Page 1

Application Note

Interfacing the CS5525/6/9 to the PIC16F84

By Keith Coffey

AN88

INTRODUCTION

This applica tion note details the interfac e of Crys-

tal Semiconductor’s CS5525/6/9 Analog-to-Digital Converter (ADC) to the Microchip PIC16

microcontroller series. This note takes the reader

through a sim ple e xa mpl e desc ribin g h ow to co mmunicate w ith the ADC. All algo rithms discussed

are included in the Appendix at the end of this

note.

ADC DIGITAL INTERFACE

The CS5525/6/9 interfaces to the PIC16F84

through either a three-wire or a four-wire interface.

Figure 1 depict s the inte rface be tween the two devices. Though this software was written to interface to Port A (RA) on th e PIC16F 84 with a four wire interfa ce, the algorit hms can be easily modified to work with the three-wire format.

The ADC’s serial port consists of four control

lines: CS

CS

, SCLK, SDI, and SDO.

, Chip S elect, is the contro l line w hich e nables

access to the serial port.

SCLK, Serial Clock, is the bit-clock which controls

the shifting of data to or from the ADC’s serial

port.

SDI, Serial Data In, is the data signal used to transfer data from the PIC16F84 to the ADC.

SDO, Serial Data Out, is the data signal used to

transfer output data from the ADC to the

PIC16F84.

SOFTWARE DESCRIPTION

This note presents algorithms to initialize the

PIC16F84 and the CS5525/6/9, perform a se l f-offset calibratio n, modi fy the C S5525/ 6/9 gai n register, and then acquire a conversion. Figure 2 depicts

CS5525/6/9 PIC16F84

CS

SDI

SDO

SCLK

Cirrus Logic, Inc.

Crystal Semiconductor Products Division

P.O. Box 17847, Austin, Texas 78760

(512) 445 7222 FAX: (512) 445 7581

http://www.crystal.com

NC (RA0)

RA1

RA2

RA3

Figure 1. 3-Wire and 4-Wire Interfaces

CS5525/6/9 PIC16F84

CS

SDI

SDO

SCLK

Copyright Cirrus Logic, I nc. 1997

(All Rights Reserv ed)

RA0

RA1

RA2

RA3

NOV ‘97

AN88Rev2

1

Page 2

AN88

a block diagra m overview. While readi ng this application note, please refer to the Appendix for the

code listing.

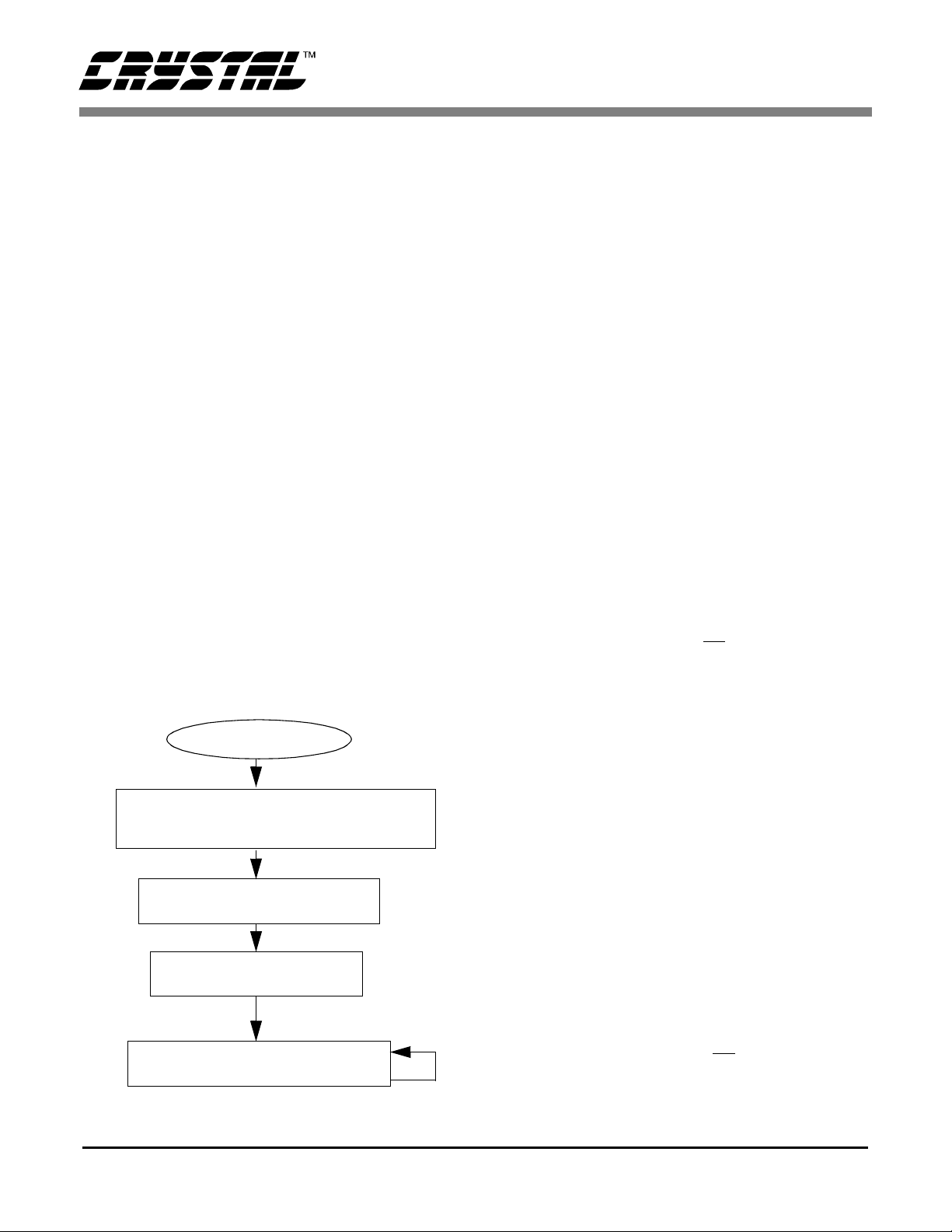

Initialize

Initialize is a subroutine that configures Port A

(RA) on the PIC1 6F84 a nd place s the C S5525/ 6/9

in the command-state. First, RA’s data direction is

configured as dep ic te d i n Figure 1 (for more infor mation on configuring ports refer to Microchip’s

PIC16F8X Data Sheet). After configuring the port,

the control ler en te rs a de lay st ate t o al low tim e fo r

the CS5525/6 /9’s power-on-re set and oscillato r to

start-up (oscillator start-up time is typically 500

ms). The last step is to reinitialize the serial port on

the ADC (r einitializing t he serial port is unnecessary here, it was added for demonstration purposes

only). This is implemented by sending the converter sixteen byte s of logic 1’s foll owed by one fin al

byte, with its LSB logic 0. Once sent, the sequence

places the serial port of the ADC into the command-state, where it aw aits a valid command.

After returning to main, the software demo nstrates

how to calibra te the convert er’s offset.

START

INITIALIZE

MICROCONTROLLER/CS5525/6/9

SELF-OFFSET CAL.

MODIFY GAIN

ACQUIRE CONVERSION

Figure 2. CS5525/6/9 Software Flowchart

Self-Offset Calib r ation

Calibrate is a subroutine that calibrates the converter’s offset. Calibrate first sends 0x000001

(Hex) to the conf iguration register. This i nstructs

the converter to perform a self-offset calibration.

Then the Done Flag (D F) bit in th e configuration

register i s polled until set. Onc e DF is set, it indicates that a valid calibration was performed. To

minimize digital noise (while performing a calibration or a c onver sion ), ma ny sy ste m d esigners may

find it advantageous to add a software delay equivalent to a conversion or calibration cycle before

polling the DF bit.

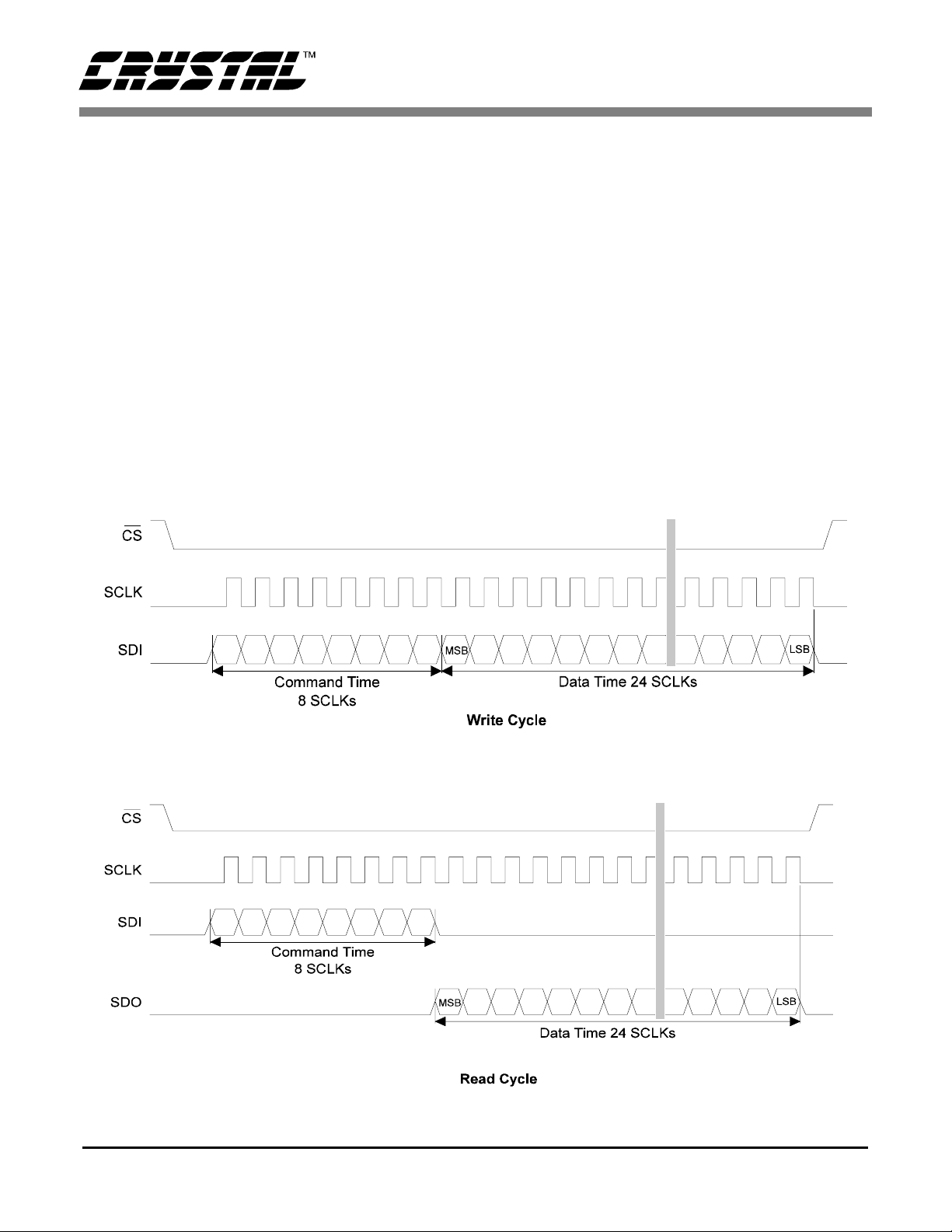

Read/Write Gain Register

To modify the gain register the command-byte and

data-byte variables are first initialized. This is accomplished by the MOVLW and MOVWF opcodes. The subroutine write_register uses these

variables to set th e conten ts of the gain regi ster in

the CS5525/6/9 to 0x800000 (HEX). To do this,

write_register first asserts CS

and then it calls

send_spi four times (once for the command-byte

and three a dditional times for t he 24 bit s of data).

Send_spi is a subroutine used to ‘bit-bang’ a byte of

information from the PIC16F84 to the CS5525/6/9.

A byte is tra nsferre d one bit at a time , MSB (most

significan t bit) first, by placing an info rmation b it

on RA1 (SDI) and then pulsing RA3 (SCLK). This

process is repeated eight times. Figure 3 depicts the

timing diag ram for t he write-c ycle in the CS5525/

6/9’s serial port. Th is al gorit hm de mo nstrat es how

to write to the g ain register . It doe s not pe rform a

gain calibration. To perform a gain calibration, follow the procedu r es ou tlined in the data shee t.

To verify if 0x800000 (HEX) was written to the

gain register, read_register is call ed. It dup licates

the read-cycle timing diagram depicted in Figure 4.

Read_register first asserts CS

and then calls

send_spi once to transfe r the com ma nd- byte to the

CS5525/6/9. This places the converter into the

2 AN88Rev2

Page 3

AN88

data-state where it wa its unt il data is rea d from its

serial port. To re ceiv e th e da ta, read_register ca ll s

receive_spi th ree times. Receive_sp i is a subroutine

used to ‘bit-ba ng’ a byte of informa tion from the

ADC to the PIC16F84. Similar to send_spi,

receive_spi acquires this information one bit at a

time MSB first. When the transfer is complete, the

variables high byte, midbyte, and lowbyte contain

the CS5525/6/ 9’s 24-bit gain registe r.

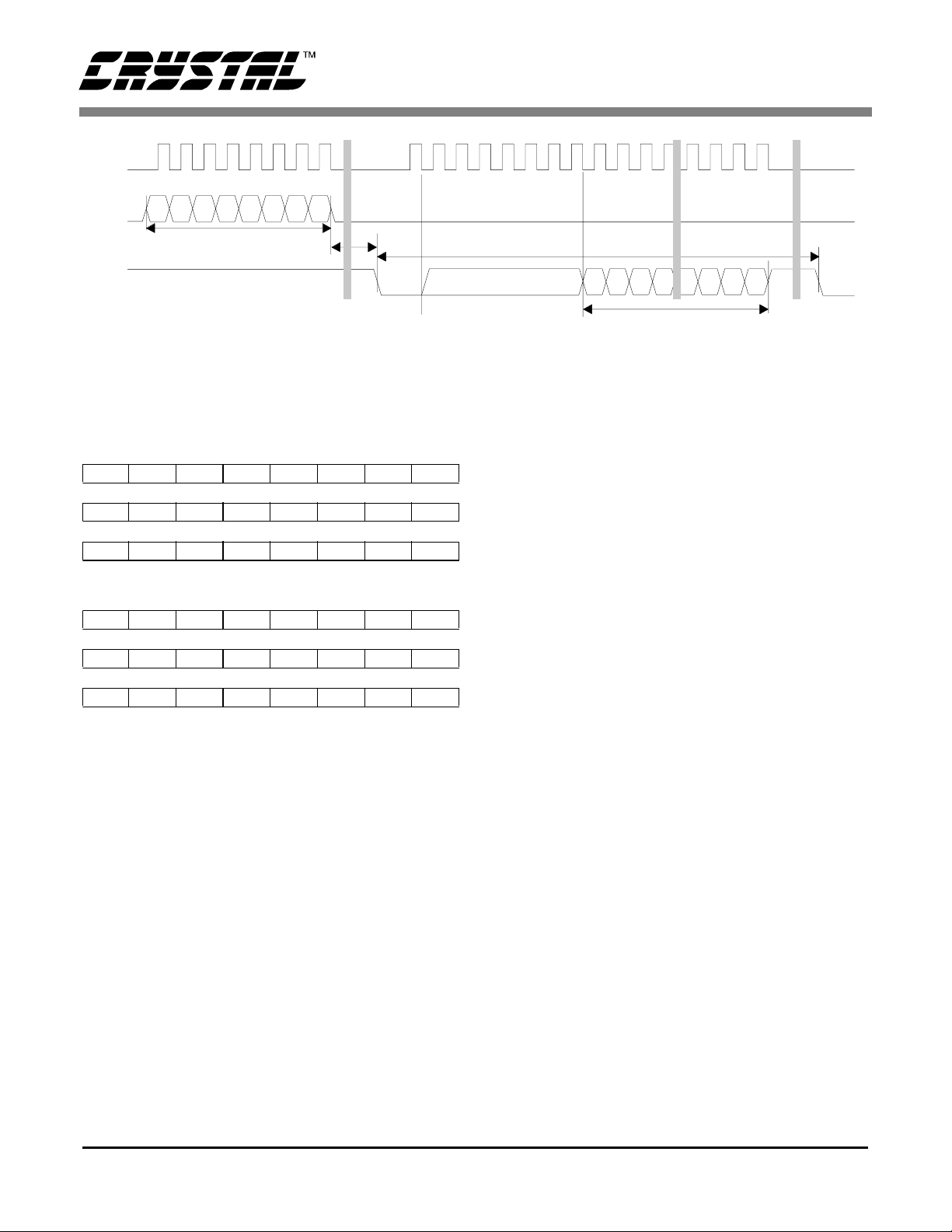

Acquire Conversion

To acquire a c onversion the subroutine convert is

called. Convert se nds the command-byte 0x0 C to

the convert er. This instructs the converter to perform a single conversion. Then the Done Flag (DF)

bit in the configuration register is polled. When set,

DF indicates that a conversion was performed.

Once DF is s et, the cont roller reads the conve rs ion

data register to acquire the conversion.Figure 6 depicts how 16-bit and 2 0-bit conversion words are

stored in th e microcontroller.

An alternate m ethod ca n be used to acquire a conversion. By se tting the Port Flag bit (PF, the fifth

bit in the configuration register), SDO’s function is

modified to fall to logic 0 when a conversion is

complete (refer to Fi gure 5). By tying SDO t o the

controller’s interrupt pin, conversions can be acquired via an interrupt service routine.

Figure 3. Write-Cycle Timing

Figure 4. Read-Cycle Timing

AN88Rev2 3

Page 4

SCLK

SDI

*

t

ommand Time

C

8SCLKs

DO

S

td = XIN/OWR clock cycles for each conversion except the

*

first conversion whichwilltakeXIN/OWR+ 7 clockcycles

Figure 5. Conversion/Acquisition Cycle with the PF Bit Asserted

d

Data SDO Continuous Conversion Read (PF bit = 1)

SCLKs Clear SDO Flag

8

AN88

IN/OWR

X

Clock Cycles

SB

M

ataTime

D

24 SCLKs

SB

L

MSB High-Byte

D19 D18 D17 D16 D15 D14 D13 D12

Mid-Byte

D11 D10 D9 D8 D7 D6 D5 D4

Low-Byte

D3 D2 D1 D0 0 0 OD OF

A) 20-Bit Conversion Data Word

MSB High-Byte

D15 D14 D13 D12 D11 D10 D9 D8

Mid-Byte

D7 D6 D5 D4 D3 D2 D1 D0

Low-Byte

111100ODOF

B) 16-Bit Conversion Data Word

0- always zero, 1

OD - Oscillation Detect, OF - Overflow

Figure 6. Bit Representation/Storage in PIC16F84

- always one,

MAXIMUM SCLK RATE

A machine cyc le in the PIC16F84 c onsists 4 oscil-

lator periods o r 400 ns i f the mic rocontrol ler’s os cillator frequency is 10 MHz. Sinc e the CS5525/6/

9’s maximum SCLK ra te is 2MHz, additiona l no

operation (NOP) delays may be necessary to reduce the tr ansfer rate if the micro controller s ys tem

requires higher ra te oscillators.

SERIAL PERIPHERAL INTERFACE

The Serial Peripheral Interface (SPI) developed for

Microchip’s controllers wasn’t designed to be as

flexible as the SPI port on Motorola’s 68HC05. To

get the Micr ochip’s SPI port to functi on with the

CS5525/6/9, th e port n ee ds to be ini tia lized t o id le

high, and th e CS55 25/6/9’s se rial po rt needs to be

reset anytime information is transmitted between

the microcontroller and th e c onverter.

DEVELOPMENT TOOL DESCRIPTION

The code in this a ppl ication note was developed

TM

using MPLAB

development pa cka ge from Microchip, Inc .

4 AN88Rev2

, an integrated software

Page 5

AN88

CONCLUSION

This applicat ion note prese nts an example of how

to interface t he CS5525/6/9 to the PIC16 F84. It is

divided into two main sec ti ons: har dware and software. The hardware section illustrates both a threewire and a four-wire interface. The three-wire is

TM

SPI

and MICROWIRE

ware, develope d w ith dev elopme nt to ols fro m Microchip, Inc., illustrates how to initialize the

converter and microcontroller, calibrate the con-

TM

compat ible. The soft-

verters offset, write to and read from the ADC’s internal register, and acquire a conversion. The

software is modularized and illustrates important

subroutines, e .g. wr ite_ regi ste r and read _register.

The softwa re described in the no te is included in

the Appendix at the end of this do cument.

SPITM is a trademark of Motorola.

MICROWIRE

MPLAB

TM

is a trademark of National Semiconductor.

TM

is a trademark of Microchip.

AN88Rev2 5

Page 6

APPENDIX

PIC16F84 Microcode to Interface to the CS552 5/ 6/9

;*************************************************************************************

;* File: 55261684.asm

;* Date: November 15, 1996

;* Programmer:Keith Coffey

;* Revision: 0

;* Processor: PIC16F84

;* Program entry point at routine "main". The entry point is address 0x05.

;*************************************************************************************

;* Program is designed as an example to interface a PIC16F84 to a CS5525/6/9

;* ADC. The program interfaces via a software SPI which controls the

;* serial communications, calibration, and conversion signals. Other ADC’s

;* (16-bit and 20-bit) in the product family can be used.

;*************************************************************************************

;******** Memory Map Equates

INDF equ 0x00 ; Indirect Address Register

STATUS equ 0x03 ; STATUS register equate

FSR equ 0x04 ; File Select Register

PORTA equ 0x05 ; General Purpose I/O Port

TRISA equ 0x85 ; Data Direction Control For Port A

RP0 equ 0x05 ; Register Bank Select Bit

CS equ 0x00 ; Port A bit 0

SDI equ 0x01 ; Port A bit 1

SDO equ 0x02 ; Port A bit 2

SCLK equ 0x03 ; Port A bit 3

LED equ 0x04 ; Port A bit 4

TRUE equ 0x01 ; Represents logic 1

HIGHBYTE equ 0x0C ; Upper 8 bits of Conversion Register

MIDBYTE equ 0x0D ; Middle 8 bits of Conversion Register

LOWBYTE equ 0x0E ; Lowest 8 Bits of Conversion Register

COMMANDBYTE equ 0x0F ; One byte RAM storage location

TEMP equ 0x10 ; A Temporary Data Storage Register

COUNT equ 0x11 ; Used to store count for delay routine

SPDR equ 0x12 ; Reserved for Se rial Peri pheral D ata Reg.

CARRY_BIT equ 0x00 ; Represents the Carry Bit in Status Reg.

AN88

6 AN88Rev2

Page 7

;*************************************************************************************

;* Program Code

;*************************************************************************************

processor 16C84 ; Set Processor Type

org 0x00 ; Reset Vector

goto Main ; Start at Main

;*************************************************************************************

;* Routine - Main

;* Input - none

;* Output - none

;* This is the entry point to the program.

;*************************************************************************************

org 0x05

Main ; Start fr om Reset Vector

;******** Initialize System and Perform SELF OFFSET Calibration

CALL initiali ze ; Initialize the syste m

CALL calibrate ; Calibrate the ADC Offset

;******** Write to the GAIN Register

MOVLW 0x82 ; Prepare COMMANDBYTE

MOVWF COMMANDBYTE

MOVLW 0x80 ; Prepare HIGHBYTE

MOVWF HIGHBYTE

CLRF MI DBYTE ; Prepare MIDBYTE

CLRF LOWBYTE ; Prepare LOWBYTE

CALL write_register ; Write to Gain Register

;******** Read from the GAIN Register

MOVLW 0x92 ; Prepare COMMANDBYTE

MOVWF COMMANDBYTE

CALL read_register ; Read the Gain Register

;******** Perform Single Conversions

LOOP CALL convert ; Convert Analog input

goto LOOP ; Repeat Loop

;******** End MAIN

AN88

AN88Rev2 7

Page 8

;*************************************************************************************

;* Subroutines

;*************************************************************************************

;*************************************************************************************

;* Routine - initialize

;* Input - none

;* Output - none

;* This subroutine initializes port A for interfacing to the CS5525/6/9 ADC.

;* It provides a time delay for oscillator start-up/wake-up period.

;* A typical start-up time for a 32768 Hz crystal, due to high Q, is 500 ms.

;* Also 1003 XIN clock cycles are allotted for the ADC’s power on reset. The

;* total delay is 555 ms upon power-up (assume uC start-up time is zero).

;*************************************************************************************

initiali ze CLRF PORTA ; Initialize POR TA by setting output

; data latches.

BSF STATUS, RP0 ; Select Bank 1

MOVLW 0x04 ; Value used to initialize direction

MOVWF TRISA ; Set RA2 as inputs

; RA0, RA1, RA3, & RA4 as outputs

AN88

BCF STATUS, RP0 ; Select Bank 0

BCF PORTA,SDO ; Clear SDO

MOVLW 0x32 ; Load W with delay count

CALL delay ; Delay, Power on Reset 1003 XIN

MOVLW 0xFF ; Load W with delay count

CALL delay ; Delay, Oscillator start-up 158 ms

CALL delay ; Delay, Oscillator start-up 158 ms

CALL delay ; Delay, Oscillator start-up 158 ms

CALL delay ; Delay, Oscillator start-up 158 ms

MOVLW 0x0F ; Reset Serial Port on ADC

MOVWF TEMP

BCF PORTA,CS ; Clear CS

loop MOVLW 0xFF ; Load W with 0xFF

CALL send_spi ; Send 15 0xFF through SPI

DECFSZ TEMP,1 ; Decre ment the c ounter

goto loop ; Repeat loop if counter not zero

MOVLW 0xFE ; Load W with last byte

CALL send_spi ; Move 0xFE to SPDR

BSF PORTA,CS ; Clear CS

RETURN ; Exit subroutine

8 AN88Rev2

Page 9

;*************************************************************************************

;* Routine - calibrate

;* Input - none

;* Output - none

;* This subroutine instructs the CS5525/6/9 to perform self-offset calibration.

;*************************************************************************************

calibrate MOVLW 0x84 ; set command byte for config write

MOVWF COMMANDBYTE ; set COMMAND BYTE

CLRF HIGHBYTE ; clear HIGHBYTE

CLRF MIDBYTE ; clear MIDBYTE

MOVLW 0x01 ; get ready for self offset cal

MOVWF LOWBYTE ; set LOWBYTE

CALL write_register ; Write to Config Register

MOVLW 0x94 ; set command byte for config read

MOVWF COMMANDBYTE ; set COMMAND BYTE

poll_done: CALL read_register ; Poll done flag until cal complete

BTFSS LOWBYTE,3 ; repeat if flag not set

goto poll_done

RETURN ; Exit subroutine

AN88

;*************************************************************************************

;* Routine - convert

;* Input - none

;* Output - Conversion results in memory locations HIGHBYTE, MIDBYTE and

;* LOWBYTE. This algorithm performs only single conversions. If

;* continuous conversions are needed the routine needs to be

;* modified. Port flag is zero.

;* HIGHBYTE MIDBYTE LOWBYTE

;* 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0

;* 16-bit results MSB LSB 1 1 1 1 0 0 OD OF

;* 20-bit results MSB LSB 0 0 OD OF

;* This subroutine initiates a single conversion.

;*************************************************************************************

convert MOVLW 0xC0 ; Set COMMANDBYTE for single CONV

MOVWF COMMANDBYTE

BCF PORTA,CS ; Clear Chip Select

CALL send_spi ; Transmit command out SPI

MOVLW 0x94 ; Set command byte for config read

MOVWF COMMANDBYTE ; Send COMMAND BYTE

done1 CALL read_register ; Poll done flag until CONV complete

BTFSS LOWBYTE,3 ; Repeat if Done Flag not Set

goto done1

MOVLW 0x96 ; Set Byte to Read Conversion Reg.

MOVWF COMMANDBYTE ; Store COMMAND BYTE

CALL read_register ; Acquire the Conversion

BSF PORTA,CS ; Set Chip Select

RETURN ; Exit subroutine

AN88Rev2 9

Page 10

;*************************************************************************************

;* Routine - write_re gister

;* Input - COMMANDBYTE, HIGHBYTE, MIDBYTE, LOWBYTE

;* Output - none

;*

;* This subroutine instructs the CS5525/6/9 to write to an internal register.

;*************************************************************************************

write_register BCF PORTA,CS ; Clear Chip Select

MOVF COMMANDBYTE,0 ; Load W with COMMANDBYTE

CALL send_spi ; transfer byte

MOVF HIGHBYTE,0 ; Load W with HIGHBYTE

CALL send_spi ; transfer byte

MOVF MIDBYTE,0 ; Load W with MIDBYTE

CALL send_spi ; transfer byte

MOVF LOWBYTE,0 ; Load W with LOWBYTE

CALL send_spi ; transfer byte

BSF PORTA,CS ; Set Chip Select

RETURN ; Exit Subroutine

AN88

;*************************************************************************************

;* Routine - read_register

;* Input - COMMANDBYTE

;* Output - HIGHBYTE, MIDBYTE, LOWBYTE

;* This subroutine reads an internal register of the ADC.

;*************************************************************************************

read_register BCF PORTA,CS ; Clear Chip Select

MOVF COMMANDBYTE,0 ; Load W with COMMANDBYTE

CALL send_spi ; transfer byte

CALL receive_spi ; receive byte

MOVWF HIGHBYTE ; Move W to HIGHBYTE

CALL receive_spi ; receive byte

MOVWF MI DBYTE ; Move W to MIDBYTE

CALL receive_spi ; receive byte

MOVWF LOWBYTE ; Move W to LOWBYTE

BSF PORTA,CS ; Set Chip Select

RETURN ; Exit Subroutine

10 AN88Rev2

Page 11

;*************************************************************************************

;* Routine - send_spi

;* Input - Byte to be transmitted is placed in W

;* Output - None

;* This subroutine sends a byte to the ADC.

;*************************************************************************************

send_spi: MOVWF SPDR ; Move W to SPDR

MOVLW 0x08 ; Set COUNT to count to 8

MOVWF COUNT ; to transmit byte out SPI

BCF PORTA,SCLK ; Clear SCLK

wait0 ; Send Bit

RLF SPDR,1 ; Rotate SPDR, send MSB 1st

BTFSC STATUS,CARRY_BIT ; If bit low skip next instruct.

BSF PORTA,SDI ; Set SDI

BTFSS STATUS,CARRY_BIT ; If bit high, skip next instruct.

BCF PORTA,SDI ; Clear SDI

BSF PORTA,SCLK ; Toggle Clock

BCF PORTA,SCLK

DECFSZ COUNT,1 ; Loop until byte is transmitted

goto wait0

BCF PORTA,SDI ; Return Pin low

RETURN ; Exit Subroutine

AN88

;*************************************************************************************

;* Routine - receive_spi

;* Input - none

;* Outpu t - B yte recei ved is placed in W

;* This subroutine receives a byte from the ADC.

;*************************************************************************************

receive_spi: MOVLW 0x08 ; Set COUNT to count to 8

MOVWF COUNT ; to transmit byte out SPI

BCF PORTA,SCLK ; Clear SCLK

wait1: ; Receive bit

BTFSC PORTA,SDO ; If bit low skip next instruct.

BSF STATUS,CARRY_BIT ; Set SDI

BTFSS PORTA,SDO ; If bit high, skip next instruct.

BCF STATUS,CARRY_BIT ; Clear SDI

RLF SPDR,1 ; Rotate SPDR, Receive MSB 1st

BSF PORTA,SCLK ; Toggle Clock

BCF PORTA,SCLK

DECFSZ COUNT,1 ; Loop until byte is transmitted

goto wait1

MOVF SPDR,0 ; Put byte attained in W

RETURN ; Exit Subroutine

AN88Rev2 11

Page 12

;*************************************************************************************

;* Routine - delay

;* Input - Count in register A

;* Output - none

;* This subroutine delays by using count from register W. The PIC16F84

;* development board uses a 10 MHz clock (E = 2.5 MHz), thus each cycle is

;* 400 nS. This delay is approximately equivalent to

;* (400ns)*(1545)*(count value), (a count of 720 provides a 445ms delay).

;*************************************************************************************

delay MOVWFCOUNT ; Put the delay count into COUNT

outlp CLRF TEMP ; TEMP used as inner loop count

innlp NOP ; 1 cycle

NOP ; 1 cycle

NOP ; 1 cycle

NOP ; 1 cycle

DECFSZ TEMP,1 ; FF-FE, FE-FD, ....1-0 256 loops

; 10 cycles*256*500ns=1.28 ms

goto innlp ; If count not done repeat loop

DECFSZ COUNT,1 ; Countdown the accumulator

goto outlp ; 2569 cycles*500ns*A

RETURN ; Exit subroutine

AN88

;*************************************************************************************

;* Interrupt Vectors

;*************************************************************************************

NOT_USED RETFIE

ORG 0x04 ; O riginate Interrupt Vector here

goto NOT_USED ; No Interrupts Enabled

end ; End Program Listing

12 AN88Rev2

Page 13

• Notes •

Page 14

Loading...

Loading...