Page 1

POWER QUALITY ANALYZER

QNA500 8IO

INSTRUCTION M ANUAL

(M98239501-03-13A)

Page 2

POWER QUALITY ANALYZER QNA500 8IO

Una conexión incorrecta del equipo puede producir la muerte, lesiones graves y riesgo de incendio. Lea y

ATENCIÓN

Death, serious injury, or fire hazard could result from improper connection of this instrument. Read and

WARNING

Un branchement incorrect de l’appareil peut entraîner la mort ou des lésions graves et peut provoquer un

ATTENTION

ADVERTENCIAS / SÍMBOLOS

PELIGRO

DANGER

entienda el manual antes de conectar el equipo. Observe todas las instrucciones de instalación y operación

durante el uso de este instrumento.

La instalación, operación y mantenimiento de este instrumento debe ser efectuado por personal cualificado

solamente. El Código Eléctrico Nacional define a una persona cualificada como una que esté familiarizada

con la construcción y operación del equipo y con los riesgos involucrados.

Consultar el manual de instrucciones antes de utilizar el equipo

En el presente manual, si las instrucciones precedidas por este símbolo no se respetan o realizan

correctamente, pueden ocasionar daños personales o dañar el equipo y /o las instalaciones.

WARNINGS / SYMBOLS

understand this manual before connecting this instrument. Follow all installation and operating instructions

while using this instrument.

Installation, operation, and maintenance of this instrument must be performed by qualified personnel only.

The National Electrical Code defines a qualified person as one who has the skills and knowledge related to

the construction and operation of the electrical equipment and installations, and who has received safety

training on the hazards involved.

DANGER

Read the instructions manual before using the equipment.

In this manual, if the instructions preceded by this symbol are not met or done correctly, can cause personal

injury or equipment damage and / or facilities.

ADVERTISEMENTS / SYMBOLE

incendie. Avant de brancher votre appareil, lisez attentivement le manuel et assurez-vous de bien avoir

compris toutes les explications données. Respectez toutes les instructions concernant le mode

d’installation de l’appareil et son fonctionnement.

L’installation, le fonctionnement et la maintenance de cet appareil doivent être réalisés uniquement par

du personnel qualifié. Le code électrique national définit en tant que personne qualifiée toute personne

connaissant le montage et le fonctionnement de l’appareil ainsi que les risques que ceux-ci comportent.

Consulter le manuel d’instructions avant d’utiliser l’appareil

Si les instructions suivantes, précédées dans le manuel d’un symbole, ne sont pas respectées ou sont

réalisées incorrectement, elles pourront provoquer des dommages personnels ou abîmer l’appareil et/ou

les installations.

QNA500 8IO Instruction manual

2 / 111

Page 3

POWER QUALITY ANALYZER QNA500 8IO

Durch einen nicht sachgemäßen Anschluss der Anlage können Tod, schwere Verletzungen und

ACHTUNG

Uma ligação incorrecta do equipamento pode provocar a morte, lesões graves e risco de incêndio. Leia e

compreenda o manual antes de ligar o equipamento. Observe todas as instruções de instalação e

vadas a cabo exclusivamente por

ATENÇÃO

No presente manual, se as instruções que precedem este símbolo não forem respeitadas ou realizadas

Un collegamento errato del dispositivo può provocare morte, lesioni gravi nonché rischio di incendio.

Prima di collegare il dispositivo leggere attentamente il manuale. Osservare tutte le istruzioni relative

L’installazione, operatività e manutenzione di questo strumento devono essere realizzate solamente da

ATTENZIONE

Qualora le istruzioni riportate nel presente manuale precedute da questo simbolo non vengano osservate

realizzate correttamente, possono provocare danni personali o danneggiare il dispositivo e/o gli

WARNHINWEISE / SYMBOLE

GEFAHR

PERIGO

Brandrisiko hervorgerufen werden. Bevor Sie die Anlage anschließen, lesen Sie bitte das Handbuch

durch und machen Sie sich dessen Inhalt klar. Beachten Sie bei Einsatz dieses Instrumentes sämtliche

Installations- und Betriebshinweise.

Installation, Betrieb und Wartung dieses Instrumentes müssen ausschließlich von entsprechend

qualifiziertem Personal vorgenommen werden. Von dem nationalen Elektrocode wird eine qualifizierte

Person als jemand definiert, der mit der Konstruktion und dem Betrieb einer Anlage und der damit

verbundenen Risiken vertraut ist.

Vor Inbetriebnahme der Anlage ist das Handbuch zu lesen.

Werden die in dem vorliegenden Handbuch mit diesem Symbol versehenen Hinweise nicht beachtet oder

falsch verstanden, können Personenschäden und Schäden an der Anlage und/oder den Installationen

verursacht werden.

ADVERTÊNCIAS / SÍMBOLOS

operação durante o uso deste aparelho.

A instalação, operação e manutenção deste aparelho devem ser le

pessoal qualificado. O Código Eléctrico Nacional define uma pessoa qualificada como uma pessoa que

se encontre familiarizada com a construção e operação do equipamento assim como com os riscos

inerentes.

Consultar o manual de instruções antes de utilizar o equipamento

de forma correcta, podem ocorrer ferimentos pessoais ou danos no equipamento e/ou nas instalações.

AVVERTENZE / SIMBOLI

PERICOLO

all’installazione e all’operatività durante l’uso di questo strumento.

personale qualificato. Il Codice Elettrico Nazionale definisce una persona qualificata come colui che ha

familiarità con la costruzione e operativ ità del dis po sitiv o e co n i rischi che ne possano der ivar e.

Consultare il manuale di istruzioni prima di utilizzare il dispositivo

o

QNA500 8IO Instruction manual

impianti.

3 / 111

Page 4

POWER QUALITY ANALYZER QNA500 8IO

CONTENTS

1.- DISCLAIMER ................................................................................................................................ 7

2.- SAFETY PRECAUTIONS.............................................................................................................. 7

3.- INTRODUCTION ........................................................................................................................... 7

3.1.- GENERAL DESCRIPTION .................................................................................................... 7

3.2.- MULTIFIT SYSTEM MODULES ............................................................................................ 8

3.3.- REGISTRY VARIABLES ....................................................................................................... 9

4.- INTERCONNECTING MODULES ............................................................................................... 10

5.- INSTALLATION ........................................................................................................................... 10

5.1.- VERIFICATION UPON RECEPTION .................................................................................. 10

5.2.- ASSEMBLY ......................................................................................................................... 11

5.3.- INSTALLATION METHODS ................................................................................................ 12

5.3.1.- PROCEDURE ............................................................................................................ 12

5.4.- CONNECTING THE ANALYZER ........................................................................................ 13

5.4.1.- AUXILIARY POWER SUPPLY ................................................................................... 13

5.4.2.- NOMINAL VOLTAGE OF THE VOLTAGE MEASUREMENT CIRCUIT ..................... 13

5.4.3.- NOMINAL CURRENT OF THE CURRENT MEASUREMENT CIRCUIT .................... 13

5.4.4.- OPERATING CONDITIONS ...................................................................................... 13

5.4.5.- SAFETY ..................................................................................................................... 13

5.5.- DESCRIPTION OF THE TERMINALS ................................................................................ 14

5.5.1.- CONNECTING THE POWER SUPPLY MODULE ..................................................... 14

5.5.2.- VOLTAGE AND CURRENT CONNECTIONS ............................................................ 15

5.5.3.- CONNECTING INPUTS-OUTPUTS ........................................................................... 16

5.6.- COMMUNICATION CONNECTION DIAGRAM ................................................................... 17

5.6.1.- RS-232 ...................................................................................................................... 17

5.6.2.- RS-485 ...................................................................................................................... 18

5.6.3.- ETHERNET ............................................................................................................... 18

5.7.- MEASUREMENT CONNECTION DIAGRAMS .................................................................... 20

5.7.1.- 4 CURRENT TRANSFORMERS AND 5 VO LT AGE REFERENCES.......................... 20

5.7.2.- 3 CURRENT TRANSFORMERS AND 2 VOLTAGE TRANSFORMERS .................... 20

5.8.- CONNECTING POWER SUPPLY ....................................................................................... 21

6.- OPERATION OF THE QNA500 (MULTIFIT SYSTEM DESCRIPTION) ....................................... 22

QNA500 8IO Instruction manual

4 / 111

Page 5

POWER QUALITY ANALYZER QNA500 8IO

6.1.- PHYSICAL DESCRIPTION .................................................................................................. 22

6.1.1.- BASE MODULE (M-BASE) ......................................................................................... 22

6.1.2.- MEASUREMENT MODULE (QNA500) ....................................................................... 23

6.1.3.- INPUT-OUTPUT CENTRALIZER MODULE (M-8IO) .................................................. 24

6.2.- SUPPLY THE POWER QUALITY ANALYZER..................................................................... 25

7.- BASE MODULE SETUP (M-BASE) ............................................................................................. 26

7.1.- COMMUNICATIONS............................................................................................................ 26

7.1.1.- IP ADDRESS CONFIGURATION ............................................................................... 27

7.1.1.- IGMP CONFIGUARTION ............................................................................................ 28

7.1.2.- NTP SYNCHRONIZATION ......................................................................................... 29

7.1.3.- DEVICE NUMBER CONFIGURATION ....................................................................... 29

8.- POWER QUALITY ANALYZER SETUP (M-QNA500) .................................................................. 30

8.1.- COMMUNICATIONS............................................................................................................ 30

8.2.- MEASUREMENT ................................................................................................................. 30

8.3.- POWER QUALITY ............................................................................................................... 32

8.4.- TRANSIENTS ...................................................................................................................... 32

8.5.- REMOVE FILES .................................................................................................................. 33

8.6.- CLOCK ................................................................................................................................ 34

8.7.- BATTERY ............................................................................................................................ 34

8.8.- STANDARD RECORDING PERIOD .................................................................................... 34

8.9.- ENERGY RECORDING PERIOD ........................................................................................ 34

8.10.- SELECTING VARIABLES TO BE RECORDED ................................................................. 34

8.11.- ALARM SETUP (DIGITAL OBJECTS) ............................................................................... 35

8.12.- FACTORY PRESETS ........................................................................................................ 37

8.13.- RECORDING FILES .......................................................................................................... 38

8.13.1.- .STD FILE ................................................................................................................. 38

8.13.2.- .WAT FILE ................................................................................................................ 41

8.13.3.- .EVQ FILE ................................................................................................................ 41

8.13.4.- .EVA FILE ................................................................................................................. 42

8.13.5.- .CFG AND .DAT FILES............................................................................................. 42

9.- INPUT/OUTPUT MODULE SETUP (M-8IO) ................................................................................ 43

9.1.- COMMUNICATIONS............................................................................................................ 43

9.2.- DIGITAL INPUTS ................................................................................................................. 44

QNA500 8IO Instruction manual

5 / 111

Page 6

POWER QUALITY ANALYZER QNA500 8IO

9.3.- DIGITAL OUTPUTS ............................................................................................................ 44

9.4.- FILES .................................................................................................................................. 45

9.4.1.- .STD FILE .................................................................................................................. 45

9.4.2.- .EVA FILE .................................................................................................................. 45

9.5.- ALARM SETUP (DIGITAL OBJECTS) ................................................................................ 46

10.- WEB SERVER ...................................................................................................................... 47

10.1.- INTRODUCTION ............................................................................................................... 47

10.2.- M-BASE SETUP ............................................................................................................... 47

10.3.- QNA500 SETUP ............................................................................................................... 54

10.4.- M-8IO SETUP ................................................................................................................... 70

11.- COMMUNICATIONS PROTOCOLS ..................................................................................... 84

11.1.- MODBUS / RTU ................................................................................................................ 84

11.1.1.- MODBUS/RTU MEMORY ADDRESS LIST OF THE QNA500 ................................. 85

11.1.2.- MODBUS/RTU MEMORY ADDRESS LIST OF THE M-8IO MODULE ..................... 99

11.2.- MODBUS/TCP ................................................................................................................ 100

11.3.- ZMODEM ........................................................................................................................ 100

11.4.- CIRBUS .......................................................................................................................... 101

11.4.1.- CIRBUS INSTRUCTIONS LIST ............................................................................. 101

11.5.- FTP ................................................................................................................................. 105

12.- MAINTENANCE .................................................................................................................. 106

13.- TECHNICAL FEATURES .................................................................................................... 107

14.- SAFETY .............................................................................................................................. 109

15.- DIMENSIONS ..................................................................................................................... 109

16.- TECHNICAL SERVICE ....................................................................................................... 109

17.- APPENDIX 1 – COMMUNICATIONS RS-485 WITH CVM POWER ANALYZERS .............. 110

18.- APPENDIX II – WIRING DIAGRAM TO CONNECT ENERGY METERS WITH

PULSE OUTPUT WITH M-8IO ........................................................................................................... 111

QNA500 8IO Instruction manual

6 / 111

Page 7

POWER QUALITY ANALYZER QNA500 8IO

1.- DISCLAIMER

CIRCUTOR, SA reser ves the right to make modifications to the device or the equipment specifications

set out in this instruction manual without prior notice. CIRCUTOR, SA ad vises the user to obtain the

latest version of the specifications and applications of the device at http://www.circutor.com

CIRCUTOR, SA recommends the use of the original cables and accessories supplied

with the equipment.

2.- SAFETY PRECAUTIONS

Follow the warnings described in this manual with the symbols shown below.

DANGER

Warns about an electrical risk.

ATTENTION

Indicates message or warning requiring special attention.

3.- INTRODUCTION

3.1.- General description

This manual provides the information required to install, configure and handle the QNA500 8IO (to

simplify QNA500) power quality analyzer and to achieve the optimum performance. Read it carefully

and observe the safety instructions and regulations at all times.

QNA500 8IO is a power quality analyzer that measures, calculates and records the main electrical

parameters of three-phase balanced or RMS industrial networks, as well as the power quality

parameters in the same electrical network.

The measurements are taken in true root mean squared (TRMS), with five alternating voltage inputs

(3P+N+PE) and five current inputs (3P+N+I

to external current transformers. The power quality analyzer QNA500 is a programmable measuring

instrument. It offers a series of operating options that can be selected from the menus on its WEB

server or the software supplied by CIRCUTOR. Read carefully the following sections before start-up

the product: power supply, connection and configuration. In addition, select the most suitable operating

mode to collect the required data.

leak) to measure the secondaries of /1A or /5A, connected

QNA500 8IO Instruction manual

7 / 111

Page 8

POWER QUALITY ANALYZER QNA500 8IO

CODE

DESCRIPTION

M-QNA500

Power quality analyzer

M-8IO

Centralizer with 8 digital inputs / 8 digital outputs (optomosfet):

M-8IOR

Centralizer with 8 digital inputs / 8 digital outputs (relay):

QM-500 DISPLAY

On-line display to monitor variables of the QNA500 module

The advanced power handling features of the QNA500 analyzer can measure and record over 500

electrical parameters, in order to analyze and control the electrical network.

The main features of the analyzer are as follows:

• 5 voltage measurement inputs (3P+N+PE)

• 5 current measurement inputs (3P+In+Id (

Earth-leakage current))

• Class 0.2 energy and power ac cur ac y

• 512 samples/cycle

• Configurable capture of transients and other disturbances in the installation

• Configurable register of over 500 electrical variables

• Maximum and minimum value registers

• DIN rail or rear PANEL fixing.

• WEB Serve r

• 3 communications ports (RS-232, RS-485 and ETHERNET)

• Communications protocols: MODBUS/RTU, MODBUS/TCP, COMTRADE, HTTP, FTP and

ZMODEM

• Additional input and output modules to expand the performance of the analyzer

• Internal battery to guarantee the operation of the power quality analyzer in the absence of

power supply

3.2.- MULTIFIT System modules

The MULTIFIT system has various expansion modules that can expand its performance features.

The modules available are the followings:

• Base power supply and communications station (M-BASE)

• Power quality analyzer (M-QNA500)

• Energy manager and alarms for 8inputs + 8outputs (M-8IO)

Additional modules can be added to the assembly to cater f or future expansion requirements. Also take

into account that each M-BASE module can power a maximum number of modules, in accordance with

the total consumption.

The following cards are available:

QNA500 8IO Instruction manual

8 / 111

Page 9

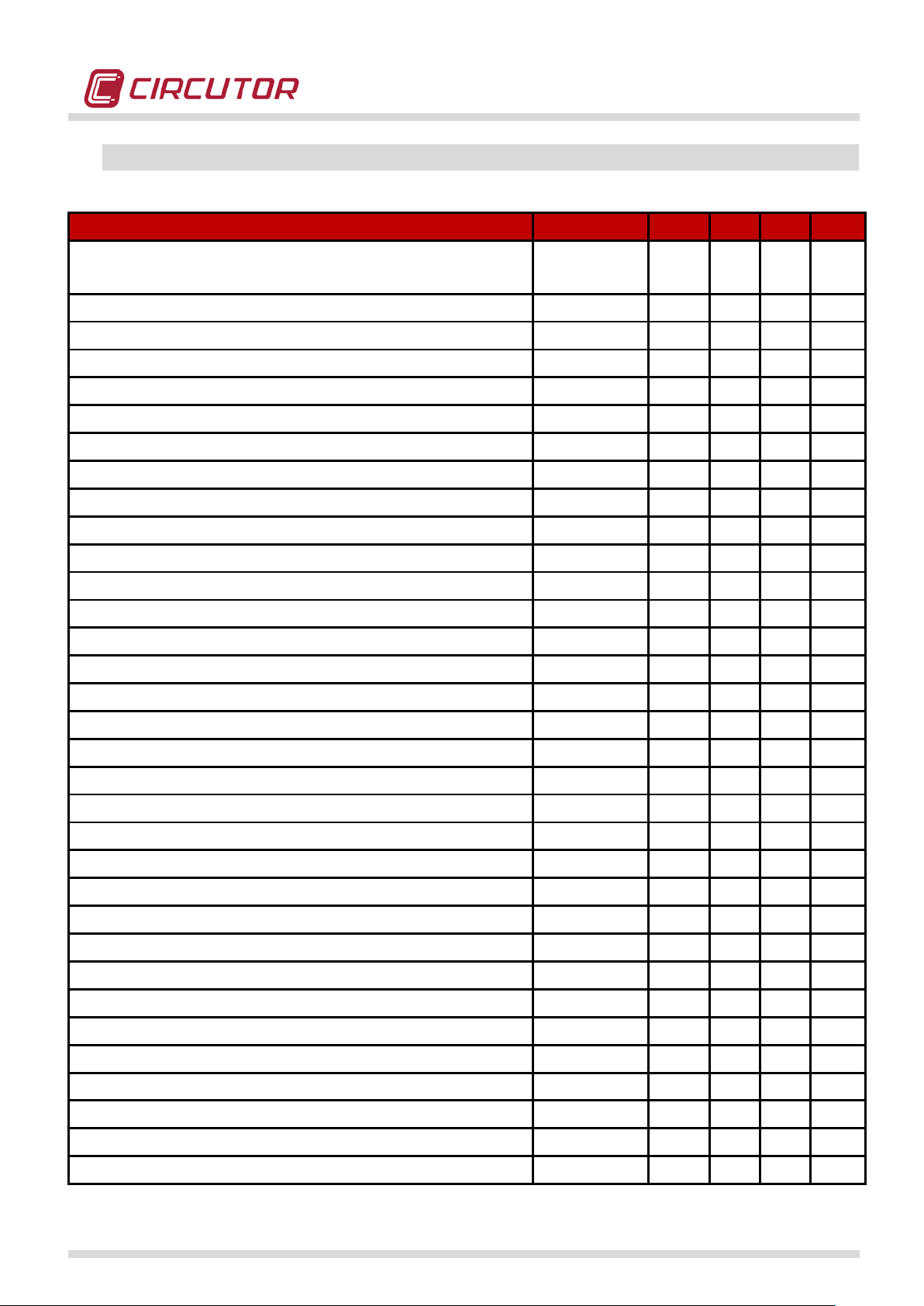

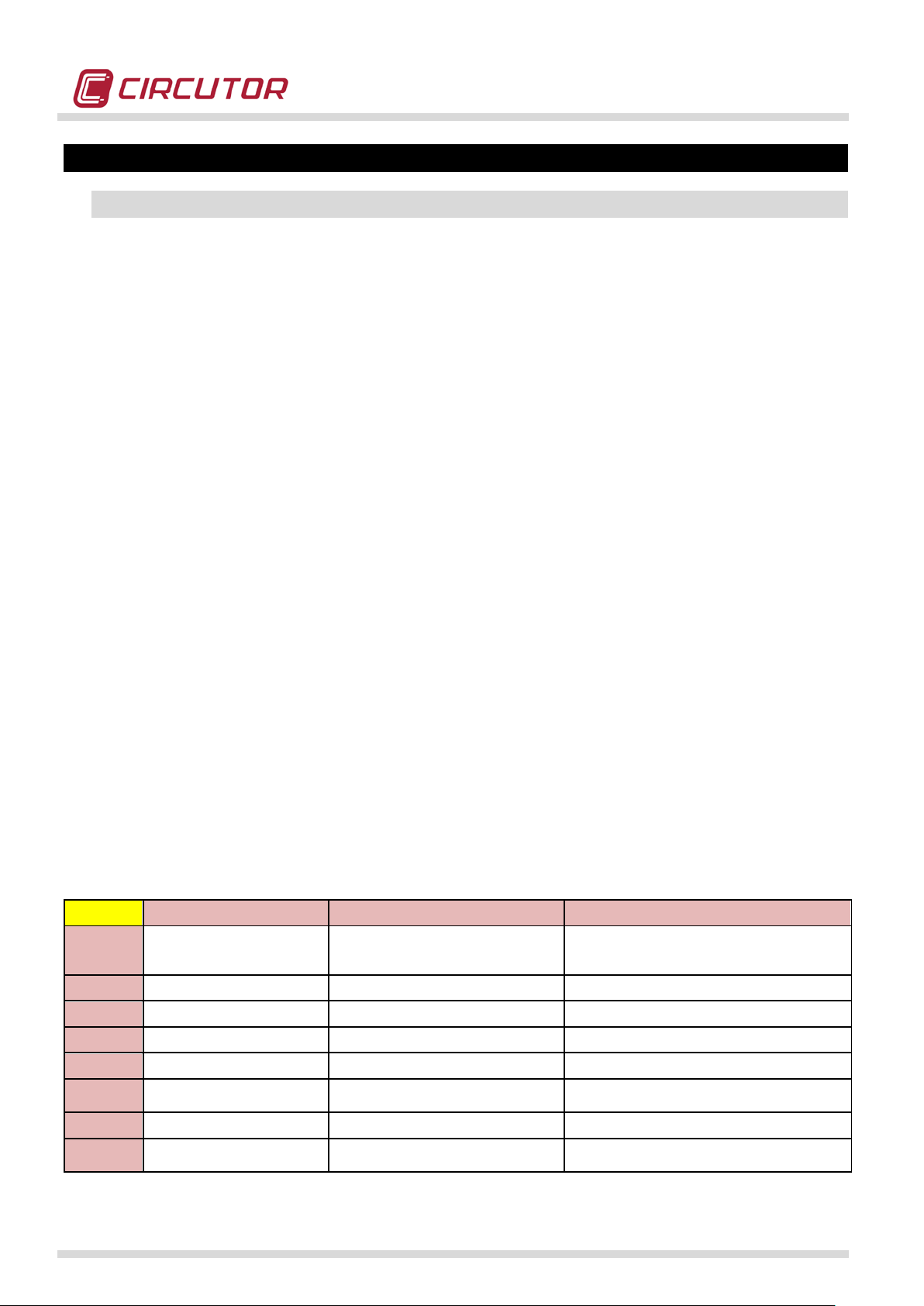

3.3.- REGISTRY VARIABLES

Register variables

Unit

L1

L2

L3

III

Phase-phase and phase-neutral voltage (average,

V

X X X

X

Current (average, maximum, minimum)

A

X X X X Neutral current (average, maximum, minimu m)

A

X Earth-Leakage current (average, maximum, minimum)

A

X Neutral-Ground voltage (average, maximum, minimum)

V

X Frequency (average, maximum, mini mu m)

Hz

X X X Active power (average, maximum, mini mum)

kW

X X X X Inductive reactive power (average, maximum, min imum)

kvar

X X X X Capacitive reactive power (average, maximum, min imum)

kvar

X X X X Apparent power (average, maximum, minimum )

KVAR

X X X X Maximum demand

kW

X X X Power factor (average, maximum, mini mum)

X X X X Crest factor (voltage and current)

V or A

X X X K Factor

X X X Active energy

kWh

X X X X Inductive reactive energy

kvarh

X X X X Capacitive active energy

kvarh

X X X X Voltage THD (average, maximum, minimum)

%

X X X Current THD (average, maximum, minimum))

%

X X X Voltage harmonics (up to 50th order)

V Harm

X X X Current harmonics (up to 50th order)

A Harm

X X X Voltage interharmonics (up to 50th order)

V Harm

X X X Current interharmonics (up to 50th order)

A Harm

X X X Flicker (PST)

X X X Overvoltage

%

X X X Sags

%

X X X Interruptions

%

X X X Voltage transients

X X X Current transients

X X X Voltage Unbalance (Vd/Vi)

X Voltage Asymmetry (Vh/Vi)

X Current Unbalance (Id/Ii)

X Current Asymmetry (Ih/Ii)

X

The power quality analyzer can measure:

maximum, minimum)

POWER QUALITY ANALYZER QNA500 8IO

QNA500 8IO Instruction manual

9 / 111

Page 10

POWER QUALITY ANALYZER QNA500 8IO

NOTE: do not connect more modules than those stated in the specifications. Otherwise,

4.- INTERCONNECTING MODULES

The MULTIFIT unit system can be used to interconnect various modules. Modules do not have to be

connected in a specific order. In any case, CIRCUTOR supplies two factory configurations:

1. M-BASE + M-QNA500

2. M-BASE + M-QNA500 + M-8IO

The MULTIFIT internal communications system allows each module to operate independently (Master

mode), so that each module can take its own decisions, regardless of the type of c onnection.

Modules are interconnected with a communications connector (26 PINS) located on the side of each

module. Once all modules have been installed, it is advisable to close the side connector of the last

module with the cover supplied with the equipment. The M-BASE can only power a specific number of

modules, due to the consumption of each one. The maximum capacity of each M-BASE module can be

used to power 2 QNA500 systems and 2 M-8IO or 4 M-8IO systems.

the equipment's operation could be severely affected.

5.- INSTALLATION

This manual contains information and warnings that the user must observe in order to guarantee the

safe operation of the equipment, so that it is in perfect working order and respects the safety

regulations.

If the equipment is used in a manner other than that specified by the manufacturer, its

protection elements may be compromised.

5.1.- VERIFICATION UPON RECEPTION

Check the following points when you receive the instrument:

• Make sure that the equipment is as specified on your order.

• Make sure that it has not been dam aged during transport.

• Make sure that there is a quick guide and/or adequate manuals with the equipment.

• Make sure that the following accessories have been supplied with the equipment:

o RS-232 Communications cable

o Ni-MH Battery

o DIN RAIL Fixing guides (1 guide + 1 fixing element per module)

o REAR PANEL fixing brackets

o Power supply and measurement connection terminal strip

QNA500 8IO Instruction manual

10 / 111

Page 11

POWER QUALITY ANALYZER QNA500 8IO

The safe use of the QNA500 power quality analyzer requires people who install or

it to follow the general safety measures, as well as the warnings documented in

This power quality analyzer should only be installed and maintained by qualified staff.

The product must be disconnected from the auxiliary power supply sources and from the

measurement in case its safety protection elements have been overridden (visible

damage has been detected). In this case, contact a qualified technical service

o Input and output terminal strips (when using a M-8IO module)

handle

the Instruction Manual.

5.2.- ASSEMBLY

ENVIRONMENTAL CONDITIONS

This equipment should be used at a temperature of -10ºC to +55ºC to guarantee its optimum operation,

with a relative humidity of 5 to 95%, with no condensation (temperature margin, as stated in the UL

certification). These technical features are guaranteed under internal laboratory tests at -10...55ºC.

CONSIDERATIONS

QNA500 8IO must be installed in a distribution cabinet that protects the analyzer from environmental

contaminating substances, such as oil, humidity, dust and corrosive vapours or other volatile

substances.

representative.

The analyzer has two basic installation methods:

• As a compact equipment in a distribution cabinet, installed on the rear PANEL

• As a modular equipment, installed on a DIN 46277 rail (EN 50022)

QNA500 8IO Instruction manual

11 / 111

Page 12

POWER QUALITY ANALYZER QNA500 8IO

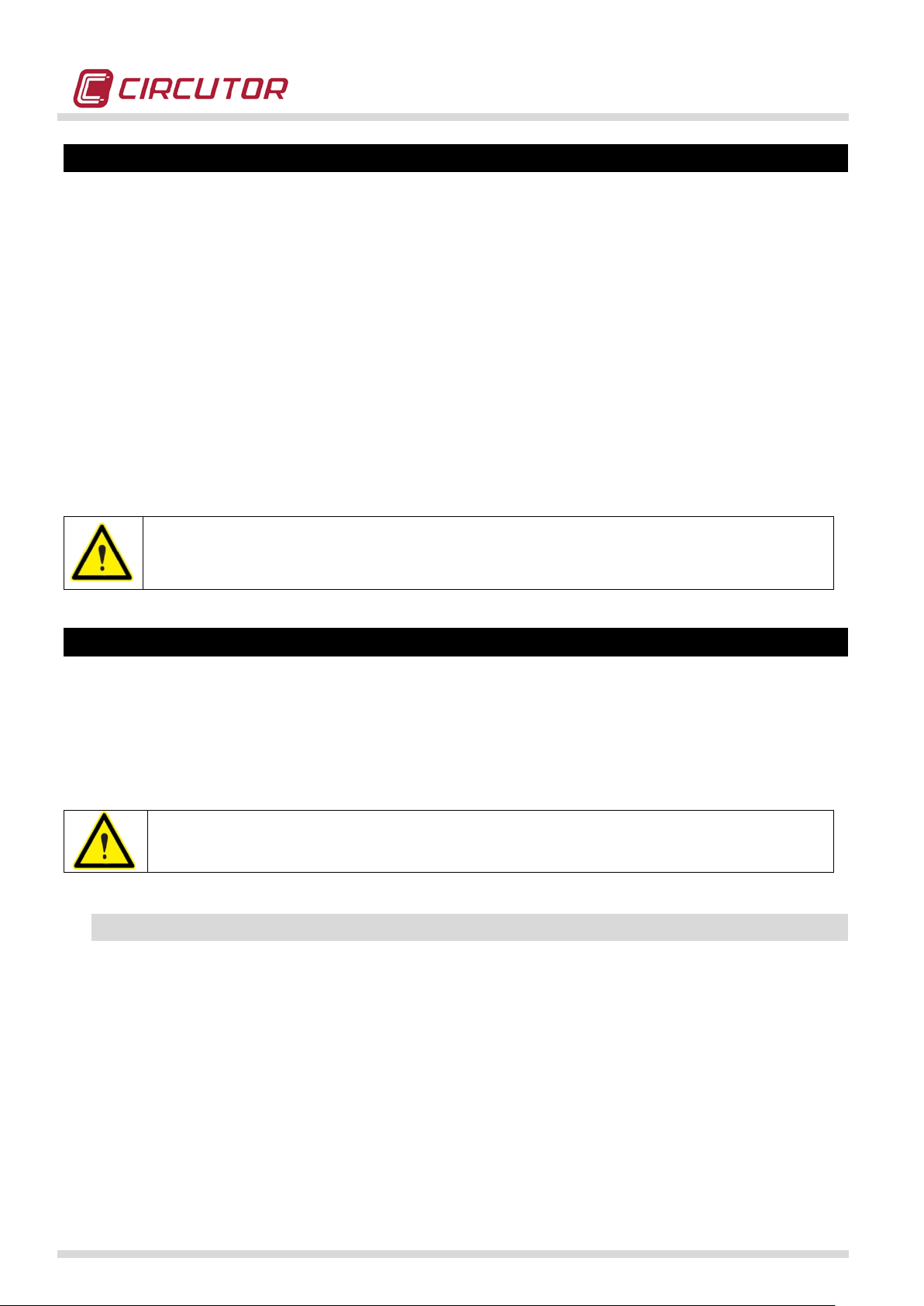

Illustration 3

Illustration 4

Illustration 6

Illustration 5

Illustration 1

Illustration 2

5.3.- INSTALLATION METHODS

The following figures show the different installation options established when the analyzer is

designed. The equipment's design allows an installation on a rear PANEL or DIN rail.

5.3.1.- PROCEDURE

Illustration 1: Shows how the DIN rail fixing elements should be attached to the rear of the analyzer. Once the guides are in place and the

analyzer has been attached to the DIN rail, remember to raise the guides to make sure they are correctly fastened.

Illustration 2: Shows how the analyzer's battery must be installed on the side of the M-BASE module.

Illustration 3: Shows one of the options for mounting the PANEL base attachment guides. The modules are somewhat symmetrical, and can

therefore be attached to the panel in various ways.

Illustration 4: Shows one of the options for mounting the PANEL base attachment guides.

Illustration 5: Shows how to insert the screws for fastening the analyzer to the PANEL base attachment elements.

Illustration 6: Shows how to insert the plastic clamps to fasten the modules. This point is very important, since the purpose of the clamps is to

guarantee that the modules are firmly secured.

QNA500 8IO Instruction manual

12 / 111

Page 13

POWER QUALITY ANALYZER QNA500 8IO

Disconnect the QNA500 from the power supply and measurement sources

before working on it to expand it with expansion modules, to modify the

is dangerous to handle the

equipment while it is under power.

5.4.- CONNECTING THE ANALYZER

Check the following sections before connecting the equipment:

1. Auxiliary voltage features

2. Maximum voltage of the voltage measurement circuit

3. Maximum current of the current measurement circuit

4. Operating conditions

5. Safety

5.4.1.- AUXILIARY POWER SUPPLY

Standard power supply: 90-300VAC / 100-300VCC

Frequency: 50…60 Hz

5.4.2.- NOMINAL VOLTAGE OF THE VOLTAGE MEASUREMENT CIRCUIT

Measurement voltage: 0…500 V (phase-neutral)

Maximum measurement voltage: 500/866 V (phase-neutral / phase-phase)

Frequency: 42.5…69 Hz

5.4.3.- NOMINAL CURRENT OF THE CURRENT MEASUREMENT CIRCUIT

Secondary current: /5 A

(standard model)

Secondary current: /1 A (depending on the model)

Maximum Current: 1.2 x I

secondary

5.4.4.- OPERATING CONDITIONS

Operating temperature: -10ºC to +55ºC

Relative humidity: 5…95%

Altitude: 2000 m

5.4.5.- SAFETY

The QNA500 has been specially designed for CAT IV 600V (CAT III 1000V) installations, in

compliance with the EN61010 standard. Designed and identified with the EC mark.

connections or to replace the equipment. It

QNA500 8IO Instruction manual

13 / 111

Page 14

5.5.- DESCRIPTION OF THE TERMINALS

The equipment must be connected to a power circuit protected with gl-type

breaker switch or equivalent

. (AWG 17). The current

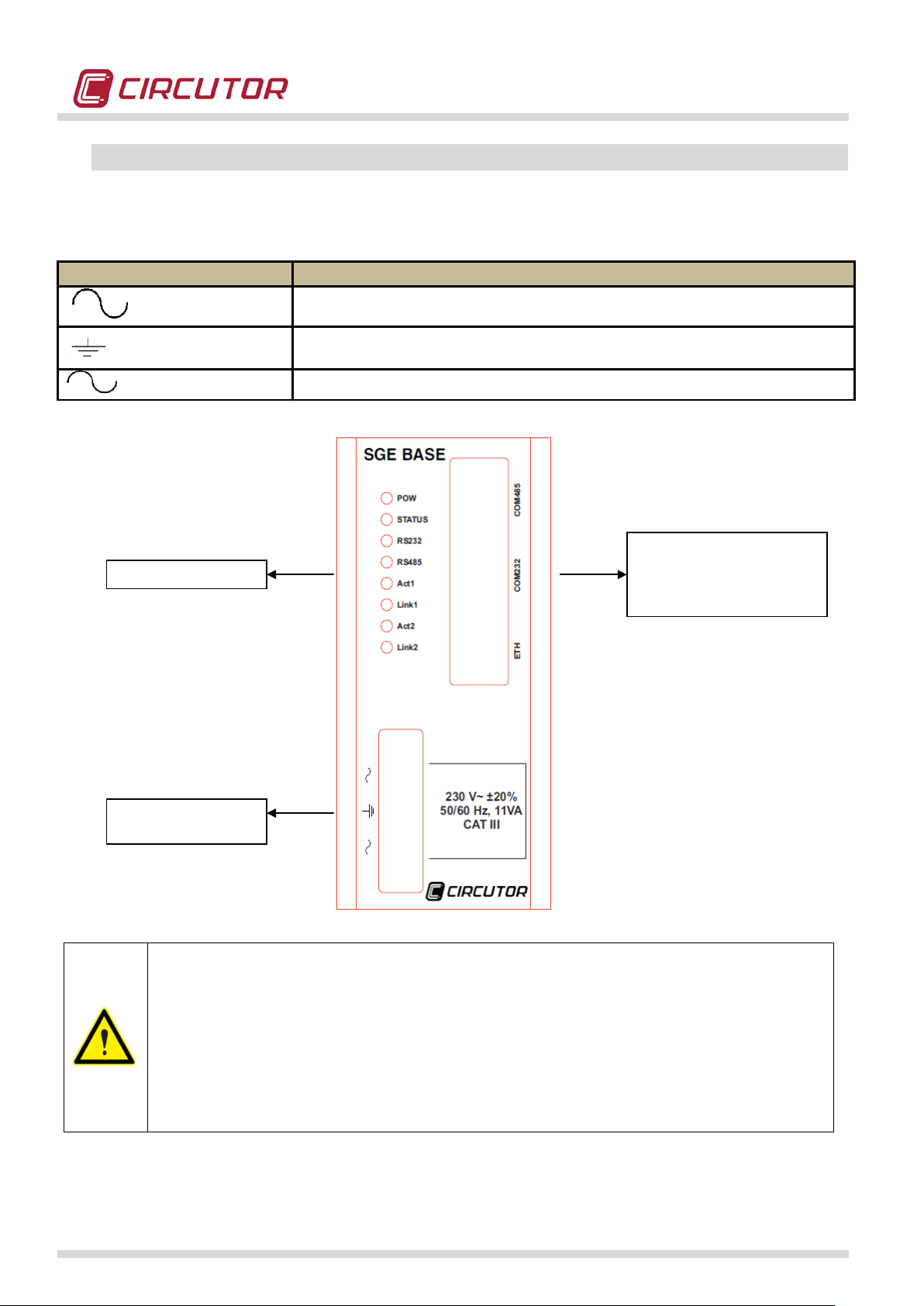

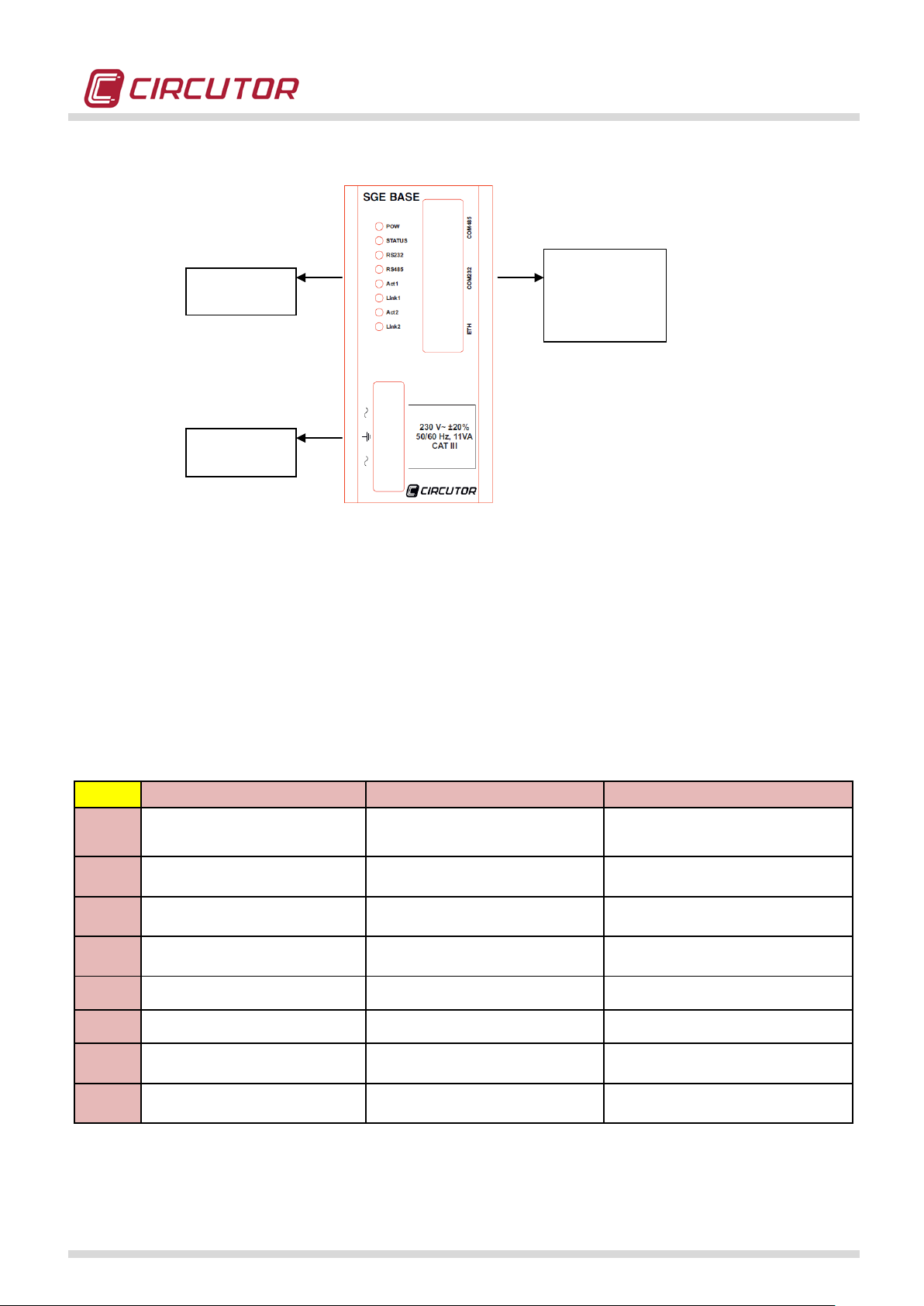

TERMINAL

DESCRIPTION

Power supply connection

Ground connection

Power supply connection

Indicator LED

Communications ports

ETHERNET

Auxiliary power

supply

5.5.1.- CONNECTING THE POWER SUPPLY MODULE

POWER QUALITY ANALYZER QNA500 8IO

RS-485

RS-232

fuses, in compliance with I EC 269, or M-type, with values from 0.5 to 1 A / 600

V (UL listed). It must be fitted with a circuitdevice, in order to be able to disconnect the device from the power supply.

The power circuit and voltage measurement circuits are connected with a

cable with a minimum cross-section of 1 mm

2

transformer's secondar y connection line must have a minimum cross-section

2

of 2 mm

. (AWG 14 Cu) and withstand a minimu m of 60ºC.

QNA500 8IO Instruction manual

14 / 111

Page 15

5.5.2.- VOLTAGE AND CURRENT CONNECTIONS

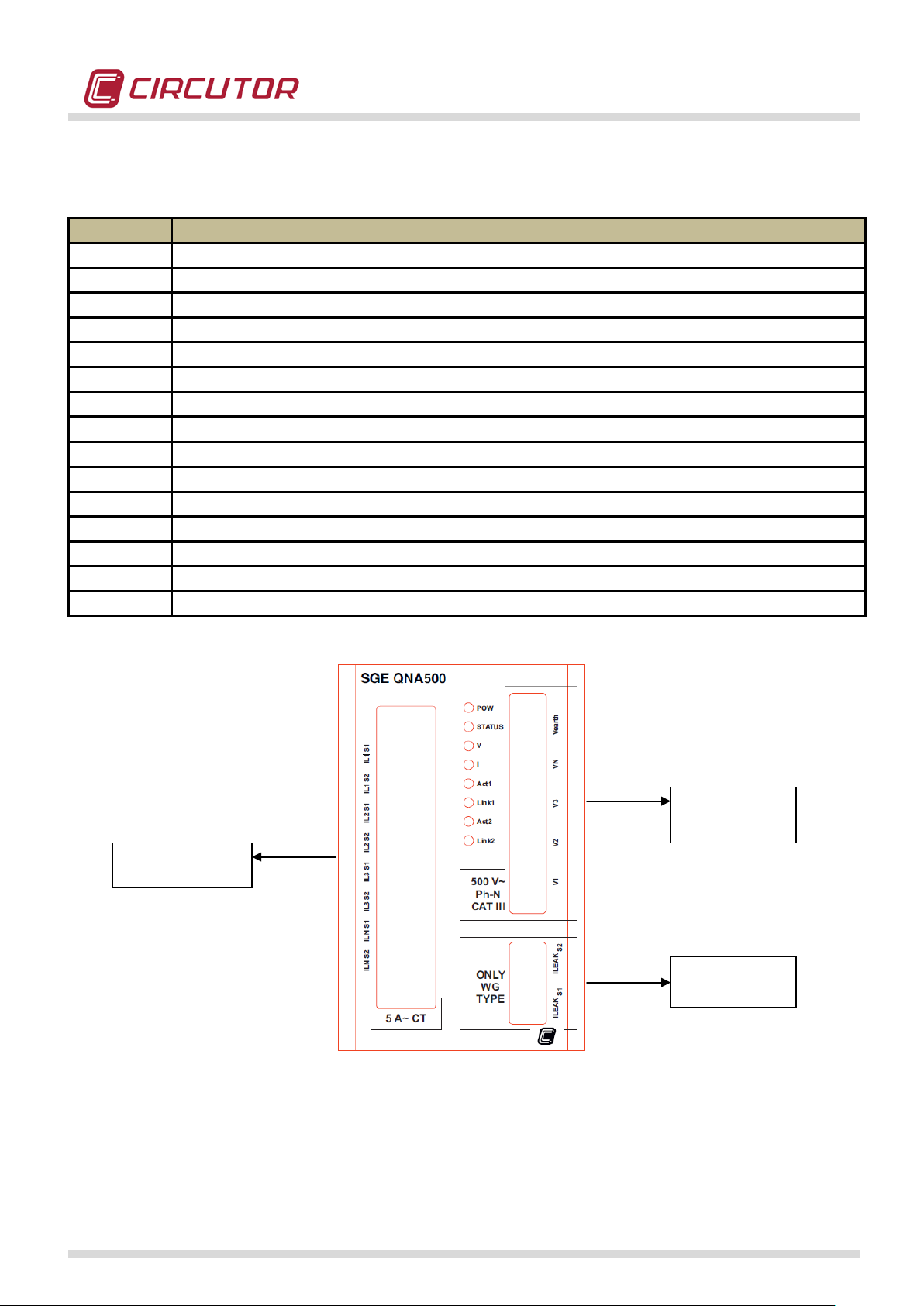

TERMINAL

DESCRIPTION

IL1 S1

S1 connection of CT Phase 1

IL1 S2

S2 connection of CT Phase 1

IL2 S1

S1 connection of CT Phase 2

IL2 S2

S2 connection of CT Phase 2

IL3 S1

S1 connection of CT Phase 3

IL3 S2

S2 connection of CT Phase 3

ILN S1

S1 connection of CT Neutral

ILN S2

S2 connection of CT Neutral

ILEAK S1

S1 connection of the earth leakage current transformer (I leak)

ILEAK S2

S2 connection of the earth leakage current transformer (I leak)

V1

Phase 1 voltage input

V2

Phase 2 voltage input

V3

Phase 3 voltage input

VN

Neutral voltage input

Vground

V Ground voltage input (PE)

Voltage

I leak

Current

measurement

POWER QUALITY ANALYZER QNA500 8IO

measurement

Measurement

QNA500 8IO Instruction manual

15 / 111

Page 16

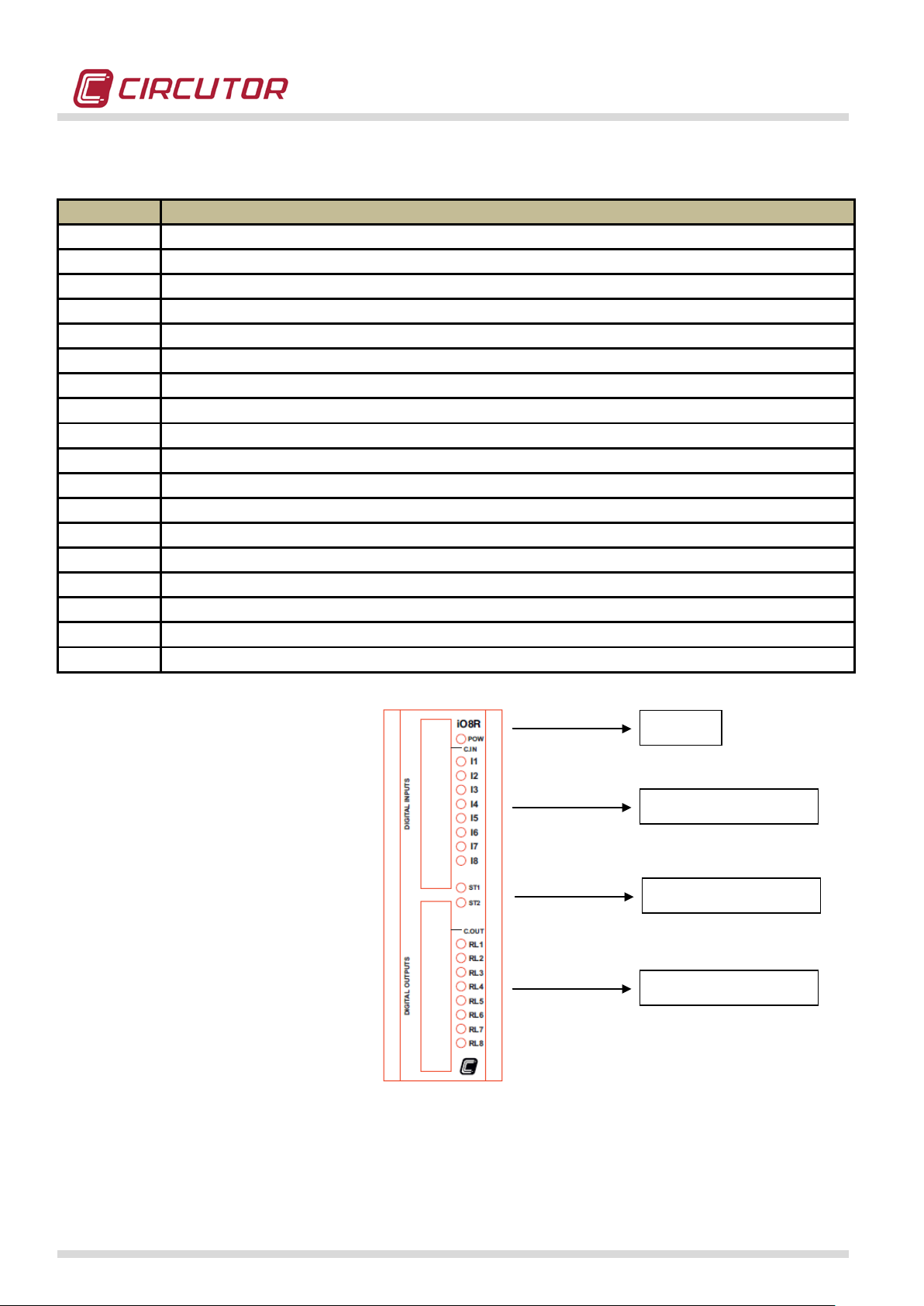

5.5.3.- CONNECTING INPUTS-OUTPUTS

TERMINAL

DESCRIPTION

CIN

Common input

I1

Digital input 1

I2

Digital input 2

I3

Digital input 3

I4

Digital input 4

I5

Digital input 5

I6

Digital input 6

I7

Digital input 7

I8

Digital input 8

C.OUT

Common output

O1 or RL1

Digital output 01 (transistor or relay, depending on the model)

O2 or RL2

Digital output 02 (transistor or relay, depending on the model)

O3 or RL3

Digital output 03 (transistor or relay, depending on the model)

O4 or RL4

Digital output 04 (transistor or relay, depending on the model)

O5 or RL5

Digital output 05 (transistor or relay, depending on the model)

O6 or RL6

Digital output 06 (transistor or relay, depending on the model)

O7 or RL7

Digital output 07 (transistor or relay, depending on the model)

O8 or RL8

Digital output 08 (transistor or relay, depending on the model)

Power

Digital inputs

Digital outputs

Status

POWER QUALITY ANALYZER QNA500 8IO

QNA500 8IO Instruction manual

16 / 111

Page 17

POWER QUALITY ANALYZER QNA500 8IO

FRONT VIEW

(RJ45)

1 (Tx)

2 (Rx)

2 (Rx)

3 (Tx)

3 (CTS)

8 (DSR)

4 (GND)

5 (GND)

5 (GND)

5 (GND)

6 - 7 - 8

-

5.6.- COMMUNICATION CONNECTION DI AGRAM

M-BASE has 3 built-in communications ports that can send the information from the connected

modules to external devices. The ports are as follows:

• RS-232

• RS-485

• ETHERNET (TCP/IP)

The 3 communications ports operate as independent systems. In other words, they can simultaneously

request information from all connected modules.

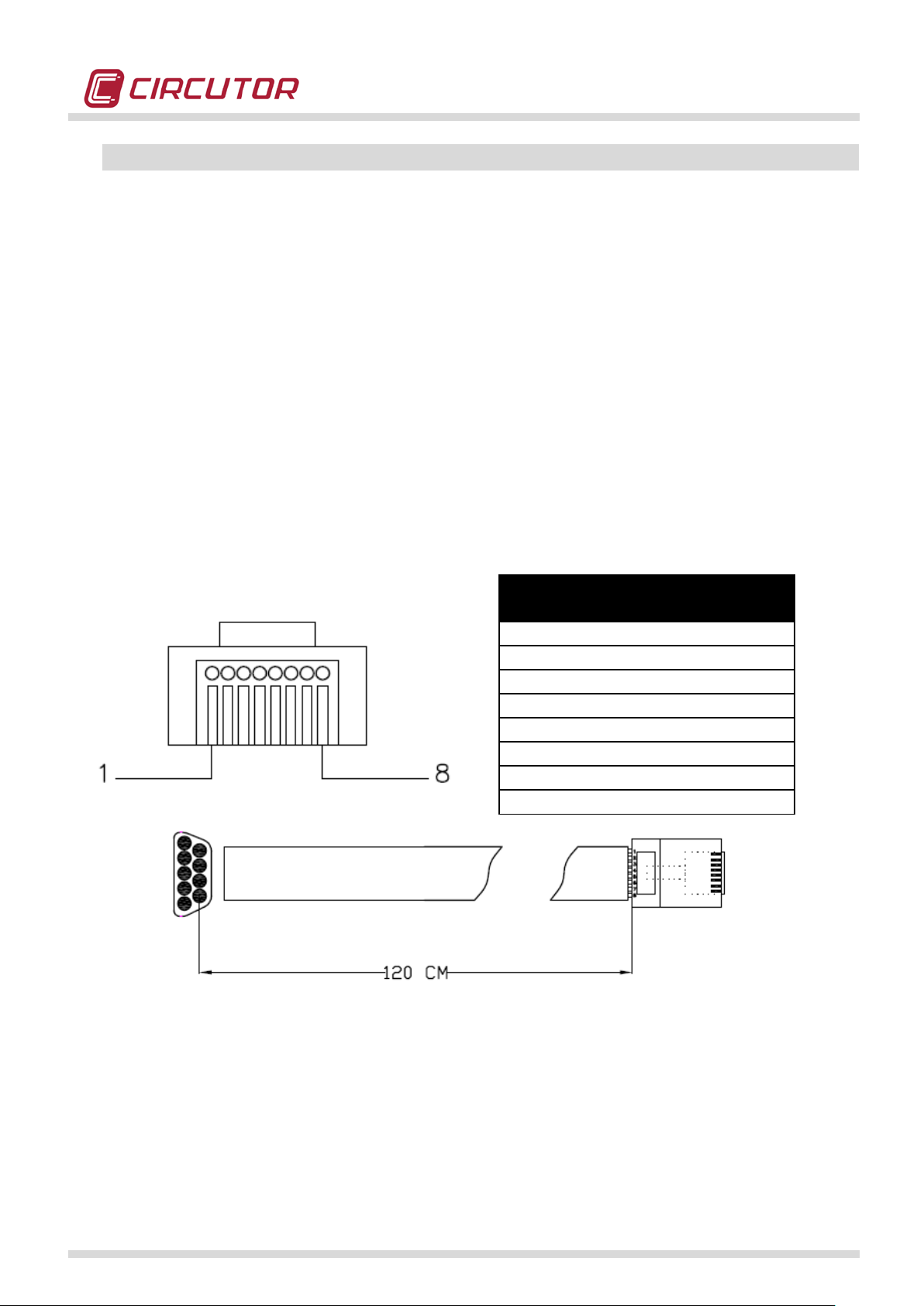

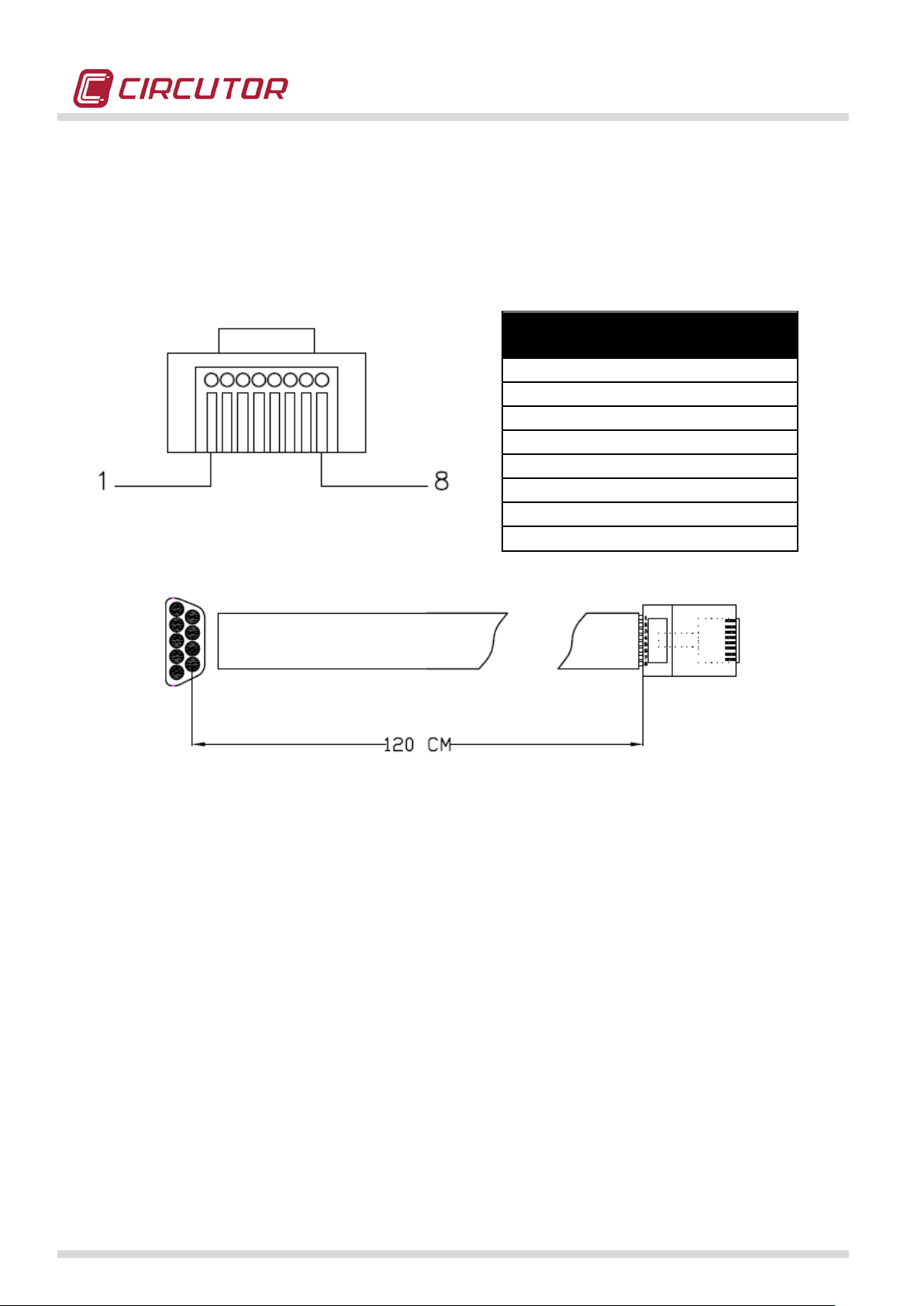

5.6.1.- RS-232

QNA 500 system is supplied with an RS-232 communications cable. The cable wiring diagram is as

follows:

The RS-232 communications port can be used to access the different modules connected to the M-

BASE m odule. Each module has a peripheral number (default: M-BASE = 01, M-QNA500= 02 and M-

8IO = 10, M-8IOR=10), wh ich m ust be taken into account when establishing communications.

DB-9 CONNECTOR

QNA500 8IO Instruction manual

17 / 111

Page 18

POWER QUALITY ANALYZER QNA500 8IO

FRONT VIEW

(RJ45)

1 (Tx)

2 (Rx)

2 (Rx)

3 (Tx)

3 (CTS)

-

4 (GND)

-

5 (GND)

- 6 - 7 - 8 -

5.6.2.- RS-485

The QNA500 has a RS-485 communication port. This port can be used to communicate with several

devices. This type of bus uses two signals (Rx,Tx) to send and receive dat a. QNA500 is not supplied

with a RS-485 cable, since the cable lengths can change in each installation. The following diagram

must be taken into account to connect the RS-485 cable:

DB-9 CONNECTOR

The RS-485 LED of the M-BASE module will start flashing when communications are established

through this port.

RECOMMENDED CABLE:

Flexible cable, category 5, with 2 conductors x 0.25 mm

2

( AWG23) with a non-rigid cable, plus shield.

The shield must be grounded on one end t o discharge the noise induced on the cable. This cable can

also have a 0.22 mm

with a 0.25 mm

2

2

conductor cross-section (AWG24), although we recommend the use of cable

(or higher) cross-section.

5.6.3.- ETHERNET

The QNA500 has an ETHERNET communications port. The Ethernet communications are used to

connect the equipment in a LAN or WAN networks through various protocols, such as MODBUS/TCP,

CIRBUS/TCP, Z MODEM, HTTP or FTP. All use TCP/IP connections. Various ports are used for each

protocol through the IP configured for the port. These ports are as follows:

QNA500 8IO Instruction manual

18 / 111

Page 19

POWER QUALITY ANALYZER QNA500 8IO

Led

Power on

Flashing

Act1

No external activity

External TX/RX ETH activity established

Link1

ETH No external link

Act2

No activity with the modules

TX/RX ETH activity with the modules

Link2

ETH No link with the modules

10002: CIRBUS

14001: ZMODEM (telnet)

14002: ZMODEM (RAW)

20003: MODBUS/RTU

30003: MODBUS/TCP

80: HTTP

21: FTP

A standard UTP CAT 5 cable will be used.

M-BASE module has various activity LEDs for the Ethernet port, as in the case of a PC.

QNA500 8IO Instruction manual

19 / 111

Page 20

POWER QUALITY ANALYZER QNA500 8IO

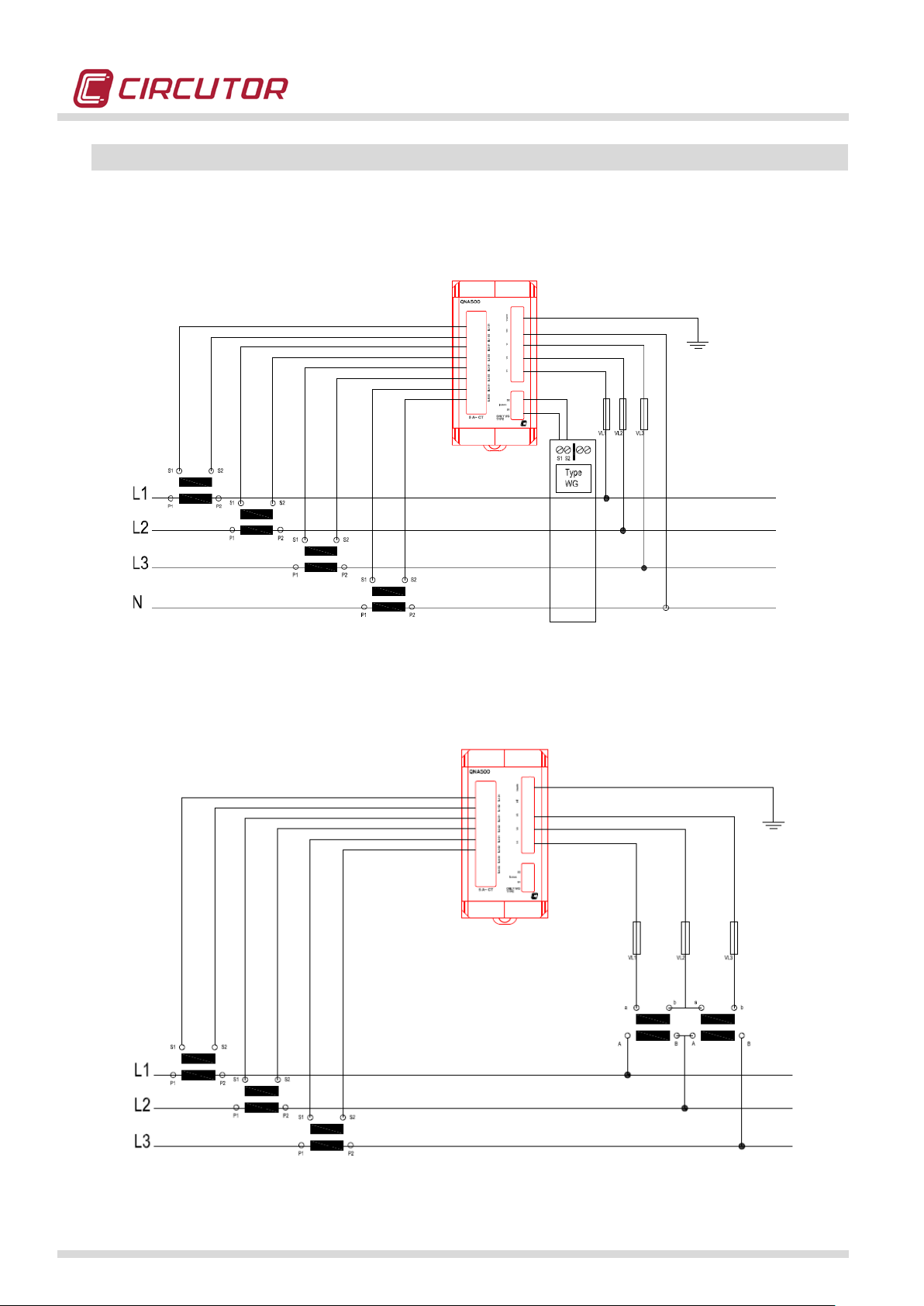

5.7.- MEASUREMENT CONNECTION DIAGRAMS

5.7.1.- 4 CURRENT TRANSFORMERS AND 5 VOLTAGE REFERENCES

5.7.2.- 3 CURRENT TRANSFORMERS AND 2 VOLTAGE TRANSFORMERS

QNA500 8IO Instruction manual

20 / 111

Page 21

POWER QUALITY ANALYZER QNA500 8IO

The equipment must be connected to a power circuit protected with gl-type

voltage measurement circuits are connected with a cable with a minimum

. (AWG 17). The current transformer's secondary

5.8.- CONNECTING POWER SUPPLY

The MULTIFIT system is powered with the M-BASE module. This power supply also powers all other

interconnected modules.

M-BASE power supply is powered with a connector with three terminals for power supply and

grounding purposes.

fuses, in compliance w ith IEC 269, or M-type, fro m 0.5 to 1A / 600 V ( UL listed ).

It must be fitted with a circuit b reaker switch or equivalent device, i n order to

be able to disconnect the device fro m the power sup ply. The power circu it and

cross-section of 1 mm

connection line must have a minimum cross-section of 2mm2. (AWG 14) and

withstand a minimum of 60ºC.

2

QNA500 8IO Instruction manual

21 / 111

Page 22

POWER QUALITY ANALYZER QNA500 8IO

ETH Link with external

sources

ETH Link with the next

module

6.- OPERATION OF THE QNA500 (MULTIFIT SYSTEM DESCRIPTION)

6.1.- Physical description

The QNA500 is a top performance power quality analyzer that is part of a new generation of products the MULTIFIT range. This innovative system can be used to add various modules to expand the

performance of the system while controlling the global electrical installation.

The QNA500 is com posed of an M-BASE power supply and communications module that can power

the set of modules and intercommunicate them through its internal bus. This optimises the installation,

since various modules can be connected in parallel to a single M-BASE b ase module. In addition, this

module can communicate with any other module via its RS-232, RS-485 or ETHERNET ports.

Likewise, the QNA500 can take electrical voltage (5 independent channels) and current measurements

(5 independent channels) to supervise the installation and to detect existing anomalies, with the

purpose of analysing it and carrying out predictive maintenance.

6.1.1.- BASE MODULE (M-BASE)

M-BASE is the main module of the MULTIFIT system. This module is vital in any combination with the

systems of the MULTIFIT range, since it is responsible for powering all other modules and establishing

the communications with external devices.

M-BASE has 3 communications ports that can communicate the information of the connected modules

to external devices and systems. The ports are as follows:

• RS-232

• RS-485

• ETHERNET (TCP/IP)

The 3 communications ports operate as independent systems. In other words, they can simultaneously

request information from all connected modules. M-BASE module has a series of LED indicators that

are used to show the correct operation of the power supply and communication systems.

LED Power off Power on Flashing

POW

STATUS

RS-232

RS-485

Act1

No power External power supply (1 sec.)

Battery power supply (200 ms)

No error Ethernet not initialised Memory error

Rest Data reception

Rest Data reception

No activity with external sources External TX/RX ETH activity established

Link1

Act2

Link2

QNA500 8IO Instruction manual

ETH No link with external sources

No activity with the next module TX/RX ETH activity with the next module

ETH No link with the next module

22 / 111

Page 23

POWER QUALITY ANALYZER QNA500 8IO

TX/RX ETH activity with the previous

module

ETH Link with the previous

module

ETH No link with the previous

module

LED indicator

Communications

ETHERNET

External power

lights

ports:

RS-485

RS-232

supply

6.1.2.- MEASUREMENT MODULE (QNA500)

QNA500 is the module that measures the electrical parameters of the MULTIFIT system. This module

has 5 voltage measurement channels, 4 current measurement channels and 1 earth leakage current

measurement channel.

QNA500 has a series of LEDs that provide information about the correct connections of the power

quality analyzer and its correct operation.

LED Power off Power on Flashing

POW

STATUS

Act1

Link1

No power External power supply (1 sec.)

Battery power supply (200 ms)

No error Ethernet not initialised Memory error

V

No measurement

I

No measurement

Correct connection: 3 balanced

voltages

Correct connection: 3 balanced

currents

No activity with the previous module

Incorrect connection: RMS voltages

Incorrect connection: RMS currents

Act2

Link2

ETH Link with the next connected

module

QNA500 8IO Instruction manual

No activity with the next module

ETH No link with the next connected

module

TX/RX ETH activity with the next

module

23 / 111

Page 24

POWER QUALITY ANALYZER QNA500 8IO

LED

Power off

Power on

Flashing

POW

No power

Powered

External power supply (1 s)

ST1

No errors

Memory error

ST2

No errors

Update in progress

Voltage

measurement

Earth-leakage

Current

measurement

current

Measurement

6.1.3.- INPUT-OUTPUT CENTRALIZER MODULE (M-8IO)

M-8IO is the input-output module of the MULTIFIT system. This module has 8 digital inputs and 8

digital outputs (relay or transistor, in accordance with the module) that can be used for various

functions.

Digital inputs:

• Pulse counter

• Status change control

Digital outputs:

• Pulse transfer

• Alarms

• Remote control

M-8IO has a series of LEDs that provide information about the correct connections of the analyzer and

its correct operation.

QNA500 8IO Instruction manual

Battery power supply (200 ms)

24 / 111

Page 25

POWER QUALITY ANALYZER QNA500 8IO

Make sure that all cables have been correctly connected before powering the

Power

Digital inputs

Digital outputs

Status

6.2.- Supply the power quality analyzer

equipment. The incorrect connection of the cables can cause serious inj uries to the

persons handling the equipment and damage to the equipment.

When the M-BASE module is powered, the equipment performs a series of checks associated to selfdiagnosis, connected module detection and verification of communications.

When the STATUS LED is off, the initialisation and module self-detection process will be complete and

successful.

Any anomaly or error detected during the st art-up of t he power quality analy zer must

be notified to CIRCUTOR SA technical service.

QNA500 8IO Instruction manual

25 / 111

Page 26

POWER QUALITY ANALYZER QNA500 8IO

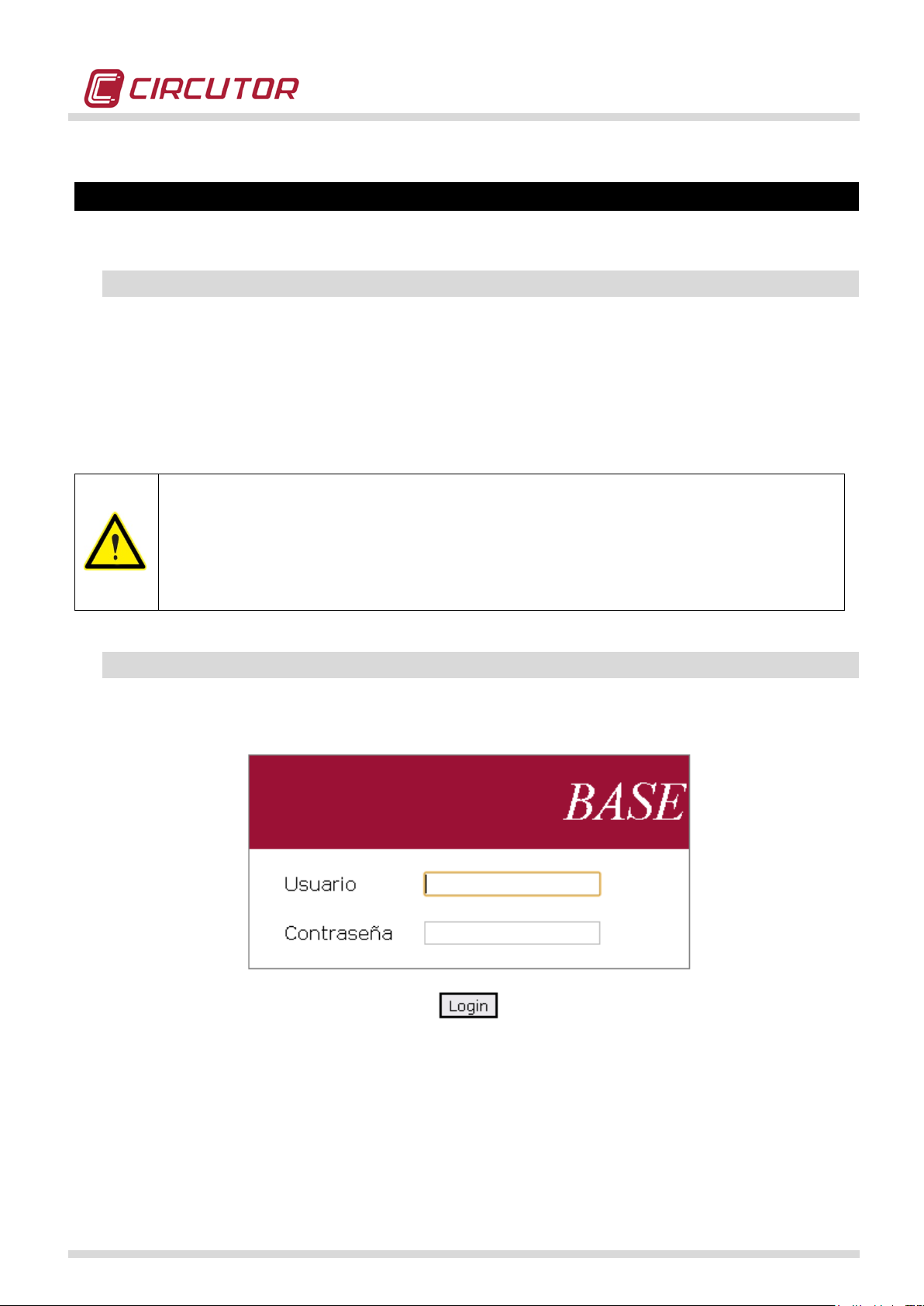

7.- BASE MODULE SETUP (M-BASE)

The QNA500 analyzer can be configured with the software supplied by CIRCUTOR, using the

analyzer's WEB server or editing the Setup.XML file.

This file can be edited with non-proprietary software and can configure the analyzer, in accordance with

the installation's requirements.

The M-BASE module has been designed to power all other MULTIFIT modules connected to it,

establish communications with external devices via any of the 3 communications ports (RS-232, RS485 or ETHERNET) and act as an external and internal communications switch.

We recommend using an ETHERNET cable to configure the M-BASE module. Connect to the WEB

server hosted in this module with a PC f or such procedures. You can easily and quickly configure the

module in a few seconds.

(*) Refer to the corresponding software manual for more information related to the configuration of the

analyzer with the use of CIRCUTOR software.

(**) R efer to t he specific section in this manual for more information related to the configuration of the

analyzer with the use of the WEB Server.

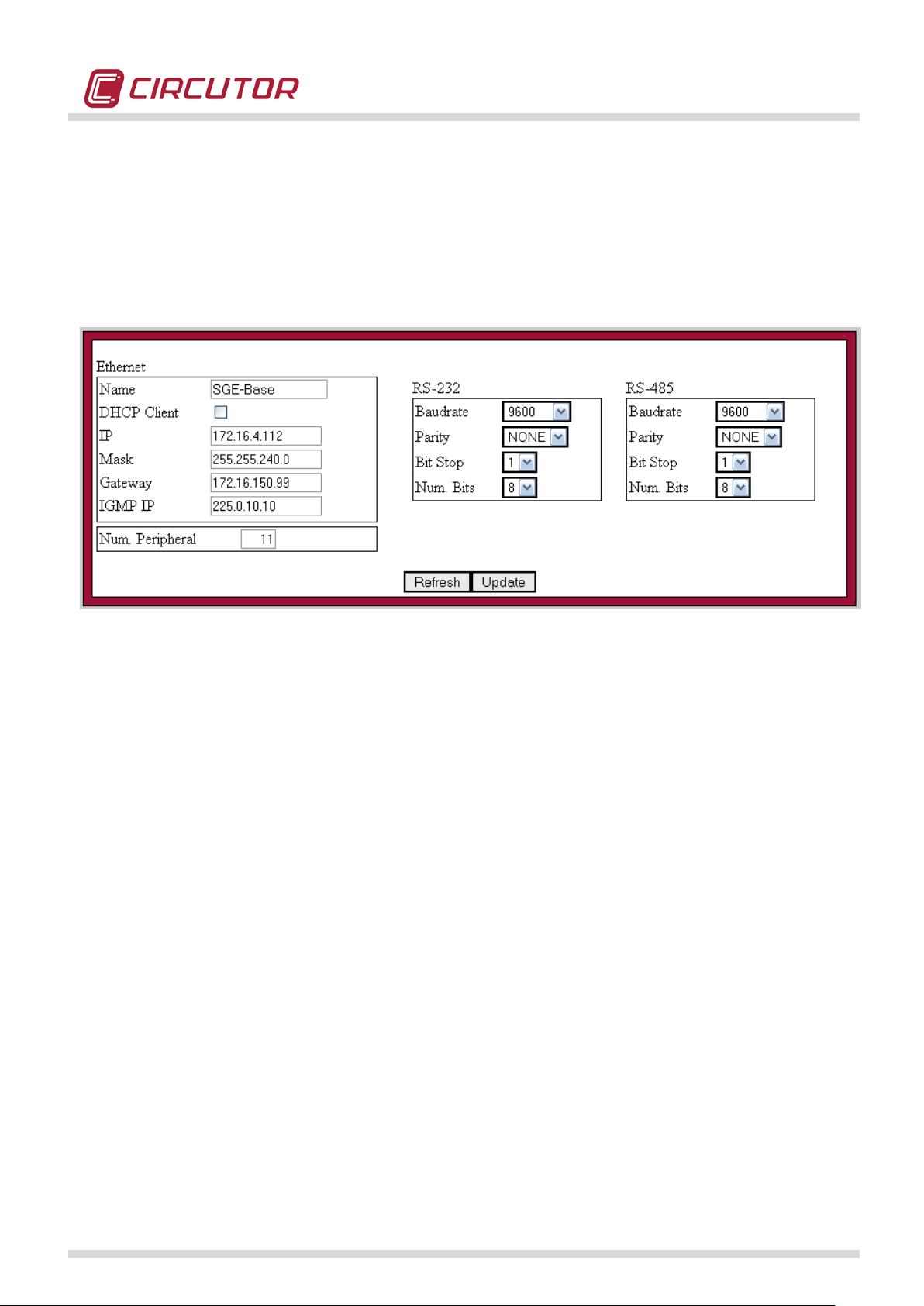

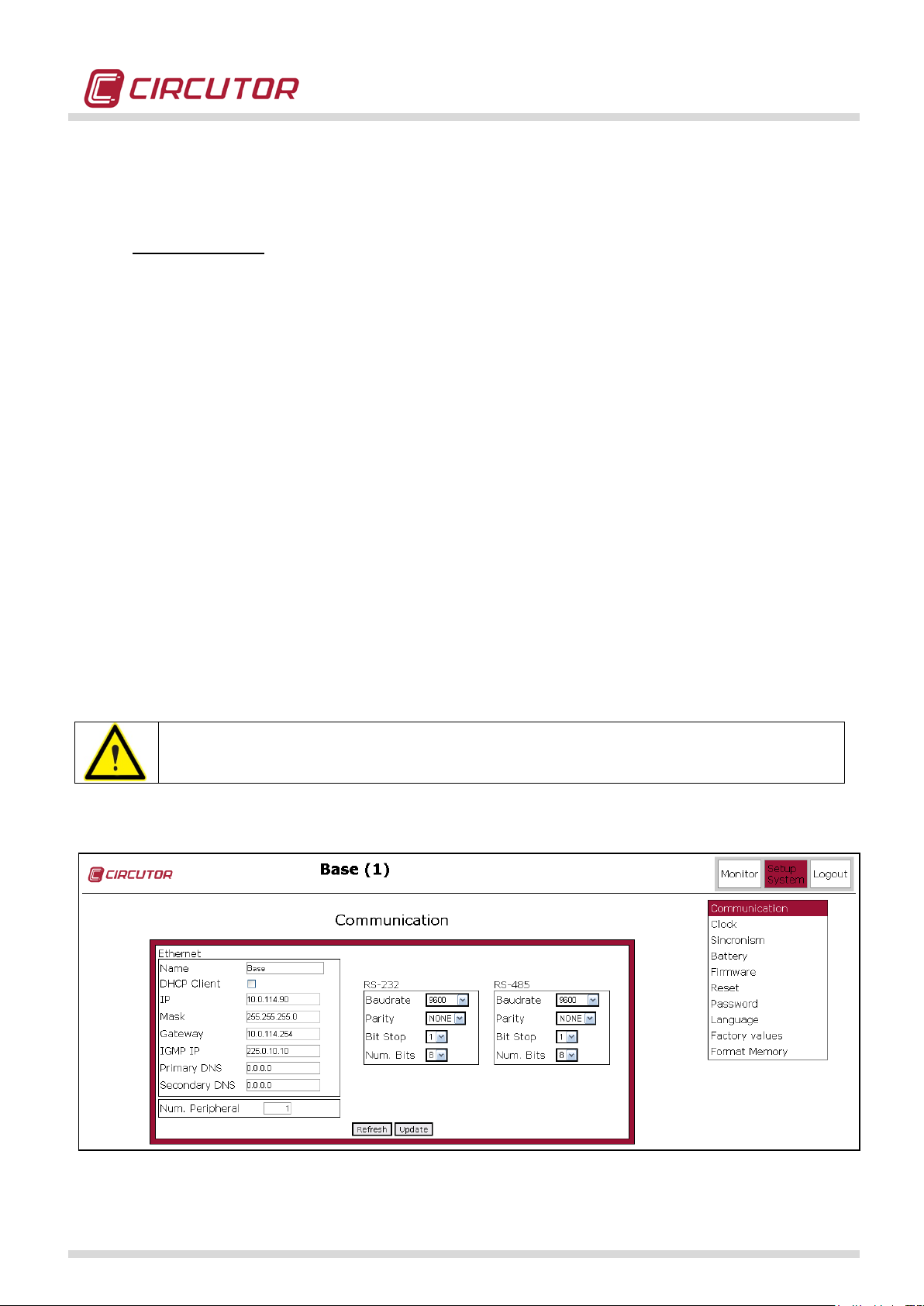

7.1.- COMMUNICATIONS

We recommend using the WEB server or software provided by CIRCUTOR to access the

communications setup menu of the M-BASE.

When using the Ethernet port, QNA500 8IO is configured with the DHCP option enabled. When it is

connected to an intranet with a DHCP server, the server will automatically assign an IP address to the

analyzer.

Use the IP Setup software supplied with the analyzer to know t he IP address assigned by the server or

assign a specific IP address. To do so, it is vital to know the MAC address shown on the silver

adhesive label attached to the top of the product.

The QNA500 analyzer's default configuration is as follows:

• (M-BASE): Peripheral no., speed - length - parity - stop bits: 1, 9600-8-N-1

• (QNA500 8IO): Peripheral no., speed - length - parity - stop bits: 2, 9600-8-N-1

The default configuration of the input-output module (M-8IO and M-8IOR) is as follows:

• (M-8IO): Peripheral no., speed - length - parity - stop bits: 10, 9600-8-N-1

• (M-8IOR): Peripheral no., speed - length - parity - stop bits: 10, 9600-8-N-1

All communications ports are MULTI-PROTOCOL, so that the port can communicate with all protocols

supported by the MULTIFIT system.

Available protocols:

QNA500 8IO Instruction manual

26 / 111

Page 27

POWER QUALITY ANALYZER QNA500 8IO

• MODBUT/RTU (on-line communications)

• MODBUS/TCP (on-line communications)

• CIRBUS (on -line communications of the question-answer type in the ASCII format)

• ZMODEM (partial or complete file download)

• HTTP (web protocol)

• FTP (complete file download)

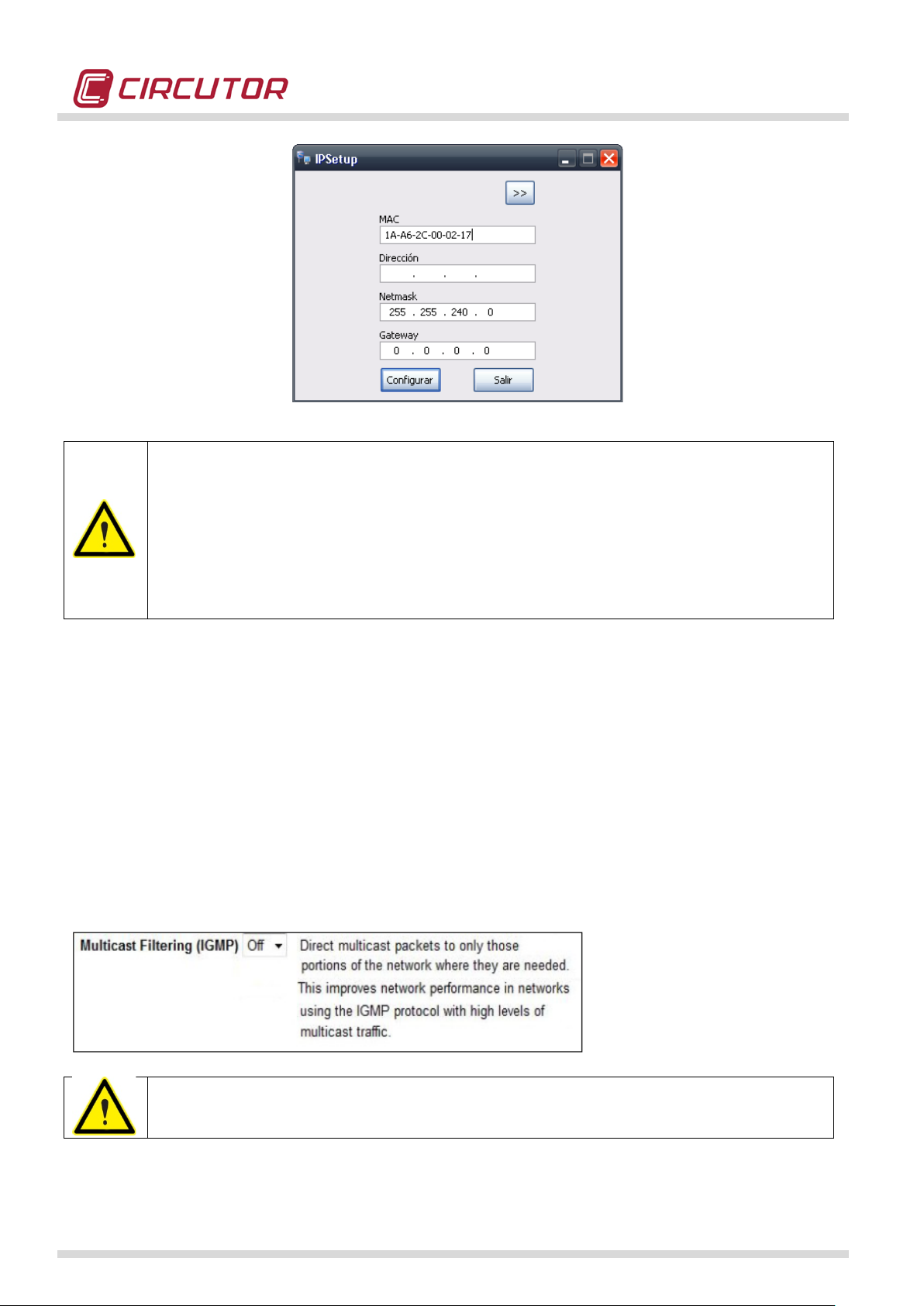

The previous figure shows how the WEB server of the M-BASE module can be used to program its I P

address and configure the RS-232 and RS-485 ports.

7.1.1.- IP ADDRESS CONFIGURATION

Once the equipment has been installed in an IT network with a DHCP server, the server will

automatically assign an IP address to each MULTIFIT module. The IP address of each module must be

known to communicate with them or integrate them in an IT application.

To do so, CIRCUTOR supplies the IPSetup application, which can be used to assign a specific IP

address to each MULTIFIT module.

It is vital to know the MAC address shown on the silver adhesive label attached to the top of the

product before programming this IP address.

QNA500 8IO Instruction manual

27 / 111

Page 28

POWER QUALITY ANALYZER QNA500 8IO

In a LAN network, servers have the option to assign IP addresses with an expiration

ime is configurable on the server depending on the

request an IP address. If the server is not active at that time, or t he Ethernet cable is not

power quality analyzer has DHCP option enabled, is

avoid this situation.

time from hours to weeks. This t

target of the IT Administrator. After this time, the power quality analyzer must again

connected, IP address will be lost.

This means that if QNA500

mandatory to have Ethernet cable always connected and DHCP server always active to

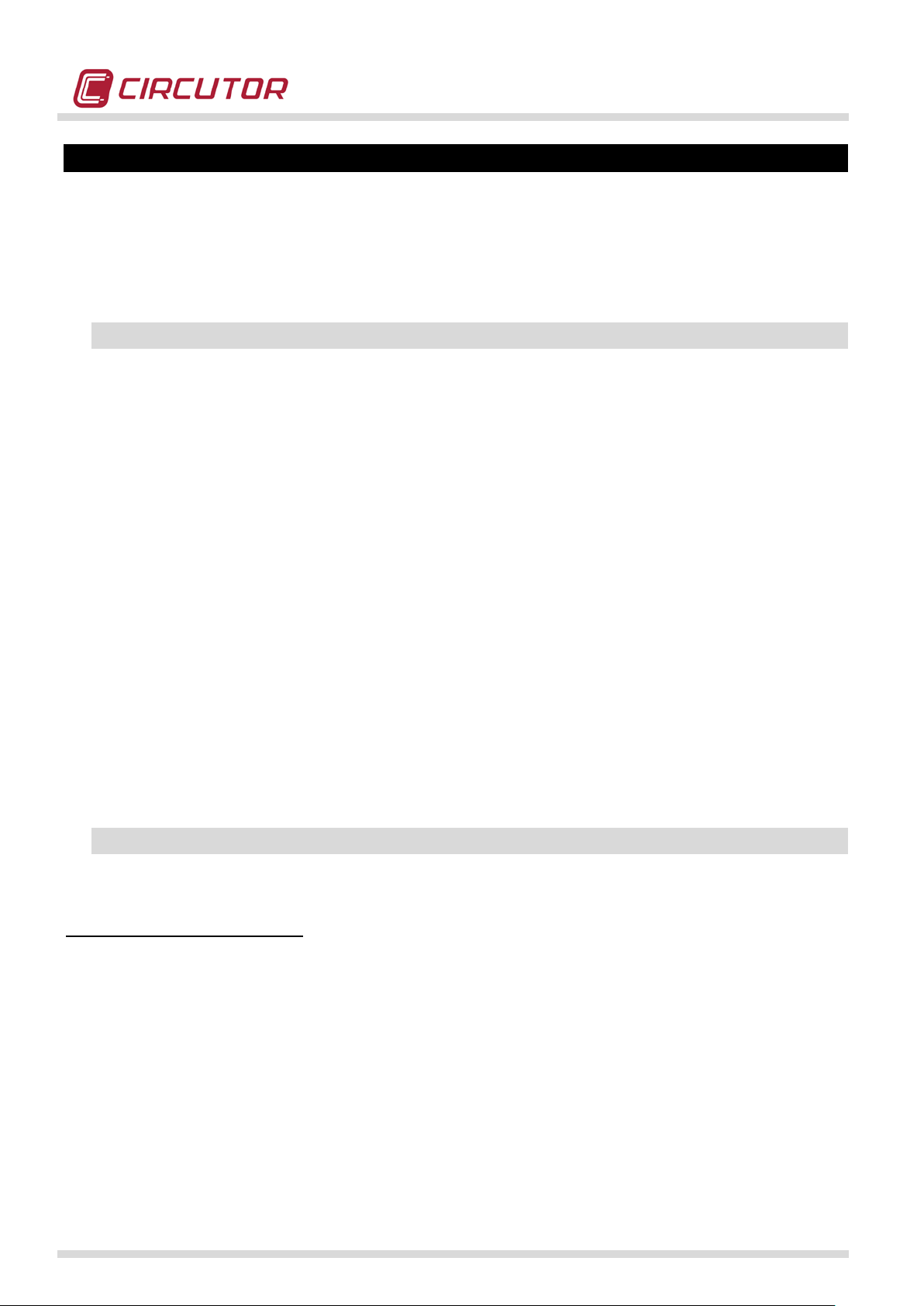

7.1.1.- IGMP CONFIGUARTION

IGMP default address is 225.0.10.10.

This address allows to each module to detect others and to communicate between them. To allow

management actions and communications between modules is mandatory that all MULTIFIT modules

have same IGMP address.

User must take care of following requirements:

• All modules must have same IGMP IP address

• IGMP range is from 224.0.0.0 to 239.255.255.255

• If two modules have different IGMP IP addresses, they don’t detect each other and they cannot

send messages between them.

• If exists Ethernet switches in the LAN, these cannot have activated multicast message filters

Some industrial switch are provided with IGMP message filters. Keep in mind that if this

switches are activated, QNA500 won’t be able to send messages between modules.

QNA500 8IO Instruction manual

28 / 111

Page 29

POWER QUALITY ANALYZER QNA500 8IO

7.1.2.- NTP SYNCHRONIZATION

NTP synchronization allows to QNA500 modules to synchronize its clocks with milliseconds of

resolution.

This synchronization allows that many devices works with the same date and time, avoiding errors with

different time flags in data.

M-BASE is able to synchronize all modules connected to itself by activating this option. You can set up

to 2 different NTP servers, a primary server and an auxiliary server.

To configure NTP synchronization is mandatory to set-up following fields:

NTP IP: IP address of the NTP server.

NTP Port: port number of the NTP server.

Additionally, you can check if communication is working properly using ‘Get Time’. If communication is

working properly, you will see UTC Time. If not, you will see 00/00/00 00:00:00.

7.1.3.- DEVICE NUMBER CONFIGURATION

MULTIFIT system allows to assign a device number to each module and an IP address. Device

number must be unique in the bus and cannot be repeated by any-other MULTIFIT module or a device

in the RS485 connected to a M-BASE. If this happens, modules will detect a repeated device number

an communications won’t work correctly.

M-BASE works as a GATEWAY of other devices connected to the RS-485 port (i.e. power analyzers

CVM). It’s very important to check that these devices have different device number of the MULTIFIT

modules.

QNA500 8IO Instruction manual

29 / 111

Page 30

POWER QUALITY ANALYZER QNA500 8IO

8.- POWER QUALITY ANALYZER SETUP (M-QNA500)

The QNA500 power quality analyzer can measure the voltages and currents of the electrical

installation, with the purpose of achieving the global supervision and control of the whole installation.

The following sections describe the main configuration options and the configuration options.

8.1.- COMMUNICATIONS

To access to the setup it’s recommendable to use WEB-Server or software provided by CIRCUTOR.

In case of using ETHERNET port, QNA500 is setup with DHCP as default, so if this is connected to a

LAN network, DHCP server of this LAN will provide IP addresses to each module automatically.

To know assigned IP address, or to assign an specific IP address, you can use IP setup software,

which ask you MAC address and allows you to set an specific IP to each module.

By default, QNA500 has following configuration:

• (QNA500): Device Number, Baud Rate, Length, Parity, Stop Bits: 2, 9600-8-N-1

All communication ports are MULTIPROTOCOL which means that you can communicate using any of

the supported protocols.

Available protocols are the following:

• MODBUS/RTU (on-line communications)

• MODBUS/TCP (on-line communications)

• CIRBUS (on-line communications)

• ZMODEM (protocol to download files)

• FTP (protocol to download files)

• HTTP (protocol to connect using Web-Browser)

8.2.- MEASUREMENT

The following measurement parameters can be configured:

TRANSFORMATION RATIOS:

• Voltage Primary / Voltage Secondary: It will be programmed in accordance with the voltage

transformer ratio used to take the measurement. Direct measurements must be programmed to

1/1. This ratio must not exceed 9999. Maximum primary and secondary values are 500000 and

999,9 respectively.

• Current primary: The current transformer primary used to measure the current will be

programmed. Maximum primar y value is 10000.

• Current secondary: The current transformer secondary used to measure the current will be

programmed (default: 5 A).

QNA500 8IO Instruction manual

30 / 111

Page 31

POWER QUALITY ANALYZER QNA500 8IO

• Neutral Current Primary: The current transformer primary used to measure the neutral current

will be programmed.

• Primary VT * Primary CT ratios: Maximum primary value of VT multiplied by primary

value of CT must be lower than 2000000000

NOMIN AL VALUES

• Nominal Voltage: Corresponds to the nominal voltage measured by the power quality analyzer.

In the ca se of t he 3-wire configuration, the phase-phase voltage must be programmed (e.g. 400

V), and the phase-neutral voltage must be programmed for 4-wire configurations (e.g. 230 V).

When the measurement is recorded through the voltage transformers, the nominal voltage must

be programmed so that it is referred to the secondary (e.g. 63.5 V). This value is vital for the

correct recording of events.

• Nominal Current: Corresponds to the nominal current being measured by the analyzer, which

will be used to establish the maximum and minimum % to record disturbances. The default

value is 5 A. The value used to program measuring transformers is recommended.

• Nominal Frequency: Nominal frequency of the network being analyzed. This parameter is

required to calculate the effective value of the signal in top quality networks.

TYPE OF CONNECTION

• 3-wire / 4-wire: QNA500 8IO is prepared for an operation in installations with a neutral (4-

wires) or installations without a neutral (3-wires). The type of connection is defined at this point.

This is important, since the value programmed for this variable will be used to detect and record

voltage events. When programmed for 4-wires, all measurements will be taken from phaseneutral, and when programmed for 3-wires, the reference values will be phase-phase.

MEASURING POINT

• Description: This field is only used for identification purposes by the user.

• Comments: This field is only used for information purposes by the user.

QNA500 8IO Instruction manual

31 / 111

Page 32

POWER QUALITY ANALYZER QNA500 8IO

8.3.- POWER QUALITY

The voltage levels must be defined to calculate the power quality events.

• % Overvoltage threshold: Overvoltage detection depends on the value programmed in this

section. Any semi-cycle with an RMS value that exceeds this threshold (% over the nominal

voltage) will be understood as an overvoltage. The events file (EVQ) will save a record when

this value is exceeded, stating the phase, maximum voltage recorded, mean voltage, voltage

before the event occurred and the time during which this threshold has been exceeded.

• Overvoltage hysteresis: An overvoltage hysteresis will be defined so that the event start

voltage is not the same as the event end voltage. Therefore, an overvoltage starts when the

semi-cycle voltage exceeds the overvoltage threshold and ends when it goes below the said

threshold + the hysteresis programmed for this threshold.

• % Sag threshold: Sag detection depends on the value programmed in this section. Any semi-

cycle with an effective value that does not reach this threshold (% over the nominal voltage) will

be understood as a sag. The events file (EVQ) will save a record each time this value is not

exceeded, stating the minimum voltage recorded, mean voltage and the time during which this

threshold was not exceeded.

• Sag hysteresis: A sag hysteresis will be defin ed so tha t the s ag start vo ltage is n ot the same

as the sag end voltage. Therefore, a sag is started when the voltage does not exceed the sag

threshold and it ends when this threshold is exceeded + the hysteresis programmed for this

threshold.

• % Interruption threshold: Interruption detection depends on the value programmed in this

section. Any semi-cycle with an effective value that does not reach this threshold (% over the

nominal voltage) will be understood as an interruption. The events file (EVQ) will save a record

each time this value is not exceeded, stating the minimum voltage recorded, mean voltage and

the time during which this threshold was not exceeded.

• Interruption hysteresis: An interruption hysteresis will be defined so that the interruption start

voltage is not the same as the interruption end voltage. Therefore, an interruption is started

when the voltage does not exceed the interruption threshold and it ends when this threshold is

exceeded + the hysteresis programmed for this threshold.

8.4.- TRANSIENTS

QNA500 can detect transients, according to different conditions. Transients can be detected in

accordance with 2 different conditions:

The following variables must be configured to record the transients:

1. Semi-cycle RMS value: RMS value of each cycle is calculated, updated each semi-cycle, and

compared with the maximum and minimum values programmed by the user. When the

maximum or minimum RMS value is exceeded, this is considered the moment when a tr ansient

or disturbance is set off. We advise setting the maximum or minimum values far from the

nominal value existing in the installation. Otherwise, the analyzer will record many different

transients that will not be relevant in a future user analysis.

QNA500 8IO Instruction manual

32 / 111

Page 33

POWER QUALITY ANALYZER QNA500 8IO

2. dV/dt detection (ramp met hod): This detection is achieved by comparing the measured wave

shape with an ideal wave shape. Each one of the 512 samples is compared to the previous

sample; when this value exceeds the value of the maximum ramp calculated for each point, the

system will consider that a transient or disturbance has been generated, depending on the

sensitivity selected by the user. The maximum ramp is the tangent calculated for each point of

the sine wave.

Rm = Vp * w/oϕ * trigger level

The following variables must be configured to record the wave shape:

• Nº pre-trigger cycles: Number of cycles registered before activating the record (1 to 10.

Default: 5)

• Nº. post-trigger cycles: Number of cycles registered after activating the record (1 to 50.

Default: 15)

• Trigger level (maximum ramp detection): Value that determines the transient detection

sensitivity level. Th e value entered must be from 1 to 100.

When the sensitivity value entered is very low, the analyzer will be very sensitive when

detecting transients. On the other hand, when the sensitivity value entered is very high, the

deformation of the signal must be greater for the analyzer to start detecting it.

• Maximum and minimum effective comparison values (RMS system): A maximum and

minimum voltage / current percentage must be programmed, when compared to the nominal

value.

The trigger is activated when the effective value of a cycle updated each semi-cycle exceeds

the maximum value or is under the minimum programmed value.

• Trigger variables: Variable or variables that will trip the trigger, in accordance with the

conditions described above. The trigger is activated by the f irst programmed variable that meets

the conditions when more than one variable is programmed.

The transient will be recorded in the COMTRADE format (according IEEE C37.111) and the data will

be saved in the WAVE directory of the memor y. The waveform of the 4 voltage and current channels

(P1, P2, P3, N) will be stored for each disturbance detected. The memory record is stored at 204

samples per cycle.

The date of the last disturbance detected can be checked to guarantee the correct configuration of the

transient setup, adjusting the most adequate sensitivity degree for the installation.

The same configuration can be easily and quickly saved with CIRCUTOR's PC software.

8.5.- REMOVE FILES

Records can be deleted from the MULTIFIT system through the WEB server or the software supplied

by CIRCUTOR.

Refer to the specific section in this manual for more information about deleting records via the WEB

server. This action deletes all files associated to the measurements taken by the analyzer.

QNA500 8IO Instruction manual

33 / 111

Page 34

POWER QUALITY ANALYZER QNA500 8IO

8.6.- CLOCK

Make sure that the correct time has been pr ogrammed before the analyzer's programming pr ocedures

have been completed. Use the analyzer's WEB server (see corresponding section) or the specific

CIRCUTOR software to make sure that the correct time has been programmed in the analyzer.

QNA500 offers the Local Time or UTC Time options.

8.7.- BATTERY

M-BASE module has an internal battery that can be used to power all connect ed modules. The m ain

purpose of this battery is to make sure that all modules continue to operate during a limited period of

time in case there is an interruption in the electric supply.

The most common function entails storing voltage sags or interruptions, and moreover keep active the

communication with the device or perform certain operations (activate/deactivate loads).

The main feature of the product s of t he MULTIFIT range is based on the connection of said products to

the same M-BASE module, which will operate as independent products. The battery can power the

modules connected to the system during a period of time configured by the user. The default time is 1

minute and it can be configured to up to 15 minutes. The M-BASE module can power a maximum of 2

QNA500 modules + 1 M-8IO module simultaneously with the battery.

8.8.- STANDARD RECORDING PERIOD

The recording period shows the number of minut es that QNA500 8IO uses to create a new register in

the memory. All electrical parameters will be recorded (only those selected) at the end of the

programmed time. Average, maximum and minimum values obtained during this period of time will be

recorded. The default recording time is 10 minutes. This value can be modified to a period of between

1 minute and 2 hours. This time only affects the data file (.STD).

8.9.- ENERGY RECORDING PERIOD

The recording period shows the number of minutes that QNA500 8IO uses to create a new register with

energy values in the memory.

8.10.- SELECTING VARIABLES TO BE RECORDED

QNA500 analyzer can be used to select the variables that will be recorded. These variables can be

selected via the WEB server (see the corresponding section in this manual) or via specif ic CIRCUTOR

software.

QNA500 8IO Instruction manual

34 / 111

Page 35

POWER QUALITY ANALYZER QNA500 8IO

Variable description

Variable code

L1 Voltage

1

L2 Voltage

2

L3 Voltage

3

N-G Voltage

4

Voltage III

5

L1-L2 Voltage

10

L2-L3 Voltage

11

L3-L1 Voltage

12

L1 Current

20

L2 Current

21

L3 Current

22

Neutral Current

23

Current III

24

L1 Active Power

30

L2 Active Power

31

L3 Active Power

32

III Active power

33

L1 Inductive Power

35

L2 Inductive Power

36

L3 Inductive Power

37

III Inductive Power

38

L1 Capacitive Power

40

L2 Capacitive Power

41

L3 Capacitive Power

42

III Capacitive Power

43

L1 Apparent Power

45

L2 Apparent Power

46

L3 Apparent Power

47

III Apparent power

48

Angle V1-V2

60

Angle V2-V3

61

QNA500 analyzer will record all variables selected every X minutes once the variables have been

selected and the new configuration has been sent, in accordance with the programmed standard

recording time period.

These records are saved in various files, depending on the type of data. Refer to the file section for

more information related to the location of these information records.

8.11.- ALARM SETUP (Digital objects)

QNA500 power q uality analyzer can configure a list of alarms (up to 16 alarms) for an improved and

more accurate supervision of the electrical installation and its status.

These alarms can be simply recorded in the memory or used to create actions in other MULTIFIT

modules, such as, for example, the activation of the relay of a M-8IO module.

There are 2 different types of alarms (or digital objects), as described:

• ALARM OBJECTS: can enable any alarm condition associated to an electrical variable

measured by the QNA500 module.

• ENERGY OBJECTS: these are necessary when associating a pulse output of a M-8IO module.

The most common application is where the pulse outputs can produce pulses proportional to

the energy (A+, A-, Q1, Q2, Q3 or Q4) measured by the QNA500. To do so, first activate an

energy object and activate the pulse output on the M-8IO module. This configuration is

explained in the corresponding chapter of this module.

These alarms (or digital objects) can be associated with the following variables:

QNA500 8IO Instruction manual

35 / 111

Page 36

POWER QUALITY ANALYZER QNA500 8IO

Angle V1-I1

65

Angle V2-I2

66

Angle V3-I3

67

L1 Power Factor

70

L2 Power Factor

71

L3 Power Factor

72

III Power Factor

73

L1 Cos fi

75

L2 Cos fi

76

L3 Cos fi

77

III Cos fi

78

Unbalance V

90

Asymmetry V

91

Unbalance I

92

Asymmetry I

93

THD VL1

100

THD VL2

101

THD VL3

102

THD Vn-G

103

THD IL1

105

THD IL2

106

THD IL3

107

THD In

108

Active Energy

120

Reactive Energy L

121

Reactive Energy C

122

Active Energy -

130

Reactive En. L-

131

Reactive En. C -

132

Flicker L1

140

Flicker L2

141

Flicker L3

142

Earth leakage current

150

Frequency

160

Transient

170

Active energy T1

171

Reactive energy L T1

172

Reactive energy C T1

173

Active energy – T1

174

Reactive energy L- T1

175

Reactive energy C – T1

176

Active energy T2

177

Reactive energy L T2

178

Reactive energy C T2

179

Active energy – T2

180

Reactive energy L- T2

181

Reactive energy C – T2

182

Active energy T3

183

Reactive energy L T3

184

Reactive energy C T3

185

Active energy – T3

186

Reactive energy L- T3

187

Reactive energy C – T3

188

Active energy T4

189

Reactive energy L T4

190

Reactive energy C T4

191

Active energy – T4

192

Reactive energy L- T4

193

Reactive energy C – T4

194

Active energy T5

195

Reactive energy L T5

196

Reactive energy C T5

197

Active energy – T5

198

Reactive energy L- T5

199

Reactive energy C – T5

200

Active energy T6

201

Reactive energy L T6

202

Active energy – T6

204

Reactive energy L- T6

205

Reactive energy C – T6

206

Active energy T7

207

Reactive energy L T7

208

Reactive energy C T7

209

Active energy – T7

210

Reactive energy L- T7

211

Reactive energy C – T7

212

Active energy T8

213

Reactive energy L T8

214

Reactive energy C T8

215

Active energy – T8

216

Reactive energy L- T8

217

Reactive energy C – T8

218

Active energy T9

219

Reactive energy L T9

220

Reactive energy C T9

221

Active energy – T9

222

Reactive energy L- T9

223

Reactive energy C – T9

224

QNA500 8IO Instruction manual

36 / 111

Page 37

The following additional conditions can be assigned to each variable:

When this instruction is sent, the analyzer will delete the current data file and the

existing configuration will be lost. You must make sure that this process is going to be

• Maximum Value

• Minimum Value

• Activation Delay (in seconds)

• Deactivation Delay (in seconds)

• Memory record (Yes/No)

• Mail Group (no, group 1, …, group 4)

Once all desired alarms have been configured, the QNA500 8IO network power quality analyzer will

permanently monitor whether the conditions of one of the programmed alarms are met or not. If this is

the case, it will generate a memory record (if programmed as such), indicating the date when the alarm

was triggered.

In addition, in case the user considers that it is important to send the notification of the alarm detected

in a different MULTIFIT module, this option can be used to perform actions on the installation, such as,

for example, closing a relay for signalling purposes.

8.12.- FACTORY PRESETS

If you wish to program the configuration values again due to an initial error, the analyzer can be

configured with the factory presets, which will load the default programming.

carried out, since it does not offer the option of retrieving former values.

Page 38

POWER QUALITY ANALYZER QNA500 8IO

Registry variables

Unit

L1

L2

L3

III

Phase-phase and phase-neutral voltage (average,

V

X X X

X

Current (average, maximum, minimum)

A

X X X X Neutral current (average, maximum, minimu m)

A

X Earth-Leakage current (average, maximum, minimum)

A

X Neutral Ground voltage (average, maximum, minimum)

V

X Frequency (average, maximum, mini mu m )

Hz

X X X Active power (average, maximum, mini mum)

kW

X X X X Inductive reactive power (average, maximum, min imum)

kvar

X X X X Capacitive reactive power (average, maximum, min imum)

kvar

X X X X Apparent power (average, maximum, minimum)

KVA

X X X X Maximum demand

kW

X X X Power factor (average, maximum, mini mum)

X X X X Crest factor (voltage and current)

V or A

X X X K Factor

X X X Active energy

kWh

X X X X Inductive reactive energy

kvarh

X X X X Capacitive active energy

kvarh

X X X X Voltage THD (average, maximum, minimu m)

%

X X X X Current THD (average, maximum, minimum))

%

X X X X Voltage harmonics (up to 50th order)

V Harm

X X X X Current harmonics (up to 50th order)

A Harm

X X X X Voltage interharmonics (up to 50th order)

V Harm

X X X X Current interharmonics (up to 50th order)

A Harm

X X X

X

8.13.- RECORDING FILES

QNA500 power quality analyzer records different files, in accordance with the type of data (voltage,

events, energy, etc).

The power quality analyzer records the following files:

8.13.1.- .STD FILE

The Standard File (STD) is used to store all parameters that are stored periodically.

The records will be stored with the following electrical parameters (depending on the selection),

respecting the recording period programmed with the analyzer:

maximum, minimum)

QNA500 8IO Instruction manual

38 / 111

Page 39

POWER QUALITY ANALYZER QNA500 8IO

Flicker (PST)

X X X Voltage Unbalance

X Voltage asymmetry

X Current Unbalance

X Current asymmetry

X

The variable recording period can be configured by the user.

FLICKER:

• Pst: QNA500 analyzer will record the Flicker value (Pst) obtained during the recording period.

The Plt value is calculated with the PC's analysis software Flicker is defined as t he variation of

the RMS value or amplitude of the voltage within a range of less than 10% of the nominal value.

This variation in voltage amplitude produces a fluctuation of the luminous flux in lamps, at the

same time inducing a sensation of visual instability (visual flashing effect).

HARMONICS:

• Harmonic Distortion: QNA500 anal yzer measures, calculates and records the mean harmonic

distortion of the voltage and current detected from the analyzed network.

• Individual Harmonics: QNA500 analyzer measures, calculates and records the mean value of

the individual harmonic distortion rate of each voltage and current harmonic from the analyzed

network (up to the 40th harmonic). (Breakdown of each 10-cycle block integrated in a recording

period).

INTERHARMONICS:

QNA500 measure and register voltage and current interhamornics. These are signals introduced in the

power cable with frequencies non-multiple of the fundamental frequency (50 or 60Hz). QNA500 is able

to measure up to interharmonic 50, corresponding to signals with frequency of 2525Hz.

UNBALANCE:

• Voltage unbalance coefficient (Kd): homopolar and direct voltage ratio.

• Voltage asymmetry coefficient (Ka): inverse and direct voltage ratio.

QNA500 8IO Instruction manual

39 / 111

Page 40

POWER QUALITY ANALYZER QNA500 8IO

• Current asymmetry coefficient (Kd): homopolar and direct current ratio.

• Current unbalance coefficient (Ka): inverse and direct current ratio.

K FACTOR:

K Factor is a transformer power reduction factor. The losses generated by harmonics are taken into

account when calculating the K Factor.

It is always higher than the unit in installations with non-linear loads.

e: represents the transformer's copper loss and iron loss ratio. This value can be obtained from the

transformer test data or, alternatively, an approximate value of 0.3 can be used.

q: exponent with a value between 1.7 and 1.8.

CREST FACTOR:

The Crest Factor is equal to the amplitude of the wave shape peak divided by the RMS value. The

crest factor is calculated to provide the analyst with a quick idea of the impact on the wave shape. The

impact is constantly associated with the wear of the roller bearing, cavitation and wear of the gear

cogs, etc.

The crest factor is an important measurement associated to the status of the machine and it analyses

the wave shape, which would not be visible with the calculation of the harmonic distortion rate alone.

QNA500 8IO Instruction manual

40 / 111

Page 41

POWER QUALITY ANALYZER QNA500 8IO

Registry variables

Unit

L1

L2

L3

III

Active energy

kWh

X X X X Inductive reactive energy

kvarh

X X X X Capacitive active energy

kvarh

X X X

X

It is a perfect sine wave, with a "1" amplitude", RMS value equal to 0.707, so that the crest factor is

equal to 1.41. A perfect sine wave has no impacts and, therefore, the crest factor with a value of over

1.41 means that there is a certain impact degree.

8.13.2.- .WAT FILE

The variable recording period can be configured by the user and is different to the recording period of

an .STD file.

8.13.3.- .EVQ FILE

Events detected are stored in this file. The following data are stored from each one of the events:

• Event Type: Overvoltage, Sag or Interruption.

• Event Date: Date the event occurred. This value is obtained with a ½ Cycle accuracy.

• Event Type: This is stored when the event detected is an interruption, sag or overvoltage.

These events are defined in accordance with the specifications programmed in the QNA500.