Page 1

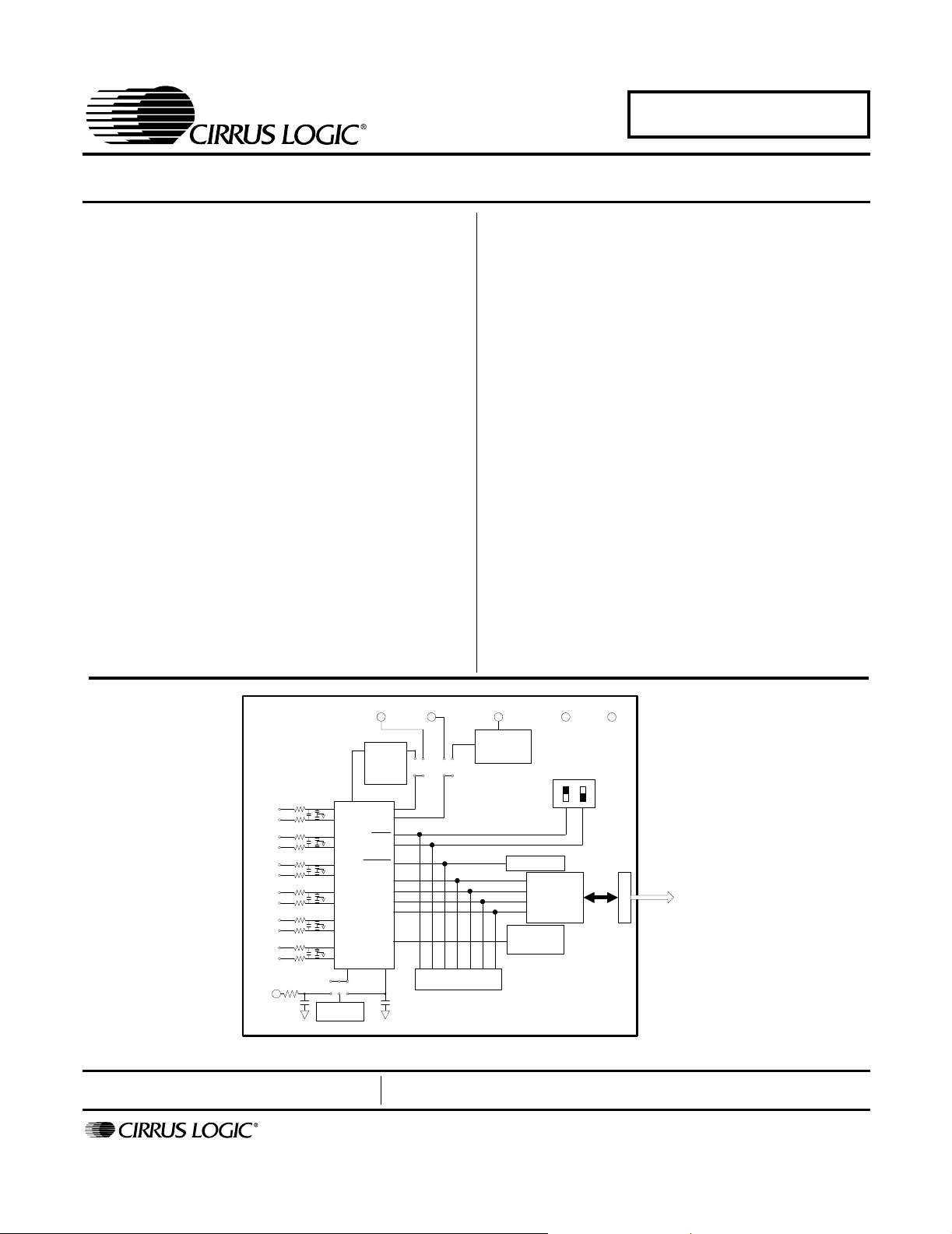

CDB5451A

CDB5451A Evaluation Board and Software

Features

Direct Shunt Sensor and Current

Transformer Interface for 3-Phase Power

On-Board Voltage Reference

On-board crystal for XIN

Digital Interface to PC

Lab Windows/CVI

- Real-Time RMS calculation

- Fast Fourier Transform (FFT) Analysis

- Time Domain Analysis

- Noise Histogram Analysis

™

Evaluation Software

General Description

The CDB5451A is an inexpensive tool designed to evaluate the functionality/performance of the CS5451A 6channel A/D Converter. In addition to this data sheet, the

CS5451A Data Sheet is required in conjunction with the

CDB5451A Evaluation Board.

Six terminal block connectors serve as inputs to the

CS5451A’s six analog input pairs. The CDB5451A includes an optional voltage reference source for

CS5451A. A 4.096MHz crystal is provided as a source

for the CS5451A XIN pin, or an external clock source can

be supplied by the user. Digital output data from the

CS5451A is transferred to the user’s IBM-compatible PC

via the included 25-pin parallel port cable.

The CDB5451A includes PC software, allowing the user

to perform data capture (includes option for time domain

analysis, histogram analysis, and frequency domain

analysis). The software also allows real-time RMS calculation/analysis to be performed simultaneously on all six

channels.

ORDERING INFORMATION

CDB5451A Evaluation Board

VIN1+

VIN1-

IIN1+

IIN1-

VIN2+

VIN2-

IIN2+

IIN2-

VIN3+

VIN3-

IIN3+

IIN3-

V

REF

CPD

CS5451A

IN OU T

Voltage

Reference

Preliminary Product Information

http://www.cirrus.com

OWRS

RESET

V

REF

VA-

Charge

Pump

Circuitry

VA-

VA+

GAIN

FSO

SDO

CLK

SE

XIN

Header

+5 VINVA+

3 V

Regulator

(Not Populated)

Reset Circuit

4.096 MHz

Control Switches

Serial-to-

Parallel

Interfac e

Crystal

VD+GND

DB25

To PC

This document contains information for a new product.

Cirrus Logic reserves the right to modify this product without notice.

Copyright © Cirrus Logic, Inc. 2001

(All Rights Reserved)

Nov ‘03

DS458DB3

1

Page 2

TABLE OF CONTENTS

1. INTRODUCTION........................................................................................................................ 3

1.1 CS5451A ........................................................................................................................... 3

1.2 Data Flow on Evaluation Board ......................................................................................... 3

2. HARDWARE .............................................................................................................................. 4

2.1 Evaluation Board Description............................................................................................. 4

2.2 Power Supply Connections................................................................................................ 4

2.2.1 Analog Power Supply ............................................................................................... 4

2.2.2 Digital Power Supply ................................................................................................ 4

2.2.3 Charge Pump Options.............................................................................................. 5

2.3 Eval Board Control - Headers/Switches............................................................................. 5

2.3.1 Analog Inputs ........................................................................................................... 7

2.3.2 Voltage Reference Input........................................................................................... 8

2.3.3 Clock Source for XIN................................................................................................ 8

2.3.4 S1 DIP Switch .......................................................................................................... 8

2.3.5 Reset Circuit............................................................................................................. 8

2.3.6 External Signal In/Out Header.................................................................................. 8

2.3.7 Serial-to-Parallel Interface ........................................................................................ 8

2.3.8 Connecting the Eval Board to PC............................................................................. 9

3. SOFTWARE............................................................................................................................. 13

3.1 Installing the Software...................................................................................................... 13

3.2 Running the Software ...................................................................................................... 13

3.2.1 Getting Started ....................................................................................................... 13

3.2.2 The Start-Up Window ............................................................................................. 14

3.2.3 The Conversion Window ........................................................................................ 15

3.2.4 Data Collection Window ......................................................................................... 16

3.2.5 Config Window ....................................................................................................... 17

3.2.6 Analyzing Data ....................................................................................................... 18

3.2.7 Time Domain Information ....................................................................................... 18

3.2.8 Frequency Domain Information .............................................................................. 19

3.2.9 Histogram Information ............................................................................................ 20

CDB5451A

LIST OF FIGURES

Figure 1. Power Supply, CS5451A, and Oscillator ......................................................... 10

Figure 2. Analog Inputs .................................................................................................. 11

Figure 3. Digital Circuitry ................................................................................................ 12

Figure 4. Start-Up Window ............................................................................................. 14

Figure 5. Conversion Window ........................................................................................ 15

Figure 6. Data Collection Window (Time Domain) ......................................................... 16

Figure 7. Configuration Window ..................................................................................... 18

Figure 8. Data Collection Window (FFT) ........................................................................ 19

Figure 9. Data Collection Window (Histogram) .............................................................. 20

Figure 10.Silkscreen ........................................................................................................ 22

Figure 11.Circuit Side ...................................................................................................... 23

Figure 12.Solder Side ...................................................................................................... 24

2 DS458DB3

Page 3

CDB5451A

1. INTRODUCTION

The CDB5451A Evaluation Board demonstrates

the performance of the CS5451A 6-channel A/D

converter.

The CDB5451A evaluation board provides a quick

means of evaluating the CS5451A. Analysis software supplied with the CDB5451A allows the user

to observe the CS5451A’s digital output data on

the user’s PC monitor. The PC software allows the

user to quantify the device’s performance in the

time-domain and frequency domain. The user can

save raw data from the CS5451A to a data file,

which allows to user to analyze performance with

other tools that may be preferable to the user.

1.1 CS5451A

The CS5451A is a highly integrated Six-Channel

Delta-Sigma Analog-to-Digital Converter (ADC)

developed for three-phase power/energy metering

applications. However the CS5451A has other potential uses in other data acquisition applications,

particularly in motor/servo control applications that

require very high precision. The CS5451A combines six delta-sigma modulators with decimation

filters, along with a master-mode serial interface on

a single-chip device. The CS5451A was designed

for the purpose of performing the A/D conversion

operations required at the front-end of a digital 3phase metering system. The six ADC channels

can be thought of as three pairs of voltage/currentchannel ADC’s in a digital 3-phase power metering

application.

The CS5451A contains one three-channel programmable gain amplifier (PGA) for the three current input channels. The PGA sets the maximum

input levels of the all three current channels at

±800 mV DC (for gain = 1x) or ±40 mV DC (for gain

= 20x). The voltage channels have only the 1x gain

setting, and so the range of input levels on the voltage channels is

±800 mV DC.

Additional features of CS5451A include a charge

pump driver, on-chip 1.2 V reference, and a digital

input that can select between two different output

word rates. (The two output word rates are equal to

XIN/2048 and XIN/1024.)

The CS5451A requires a 1.2 V reference input on

VREFIN. The ∆Σ modulators and high rate digital

filters allow the user to measure instantaneous

voltage and current at an output word rate of 4 kHz

(or 2000 kHz, depending on the state of the OWRS

pin) when a 4.096 MHz clock source is used.

1.2 Data Flow on Evaluation Board

The output serial bit-stream from the CS5451A is

shifted into an 8-bit latch circuit so that it can be

quickly ported to the DB25 connector. From this

connector, the data can be sent through the provided 25-pin printer cable to the parallel port of the user’s IBM-compatible PC (the PC must run under

Windows ‘95/’98/2000 operating system).

Once the 8-bit segments of data are ported to the

user’s PC, the LabWindows software (included

with this kit) will re-segment the data into the appropriate 16-bit word format for each of the

CS5451A’s six data channels. The data is sent

quickly to the user’s PC, which allows the software

to perform various data processing and graphical

illustrations on the digital output data. This includes real-time RMS, variance, and standard deviation calculations for all six channels. The output

data from each channel can be plotted on-screen

in the time domain or in the frequency domain. A

histogram function is also included to help the user

to evaluate the noise characteristics of each channel. The software can also calculate the mean and

standard deviation of the output codes for all six

channels. This feature allows the user to scrutinize

the variation of the A/D converters if the user applies constant DC voltage levels to the inputs.

RMS calculation is also provided to assist in the

quick analysis AC input signals.

DS458DB3 3

Page 4

CDB5451A

2. HARDWARE

2.1 Evaluation Board Description

The CDB5451A board contains circuitry that will:

• Accept appropriate DC voltage levels from

the user’s +3V and/or +5V power supplies,

and direct this power to the VA+, VD+, VAand DGND pins of the CS5451A.

• Direct the six analog input signals to the six

input pairs of the CS5451A.

• Supply necessary voltage reference input

for the CS5451A’s VREFIN pin.

• Supply appropriate crystal/oscillator stimulus to the CS5451A’s XIN pin.

• Direct the output driver signal from the

CS5451A’s charge-pump driver pin (CPD)

which is used produce the negative power

supply source for the CS5451A’s VA- pin.

• Provide a reset switch that allows the user to

set the CS5451A’s RESET pin from logic “1”

to logic “0”.

• Provide two DIP switches which allow the

user to set the logic levels on the CS5451A’s

GAIN and OWRS input pins.

• Detect and receive the data frame signal

and digital serial output data signals from

the CS5451A’s FSO and SDO pins, and

send this output data through the included

parallel cable, and up to user’s PC.

Several areas of blank proto-board space are provided so that, if desired, the user can interface their

own electronic sensor equipment onto the board.

The output from these sensors can be wired to the

six nearby analog input terminal block connectors,

which is then fed to the six analog input channels

of the CS5451A. Examples of such sensors would

include voltage and current transformers, shunt resistors, and resistor divider networks.

The next section of this document describes the

various sections of the board. After this, operation

of the PC software is described in detail.

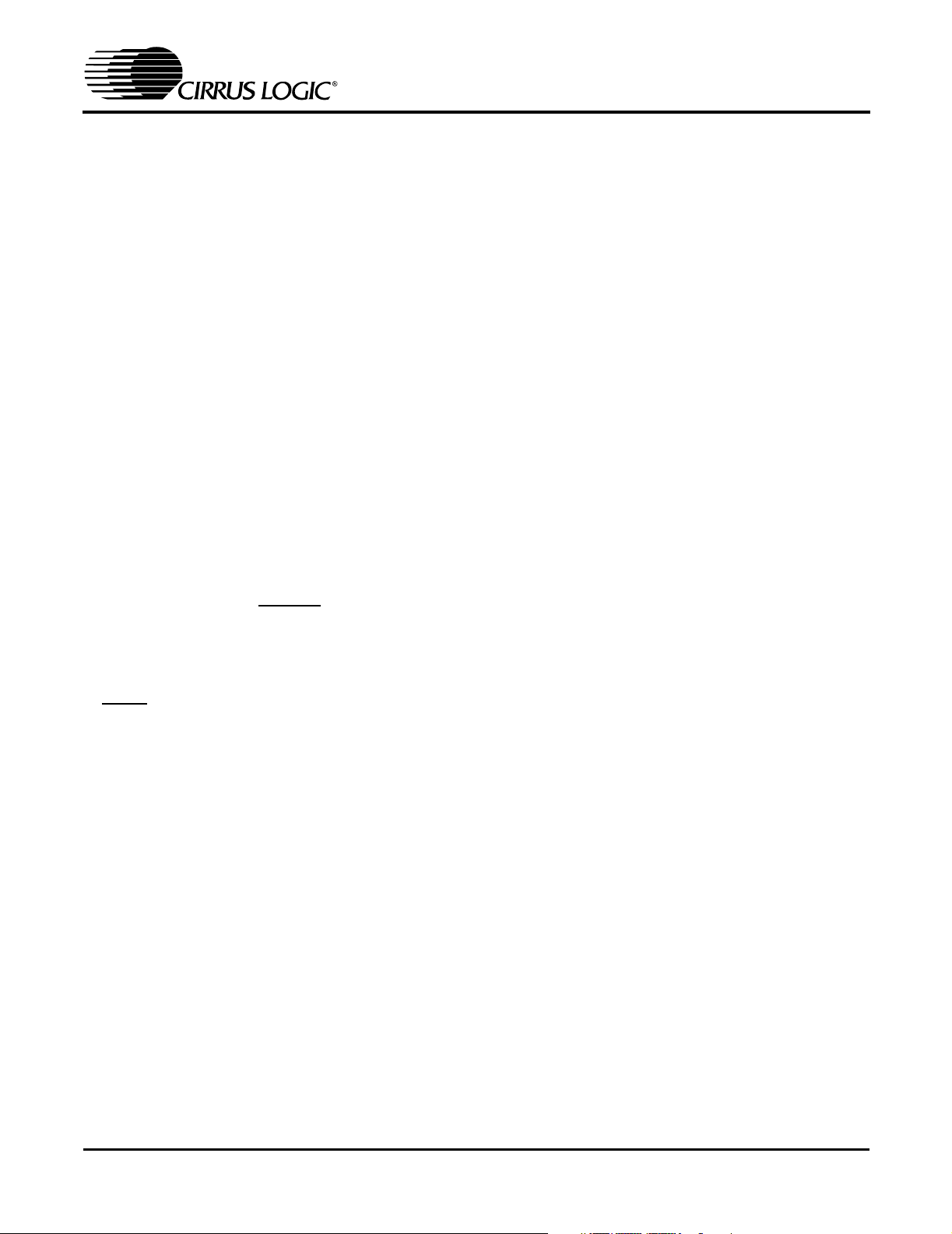

2.2 Power Supply Connections

The CDB5451A can be used in several different

power supply configurations. Table 1 shows the

various possible power connections with the required jumper settings. There are various +3 V

and +5 V options. The user must supply the +3V,

+5V, GND, and sometimes -2V voltage levels

needed to power the evaluation board.

2.2.1 Analog Power Supply

Referring to Figure 1, the A+ post supplies power

to the positive analog power input pin (VA+) of the

CS5451A. This post also supplies power to the

LT1004 voltage reference (D3) and the optional

+3V regulator (U5). If HDR9 is set to the “A-” setting, the A- post can supply the required negative

voltage to the VA- pin of the CS5451A.

Note that the evaluation board contains the footprints and connectivity which allows the user to install a LM317 voltage regulator (U5), which can be

used to create +3 V from a +5 V supply. This option is useful if the user wants to interface the evaluation board to another board that can only

operate from a +5V supply. With HDR17 set to

“+5V_IN”, one single +5 V supply can be used to

provide both the +5 V power to a microcontroller

and/or other devices, as well as +3 V for the

CDB5451A board. The included schematic diagram shows the circuitry for the +5V regulator circuitry inside a box with dashed lines. These

components are not populated when the board is

shipped from the factory, but the user can install

these components if desired.

2.2.2 Digital Power Supply

The A+ post can be used to supply both the analog

power (to CS5451A VA+ pin) as well as the digital

power (to CS5451A VD+ pin). However if a separate supply voltage is desired for the digital power

supply, the “VD+” banana connector post can be

used to independently supply a separate digital

power supply to the input of the CS5451A (VD+

pin), the 4.096 MHz oscillator (U1), and circuitry for

the parallel port interface. This is controlled by the

setting on HDR18.

The user should note that the CS5451A can operate with a digital supply voltage of either +3V or

4 DS458DB3

Page 5

CDB5451A

+5V. This voltage is defined as the voltage presented across VD+ and DGND.

2.2.3 Charge Pump Options

The output from CS5451A’s charge-pump driver

pin (CPD) can be used to generate a -2V supply

when the proper jumper settings are selected on

HDR9. This -2V supply can be used as the negative power supply connection for the CS5451A’s

VA- pin. Referring to Figure 1, circuitry for a

charge-pump circuit is included on-board. The

charge pump circuit consists of capacitors C11,

C12, and C36, and diodes D1 and D2.

As an alternative to using the charge pump circuit,

the user can supply an off-board -2V DC power

source to the “A-” banana connector. This option

is controlled by the setting on HDR9.

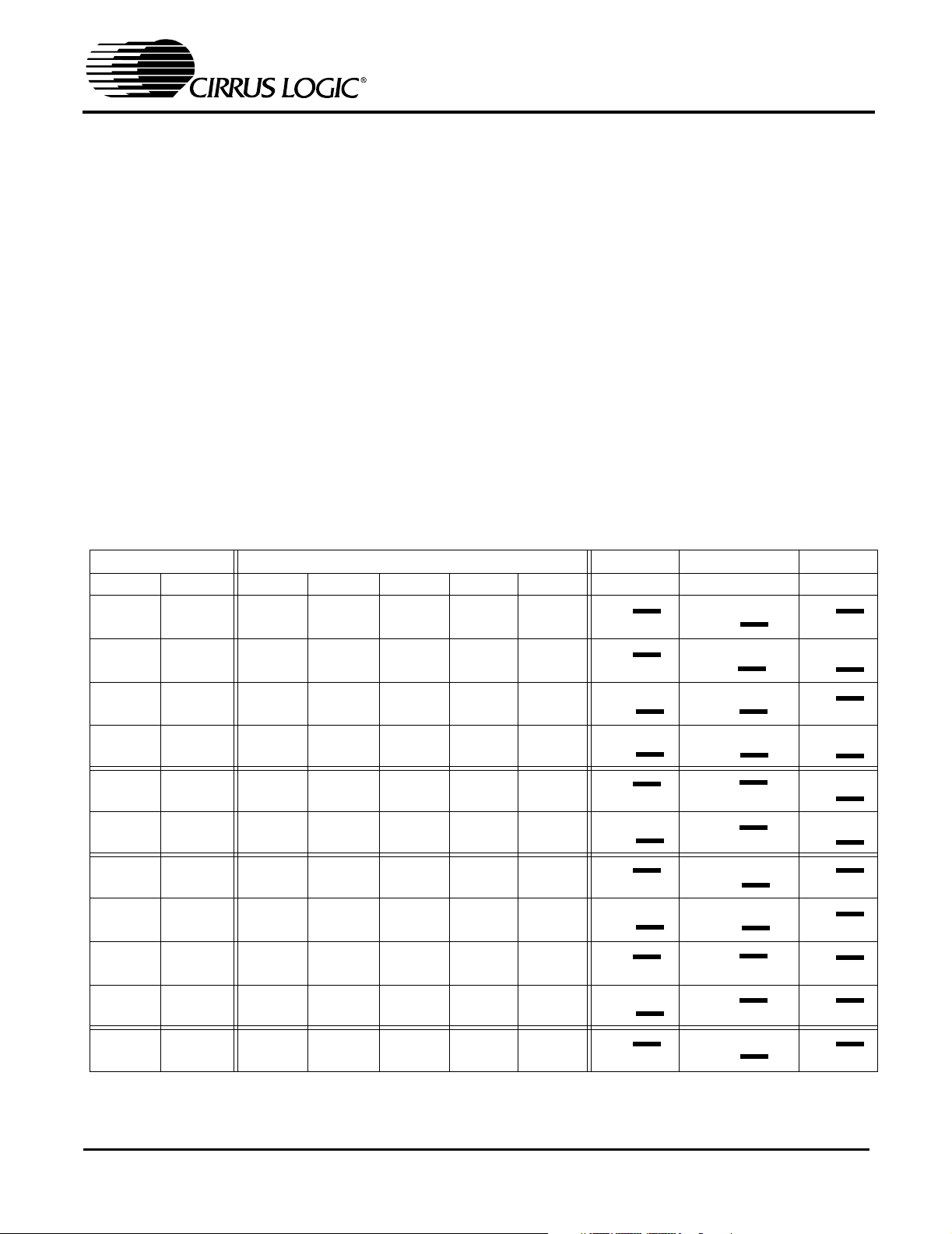

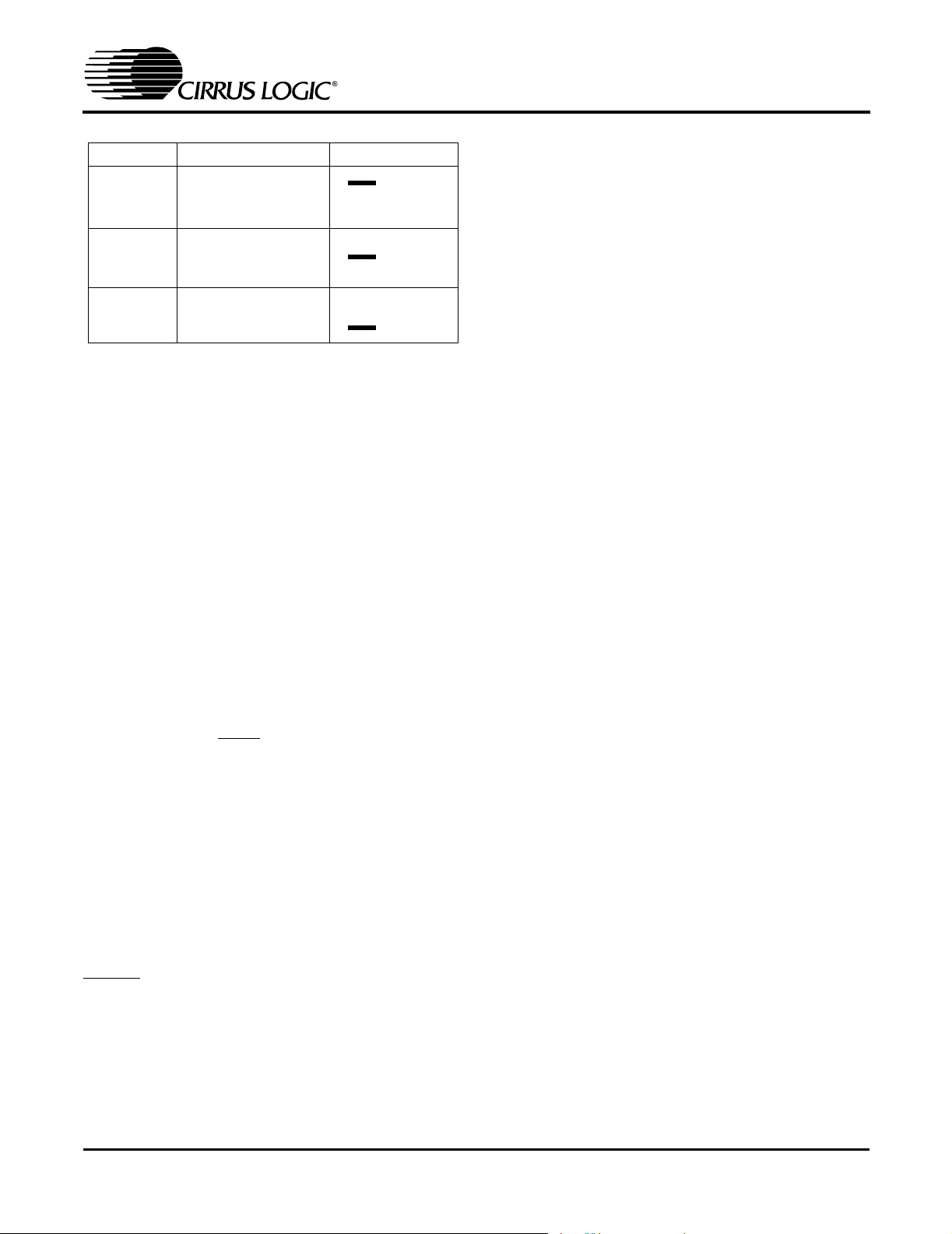

2.3 Eval Board Control Headers/Switches

Table 2 lists the various adjustable headers and

switches on the CDB5451A Evaluation Board, as

well as their default settings (as shipped from the

factory). The header settings can be adjusted by

the user to select various options on the evaluation

board. These options are described further in the

following paragraphs.

2.3.1 Analog Inputs

Refer to Figure 2. The settings on the 12 analog input headers (2 headers per channel) which are

designated as HDR1 up to HDR8, and HDR10 up

to HDR13, determine which inputs will carry a signal, and which inputs may be grounded. They can

be configured to accept either a single-ended or

Power Supplies Power Post Connections

Analog Digital A+ A- GND D+ +5 V_IN HDR9 HDR17 HDR18

+3 +3 +3 -2 0 +3 NC

A-

CPD

O O

O O

+5V_IN

A+

O O

O O

VD+

V+

O O

O O

+3 +3 +3 -2 0 NC NC

+3 +3 +3 NC 0 +3 NC

+3 +3 +3 NC 0 NC NC

+3 +3 NC -2 0 NC +5

+3 +3 NC NC 0 NC +5

+3 +5 +3 -2 0 +5 NC

+3 +5 +3 NC 0 +5 NC

+3 +5 NC -2 0 +5 +5

+3 +5 NC NC 0 +5 +5

+5 +3 +5 0 +2 +5 NC

Table 1. Power Supply Connections

A-

CPD

A-

CPD

A-

CPD

A-

CPD

A-

CPD

A-

CPD

A-

CPD

A-

CPD

A-

CPD

A-

CPD

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

+5V_IN

A+

+5V_IN

A+

+5V_IN

A+

+5V_IN

A+

+5V_IN

A+

+5V_IN

A+

+5V_IN

A+

+5V_IN

A+

+5V_IN

A+

+5V_IN

A+

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

VD+

V+

VD+

V+

VD+

V+

VD+

V+

VD+

V+

VD+

V+

VD+

V+

VD+

V+

VD+

V+

VD+

V+

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

O O

DS458DB3 5

Page 6

CDB5451A

Name Function Description Default Setting Default Jumpers

HDR1

HDR2

HDR3

HDR4

HDR5

HDR6

HDR7

HDR8

HDR9

Used to switch IIN3+ on the CS5451A between J2

and AGND.

Used to switch VIN3- on the CS5451A between J3

and AGND.

Used to switch VIN3+ on the CS5451A between J1

and AGND.

Used to switch IIN3- on the CS5451A between J4

and AGND.

Used to switch VIN2- on the CS5451A between J6

and AGND.

Used to switch IIN2+ on the CS5451A between J7

and AGND.

Used to switch IIN2- on the CS5451A between J5

and AGND.

Used to switch VIN2+ on the CS5451A between J8

and AGND.

Used to switch between external VA- and on-board

CS5451A charge-pump circuit, CPD

IIN3+ Set to BNC J2

VIN3- Set to BNC J3

VIN3- Set to BNC J1

IIN3- Set to BNC J4

VIN2- Set to BNC J6

IIN2+ Set to BNC J7

IIN2+ Set to BNC J5

VIN2+ Set to BNC J8

CPD active

O O IIN3+

O O AGND

O O VIN3O O AGND

O O VIN3+

O O AGND

O O IIN3O O AGND

O O VIN2O O AGND

O O IIN2+

O O AGND

O O IIN2O O AGND

O O VIN2+

O O AGND

A-

CPD

O O

O O

HDR10

HDR11

HDR12

SW1

HDR13

HDR14

Used to switch VIN1+ on the CS5451A between J9

and AGND.

Used to switch IIN1- on the CS5451A between J12

and AGND.

Used to switch IIN1+ on the CS5451A between J10

and AGND.

S1-1 sets logic level on CS5451A OWRS input pin

S1-2 sets logic level on CS5451A

GAIN input pin

Used to switch VIN1- on the CS5451A between J11

and AGND.

Used to switch the VREFIN from external VREF

post connector, to the on board LT1004 reference,

or to the on-chip reference VREFOUT. Refer to

Table 3.

Table 2. Default Header Settings

VIN1+ Set to BNC J9

IIN1- Set to BNC J12

IIN1- Set to BNC J10

SW1-2 Open (XIN/1024)

SW1-1 Open (GAIN

=x1)

VIN1- Set to BNC J11

VREFIN Set to on-

chip reference

VREFOUT

O O VIN1+

O O AGND

O O IIN1O O AGND

O O IIN1+

O O AGND

23

OPEN

O O VIN1O O AGND

O O LT1004

O O VREFOUT

O O EXT VREF

6 DS458DB3

Page 7

CDB5451A

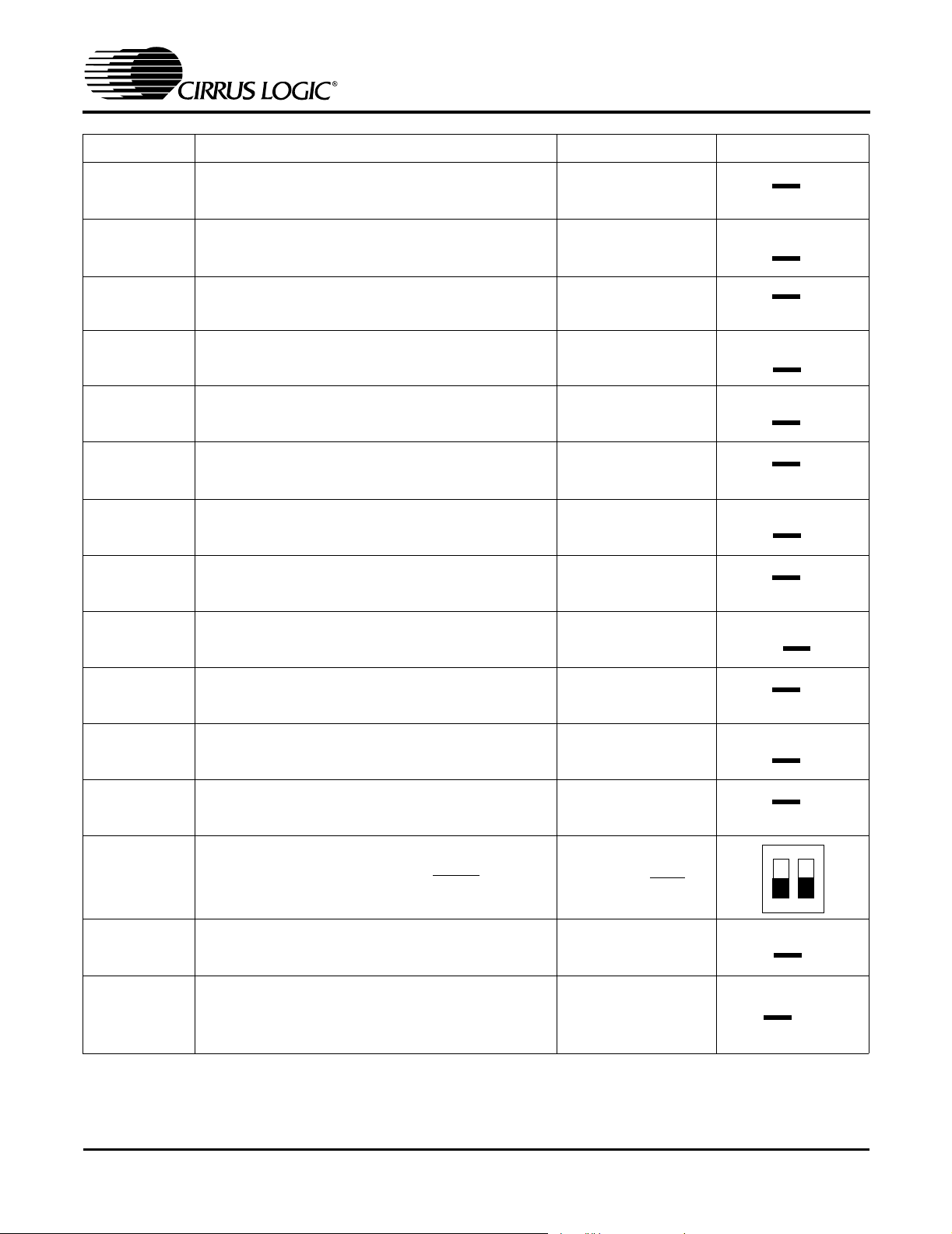

Name Function Description Default Setting Default Jumpers

HDR15

HDR16 This header should always be shorted. Short this header

HDR17

HDR18

differential signal. Using voltage channel #1 as an

example (see Figure 2), note that HDR10 sets the

input to the positive side of the first voltage channel

input (VIN1+ pin). HDR13 sets the input to the

negative side of the first voltage channel input

(VIN1- pin). In a single-ended input configuration,

HDR13 would be set to the “AGND” setting, and

HDR10 would be set to “VIN1+” and would conduct

the single-ended signal. In a differential input configuration, HDR13 would be set to “VIN1-” and

HDR10 would be set to “VIN1+” and this pair of inputs would form the differential input pair into the

VIN1+ and VIN1- pins of the CS5451A.

Controls the source for the CS5451A XIN clock

input.

Determines whether the main analog supply will be

powered from the A- post, or from the regulated 3V

voltage (generated from the +5V_IN) post input.

Choose whether the digital circuitry will be powered

by main analog supply, or powered by separate digital supply (through VD+ post).

Table 2. Default Header Settings (Continued)

current/voltage transformers and reduced in magnitude before they can be safely applied to the

evaluation board.

Several patch-circuit areas are provided near the

voltage/current input headers, in case the user

wants to connect special sensor circuitry to the analog inputs (such as transformers, shunt resistors,

etc., for monitoring a 3-phase power line). For

each of the three channels, a Shunt Resistor or

Current Transformer can be mounted in these areas and connections can be made to the individual

current-channel input pairs. Likewise, for each of

the three voltage channels, a Voltage Divider or

Set to on-board 4.000

MHz crystal (U1).

Set to A-

Set to main analog

supply

Voltage Transformer can be inserted to drive the

CS5451A’s three voltage input pairs. Note from

Figure 2 that a simple R-C network filters each

sensor’s output to reduce any noise that might be

coupled into the input leads. The 3 dB corner of the

filter is approximately 50 kHz differential and com-

WARNING: DANGER! One of the possible applications for the CS5451A includes data acquisition

for a power metering system. However, the user

should not attempt to directly connect any lead

from a high-voltage power line to the evaluation

board inputs, even if the current/voltage levels are

gain reduced by resistive dividers and/or shunts.

Because the ground terminal of the parallel cable

(from the PC) is near or at earth ground potential,

the ground node on the evaluation board will also

be forced to earth ground potential. Serious damage and even personal injury can occur if a “hot”

voltage main is connected to any point on the evaluation board, including the analog input connectors. Such power line signals must be isolated by

mon mode.

Other header options listed in Table 2 allow the

user to set the source of the input clock signal and

the source of the voltage reference (VREFIN) input, etc. The voltage reference options and clock

input options are discussed next.

2.3.2 Voltage Reference Input

To supply the CS5451A with a suitable 1.2 V voltage reference input at the VREFIN pin, the evaluation board provides three voltage reference

options: on-chip, on-board, and external. See

HDR14 as shown in Figure 1. Table 3 illustrates

the available voltage reference settings for

HDR14. With HDR14’s jumpers in position “VRE-

O O EXT XIN

O O DGND

O O 4.0096 MHz

O O

O O +5V_IN

O O A+

VD+

O O

O O

V+

OSC

DS458DB3 7

Page 8

CDB5451A

Reference Description HDR14

LT1004

VREFOUT

EXTVREF

Select on board

LT1004 Reference

(5 ppm/

Select reference sup-

plied from CS5451A

VREFOUT pin

Select external

Table 3. Reference Selection

°C)

reference

O O LT1004

O O VREFOUT

O O EXT VREF

O O LT1004

O O VREFOUT

O O EXT VREF

O O LT1004

O O VREFOUT

O O EXT VREF

FOUT,” the CS5451A’s on-chip reference provides

1.2 volts. With HDR14 set to position “LT1004,” the

LT1004 provides 1.23 volts (the LT1004 temperature drift is typically 50 ppm/°C). By setting

HDR14’s jumpers to position “EXT VREF,” the

user can supply an external voltage reference to

J16 connector post (VREF) and AGND inputs.

2.3.3 Clock Source for XIN

A 4.000 MHz crystal is provided to drive the XIN input of the CS5451A. (See Figure 1.) However, the

user has the option to provide an external oscillator

signal for XIN, by switching the setting of HDR15.

2.3.4 S1 DIP Switch

Referring to Figure 3, the two single-pole singlethrow switches on SW1 DIP switch should be used

to control the logic settings on the CS5451A’s

OWRS pin and GAIN

pin. When these SW1

switches are set to “OPEN” the corresponding pin

on CS5451A is set to D+ potential, which creates a

logic-high state. When the user closes either of

these SW1 switches, the corresponding pin on

CS5451A is grounded, which creates a logic-low

state on the pin.

2.3.5 Reset Circuit

Circuitry has been provided which allows the user

to execute a hardware reset on the CS5451A.

(See Figure 3). By pressing on the S1 switch, the

RESET

pin on the CS5451A will be held low until

the switch is released.

2.3.6 External Signal In/Out Header

Note that HDR16 is included on the CDB5451A

Evaluation Board as a header that is normally left

unconnected. This header provides a way for the

user to interface the CDB5451A Evaluation Board

to other prototype boards, calibrators, logic analyzers, other peripherals, etc. in order to further evaluate the CS5451A device and/or to use the

evaluation board as a platform for the prototype

development of a digital power meter solution.

However, please note that the CDB5451A Evaluation Board is not intended to be integrated directly

into a commercial power meter. The layout of the

board is not optimized for practical power metering

situations.

2.3.7 Serial-to-Parallel Interface

Glue-logic on the evaluation board converts the

CS5451A serial data into 8-bit segments (bytes).

The bytes are sent to the DB25 connector (J17),

and then through the standard printer cable to the

user’s PC. This section briefly describes the operation of the digital circuitry on the CDB5451A that

provides the 8-bit parallel data to the PC. Refer to

Figure 3.

The user should recall from CS5451A Data Sheet

that the serial interface on the CS5451A device is

a “master-mode” interface, which means that the

device provides the clock. Once the CS5451A is

powered on, the SCLK pin produces a clock signal,

and data is sent out on the SDO pin of the device.

When the evaluation software is instructed (by the

user) to acquire data through the parallel interface,

a two-step process is performed: First the software synchronizes itself to the frame rate of the

CS5451A, then the software acquires multiple

frames of data from the CS5451A.

2.3.7.1. Synchronization

When the software is commanded to acquire data,

the software will first synchronize itself to the frame

rate of the CS5451A (see CS5451A Data Sheet).

This is done by measuring the amount of time between rising and falling edges of the “BUSY” signal. (BUSY will change state every time the

CS5451A issues eight SCLKs--See next section

for a more detailed description.) By measuring this

time period, the software can determine the idle

period of the frame, which allows it to be prepared

to collect a complete frame’s worth of data when

the next CS5451A frame is received. This acquisition sequence is described next.

8 DS458DB3

Page 9

CDB5451A

2.3.7.2. Acquisition

Referring to Figure 3, the CS5451A’s SCLK line is

used to clock the 8-bit serial-in/parallel-out shiftregister (U7) which accepts the serial data on SDO

and shifts it into the 8 output bits QA-QG. The

SCLK signal is also fed into the up/down counter

U6 and after every 8 SCLKs, the “QC” pin of U6 will

latch the QA-QG output bits of U6 into the 8-bit DFlip-Flop (U3). While this is happening, the software monitors the “BUSY” signal (from the “QD”

pin of U6). BUSY is the critical handshake signal.

A rising or falling transition on BUSY indicates to

the software that it is now time to collect another

byte of data from the latched output on U3.

After sixteen SCLKs, the PC software has acquired

two bytes (16 bits) which represents one data sample. The 4-bit up/down counter (U6) will roll over

after every 16 SCLKs. (Note that U6 is cleared by

the CS5451A’s FSO signal at the beginning of

each frame, which insures that the counter begins

the frame in the correct state--cleared). This sequence, which lasts for 16 SCLKs, is performed a

total of six times in order to obtain the six 16-bit

words from the CS5451A.

After the last 16-bit word is acquired, the software

recognizes that the end of a data frame has been

reached, and it will continue to wait for the next

transition on the “BUSY” line. This will not occur

until the first 8 SCLKs of the next frame are sent

from the CS5451A. Various other signals in Figure

3 (STRB, FEED, ACK, etc.) are not used during

data capture and are only used for testing (internal

use only).

2.3.8 Connecting the Eval Board to PC

The CDB5451A connects to the user’s IBM-compatible PC with the included 25-pin parallel port cable. The user should not connect this cable

between the CDB5451A and the parallel port on

the PC until all of the header options in Table 2

have been set to appropriate settings and the

user has applied power to the CDB5451A. The

parallel cable attached to the CDB5451A Evaluation Board at J17. After connecting the parallel

port cable between the PC and CDB5451A, the

user should always actuate (press down on) the

“

RESET” switch (S1) at least one time before per-

forming any other evaluation activities.

DS458DB3 9

Page 10

CDB5451A

VD+

J20

CON_B A NANA

Z3

P6KE6V8P

C23

47UF

GND

C22

43

21

HDR1 8

D+ V+

1K

R29

GND

22UF

C41

C40

.1UF

3. 0V

100

TP77

TP40

2

OUT

1

U5

ADJ

LM317L Z

IN

3

C39

+5V

C42

140

R31

C38

.1UF

10UF

.1UF

HDR2 X2

21

HDR1 6

HDR1 X2

.1UF

C14

10UF

C21

XI N

/RESET

OWRS

VI N1+

VI N1-

TP78TP79

TP22TP23

TP20TP21

TP18TP19

TP16TP17

TP72

TP74 TP75

TP73

TP14 TP15

28272625242322212019181716

VD+

CPD

XIN

OWRS

DGND

VIN1+

VIN1-

/RESET

U4

AGND

SCLK

SDO

FSOSE/GAI N

VREFI N

VREFOUT

TP37TP36

TP50 TP51

TP48 TP49

TP46 TP47

TP44 TP45

TP42 TP43

TP40 TP41

TP38 TP39

SE

SDO

FSO

SCLK

/GAIN

GND

R30

TANT

. 33UF

GND

GND

IIN2-

IIN2+

VI N2-

VI N2+

IIN1-

IIN1+

TP34TP35

TP32TP33

TP30TP31

TP28TP29

TP26TP27

TP24TP25

1514

IIN1+

IIN1-

VIN2+

VIN2-

IIN2+

IIN2-

28272625242322212019181716

VD+

DGND

U2

VA+

VA-

VIN3+

VIN3-

IN3+

IN3-

SSOP28_200_P65MM

SCLK

13121110987654321

TP62 TP63

TP60 TP61

TP58 TP59

TP56 TP57

TP54 TP55

TP52 TP53

IN3+

IN3-

VI N3-

VI N3+

C20

.1UF

SDO

GND

SDO

SCLK

TANT

4. 7UF

C37

V+

GND

L1

FERRI TE_BEAD

10R2

R3

+3V

43

21

HDR1 7

HDR2 X2

C17

C13

CPD

FSOSE/GAI N

FSO

TP40

4. 99K

47UF

XI N

XIN

SE

TP76

.1UF

/RESET

/RESET

/GAIN

HDR3 X2

TP40

OWRS

VI N1+

OWRS

VIN1+

AGND

VREFI N

21

HDR1 4

TP1

J13

VI N1-

IIN1+

IIN1-

VIN1-

IIN1+

IIN1-

VREFOUT

VA+

VA-

+3V

65

43

1. 2V

2

D3

VI N2+

VIN2+

VIN3+

VI N3+

C16

C19

LT1004

XI N

123456

GND

HDR1 5

HDR3 X2

BNC_RA

EXT_IN

GND

4. 0960MHZ

GND

GND

8

U1

VCC

14

7

C18

.1UF

10R32

D+

BAT85

VI N2-

IIN2+

IIN2-

1514

IIN2-

IIN2+

VIN2-

GND

D1

. 039UF

C11

BAT85

D2

GND

C36

SKT_SSOP28_ENP

IN3-

IN3+

VIN3-

13121110987654321

IN3-

IN3+

VI N3-

.1UF

.1UF

TANT

TP2

TP40

GND

GND

GND

.1UFC2

4. 7UF

43

TANT

21

2. 2UF

HDR9

HDR2 X2

C15

Z1

GND

C12

.1UF

47UF

C1

P6KE6V8P

Figure 1. Power Supply, CS5451A, and Oscillator

3

GND

GND

Do Not Popul ate

Z4

J21

P6KE6V8P

CON_B A NANA

GND

J18

CON_B A NANA

Z2

J14

CON_B A NANA

A+

+5V_ I N

GND

P6KE6V8P

J16

CON_B A NANA

J15

CON_B A NANA

A-

EXT VREF

10 DS458DB3

Page 11

CDB5451A

VI N3-

. 01UF

C33

GND

43

21

HDR2

HDR2 X 2

HDR3

HDR2 X 2

VI N3+

C32

12

34

GND

TP71

R19 301

1

2

3

4

J24

J1

TP70

4700PF

C6

0. 1%

0. 1%

R18 301

BNC_RA

J3

BNC_RA

IN3+

. 01UF

C34

GND

43

21

HDR1

HDR2 X 2

GND

TP69

0. 1%

301R17

J2

BNC_RA

IN3-

. 01UF

GND

GND

HDR4

HDR2 X 2

C35

12

34

. 01UF

GND

GND

TP68

C5

4700PF

0. 1%

301R20

4

3

J27

2

1

J4

BNC_RA

GND

IIN1+

.01UF

C29

GND

43

21

HDR1 2

HDR2 X 2

GND

TP5

HDR2 X 2

TP4

IIN1-

C28

12

34

HDR1 1

IIN2-

C24

43

21

HDR7

HDR2 X 2

IIN2+

.01UF

GND

HDR6

HDR2 X 2

C25

12

34

GND

TP67

TP66

VI N2-

.01UF

GND

HDR5

HDR2 X 2

C26

12

34

GND

TP65

VI N2+

.01UF

GND

C27

.01UF

GND

43

21

HDR8

HDR2 X 2

GND

GND

TP64

VI N1-

.01UF

C30

GND

43

21

HDR1 3

HDR2 X 2

GND

TP6

VI N1+

.01UF

C31

.01UF

GND

GND

Figure 2. Analog Inputs

HDR1 0

12

34

HDR2 X 2

GND

TP3

GND

C10

4700PF

C8

4700PF

0. 1%

301R23

1

2

3

4

J22

J5

BNC_RA

0. 1%

301R22

J7

BNC_RA

C7

4700PF

0. 1%

R21 301

J6

BNC_RA

0. 1%

R24 301

J25

J23

1

4

2

3

3

2

4

1

J8

BNC_RA

C9

0. 1%

301R26

0. 1%

301R27

R28 301

J12

BNC_RA

J10

BNC_RA

J11

GND

4700PF

0. 1%

0. 1%

R25 301

4

3

J26

2

1

BNC_RA

J9

BNC_RA

GND

DS458DB3 11

Page 12

CDB5451A

J17

D+

10KR6

DB25M_RA

1

17

16

15

14

4

3

2

21

20

19

18

9

8

765

D+

SE

BUSY

INIT

ACK

470

R9

FSO

470

16151413121110

VCC

U6

DAT A B

1

R8

CLR

DAT A A

BORROW

QB

QACDCUQCQD

9

LOAD

CARRY

DAT A C

DAT A D

GND

MM74HC193N

8765432

D+

.1UFC43

GND

753

2Y4

2Y3

2Y2

2Y1

U8

2A4

2A3

2A2

2A1

2/ G

19

GND

SN74HC240N

171513

11 9

C45

220PF

4. 7K

470

R7

R15

.1UF

GND

C4

10

GND

SN74HC374N

8Q

7Q

6Q6D

VCC

8D

7D

5D4D3D2D1D

18171413874311

GND

COG

GND

SN74HC164N

7

GND

654

131211

10

QGQFQEQDQCQBQA

BACLK

GND

25

24

23

22

13

12

11

10

GND

10KR5

D+

10KR4

SEL

10KR1

25691215161920

1Q2Q3Q4Q5Q

4. 7K

D+

STRB

FEED

4. 7KR14

4. 7KR12

U3

CLK

/OC

R13

1

D+

3

14

.1UFC3

VCC

U7

GND

GND

U8

C44.1UF

D+

1A2

1A1

1Y2

1Y1

VCC 1 / G

2018161412

86421

1A4

1A3

GND

1Y4

1Y3

SN74HC240N

10

GND

/CLR

9

8

2

1

D+

470

R10

SDO

470

R11

SCLK

Figure 3. Digital Circuitry

GND

OP E N

SW1

SW_DIP_2

2

GND

1413

1211

10987654321

HDR1 9

HDR7 X 2

SE

SDO

FSO

SCLK

OWRS

/GAI N

/RESET

D+

10KR33

1

R16 10K

/RESET

20K

R35 10K

R34 10K

OWRS

/GAI N

R36

D+

GND

S1

SW_B3W_1100

49. 9

R37

.1UFC46

GND

12 DS458DB3

Page 13

CDB5451A

3. SOFTWARE

The evaluation software was developed with Lab

Windows/CVI

from National Instruments. The software is designed to run under Windows 95

quires about 3 MB of hard drive space (2 MB for

the CVI Run-Time Engine

uation software). Before installing the software,

read the readme.txt file for any last minute updates

or changes. More sophisticated analysis software

can be developed by purchasing the development

package from National Instruments (512-794-

0100).

™

, a software development package

™

or later, and re-

™

, and 1 MB for the eval-

3.1 Installing the Software

Installation Procedure:

1) Turn on the PC, running Windows 95

2) Insert the Installation CD into the PC.

3) Run the appropriate installer package (either

instmsi.exe or instmsiw.exe, depending on the

operating system). See the readme.txt file for

more information.

4) Run EVL5451A.msi to begin installation.

5) During installation the user will be prompted to

enter the directory in which to install the LabWindows CVI Run-Time Engine

™

Time Engine

with Lab Windows/CVI

manages executables created

™

. If the default directory

is acceptable, select OK and the Run-Time En-

™

gine

will be installed there.

6) After the Run-Time Engine

™

is installed, the

user is prompted to enter the directory in which

to install the CDB5451A software. Select OK to

accept the default directory.

™

or later.

™

. The Run-

chosen to accommodate a variety

of computers).

3.2 Running the Software

3.2.1 Getting Started

The CDB5451A Evaluation software allows the

user to obtain, display, and save data that is acquired by the CS5451A chip. Before running the

software, the first step is to make sure that all of the

headers that are listed in Table 2 are set to an appropriate setting, the exact setting should be determined by the user. Next, with the user’s DC power

supplies still turned off, the user should connect

the necessary power leads to the banana jack

power connectors on the evaluation board. Refer

to Table 1 for various acceptable power supply

connection configurations. Then at this time the

user should turn on their DC power supplies, which

should apply power to the CDB5451A. Several

test point locations are available on the evaluation

board. The user can check these test points with a

voltmeter, to make sure that the voltages at these

test points are at the expected levels. When the

user has verified that the power supply levels are

constant, the user should connect the included 25pin cable between J17 of the evaluation board and

the parallel port on the user’s PC. The user should

then press down on the S1 “RESET” switch, and

make sure to hold it down for at least ~0.5 seconds

before releasing. Finally, the user can start the PC

software. To start the software, double click on the

EVAL5451A icon, or initiate through the Start

menu.

7) Once the program is installed, it can be run by

double clicking on the EVL5451A icon, or

through the Start menu.

Note: The software is written to run with 640 x 480

resolution; however, it will work with 1024 x 768

resolution. If the user interface seems to be a

little small, the user might consider setting the

display settings to 640 x 480. (640x480 was

DS458DB3 13

Page 14

CDB5451A

Figure 4. Start-Up Window

3.2.2 The Start-Up Window

When the software first executes, the user should

see the Start-Up Window appear on the user’s PC

monitor. This window is shown in Figure 4. From

this window, the user can navigate to three other

main windows: the Conversion Window, the Data

Collection Window, and CS5451A Pinout Diagram.

(The CS5471 Pinout Diagram is included in a

fourth window. Cirrus Logic’s CS5471 device is

very similar to CS5451A, except this device has

only the first pair of voltage/current input channels.) To navigate to these windows, use the

mouse to click on the “Menu” item, which is located

towards the upper left corner of the Start-Up Window. “Menu” is a pull-down menu which contains

four options. From this pull-down menu, the user

can select any of the three windows mentioned

above, and once this is done, the new window

should appear. A fourth option called “Exit” should

be selected when the user wants to terminate execution of the evaluation board software program.

If the user selects the “CS5451A Pinout Diagram”

option in the “Menu” pull-down, the software will

display a window which contains the pin diagram of

the CS5451A. This pin diagram is included for the

user’s reference. Note that this window has no actual functionality.

The functionality of the Conversion Window and

the Data Collection Window is described next.

14 DS458DB3

Page 15

CDB5451A

3.2.3 The Conversion Window

Refer to Figure 5. After the user presses on the

green-colored “START” button in this window, the

software will begin to collect data for all six channels of the CS5451A. For each of the six channels,

a certain number of continuous instantaneous data

samples are bundled together. The period over

which each bundle of samples is taken is called a

“computation cycle.” The user controls the number

of instantaneous data samples that will be taken

(per channel) during one computation cycle by adjusting the number in the box labeled “Evaluation

Software Cycle Count.” Note that the default value

for this is set to 4000. Thus during every computation cycle, the PC software will acquire 4000 samples (from each of the six channels) and it will

update the on-screen results of all six channels after calculating the results on each successive set

of 4000 samples. The results that are displayed on

this screen are therefore updated after each computation cycle. Note that the results of the very first

computation cycle (after the “START” button has

been activated) will not be valid. Accuracy of the

Mean/Std. Dev/RMS results increases as the

“Evaluation Software Cycle Count:” value is increased.

The user should understand how to interpret the

values that are displayed in the 4x6 array of number boxes in the Conversion Window. The result

values displayed in these 24 numeric output boxes

are expressed on a normalized scale. The highest

value (0.999...) represents the highest digital output code that can be issued from the CS5451A

(which is +32767), while the lowest value -0.999...

represents the lowest output code that can be issued from the CS5451A (which is -32768). This is

because the CS5451A issues instantaneous output codes as two’s complement 16-bit words.

Therefore, the range of values that can be returned

from the CS5451A are between -32768 and

+32767. The CS5451A issues instantaneous data, and every computation cycle, the software computes/displays the quantities which are described

below:

Figure 5. Conversion Window

DS458DB3 15

Page 16

CDB5451A

Figure 6. Data Collection Window (Time Domain)

3.2.3.1. Last Value

The first column is labelled as “Last Value.” The

value in this box represents the value of the very

last instantaneous sample that was taken (for each

channel) in the most recently-completed computation cycle. If the user’s analog input waveforms are

AC in nature, then this column of results will rarely

have any meaning. But if the user applies a constant DC input signal to any of the analog input

channels, then the Last Value column for that

channel should display an output code that is relatively constant from one conversion cycle to the

next.

3.2.3.2. Mean

The values in this column represent the simple average of the sample values in the latest computation cycle.

3.2.3.3. Std Dev.

The values in this column represent the computed

standard deviation over the set of values in the

most recent computation cycle.

3.2.3.4. RMS

The values in this column represent the computed

RMS value over the most recently-completed computation cycle.

3.2.4 Data Collection Window

The Data Collection Window (Figs 6, 8, and 9) allows the user to collect samples sets of data from

CS5451A and analyze them using time domain,

FFT, and histogram plots. The Data Collection

Window is accessible through the Menu option, or

by pressing F4.

3.2.4.1. Collect Button

This button will collect data from the CS5451A, to

be analyzed in the plot area. See the section on

Collecting Data Sets for more information.

16 DS458DB3

Page 17

CDB5451A

3.2.4.2. Time Domain / FFT / Histogram

Selector

This selector button is located just to the right of the

Collect Button. The label on this button will change

as the user selects which analysis is to be performed (“Time Domain” or “FFT” or “Histogram”).

When the software is first started, the default mode

on this selector button is Time Domain. This user

should click on this button to select which type of

data processing to perform on the collected data

and display in the plot area. Refer to the section on

Analyzing Data for more information.

3.2.4.3. “Crystal” Value Indicator Box

The value in this box reflects the frequency of the

CS5451A’s clock input (at the XIN pin). Since the

XIN frequency affects the sampling rate (the output

word rate) of the CS5451A, this information must

be specified to the software so that it can accurately depict the frequency-content of the sampled

data (in Hz) when performing an FFT analysis.

The user can enter the crystal frequency that is

used on the CDB5451A board into this box. The

default value of this box is set for the on-board

4.096MHz oscillator.

3.2.4.4. OWRS Pin Setting:

This switch should be adjusted whenever the user

toggles the S1-1 DIP switch (on the evaluation

board). The default setting of this switch is HI, corresponding to the default setting on S1-1 (default

setting is “OPEN”). S1-1 drives the CS5451A’s

OWRS pin to logic “1”. A logic “1” on OWRS sets

the sampling frequency of all six CS5451A input

channels to XIN/1024. To toggle the state of the

on-screen switch, simply click on the switch with

the mouse.

3.2.4.5. Config Button

This button will bring up the configuration window

(shown in Fig 7) in which the user can modify the

data collection specifications. See the discussion

of the Config Window in this document.

3.2.4.6. Save Button

The red-colored SAVE button will save the data in

the current plot to a file. The exact path and filename can be specified by the user in the text window

located just to the left of the SAVE button. The

data collected for all six channels will be saved to

a text file.

3.2.4.7. Load Button

The green colored LOAD button will load any data

file that was previously generated by clicking on

the red SAVE button. The exact path and filename

must be specified by the user in the text window located just to the left of the LOAD button.

3.2.4.8. Channel Selector Buttons

Clicking on six buttons labeled as “V1” “V2” “V3”

and “I1” “I2” “I3” will display a certain channel of data. “V1” refers to the data taken from the

Vin1+/Vin1- input pins of the CS5451A. This is

similar for “V2” and “V3”. In a similar manner, clicking on the “I1” “I2” “I3” buttons will display the voltage measured across the first, second, and third

pairs of current channel input pins (designated as

IinA+/IinA- for A = 1, 2, 3).

3.2.5 Config Window

See Figure 7. Clicking on the Config button will

bring up a small pop-up window called the Config

Window. The Config Window allows the user to

set up the data collection and analysis parameters,

which are described next.

3.2.5.1. Number of Samples

This box allows the user to select the number of

samples to collect. The user can choose any

whole-number power of 2 between 16 and 32768.

3.2.5.2. Average

When performing FFT processing, this box will determine the number of FFTs to average. FFTs will

then be collected and averaged when the user

clicks on the Collect Button.

3.2.5.3. FFT Window

This box allows the user to select the type of windowing algorithm for FFT processing. Windowing

algorithms include the Blackman, Black-Harris,

Hanning, 5-term Hodie, and 7-term Hodie. The 5term Hodie and 7-term Hodie are windowing algorithms developed at Cirrus Logic.

DS458DB3 17

Page 18

Figure 7. Configuration Window

3.2.5.4. Histogram Bin Width

This box allows for a variable “bin width” when plotting histograms of the collected data. Each vertical

bar in the histogram plot will contain the number of

output codes contained in this box. Increasing this

number may allow the user to view histograms with

larger input ranges.

3.2.5.5. Samples to Discard

This number represents the number of CS5451A

sample periods that will be ignored before the software starts to collect samples (when the user

presses on the Collect Button). After the software

has skipped over this many data samples, the software will then begin to save samples from the device (for all six channels). The number of samples

that are actually saved is equal to the number

specified in the Number of Samples box.

3.2.5.6. Ready Button

After the user has adjusted the parameters in the

Config Window to the desired settings, the user

must click on the READY button to close the Config Window and return to the Data Collection Window.

CDB5451A

3.2.5.7. Crystal (MHz)

This frequency value is used to properly perform

the FFT operation on a set of collected data. The

user can adjust this value. Default value is 4.096

(Mhz), which is the frequency of the crystal oscillator (U1) on the evaluation board.

3.2.6 Analyzing Data

The evaluation software provides three types of

analysis tests - Time Domain, Frequency Domain,

and Histogram. The Time Domain analysis processes acquired conversions to produce a plot of

Output Code versus Conversion Sample Number.

The Frequency Domain analysis processes acquired conversions to produce a magnitude versus

frequency plot using the Fast-Fourier transform

(results up to Fs/2 are calculated and displayed).

The Histogram analysis test processes acquired

conversions to produce a histogram plot. Statistical noise calculated are also calculated and displayed.

3.2.7 Time Domain Information

The following controls and indicators are associated with the Time Domain Analysis. Time domain

data can be plotted in the Data Collection Window

by setting the Time Domain / FFT / Histogram selector to “Time Domain.”

3.2.7.1. Count

Displays current x-position of the cursor on the

time domain display.

3.2.7.2. Magnitude

Displays current y-value of the cursor on the time

domain display.

3.2.7.3. Maximum

Indicator for the maximum value of the collected

data set.

3.2.7.4. Minimum

Indicator for the minimum value of the collected

data set.

18 DS458DB3

Page 19

CDB5451A

3.2.8 Frequency Domain Information

The following section describes the indicators associated with Fast Fourier Transform (FFT) analysis. FFT data can be plotted in the Data Collection

Window by setting the Time Domain / FFT / Histogram selector button to “FFT.”

3.2.8.1. Frequency

Displays the x-axis value of the cursor on the FFT

display.

3.2.8.2. Magnitude

Displays the y-axis value of the cursor on the FFT

display.

3.2.8.3. S/D

Indicator for the Signal-to-Distortion Ratio, 4 harmonics are used in the calculations (decibels).

3.2.8.4. SINAD

Indicator for the Signal-to-Noise + Distortion Ratio

(decibels).

3.2.8.5. SNR

3.2.9.2. Magnitude

Indicator for the maximum value of the collected

data set.

3.2.9.3. Mean

Average value of the collected data set.

3.2.9.4. Variance

Indicator for the calculated variance of the collected data set.

3.2.9.5. STD_DEV

Indicator for the calculated standard deviation of

the collected data set.

3.2.9.6. Maximum

Indicator for the maximum value of the collected

data set.

3.2.9.7. Minimum

Indicator for the minimum value collected in the

data set.

Indicator for the Signal-to-Noise Ratio, first 4 harmonics are note included (decibels).

3.2.8.6. S/PN

Indicator for the Signal-to-Peak Noise Ratio (decibels).

3.2.8.7. FS-PdB

Not using windowing, how far down from zero the

peak voltage input value is (decibels).

3.2.9 Histogram Information

The following is a description of the indicators associated with Histogram Analysis. Histogram can

plotted in the Data Collection Window by setting

the Time Domain / FFT / Histogram selector to

“Histogram.”

3.2.9.1. Bin

Displays the x-axis value of the cursor on the Histogram.

DS458DB3 19

Page 20

CDB5451A

Figure 8. Silkscreen

20 DS458DB3

Page 21

CDB5451A

Figure 9. Circuit Side

DS458DB3 21

Page 22

CDB5451A

Figure 10. Solder Side

22 DS458DB3

Page 23

CDB5451A

DS458DB3 23

Page 24

CDB5451A

A

A

A

Contacting Cirrus Logic Support

For all product questions and inquiries contact a Cirrus Logic Sales Representative.

To find the one nearest to you go to www.cirrus.com

IMPORTANT NOTICE

"Preliminary" product information describes products that are in production, but for which full characterization data is not yet

available. Cirrus Logic, Inc. and its subsidiaries ("Cirrus") believe that the information contained in this document is accurate and

reliable. However, the information is subject to change without notice and is provided "AS IS" without warranty of any kind

(express or implied). Customers are advised to obtain the latest version of relevant information to verify, before placing orders,

that information being relied on is current and complete. All products are sold subject to the terms and conditions of sale supplied

at th e tim e of orde r ackn owled gment, including those pertain ing to warranty, patent infringem ent, and limitation of liability. No

responsibility is assumed by Cirrus for the use of this information, including use of this information as the basis for manufacture or

sale of any items, or for infringement of patents or other rights of third parties. This document is the property of Cirrus and by

furnishing this information, Cirrus grants no license, express or implied under any patents, mask work rights, copyrights,

trademarks, trade secrets or other intellectual property rights. Cirrus owns the copyrights associated with the information

contained herein and gives consent for copies to be made of the information only for use within your organization with respect to

Cirrus integrated circuits or other products of Cirrus. This consent does not extend to other copying such as copying for general

distribution, advertising or promotional purposes, or for creating any work for resale.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF DEATH,

PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL APPLICATIONS”). CIRRUS

PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARRANTED FOR USE IN AIRCRAFT SYSTEMS, MILITARY

PPLICATIONS, PRODUCTS SURGICALLY IMPLANTED INTO THE BODY, LIFE SUPPORT PRODUCTS OR OTHER

CRITICAL APPLICATIONS (INCLUDING MEDICAL DEVICES, AIRCRAFT SYSTEMS OR COMPONENTS AND PERSONAL OR

UTOMOTIVE SAFETY OR SECURITY DEVICES). INCLUSION OF CIRRUS PRODUCTS IN SUCH APPLICATIONS IS

UNDERSTOOD TO BE FULLY AT THE CUSTOMER’S RISK AND CIRRUS DISCLAIMS AND MAKES NO WARRANTY,

EXPRESS, STATUTORY OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

PARTICULAR PURPOSE, WITH REGARD TO ANY CIRRUS PRODUCT THAT IS USED IN SUCH A MANNER. IF THE

CUSTOMER OR CUSTOMER’S CUSTOMER USES OR PERMITS THE USE OF CIRRUS PRODUCTS IN CRITICAL

PPLICATIONS, CUSTOMER AGREES, BY SUCH USE, TO FULLY INDEMNIFY CIRRUS, ITS OFFICERS, DIRECTORS,

EMPLOYEES, DISTRIBUTORS AND OTHER AGENTS FROM ANY AND ALL LIABILITY, INCLUDING ATTORNEYS’ FEES AND

COSTS, THAT MAY RESULT FROM OR ARISE IN CONNECTION WITH THESE USES.

Cirrus Logic, Cirrus, and the Cirrus Logic logo designs are trademarks of Cirrus Logic, Inc. All other brand and product names in

this doc um ent may be trademarks or service m arks of their respective owners.

IBM is a tradem ark of International Business Machines Corporation.

Windows is a trademark of Microsoft Corporation.

Lab Windows and CVI are trademarks of National Instruments.

SP I is a tradem ark of M otorola, Inc.

Microwire is a trademark of National Semiconductor.

24 DS458DB3

Loading...

Loading...