Page 1

Application Note

USING THE CDBCAPTURE SYSTEM

WITH EMBEDDED A/D CONVERTERS

by

John Lis

AN44

INTRODUCTION

The CDBCAPTURE system can be used to

collect data from embedded Analog to Digital

Converters (ADCs). Thus system performance of

the analog front end can be measured, analyzed

and quantified. By analyzing the measured

performance, noise sources can be identified,

isolated, and corrective actions taken. Here

CDBCAPTURE is used as an engineering tool,

reducing development time during system test

and integration. Another application could be

using CDBCAPTURE in production for testing

finished products and verifying system

performance.

CDBCAPTURE

The CAPTURE interface board is a development

tool that interfaces a Crystal Semiconductor

ADC to a PC compatible computer. Digital data

from the ADC is collected in a high speed

digital FIFO, then transmitted to the PC over a

serial COM port. Evaluation software is included

to analyze the data and demonstrate the ADC’s

performance. The entire system consists of a

CAPTURE interface board, serial cable, RS232

cable, and software.

The software included with the CDBCAPTURE

system quantifies static and dynamic

performance of ADC systems. Static testing

includes Histogramming and calculation of the

mean, standard deviation and variance. Dynamic

testing includes Fast Fourier Transforms and

analysis of the power spectrum. Here Signal to

Noise Ratio (SNR), Signal to Noise plus

Distortion (SINAD), Signal to Distortion Ratio

(SDR), and Signal to Peak Noise (SPN) figures

are calculated. Time domain plots are available

to visualize signals in the time domain and

confirm operation.

CDBCAPTURE WITH EMBEDDED ADCs

The CDBCAPTURE circuit board is designed to

directly interface with most Crystal

Semiconductor ADC evaluation boards. This

permits a quick and ea sy method to quantify and

verify the ADC’s performance. However, it is

often desirable to measure the ADC’s

performance in the actual system or to measure

the overall system performance. To collect data

from an embedded ADC, a special serial cable

needs to be designed. This cable incorporates the

digital interface circuitry which exists on the

evaluation board. This cable is connected to the

appropriate signals on the ADC.

To collect data from an embedded ADC, the

digital inte rface circuit ry on the e valuation boa rd

needs to be incorporated on a modified serial

Crystal Semiconductor Corporation

P.O. Box 17847, Austin, TX 78760

(512) 445-7222 FAX 445-7581

http://www.crysta l.com

Copyright Crystal Semiconductor Corporation 1996

(All Rights Reserved)

FEB ’95

AN44REV2

1

Page 2

Using The CDBCapture System with Embedded A/D Converters

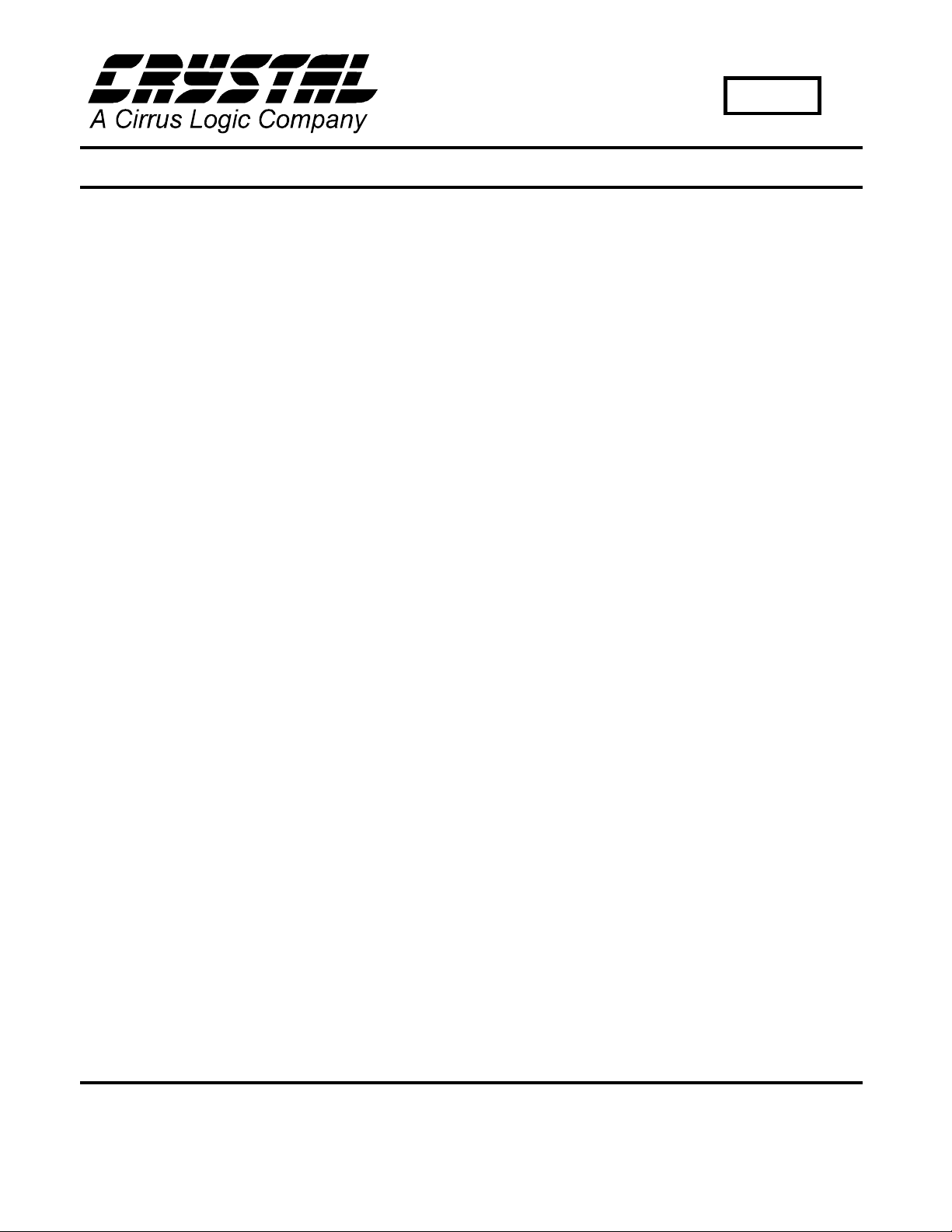

cable. Figure 1 is a block diagram illustrating

the process. On the top of Figure 1, the

evaluation board CDBXXXX contains digital

interface circuitry which translates signals from

the ADC to three standard serial signals named

FRAME, SCLK and SDATA. The timing and

format of these signals vary from device ty pe to

device type .

In an embedded ADC application, the digital

interface circuit, between the ADC and the

CDBCPATURE circuit card, should be

implemented on a small card attached to the

serial cable as shown at the bottom of Figure 1.

The appropriate digital input signals need to be

identified. A method to connect to these signals

from the embedded system to the cable is then

CDBXXXX EVALUATION BOARD CDBCAPTURE

5 V

A

D

C

INTERFACE

CIRCUIT

GND

FRAME

SCLK

SDATA

implemented. The connection scheme varies for

each application and is easy to implement.

The schematic for the digital interface circuitry

is provided with th e evaluation board data sheet.

Locate the serial interface connector containing

the signals: +5 V, GND, FRAME, SCLK, and

SDATA on the schematic. Working from this

connector, back to the ADC, identify the

circuitry required to create the serial signals.

This circuitry is implemented on a separate

circuit board, attached to a 10 conductor ribbon

cable with an IDC socket for its CDBCAPTURE

interface. The ADC interface can be any

connector scheme that is easy to implement.

Possible alternatives include stake headers, test

clips, circular connectors, or "D" style

connectors.

SERIAL RIBBON

CABLE

EMBEDDED ADC CDBCAPTURE

A

D

C

2 AN44REV2

INTERFACE

CIRCUIT

Figure 1. CDBCAPTURE INTERFACE

MODIFIED

SERIAL RIBBON

CABLE

Page 3

Using The CDBCapture System with Embedded A/D Converters

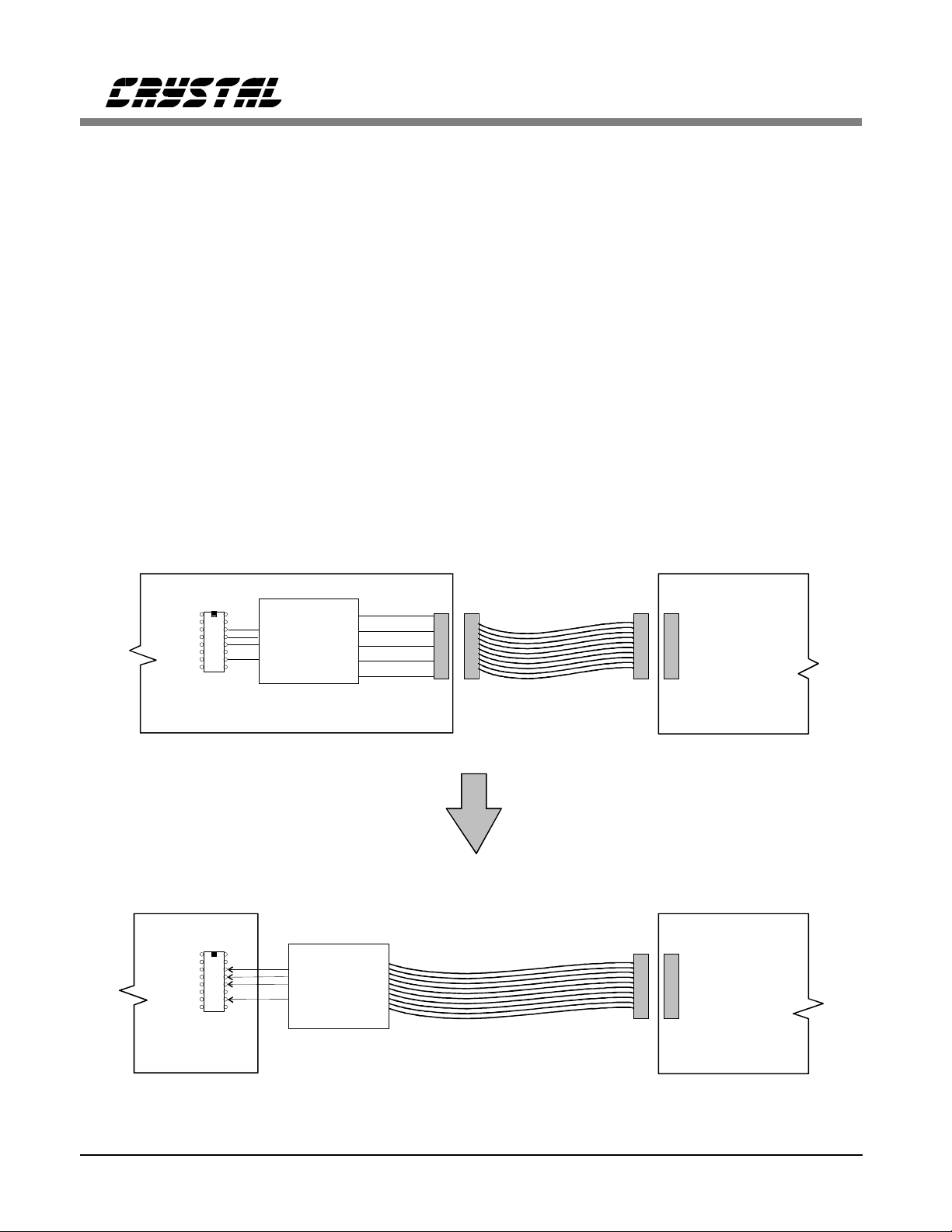

CS5508 EXAMPLE

The following example uses a CS5508 to

illustrate the process of designing a modified

serial cabl e. By examining the schematic for the

CDB5508 evaluation board, the digital interface

circuitry is identified. The schematic for the

CDB5508 evalu ation board is pro vided in Figure

1 of the CDB5505/6/7/8 data sheet. The digital

interface portion is shown in Figure 2 below.

Resistors R23, R24 and R25 are not required if

the

CS is always active. Also, U3B is always

U1

CS5505

CS5506

CS5507

OR

CS5508

DRDY

SDATA

SCLK

16

15

14

R23

100k

R24

100k

R25

100k

U2E

U2F

1211

1514

8

5

U3B

active when using the CAPTURE board, thus it

can be changed to a general purpose buffer such

as U2.

Figure 3 shows the schematic for the modified

cable derived fro m Figure 2. The

DRDY, SCLK

and SDATA signals are buffered to create the

serial cable signals for the CAPTURE board.

Five volt power is obtained from the embedded

system and filtered by R1 and C1 before it is

provided to the CAPTURE board. C2 is a

bypass capacito r for U1.

R22

+5

6

4

10

+

C16

10 uF

+5

+5

DRDY

SCLK

SDATA

+5 V

GND

DRDY

SCLK

SDATA

Figure 2. CDB5508 Evaluation Board Schematic for the Digital Interface

R1

+

HC4050

R2

100k

R3

100k

R4

100k

10

C2

0.1 uF

1

23

U1A

8

45

U1B

7

6

U1C

C1

10 uF

9

11

14

U1D

U1E

U1F

10

12

15

Figure 3. Modified Serial Cable Implementation of the Digital Interface

+5

+5

DRDY

SCLK

SDATA

AN44REV2 3

Page 4

Using The CDBCapture System with Embedded A/D Converters

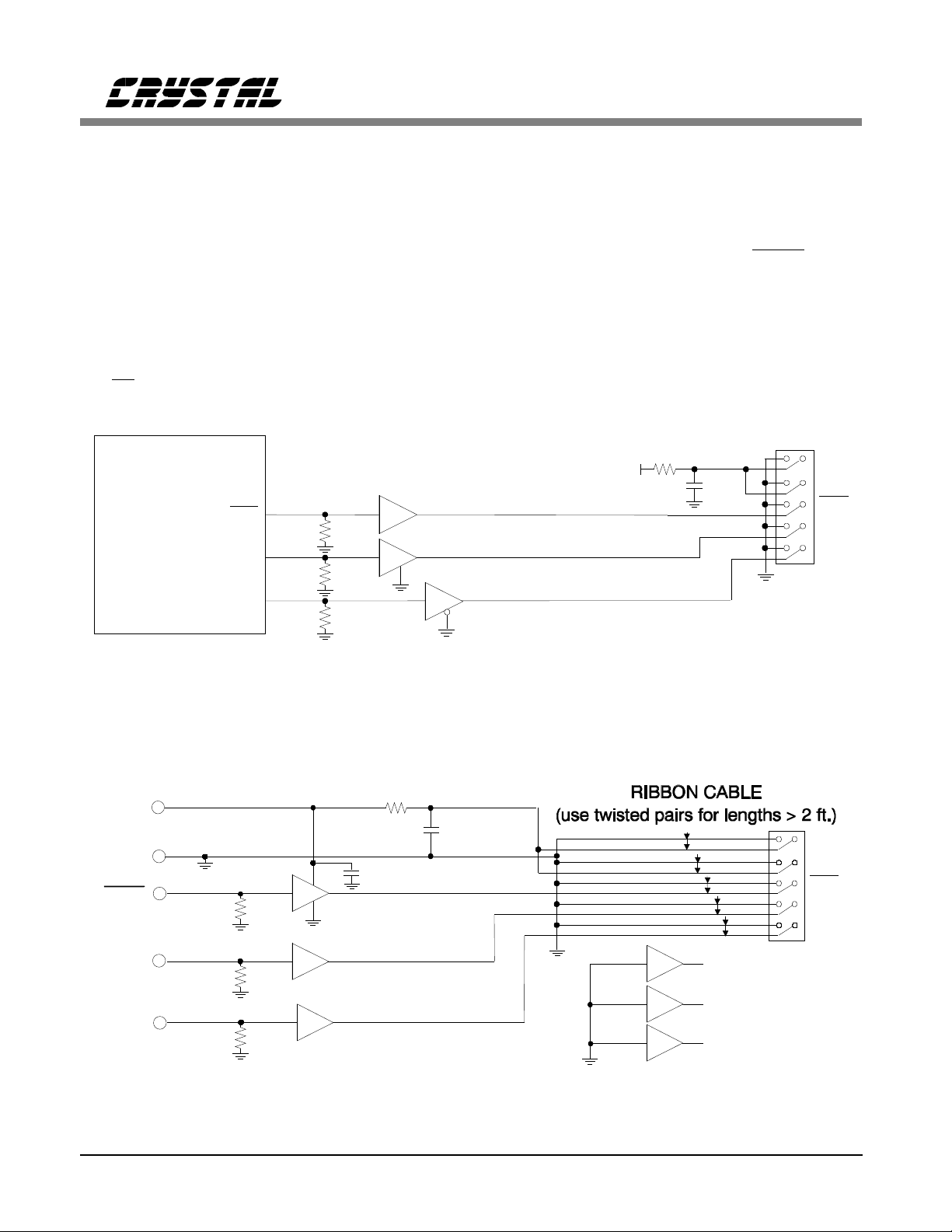

Figure 4 shows how the hardware can be

implemented. The digital interface circuitry is

built upon a small circuit board. A ribbon cable

with a 10 circuit IDC socket is used for the

CDBCAPTURE interfac e. Separate ground wires

should be used for each signal return, and

twisted pa ir ribbon cable u sed fo r lengths greater

than two feet. The embedded interface uses

color coded test clips. The test clips provide a

means of interfacing an ADC without any

special connectors designed in the system.

However this method requires a little more setup

time, since the appropriate signals need to be

located on th e circui t board.

CS5102A EXAMPLE

The CS5102A is used in the second example of

an embedded application. The methodology for

the cable design is the same as that in the first

example usin g the CS5508. The digital interface

circuitry is obt ained from the CDB51 01A/5102A

evaluation board data sheet. This information is

contained in the evaluation board’s data sheet

U1

CS5101A

or

CS5102A

SDATA

SCLK SCLK

SSH/SDL

TRK1

TRK2

SDATA

SCLK

Figure 4. Construction of the Modified Serial Cable

+5V

JP4

1

3

5

HDR8D

+

C47

10 uF

+5V

2

4

6

BOTH

CH2

CH1

SDATA

SSH/SDL

TRK1

TRK2

.1 uFC48

15

14

1

2

6

U12

OE1

OE2

A0

A2

A5

74HC365

Y2

Y0

Y5

7

3

13

SSH/SDL

+5V

TRK2

TRK1

R3

10

TP00

R16

10k

8

JP5

HDR10D

9

U2

10

+5V

+5V

+5V

SLATCH

SCLK

SDATA

U3

10

S

11

CLK

12

D

13

R

74HC74

9

Q

8

4

5

U2

6

Figure 5. CDB5102A Evaluation Board Schematic for the Digital Interface

4 AN44REV2

Page 5

Using The CDBCapture System with Embedded A/D Converters

Figures 4, 5 and 6. The digital inte rface circuitry

for the CS5102A is s how in Figure 5.

Figure 6 is the way the digital circuitry is

implemented on the modified serial cable.

Figure 7 is the hardware implementation of the

modified serial cable shown in Figure 6. In this

P1

+5V

GND

TRK1

TRK2

SSH/SDL

SCLK

SDATA

JP1

R1

10k

BOTH

CH1

CH2

+5V

10

9

13

12

74HC74

10

11

12

13

U2-C

U2-B

S

D

R

+

U3B

8

11

C1

0.1 µF

Q

C2

+

0.1 µF

9

8

74HC00

1

U2A

2

example, the embedded system is designed with

a test connector. The modified serial cable is

built with a conne ctor which mates to t he syst em

test connector. The test connector provides a

convenient and reliable means of interfacing the

ADC.

R3

C3

10

4

3

U2B

5

+

10 µF

6

+5V

U3A

4

3

2

1

5

S

Q

D

6

R

P2

+5V

+5V

SLATCH

SCLK

SDATA

Figure 6. Modified Serial Cable Implementation of the Digital Interface

Figure 7. Construction of the Modified Serial Cable

AN44REV2 5

Page 6

Using The CDBCapture System with Embedded A/D Converters

Testing An Embedded ADC

System performance can be measured by

interfacing the embedded ADC. The previous

sections described the hardware modification

required to interface a Crystal Semiconductor

ADC with the CAPTURE board. Figures 8, 9,

and 10 are the results of using the histogram tes t

on a CS5101A in an embedded system.

Figure 8 is a histogram of a CS5101A ope rating

in the bipolar mode with the analog input pin

grounded right at the package. Data book

performance is expected, if proper design

practices have been used in developing the

circuit an d layout. In Figure 8, t he mean is -0.69

counts, which is well within the typical

specification o f two counts for the bipolar offset.

The standard deviation is 0.49 counts. This

translat es to 67 uV

( 0.49 x 9 volts ⁄

RMS

CS5101A data s heet specifie s 70 uV

16

). The

2

RMS typical.

Figure 8. Histogram of a CS5101A with the Input

Grounded

A buffer op-amp is integrated in the system and

a data set is collected and displ ayed in Figure 9.

Both the mean and standard deviation numbers

changed with the addition of the op-amp. The

op-amp added 0.66 counts to the offset or

91 uV. The RMS noise increased to 0.63 counts

or 87 uV.

Figure 10 shows the histogram for the ADC,

buffer op-amp, and signal source. The signal

source outpu t is set at zero volts. The histogram

statistics indicate an o ffset of 1.59 count s or 218

uV and the RMS noise is at 218 uV. Note, that

as more components are added to the system, the

offset changes and the noise increases. These

changes can be used to isolate and identify

problems.

Figure 9. Hist ogram of a CS51 01A with a Buff er Op-Amp

Figure 10. Histogram of a CS5101A with a Signal Source

6 AN44REV2

Page 7

Using The CDBCapture System with Embedded A/D Converters

CONCLUSION

The CDBCAPTURE system is designed to

easily connect to most Crystal Semiconductor

ADC evaluation boards. Digital circuitry is

included on the evaluation boards to implement

a standard serial data bus. The CAPTURE board

is software reconfigurable to adjust for different

ADCs and fu ture products. Th e CDBCAPTURE

system permits easy transfer of digital data to a

PC for analysis.

Many times it is desirable to collect data from

the ADC while it is operating inside a complete

acquisition system. In this case, the digital

interface circuitry for the CAPTURE board is

implemented outside the system on a modified

cable. The electrical system has to provide the

appropriate interconnect scheme, using either

connectors or test poin ts to clip o nto.

The modified serial cable allows the user to

measure performance of the ADC while it is

embedded in an electrical system. The ADC as

well as the system performance can be measured

and quantified. This information is used to

isolate problems and investigate how certain

subsystems interact with each other.

AN44REV2 7

Page 8

Using The CDBCapture System with Embedded A/D Converters

• Notes •

8 AN44REV2

Loading...

Loading...