Page 1

Low voltage capacitor bank with static

switching operation.

OPTIM EMS-C series

INSTRUCTION MANUAL

(M057B01-03-14A)

Page 2

OPTIM EMS-C series

2

Instruction Manual

Page 3

OPTIM EMS-C series

SAFETY PRECAUTIONS

Follow the warnings described in this manual with the symbols shown below.

DANGER

Warns of a risk, which could result in personal injury or material damage.

ATTENTION

Indicates that special attention should be paid to a speci c point.

If you must handle the unit for its installation, start-up or maintenance, the following

should be taken into consideration:

Incorrect handling or installation of the unit may result in injury to personnel as well as damage

to the unit. In particular, handling with voltages applied may result in electric shock, which may

cause death or serious injury to personnel. Defective installation or maintenance may also

lead to the risk of re.

Read the manual carefully prior to connecting the unit. Follow all installation and maintenance

instructions throughout the unit’s working life. Pay special attention to the installation standards of the National Electrical Code.

Refer to the instruction manual before using the unit

In this manual, if the instructions marked with this symbol are not respected or carried out correctly, it can

result in injury or damage to the unit and /or installations.

CIRCUTOR, SA reserves the right to modify features or the product manual without prior noti cation.

DISCLAIMER

CIRCUTOR, SA reserves the right to make modi cations to the device or the unit speci ca-

tions set out in this instruction manual without prior notice.

CIRCUTOR, SA on its web site, supplies its customers with the latest versions of the device

speci cations and the most updated manuals.

www.circutor.com

Instruction Manual

3

Page 4

OPTIM EMS-C series

CONTENTS

SAFETY PRECAUTIONS .......................................................................................................................................3

DISCLAIMER ..........................................................................................................................................................3

CONTENTS ............................................................................................................................................................. 4

REVISION LOG .......................................................................................................................................................5

1.- VERIFICATION UPON RECEPTION ................................................................................................................. 6

1.1.- RECEPTION PROTOCOL .......................................................................................................................... 6

1.2.- TRANSPORT AND HANDLING .................................................................................................................6

1.3.- STORAGE...................................................................................................................................................7

2.- PRODUCT DESCRIPTION ................................................................................................................................ 8

2.1.- CAPACITOR BANK COMPONENTS ......................................................................................................... 8

2.1.1. FAST REGULATOR .............................................................................................................................. 8

2.1.2. CPC4 BOARD: ZERO SWITCHING STEP CONNECTION CONTROL...............................................8

2.1.3. POWER BLOCK ................................................................................................................................... 9

3.- INSTALLATION ...............................................................................................................................................10

3.1.- PRELIMINARY RECOMMENDATIONS ...................................................................................................10

3.2.- PREPARATION ......................................................................................................................................... 11

3.3.- INSTALLATION LOCATION ..................................................................................................................... 12

3.4.-CONNECTION OF THE CAPACITOR BANK TO THE MAINS ................................................................. 13

3.5.-POWER CIRCUIT ...................................................................................................................................... 13

3.6.- EXTERNAL ISOLATION AND PROTECTION ELEMENTS ..................................................................... 14

3.7.- AUXILIARY CONTROL VOLTAGE ...........................................................................................................14

3.8.- EARTH CABLE CONNECTION ...............................................................................................................14

3.9.- CURRENT TRANSFORMER (CT) CONNECTION .................................................................................15

4.- STATIC CAPACITOR BANK START-UP .........................................................................................................17

4.1.- BEFORE START-UP .................................................................................................................................17

4.2.- START-UP .................................................................................................................................................17

4.3.- CHECKS AFTER THE CAPACITOR BANK IS CONNECTED AND THE REGULATOR ADJUSTED .... 19

5.- MAINTENANCE ............................................................................................................................................... 20

5.1.- SAFETY REGULATIONS .........................................................................................................................20

5.2.- MAINTENANCE WITH THE CAPACITOR BANK DISCONNECTED ...................................................... 20

5.2.1. BASIC MAINTENANCE PROTOCOL ................................................................................................20

5.2.2. TIGHTENING TORQUE OF THE ELECTRICAL CONNECTIONS ....................................................21

5.2.3. KEY POINTS FOR INSPECTING STATIC SWITCHES ......................................................................21

5.2.4. KEY POINTS FOR INSPECTING CAPACITORS ...............................................................................21

5.2.5. KEY POINTS FOR INSPECTING THE REGULATOR .......................................................................21

5.2.6. CLEANING THE CABINET ................................................................................................................22

5.3.- MAINTENANCE WITH THE CAPACITOR BANK CONNECTED ............................................................ 22

5.3.1. REGULATOR CHECKS ...................................................................................................................... 23

6.- TECHNICAL FEATURES ................................................................................................................................24

7.- OPTIM EMS-C TYPE DIAGRAM ..................................................................................................................... 25

8.- MAINTENANCE AND TECHNICAL SERVICE ................................................................................................26

9.- GUARANTEE ...................................................................................................................................................26

10.- CE CERTIFICATE .......................................................................................................................................... 27

4

Instruction Manual

Page 5

OPTIM EMS-C series

REVISION LOG

Table 1: Revision log.

Date Revision Description

10/14 M057B01-03-14A Initial Version

Note: The images of the units are solely for the purpose of illustration and may differ from the

original unit.

Instruction Manual

5

Page 6

OPTIM EMS-C series

1.- VERIFICATION UPON RECEPTION

1.1.- RECEPTION PROTOCOL

Check the following points when you receive the unit:

a) The unit meets the specications described in your order.

b) The unit has not suffered any damage during transport.

c) Perform an external visual inspection of the unit prior to switching it on.

d) Check that it has been delivered with the following:

- The unit manual

- The regulator installation guide.

If any problem is noticed upon reception, immediately contact the transport

company and/or CIRCUTOR's after-sales service.

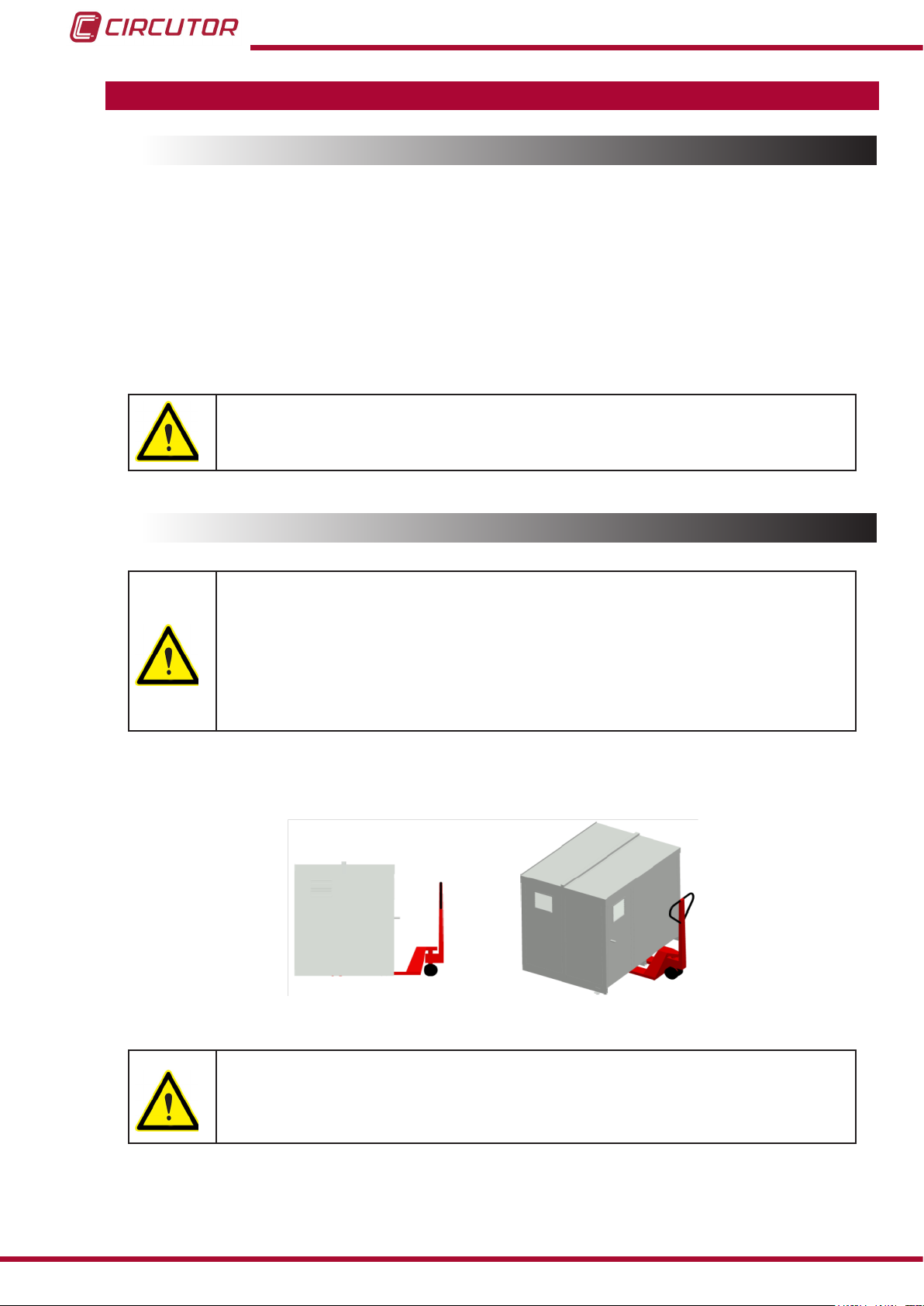

1.2.- TRANSPORT AND HANDLING

The transport, loading and unloading and handling of the unit must be carried out with proper precautions and using the proper manual and mechanical tools so as not to damage it.

If the unit is not to be immediately installed, it must be stored at a location

with a rm and level oor, and the storage conditions listed in the technical

features section must be observed. In this case, it is recommended that the

unit be stored with its original protective packaging.

To move the unit a short distance, the unit's oor support proles facilitate handling with a pallet

jack or forklift. (Figure 1)

Figure 1: Transport with pallet jack.

The centre of gravity of some units may be found at a considerable height.

Therefore, when handling with a forklift, it is recommended that the unit be

securely fastened and that no abrupt manoeuvres made. The unit should

not be lifted more than 20 cm off the ground

6

Instruction Manual

Page 7

OPTIM EMS-C series

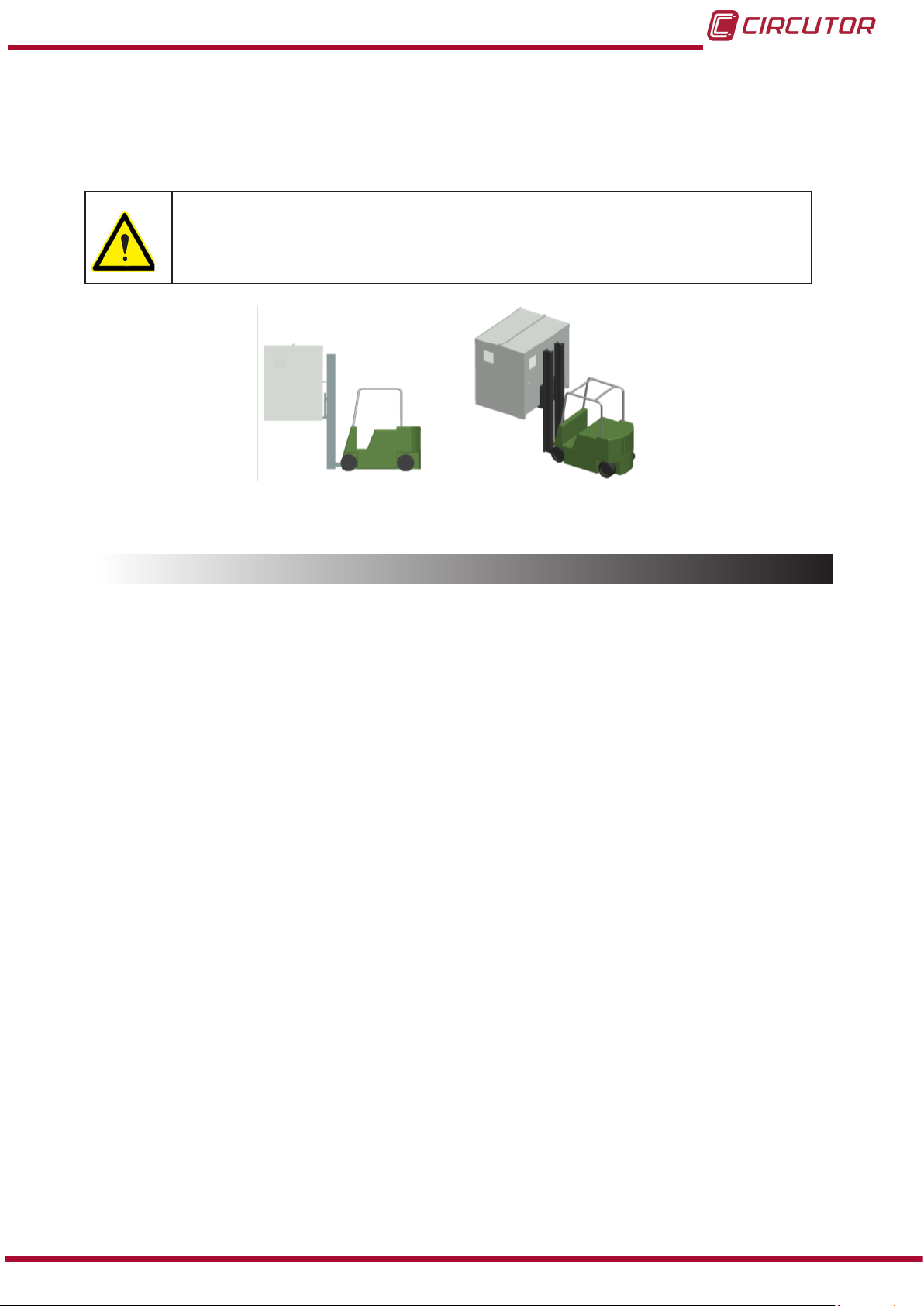

When unloading and moving the unit, use a forklift with forks long enough to support the entire

length of the base. Otherwise, the forks should be long enough to support at least ¾ of said

depth. The forks must be at and supported rmly by the base. Raise the cabinet by placing the

forks underneath the prole that supports the unit. (Figure 2).

There might be an offset in the centre of gravity from the centre of the cabinet,

as a result of the uneven distribution of loads inside the unit. The necessary

precautions must be taken to prevent the unit from tipping over during abrupt

operations.

Figure 2: Unloading with a forklift.

1.3.- STORAGE

The following storage recommendations shall be followed for the static capacitor banks:

Avoid placing them on uneven surfaces.

Do not store them in outdoor areas, humid areas or areas exposed to splashing

water.

Avoid hot spots (maximum ambient temperature: 40 ºC)

Avoid salty and corrosive environments.

Avoid storing the units in areas where a lot of dust is generated or where the risk of

chemical or other types of contamination is present.

Do not place any weight on top of the unit cabinets.

Instruction Manual

7

Page 8

OPTIM EMS-C series

2.- PRODUCT DESCRIPTION

The purpose of this manual is to assist during the installation, start-up and maintenance of

OPTIM EM-C series low voltage (LV) capacitor banks with static switching operation. Carefully

read the manual to achieve the best performance from said units.

2.1.- CAPACITOR BANK COMPONENTS

From the electrical standpoint, the unit is made up of the following blocks:

2.1.1. FAST REGULATOR

The static capacitor banks are equipped with Computer Max 6f V12dc fast regulators, which

have static outputs, that is, instead of an output via relay contact, these regulators have a semiconductor-based switch, which enables them to perform operations in fast succession and in

practically every network cycle.

These outputs provide a 12 Vdc activation signal to the + and - inputs of the connection controller boards, as opposed to the CPC4 type zero voltage.

Fast regulators enable regulation with minimum delay, generally between 20 and 100 ms (See

the manual or quick guide of the specic regulator being used)

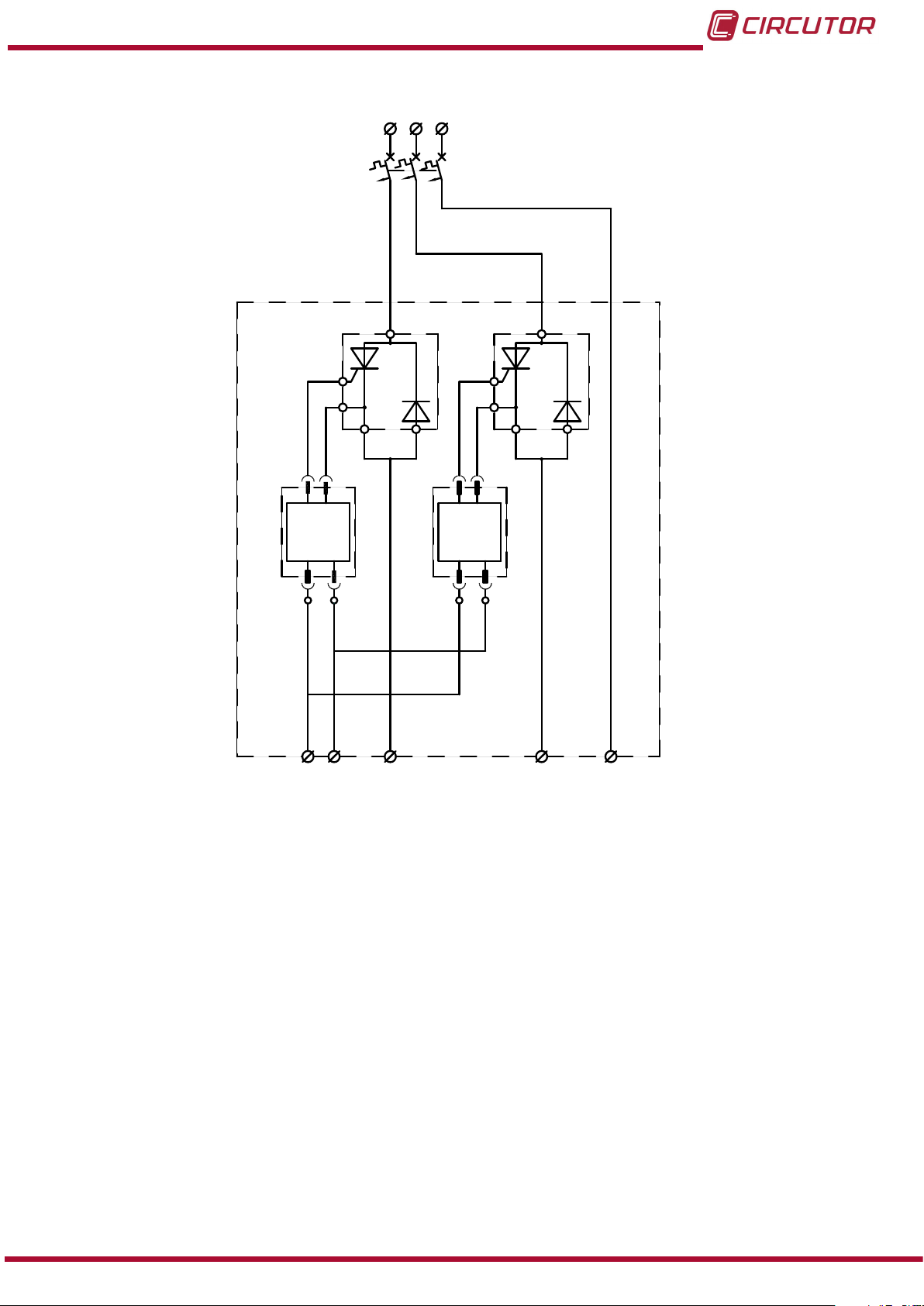

2.1.2. CPC4 BOARD: ZERO SWITCHING STEP CONNECTION CONTROL

The static capacitor banks come equipped with CP4 boards.

The role of the CPC panel is to control the zero switching step connection of the thyristor-diode

modules, and so avoid connection current transients.

The standard connection diagram of a step can be seen in Figure 3 and with more detail in

section “7.- OPTIM EMS-C TYPE DIAGRAM”.

The CPC panels are activated via a 12 Vdc signal supplied by the 6f V12dc Computer Max

regulator outputs. The standard CPC4 is ready for Umax = 440 V mains.

8

Instruction Manual

Page 9

Th-D 1

Q

Th-D 2

PPPC1

PPPC2

U2 V2 W2

1 3 5

2 4 6

U1

U2

1

32

4

5

Radiador

V1

V2

1

32

4

5

PLACA

1G1

+

-

CPC4

CONTROL

1K1

PLACA

1G1

+

-

CPC4

CONTROL

1K1

12VDC

12VDC

Mando

Alimentación Potencia

Conexión a Condensador de 3 Bornes

OPTIM EMS-C series

Figure 3: Basic connection diagram of the CPC4 to the power block.

2.1.3. POWER BLOCK

The power block of an OPTIM EMS-C unit consists of 2 to 4 groups of thyristor-diode semiconductors + three-phase capacitor + three-pole circuit breaker.

Each group is composed of a cylindrical capacitor with 3 terminals, 2 thyristor-diode modules

attached to a general heatsink and suitable protection elements for the module power (threepole circuit breaker).

Instruction Manual

9

Page 10

3.- INSTALLATION

3.1.- PRELIMINARY RECOMMENDATIONS

In order to use the unit safely, it is critical that individuals who handle it follow the

safety measures set out in the standards of the country where it is being used,

use the personal protective equipment necessary, and pay attention to the various warnings indicated in this instruction manual.

Installation or maintenance personnel should read and understand this manual

before operating the unit.

A copy of this manual should always be available to maintenance personnel for

reference purposes

Connecting the unit to the public mains must be carried out in compliance with

the EN-IEC60204-1 standard, regarding the safety of LV electrical installations.

OPTIM EMS-C series

It is recommended that several personnel are present when handling the unit for

installation or maintenance.

If damage or faults are detected during unit operation, or in circumstances that

compromise safety, immediately stop work in that area and disconnect the unit in

order to check it without voltage.

The manufacturer of the unit is not responsible for any damage resulting from failure by the

user or installer to heed the warnings and/or recommendations set out in this manual, nor for

damages resulting from the use of non-original products or accessories or those made by other

manufactures.

If an anomaly or malfunction is detected in the unit, do not use it to perform any operation.

Modifying, upgrading or rebuilding the unit without written authorisation from the

manufacturer is prohibited.

The installation, operation and maintenance of low voltage (LV) units must only

be carried out by authorised installers. LV regulations (Art. 22) specically dene

the requirements that authorised installers must meet.

10

Do not access the active elements of a capacitor bank with static operation that

has been powered and might have voltages present. Wait at least 5 minutes after the power supply has been disconnected.

Instruction Manual

Page 11

OPTIM EMS-C series

Do not touch the terminals or active parts of the unit until you have veried that

voltage is not present. If you have to handle or touch the terminals or other control

panel components, use adequately insulated personal protection equipment and

tools.

After any maintenance and before re-connecting the power supply to the unit,

check that its enclosure is properly closed and that no items or tools were left

inside that could cause a short-circuit.

Do not disconnect the current transformer secondary without short-circuiting it

rst. The operation of a current transformer with an open secondary will cause an

overvoltage that could damage it and electrocute the person handling it.

3.2.- PREPARATION

CIRCUTOR OPTIM EMS-C static capacitor banks come ready for easy installation and startup.

Remove the packaging of the unit and verify that its electrical features are suitable for connection to the available mains. To do so, check the features label located inside the cabinet next to

the regulator, see Figure 4 .

Key data to be checked:

Mains frequency and voltage, Un / fn.

Nominal power of the capacitor bank, Qn (kvar) and composition

Current consumption, I

. This current must be considered to select the proper size

max

of the power supply cable of the unit and ultimately the circuit breakers and protection

elements to be connected in front of it.

Environmental conditions. (See “6.- TECHNICAL FEATURES”)

Instruction Manual

Figure 4: Features label.

11

Page 12

460

710

542.7

110

76.7 306 160

160

200

OPTIM EMS-C series

3.3.- INSTALLATION LOCATION

It is important to maintain a minimum distance around the unit to facilitate cooling.

As it is a wall-assembled cabinet, use the three 10 mm diameter holes made in the rear of the

cabinet for wall mounting, as shown in Figure 5, use suitable xing elements for supporting its

weight.

In self-supporting cabinets, the back and front sides of the cabinet must be kept at least 60 cm

away from walls of other units and infrastructures to allow for ventilation.

As regards side walls, it is recommended leaving at least a 20 cm separation between adjacent

cabinets.

Note: Static units have an aluminium heatsink to cool the thyristors. Periodically clean these

heatsinks with a brush or with compressed air and ensure that they have maximum ventilation.

Make sure the unit can be accessed easily.

The environmental conditions of the location where the unit is installed must not exceed the

limits set forth in the technical features (See “6.- TECHNICAL FEATURES”)

To ensure proper ventilation, the unit must be installed in a vertical position.

In accordance with the LVR, once the unit is installed, the installation must be protected against

direct and indirect contacts. Therefore, a circuit breaker and earth leakage protection for the

capacitor bank power supply line should be installed.

Figure 5: Points for xing OPTIM EMS-C capacitor banks to the wall.

12

Instruction Manual

Page 13

OPTIM EMS-C series

3.4.-CONNECTION OF THE CAPACITOR BANK TO THE MAINS

Check that the rated voltage of the capacitor bank matches the voltage between

phases of the mains to which it is being connected.

For more information see section “3.2.- PREPARATION” and check the label for

the voltage value Un and the rated frequency fn of the EMS-C capacitor bank.

For feeding cables into the capacitor bank cabinet, always use the entry point

enabled for this purpose, located on the left side of the cabinet base (relative to

the front panel).

Do not cut holes in other parts of the cabinet for feeding cables through or for

installing support brackets.

It may produce trimmings that can cause short-circuits.

3.5.-POWER CIRCUIT

Connect input terminals L1, L2 and L3 (power circuit) to the mains using a cable with a suitable

cross-section, in accordance with the LVR, ITC-BT-19.

Generally, the cables of the phases are according to the following colour code: L1 (black), L2

(brown), L3 (grey).

To determine the size of the phase cables, the maximum nominal current I

label, and a transients overload of up to 1.5 times I

must be taken into account.

max

shown on the unit

max

Figure 6: Input terminals L1, L2, and L3 for the connection of the OPTIM EMS-C capacitor banks to the mains.

Instruction Manual

13

Page 14

OPTIM EMS-C series

3.6.- EXTERNAL ISOLATION AND PROTECTION ELEMENTS

The capacitor bank has a manual internal four-pole isolator, but it must be connected to a line

that is protected by a circuit breaker as well as earth leakage protection at the header, in accordance with Spanish Low-Voltage Electrotechnical Regulations (LVR) and depending on the

earthing system of the installation.

The protection elements, isolation switches and/or switches that are added externally to the capacitor bank must be of a minimum size to withstand a current 1.5

times greater than what is indicated on the label (LVR, ICT-BT-48)

If an earth leakage protection for the capacitor bank is installed, its sensitivity and

trip delay must be adjustable.

For capacitor banks equipped with a standard regulator that measures the current in a single

phase, we advise installing the current transformer (CT) in the phase connected to L1 (black

cable).

The CT S1 and S2 outputs must be connected to the terminals with the same name on the

capacitor bank.

For more details about the CT connection, see section “3.9.- CURRENT TRANSFORMER (CT)

CONNECTION”

3.7.- AUXILIARY CONTROL VOLTAGE

The standard model of the OPTIM EMS-C capacitor banks does not require auxiliary voltage

for control or operation.

3.8.- EARTH CABLE CONNECTION

Connect the earth terminal of the capacitor bank housed inside the operations panel of the

unit (see (Figure 7) to the exterior earth connection.

The earth cable cross-section must be selected in accordance with the admissible current

limits established in the LVR (ITC-BT-19 – Indoor or receiver installations).

14

Figure 7: Earth terminal for the connection to the external earth of the OPTIM EMS-C capacitor banks.

Instruction Manual

Page 15

OPTIM EMS-C series

3.9.- CURRENT TRANSFORMER (CT) CONNECTION

A current transformer (CT) outside the capacitor bank must be installed to

measure the total load current, plus that of the capacitor bank itself

(Figure 8).

The standard transformer must have a nominal output of 5 A at the secondary.

We recommend connecting the CT to phase L1 in the direction of the current ow

from P1 to P2 (Figure 8) and connecting the secondary (terminals S1, S2) to the

capacitor bank terminals with the same name (Figure 8).

Avoid the ow of current through the CT's primary before connecting the secondary to the S1 and S2 terminals of the capacitor bank.

If the CT must be installed while the installation is under load, short-circuit S1 and

S2 while they are not connected to the capacitor bank.

The current value of the CT primary winding must be equal to or slightly greater than the size of

the mains switch of the installation. Therefore, the CT must be able to measure the maximum

current expected to be consumed by all the loads being compensated.

Figure 8: Installation of the external current transformer (CT).

The connection point of the CT for a capacitor bank that compensates an entire installation is

after the mains switch of the installation.

To prevent excessive attenuation of the signal, it is recommended that the minimum cross-section of the secondary winding cable (terminals S1, S2) is at least 2.5 mm2.

Instruction Manual

15

Page 16

OPTIM EMS-C series

Figure 9: Current transformer (CT) connection terminals.

Once the cables are installed, disconnect the jumper connecting the S1 and S2 terminals of the

capacitor bank (Figure 10)

Figure 10: Jumper for short-circuiting the secondary winding of the current transformer (CT).

Any time you wish to change or disconnect a current transformer that is already

installed, it is important to install the jumper connecting S1 and S2.

16

Instruction Manual

Page 17

OPTIM EMS-C series

4.- STATIC CAPACITOR BANK START-UP

4.1.- BEFORE START-UP

The static capacitor banks include a power factor regulator.

Prior to start-up, the operation of said regulator must be known; for this reason, all capacitor

banks come with the specic manual of the regulator being used.

Ensure you have this manual available for the start-up process.

For the OPTIME EMS-C, the regulator must have a Computer Max 6f V12dc type, 12 Vdc

static output control voltage, or equivalent.

Carrying out the adjustment of the regulator incorporated in the capacitor bank,

and carrying out an optimum start-up, requires that the installation load be at least

30% or 40% of the nominal load for which the capacitor bank has been sized.

If all the stages are not arriving, the connection can be done manually to check

them all.

The entire capacitor bank should not be connected manually during low load

moments, because under certain circumstances it could produce resonance phenomena with the installation's power transformer.

4.2.- START-UP

Apply the safety regulations listed in section “3.- INSTALLATION” of this manual

before operating the units.

The National Electric Code of the country where the capacitor bank is installed or operated should be strictly followed.

1.- Ensure the internal two-pole circuit breaker that starts the regulator (shown in Figure 11) is

in place.

Instruction Manual

Figure 11: Two-pole circuit breaker of the regulator power circuit .

17

Page 18

OPTIM EMS-C series

2.- Connect the power supply to the panel and check that the regulator display illuminates immediately.

Otherwise, stop and check the previous step.

3.- Check the regulator's cos φ indication.

If the indication is out of the 0.5 to 1 range, it may be possible that the current transformer and

/ or the power supply to the regulator are improperly connected.

The Computer Max 6f 12Vdc regulator (Figure 12) uses a single current transformer.

Its connection is made as shown in Figure 13 (we recommend connecting the current transformer on phase L1 and drawing the voltage power supply from phases L2 and L3).

Figure 12: Computer Max Regulator (Photo for illustrative purposes, the model used in your unit may differ).

POWER

SUPPLY

400 V ac

L1

L2

L3

N

5

A B

S1 S2

P1 P2

Figure 13: Computer Max regulator connection.

-

- + C1 ... C6

3

1 2

6

4

0

C D

4.- Once ensured that the regulator is properly connected, adjust the regulator parameters for

the installation you are attempting to compensate.

For this, follow the instructions in the regulator manual or quick guide that comes with the capacitor bank.

18

Instruction Manual

Page 19

OPTIM EMS-C series

4.3.- CHECKS AFTER THE CAPACITOR BANK IS CONNECTED AND THE

REGULATOR ADJUSTED

1.- After start-up, make sure that the unit is operating correctly. A sign of proper operation after

the regulator's reaction time has passed is that the display shows a cos φ approaching 1, and

the reactive energy meter must stop.

2.- Check that the power supply voltage does not exceed the nominal value +10%

(IEC 60831-1).

3.- Check the current absorbed by each capacitor group.

Under normal working conditions, it must be close to the nominal values (See Table 5) and nev-

er more than 1.3 times this value continuously.

Continuous consumption in all the capacitors over the nominal value may be caused by the

presence of harmonics in the mains or an excessively high power supply voltage. Both circumstances are harmful for capacitors and control panels.

If there is unusual consumption in only some of the capacitors, it is a sign that there are damaged capacitors.

4.- In accordance with the IEC 60831-1 Standard, the capacitor is prepared to operate at the

permanent voltage assigned to it and with an overvoltage of up to 10% for 8 out of every 24

hours.

Check the working temperature of the capacitors after they have been operating

for 24 hours.

The capacitor capsule must be under 40 ºC.

Instruction Manual

19

Page 20

5.- MAINTENANCE

5.1.- SAFETY REGULATIONS

Take the safety regulations listed in section of this manual into account before

operating the units “3.1.- PRELIMINARY RECOMMENDATIONS”

The National Electric Code of the country where the capacitor bank is installed or

operated should be strictly followed.

5.2.- MAINTENANCE WITH THE CAPACITOR BANK DISCONNECTED

5.2.1. BASIC MAINTENANCE PROTOCOL

Monthly:

Visually inspect the capacitors.

OPTIM EMS-C series

Check the protection circuit breakers.

Control the ambient temperature (average of 30 ºC In accordance with IEC 60831 ).

Control the service voltage (especially during moments of low load, it must not exceed

the nominal +10%).

Bi-annually:

Keep the capacitor and reactor terminals clean.

Check that the thyristors are not short-circuited.

To do so, check that if you cut the power supply of the regulator there is no current in any

of the capacitor phases.

Check that the capacitor current is not lower than 75% nor greater than 120% of the

nominal value by phase and that there is no phase unbalance greater than 15%.

Annually:

Check the capacity of the capacitors at the different steps.

An indirect verication can be performed by checking that the consumption matches the

value indicated in Table 5, with a maximum deviation of ± 10%.

Check the tightening torque of all terminal connections on the different power ele-

ments.

20

Inspect the circuit breakers.

- Power Circuit: Check the continuity and temperature of the circuit breakers.

- Control Circuit: Check the continuity and temperature of the two-pole circuit breaker.

Instruction Manual

Page 21

OPTIM EMS-C series

5.2.2. TIGHTENING TORQUE OF THE ELECTRICAL CONNECTIONS

The connections must be tight.

The tightening torques for the fuse bases are indicated in Table 2.

Table 2:Torques for the power cables of the three-pole circuit breakers.

Circuit breaker Torque (Nm)

In ≤ 3 x 63 A 2

5.2.3. KEY POINTS FOR INSPECTING STATIC SWITCHES

Check that the plastic parts are not blackened and do not show signs of burning or hardening.

Check that the head is properly inserted.

Check the tightness of cables and terminals, as shown in Table 3.

Table 3:Torques of cables to semiconductors

Thyristor type Power cable connection torque (Nm)

IXYS 3.25

The terminals must be clean.

Cleaning: In dirty environments (dust, sawdust, metal trimmings, etc.). Vacuum the dust and

solid waste regularly.

There is no estimated time frame for cleaning, it depends on the amount of dirt that penetrates

the cabinet of the capacitor bank.

5.2.4. KEY POINTS FOR INSPECTING CAPACITORS

Inspect the cables and terminals. They should not be overheated or blackened.

The terminals must be clean.

Check the tightness of the capacitor terminals, as shown in Table 4.

Table 4:Torques of the cables to the capacitor terminals.

Capacitor Torque (Nm)

CLZ FP 2

5.2.5. KEY POINTS FOR INSPECTING THE REGULATOR

Check that the regulator does not show signs of deterioration and the display is lit as normal.

Inspect the cables and terminals. They should be clean and should not be hardened or over-

heated.

Check the connections.

Check that the terminals are tightened properly. The recommended torque is 0.6 Nm.

Instruction Manual

21

Page 22

OPTIM EMS-C series

5.2.6. CLEANING THE CABINET

Remove any solid particles.

Clean the inside of the cabinet.

Clean ventilation grilles.

5.3.- MAINTENANCE WITH THE CAPACITOR BANK CONNECTED

Check that the main switch turns on and off without having to force the mechanism.

If there is an individual earth leakage protection for the capacitor bank, check its proper

operation by pressing the test button.

Force the connection and disconnection of the capacitors in manual mode. (see the regula-

tor manual or quick guide before carrying out this operation) and perform the following checks:

▪ Check that the steps connect and disconnect properly.

▪ Check that there is no consumption in any phase with the step disconnected. If there is

consumption this means that some of the thyristors are defective and are short-circuited.

▪ Check the consumption of the different steps in each phase. The normal values are

shown in Table 5, in accordance with the power of each step.

Table 5:Nominal consumption of the capacitor paths, by power.

Power at 3 x 400 V In

2.5 kvar 3.6 A

5 kvar 7.2 A

7.5 kvar 10.8A

10 kvar 14.4 A

12.5 kvar 18 A

15 kvar 21.6 A

20 kvar 28.8 A

25 kvar 36 A

Note: When the consumption of the steps is 25% less than that stated in Table 5 and the voltage is within the tolerance limits, this is usually a sign of degradation of the capacitors. They

must be replaced with a suitable spare part if this is detected in a step.

22

Note: When the consumption of the steps is 10% more than the values stated in Table 5, this

may be caused by the presence of resonances. If this is detected, measure the THD of the

mains voltage (it should be below 5%).

Instruction Manual

Page 23

OPTIM EMS-C series

5.3.1. REGULATOR CHECKS

See the specic regulator manual or quick guide used for the capacitor bank. The

manual or quick guide is always provided with the capacitor bank

Make sure that there are no damaged segments on the display (abnormal brightness).

Make sure that the regulator's keyboard is working properly:

▪ Enter Setup and check the adjusted values.

▪ Force the manual connection and disconnection of a step.

Instruction Manual

23

Page 24

OPTIM EMS-C series

6.- TECHNICAL FEATURES

Electrical features

Working voltage and nominal frequency Un / fn, listed on the label

Design voltage Un+ 10% (440 V for 400V units)

Nominal power and distribution of steps Qn and composition, (see label)

Total losses Typical 1 W/kvar

Residual discharge voltage 75 V after 3 minutes

Overload capacity 1.3 in all the elements

Auxiliary voltage Uaux, listed on the label.

Current Transformer

Protections

Fuses

Capacitor features

Capacity tolerance ± 10%

Insulation level from earth 3 kV /50 Hz

Impulse test 15 kV , ray-type wave 1.2/50 µs

Protections Internal fuses and over-pressure system

In accordance with Standards UNE EN 60831

Environmental features

Maximum temperature of capacitors

Cabinet ventilation

Maximum relative humidity 80%

Maximum altitude 1000 m

Protection degree Marked on the label

Three-pole circuit breaker by stage, C curve.

Maximum during 1 h. 24 h average Annual mean

Natural for external temp. ≤ 40 ºC.

For external temp. of > 40 ºC the room where the capacitor

is installed must be cooled

Secondary winding 5 A, (Transformer In/5 A)

NOTE: Minimum cable section of 2.5 mm2.

Idc= 6 kA / 400 V

Category D in accordance with EN 60831-1

55 ºC 45 ºC 35 ºC

24

Mechanical features

Dimensions 545 x 710 x 220 mm

Maximum Weight 41 Kg.

Paint Epoxy type, oven-dried

Standard colours RAL 7035 Grey; RAL 3005 Maroon

Standards

Power capacitors. Low voltage power factor correction capacitor banks. UNE-EN 61921:2004

Industrial alternating current networks affected by harmonics. Use of

lters and shunt capacitors.

UNE-EN 61642:2000

Instruction Manual

Page 25

DENOMINACION

FECHA

UNIDAD DIM

ESCALA

APROBADO

DIBUJADO

NOMBRE

SUSTITUIDO POR

SUSTITUYE A

CODIGO

EQUIPO/S

07/10/2014

07/10/2014

L1L2L3

RG1

C1

3N

N

50 Hz 440 V3N

EMS-C-XXX-440

CON MANIOBRA ESTÁTICA

RED CARGA

50 Hz 400 V

TI .../5A

BATERIA AUT. CONDENSADORES

L1L2L3

Th-D 1

Q1

Th-D 2

C2

Th-D 3

Q2

Th-D 4

C3

Th-D 5

Q3

Th-D 6

C4

Th-D 7

Q4

Th-D 8

TB1

Q5

PPPC1

PPPC2

PPPC3

PPPC4

PPPC5

PPPC6

PPPC7

PPPC8

S1

C04 C04 C04 C04

400V

0V

S2

S1

cos

Paso 1

S1 S2

S1 S2

Regulador Automático

POWER

SUPPLY

Computer Max Fast 6

C4

C3

C2

C1

U1

U2

1

32

4

5

12

11

Radiador

700mm

V1

V2

1

32

4

5

Paso 2

U1

U2

1

32

V1

V2

1

32

4

5

Paso 3

U1

U2

1

32

V1

V2

1

32

4

5

Paso 4

U1

U2

1

32

V1

V2

1

32

4

5

4

5

PLACA

1G1

+

-

CPC

CONTROL

1K1

PLACA

1G1

+

-

CPC

CONTROL

1K1

PLACA

1G1

+

-

CPC

CONTROL

1K1

PLACA

1G1

+

-

CPC

CONTROL

1K1

PLACA

1G1

+

-

CPC

CONTROL

1K1

PLACA

1G1

+

-

CPC

CONTROL

1K1

4

5

PLACA

1G1

+

-

CPC

CONTROL

1K1

4

5

PLACA

1G1

+

-

CPC

CONTROL

1K1

-

* (Numeración bornes de Tiristor-Diodo (Th-D) correspondiente a modelo MCMA de IXYS)

(Versión salida 12VDC)

12VDC

12VDC

12VDC

12VDC

12VDC

12VDC

12VDC

12VDC

CIR_058

08232 Viladecavalls (Barcelona)

Vial Sant Jordi s/n

3x200-250A

3x16-63A

Icu=6kA/400VCA

3x16-63A

Icu=6kA/400VCA

3x16-63A

Icu=6kA/400VCA

3x16-63A

Icu=6kA/400VCA

2x16A

Icu=10kA/400VCA

OPTIM EMS-C series

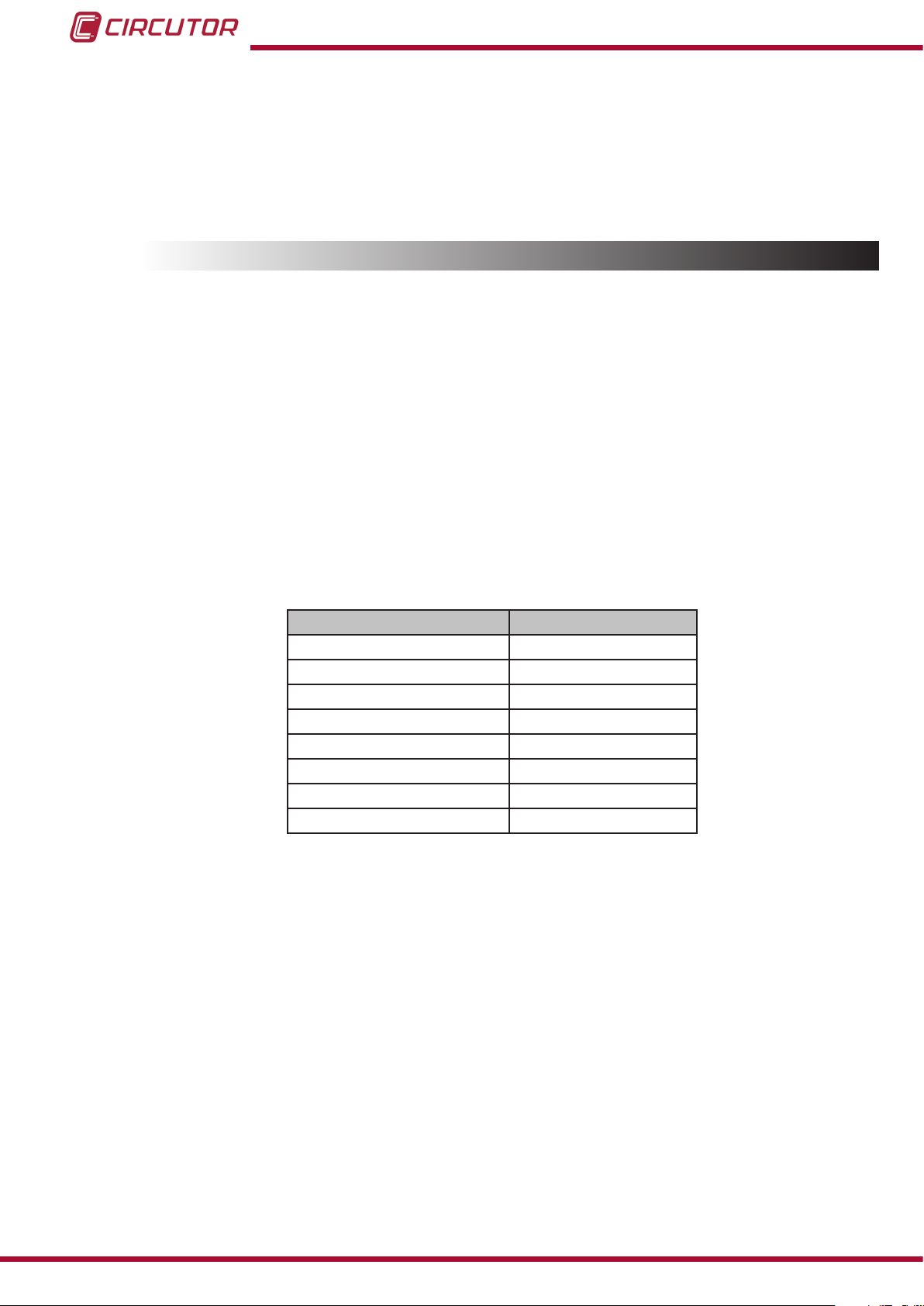

7.- OPTIM EMS-C TYPE DIAGRAM

Instruction Manual

Figure 14: OPTIM EMS-C diagram.

25

Page 26

OPTIM EMS-C series

8.- MAINTENANCE AND TECHNICAL SERVICE

In the case of any query in relation to unit operation or malfunction, please contact the

CIRCUTOR, SA Technical Support Service.

Technical Assistance Service

Vial Sant Jordi, s/n, 08232 - Viladecavalls (Barcelona)

Tel: 902 449 459 ( España) / +34 937 452 919 (outside of Spain)

email: sat@circutor.es

9.- GUARANTEE

CIRCUTOR guarantees its products against any manufacturing defect for two years after the

delivery of the units.

CIRCUTOR will repair or replace any defective factory product returned during the guarantee

period.

• No returns will be accepted and no unit will be repaired or replaced if it is not accompanied by a report indicating the defect detected or the reason for the return.

•The guarantee will be void if the units has been improperly used or the storage, installation and maintenance instructions listed in this manual have not been

followed. “Improper usage” is de ned as any operating or storage condition contrary to the national electrical code or that surpasses the limits indicated in the

technical and environmental features of this manual.

• CIRCUTOR accepts no liability due to the possible damage to the unit or other

parts of the installation, nor will it cover any possible sanctions derived from a possible failure, improper installation or “improper usage” of the unit. Consequently,

this guarantee does not apply to failures occurring in the following cases:

- Overvoltages and/or electrical disturbances in the supply;

- Water, if the product does not have the appropriate IP classi cation;

- Poor ventilation and/or excessive temperatures;

- Improper installation and/or lack of maintenance;

- Buyer repairs or modi cations without the manufacturer’s authorisation.

26

Instruction Manual

Page 27

OPTIM EMS-C series

10.- CE CERTIFICATE

Instruction Manual

27

Page 28

CIRCUTOR, SA

Vial Sant Jordi, s/n

08232 -Viladecavalls (Barcelona)

Tel.: (+34) 93 745 29 00 - Fax: (+34) 93 745 29 14

www.circutor.es central@circutor.es

Loading...

Loading...