Page 1

DIELECTRIC STRENGTH TESTER

FOR ISOLATING OILS

OT-60

( Código: P60311 )

INSTRUCTION MANUAL

( M98112801-03 / 04B )

(c)

CIRCUTOR S.A.

Page 2

DIELECTRIC STRENGTH TESTER FOR ISOLATING OILS

OT-60

1. BASIC INSTRUCTIONS

1.1 Delivery spot check

This manual is issued to help all the users to install and use the dielectric strength

tester for isolating oils OT-60, and also to help them to get the best from it. After receiving

the equipment, please check the following points:

(a) The equipment corresponds to your order specification

(b) Check if any damage was done during the shipment process

(c) Verify that you have received all the components specified on 2

nd

point.

1.2 Connection procedures

The manual you hold in your hands contains information and warnings that the user

should respect in order to guarantee a proper operation of all the functions of the OT-60

and keep its safety conditions. Also you must follow the usual security actions.

1.3 Considerations related to the standards

All the comments and advices that you can read on this manual related to the

procedure that you must follow to do dielectric strength tests, are referred to the IEC 156

standard, being only valid if you are following it. If you want to follow another standard, the

comments and advices of this manual can be different (Go to 10

th

point)

2. VERIFICATION OF THE DELIVERIED COMPONENTS

When you receive the equipment, please check that the following components are

included:

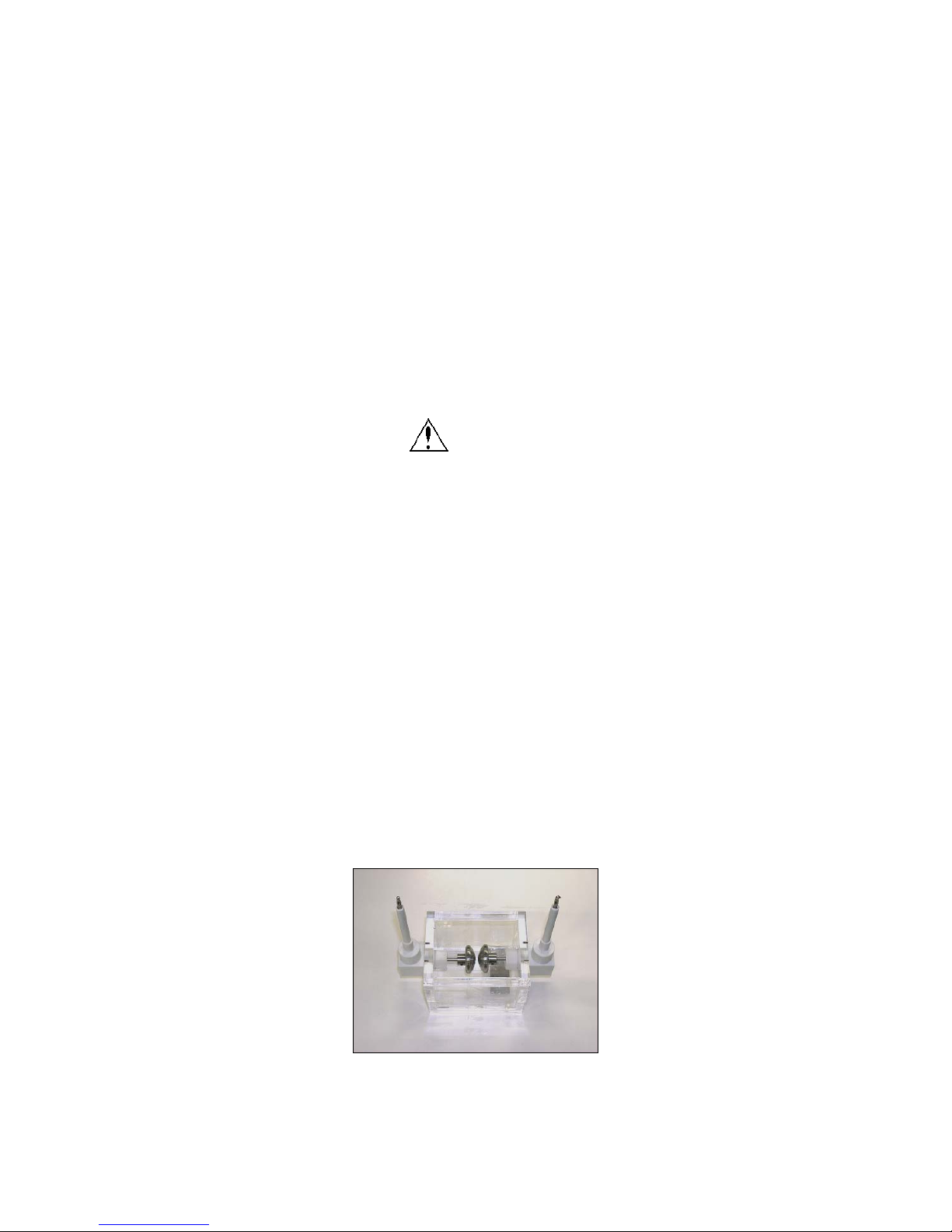

2.1 Test Cell:

Open the equipment’s door and pull out the test cell’s white connectors firmly.

Inside the test cell we can find a small bag including the components specified on

the following point.

Page 3

2.2 Small Bag including the following components: gauge, Allen spanner and teflon

coated magnet

Look for this small bag inside the test cell.

The delivered gauge is 2,5 mm ± 0,05 mm in width, according to the IEC-156 standard . If

you need other widths go to 10

th

point.

2.3 OT-60 equipment:

Once extracted the test cell, we will see the following image:

Sometimes we can find the keys inside the bag specified on point 2.2

2.4 Connection cable:

It’s a standard connection cable.

Page 4

3. INTRODUCTION

The OT-60 range is automatic equipment especially designed to test the disruptive

voltage of isolating oils in new or used transformers, cables with oil, automatic switches,

capacitors, etc.

The disruptive voltage is not a basic property of the oil, but it indicates us the degree

of contamination of this oil (water, solid materials in suspension), allowing us to decide on

the possibility of carrying out a treatment of drying and filtration, or replacing the oil.

The method that the OT-60 uses can be applied to oils of nominal viscosity of up to

350 mm

2

/s at 40ºC, according to IEC-156 standard.

The OT-60 is supplied with a complete series of protectors making it highly protected

and reliable.

It is easy to handle, all buttons or illuminated switches are on the front control panel;

there is also an audible signal each time a key is pressed or when the oil sample is

perforated.

The test cell is especially designed to easily change the electrodes in accordance

with the different standards in operation, the easy insertion into the registering transformer

terminals and for its complete cleaning.

The equipment also has a magnetic stirrer to completely mix the oil to be tested. The

moving part ot the stirrer is a small teflon coated magnet.

Page 5

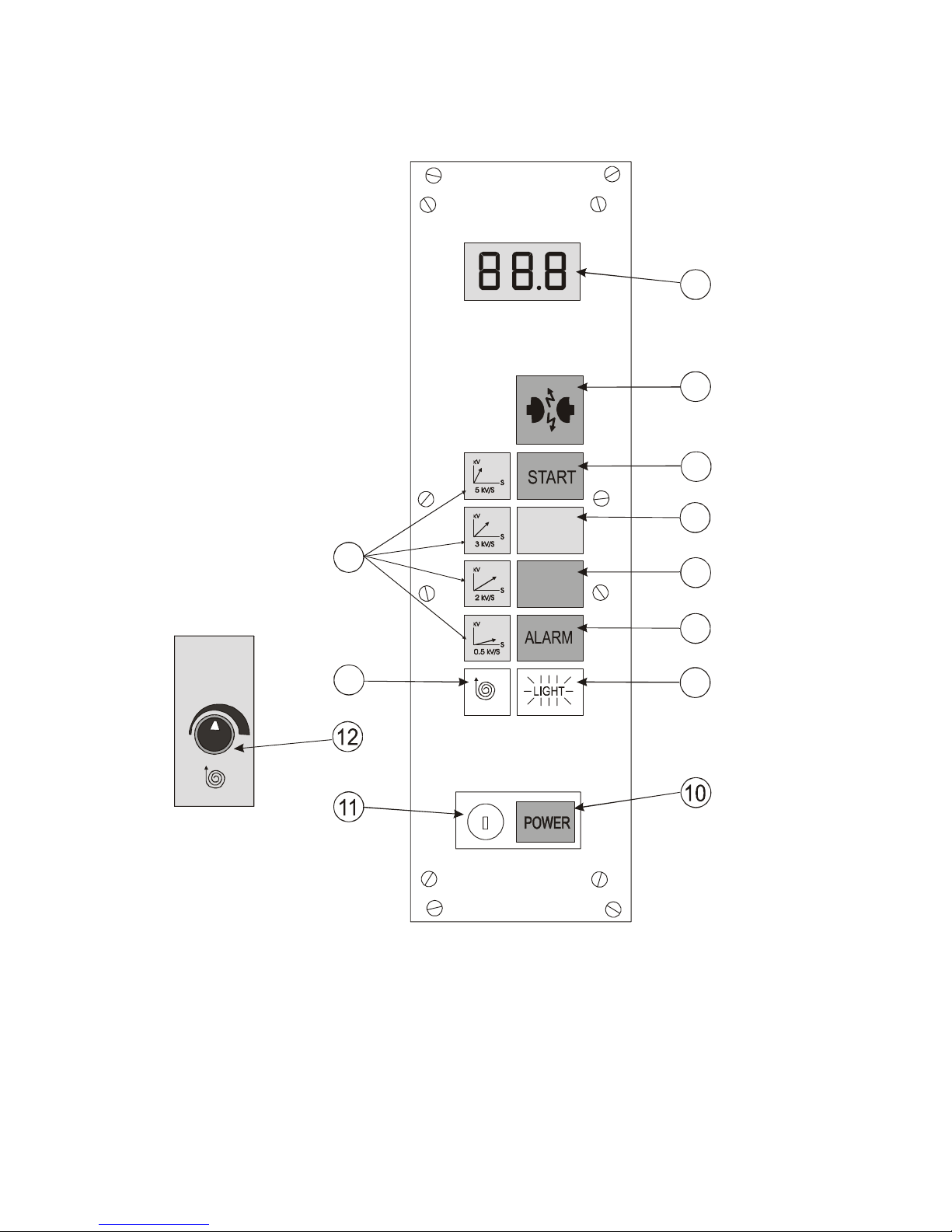

4. DESCRIPTION OF THE CONTROLS

Next we can see a representation of the controls of the equipment and the description of its functions:

STOP

PAUSE

2

3

4

5

6

7

9

8

1

Page 6

1- DISPLAY : "--,-" usually appears, indicating that the equipment is awaiting a

command. When the voltage begins to increase, it is shown on the

DISPLAY. The value that we can see corresponds to the DISRUPTIVE

VOLTAGE of the oil, and its unity is the kV. When an arch appears, the

DISPLAY shows the disruptive voltage of the oil until "STOP" is pressed.

2- ARCH : This is lit when the oil sample is perforated.

3- START : Cycle start button

This is lit when the cycle start is pressed.

4- PAUSE : Pause button

This is lit when the pause function is started. Only one pause per cycle is

permitted and its maximum duration is 60 seconds (we can resume the

cycle returning to make use of this button)

5- STOP : Stop button.

This is lit when the stop function is started.

6- ALARM : Light indicating any type of anomaly.

7- LIGHT : Switch for the fluorescent light inside the chamber

8- RAMPS : Ramp selector buttons. These are lit when pressed and only one ramp

may be selected. Another ramp may only be selected when the

equipment is on "STOP".

9- STIRRER : Stirrer selection button.

This lights up and a stirring function is selected by pressing once.

Pressing again cancels the selection. This may only be selected when

the equipment is on "STOP".

10- POWER : Operation indicating light

11- KEY : Stop and start key.

12- SELECTOR : Speed selector (open the equipment’s door to find this selector and fit

the speed to the wished one following the instructions of the point 7.2).

Page 7

5. STARTING THE EQUIPMENT.

5.1- Transport:

Transport the equipment to the zone where the tests will be done, using for it the lateral handles:

Remarks: If it is decided to transport the equipment outside the enclosure of habitual use,

is very important that the option of FRAGILE TRANSPORT is used.

5.2- Earth connection

Connect the earthing screw on the rear panel to the general earth of the installation. The conductor

used for this purpose must not be less than 2.5 mm in diameter.

5.3- Power supply connection

Connect the power supply cable to the base of the rear panel and to the socket. Ensure that the

start key is on “O” (Stop position).

Page 8

5.4- Test cell extraction

If still it has not been done, open the door of the equipment and pull out the test cell from the

chamber. In order to extract the test cell, pull out both of white supports simultaneously and firmly,

one with each hand.

5.5- Adjustment of the distance between electrodes

In order to adjust the distance between electrodes we will use the gauge delivered with the

equipment. The gauge must be placed between the electrodes, and the distance between them

will be corrected relaxing its subjection by means of provided Allen spanner. Later it will be

necessary to tighten to maintain the required distance.

Remarks: The supplied gauge follows the IEC-156 standard. This Standard specifies that the

gauge must be 2,5 mm ± 0,05 mm in width. If other standards are required, you should

use a different gauge under request (Go to 10

th

point)

Page 9

6. PREPARATION OF THE SAMPLE

6.1- Collection of the sample

It is very important to obtain results that adjust to the reality that you strictly carry out the

measures as it is mentioned next, otherwise, the obtained results could be erroneous.

According to the IEC-156 standard it will be necessary to adopt the following indications.

The oil sample will be taken in the place of the transformer, circuit breaker, etc. where the oil is

more contaminated, generally in the lowest zone of the containers that contains it.

The amount of sample will be approximately three times superior to the capacity of the test cell.

A topaz coloured glass bottle is the most appropriate container. The transparent glass bottles can

be used, but they must be protected of the direct action of the light until the test is made. The

plastic containers don’t have to be attacked by the oil to test and if they are used, they cannot be

reused.

In order to close the bottles, use a spiral cap, preferably of polyolefines or polytetrafluorethylene.

The containers will be filled almost until the top, leaving approximately a 3% of the volume of the

container as free air space.

In case the container is reused, it must be cleaned (don’t forget the cap) by means of washing with

a suitable dissolvent to eliminate the rests of the last sample. The containers will be washed finally

with acetone, and the rests of this dissolvent will be eliminated by means of hot air blown.

After the cleaning, the containers must be closed immediately and stay closed until the moment of

their use.

6.2- Preparation of the sample to test

According to the IEC-156 standard it will be necessary to adopt the following indications.

The test will be done, if another thing is not specified, with the sample as it’s received, without

drying or extracting the gas.

The operation of sample preparation will we done in a dry and free of dust place.

At the moment of the test, the temperature of the test liquid and the room temperature will not

differ more than 5ºC and for the arbitration tests the temperature of the oil will be between 20ºC ±

5ºC.

The container that contains the oil sample to test must be shacked softly and turned upside down

several times to assure the most homogenous distribution of the impurities contained in the oil,

trying to avoid the formation of air bubbles. Avoid the unnecessary exposing of the sample to the

air of the atmosphere.

Immediately before its use the cell will be cleaned according to 8

th

point.

The oil is now spilled slowly in the test cell, avoiding the formation of air bubbles.

The temperature of the liquid is measured and written down.

It is very important for the correct development of the test that the electrodes are totally covered

by the oil, so that the distance from the surface of the oil to the axis of the electrodes is not less

than 40 mm.

Page 10

7. TEST METHOD

The test method consists of submitting the oil to an electric field from a continuously increasing AC

current until the oil is perforated because its dielectric properties are surpassed (insulation

properties). When this occurs, on the display is shown the disruptive voltage in kV.

If we wanted to obtain the dielectric strength of the oil (kV/cm), we would have to divide the value

shown on the display (kV) by the distance between electrodes (cm). In the case of the IEC-156

standard, this distance is 0,25 cm, therefore, if we multiply by 4 (1/0,25=4) the value shown on the

display, we obtain the dielectric strength value of the oil (kV/cm).

7.1- Positioning the test cell in the chamber

Open the door of the equipment and place the test cell (filled with the sample of oil) inside the

chamber, introducing the contacts in the holes on the bottom of it (sockets of the high voltage

transformer). Press firmly until the pieces fit. This is important, because the equipment could

work wrong if there was a bad connection.

7.2- Stirrer

If it is desired to use the stirrer, it will be necessary to introduce the teflon coated magnet inside

the cell, being it clean and dry. The teflon coated magnet will automatically locate in its site

when introducing the cell in the chamber.

Page 11

It is possible to modify the rotation speed of the stirrer. To do this, open the door of the

equipment and turn the selector (12) by means of a screwdriver or a similar object, as we can

see next:

7.3- Closing the door

Close the door, since if it is not closed, the protection circuit will prevent the operation of the

equipment.

Once we have done all the steps specified before, the equipment is already prepared for a

correct use.

7.4- Enabling by means of key

Turn the key to the “I” position (start). The equipment will starts doing a test that turns on the

light of all the buttons, indicating that are running right.

Page 12

7.5- Selecting the test type

Arrived this moment we must select:

a) The type of ramp we desire between the four possible ones, depending on the standard

we follow or depending on the indications of the oil manufacturer:

5kV/s, 3kV/s, 2kV/s o 0.5kV/s.

2 kV/s is selected according to IEC-156 standard.

b) The stirrer function. It consists on the agitation of the oil sample during 60 seconds and a

waiting time of other 60 seconds before the ramp starts.

c) The presence of light inside the chamber. The light allows us to see the test in a clearer

way.

Page 13

7.6- Doing the test

Once we have selected the parameters explained before, we will press “START” and the

equipment will start to do the complete cycle:

a) If the stirring function is selected, the oil sample will be stirred for 60 seconds. After this

time the "STIRRER" light will go off and another 60 second waiting period will start to

remove turbulence in the oil.

b) If the stirring function is not selected or it has finished, the "--,-" symbol on the display will

disappear and the increasing voltage ramp will start until the oil is perforated or, if this

does not occur, until the equipment reaches 60 kV. Then the cycle will stop and the

"STOP" light comes on.

If during the increasing voltage ramp, the oil sample is perforated, then the display will

retain the voltage at which the perforation occurred, the "ARCH" light is lit and an alarm

goes off cutting the high voltage. The "ARCH" light remains on until the "STOP" button is

pressed.

Once the "STOP" button is pressed the value on the display is lost and the "--,-" symbol

reappears, therefore, is better to write down the value before it disappears.

Remarks: It is important to respect the times of the automatic program. If we are

doing tests stopping the cycle by means of the turn of the key without waiting the

necessary time until the next test, we are overloading the transformer and it can be

damaged.

Page 14

7.7- Repeating the test

The cycle previously described will be carried out six times with the same sample of oil.

Between the cycles it will be necessary to wait to the disappearance of the gas bubbles that

have possibly been produced, either waiting for 5 minutes, or selecting the stirring function.

7.8- Stopping the equipment

When the equipment is not used, turn the key to the stop position (“O”).

7.9- Evaluating the results

Once we have finished all the cycles (six), we will write down the following data to do the report:

- Sample identification

- The value of each one of the six disruptive voltages (kV)

- The average value of the six tests (kV)

- The type of electrodes we have used and the distance between them

- The frequency of the test voltage (50 Hz)

- The oil’s temperature

- If we have used the stirrer function or not

In order to determine if the state of the oil is correct or not, we will see if the average value of the

six tests is within the right operation range that indicates the manufacturer of the oil. If the value

is outside this range we will have to adopt the opportune measures to diminish the degree of

contamination of the oil.

If you are not able to find another value, an habitually used criterion (but not indicated by the

standard) is to consider as good the oils that have an average value of dielectric strenght higher

than 80 kV/cm (remember that we can obtain the dielectric strenght multiplying the disruptive

voltage by 4, in the case of following the IEC-156 standard).

8. MAINTENANCE

The electrodes will be examined frequently to observe punctures or other deteriorations and must

be maintained in good state or to replace them when it is observed that they are deteriorated (for

example punctures by effect of discharges).

The new electrodes, the pricked electrodes, and those that suitably have been kept during a

considerable time must be cleaned of the following form:

- Disassemble the electrodes of the cell using the provided Allen spanner, very carefully,

avoiding to touch directly with the fingers, very important at the end of the electrodes, in which

the electrical arc takes place.

- Clean all the surfaces with an appropriate volatile dissolvent and let it evaporate.

- Polish with an abrasive powder (for instance, red fine dust to polish) or with an abrasive paper

or cloth (for instance, very fine polishing cloth or canvas).

Page 15

- After polishing, clean with petroleum ether (reactive for analysis, rank of boiling 60ºC to 80ºC),

followed of acetone (reactive for analysis).

- Mount the electrodes in the cell, fill it with clean and new oil, of the same type than the one

that is going to test later, and elevate the voltage until rupture 24 times.

In the case of changing the type of the test oil, eliminate all the rests of the previous oil using a

suitable dissolvent, wash the cell with the same oil that you are going to test, drain the cell and

return to fill up it to carry out the test.

During the periods of inactivity it is recommended to keep the cell full of clean and new oil in a

clean enclosure, dry and free of dust.

9. ENVIRONMENT CONSIDERATIONS

Once finalized the tests the opportune measures will be done to manage the used oil, since this

one is an injurious substance for the environment. If you don’t know how to deal with this type of

material, contact with your manager of remainders.

10. TECHNICAL FEATURES

- SUPPLY VOLTAGE : 230V-50Hz.

- TEST VOLTAGE : SENOIDAL 0-60 kV, 50Hz.

- CONSUMPTION : 100 W/1200 W

- MEASUREMENT TOLERANCE : + - 2%

- RESPONSE TIME AFTER

DISCONNECTION : < 20 ms

- TEST STANDARDS : IEC 156. Other types of electrodes and gauges for other

standards can be supplied on request: ASTM 877, ASTM

1816, etc.

- OPERATING TEMPERATURE : +15 /+25 °C

STORAGE TEMPERATURE : 0 / +60 °C

- OUTSIDE MEASUREMENTS : 385 * 300 * 400 mm

- WEIGHT : 38.0 kg

11. WARNINGS

11.1 - If the equipment detects any form of anomaly, the "ALARM" light will come on and a continuous

alarm will sound. In this event the equipment has to be stopped with the key. Your distributor has

to be consulted if this occurs.

11.2 - If the front cover is opened, the equipment and the active earthed parts will not operate.

11.3 - IT IS NOT RECOMMENDED TO USE THE EQUIPMENT WITHOUT THE TEST CELL AND

WITHOUT OIL IN THE CELL

11.4 - UNDER NO CIRCUMSTANCES SHOULD THE EQUIPMENT BE OPENED, HANDLED OR

USED IN WAYS OTHER THAN THOSE INDICATED IN THIS MANUAL. IN THIS EVENT THE

GUARANTEE WILL BE NULLIFIED. THE COMPANY IS NOT RESPONSIBLE FOR DAMAGE

TO GOODS OR PERSONS RESULTING FROM MISHANDLING.

Loading...

Loading...