Page 1

AN366

Application Note

CS5480/84/90 Energy Measurement IC Calibration

1 Introduction

The Cirrus Logic CS5480/ 84/ 90 energy measurement IC is designed with industry-leading calibration algorithms

that simplify measurement applications. The CS5480/84/90 calibration is engineered so power meter manufacturers

can use low-cost components to achieve highly accurate power measurement. Calibration methods specified by IC

manufacturers can vary substantially despite the power meter manufacturers’ requirements to comply with tightly

regulated standards. This application note will introduce the procedures available for calibrating the CS5480/84/90

devices, empowering power meter manufacturers to exceed industry standards.

2Overview

This application note covers system scaling concepts, including hardware scaling, analog front end (AFE) scaling,

and controller (MCU) scaling. The relationship between full-scale measurements and AFE measurements is

discussed, and a corresponding application processor example is presented. The typical hardware configuration

required to perform calibration and compensation is also presented. Then the types of calibrations in the

CS5480/84/90 are detailed. The calibration and compensation procedure is provided in a step-by-step process that

determines the AFE calibration and compensation constants.

Flow diagrams are provided for each calibration and compensation process. The customer demonstration board

(CDB5484U) is used to illustrate the calibration process and provide examples of the serial port reads / writes

transmitted at each calibration step.

Below are the calibration essentials discussed in this document:

- System Scaling

- Types of Calibration and Compensation

- Calibration and Compensation Procedure

- Calibration and Compensation Example with Hardware Configuration

3 System Level Configurations

Upon power-up, the CS5480/84/90 requires an initial register configuration before executing power measurements.

One of the key configurations is adjusting the system scaling for the power meter application. The key scaling

constants are identified through calibration and compensations performed at the power meter manufacturer. After

the configuration and calibration constants are established, the calibration constants are downloaded during a

normal power-on reset. The application will start conversions and report power and input performance over time.

During power conversions and calculations, the analog inputs are sampled at 512 kHz, decimated down to 4 kHz

high-rate conversion cycles. The high-rate samples are averaged to produce a 1 second low-rate power

accumulation measurement, which is used to update registers and, when enabled, generate pulses that represent

the power results (N = 4000, MCLK = 4.096 MHz). The CS5480/84/90 performs signal conditioning along the digital

data path, which improves the accuracy of the power meter measurements. Signal conditioning is provided in the

high-rate path (gain, phase, and DC offset) and in the lower rate path (no load current RMS offset, AC offset, active

and reactive power offset).

Cirrus Logic, Inc.

http://www.cirrus.com

Copyright Cirrus Logic, Inc. 2012

(All Rights Reserved)

MAY’12

AN366REV2

Page 2

AN366

3.1 System Scaling Overview

The maximum voltage, current, and power measurements are unique in each meter design and dependent on

the sensors used in the measurement of these parameters. The CS5480 / 84/ 90 solves this problem using scaling. Instead of recording the actual voltage, current, or power sensed by the power meter, the IC records a ratio

of each measurement that is proportional to the meter’s full-scale. Using this ratio, the actual voltage, current,

and power can be calculated based on the values of the AFE registers.

There are two methods of obtaining the most recent power measurement readings:

- Voltage, current and power measurements are read directly from registers using the serial port.

- Power measurements are accumulated using the pulses on the DO pin(s).

Both methods are dependent on full-scale calibration to accurately scale the most recent power measurement.

Traditional power meters typically use the pulse accumulation method. Since calibration constants are recorded

in registers and power measurements are reported by register reads/writes, this document will focus on the register read/write method.

To use the built-in calibration functions, an understanding of the scaling factors due to the different system components within a typical meter is required. Below are three general scale factors in the signal path:

- Hardware Scale: The real voltage and currents are provided to the meter using sensors that must be

attenuated on the meter board or by the sensor before applying the sensed signal to the input of the

CS5480/84/ 90.

- AFE Register Scale: The device stores information for each voltage, current, and power parameter to

internal registers. Each register value is scaled to a range of ±1 or 0 to 1 and stored in a 24-bit register.

The values measured at the input (for example, 500mVpp) are stored as a scaled version of input signal

amplitudes. Refer to the CS5480/ 84/ 90 data sheet for register formats. The gain and offset registers

are scaled to be within the range of 0 to 4 and ±1, respectively. Therefore, the MCU does not read the

sensor output voltage and current; instead, it reads the scaled values recorded in the registers.

- MCU Scale: The MCU is typically used to rescale the real voltage, current, and power values for display.

2 AN366REV2

Page 3

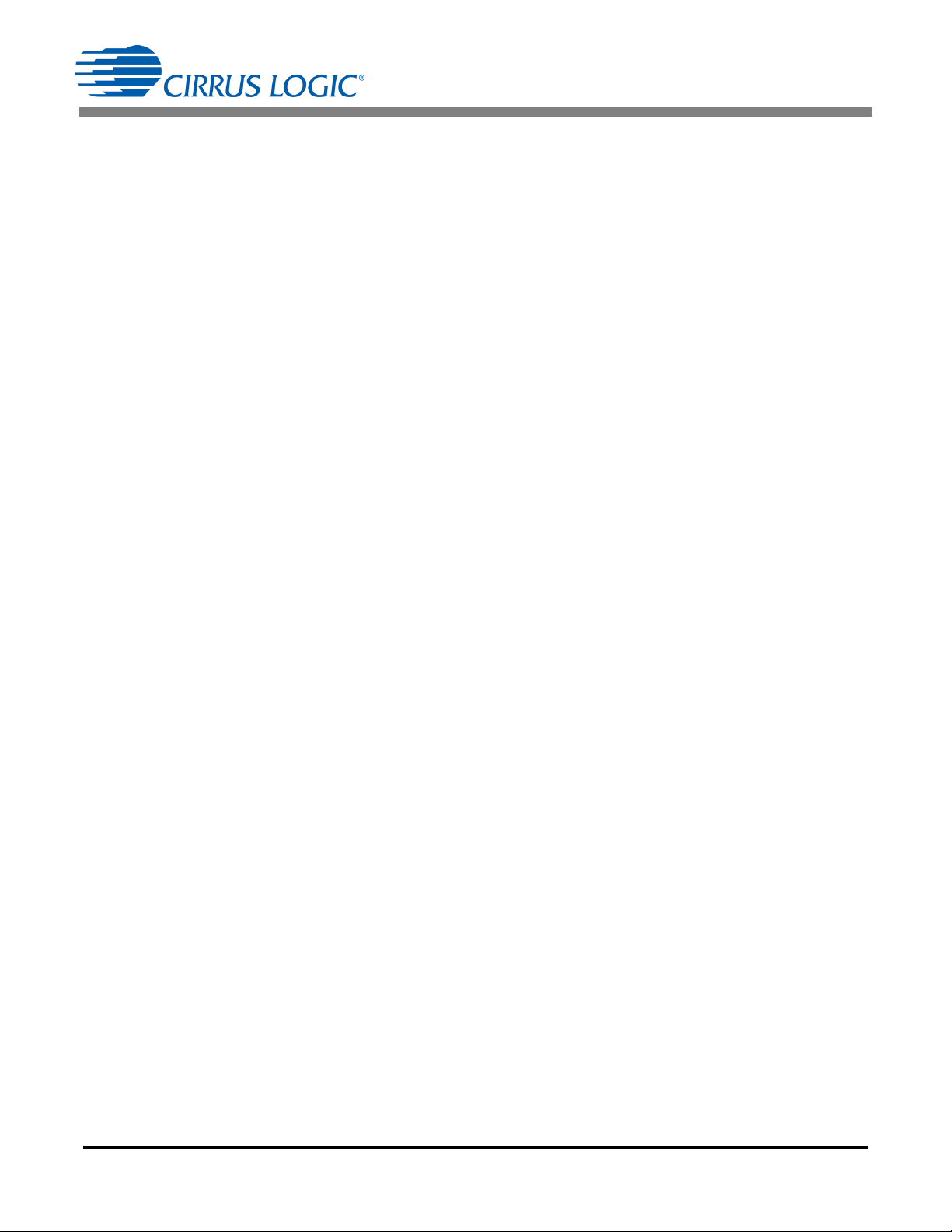

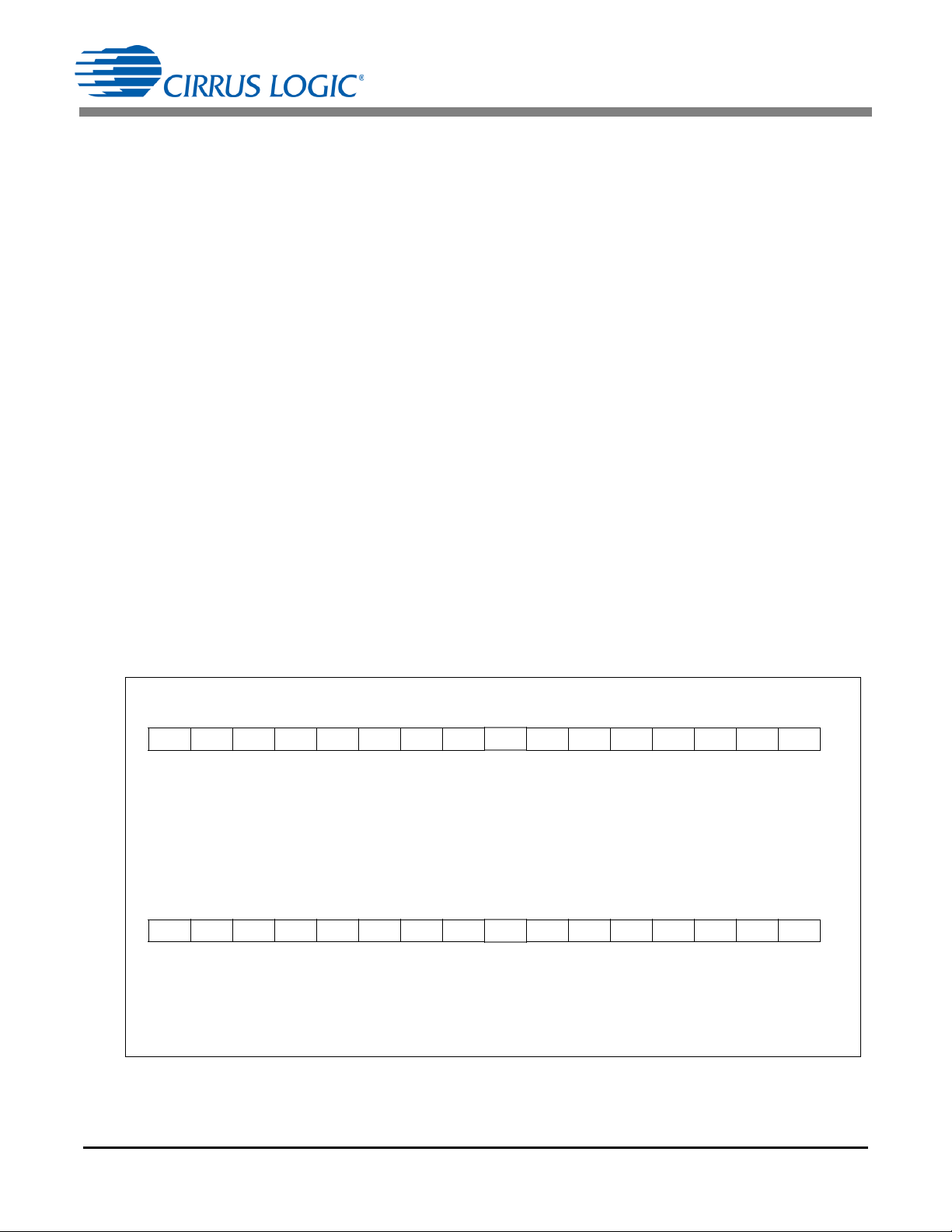

3.2 System Scale Example

CS 5480 / 84 / 90

(AF E)

LN

VIN-

VIN+

IIN+

IIN-

Application

Pro cessor

LOAD

CT

Pulse

Pulse

OR

Display

Power

19 .2 kW

240 V

RMS

,

80 A

RMS

176 m V

RMS

,

35 m V

RMS

19 .2 kW

240 V

RMS

,

80 A

RMS

Pavg: ±0.36

V

RMS

: 0.6

I

RMS

: 0.6

Hardware

Scale

AFE

Scale

MCU

Scale

19 .2 k W

240 V

RMS

,

80 A

RMS

Input Output

Seri al

Port

Figure 1 illustrates an example of the system scaling.

AN366

Figure 1. System Scaling

- Hardware Scale: The CS5480/ 84 /90 inputs are scaled using attenuation circuits that apply a maximum

input amplitude of 176mV

RMS

or 35mV

, which is dependent on an AFE gain setting of 10x gain or

RMS

50x gain, respectively.

- AFE Scale: The AFE registers record input levels that are displayed as a ratio of the most recent

measurement to the maximum RMS voltage and RMS current. The maximum RMS register value is

generated using a 0.6 ratio. The register value is read as a 24-bit hexadecimal number, which is

proportioned to represent a 0.6 V

the maximum power is P

- MCU Scale: The MCU is required to read all registers and interpret the 24-bit hexadecimal numbers

MAX

= V

full scale. At maximum voltage (0.6) and maximum current (0.6)

RMS

RMSMAX

× I

RMSMAX

= 0.6 × 0.6 = 0.36.

based on full-load conditions. Knowing the maximum hardware scaling and the most recent AFE

register values in relation to the full-scale input, the MCU routines are able to calculate the actual power

measurements.

AN366REV2 3

Page 4

AN366

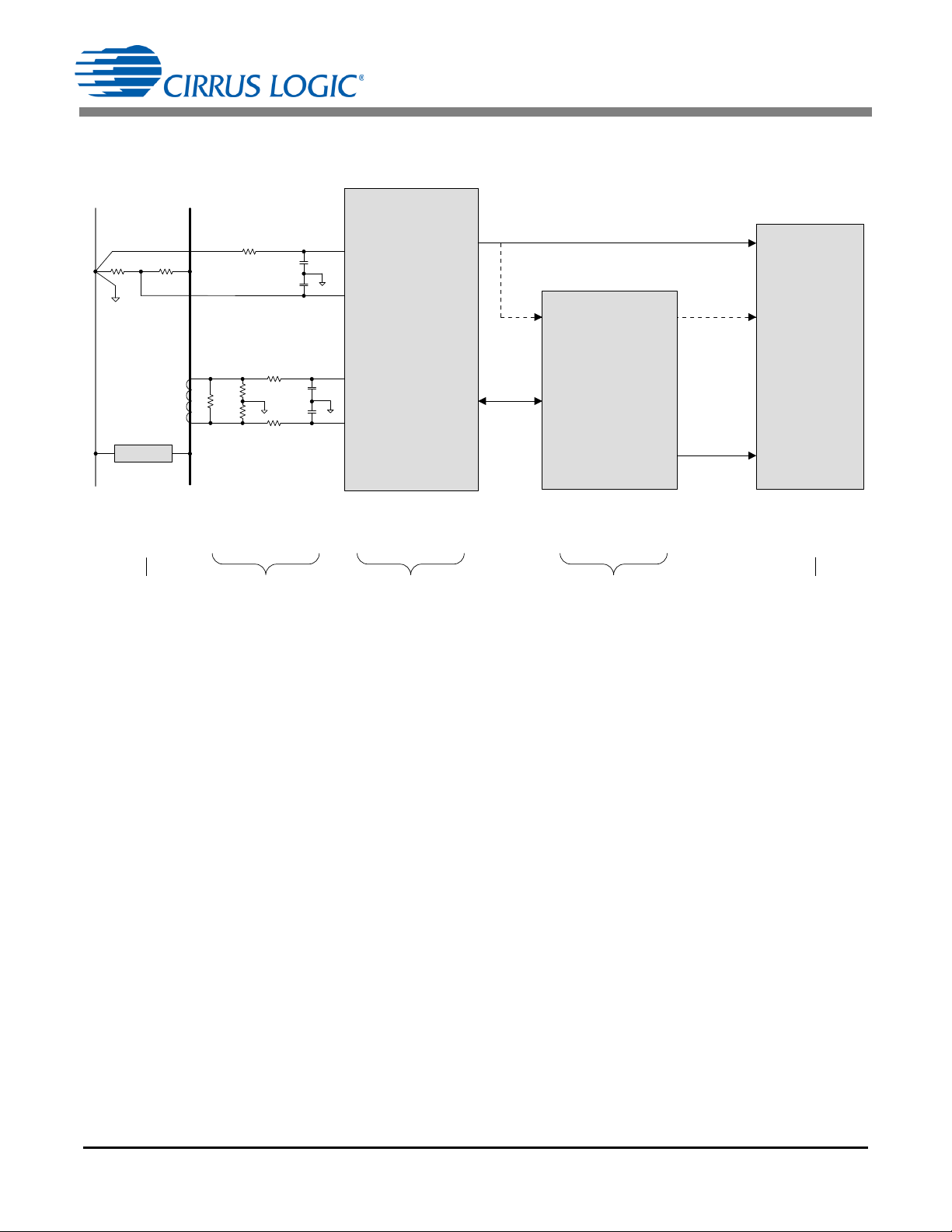

RMS 1 Current (I1

RMS

) – Page 16, Address 6

Default = 0x00 0000

I1

RMS

contains the root mean square (RMS) values of I1, calculated during each low-rate interval.

This is an unsigned value in the range of 0 value 1.0, with the binary point to the left of the MSB.

RMS Voltage 1 (V1

RMS

) – Page 16, Address 7

Default = 0x00 0000

V1

RMS

contains the root mean square (RMS) value of V1, calculated during each low-rate interval.

This is an unsigned value in the range of 0 value 1.0, with the binary point to the left of the MSB.

MSB LSB

2

-1

2

-2

2

-3

2

-4

2

-5

2

-6

2

-7

2

-8

.....

2

-182-192-202-212-222-232-24

MSB LSB

2

-1

2

-2

2

-3

2

-4

2

-5

2

-6

2

-7

2

-8

.....

2

-182-192-202-212-222-232-24

Figure 2. Example of I

RMS

and V

RMS

Registers

VALUE

Decimal

1

2

24

1–

------------------

hex2dec VALUE

Hexidecimal

=

[Eq: 1]

V

PEAK

V

RMS

2 0.6 2 0.85===

[Eq: 2]

3.3 AFE Scaling Range

The CS5484 full scale RMS register values are commonly reported as 0.6 when the inputs are at a maximum

level. The ratio of the AFE inputs to full scale defines the reference point for all other input levels. The 24-bit

I1

and V1

RMS

does not match the scaling for power (signed). Section 6.2 Main Calibration Flow Diagram Using the CDB5484

on page 29 describes the scaling ratio of the AFE inputs when maximum input levels are applied.

registers are defined in Figure 2. Note that the digital scaling for RMS current (positive only)

RMS

Use Equation 1 to convert the hexadecimal value to a decimal value:

Using Equation 1, the following key values are identified:

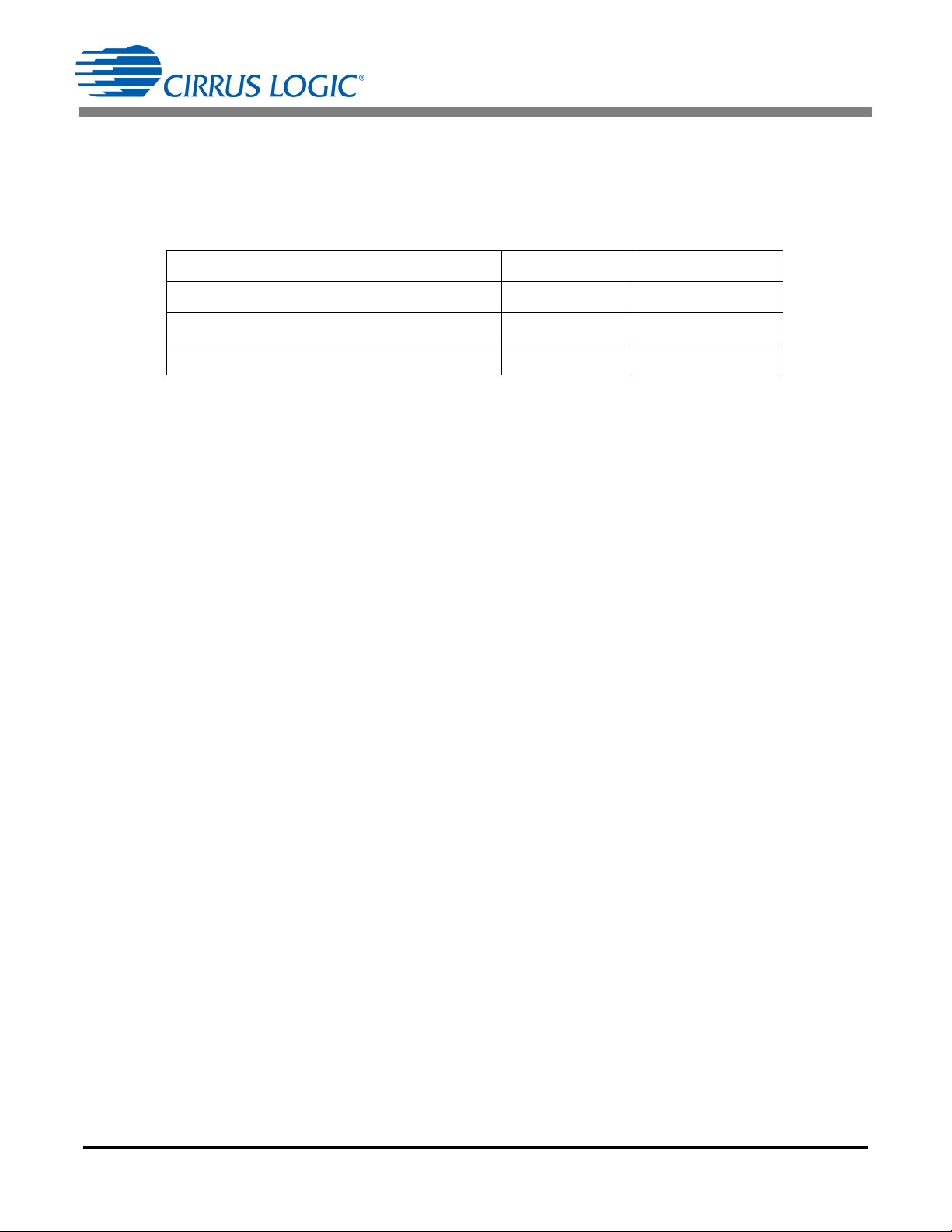

Key RMS Register Values Range (0 to 1) Decimal Value Register Value

Maximum RMS Register 1 0xFFFFFF

Maximum RMS Input 0.6 0x999999

Half RMS Input 0.36 0x5C28F6

No Load Input 0 0x000000

If a sine wave is applied to the voltage channel input at full scale, then the peak voltage can be determined using

Equation 2:

The V

The CS5480/84/ 90 provides a current channel scale register that allows a small load current during calibration.

By default, the range is 0.6 (full-scale current load), but this value can be adjusted according to the load current

available.

PEAK

register will have a maximum input margin of 15%, which prevents clipping.

4 AN366REV2

Page 5

AN366

ReportedCurrent

ACTUAL

Current

REGISTER

Current

FULLSCALE

0.6

-----------------------------------------------------------------------------------------------------------

0.25 50A

0.6

-----------------------------

20.8A===

[Eq: 3]

ReportedPower

ACTUAL

Power

REGISTER

Power

FULLSCALE

0.36

---------------------------------------------------------------------------------------------------

=

Power

REGISTER

Vch

FULLSCALE

Ich

FULLSCALE

0.36

---------------------------------------------------------------------------------------------------------------------------------------------

=

0.15 140 50

0.36

---------------------------------------------

2916.7W==

[Eq: 4]

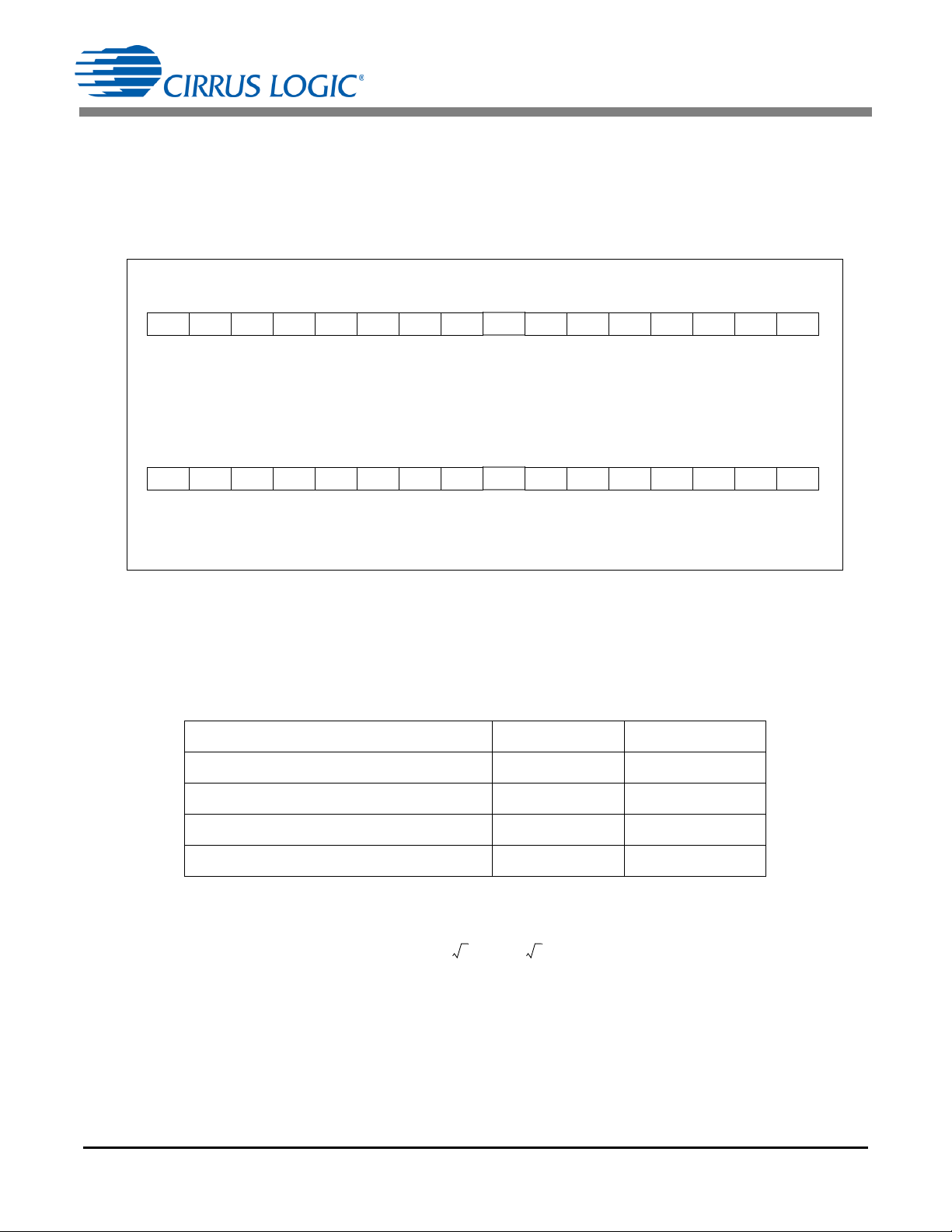

Active Power 1 (P1

AVG

) – Page 16, Address 5

Default = 0x00 0000

Instantaneous power is averaged over each low-rate interval (SampleCount samples) and then added

with power offset (P

OFF

) to compute active power (P

AVG

).

This is a two's complement value in the range of -1.0value1.0, with the binary point to the right of the

MSB.

Active Power 2 (P2

AVG

) – Page 16, Address 11

Default = 0x00 0000

Instantaneous power is averaged over each low-rate interval (SampleCount samples) to compute active

power (P2

AVG

).

This is a two's complement value in the range of -1.0value1.0, with the binary point to the right of the

MSB.

MSB LSB

-(20)2-12

-2

2

-3

2

-4

2

-5

2

-6

2

-7

.....

2

-172-182-192-202-212-222-23

MSB LSB

-(2

0

)2-12

-2

2

-3

2

-4

2

-5

2

-6

2

-7

.....

2

-172-182-192-202-212-222-23

Figure 3. Example of P1

AVG

and P2

AVG

Registers

3.4 Application Processor Scaling Example

The scaling example below demonstrates how to convert from the current register value to the reported current

using the full-scale value. The specified full-load (Current

(Current

REGISTER

) is 0.25 (0x40 0000), then the actual current value (ReportedCurrent

FULLSCALE

the application processor using Equation 3.

Use Equation 3 to convert the current register value to the real current:.

Scaling for power requires a change in the denominator to reflect a power scaling ratio of 0.36, which is equal

to the voltage (0.6) multiplied by current (0.6). The input full load (Ich

voltage (Vch

register (Power

FULLSCALE

REGISTER

) is 140V. If the present load is applied to the meter results in a power

) reading of 0.15 (0x13 3333), then the application processor needs to convert the

power register value to the real current value. Use Equation 4 to convert the power register value to real reported

power.

) is 50A. If the AFE current register value

) is calculated by

FULLSCALE

ACTUAL

) is 50A and the maximum

Cirrus Logic power meters are bidirectional, which allows power to be measured in both directions (consumed

or delivered). This reduces the digital scaling by one bit due to polarity, unlike the unsigned RMS current register.

The 24-bit P1

and P2

AVG

registers are defined in Figure 3.

AVG

AN366REV2 5

Page 6

AN366

VALUE

Decimal

MSB–

1

2

23

1–

------------------

hex2dec VALUE

Hexidecimal

=

[Eq: 5]

Use Equation 5 to convert the hexadecimal value to a decimal ratio value:

Using Equation 5, the following table identifies the key values.

Key Power Register Values Range (-1 to 1) Decimal Value Register Value

Maximum Power Register 1 0x7FFFFF

Maximum Power Input 0.36 0x2E147B

No Load Input 0 0x000000

4 Types of Calibration and Compensations

Calibration is self-contained within the CS5480/ 84/ 90, and all calculations are performed by the device and

stored in internal registers. Compensations require that the MCU perform some of the calculations and then

store the results back into the CS5480/ 84 /90 registers. Since the CS5480/ 84 / 90 does not have non-volatile

memory (NVM), permanent storage of calibration and compensation must be placed in the MCU NVM and reloaded after any AFE reset condition.

In general, each calibration and compensation requires the following steps:

1. Configure the CS5480/84/ 90 initial conditions

2. Apply the analog input with stimulus from an accurate source

3. Enable the desired calibration

4. Execute calibration

5. Read the results

6. Calculate the new register values for compensations

7. Store the results in the AFE and NVM

It is common to perform calibration and compensation simultaneously. For example, since an AC gain calibration

and a phase compensation require a similar input signal to be applied to the current and voltage channels, calibration and compensation are performed simultaneously.

6 AN366REV2

Page 7

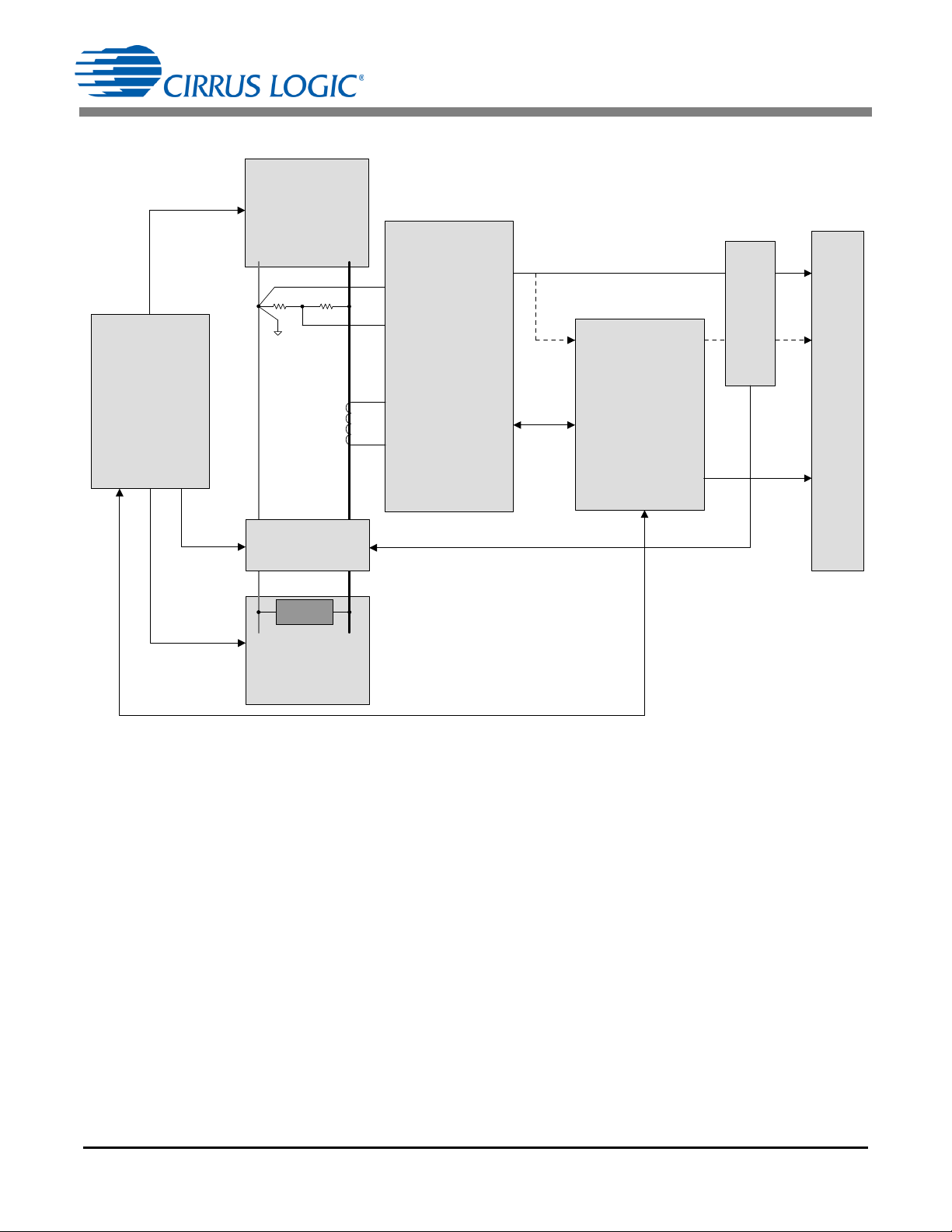

Figure 4 illustrates a typical hardware configuration for calibration and compensation:

AC

LOAD

AC

SOURCE

CS5480 /84 /90

(A FE)

LN

VIN -

VIN +

IIN +

IIN -

Application

Processor

LOAD

CT

Pulse

Pulse

OR

Display

Power

Seri al

Port

Reference

Meter

Optical

Sensor

Calibration

Controller

AN366

Automation can be established by a calibration controller that starts the calibration and/or the compensation,

performs the required calculations, and finally initiates the storage of results. A calibration controller will control

the AC source and load during calibration by adjusting the load for different AFE input conditions. The controller

will also monitor the precision reference meter to confirm that load adjustments have been successfully executed, and the optical accumulation results are accurate from the Cirrus AFE. Communication from the controller

to the Cirrus AFE is processed through the meter application processor to the calibration controller. Calculations

and NVM results stored within the application processor are initiated by the controller when the calibration is

completed.

AN366REV2 7

Figure 4. Calibration and Compensation Hardware Configuration

Page 8

AN366

V

RMS

*

, I

RMS

*

Registers

V*, I*, P*, Q

*

Registers

N

I

GAIN

*

, V

GAIN

*

Registers

*

Denotes readable/writable register

Ϯ Applies only to the curr ent path

N

N

-1

N

DC

RMS

-1

RMS

0.6(Scale

*

Ϯ

)

P

AVG

*

, Q

AVG

*

Registers

N

N

Modulator

I

DCOFF

*

, V

DCOFF

*

Registers

PC

Register

Sinc IIR

SYS

GAIN

Register

IN

P

OFF

*

, Q

OFF

*

Registers

I

ACOFF

*

Ϯ

Register

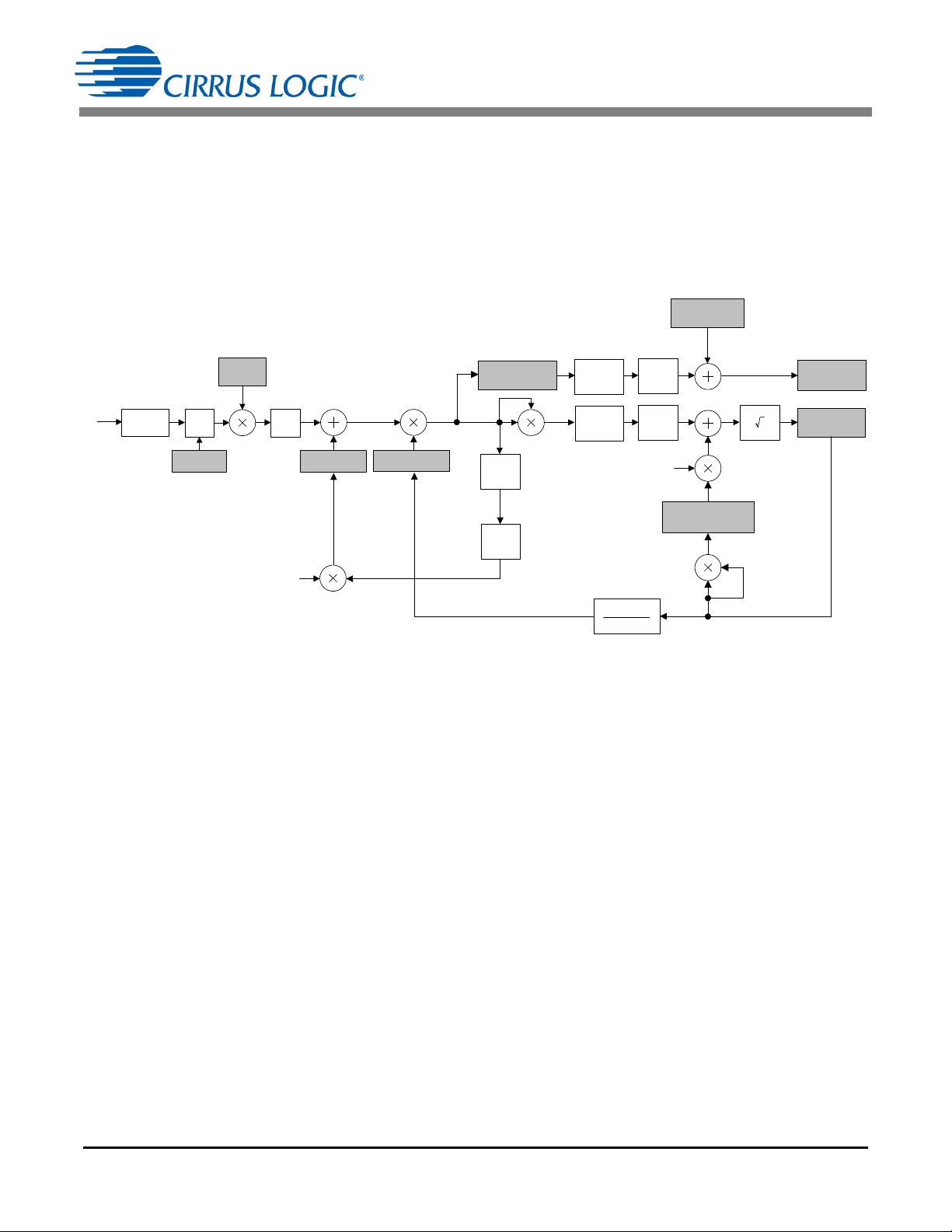

4.1 AFE Calibrations

The CS5480/84/90 AFE incorporates three calibrations: gain, AC offset, and DC offset. Gain calibration is always required. AC offset calibration is only required when I

offset calibration is made available but not recommended for AC power meters. Instead, high-pass filters are

used to remove DC offset. The high-pass filter included in the CS5480/ 84 /90 will remove any DC offset in real

time, and it is the best choice for AC power meters.

Figure 5 shows a flow diagram of the calibration process included in the Cirrus AFE. Refer to the CS5480/84/90

data sheet for detailed information.

needs to be accurate at low input levels. DC

RMS

Figure 5. Calibration Data Flow

4.1.1 DC Offset Calibration

DC offset calibration is designed to remove the DC component from the ADC output. DC offset calibration

is seldom used in AC power meters. The high-pass filter is the recommended choice and should be enabled

at the modulator output, as illustrated in Figure 5.

4.1.2 Gain Calibration

Gain calibration will adjust the input for hardware and sensor variations and customer-specific inputs. It is

recommended to use full-load conditions (full-scale voltage and current). (For non-full-load conditions, see

section 4.1.2.1 on page 8). When the full current load is not available, the CS5480/84/90 allows the scale

register to adjust for lower current loads to be provided. (See 3.3 on page 4 for adjusting the scale register.)

After gain calibration, full-scale input will yield:

- The Voltage RMS register, V

- The Current RMS register, I

- The Active Power register, P

- The Reactive Power register, Q

- The Apparent Power register, S, value: 0.6

4.1.2.1 When AC Source or AC Load Are Less Than Ideal

If the AC source or AC load are less than ideal, the meter can still be calibrated with an accurate reference

meter using the Non-full-scale Gain Calibration procedure on page 9. It is common to see an AC load set to

15A actually measure in the range of 14.55 A to 15.45A using a reference meter. When using the full-scale

, value: 0.6

RMS

, value: 0.6

RMS

, value: 0.6 0.6 = 0.36 at PF = 1

AVG

, value: 0.6 0.6 = 0.36 at PF = 0

AVG

0.6 = 0.36

current, it may be necessary to use the Non-full-scale Gain Calibration procedure on page 9 to account for

inaccurate resources.

8 AN366REV2

Page 9

AN366

V

GAIN pre

V

MAX

V

REF

---------------

2

22

=

[Eq: 6]

I

GAIN pre

I

MAX

I

REF

------------

2

22

=

[Eq: 7]

4.1.2.2 Non-full-scale Gain Calibration

When resources are limited, it may be necessary to provide non-full-scale amplitudes and perform built-in

calibration to provide the maximum voltage and current during calibration. To perform a non-full-scale calibration, the initial gain register conditions of the device must be identified before calibration. Usually, initial

gain register conditions are set to a default value of one, but this is not required. Instead, the initial gain register conditions are set to accommodate the non-full-scale input calibration. Before calibration is executed,

the gain register can be set using the following equations:

where:

V

GAIN(pre)

I

GAIN(pre)

V

MAX

I

MAX

V

REF

Value stored in voltage gain register (page 16, address 35) before calibration starts

Value stored in current gain register (page 16, address 33) before calibration starts

Maximum voltage of the meter defined by customer

Maximum current of the meter defined by customer

Voltage of the line just before calibration as measured with reference meter assumes

stable input

I

REF

Load current just before calibration as measured with reference meter assumes stable

input

Follow the steps below to perform a non-full-scale gain calibration:

1. Set the line voltage and load current V

2. Confirm that the reference meter shows V

3. Set V

GAIN(pre)

per Equation 6 and I

GAIN(pre)

and I

REF

REF

REF

and I

per Equation 7.

, respectively.

of the input.

REF

4. Send the calibration command.

5. After calibration, the meter is adjusted for a full-scale voltage of V

measuring the V

REF

and I

measurements.

REF

MAX

and I

and will currently be

MAX

Reference Limits

The calibration line voltage (V

) or load current (I

REF

) must not be set too low. It is recommended to keep

REF

the register values at a minimum of ½ of the maximum levels. Since the gain register can be set to a maximum value of 4, the input could be set to ¼ of the maximum levels. It is not recommended to set the input

to ¼ of the maximum levels due to variations in setup conditions. If the input is too low, the gain register will

set the default value of one after calibration.

AN366REV2 9

Page 10

AN366

I

SCALE

I

REF

I

MAX

------------

0.6 2

23

=

[Eq: 8]

Current Scale Register

To perform calibration with less than full scale load without using the above procedure, it is possible to set

the current channel's Scale register. The current channel calibration data path contains a Scale register

(page 18, address 63) that can be adjusted before calibration to accommodate the non-full-scale load.

where:

I

SCALE

I

MAX

I

REF

Value stored in the Scale register before calibration

Maximum current of the meter defined by the customer

Load current before calibration, as measured with a reference meter, assuming stable

input

Follow the steps below to set the current channel’s Scale register.

1. Set the load current, I

2. Confirm that the reference meter shows V

(assuming V

REF

is set to full scale).

REF

and I

REF

REF

of the input.

3. Set the Scale register per Equation 8.

4. Send the calibration command.

5. After calibration, the meter is adjusted for a full-scale voltage of V

measuring the V

REF

and I

measurements.

REF

MAX

and I

and will currently be

MAX

6. The Scale register is not in the normal data path but instead in the calibration path.

4.1.3 AC Offset Calibration

Following gain calibration, there may still be some AC offset remaining. AC offset calibration will allow for

the removal of the remaining offset. The AC offset effects are only applicable to the I

input. The AC offset calibration only needs to be performed when I

readings are required to span a large

RMS

registers at small

RMS

dynamic range with high accuracy.

4.2 Available Compensations

Three compensations are available in the CS5480/84/ 90: phase, no-load active power, and no-load reactive

power offset.

4.2.1 Phase Compensation

Phase compensation adjusts phase mismatches between the voltage and current channels. Setting the current to lag the voltage by 60º (the center of the COS range of 0º - 90º) allows the system to distinguish additional or less phase delay from the power factor (PF) directly. Follow the steps below to perform this

compensation:

1. Apply source at full scale with a 60º phase shift (PF = 0.5 lagging)

2. Start continuous convert

3. Read the PF register and calculate:

Phase error = ACOS(register PF)-60º

4. Calculate phase compensation (PC) register (MCLK=4.096MHz):

50Hz PC register = phase error/0.008789

60Hz PC register = phase error/0.010547

Phase error can be adjusted when it falls within ±8.99º at 50Hz or ±10.79º at 60Hz. Figure 6 shows the

phase offset error range. When phase error is below -4.5º at 50Hz or -5.4º at 60Hz and above 0 º, it is necessary to adjust both coarse compensation and fine compensation. The coarse and fine compensation settings for each region are shown in Figure 6.

10 AN366REV2

Page 11

AN366

0º

Before Calibration V is delayed from I

Delay added to I

8 .99 º @ 50 H z

10.79 º @ 60Hz

4.5º @ 50Hz

5.4º @ 60Hz

-4.5º @ 50Hz

-5.4º @ 60Hz

-8.99º @ 50 Hz

-10 .79 º @ 60Hz

Before Calibration I is delayed from V

Delay added to V

Set C PC C = 11 of 2OW R on V

+ FPC C prov i des adjus tm ent

Set C PC C = 10 of 1OW R on V

+ FPC C prov i des adjus tm ent

Clear CPCC = 00

+ FPC C prov i des adjus tm ent

Set CPCC = 01 of 1OWR on I

+ FPC C prov i des adjus tm ent

Figure 6. Phase Compensation and Phase Offset Error

4.2.2 No Load Power Compensation

There are two power compensations in the CS5480/ 84 / 90: active and reactive power offset. When no load

is applied, the average active power register, P

, and average reactive power register, Q

AVG

AVG

offsets. To remove any remaining active or reactive power, it is necessary to perform the following compensation:

- Apply full scale voltage source

- Apply no load to the current channel(s)

- Start continuous conversion

- Read P

- Write -P

and Q

AVG

and -Q

AVG

AVG

AVG

register

to P

OFF

and Q

, respectively

OFF

, may have

AN366REV2 11

Page 12

AN366

5 Calibration and Compensation Procedures

A CS5480/84/ 90 power meter normally has two modes of operation: calibration, which is executed only once at the

factory, and normal operation in the field.

Calibration will compensate for system-level errors and is only performed at the factory. Normal operation is a

continuous running mode (continuous conversion mode) or user-initiated, single execution mode (single conversion

mode). Most designs are continuously running and use the continuous conversion command. Normal operation is

resetting the device, loading calibration and configuration information from non-volatile memory, and executing

continuous conversion command. The MCU then needs to read various device registers to obtain the power, current,

and voltage. As these registers are updated, the MCU will need to post the information to the user interface. This is

accomplished by using DO pin interrupts or by periodically reading the status register. The default configuration of

the part sets most of the registers to a common configuration. When continuous conversion is performed, the device

will provide most register updates once per second (default at reset).

The normal field operation is simple and there is no need for extensive computation by the MCU. A simple, low cost

MCU may be used to assist the normal operation.

5.1 Normal Operation Procedure (Performed at Every Reset in the Field)

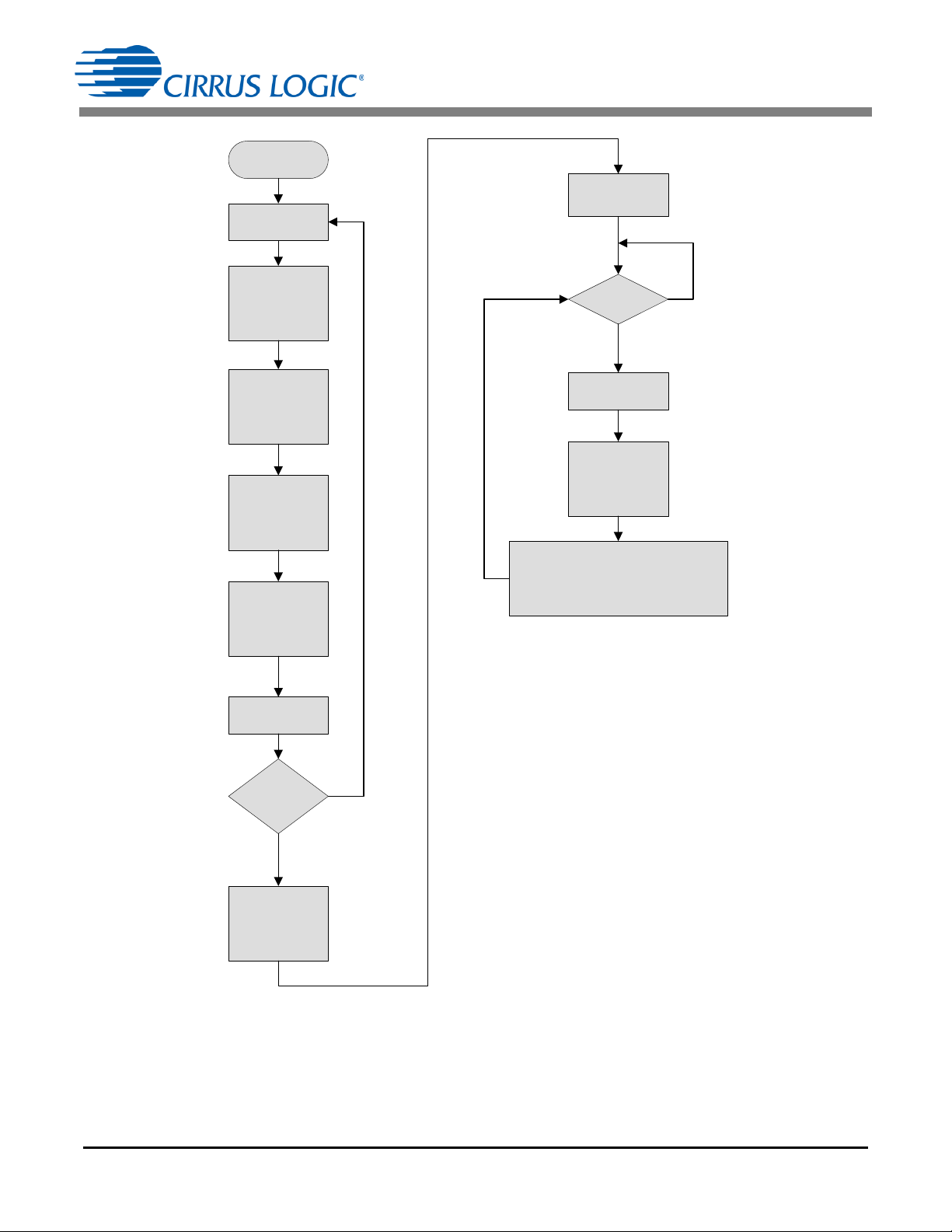

The following procedure outlines the steps required to put the meter in normal operation mode. Figure 7 shows

a simplified flow chart for the normal operation in the field.

1. Reset the CS5480/84 / 90.

2. Restore configuration and control registers.

3. Restore the V

GAIN

and I

registers from the non-volatile memory (NVM).

GAIN

4. If needed, restore the offset registers from NVM.

5. If needed, restore the phase compensation registers from the NVM.

6. If needed, restore the no load compensation to the P

OFF

and Q

OFF

7. Send the single conversion command to the CS5480/84/90.

8. Confirm that the register checksum is valid, or return to step 1.

9. Send the continuous conversion command to the CS5480/84/90.

10. Enable and clear DRDY.

11. Poll DRDY.

12. If DRDY is set, clear DRDY.

13. Read I

RMS

, V

RMS

, and P

. Scale the I

AVG

Amps = Full_Scale_Current

Volts = Full_Scale_Voltage

Watts = Full_Scale_Power

(I

(V

(P

RMS

RMS

AVG

RMS

/0.6)

/0.6)

/0.36)

, V

RMS

, and P

back into true value by:

AVG

14. Loop back to "Poll DRDY" step.

registers from the NVM.

12 AN366REV2

Page 13

START

CONTINUOUS

CONVERSION

0xD5

CLEAR

DRDY

READ IRMS,

VRMS, PAVG

DRDY

SET?

POWER UP

RESTORE

CONFIGURATION

and CONTROL

REGISTERS

From NVM

RESTORE

GAIN

REGISTERS

From NVM

RESTORE

OFFSET

REGISTERS

From NVM

RESTORE

POFF and QOFF

REGISTERS

CLEAR

DRDY

CALCULATE

VOLTS = FS_Voltage · (VRMS/0.6)

AMPS = FS_Current · (VRMS/0.6)

WATTS = FS_Scale _Pow er · (VRMS/0.36)

RESET

VALID

REGISTER

CHECKSUM

?

SINGLE

CONVERSION

YES

NO

YES

NO

Figure 7. Normal Field Flow

AN366

AN366REV2 13

Page 14

AN366

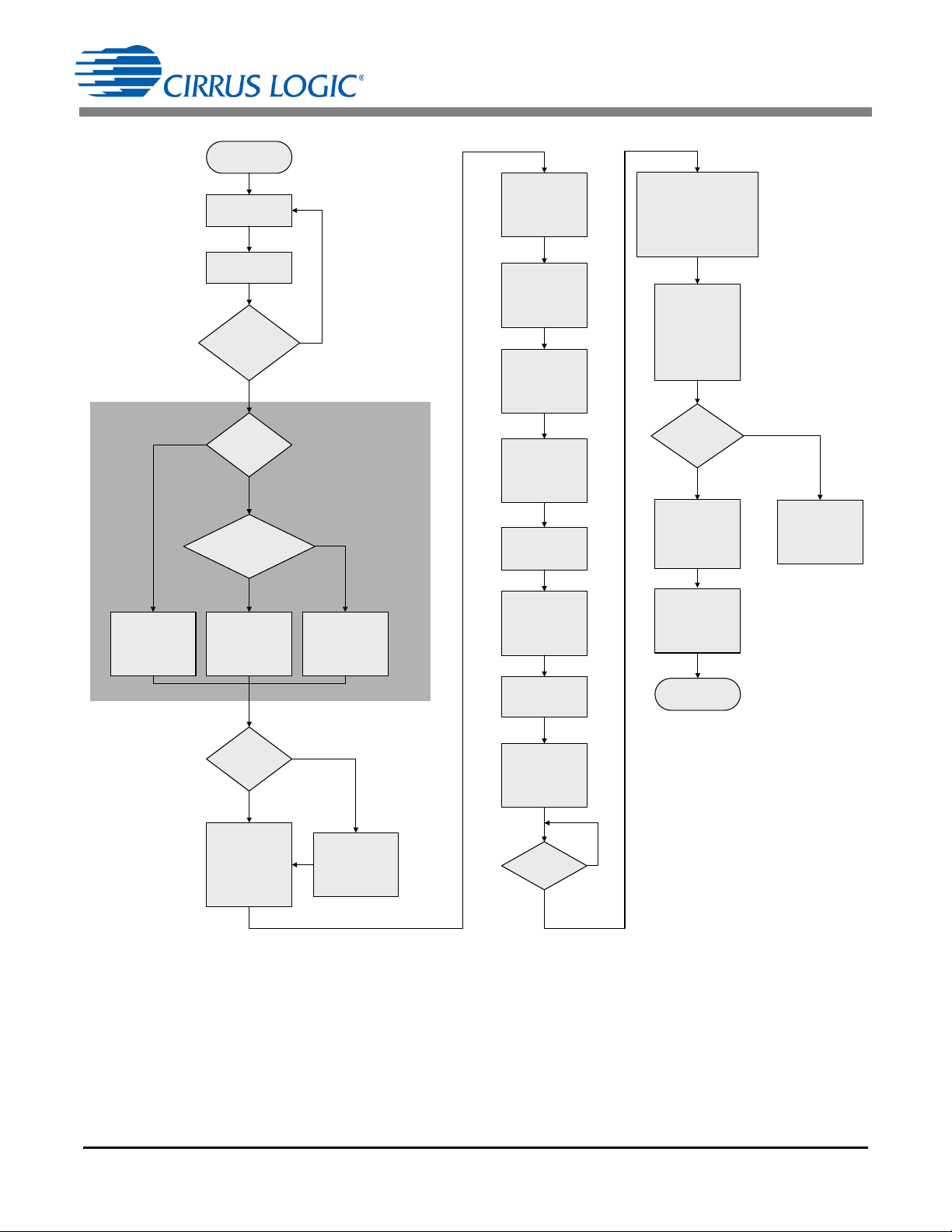

5.2 Full Calibration and Compensation Procedure (Performed Once at Factory)

The following procedure shows the steps required to perform calibration and compensation. A flow chart showing the full calibration procedure is shown in Figure 5.

1. Power up the CS5480/84/90 device.

2. Reset the CS5480/84 / 90 device.

3. Verify the register checksum to confirm the reset is successful.

4. Restore configuration and control registers.

5. Connect the reference line voltage and load current to the meter with a phase angle of 60º current lagging.

6. If the reference load current is not the full load, set the Scale register to a ratio of 0.6 2

current ÷ full scale current. See Non-full-scale Gain Calibration on page 9 if the reference line voltage is

lower than the maximum line voltage.

7. Perform continuous conversion (0xD5 command) for 2 seconds.

8. Stop the continuous conversion (0xD8 instruction).

9. Read I

attached by verifying if the I

RMS

, V

RMS

, P

, and PF, and confirm the reference voltage and current signals are correctly

AVG

RMS

, V

RMS

, P

, and PF are in a reasonable range.

AVG

10. Clear DRDY status bit.

11. Send AC gain calibration command (0xFE) to the CS5480/ 84 /90.

12. Wait for DRDY to be set.

23

reference load

13. If needed, perform phase compensation, AC offset calibration, and power offset correction.

14. Send continuous conversion (0xD8 command).

15. Verify measurement accuracy. Check the setup or fail the meter if the accuracy is not within specifications.

16. Read V

GAIN

, I

GAIN

, I

ACOFF

, P

OFF

, Q

, PC, and register checksum and save them into flash/eeprom.

OFF

17. Calibration completed.

14 AN366REV2

Page 15

RESET

(See Note 1)

ROGOWSKI

SENSOR?

ENABLE

HIGH PASS

FILTER

ENABLE

INTEGRATOR on

CURRENT &

HIGH PASS on

VOLTAGE

FULL LOAD

AVAILABLE ?

APPLY

REFERENCE

LINE VOLTAGE

AND LOAD

CURRENT

(Note 5)

SET SCALE

REGISTER

0.6 · LOAD ÷ FS

(Note 6)

READ

IRMS, VRMS,

PAVG, QAVG, PF

START

CONTINUOUS

CONVERT

0xD5

STOP

CONVERSIONS

0xD8

SEND AC GAIN

CALIBRAT ION

0xFE

ACCURACY

IN SPEC?

CHECK

SETUP or

FAIL

READ VGAIN,

IGAIN, IACOFF,

POFF, QOFF, PC,

RegChk

STORE

CALIBRAT ION

CONSTANTS &

REGISTER

CHECKSU M

POWER UP

CALIBRAT ION

COMPLETE

DC

MEASUREMENT?

PERFORM

DC

CALIBRAT ION

DRDY

SET?

SINGLE

CONVERSION

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

VALID RESET

CHECKSUM?

(Note 3)

CONFIRM

REFERENCE

SIGNALS ARE

APPLIED

CORRECTLY

Tsettle =

2000ms

(Note 2)

SampleCount (N) =

16,000

(Note 2)

START

CONTINUOUS

CONVERSION

AND VER IF Y

METER

ACCURACY

CLEAR

DRDY

PERFORM PHASE

COMPENSATI ON,

IACOFF CALIBRATION,

and POWER OFFSET

CORRECTION if

NECESSARY

Note 1: The default setting for all registers should be set before performing calibration. Resetting the device restores the default setting

for all registers.

Note 2: Larger numbers in the Tsettle and SampleCount registers will increase calibration precision.

Note 3: Other configurations and controls might be necessary.

Note 4: For an expanded view showing more information about the main calibration flow, see Main Calibration Flow Diagram Using the

CDB5484 on page 29.

Note 5: See Non-full-scale Gain Calibration on page 9.

Note 6: Scale register is only in calibration path and does not require resetting to 0.6 after the calibration.

Figure 8. Main Calibration Flow

AN366

AN366REV2 15

Page 16

RESOLUT ION

MULTIPLIER

0.008789 (50Hz)

(Note 1)

-8.9 9º <

PHASE OFF SET

< +8.99º (50Hz)

?

(Note 2)

PHASE OFF SET

NEGAT IVE

?

FINE

COMPENSAT ION

(FP CC) = -PHASE

OFFSET ÷

0.008789 (50Hz)

0 <

PHASE OFF SET

< 512 · 0.008789

(50Hz)

?

FINE

COMPENSAT ION

(FPCC) = PH ASE

OFFSET ÷

0.008789 (50Hz)

SET COAR SE

COMPENSAT ION

(CPCC = 01)

1 OWR on I

PHASE OFF SET =

PHASE OFF SET +

4.5º (50Hz)

SET COAR SE

COMPENSAT ION

(CPCC = 11)

2 OWR on V

PHASE OFF SET =

8.99º - PH ASE

OFFSET (50Hz)

FAIL

METER

PHASE COMPENSAT ION COMPLETE

(RETURN CPCC & FPCC to MAIN)

ACCUMULATE MULTIPLE

PF READ ING AND

CONFIRM PF = 0.5

SET COAR SE

COMPENSAT ION

(CPCC = 10)

1 OWR on V

PHASE OFF SET =

4.5º - PHASE

OFFSET

(50Hz)

±10.79º @ 60Hz

0.010547 @ 60H z

0 to 512 0.010547 @ 60 Hz-512 0.010547 to 0 @ 60 Hz

5.4º @ 60Hz 10.79º @ 60Hz5.4º @ 60Hz

0.010547 @ 60Hz

NO

YES

NOYES

NO

YES

NO

YES

-512 · 0.008789 <

PHASE OFF SET

< 0 (5 0Hz)

?

Note 4 Note 5

No co ar se

comp .

CPCC=00

APPLY

REFERENCE

LINE VOLT AGE

AND

60

O

LAGGING

LOAD CUR RENT

PF=0.5

START

CONTINUOUS

CONVERSI ON

0xD 5

FROM MAIN

FLOW

READ PF

CALCULATE

PHASE

OFFSET =

arccos(PF)-60º

STOP

CONVERSIONS

0xD 8

Tsettle =

2000 ms

(Note 1)

SampleCount

(N) = 16,000

(Note 1)

Figure 9. Phase Compensation Flow

Note 1:Larger numbers in the Tsettle and SampleCount registers will increase calibration precision.

Note 2: OWR= 4000, MCLK = 4.096 Mhz.

Note 3: For an expanded view showing more information about the phase compensation flow, see Phase Compensation Flow Diagram

on page 40.

Note 4: Before calibration: Angle < 60; Phase offset < 0; I leads V; PF is leading--for more positive, delay I.

Note 5: Before calibration: Angle < 60; Phase offset < 0; I lags V; PF is lagging--only coarse adjustment can delay V, therefore delay

V by 1 or 2 OWR and delay I by less than 1 or 2 OWR.

AN366

16 AN366REV2

Page 17

FROM MAIN

FLOW

CLEAR DRDY

SEND AC

OFFSET

CALIBRATI ON

0xF6

REMOVE LOAD

CURRENT

READ IRMS,

IACOFF

DRDY

SET?

CHECK

INPUT

OR

FAIL

RETURN

IACOFF

to

MAIN FLOW

IACOFF = 0

?

AC OFFSET

CALIBRATI ON

COMPLETE

Tsettle = 2000

SampleCount

N = 16000

NO

YES

YES

NO

Figure 10. AC Offset

Calibration Flow

Note: For an expanded view showing

more information about the AC offset

calibration flow, see AC Offset Calibration

Flow Diagram on page 44.

FROM MAIN

FLOW

CLEAR DRDY

SEND D C

OFFSET

CALIBRATION

0xE6

SHORT

VOLTAGE AND

CURRENT

INPUTS

READ IR MS,

VRMS, IDCOFF,

VDCOFF

DRDY

SET ?

CHECK

INPUT

OR

FAIL

RETURN

IDCOFF

VDCOFF

to

MAIN FLOW

IDCOFF = 0 ?

or

VDCOFF = 0 ?

DC OFF SET

CALIBRATION

COMPLETE

Tsettle = 2000

SampleCount

N = 16000

NO

YES

YES

NO

Figure 11. DC Offset

Calibration Flow

Note: For an expanded view showing

more information about the DC offset

calibration flow, see DC Offset

Calibration Flow Diagram on page 46.

FROM MAIN

FLOW

APPLY FU LL

SCALE VOLTAGE

AND ZERO LOAD

CURRENT

READ PAVG and

QAVG

DRDY

SET ?

RETURN

POFF

QOFF

to

MAIN FLOW

POWER OFFS ET

CALIBRATION

COMPLET E

Tsettle = 2000

SampleC ount

N = 16000

NEGATE

QAVG

& STORE IN

QOFF

NEGATE

PAVG

& STORE IN

POFF

START

CONTINUOUS

CONVERT

0xD5

NO

YES

CLEAR DRDY

Figure 12. No Load Offsets

Calibration Flow

Note: For more information, see No Load

Offset Compensation Flow Diagram on

page 47.

AN366

AN366REV2 17

Page 18

AN366

6 Full Calibration and Compensation Example Using the CDB5484 and MTE Meter Test

Equipment

The calibration and compensation flows have been implemented using the CDB5484U and a PC as the controller.

Using a MTE Meter Test Equipment AG PTS 400.3 Modular Portable Test System source and reference meter, the

results of this calibration can be shown. More information can be found by visiting the MTE Meter Test Equipment

website.

The CDB5484U connections are as follows:

1. The USB connects to the CDB5484U on the right. Using the standard CDB5484U GUI, commands and read

results from the Cirrus AFE can be sent.

2. The DUT supplies are connected to terminals J36 and J37. It is not recommended to use the USB supply to

power the Cirrus AFE during accuracy tests. Instead, use terminals J36 and J37.

3. Voltage is applied directly to the CDB5484U. Current inputs are looped through a terminal board and outputs are

sent to the CDB5484U.

4. The PC was connected to the RS232 connection on the MTE Meter Test Equipment power source and power

reference.

5. The pulse output is connected to an external counter or optically back to the MTE Meter Test Equipment power

reference.

6. The controller in this example is the CDB5484U and PC. While the CDB5484U is good for presentation, it is not

recommended to be used as a production solution.

18 AN366REV2

Page 19

AN366REV2 19

MTE Meter Test Equipment AG

PTS 400.3 Modular Portable Test System

Reference

Meter

Optical

Connection

AC

Source

Voltage Inputs

UART to PC Controller

Line Reference

Current Inputs

DUT Supply Rogowski Sensor USB to PC Controller

Pulse to Optical Counter

Figure 13. MTE Meter Test Equipment Calibration Hardware Setup

AN366

Page 20

POWER UP

From NVM

RESTOR E

FILTER

CONFIGURATION

RESET

21

AN366

6.1 Normal Operation Flow Diagram Using the CDB5484

The following flow diagram shows the implementation of normal flow executed in the field. The CDB5484U is

used to load calibration constants obtained during the factory calibration. Obviously, the GUI is not used during

actual execution, but it provides an excellent debugger for customer flow evaluation and modifications. The onetime factory calibration and compensation flows are discussed after the normal flow. The MTE Meter Test Equipment source is used to provide the source voltage and load current, but it is only required during this flow to

simulate different loading conditions. Each step of the flow shows the CDB5484U GUI screen capture of execution and reading results. The register writes and reads are all identified for easy comparison to the GUI screen.

POWER UP

Power up CDB5484U per data sheet using terminals J36 and J37.

RESET

SDI = 0xC1 Reset CS5484 software Reset

RESTORE FILTER CONFIGURATION

(See Figure 14.)

Config 2 Register

SDI = 0x90 0x40 0x0602AA Write Register Config2 to enable HPFs

SDO = 0xFF 0xFF 0xFFFFFF (Page 16, Register 0)

SDI = 0x90 0x00 0xFFFFFF Read Register Config2 to enable HPFs

SDO = 0xFF 0xFF 0x0602AA (Page 16, Register 0)

Figure 14. Setup Window

20 AN366REV2

Page 21

2

1

43

RESTOR E

CONFIGURATIONS

AN366

RESTORE REGISTERS

Various configurations include writes to registers (see Figure 14):

Config 0 Register

SDI = 0x80 0x40 0x400000 Write Register Config0

SDO = 0xFF 0xFF 0xFFFFFF (Page 0, Register 0)

SDI = 0x80 0x00 0xFFFFFF Read Register Config0

SDO = 0xFF 0xFF 0x400000 (Page 0, Register 0)

Config 1 Register

SDI = 0x80 0x41 0x10FEE0 Write Register Config1

SDO = 0xFF 0xFF 0xFFFFFF (Page 0, Register 1)

SDI = 0x80 0x01 0xFFFFFF Read Register Config1

SDO = 0xFF 0xFF 0x10FEE0 (Page 0, Register 1)

Pulse Control Register

SDI = 0x80 0x49 0x000000 Write Register Pulse Control

SDO = 0xFF 0xFF 0xFFFFFF (Page 0, Register 9)

SDI = 0x80 0x09 0xFFFFFF Read Register Pulse Control

SDO = 0xFF 0xFF 0x000000 (Page 0, Register 9)

Phase Comp Register

SDI = 0x80 0x45 0x007C40 Write Register Phase Compensation

SDO = 0xFF 0xFF 0xFFFFFF (Page 0, Register 5)

SDI = 0x80 0x05 0xFFFFFF Read Register Phase Compensation

SDO = 0xFF 0xFF 0x007C40 (Page 0, Register 5)

Pulse Width Register

SDI = 0x80 0x48 0x0613F0 Write Register Pulse Width

SDO = 0xFF 0xFF 0xFFFFFF (Page 0, Register 8)

SDI = 0x80 0x08 0xFFFFFF Read Register Pulse Width

SDO = 0xFF 0xFF 0x0613F0 (Page 0, Register 8)

Pulse Rate Register

SDI = 0x92 0x5C 0x800000 Write Register Pulse Rate

SDO = 0xFF 0xFF 0xFFFFFF (Page 18, Register 28)

SDI = 0x92 0x1C 0xFFFFFF Read Register Pulse Rate

SDO = 0xFF 0xFF 0x800000 (Page 18, Register 28)

Sample Count Register

SDI = 0x90 0x73 0x000FA0 Write Register Sample Count

SDO = 0xFF 0xFF 0xFFFFFF (Page 16, Register 51)

SDI = 0x90 0x33 0xFFFFFF Read Register Sample Count

SDO = 0xFF 0xFF 0x000FA0 (Page 16, Register 51)

Settle Time

SDI = 0x90 0x79 0x800000 Write Register T Settle

SDO = 0xFF 0xFF 0xFFFFFF (Page 16, Register 57)

SDI = 0x90 0x39 0xFFFFFF Read Register T Settle

SDO = 0xFF 0xFF 0x800000 (Page 16, Register 57)

AN366REV2 21

Page 22

AN366

From NVM

RESTORE

GAIN

CONFIGURATION

6

5

43

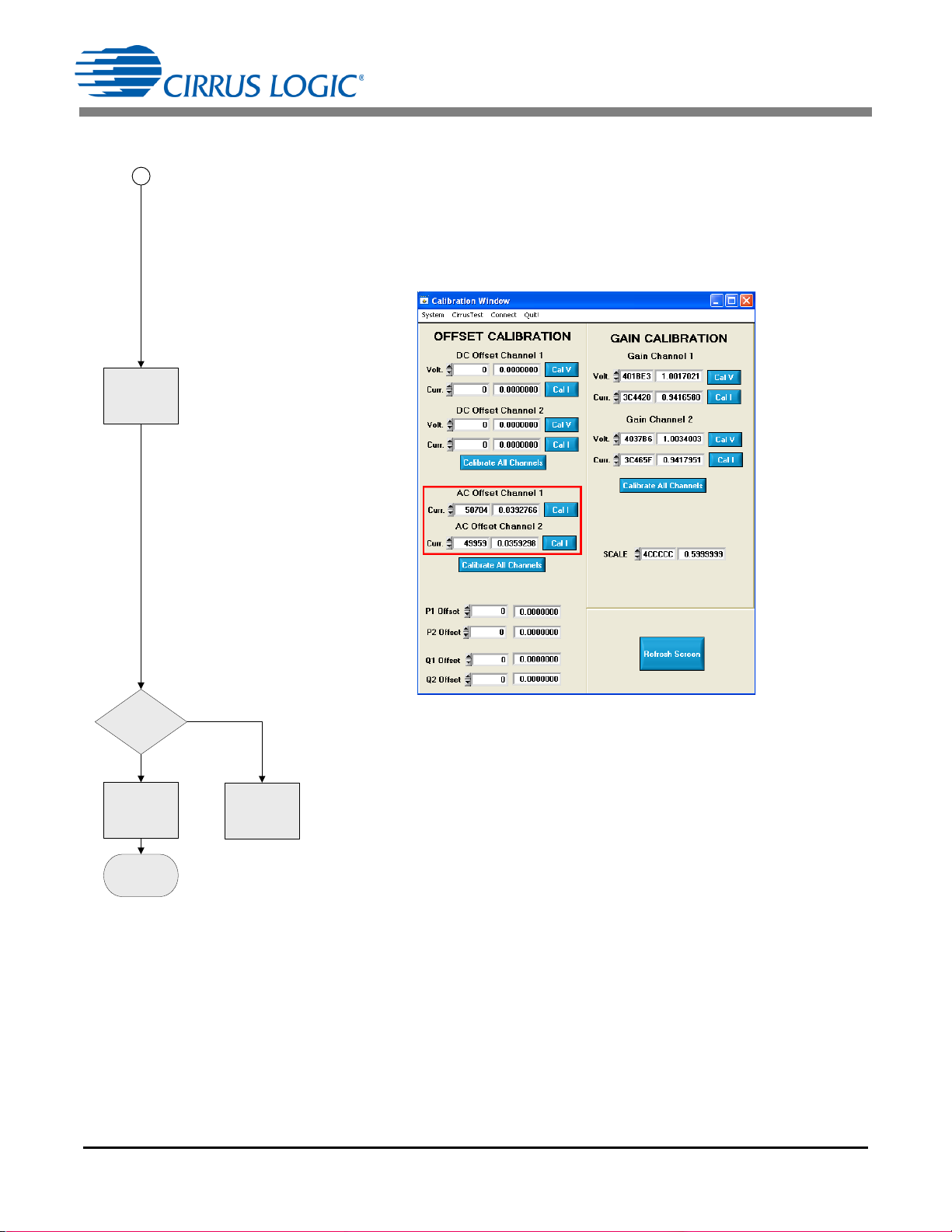

RESTORE GAIN CONFIGURATION

(See Figure 15.)

Gain Channel 1, Volt.

SDI = 0x90 0x63 0x401BE3 Write Register V1 Gain

SDO = 0xFF 0xFF 0xFFFFFF (Page 16, Register 35)

SDI = 0x90 0x23 0xFFFFFF Read Register V1 Gain

SDO = 0xFF 0xFF 0x401BE3 (Page 16, Register 35)

Gain Channel 1, Curr.

SDI = 0x90 0x61 0x3C4420 Write Register I1 Gain

SDO = 0xFF 0xFF 0xFFFFFF (Page 16, Register 33)

SDI = 0x90 0x21 0xFFFFFF Read Register I1 Gain

SDO = 0xFF 0xFF 0x3C4420 (Page 16, Register 33)

Gain Channel 2, Volt.

SDI = 0x90 0x6A 0x4037B6 Write Register V2 Gain

SDO= 0xFF 0xFF 0xFFFFFF (Page 16, Register 42)

SDI= 0x90 0x2A 0xFFFFFF Read Register V2 Gain

SDO= 0xFF 0xFF 0x4037B6 (Page 16, Register 42)

Gain Channel 2, Curr.

SDI = 0x90 0x68 0x3C465F Write Register I2 Gain

SDO = 0xFF 0xFF 0xFFFFFF (Page 16, Register 40)

SDI = 0x90 0x28 0xFFFFFF Read Register I2 Gain

SDO= 0xFF 0xFF 0x3C465F (Page 16, Register 40)

Figure 15. Calibration Window

22 AN366REV2

Page 23

From NVM

RESTORE

OFFSET

CONFIGURATION

87

6

5

AN366

RESTORE OFFSET CONFIGURATION

(See Figure 15.)

DC Offset Channel 1, Volt.

SDI = 0x90 0x62 0x000000 Write Register V1 DC Offset

SDO = 0xFF 0xFF 0xFFFFFF (Page 16, Register 34)

SDI = 0x90 0x22 0xFFFFFF Read Register V1 DC Offset

SDO = 0xFF 0xFF 0x000000 (Page 16, Register 34)

DC Offset Channel 1, Curr.

SDI = 0x90 0x60 0x000000 Write Register I1 DC Offset

SDO = 0xFF 0xFF 0xFFFFFF (Page 16, Register 32)

SDI = 0x90 0x20 0xFFFFFF Read Register I1 DC Offset

SDO = 0xFF 0xFF 0x000000 (Page 16, Register 32)

DC Offset Channel 2, Volt.

SDI = 0x90 0x69 0x000000 Write Register V2 DC Offset

SDO = 0xFF 0xFF 0xFFFFFF (Page 16, Register 41)

SDI = 0x90 0x29 0xFFFFFF Read Register V2 DC Offset

SDO = 0xFF 0xFF 0x000000 (Page 16, Register 41)

DC Offset Channel 2, Curr.

SDI = 0x90 0x67 0x000000 Write Register I2 DC Offset

SDO = 0xFF 0xFF 0xFFFFFF (Page 16, Register 39)

SDI = 0x90 0x27 0xFFFFFF Read Register I2 DC Offset

SDO = 0xFF 0xFF 0x000000 (Page 16, Register 39)

AC Offset Channel 1, Curr.

SDI = 0x90 0x65 0x050704 Write Register I1 AC Offset

SDO = 0xFF 0xFF 0xFFFFFF (Page 16, Register 37)

SDI = 0x90 0x25 0xFFFFFF Read Register I1 AC Offset

SDO = 0xFF 0xFF 0x050704 (Page 16, Register 37)

AC Offset Channel 2, Curr.

SDI = 0x90 0x6C 0x049959 Write Register I2 AC Offset

SDO = 0xFF 0xFF 0xFFFFFF (Page 16, Register 44)

SDI = 0x90 0x2C 0xFFFFFF Read Register I2 AC Offset

SDO = 0xFF 0xFF 0x049959 (Page 16, Register 44)

AN366REV2 23

Page 24

From NVM

RESTORE

NO LOAD

CONFIGURATION

10

9

87

SINGLE

CONVERSION

AN366

RESTORE NO LOAD CONFIGURATION

(See Figure 15.)

P1 Offset

SDI = 0x90 0x64 0x000003 Write Register P1 Active Power Offset

SDO = 0xFF 0xFF 0xFFFFFF (Page 16, Register 36)

SDI = 0x90 0x24 0xFFFFFF Read Register P1 Active Power Offset

SDO = 0xFF 0xFF 0x000003 (Page 16, Register 36)

Q1 Offset

SDI = 0x90 0x66 0x000002 Write Register Q1 Reactive Power Offset

SDO = 0xFF 0xFF 0xFFFFFF (Page 16, Register 38)

SDI = 0x90 0x26 0xFFFFFF Read Register Q1 Reactive Power Offset

SDO = 0xFF 0xFF 0x000002 (Page 16, Register 38)

P2 Offset

SDI = 0x90 0x6B 0x000001 Write Register P2 Active Power Offset

SDO = 0xFF 0xFF 0xFFFFFF (Page 16, Register 43)

SDI = 0x90 0x2B 0xFFFFFF Read Register P2 Active Power Offset

SDO = 0xFF 0xFF 0x000001 (Page 16, Register 43)

Q2 Offset

SDI = 0x90 0x6D 0x000002 Write Register Q2 Reactive Power Offset

SDO = 0xFF 0xFF 0xFFFFFF (Page 16, Register 45)

SDI = 0x90 0x2D 0xFFFFFF Read Register Q2 Reactive Power Offset

SDO = 0xFF 0xFF 0x000002 (Page 16, Register 45)

SINGLE CONVERSION

(See Figure 16.)

Figure 16. Conversion Window

24 AN366REV2

Page 25

9 10

11

NO

YES

VALID

REGISTER

CHECKSUM

?

AN366

VALID REGISTER CHECKSUM?

Read register checksum and compare to stored value in NVM (see Figure 17).

SDI = 0x90 0x01 0xFFFFFF Read Register Checksum

SDO = 0xFF 0xFF 0x5C0ED4 (Page 16, Register 1)

Figure 17. Setup Window

AN366REV2 25

Page 26

AN366

WAIT 2 SEC

Tsettle = 2000ms

START

CONTINUOUS

CONVERSI ON

0xD5

11

12

CLEAR DRDY

DRDY

SET?

NO

YES

13

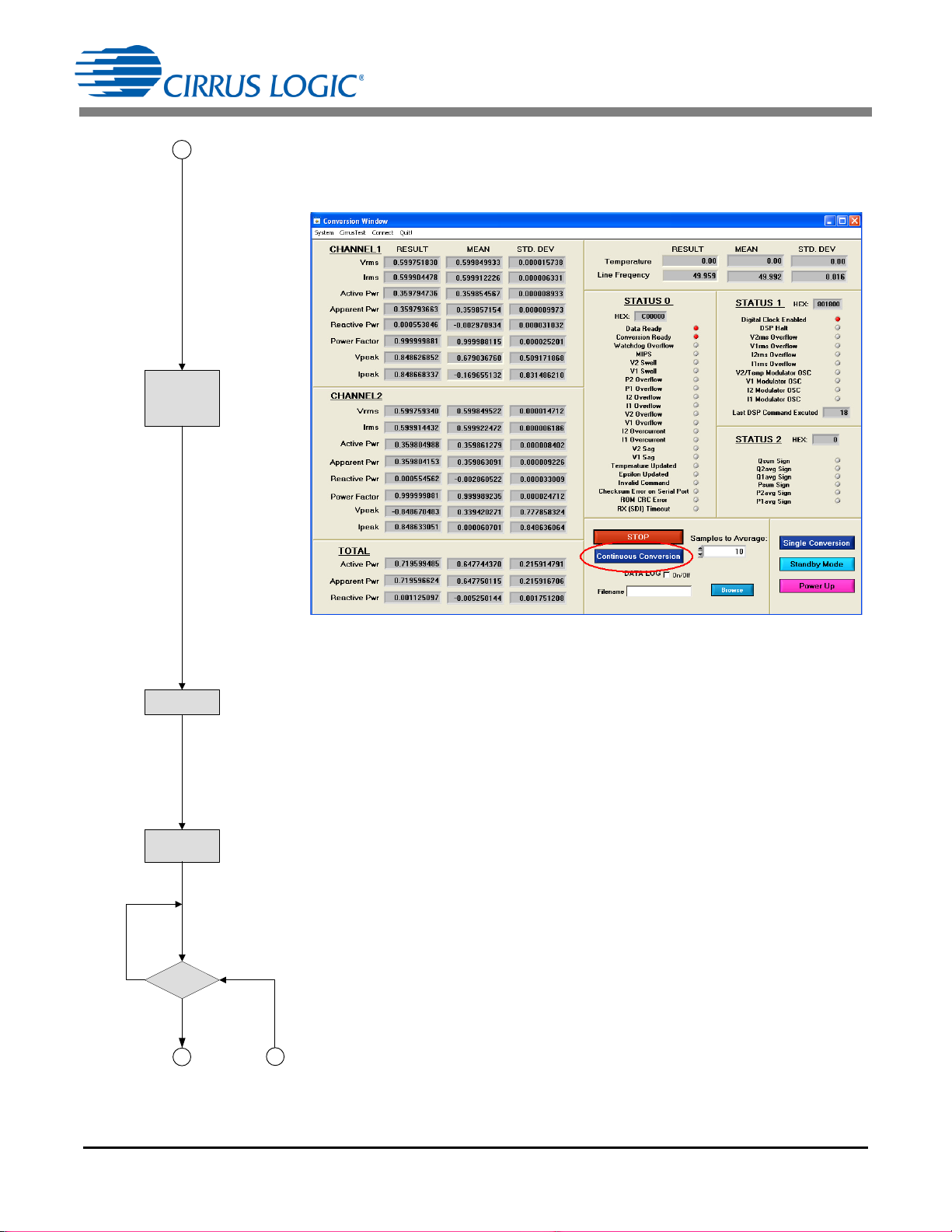

START CONTINUOUS CONVERSION

(See Figure 18.)

SDI = 0xD5 Send Continuous Conversion Command

Figure 18. Conversion Window

WAIT FOR TSETTLE TIME

Wait for Tsettle time.

CLEAR DRDY in INTERRUPT STATUS

SDI = 0x80 0x57 0x800000 Write DRDY Interrupt in Status 0

SDO = 0xFF 0xFF 0xFFFFFF (Page 0, Register 23)

DRDY SET?

SDI = 0x80 0x18 0xFFFFFF Read Status 1 for DRDY Interrupt (Not Set).

SDO = 0xFF 0xFF 0x4XXXXX (Page 0, Register 24)

SDI = 0x80 0x18 0xFFFFFF Read Status 1 for DRDY Interrupt (Set).

SDO = 0xFF 0xFF 0xCXXXXX (Page 0, Register 24)

26 AN366REV2

Page 27

CLEAR DRDY in INTERRUPT STATUS

READ IR MS,

VRMS, PAVG

CLEAR

DRDY

14

12 13

15

SDI = 0x80 0x57 0x800000 Write DRDY Interrupt in Status 0

SDO = 0xFF 0xFF 0xFFFFFF (Page 0, Register 23)

AN366

READ IRMS, VRMS PAVG

(See Figure 19.)

Channel 1

SPI = 0x06 0xFFFFFF Read I1RMS

SPO = 0xFF 0x999357 (Page 16 Register 6)

SPI = 0x07 0xFFFFFF Read V1RMS

SPO = 0xFF 0x998956 (Page 16 Register 7)

SPI = 0x05 0xFFFFFF Read P1AVG

SPO = 0xFF 0x2E0DC1 (Page 16 Register 5)

SPI = 0x14 0xFFFFFF Read S1

SPO = 0xFF 0x2E0DB8 (Page 16 Register 20)

SPI = 0x0E 0xFFFFFF Read Q1AVG

SPO = 0xFF 0x001226 (Page 16 Register 14)

SPI = 0x15 0xFFFFFF Read PF1

SPO = 0xFF 0x7FFFFF (Page 16 Register 21)

SPI = 0x13 0xFFFFFF Read V1PEAK

SPO = 0xFF 0x6C9FCE (Page 16 Register 19)

SPI = 0x12 0xFFFFFF Read I1PEAK

SPO = 0xFF 0x6CA12A (Page 16 Register 18)

Channel 2

SPI = 0x0C 0xFFFFFF Read I2RMS

SPO = 0xFF 0x9993FE (Page 16 Register 12)

SPI = 0x0D 0xFFFFFF Read V2RMS

SPO = 0xFF 0x9989D4 (Page 16 Register 13)

SPI = 0x0B 0xFFFFFF Read P2AVG

SPO = 0xFF 0x2E0E17 (Page 16 Register 11)

SPI = 0x18 0xFFFFFF Read S2

SPO = 0xFF 0x2E0E10 (Page 16 Register 24)

SPI = 0x10 0xFFFFFF Read Q2AVG

SPO = 0xFF 0x00122C (Page 16 Register 16)

SPI = 0x19 0xFFFFFF Read PF2

SPO = 0xFF 0x7FFFFF (Page 16 Register 25)

SPI = 0x17 0xFFFFFF Read V2PEAK

SPO = 0xFF 0x935EC4 (Page 16 Register 23)

SPI = 0x16 0xFFFFFF Read I2PEAK

SPO = 0xFF 0x6CA002 (Page 16 Register 22)

Total

SPI = 0x1D 0xFFFFFF Read PSUM

SPO = 0xFF 0x5C1BD6 (Page 16 Register 29)

SPI = 0x1E 0xFFFFFF Read SSUM

SPO = 0xFF 0x5C1BBE (Page 16 Register 30)

SPI = 0x1F 0xFFFFFF Read QSUM

SPO = 0xFF 0x0024DE (Page 16 Register 31)

SPI = 0x1B 0xFFFFFF Read T

SPO = 0xFF 0x000000 (Page 16 Register 27)

SPI = 0x31 0xFFFFFF Read Epsilon

SPO = 0xFF 0x019943 (Page 16 Register 49)

AN366REV2 27

Page 28

AN366

1514

CALCULATE

VOLTS = FS_Voltage

(VRMS/0.6)

AMPS = FS_Current

(VRMS/0.6)

WATTS = FS_Scale _Power

(VRMS/0.36)

Figure 19. Conversion Window

CALCULATE VOLTS, AMPS, AND WATTS

Channel 1

AMPS1 = HEX2DEC(I1RMS) / 0xFFFFFF / 0.6

VOLTS1 = HEX2DEC(V1RMS) / 0xFFFFFF / 0.6 FS_Voltage

If (P1AVG ≤ 0x7FFFFF) Then

WATTS1 = HEX2DEC(P1AVG) / 0x7FFFFF / 0.36 FS_Power

Else

WATTS1 = (HEX2DEC(P1AVG) - 0xFFFFFF) / 0x7FFFFF / 0.36

Channel 2

AMPS2 = HEX2DEC(I2RMS)/0xFFFFFF / 0.6

VOLTS2 = HEX2DEC(V2RMS) / 0xFFFFFF / 0.6

If (P2AVG ≤ 0x7FFFFF) Then

WATTS2 = HEX2DEC(P2AVG) / 0x7FFFFF / 0.36

Else

WATTS2 = (HEX2DEC(P2AVG) - 0xFFFFFF) / 0x7FFFFF / 0.36

FS_Current

FS_Power

FS_Current

FS_Voltage

FS_Power

FS_Power

28 AN366REV2

Page 29

RESET

POWER UP

1 2

AN366

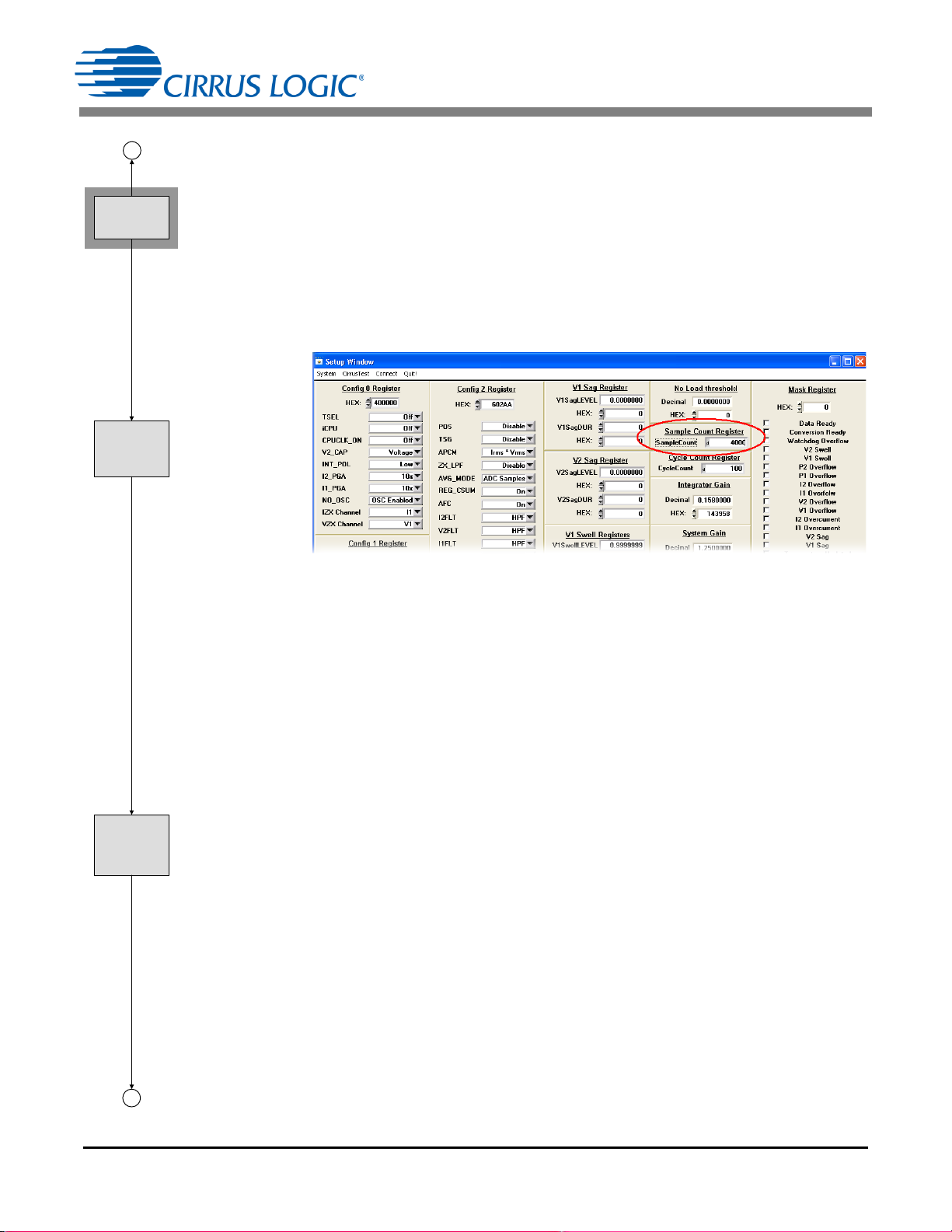

6.2 Main Calibration Flow Diagram Using the CDB5484

The following flow diagram shows the implemented of gain calibration using the CDB5484U and a PC as the

controller. The MTE source is used to provide the source voltage and load current. Each step of the flow shows

the CDB5484 GUI screen capture of execution and reading results. The register writes and reads are all identified for easy compares to the GUI screen. The GUI is not promoted for production level calibration but does provide an excellent debugger for customer flow evaluation.

POWER UP

Power up CDB5484U per data sheet using terminals J36 and J37.

RESET

(See Figure 20.)

SDI = 0xC1 Reset CS5484 software Reset.

Figure 20. Setup Window

AN366REV2 29

Page 30

SINGLE

CONVERSION

1 2

3

YES

NO

VALID

RESET

REGISTER

CHECKS UM

?

AN366

SINGLE CONVERSION

The register checksum is computed each time a conversion is completed (Single or Continuous).

(See Figure 21.)

SDI = 0xD4 Send Single Conversion Command

Figure 21. Conversion Window

VALID REGISTER CHECKSUM TEST

PC/Controller tests if valid checksum is received (see Figure 22).

SDI = 0x90 0x01 0xFFFFFF Read Register Checksum

SDO = 0xFF 0xFF 0x46ECA1

Figure 22. Setup Window

30 AN366REV2

Page 31

AN366

4

3

ENABLE

HIGH PASS

FILTER

ENABLE HIGH PASS ON VOLTAGE AND CURRENT

(See Figure 23.)

SDI = 0x90 0x40 0x0602AA Write Register Config2 to enable HPFs

SDO = 0xFF 0xFF 0xFFFFFF

SDI = 0x90 0x00 0xFFFFFF Read Register Config2 to enable HPFs

SDO = 0xFF 0xFF 0x0602AA

Figure 23. Setup Window

AN366REV2 31

Page 32

AN366

APPLY FU LL-

SCALE ( FS)

VOLTAGE

TO SOURCE

PF=1

FULL LOAD

AVAILABLE ?

APPLY

LOAD

SET SCALE

REGISTER

0.6

LOAD ÷ FS

4

5

YES

NO

PERFOR M

PHASE

COMPENSAT ION

6

APPLY FULL-SCALE VOLTAGE TO SOURCE

(See Figure 24.)

Figure 24. Meter Test Equipment

See Non-full-scale Gain Calibration on page 9.

FULL LOAD AVAILABLE

PC/Controller knows if full load or partial load is available (see Figure 25 for partial load).

SDI = 0x92 0x7F 0x200000 Write Scale 0.25

SDO = 0xFF 0xFF 0xFFFFFF

SDI = 0x92 0x3F 0xFFFFFF Read Scale 0.25

SDO = 0xFF 0xFF 0x200000

Figure 25. Calibration Window

32 AN366REV2

Page 33

SET TSETTLE

Tsettle =

2000 ms

SampleCount

(N) = 16,000

5

7

8

6

(See Figure 26.)

SDI = 0x90 0x79 0x001F40 Write TSETTLE = 2000ms

SDO = 0xFF 0xFF 0xFFFFFF (Page 16, Register 57)

SDI = 0x90 0x39 0xFFFFFF Read TSETTLE = 2000ms

SDO = 0xFF 0xFF 0x001F40 (Page 16, Register 57)

AN366

Figure 26. Setup Window

SET SAMPLE COUNT

(See Figure 27.)

SDI = 0x90 0x73 0x003E80 Write Sample Count = 16,000

SDO = 0xFF 0xFF 0xFFFFFF (Page 16, Register 51)

SDI = 0x90 0x33 0xFFFFFF Read Sample Count = 16,000

SDO = 0xFF 0xFF 0x003E80 (Page 16, Register 51)

Figure 27. Setup Window

AN366REV2 33

Page 34

START CONTINUOUS CONVERSION

READ

IRMS, VRMS,

PAVG, QAVG, PF

START

CONTINUOUS

CONVERT

0xD5

7

9 10

8

(See Figure 28.)

SDI = 0xD5 Write Continuous Conversion

SDO = 0xFF

AN366

Figure 28. Conversion Window

START CONTINUOUS CONVERSION

(See Figure 28.)

Channels 1 and 2, Current

SDI = 0x90 0x06 0xFFFFFF Read I1RMS (page 16, register 6)

SDO = 0xFF 0xFF 0x9AC11C (0.604509151)

SDI = 0x90 0x0C 0xFFFFFF Read I2RMS (page 16, register 12)

SDO = 0xFF 0xFF 0x9ABB62 (0.604421771)

Channels 1 and 2, Voltage

SDI = 0x90 0x07 0xFFFFFF Read V1RMS (page 16, register 7)

SDO = 0xFF 0xFF 0xA3A8BE (0.63929359)

SDI = 0x90 0x0D 0xFFFFFF Read V2RMS (page 16, register 13)

SDO = 0xFF 0xFF 0xA396E2 (0.639021077)

Channels 1 and 2, Active Power

SDI = 0x90 0x05 0xFFFFFF Read P1AVG (page 16, register 5)

SDO = 0xFF 0xFF 0x3177E9 (0.386471914)

SDI = 0x90 0x0B 0xFFFFFF Read P2AVG (page 16, register 11)

SDO = 0xFF 0xFF 0x3170AF (0.3862514)

Channels 1 and 2, Reactive Power

SDI = 0x90 0x0E 0xFFFFFF Read Q1AVG (page 16, register 14)

SDO = 0xFF 0xFF 0x000A92 (0.0003226)

SDI = 0x90 0x10 0xFFFFFF Read Q2AVG (page 16, register 16)

SDO = 0xFF 0xFF 0x000C84 (0.0003819)

Channels 1 and 2, Power Factor

SDI = 0x90 0x15 0xFFFFFF Read PF1 (page 16, register 21)

SDO = 0xFF 0xFF 0x7FFFFF (1)

SDI = 0x90 0x19 0xFFFFFF Read PF2 (page 16, register 25)

SDO = 0xFF 0xFF 0x7FFFFF (1)

Total

SDI = 0x90 0x1D 0xFFFFFF Read PSUM (page 16, register 29)

SDO = 0xFF 0xFF 0x000000 (0)

SDI = 0x90 0x1E 0xFFFFFF Read QSUM (page 16, register 30)

SDO = 0xFF 0xFF 0x000000 (0)

SDI = 0x90 0x1F 0xFFFFFF Read SSUM (page 16, register 31)

SDO = 0xFF 0xFF 0x000000 (0)

34 AN366REV2

Page 35

IS PF=1?

STOP

CONVERSIONS

0xD8

IS PF = 1 ?

CLEAR DRDY

SEND AC GAI N

CALIBRATI ON

0xFE

9

11

YES

10

NO

PC/Controller tests if PF returned is 1.

AN366

STOP CONVERSIONS

(See Figure 29.)

SDI = 0xD8 Write Halt Conversion

SDO = 0xFF

Figure 29. Conversion Window

CLEAR DRDY in INTERRUPT STATUS

SDI = 0x80 0x57 0xFFFFFF Write INT STATUS DRDY (page 0, register 23)

SDO = 0xFF 0xFF 0x800000 (Set DRDY INT)

SEND AC GAIN CALIBRATION

(See Figure 30.)

SDI = 0xFE Write Gain Calibration – All Channels

SDO = 0xFF

Figure 30. Calibration Window

AN366REV2 35

Page 36

READ IRMS,

VRMS, PAVG,

PSUM, QSUM,

SSUM

DRDY

SET ?

VRMS = 0.6 ?

IRMS = SCALE(0.6)?

PAVG = 0.36 ?

CHECK

SETUP o r

FAIL

SCALE = 0.25, T herefore

IRMS = 0.25 after calibration

YES

NO

YES

NO

12

YES

NO

11

PERFORM

NO LOAD

COMPENSATION

& READ PAVG

AN366

CHECK STATUS OF DRDY

SDI = 0x80 0x17 0xFFFFFF Read INT STATUS DRDY (page 0, register 23)

SDO = 0xFF 0xFF 0x4XXXXX (DRDY not Set)

SDI = 0x80 0x17 0xFFFFFF Read INT STATUS DRDY (page 0, register 23)

SDO = 0xFF 0xFF 0xCXXXXX (DRDY Set)

READ POWER REGISTERS

(See Figure 31.)

SDI = 0x90 0x06 0xFFFFFF Read I1RMS (page 16, register 6)

SDO = 0xFF 0xFF 0x40081D (0.2501238)

SDI = 0x90 0x0C 0xFFFFFF Read I2RMS (page 16, register 12)

SDO = 0xFF 0xFF 0x40086D (0.2501286)

SDI = 0x90 0x07 0xFFFFFF Read V1RMS (page 16, register 7)

SDO = 0xFF 0xFF 0x99ACE6 (0.6002945)

SDI = 0x90 0x0D 0xFFFFFF Read V2RMS (page 16, register 13)

SDO = 0xFF 0xFF 0x99ADA6 (0.600306)

SDI = 0x90 0x05 0xFFFFFF Read P1AVG (page 16, register 5)

SDO = 0xFF 0xFF 0x133936 (0.1501835)

SDI = 0x90 0x0B 0xFFFFFF Read P2AVG (page 16, register 11)

SDO = 0xFF 0xFF 0x133966 (0.1501892)

SDI = 0x90 0x1D 0xFFFFFF Read PSUM (page 16, register 29)

SDO = 0xFF 0xFF 0x266DFD (0.3002316)

SDI = 0x90 0x1E 0xFFFFFF Read QSUM (page 16, register 30)

SDO = 0xFF 0xFF 0x000616 (0.0001857)

SDI = 0x90 0x1F 0xFFFFFF Read SSUM (page 16, register 31)

SDO = 0xFF 0xFF 0x266E40 (0.3002396)

36 AN366REV2

Figure 31. Conversion Window

PROPER CALIBRATION RESULTS?

PC/Controller should test for proper calibration results.

PERFORM NO LOAD COMPENSATION

No Load Offset Compensation Flow Diagram on page 47

Page 37

READ VGAIN ,

IGAIN, IACOF F,

POFF, QOFF

PERFORM

AC OFFSET

& READ IRMS

SampleCount =

4,000

12

13

AN366

PERFORM AC OFFSET AND READ IRMS

Note: AC offset is only required when IRMS measurements are needed with high dynamic range

(only helpful at very low input levels).AC Offset Calibration Flow Diagram on page 44

SET SAMPLE COUNT

(See Figure 32.)

SDI = 0x90 0x73 0x000FA0 Write SampleCount (page 16, register 51)

SDO = 0xFF 0xFF 0xFFFFFF (4000)

SDI = 0x90 0x33 0xFFFFFF Read SampleCount (page 16, register 51)

SDO = 0xFF 0xFF 0x000FA0 (4000)

Figure 32. Setup Window

READ POWER REGISTERS

(See Figure 33.)

Gain Calibration, Channels 1 and 2, Voltage

SDI = 0x90 0x23 0xFFFFFF Read V1GAIN (page 16, register 35)

SDO = 0xFF 0xFF 0x3C1078 (0.9385054)

SDI = 0x90 0x2A 0xFFFFFF Read V2GAIN (page 16, register 42)

SDO = 0xFF 0xFF 0x3C1751 (0.9389233)

Gain Calibration, Channels 1 and 2, Current

SDI = 0x90 0x21 0xFFFFFF Read I1GAIN (page 16, register 33)

SDO = 0xFF 0xFF 0x1A77A0 (0.4135514)

SDI = 0x90 0x28 0xFFFFFF Read I2GAIN (page 16, register 40)

SDO = 0xFF 0xFF 0x1A78C4 (0.413621)

Offset Calibration, Channels 1 and 2, Current

SDI = 0x90 0x25 0xFFFFFF Read I1ACOFF (page 16, register 37)

SDO = 0xFF 0xFF 0x000000 (0)

SDI = 0x90 0x2C 0xFFFFFF Read I2ACOFF (page 16, register 44)

SDO = 0xFF 0xFF 0x000000 (0)

Offset Calibration, Channels 1 and 2, Active Power Offset

SDI = 0x90 0x24 0xFFFFFF Read P1OFF (page 16, register 36)

SDO = 0xFF 0xFF 0x000000 (0)

SDI = 0x90 0x2B 0xFFFFFF Read P2OFF (page 16, register 43)

SDO = 0xFF 0xFF 0x000000 (0)

Offset Calibration, Channels 1 and 2, Reactive Power Offset

SDI = 0x90 0x26 0xFFFFFF Read Q1OFF (page 16, register 38)

SDO = 0xFF 0xFF 0x000000 (0)

SDI = 0x90 0x2D 0xFFFFFF Read Q2OFF (page 16, register 45)

SDO = 0xFF 0xFF 0x000000 (0)

AN366REV2 37

Page 38

AN366

SET SCAL E REGIST ER

0.6

13

FULL LOAD

AVAILABLE ?

YES

NO

14 15

Figure 33. Calibration Window

CHECK IF FULL LOAD IS AVAILABLE

PC/Controller knows if full load or partial load set. The following step is not require if full

load is used.

(See Figure 34.)

SDI = 0x92 0x7F 0x4CCCCC Write Scale 0.6

SDO = 0xFF 0xFF 0xFFFFFF

SDI = 0x92 0x3F 0xFFFFFF Read Scale 0.6

SDO = 0xFF 0xFF 0x4CCCCC

38 AN366REV2

Figure 34. Calibration Window

Page 39

COMPUTE

CALIBR ATED

REGISTER

CHECKSUM

CALIBRATI ON

COMPLETE

STORE

CALIBRATI ON

CONSTANTS &

CHECKSUM

14 15

AN366

COMPUTE CALIBRATED REGISTER CHECKSUM

The register checksum is computed each time a conversion is completed (Single or Continuous). If no register have changed the user needs only read the checksum register after

prior conversion. But if a register has been updated (Scale for example) then the user must

perform another conversion before the read (see Figure 35).

If register(s) changed since conversion (SCALE changed), then perform single conversion

first, then read checksum:

SDI = 0xD4 Single Conversion Command (Optional)

SDO = 0xFF

SDI = 0x90 0x01 0xFFFFFF Read Checksum (Page 16, Register 1)

SDO = 0xFF 0xFF 0xF40578

Figure 35. Setup Window and Conversion Window

STORE CALIBRATION CONSTANTS & CHECKSUM

Write to MCU Flash all the calibration constants and checksum.

AN366REV2 39

Page 40

APPLY VOLTAGE

TO SOURCE &

60º LAGGING

LOAD

PF=0.5

FROM MAIN

FLOW

Tsettle =

2000ms

SampleCount

(N) = 16,000

Shown

In

Main

Flow

1

START

CONTINUOUS

CONVERSI ON

0xD5

Current

Voltag e

AN366

6.2.1 Phase Compensation Flow Diagram

The following flow diagram shows the implemented of phase compensation using the CDB5484U and a PC

as the controller. The MTE Meter Test Equipment source is used to provide the source voltage and load current

with a 60º phase shift (PF = 0.5). Each step of the flow shows the CDB5484 GUI screen capture of execution

and reading results. The register writes and reads are all identified for easy compares to the GUI screen

APPLY VOLTAGE AND 60* LAGGING LOAD TO SOURCE

(See Figure 36.)

.

Figure 36. Meter Test Equipment

40 AN366REV2

Page 41

AN366

READ PF

2

1

CALCULATE

PHASE

OFF SET =

arccos(PF)-60º

RESOLUTION

MULTIPLIER

0.008789 (50Hz)

0.010547 @ 60Hz

STOP

CONVERSIONS

0xD8

Shown

In

Main

Flow

STOP CONVERSIONS

(See Figure 37.)

SDI = 0x90 0x15 0xFFFFFF Read PF1 (page 16, register 21)

SDO = 0xFF 0xFF 0x410F40 (0.508278)

SDI = 0x90 0x19 0xFFFFFF Read PF2 (page 16, register 25)

SDO = 0xFF 0xFF 0x4106A8 (0.5080157)

For 1 to Count {

PF1SUM = PF1SUM + PF1

PF2SUM = PF2SUM + PF2}

Figure 37. Conversion Window

PF1AVG = PF1SUM ÷ Count

PF2AVG = PF1SUM ÷ Count

PHASE1_OFFSET = ARCCOS(0.5083238) - 60º = -0.55224327

PHASE2_OFFSET = ARCCOS(0.5085984) - 60º = -0.57051489

Use this constant stored from PC/Controller memory in following calculations.

AN366REV2 41

Page 42

-8.99º <

PHASE OFF SET

< +8.99º ? (50Hz)

PHASE OFF SET

NEGAT IVE?

-512 · 0.008789 <

PHASE OFF SET

< 0 (50Hz)

?

FINE

COMPENSAT ION

(F PCC) = -PHASE

OFFSET ÷

0.008789 (50Hz)

SET COAR SE

COMPENSAT ION

(CPCC = 01)

1 OWR on I

PHASE OFF SET =

PHASE OFF SET +

4.5º (50Hz)

±10.79º @ 60Hz

0 to 512 · 0.010547 @ 60Hz

5.4º @ 60Hz

0.010547 @ 60Hz

FAIL

METER

2

YES

NO

YES

NO

3

YES

Exam pl e Location

0º

Before Calibration V is delayed from I

Delay added to I

8.99º @ 50Hz

10.79 º @ 60Hz

4.5º @ 50Hz

5.4º @ 60Hz

-4.5º @ 50Hz

-5.4º @ 60Hz

-8 . 99 º @ 50H z

-10 .79 º @ 60 Hz

AN366

PHASE OFFSET

PC/Controller test for phase calibration range meet or fail meter. This example shows negative phase offset.

PHASE OFFSET

PC/Controller test for coarse phase calibration range.

When > 1 OWR, PC/Controller calculates Coarse Compensation

PC/Controller calculates Fine Compensation

CPCC1=0, FPCC1 = 62, CPCC2=0, FPCC2 = 64

SDI = 0x80 0x45 0x007C40 Write Phase Comp (page 0, register 69)

SDO = 0xFF 0xFF 0xFFFFFF

SDI = 0x80 0x05 0xFFFFFF Write Phase Comp (page 0, register 69)

SDO = 0xFF 0xFF 0x007C40

Figure 38. Negative Phase Offset

CPCC1 = 0

CPCC2 = 0

FPCC1 = -(-0.55224327) / 0.008789 @ 50Hz = 62,

FPCC2 = -(-0.57051489) / 0.008789 @ 50Hz = 64,

42 AN366REV2

Page 43

AN366

PHASE COMPENSATION COMPLETE

(RETURN CPCC & FPCC to MAIN)

ACCUMULATE MULTIPLE

PF READIN G AND

CONFIRM PF = 0.5

3

ACCUMULATE MULTIPLE PF READING AND CONFIRM

(See Figure 39.)

SDI = 0x90 0x15 0xFFFFFF Read PF1 (page 16, register 21)

SDO = 0xFF 0xFF 0x410F40 (0.508278)

SDI = 0x90 0x19 0xFFFFFF Read PF2 (page 16, register 25)

SDO = 0xFF 0xFF 0x4106A8 (0.5080157)

For 1 to Count {

PF1SUM = PF1SUM + PF1

PF2SUM = PF2SUM + PF2}

PF1AVG = PF1SUM ÷ Count

PF2AVG = PF1SUM ÷ Count

Figure 39. Conversion Window

43

Page 44

FROM MAIN

FLOW

CLEAR DRDY

REMOVE

LOAD CURRENT

Tsettle = 2000

SampleCount

N = 16000

Shown

In

Main

Flow

1

AN366

6.2.2 AC Offset Calibration Flow Diagram

The following flow diagram shows the implemented of AC offset calibration using the CDB5484U and a PC

as the controller. The MTE Meter Test Equipment source is used to provide the source voltage and no load

current. Each step of the flow shows the CDB5484 GUI screen capture of execution and reading results.

The register writes and reads are all identified for easy compares to the GUI screen.

REMOVE LOAD CURRENT

(See Figure 40.)

Figure 40. Meter Test Equipment

CLEAR DRDY in INTERRUPT STATUS

SDI = 0x80 0x57 0xFFFFFF Write INT STATUS DRDY

SDO = 0xFF 0xFF 0x800000 (Set DRDY INT) (page 0, register 23)

44

Page 45

SEND AC

OFFSET

CALIBRATION

0xF6

DRDY

SET ?

YES

NO

1

2

AN366

SEND AC OFFSET CALIBRATION

(See Figure 41.)

SDI = 0xF6 Write AC Offset Calibration – All Channels

SDO =0xFF

Figure 41. Calibration Window

DRDY SET?

SDI = 0x80 0x17 0xFFFFFFRead INT STATUS DRDY (page 0, register 23)

SDO =0xFF 0xFF 0x4XXXXX (DRDY not Set)

SDI = 0x80 0x17 0xFFFFFFRead INT STATUS DRDY (page 0, register 23)

SDO =0xFF 0xFF 0xCXXXXX (DRDY Set)

45

Page 46

AN366

CHECK

INPUT

OR

FAIL

RETURN

IACOFF

to

MAIN FLOW

IACOFF = 0?

AC OFFSET

CALIBR ATION

COMPLETE

NO

YES

READ IRMS,

IACOFF

2

READ POWER REGISTERS

Reading IRMS is shown in main flow (see Figure 42).

SDI = 0x90 0x25 0xFFFFFF Read I1ACOFF (page 16, register 37)

SDO = 0xFF 0xFF 0x050704 (0.0392766)

SDI = 0x90 0x2C 0xFFFFFF Read I2ACOFF (page 16, register 44)

SDO = 0xFF 0xFF 0x049959 (0.0359298)

46

Figure 42. Conversion Window

PC/Controller tests for change in IACOFF register to check for success.

6.2.3 DC Offset Calibration Flow Diagram

The implemented of DC offset calibration follows the same structure as AC offset except that the voltage

and current source are both zero. The high pass filters must not be enabled and instead of sending AC Calibration command (F6), the DC Calibration command is sent (E6). Refer to the main flow for reading the DC

offset registers.

Page 47

FROM MAIN

FLOW

CLEAR DRDY

APPLY FU LL

SCALE VOLT AGE

AND Z ERO LOAD

CURRENT

DRDY

SET?

TSETTLE = 2000

Sample Count

N = 16000

Shown

In

Main

Flow

NO

YES

1

START

CONTINUOUS

CONVERT

0xD5

AN366

6.2.4 No Load Offset Compensation Flow Diagram

The following flow diagram shows the implemented of no load power offset compensation using the

CDB5484U and a PC as the controller. The MTE Meter Test Equipment source is used to provide the source

voltage and no load current. Each step of the flow shows the CDB5484 GUI screen capture of execution

and reading results. The register writes and reads are all identified for easy compares to the GUI screen.

APPLY FULL SCALE VOLTAGE AND ZERO LOAD CURRENT

(See Figure 43.)

Figure 43. Meter Test Equipment

47

Page 48

1

ACCUMUL ATE

MULTIPLE

PAVG, QAVG

READIN GS

2

AN366

ACCUMULATE MULTIPLE PAVG, QAVG READINGS

(See Figure 44.)

Channels 1 and 2, Active Power

SDI = 0x90 0x05 0xFFFFFF Read P1AVG (page 16, register 5)

SDO = 0xFF 0xFF 0xFFFFFC (-0.00000048)

SDI = 0x90 0x0B 0xFFFFFF Read P2AVG (page 16, register 11)

SDO = 0xFF 0xFF 0xFFFFFF (-0.00000012)

Channels 1 and 2, Reactive Power

SDI = 0x90 0x0E 0xFFFFFF Read Q1AVG (page 16, register 14)

SDO = 0xFF 0xFF 0xFFFFFE (-0.00000024)

SDI = 0x90 0x10 0xFFFFFF Read Q2AVG (page 16, register 16)

SDO = 0xFF 0xFF 0xFFFFFC (-0.00000048)

Figure 44. Conversion Window

48

Page 49

AN366

RETURN

POFF

QOFF

to

MAIN FLOW

POWER OFF SET

CALIBRATION

COMPLETE

NEGAT E

QAVG

& STORE IN

QOFF

NEGAT E

PAVG

& STORE IN

POFF

2

SET POFF AND QOFF

Negate PAVG and QAVG registers and store in POFF and QOFF respectively (see

Figure 44).

SDI = 0x90 0x64 0xFFFFFF Write P1OFF (page 16, register 36)

SDO = 0xFF 0xFF 0x000003 (3.57628E-07)

SDI = 0x90 0x24 0xFFFFFF Read P1OFF (page 16, register 36)

SDO = 0xFF 0xFF 0x000003 (3.57628E-07)

SDI = 0x90 0x6B 0xFFFFFF Write P2OFF (page 16, register 43)

SDO = 0xFF 0xFF 0x000001 (1.19209E-07)

SDI = 0x90 0x2B 0xFFFFFF Read P2OFF (page 16, register 43)

SDO = 0xFF 0xFF 0x000001 (1.19209E-07)

SDI = 0x90 0x66 0xFFFFFF Write P1OFF (page 16, register 38)

SDO = 0xFF 0xFF 0x000002 (2.38419E-07)

SDI = 0x90 0x26 0xFFFFFF Read P1OFF (page 16, register 38)

SDO = 0xFF 0xFF 0x000002 (2.38419E-07)

SDI = 0x90 0x6D 0xFFFFFF Write P2OFF (page 16, register 45)

SDO = 0xFF 0xFF 0x000002 (2.38419E-07)

SDI = 0x90 0x2D 0xFFFFFF Read P2OFF (page 16, register 45)

SDO = 0xFF 0xFF 0x000002 (2.38419E-07)

Figure 45. Calibration Window

49

Page 50

Revision History

Contacting Cirrus Logic Support

For all product questions and inquiries contact a Cirrus Logic Sales Representative.

To find one nearest you go to http://www.cirrus.com

IMPORTANT NOTICE

Cirrus Logic, Inc. and its subsidiaries ("Cirrus") believe that the information contained in this document is accurate and reliable. However, the information is subject

to change without notice and is provided "AS IS" without warranty of any kind (express or implied). Customers are advised to obtain the latest version of relevant

information to verify, before placing orders, that information being relied on is current and complete. All products are sold subject to the terms and conditions of sale

supplied at the time of order acknowledgment, including those pertaining to warranty, indemnification, and limitation of liability. No responsibility is assumed by Cirrus

for the use of this information, including use of this information as the basis for manufacture or sale of any items, or for infringement of patents or other rights of third

parties. This document is the property of Cirrus and by furnishing this information, Cirrus grants no license, express or implied under any patents, mask work rights,

copyrights, trademarks, trade secrets or other intellectual property rights. Cirrus owns the copyrights associated with the information contained herein and gives consent for copies to be made of the information only for use within your organization with respect to Cirrus integrated circuits or other products of Cirrus. This consent

does not extend to other copying such as copying for general distribution, advertising or promotional purposes, or for creating any work for resale.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE ("CRITICAL APPLICATIONS"). CIRRUS PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARRANTED FOR USE