Page 1

TCP2RS+

Before performing any maintenance operations,

disconnect the unit from the power supply. If you

suspect an operational fault in the unit or in its

The TCP2RS+ is a communications gateway used to

convert the physical Ethernet environment to serial

RS-485 or RS-232 communications or vice versa in

the routing mode.

This document provides the instructions for use and describes

the operation of the TCP2RS + device. You can download the

manual from CIRCUTOR's web site in case it is misplaced:

connection modifications, repairs, etc., you must

protection system, remove the unit from service. The design of

the unit makes it easy to replace in the event of a fault.

www.circutor.com

1.- DESCRIPTION

The purpose of the TCP2RS+ device is to convert the

physical series environment to Ethernet

communications with TCP/IP communication

packets. The gateway is responsible for the

transparent conversion under TCP or UDP

connections. The operation is determined by the

parameterisation carried out in the internal

configuration web menu.

2.- COMMUNICATION

The device is equipped with a self-detecting 10BaseT

/ 100Base TX connection for the physical connection

of the TCP2RS+ converter to an Ethernet network.

For its configuration has an internal web site from

which the user can define the network protocol used

to communicate with the management software or

communications system master.

2.1.- Ethernet addressing

The device is connected to the master communication system by means of an IP connection, and the addressing parameters must be configured. The configuration modes include the assignment of a fixed IP or configuration of a DHCP name.

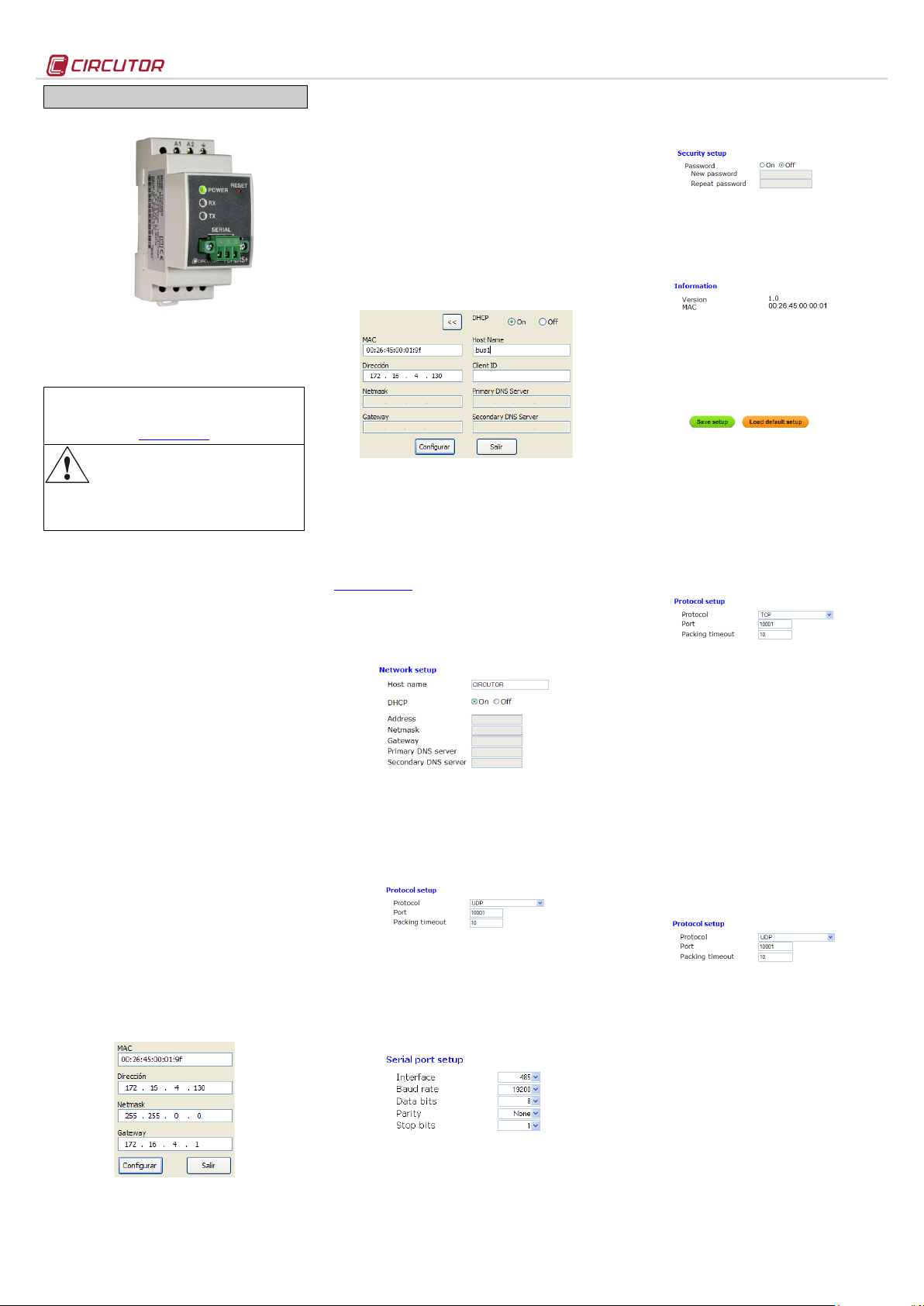

2.1.1.- Ethernet address assignment

To configure the IP address configuration in any of the available formats, run program IPSetup.exe, supplied with the equipment.

2.1.2.- Fixed IP assignment

To assign the fixed IP address, enter the MAC

address shown on the permanent side label attached

to the device, the format of which is

00:26:45:XX:XX:XX.

In the Address field, enter the IP address being

configured; do the same with the (Netmask) and the

(Gateway) port if necessary. After entering the device

settings, press “Setup” to send the configuration to

the equipment.

2.1.3.- DHCP IP assignment

To assign the DHCP name, choose this option using

the arrow on the upper right, and select On. Once the

configuration fields have been enabled, enter the

MAC address that can be seen on the permanent side

label attached to the device, the format of which is

00:26:45:XX:XX:XX. In the Address field, enter an

unused, temporary IP address, which is within the

working range of your computer. In the Host Name

field, enter the DHCP name to be assigned to the

equipment. Optionally, the user can configure the

parameters of the ClientID field. The default VendorID

of the device is CIRCUTOR.

2.2.- Configuration web site

After connecting to the Local Area Network (LAN),

and configuring the IP address or the DHCP name,

the device has an internal web site where all the

parameters related to the network protocol and

configuration of the serial port can be configured. To

access the web site, simply use a conventional

Internet browser and enter the IP address or the

name assigned to the device (for example .

http://172.16.4.130)

2.2.1.- IP address or DHCP name

The internal web site can be used by the user to

apply changes to the DHCP name or to the IP

address previously assigned to the device.

2.2.2.- Network protocol

The device can be connected to the master

communications system by means of three types of

network protocols and to a configurable port (TCP,

UDP or Modbus/TCP). In the case of the

Modbus/TCP protocol, port modification will be

disabled and fixed at 502.

2.2.3.- Configuration of the Serial port

The communications bus parameters can be fully

configured in terms of type of serial Interface (RS485/RS-232), transmission speed (from 4800 bps to

115.2 kbps), data bits (7 or 8), parity (no parity, odd

or even) and stop bit (1 or 2). The data will be

configured by default to 8 by selecting the

Modbus/TCP communications protocol.

TCP2RS+

2.2.4.- Configuration of the setup password

Password can be activated to enable the edition

password. In case to use, the access user is "admin"

and the setup password introduced.

2.2.5.- Device information

The lower part of the screen shows the firmware

version and the machine address of the device (the

same address as that shown on the permanent side

label).

2.2.6.- Save changes

Once any change has been made to the

aforementioned sections, the information must be

saved using the “Save Setup” option. If you wish to

return to the default configuration, select “Load

default setup”.

2.3.- Configuration of network protocols

2.3.1.- TCP Protocol

In the protocol stackTCP/IP, TCP is the intermediate

layer between the Internet protocol (IP) and the

application. In general, applications need reliable

communications. The IP layer offers an unreliable

datagram service (no confirmation), so the TCP adds

the functions required to offer a secure, error-free and

zero loss service for the communications between

two systems.

- Protocol: TCP Mode

- Port: Destination TCP Port Lumber

*In any case you can configure the port 80, so is the

web configuration port

- Packing timeout: maximum waiting time

2.3.2.- UDP Protocol

The User Datagram Protocol (UDP) is a messageoriented minimum transport level protocol that has

been documented in the RFC 768 of the IETF.

In the Internet protocol family, UDP provides a simple

interface between the network layer and the

application layer. UDP does not offer guarantees

during the delivery of its messages and the UDP

origin does not withhold the states of UDP messages

sent to the network. UDP only adds the multiplexing

functionality to the application and the verification

sum of the header and useful load. Any type of

guarantees for the transmission of information must

be implemented in higher layers.

- Protocol: UDP Mode

- Port: Destination UDP Port Lumber

*In any case you can configure the port 80, so is the

web configuration port

- Packing timeout: maximum waiting time

2.3.3.- Modbus/TCP Protocol

Modbus/TCP is a variation or extension of the

Modbus® protocol, which enables it to be used on

the TCP/IP transport layer. Therefore, Modbus/TCP

can be used throughout the Local Area Network or

the Internet. This was one of the objectives that

motivated its development (the specification of the

protocol was submitted to the IETF (Internet

Engineering Task Force).

M98233201-03-12A

Page 2

Power circuit:

- Humidity (no condensation) :

5 … 95%

LED symbols:

Mechanical features:

- Maximum operating height:

2,000 m

Network interface:

Serial interface:

- Stop bit

1 or 2

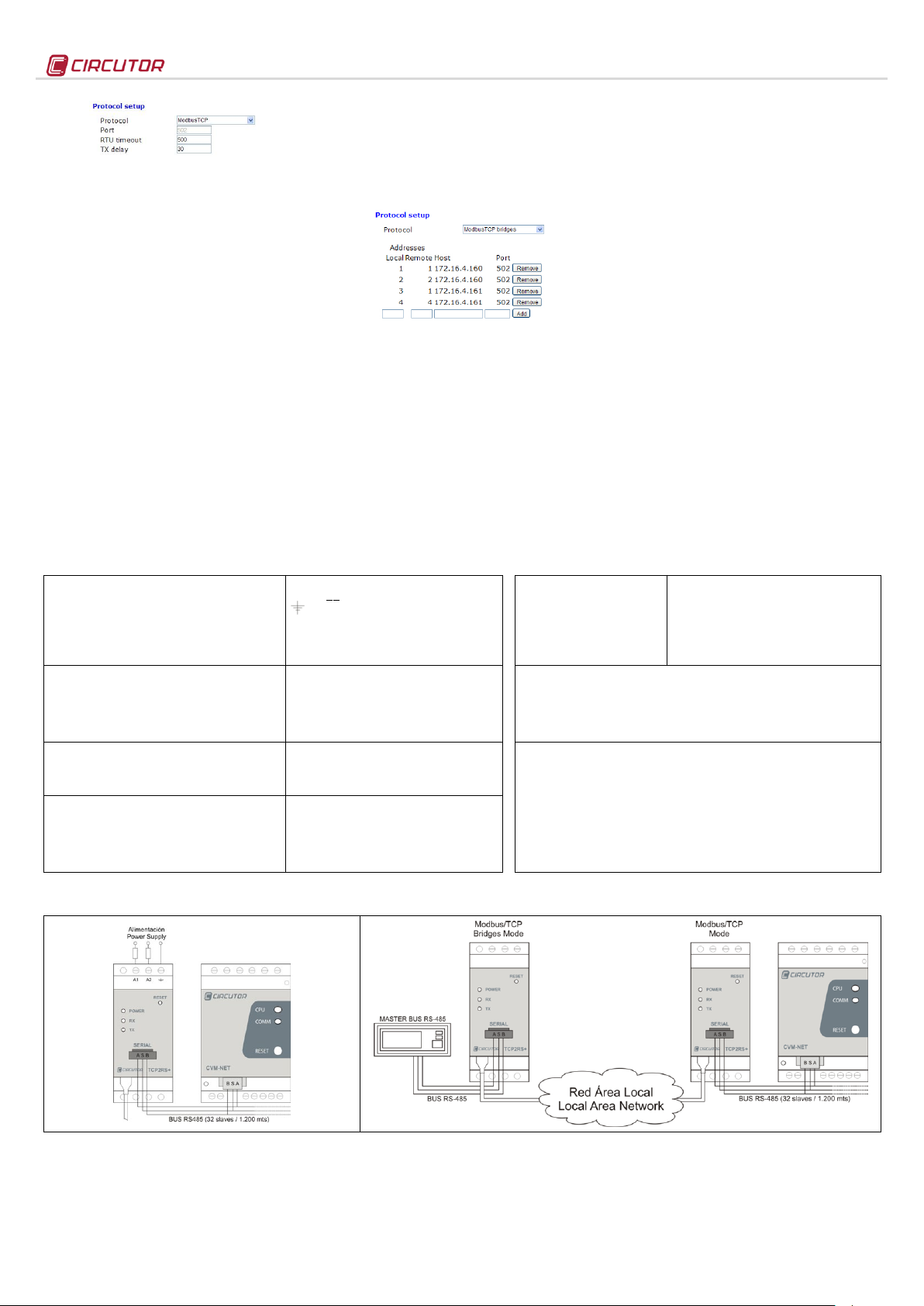

Figure 1. Standard connection of serial equipment

Figure 2. RS-485 Systems over Ethernet infrastructures (Modbus/TCP Bridges Mode)

- Protocol: Modbus/TCP Mode

- Port: Fixed port number 502

- RTU timeout: maximum bus waiting time

- TX delay: additional delay on serial RS bus

2.3.4.- Modbus Protocol/TCP Bridges (routing)

The purpose of this work mode is to implement RS485 or RS-232 networks over existing Ethernet

network infrastructures, either Local Area Networks

or remote networks.

In the Modbus/TCP Bridges mode the unit performs

a constant supervision of the Modbus RTU frames

received through the serial port of the TCP2RS+, and

its function is to address the frames in accordance

with the features programmed in the unit's

configuration web menu.

To do so, the master TCP2RS+ must be configured

with the Modbus Protocol/TCP Bridges, as shown in

Figure 2. Its purpose is to address the frames

received through the RS port, depending on the node

number and destination IP at which the Modbus

sentence is sent.

The paths must be loaded into the device before

performing the addressing operations.

The slave TCP2RS+ device(s) must be configured

with the standard procedure in the Modbus/TCP

protocol, with the serial port communications

parameters and in accordance with the equipment

that is physically connected to the RS-232 or RS-485

3.- TECHNICAL SPECIFICATIONS

communications bus (speed, parity, data bits and

stop bit).

2.3.4.1.- Loading path to the master equipment

In the case of RS-232 or RS-485 topologies over

Ethernet networks, the paths being addressed must

be loaded to the master, according the Modbus®

node number.

List of routes

TCP2RS+ can be used to address the node

numbers. In some cases, the slave equipment

located in different Ethernet networks and connected

to different TCP2RS+ can have a peripheral number

parameterised that is the same as other devices in

other IP networks.

To make sure that the user does not have to change

the node numbers, TCP2RS+ can convert the node

number in the Modbus frame, replacing the local

node number issued by the communications master

number with the real node that the equipment has

available.

In the List of routes, in the example of the Local

node No. 3, how the master sends the Modbus

command for node 03 and TCP2RS+ replaces node

TCP2RS+

03 with node 01 in the Modbus/TCP frame, sending

the Modbus command to the slave TCP2RS+

converter with 172.16.4.161. Even when there is a

different node number that is identical to that of bus

IP 172.16.4.160 (first path position), TCP2RS+ routes

the information in accordance with the node number

and Ethernet address (IP) previously loaded to the

device.

- Local Address: Local node in the master

- Remote Address: Real node in the slave

- Host: IP of the destination or slave TCP2RS+

- Port: IP Port of the destination connection (502)

2.3.4.2.- Parameterisation of IP connection ports

Modbus/TCP works in the fixed mode with TCP port

number 502. For this reason, there may be a problem

when working in remote mode, with installations

where the connection is established through a router,

in which various communication buses may operate

in parallel to slave TCP2RS+.

In the Modbus Bridges mode, TCP2RS+ allows the

random parameterisation of the connection TCP port,

receiving the prior configurations on the router

connecting to the Internet. It is worth noting that, in

this mode, the routing functions would be carried out

by the connection router first, and then by the

configuration of the internal web menu of the device

(path load).

- Single-phase (A1 – A2) :

- Earth connection terminal:

- Frequency:

- Maximum consumption:

- Working temperature:

- Case material:

- Equipment protection degree:

- Dimensions (mm):

- Weight:

- Type:

- Connector:

- Network Protocols - Accesses:

- Type:

- Transmission speed (configurable):

- Data bits:

- Parity:

4.- CONNECTIONS

85…264 Vac / 120…300 Vdc

47…63 Hz

4.6 …7.5 VA

-10 …+60 ºC

UL94 - V0 self-extinguishing plastic

IP 20

35.4 x 73 x 84.68 mm (2 modules)

120 g

Ethernet 10BaseT / 100BaseTX self-detectable

RJ45

TCP / UDP / Modbus/TCP - HTTP

RS-485 / RS-232 three wires (A/S/B) (RX/GND/TX)

4800, 9600,19200, 34800, 57600, 115200 bps

7, 8

No parity, odd, even

- Flashing power LED

- Flashing RX

- Flashing TX

- Full/Half (left in RJ45)

- 10 M/100 M (right in RJ45)

Standards:

IEC 60664, VDE 0110, UL 94, EN61010-1, EN55011, EN 61000-4-2, EN 61000-4-3,

61000-4-11, EN 61000-6-4, EN 61000-6-2, EN 61000-6-1, EN 61000-6-3, EN 61000-4-5,

CE

Safety:

Installation category Category III / EN61010 double-insulated electric shock protection

class II. The equipment must be connected to a power circuit protected with type gl fuses,

in compliance with IEC 269, or type M, with values from 0.5 to 1A. It must be fitted with a

circuit breaker switch or an equivalent device, in order to be able to disconnect the

equipment from the power supply grid. The minimum section of the power supply cable

shall be of 1 mm

If the equipment is not used according to the manufacturer's specifications, the protection

provided by the equipment may be compromised.

2

.

Powered unit and CPU activity

Activity in the receipt of RS-485 / RS-232 frames

Activity in the output of RS-485 / RS-232 frames

Green: Full Duplex connection / Yellow: Half Duplex

Green: Speed 100 Mbps / Yellow: 10 Mbps

5.- TECHNICAL SERVICE

If you have any doubts about the operation of the unit or suspect any malfunction, contact our service staff at CIRCUTOR, SA

CIRCUTOR, SA - Technical Assistence

Vial Sant Jordi, s/n

08232 – Viladecavalls (Barcelona), SPAIN

Tel: (+34) 93 745 29 00 / email: sat@circutor.es

M98233201-03-12A

Loading...

Loading...