Page 1

STEP AND TOUCH VOLTAGE TESTER

GROUND RESISTANCE

TESTER

MPC-20 (20 A) code 7 70 123

MPC-50 (50 A) code 7 70 075

INSTRUCTION MANUAL

( M98113601-20 / 03A )

(c)

CIRCUTOR S.A.

Page 2

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

2

1.- MPC-20 - MPC-50 .................................................................... 4

1.1 Usual operating procedure 4

1.2 Precautions whilst operating 5

2.- DESCRIPTION OF THE MAIN COMPONENTS ...................................... 6

2.1 Source of regulated voltage 6

2.2 Control and protection circuit 6

2.3 Voltage and current tester 6

2.4 Touch electrodes 6

2.5 Accessories 6

3.- CONTROL AND CONNECTION FEATURES OF THE MPC-20 / MPC-50 .... 7

3.1 Control Components 7

3.2

External connection components 7

3.3

Internal connection components 8

4.- MAIN FEATURES ............................................................................. 10

4.1.- Power supply 10

4.2.- Dimensions, weight:

5.1.1 Attaching the equipment 14

4.3.1 Features as a step and touch voltage tester. MPC-20 TESTER 11

4.3.2 Features as a step and touch voltage tester. MPC-50 TESTER 12

4.4.- Features as an ground resistance tester 13

5.- TESTING STEP OR CONTACT VOLTAGE............................................ 14

5.1 Installation and start-up 14

5.2 Attaching the MPC-20 / MPC-50 14

5.3 Auxiliary ground for current injection 14

5.4 Connecting the current circuit 16

5.5

Connecting the power supply 16

5.6

Setting the maximum default current 17

5.7

Attaching the testing electrodes 18

5.8

Button for testing erratic currents 18

5.9 Adjusting the current and testing the

STEP or TOUCH VOLTAGE 19

5.10

Test results 20

6.- TESTING GROUND RESISTANCE ..................................................... 21

6.1 Attaching and connecting the MPC-20 / MPC-50 22

6.2 Attaching the "MEASURING ROD" 22

6.3 Testing erratic voltages 22

6.4 Testing ground resistance 22

6.5 Test results 23

6.6 Repeating tests 24

Page 3

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

3

CHAPTER II

7.- EXISTING STANDARDS ................................................................... 25

7.1 Abstract and table of voltages 25

7.2 Standards relating to the MPC-20 / MPC-50 26

8.- CORRECTION OF THE READ OUTS .......................................................... 27

9.- MAINTENANCE............................................................................... 29

10.- TECHNICAL SERVICE ..................................................................... 29

Page 4

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

4

MPC-20 & MPC-50

1.- PRELIMINARY WARNINGS:

1.1.- USUAL OPERATING PROCEDURE

The MPC-20 and MPC-50 testers are compact and robust and are

designed to test where large powers are needed for a short period of time:

- MPC-20: up to 12 kVA

- MPC-50: up to 20 kVA

Its microprocessor controlled testing system ensures that tests are made

in approximately 10 seconds.

Its portability means that weight has been kept to a minimum with the

use of minimal loss toroidal transformers.

Heat generated by the transformer windings is continuously eliminated

by an in-built ventilation system. It is able to operate indefinitely, making 12 sec.

tests at 40 sec. intervals. If for any reason it overheats, a red indicator light will

show why and will prevent it from operating until normal temperature is reestablished.

Page 5

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

5

1.2.- WARNINGS!

THE CURRENT USED FOR MEASUREMENTS, 20 A with the MPC20 and 50 A in the MPC-50, IS SUFFICIENT TO CREATE SIGNIFICANT

VOLTAGES AROUND THE ELECTRODES, ESPECIALLY THE AUXILIARY

ELECTRODES.

PLEASE TAKE ALL NECESSARY PRECAUTIONS TO AVOID

ACCIDENTS.

For example: A 5 Ohms auxiliary electrode creates a voltage of 250 V around

itself.

VOLTAGE MAY REACH 600 V AROUND THE CABLE OUTPUT with the

MPC-20 and 400 V with the MPC-50.

THE POWER CIRCUIT CONNECTIONS MUST NEVER BE

HANDLED WITHOUT HAVING FIRST STOPPED THE EQUIPMENT AND

REMOVED THE OPERATING KEY.

BEFORE ANY MEASUREMENTS ARE TAKEN, SIGNS MUST

PREVENT PEOPLE FROM PASSING THROUGH OR REMAINING IN THE

INJECTED CURRENT AREA. IN THE EVENT OF HIGH GROUND

RESISTANCES, VOLTAGES UP TO 600 V MAY BE CREATED, WHICH ARE

FATAL TO ANIMALS OR PERSONS NEAR TO THE DISPERSERS DURING

TESTS.

Page 6

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

6

2.- DESCRIPTION OF THE MAIN COMPONENTS

2.1.- VOLTAGE SOURCE

MPC-20: voltage source, with 10 regulating scales using a switch and

fine adjustment using a dial. Supplies a regulable voltage between 0 and 600 V

and is set for a current of 20 A. It can test to 20 A in installations with a 30

Ohms resistance (ground and auxiliary added).

MPC-50: voltage source, with 8 regulating scales using a switch and fine

adjustment using a dial. Supplies a regulable voltage between 0 and 400 V and

is set for a current of 50 A. It can test to 50 A in installations with a 8 Ohms

resistance (ground and auxiliary added).

The remaining components are the same in each:

2.2.- CONTROL AND PROTECTION CIRCUIT

Button for testing erratic currents. Two directional selector key to control the

current injection (0º and 180º): Line voltage indicator. Over heating indicator.

Fuse protection for the operating circuit Protective circuit breakers for all the

equipment and for the output circuit.

2.3.- VOLTAGE AND CURRENT TESTER, controlled by micro-processor. It

test and also calculates Vp, Vc and Rt. The alphanumeric liquid crystal display

shows preset data, measurements and calculations.

2.4.- TOUCH ELECTRODES, that are cylindrical, 200 square cm at the base

and weigh 250 N, with carrying handles and terminals for connecting the testing

cables.

2.5.- ACCESSORIES. 50 metre cables, 10 mm in diameter with terminals for

current injection. 50 metre cables for voltage reading. Bridging cable to join the

two touch electrodes.

Page 7

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

7

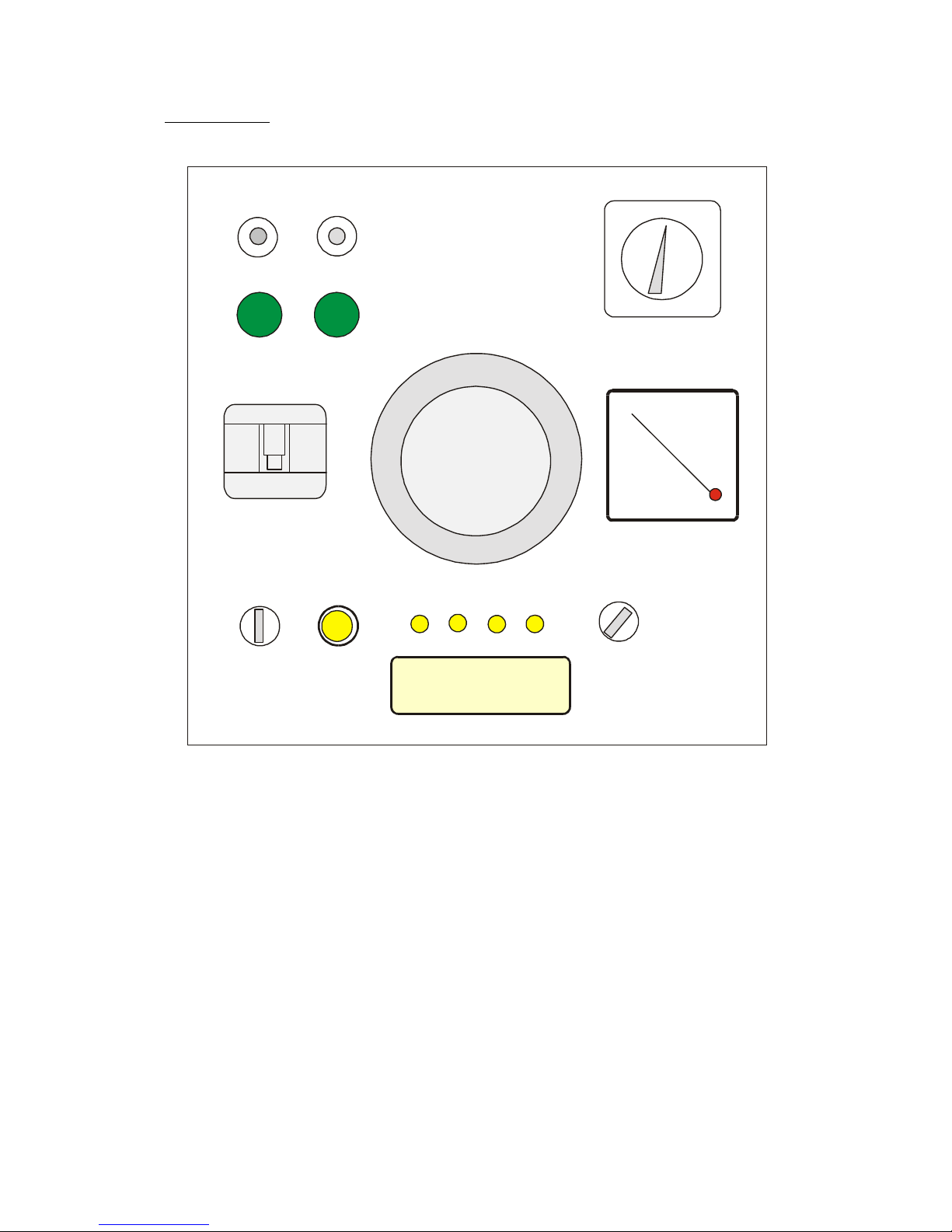

3.- CONTROL AND CONNECTION COMPONENTS OF THE MPC-20 & MPC-50

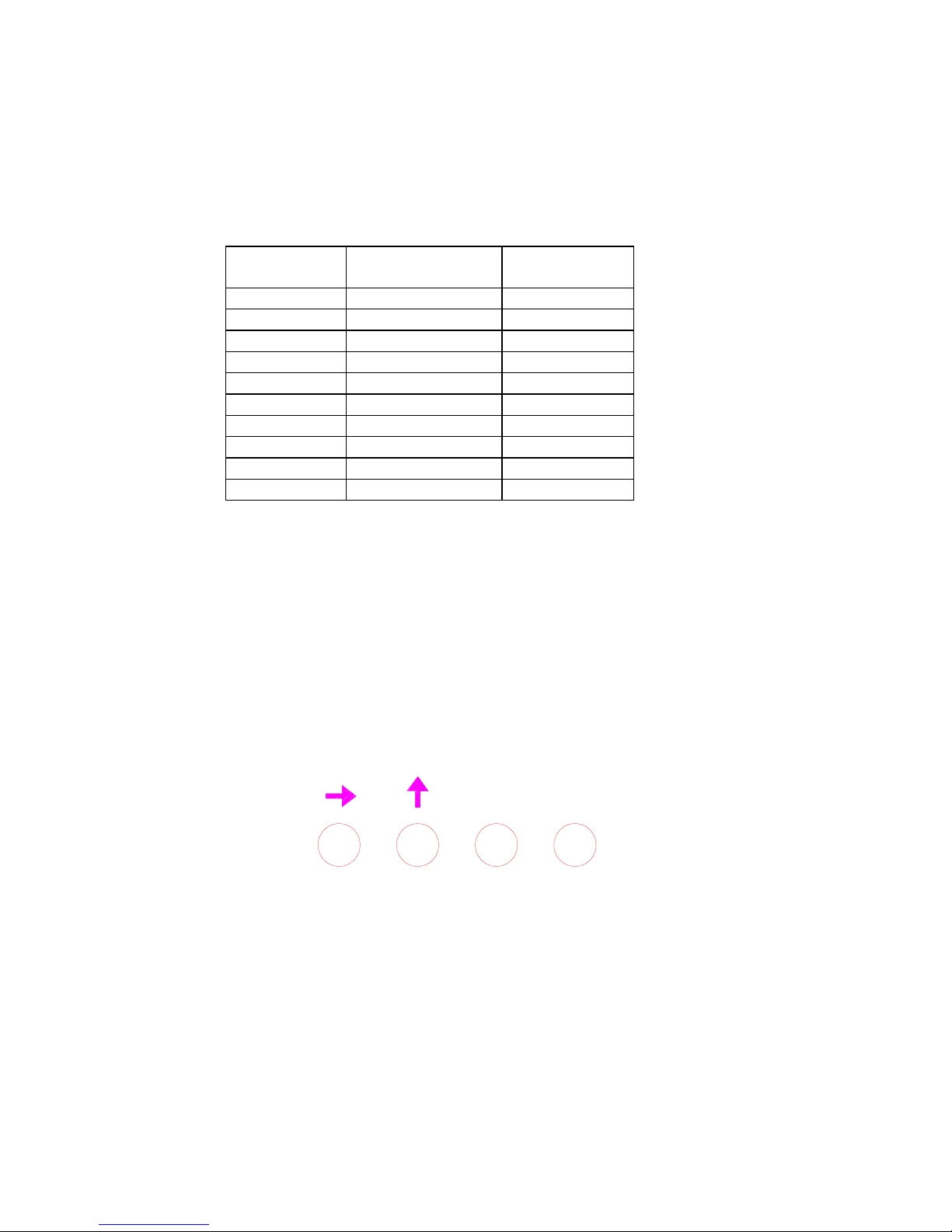

3.1.- CONTROL ELEMENTS

1 VOLTAGE OUTPUT SWITCH

MPC-20: FROM 1 TO 10

MPC-50: FROM 1 TO 8

Switch

Position

MPC-20 MPC-50

1 0 to 60 V 0 to 50 V

2 0 to 120 V 50 to 100 V

3 20 to 180 V 100 to 150 V

4 180 to 240 V 150 to 200 V

5 240 to 300 V 200 to 250 V

6 300 to 360 V 250 to 300 V

7 360 to 420 V 300 to 350 V

8 420 to 480 V 350 to 400 V

9 480 to 540 V

10 540 to 600 V

2 FINE REGULATION CONTROL (according to previous table)

3 RED TEMPERATURE INDICATOR

4 RED SYSTEM VOLTAGE INDICATING LIGHT

5 ANALOGUE AMMETER FOR ADJUSTMENT AND ASSISTANCE

6 GENERAL AND OUTPUT CIRCUIT BREAKER

7 SELECTOR WITH KEY OPERATE THE TEST

8 LIQUID QUARTZ DISPLAY

9 3 BUTTONS TO PRESET Imax VALUE

10 BUTTON TO SELECT OPERATING MODE (Vp/c or Rt)

11 BUTTON FOR ERRATIC VOLTAGE MEASUREMENTS

999

999999

999

ENTER

ENTERENTER

ENTER MODE

MODEMODE

MODE

3.2.- EXTERNAL CONNECTION COMPONENTS

12 OUTPUT TERMINALS: MAX 50 A, MAX 600 V

13 VOLTAGE INPUT TERMINALS TO THE VOLTMETER

Page 8

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

8

3.3.- INTERNAL CONNECTION COMPONENTS

MPC-20:

30 AND 31 SINGLE PHASE POWER SUPPLY: 230 V

T.T TERMINAL WITH OBLIGATORY EARTHING CONNECTION

MPC-50:

30 AND 32 SINGLE PHASE POWER SUPPLY: 400 V

30 AND 31 SINGLE PHASE POWER SUPPLY: 230 V (EXCEPTIONAL)

T.T TERMINAL WITH OBLIGATORY EARTHING CONNECTION

SIZE:

Page 9

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

9

Control panel:

999-> 999 ENTER ESC

RT-VPC

0º OFF 180º

(LLAVE)

ERRATICAS

ENTRADA TENSION

Vm

PILOTO RED

PILOTO TERMICO

CONMUTADOR DE

SALIDAS 1 AL 8

1

2

0

50

A

MPERIMETRO

INT. GENERAL

DISPLAY

VOLTAGE INPUT

CIRCUIT BREAKER LIGHT

SYSTEM LIGHT

GENERAL SWITCH

AMMETER

OUTPUT 1 TO 8

SWITCH

ERRATICS

(KEY)

Page 10

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

10

4.- MAIN FEATURES

4.1.- POWER SUPPLY

POWER SUPPLY MPC-20 MPC-50

VOLTAGE

FREQUENCY

MAXIMUM CURRENT

CIRCUIT BREAKER

POWER SUPPLY CABLE

MAXIMUM POWER

230 ± 10 %

SINGLE PHASE

50 / 60 Hz

54 A

100 A

2 X 10 + 6 T.T.

12 kVA

400 ± 10 %

SINGLE PHASE

230 V exception

50 / 60 Hz

57 A to 400 V

(95 A to 230 V)

100 A

2 x 16 + 16 T.T.

20 kVA

4.2.- SIZES AND WEIGHT

SIZES:

HEIGHT 800 mm

WIDTH 550 mm

LENGTH 500 mm

WEIGHT: 142 Kg WITHOUT ELECTRODES

ELECTRODE SIZES:

HEIGHT 210 mm APPROX.

DIAMETER 160 mm APPROX.

WEIGHT: 25.5 Kg EACH

Page 11

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

11

4.3.- TESTING STEP AND CONTACT VOLTAGE

4.3.1.- MPC-20 TESTER

CURRENT 0 ÷ 20 A REGULABLE

OVERVOLTAGE 1, 1 In, 1 Min

VOLTAGE 0 ÷ 600 V,

10 SCALES AND FINE ADJUSTMENT

MAX. RESISTANCE 30 OHMS (GROUND TESTED + AUXILIARY

GROUND)

RESISTANCE OF

HIGHER VALUES

ALLOWS TESTING AT LOWER CURRENTS

METHOD USED INJECTION AND TESTING OF CURRENT

(Ip)

TESTING VOLTAGE IN SURFACE AREA

(Vm)

DEFAULT SETTING Imax

CALCULATES: Vp/c=Vm xMax/Ip

ANALOGUE AMMETER CLASS: 1.5

RANGE: 20 A

DIGITAL AMMETER CONTROLLED BY MICROPROCESSOR

ACCURACY: 0.5 % MEASUREMENTS ± 2

digits

MAX. : 99.9 A

RESOLUTION : 10 mA

MINIMUM READING : 20 mA

DIGITAL VOLTMETER CONTROLLED BY MICROPROCESSOR

SCALES : 30 V and 600 V

SCALE CHANGE : AUTOMATIC

ACCURACY: 0.5 % MEASUREMENTS ± 2

digits

MINIMUM READING : 20 mV

IMPEDANCE CUR. : 1000 ohms or 600

kohms (switch)

RESOLUTION : 10 mV

MAX. PROGRAMMABLE

CURRENT VALUE

9999 A

SELECTION OPERATING

MODE (Vp/c or Rt)

BY BUTTON (MODE) + Rt/Vp-c Selector

DEFAULT CURRENT

PRESELECTION

BY BUTTONS

TESTING ERRATIC

VOLTAGES

VOLTMETER CONTROL BY BUTTON

CONTROL OF STOP AND

START

BY SELECTOR WITH KEY:

ON 0°--- OFF --- ON 180º

Page 12

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

12

4.3.2.- TESTING STEP AND CONTACT VOLTAGE: MPC-50 TESTER

CURRENT 0 ÷ 50 A REGULABLE

OVERVOLTAGE 1, 1 In, 1 Min

VOLTAGE 0 ÷ 400 V,

8 SCALES AND FINE ADJUSTMENT

MAX. RESISTANCE 8 OHMS (GROUND TESTED + AUXILIARY

GROUND)

RESISTANCE OF

HIGHER VALUES

ALLOWS TESTING AT LOWER CURRENTS

METHOD USED INJECTION AND TESTING OF CURRENT

(Ip)

TESTING VOLTAGE IN SURFACE AREA

(Vm)

DEFAULT SETTING Imax

CALCULATES: Vp/c=Vm x Max/Ip

ANALOGUE AMMETER CLASS : 1.5

RANGE : 50 A

OVERRANGE : 300 A

DIGITAL AMMETER CONTROLLED BY MICROPROCESSOR

ACCURACY: 0.5 % MEASUREMENTS ± 2

digits

MAX. : 99.9 A

RESOLUTION : 10 mA

MINIMUM READING : 20 mA

DIGITAL VOLTMETER CONTROLLED BY MICROPROCESSOR

SCALES : 30 V and 500 V

SCALE CHANGE : AUTOMATIC

ACCURACY: 0.5 % MEASUREMENTS ± 2

digits

MINIMUM READING : 20 mV

IMPEDANCE CUR. : 1000 ohms or 600

kohms (switch)

RESOLUTION : 10 mV

MAX PROGRAMMABLE

CURRENT VALUE

9999 A

SELECTION WORK

MODE (Vp/c or Rt)

BY BUTTON (MODE) + Rt/Vp-c Selector

DEFAULT CURRENT

PRESELECTION

BY BUTTONS

TESTING ERRATIC

VOLTAGES

VOLTMETER CONTROL BY BUTTON

CONTROL OF STOP AND

START

BY SELECTOR WITH KEY

ON 0°-- OFF --- ON 180º

4.4.- TESTING GROUND RESISTANCES

(USING CURRENTS UP TO 20 A or 50 A)

Page 13

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

13

METHOD USED INJECTION AND TESTING OF CURRENT

MPC-20 : 0 ÷ 20 A

MPC-50 : 0 ÷ 50 A

TESTING VOLTAGE BETWEEN GROUND AND NEUTRAL AREA

(Vm)

CALCULATES: Rt.=Vm/Ip

ELECTRODES NEEDED GROUND TO MEASURE

DISTANT AUX ELECTRODE

"ROD" ELECTRODE FOR TAKING

VOLTAGE

MAXIMUM ERROR 3 % OF MEASUREMENTS ± 2 digits

DIGITAL AMMETER CONTROLLED BY MICROPROCESSOR

ACCURACY: 0.5 % MEASUREMENTS ± 2

digits

MAX. : 99.9 A

RESOLUTION : 10 mA

MINIMUM READING : 20 mA

DIGITAL VOLTMETER CONTROLLED BY MICROPROCESSOR

RANGES : 30 V and 500 V

RANGE CHANGE : AUTOMATIC

ACCURACY: 0.5 % MEASUREMENTS ±

2 digits

MINIMUM READING : 20 mV

IMPEDANCE CUR. : 600 kohms

RESOLUTION : 10 mV

SELECTION WORK

MODE (Vp/c or Rt)

BY BUTTON (MODE) + Rt/Vp-c Selector

TESTING ERRATIC

VOLTAGES

VOLTMETER CONTROL BY BUTTON

CONTROL OF STOP

AND START

BY SELECTOR WITH KEY

ON 0°-- OFF --- ON 180º

Page 14

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

14

5.- TESTING STEP OR CONTACT VOLTAGE

5.3.- INSTALLATION AND START-UP

This manual contains information and warnings that must be followed by the

user to ensure the safe operation of the equipment and to maintain it in a safe

condition.

Usual operation must not be started until the final assembly of the cables

and weights, as recommended in section 1.2.- Connection instructions of this

manual.

If the equipment is used in a way not specified by the manufacturer, the

protection of the equipment and the people operating it may be

compromised.

When it is likely that there has been a loss of safety (e.g. when damage is

visible), the equipment must be disconnected from the power supply. In the

event please contact a qualified service representative.

5.4.- ATTACHING THE MPC-20/ MPC-5

To test correctly, the MPC-20 or the MPC-50 must be placed 20 or more

metres from the ground to be tested. Do not place it in the area occupied by the

electrodes in the ground.

5.5.- AUXILIARY GROUND FOR CURRENT INJECTION

There must be auxiliary ground for current injecting 50 or more metres away

from the ground to be tested Resistance between the auxiliary ground added to

the ground to be measured must not exceed 8 ohms for the MPC-50 and 30

Ohms for the MPC-20.

-----------------------------------------------------------------

Page 15

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

15

DIAGRAM FOR TESTING STEP VOLTAGE

-----------------------------------------------------------------------------------------------------------

DIAGRAM FOR TESTING CONTACT VOLTAGE

GROUND

TO BE

TESTED

1 metre

Tested

voltage

L (minimum 20

metres)

Test intensity lp

AUXILIARY

GROUND

L (minimum 20 metres)

GROUND

TO BE

TESTED

Metal parts

Tested

voltage

L (minimum 20

metres)

Test intensity lp

AUXILIARY

GROUND

Page 16

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

16

5.6.- CONNECTING THE CURRENT CIRCUIT

ENSURE THAT THE SELECTOR (ON-OFF-ON) ON THE

MPC-20 & MPC-50 IS DISCONNECTED AND WITHOUT THE KEY.

Connect the "OUTPUT CABLES": to the ground to be measured and the

other to the auxiliary ground.

5.7.- CONNECTING THE POWER SUPPLY

5.7.1.- POWER SUPPLY FOR THE MPC-20:

Connect the supply cable to a 230 V II+TT system or an independent

generator with the same VOLTAGE.

5.7.2.- POWER SUPPLY FOR THE MPC-50:

Connect the supply cable to a 400 V II+TT system or an independent

generator with the same VOLTAGE (As an exception the MPC-50 may be

connected to 230 V).

Page 17

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

17

5.8.- SETTING THE MAXIMUM DEFAULT CURRENT

Once the connections described above have been made and after taking

SAFETY MEASURES, testing can be done in the following way:

Place the regulator on the "0%" position.

Place the Voltage switch on position "1".

CONNECT THE MPC SWITCH. The model type and the version of the

setting will appear on the display.

Place the "OPERATING MODE" selector on "V p/c".

(Connect the 1000 Ohms resistance switch located on the back of the

equipment: voltmeter internal impedance of 1000 Ω).

PRESS the upper right "MODE" button (operating mode) and the display is

ready to start testing voltage ("V") or resistance ("Rt"). Use the said button to

select "V" on the display.

MAXIMUM CURRENT must be entered as preset in the installation

procedure. The value in A of the maximum current must be entered as a testing

constant. This value must be supplied by the electricity supply company

according to MIE-RAT-19.

Using the 3 buttons above the display, (, and Enter), SET THE

MAXIMUM DEFAULT CURRENT (maximum 9999):

a.- To enter setting, press () . The first lx digit will flash.

b.- To enter or change this value press ( ) repeatedly: the digit flashing

at that time will increase.

c.- When the required value appears on the screen move on to the next

digit by pressing (), and so on changing the remaining values.

d.- To enter press (Enter) button.

Page 18

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

18

5.9.- ATTACHING THE TESTING ELECTRODES

- Attach the touch electrodes (25 kg weights) in a suitable place to start

testing:

STEP VOLTAGE

Attach the two touch electrodes 1 metre apart and near to the ground to be

tested. Each electrode are joined by a different cable from the voltmeter.

TOUCH VOLTAGE

Attach the two electrodes together 1 metre from the vertical of the tested

object, both connected by a single cable from the voltmeter. The other

voltmeter cable is connected to the tested object with a crocodile clip.

NUMBER OF TESTS

To ensure that there are no dangerous step or touch voltages, it is

necessary to take many measurements within the test area as well as on

neighbouring land. To do this, it is useful to have a plan of the installation with

distances of 1 metre marked on it.

Whilst testing touch voltage, one must be aware of the possible transmission of

dangerous voltages away from the ground electrode via long metallic structures

(metal fences, pipes, rails etc). Testing must be done further away from these

conductive devices.

5.10.- TESTING VOLTAGES DUE TO STATIC CURRENTS

Prior to starting, press the "ERRATIC VOLTAGES" button (keeping it

pressed down).

If the Vm value remains at 0 V the presence of erratic voltages and

currents will be ruled out. If any value appears, it must be noted to

subsequently compare it with the 20 A and 50 A measurements and to

make the appropriate numerical corrections).

(See section 8 "CORRECTING READ OUTS").

Page 19

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

19

5.11.- ADJUSTING THE CURRENT AND TESTING OF STEP OR TOUCH

VOLTAGE

Turn the key in one of the two directions and keep it there.

BEFORE TURNING THE SELECTOR MAKE SURE THAT NO ONE IS

USING THE POWER OR TESTING CIRCUIT. PREVENT PEOPLE

REMAINING OR PASSING THROUGH THE AREA WHERE THE CURRENT

IS TO BE INJECTED BY USING THE APPROPRIATE SIGNS. IN THE EVENT

OF HIGH GROUND RESISTANCES, VOLTAGES UP TO 600 V MAY BE

CREATED, WHICH ARE FATAL TO ANIMALS OR PERSONS NEAR TO THE

DISPERSERS DURING TESTS.

Adjust the current to 20 A with the MPC-20 and 50 A or slightly higher

for the MPC-50:

FINE REGULATOR:

Starting with the switch on position "1", slowly turn the fine regulator towards

the right (from 0% to 100%). To find out the current being injected, the needle

on the analogue ammeter is the guide at first and then the read out lp. on the

digital indicator.

SWITCHING SCALES:

If the nominal current is not reached, even with the regulator on 100%, it will

then be necessary to increase the switch regulation by one scale.

Adjustments are done by trial and error between the different regulation

scales, starting with the lowest: 1 to 10 on the MPC-20 and from 1 to 8 on the

MPC-50. Switching from one scale to another is always done “off line”, i.e.

without turning the selector key and placing the regulator in the 0% position.

Voltage testing will be done AUTOMATICALLY at the same time as

the MPC-20 or MPC-50 are adjusted with the operating key. (The voltmeter

begins testing when the key is turned and blocks measurements when the key

is no longer turned.)

Page 20

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

20

READ TESTED VOLTAGE (V) on the display.

Note: If the read out on the display is less than 30 V the internal scale is

automatically changed to 30 V AC.

DISENGAGE THE OPERATION SELECTOR. Once the test has

finished the values remain displayed until the key is turned again, the

equipment is switched off or the Imax value is set again.

5.12.- TEST RESULTS (THAT WILL REMAIN DISPLAYED)

Real current Maximum current

of the test made

Im. NN,N I x. NNNN

default theory

Voltage tested

during the test

Vm. NN,N V NNNNN

Calculated voltage

default theory

(step or touch)

Vm x Ix

STEP VOLTAGE (Vp) : V = ------------------- Im

Vm x Ix

TOUCH VOLTAGE (Vc) : V = ---------------------

Im

Page 21

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

21

6.- TESTING GROUND RESISTANCE

The main advantage of testing ground resistance using high currents is

that as well as being measured, the ground is also being tested to see if it is

capable of accepting such a current. By doing it this way, one avoids errors of

measurement from low currents due to, for example, surface moisture or a

highly corroded cable or one with defective lining.

CONNECTION DIAGRAM

TESTED

VOLTAGE

TESTING

ROD

TESTING GROUND RESISTANCE

GROUND TO

BE TESTED

AUXILIARY

GROUND

TEST INTENSITY lp

Page 22

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

22

6.3.- ATTACHING AND CONNECTING THE MPC-20 or MPC-50

The "OPERATING MODE" selector must be placed on Rt.

Attaching and connecting the MPC to the system is the same as that

for testing step and touch voltage.

Connecting the current circuit using the two output sockets is also the

same.

6.4.- ATTACHING THE MEASURING ROD

One of the voltmeter cables is connected to the ground to be

measured.

The other voltmeter cable is connected to the GROUND using the

"MEASURING ROD" in an area in between the ground to be measured and the

auxiliary ground.

6.5.- TESTING VOLTAGES DUE TO ERRATIC CURRENTS

Prior to starting, press the "ERRATIC VOLTAGES" button (keeping it

pressed down).

If the Vm value remains at 0 V the presence of erratic voltages and

currents will be ruled out. If any value appears, it must be noted to be

subsequently compared with the 20 A and 50 A measurements and the

appropriate numerical corrections made).

(See section 8 "CORRECTING READ OUTS").

6.6.- TESTING GROUND RESISTANCE

If testing has to be done at 20 A (MPC-20) or at 50 A (MPC-50),

adjustments are made according to section 11.3.2.

If testing has to be done with currents below 20 A or 50 A respectively,

the adjustment is also done by trial and error between the different regulation

scales starting with the lowest (1, 2, 3, ...). Switching from one scale to another

is always done “off line”, i.e. without turning the selector key (according to

section 11.3.2.).

Page 23

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

23

Measurements are taken automatically on turning the key (the

voltmeter and the ammeter begin testing on turning the key and block

measurements when the key is no longer turned).

BEFORE TURNING THE SELECTOR MAKE SURE THAT NO ONE

IS USING THE POWER OR TESTING CIRCUIT.

READ TESTED VOLTAGE (V) on the display.

Note: If the read out on the display is less than 30 V the internal scale is

automatically changed to 30 V AC.

DISENGAGE THE OPERATION SELECTOR Once the test has

finished the values remain displayed until the key is turned again, the

equipment is switched off or the equipment is disconnected.

The MPC-5 will automatically calculate resistance and store the

results.

6.7.- MEASUREMENT RESULTS (THAT WILL REMAIN DISPLAYED)

Real current

of the test made

Im. NN,N Rt :

Voltage tested

during the test

Vm. NN,N NNN.N

Calculated ground

resistance

Rt.= Vm./Im.

Ensure that the measuring electrode is actually testing the voltage drop in

the ground that is being tested which is a consequence of the current injected

by the MPC itself. Placing the measuring electrode in the right position is vital. It

is important that it is far from the area under the influence of both the

measuring electrode and the auxiliary electrode to obtain maximum accuracy.

Page 24

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

24

6.8.- REPEATING TESTS

Ensure that the measuring electrode is actually testing the voltage drop in

the ground that is being tested which is a consequence of the current injected

by the MPC itself. Placing the measuring electrode in the right position is vital. It

is important that it is far from the area under the influence of both the

measuring electrode and the auxiliary electrode to obtain maximum accuracy.

It is advised that the measuring rod is moved +10% and then -10% from its

starting position along the axis formed by the earthing and the auxiliary

electrode separated by a distance L (if its position L=20 metres, it is to be

moved 2 metres from its original position). Make a note of the resistance value

for each position of the rod. If the values are the same or vary slightly the

measurement is correct. On the other hand if it is within the area influenced by

the two power slopes. The distance between the ground to be measured and

the auxiliary ground has to be increased.

Page 25

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

25

CHAPTER II

7.- EXISTING STANDARDS

7.3.- SUMMARY OF HIGH VOLTAGE REGULATIONS

The Technical Complementary instruction MIE-RAT-13 published in the

B.O.E. (Official State Gazette) 183 of 1st August 1984, section 1.1. sets the

maximum admissible step and touch voltages for EARTHING

INSTALLATIONS.

In sections 8.1 and 8.2 it establishes the requirement to verify that the

step and touch voltages are within the admissible limits. It establishes the

requirement for periodical checking every 3 years as a maximum. It lays down

that the measuring electrodes that simulate feet must have a surface area of

200 square cm each and that they each have a downward force onto the

ground of 250 N.

STEP VOLTAGE

-The voltage that can occur between the feet of somebody standing one

step away whilst the installation is operating" (I.E.C. standard 11-8, sec.176).

TOUCH VOLTAGE

-The voltage that a human body may experience whilst in contact with

housings and metallic structures that normally do not carry voltages.

MAXIMUM ADMISSIBLE VOLTAGES

- Maximum admissible step and touch voltages in a certain installation,

(B.O.E. 291 5-12-87), are determined by the following summarised formulae:

10 K K

Vp = -------------- Vc = -----------

t

n t n

Being:

K=72 and n=1 for times less than 0.9 s.

K=78.5 and n=0.18 for times between 0.9 and 3 s.

t = length of the fault in seconds.

For times between 3 and 5 seconds the touch voltage will not exceed 64

V and the step voltage 640 V.

For times above 5 seconds touch voltage will not exceed 50 V and step

voltage 500 V.

Page 26

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

26

SUMMARY TABLE OF MAXIMUM VOLTAGES

TIME MAXIMUM STEP

VOLTAGE

VOLTAGE TOUCH

VOLTAGE

Over 5 s 500 V * 50 V

From 3 to 5 s 640 V 64 V

2 s 690 V 69 V

1 s 785 V 78.5 V

0.9 s 800 V 80 V

0.7 s 1020 V 102 V

0.5 s 1440 V 144 V

0.2 s 3600 V 360 V

0.1 s or less 7200 V 720 V

* Supposes that the real step voltage on the human body is less than that

measured (shoes, etc.).

7.4.- STANDARDS REFERRING TO THE MPC-20 / MPC-50

MIE-RAT-01

MIE-RAT-13

MIE-RAT-19

BOE 183 1st August 1984

BOE 291 5th December 1987

Page 27

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

27

8.- CORRECTING THE READ OUTS

Results from testing touch or step voltages may be incorrect due to the

existence of erratic, vagabond or parasite currents passing through the ground.

The B.O.E. 291, of 5 of December of 1987 establishes:

1.1.12 "... unless a test method is used that eliminates the effect (in testing)

of these parasite currents, e.g. polarity inversion, it will mean that the injected

current will be 1% of the current set for the installation and will not be less than

50 A for stations and substations and 5 A for transforming stations."

As a result of currents not indicated by the B.O.E. being used, it will be

necessary to use phase inversion for testing.

It is also found that in practice, the tested erratic voltages are always

negligible in terms of those created by injected currents (as long as they

conform to the set minimum).

However, in certain cases it will be possible to do a pretest on existing

voltages without injecting a current. To do this tests by pressing "Erratic

voltages" are done. Only when measurements of erratic voltages are above

10% of measurements with current injection, the following calculation must be

made:

Vp =

(º)( º)

()

VV

Ve

0 180

2

22

2

+

−

Vp = Step or touch voltage

Ve = Voltage tested "ERRATIC VOLTAGES"

V0° = Voltage tested "ON 0°"

V180° = Voltage tested "ON 180°"

Page 28

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

28

DERIVATION OF THE FORMULA FOR STEP AND CONTACT VOLTAGE

The following equations are derived from the graph:

V Vp Ve ß Ve ß1

222

=+× +×( sen ) ( cos )

Vp Ve ß Ve ß2

222

=−× +×( sen ) ( cos )

Developing the equations:

Vp Vp Ve ß Ve ß Ve ß12

22 2222

=+×× +× +×sen sen cos

Vp Vp Ve ß Ve ß Ve ß22

22 2222

=− ×× +× +×sen sen cos

If the two equations are added, we have to:

V VpVe ß ß VpVe1222 22

22 222 2 22

+= + + = +(sen cos )

Solving Vp: Vp =

() ( )

()

VV

Ve

12

2

22

2

+

−

V1 = read voltage on injecting current at 0º

V2 = read voltage on injecting current at 180º

Ve = read voltage without injecting current

Page 29

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

29

9.- MAINTENANCE

The MPC does not require specialised maintenance. As far as possible

avoid any adjustment, maintenance or repairs when the equipment is open. If

this is unavoidable it must be done by qualified personnel or technicians well

informed of the procedure to follow.

Before any modification to the connections, replacement, maintenance or

repair, the equipment must be disconnected from the supply.

If any operating fault or equipment protection fault is suspected, the

equipment must be taken out of service ensuring that no accidental

reconnection may occur. The equipment is designed to have any of its

components replaced quickly in the event of breakdown.

10.- TECHNICAL SERVICE

In the event of any equipment failure or any operational queries please

contact the technical service of CIRCUTOR S.A.

CIRCUTOR S.A. - After sales service

c / Lepanto , 49

08223 - TERRASSA

tel - (+34) 93 - 745 29 00

e-mail: central@circutor.es

Page 30

--- MPC 20 & 50 TESTER - M-981136 (vers. BD) --- Page

30

APPENDIX

MPC-50 INTERNAL TERMINAL BOARD

FUSIBLE

MANIOBRA

400 V 230 V

CAMBIO DE

TENSIÓN

CHANGE OF VOLTAGE:

- Attach the voltage bridge in the required position

- Attach the indicating tag on the external supply cable

OPERATING

FUSE

CHANGING

VOLTAGE

Loading...

Loading...