Page 1

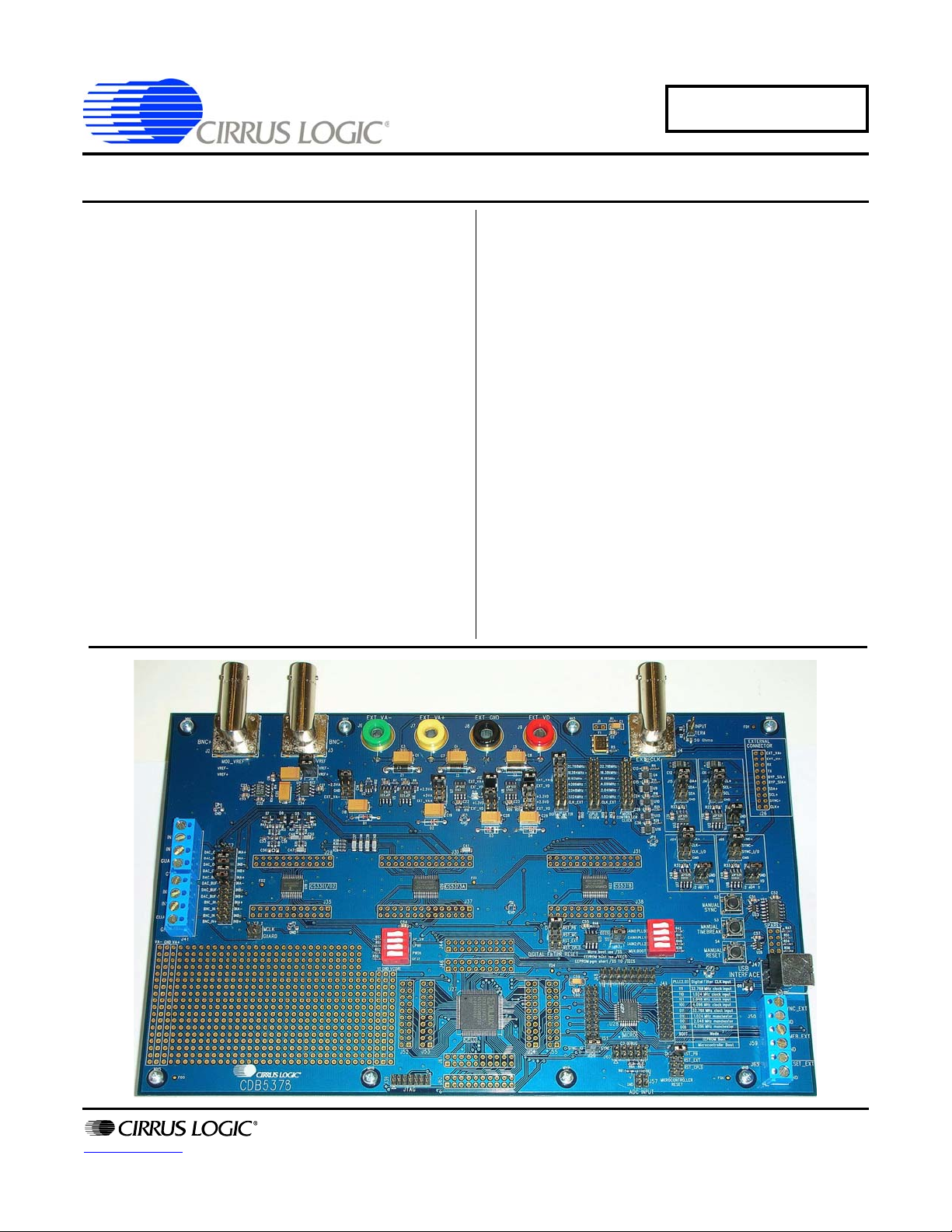

CDB5378

Single-channel Seismic Evaluation System

Features

z Single-channel Seismic Acquisition Node

– CS3301A geophone amplifier

– CS5373A ∆Σ modulator + test DAC

– CS5378 digital filter + PLL

– Precision voltage reference

z On-board Microcontroller

– SPI™ interface to digital filter

– USB communication with PC

z PC Evaluation Software

– Register setup & control

– FFT frequency analysis

– Time domain analysis

– Noise histogram analysis

General Description

The CDB5378 board is used to evaluate the functionality

and performance of the Cirrus Logic single-channel se ismic chip set. Data sheets for the CS3301A, CS5373A,

and CS5378 devices should be consulted when using

the CDB5378 evaluation board.

Screw terminals connect an external differential geophone or hydrophone sensor to the analog inputs of the

measurement channel. An on-board test DAC creates

precision differential analog signals for in-circuit performance testing without an external signal source.

The evaluation board includes an 8051-type microcontroller with hardware SPI™ and USB serial interfaces.

The microcontroller communic ates with the digital filter

via SPI and with the PC evaluation software via USB.

The PC software controls register and coefficient initialization and performs time domain, histogram, and FFT

frequency analysis on captured data.

ORDERING INFORMATION

CDB5378 Evaluation Board

www.cirrus.com

Copyright © Cirrus Logic, Inc. 2007

(All Rights Reserved)

NOV ‘07

DS639DB4

Page 2

CDB5378

Contacting Cirrus Logic Support

For all product questions and inquiries contact a Cirrus Logic Sales Representative.

To find the one nearest to you go to www.cirrus.com

IMPORTANT NOTICE

Cirrus Logic, Inc. and its subsidiaries ("Cirru s") b eli eve that the information contained in this document is accurate and reli a b le. However, the information is subjec t

to change without notice and is provided "AS IS" without warranty of any kind (express or implied). Customers are advised to obtain the latest version of relevant

information to verify, before placing orders, tha t inform ation be ing reli ed on is current an d com plete. A ll prod ucts are sold subj ect to the term s and conditions of sale

supplied at the time of order ackno wledgment, inclu ding those pertaining to warranty, indemn ification, and limitatio n of liability. No responsibility is assumed by Cirrus

for the use of this information, including use of this information as the basis for manufacture or sale of any items, or for infringement of patents or other rights of third

parties. This document is the prop erty o f C irrus a nd by furn ishing this inform ation, Cirru s grants no lice nse, expres s or implied under any patents, mask work rights,

copyrights, trade marks, trade secrets or o ther int ellectual p roperty ri ghts. Cirrus owns the copyr ights ass ociated with t he inf ormation contained herein and gives

consent for copies to be made of the inform ation only for u se withi n your orga nization w ith resp ect to Cirrus integr ated circ uits or other p rodu cts of C irrus. This co nsent does not extend to other copying such as copying for general distribution, advertising or promotional purposes, or for creating any work for resale.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE ("CRITICAL APPLICATIONS"). CIRRUS PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARRANTED FOR

USE IN PRODUCTS SURGICALLY IMPLANTED INTO THE BODY, AUTOMOTIVE SAFETY OR SECURITY DEVICES, LIFE SUPPORT PRODUCTS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF CIRRUS PRODUCTS IN SUCH APPLICATIONS IS UNDERSTOOD TO BE FULLY AT THE CUSTOMER'S RISK

AND CIRRUS DISCLAIMS AND MAKES NO WARRANTY, EXPRESS, STATUTORY OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSE, WITH REGARD TO ANY CIRRUS PRODUCT THAT IS USED IN SUCH A MANNER. IF THE CUSTOMER

OR CUSTOMER'S CUSTOMER USES OR PERMITS THE USE OF CIRRUS PRODUCTS IN CRITICAL APPLICATIONS, CUSTOMER AGREES, BY SUCH USE,

TO FULLY INDEMNI FY CIRRUS , ITS O FFICERS , DIRECT ORS, EMPL OYEES, DIST RIBUTORS AND OTHER AGENTS FROM ANY AND ALL LIABILI TY, INCLUDING ATTORNEYS' FEES AND COSTS, THAT MAY RESULT FROM OR ARISE IN CONNECTION WITH THESE USES.

Cirrus Logic, Cirrus, and the Cirrus Logic logo designs are trademarks of Cirrus Logic, Inc. All other brand and product names in this document may be trademarks

or service marks of their respective owners.

Windows is a registered trademark of Microsoft Corporation.

SPI is a trademark of Motorola, Inc.

2

C is a registered trademark of Philips Semiconductor Corporation.

I

USBXpress is a registered trademark of Silicon Laboratories, Inc.

2 DS639DB4

Page 3

TABLE OF CONTENTS

1. INITIAL SETUP ......................................................................................................................... 5

1.1 Kit Contents ..................................... ....................................... ... ... ... .... .............................. 5

1.2 Hardware Setup ............................... ....................... ...................... ....................... .............. 5

1.2.1 Default Jumper Settings ................................... ....................................... ... ... .... . 6

1.2.2 Default DIP Switch Settings ............................................... .... ... ... ........................ 8

1.3 Software Setup .......................................... ... ....................................... ... ... ... ..................... 9

1.3.1 PC Requirements ............................. ....................................... ... ... ... .... ................. 9

1.3.2 Seismic Evaluation Software Installation .............................................................. 9

1.3.3 USBXpress Driver Installation ............................................................................... 9

1.3.4 Launching the Seismic Evaluation Software .............................. ......................... 10

1.4 Self-testing CDB5378 ............................ .... ... ... ... .... ... ....................................... ... ... ... ...... 11

1.4.1 Noise test ..... .... ... ... ... .... ...................................... .... ... ... ...................................... 11

1.4.2 Distortion Test .. ...................................... .... ... ... ... ....................................... ... ... ... 12

2. HARDWARE DESCRIPTION ................................................................................................. 13

2.1 Block Diagram ................................................................................................................ 13

2.2 Analog Hardware ....................... ... ... ... ... .... ...................................... .... ... ... ...................... 14

2.2.1 Analog Inputs ...... ... ... .... ... ... ....................................... ... ... ... ................................ 14

2.2.2 Differential Amplifiers ................................................. ... ... ... .... ............................ 17

2.2.3 Delta-Sigma Modulator ....................................................................................... 18

2.2.4 Delta-Sigma Test DAC ............................... ...................................... .... ... ... ... ...... 19

2.2.5 Voltage Reference .................... ....................................... ... .... ... ... ...................... 20

2.3 Digital Hardware .............................................................................................................. 20

2.3.1 Digital Filter ................................................ ... ... ... ....................................... ... ... ... 20

2.3.2 Interface CPLD ............................................................. ... ... .... ... ... ...................... 23

2.3.3 Digital Control Signals ......................... ....................................... ... ... .... ... ............ 25

2.3.4 Microcontroller ................................................. ... .... ... ... ... ... .... ............................ 25

2.3.5 RS-485 Telemetry ............................................................................................... 27

2.3.6 UART Connection .. ... .... ... ... ... ....................................... ... ... .... ............................ 29

2.3.7 External Connector .......................... ... ....................................... ... ... .... ... ............ 30

2.4 Power Supplies ................ ....................................... ... ... ... .... ...................................... ...... 30

2.4.1 Analog Voltage Regulators ................. ... .... ... ....................................... ... ... ... ...... 30

2.4.2 Digital Voltage Regulators .................................................................................. 31

2.5 PCB Layout ............................................... ... ... ... .... ...................................... .... ... ... ... ...... 32

2.5.1 Layer Stack ...... ... ... ... .... ... ....................................... ... ... ... ................................... 32

2.5.2 Differential Pairs ............................ ... ....................................... ... ... ... .... ............... 32

2.5.3 Bypass Capacitors ..................................... ... ... ... .... ...................................... ... ... 33

2.5.4 Dual-row Headers .. ... .... ... ....................................... ... ... ... ... ................................ 34

3. SOFTWARE DESCRIPTION .................................................................................................. 35

3.1 Menu Bar ......................................... ... ....................................... ... ... .... ... ......................... 35

3.2 About Panel ..................................................................................................................... 36

3.3 Setup Panel ..................................................................................................................... 37

3.3.1 USB Port ...... .... ... ... ... ....................................... ... .... ... ... ...................................... 38

3.3.2 Digital Filter ................................................ ... ... ... ....................................... ... ... ... 39

3.3.3 Analog Front End ...... .... ... ... ... ... ....................................... ... .... ... ......................... 40

3.3.4 Test Bit Stream ......................... .... ...................................... .... ... ... ... ................... 41

3.3.5 Gain / Offset .................................. ... ... ... ....................................... ... .... ... ... ......... 42

3.3.6 Data Capture .......................... ....................................... ... ... .... ... ......................... 43

3.3.7 External Macros ..... ... .... ... ... ... ....................................... ... ... .... ............................ 44

3.4 Analysis Panel ................................................................................................................. 45

3.4.1 Test Select ... .... ... ... ... ....................................... ... .... ... ... ...................................... 46

3.4.2 Statistics ........................ ... ... ... ... .... ... ... ... ....................................... ... .... ... ... ... ...... 47

CDB5378

DS639DB4 3

Page 4

CDB5378

3.4.3 Plot Enable ............................. ... .... ... ... ... ....................................... ... .... ... ............47

3.4.4 Cursor ................................................. ... .... ... ... ... ....................................... ... ... ... 47

3.4.5 Zoom ............................................. ... ... ... ....................................... ... .... ... ............48

3.4.6 Refresh ...................... ....................................... ... .... ... ... ...................................... 48

3.4.7 Harmonics ........................................... ... ....................................... ... .... ... ... .........48

3.4.8 Spot Noise .............. ... .... ... ... ... ... .... ...................................... .... ... ... ... ...................48

3.4.9 Plot Error ............................................. ... .... ... ....................................... ... ... ... ... ... 48

3.5

Control Panel ....................................................... ... ... ... .... ...................................... ... ... 49

3.5.1 DF Registers ............. ....................................... ... .... ... ... ...................................... 50

3.5.2 DF Commands ........................................... ... ....................................... ... ... ... ... ... 50

3.5.3 SPI ................................................... ... ... .... ... ... ....................................... ... ... ... ...50

3.5.4 Macros ................................................ ... .... ... ... ....................................... ... ... ... ... 51

3.5.5 GPIO ............ .... ...................................... .... ... ... ... ....................................... ... ... ... 51

3.5.6 Customize ........... ....................................... ... ... ... .... ...................................... ... ... 52

3.5.7 External Macros ............... ... ....................................... ... ... ... .... ............................ 52

4. BILL OF MATERIALS ........................................................................................................... 53

5. LAYER PLOTS ...................................................................................................................... 56

6. SCHEMATICS ........................................................................................................................ 62

7. REVISION HISTORY ..............................................................................................................72

4 DS639DB4

Page 5

LIST OF FIGURES

Figure 1. CDB5378 Block Diagram............................................................................................... 13

Figure 2. Quad Group Routing of RC Filter Components ............................................................. 18

Figure 3. CPLD Default Signal Assignments ................................................................................ 24

Figure 4. Differential Pair Routing................................................................................................. 32

Figure 5. Quad Group Routing...................................................................................................... 33

Figure 6. Bypass Capacitor Placement......................................................................................... 33

Figure 7. Dual-row Headers with Shorts....................................................................................... 34

CDB5378

DS639DB4 5

Page 6

LIST OF TABLES

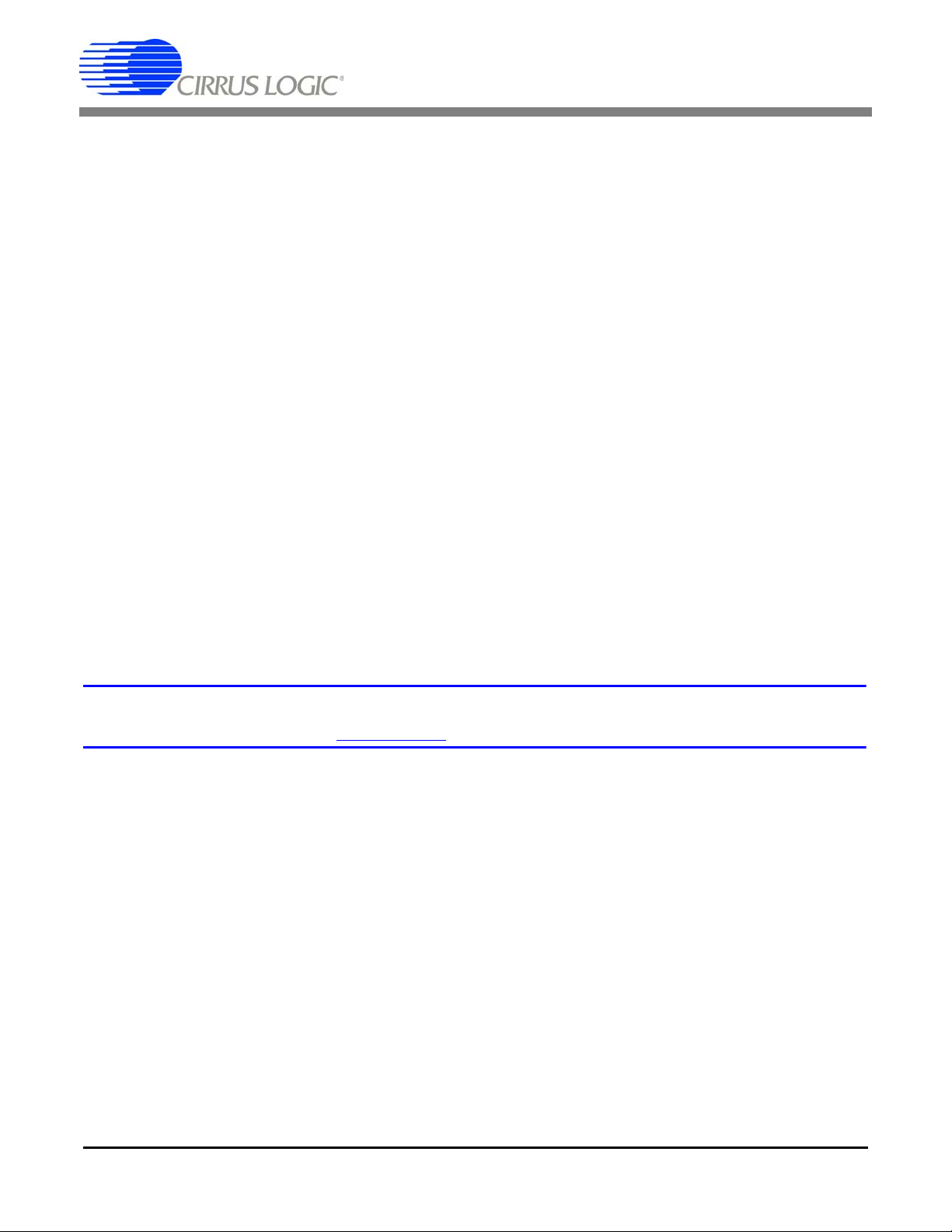

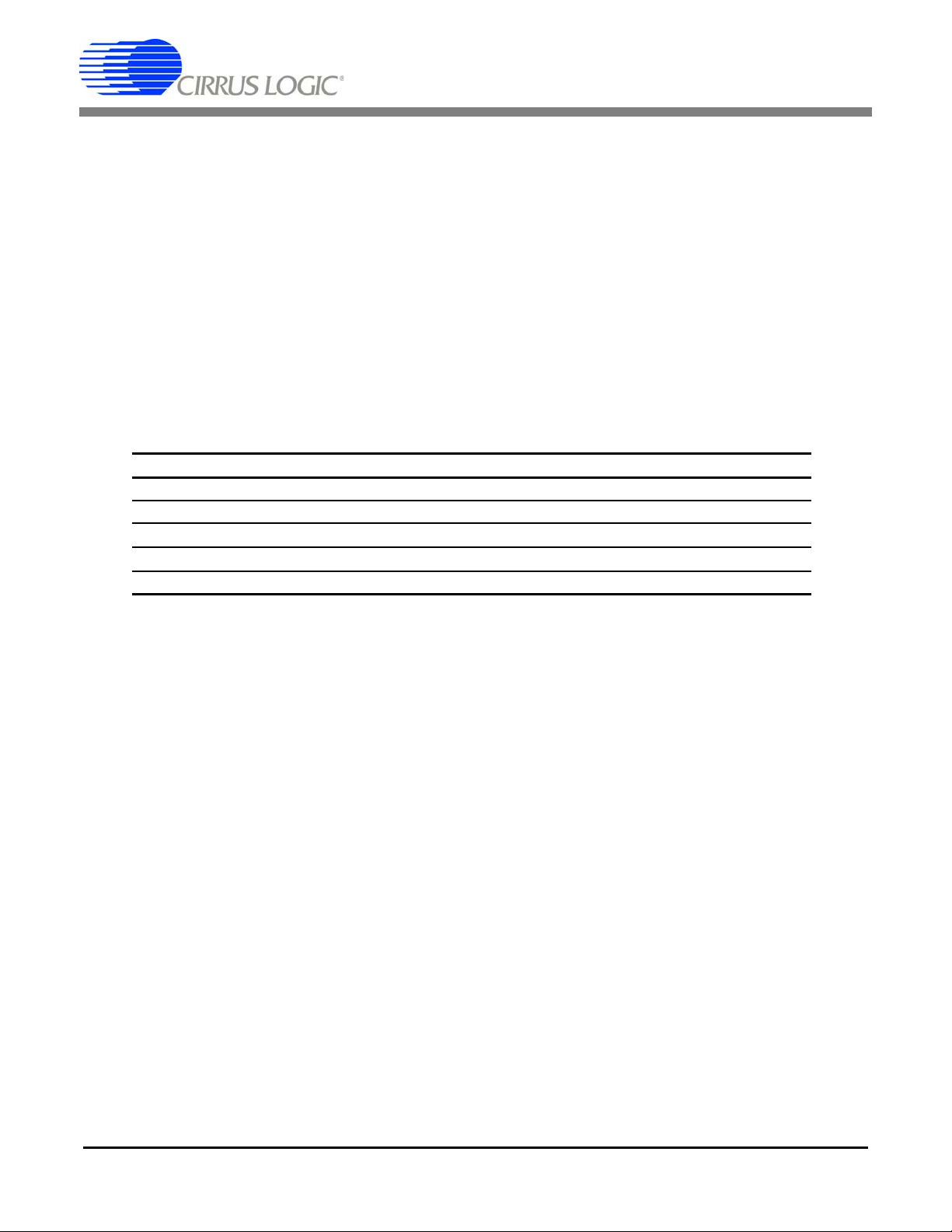

Table 1. Analog Input Default Jumper Settings...............................................................................6

Table 2. RESET, SPI, SYNC Default Jumper Settings ................................................................... 6

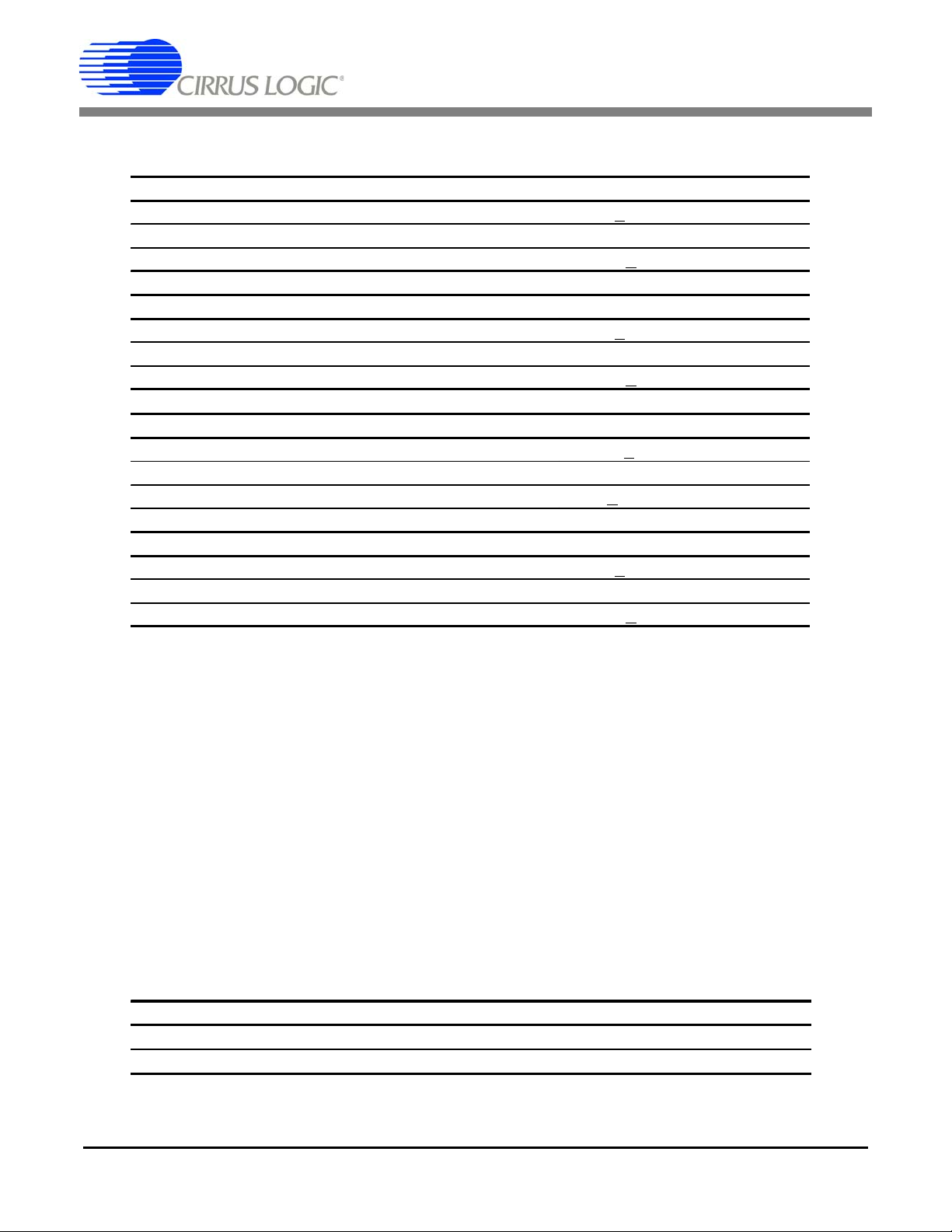

Table 3. VREF, Power Supplies Default Jumper Settings .............................................................. 7

Table 4. Clock Default Jumper Settings............................................... ... ... ... .... ... ... ... .....................7

Table 5. RS-485 Default Jumper Settings.......................................................................................8

Table 6. DIP Switch Default Settings ..............................................................................................8

Table 7. Screw Terminal Input Connectors...................................................................................14

CDB5378

6 DS639DB4

Page 7

1. INITIAL SETUP

1.1 Kit Contents

The CDB5378 evaluation kit includes:

• CDB5378 Evaluation Board

• USB Cable (A to B)

• Software Download Information Card

The following are required to operate CDB5378, and are not included:

• Bipolar Power Supply with Banana Jack Outputs (+/-12 V @ 100 mA)

• Banana Jack Cables (4x)

• PC Running Windows 2000 or XP with an Available USB Port

• Internet Access to Download the Evaluation Software

CDB5378

1.2 Hardware Setup

To set up the CDB5378 evaluation board:

• Set all jumpers and DIP switches to their default settings (see next sections).

• With power off, connect the CDB5378 power inputs to the power supply outputs.

VA- = -12 V

VA+ = +12 V

GND = 0 V

VD = +12 V

• Connect the USB cable between the CDB5378 USB connector and the PC USB port.

• Proceed to the Software Setup section to install the evaluation software and USB driver.

DS639DB4 7

Page 8

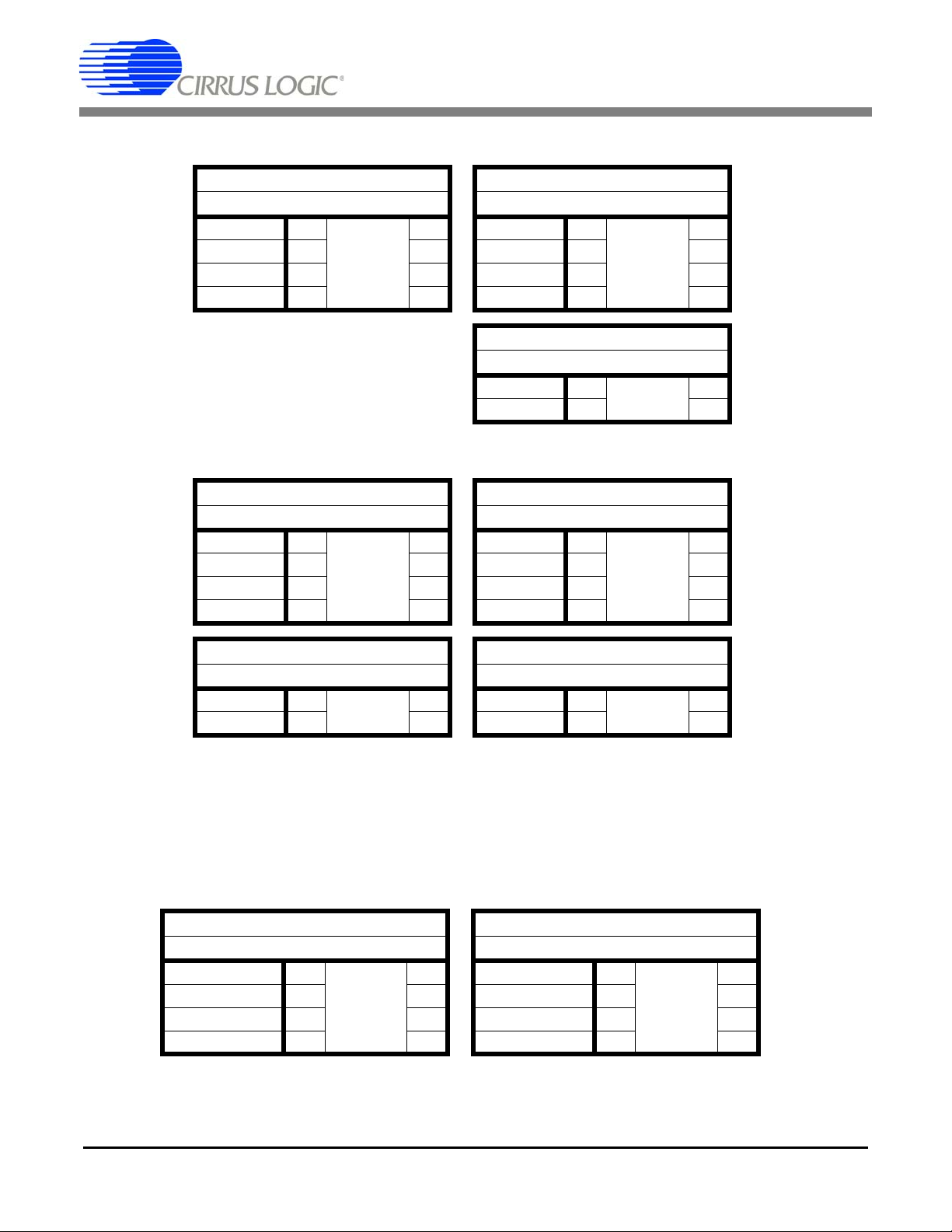

1.2.1 Default Jumper Settings

DAC_OUT+ 1 **2INA+

DAC_OUT- 3 **4INA-

DAC_OUT- 5 ---------- 6INBDAC_OUT+ 7 ---------- 8INB+

DAC_BUF+ 9 ---------- 10 INA+

DAC_BUF- 11 ---------- 12 INA-

DAC_BUF- 13 **14 INB-

DAC_BUF+ 15 **16 INB+

BNC_IN+ 17 **18 INA+

BNC_IN- 19 **20 INA-

BNC_IN- 21 **22 INB-

BNC_IN+ 23 **24 INB+

CDB5378

J27

Analog Input Selections

Table 1. Analog Input Default Jumper Settings

J40

Digital Filter RESET Selection

RST_PB 1 ---------- 2

RST_MC 3 **4

RST_EXT 5 **6

RST_CPLD 7 **8

SPI Chip Select Input

EECS 4 **3SS

SS 2 ---------- 1SS

SYNC Source Selection

SYNC_IO 2 ---------- 1 SYNC

J58

Microcontroller RESET Selection

RST_PB 1 ---------- 2

RST_EXT 3 **4

RST_CPLD 5 **6

7 **8

J43

J56

Table 2. RESET, SPI, SYNC Default Jumper Settings

8 DS639DB4

Page 9

CDB5378

J19

Voltage Reference Jumpers

VREF- 4 ---------- 3

VREF+ 2 ---------- 1

J10

VA- Voltage Selection

-2.5VA 1 ---------- 2

GND 3 **4

EXT_VA- 5 **6

J12

VD Input Voltage Source

EXT_VA+ 1 **2

EXT_VD 3 ---------- 4

J22

VD Voltage Selection

+3.3VD 1 ---------- 2

EXT_VD 3 **4

Table 3. VREF, Power Supplies Default Jumper Set ting s

J11

VA+ Voltage Selection

+2.5VA 1 ---------- 2

+5VA 3 **4

EXT_VA+ 5 **6

J13

VCORE Input Voltage Source

EXT_VA+ 1 **2

EXT_VD 3 ---------- 4

J21

VCORE Voltage Selection

+3.3VD 1 ---------- 2

+2.5VD 3 **4

EXT_VD 5 **6

J16, J17, J18

Digital Filter, CPLD,

Microcontroller

Input Clock Selections

32.768 MHz 1 ---------- 2

16.384 MHz 3 **4

8.192 MHz 5 **6

4.096 MHz 7 **8

2.048 MHz 9 **10

1.024 MHz 11 * *12

CLK_EXT 13 **14

15 **16

Table 4. Clock Default Jumper Settings

DS639DB4 9

50 Ohms 2 **1

Clock Input TERM

J5

Page 10

CDB5378

J15

I2C Data

SDA+ 1 ---------- 2

SDA- 3 ---------- 4

SDA 5 **6

GND 7 **8

J24

Clock Source

CLK+ 1 ---------- 2

CLK- 3 ---------- 4

CLK_I/O 5 **6

GND 7 **8

J14

I2C Clock

SCL+ 1 ---------- 2

SCL- 3 ---------- 4

SCL 5 **6

GND 7 **8

J23

I2C Clock Driver Enable

GND 1 ---------- 2

VD 3 **4

J25

Sync Source

SYNC+ 1 ---------- 2

SYNC- 3 ---------- 4

SYNC_I/O 5 **6

GND 7 **8

J33

Clock Driver Enable

GND 1 ---------- 2

VD 3 **4

Table 5. RS-485 Default Jumper Settings

1.2.2 Default DIP Switch Settings

S5

* = down, - = up

SP_SW1 1 *-2

LOGIC_GND 3 *-4

PWDN 5 *-6

7 *-8

Table 6. DIP Switch Default Settings

J34

Sync Driver Enable

GND 1 ---------- 2

VD 3 **4

S1

* = down, - = up

GAIN0:PLL0 1 *-2

GAIN1:PLL1 3 *-4

GAIN2:PLL2 5 *-6

MUX:BOOT 7 -*8

10 DS639DB4

Page 11

CDB5378

1.3 Software Setup

1.3.1 PC Requirements

The PC hardware requirements for the Cirrus Seismic Evaluation system are:

• Windows XP, Windows 2000, Windows NT

• Intel Pentium 600MHz or higher microprocessor

• VGA resolution or higher video card

• Minimum 64MB RAM

• Minimum 40MB free hard drive space

1.3.2 Seismic Evaluation Software Installation

Important: For reliable USB communication, the USBXpress driver must be installed after the Seismic

Evaluation Software installation but before launching the application. The USBXpress driver files are in-

cluded in a sub-folder as part of the installation.

To install the Cirrus Logic Seismic Evaluation Software:

• Go to the Cirrus Logic Industrial Software web page (http://www.cirrus.com/industrialsoftware

the link for “Cirrus Seismic Evaluation GUI” to get to the download page and then click the link for “Cir-

rus Seismic Evaluation GUI Release Vxx” (xx indicates the version number).

• Read the software license terms and click “Accept” to download the “SeismicEvalGUI_vxx.zip” file to

any directory on the PC.

• Unzip the downloaded file to any directory and a “Distribution\Volume1” sub-folder containing the installation application will automatically be created.

• Open the “Volume1” sub-folder and run “setup.exe”. If the Seismic Evaluation Software has been previously installed, the uninstall wizard will automatically remove the previous version and you will need

to run “setup.exe” again.

• Follow the instructions presented by the Cirrus Seismic Evaluation Installation Wizard. The default installation location is “C:\Program Files\Cirrus Seismic Evaluation”.

An application note, AN271 - Cirrus Seismic Evaluation GUI Installation Guide, is available from the Cirrus

Logic web site with step-by-step instructions on installing the Seismic Evaluation Software.

). Click

1.3.3 USBXpress Driver Installation

Important: For reliable USB communication, the USBXpress driver must be installed after the Seismic

Evaluation Software installation but before launching the application. The USBXpress driver files are in-

cluded in a sub-folder as part of the installation.

The Cirrus Logic Seismic Evaluation Software communicates with CDB5378 via USB using the USBXpress driver from Silicon Laboratories (http://www.silabs.com

files are included as part of the installation package.

). For convenience, the USBXpress driver

To install the USBXpress driver (after installing the Seismic Evaluation Software):

• Connect CDB5378 to the PC through an available USB port and apply power. The PC will detect

DS639DB4 11

Page 12

CDB5378

CDB5378 as an unknown USB device.

• If prompted for a USB driver, skip to the next step. If not, using Windows Hardware Device Manager

go to the properties of the unknown USB API device and select “Update Driver”.

• Select “Install from a list or specific location”, then select “Include this location in the search” and then

browse to “C:\Program Files\Cirrus Seismic Evaluation\Driver\”. The PC will recognize and install the

USBXpress device driver.

• After driver installation, cycle power to CDB5378. The PC will automatically detect it and add it as a

USBXpress device in the Windows Hardware Device Manager.

An application note, AN271 - Cirrus Seismic Evaluation GUI Installation Guide, is available from the Cirrus

Logic web site with step-by-step instructions on installing the USBXpress driver.

1.3.4 Launching the Seismic Evaluation Software

Important: For reliable USB communication, the USBXpress driver must be installed after the Seismic

Evaluation Software installation but before launching the application. The USBXpress driver files are in-

cluded in a sub-folder as part of the installation.

To launch the Cirrus Seismic Evaluation Software, go to:

• Start

or:

• C:\Program Files\Cirrus Seismic Evaluation\SeismicGUI.exe

For the most up-to-date information about the software, please refer to its help file:

• Within the software: Help

or:

• C:\Program Files\Cirrus Seismic Evaluation\SEISMICGUI.HLP

Ö

Programs Ö Cirrus Seismic Evaluation Ö Cirrus Seismic Evaluation

Ö

Contents

12 DS639DB4

Page 13

CDB5378

1.4 Self-testing CDB5378

Noise and distortion self-tests can be performed once hardware and software setup are complete.

First, initialize the CDB5378 evaluation system:

• Launch the evaluation software and apply power to CDB5378.

• Click ‘OK’ on the About panel to get to the Setup panel.

• On the Setup panel, select Open Target on the USB Port sub-panel.

• When connected, the Board Name and MCU code version will be displayed.

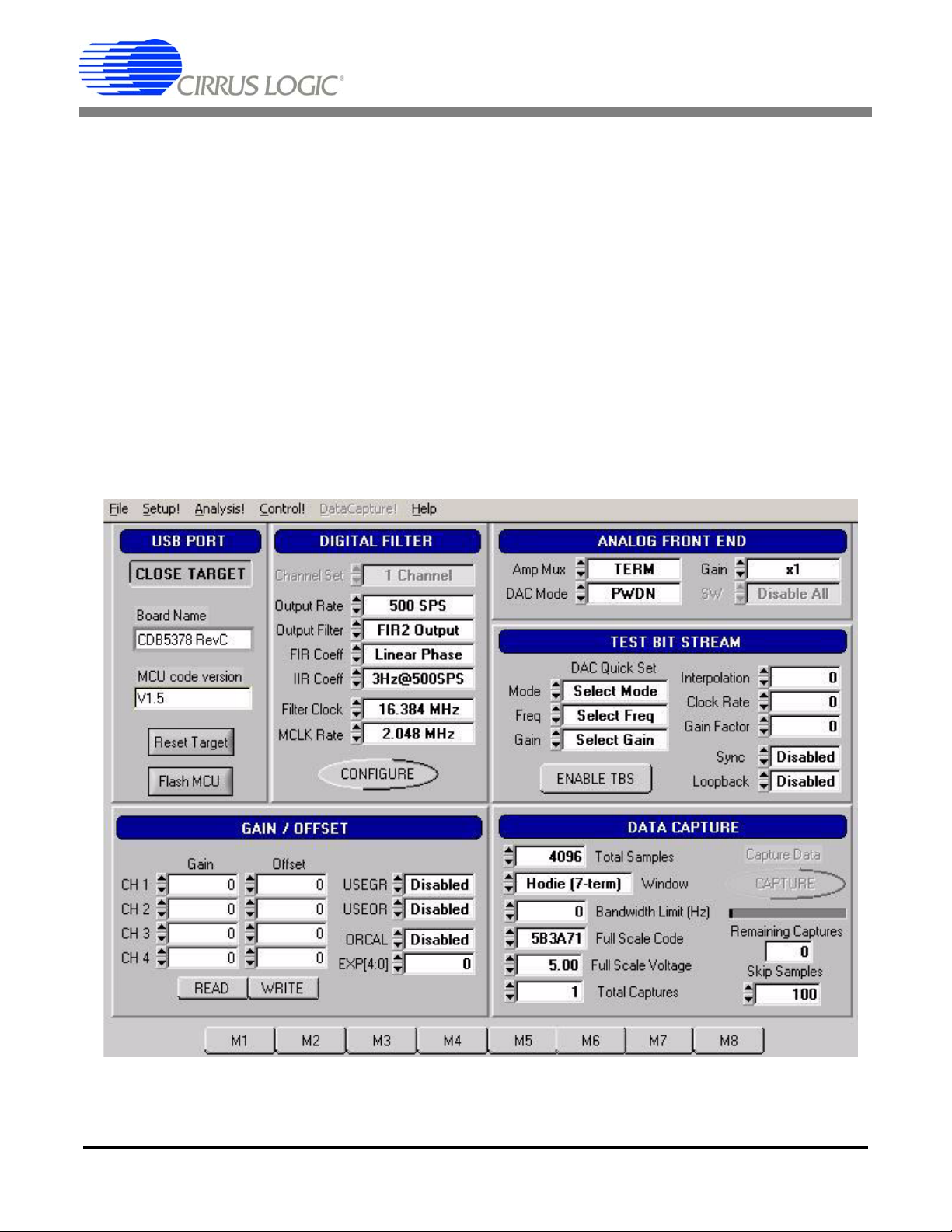

1.4.1 Noise test

Noise performance of the measurement channel can be tested as follows:

• Set the controls on the Setup panel to match the picture:

DS639DB4 13

Page 14

• Once the Setup panel is set, select Configure on the Digital Filter sub-panel.

• After digital filter configuration is complete, click Capture to collect a data record.

• Once the data record is collected, the Analysis panel is automatically displayed.

• Select Noise FFT from the Test Select control to display the calculated noise statistics.

• Verify the noise performance (S/N) is 124 dB or better.

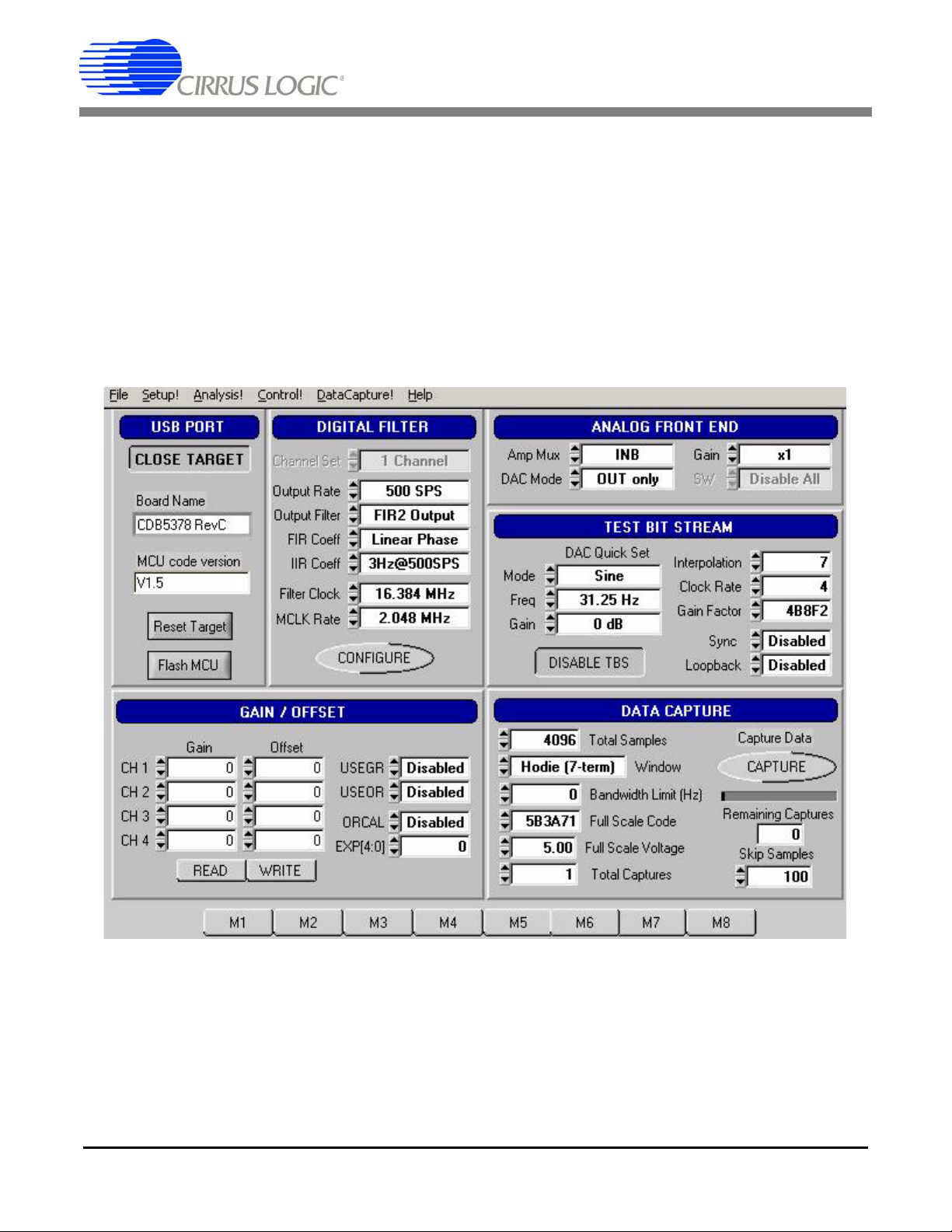

1.4.2 Distortion Test

• Set the controls on the Setup panel to match the picture:

CDB5378

• Once the Setup panel is set, select Configure on the Digital Filter sub-panel.

• After digital filter configuration is complete, click Capture to collect a data record.

• Once the data record is collected, the Analysis panel is automatically displayed.

• Select Signal FFT from the Test Select control to display the calculated signal statistics.

• Verify the distortion performance (S/D) is 112 dB or better.

14 DS639DB4

Page 15

2. HARDWARE DESCRIPTION

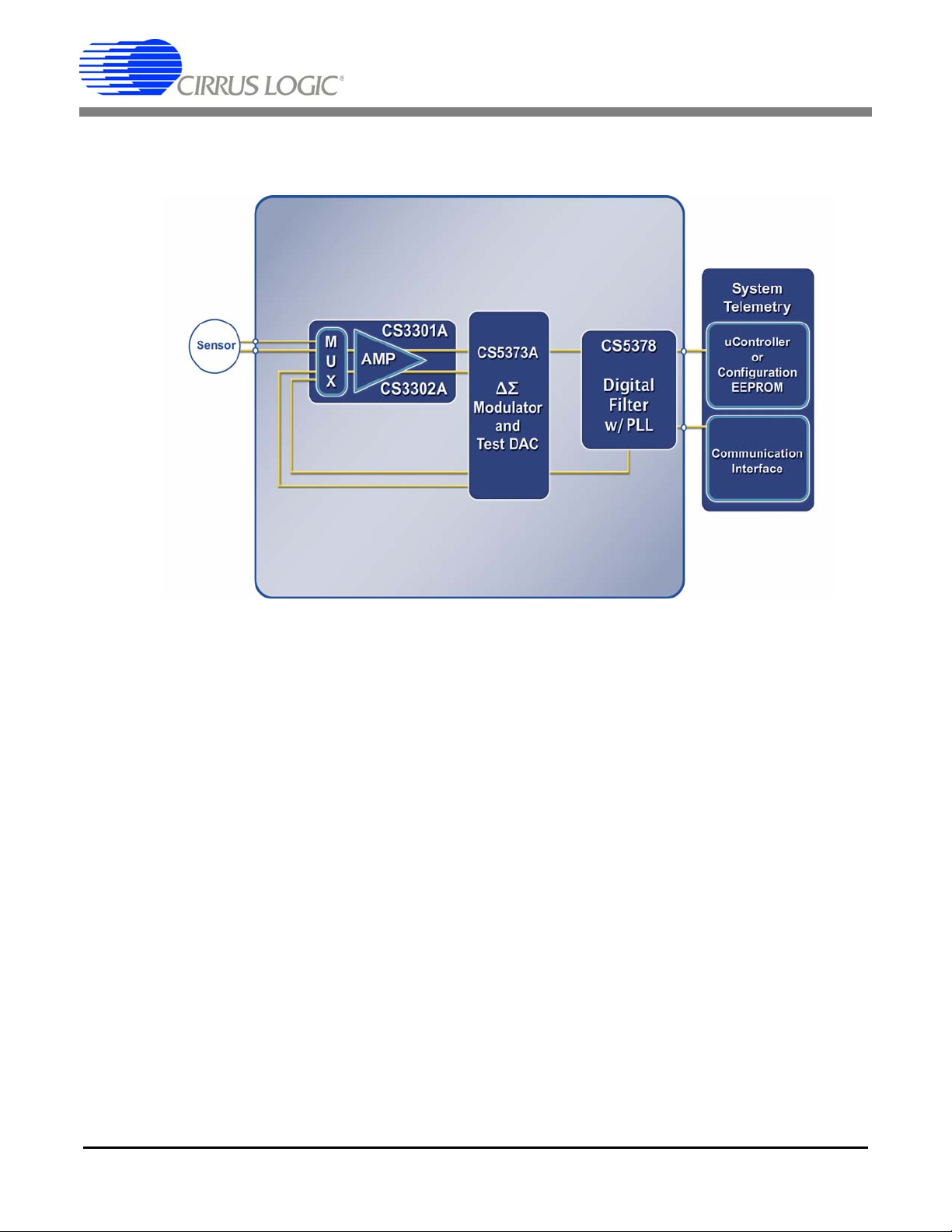

2.1 Block Diagram

CDB5378

Figure 1. CDB5378 Block Diagram

Major blocks of the CDB5378 evaluation board include:

• CS3301A Geophone Amplifier

• CS5373A ∆Σ Modulator + Test DAC

• CS5378 Digital Filter + PLL

• Precision Voltage Reference

• Interface CPLD

• Microcontroller with USB

• RS-485 Transceivers

• Voltage Regulators

DS639DB4 15

Page 16

CDB5378

2.2 Analog Hardware

2.2.1 Analog Inputs

2.2.1.1 External Inputs - INA, INB, BNC

External signals into CDB5378 are from two major classes of sensors, moving coil geophones and piezoelectric hydrophones. Geophones are low-impedance sensors optimized to measure vibrations in land

applications. Hydrophones are high-impedance sensors optimized to measure pressure in marine applications. Other sensors for earthquake monitoring and military applications are considered as geophones

for this datasheet.

External signals connect to CDB5378 through screw terminals on the left side of the PCB. These screw

terminals make connections to two external differential inputs, INA and INB. In addition, GND and GUARD

connections are provided for connecting sensor cable shields, if present.

Signal Input Screw Terminal

INA J32

INB J41

Table 7. Screw Terminal Input Connectors

BNC inputs for connecting external signals are not populated during board manufacture, but the empty

PCB footprints exist and can be installed. The inner conductors of the BNC inputs make connections to

the + and - differential signal traces, with the outer shields connected to ground. The BNC inputs can be

connected to the INA or INB inputs through the input selection jumpers.

2.2.1.2 GUARD Output, GND Connection

By default, CDB5378 uses the CS3301A differential geophone amplifier. By replacing the amplifier and

changing the pin 13 signal assignment (J42) it is possible to use the CS3302A hydrophone amplifier instead. The CS3301A amplifier expects an MCLK clock input to pin 13 while the CS3302A amplifier produces an analog GUARD signal output to pin 13.

The CS3302A hydrophone amplifier analog GUARD signal output is designed to actively drive the cable

shield of a high impedance sensor with the common mode voltage of the sensor differential signal. This

GUARD output on the cable shield minimizes leakage by minimizing the voltage differential between the

sensor signal and the cable shield.

When using the CS3301A amplifier, which does not have a GUARD output, a separate GND screw terminal is provided for the sensor cable shield. When jumper J42 is set for the CS3301A amplifier the

GUARD output screw terminal is left floating.

2.2.1.3 Internal Inputs - DAC_OUT, DAC_BUF

The CS5373A test DAC has two high-performance differential test outputs, a precision output

(DAC_OUT) and a buffered output (DAC_BUF). These test outputs can be connected to the INA or INB

inputs through the input selection jumpers.

16 DS639DB4

Page 17

CDB5378

By default, CDB5378 is populated with passive RC filter components on the INA inputs, and no filter components on the INB inputs (though the component footprints are present on the INB inputs). Because the

CS5373A precision output will not tolerate significant loading, the DAC_ OUT signal should only jumper to

the INB inputs on CDB5378. The CS5373A buffered outputs are less sensitive to the RC filter load and

DAC_BUF can be jumpered to either the INA or INB inputs.

2.2.1.4 Input Protection

Sensor inputs must have circuitry to protect the analog electronics from voltage spikes. Geophone coils

are susceptible to magnetic fields (especially from lightning) and hydrophones can produce large voltag e

spikes if located near an air gun source.

Discrete switching diodes quickly clamp the analog inputs to the power supply rails when the input voltage

spikes. These diodes are reverse biased in normal operation and have low reverse bias leakage and capacitance characteristics to maintain high linearity on the analog inputs.

Specification Value

Dual Series Switching Diode - ON Semiconductor BAV99LT1

Surface Mount Package Type SOT-23

Non-Repetitive Peak Forward Current (1 µs, 1 ms, 1 s)

Reverse Bias Leakage (25 C to 85 C)

Reverse Bias Capacitance (0 V to 5 V) 1.5 pF - 0.54 pF

2.0 A, 1.0 A, 500 mA

0.004 µA - 0.4 µA

2.2.1.5 Input RC Filters

Following the diode clamps is an RC filter network that bandwidth limits the sensor inputs into the amp lifier

to “chop the tops off” residual voltage spikes not clamped by the discrete diodes. In addition, all Cirrus

Logic component ICs have built in ESD protection diodes guaranteed to 2000 V HBM / 200 V MM (JEDEC

standard). The small physical size of these ESD diodes restricts their current capacity to 10 mA.

For land applications using the CS3301A amplifier, the INA input has a common mode and differential RC

filter. The common mode filter sets a low-pass corner to shunt very-high-frequency components to ground

with minimal noise contribution. The differential filter sets a low-pass corner high enough not to affect the

magnitude response of the measurement bandwidth.

For marine applications that use the CS3302A amplifier, the inherent capa citance of the piezoelectric sensor is combined with large resistors connected to the input signal common mode to create an analog highpass RC filter to eliminate the low-frequency components of ocean noise. Following the high-pass common mode filter is a differential low-pass filter to reject high-frequency signals into the amplifier. The cutoff

frequency for the low-pass filter is high enough not to affect the magnitude response of the measurement

bandwidth.

By default, CDB5378 uses the CS3301A differential geophone amplifier and so the input RC filter on the

INA inputs are set for land applications. Marine applications using the CS3302A amplifier will need to

modify the input RC filter components.

DS639DB4 17

Page 18

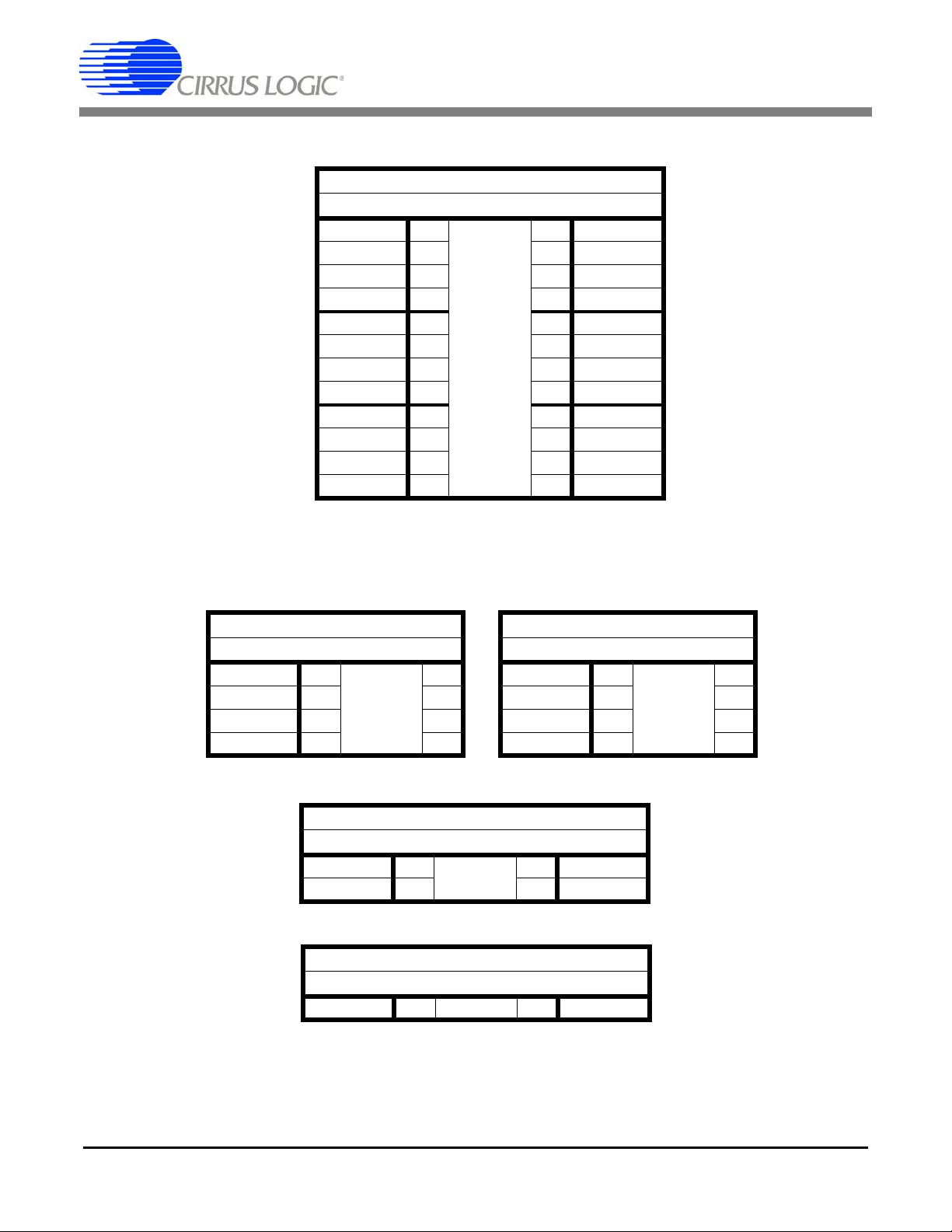

Land Common Mode Filter Specification Value

Common Mode Capacitance 10 nF + 10%

Common Mode Resistance

200 Ω

Common Mode -3 dB Corner @ 6 dB/octave 80 kHz + 10%

Land Differential Filter Specification Value

Differential Capacitance 10 nF + 10%

Differential Resistance

200 Ω + 200 Ω = 400 Ω

Differential -3 dB Corner @ 6 dB/octave 40 kHz + 10%

Marine Common Mode Filter Specification Value

Hydrophone Group Capacitance 128 nF + 10%

Common Mode Resistance

825 kΩ || 825 kΩ = 412 kΩ

-3 dB Corner @ 6 dB/octave 3 Hz + 10%

Marine Differential Filter Specification Value

Differential Capacitance 10 nF + 10%

Differential Resistance

200 Ω + 200 Ω = 400 Ω

-3 dB Corner @ 6 dB/octave 40 kHz + 10%

CDB5378

2.2.1.6 Common Mode Bias

Differential analog signals into the CS3301A/02A amplifiers are required to be biased to the center of the

power supply voltage range, which for bipolar supplies is near ground potential. This common mode bias

voltage is created by buffering the voltage reference, which is nominally +2.5 V relative to the VA- power

supply.

By default, CDB5378 uses the CS3301A differential geophone amplifier and so the common mode bias

resistors on the INA inputs are set for land applications. Marine application s using the CS3302A amplifier

will need to modify the default common mode bias resistors.

Resistors to create the common mode bias are normally selected based on the sensor impedance and

may need to be modified from the CDB5378 defaults depending on the sensor used. Refer to the recommended operating bias conditions for the selected sensor, which are available from the sensor manufacturer.

Specification Value

Geophone Sensor Bias Resistance

Hydrophone Sensor Bias Resistance

20 kΩ || 20 kΩ = 10 kΩ

18 MΩ || 18 MΩ = 9 MΩ

18 DS639DB4

Page 19

CDB5378

2.2.2 Differential Amplifiers

The CS3301A/02A amplifiers act as a low-noise gain stage for internal or e xternal differe ntial analog signals.

Analog Signals Description

INA Sensor analog input

INB Test DAC analog input

OUTR, OUTF Analog rough / fine outputs

GUARD CS3302A guard output (jumper selection)

Digital Signals Description

MUX[0..1] Input mux selection

GAIN[0..2] Gain range selection

PWDN Power down mode enable

CLK CS3301A clock input (jumper selection)

2.2.2.1 MCLK Input vs. GUARD Output

By default, CDB5378 uses the CS3301A geophone amplifier which is chopper stabilized. The CS3301A

connects pin 13 to a clock source (MCLK) to run the chopper circuitry synchronous to the modulator analog sampling clock. The CS3302A hydrophone amplifier is not chopper stabilized (with 1/f noise typically

buried below the low-frequency ocean noise) to achieve very high input impedance. To minimize le akage

from high-impedance sensors connected to the CS3302A amplifier, pin 13 produces a GUARD signal output to actively drive a sensor cable shield with the common mode voltage of the sensor signal.

Comparing the CS3301A and CS3302A amplifiers, the functionality of pin 13 (MCLK input vs. GUARD

output) is the only external difference. CDB5378 can be converted to use either the CS3301A or CS3302A

by replacing the amplifier device and properly setting the pin 13 jumper (J42). By default this jumper is not

populated and has a shorting trace between pins on the back side of the PCB. Converting between amplifier types requires carefully cutting the default short and installing a jumper. A replacement amplifier

can be requested as a sample from your local Cirrus Logic sales representative.

2.2.2.2 Rough-Fine Outputs - OUTR, OUTF

The analog outputs of the CS3301A/02A differential amplifiers are split into rough-charge and fine-charge

signals for input to the CS5373A ∆Σ modulator.

Analog signal traces out of the CS3301A/02A amplifiers and into the CS5373A modulator are 4-wire

INR+ / INF+ / INF- / INR- quad groups, and are routed with INF+ and INF- as a traditional differential pair

and INR+ and INR- as guard traces outside the respective INF+ and INF- traces.

2.2.2.3 Anti-alias RC Filters

The CS5373A ∆Σ modulator is 4th order and high-frequency input signals can cause instability. Simple

single-pole anti-alias RC filters are required between the CS3301A/02A amplifier outputs and the

CS5373A modulator inputs to bandwidth limit analog signals into the modulator.

DS639DB4 19

Page 20

CDB5378

The CS3301A/02A amplifier outputs require a differential anti-alias RC filter, which is created by connecting external 680

tween each half of the rough and fine signals.

Ω series resistors with 20 nF of high-linearity differential capacitance (2x 10 nF C0G) be-

INR+

INF+

INFINR-

Figure 2. Quad Group Routing of RC Filter Components

INR+

INF+

INFINR-

2.2.3 Delta-Sigma Modulator

The CS5373A ∆Σ modulator performs the A/D function for the differential analog signal from the

CS3301A/02A amplifier. The digital output from the modulator is an oversampled ∆Σ bit stream.

Analog Signals Description

INR, INF Modulator analog rough / fine inputs

VREF Voltage reference analog inputs

Digital Signals Description

MDATA Modulator delta-sigma data output

MFLAG Modulator over-range flag output

MCLK Clock input

MSYNC Synchronization input

2.2.3.1 Rough-Fine Inputs - INR, INF

The modulator analog inputs are separated into rough and fine signals, each of which has a differential

anti-alias RC filter to limit the input signal bandwidth.

20 DS639DB4

Page 21

CDB5378

2.2.4 Delta-Sigma Test DAC

The CS5373A ∆Σ DAC creates differential analog signals for system tests. Multiple test modes are available and their use is described in the CS5373A data sheet.

Analog Signals Description

OUT Precision differential analog output

BUF Buffered differential analog output

CAP Capacitor connection for internal anti-alias filter

VREF Voltage reference analog inputs

Digital Signals Description

TDATA Delta-sigma test data input

MCLK Clock input

MSYNC Synchronization input

MODE[0..2] Test mode selection

ATT[0..2] Attenuation range selection

2.2.4.1 Precision Output - DAC_OUT

The CS5373A test DAC has a precision output (DAC_OUT) that is routed to the input selection jumper.

This output is sensitive to loading, and on CDB5378 should only be jumpered into the INB input which

does not have passive RC filter components installed. The input impedance of the CS3301A/02A amplifiers are high enough that the DAC precision output can be connected to the INB input directly.

2.2.4.2 Buffered Output - DAC_BUF

The CS5373A test DAC has a buffered output (DAC_BUF) that is also routed to the input selection jumper. This output is less sensitive to loading than the precision output, and can be jumpered into either the

INA or INB input without affecting performance. The buffered output can also drive a sensor attached to

the input screw terminals, provided the sensor meets the impedance requirements specified in the

CS5373A data sheet.

DS639DB4 21

Page 22

CDB5378

2.2.5 Voltage Reference

A voltage reference on CDB5378 creates a precision voltage from the regulated analog supplies for the

CS5373A VREF input. Because the voltage reference output is generated relative to the negative analog

power supply, VREF+ is near GND potential for bipolar power supplies.

Specification Value

Precision Reference - Linear Tech LT1019AIS8-2.5

Surface Mount Package Type SO-8

Output Voltage Tolerance +/- 0.05%

Temperature Drift 10 ppm / degC

Quiescent Current 0.65 mA

Output Voltage Noise, 10 Hz - 1 kHz 4 ppm

Ripple Rejection, 10 Hz - 200 Hz > 100 dB

2.2.5.1 VREF_MOD

The voltage reference output is provided to the CS5373A modulator and test DAC through a low-pass RC

filter. By filtering the voltage reference input to the device, high-frequency noise is eliminated and any signal-dependent sampling of VREF is isolated. The voltage reference signal is routed as a differential pair

from the large RC filter capacitor to control the sensitive VREF source-return currents and keep them out

of the ground plane. In addition to the RC filter function, the 100 uF filter capacitor provides a large chargewell to help settle voltage reference sampling transients.

RMS

2.2.5.2 Common Mode Bias

A buffered version of the voltage reference is created as a low-impedance common mode bias source for

the analog signal inputs. The bias resistors connected between the buffered voltage reference and each

analog signal input half depends on the sensor type and should be modified to match the sensor manufacturer recommendations.

2.3 Digital Hardware

2.3.1 Digital Filter

The CS5378 digital filter performs filtering and decimation of the ∆Σ bit stream from the CS5373A modulator. It also creates a ∆Σ test bit stream output to create analog test signals in the CS5373A DAC.

The CS5378 requires several control signal inputs from the external system.

Control Signals Description

CLK Master clock input.

RESETz Reset input, active low

SYNC Master synchronization input, rising edge triggered

TIMEB Time Break input, rising edge triggered

22 DS639DB4

Page 23

CDB5378

Configuration and data collection are through the SPI port.

SPI1 Signals Description

DRDYz Data ready output, active low

SCK Serial clock

MISO Master in / slave out serial data

MOSI Master out / slave in serial data

SS:EECSz Serial chip select, active low

Modulator ∆Σ data is input through the modula tor interface, and test DAC ∆Σ data is generated by the test

bit stream generator.

Modulator Signals Description

MCLK Modulator clock output

MSYNC Modulator synchronization output

MDATA Modulator delta-sigma data inputs

MFLAG Modulator over-range flag inputs

TBSDATA Test DAC delta-sigma data output

Amplifier, modulator and test DAC pin settings are controlled through the GPIO port.

GPIO Signals Description

GPIO[0]:MUX[0] Amplifier input mux selection

GPIO[1..3]:MODE[0..2] Test DAC mode selection

GPIO[4..6]:GAIN[0..2] Amplifier gain / test DAC attenuation

GPIO[7]:MUX[1] Amplifier input mux selection

2.3.1.1 Reset Options - BOOT, PLL

Immediately following the reset signal rising edge, the CS5378 digital filter latches the states of the

GPIO[4..6]:PLL[0..2] and GPIO7:BOOT pins. The reset states of the GPIO[4..6]:PLL[0..2] pins select the

master clock input frequency and type, while the reset state of the GPIO7:BOOT pin selects how the

CS5378 digital filter receives configuration data.

At reset the CS5378 digital filter GPIO pins default as inputs with weak pull-up resistors enabled. If left

floating, the GPIO state reads high at reset because of the internal pull-up resistor. A four-position DIP

switch on CDB5378 (S5) can connect 10k Ω pull-down resistors to the GPIO[4..6]:PLL[0..2] or

GPIO7:BOOT pins so they will read low at reset. Because the pin states are latched at reset, GPIO pins

can be programmed and used normally after reset without affecting the PLL and BOOT selections.

Detailed information about the PLL input clock and BOOT mode selections at reset can be found in the

CS5378 data sheet.

DS639DB4 23

Page 24

CDB5378

2.3.1.2 Configuration - SPI Port

On CDB5378, configuration of the digital filter is through the SPI port by the o n-board 8051 microcontroller, which receives commands from the PC evaluation software via the USB interface. Evaluation software

commands can write/read digital filter registers, specify digital filter coefficients and start/sto p dig ital filter

operation. Alternately, the digital filter can automatically load configuration information from an on-board

serial EEPROM.

The configuration method for the digital filter is selected by the BOOT signal from a dip switch (S1, #4).

By default the BOOT signal is set low (S1, #4 - LO) to indicate configuration information is written by the

microcontroller. If BOOT is instead set high (S1, #4 - HI), the digital filter attempts to automatically read

configuration information from the serial EEPROM after reset. Configuration information is initially written

into the serial EEPROM by jumpering its chip select input (EECS) to the microcontroller chip select output

(SS) and sending EEPROM programming commands and data from the PC evaluation software.

2.3.1.3 Phase Locked Loop

To make synchronous analog measurements throughout a distributed system, a synchronous system

clock is required to be provided to each measurement node. For evaluation testing purposes, a BNC clock

input on CDB5378 can receive an external system clock and create a synchronous local clock using the

CS5378 PLL.

The system clock into the BNC clock input is applied to the CS5378 CLK input by selecting CLK_EXT on

the DIGITAL FILTER CLOCK jumper (J16). The CS5378 PLL input frequency is specified at reset by the

state of the GPIO[4..6]:PLL[0..2] pins, as detailed in the CS5378 data sheet.

Specification Value

Input Clock Frequency 1.024, 2.048, 4.096 MHz

Distributed Clock Synchronization ± 240 ns

Maximum Input Clock Jitter, RMS 1 ns

Specification Value

PLL Internal Clock Frequency 32.768 MHz

Maximum Jitter, RMS 300 ps

Loop Filter Architecture Internal

24 DS639DB4

Page 25

CDB5378

If no system clock is supplied to CDB5378, the DIGITAL FILTER CLOCK jumper (J16) can select a PLL

input clock from a local oscillator. Using a clock divider, the on-board oscillator produces 1.024 MHz,

2.048 MHz, 4.096 MHz and 32.768 MHz clock outputs that can be applied to the CS5378 CLK input.

Specification Value

Oscillator - Citizen 32.768 MHz VCXO CSX750VBEL32.768MTR

Surface Mount Package Type Leadless 6-Pin, 5x7 mm

Supply Voltage, Current 3.3 V, 11 mA

Frequency Stability, Pullability ± 50 ppm, ± 90 ppm

Startup Time 4 ms

Specification Value

Clock Divider - TI LittleLogic D-Flop SN74LVC2G74DCTR

Surface Mount Package Type SSOP8-199

Supply Voltage, Current

2.3.2 Interface CPLD

3.3 V, 10 µA

A Xilinx CPLD is included on CDB5378 (XCR3128XL-10VQ100I) as an interface between the CS5378

digital filter and the microcontroller. By default the CPLD only passes through the interface signals, but

can be reprogrammed to disconnect the on-board 8051 microcontroller and connect to another external

microcontroller through the spare dual-row headers. Control signals taken off the CDB5378 board to an

external microcontroller should pair with a ground return wire to maintain signal integrity.

Free software tools and an inexpensive hardware programmer for the Xilinx CPLD are available from the

internet (http://www.xilinx.com

port (J39) on CDB5378. Note that early versions of the Xilinx WebPack tools (7.1i SP1 and earlier) have

a bug in the JEDEC programming file for the CPLD included o n CDB5378, and WebPack version 7.1i SP2

or later is required.

Included below is the default Verilog HDL file used by CDB5378 inside the interface CPLD. Comparing

the input and output definitions of this file with the CPLD schematic pinout should demonstrate how signals are selected and passed through from the microcontroller to the CS5378 digital filter. Seve ral signa l

connections to the CPLD are not defined in the default HDL file, but are routed to the CPLD on CDB5378

for convenience during custom reprogramming.

). The hardware programmer interfaces with the Xilinx JTAG programming

DS639DB4 25

Page 26

CDB5378

///////////////////////////////////////////////////////////////////////////

// MODULE: CDB5378 top module

//

// FILE NAME: Top module for connecting CS5378 to C8051F320

// VERSION: 1.0

// DATE: November 27, 2007

// COPYRIGHT: Cirrus Logic, Inc.

//

// CODE TYPE: Register Transfer Level

//

// DESCRIPTION: This module includes assignments for signals between

// the serial port of Rodney and the SLAB micro.

//

///////////////////////////////////////////////////////////////////////////

module cdb5378(

sck_mc, // 5 I serial clock from printer port

miso_mc, // 6 O serial output

mosi_mc, // 7 I serial input

ssz_mc, // 8 I slave select (active low)

drdyz_mc, // 9 O data ready (active low)

sck, // 61 O serial clock

miso, // 60 I serial output

mosi, // 58 O serial input

ssz, // 57 O slave select (active low)

drdyz, // 56 I data ready (active low)

timeb_mc, // 14 I timebreak pulse (active high)

timeb_pb, // 93 I pushbutton timebreak

timeb_ext, // 98 I external timebreak

timeb, // 52 O timebreak pulse to digital filter

sync_pb, // 94 I pushbutton sync

sync_mc, // 13 I sync from uC

sync_ext, // 99 I external sync

sync); // 53 O sync to CS5378

cdb5378.v

//////////////////

// input signals

//////////////////

input sck_mc, mosi_mc, ssz_mc;

input miso, drdyz;

input sync_mc, sync_pb, sync_ext;

input timeb_pb, timeb_mc, timeb_ext;

wire sck_mc, mosi_mc, ssz_mc;

wire miso, drdyz;

wire sync_pb, sync_mc, sync_ext;

wire timeb_pb, timeb_mc, timeb_ext;

//////////////////

//output signals

//////////////////

output miso_mc, drdyz_mc;

output sck, mosi, ssz;

output sync;

output timeb;

wire miso_mc, drdyz_mc;

wire sck, mosi, ssz;

wire sync;

wire timeb;

///////////////////////

// signal assignments

///////////////////////

assign mosi = ssz_mc? 1'bz:mosi_mc;

assign ssz = ssz_mc? 1'bz:ssz_mc;

assign sck = (ssz_mc & drdyz )? 1'bz:sck_mc;

assign miso_mc = miso;

assign drdyz_mc = drdyz;

assign sync = sync_pb | sync_mc | sync_ext;

assign timeb = timeb_pb | timeb_mc | timeb_ext;

endmodule

Figure 3. CPLD Default Signal Assignments

26 DS639DB4

Page 27

CDB5378

2.3.3 Digital Control Signals

The reset, synchronization and timebreak signals to the CS5378 digital filter can be generated by push

buttons, received from external inputs or generated by the on-board microcontroller. By default, push buttons SYNC_PB and TIMEB_PB and external inputs SYNC_EXT (J50) and TIMEB_EXT (J59) are connected through the interface CPLD to the CS5378 digital filter SYNC and TIMEB inputs. In contrast, push

button RESET_PB is connected directly to the CS5378 digital filter reset through (J40 & J58) jumper configurations.

A four-position DIP switch on CDB5378 (S5) sets static digital control signals not normally changed during

operation. The LGND signal (S5, #2) is connected to a logic ground pin of the CS3301A/02A device and

therefore needs to be held to ground. The PWDN signal (S5, #3) disables the analog components by placing them in a micropower sleep state.

2.3.4 Microcontroller

Included on CDB5378 is an 8051-type microcontroller with integrated hardware SPI and USB interf aces.

This C8051F320 microcontroller is a product of Silicon Laboratories (http://www.silabs.com

of the C8051F320 microcontroller are:

8051 compatibility - uses industry-standard 8051 software development tools

In-circuit debugger - software development on the target hardware

Internal memory - 16k flash ROM and 2k static RAM included on-chip

). Key features

Multiple serial connections - SPI, USB, I2C, and UART

High performance - 25 MIPS maximum

Low power - 0.6 mA @ 1 MHz w/o USB, 9 mA @ 12 MHz with USB

Small size - 32 pin LQFP package, 9mm x 9mm

Industrial temperature - full performance (including USB) from -40 C to +85 C

Internal temperature sensor - with range violation interrupt capability

Internal timers - four general purpose plus one extended capability

Power on reset - can supply a reset signal to external devices

Analog ADC - 10 bit, 200 ksps SAR with internal voltage reference

Analog comparators - arbitrary high/low voltage compare with interrupt capability

The exact use of these features is controlled by embedded firmware.

C8051F320 has dedicated pins for power and the USB connection, plus 25 general-purpose I/O pins that

connect to the various internal resources through a programmable crossbar. Hardware connections on

CDB5378 limit how the blocks can operate, so the port mapping of microcontroller resources is detailed

below.

DS639DB4 27

Page 28

CDB5378

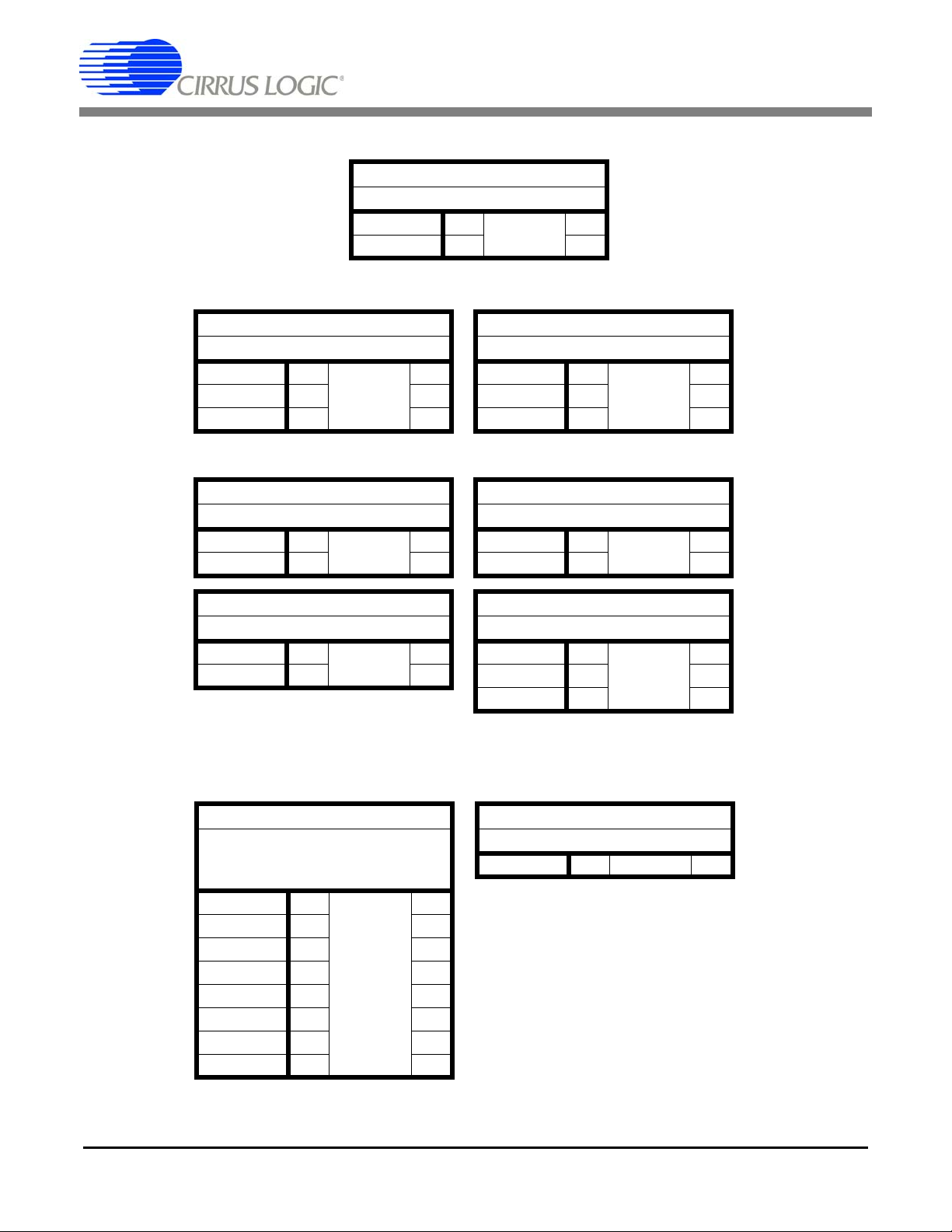

Pin # Pin Name Assignment Description

1 P0.1 SYNC_IO SYNC signal input from RS-485

2 P0.0 SYNC_MC S YNC signal output

3 GND Ground

4 D+ USB differential data transceiver

5 D- USB differential data transceiver

6 VDD +3.3 V power supply input

7 REGIN +5 V power supply input (unused on CDB5378)

8 VBUS USB voltage sense input

Pin # Pin Name Assignment Description

9 /RST

C2CK

10 P3.0

C2D

11 P2.7 AIN- ADC input

12 P2.6 AIN+ ADC input

13 P2.5 CPLD5_MC General Purpose I/O

14 P2.4 CPLD4_MC General Purpose I/O

15 P2.3 CPLD3_MC General Purpose I/O

16 P2.2 CPLD2_MC General Purpose I/O

RESETz Power on reset output, active low

Clock input for debug interface

GPIO General purpose I/O

Data in/out for debug interface

Pin # Pin Name Assignment Description

17 P2.1 CPLD1_MC General Purpose I/O

18 P2.0 CPLD0_MC General Purpose I/O

19 P1.7 BYP_EN I2C bypass switch control

20 P1.6 SDA_DE I2C data driver enable

21 P1.5 SCL I2C clock in/out

22 P1.4 SDA I2C data in/out

23 P1.3 SS_MCz SPI chip select output, active low

24 P1.2 MOSI_MC SPI master out / slave in

Pin # Pin Name Assignment Assignment

25 P1.1 MISO_MC SPI master in / slave out

26 P1.0 SCK_MC SPI serial clock

27 P0.7 Internal VREF bypass capacitors

28 P0.6 DRDY_MCz Data ready input, active low

29 P0.5 RX UART receiver

30 P0.4 TX UART transmitter

31 P0.3 CLOCK_MC External clock input

32 P0.2 TIMEB_MC Time Break output

28 DS639DB4

Page 29

CDB5378

Many connections to the C8051F320 microcontroller are inactive by default, but are provided for convenience during custom reprogramming. Listed below are the default active connections to the microcontroller and how they are used.

2.3.4.1 SPI Interface

The microcontroller SPI interface communicates with the CS5378 digital filter to write/read configuration

information and collect conversion data from the SPI port. Detailed information about interfacing to the

digital filter SPI port can be found in the CS5378 data sheet.

2.3.4.2 USB Interface

The microcontroller USB interface communicates with the PC evaluation software to rece ive configuration

commands and return collected conversion data. The USB interface uses the Silicon Laboratories API

and Windows drivers, which are available free from the internet (http://www.silabs.com

2.3.4.3 Reset Source

By default, the C8051F320 microcontroller receives its reset signal from the RESET_PBz push button.

2.3.4.4 Clock Source

).

By default, the C8051F320 microcontroller uses an internally generated 12 MHz clock for compatibility

with USB standards.

2.3.4.5 Timebreak Signal

By default, the C8051F320 microcontroller sends the TIMEB_MC signal to th e digital filter for the first collected sample of a data record. By default, 100 initial samples are skipped during data collection to ensure

the CS5378 digital filters are fully settled, and the timebreak signal is automatically set for the first “real”

collected sample.

2.3.4.6 C2 Debug Interface

Through the PC evaluation software, the microcontroller default firmware can be automatically flashed to

the latest version without connecting an external programmer. To flash custom firmware, software tools

and an inexpensive hardware programmer (DEBUGADPTR1-USB) that connects to the C2 Debug In terface on CDB5378 are available from Silicon Laboratories.

2.3.5 RS-485 Telemetry

By default, CDB5378 communicates with the PC evaluation software through the microcontroller USB

port. Additional hardware is designed onto CDB5378 to use the microcontroller I2C port as a low-level

local telemetry, but it is provided for custom programming convenience only and is not directly supported

by the CDB5378 PC evaluation software or microcontroller firmware.

DS639DB4 29

Page 30

CDB5378

Telemetry signals enter CDB5378 through RS-485 transceivers, which are differential current mode transceivers that can reliably drive long distance communication. Data passes through the RS-485 transceivers to the microcontroller I2C interface and the clock and synchronization inputs.

Specification Value

RS-485 Transceiver - Linear Tech LTC1480IS8

Surface Mount Package Type SOIC-8, 5mm x 6mm

Supply Voltage, Quiescent Current

Maximum Data Rate 2.5 Mbps

Transmitter Delay, Receiver Delay 25 - 80 ns, 30 - 200 ns

Transmitter Current, Full Termination (60 Ω)

Transmitter Current, Half Termination (120 Ω)

2.3.5.1 CLK, SYNC

Clock and synchronization telemetry signals into CDB5378 are received through RS-485 twisted pairs.

These signals are required to be distributed through the external system with minimal jitter and timing

skew, and so are normally driven through high-speed bus connections.

3.3V, 600 µA

25 mA

13 mA

Specification Value

Synchronous Inputs, 2 wires each CLK±, SYNC±

Specification Value

Distributed SYNC Signal Synchronization ± 240 ns

Distributed Clock Synchronization ± 240 ns

Analog Sampling Synchronization Accuracy ± 480 ns

Synchronization of the measurement channel is critical to ensure simultaneous analog sampling across

a network. Several options are available for connecting a SYNC signal through the RS-485 telemetry to

the digital filter.

A direct connection is made when the SYNC_IO signal is received over the dedicat ed RS-485 twisted pair

and sent directly to the digital filter SYNC pin through jumper J56. The incoming SYNC_IO signal must be

synchronized to the network at the transmitter since no local timing adjustment is available.

A microcontroller hardware connection is made when the SYNC_IO signal is received over the dedicated

RS-485 twisted pair and detected by a microcontroller interrupt. The microcontroller can then use an internal counter to re-time the SYNC_MC signal output to the digital filter SYNC input as required.

A microcontroller software connection is made when the SYNC_MC signal output is created by the microcontroller on command from the system telemetry. The microcontroller can use an in ternal counter to retime the SYNC_MC signal output to the digital filter SYNC input as required.

30 DS639DB4

Page 31

CDB5378

2.3.5.2 I2C - SCL, SDA, Bypass

The I2C telemetry connections to CDB5378 transmit and receive through RS-485 twisted pairs. Because

signals passing through the transceivers are actively buffered, full I2C bus arbitration and error detection

cannot be used (i.e. high-impedance NACK).

The I2C inputs and outputs can be externally wired to create either a daisy chain or a bus-type network,

depending how the telemetry system is to be implemented. Analog switches included on CDB5378 can

bypass the I2C signals to create a bus network from a daisy chain network following address assignment.

Specification Value

I2C Inputs, 2 wires each SCL±, SDA±

I2C Outputs, 2 wires each BYP_SCL±, BYP_SDA±

I2C Bypass Switch Control BYP_EN

When CDB5378 is used in a distributed measurement network, each node must have a unique address.

This address is used to transmit individual configuration commands and tag the source of returned conversion data. Address assignment can be either dynamic or static, depending how the telemetry system

is to be implemented.

Dynamic address assignment uses daisy-chained I2C connections to assign an address to each measurement node. Once a node receives an address, it enables the I2C bypass switches to the next node

so it can be assigned an address.

Static address assignment has a serial number assigned to each node during manufacturing. When

placed in the network, the location is recorded and a master list of serial numbers vs. location is maintained. Alternately, a location-dependent serial number can be assigned during installation.

2.3.6 UART Connection

A UART connection on CDB5378 provides a low-speed standardized connection for telemetry solutions

not using I2C. UART connections are provided for custom programming convenience only and are not

directly supported by the CDB5378 PC evaluation software or microcontroller firmware.

Specification Value

UART Connections, 2 wires each TX/GND, RX/GND

DS639DB4 31

Page 32

CDB5378

2.3.7 External Connector

Power supplies and telemetry signals route to a 20-pin double row connector with 0.1" spacing (J26). This

header provides a compact standardized connection to the CDB5378 external signals.

Pins Name Signal

1, 2 CLK+, CLK- Clock Input

3, 4 SYNC+, SYNC- Synchronization Input

5, 6 SCL+, SCL- I2C Clock

7, 8 SDA+, SDA- I2C Data

9, 10 BYP_SDA+, BYP_SDA- I2C Data Bypass

11, 12 BYP_SCL+, BYP_SCL- I2C Clock Bypass

13, 14 TX, GND UART transmit

15, 16 RX, GND UART receive

17, 18 EXT_VA-, GND Negative Power Supply

19, 20 EXT_VA+, GND Positive Power Supply

2.4 Power Supplies

Power is supplied to CDB5378 through banana jacks (J6, J7, J8, J9) or through the external connector

(J26). The banana jacks make separate connections to the EXT_VA-, EXT_VA+, GND, and EXT_VD

power supply nets, which connect to the analog and digital linear voltage regulator inputs. The external

connector makes separate connections only to the EXT_VA-, GND, and EXT_VA+ power supply inputs

and it is required to jumper EXT_VA+ to EXT_VD when powering CDB5378 from the external connector.

The EXT_VA-, EXT_VA+ and EXT_VD power supply inputs have zener protection diodes that limit the

maximum input voltages to +13 V or -13 V with respect to ground. Each input also has 100 uF bulk capacitance for bypassing and to help settle transients and another 0.01 uF capacitor to bypass high-frequency noise.

2.4.1 Analog Voltage Regulators

Linear voltage regulators create the positive and negative analog power supply voltages to the analog

components on CDB5378. These regulate the EXT_VA+ and EXT_VA- power supply inputs to create the

VA+ and VA- analog power supplies.

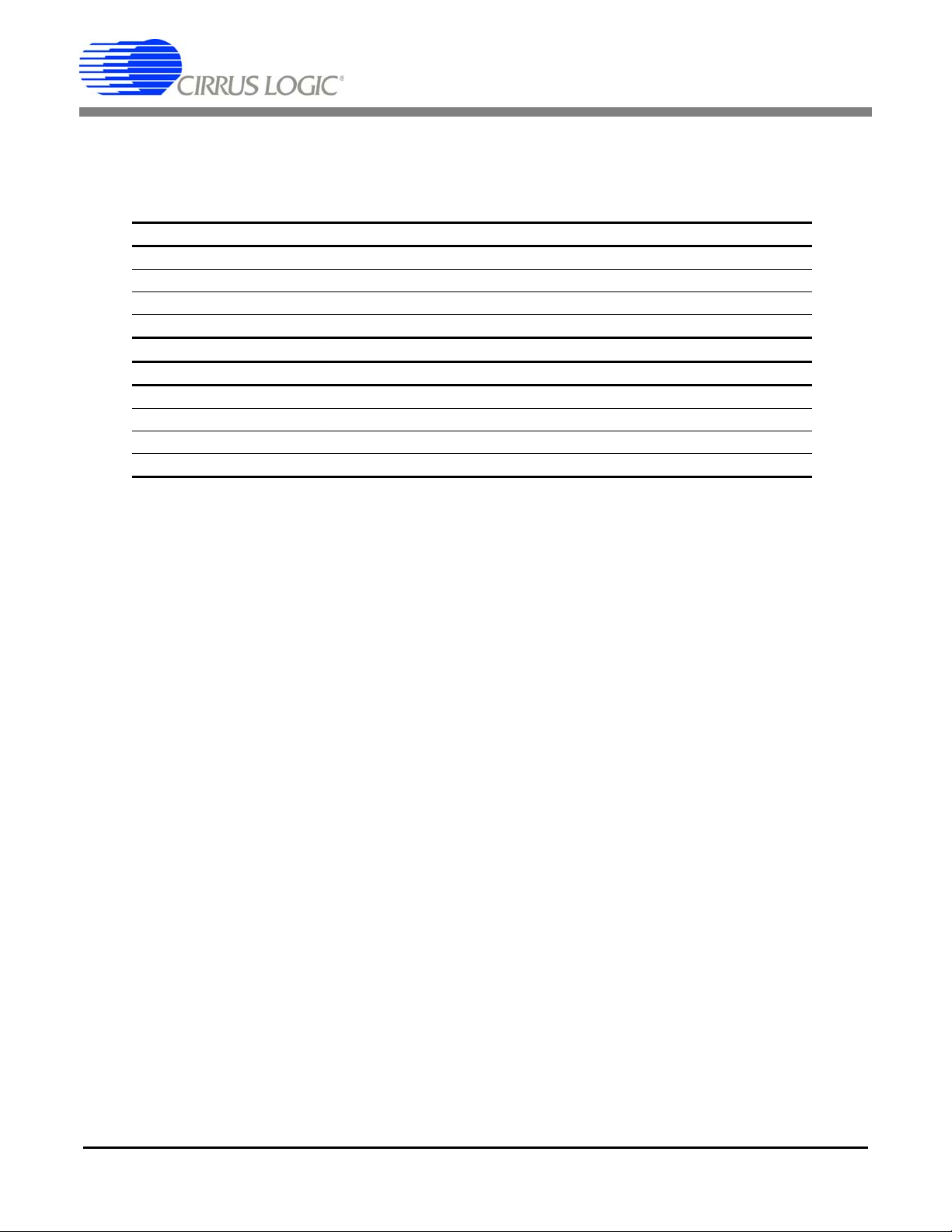

Specification Value

Positive Analog Power Supply +2.5 V, +5 V

Low Noise Micropower Regulator - Linear Tech LT1763CS8

Surface Mount Package Type SO-8

Load Regulation, -40 C to +85 C +/- 25 mV

Quiescent Current, Current @ 100 mA Load

Output Voltage Noise, 10 Hz - 100 kHz

40 µA, 2 mA

20 µV

RMS

Ripple Rejection, DC - 200 Hz > 50 dB

32 DS639DB4

Page 33

CDB5378

Specification Value

Negative Analog Supply, -2.5VA -2.5 V

Low Noise Micropower Regulator - Linear Tech LT1964ES5-BYP

Surface Mount Package Type SOT-23

Load Regulation, -40 C to +85 C +/- 30 mV

Quiescent Current, Current @ 100 mA Load

Output Voltage Noise, 10 Hz - 100 kHz

Ripple Rejection, DC - 200 Hz > 45 dB

The VA+ and VA- power supplies to the analog components on CDB5378 can be jumpered to use regulated bipolar power supplies (+2.5 V, -2.5 V) or unregulated direct connections (EXT_VA+, EXT_VA-).

When using direct connections to EXT_VA+ and EXT_VA-, extreme care must be taken not to exceed the

maximum specified power supply voltages of the analog components on CDB5378. It is recommended to

always use the regulated bipolar analog power supplies for optimal performance.

The VA+ and VA- power supply nets to the analog components on CDB5378 include reverse-biased

Schottkey diodes to ground to protect against reverse voltages that could latch-up the CMOS analog components. Also included on VA+ and VA- are 100 uF bulk capacitors for bypassing and to help settle transients plus individual 0.1 uF bypass capacitors local to the analog power supply pins of each device.

30 µA, 1.3 mA

20 µV

RMS

2.4.2 Digital Voltage Regulators

Linear voltage regulators create the positive digital power supply voltages on CDB5378. Jumper options

select which external power supply input voltage, EXT_VD or EXT_VA+, is supplied to the digital voltage

regulators to create the VD and VCORE power supplies.

Specification Value

Positive Digital Power Supply +2.5 V, +3.3 V

Low Noise Micropower Regulator - Linear Tech LT1763CS8

Surface Mount Package Type SO-8

Load Regulation, -40 C to +85 C +/- 25 mV

Quiescent Current, Current @ 100 mA Load

Output Voltage Noise, 10 Hz - 100 kHz

40 µA, 2 mA

20 µV

RMS

Ripple Rejection, DC - 200 Hz > 50 dB

The VD and VCORE power supplies on CDB5378 can be jumpered to use regulated +3.3 V or +2.5 V

power supplies or an unregulated direct connection to EXT_VD. Extreme care must be taken when using

a direct connection to EXT_VD not to exceed the maximum specified power supply voltages of the digital

components on CDB5378.

Even though the Cirrus Logic components on CDB5378 will tolerate up to 5 V from the VD power supply,

other components are specified for +3.3 V operation only and so it is recommended to use only the regulated +3.3 V jumper setting for VD.

DS639DB4 33

Page 34

CDB5378

The VD and VCORE power supplies on CDB5378 include reverse-biased Schottkey diodes to ground to

protect against reverse voltages that could latch-up the CMOS components. Also included on VD and

VCORE are 100 uF bulk capacitors for bypassing and to help settle transients plus individual 0.1 uF bypass capacitors local to the digital power supply pins of each device.

2.5 PCB Layout

2.5.1 Layer Stack

CDB5378 layer 1 is dedicated as an analog routing layer. All critical analog signal routes are on this layer.

Some CPLD and microcontroller digital routes are also included on this layer away from the analog signal

routes.

CDB5378 layer 2 is a solid ground plane without splits or routing. A solid ground plane pro vides the best

return path for bypassed noise to leave the system. No separate analog ground is required since analog

signals on CDB5378 are differentially routed.

CDB5378 layer 3 is dedicated for power supply routing. Each power supply net includes at least 100 µF

bulk capacitance as a charge well for settling transient current loads.

CDB5378 layer 4 is dedicated as a digital routing layer.

2.5.2 Differential Pairs

Analog signal routes on CDB5378 are differential with dedicated + and - traces. All source and return analog signal currents are constrained to the differential pair route and do not return through the ground

plane. Differential traces are routed together with a minimal gap between them so that noise events affect

them equally and are rejected as common mode noise.

IN+ IN-

Figure 4. Differential Pair Routing

Analog signal connections into the CS3301A/02A amplifiers are 2-wire IN+ and IN- differential pairs, and

are routed as such. Analog signal connections out of the CS3301A/02A amplifiers and into the CS5373A

34 DS639DB4

Page 35

CDB5378

modulator is a 4-wire INR+, INF+, INF-, INR- quad group, and is routed with INF+ and INF- as a traditiona l

differential pair and INR+ and INR- as guard traces outside the respective INF+ and INF- traces.

INR+

INF+

INFINR-

Figure 5. Quad Group Routing

INR+

INF+

INFINR-

2.5.3 Bypass Capacitors

Each device power supply pin includes 0.1 µF bypass capacitors placed as close as possible to the pin

on the back side of the PCB. Each power supply net includes at least 100 µF bulk capacitance as a charge

well for transient current loads.

TOP BOTTOM

Figure 6. Bypass Capacitor Placement

DS639DB4 35

Page 36

CDB5378

2.5.4 Dual-row Headers

To simplify signal tracing on CDB5378, all device pins connect to dual-row headers. These dual-row headers are not populated during board manufacture, but the empty PCB footprint exists on the boards and

can be used as test points.

Figure 7. Dual-row Headers with Shorts

The dual-row header pins are shorted on the bottom side of the PCB to pass signals through to the rest

of the board. These shorted traces between the dual-row pins can be carefully

signals from the rest of the PCB to permit wiring changes to the existing route. To restore the previous

connection, install a jumper to short across the dual-row pins.

Signals taken off the PCB should not be wired directly from the dual-row header pins, as there is no clean

path for the signal return current. Instead, install a connector into the prototying area and wire the signal

and a ground connection to it. Pairing the signal with a ground return before taking it off the PCB will improve signal integrity.

cut to isolate the device

36 DS639DB4

Page 37

CDB5378

3. SOFTWARE DESCRIPTION

3.1 Menu Bar

The menu bar is always present at the top of the software panels and provides typical File and Help pulldown menus. The menu bar also selects the currently displayed panel.

Control Description

File

Load Data Set Loads a data set from disk.

Save Data Set Saves the current data set to disk.

Copy Panel to Clipboard Copies a bitmap of the current panel to the clipboard.

Print Analysis Screen Prints the full Analysis panel, including statistics fields.

Print Analysis Graph Prints only the graph from the Analysis panel.

High Resolution Printing Prints using the higher resolution of the printer.

Low Resolution Printing Prints using the standard resolution of the screen.

Quit Exits the application software.

Setup! Displays the Setup Panel.

Analysis! Displays the Analysis Panel.

Control! Displays the Control Panel.

DataCapture! Displays the Setup Panel and starts Data Capture.

Help

Contents Find help by topic.

Search for help on Find help by keywords.

About Displays the About Panel.

DS639DB4 37

Page 38

3.2 About Panel

CDB5378

The About panel displays copyright information for the Cirrus Seismic Evaluation software.

Ö

Click OK to exit this panel. Select Help

38 DS639DB4

About from the menu bar to display this panel.

Page 39

3.3 Setup Panel

CDB5378

The Setup panel initializes the evaluation system to perform data acquisition. It consists of the following

sub-panels and controls.

• USB Port

• Digital Filter

• Analog Front End

• Test Bit Stream

• Gain/Offset

• Data Capture

• External Macros

DS639DB4 39

Page 40

CDB5378

3.3.1 USB Port

The USB Port sub-panel sets up the USB communication interface between the PC and the target board.

Control Description

Open Target Open USB communication to the target board and read the board name and micro-

controller firmware version. When communication is established, the name of this

control changes to ‘Close Target’ and Setup, Analysis and Control panel access

becomes available in the menu bar.

Close Target Disconnects the previously established USB connection. On disconnection, this con-

trol changes to ‘Open Target’ and the Setup, Analysis and Control panel access

becomes unavailable in the menu bar. The evaluation software constantly monitors

the USB connection status and automatically disconnect s if the target board is turned

off or the USB cable is unplugged.

Board Name Displays the type of target bo ard currently connected.

MCU code version Displays the version number of the microcontroller code on the connected target

board.

Reset Target Sends a software reset command to reset the microcontroller.

Flash MCU Programs the microcontroller code on the target board using the .thx file found in the

“C:\Program Files\Cirrus Seismic Evaluation” directory. This feature permits reprogramming of the microcontroller (without using a hardware programmer ) when a new

version of the MCU code becomes available.

40 DS639DB4

Page 41

CDB5378

3.3.2 Digital Filter

The Digital Filter sub-panel sets up the digital filter configuration options.

By default the Digital Filter sub-panel configures the system to use on-chip digital filter coefficients. The

on-chip data can be overwritten by loading custom coefficients from the Customize sub-panel on the

Control panel.

Any changes made under this sub-panel will not be applied to the target board until the Configure button

is pushed. The Configure button writes the new configuration to the target board and then enables the

data Capture button.

Control Description

Channel Set Disabled for CDB5378. One channel operation only.

Output Rate Selects the output word rate of the digital filter. Output word rates from 4000 SPS to

1 SPS (0.25 mS to 1 S) are available.

Output Filter Selects the output filter stage from the digital filter. Sinc output, FIR1 output, FIR2

output, IIR 1st order output, IIR 2nd order output, or IIR 3rd order output can be

selected. FIR2 output provides full decimation of the modulator data.

FIR Coeff Selects the on-chip FIR coefficient set to use in the digital filter. Linear phase or min-

imum phase FIR coefficients can be selected.

IIR Coeff Selects the on-chip IIR coefficient set to use in the digital filter. Coefficient sets pro-

ducing a 3 Hz high-pass corner at 2000 SPS, 1000 SPS, 500 SPS, 333 SPS, and

250 SPS can be selected.

Filter Clock Sets the digital filter internal clock rate. Lower internal clock rates can save power

when using slow output word rates.

MCLK Rate Sets the analog sample clock rate. The CS5373A modulator and test DAC typically

runs with MCLK set to 2.048 MHz.

Configure Writes all information from the Setup panel to the digital filter. The data Capture but-

ton becomes available once the configuration information is written to the target

board.

DS639DB4 41

Page 42

CDB5378

3.3.3 Analog Front End

The Analog Front End sub-panel configures the amplifier, modulator and test DAC pin options. Pin op-

tions are controlled through the GPIO outputs of the digital filter.

Any changes made under this sub-panel will not be applied to the target board until the Configure button

is pushed. The Configure button writes the new configuration to the target board and then enables the

data Capture button.

Control Description

Amp Mux Selects the input source for the CS3301A/02A amplifiers. An internal termination,

external INA inputs or external INB inputs can be selected.

DAC Mode Select s the operational mode of the CS5373A test DAC. The test DAC operational

modes are AC dual output (OUT&BUF), AC precision output (OUT only), AC buffered

output (BUF only), DC common mode output (DC Common), DC differential output

(DC Diff), or AC common mode output (AC Common). The test DAC can also be

powered down (PWDN) when not in use to save power.

Gain Sets the amplifier gain range and test DAC attenuation. Amplifier gain and DAC

attenuation settings of 1x, 2x, 4x, 8x, 16x, 32x, or 64x can be selected and are controlled together.

Pwdn Disabled for CDB5378. PWDN routes to DIP switch S5.

42 DS639DB4

Page 43

CDB5378

3.3.4 Test Bit Stream

The Test Bit Stream sub-panel configures test bit stream (TBS) generator parameters. The digitial filter