Page 1

AN374

Application Note

Considerations for Light Engine Selection

for a CS1630/31 2-Channel TRIAC Dimmable Circuit

1 Overview of the CS1630

The CS1630/31 is a high-performance offline AC to DC LED controller for dimmable and high color rendering index

(CRI) LED replacement lamps and luminaires. It features Cirrus Logic's proprietary digital dimmer compatibility control technology and digital correlated color temperature (CCT) control system that enables two-channel LED color

mixing.

The CS1630/31 offers tremendous flexibility to achieve constant CCT control to match an incandescent dimming

profile. The digital CCT control system provides the ability to program dimming profiles, such as constant CCT dimming and black body line dimming. The CS1630/ 31 optimizes LED color mixing by temperature compensating the

LED current with an external negative temperature coefficient (NTC) thermistor. The IC controller is equipped with

power line calibration for remote system calibration and end-of-line programming. The CS1630 provides a register

lockout feature for security against potential access to proprietary registers.

During the course of two-channel design, several design tradeoffs are made based on cost, size, and performance.

This document considers the requirements when designing a system around the CS1630/31. This document helps

answer the following system questions:

• How can the light engine be designed or modified to maximize the benefits of the CS1630/31?

• How can clear specifications be derived for the system and the LED driver that can reduce the light bulb

development time with the CS1630/31?

Further Reading

• See data sheet DS954 2-Channel TRIAC Dimmable LED Driver IC to review the features and

specifications of the CS1630/31

• See application note AN368 Design Guide for a CS1630/31 2-Channel TRIAC Dimmable SSL Circuit for

questions on how to design the LED driver using the CS1630/31

• See application note AN369 Device Programmer User Guide to review the CS1630/31 application software

and graphical user interface (GUI)

Cirrus Logic, Inc.

http://www.cirrus.com

Copyright Cirrus Logic, Inc. 2013

(All Rights Reserved)

FEB’13

AN374REV2

Page 2

AN374

Contacting Cirrus Logic Support

For all product questions and inquiries contact a Cirrus Logic Sales Representative. To find the one nearest to you

go to www.cirrus.com

IMPORTANT NOTICE

Cirrus Logic, Inc. and its subsidiaries ("Cirrus") believe that the information contained in this document is accurate and reliable. However, the information is subject

to change without notice and is provided "AS IS" without warranty of any kind (express or implied). Customers are advised to obtain the latest version of relevant

information to verify, before placing orders, that information being relied on is current and complete. All products are sold subject to the terms and conditions of sale

supplied at the time of order acknowledgment, including those pertaining to warranty, indemnification, and limitation of liability. No responsibility is assumed by Cirrus

for the use of this information, including use of this information as the basis for manufacture or sale of any items, or for infringement of patents or other rights of third

parties. This document is the property of Cirrus and by furnishing this information, Cirrus grants no license, express or implied under any patents, mask work rights,

copyrights, trademarks, trade secrets or other intellectual property rights. Cirrus owns the copyrights associated with the information contained herein and gives

consent for copies to be made of the information only for use within your organization with respect to Cirrus integrated circuits or other products of Cirrus. This consent does not extend to other copying such as copying for general distribution, advertising or promotional purposes, or for creating any work for resale.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE ("CRITICAL APPLICATIONS"). CIRRUS PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARRANTED FOR

USE IN PRODUCTS SURGICALLY IMPLANTED INTO THE BODY, AUTOMOTIVE SAFETY OR SECURITY DEVICES, LIFE SUPPORT PRODUCTS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF CIRRUS PRODUCTS IN SUCH APPLICATIONS IS UNDERSTOOD TO BE FULLY AT THE CUSTOMER'S RISK

AND CIRRUS DISCLAIMS AND MAKES NO WARRANTY, EXPRESS, STATUTORY OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSE, WITH REGARD TO ANY CIRRUS PRODUCT THAT IS USED IN SUCH A MANNER. IF THE CUSTOMER

OR CUSTOMER'S CUSTOMER USES OR PERMITS THE USE OF CIRRUS PRODUCTS IN CRITICAL APPLICATIONS, CUSTOMER AGREES, BY SUCH USE,

TO FULLY INDEMNIFY CIRRUS, ITS OFFICERS, DIRECTORS, EMPLOYEES, DISTRIBUTORS AND OTHER AGENTS FROM ANY AND ALL LIABILITY, INCLUDING ATTORNEYS' FEES AND COSTS, THAT MAY RESULT FROM OR ARISE IN CONNECTION WITH THESE USES.

Use of the formulas, equations, calculations, graphs, and/or other design guide information is at your sole discretion and does not guarantee any specific results or

performance. The formulas, equations, graphs, and/or other design guide information are provided as a reference guide only and are intended to assist but not to

be solely relied upon for design work, design calculations, or other purposes. Cirrus Logic makes no representations or warranties concerning the formulas, equations, graphs, and/or other design guide information

Cirrus Logic, Cirrus, the Cirrus Logic logo designs, EXL Core, the EXL Core logo design, TruDim, and the TruDim logo design are trademarks of Cirrus Logic, Inc.

All other brand and product names in this document may be trademarks or service marks of their respective owners.

IMPORTANT SAFETY INSTRUCTIONS

Read and follow all safety instructions prior to using this demonstration board.

This Engineering Evaluation Unit or Demonstration Board must only be used for assessing IC performance in a

laboratory setting. This product is not intended for any other use or incorporation into products for sale.

This product must only be used by qualified technicians or professionals who are trained in the safety procedures

associated with the use of demonstration boards.

Risk of Electric Shock

• The direct connection to the AC power line and the open and unprotected boards present a serious risk of electric

shock and can cause serious injury or death. Extreme caution needs to be exercised while handling this board.

• Avoid contact with the exposed conductor or terminals of components on the board. High voltage is present on

exposed conductor and it may be present on terminals of any components directly or indirectly connected to the AC

line.

• Dangerous voltages and/or currents may be internally generated and accessible at various points across the board.

• Charged capacitors store high voltage, even after the circuit has been disconnected from the AC line.

• Make sure that the power source is off before wiring any connection. Make sure that all connectors are wel

connected before the power source is on.

• Follow all laboratory safety procedures established by your employer and relevant safety regulations and guidelines

such as the ones listed under, OSHA General Industry Regulations - Subpart S and NFPA 70E.

Suitable eye protection must be worn when working with or around demonstration boards. Always

comply with your employer’s policies regarding the use of personal protective equipment.

All components and metallic parts may be extremely hot to touch when electrically active.

2 AN374REV2

Page 3

AN374

TABLE OF CONTENTS

1 OVERVIEW OF THE CS1630 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Definition of Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Definition of Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 INTRODUCTION TO THE COLOR SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 LIGHT ENGINE CHOICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.1 Considerations for the Color System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Constraint 1: Translating current versus dim requirements into a fourth-order or lower polynomial. . . . . . 7

Constraint 2: The current versus dim plot should have intercept at origin . . . . . . . . . . . . . . . . . . . . . . . . . .7

Constraint 3: Placement of NTC with respect to light engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Constraint 4: Red currents increase with an increase in ambient temperature . . . . . . . . . . . . . . . . . . . . . .8

Constraint 5: Maximum allowable color gain is 4.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4.2 Constraints Imposed by Second Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Constraint 1: Currents in either channel should not be zero at non-zero dim values . . . . . . . . . . . . . . . . . 8

Constraint 2: No abrupt change in current ratios at a dim point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Constraint 3: Ratio of peak currents between the two channels must be less than 4 . . . . . . . . . . . . . . . . .9

Constraint 4: Both strings cannot have identical configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Constraint 5: Maximum differential between string voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Constraint 6: The implications when determining LED string configuration and topology . . . . . . . . . . . . . .9

Constraint 7: Note on Frequency and EMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.3 Synchronizer Design Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Constraint 1: Non-isolated synchronizer circuit considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4 Constraints on the Boost Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Constraint 1: Maximum power should be power at full AC sine wave . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Constraint 2: Power should be monotonically increasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5 DESIGN FLOWCHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6 DATA IMPROVEMENTS FOR THE CURVE FITTING PROCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1 Typical Light Engine System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2 Translation into Input Specifications for Calculating Color Gains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.3 Methods to Collect Required Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.3.1 Experimental Measurement in Lab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.3.2 Simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.3.3 Experiment and Approximation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.4 Improving Data for Feeding the Curve Fitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.4.1 Understanding the Data and Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.4.2 Manipulating Data for Better Curve Fit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7 PERFORMING CURVE FITTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.1 Using the CS1630/ 31 Application Software to Perform Curve Fit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.2 Register Bits in OTP Map Affected by the Curve Fitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.3 Using Commercially Available Curve Fitting Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.4 Process of Converting a Given Gain Coefficients to CS1630/31 OTP Map . . . . . . . . . . . . . . . . . . . . . . . 34

8 REVISION HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

AN374REV2 3

Page 4

AN374

2 Introduction

This application note provides a guide to designing a solid-state lighting (SSL) LED lamp circuit using Cirrus Logic's

CS1630/31. The first half of the document presents an introduction to the CS1630/31 color control system and the

criterion for selecting a compatible light engine. The second half of the document supports the design effort by detailing the requirements to curve fit the polynomial gain equations for a robust color correlation temperature solution.

2.1 Definition of Acronyms

Acronym Description

PFC Power Factor Correction

ZCD Zero-current Detection

BOP Boost Overvoltage Protection

COP Clamp Overpower Protection

OVP Second-stage Output Open Circuit Protection and Overvoltage Protection

OCP Second-stage Overcurrent Protection

OLP Second-stage Open Loop Protection

SCP Short Circuit Protection

iOTP Internal Overtemperature Protection

eOTP External Overtemperature Protection

PLC Power Line Calibration

OTP One-time Programmable

LED Light Emitting Diode

TX Transformer

TRIAC

NTC

SSL

CSV Comma-separated Values File

CCT Correlated Color Temperature

DAC Digital-to-Analog Converter

TRIode for Alternating Current, which is an electronic component that can conduct current in either

direction when it is triggered. It is formally called a bidirectional triode thyristor.

Negative Temperature Coefficient thermistor

Solid-state lighting. Refers to a type of lighting that uses semiconductor LEDs as a source of illumination rather than electrical filaments, plasma, or gas.

4 AN374REV2

Page 5

2.2 Definition of Symbols

T1

CH1

TT

CH1

----------------

T1

CH2

TT

CH2

----------------

Symbol Description

F

sw

F

& F

sw1

sw2

TT Second-stage switching period

& TT

TT

T1

T2

T3

CH1

CH1

CH1

CH1

& T1

& T2

& T3

CH2

CH2

CH2

CH2

Second-stage switching frequency

Switching frequency for channel 1 and channel 2

Switching period for channel 1 and channel 2

Second-stage primary FET ‘ON’ time for channel 1 and channel 2

Second-stage secondary rectifier diode conduction time for channel 1 and channel 2

Time the second-stage FET and rectified diode are ‘OFF’ for channel 1 and channel 2

AN374

D

MODE1

I

PK1(FB)

I

MODE1

V

MODE1

R

I

GAIN

& D

V

V

Reflected

V

CLAMP

I

PK(FB)

& I

& I

& V

R

Sense

& T

NTC

I

PK(BST)

L

L

BST

V

BST

N

V

CH1

V

CH2

& I

CH1

P

OUT

I

Red

I

White

dim

& GAIN

DR

MODE2

IN

PK2(FB)

MODE2

NTC

P

CH2

MODE2

DTR

Duty ratio for Mode 1 and Mode 2

Input line voltage

Voltage across secondary winding reflected onto primary

Primary clamping voltage above boost output voltage (V

BST

)

Maximum second-stage peak current in primary-side FET

Maximum second-stage peak current in primary-side FET for Mode 1 and Mode 2

Output current for Mode 1 and Mode 2

Output voltage for Mode 1 and Mode 2

Second-stage primary current sense resistor

Negative temperature coefficient resistance and corresponding temperature

Maximum boost inductor current

Second-stage primary inductance

Boost inductance

Boost output voltage

Flyback transformer turns ratio N

P/NS

Channel 1 secondary output VDC (channel 1 LED string supply voltage)

Channel 2 secondary output VDC (channel 2 LED string supply voltage)

Channel 1 and channel 2 LED string current

Load power = Power to the LED string

Output current that flows through the amber/red color LED string

Output current that flows through the white/blue color LED string

The CS1630/31 color control system has the ability to maintain a constant CCT or change

CCT as the light dims. OTP configurations allow the selection of the dimming profile. A

specific CCT profile can be programmed to the digital mapping device. The mapping is

two-dimensional: one current versus temperature profile is generated for each dim level.

The CS1630/31 provides two-dimensional mapping for the color LED’s current only, and

one-dimensional mapping (current versus dim level) for the other string.

The dim-regulated gain and dim-regulated plus temperature-regulated gain

AN374REV2 5

Page 6

AN374

dim

NTC

(From Boost)

12

8

÷ 4096

÷ 256

D

T

Normalize

Normalize

Saturation

Logic

GAIN

DR

= Q3 × D3 + Q2 × D2 + Q1 × D + Q0

GAIN

DTR

= P30 × T3 + P20 × T2 + P10 × T + P03 × D3 + P02 × D2 + P01 × D +

P21 × T

2

× D + P12 × T × D2 + P11 × T × D + P00

I

White(ref)

I

Red(ref)

I

White

I

Red

dim

dim

Temperature

(ADC Fast Filter)

Figure 1. Color Control System

GAIN

DTR

P30 T3 P20 T2 P10++T P03 D3 P02++D2 P01 D P21 T2D++= P12 T D2 P11 T D P00+++

GAIN

DR

Q3= D3 Q2 D2 Q1 D Q0+++

[Eq. 1]

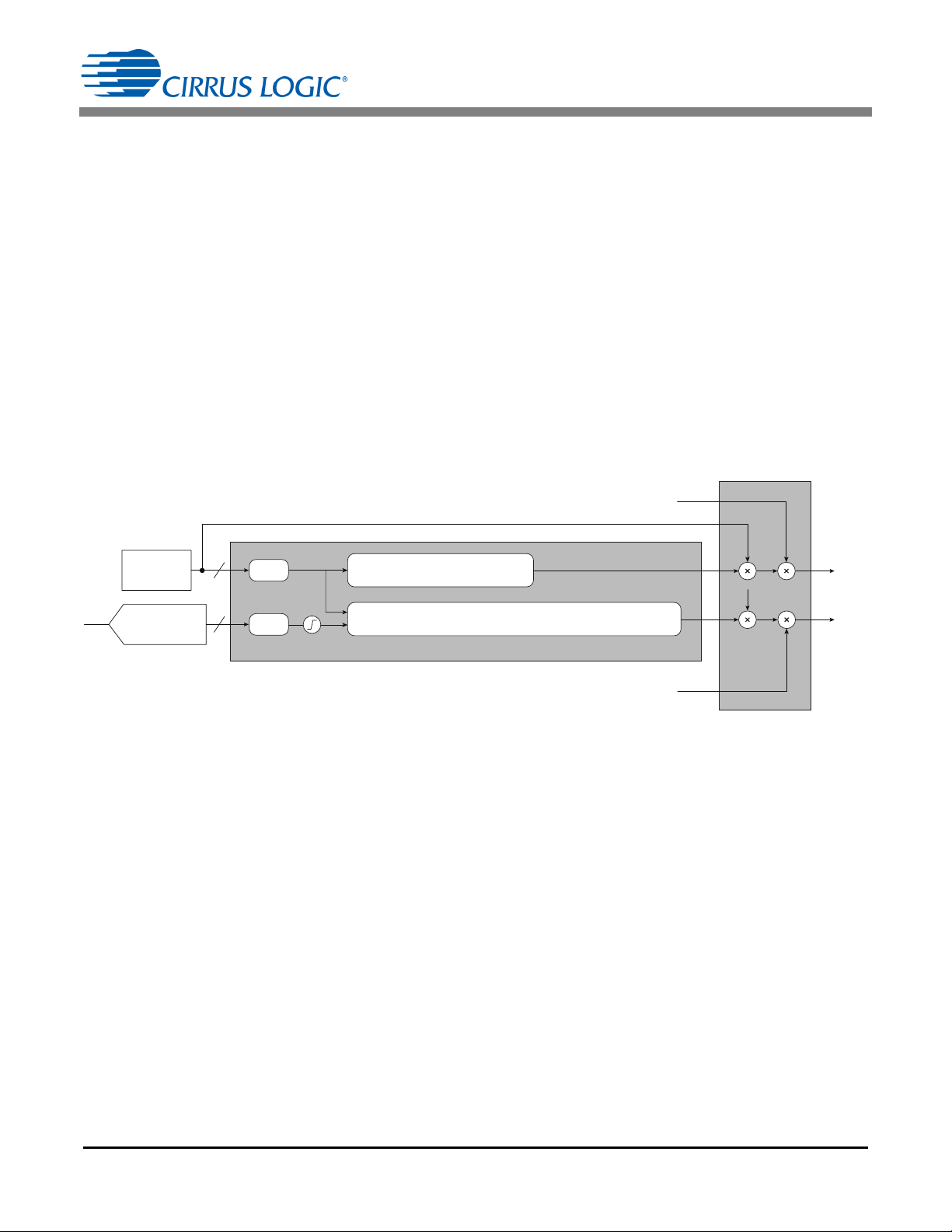

3 Introduction to the Color System

The CS1630/31 is a two-channel TRIAC dimmable LED driver IC designed to change the color temperature of the

light output by independently varying the gains of the two different color LED strings to establish levels of color mixing. This feature can be used to make the color temperature versus dim characteristics of the light similar to that of

an incandescent light bulb. In many such designs, one of the LED strings is composed of red or amber LEDs, and

the other string is composed of cool-white or blue-white LEDs. While the lumen output of white LEDs does not vary

significantly across temperature, the lumen output of red LEDs can vary as much as 40% across temperature. To

achieve a consistent light output across temperature, the current in the red LED string needs to be compensated

with respect to temperature. Depending on the design, either channel can be temperature compensated.

Cirrus Logic, Inc. and its affiliates and subsidiaries generally make no representations or warranties that the combination of Cirrus Logic’s products with light-emitting diodes (“LEDs”), converter materials, and/or other components

will not infringe any third-party patents, including any patents related to color mixing in LED lighting applications,

such as, for example, U.S. Patent No. 7,213,940 and related patents of Cree, Inc. For more information, please see

Cirrus Logic’s Terms and Conditions of Sale, or contact a Cirrus Logic sales representative.

Figure 1 illustrates the block diagram of the color control block inside of the CS1630. The color temperature of the

light engine can be modified by changing the gains of each channel based on the current dim level. On the temperature-controlled channel, the currents can be varied according to the temperature sensed by an external NTC.

The required gain value for a particular combination of dim and temperature is obtained using polynomial curves,

the coefficients of which are programmed into the CS1630/31 OTP memory. A different polynomial is used for each

channel. One of these is a polynomial in two variables, dim and temperature, while the other is a polynomial in dim

only. If D and T are assumed to be the normalized dim and temperature values, respectively, between 0 and 1.0,

then GAIN

refers to the dim-regulated gain and temperature-regulated gain, and GAINDR refers to the dim-reg-

DTR

ulated gain.

As shown in Equation 1, the gain equation for the white is a third-order polynomial in dim, and the gain equation for

the red is a third-order polynomial in both dim and temperature. The color gain is third order to provide good tradeoffs

between computational overhead and being able to operate over the largest variety of LEDs across a wide range of

temperature. A lower-order polynomial fit, such as a quadratic or a linear fit, would not allow a large range of gain

values across the entire operating range. This would limit the sample space of available LEDs, since the gain is an

indirect reflection of its variation across temperature and required dim. As a result, a third-order fit allows the system

engineer to achieve a large variation in CCT and lumens across dim.

6 AN374REV2

Page 7

AN374

I

RedIRed ref

dim GAIN

DTR

=

[Eq. 2]

I

WhiteIWhite ref

dim GAIN

DR

=

[Eq. 3]

4 Light Engine Choices

This section examines key design considerations for a complete lamp design using the CS1630/31 two-channel

TRIAC dimmable driver IC. It provides some of the appropriate design choices based on a comprehensive

understanding of the CS1630/31 driver and digital control algorithms.

4.1 Considerations for the Color System

Constraint 1: Translating current versus dim requirements into a fourth-order or lower polynomial

Numerous smooth curves that do not have asymptotes at the origin can be modeled as a polynomial function.

The few exceptions are notable functions where the output current equals log

converter design requires a light engine that has a color curve that trends to any of these functions, then some

design tradeoffs must be considered. Such output current profiles are not widely prevalent in the consumer or

commercial lighting applications in which two-channel LEDs are typically used.

Constraint 2: The current versus dim plot should have intercept at origin

The final output currents for red current I

and white current I

Red

are calculated using Equations 2 and 3:

White

(dim) or 1/dim. If the power

10

These equations show that the current versus the dim will tend to the origin even for non-zero coefficients P00

and Q0.

The dim axis is an imaginary axis with no physical significance to an LED designer. This constraint causes

problems that can be substantially mitigated by remapping the dim axis, as demonstrated in section

Manipulating Data for Better Curve Fit on page 27.

Constraint 3: Placement of NTC with respect to light engine

The NTC can be placed close to the LEDs when the LEDs represent the junction temperature of the LEDs or

it can be placed farther away from the LEDs, where it represents the heat sink temperature or even the ambient

temperature inside the bulb. Each placement comes with its own advantages, and Steps 1 and 2 below

describe the implications of placing the LEDs in either location.

Step 1) Advantages of placing the NTC close to the LEDs

1. The problem of thermal mass is greatly reduced, which allows using simpler temperature protection and

thermal fold back.

2. Since the NTC is a good representation of the junction temperature, it is simpler to make light-system

models that can be used for designing the light engine.

3. Temperature protection systems such as thermal fold back and thermal shutdown can be more accurately

designed if needed, improving reliability in such applications.

Step 2) Disadvantages of placing the NTC close to the LEDs

1. The

of the NTC varies across temperature, and a narrow temperature range produces a more accurate

linear approximation. By having a large temperature rise on the NTC, the NTC is no longer accurate, since

the CS1630/31 can only accept a single

value and a single expression for the temperature.

2. If the thermal impedance between the NTC and the LED junction is large, the NTC will not accurately

represent the LED junction temperature, and the red current I

compensation may be incorrect. For

Red

example, when the NTC is placed close to the LED strings, then the measured temperature is a close

representation of the LED junction temperature. In a tight form factor and at full brightness, the

temperature rise from ambient to thermal equilibrium is significant. Typically, LED strings can take up to a

few minutes before they reach thermal equilibrium. When the system is started at ambient temperature

T

= 25C and full brightness, the NTC temperature and the junction temperature of the LEDs are at

amb

25

C. Since the curve fitter produces a gain function that is dependent on a combination of the red current

AN374REV2 7

Page 8

AN374

I

PK1 FBVBST

T1

CH1

L

P

----------------

200V

5.3s

3543H

---------------------

299m A== =

[Eq. 4]

I

MODE1 avgIPK1 FB

N

T2

CH1

2TT

----------------

299m

A 5.57

9.0s

2 35.05s

------------------------------

214m A== =

[Eq. 5]

I

, NTC, and dim variables, the curve fitter will have to compute gains across a larger number of points,

Red

which creates the risk of increased error. Failure to compensate for these points may cause a color shift

during startup until the LED strings reach thermal equilibrium.

Constraint 4: Red currents increase with an increase in ambient temperature

The current I

value.

in the red channel should increase monotonically with ambient temperature at a given dim

Red

Ambient Temperature

0

C300mA

25

C330mA

50

C360mA

Red Current Flowing in

Current Compensated Channel

Table 1. Maximum Measurable Switching Period

For example, if the current at ambient temperature T

T

= 25C, then the currents are non-monotonic with ambient temperature.

amb

= 50C is less than the current at ambient temperature

amb

Constraint 5: Maximum allowable color gain is 4.0

The recommended maximum gain value that the color system generates is 4.0. For example, the red current

at 25

C cannot be four times larger or smaller than any other current at the same dim value.

4.2 Constraints Imposed by Second Stage

Constraints in this section are imposed by the second stage. Calculations of these parameters are detailed in

application note AN368 Design Guide for a CS1630/31 2-Channel TRIAC Dimmable SSL Circuit. All variables

referenced in this document are computed in application note AN368.

Constraint 1: Currents in either channel should not be zero at non-zero dim values

Calculate peak current I

PK1(FB)

during Mode 1 using Equation 4:

Calculate the average current I

MODE1(avg)

during Mode 1 using Equation 5:

Equations 4 and 5 show that both channel currents share the same peak currents. It is difficult to have zero

current in one channel and have a non-zero current in the other channel. As a result, currents must be greater

than zero at all non-zero dim values.

Constraint 2: No abrupt change in current ratios at a dim point

It is recommended to avoid any abrupt change in the ratio of two-channel currents because it may cause color

flicker. The ratio of the channel current and the actual value of the string current should be a smooth function

which does not have any abrupt changes that become visible.

8 AN374REV2

Page 9

AN374

I

PK1 FB

I

PK2 FB

-------------------

P

MODE1

P

MODE2

--------------------=

[Eq. 6]

Constraint 3: Ratio of peak currents between the two channels must be less than 4

The DAC reference on the current sense comparator has a 1.4V full-scale threshold. There is a minimum peak

current I

ratio of the peak currents is 5.6. However, a range is required to dim down to the lower dimming settings.

Hence a ratio of 1.5 is considered optimum. Any peak ratio beyond 2.5 is considered a difficult requirement for

the driver to guarantee regulation across the dimming range. If the resonant reset time T3 is short and can be

neglected, then the ratio of the peak currents can be given as follows:

Refer to application note AN368 for detailed calculation.

Constraint 4: Both strings cannot have identical configuration

Either the output voltage differential should be maintained, or the output current differential should be

maintained. If the strings are placed in series, then the currents should never be the same at any point of the

dimming curve. If the strings are placed in parallel, then the voltage cannot be the same. The currents can

cross in a parallel load configuration. In a commercial lighting space that requires mixing white LEDs of

different wavelengths to produce a higher CCT white light (>3000K), it is recommended to have a different

number of white LEDs in the two LED strings when using the CS1630/31.

Constraint 5: Maximum differential between string voltages

The overvoltage protection (OVP) threshold is set to 1.25V and the FBSENSE comparator threshold is set at

a 200mV. As the dimmer conduction angle is reduced, the flyback operates continuously in DCM, while

maintaining valley switching for low losses. At very low conduction angles, the flyback may switch on the third

valley. Therefore, a minimum signal of 400mV on the FBAUX pin is recommended, which means that the string

voltage of one channel cannot be greater than three times the string voltage of the other channel in a parallel

load configuration. The FBAUX pin is used exclusively for overvoltage protection. In the event that a higher

string voltage differential is desired, an external circuit must be designed such that different divider ratios are

chosen for both modes of operation.

The OVP point is fixed for the higher of the two strings. For example, if one string has an output voltage of 5V

and the other string has an output voltage of 15V, the OVP point is still considered to be at greater than 15V.

Therefore, both output capacitors must be rated for the OVP voltage, which is in this case greater than 15V.

at full brightness threshold that is usually set at approximately 25%, so the theoretical maximum

PK(FB)

Constraint 6: The implications when determining LED string configuration and topology

Identify the light engine and select an appropriate second stage topology. There are two aspects that need to

be considered: first, whether to use the series or parallel LED configuration and second, which power train

topology to use.

AN374REV2 9

Page 10

AN374

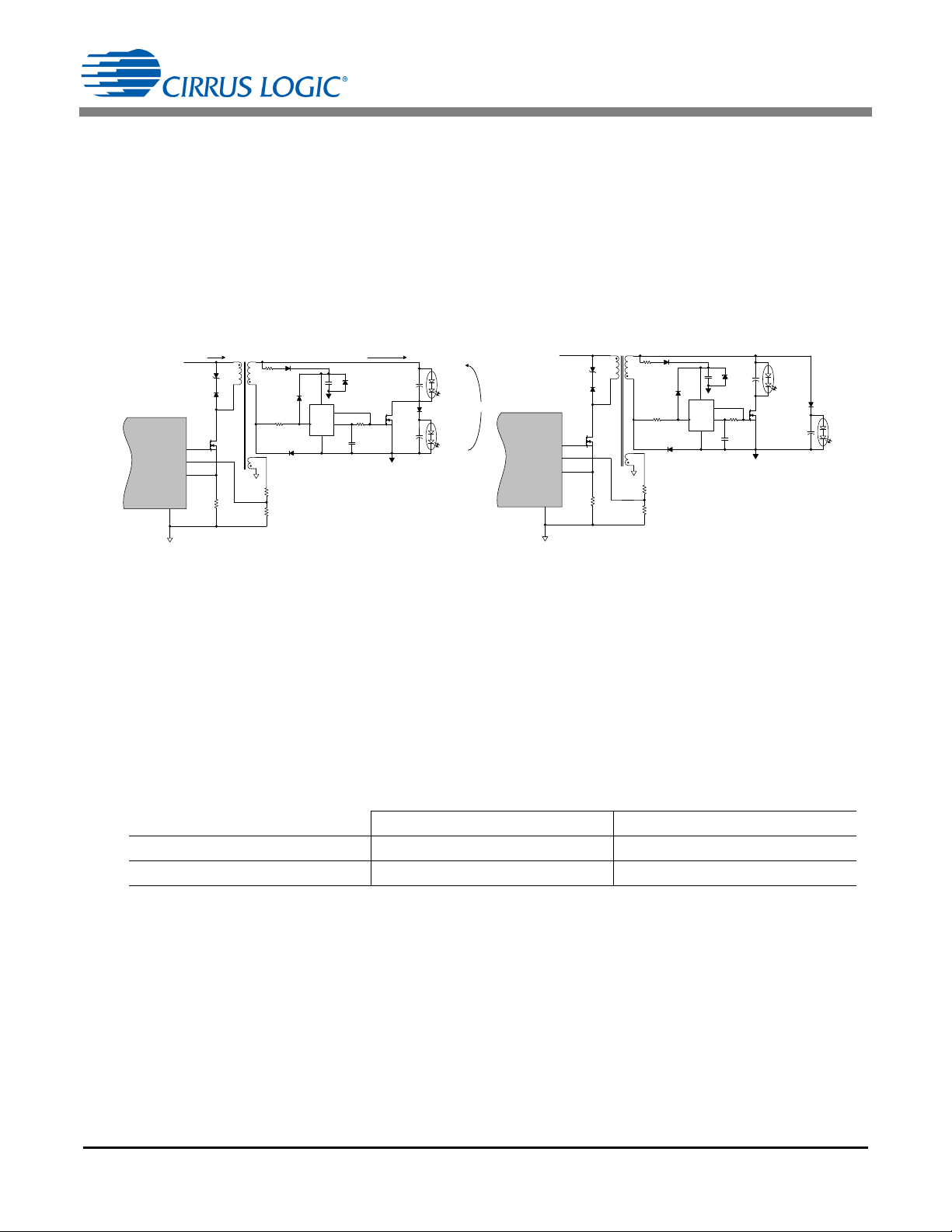

Figure 2a. Flyback Series Output Model Figure 2b. Flyback Parallel Output Model

D2

R22

Z3

R21

R23

Q5

CS1630 /31

FBAUX

GND

13

GD

FBSEN SE

15

12

11

TX1

V

BST

R3

D6

U2

C10

C8

C15

D5

D

GND

_

Q

VCC

D15

R12 D10

Q3

R2

C16

Channel 1 LED

(White)

Channel 2 LED

(Red)

GND

IGND

I

MODEx

I

PRI

V

MODEx

D9

D2

R22

Z2

R21

R23

Q5

CS1630 /31

FBAUX

GND

13

GD

FBSEN SE

15

12

11

TX1

V

BST

R3

D6

U2

C10

C15

C8

D5

D

GND

_

Q

VCC

D15

R12 D10

Q3

R2

C16

Channel 1 LED

(Whi te )

Channel 2 LED

(Red)

GND

IGND

D9

Step 1) LED string configuration

Determine if a series configuration or a parallel configuration is a viable solution for the identified light engine.

Figure 2a illustrates a series light configuration. The two LED strings are arranged in series so that current

passes through either one or both LED strings. A MOSFET is used to shunt current around one string on

alternating switching cycles. In this configuration, one string is required to have a larger current than the other

string. When considering a series design, it is recommended that the current flowing through one of the LED

channels be 80% or lower than that of the other LED channel at all times. The LED string that has current

flowing continuously is referred to as channel 1 LED (I

as channel 2 LED (I

CH2

); I

CH2

0.8I

CH1

.

), while the string with the bypass FET is referred to

CH1

Figure 2b illustrates a parallel light configuration. The two LED strings are networked in parallel so that current

flows to either the channel 1 LED string or the channel 2 LED string at any given T2 time. The CS1630/31

controller uses the LED forward voltage to detect which LED string is being driven. One LED string must

always have a larger forward voltage compared to the other LED string. The LED string with the higher voltage

is referred to as channel 1 LED with forward voltage V

to as channel 2 LED with a forward voltage of V

CH2

and the LED string with the lower voltage is referred

CH1

.

A good rule of thumb is that channel 2 LED must always have a forward voltage of 85% or lower than the

channel 1 LED to consider a parallel design. Table 2 defines the selection process based on the requirements

of the series and parallel output configuration.

V

< V

I

CH1

I

CH2

and I

CH2

< I

CH1

Cross Parallel Configuration Not Functional

CH2

Series or Parallel Configuration Series Configuration

CH1

Table 2. Series vs. Parallel

If there are problems converging on a target design using an existing light engine, the current and voltage

profile can be modified by adding, removing, or moving LEDs between the two LED channels. Figure 3

illustrates the parallel and series scenarios that can be configured using the CS163X Customer Application

tool.

10 AN374REV2

V

CH1

and V

CH2

Cross

Page 11

AN374

Step 2a:

Select Series

vs. Parallel

Step 2b:

Select Flyback,

Buck, or

Tapped Buck

Figure 3. Second Stage String Configuration

Bit STRING in register Config3 at address 7 selects the second stage output channel configuration. When bit

STRING is set to ‘1’ a series configuration is selected. Figure 3 illustrates the process used to select the

second stage flyback mode using the CS163X system design application.

Step 2) Select power train topology

The CS1630/31 supports three possible power train configurations: tapped buck, buck, and flyback (see

Figure 4a, 4b, and 4c). The two most important factors for selecting a power train configuration is whether the

output requires Underwriters Laboratory (UL) approved isolation and the input to output voltage ratio. The

flyback power train can be either isolated or non-isolated. Buck and tapped-buck designs are expected to

always be non-isolated. If isolation is not required, one of the three possible solutions must be selected. If

isolation is required, the design will be a flyback.

AN374REV2 11

Page 12

AN374

Figure 4a. Tapped Buck Series Output Model Figure 4b. Buck Series Output Model

R22

R21

R23

Q5

L3

D3

CS1630 /31

FBAUX

GND

13

GD

FBSENSE

15

12

11

V

BST

R3

D9

U2

C10

C8

C15

D11

D

GND

_

Q

VCC

R12 D10

Q3

R2

C14

Channel 1 LED

(White)

Channel 2 LED

(Red)

GND

IGND

D9

R22

R21

R23

Q4

L3

CS1630 /31

FBAUX

GND

13

GD

FBSENSE

15

12

11

D3

V

BST

R25

D9

U2

C13

C15

C16

D11

D

GND

_

Q

VCC

R26 D10

Q5

R27

C14

Z3

Channel 1 LED

(Whi te )

Channel 2 LED

(Red)

GND

IGND

Figure 4c. Flyback Series Output Model

D2

R22

Z3

R21

R23

Q5

CS1630 /31

FBAUX

GND

13

GD

FBSENSE

15

12

11

TX1

V

BST

R3

D6

U2

C10

C8

C15

D5

D

GND

_

Q

VCC

D15

R12 D10

Q3

R2

C16

Channel 1 LED

(White)

Channel 2 LED

(Red)

GND

IGND

I

MODEx

I

PRI

V

MODE x

D9

Flyback topology is enabled by setting bit S2CONFIG to ‘1’ in register Config12 at address 44. A flyback

topology is selected as a design guide example in application note AN368 so bit S2CONFIG is set to ‘1’. The

flyback transformer input-to-output voltage ratio is used to determine the duty cycle and minimum turn on time

T1 for the power FET. Buck topology is enabled by setting bit S2CONFIG to ‘0’ in register Config12 at address

44. If a buck topology is selected, the buck inductor is configured using bits BUCK[3:0] in register Config10 at

address 42. Set bits BUCK[3:0] to ‘0’ or ‘1’ for a normal buck topology. Tapped buck topology is enabled by

setting bit S2CONFIG to ‘0’ in register Config12 at address 44 and by setting bits BUCK[3:0] in register

Config10 at address 42 to the required value N, where N equals the turns ratio between primary and secondary

windings.

12 AN374REV2

Page 13

AN374

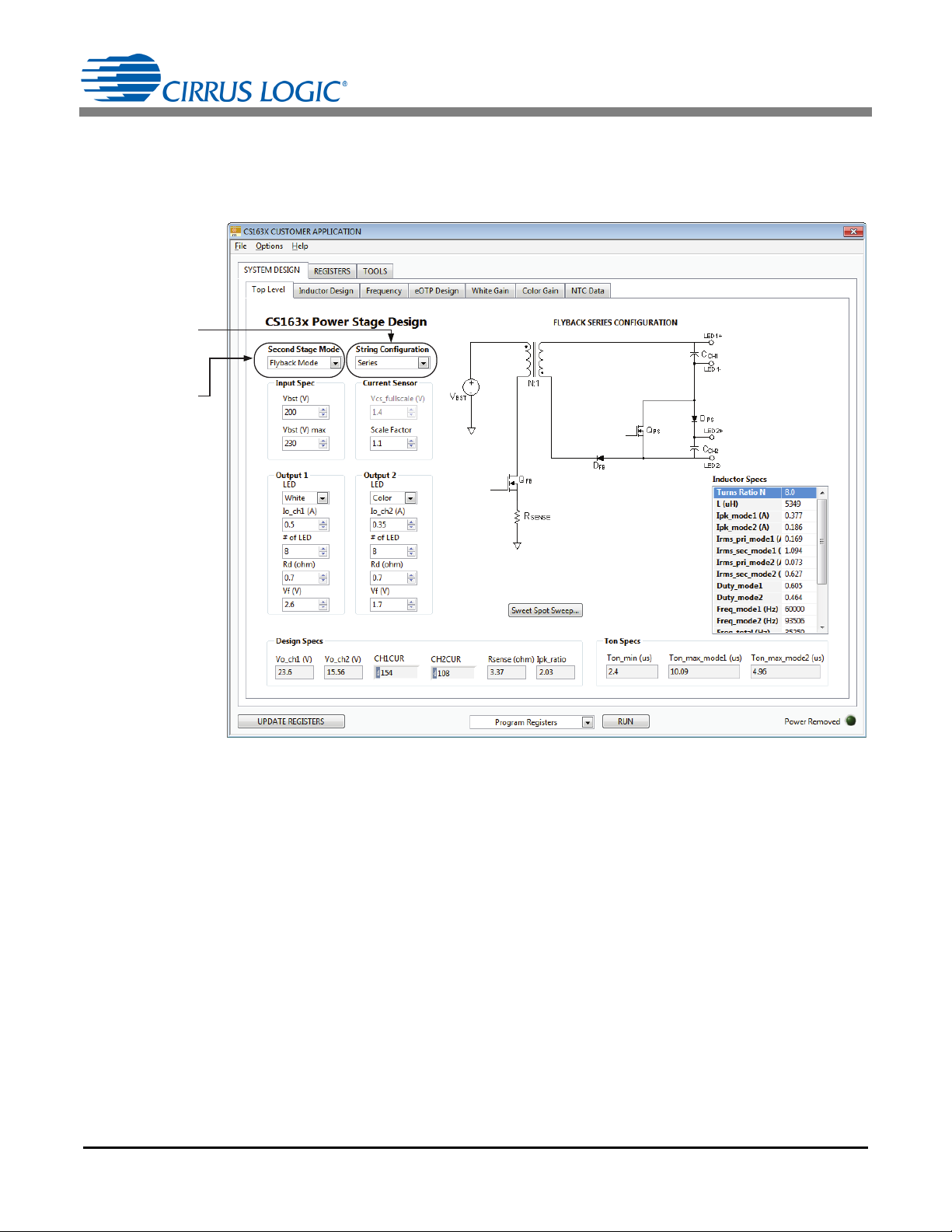

Figure 5. Selecting the Second Stage Mode Using the CS1630/ 31 System Design Utility

P

MODE1

V

CH1VCH2

+I

CH2

=

[Eq. 7]

Figure 5 illustrates the process used to select the second stage flyback mode using the CS1630 / 31 system

design utility.

The CS1630/31 has a minimum required T1 time that is dependent on leading edge blanking time T

Blanking time T

is programmable from 150ns to 800 ns and is used to effectively disable the peak current

LEB

comparator from turning off the gate drive too early due to spurious switching noise. In applied systems, a good

rule of thumb is to target a minimum duty cycle of 10% or greater.

Step 3) General considerations for all topology

1. In the series configurations, the current in one string will always be higher than the current in the second

string across the entire dim and temperature range. There are specific advantages to using the series configuration if the light engine specifications comply with the constraints. In Mode 1, the phase synchronizer

MOSFET is ‘OFF’ and the output power P

delivered to the load in a series design is calculated using

MODE1

Equation 7:

AN374REV2 13

LEB

.

Page 14

AN374

P

MODE2

I

CH1ICH2

–V

CH1

=

[Eq. 8]

P

MODE1

V

CH1ICH1

=

[Eq. 9]

P

MODE2

V

CH1ICH2

=

[Eq. 10]

In Mode 2 the phase synchronizer MOSFET is turned ‘ON’ and the output power P

MODE2

is:

2. In the parallel configuration, the voltages of the two strings should at least have a 20% difference between

the two strings in order for the CS1630/31 to distinguish between the two strings. The most common

application of a parallel string is to achieve low CCT at low dim (<2000 K) and maintain ~ 2700 K at full

brightness using a combination of mint/blue/white on one channel and amber/red on the other channel.

Depending on the configuration, the current I

in the white channel at low dim, whereas the current I

brightness. When the phase synchronizer MOSFET is ‘OFF’ the output power P

in the red channel may be higher than the current I

Red

may be higher than current I

White

MODE1

delivered to the

Red

White

at full

load in a parallel design is as follows:

and when the phase synchronizer MOSFET is turned ‘ON’ the output power P

MODE2

is as follows:

3. If the power delivered to the load is similar in both configurations, then the magnetic utilization will be the

maximum and the inductor size will be the smallest. For an LED configuration, the power can be computed

in the four possible scenarios and it can be determined which design would be the optimum if the size of

the inductor were the dominant factor in deciding between series and parallel configurations.

4. To quantify magnetic size, consider analyzing the peak current I

inductance L

of a system designed to drive a single LED string. For example, examine a design with the

P

, turns ratio N, and primary

PK(FB)

single string CS1610/11/12/13 driver IC. For a comparable CS1630/31-based system converting the same

level of output power, let peak current I

be I

PK2(FB)

. It is assumed that I

PK1(FB)

for Mode 1 be I

PK(FB)

> I

PK2(FB)

PK1(FB)

and peak current I

PK(FB)

for Mode 2

. Let turns ratio N be such that the effective reflected

voltage be the same so that their peak currents would be comparable between the two systems under

comparison.

14 AN374REV2

Page 15

AN374

Pow er Transf erred in a S ingle S tring Cont roller

Pow er Transf erred in a Tw o String C ontrol ler with

Unequal Balanc e between Two S trings

t

i(t)

T1 T2

TT

T3T1 T2

TT

T3

TT

T1

CH1

T2

CH1

TT

CH1

T3

CH1

T1

CH2

T2

CH2

TT

CH2

T3

CH2

t

Figure 6. Current Comparison through the Inductor

P

OUT dualPMODE1PMODE2

+= 2P

OUT glesin

[Eq. 11]

P

MODE1

P

OUT glesin

-----------------------------

2

1 +

------------------

[Eq. 12]

2F

sw

1 +F

sw1

------------------------------------

[Eq. 13]

Figure 6 illustrates the current comparison through the inductor. In this case, the buck is chosen to explain

the point. The same logic can be extended to the flyback topology as well.

In a single-string design, power P

OUT(single)

ered in the second switching period and the total power is equal to two times power P

channel design, the total power P

OUT(dual)

delivered in the first switching period TT equals power deliv-

OUT(single)

. In a two-

is approximately equal to:

The above equation yields Equation 12:

where

= P

MODE2/PMODE1

The size of the inductor depends on the amount of energy stored at a first-order approximation. The energy

stored in the inductor of a single string system is equal to P

in the inductor of a two string system is equal to P

by:

From Equation 13, it can be seen that the inductor for a CS1630/31-based equivalent system will be

Fsw. The maximum energy stored

. The size factor of the inductor is defined

MODE1

OUT(single)

F

sw1

times larger.

AN374REV2 15

Page 16

AN374

F

SW2

F

SW1

V

BST

NV

MODE1

+

V

BST

NV

MODE2

+

----------------------------------------------------------

I

MODE1VMODE2

I

MODE2VMODE1

------------------------------------------

=

[Eq. 14]

The following are disclaimers for this analysis:

a. This analysis works better for a non-isolated design. For isolated flyback designs, the size may be deter-

mined by safety requirements for either triple insulated wire or margin tape spacing. As a result,

increased peak current may or may not translate into the size of the inductor easily.

b. The explanation above shows a qualitative trend in understanding the tradeoffs of having power deliv-

ered to two strings unevenly. It is understood that it is not possible to determine a true analogy since the

reflected voltage and frequency vary over the two modes of operation in the CS1630/31. This comparison should only be viewed from a qualitative understanding of the system.

5. When considering efficiency, if the power delivered to the load in the two modes is significantly different,

then the frequency of operation of switching frequency F

the converter operates in CRM at full brightness.

The converter will switch at a very high frequency while converting very little power. The power converter’s

efficiency is low, however the power is transferred at two different frequencies and some amount of

spreading effects of the spectral energy can be observed. This can potentially be favorable from an EMI

perspective.

Step 4) Analyze system tradeoffs for efficiency when using a flyback topology

In a parallel configuration, the turns ratio will be higher for a given reflected voltage, so the leakage inductance

will also be higher. As a result, the peak voltage on the drain of the flyback MOSFET must be taken into

account. Since the effective output voltage is smaller, the synchronizer diode drop amounts to a much bigger

efficiency penalty as opposed to the parallel design case.

In a series design, the leakage inductance will be smaller for the same reflected voltage. The maximum voltage

on the rectifier diode is given by V

/ N + V

IN

. The diode must be a higher voltage rated diode, which

OVP

increases cost and may impact efficiency, depending on the reflected voltage.

In a flyback topology, it is difficult to predict the diode losses prior to the development of a system, since diode

losses vary significantly with junction temperature. This step is meant to serve as an added consideration when

choosing a certain load configuration.

sw1

and F

will be significantly different because

sw2

Step 5) Analyze system tradeoffs for efficiency when using a buck topology

The minimum voltage rating for the power diode is greater than 250V for the CS1630 and greater than 450V

for the CS1631. In order to guarantee optimum output current regulation in a buck converter, it is desirable to

have a duty cycle of at least 10%, and any duty cycle above 15% is considered optimal for the buck converter.

In a parallel configuration, the effective output voltage is lower, and the diode losses higher. The duty cycle is

smaller, since the effective output voltage is smaller. In a series configuration, the diode losses are lower, since

the diode drop is still set by the boost voltage V

and not the output voltage.

BST

Constraint 7: Note on Frequency and EMI

The frequency of the double pulse is dependent on the ratio of the power delivered in each mode. Both strings

having different power levels provides natural spreading of the spectrum for EMI. However, it decreases the

magnetic utilization of the core.

The following are the hard constraints on the frequency of operation:

1. Maximum switching frequency cannot exceed 200kHz.

2. Minimum switching frequency cannot be lower than the value programmed in the OTP register TTMAX at

Address 38.

16 AN374REV2

Page 17

AN374

R22

R21

R23

Q4

L3

CS1630 /31

FBAUX

GND

13

GD

FBSEN SE

15

12

11

D3

V

BST

C16

C15

D11

R27

Channel 1 LED

(Wh ite )

Channel 2 LED

(Red)

GND

R25

Q6

R26

SYNC

Q5

GND

Figure 7. Non-isolated Synchronizer Buck Series Output Model

4.3 Synchronizer Design Considerations

The synchronizer circuit drives an external MOSFET, which may be ground referenced depending on the topology.

Constraint 1: Non-isolated synchronizer circuit considerations

In the case of a non-isolated flyback, the secondary ground of the flyback can be referenced to the primary

ground thereby having the least expensive synchronous circuit solution consisting of the synchronous

MOSFET and the diode. The MOSFET is directly driven from the SYNC pin of the CS1630/31.

In the case of the buck topology, the outputs are referenced to link voltage and the following two options are

possible:

1. Level shifting the SYNC pin output to a higher voltage using an external BJT and a P-channel MOSFET

(see Figure 7).

2. Driving the synchronizer externally using flip-flop from the switching node or another winding off of the

buck converter.

4.4 Constraints on the Boost Stage

Constraint 1: Maximum power should be power at full AC sine wave

It is recommended to design the dimming curve such that the maximum output power is delivered to the load

at 100% brightness when the driver is behind the full AC sine wave.

Constraint 2: Power should be monotonically increasing

The output power in the driver should be close to monotonically increasing. If the available power from the

dimmer cut waveform at any conduction angle is smaller than the requested output power, then the link voltage

may not be in regulation at that conduction angle. In such a case, the peak currents on the boost inductor need

to be increased, and all design calculations mentioned in application note AN368 are no longer valid for that

particular design. Increasing peak currents may compromise EMI and efficiency.

AN374REV2 17

Page 18

5 Design Flowchart

Yes

No

Yes

No

Yes

No

Pick a light engine

candidate across dim

Compute peak currents

for a given transformer

using AN368

Start

Polynomial

approximation

possible?

Non-zero

currents across

dim?

Peak

current 4 times

smaller?

Proceed to choosing

string configuration

No abrupt

change in

current

ratio

?

Nonidentical string

configurations

across

dim?

Yes

Yes

No

No

No fundamental

limitations to using

light engine?

Figure 8. Eliminating Incompatible Light Engines

Figure 8 shows the flowchart for eliminating incompatible light engines.

AN374

18 AN374REV2

Page 19

Figure 9 shows a way for selecting the correct second stage string configuration.

Yes

No

Yes

No

Yes

No

Provide completed light

engine design across

dim and temperature

Not compatible

No hard limitations to

using either

string configuration

Start

Parallel string

configuration

Series string

configuration

Currents

cross at

any dim?

Voltage

Same?

Voltage

same?

Yes

No

Flyback topology. Series

and parallel string

configurations are sufficient

Buck?

Proceed to selecting

the topology

The series string

configuration has

higher efficiency

Figure 9. Selecting the Correct Second Stage String Configuration

AN374

AN374REV2 19

Page 20

Figure 10 shows a method for selecting the correct power train topology.

No

Yes

No

Start

Flyback

Flyback

Buck

Isolation

required?

Required

V

MODEx

/ V

BST

< 10%

Yes

Figure 10. Selecting the Correct Power Train Topology

AN374

20 AN374REV2

Page 21

AN374

1600

650

1

2

3

2700

Brightness (lm)

CCT (K)

Figure 11. Typical LED Light Engine Specifications

0.02

650

Brightness (lm)

1.0

1

0.02

2700

1600

CCT (K)

Dim

1.0

2

3

Figure 12. Light Engine Specifications Translated to an Imaginary Dim Axis

6 Data Improvements for the Curve Fitting Process

The curve-fitting process consists of translating a typical LED system specification into polynomial gain equations

that the curve fitter can then calculate the required current for a given dim and NTC reading. The gains can be used

in conjunction with the design of the power stage to complete a system design for a CS1630/31-based LED driver.

6.1 Typical Light Engine System Specifications

A typical light engine system specification is concisely captured in Figure 11. It is essentially a plot of the target

lumen output at a given target color correlated temperature (CCT). Points 1, 2, and 3 are some data points of

interest. These points have been used to define system behavior. The graph shows that the behavior is

expected to be constant across the entire operating temperature of the driver. If the behavior over temperature

were different, it can be represented as separate parameterized curves using the same axis.

6.2 Translation into Input Specifications for Calculating Color Gains

The light engine specifications above need to be translated into typical driver specifications that can be used

by the second stage of the CS1630/31 based driver.

Step 1) Introduction of an independent dim axis

The curve fitter polynomial equation is an equation across dim and NTC temperature. The independent dim

axis can be introduced as shown in Figure 12. At this point, the specifications can be redefined as needed to

find a trajectory the light engine needs to traverse in terms of CCT and brightness when the input dim level to

the system changes.

AN374REV2 21

Page 22

Step 2) Translate into LED current profile at room temperature

m1, I

Red

, m2, I

White

I

Red

/ I

White

Ratio of the 2

Channel’s Lumens

Sum of Each

Channel’s Lumens

Approximated

Using Current

Approximated

Using Current

0.02

650

1.0

1

0.02

2700

1600

Dim Dim Dim

1.0

2

3

0.02 1.0

1

0.02

Ratio

1.0

2

3

0.02 1.0

1

0.02

Ratio

1.0

2

3

K

1

, P

Red

+ K2, P

White

K1, P

Red

K

2

, P

White

Brightness (lm)

Brightness (lm)

Relative Brightness (lm)

CCT (K)

Figure 13. Translate Data and CCT Lumen Dependence on Output Current

0.02

Red

1.0

T

amb

= 5°C

T

amb

= 25°C

T

amb

= 40°C

T

amb

= 55°C

Figure 14. Red Current Across Dim at Various Ambient Temperatures

The translation is as shown in Figure 13.

AN374

Variables K

and K2 represent the luminous efficacy of the LED, and variables m1 and m2 are arbitrary

1

constants. The plot in Figure 13 illustrates the relationship between CCT and output currents, lumens, and

output power.

The data points 1, 2, and 3 are recreated under thermal equilibrium with the target LED light engine at room

temperature to obtain the LED current profiles for each channel across the entire range of the target lumen

output. The NTC temperature recorded on the final measurement is used on the driver. At the end of this

procedure, the following are obtained: the current versus dim, forward voltage versus dim, NTC resistance

versus dim, current ratio versus dim, and the LED light engine power profile data at room temperature.

Step 3) Validate data across various ambient temperatures

Finally, the same step needs to be completed across different ambient temperatures. All the measurements

should be performed when the system has reached thermal equilibrium. Once the data is taken, the sample

data is shown in Figures 14 and 15.

(A)

I

Dim

22 AN374REV2

Page 23

Note that any variation of the white string should be compensated for by changing the currents in the other

0.02 1.0

Dim

T

amb

= 5°C

T

amb

= 25°C

T

amb

= 40°C

T

amb

= 55°C

NTC Resistance (:

Figure 15. NTC Codes Across Dim at Various Ambient Temperatures

string so that the correct lumen and CCT are maintained across the entire temperature range of interest. At

this point, both the currents of the white LED across dim and the data represented in Figures 14 and 15 should

be available for the design.

6.3 Methods to Collect Required Data

The following sections describe the methods to collect the necessary data required for performing curve fitting.

6.3.1 Experimental Measurement in Lab

Experimental measurements are the most robust way to collect data. However, it is time consuming and

requires expensive test equipment. It also requires the final light engine that is to be used for the design. The

thermal resistance between the LED junction and the NTC should be known. In other words, the NTC should

be placed at its final location to best mimic the thermal resistance. The light engine should be placed in an

integrating sphere and characterized. For example, specifications with regards to CCT, Cx, Cy, lumens, and

CRI can be measured.

Each output string is connected to an independent DC source that can source the required voltage and

currents. The currents are experimentally changed until the desired points 1, 2, and 3 are obtained on

Figure 11. At each of these points, measure the NTC resistance when it stabilizes to a constant value. If the

NTC is not placed, then a thermocouple can be placed close to where the NTC will be placed and the

temperature can be recorded.

The process should be repeated at various ambient temperatures. The entire data is collected across the

various ambient temperatures to cover the thermal operating point space of the LEDs, which it is forced to

traverse during transients (even though the actual ambient temperature is not what was specified in the

spreadsheet). For example, it can alleviate the color shift problem at cold startup, as discussed in

sectionTranslation into Input Specifications for Calculating Color Gains on page 21.

Another advantage of this approach is that it naturally compensates for any variation in the behavior of the

other string across the various ambient temperatures by adjusting the two strings accordingly. Performing this

experiment of accurately measuring the data across various ambient temperatures using an integrating sphere

is not easy.

AN374

6.3.2 Simulation

Some of the designs can be done on the spreadsheet if at the least the following are available:

• Theoretical models for LED behavior across junction temperature

• Thermal model of the junction to NTC temperature thermal resistance

• NTC model

• Good optics and reflector model with respect to diffuser and LED beam angles

AN374REV2 23

Page 24

AN374

T

amb

TJT

25 C

–=

[Eq. 15]

T

NTC

TJT

NTC

–=

[Eq. 16]

TJT

amb 0CTamb

+=

[Eq. 17]

T

NTC

T

amb 0CTNTC

+=

[Eq. 18]

R

T1

RT0e

1

T1

-------

1

T0

-------

–

=

[Eq. 19]

I

Red 0CIRed 25C

1

2

-------

=

[Eq. 20]

I

Red 40CIRed 25C

1

3

-------

=

[Eq. 21]

6.3.3 Experiment and Approximation

In many cases, collecting data at room ambient is not difficult. However, getting data across various ambient

temperatures, particularly at low temperatures, is not easy. In an event where getting data is not feasible at

ambient temperatures outside of room temperature, existing 25

based on data sheet numbers of the LED and measured temperature rises. If the requested operating

temperature is very large (

T

> 50C), then the errors due to this simple linear approximation may be too

amb

high. Remember that the method is a simple approximation and subject to errors that may vary depending on

the system under investigation.

The following method is suggested to extend data to other ambient temperatures. In this case, two ambient

temperatures of 0

C and 40C are chosen. These are some of the assumptions that are made. The

temperature rise from ambient is assumed to be constant irrespective of the actual ambient temperature level.

Step 1) Collect red current I

25

C ambient temperature T

, white current I

Red

amb(25C)

, and NTC data and junction temperature TJ of the LED at

White

from 0% dim to 100% dim.

Step 2) Calculate the following:

C data can be extended to other temperatures

Step 3) Calculate the various NTC temperature T

and junction temperature TJ of the LED at various

NTC

ambient temperatures across the entire dimming range as follows:

Step 4) Calculate the NTC resistance using the equation of the system at 25

C ambient and the expression

At this point, a complete sample space has been recreated using the temperature rise. The remaining steps

are focused on recreating the red currents I

across temperature.

Red

Step 5) Refer to the LED data sheet for the Relative Luminous Flux Curve and note the relative luminous flux

at ambient temperature T

fluxes at 25

C, 0C, and 40C ambient, then the red currents can be calculated using Equations 20

= 25C, 0C, and 40C. If 1, 2, and

amb

are the relative luminous

3

and 21:

Thus by performing this at every dim level, the entire dimming data required can be constructed.

24 AN374REV2

Page 25

6.4 Improving Data for Feeding the Curve Fitter

NTC Beta 4334 Vref 1.25 ENTER DIM VALUES (BwDim, RedDim), CURRENTS (I_bw, I_red)AND NTC TEMPERATURE (Tntc) in deg. C

NTC T0 °C 25 Nbit 8 NTC code IS COMPUTED FROM Tntc AND NTC PARAMETERS

NTC Rs at T0 100000 Ifs 8.00E-05

Series R 14000 іNTC PARAMETERS

љљ

BwDim I_bw (A) ї enter 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

0.1 0.068

0.2 0.131 Tamb(room)

computedќ

enter ќ

0.3 0.190 ї enter 5.00 0.042 0.078 0.110 0.138 0.161 0.180 0.196 0.207 0.216 0.221 0.09 0.16 0.23 0.28 0.33 0.37 0.40 0.42 0.44 0.45

0.4 0.246 15.00 0.044 0.083 0.116 0.145 0.170 0.190 0.206 0.218 0.227 0.233 0.09 0.17 0.24 0.30 0.35 0.39 0.42 0.45 0.46 0.48

0.5 0.297 25.00 0.046 0.087 0.122 0.153 0.179 0.200 0.217 0.230 0.239 0.245 0.09 0

.18 0.25 0.31 0.36 0.41 0.44 0.47 0.49 0.50

0.6 0.344 45.00 0.049 0.091 0.128 0.160 0.187 0.210 0.228 0.241 0.251 0.257 0.10 0.19 0.26 0.33 0.38 0.43 0.46 0.49 0.51 0.53

0.7 0.386 65.00 0.051 0.096 0.135 0.168 0.197 0.220 0.239 0.253 0.264 0.270 0.10 0.20 0.28 0.34 0.40 0.45 0.49 0.52 0.54 0.55

0.8 0.425 85.00 0.053 0.101 0.142 0.177 0.207 0.231 0.251 0.266 0.277 0.284 0.11 0.21 0.29 0.36 0.42 0.47 0.51 0.54 0.57 0.58

10.490

Tamb(room) enter ќ

5.00 5.20 7.40 9.60 11.80 14.00 16.20 18.40 20.60 22.80 25.00

15.00 15.20 17.40 19.60 21.80 24.00 26.20 28.40 30.60 32.80 35.00

25.00 25.20 27.40 29.60 31.80 34.00 36.20 38.40 40.60 42.80 45.00

45.00 45.20 47.40 49.60 51.80 54.00 56.20 58.40 60.60 62.80 65.00

65.00 65.20 67.40 69.60 71.80 74.00 76.20 78.40 80.60 82.80 85.00

computedќ

13.5 15.2 17.0 19.0 21.2 23.6 26.1 28.9 31.9 35.1

22.5 25.0 27.6 30.5 33.6 36.9 40.5 44.2 48.2 52.4

35.4 38.8 42.5 46.3 50.4 54.7 59.2 64.0 68.9 73.9

74.4 79.7 85.1 90.6 96.2 102.0 107.7 113.6 119.5 125.3

Hight Temp Code Limit 185 125.9 131.7 137.5 143.3 149.0 154.6 160.0 165.4 170.7 175.8

Low Temp Code Limit 12 176.2 181.1 185.9 190.6 195.0 199.3 203.4 207.4 211.2 214.8

RedDim

RaƟo (String2/String1)

Tntc[C]

NTC code

I_red

0.00

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0 0.2 0.4 0.6 0.8 1 1.2

RaƟo

Dim

Current RaƟos Vs Dim

Tamb = 5C

Tamb=15C

Tamb = 25C

Tamb=45C

Tamb=65C

Tamb=85C

0.000

0.100

0.200

0.300

0.400

0.500

0.600

0 0.2 0.4 0.6 0.8 1 1.2

Output Current (mA)

Dim

Currents Vs Dim

I_BW

I_RED 5C

I_RED 15C

I_RED 25C

I_RED 45C

I_RED 65C

I_RED 85C

Step 1:

Enter NTC

Configuration

Step 4:

Enter Current Ratio

vs Dim and Temp

Step 5:

Enter Temperature or

NTC Resistance

Step 6:

Compute NTC Code

Step 3:

Enter Red Current vs

Dim and Temperature

Step 2:

Enter Blue

Current vs Dim

Figure 16. Example Spreadsheet Used to Collect Curve Fitting Data

NTC Beta 4334 Vre f 1.25

NTC T0 °C 25 Nbit 8

NTC Rs at T0 100000 Ifs 8.00E-05

Se ries R 14000

Does Not Change

Figure 17. NTC Specification from Example Spreadsheet

NTC

CODE

4M

R

Series

RT0e

1

T1

-------

1

T0

-------

–

+

--------------------------------------------------------------------------

=

[Eq. 22]

This section demonstrates the use of a spreadsheet to manipulate the data collected in the previous section

to get a more accurate curve fit. The data is presented in a format compatible with the curve fitter software.

6.4.1 Understanding the Data and Data Format

The final data can be collected in a spreadsheet. An example of the spreadsheet is shown in Figure 16. Steps

are provided to the left to describe the process.

enter enter

0.9 0.460

85.00 85.20 87.40 89.60 91.80 94.00 96.20 98.40 100.60 102.80 105.00

AN374

The NTC configuration section is shown in Figure 17. Values for Vref, Nbit and Ifs are internal parameters of

the IC that do not change. The beta and initial resistance at the initial temperature can be changed.

The NTC code can be generated using Equation 22. If temperature is specified in the system, then:

where

Temperature T1 and T0 are in degrees Kelvin

AN374REV2 25

Page 26

AN374

NTC

4M

R

NTCRSeries

+

--------------------------------------

=

[Eq. 23]

enter enter

љљ

0.1 0.068

0.3 0.190

0.4 0.246

0.6 0.344

0.7 0.386

0.8 0.425

0.9 0.460

Enter dim values

in ascending order

At 50% dim,

I

White

= 0.297 A

Figure 18. Example of Formatted Data for the White/Blue Current Across Dim

ї enter 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

5.00 0.042 0.078 0.110 0.138 0.161 0.180 0.196 0.207 0.216 0.221

15.00 0.044 0.083 0.116 0.145 0.170 0.190 0.206 0.218 0.227 0.233

25.00 0.046 0.087 0.122 0.153 0.179 0.200 0.217 0.230 0.239 0.245

45.00 0.049 0.091 0.128 0.160 0.187 0.210 0.228 0.241 0.251 0.257

85.00 0.053 0.101 0.142 0.177 0.207 0.231 0.251 0.266 0.277 0.284

5.00 5.20 7.40 9.60 11.80 14.00 16.20 18.40 20.60 22.80 25.00

15.00 15.20 17.40 19.60 21.80 24.00 26.20 28.40 30.60 32.80 35.00

65.00 65.20 67.40 69.60 71.80 74.00 76.20 78.40 80.60 82.80 85.00

85.00 85.20 87.40 89.60 91.80 94.00 96.20 98.40 100.60 102.80 105.00

computedќ

13.5 15.2 17.0 19.0 21.2 23.6 26.1 28.9 31.9 35.1

22.5 25.0 27.6 30.5 33.6 36.9 40.5 44.2 48.2 5 2.4

125.9 131.7 137.5 143.3 149.0 154.6 160.0 165.4 170.7 175.8

176.2 181.1 185.9 190.6 195.0 199.3 203.4 207.4 211.2 214.8

RedDim

Tntc[C]

NTC code

I_red

At 30% dim,

I

Red

= 0.122 A and

T

NTC

= 29.60°C

Enter dim values in ascending order

Enter

temperature

values in

ascending

order

Figure 19. Example of Formatted Data for Red Current and NTC Resistance/Code Across Dim

If resistance is measured, then

The data below shows the white/blue currents across the dim. The format in Figure 18 is useful because it is

required when the data is imported into the curve fitter.

BwDim I_bw (A)

0.2 0.131

0.5 0.297

10.490

The blue/white current at 100% will be considered the nominal current at full sine wave. The reference currents

are set based on this value.

The red currents and the corresponding temperature data are shown below.

Tamb(room)

Tamb(room) enter ќ

The target currents will be the currents at 100% dim and 25

Figure 19 shows the computed NTC resistance according to Equation 22. The NTC code is the internal

computed value used by the CS1630/ 31.

26 AN374REV2

computedќ

65.00 0.051 0.096 0.135 0.168 0.197 0.220 0.239 0.253 0.264 0.270

25.00 25.20 27.40 29.60 31.80 34.00 36.20 38.40 40.60 42.80 45.00

45.00 45.20 47.40 49.60 51.80 54.00 56.20 58.40 60.60 62.80 65.00

35.4 38.8 42.5 46.3 50.4 54.7 59.2 64.0 68.9 73.9

74.4 79.7 85.1 90.6 96.2 102.0 107.7 113.6 119.5 125.3

C ambient temperature. The NTC code data in

Page 27

AN374

6.4.2 Manipulating Data for Better Curve Fit

As mentioned previously, the curve fitter looks for a polynomial fit with a maximum of fourth order. There are

a few quick techniques that can be performed to make a better fit. This section shows some of the common

techniques used to improve the quality of data and therefore the quality of the fit. In this section, it is assumed

that the data, if attempted to be fitted using a curve fitter, provides a large error, so improvements are

necessary.

Step 1) Use a weighted fit

A weighting inequality can be enforced such that some regions can be given higher weights thereby forcing

the curve fitter to reduce the error while fitting in those regions. This is particularly useful when the observed

error is skewed more towards the region of interest as opposed to regions where the light bulb may not operate

regularly.

Step 2) Identify the region of interest

Some data points on the curve fitter have a larger significance to the light bulb as opposed to others. These

regions should be identified immediately and the curve fitting should be done in such a way that the errors in

these regions are minimized as a first priority.

Consider an example where an incandescent dimming profile is requested with 2% lumen output is required

at the lowest dim settings. Since all the major standards and specifications such as UL, LM79 are based on

full sine wave operation, that region is important and high accuracy in both lumen output and CCT is desirable.

From experience, it has been observed that at a low conduction angle, the light output is so small that the eye

is not yet saturated and if the two strings are not mixed correctly along the Planckian locus, the individual

components will be visible. It is important for the curve-fitting process to have minimal error in this region. In

most of the other regions, some amount of allowance could possibly be made depending on the application.

Step 3) Add trendline in a spreadsheet to see outliers in data

The trendline function in a spreadsheet or any other function in a compatible software helps identify any

outliers in the data. The following guidelines describe what to consider while using this trendline functions:

1. Choose a polynomial function of order 2, 3, or 4 for the current versus dim on the red and white currents.

A linear fit is acceptable if it produces a lower mean squared error (MSE).

2. Set intercept to origin

3. Display the equation on the chart

4. Display MSE on the chart (R2)

5. The trendline provides physical intuition in understanding where the potential problems may lie in trying to

fit the data into a polynomial curve.

Step 4) Dim axis remapping

Many data that may even look fundamentally incompatible with the curve fitter can be made to fit well by

remapping the dim axis. Mathematically a straight line with an equation Y = Mx + B can be made to be a line

Y = Mx by adding -B/M to every point on the x axis. Thus by shifting the whole axis to the right by B/M, the

curve can be made to pass through the origin.

Figure 20 shows another example of the above statement. In this case, by merely changing the dim point on

the axis from 0.4 to 0.5, the data that was an outlier is now part of the good data set. From a physics standpoint,

this still does not have any impact to the system specifications since the red current and the white current

combination remain the same.

AN374REV2 27

Page 28

AN374

0.05

0.125

0.25

0.375

0.5

0.03

0.075

0.15

0.225

0.3

0

0.1

0.2

0.3

0.4

0.5

0.6

0 0.2 0.4 0.6 0.8 1 1.2

LED Current (A)

Red LED Current

White LED Current

Figure 20. White and Red LED Current vs Dim

Notes: 1. Based on relative brightness.

Dim

1

I

White

(mA) I

Red

(mA)

0.10 0.050 0.030

0.25 0.125 0.075

0.40 0.250 0.150

0.75 0.375 0.225

1.00 0.500 0.300

0.05

0.125

0.25

0.375

0.5

0.03

0.075

0.15

0.225

0.3

0

0.1

0.2

0.3

0.4

0.5

0.6

0 0.2 0.4 0.6 0.8 1 1.2

Current (A)

White LED Current

Red LED Current

Figure 21. Corrected White and Red LED Current vs Dim

Notes: 1. Based on relative brightness.

Dim

1

I

White

(mA) I

Red

(mA)

0.10 0.050 0.030

0.25 0.125 0.075

0.50 0.250 0.150

0.75 0.375 0.225

1.00 0.500 0.300

When re-mapping the dim axis, remember the following points:

• The dim axis needs to be remapped to the white current and the red current axis simultaneously.

Otherwise, the data will be altered.

• In the plot in Figure 20 it can be seen that the data point is to the left of the trendline for the red current and

the white current. Moving the dim axis helps mitigate the problem under these circumstances.

Dim (%)

• If the red point and the white point were tending in the opposite way, remapping the dim axis to the center

could split the error for the same polynomial. One can change the shape of the trendline used for either one