Page 1

Evaluation Board For CS424xx

CDB42428

Features

Single-Ended Analog Inputs and Outputs

CS8416 S/PDIF Receiver

CS5361 converters supply ADCIN1 and

ADCIN2 for CS424xx One Line Modes

CS8406 S/PDIF Digital Audio Transmitter

Header for optional external configuration of

CS424xx and board

Header for external DSP serial audio I/O

3.3 or 5.0 Volt Logic Interface supply

Demonstrates recommended layout and

grounding arrangements

Microsoft Windows® compatible software

interface to configure CS424xx and interboard connections

I

Description

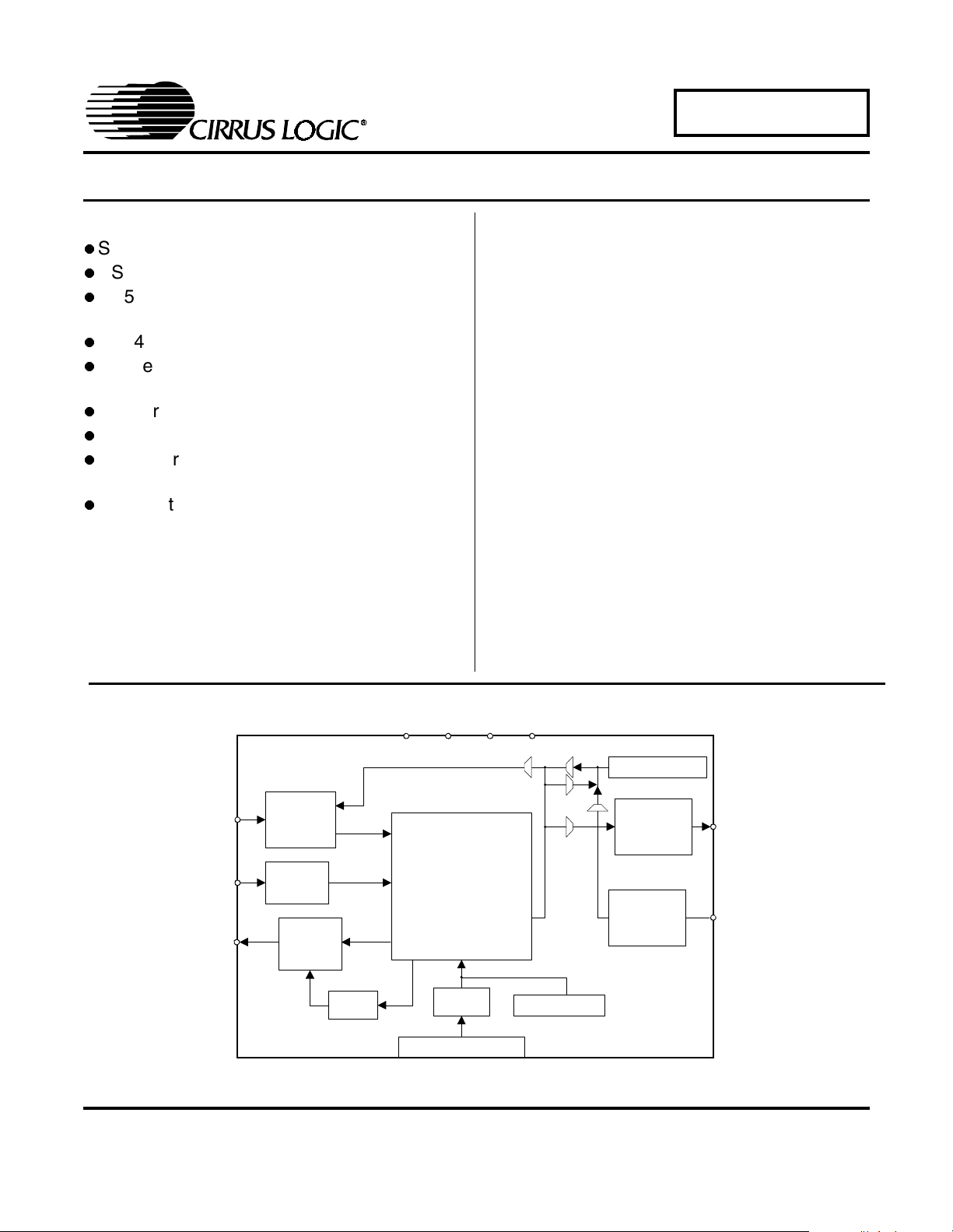

The CDB42428 demonstration board is an excellent

means for evaluating the CS424xx family of highly integrated multi-channel CODECs. Evaluation requires an

analog/digital signal source and analyzer, Windows®

compatible computer, and power supplies.

System timing can be provided by an on-board oscillator

or a master clock recovered from the S/PDIF input to the

CS8416. RCA phono jacks are provided for the CS5361

analog inputs and CS424xx analog inputs and outputs.

Digital data I/O is available via RCA phono jacks or optical connectors to the CS8416 and from the CS8406.

The Windows® software provides a graphical user interface to make configuration of the board easy. The

software communicates through the computer’s parallel

port, and will configure the hardware to allow all features

of the CS424xx to be evaluated. The evaluation board

may also be configured to accept external timing and

data signals for operation in a user application during

system development.

ORDERING INFORMATION

CDB42428 Evaluation Board

Ana log Inputs

Ana log Inputs

Analog O utputs

Cirrus Logic, Inc.

http://www.cirrus.com

CS5361

(x2)

Analog

Filter

8-ch

Analog

Output

Mute

+18V -18V +5V GND

C S 42428

CPLD

PC Parallel Port

Copyright Cirrus Logic, Inc. 2003

(All Rights Reserved)

Ext. Control

DSP Header

CS8406

CS8416

S/PDIF Output

S/PDIF Input

Nov ‘03

DS605DB1

1

Page 2

TABLE OF CONTENTS

1. SYSTEM OVERVIEW ...............................................................................................................4

1.1 CS424xx ............................................................................................................................ 4

1.2 CS8406 .............................................................................................................................. 4

1.3 CS8416 .............................................................................................................................. 4

1.4 CS5361 .............................................................................................................................. 4

1.5 Crystal Oscillator ................................................................................................................ 4

1.6 Analog Input ....................................................................................................................... 4

1.7 Analog Outputs .................................................................................................................. 4

1.8 CPLD ................................................................................................................................. 6

1.9 DB-25 Computer Parallel Port ...........................................................................................6

1.10 External Control Header .................................................................................................. 6

1.11 DSP Header ..................................................................................................................... 6

1.12 LED Function Indicator ....................................................................................................6

1.13 Power ............................................................................................................................... 6

1.14 Grounding and Power Supply Decoupling ....................................................................... 6

1.15 External Control Header Signals ...................................................................................... 7

1.16 DSP Header Signals ........................................................................................................9

2. INITIAL BOARD SETUP .........................................................................................................10

2.1 Power Supplies: ............................................................................................................... 10

2.2 Installing the Software: ..................................................................................................... 10

3. CDB425XX.EXE USER'S GUIDE ........................................................................................... 11

3.1 Main Window ................................................................................................................... 11

3.2 CS42428 Window ............................................................................................................ 11

3.3 Preset Scripts ................................................................................................................... 11

3.4 Quick Start Preset - Analog In to Analog Out ..................................................................11

3.5 Quick Start Preset - Analog In to Digital Out ....................................................................11

3.6 Quick Start Guide - Digital In to Analog Out .................................................................... 12

3.7 Quick Start Preset - One-Line Mode (OLM) ..................................................................... 13

4. MUTING SCHEME ................................................................................................................. 14

5. SCHEMATICS AND LAYOUT ........................................................................................... 15

6. ADDENDUM ...........................................................................................................................32

CDB42428

LIST OF FIGURES

Figure 1. Instrumentation Amplifier Configuration ........................................................................... 5

Figure 2. Output Channel Mute Select ..........................................................................................14

Figure 3. CS424xx......................................................................................................................... 15

Figure 4. Clocks, Data, and DSP Header ...................................................................................... 16

Figure 5. SPDIF............................................................................................................................. 17

Figure 6. CS5361 External ADC #1 .............................................................................................. 18

Figure 7. CS5361 External ADC #2 .............................................................................................. 19

Figure 8. CS424xx Analog Inputs.................................................................................................. 20

Figure 9. Analog Outputs A1 and B1............................................................................................. 21

Figure 10. Analog Outputs A2 and B2........................................................................................... 22

Figure 11. Analog Outputs A3 and B3........................................................................................... 23

Figure 12. Analog Outputs A4 and B4........................................................................................... 24

Figure 13. DB-25, Ext Ctrl Header, Reset .....................................................................................25

Figure 14. CPLD............................................................................................................................ 26

Figure 15. Power ...........................................................................................................................27

Figure 16. CS8416 ........................................................................................................................ 28

Figure 17. Component Placement and Reference Designators ....................................................29

2

Page 3

Figure 18. Top Layer..................................................................................................................... 30

Figure 19. Bottom Layer................................................................................................................ 31

LIST OF TABLES

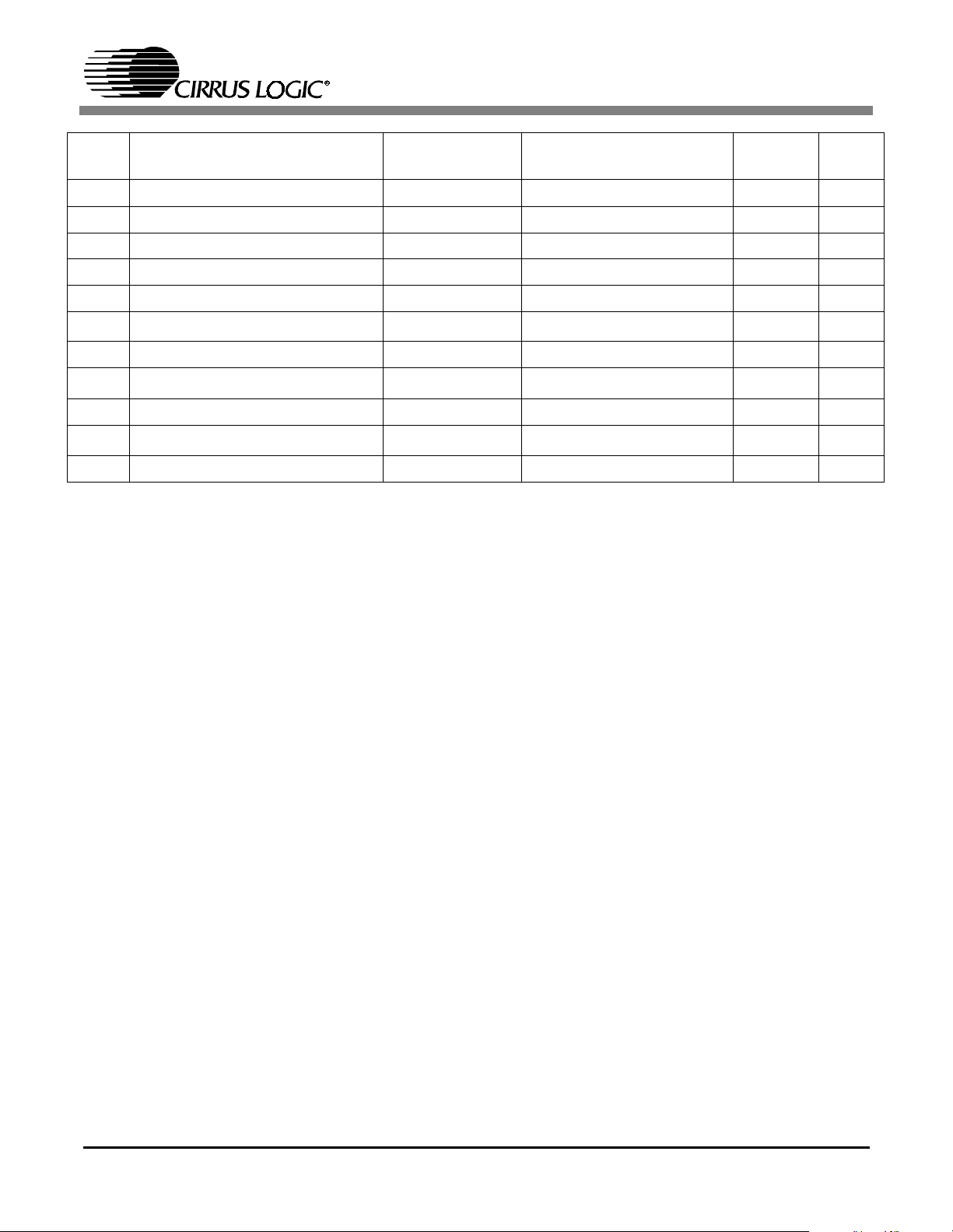

Table 1. System Connections ......................................................................................................... 6

Table 2. Jumper Settings................................................................................................................ 7

Table 3. CS424xx External Control Header Signals ....................................................................... 7

Table 4. CS424xx DSP Header Signals.......................................................................................... 9

CDB42428

3

Page 4

CDB42428

1. SYSTEM OVERVIEW

The CDB42428 demonstration board is an excellent means for evaluating the CS42428/26/18/16 family of highly

integrated CODECs. Analog and digital audio signal interfaces are provided, as well as a DB-25 computer parallel

port interface for use with the supplied Windows® configuration software.

The CDB42428 schematic set has been partitioned into 14 pages as shown in Figures 3 through 16.

1.1 CS424xx

A complete description of each member of the CS42428/26/18/16 family is included in each respective product data

sheet.

1.2 CS8406

The CS8406 S/PDIF transmitter on the demonstration board (see Figure 5) allows the performance of the CS424xx

internal ADC’s to be measured digitally. Either the CS424xx DAC port or the ADC port can be multiplexed to the

CS8406. The CS8406 transmitter is configured to operate in slave mode only, and will receive the required clocks

from the CS424xx. The data format for the CS8406 is selectable and must match that of its source. The CS8406

must be configured using the supplied software.

1.3 CS8416

The CS8416 S/PDIF receiver on the demonstration board (see Figure 5) allows the performance of the CS42428

internal DAC’s to be evaluated through the use of a digital (S/PDIF) input source. The CS8416 receiver interfaces

with the DSP header and can be configured to master the CS424xx DAC and ADC as well as the CS8406. The data

format is selectable and must match that of the CS424xx. The CS8416 must be configured using the supplied software.

1.4 CS5361

There are two CS5361 A/D converters on the CS424xx demonstration board (see Figures 6 and 7). These converters supply the CS424xx ADCIN signals, and must operate in left-justified, 24-bit mode only. Their serial data outputs

are used when supporting the CS424xx One Line Mode of operation.

RCA analog connectors supply the inputs to each CS5361 channel through a unity gain, AC-coupled, single-todif ferential circuit. Each CS5361 input circuit is biased to 1/2 VA, and a 1V

scale. The CS5361 converters are set to operate in slave mode and will receive their clocks from the CS424xx. The

SCLK and LRCK signals can be provided from either the CS424xx DAC or ADC port, and must be selected using

the configuration software.

signal will drive the converter to full

RMS

1.5 Crystal Oscillator

Oscillator Y1 (see Figure 4) provides the System Clock (OMCK) for the CS424xx. The crystal oscillator on the board

is mounted in pin sockets that allow it to be removed or replaced. The board is shipped with a 24.576 MHz crystal

oscillator stuffed at Y1. Please refer to the CS424xx data sheet for details on OMCK operation.

The buffer on the output of the oscillator provides for signal level shifting to the proper VLS supply. This buffer can

be removed if the oscillator is powered from the same VLS voltage source as the codec.

Oscillator Y2 provides the OMCK clock for the CS8416. Please refer to the CS8416 data sheet for details on automatic clock switching operation.This oscillator is not populated.

1.6 Analog Input

RCA phono connectors supply the CS424xx analog inputs through unity gain, AC-coupled single-to-differential circuits (see Figure 8). Each input circuit is biased to match the 2.7V

the CS424xx converter to full scale.

VQ, and a 1V

DC

differential signal will drive

RMS

1.7 Analog Outputs

Each CS424xx analog output is routed through a differential to single-ended, unity-gain low pass filter, which is ACcoupled to an RCA phono jack (see Figures 9 through 12). The analog output filter on the CDB42428 has been designed to add flexibility when evaluating the CS424xx DAC outputs. The output filter was designed in a two stage

format, with the first stage being an optional instrumentation amplifier, and the second stage a 2-pole butterworth

low pass filter.

4

Page 5

CDB42428

The 2-pole low pass filter provides an example of an inexpensive circuit with good distortion and dynamic range performance. It is designed to have the in-band impedance matched between the positive and negative legs. It also

provides a balanced to single-ended conversion for standard un-balanced outputs. Evaluate this circuit by placing

the FILT jumpers (three per output channel) to position 1 (selectable by J9, J10 & J11 for OUTA1, etc.).

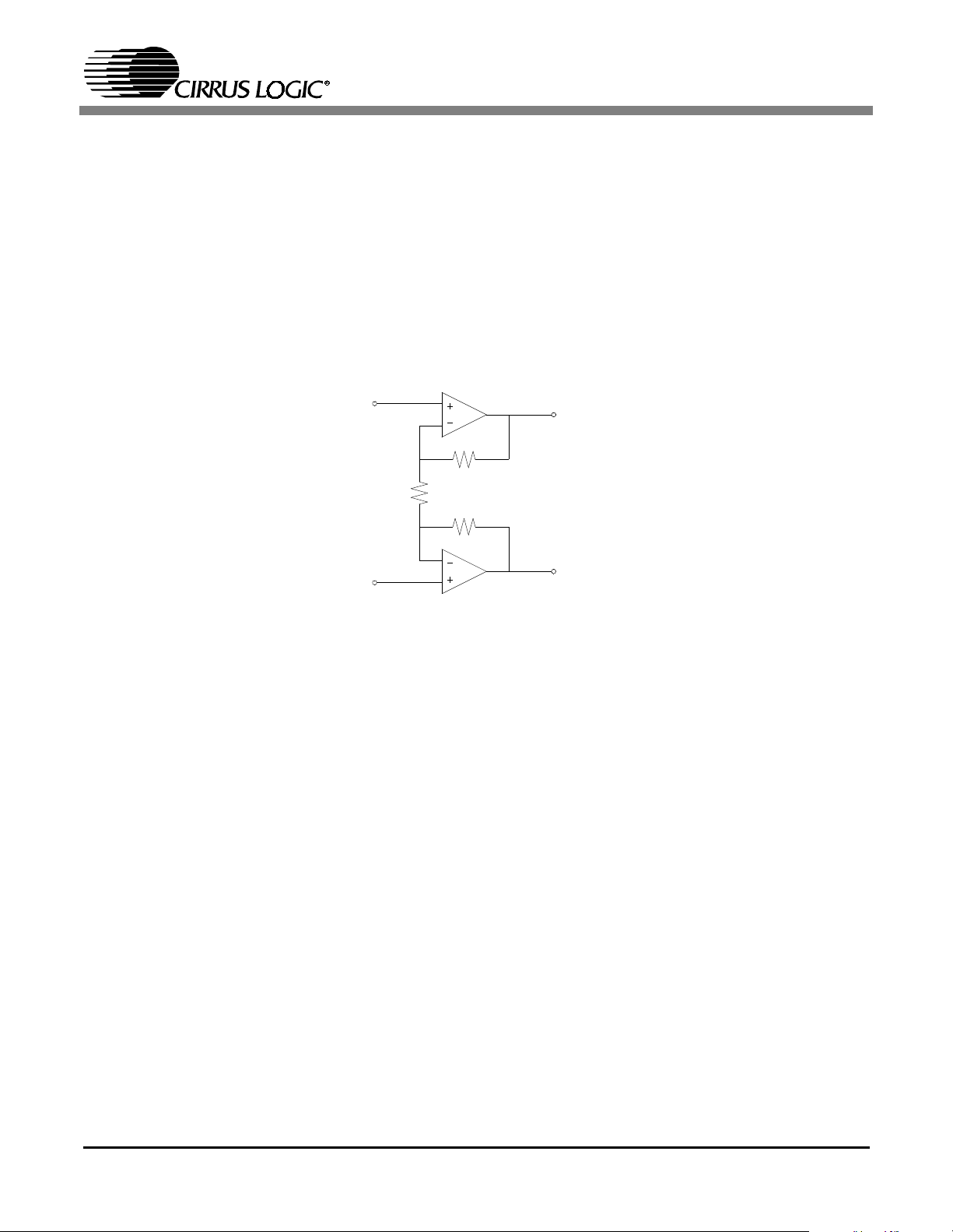

The instrumentation amplifier is optionally inserted before the LPF by changing the FILT jumpers to position 2. The

instrumentation amplifier incorporates a 5x gain (+14dB) which effectively lowers the noise contribution of the following 2-pole LPF. This improves the overall dynamic range of the system. The gain of this stage is determined from

the following equation:

Gain 1

The resistor designated by R

feedback resistors on the two sides of the instrumentation amp ‘R’ must be equal.

(see Figure 1) can be adjusted to change the gain of the instrumentation amp. The

2

2R()

------------+=

R

2

IN+

R

R2

R

IN-

Figure 1. Instrumentation Amplifier Configuration

A resistor divider pad (parallel combination of R59 // R56 // R80 and R93 for AOUTA1) has been placed after the

low pass filter to bring the circuit back to unity gain (selectable with jumper J12 for AOUTA1).

In the resistor divider pad, three 3.01 kΩ, 1/4 W, 1210 size resistors are used in parallel to provide a combined resistance of 1 kΩ and a combined power handling of 3/ 4W. This is done to provide sufficient power handling capability to accommodate the high signal levels output from the instrumentation amplifier stage. When not using the

instrumentation amplifier, these resistors may be reduced to a single 1kΩ, 1/10 W, 0805 size resistor (for muting

attenuation purposes).

In certain places throughout the output circuit, 1 /8W, 1206 size and 1/4W, 1210 size resistors are used. Similar to

the parallel resistors in the resistor divider pad, these are used to provide sufficient power handling capability in order

to accommodate the high signal levels output from the instrumentation amplifier stage. When not using the instrumentation amplifier, these resistors may all be replaced with 1/ 10W, 0805 size resistors.

The attenuation provided by the output mute transistor (Q2 for OUTA1) is determined by the resistor-divider formed

between the collector-emitter on-resistance and the output resistor of the LPF. The greater the output resistor, the

greater the attenuation will be for a given transistor. The trade off is that a high output impedance is not usually desirable, and may affect the voltage transfer to the next stage based upon its input impedance.

The same resistor that affects the transistor mute level also affects the HPF formed with the output DC-block capacitor (C71 for OUTA1). For LPF configuration 2, the values for the DC-block capacitor and output resistor pad were

chosen to give uniform distortion performance across the audio bandwidth, particularly at low frequency. The HPF

formed by this R-C pair must be such that the voltage across the aluminum electrolytic DC-block capacitor must be

a minimum at 20 Hz. This keeps the distortion due to the electrolytic's dielectric absorption properties to a minimum.

For a design utilizing only LPF configuration 1, there is no post-LPF resistor-divider pad, and a much smaller value

capacitor can be used.

OUT+

OUT-

5

Page 6

CDB42428

1.8 CPLD

The CPLD controls the on-board signal routing and configuration (see Figure 14). The CPLD interfaces with the

computer software through the DB-25 parallel port header, or can communicate with an external processor via the

External Control header.

1.9 DB-25 Computer Parallel Port

On-board clock and data routing and configuration logic, as well as the CS424xx part are configured using a computer with the supplied Windows®-based software. The software communicates via the DB-25 parallel port interface

(see Figure 13) to a local CPLD that can configure all parts on the board.

1.10 External Control Header

A 26-pin dual-row header allows access to the control signals needed to configure the CS424xx. The external controller has access to the CS424xx I

able (see Figure 13). All control header signals are buffered, and are referenced to VLC levels. See Table 3 for a

complete description of External Control Header signals.

1.11 DSP Header

A 32-pin dual-row header provides access to the serial audio signals required to interface with a DSP (see Figure 4).

Either the CS42428 (using the PLL recovered from the input ADC_LRCK or the OMCK oscillator), the CS8416 or

the DSP header can be the master of the MCLK signal. The CS8416 can supply the DSP header with its recovered

master clock (RMCK), or pass the local oscillator-sourced OMCK (of the CS8416).

The CS424xx ADC and DAC ports are individually selectable to be master or slave, and should source/receive their

clocks to/from the DSP as required. All serial port timings must be synchronous to the CS424xx OMCK or RMCK whichever is used to clock the codec. See the data sheet for a complete description of serial port modes of operation.

All DSP header signals are buffered, and are referenced to VLS levels. DSP interface power VLS and ground are

supplied to the header. See Table 4 for a complete description of DSP Header signals.

2

C/SPI signals, master mute and reset, and the CS424xx interrupt signal is avail-

1.12 LED Function Indicator

D1 (see Figure 13) indicates that a master reset condition has occurred on the board. D4 (see Figure 14) is sourced

from the CPLD and is currently unsupported.

1.13 Power

Power can easily be supplied to the evaluation board through three binding posts, all referenced to the single black

binding post ground connector (see Figure 15).

Supply +18.0 VDC to the green binding post to provide the positive analog rail. Supply -18.0 VDC to the yellow binding post to provide the negative analog rail. +18 V and -18 V supply power to the op-amps and can be +/-12 to +/18 volts (must be +/-18 V when filter 2 is selected).

Supply +5.0 VDC to the red binding post. This directly supplies the digital +5 V, is regulated down to provide the

digital +3.3 V, and is filtered to supply VLC, and VA.

VLS and VD must be individually set with jumpers to either +3.3 V or +5 V.

1.14 Grounding and Power Supply Decoupling

The CS424xx requires careful attention to power supply and grounding arrangements to optimize performance.

Figures 18 and 19 detail the routing and component placement for both top and bottom layers of the demonstration

board. Power supply decoupling capacitors are located as close to the CS424xx as possible. Extensive use of

ground plane fill in the demonstration board yields large reductions in radiated noise.

CONNECTOR INPUT/OUTPUT SIGNAL PRESENT

+5V Input + 5VDC power

-18V Input -18 to -12 VDC negative supply for the op-amps

+18V Input +12 to +18 VDC positive supply for the op-amps

GND Input Ground connection from power supply

J39 Input CS8416 digital audio interface input via coax

Table 1. System Connections

6

Page 7

CDB42428

OPT4 Input CS8416 digital audio interface input via optical

SPDIF TX - J2 Output CS8406 digital audio interface output via coax

SPDIF TX - OPT2 Output CS8406 digital audio interface output via optical

PC Port - J22 Input/Output

EXTERNAL CONTROL

Input/Output

Parallel connection to computer for SPI / I

2

I/O for SPI / I

C control port signals - see signal descriptions below

HEADER - J17

DSP HEADER - J36 Input/Output I/O for DSP serial port signals - see signal descriptions below

ANALOG IN LFT/RT Input

RCA phono jacks for analog input signal to CS424xx internal ADCs

EXT A/D #1 LEFT/RIGHT Input RCA phono jacks for analog input signal to CS5361 ADC #1

EXT A/D #2 LEFT/RIGHT Input RCA phono jacks for analog input signal to CS5361 ADC #2

OUT_A1 to OUT_B4 Output RCA phono jacks for channels A1 to B4 analog outputs

Table 1. System Connections

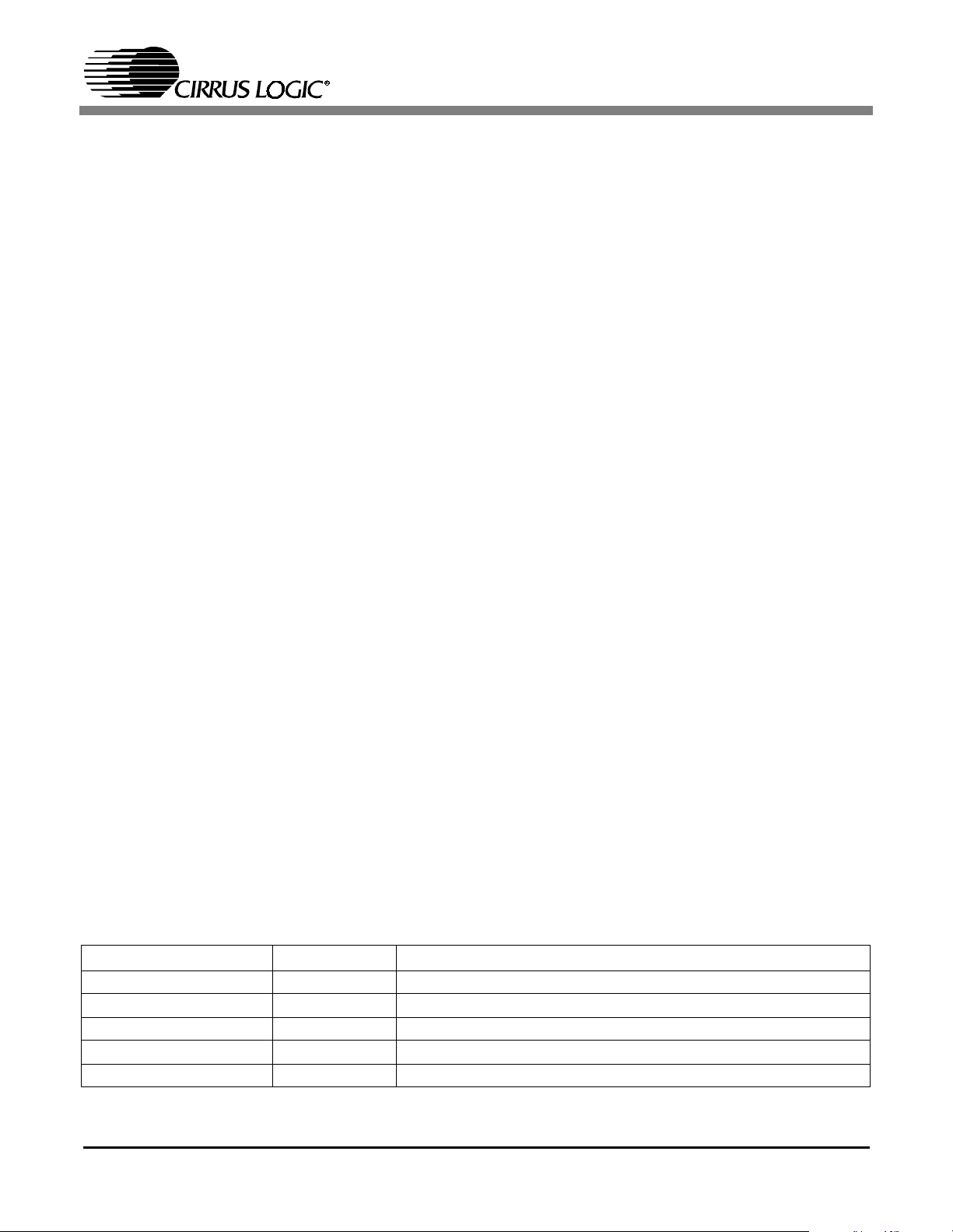

JUMPER / SWITCH PURPOSE POSITION FUNCTION SELECTED

J37 Selects source of voltage for the

VLS supplies

J38 Selects source of voltage for the

VD supply

S2 Stand-Alone Mode Select SAM0

J9,J10,J11

DAC Output Filter select - FILT *1

+3.3 V

*+5 V

+3.3 V

*+5 V

SAM1

Voltage source is +3.3 V regulator

Voltage source is +5 V binding post

Voltage source is +3.3 V regulator

Voltage source is +5 V binding post

Stand-Alone Modes are for debug use

and are presently unsupported

Selects standard 2-pole LPF

J13,J15,J16

J18,J19,J20

2

Selects instrumentation-amp/LPF/pad

J23,J25,J26

J28,J29,J30

J32,J34,J35

J39,J40,J41

J43,J45,J46

*Default Factory Settings

2

C control port signals

Table 2. Jumper Settings

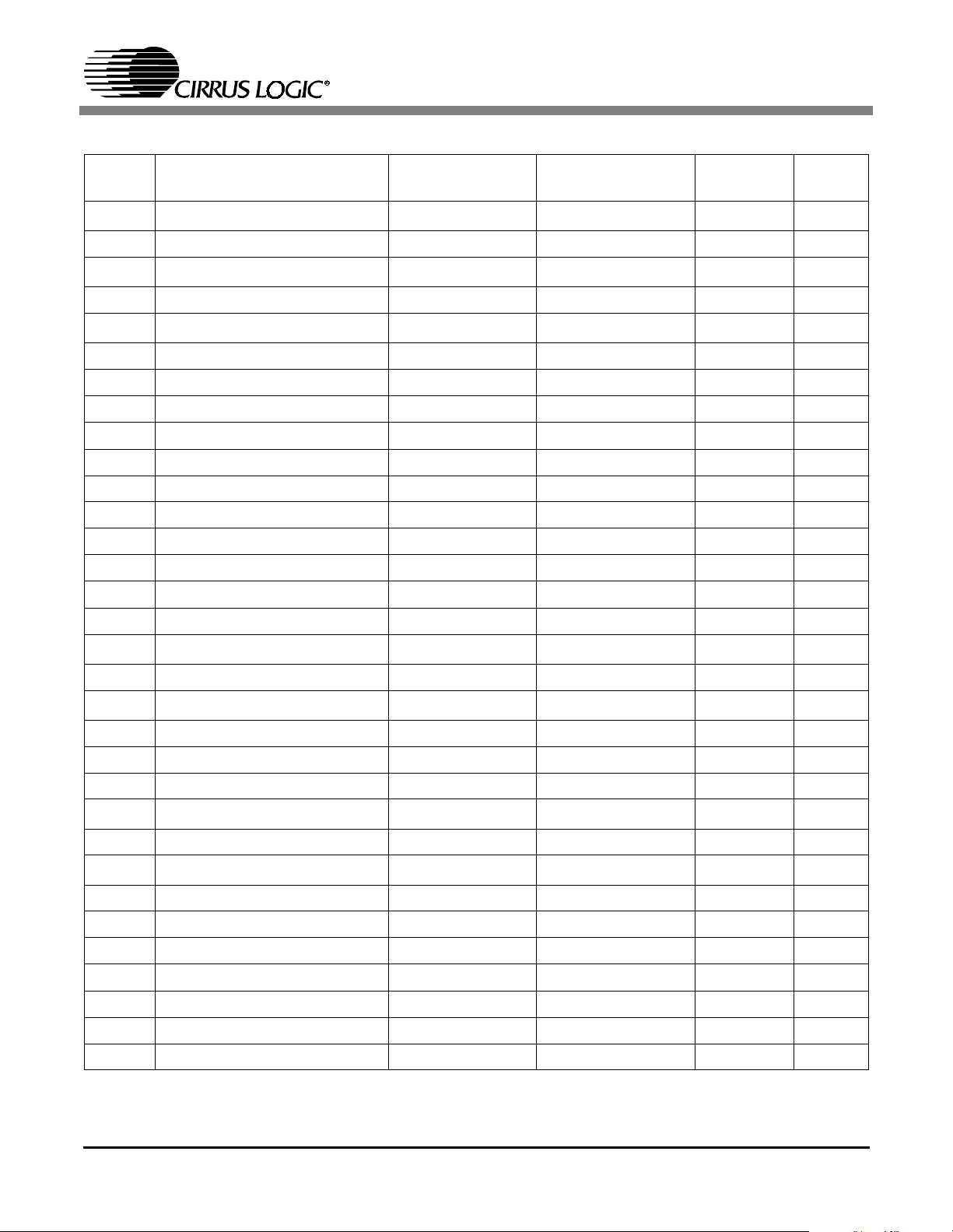

1.15 External Control Header Signals

Header

Pin #

1 External Control Present Signal CTRL EXT_CONTROL_PRESENT- - -

2 Ground CDB GND - -

3

Address Bit 0 (I

4 Ground CDB GND - -

5

Address Bit 1 (I

6 Ground CDB GND - -

7

SDA (I

8 Ground CDB GND - -

9 Serial Control Port Clock CTRL SCL/CCLK 74VHC125 VLC

Signal Description Source Schematic Signal Name Buffer Buffer

2

C) / CS- (SPI)

2

C) / CDIN (SPI)

2

C) / CDOUT (SPI)

CTRL AD0/CS 74VHC125 VLC

CTRL AD1/CDIN 74VHC125 VLC

CTRL or CS424xx

SDA/CDOUT MOSFET VLC

Table 3. CS424xx External Control Header Signals

Vol t a ge

7

Page 8

CDB42428

Header

Pin #

10 Ground CDB GND - -

11 Master MUTE to all Outputs CTRL EXT_MUTE 74VHC125 VLC

12 Ground CDB GND - -

13 Master RESET CTRL EXT_RESET Diode -

14 Ground CDB GND - -

15

CS424xx Interrupt (Programmable) CS424xx

16 Ground CDB GND - -

17

Enable external I

18 Ground CDB GND - -

19

Enable external I

20 Ground CDB GND - -

Signal Description Source Schematic Signal Name Buffer Buffer

EXT_HDR_INT 74VHC125 VLC

2

C interface

2

C interface

Table 3. CS424xx External Control Header Signals (Continued)

CTRL EXT_EN_SCL 74VHC125 VLS

CTRL EXT_EN_SDA 74VHC125 VLS

Vol t a ge

8

Page 9

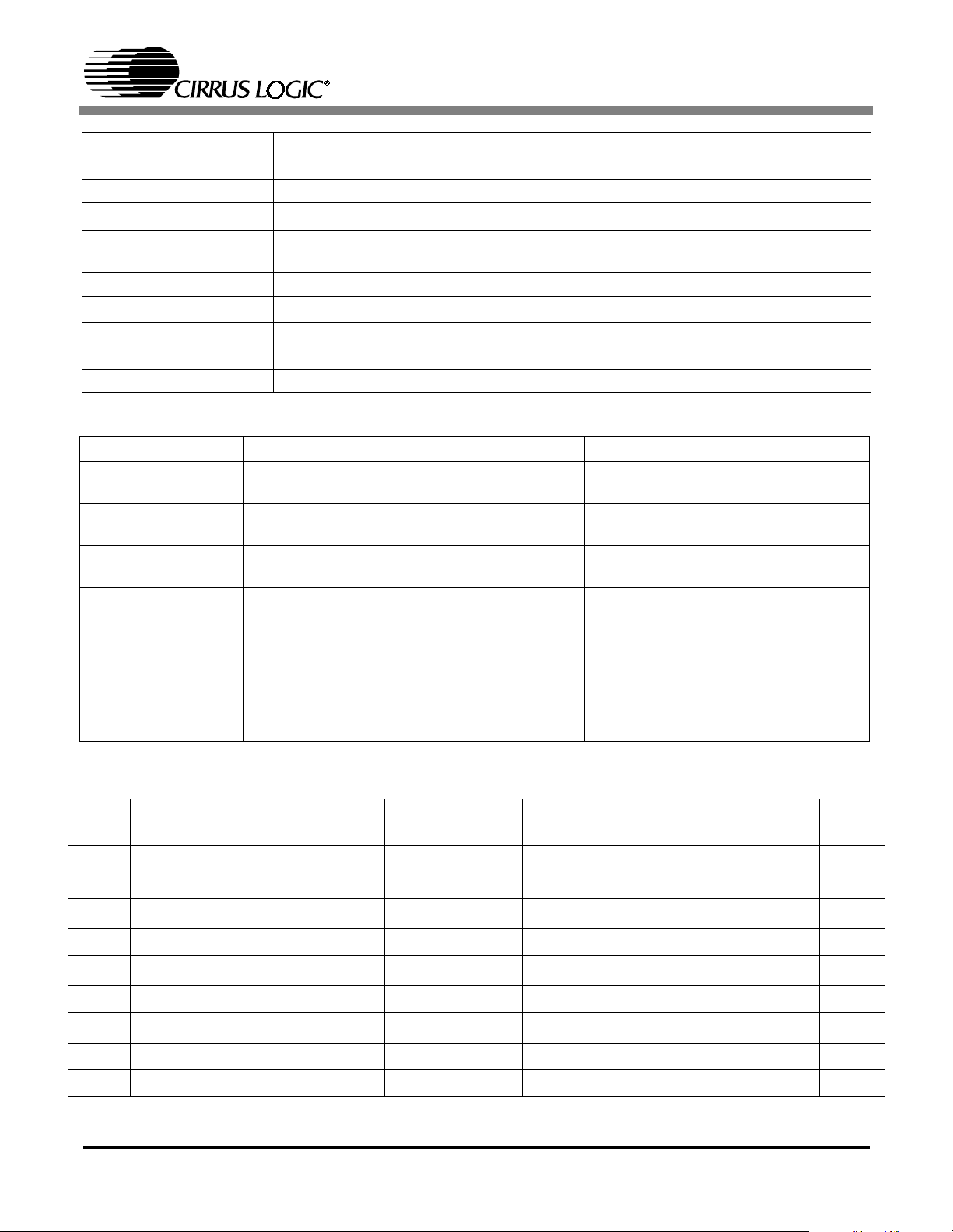

1.16 DSP Header Signals

CDB42428

Header

Pin #

1 Master Clock

2 Ground CDB GND - -

3 DAC port LRCK

4 Ground CDB GND - -

5 DAC port SCLK

6 Ground CDB GND - -

7 DAC port SDATA Input 1 DSP DSP_SDAT1 74VHC125 VLS

8 Ground CDB GND - -

9 DAC port SDATA Input 2 DSP DSP_SDAT2 74VHC125 VLS

10 Ground CDB GND - -

11 DAC port SDATA Input 3 DSP DSP_SDAT3 74VHC125 VLS

12 Ground CDB GND - -

13 DAC port SDATA Input 4 DSP DSP_SDAT4 74VHC125 VLS

14 Ground CDB GND - -

15 no connect - - - -

16 Ground CDB GND - -

Signal Description Source Schematic

Signal Name

CS424xx or DSP

CS424xx or DSP

CS424xx or DSP

DSP_MCLK 74VHC125 VLS

DSP_DAC_LRCK 74VHC125 VLS

DSP_DAC_SCLK 74VHC125 VLS

Buffer Buffer

Vol t a ge

17 ADC port LRCK

18 Ground CDB GND - -

19 ADC port SCLK

20 Ground CDB GND - -

21 no connect - - - -

22 Ground CDB GND - -

23 ADC port SDATA Output

24 Ground CDB GND - -

25 Unused Buffered Output

26 Ground CDB GND - -

27 No Connect - - - -

28 Ground CDB GND - -

29 Serial Port Interface Power CDB VLS - -

30 Ground CDB GND - -

31 Serial Port Interface Power CDB VLS - -

32 Ground CDB GND - -

Table 4. CS424xx DS P Header Signals

CS424xx or DSP

CS424xx or DSP

CS424xx

-

DSP_ADC_LRCK 74VHC125 VLS

DSP_ADC_SCLK 74VHC125 VLS

DSP_ADC_SDOUT 74VHC125 VLS

- 74VHC125 VLS

9

Page 10

CDB42428

2. INITIAL BOARD SETUP

2.1 Power Supplies:

1) Verify that all power supplies are off before making connections.

2) Connect a +5.0 VDC power supply to the +5 V (J48) red binding post. Select VLS and VD operating voltage by

placing a jumper on J37 and J38 to select either +5 V or +3.3 V.

3) Connect a +12.0 to +18.0 VDC power supply to the +18 V (J50) green binding post. If using the FILT position

number 2 for the output filter stage, then supply +18.0 V only.

4) Connect a -12.0 to -18.0 VDC power supply to the -18 V (J51) yellow binding post. If using the FILT position

number 2 for the output filter stage, then supply -18.0 V only.

5) Connect the common ground of the power supplies to the GND (J49) binding post.

6) Attach parallel port cable between board and computer.

7) Attach all required analog and digital cables to the board jacks and connectors.

8) If using the DSP Header connection, attach the required user supplied flat ribbon cable to the header with the

power supplies turned off.

9) If using the External Control Header connection, attach the required user supplied flat ribbon cable to the header

with the power supplies turned off. Note that external controller must ground the EXT_CONTROL_PRESENTsignal to gain control of the I

1 and 2 together.

10) With all cables and connections in place, turn on the power supplies to the board. Turn on supplies in this order:

+5 V, +18 V, -18 V.

11) Press and release the MASTER RESET switch S1. The LED, D1, will illuminate as long as S1 is depressed indicating a reset condition. Once S1 is released, the LED should turn off. If it remains on, an error has occurred.

At this point, power off the power supplies and re-check all connections. Apply power to the board and press

and release S1. Once the LED has turned off, the board should now be ready for setup and use.

2

C/SPI signals. This can be done easily by connecting External Control Header pins

2.2 Installing the Software:

1) Copy the “CDB GUI” folder and all of its contents from the included CD to a convenient location on your PC.

2) If desired, create a shortcut to CDB425xx.EXE on your desktop. You should now be able to run CDB425xx.EXE.

Double-click on CDB425xx.EXE or its shortcut. Note that the software will configure itself to operate with a

CDB424xx depending upon which is connected to the parallel port.

3) Select the LPT port you are using to connect to the CDB42428.

4) Shut down the application, reset the board, and then restart the application.

10

Page 11

CDB42428

3. CDB425XX.EXE USER'S GUIDE

3.1 Main Window

The main window of the CDB42428 control application allows the user to configure the CDB42428 inter-board routing of clocks and data, as well as setup the CS5361, CS8416 and CS8406 parts. To make changes to the CS5361,

CS8406, CS8416, or inter-board routing, the “Configure Board” radio button must be selected.

The RESET CS425xx button will reset only the part. The MASTER RESET button will reset the CS424xx, as well

as reset the board into its default state.

3.2 CS42428 Window

To configure the CS424xx, the “Configure CS424xx” radio button must be selected, then press the “CS424xx” button. This will bring up the complete CS424xx configuration window.

3.3 Preset Scripts

To make configuring the board and part easier, preset scripts can be saved and recalled. A preset script is a “snapshot” of all GUI board and component settings. This can done using the File pulldown menu and choosing Load or

Save. Scripts are saved with the default .LVS extension, and when loaded, will create a .LOG file. There are several

preset scripts included with the software. The following sections represent four common setup modes with scripts

for quick evaluation of the board.

3.4 Quick Start Preset - Analog In to Analog Out

To measure analog in to analog out performance, you will need the following:

• CS424xx Demonstration Board

• +18 VDC, -18 VDC, and +5 VDC power supplies

• Analog signal source and analyzer

• Windows® compatible computer with parallel port cable and CDB425xx software

Step 1 - Follow Initial Board Setup procedure as described above

Step 2 - Select Output Filter Jumpers

Set all CDB42428 analog output filter jumpers to the FILT2 settings.

Step 3 - Connect to Windows® Software

Connect the computer to the board and launch the CDB425xx software.

Step 4 - Connect Signal Source

Connect the analog output from the analyzer to the Left Analog Input J7. Connect J11 analog OUTA1 RCA to the

input of the analyzer. Set the analyzer output to 1.0 VRMS, 1 kHz. Set the analyzer input to measure signal level

and apply a 22 Hz-22 kHz filter.

Step 5 - Configure the Board

Using the Windows® software, load the preset script “Single Speed Analog In To Analog Out.LVS”. This preset will

configure the CS424xx to use OMCK as the master clock, DAC and ADC ports will be masters, and the

ADC_SDOUT data will source all DAC_SDIN inputs. The left/right analog inputs will appear at all odd/even analog

outputs. The single speed sample rate will be 48 kHz based upon the 24.576 MHz OMCK. You may load the similar

double speed or quad speed presets to investigate higher sample rates.

Step 6 - Measure Audio

You should now have audio appearing at the Analog A1 output.

3.5 Quick Start Preset - Analog In to Digital Out

To measure the analog to digital converter performance, you will need the following:

• CS424xx Demonstration Board

• +18 VDC, -18 VDC, and +5 VDC power supplies

11

Page 12

CDB42428

• Analog signal source and analyzer

• Digital signal source and analyzer

• Windows® compatible computer with parallel port cable and CDB425xx software

Step 1 - Follow Initial Board Setup procedure as described above

Step 2 - Connect to Windows® Software

Connect the computer to the board and launch the CDB425xx software.

Step 3 - Connect Signal Source

Connect the analog output from the analyzer to the Left Analog Input J7. Connect the CS8406 digital output (coax

J2 or optical OPT2) to the input of the analyzer. Set the analyzer output to 1.0 VRMS, 1 kHz. Set the analyzer input

to measure digital signal level and apply a 22 Hz-22 kHz filter.

Step 4 - Configure the Board

Using the Windows® software, load the preset script “Single Speed Analog In To Digital Out.LVS”. This preset will

configure the CS424xx to use OMCK as the master clock, DAC and ADC ports will be masters, and the ADC clocks

data will source the CS8406 inputs. The CS8406 will output the ADC digital data to both the optical and RCA jacks.

The single speed sample rate will be 48 kHz based upon the 24.576 MHz OMCK. You may load the similar double

speed or quad speed presets to investigate higher sample rates.

Step 5 - Measure Audio

You should now have digital audio appearing at the ADC_SDOUT port and the CS8406 digital output.

3.6 Quick Start Guide - Digital In to Analog Out

To measure digital to analog performance, you will need the following:

• CS424xx Demonstration Board

• +18 VDC, -18 VDC, and +5 VDC power supplies

• Analog signal source and analyzer

• Digital signal source and analyzer

• Windows® compatible computer with parallel port cable and CDB425xx software

Step 1 - Follow Initial Board Setup procedure as described above

Step 2 - Select Output Filter Jumpers

Set all CDB42428 analog output filter jumpers to the FILT2 settings.

Step 3 - Connect to Windows® Software

Connect the computer to the board and launch the CDB425xx software.

Step 4 - Connect Signal Source

Connect the S/PDIF digital output from the analyzer to the optical input connector OPT4. Connect the analog OUTA1

RCA phono jack J11 to the input of the analyzer. Set the analyzer output to 0 dBFS, 1 kHz, sample rate at 48 kHz.

Set the analyzer input to measure signal level and apply a 22 Hz-22 kHz filter.

Step 5 - Configure the Board

Using the Windows® software, load the preset script “Single Speed Optical In to Analog Out.LVS”. This preset will

configure the CS8416 to source all DAC_SDIN inputs. The test source left/right data will appear at all odd/even analog outputs. You may load the similar double speed or quad speed presets to investigate higher sample rates, but

you must be sure to supply an appropriate speed SPDIF signal.

Step 6 - Measure Audio

You should now have audio appearing at the Analog A1 output.

12

Page 13

CDB42428

3.7 Quick Start Preset - One-Line Mode (OLM)

To measure one-line mode analog in to analog out performance, you will need the following:

• CS424xx Demonstration Board

• +18 VDC, -18 VDC, and +5 VDC power supplies

• Analog signal source and analyzer

• Windows® compatible computer with parallel port cable and CDB425xx software

Step 1 - Follow Initial Board Setup procedure as described above

Step 2 - Select Output Filter Jumpers

Set all CDB42428 analog output filter jumpers to the FILT2 settings.

Step 3 - Connect to Windows® Software

Connect the computer to the board and launch the CDB425xx software.

Step 4 - Connect Signal Source

Connect the analog output from the analyzer to the Left Analog Input J7. Connect J11 analog OUTA1 RCA to the

input of the analyzer. Set the analyzer output to 1.0 VRMS, 1 kHz. Set the analyzer input to measure signal level

and apply a 22 Hz-22 kHz filter.

Step 5 - Configure the Board

Using the Windows® software, load the preset script “One-Line Mode.LVS”. This preset will configure the CS424xx

to use OMCK as the master clock, DAC and ADC ports will be masters, and the ADC_SDOUT data will source the

DAC_SDIN1 input. The left/right analog inputs will appear at OUT_A1 and OUT_B1 analog outputs; the

EXT_ADC#1 Left and Right inputs will appear on the OUT_A2 and OUT_B2 analog outputs, respectively; the

EXT_ADC#2 Left and Right inputs will appear on the OUT_A3 and OUT_B3 analog outputs, respectively. The sample rate will be 48 kHz based upon the 24.576 MHz OMCK.

Step 6 - Measure Audio

You should now have audio appearing at the Analog outputs.

13

Page 14

4. MUTING SCHEME

CDB42428

CHANNEL

MUTE CONTROL

1

and MUTEC

EXT_MUTE

and MUTEC

EXT_MUTE

2

or

and GPO7

EXT_MUTE

and MUTEC

EXT_MUTE

3 - 8

or

and GPO6

EXT_MUTE

MUTE CH 1

MUTE CH 2

+V

MUTEC

EXT_MUTE

EN_MUTE7

GPO7

Figure 2. Output Channel Mute Select

MUTEC

MUTE CH 3 - 8

MUTEC

EN_MUTE6

GPO6

14

Page 15

5. SCHEMATICS AND LAYOUT

CDB42428

Figure 3. CS424xx

15

Page 16

CDB42428

16

Figure 4. Clocks, Data, and DSP Header

Page 17

CDB42428

Figure 5. SPDIF

17

Page 18

CDB42428

18

Figure 6. CS5361 External ADC #1

Page 19

CDB42428

Figure 7. CS5361 External ADC #2

19

Page 20

CDB42428

20

Figure 8. CS424xx Analog Inputs

Page 21

CDB42428

Figure 9. Analog Outputs A1 and B1

21

Page 22

CDB42428

22

Figure 10. Analog Outputs A2 and B2

Page 23

CDB42428

Figure 11. Analog Outputs A3 and B3

23

Page 24

CDB42428

24

Figure 12. Analog Outputs A4 and B4

Page 25

CDB42428

Figure 13. DB-25, Ext Ctrl Header, Reset

25

Page 26

CDB42428

Figure 14. CPLD

26

Page 27

CDB42428

Figure 15. Power

27

Page 28

CDB42428

Figure 16. CS8416

28

Page 29

CDB42428

Figure 17. Component Placement and Reference Designators

29

Page 30

CDB42428

Figure 18. Top Layer

30

Page 31

CDB42428

Figure 19. Bottom Layer

31

Page 32

CDB42428

6. ADDENDUM

The following silkscreen markings on the evaluation board are mislabeled and should be labeled as specified (all

schematic labels in Figures 3-16 are correct):

1) DSP HEADER pin 23 (DAC_SDOUT) should be labeled “DSP_ADC_SDOUT”.

2) DSP HEADER pin 25 (ADC_SDOUT) should be labeled “DSPHDR_PIN25”.

3) Test point ADC_SDOUT should be labeled “U27_PIN54”.

4) Test point DAC_SDOUT should be labeled “ADC_SDOUT”.

Contacting Cirrus Logic Support

For all product questions and inquiries contact a Cirrus Logic Sales Representative.

To find one nearest you go to www.cirrus.com

IMPORTANT NOTICE

Cirrus Logic, Inc. and its subsidiaries ("Cirrus") believe that the information contained in this document is accurate and reliable. Ho wever, the information is subject to change without notice and is provided "AS IS" without warranty of any kind (expres s or implied) . Cust omers are advised to obtain the latest version of

relevant information to verify, before placing orders, that information being relied on is current and complete. All products are sold subject to the te rms and conditions of sale supplied at the time of order acknowledgment, including those pertaining to warranty, patent infringement, and limita tion of li a bility. N o responsibility is assum ed by C irrus fo r the u se o f this information , includ in g us e of this infor m ation as the basis for man ufacture or sale of any items, or for infringement

of patents or other rights of third parties. This document is the property of Cirrus and by furnishing this information, Cirr us grants no licens e, expres s or implied

under any patents, mask work rights, copyrights, trademarks, trade secrets or other intellectual property rights. Cirrus owns th e copyrights associated with the

information contained herein and gives consent for copies to be made of the information only for use within your organization wi th respec t to C irru s i ntegrated

circuits or other products of Cirrus. This consent does not extend to other copying such as copying for general distribution, advertising or promotional purposes,

or for creating any work for resale.

An export permit needs to be obtained from the competent authorities of the Japanese Government if any of the products or technologies described in this material and controlled under the "Foreign Exchange and Foreign Trade Law" is to be exported or taken out of Japan. An export license and/or quota needs to be

obtained from the competent authorities of the Chinese Government if any of the products or technologies described in this material is subject to t he PRC Foreign

Trade Law and is to be exported or taken out of the PRC.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF DEATH, PERSONAL INJURY, OR SEVERE

PROPERTY OR ENVIRONMENTAL DAMAGE ("CRITICAL APPLICATIONS"). CIRRUS PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARRANTED FOR USE IN AIRCRAFT SYSTEMS, MILITARY APPLICATIONS, PRODUCTS SURGICALLY IMPLANTED INTO THE BODY, LIFE SUPPORT PRODUCTS

OR OTHER CRITICAL APPLICATIONS (INCLUDING MEDICAL DEVICES, AIRCRAFT SYSTEMS OR COMPONENTS AND PERSONAL OR AUTOMOTIVE

SAFETY OR SECURITY DEVICES). INCLUSION OF CIRRUS PRODUCTS IN SUCH APPLICATIONS IS UNDERSTOOD TO BE FULLY AT THE CUSTOMER'S RISK AND CIRRUS DISCLAIMS AND MAKES NO WA RRA NTY, EXPRESS, STATUTOR Y OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSE, WITH REGARD TO ANY CIRRUS PRODUCT THAT IS USED IN SUCH A MANNER. IF

THE CUSTOMER OR CUSTOMER'S CUSTOMER USES OR PERMITS THE USE OF CIRRUS PRODUCTS IN CRITICAL APPLICATIONS, CUSTOMER

AGREES, BY SUCH USE, TO FULLY INDEMNIFY CIRRUS, ITS OFFICERS, DIRECTORS, EMPLOYEES, DISTRIBUTORS AND OTHER AGENTS FROM

ANY AND ALL LIABILI TY, INCLUDING ATTORNEYS' FEES AND COSTS, THAT MAY RESULT FROM OR ARISE IN CONNECTION WITH THESE USES.

Cirrus Logic, Cirrus, and the Cirrus Logic logo designs are trademarks of Cirrus Logic, Inc. All other brand and product names in this document may be trademarks or service marks of their respective owners.

I2C is a registered trademark of Philips Semiconductor. Purchase of I2C Components of Cirrus Logic, Inc., or one of its sublicensed Associated Companies

conveys a license under the Philips I2C Patent Rights to use those components in a standard I2C system.

Microsoft Windows is a registered trademark of Microsoft Corporation.

32

Loading...

Loading...