Page 1

DIELECTRIC STRENGTH TESTER FOR

ISOLATING OILS

OT2-60 D

( Cod. P60312. )

INSTRUCTION MANUAL

(

M98227301-03-09A)

(c)

CIRCUTOR S.A.

Please Refer to

Documentation

Before Operation

Page 2

DIELECTRIC STRENGTH TESTER FOR ISOLATING OILS OT2-60D --------- Page 2

Page 3

DIELECTRIC STRENGTH TESTER FOR ISOLATING OILS OT2-60D --------- Page 3

DIELECTRIC STRENGTH TESTER FOR ISOLATING OILS

OT2-60D

1. BASIC INSTRUCTIONS

1.1. Delivery spot check

This manual is issued to help all the users to install and use the dielectric

strength tester for isolating oils OT2-60D, and also to help them to get the best

from it. After receiving the equipment, please check the following points:

(a) The equipment corresponds to your order specification

(b) Check if any damage was done during the shipment process

(c) Verify that you have received all the components specified on 2nd point.

1.2. Connection procedures

The manual you hold in your hands contains information and warnings that the

user should respect in order to guarantee a proper operation of all the functions

of the OT2-60D and keep its safety conditions. Also you must follow the usual

security actions.

1.3. Considerations related to the standards

All the comments and advices that you can read on this manual related to the

procedure that you must follow to do dielectric strength tests, are referred to the

IEC 156 standard, being only valid if you are following it. If you want to follow

another standard, the comments and advices of this manual can be different

(Go to 10th point).

2. VERIFICATION OF THE DELIVERIED COMPONENTS

When you receive the equipment, please check that the following components are

included

:

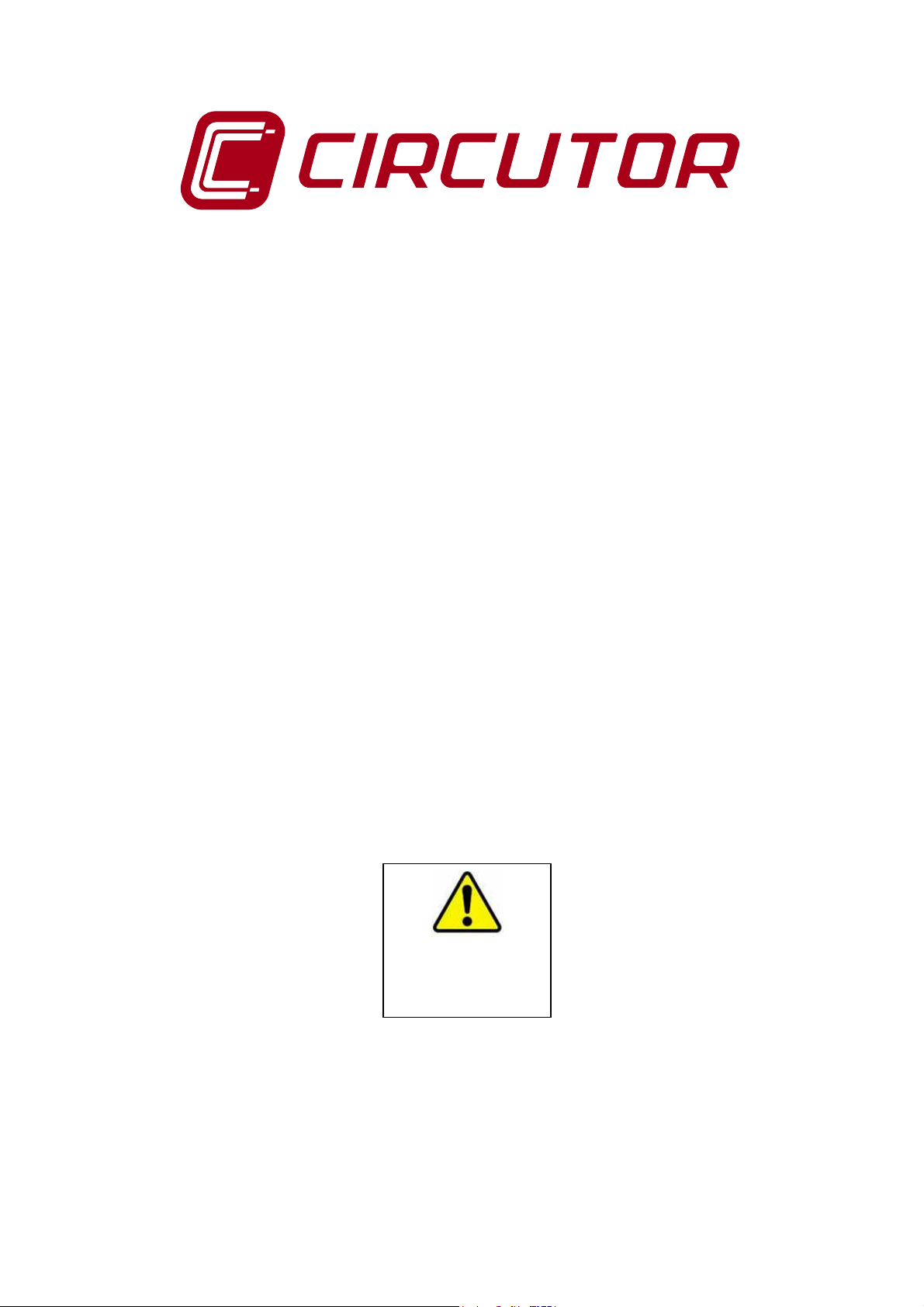

2.1. OT2-60D equipment:

Page 4

DIELECTRIC STRENGTH TESTER FOR ISOLATING OILS OT2-60D --------- Page 4

2.2. Protection Unit

Open the equipment’s door and the protection will be inside with the others

components:

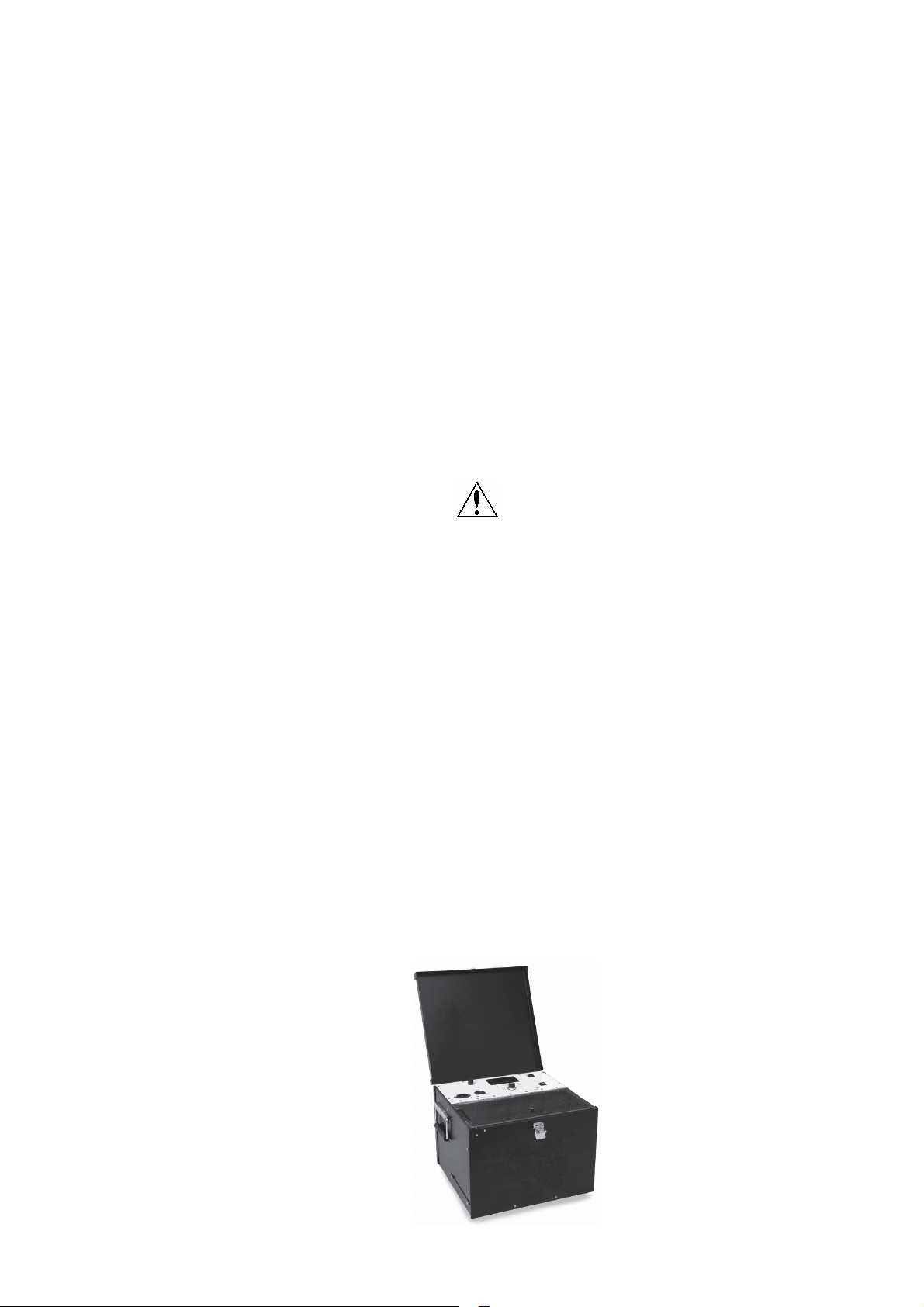

2.2.1. Test Cell

Inside the protection unit it is the test cells:

2.2.2. Gauge, Allen spanner and Fuse

Look for in the protection unit where it is the bag of fuses. Allen and

gauge are in the test cell.

The delivered gauge is 2,5 mm ± 0,05 mm in width, according to the

IEC-156 standard .

Page 5

DIELECTRIC STRENGTH TESTER FOR ISOLATING OILS OT2-60D --------- Page 5

2.3. Connection cable:

It’s a standard connection cable.

3. INTRODUCTION

The OT2-60D range is automatic equipment especially designed to test the disruptive

voltage of isolating oils in new or used transformers, cables with oil, automatic

switches, capacitors, etc.

The disruptive voltage is not a basic property of the oil, but it indicates us the degree

of contamination of this oil (water, solid materials in suspension), allowing us to decide

on the possibility of carrying out a treatment of drying and filtration, or replacing the oil.

The method that the OT2-60D uses can be applied to oils of nominal viscosity of up to

350 mm2/s at 40ºC, according to IEC-156 standard.

The OT2-60D is supplied with a complete series of protectors making it highly

protected and reliable.

It is easy to handle, all buttons or illuminated switches are on the front control panel.

The test cell is especially designed to easily change the electrodes in accordance with

the different standards in operation, the easy insertion into the registering transformer

terminals and for its complete cleaning.

Page 6

DIELECTRIC STRENGTH TESTER FOR ISOLATING OILS OT2-60D --------- Page 6

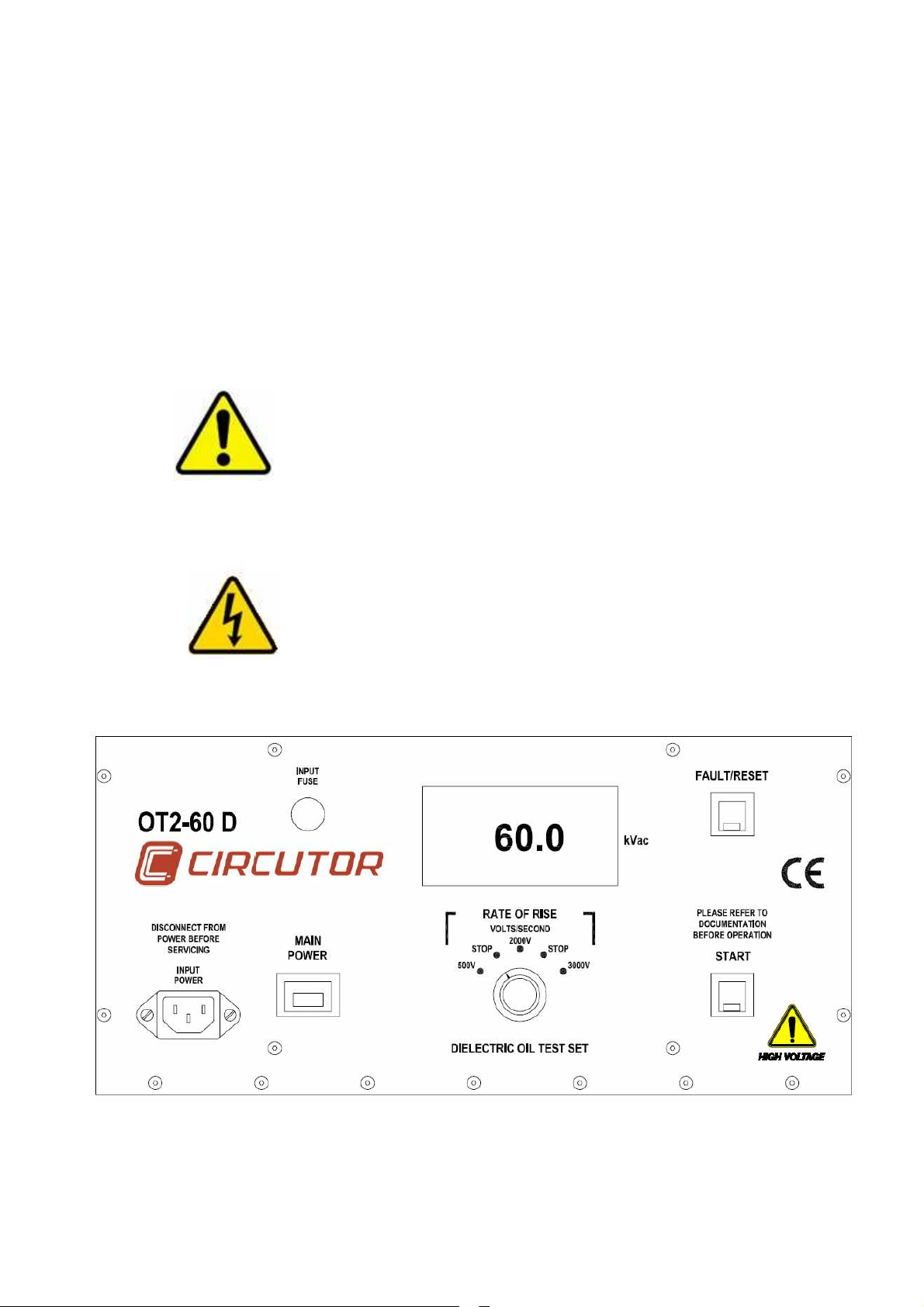

4. DESCRIPTION OF THE CONTROLS

Next we can see a representation of the controls of the equipment and the description

of its functions:

Safety Symbol Identification

Warning! Please refer to documentation before

operation

Warning! Hazardous

Voltage

Page 7

DIELECTRIC STRENGTH TESTER FOR ISOLATING OILS OT2-60D --------- Page 7

4.1. Input power

The INPUT POWER connector accepts most standard electrical equipment type

cords. The power supplied to the input connector must be from a grounded

source rated to match the input power specifications noted in Table 1.

4.2. Main power

The MAIN POWER switch provides the power to the control and power circuits.

The neon lamp will light when the power is on and voltage is available through

the input line cord. The INPUT FUSE located electrically before the MAIN

POWER switch provides line fault protection for the unit.

4.3. START

The START pushbutton activates the high voltage power circuits. The GREEN

LED indicator lamp provides long life indication of the circuit status. The LED

lights when high voltage is energized and the unit is ramping up in voltage.

4.4. Rate of rise

The RATE OF RISE output control sets the output voltage rise in three fixed

rates, 500v/2000v/3000v per second. The STOP positions between the rise

voltages allow for manual override and calibration check of the output.

4.5. KILOVOLTMETER

The digital Kilovoltmeter indicates the output voltage between the high voltage

bushings in the test chamber. The calibration accuracy is 3% of full scale. At

failure of the test sample, the meter will hold the breakdown voltage reading until

the Fault/Reset pushbutton is depressed.

4.6. Fault/reset

The FAULT/RESET pushbutton resets the hold circuits after a breakdown of the

test sample. This control can also be used to de-energize the high voltage power

circuit. The RED LED indicator lamp provides long life indication of FAULT

status. The LED lights when the output has de-activated from an arc in the test

sample. When reset, the output control must ramp back to zero before the high

voltage can be energized again.

4.7. Access interlock(not on control panel)

The Access Interlock. is provided for safety. It interlocks the access lid to the

high voltage bushings and precludes the potential for shock by requiring the

access door to be closed when high voltage is energized.

4.8. ic/iec oil vessel

This Oil Vessel is used with the OT2-60D at 2000v/SEC for testing in accord with

IEC Standard IEC-156.

Page 8

DIELECTRIC STRENGTH TESTER FOR ISOLATING OILS OT2-60D --------- Page 8

Under demand:

4.9. TC/DE oil vessel - ASTM Specification D877

This Oil Vessel is used with the OT2-60D at 3000V/SEC for testing in accord with

ASTM Specification D877. This standard can be obtained from the American

Society For Testing and Materials.

4.10. TC/VDE oil vessel - ASTM Specification D1816

This Oil Vessel and motorized stirring assembly is used with the OT2-60D at

500v/SEC for testing in accord with ASTM Specification D1816. This standard

can be obtained from the American Society For Testing and Materials.

5. PREPARATION OF THE SAMPLE

5.1.

Collection of the sample

It is very important to obtain results that adjust to the reality that you

strictly carry out the measures as it is mentioned next, otherwise, the

obtained results could be erroneous.

According to the IEC-156 standard it will be necessary to adopt the following

indications.

The oil sample will be taken in the place of the transformer, circuit breaker,

etc. where the oil is more contaminated, generally in the lowest zone of the

containers that contains it.

The amount of sample will be approximately three times superior to the

capacity of the test cell.

A topaz coloured glass bottle is the most appropriate container. The

transparent glass bottles can be used, but they must be protected of the direct

action of the light until the test is made. The plastic containers don’t have to be

attacked by the oil to test and if they are used, they cannot be reused.

In order to close the bottles, use a spiral cap, preferably of polyolefines or

polytetrafluorethylene.

The containers will be filled almost until the top, leaving approximately a 3% of

the volume of the container as free air space.

In case the container is reused, it must be cleaned (don’t forget the cap) by

means of washing with a suitable dissolvent to eliminate the rests of the last

sample. The containers will be washed finally with acetone, and the rests of

this dissolvent will be eliminated by means of hot air blown.

After the cleaning, the containers must be closed immediately and stay closed

until the moment of their use.

Page 9

DIELECTRIC STRENGTH TESTER FOR ISOLATING OILS OT2-60D --------- Page 9

5.2.

According to the IEC-156 standard it will be necessary to adopt the following

The test will be done, if another thing is not specified, with the sample as it’s

The operations of sample preparation will we done in a dry and free of dust

At the moment of the test, the temperature of the test liquid and the room

The container that contains the oil sample to test must be shacked softly and

Immediately before its use the cell will be cleaned according to 8th point.

The oil is now spilled slowly in the test cell, avoiding the formation of air

The temperature of the liquid is measured and written down.

Preparation of the sample to test

indications.

received, without drying or extracting the gas.

place.

temperature will not differ more than 5ºC and for the arbitration tests the

temperature of the oil will be between 20ºC ± 5ºC.

turned upside down several times to assure the most homogenous

distribution of the impurities contained in the oil, trying to avoid the formation

of air bubbles. Avoid the unnecessary exposing of the sample to the air of the

atmosphere.

bubbles.

It is very important for the correct development of the test that the electrodes

are totally covered by the oil, so that the distance from the surface of the oil to

the axis of the electrodes is not less than 40 mm.

6. SETTING UP THE EQUIPMENT

The setup of this equipment has been minimized by careful consideration of the

operator during design. The OT2-60D one-piece construction permits convenient

portability. The OT2-60D test set requires that the unit be operated with the control

panel in the horizontal position to keep oil over the high voltage transformer in the high

voltage tank.

6.1.

Select a location for the unit that will allow easy viewing of the kilovolt meter.

Using for it the lateral handles.

Page 10

DIELECTRIC STRENGTH TESTER FOR ISOLATING OILS OT2-60D --------- Page 10

Remarks: If it is decided to transport the equipment outside the

enclosure of habitual use, is very important that the option of FRAGILE

TRANSPORT is used.

6.2.

6.3.

6.4.

Be sure that all the controls are off, in their de-energized or fully

counterclockwise position.

Remove all components and oil vessels from the test chamber. Remember

that you have to quit the screws of transport box.

Install the input line cord into the Input Power receptacle.

6.5.

Connect the line cord to a suitable (230v, see Specification Table) grounded

power source.

CAUTION - Disconnect all power before servicing!

Page 11

DIELECTRIC STRENGTH TESTER FOR ISOLATING OILS OT2-60D --------- Page 11

6.6.

6.7.

6.8.

6.9.

Clean the Test Cell and Electrodes thoroughly and adjust the spacing of

the electrodes to conform to the proper IEC Specification. Be sure the

electrodes are securely tightened on the adjustment posts inside the oil

vessel. In order to adjust the distance between electrodes we will use the

gauge delivered with the equipment. The gauge must be placed between the

electrodes, and the distance between them will be corrected relaxing its

subjection by means of provided Allen spanner. Later it will be necessary to

tighten to maintain the required distance.

Locate sufficient insulating liquid for the testing to be performed.

Adjust the Voltimeter to zero if required.

Set the Rate of Rise to the appropriate rate for the test being performed.

The type of ramp we desire between the four possible ones, depending on the

standard we follow or depending on the indications of the oil manufacturer:

- 0.5kV/s, 2kV/s o 3kV/s.

2 kV/s is selected according to IEC-156 standard.

A note about the Oil Vessels made by Circutor.

All the oil vessels designed and made by Circutor Inc. have interchangeable posts and

electrodes. These oil vessels were designed to conform to the IEC-156 test

specifications requiring simple disassembly for cleaning. This design greatly reduces

the time and effort required keeping your oil vessels in top operating condition.

Page 12

DIELECTRIC STRENGTH TESTER FOR ISOLATING OILS OT2-60D --------- Page 12

7. OPERATING THE EQUIPMENT

There are standard tests specified (ASTM D877, ASTM D1816) for testing dielectric

oils. This manual provides step-by-step instruction on operation of the OT2-60D in

conjunction with the necessity of following the aforementioned test specifications.

Many facilities have their own in-house test standards structured around the IEC

specifications, and this manual is not to supercede these. The purpose of this section

is to explain the capabilities of this test set in real-world applications.

The test method consists of submitting the oil to an electric field from a continuously

increasing AC current until the oil is perforated because its dielectric properties are

surpassed (insulation properties). When this occurs, on the display is shown the

disruptive voltage in kV.

If we wanted to obtain the dielectric strength of the oil (kV/cm), we would have to

divide the value shown on the display (kV) by the distance between electrodes (cm). In

the case of the IEC-156 standard, this distance is 0,25 cm, therefore, if we multiply by

4 (1/0,25=4) the value shown on the display, we obtain the dielectric strength value of

the oil (kV/cm).

7.1.

7.2.

7.3.

7.4.

Ensure that setup has been accomplished as noted in Setting Up the Equipment.

After checking the Test cell for proper electrode tightness, spacing and

cleanliness, fill the selected oil vessel with sample oil to the level specified in

the IEC-156 Standard. The test sample oil temperature must be at or

below 100C to avoid damage to oil vessel.

Gently stir the oil test sample release trapped air on sides of test cup. Avoid

creating any additional air into the test solution.

Place the filled test cell onto the bushing cradle toroids. Open the door of the

equipment and place the test cell (filled with the sample of oil) inside the

chamber.

7.5.

7.6.

Close the door, since if it is not closed, the protection circuit will prevent the

operation of the equipment.

Allow the sample to stand for a minimum of three minutes. If the VDE cell

used, plug the line cord from the stirring assembly into the receptacle in the

test chamber.

Page 13

DIELECTRIC STRENGTH TESTER FOR ISOLATING OILS OT2-60D --------- Page 13

***CAUTION***

7.7.

7.8.

7.9.

7.10.

7.11.

Turn on MAIN POWER

POTENTIALLY LETHAL VOLTAGES MAY BE

PRESENT

Depress the START pushbutton to start the test. Observe the test cell as the

output ramps up at the preset rate. The voltage will rise until the sample

breaks down. At breakdown, the unit will turn off, light the Fault LED and hold

the breakdown voltage reading.

After recording the breakdown voltage, depress the Reset/Fault pushbutton.

Allow the output control to return to zero.

The cycle previously desvribed will be carried out six times with the same

sample of oil. Between the cycles it will be necessary to wait to the

disappearance of the gas bubbles that have possibly been produced, either

waiting for 5 minutes, or selecting the stirring function.

Stopping the equipment

POWER and the red Neon will be turned off.

, w

hen the equipment is not used, turn off MAIN

7.12. Evaluating the results

Once we have finished all the cycles (six), we will write down the following

data to do the report:

- Sample identification

- The value of each one of the six disruptive voltages (kV)

- The average value of the six tests (kV)

- The type of electrodes we have used and the distance between them

- The frequency of the test voltage (50 Hz)

- The oil’s temperature

- If we have used the stirrer function or not

In order to determine if the state of the oil is correct or not, we will see if the

average value of the six tests is within the right operation range that indicates

the manufacturer of the oil. If the value is outside this range we will have to

adopt the opportune measures to diminish the degree of contamination of the

oil.

If you are not able to find another value, an habitually used criterion (but not

indicated by the standard) is to consider as good the oils that have an

average value of dielectric strenght higher than 80 kV/cm (remember that we

can obtain the dielectric strenght multiplying the disruptive voltage by 4, in the

case of following the IEC-156 standard).

Page 14

DIELECTRIC STRENGTH TESTER FOR ISOLATING OILS OT2-60D --------- Page 14

8. PERFORMING SPECIAL OPERATIONS (MAINTENANCE)

The following section contains information on the care and upkeep of your new OT260D AC Dielectric Oil Test Set . There are some notes on troubleshooting and service,

which will save much time and money over the life of the unit.

8.1.

8.2.

Adjust the Voltimeter to zero if required.

The OT-60D Dielectric Oil Test Set uses precision metal film resistors for

measurement and calibration of the voltmeter. The use of these resistors has

minimized circuit drift due to aging and temperature. But, a potentiometer (R16

on the voltmeter PCB-037 can be used to correct for movement changes from

the aging of the meter.

The certification of meters on a yearly basis is recommended to ensure

accurate test results.

Other adjustments

The electrodes will be examined frequently to observe punctures or other

deteriorations and must be maintained in good state or to replace them when it

is observed that they are deteriorated (for example punctures by effect of

discharges).

The new electrodes, the pricked electrodes, and those that suitably have been

kept during a considerable time must be cleaned of the following form:

- Disassemble the electrodes of the cell using the provided Allen

- Clean all the surfaces with an appropriate volatile dissolvent and let

- Polish with an abrasive powder (for instance, red fine dust to polish)

- After polishing, clean with petroleum ether (reactive for analysis,

spanner, very carefully, avoiding to touch directly with the fingers,

very important at the end of the electrodes, in which the electrical

arc takes place.

it evaporate.

or with an abrasive paper or cloth (for instance, very fine polishing

cloth or canvas).

rank of boiling 60ºC to 80ºC), followed of acetone (reactive for

analysis).

Page 15

DIELECTRIC STRENGTH TESTER FOR ISOLATING OILS OT2-60D --------- Page 15

- Mount the electrodes in the cell, fill it with clean and new oil, of the

same type than the one that is going to test later, and elevate the

voltage until rupture 24 times.

In the case of changing the type of the test oil, eliminate all the rests of the

previous oil using a suitable dissolvent, wash the cell with the same oil that you

are going to test, drain the cell and return to fill up it to carry out the test.

During the periods of inactivity it is recommended to keep the cell full of clean

and new oil in a clean enclosure, dry and free of dust.

9. ENVIRONMENT CONSIDERATIONS

Once finalized the tests the opportune measures will be done to manage the used oil,

since this one is an injurious substance for the environment. If you don’t know how to

deal with this type of material, contact with your manager of remainders.

Page 16

DIELECTRIC STRENGTH TESTER FOR ISOLATING OILS OT2-60D --------- Page 16

10. ENVIRONMENT CONSIDERATIONS

The OT2-60D AC Dielectric Oil Test Set provides repeatable, accurate measurement

of breakdown voltage of insulating oils used in electrical equipment. The OT2-60D can

also be setup as a voltage source for an external vacuum bottle or chamber by the use

of two shielded output cables which mate to the oil cup cradle electrodes.

Standard features of the OT2-60D of AC Dielectric Oil Test Set:

- Three Fixed rates of rise, 500V/2000V/3000V per second

- Arc detection with 30 millisecond shutdown

- “Zero Start” and Access Interlock provision

- Primary connected 3.5 digit LED voltmeter display

- One piece portable design (cables and oil vessels store in the control

case).

- Rugged aluminum case

- Window for observation of oil test (special window required for use of

cables)

- Stop/Dwell rate of rise positions

- Simple controls

Page 17

DIELECTRIC STRENGTH TESTER FOR ISOLATING OILS OT2-60D --------- Page 17

MODEL SPECIFICATIONS AND OPERATING ENVIRONMENT

Input

Output

Output Termination

Oil Test Cells

Available

Oil Test Cells

Under demand

Operating

Temperature

Distortion

Meter Accuracy

Kilovoltmeter

Dimensions

OT2-60D

230 V ± 10 % , 50/60 Hz, 3 A, single fase.

0-60kVac, 800VA resistive load, between bushings.

Dual Capacitively Graded Bushings.

IEC 156

ASTM D1816, ASTM D877

5°C a 40°C

<5%

2% Full Scale.

3.5 digit LED Escalado 0-60.0 kV AC (RMS)

380mm wide x 360mm deep x 295mm high

Weight

Altitude

(27kg)

100% of rating; Sea-level, up to 1500M. The maximum output

voltage is de-rated 5% above 1500M altitude, 10% above

3600M, and 15% above 4500M.

Storage Temperature

Operating

-10°C to 60°C, (14°F to 140°F).

5°C to 40°C (40°F to 104°F).

Temperature

Maximum Relative

Humidity

Installation

Pollution

80% up to 31°C(88°F), decreasing linearly to 50% at 40°C(104°F)

Category II

Degree 2

Table OT2-60D specifications

Page 18

DIELECTRIC STRENGTH TESTER FOR ISOLATING OILS OT2-60D --------- Page 18

11. WARNINGS

11.1.

11.2.

11.3.

11.4.

If the equipment detects any form of anomaly, the "ALARM" light will come on

and a continuous alarm will sound. In this event the equipment has to be

stopped with the key. Your distributor has to be consulted if this occurs.

If the front cover is opened, the equipment and the active earthed parts will not

operate.

IT IS NOT RECOMMENDED TO USE THE EQUIPMENT WITHOUT THE

TEST CELL AND WITHOUT OIL IN THE CELL.

UNDER NO CIRCUMSTANCES SHOULD THE EQUIPMENT BE OPENED,

HANDLED OR USED IN WAYS OTHER THAN THOSE INDICATED IN THIS

MANUAL. IN THIS EVENT THE GUARANTEE WILL BE NULLIFIED. THE

COMPANY IS NOT RESPONSIBLE FOR DAMAGE TO GOODS OR

PERSONS RESULTING FROM MISHANDLING.

Loading...

Loading...