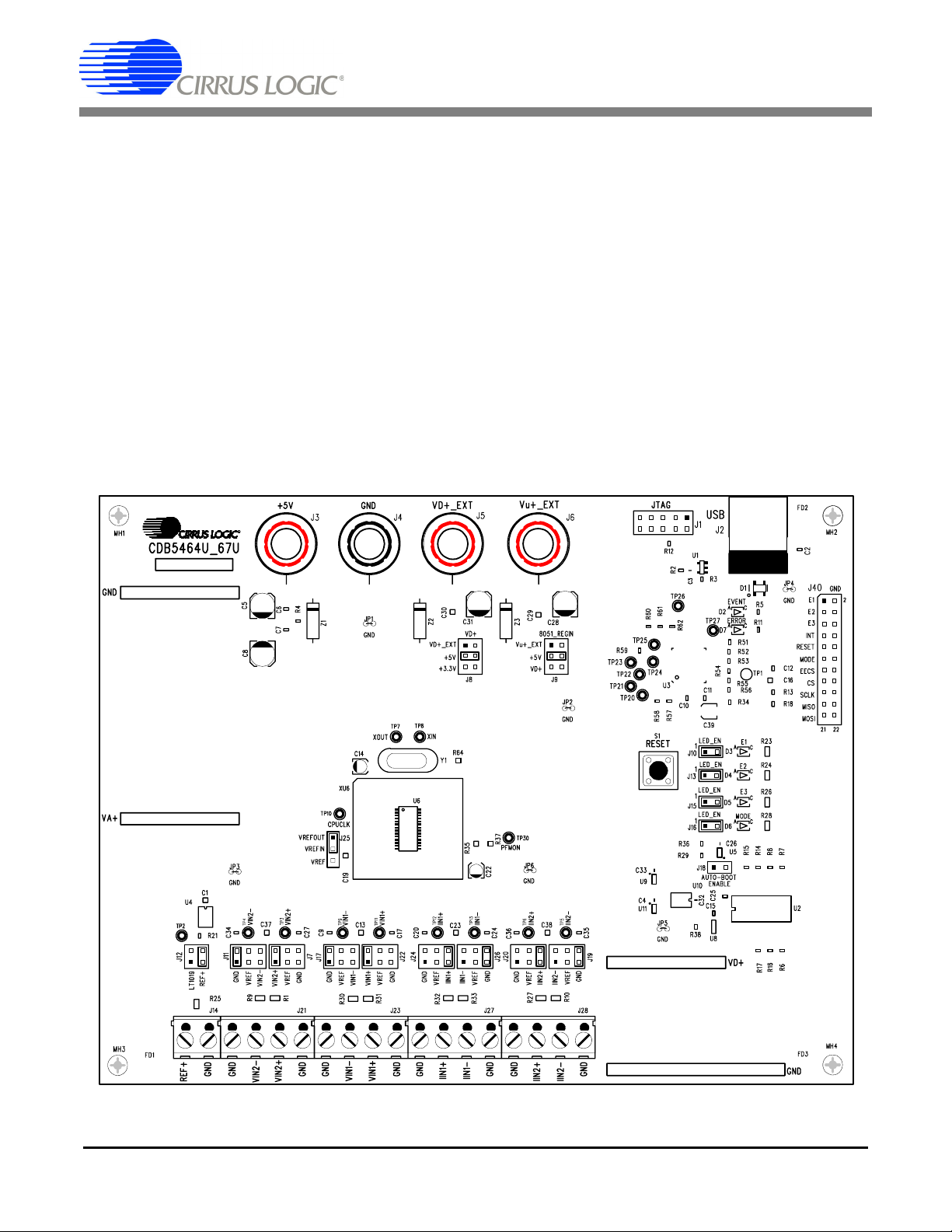

1.2 Evaluation Board Overview

The board is partitioned into two main sections: analog and digital. The analog section consists of the

CS5467 and a precision voltage reference. The digital section consists of the C8051F320 microcontroller,

EEPROM, the hardware test switches, the reset circuitry, and the USB interface. The board also has a

user friendly power supply connection.

CDB5467U

4.096 MHz

5467

Figure 1. CDB5467U Assembly Drawing

DS714DB1 3

CDB5467U

1.3 Analog Section

The CDB5467U evaluation board provides screw-type terminals (J21, J23, J27, & J28) to connect input

signals to the voltage and current channels. The screw terminals are labels as VIN2-, VIN2+, VIN1-,

VIN1+, IIN1+, IIN1-, and IIN2+, IIN2-. An R-C network at each channel input provides a simple anti-alias

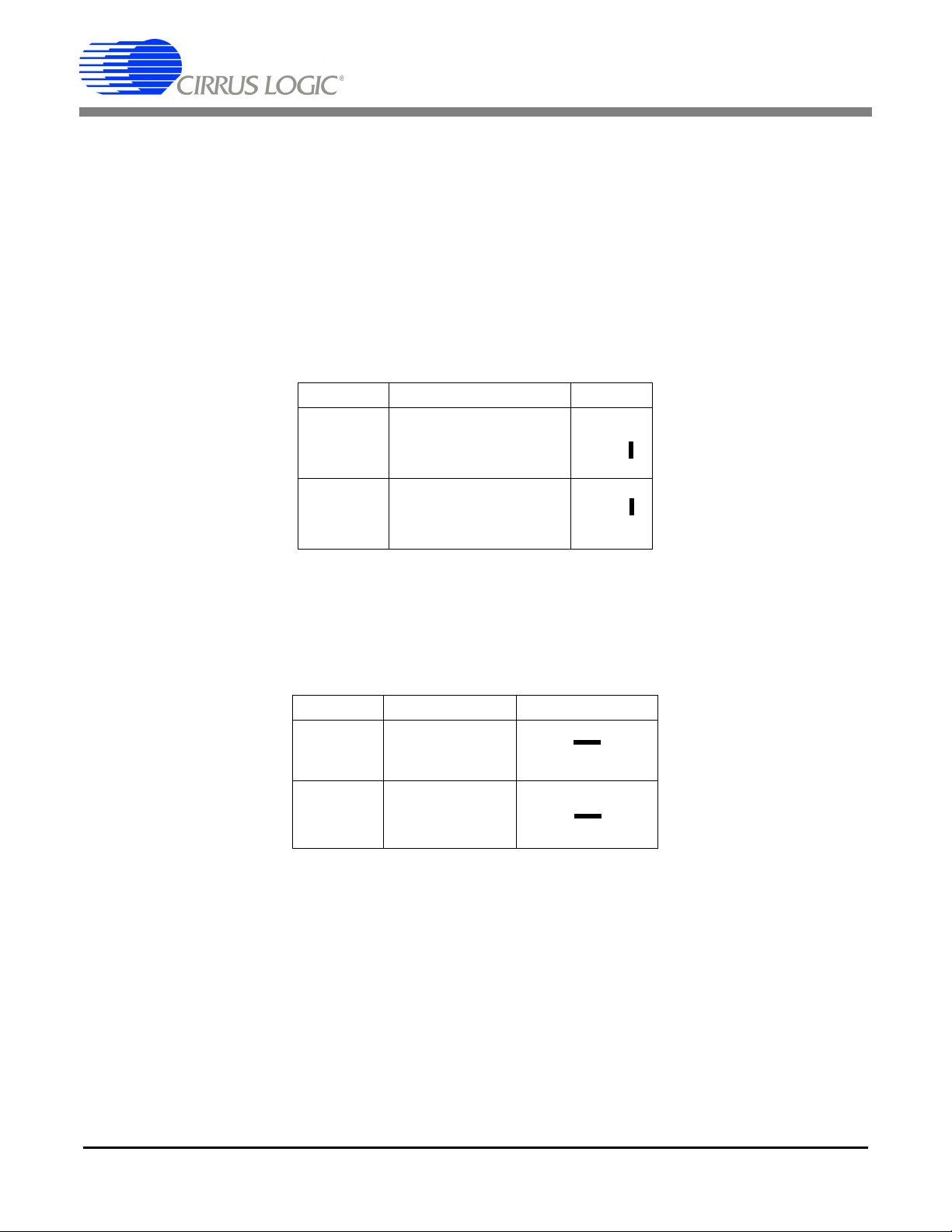

filter.

The evaluation board provides three voltage reference options for VREFIN to the CS5467. The three voltage reference options include: VREFOUT from CS5467, the on-board +2.5V reference, and external

REF+ (screw terminal J14).

on J25 in the position labeled VREFOUT, the reference is supplied by the on-chip voltage reference. With

a jumper on J25 in the position labeled VREF, the reference is supplied by an off-chip voltage reference.

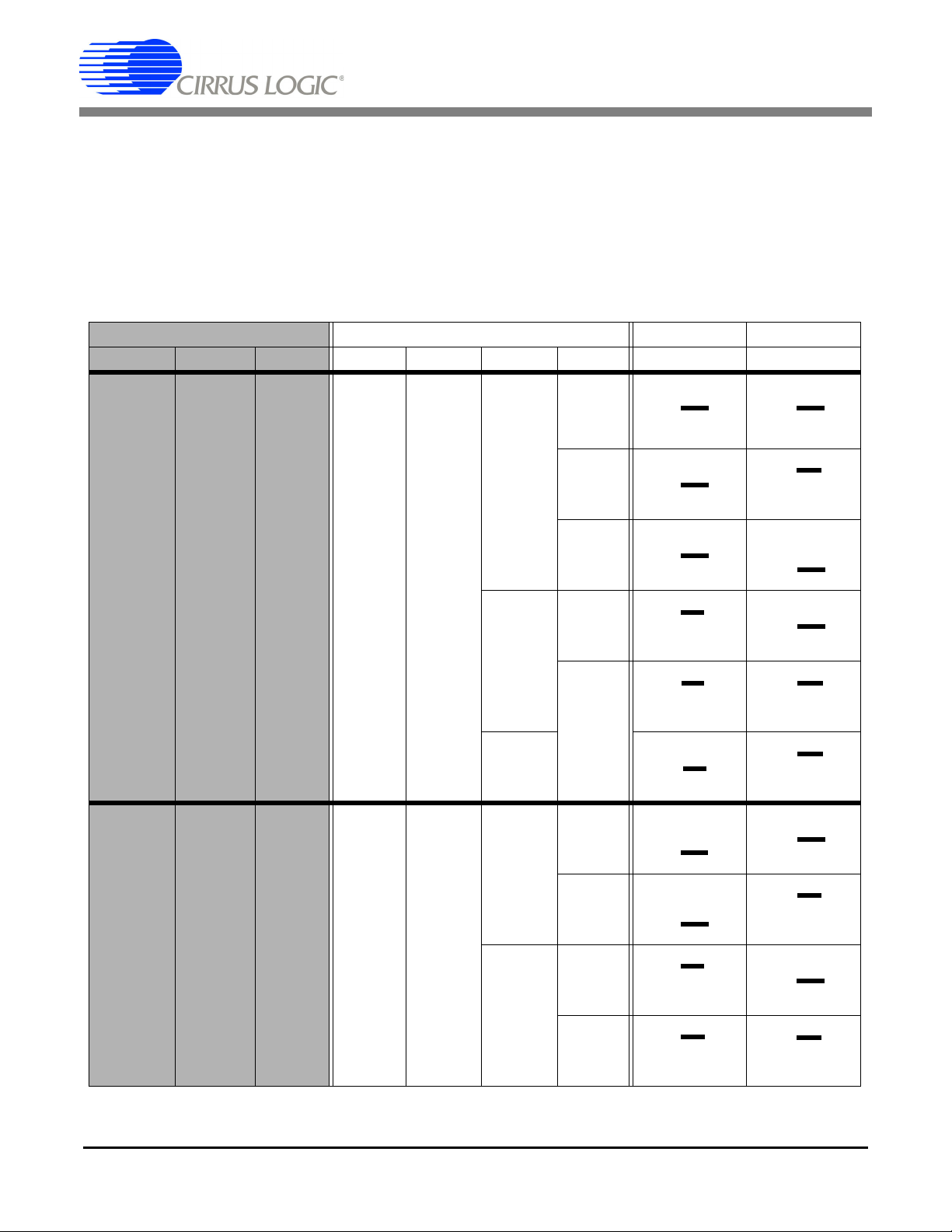

Table 1 and Table 2 illustrate the options available for VREFIN. With a jumper

Reference Description J25

VREFOUT

VREF

Selects On-chip

Reference (25 ppm/

°C)

Selects External or

LT1019 Reference(J12)

VREFIN

VREFOUT

(Default)

VREFIN

VREFOUT

VREF

O

O

O

O

VREF

Table 1. Internal Voltage Reference Selection for VREF

Table 2 illustrates the options available for VREF. With a jumper on J12 in position LT1019, the LT1019

provides a +2.5V reference (the LT1019 was chosen for its low drift - typically 5 ppm/°C). By setting the

jumper on J12 to position REF+, an external voltage reference is supplied via screw terminal J14's REF+

input.

Reference Description J12

LT1019

REF+

Selects On-board

LT1019 Reference

(5 ppm/

°C)

Selects External

Reference Source

(J14)

LT1019

REF+

LT1019

REF+

O VREF

O O VREF

O VREF

O O VREF

(Default)

Table 2. External Voltage Reference Selection for VREF

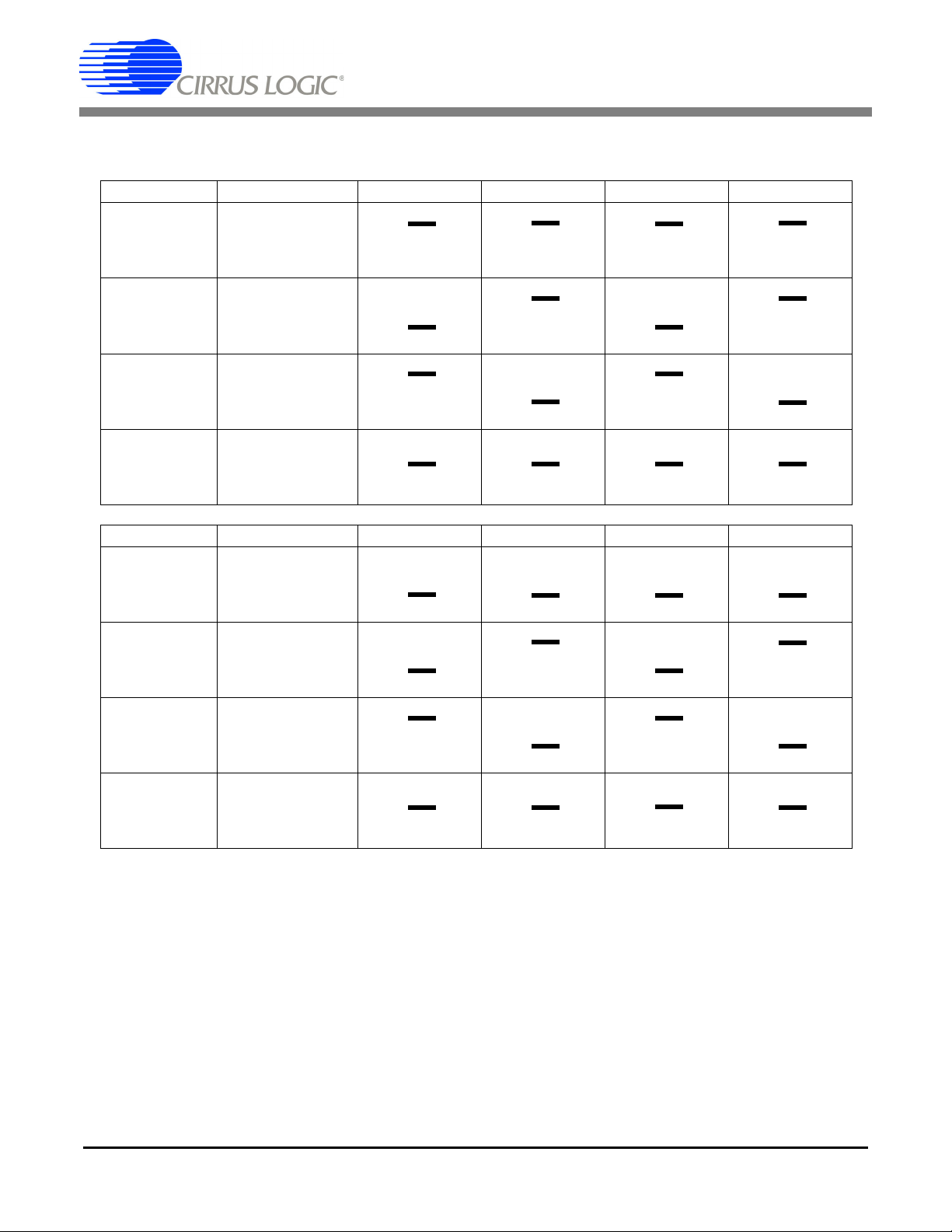

The three input signal options for the voltage (VIN1±, VIN2±) and current (IIN1±, IIN2±) channels input

include: an external signal (screw terminals J21, J23, J27, and J28), GND, or VREF. Table3 illustrates the

options available. By installing jumpers on J11 to position VIN2-, J7 to position VIN2+, J17 to position

VIN1-, J22 to position VIN1+, J24 to position IIN1+, J26 to position IIN1-, J20 to position IIN2+, and J19

to position IIN2-, the input voltage signal is supplied from the screw terminals J21, J23, J27, and J28. With

a jumper on J11, J7, J17, J22, J24, J26, J20 and J19 in the GND position, the inputs are connected to

4 DS714DB1

CDB5467U

analog ground (AGND). With a jumper on J11, J7, J17, J22, J24, J26, J20 and J19 in position VREF, the

inputs are connected to the reference voltage selected on J12.

INPUT Description J11 J7 J17 J22

VIN2± or VIN1±

VIN2± or VIN1±

GND

VREFIN

Selects External

Signal

Selects External

Signal

Selects Grounding

the Input

Selects Reference

Source

GND

VREF

VIN2-

GND

VREF

VIN2-

GND

VREF

VIN2-

GND

VREF

VIN2-

O VIN2-

O O VIN2-

O O VIN2-

(Default)

O VIN2-

O O VIN2-

O O VIN2-

O VIN2-

O O VIN2-

O O VIN2-

O VIN2-

O O VIN2-

O O VIN2-

VIN2+

VREF

GND

VIN2+

VREF

GND

VIN2+

VREF

GND

VIN2+

VREF

GND

O VIN2+

O O VIN2+

O O VIN2+

(Default)

O VIN2+

O O VIN2+

O O VIN2+

O VIN2+

O O VIN2+

O O VIN2+

O VIN2+

O O VIN2+

O O VIN2+

GND

VREF

VIN1-

GND

VREF

VIN1-

GND

VREF

VIN1-

GND

VREF

VIN1-

O VIN1-

O O VIN1-

O O VIN1-

(Default)

O VIN1-

O O VIN1-

O O VIN1-

O VIN1-

O O VIN1-

O O VIN1-

O VIN1-

O O VIN1-

O O VIN1-

INPUT Description J24 J26 J20 J19

IIN1± or IIN2±

IIN1± or IIN2±

Selects External

Signal

Selects External

Signal

GND

VREF

IIN1+

GND

VREF

IIN1+

O IIN1+

O O IIN1+-

O O IIN1+

(Default)

O IIN1+

O O IIN1+-

O O IIN1+

IIN1-

VREF

GND

IIN1-

VREF

GND

O IIN1-

O O IIN1-

O O IIN1-

(Default)

O IIN1-

O O IIN1-

O O IIN1-

GND

VREF

IIN2+

GND

VREF

IIN2+

O IIN2+

O O IIN2+

O O IIN2+

(Default)

O IIN2+

O O IIN2+

O O IIN2+

VIN1+

VREF

GND

VIN1+

VREF

GND

VIN1+

VREF

GND

VIN1+

VREF

GND

IIN2-

VREF

GND

IIN2-

VREF

GND

O VIN1+

O O VIN1+

O O VIN1+

(Default)

O VIN1+

O O VIN1+

O O VIN1+

O VIN1+

O O VIN1+

O O VIN1+

O VIN1+

O O VIN1+

O O VIN1+

O IIN2-

O O IIN2-

O O IIN2-

(Default)

O IIN2-

O O IIN2-

O O IIN2-

GND

VREFIN

Selects Grounding

the Input

Selects Reference

Source

GND

VREF

IIN1+

GND

VREF

IIN1+

O IIN1+

O O IIN1+-

O O IIN1+

O IIN1+

O O IIN1+-

O O IIN1+

IIN1-

VREF

GND

IIN1-

VREF

GND

O IIN1-

O O IIN1-

O O IIN1-

O IIN1-

O O IIN1-

O O IIN1-

GND

VREF

IIN2+

GND

VREF

IIN2+

O IIN2+

O O IIN2+

O O IIN2+

O IIN2+

O O IIN2+

O O IIN2+

IIN2-

VREF

GND

IIN2-

VREF

GND

O IIN2-

O O IIN2-

O O IIN2-

O IIN2-

O O IIN2-

O O IIN2-

Table 3. Voltage and Current Channel Input Signal Selection

1.4 Digital Section

The digital section contains the microcontroller, USB interface, JTAG header, reset circuitry, and an external interface header (J40). The microcontroller interfaces the SPI of CS5467 with the USB connection

to the PC, enabling the GUI software to access all the CS5467 registers and functions. Interface header,

J40, is provided to allow the CDB5467U to be connected to an external energy registration device or an

external microcontroller. To connect the CS5467 to an external microcontroller, R57, R58, R59, R60, R61,

and R62 must be removed from the board. The energy output pins E1, E2, and E3 are routed to LEDs

which provide a simple visual check of the energy output pulses. The MODE pin is also routed to a LED

to indicate whether the CS5467 is operating in auto-boot mode. Jumpers J10, J13, J15, and J16 are

equipped at the factory with jumpers to enable the LEDs.

DS714DB1 5

CDB5467U

1.5 Power Supply Section

Table 4 illustrates the power supply connections to the evaluation board. The +5V binding post (J3) sup-

plies the positive analog (VA+) for the CS5467 and the +2.5V reference. The VD+_EXT binding post (J5)

supplies the digital section of the CS5467 (VD+) and level shifters. Jumper J8 allows the VD+ supply to

be sourced from the VD+_EXT binding post (J5), the +5V binding post (J3), or the regulated 3.3V supply

derived from the microcontroller. The Vu+_EXT (J6) binding post supplies the positive supply for the 8051

microcontroller (8051_REGIN). Jumper J9 allows the 8051_REGIN supply to be sourced from either the

Vu+_EXT binding post (J6), +5V binding post (J3) or VD+_EXT binding post (J5).

Power Supplies Power Post Connections VD+ 8051-REGIN

Analog (VA+) Digital (VD+) 8051 (Vu+)

+5V GND VD+EXT VU+EXT J8 J9

+5 +5 +5 +5 0

+5 +3.3 +5 +5 0

Table 4. Power Supply Connections

NC

+5

NC

NC

+3.3

NC

+5

NC

NC

+5

NC

+5

NC

+5

VD+_EXT

+5

+3.3

VD+_EXT

+5

+3.3

VD+_EXT

+5

+3.3

VD+_EXT

+5

+3.3

VD+_EXT

+5

+3.3

VD+_EXT

+5

+3.3

VD+_EXT

+5

+3.3

VD+_EXT

+5

+3.3

VD+_EXT

+5

+3.3

VD+_EXT

+5

+3.3

O VD+

O O VD+

O O VD+

(Default)

O VD+

O O VD+

O O VD+

O VD+

O O VD+

O O VD+

O VD+

O O VD+

O O VD+

O VD+

O O VD+

O O VD+

O VD+

O O VD+

O O VD+

O VD+

O O VD+

O O VD+

O VD+

O O VD+

O O VD+

O VD+

O O VD+

O O VD+

O VD+

O O VD+

O O VD+

Vu+_EXT

+5

VD+

Vu+_EXT

+5

VD+

Vu+_EXT

+5

VD+

Vu+_EXT

+5

VD+

Vu+_EXT

+5

VD+

Vu+_EXT

+5

VD+

Vu+_EXT

+5

VD+

Vu+_EXT

+5

VD+

Vu+_EXT

+5

VD+

Vu+_EXT

+5

VD+

O 8051

O O 8051

O O 8051

(Default)

O 8051

O O 8051

O O 8051

O 8051

O O 8051

O O 8051

O 8051

O O 8051

O O 8051

O 8051

O O 8051

O O 8051

O

8051

O O 8051

O O 8051

O 8051

O O 8051

O O 8051

O 8051

O O 8051

O O 8051

O 8051

O O 8051

O O 8051

O 8051

O O 8051

O O 8051

6 DS714DB1

CDB5467U

1.6 Auto-boot Mode

With a jumper connection on J18 (AUTO-BOOT ENABLE), the CS5467 operates in auto-boot mode and

the CDB5467U board operates as a stand-alone system without attaching it up to a PC. When in autoboot mode, a hardware reset (press on S1) will cause the CS5467 to boot up using the serial data from

the serial EEPROM on the board (U10). When the CS5467 is in auto-boot mode, the SPI connections

between the microcontroller and the CS5467 are removed and the GUI software can not access the

CS5467 registers and functions.

The EEPROM must be programmed prior to the auto-boot sequence. When the CDB5467U Evaluation

Board is sent from the factory, the EEPROM is programmed with the following CS5467 command/data

sequence:

1. Move to EEPROM page 1:

0x7E 0x00 0x00 0x01

2. Write Modes register, turn high-pass filters on:

0x60 0x00 0x01 0xE0

3.

Move to EEPROM page 0:

0x7E 0x00 0x00 0x00

4. Set bit 2 (LSD) in the Mask register:

0x74 0x00 0x00 0x04

5. Start continuous conversion:

0xE8

6. Write STOP bit in Control register, to terminate auto-boot sequence:

0x78 0x00 0x01 0x00

This sequence programs the CS5467 for continuous conversion mode. If voltage and current signals are

applied to the inputs, the CS5467 will issue pulses on the E1

pin. See the CS5467 data sheet for more

details on auto-boot.

DS714DB1 7

2. SOFTWARE

CDB5467U

The evaluation board comes with software and an USB cable to link the evaluation board to the PC. The

evaluation software was developed with LabWindows

tional Instruments. The evaluation software is available for download on the Cirrus Logic web site at

http://www.cirrus.com/industrialsoftware

Windows XP

®

.

and was designed to run under Windows®2000 or

®

/CVI®, a software development package from na-

2.1 Installation

To install the software, go to the Cirrus Logic web site at http://www.cirrus.com/industrialsoftware and re-

fer to application note AN278.

2.2 Using the Software

Before launching the software, check all jumper settings on the CDB5467U evaluation board as described

in Section 1, and connect the board to an open USB port on the PC using the provided cable. Once the

board is powered on, the software program can be launched.

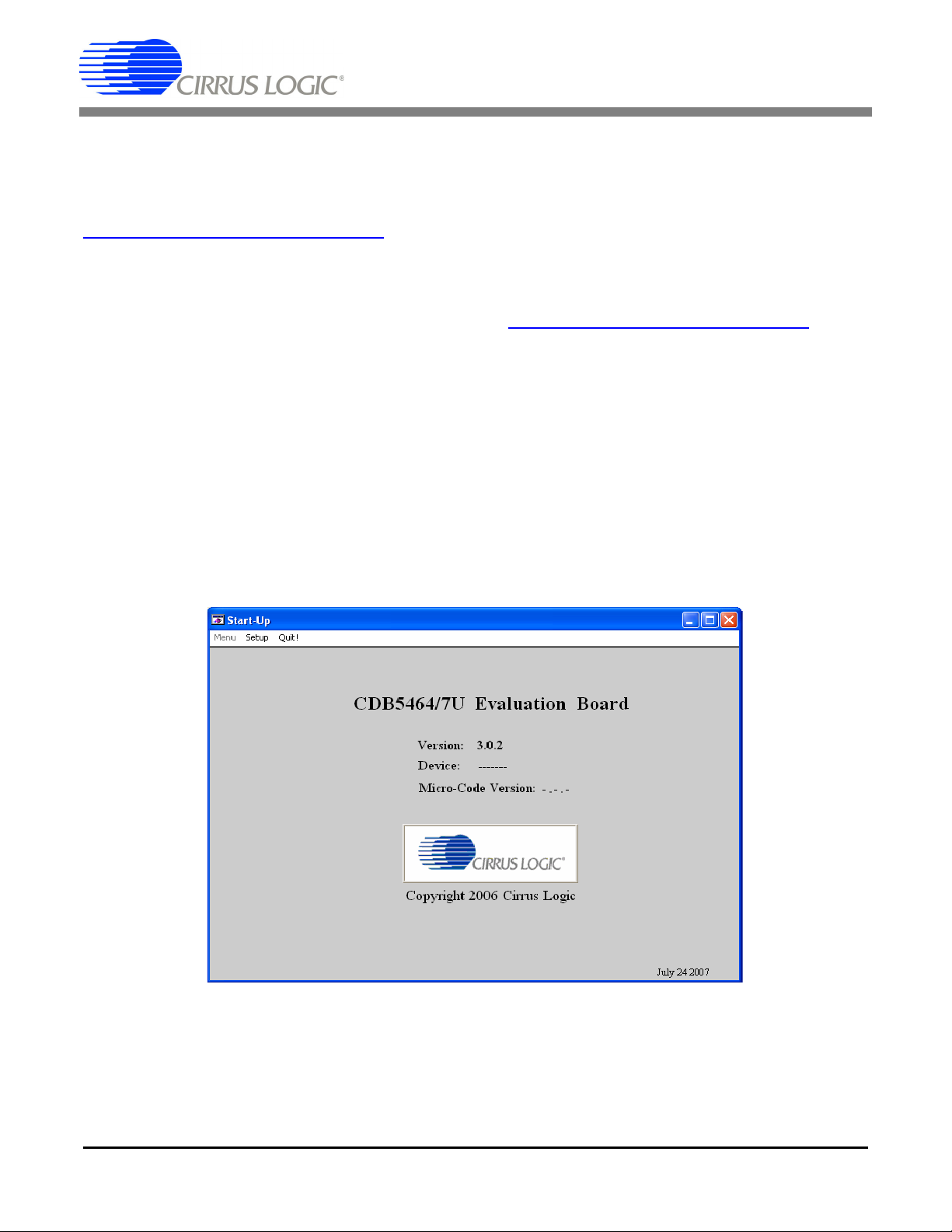

2.3 Start-up Window

When the software is launched, the start-up window will appear. This window contains information concerning the software's title, revision number, copyright date, etc. See Figure 2.

Figure 2. GUI Start-up Window

At the top of the screen is a menu bar which displays user options. The menu bar has three items: Menu,

Setup, and Quit. Initially Menu is disabled. After establishing a link to a data source, the Menu item will

become available.

8 DS714DB1

CDB5467U

2.3.1 Setup Menu

Setup allows user to establish a USB communication connection with CDB5467U board or select a previously saved data file for further analysis.

If the USB item in the Setup menu is selected, the evaluation software will poll the CDB5467U, verifying

the serial communication link is ready. At this point, the USB menu item is checked indicating that the PC

has successfully communicated with CDB5467U evaluation board, and device and micro-code version

information are read from the board and displayed on the screen. See Figure 3. Due to improvements to

the software or new features being added, the version displayed may be different than the image shown

here.

Figure 3. Setup Menu Showing Successful USB Connection

If the evaluation software is unable to establish a communication link with the CDB5467U board, a message will appear, indicating that the initial communication has failed. See Figure 4.

Figure 4. USB Error Message

Check to verify that the USB cable is connected properly and the power supply is on and connected properly to the CDB5467U. Reset the board (press the RESET button on the board) and try to setup the USB

connection again.

DS714DB1 9

CDB5467U

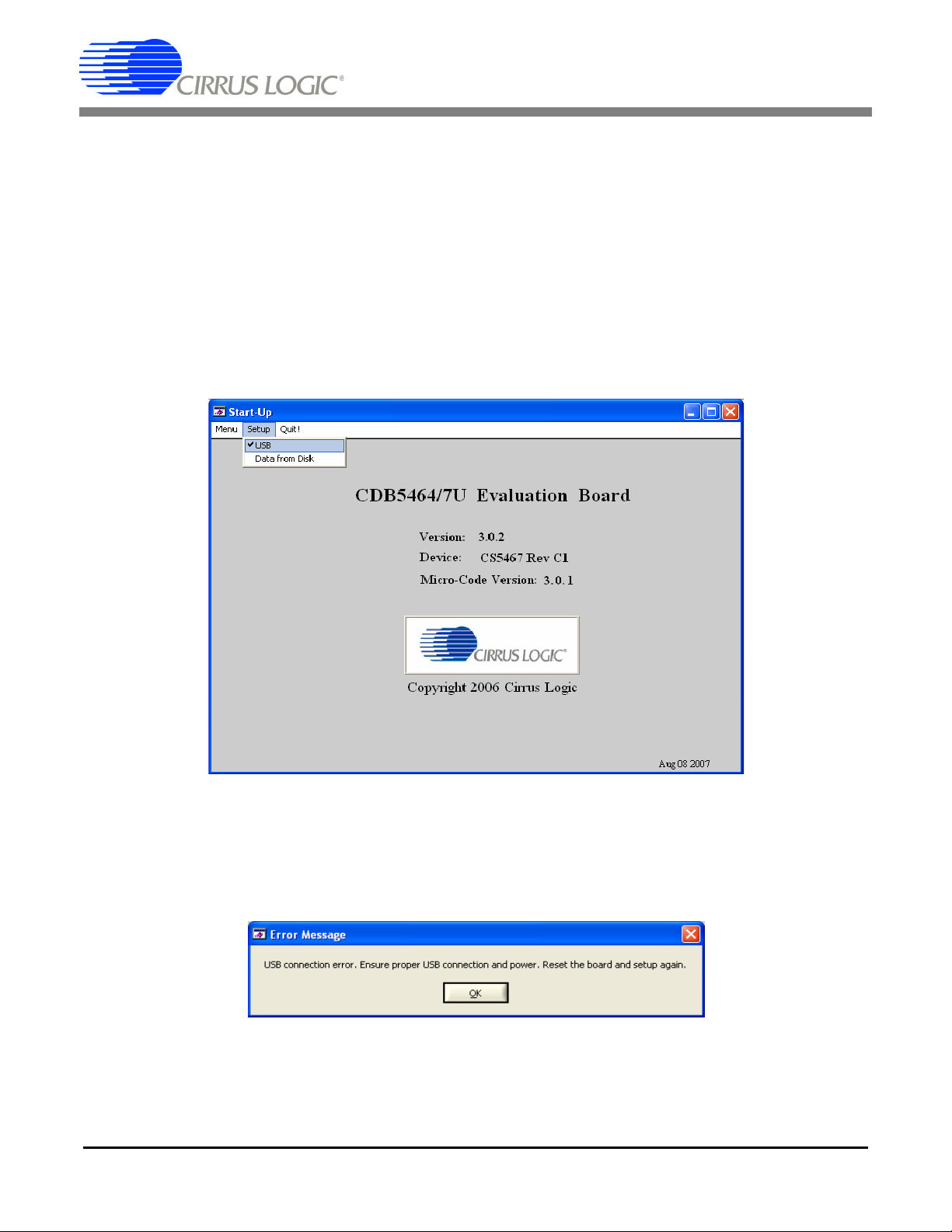

If the Data from Disk item in the Setup menu is selected, a file selection window will appear as shown in

Figure 5. User can select a pre-saved data file for further analysis using time domain, FFT, and histogram

plots in Data Collection Window of the software.

Figure 5. Data from Disc File Selection Window

2.3.2 Menu Menu

Excluding the Start-Up window, the Menu menu provides 7 options: Setup Window, Calibration Window,

Conversion Window, Pulse Rate Window, Data Collection Window, EEPROM Window, and Debug Window. Each window provides a means to evaluate the different functions and performance of the CS5467.

Each option has an associated function key (<F1>, <F2>, etc.). See Figure 6.

Figure 6. Menu Pull-down Options

10 DS714DB1

CDB5467U

2.3.3 Quit Menu

The Quit menu allows the user to exit the evaluation software. Upon selecting Quit, a message window

appears and queries if exiting the evaluation software is desired. See Figure 7.

Figure 7. Quit Dialog

DS714DB1 11

CDB5467U

2.4 Setup Window

The evaluation software provides access to the CS5467's internal registers through the Setup window.

See Figure 8. The user can enter the Setup window by pulling down the Menu menu and selecting Setup

Window, or by pressing <F2> on the keyboard.

In the Setup window, all of the CS5467's registers are displayed in hexadecimal notation and are decoded

to provide easier readability. Refer to the CS5467 data sheet for information on register functionality and

definitions. See Figure 8.

Figure 8. Setup Window

12 DS714DB1

CDB5467U

2.4.1 Refresh Screen Button

The Refresh Screen button will update the contents of the screen by reading all the register values from

the CS5467. It is a good idea to press the Refresh Screen button when entering the Setup window, or

after modifying any registers, to reflect the current status of the CS5467.

2.4.2 Reset DUT Button

The Reset DUT button will hardware reset the CS5467. The CS5467 will perform a reset as discussed in

the CS5467 data sheet. After the hardware reset to the CS5467 device, the screen contents will be automatically refreshed with the updated status of the CS5467.

2.4.3 CS5467 Crystal Frequency

The CS5467 accepts a wide range of crystal input frequencies, and can therefore run at many different

sample rates. The crystal frequency being used on the CS5467 should be entered in this box to provide

accurate frequency calculation in the FFT window. This will also help the software decide which functions

the evaluation system can perform reliably.

2.4.4 Configuration Register

In the Configuration Register box, the contents of the Config register can be modified by typing a hexadecimal value in the HEX: field, or by changing any of the values below the HEX: field to the desired settings. Although the CDB5467U software allows the user to modify any of the bits in the Config register,

changing certain bits may cause the software and board to behave erratically. For the evaluation system

to function properly, the IMODE, IINV field should be set to the default Active Low. This applies only to

the CDB5467U evaluation system, and not to the CS5467 chip itself.

2.4.5 Control Register

The Control Register section is used to make changes to and display the contents of the Ctrl register. The

Ctrl register contains various bits used to activate or terminate various features of the CS5467. Refer to

the CS5467 data sheet for descriptions of the bits. The user is able to turn each bit on or off individually.

The value of the Ctrl register is displayed in Hexadecimal format. Most of the Ctrl register bits are reserved

or unused. Only the usable bits are displayed in the Setup Window.

2.4.6 Mask Register / Status Register

The Mask Register / Status Register box displays the values for these registers in hexadecimal and decodes them to indicate each bit's function. The Mask register can be modified by typing a value in the

HEX: field, or by checking the appropriate check boxes for the bits that are to be masked. The Status register cannot be directly modified. It can only be reset by pressing the Clear Status Register button. The

HEX: field for this register and the lamps are indicators only. A lamp which is on means that the corresponding bit in the Status register is set (except the Invalid Command bit, which is inverted). The value

present in the Mask register may be changed by the software during certain operations to provide correct

functionality of the CDB5467U board.

2.4.7 Temperature, Voltage SAG, Current Fault Registers

These boxes display the values of the corresponding registers in both hexadecimal and decimal format.

Each register can be modified by typing a value in the corresponding offset, level, duration, or gain value

field (decimal) or HEX: field (hexadecimal).

DS714DB1 13

CDB5467U

2.4.8 Cycle Count / Pulse Output Registers

These fields display the values of corresponding register in both hexadecimal and decimal format. Each

register can be modified by typing a value in the corresponding Decimal Value or HEX: field.

2.4.9 Voltage Sag / Current Fault / Ichanlevel / Emin (Irmsmin) / VFrms / Tsettle / LoadMIN / Epsilon / Temperature Rigisters

These boxes display the values of the corresponding register in both hexadecimal and decimal format.

Each register can be modified by typing a value in the corresponding Decimal Value or HEX: field.

2.5 Calibration Windows

The Calibration window is used to display and write to the CS5467 offset and gain calibration registers.

The user is also able to initiate the CS5467's calibration sequences that are used to set the calibration

values. Both AC and DC calibrations can be run for offset and gain, for either the voltage channel or the

current channel, or both simultaneously. The user should refer to the CS5467 data sheet for more details

on calibration.

The Refresh Screen button will update the contents of the screen by reading all the register values from

the part. It is a good idea to press the Refresh Screen button when entering the Calibration window, or

after modifying any registers to reflect the current status of the CS5467.

Figure 9. Calibration Window

14 DS714DB1

CDB5467U

2.5.1 Offset / Gain Register

In the offset and gain register boxes, the offset and gain registers for all channels are displayed in hexadecimal and decimal. These registers can be modified directly by typing the desired value in the hexadecimal display boxes. There are three types of offset registers: DC offset, AC offset and power offset. The

AC offset registers only affect the RMS register values. The power offset registers only affect the active

power register values. The DC/AC/power offset register is a two's complement number whose value ranges from -1 to +1. The gain register value ranges from 0 to 4.

2.5.2 Performing Calibrations

AC/DC offset and gain calibrations can be performed on both the voltage and current channels of the

CS5467. It is generally a good idea to software-reset the CS5467 before running calibrations, because

the initial values in the calibration registers will affect the results of the calibration. A software reset will

reset these registers back to the default values of zero offset and unity gain. AC/DC offset calibration

should be performed before gain calibration to ensure accurate results.

2.5.2.1 Offset Calibrations

1. Ground the channel(s) you want to calibrate directly at the channel header(s), J11 and J7 for voltage channel 2, J17 and J22 for voltage channel 1, J24 and J26 for current channel 1, and J20 and J19 for current

channel 2. The channel(s) could also be grounded directly at the screw-type terminals.

2. Press the corresponding AC or DC offset calibrate button (Cal V, Cal I, or Calibrate All Channels) beside or

below the offset register boxes.

3. The offset register value(s) will automatically update when the calibration is completed.

2.5.2.2 Gain Calibrations

1. Attach an AC or DC calibration signal to the screw-type terminals, and make sure the corresponding channel headers (J11, J7, J17, J22, J24, J26, J20 and J19) are set to the input position.

2. Press the corresponding AC or DC gain calibrate button (Cal V, Cal I, or Calibrate All Channels) beside or

below the gain register boxes.

3. The gain register value(s) will automatically update when the calibration is completed.

The Calibration window also contains the Power Offset Register1 / 2 display and adjustment. The user

can read and write the values in the power offset registers (P1off / P2off).

DS714DB1 15

CDB5467U

2.6 Conversion Window

The Conversion Window allows the user to see the results of single and continuous conversions, perform

data averaging, and utilize the power-saving modes of the CS5467. See Figure 10. The Conversion Window can be accessed from the Menu pull-down and selecting Conversion Window, or by pressing <F4>.

Figure 10. Conversion Window

2.6.1 Single Conversion Button

Pressing this button will cause a single conversion to be performed. After a single conversion is complete,

the Result column will be updated with the values present in each data register.

2.6.2 Continuous Conversion Button

Pressing this button will cause continuous conversions to be performed until the user presses the Stop

button. After each conversion is complete, the Result column will be updated with the values present in

each data register. The Mean and Standard Deviation columns will be updated every N cycles, where N

is the number in the Samples to Average field. If the Samples to Average is set to a large number, it may

take many collection cycles after pressing the Stop button before the data actually stops being collected.

16 DS714DB1

CDB5467U

2.6.3 Standby / Sleep Mode Buttons

When these buttons are pressed, the CS5467 will enter either standby or sleep power saving modes. To

return to normal mode, press the Power Up button.

2.6.4 Power Up Button

This button is used to send the Power Up/Halt command to the CS5467. The part will return to normal

operating mode and halt any conversions that are being done at this time.

2.6.5 Set Line Frequency

If the AFC bit in the Mode register is set, the Epsilon register will be calculated automatically by the

CS5467 and the Line Frequency display field will be updated automatically in continuous conversion

mode. If the AFC bit in the Mode register is not set and the line frequency is other than the default value

(50Hz), to ensure the accuracy of the quadrature power (Q1, Q2) and the reactive power (Q1avg, and

Q2avg), the line frequency must be set manually here to make Epsilon be the ratio of line frequency to

the output word rate (OWR). Refer to the CS5467 datasheet for more details.

2.6.6 Temperature Settings Window

The Temperature Settings Window is used to adjust the temperature offset register (Toffset) and temperature gain register (Tgain) to convert the temperature register (T) from a Celsius scale (°C) to a Fahrenheit

scale (°F) or vice versa and to improve temperature measurement accuracy. Refer to the CS5467 data

sheet for the details of the on-chip temperature sensor.

2.6.7 Write Data to File Window

This window provides a means to write the conversion result data to a .txt text file for later analysis or

print out. The file path and name will be shown in Filename field. The Open File button is used to open a

new or existing .txt text file for data writing. Each time the Write Data button is pressed, the result data is

written into the file and the Number of Lines Written field value will be increased by 1.

2.6.8 Temperature Measurement

In the CS5467, voltage 2 and temperature are multiplexed on one ADC channel. To initiate a temperature

measurement, write 1 to the Tmeas register while in continuous conversion mode. When the Tmeas register returns to 0, the Temperature field should be updated with the data in the T (Temperature) register.

DS714DB1 17

CDB5467U

2.7 Pulse Rate Window

The CS5467 features a pulse-rate energy output. The CDB5467U has the capability to demonstrate the

functionality of this output in the Pulse Rate Output Window. See Figure 11. The Pulse Rate Output Win-

dow can be accessed by pressing <F5>, or by pulling down the Menu menu, and selecting the Pulse Rate

Window item.

Figure 11. Pulse Rate Output Window

2.7.1 Integration Seconds

This field allows the user to select the length of time over which pulses will be collected after the Start

button is pressed. Because there is a time delay (2x N / OWR) from start conversion to pulse output, the

Integration Seconds field is normally set to a delay longer than the actual pulsing period.

2.7.2 Periods To Average

This field allows the user to average a number of integration periods.

2.7.3 Start Button

When the Start button is pressed, the CDB5467U will capture pulse rate data according to the values in

the Integration Seconds and Periods to Average fields. After each integration period, the Pulse Count,

Frequency, Average Freq., and Standard Deviation columns will be updated. The Average Frequency and

Standard Deviation columns will only be updated after all the integrations have been collected. The soft-

ware stops collecting data when the user presses the Stop button, or when the data collection is finished.

Due to speed limitations of the on-board microcontroller, some higher pulse rates cannot be accurately

collected.

18 DS714DB1

CDB5467U

2.8 Data Collection Window

The Data Collection Window (Figure 12) allows the user to collect sample sets of data from the CS5467

and analyze them using time domain, FFT, and histogram plots. The Data collection Window can be ac-

cessed by pulling down the Menu menu, and selecting the Data Collection Window item, or by pressing

<F6>.

Figure 12. Data Collection Window

2.8.1 Time Domain / FFT/ Histogram Selector

This menu selects the type of data processing to perform on the collected data and display in the plot area.

Refer to the Analyzing Data section for more information.

2.8.2 Config Button

This button will bring up the Configuration window, in which the user can modify the data collection specifications. Refer to the Configuration Window section in this document for more information.

2.8.3 Collect Button

This button will collect data from the part, to be analyzed in the plot area. See the Collecting Data Sets

section for more information.

DS714DB1 19

CDB5467U

2.8.4 Output Button

This button will bring up a window in which the user can output the data to a file for later use, print out a

plot, or print out the entire screen. When saving data, only the data channel being displayed on the plot

will be saved to a file.

2.8.5 Zoom Button

This button allows the user to zoom in on the plot by selecting two points in the plot area. Press the Restore button to return to the normal data plot, or press the Zoom button again to zoom in even further.

2.8.6 Channel Select Button

After data collection, the two buttons labeled as “No Data” will be replaced with Current and Voltage buttons, allowing the user to choose the appropriate channel for display. In the time domain mode, an additional Overlay button will be present which allows the user to display all the channels on the same plot.

2.8.7 Configuration Window

The Configuration window allows the user to set up the data collection and analysis parameters.

Figure 13. Configuration Window

2.8.7.1 Number of Samples

This field allows the user to select the number of samples to collect, between 16 and 32768.

2.8.7.2 Average

When performing FFT analyses, this field determines the number of FFTs to average. FFTs will be collected and averaged when the Collect button is pressed.

20 DS714DB1

CDB5467U

2.8.7.3 FFT Window

This box allows the user to select the type of windowing algorithm for FFT processing. Windowing algorithms include the Blackman, Blackman-Harris, Hanning, 5-term Hodie, and 7-term Hodie. The 5-term

Hodie and 7-term Hodie are windowing algorithms developed at Crystal Semiconductor.

2.8.7.4 Histogram Bin Width

This field determines the "bin width" when plotting histograms of the collected data. Each vertical bar in

the histogram plot will contain the number of output codes entered in this field. Increasing this number

may allow the user to view histograms with larger input ranges.

2.8.7.5 Data to Collect

These two check boxes allow the user to select the data types that will be collected and returned to the

PC for processing.

2.8.7.6 Cycle Count

The value in the Cycle Count field will be written to the Cycle Count register in the CS5467. The Cycle

Count register determines the length of one computation cycle. The Cycle Count value should be selected

appropriately according to the Data to Collect setting. For example, if the Data to Collect is instantaneous

current, voltage, or power it is better to set Cycle Count to 1.

2.8.7.7 Accept Button

When this button is pressed, the current settings will be saved, and the user will return to the Data Collection Window.

2.8.8 Collecting Data Sets

To collect a sample data set:

1. In the Data Collection Window, press the Config button to bring up the Configuration window and view the

current settings.

2. Select the appropriate settings from the available options (see the Configuration Window section) and press

the Accept button.

3. The Data Collection Window should still be visible. Press the Collect button to begin collecting data.

4. Once the data has been collected, it can be analyzed, printed, or saved to disk.

2.8.9 Retrieving Saved Data From a File

The CDB5467U software allows the user to save data to a file, and retrieve it later when needed. To load

a previously saved file:

1. Pull down the Setup menu and select the Disk menu item. A file menu will appear.

2. Find the data file in the list and select it. Press the Select button to return.

3. Go to the Data Collection Window, and press the Collect button.

4. The data from the file should appear on the screen. The data will be ready for different types of analysis.

5. To select a different file, repeat the procedure.

DS714DB1 21

CDB5467U

2.8.10 Analyzing Data

The evaluation software provides three types of analysis tests: Time Domain, Frequency Domain, and

Histogram. The time domain analysis processes acquired conversions to produce a plot of magnitude ver-

sus conversion sample number. The frequency domain analysis processes acquired conversions to produce a plot of magnitude versus frequency using the Fast-Fourier transform (results up to Fs/2 are

calculated and plotted). Also statistical noise calculations are calculated and displayed. The histogram

analysis processes acquired conversions to produce a histogram plot. Statistical noise calculations are

also calculated and displayed.

2.8.11 Histogram Information

The following is a description of the indicators associated with histogram analysis. Histograms can be plotted in the Data Collection Window by setting the analysis type pull-down menu to Histogram.

Figure 14. Histogram Analysis

2.8.11.1 BIN

Displays the x-axis value of the cursor on the histogram.

2.8.11.2 MAGNITUDE

Displays the y-axis value of the cursor on the histogram.

22 DS714DB1

CDB5467U

2.8.11.3 MEAN

Indicates the mean of the data sample set. The mean is calculated using the following formula:

n1–

Xi

∑

Mean

2.8.11.4 STD_DEV

Indicates the standard deviation of the collected data set. The standard deviation is calculated using the

following formula:

----------------=

i0=

n

STDDEV

n1–

∑

i0=

=

------------------------------------------------

–

()

Xi

MEAN

2

n

2.8.11.5 VARIANCE

Indicates for the variance of the current data set. The variance is calculated using the following formula:

VARIANCE

n1–

i0=

------------------------------------------------=

∑

–

()

MEAN

Xi

2

n

2.8.11.6 MAXIMUM

Indicates the maximum value of the collected data set.

2.8.11.7 MINIMUM

Indicates the minimum value of the collected data set.

DS714DB1 23

CDB5467U

2.8.12 Frequency Domain Information

The following describe the indicators associated with FFT (Fast Fourier Transform) analysis. FFT data

can be plotted in the Data Collection Window by setting the analysis type selector to FFT (Figure 15).

Figure 15. FFT Analysis

2.8.12.1 FREQUENCY

Displays the x-axis value of the cursor on the FFT display.

2.8.12.2 MAGNITUDE

Displays the y-axis value of the cursor on the FFT display.

2.8.12.3 S/PN

Indicates the signal-to-peak noise ratio (decibels).

2.8.12.4 SINAD

Indicates for the signal-plus-noise-plus-distortion to noise-plus-distortion ratio (decibels).

2.8.12.5 S/D

Indicates for the signal-to-distortion ratio, 4 harmonics are used in the calculations (decibels).

24 DS714DB1

CDB5467U

2.8.12.6 SNR

Indicates for the signal-to-noise ratio, first 4 harmonics are not included (decibels).

2.8.12.7 FS-Pdb

Indicates for the full-scale to signal Ratio (decibels).

2.8.12.8 Time Domain Information

The following controls and indicators are associated with time domain analysis. Time domain data can be

plotted in the Data Collection Window by setting the analysis type selector to Time Domain (Figure 16).

Figure 16. Time Domain Analysis

2.8.12.9 COUNT

Displays current x-position of the cursor on the time domain display.

2.8.12.10 MAGNITUDE

Displays current y-position of the cursor on the time domain display.

2.8.12.11 MAXIMUM

Indicates for the maximum value of the collected data set.

DS714DB1 25

CDB5467U

2.8.12.12 MINIMUM

Indicates for the minimum value of the collected data set.

2.9 EEPROM Window

CDB5467U has an "Auto-Boot" demo feature that uses the on-board serial EEPROM, so that the

CDB5467U can operate independently without being connected to a PC. CDB5467U GUI software also

provides an EEPROM Window for reading & writing the serial EEPROM (Figure 17).

Figure 17. EEPROM Window

2.9.1 Bytes to Read/Write

The Bytes to Read/Write field allows the user to define the number of bytes to read or write.

2.9.2 Read EEPROM

First input the number of bytes to read in the Bytes to Read/Write field. After pressing the Read button,

that number of bytes starting from the address 0x00 will be read from EEPROM and displayed in the EE-

PROM table in hexadecimal format.

2.9.3 Write EEPROM

Input the number of bytes to write in the Bytes to Read/Write field and input the hexadecimal byte values

in the EEPROM table starting from address 0x00. After pressing the Write button, the bytes in the EE-

PROM table will be written to the EEPROM.

26 DS714DB1

CDB5467U

2.10 Debug Panel

The Debug panel provides the user a way to access CS5467 registers and send commands to CS5467

directly (Figure 18). Refer to 5.15 in CS5467 data sheet for more details.

Figure 18. Debug Panel

DS714DB1 27

APPENDIX A. BILL OF MATERIALS

y

g

r

CDB5467U

MFG MFG P/N Notes

BILL OF MATERIAL (Page 1 of 2)

nato

0.25T TYPE E 24/19 BLU SQUIRES

ELEC. INC.

0.25T TYPE E 24/19 BLU SQUIRES

ELEC. INC.

111-0102-001 REQUIRES WIRE, 1.5L X 0.25T X

111-0103-001 REQUIRES WIRE, 1.5L X 0.25T X

COMPONENTS

COMPONENTS

ED 100/2DS

TECHNOLOGY

SCREW

TP-101-10

CORPORATION

Reference Desi

Description Qt

CAP 0.1uF ±10% 50V NPb X7R 1206 6 C1 C18 C19 C21 C29 C30 KEMET C1206C104K5RAC

CAP 22pF ±5% 50V C0G NPb 0805 1 C2 KEMET C0805C220J5GAC

CAP 0.1uF ±10% 16V X7R NPb 0603 5 C3 C4 C26 C32 C33 KEMET C0603C104K4RAC

CAP 47uF ±20% 10V ELEC NPb CASE C 2 C5 C8 PANASONIC EEE1AA470WR

CAP 0.1uF ±5% 50V X7R NPb 0805 7 C6 C7 C10 C11 C12 C15 C25 KEMET C0805C104J5RAC

CAP 220pF ±10% 50V X7R NPb 0805 8 C9 C17 C20 C24 C27 C34 C35 C36 KEMET C0805C221K5RAC

CAP 0.018uF ±10% 50V X7R NPb 1206 4 C13 C23 C37 C38 KEMET C1206C183K5RAC

CAP 10uF ±20% 16V ELEC NPb CASE A 3 C14 C22 C39 PANASONIC EEE1CS100SR

CAP 1uF ±10% 25V X7R NPb 1206 1 C16 KEMET C1206C105K3RAC

CAP 47uF ±20% 16V NPb ELEC CASE C 2 C28 C31 PANASONIC EEE1CA470WR

DIODE ARRAY 5V (TVS) ESD NPb SOT143 1 D1 LITTELFUSE SP0503BAHTG

LED SUP RED 1.7V 1mA 1.6MCD NPb SMD 6 D2 D3 D4 D5 D6 D7 CHICAGO MINIATURE CMD28-21SRC/TR8/T1

HDR 5x2 ML .1"CTR S GLD NPb 1 J1 SAMTEC TSW-105-07-G-D

CON RA USB BLK NPb TH 1 J2 AMP 292304-1

CON BPOST 2" SILV NYLON INS RED NPb 3 J3 J5 J6 JOHNSON

CON BPOST 2" SILV NYLON INS BLK NPb 1 J4 JOHNSON

HDR 3x2 ML .1"CTR 062 S GLD NPb 10 J7 J8 J9 J11 J17 J19 J20 J22 J24 J26 SAMTEC TSW-103-07-G-D

HDR 2x1 ML .1" 062BD ST GLD NPb TH 5 J10 J13 J15 J16 J18 SAMTEC TSW-102-07-G-S

HDR 2x2 ML .1"CTR .062BD S GLD NPb 1 J12 SAMTEC TSW-102-07-G-D

CON TERM BLOCK 2POS 5mm NPb BLU TH 1 J14 ON-SHORE

CON TERM BLCK 4 POS 5mm NPb BLU TH 4 J21 J23 J27 J28 OST ED 100/4DS

HDR 3x1 ML .1" 062 ST GLD NPb TH 1 J25 SAMTEC TSW-103-07-G-S

HDR 2x1 ML .1" 062BD ST GLD NPb TH 0 J29 J30 SAMTEC TSW-102-07-G-S NO POP

HDR 11x2 ML .1"CTR 062 S GLD NPb 1 J40 SAMTEC TSW-111-07-G-D

WIRE JUMPER 2P 0.1" BRASS NPb TH 6 JP1 JP2 JP3 JP4 JP5 JP6 COMPONENTS

SPCR STANDOFF 4-40 THR .875L AL NPb 4 MH1 MH2 MH3 MH4 KEYSTONE 1809 REQUIRES 4-40- PAN HEAD

RES 470 OHM 1/3W ±1% NPb 1210 FILM 8 R1 R9 R10 R27 R30 R31 R32 R33 DALE CRCW1210470RFKEA

RES 2k OHM 1/8W ±1% NPb 0805 FILM 12 R2 R3 R6 R7 R8 R14 R15 R16 R17 R29 R36 R38 DALE CRCW08052K00FKEA

RES 10 OHM 1/8W ±1% NPb 0805 FILM 1 R4 DALE CRCW080510R0FKEA

RES 1k OHM 1/8W ±1% NPb 0805 FILM 5 R5 R11 R12 R13 R18 DALE CRCW08051K00FKEA

CIRRUS LOGIC

CDB5467U-Z NPb Rev_A.bom

RES 49.9 OHM 1/8W ±1% NPb 0805 FILM 1 R21 DALE CRCW080549R9FKEA

28 DS714DB1

CDB5467U

74LCX760WMX

C8051F320-GQ PROGRAM AT TEST

NC7WZ07P6X

NC7SZ04M5X

NC7SB3157P6X

1.5X.25TX.25T_TYPE_E

_

DALE CRCW08050000Z0EA

KEYSTONE 5001

BILL OF MATERIAL (Page 2 of 2)

R61 R62

SEMICONDUCTOR

LABORATORIES INC

SEMICONDUCTOR

TP12 TP13 TP20 TP21 TP22 TP23 TP24 TP25

TP26 TP27 TP30

SEMICONDUCTOR

SEMICONDUCTOR

Description Qty Reference Designator MFG MFG P/N Notes

RES 1k OHM 1/3W ±5% NPb 1210 FILM 4 R23 R24 R26 R28 DALE CRCW12101K00JNEA

RES 301 OHM 1/3W ±1% NPb 1210 FILM 1 R25 DALE CRCW1210301RFKEA

RES 0 OHM 1/18W ±1% NPb 0805 FILM 12 R51 R52 R53 R54 R55 R56 R57 R58 R59 R60

RES 12k OHM 1/4W ±5% NPb 1206 FILM 1 R35 DALE CRCW120612K0JNEA

RES 15k OHM 1/4W ±1% 1206 NPb FILM 1 R37 DALE CRCW120615K0FKEA

RES 0 OHM 1/4W NPb 1206 FILM 1 R64 DALE CRCW12060000Z0EA

SWT SPST 130G 0/1 5mm TACT ESD NPb 1 S1 C&K PTS645TL50 INSTALL AFTER WASH PROCESS

CON TEST PT .1"CTR TIN PLAT NPb BLK 20 TP1 TP2 TP3 TP4 TP5 TP6 TP9 TP10 TP11

CON TEST PT .1"CTR TIN PLAT NPb BLK 0 TP7 TP8 KEYSTONE 5001 NO POP

IC PGM 128BIT SER EPROM NPb SOT23-5 1 U1 MICROCHIP 24LC00-I/OT

IC DIG LOW V BUF/LDRV 5V NPb SOIC20 1 U2 FAIRCHILD

IC PGM USB 16kB FLAS MCU NPb LQFP32 1 U3 SILICON

IC LNR PREC V REF 2.5V NPb SO8 1 U4 LINEAR TECH LT1019CS8-2.5#PBF

IC LOG UHS TINY DUAL BUF NPb SC70-6 1 U5 FAIRCHILD

IC CRUS 4 CH PWR MEASURE NPb SSOP28 1 U6 CIRRUS LOGIC CS5467-ISZ/C1

IC LOG INV 5P UHS TINY NPb SOT23 1 U8 FAIRCHILD

IC LOG UHS TINY ANA SWT 6P NPb SC70 2 U9 U11 FAIRCHILD

IC PGM EEPROM 512x8 SPI NPb SOIC8 1 U10 ATMEL AT25040AN-10SU-2.7

WIRE BPOST 1.5X.25 24/19 GA BLU NPb 4 XJ3 XJ4 XJ5 XJ6 SQUIRES L-

SCREW 4-40X5/16" PH MACH SS NPb 4 XMH1 XMH2 XMH3 XMH4 BUILDING FASTENERS PMSSS 440 0031 PH

PINCH CONTACT SOCKET FOR SSOP28 0 XU6 ENPLAS OTS-28(34)-0.65-01 NO POP

XTL 4.0960MHZ HC49S 50ppm 50pF NPb 1 Y1 CAL CRYSTAL CCL-6S-4.0960C14F-R

DIODE TR 6.8V 600W NPb AXL 3 Z1 Z2 Z3 LITTLE FUSE P6KE6.8

SCHEM CDB5467U-Z NPb REF CIRRUS LOGIC 600-00213-Z2

PCB CDB5464U_67U 1 CIRRUS LOGIC 240-00213-Z1

ASSY DWG PWA CDB5464U_67U REF CIRRUS LOGIC 603-00213-01

LBL SUBASSY PRODUCT ID AND REV 1 CIRRUS LOGIC 422-00013-01

TST PROC CDB5467U REF CIRRUS LOGIC 602-00213-02

CON SHUNT 2P .1"CTR BLK NPb 16 MOLEX 15-29-1025

RES 0 OHM 1/18W ±1% 0805 FILM 0 R34 DALE NP-CRCW0805000Z DO NOT POPULATE

LBL SUBASSY PRODUCT NUMBER 1 CIRRUS LOGIC 422-00037-01 LABEL FOR PRODUCT NUMBER

CIRRUS LOGIC

CDB5467U-Z NPb Rev_A.bom

INSULATOR .312 x .145 HC49U/US NPb 1 XY1 ECS 700-9001

DS714DB1 29

APPENDIX B. SCHEMATICS

CDB5467U

Figure 19. Schematic - Analog Inputs

30 DS714DB1

CDB5467U

Figure 20. Schematic - CS5467 & Socket

DS714DB1 31

CDB5467U

Figure 21. Schematic - Microcontroller & USB Interface

32 DS714DB1

CDB5467U

Figure 22. Schematic - Power Supplies

DS714DB1 33

APPENDIX C. LAYER PLOTS

CDB5467U

Figure 23. Top Silkscreen

34 DS714DB1

CDB5467U

Figure 24. Top Routing

DS714DB1 35

CDB5467U

Figure 25. Bottom Routing

36 DS714DB1

CDB5467U

Figure 26. Bottom Silkscreen

DS714DB1 37

REVISION HISTORY

Revision Date Changes

DB1 OCT 2007 Initial Release.

CDB5467U

Contacting Cirrus Logic Support

For all product questions and inquiries contact a Cirrus Logic Sales Representative. To find the one nearest to you

go to www.cirrus.com

IMPORTANT NOTICE

Cirrus Logic, Inc. and its subsidiaries ("Cirrus") believe that the information contained in this document is accurate and reliable. However, the information is subject

to change without notice and is provided "AS IS" without warranty of any kind (express or implied). Customers are advised to obtain the latest version of relevant

information to verify, before placing orders, that information being relied on is current and complete. All products are sold subject to the terms and conditions of sale

supplied at the time of order acknowledgment, including those pertaining to warranty, indemnification, and limitation of liability. No responsibility is assumed by Cirrus

for the use of this information, including use of this information as the basis for manufacture or sale of any items, or for infringement of patents or other rights of third

parties. This document is the property of Cirrus and by furnishing this information, Cirrus grants no license, express or implied under any patents, mask work rights,

copyrights, trademarks, trade secrets or other intellectual property rights. Cirrus owns the copyrights associated with the information contained herein and gives

consent for copies to be made of the information only for use within your organization with respect to Cirrus integrated circuits or other products of Cirrus. This consent does not extend to other copying such as copying for general distribution, advertising or promotional purposes, or for creating any work for resale.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE ("CRITICAL APPLICATIONS"). CIRRUS PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARRANTED FOR

USE IN AIRCRAFT SYSTEMS, MILITARY APPLICATIONS, PRODUCTS SURGICALLY IMPLANTED INTO THE BODY, AUTOMOTIVE SAFETY OR SECURITY

DEVICES, LIFE SUPPORT PRODUCTS OR OTHER CRITICAL APPLICATIONS. INCLUSION OF CIRRUS PRODUCTS IN SUCH APPLICATIONS IS UNDERSTOOD TO BE FULLY AT THE CUSTOMER'S RISK AND CIRRUS DISCLAIMS AND MAKES NO WARRANTY, EXPRESS, STATUTORY OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSE, WITH REGARD TO ANY CIRRUS PRODUCT THAT

IS USED IN SUCH A MANNER. IF THE CUSTOMER OR CUSTOMER'S CUSTOMER USES OR PERMITS THE USE OF CIRRUS PRODUCTS IN CRITICAL

APPLICATIONS, CUSTOMER AGREES, BY SUCH USE, TO FULLY INDEMNIFY CIRRUS, ITS OFFICERS, DIRECTORS, EMPLOYEES, DISTRIBUTORS AND

OTHER AGENTS FROM ANY AND ALL LIABILITY, INCLUDING ATTORNEYS' FEES AND COSTS, THAT MAY RESULT FROM OR ARISE IN CONNECTION

WITH THESE USES.

Cirrus Logic, Cirrus, and the Cirrus Logic logo designs are trademarks of Cirrus Logic, Inc. All other brand and product names in this document may be trademarks

or service marks of their respective owners.

LabWindows and CVI are registered trademarks of National Instruments, Inc.

Windows, Windows 2000, and Windows XP are trademarks or registered trademarks of Microsoft Corporation.

PADS and PowerLogic are trademarks of Mentor Graphics Corporation.

38 DS714DB1

Loading...

Loading...