Page 1

Active multi-function filt er

AFQ-4W-25 AFQ-4W-100

AFQ-4W-50 AFQ-4W-150 AFQ-4W-200

USER MANUAL

(M98241701-03-13B)

Page 2

AFQ-4W

2 Instruction Manual

Page 3

AFQ-4W

Incorrect handling or installation of the unit may result in injury to personnel as well

Refer to the instruction manual before using the unit.

SAFETY PRECAUTIONS

Follow the warnings described in this manual with the symbols shown below.

DANGER

Warns of a risk, which could result in personal injury or material damage

ATTENTION

Indicates that special attention should be paid to a specific point.

If you must handle the unit for its installation, start-up or maintenance, the

following should be taken into consideration:

as damage to the unit. In particular, handling with voltages applied may result in

electric shock, which may cause death or serious injury to personnel. Defective

installation or maintenance may also lead to the risk of fire.

Carefully read this manual before connecting the unit. Follow all installation and

maintenance instructions throughout the unit's operating life. Pay special attention

to the installation standards of the National Electrical Code.

.

In this manual, if the instructions marked with this symbol are not respected or

carried out correctly, it can result in injury or damage to the unit and /or

installations

CIRCUTOR, SA reserves the right to modify features or the product manual without prior notification.

.

DISCLAIMER

CIRCUTOR, SA

reserves the right to make modifications to the device or the

unit specifications set out in this instruction manual without prior notice.

CIRCUTOR, SA

, on its web site, supplies its customers with the latest versions

of the device specifications and the most updated manuals.

www.circutor.com

Instruction Manual 3

Page 4

AFQ-4W

CONTENTS

SAFETY PRECAUTIONS .................................................................................................................... 3

DISCLAIMER ........................................................................................................................................ 3

CONTENTS .......................................................................................................................................... 4

LOG OF REVISIONS ........................................................................................................................... 7

1.- VERIFICATION UPON RECEIPT .................................................................................................. 8

1.1.- RECEPTION PROTOCOL ............................................................................................................8

1.2.- TRANSPORT AND HANDLING ...................................................................................................9

1.3.- STORAGE .....................................................................................................................................10

2.- PRODUCT DESCRIPTION .......................................................................................................... 11

2.1. AFQ-4W-25 .....................................................................................................................................12

2.2. AFQ-4W-50 .....................................................................................................................................13

2.3. AFQ-4W-100 ..................................................................................................................................14

2.4. AFQ-4W-150 AND AFQ-4W-200 ...................................................................................................15

3. UNIT INSTALLATION .................................................................................................................... 16

3.1.- PRELIMINARY RECOMMENDATIONS ....................................................................................16

3.2.- INSTALLATION LOCATION ........................................................................................................17

3.3.- STORAGE FOR LONG PERIODS .............................................................................................18

3.4.- SIZING THE NOMINAL CURRENT OF THE AFQ-4W ............................................................19

3.5.- CONNECTIONS ...........................................................................................................................21

3.5.1. THREE-PHASE MAINS TO NEUTRAL CONNECTION .................................................22

3.5.2. CURRENT TRANSFORMER CONNECTION ..................................................................23

3.6.- PARALLEL CONNECTION OF 2 TO 8 ACTIVE FILTERS ......................................................25

3.7.- CONNECTING THE FILTER TO THE MAINS ..........................................................................26

3.8.- FILTER START-UP .......................................................................................................................27

3.8.1- CONFIGURATION ................................................................................................................27

3.8.1.1.- CONFIGURATION OF THE CURRENT TRANSFORMER .................................................... 27

3.8.1.2.- PARALLEL MODULE CONFIGURATION ................................................................................ 28

3.8.1.3.- WORK MODE CONFIGURATION ............................................................................................. 28

3.8.2- UNIT VERIFICATION ...........................................................................................................29

3.8.3- ACTIVE FILTER START-UP ................................................................................................31

4. OPERATION ................................................................................................................................... 33

4.1.- OPERATING PRINCIPLE ...........................................................................................................33

4.1.1.- HARMONICS ........................................................................................................................33

4.1.2.- BASIC CONCEPTS .............................................................................................................33

4.1.3.- MOST COMMON HAR MONICS .......................................................................................35

4.1.4.- HARMONIC COMPENSATION .........................................................................................35

4.1.5.- OPERATING PRINCIPLE ...................................................................................................36

4.2.- DISPLAY ........................................................................................................................................37

4.2.1.- MAIN SCREEN ....................................................................................................................37

4.2.2.- DISPLAY SCREENS ...........................................................................................................38

4 Instruction Manual

Page 5

AFQ-4W

4.2.2.1.- BROWSING DIAGRAM .............................................................................................................. 39

4.2.2.2.- Voltage and current display screen ........................................................................................... 40

4.2.2.3.- General power scree n ................................................................................................................. 40

4.2.2.3.1.- Load power display screen ................................................................................................ 41

4.2.2.4.- General THD(I) screen ................................................................................................................ 43

4.2.2.4.1.- THD Display screen of the phase 1 load current ............................................................ 43

4.2.2.4.2.- THD Display screen of the phase 2 load current ............................................................ 44

4.2.2.4.3.- THD Display screen of the phase 3 load current ............................................................ 44

4.2.2.4.4.- THD Display screen of the phase 1 mains current ......................................................... 45

4.2.2.4.5.- THD Display screen of the phase 2 mains curre nt ......................................................... 45

4.2.2.4.6.- THD Display screen of the phase 3 mains current ......................................................... 46

4.2.2.4.7.-Display screen of the total THD(I) ...................................................................................... 46

4.2.2.5.- Display screen of the alarm log .................................................................................................. 47

4.3.- CONFIGURATION .......................................................................................................................48

4.3.1.- BROWSING DIAGRAM ......................................................................................................49

4.3.2.- OPERATION MODE CONFIGURATION ..........................................................................50

4.3.2.1.- FUNCTION SELECTION ............................................................................................................ 51

4.3.2.2.- SELECTIVE FILTERING ............................................................................................................. 52

4.3.2.3.- ENABLE ALARM .......................................................................................................................... 53

4.3.3.- CONFIGURATION OF PARAMETERS ............................................................................55

4.3.4.- FILTER DATA .......................................................................................................................57

4.3.5.- SCREEN CONFIGURATION .............................................................................................58

4.3.6.- PASSWORD .........................................................................................................................59

4.4.- RS-485 COMMUNICATIONS .....................................................................................................60

4.4.1. MODBUS FRAMES ..............................................................................................................62

4.4.2. PowerStudio SOFTWARE ...................................................................................................62

5.- MAINTENANCE ............................................................................................................................ 63

5.1. STANDARD MAINTENANCE ......................................................................................................64

5.2. COOLING TURBINES AND FANS ..............................................................................................65

5.2.1. INDUCTOR COOLING FANS..............................................................................................66

5.2.1.1. AFQ-4W-25 A / 50 A / 100 A MODELS ....................................................................................... 66

5.2.1.2. AFQ-4W-150 A / 200 A MODELS ................................................................................................ 68

5.2.2. COOLING FANS/TURBINES OF THE IGBTs ...................................................................71

5.2.2.1. AFQ-4W-25 A / 50 A MODELS .................................................................................................... 71

5.2.2.2. AFQ-4W-100 A / 150 A / 200 A MODELS ................................................................................... 75

5.3. DC BUS CAPACITORS ................................................................................................................81

6.- SOFTWARE UPDATE .................................................................................................................. 81

6.1. CONTROLLER SOFTWARE UPDATE ......................................................................................81

6.2. DISPLAY SOFTWARE UPDATE. ................................................................................................83

7.- TECHNICAL FEATURES ............................................................................................................. 87

8.- MAINTENANCE AND TECHNICAL SERVICE .......................................................................... 89

9.- GUARANTEE ................................................................................................................................ 89

10.- CE CERTIFICATE ....................................................................................................................... 90

Instruction Manual 5

Page 6

AFQ-4W

APPENDIX A: DISPLAY MESSAGES ............................................................................................. 91

ACTIVE FILTER STOPPED .................................................................................................................91

ACTIVE FILTER IN ALARM STATUS .................................................................................................93

ACTIVE FILTER OPERATING ............................................................................................................95

ACTIVE FILTER IN CONFIGURATION ..............................................................................................95

APPENDIX B: MODBUS MAP.......................................................................................................... 97

6 Instruction Manual

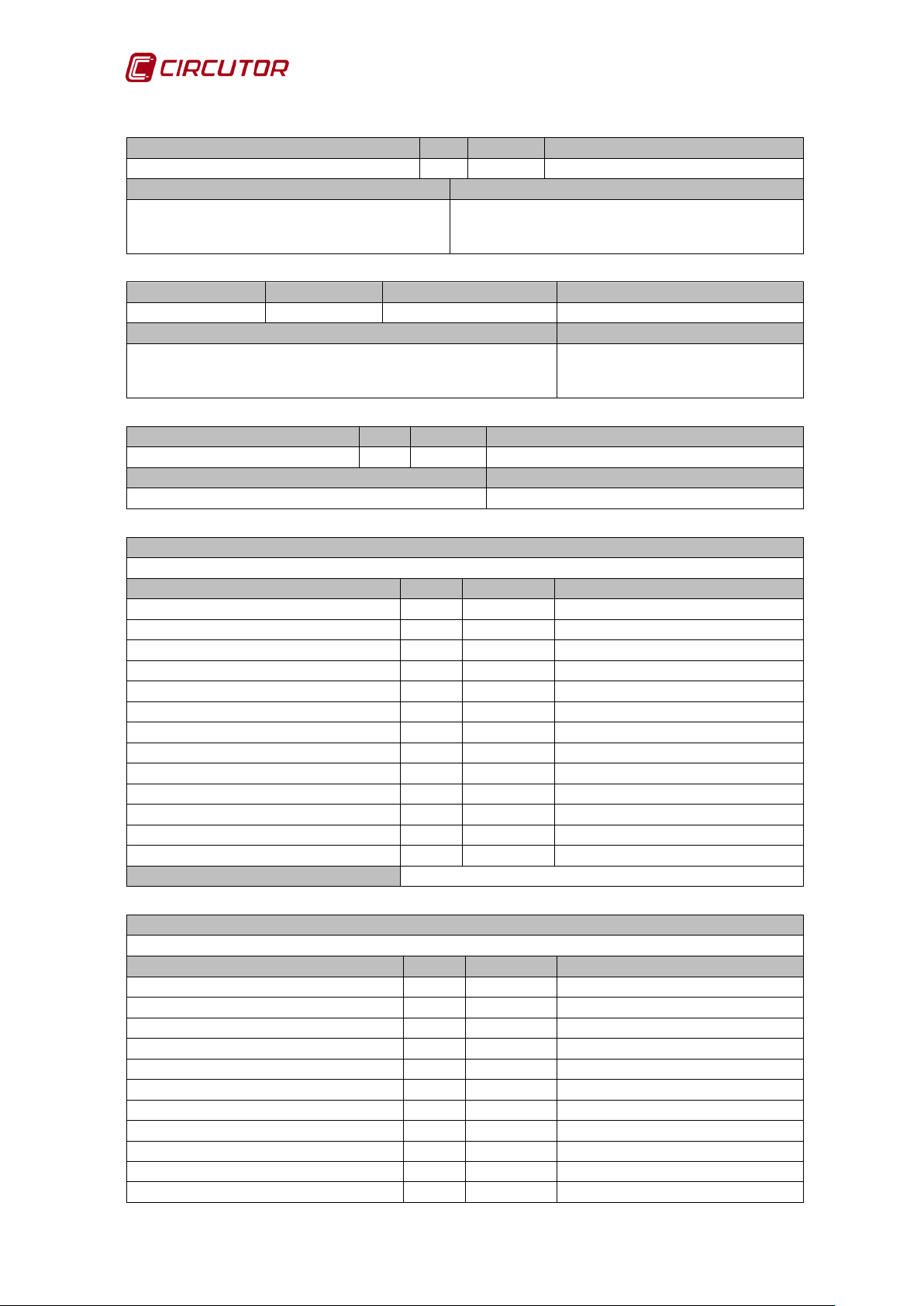

Page 7

AFQ-4W

Date

Revision

Description

11/10

Version 1.0

Original version

02/11

Version 1.1

Display change

Modification of the sections:

• User screen.

Modifications in the section:

• configuration screen.

Modification of the sections:

• Maintenance.

11/13

M98241701-01-13B

Modifications throughout the manual.

LOG OF REVISIONS

11/11 Version 1.2

05/12 Version 1.3

12/12 Version 1.4

• Installation and start-up.

• User screen.

Introduction of the sections:

• PowerStudio application.

Instruction Manual 7

Page 8

AFQ-4W

If any problem is noticed upon reception, immediately contact the

1.- VERIFICATION UPON RECEIPT

1.1.- RECEPTION PROTOCOL

• Make sure that the unit has not been damaged during transport.

• Check that the unit received matches that described in your order and

that its electrical features are suitable for the mains where it is to be

connected. See features label on the rear of the door.

(Figure 1)

Figure 1: Features label of the AFQ-4W

• Make sure that it is equipped with the following accessories:

- Main switch handle.

- 2 keys for locking the door.

- Manual.

The AFQ-4W-25 also has:

- 4 DIN 580-M8 suspension eye bolts (male).

- 4 DIN 963, M8x16 screws.

• Check the shipping documentation. The dispatch note number must

coincide with the number marked on the outer part of the unit. Unload and

transport the unit following the instructions in section 1.2.- TRANSPORT

AND HANDLING

Inspect the unit externally and internally before connecting.

• Check that all the unit's items on the packing list are present.

transport company and/or CIRCUTOR's after-sales service.

8 Instruction Manual

Page 9

AFQ-4W

If the unit is not to be immediately installed, it must be stored at a

the storage conditions listed in

In such a case, the unit should be kept in its original protective

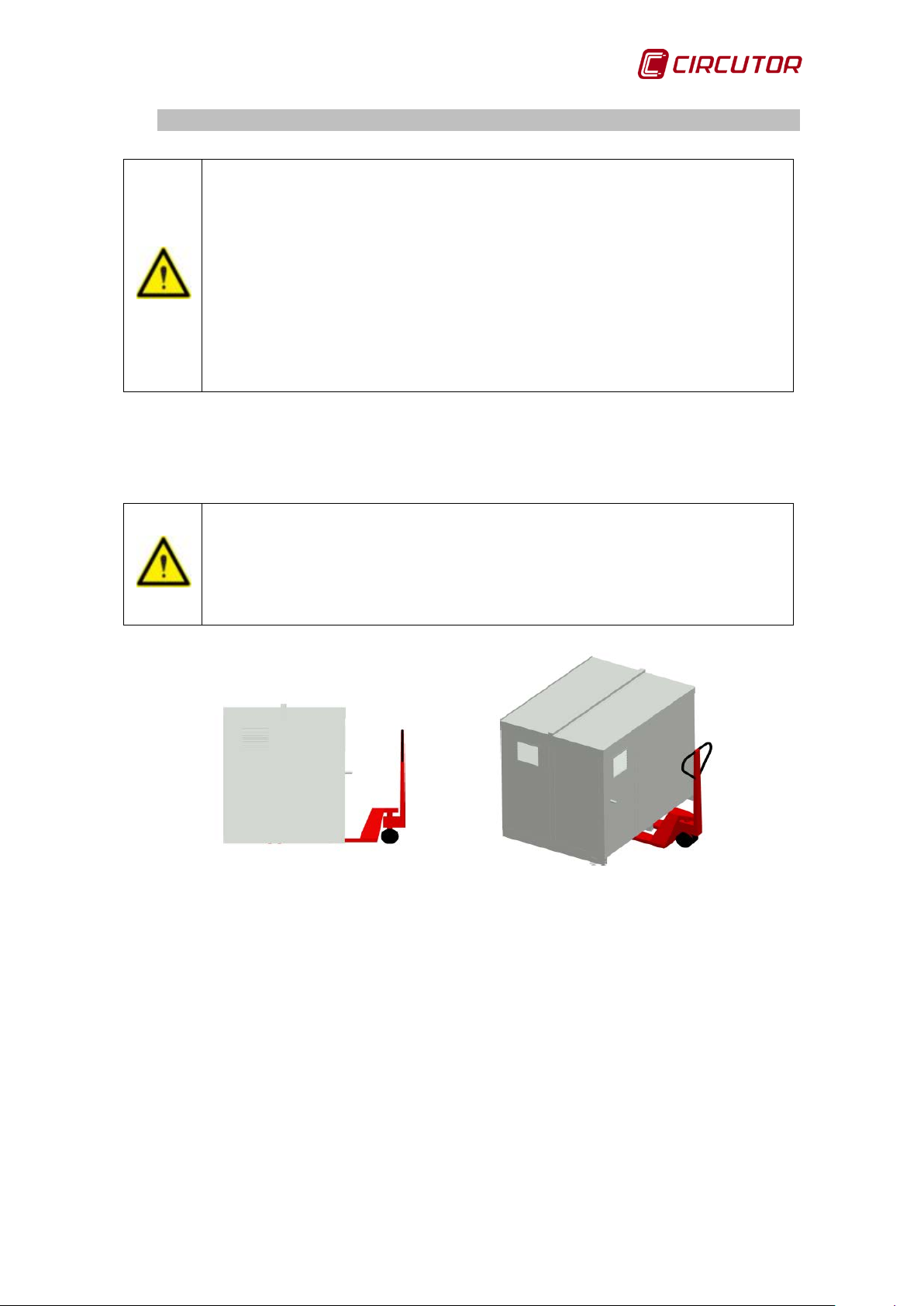

1.2.- TRANSPORT AND HANDLING

The transport, loading and unloading and handling of the unit must

be carried out with proper precautions and using the proper manual

or mechanical tools to prevent damage to the unit.

location with a firm and level floor, and

the section must be observed. 1.3.- STORAGE

packaging.

To move the unit a short distance, the unit's floor support profiles facilitate

handling with a pallet jack or forklift. (Figure 2)

The centre of gravity of some units may be found at a considerable

height. Therefore, when handling with a forklift, it is recommended

that the unit be securely fastened and that no abrupt operations are

made. The unit should not be lifted more than 20 cm off the ground.

Figure 2: Transport with pallet jack

When unloading and moving the unit, use a forklift with forks long enough to

support the entire length of the base. Otherwise, the forks should be long

enough to support at least ¾ of said depth. The forks must be flat and supported

firmly by the base. The cabinet must be raised by placing the forks underneath

the profile that supports the unit. (Figure 3).

Instruction Manual 9

Page 10

AFQ-4W

There might be an offset in the centre of gravity from the centre of

the cabinet, as a result of the uneven distribution of loads in

equipment. The necessary precautions must be taken to prevent the

equipment from tipping over during abrupt operations.

Figure 3: Unloading with a forklift

1.3.- STORAGE

The unit should be stored according to the following recommendations:

• Avoid placing it on uneven surfaces.

• Do not store in outdoor areas, humid areas or areas exposed to the

splashing of water.

• Avoid hot spots (maximum environmental temperature: 45ºC)

• Avoid saline and corrosive environments.

• Avoid storing the unit in areas where a lot of dust is generated or where

the risk of contamination by chemical agents or other types of pollution is

present.

• Do not place any weight on top of the unit's cabinets.

10 Instruction Manual

Page 11

AFQ-4W

Models

AFQ-4W-25

AFQ-4W-50

AFQ-4W-100

AFQ-4W-150

AFQ-4W-200

Harmonic phase

current

Harmonic neutral

current

Harmonic peak

current

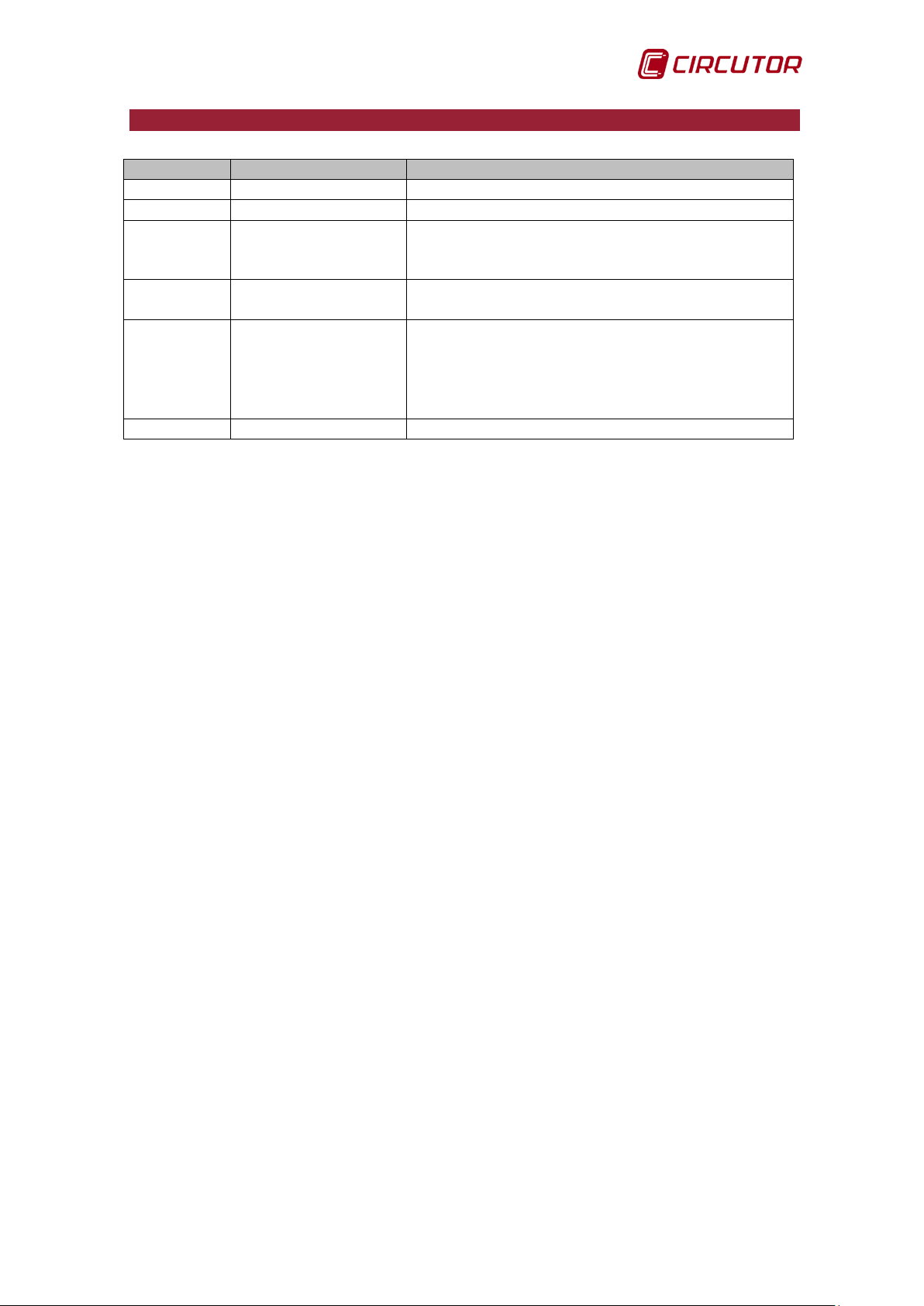

2.- PRODUCT DESCRIPTION

The AFQ-4W parallel multi-function active filters enable the following functions to

be performed:

Reduction of harmonic currents up to order 50 (2500 Hz).

Correcting unbalanced current consumption in each phase of the

electrical installation.

Reactive power compensation. Both inductive and capacitive currents.

CIRCUTOR has 5 different fil ter mo dels :

25A

75A

50A

50A

RMS

150A

RMS

100A

PEAK

100A

RMS

300A

RMS

200A

PEAK

Table 1: A FQ-4W models

All active filter models have the followi ng :

An LCD 5.7" touch display.

An RS-485 connection.

150A

RMS

450A

RMS

300A

PEAK

200A

RMS

600A

RMS

400A

PEAK

RMS

RMS

PEAK

Instruction Manual 11

Page 12

AFQ-4W

2.1. AFQ-4W-25

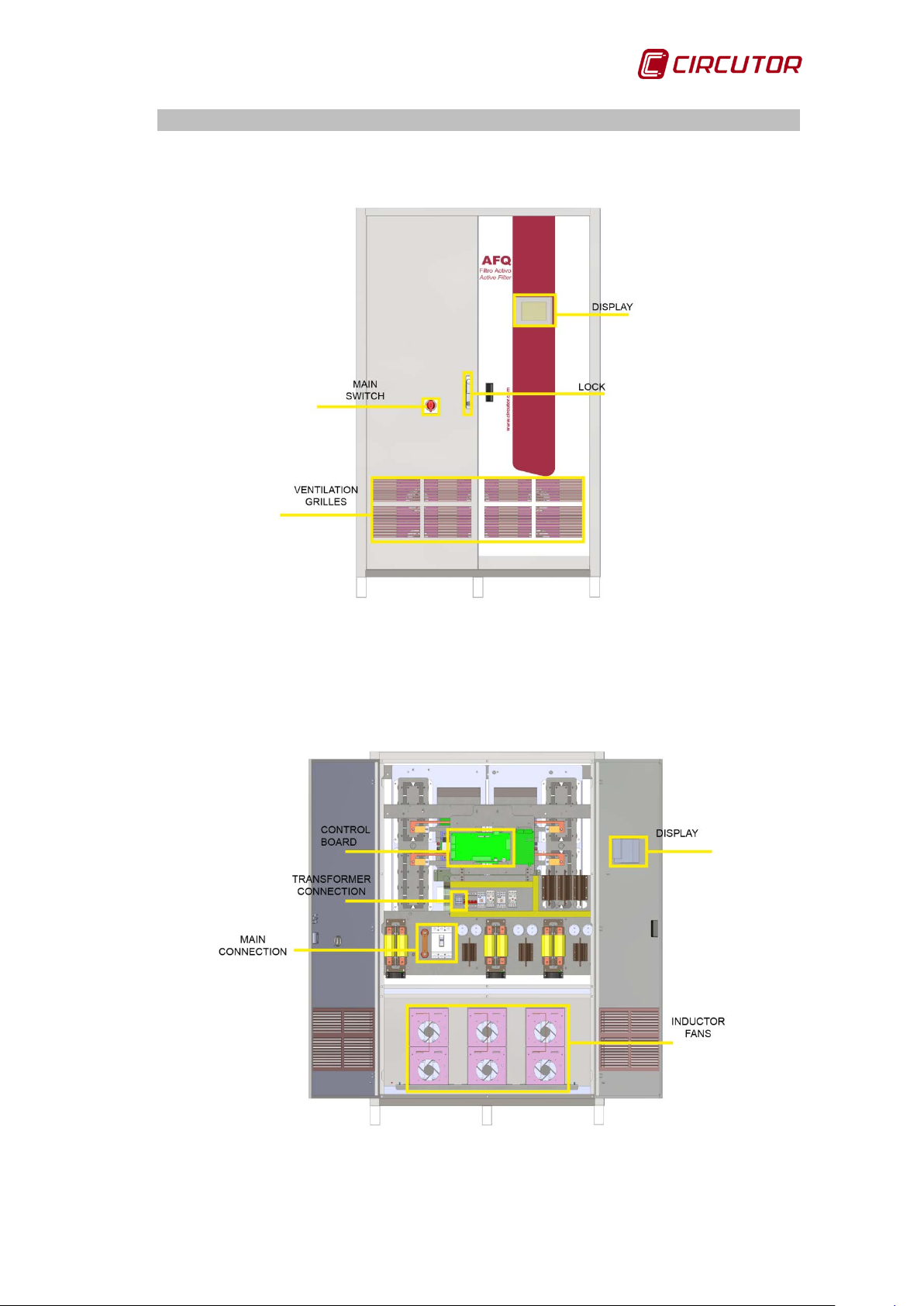

AFQ-4W-25 components seen from the front (Figure 4):

Figure 4: AFQ-4W-25 front view.

AFQ-4W-25 internal components (Figure 5):

Figure 5: AFQ-4W-25 inte rio r.

12 Instruction Manual

Page 13

AFQ-4W

2.2. AFQ-4W-50

AFQ-4W-50 components seen from the front (Figure 6):

Figure 6: AFQ-4W-50 front view.

AFQ-4W-50 internal components (Figure 7):

Figure 7: AFQ-4W-50 inte rio r.

Instruction Manual 13

Page 14

AFQ-4W

2.3. AFQ-4W-100

AFQ-4W-100 components seen from the front (Figure 8):

Figure 8: AFQ-4W-100 front view.

AFQ-4W-100 internal components (Figure 9):

Figure 9: AFQ-4W-100 interior.

14 Instruction Manual

Page 15

AFQ-4W

2.4. AFQ-4W-150 and AFQ-4W-200

AFQ-4W-150 and AFQ-4W-200 componen ts seen from the front (Figure 10):

Figure 10: A FQ-4W-150 and AFQ-4W-200 front view.

AFQ-4W-100 and AFQ-4W-200 internal components

(Figure 11):

Figure 11: AFQ-4W-150 and AFQ-4W-200 interior.

Instruction Manual 15

Page 16

AFQ-4W

st only

In order to use the unit safely, it is critical that individuals who

Incorrect installation or configuration of the unit could cause serious

. Before starting any

maintenance, wait 5 minutes and check that there is no residual

Make sure the unit is properly earthed before powering up. Any

fault in the earth connection might cause a risk of electrocution to

the user and damage to the unit itself in the case of lightning or

, make sure the

secondary is short circuited. Never open a current transformer

3. UNIT INSTALLATION

3.1.- PRELIMINARY RECOMMENDATIONS

The unit installation and the maintenance operations mu

be carried out by authorised and qualified personnel.

handle it follow the safety measures set out in the standards of the

country where it is being used, use the necessary personal

protective equipment, and pay attention to the various warnings set

forth in this instruction man ual.

damage to the unit itself and to other devices of the installation.

Disconnect the main switch before starting any maintenance

task on the active filters.

The unit has DC and AC capacitors

voltage in the capacitors.

other transients.

Before operating on the current transformers

secondary under load.

16 Instruction Manual

Page 17

AFQ-4W

Never power or start up the active filter with the front door open or

Check the section 3.4.- SIZING THE NOMINAL CURRENT OF THE

to define the correct unit size. Failing to observe the

recommendations described in this section might cause the active

filter to work incorrectly and prevent proper compensation of the

Connect a reactor of at least 3% of the impedance on the input of

the side or rear covers removed.

Check that there is a neutral in the place where three-phase active filter

connections are made w i th neutral , AFQ-4W.

The active filter must be of the correct size for the harmonic currents it has to

filter and for the install ati on's el ectr i c al fe atures.

AFQ-4W

installation's current harmonics.

each of the loads.

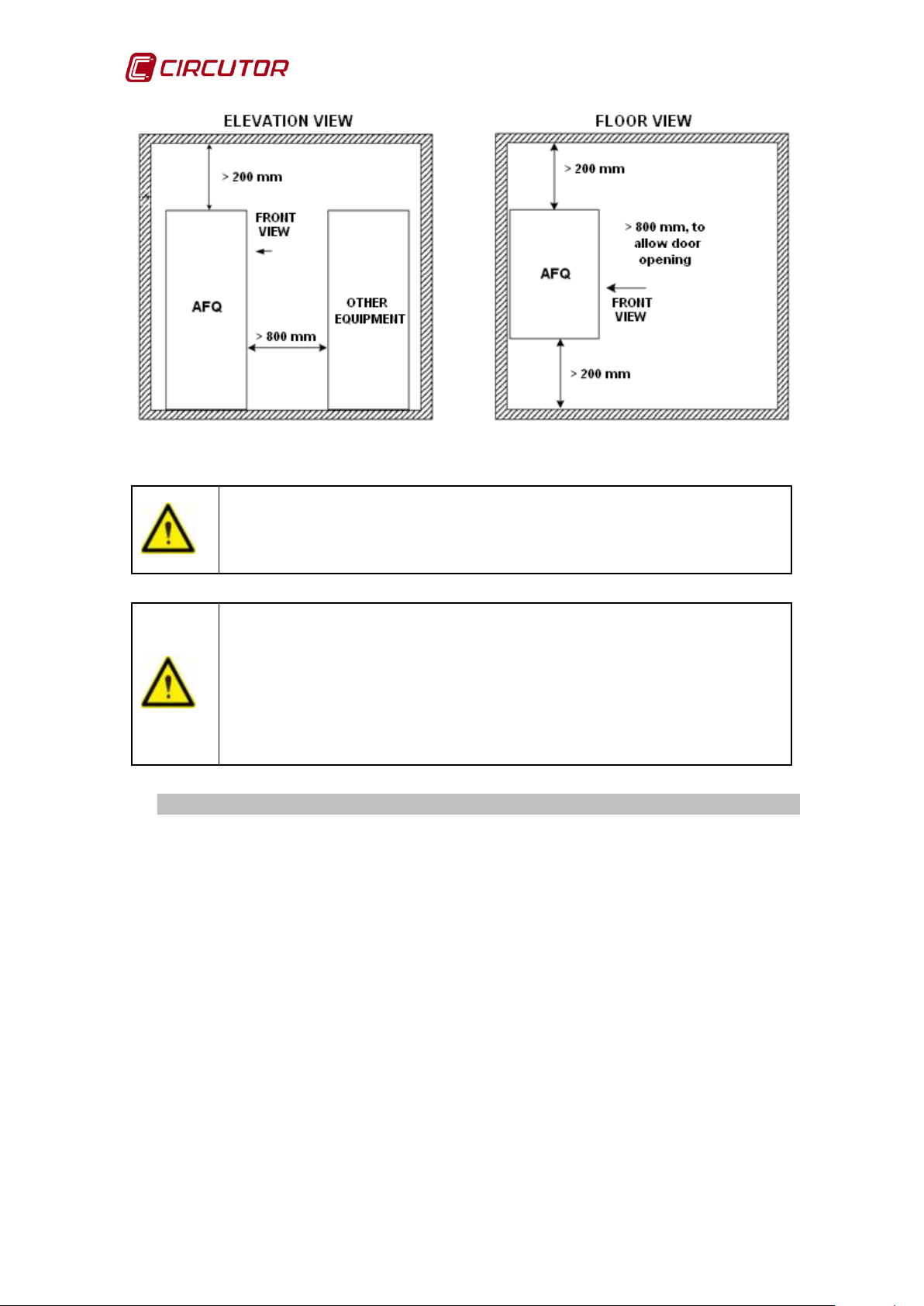

3.2.- INSTALLATION LOCATION

The unit must be installed in an environment where the temperature outside the

cabinet is between 0ºC and 40ºC, with a maximum humidity of 90% without

condensation.

Do not install the unit close to a hot spot and keep it out of direct sunlight.

Ventilation spaces must be left on the side and rear to allow for the use of fans.

There must also be sufficient space at the front of the cabinet to be able to open

the door if necessary (Figure 12):

200 mm on the sides of the cabinet.

200 mm between the top of the cabinet and the ceiling.

800 mm at the front of the cabinet.

Instruction Manual 17

Page 18

AFQ-4W

in a place protected from water, flammable

Make sure there are no reactive compensation units installed in the

. If there are any compensation units,

oid interference between them

Figure 12: Active filter spaces for ventilation.

Install the AFQ-4W

liquids, gases and corrosive substances.

same mains as the AFQ-4W

these must be untuned in order to av

and the AFQ-4W.

3.3.- STORAGE FOR LONG PERIODS

If the unit is not installed after receipt, the following recommendations must be

observed to keep the unit in a good state:

Keep the unit in a dry atmosphere and at a temperature of between 0ºC

and 50ºC.

Avoid exposure to direct sunlight.

Keep the unit in its original packaging.

If the active filter is stored for a long time disconnected from the mains, a

process must be applied to restore the internal dielectric layers of the DC bus

capacitors. Table 2 shows the recommendations for starting the unit depending

on the length of its storage period.

18 Instruction Manual

Page 19

AFQ-4W

Storage time

Process

< 1 year

No special treatment required.

Connect the AFQ-4W to the mains at least one

Connect the AFQ-4W to the mains at least one

1-2 years

> 2 years

hour before starting up the unit.

hour before starting up the unit. Restrict the

maximum load current to 5 mA.

Table 2: Start-up process depending on storage time.

3.4.- SIZING THE NOMINAL CURRENT OF THE AFQ-4W

The purchased active filter must be sized for the harmonic currents it has to filter.

The nominal current of the AFQ-4W must be at least 20% higher than the

maximum level of harmonics to be filtered. This factor may be higher depending

on the installation features.

The active filters can suffer from overloading when trying to cancel the harmonic

currents in high-impedance, short-circuit mains. The clearest symptom for

detecting such cases is that they originally start from a THD(V) (under voltage)

of over 3%. It has been seen that the higher the initial THD(V), the greater the

chance of filter overload.

The reason for this behaviour is that the load does not behave as a current

source, but rather the larger the harmonic current absorbed by the filter the more

harmonics are produced by the load, which can produce up to more than double

what was initially measured.

To avoid this phenomenon, it is best to oversize the active filter by multiplying the

initial current of harmonics measured in the load by a safety factor (SFh). In

other words:

I

(AFQ) = [SFh · I

filter

Where:

I

SF

I

THD(I): load current harmonic distortion

(AFQ): nominal current of the active filter

filter

: safety factor > 1.2.

h

: load maximum current

load

Equation 1: AFQ-4W nominal current

· THD(I) ]

load

To calculate this safety factor you must first know the parameter called shortcircuit ratio RSC at the connection point of the PCL transducers (not on the

installation input). The short -circuit ratio is defined as the ratio between the shortcircuit current of a mains (ISC) and the nominal current of the set of non-linear

transducers (I

) producing the harmonics to be filtered. (Equation 2)

NLC

Instruction Manual 19

Page 20

AFQ-4W

CNL

SC

SC

I

I

R =

Equation 2: Calculating the shor t-circuit ratio RSC.

In a real installation, the short-circuit current (ISC) in the PCL can be assessed by

having the voltage at the said point for two different load currents. For example,

full load, IA and 10% load, IB. If VOC is the rated voltage in a vacuum, the ISC, can

be calculated using the formula shown in Figure 13:

Figure 13: Graphic for calcula ting I

Figure 14 The safety factor (SF

Figure 14: Approximate graphic for calculating the SFh.

.

SC

) can be obtained from the graphic in:

h

20 Instruction Manual

Page 21

AFQ-4W

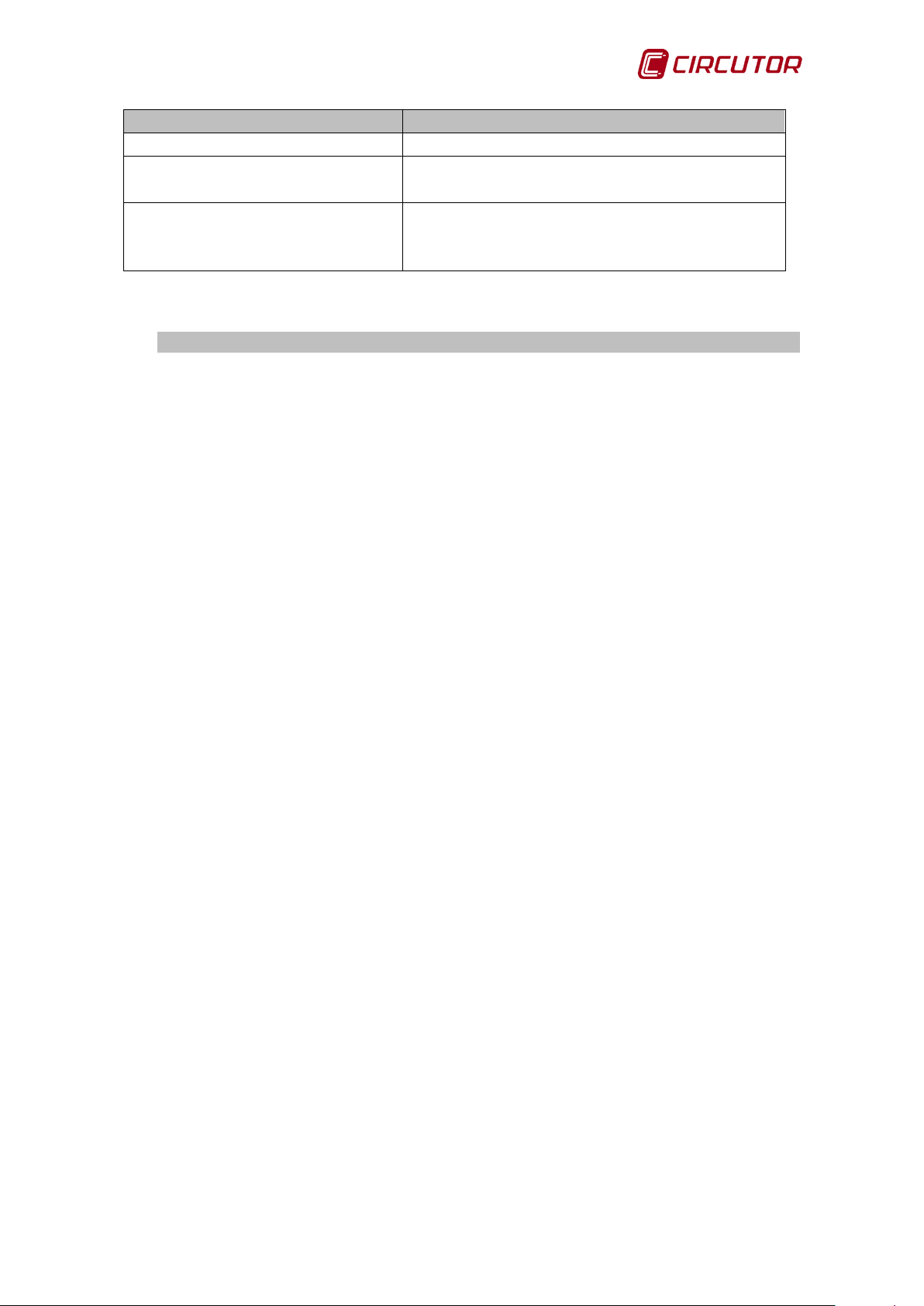

All power and current reading cables must enter the electrical cabinet

guaranteeing the IP and the user

Perform the drilling and/or milling out of the area for this

,

cabinet to

3.5.- CONNECTIONS

by the cover on the bottom,

protection against the parts of the cabinet with high voltages

( Figure 18).

Figure 15: Cable entry from the bottom of the electrical cabinet.

(Figura 15) puts at risk the integrity of the equipment and users

as well as the loss of the warranty.

Drilling the cover cable entry out of the electrical

avoid drilling debris may affect the functioring of the AFQ.

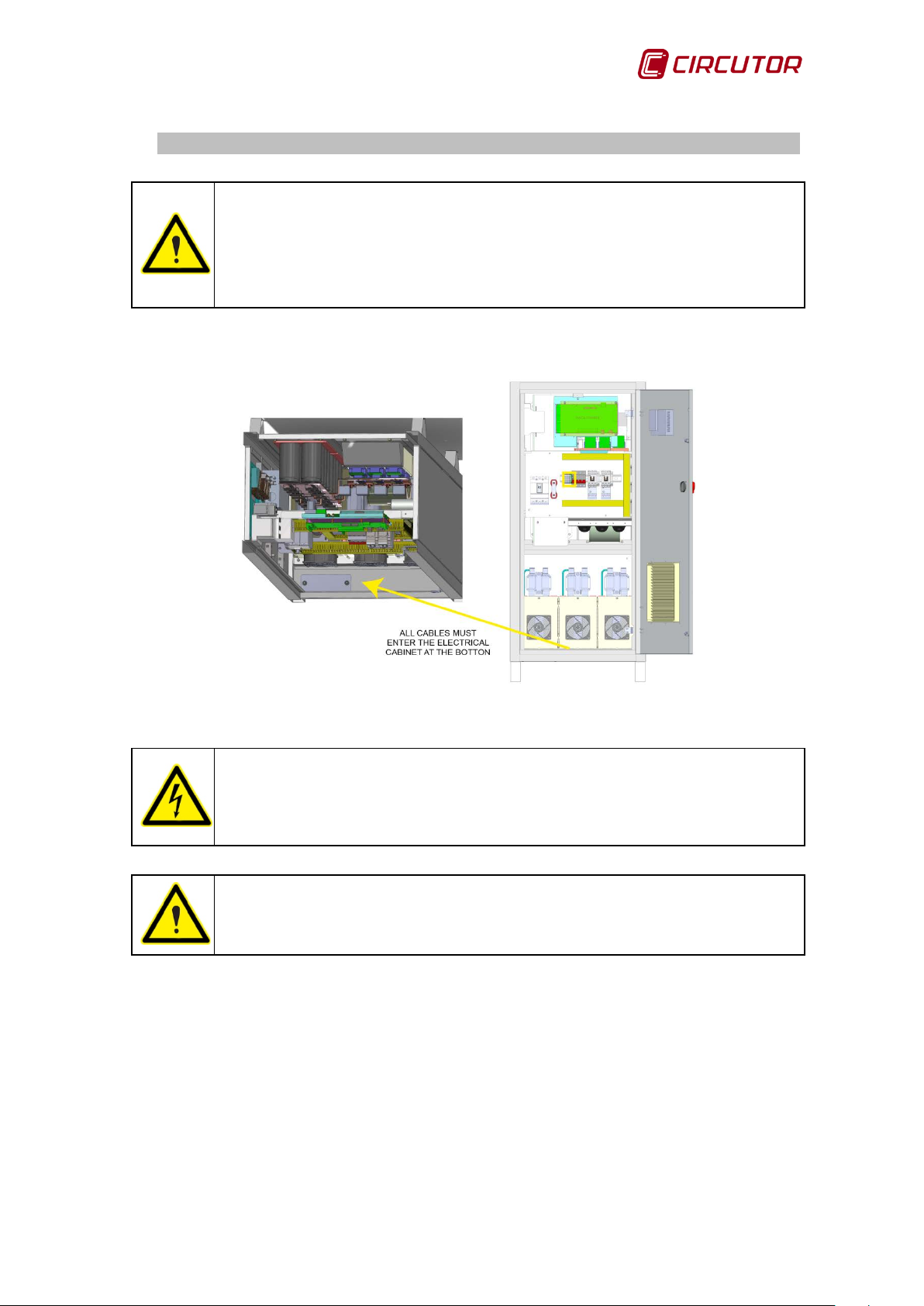

The connection diagram in Figure 16 must be used when performing the

electrical connections in the electrical cabinet:

Instruction Manual 21

Page 22

AFQ-4W

Figure 16: Connection diagr am of the AFQ-4W.

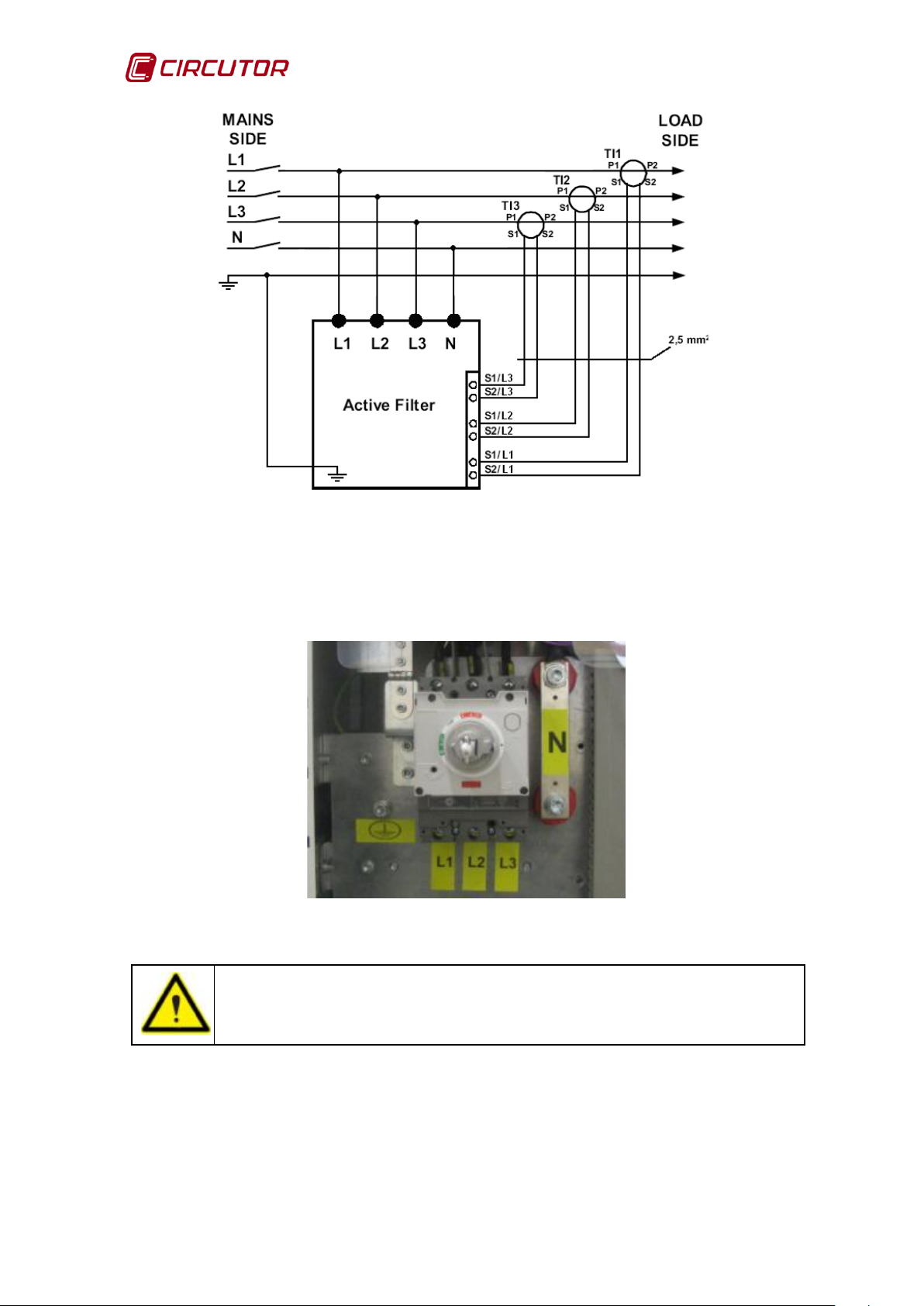

3.5.1. THREE-PHASE MAINS TO NEUTRAL CONNECTION

The connections of the three-phase mains to neutral (L1, L2, L3, N and Earth)

are identified in the active filter as in Figure 17.

Figure 17: Mains connection points in the AFQ-4W.

Use cables of a cross-section suitable for the filter nominal current.

22 Instruction Manual

Page 23

AFQ-4W

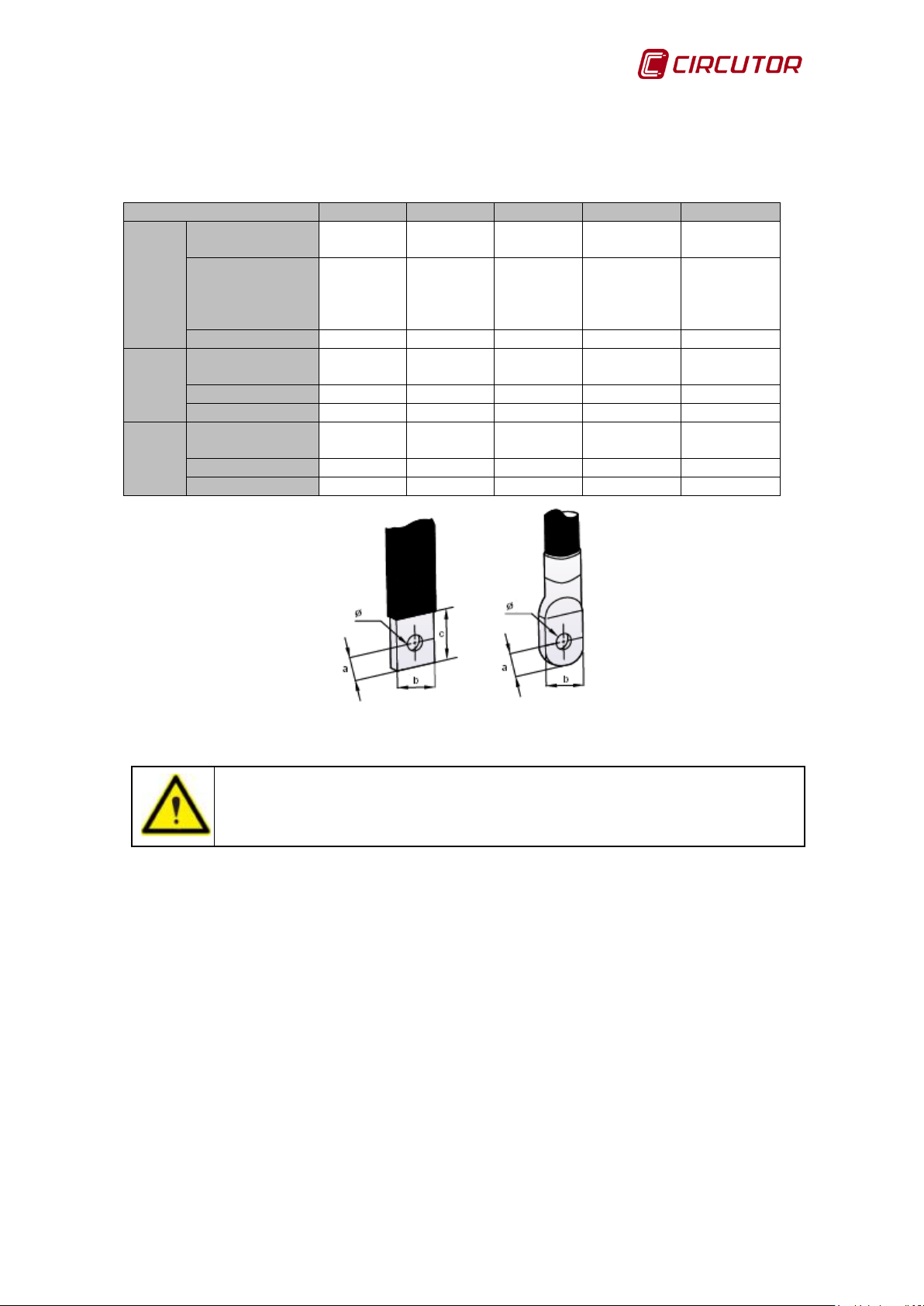

AFQ-4W

25A

50A

100A

150A

200A

Cross-section

(mm2)

a ≤ 10

Ø > 8

a ≤ 10

Ø > 8

a ≤ 10

Ø > 8

a ≤ 10

Ø > 8

a ≤ 10

Ø > 8

Torque (Nm)

7.6

7.6

7.6

14.4

14.4

Cross-section

(mm2)

Terminal (mm)

Ø > 8

Ø > 10

Ø > 10

Ø > 10

Ø > 10

Torque (Nm)

12

20

25

30

30

Cross-section

(mm2)

Terminal (mm)

Ø > 8

Ø > 8

Ø > 10

Ø > 10

Ø > 10

Torque (Nm)

12

20

25

30

30

to avoid the risk of

The minimum cable cross-section will depend on the filter range (Table 3).

L1

L2

L3

N

Earth

Terminal (mm)

10 16 35 70 95

b ≤ 20

c ≤ 21

25 50 95 2x95 2x95

25 50 95 95 95

b ≤ 20

c ≤ 21

b ≤ 20

c ≤ 21

b ≤ 20

c ≤ 21

b ≤ 20

c ≤ 21

Table 3: Minimum cross-sectio n o f input cables connected to the AFQ-4W.

Make sure that the AFQ-4W is correctly earthed

electrical discharge.

3.5.2. CURRENT TRANSFORMER CONNECTION

Current transformers TI1, TI2 and TI3, are located on the load side (downstream

of the filter) and are used for measurement and control purposes. In the active

filter, connections S1/L1, S1/L2, S1/L3 S2/L1, S2/L2, S2/L3 have to be made as

shown in Figure 18.

Instruction Manual 23

Page 24

AFQ-4W

The use of transformers with ratios close to the current to be

Current transformers TI1, TI2, TI3 must be correctly connected for the

filters to work properly. If the phases L1, L2 and L3 are

ase 1 and the transformer output cables are

measures phase 2 and the transformer output cables are

3 and the transformer output cables are

Figure 18: Transformer connection points in th e AFQ-4W.

Class 0.2S transformers of the CT or TCH series are recommended.

The use of class 0.2, 0.5s or 0.5 transformers will slightly jeopardise the

behaviour of the active filter although they always provide acceptable harmonic

filtering replies.

measured is recommended.

AFQ-4W

switched in the secondary, the filter will not work properly.

Check the connections and make sure that:

TI1 measures ph

connected in posts S1/L1 and S2/ L1 of the filter cabinet.

TI2

connected in posts S1/L2 and S2/ L2 of the filter cabinet.

TI3 measures phase

connected in posts S1/L3 and S2/ L3 of the filter cabinet.

24 Instruction Manual

Page 25

AFQ-4W

All of the active filters connected in parallel must have exactly the

MAINS side

LOAD side

AFQ-4W

AFQ-4W

AFQ-4W

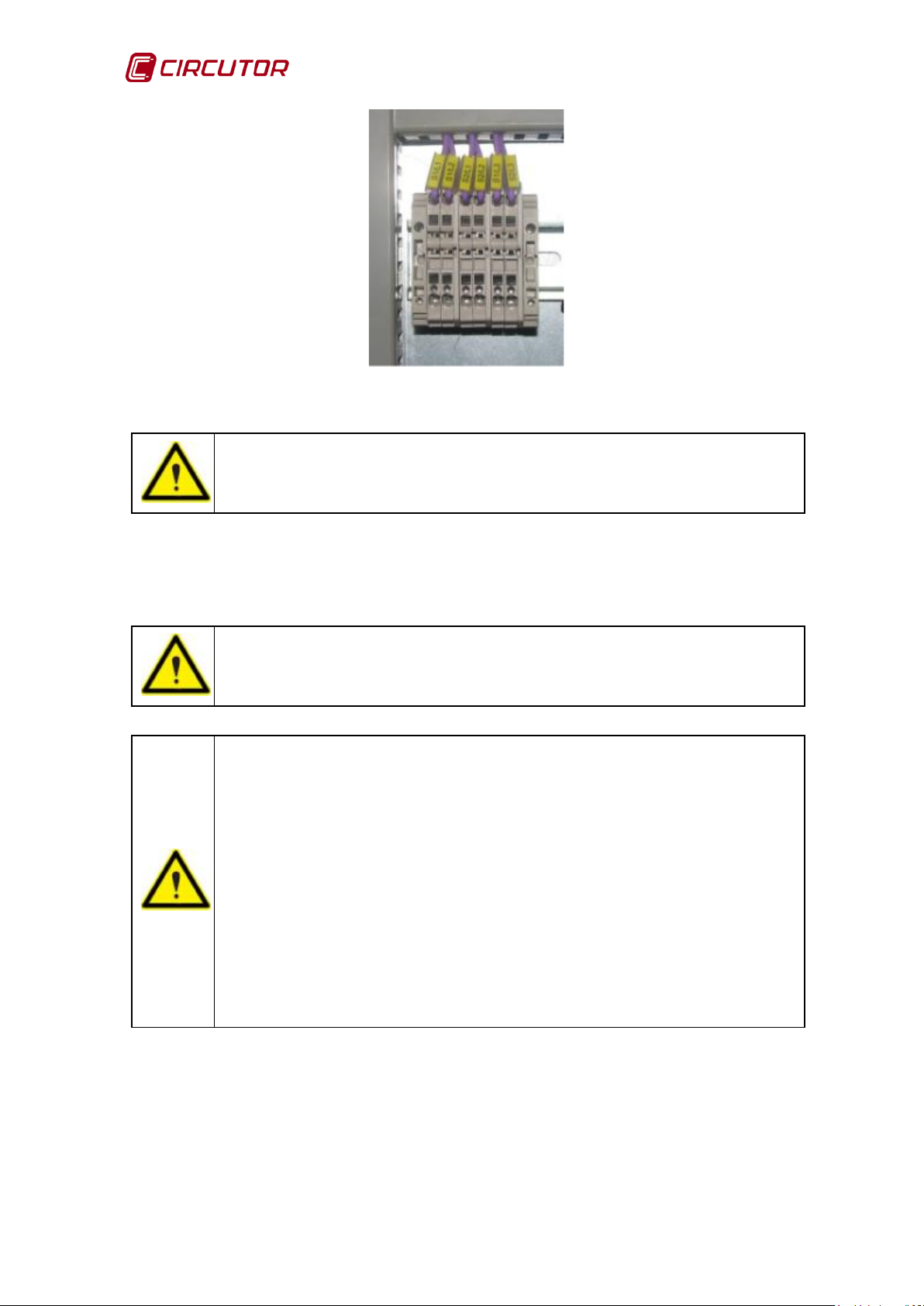

3.6.- PARALLEL CONNECTION OF 2 TO 8 ACTIVE FILTERS

You can connect up to 8 active filters by connecting the three phases plus the

neutral in parallel. The load current measurement connects in series so that all of

the filters are using the same measuring transformers on the load. (Figure 19)

Figure 19: Parallel connection of 2 to 8 filters.

Section 4.3.3. explains how to configure the active filter to work with different

active filters in parallel.

same configuration in the WORK MODE and PARAMETERS. Refer

to section

4.3.- CONFIGURATION

Instruction Manual 25

Page 26

AFQ-4W

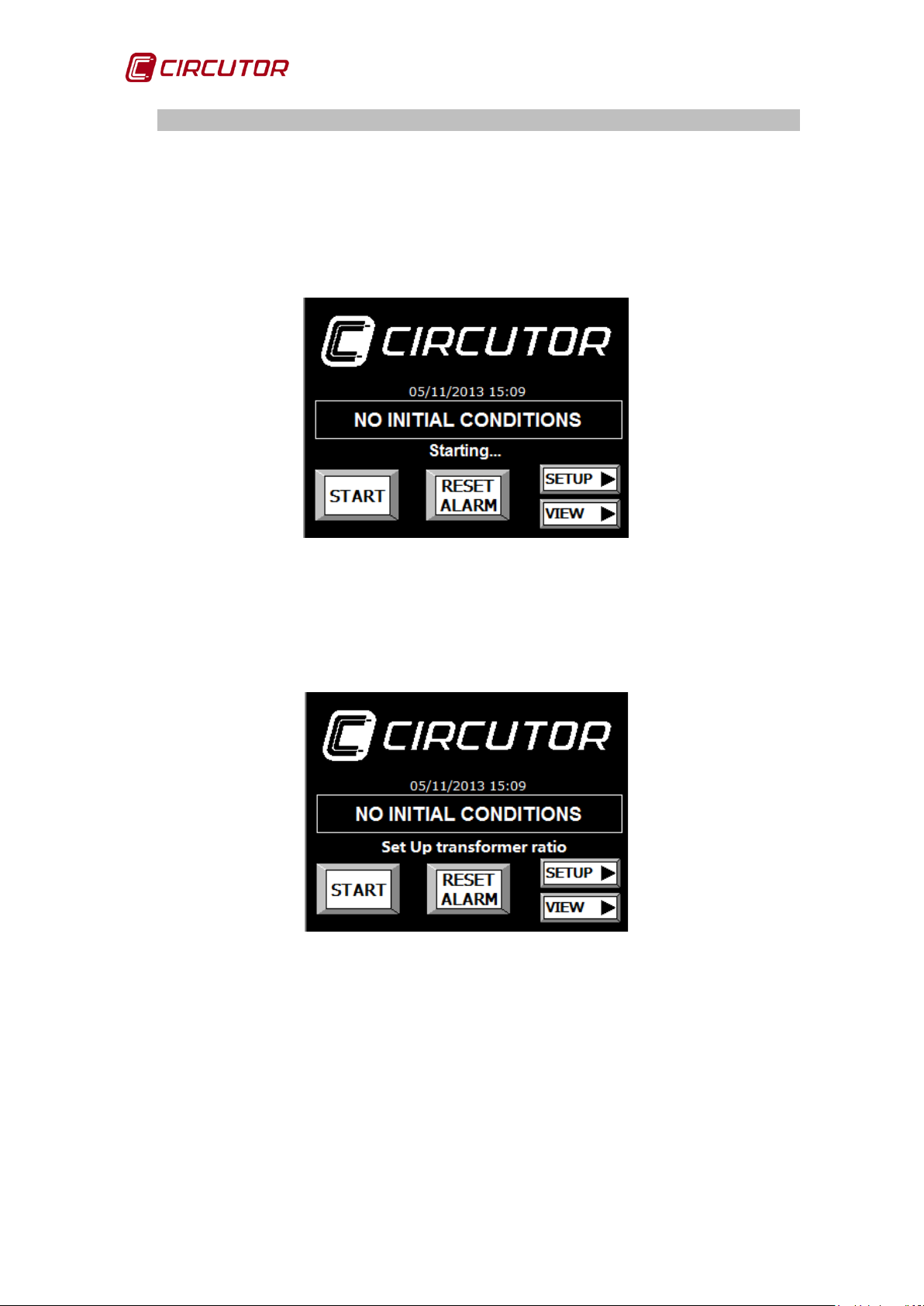

3.7.- CONNECTING THE FILTER TO THE MAINS

Once the connections specified in the above sections have been checked, the

main switch of the active filter will be switched on. When the unit is started, the

messages “NOT INITIAL CONDITIONS” and “Starting …” must appear on the

display ( Figure 20).

Figure 20: Start-up message of the AFQ-4W.

A few seconds later, the message “Set Up transformer ratio” will appear

(Figure 21).

Figure 21: Home screen displayed du ring the AFQ-4W's start-up.

Another message may appear if there is some problem in the filter connections

or the power supply. The section APPENDIX A: DISPLAY MESSAGES of this

manual describes all of the causes of malfunction and their corrective measures.

26 Instruction Manual

Page 27

AFQ-4W

, carefully follow the steps given in

If the transformer ratio is not that of the transformer installed, the

3.8.- FILTER START-UP

Finally, start-up the AFQ-4W. To consult all of the configuration parameters in

detail, see 4.3.- CONFIGURATION of this manual .

Before starting up the AFQ-4W

Configuration 3.8.1 and Verification of the unit 3.8.2.

3.8.1- CONFIGURATION

3.8.1.1.- CONFIGURATION OF THE CURRENT TRANSFORMER

Access the parameter configuration screen by pressing SETUP and select the

PARAMETERS option (Figure 22):

Figure 22: Configuration of the transformer ratio and the number of modules in parallel.

Configure the TRANSFORMER RATIO parameter with the ratio between the

primary and secondary of the load current measurement transformer.

The AFQ-4W admits the following transformation ratios: 5/5, 10/5, 15/5, 20/5,

25/5, 30/5, 40/5, 50/5, 60/5, 75/5, 100/5, 125/5, 150/5, 200/5, 250/5, 300/5,

400/5, 500/5, 600/5, 700/5, 750/5, 800/5, 1000/5, 1200/5, 1500/5, 1600/5,

2000/5, 2500/5, 3000/5, 4000/5 and 5000/5.

AFQ-4W will not work properly.

Instruction Manual 27

Page 28

AFQ-4W

An incorrect configuration may significantly affect the performance of

personnel to select

3.8.1.2.- PARALLEL MODULE CONFIGURATION

Configure the number of units in parallel in the PARALLEL MODULES

parameter (Figure 22). If there is a single unit in parallel, leave the default value

(1).

3.8.1.3.- WORK MODE CONFIGURATION

In order to configure the work mode, return to the home screen, press START

and access the work mode configuration screen.

Start the harmonic filtering, phase balancing and/or reactive compensation

functions depending on the needs of the installation (Figure 23). (For further

information on all of the functi ons, refer to section 4.3.- CONFIGURATION )

Figure 23: Configuration of the functions of the AFQ-4W.

the AFQ-4W. Consult the technician or qualified

the unit configuration, depending on the needs of the installation.

28 Instruction Manual

Page 29

AFQ-4W

3.8.2- UNIT VERIFICATION

3.8.2.1.- VERIFICATION O F THE MAINS VOLTAGE AND FREQUENCY

The voltage and current screen (Figure 24) can be accessed from the home

screen by pressing on VIEW:

Figure 24: Verify mains voltages, currents and frequency.

Make sure the mains voltage measurements correspond to the real

voltages of the installation.

Make sure the frequency measured by the AFQ-4W is the real frequency

of the installation.

Make sure the load current measurements correspond to the installation

current levels.

Instruction Manual 29

Page 30

AFQ-4W

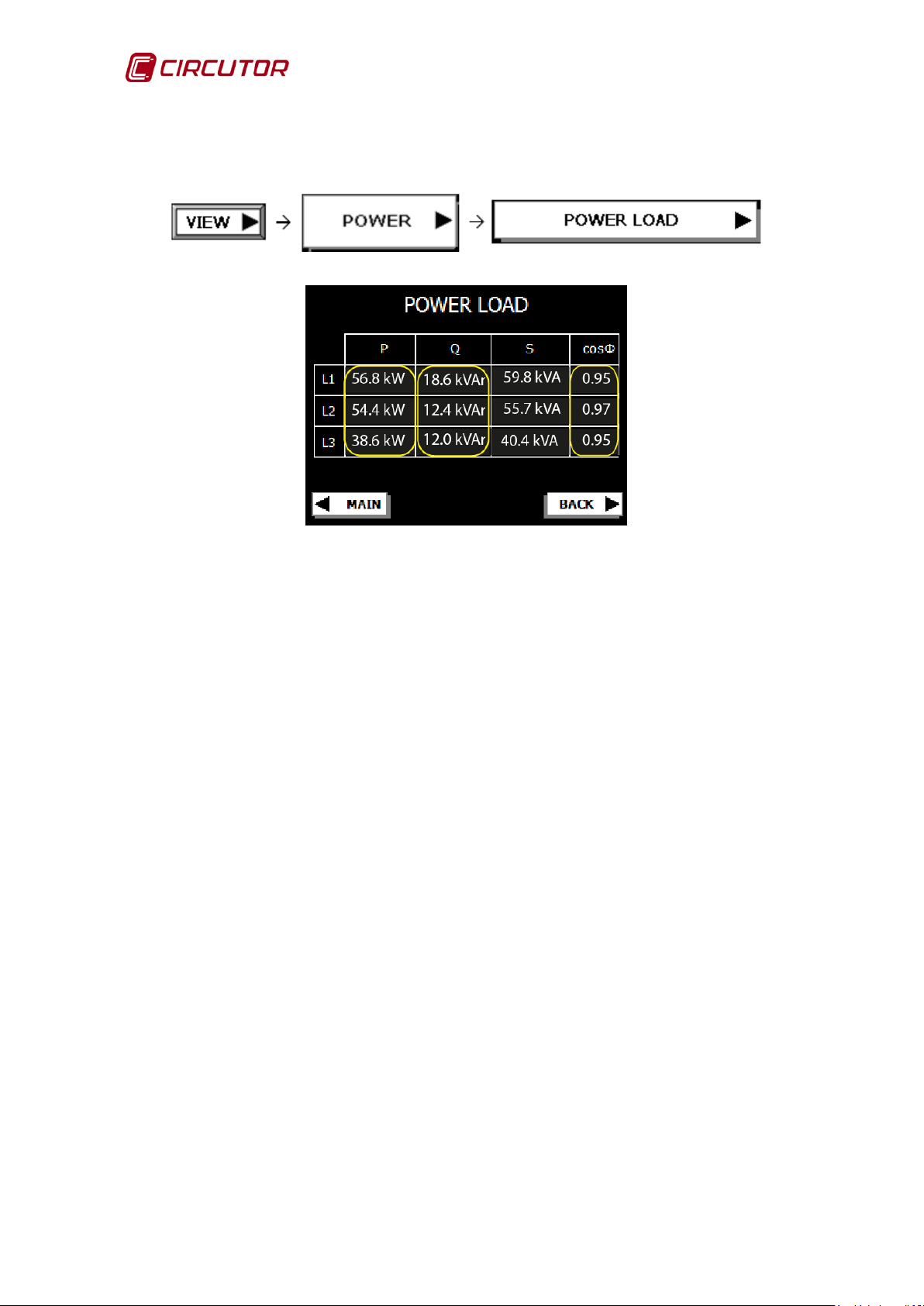

3.8.2.2.- VERIFICATION OF THE ACTIVE AND REACTIVE POWER

The load power screen (Figure 25) can be accessed from the home screen by

pressing VIEW:

Figure 25: Verify active and reactive power and load power factor readings.

Make sure the active power measurement of the load equals the power

levels of the installation.

Make sure the reactive power measurement of the mains equals the

reactive power levels of the installation.

Check the power fact or in the three phases. If there are phases with very

high reactive power and very low active power levels, this might indicate

an error in the phase order. In this case, check the connections of the

three-phase mains power supply cables with neutral and the load current

reading cables, as described in sections 3.5.1 and 3.5.2.

30 Instruction Manual

Page 31

AFQ-4W

3.8.3- ACTIVE FILTER START-UP

Having checked the active and reactive power and power factor of the

installation, you can return to the main screen to start up the AFQ-4W.

If there is no problem with the connections, the home screen should show the

message “STOP” (Figure 26).

Figure 26: Message displayed when the unit is ready for start-up.

By pressing START, the active filter will take action to neutralise the harmonics,

balance the phases and/or compensate reactive power.

If it has started up correctly, the screen will show the message “RUN”

(Figure 27).

Figure 27: Message displayed when the unit is running.

If there is any problem in the connections of the filter or in the configuration, the

“NOT INITIAL CONDITIONS” message will be shown along with a description of

the malfunction (Figure 28).

Instruction Manual 31

Page 32

AFQ-4W

Figure 28: Message displayed when the unit is not ready for start-up.

The APPENDIX A: DISPLAY MESSAGES of this manual contains all of the causes

of malfunction and their corrective measures.

If an alarm is tripped, the “ALARM” message will be shown along with a

description of the problem (Figure 29).

Figure 29: Message displayed when the unit is in an alarm state.

Refer to section APPENDIX A: DISPLAY MESSAGES to see the causes of the

alarm and to be able to apply the corrective measures.

The RESET ALARM button rearms the unit if the cause of the alarm has

disappeared or been solved.

32 Instruction Manual

Page 33

AFQ-4W

Mains frequency

Fundamental: 50 Hz

Fundamental: 60 Hz

3

150 Hz

180 Hz

5

250 Hz

300 Hz

7

350 Hz

420 Hz

4. OPERATION

4.1.- OPERATING PRINCIPLE

4.1.1.- HARMONICS

Non-linear loads such as: rectifiers, inverters, speed drives, ovens, etc, absorb

periodic non sine-wave currents from the mains.

These currents are composed of a fundamental frequency component, rated at

50 or 60 Hz, plus a series of overlapping currents, with frequencies that are

multiples of the fundamental frequency; they are defined as HARMONICS.

Figure 30: Distorted wave shape decomposition.

The result is a deformation of the current and, as a result, of the voltage, causing

a series of associated side effects. These can be machinery overload, electric

cable heating, circuit breaker disconnection, damage to sensitive units, etc.

Order (n)

Table 4: Frequ ency of each harmonic.

4.1.2.- BASIC CONCEPTS

It is best to define some terms related to harmonics, fundamental for interpreting

any measurement and study:

Instruction Manual 33

Fundamental frequency (

Order of a harmonic (n)

: Original wave frequency (50/60 Hz ) .

f

)

1

: A whole number given by the ratio between the

frequency of a harmonic and the fundamental frequency. The order

determines the frequency of the harmonic (E.g.: 5th harmonic → 5•50 Hz =

250 Hz).

Page 34

AFQ-4W

Fundamental compo n e nt (

U

: A sine wave component of order 1 of the

I

o

)

1

1

Fourier frequency serial development equal to the original periodic wave.

Harmonic component (

U

n

: A sine wave component of order over 1 of

I

o

)

n

the Fourier frequency serial development a whole multiple of the original

frequency.

Individual distortion rate (

U

% o

n

: A ratio in % between the RMS value

I

%)

n

of the voltage or harmonic current (Un o In) and the RMS value of the

fundamental component (U1 o I1).

Equation 3: Individual distortion rate

True root mean square value (TRMS)

: The square root of the sum of the

squares of all components forming the wave.

Harmonic content

Equation 4: True root mean square value

: The difference between the total voltage or current and

the corresponding fundamental v al ue.

Harmonic distortion r ate (THD)

: The ratio between the RMS value of the

harmonic content of the voltage and/or current and the value of the

fundamental component.

Equation 5: Harmonic distortion rate.

34 Instruction Manual

Page 35

AFQ-4W

Type of load

Wave shape

Harmonic spectrum THD(I)

6-pulse transducers:

4.1.3.- MOST COMMON HARMONICS

Table 5

lists the most common harmonic generator loads and the wave shape of

the current they consume, as well as their harmonic spectrum.

- Speed drives

- UPS

- Three-phase rectifiers

- Transducers for

electrolysis and baths

- Discharge lamps

- Single-phase transducers

- Lighting lines

- Computer lines

-

Sound and image units

Table 5: Most common harmonics.

4.1.4.- HARMONIC COMPENSATION

Active filters are units responsible for the compensation o f harm oni c c ur r ents.

Compensation is achieved by injecting harmonic currents equal to those in the

installation in counter phase.

This means that upstream of the filter connection point, the signal shows virtually no

harmonic distortion. (Figure 31).

Instruction Manual 35

Figure 31: General connection d iagram of an active filter

Page 36

AFQ-4W

4.1.5.- OPERATING PRINCIPLE

Active filters are based on the following principle:

I

FILTER

Equation 6: Operating principle

=

I

MAIN

-

I

LOAD

In other words, they detect the difference between the required current sine

wave (I

the difference between both waves (I

) and the signal deformed by the harmonics (I

MAIN

).

FILTER

). And they inject

LOAD

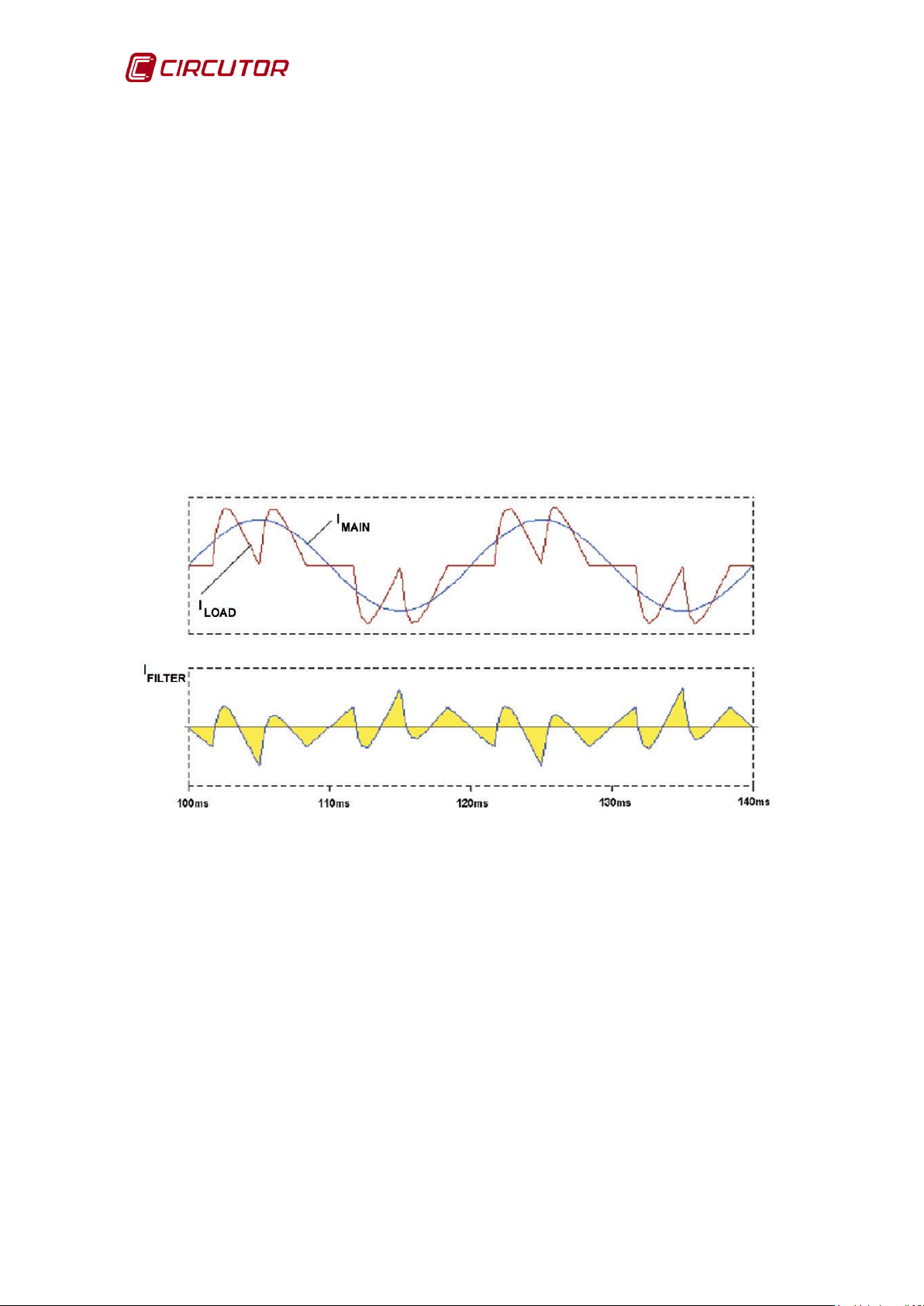

Figure 32 show the wave shapes of the currents injected by the active filters.

These show the required wave, the existing deformed wave and the filter current

(I

FILTER).

Figure 32: Current in the load, in the filter and in the mains.

36 Instruction Manual

Page 37

AFQ-4W

4.2.- DISPLAY

The active filter has a touch display with different screens used for display and

configuration purposes.

4.2.1.- MAIN SCREEN

The main screen contains information regarding the filter status, the start and

stop controls, the alarm rearm process and the accesses to the configuration

and display variables .

Figure 33: Main screen.

As we can see in Figure 33 we can distinguish the following parts:

1- START/STOP key: The start and stop active filter key. The AFQ-4W must

be "STOPPED" before it is started.

2- RESET ALARM key: Alarm rearm key. If the cause of the alarm has not

been resolved, this key allows us to restart the unit.

3- VIEW key: Access to the display screens.

4- SETUP. key: Access to the configuration screens.

5- A message with additional AFQ-4W status information: The APPENDIX A:

DISPLAY MESSAGES

explains all of the messages that can appear along

with the filter status. This information is particularly useful for detecting

and resolving operational problems with the unit and for determining its

work conditions.

Instruction Manual 37

Page 38

AFQ-4W

Message

Status

NO CONNECTION

Initial state of the display .

NOT INITIAL CONDITIONS

AFQ-4W

STOP

The AFQ4W is stopped and ready to start.

RUN

The AFQ-4W is operating

ALARM

The AFQ-4W has a tripped alarm.

6- Message indicating the filter status (Table 6):

The

Table 6: Filter status messages.

initial start-up conditions are not met.

7- Date and time: Display of the unit date and time.

4.2.2.- DISPLAY SCREENS

On pressing VIEW in the home screen (Figure 33), you access the general

display (Figure 34), from where you can access all of the display screens.

Figure 34: General display screen.

The display screens are organised into 4 groups:

• Voltage and current: this option gives us access to the voltage and

current display screen.

• Power: Access to the power display screen.

• THD I: Access to the display screen of the total harmonic distortion of the

load and mains current.

• LOG: Access to the alarm log display screen.

Click on the MAIN key to open the home screen.

38 Instruction Manual

Page 39

AFQ-4W

4.2.2.1.- BROWSING DIAGRAM

Figure 35: Display screen browsing diagram.

Instruction Manual 39

Page 40

AFQ-4W

4.2.2.2.- Voltage and current display screen

This screen (Figure 36) gives the readings of the effective voltages of the three

phases, the effective load currents, the effective mains current and the mains

frequency.

Figure 36: Voltage and current display screen.

Click on the Main key to open the home screen.

Click on the Back key to return to the general display screen.

4.2.2.3.- General power screen

This screen (Figure 37) gives access to the power display screens.

Figure 37: General power screen.

Organised into 3 groups:

• Power Load: Access to the active and reactive and apparent power

display screens of the three load phases.

• Power Mains : Access to the active and reactive and apparent power

display screens of the three mains phases.

40 Instruction Manual

Page 41

AFQ-4W

• Power Filter: Access to the display screen of the percentage of the AFQ-

4W power used with respect to the nominal power of the three phases.

Click on the Main key to open the home screen.

Click on the Back key to return to the general display screen.

4.2.2.3.1.- Load power display screen

This screen (Figure 38) shows the active, reactive, apparent powers and the

power factor of the three load phases.

Figure 38: Load power display screen.

Click on the Main key to open the home screen.

Click on the Back key to return to the general power screen.

Instruction Manual 41

Page 42

AFQ-4W

4.2.2.3.2.- Mains power display screen

This screen (Figure 39) shows the active, reactive, apparent powers and the

power factor of the three mains phases.

Figure 39: Mains power display screen

Click on the Main key to open the home screen.

Click on the Back key to return to the general power screen.

4.2.2.3.3.- Filter power display screen

This shows the instant power used in the three phases L1, L2, L3 of the active

filter as a percentage w it h respect to the pro g r ammed power limit (Figure 40).

Figure 40: Filter power display screen

42 Instruction Manual

Page 43

AFQ-4W

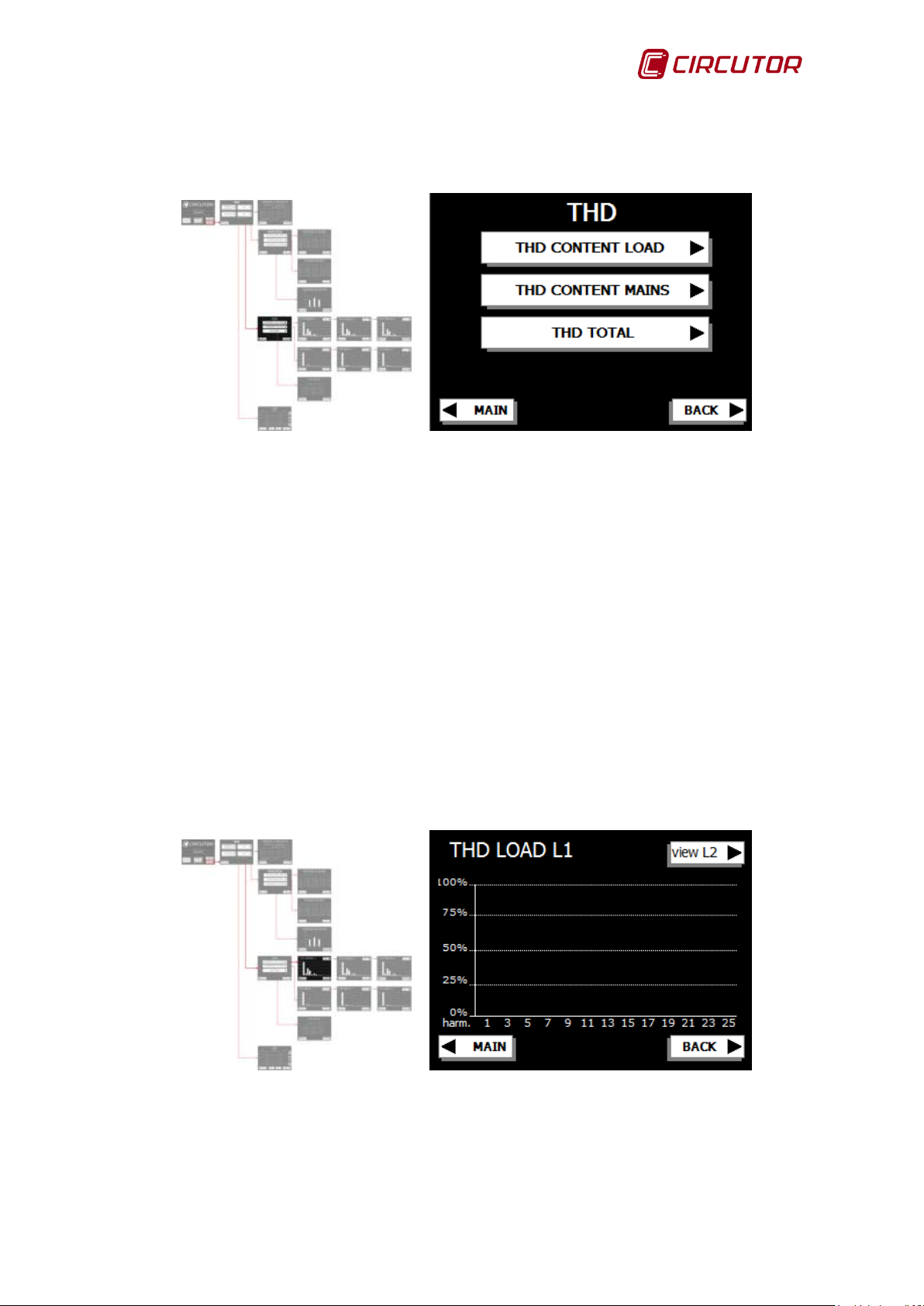

4.2.2.4.- General THD(I) screen

This screen (Figure 41) gives access to the different THD(I) display screens.

Figure 41: General THD(I) screen

• THD(I) Content Load: Access to the display screen of the spectrum in

load current frequencies.

• THD(I) Content mains : Access to the display screen of the spectrum in

mains current frequencies.

• THD(I) Total: Access to the display screen of the total mains and load

THD(I) for the three phases.

Click on the Main key to open the home screen.

Click on the Back key to return to the general display screen.

4.2.2.4.1.- THD Display screen of the phase 1 load current

This screen (Figure 42) will show the THD(I) of the phase 1 load.

Figure 42: THD Display screen of the phase 1 load current.

Click on the Main key to open the home screen.

Click on the Back key to return to the general THD(I) screen.

The view L2 key gives us access to the THD screen of the phase 2 load current.

Instruction Manual 43

Page 44

AFQ-4W

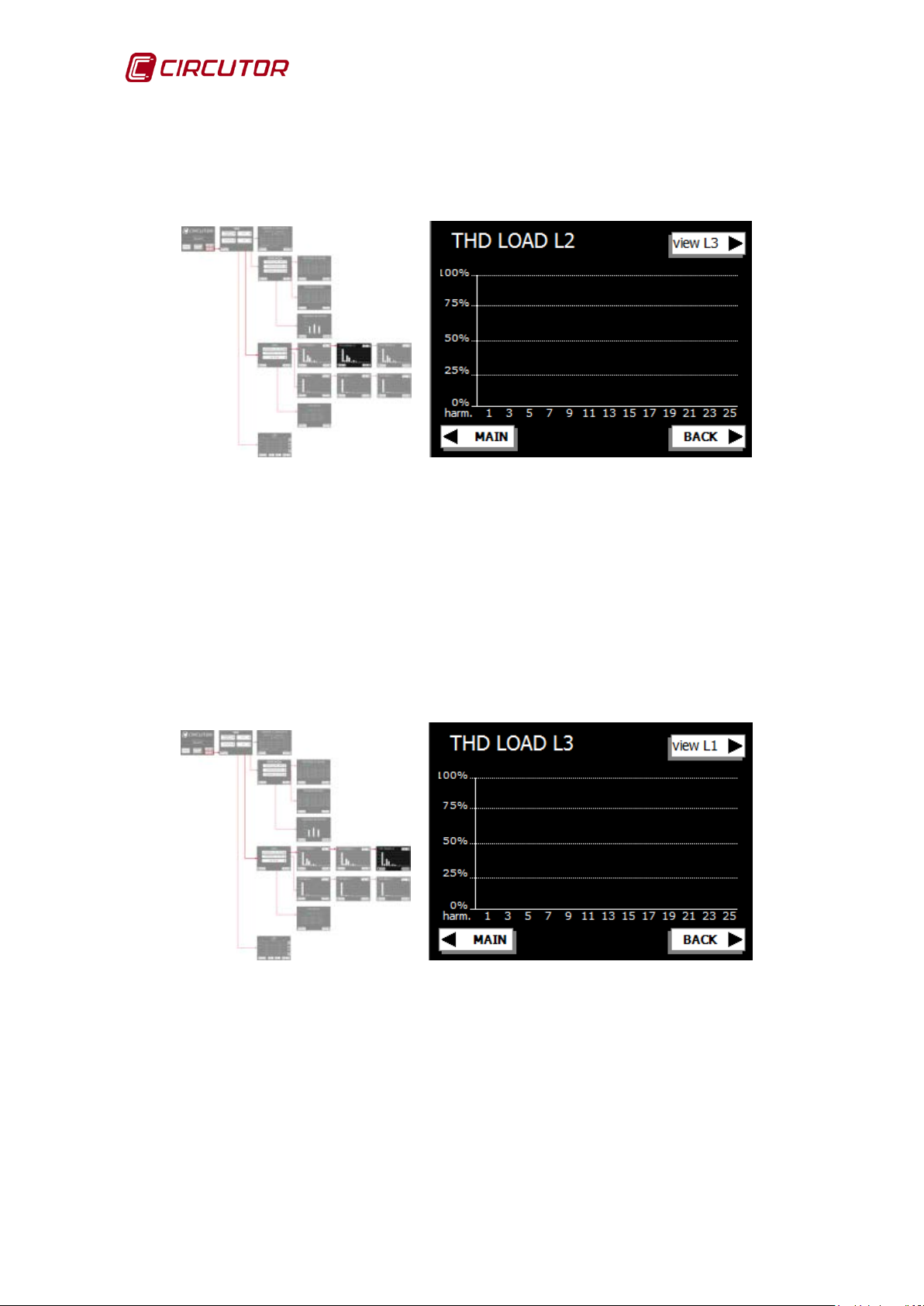

4.2.2.4.2.- THD Display screen of the phase 2 load current

This screen (Figure 43) will show the THD(I) of the phase 2 load.

Figure 43: THD Display screen of the phase 2 load current.

Click on the Main key to open the home screen.

Click on the Back key to return to the general THD(I) screen.

The view L3 key gives us access to the THD screen of the phase 3 load current.

4.2.2.4.3.- THD Display screen of the phase 3 load current

This screen (Figure 44) will show the THD(I) of the phase 3 load.

Figure44: THD Display screen of the phase 3 load current.

Click on the Main key to open the home screen.

Click on the Back key to return to the general THD(I) screen .

The view L1 key gives us access to the THD screen of the phase 1 load current.

44 Instruction Manual

Page 45

AFQ-4W

4.2.2.4.4.- THD Display screen of the phase 1 mains current

This screen (Figure 45) will show the THD(I) of the phase 1 mains.

Figure45: THD Display screen of the phase 1 mains current.

Click on the Main key to open the home screen.

Click on the Back key to return to the general THD(I) screen.

The view L2 key gives us access to the THD screen of the phase 2 mains

current.

4.2.2.4.5.- THD Display screen of the phase 2 mains current

This screen (Figure 46) will show the THD(I) of the phase 2 mains.

Figure 46: THD Display screen of the phase 2 mains current.

Click on the Main key to open the home screen.

Click on the Back key to return to the general THD(I) screen.

The view L3 key gives us access to the THD screen of the phase 3 mains

current.

Instruction Manual 45

Page 46

AFQ-4W

4.2.2.4.6.- THD Display screen of the phase 3 mains current

This screen (Figure 47) will show the THD(I) of the phase 3 mains.

Figure 47: THD Display screen of the phase 3 mains current.

Click on the Main key to open the home screen.

Click on the Back key to return to the general THD(I) screen.

The view L1 key gives us access to the THD screen of the phase 1 mains

current.

4.2.2.4.7.-Display screen of the total THD(I)

This screen (Figure 48) shows the reading of the total THD(I) of the mains and

load phases.

Figure 48: Display screen of the total THD(I).

Click on the Main key to open the home screen.

Click on the Back key to return to the general THD(I) screen.

46 Instruction Manual

Page 47

AFQ-4W

4.2.2.5.- Display screen of the alarm log

This screen (Figure 49) shows the log of events in the active filter, and indicates

the date and time when each event starts and ends.

Figure 49: Display screen of the alarm log.

Click on the Main key to open the home screen.

Click on the Back key to return to the general display screen.

Click on the CLEAR ALL key, all of the incidents are deleted.

Click on the CLEAR SELECT, the selected incident is deleted.

Click on the key to view the messages on the previous page.

Click on the key to view the messages on the following page.

Click on the key to view the messages on the above line.

Click on the key to view the messages on the following line.

Instruction Manual 47

Page 48

AFQ-4W

4.3.- CONFIGURATION

Press SETUP on the AFQ-4W home screen to open the setup menu.

Figure 50: General configuration screen.

The different sub-menus can be accessed through the initial configuration screen

(Figure 50):

• Operation mode, In this sub-menu, you can select the harmonic

neutralising, phase balancing and reactive current compensation options.

• Parameters, Contains the list of the measuring transformers, the

minimum current required to start up the AFQ-4W, the choice of the

control algorithm, the selection of the number of AFQ-4W in parallel and

the filter power limit.

• Filter data, Description of the technical features of the unit.

• Panel setup, Configuration of the language, date, time and

activation/deactivation of the screen sound.

Click on the Main key to open the home screen.

48 Instruction Manual

Page 49

AFQ-4W

4.3.1.- BROWSING DIAGRAM

Figure51: Configuration browsing diagram.

Instruction Manual 49

Page 50

AFQ-4W

4.3.2.- OPERATION MODE CONFIGURATION

In this menu (Figure 52), users can access different screens to perform the

following:

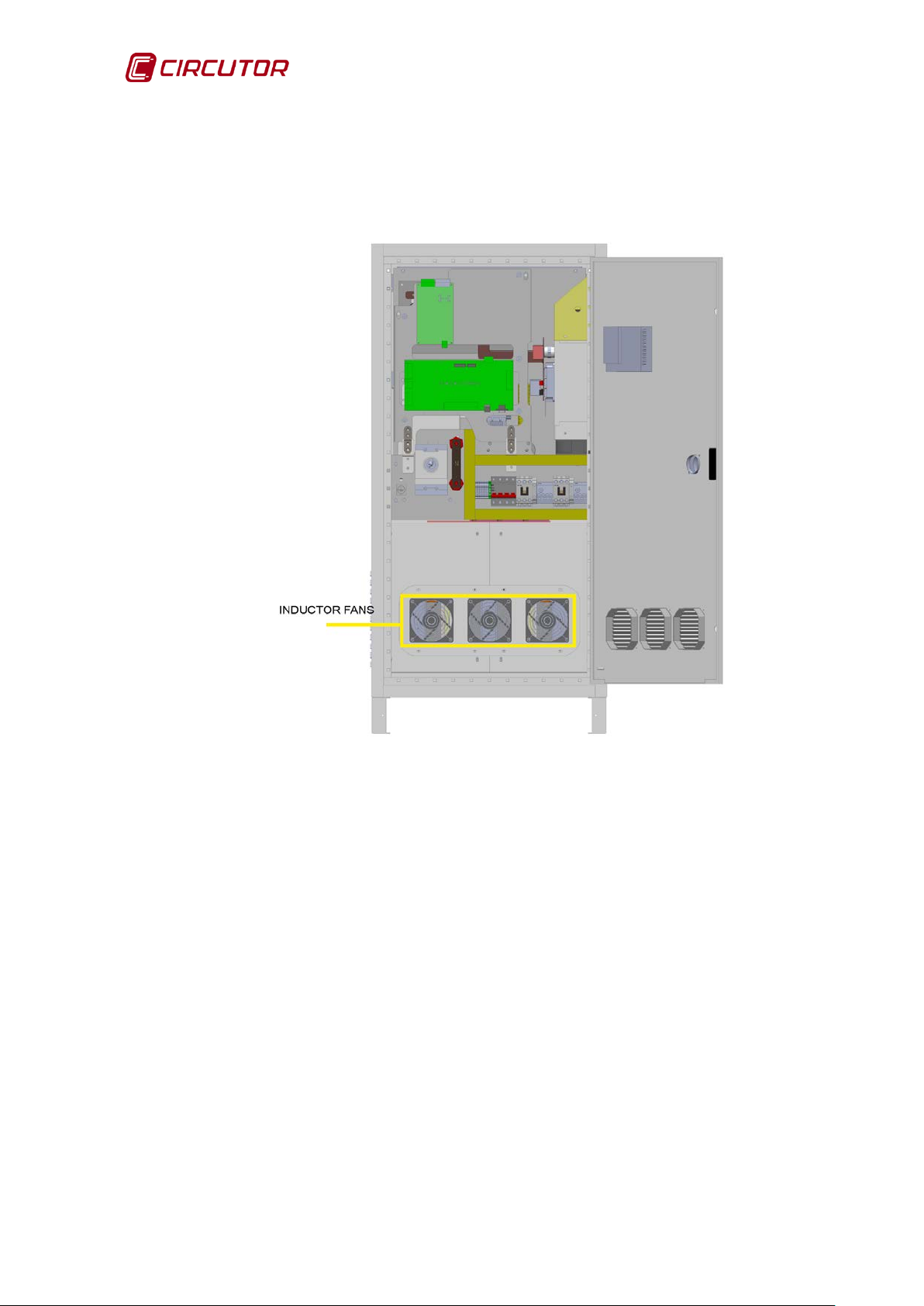

Figure 52: Work mode menu.

• Function selection: Activation or deactivation of the functions of the

AFQ-4W: harmonic filtering, reactive compensation and phase current

balancing.

• Selective filtering: Select the mains compensated harmonics.

• Enable Alarms: enable or disable the different alarms.

The password protection must be unlock ed to change all of these parameters .

Refer to section 4.3.6 to unlock the unit configuration.

Click on the Main key to open the home screen.

Click on the Back key to return to the general configuration screen.

50 Instruction Manual

Page 51

AFQ-4W

Function priority order

OFF

ON

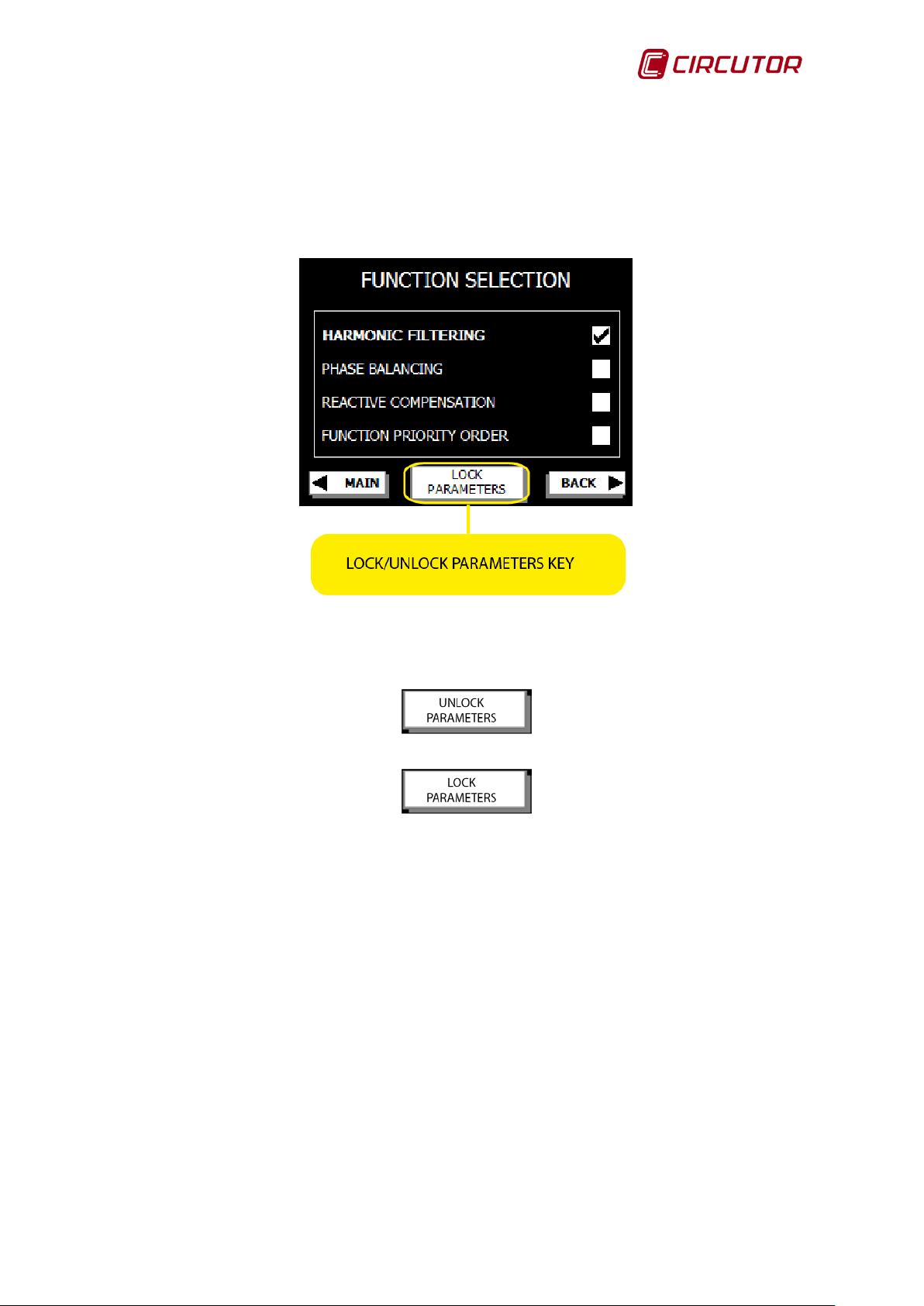

4.3.2.1.- FUNCTION SELECTION

Use this screen (Figure 53) to select the functions of the AFQ-4W:

Figure53: Function selection screen.

Harmonic filtering: Current harmonic neutralisation. (This option is enabled by

default.)

Phase balancing: Balancing of the current between phases. (This option is not

enabled by default.)

Reactive compensation: A function that allows the shifting of the cosΦ to be

compensated. (Thi s op t ion is not ena bl ed by default.)

Function priority Or der: The AFQ-4W allows the functions to be prioritised in

the event of filter current saturation by overload. When the “Function priority

order ” function is disabled, priority is given to the current harmonic filtering and

reactive compensation and overload balancing are penalised. If “Function

priority order” is activated, priority is given to current balancing between phases

and reactive current compensation, ahead of harmonic neutralisation. (This

option is not enabled by default.)

Click on the Main key to open the home screen.

Click on the Back key to return to the work mode screen.

Instruction Manual 51

Harmonic filtering

- +

PRIORITY

Table 7: Configuration of the order of priorities.

Phase balancing +

reactive compensation

Phase balancing +

reactive compensation

Harmonic filtering

Page 52

AFQ-4W

Click on the Lock/Unlock parameters key to lock or unlock the configuration

parameters. (Refer to section 4.3.6)

4.3.2.2.- SELECTIVE F ILTERING

Select the harmonics to be filtered on this screen (Figure 54):

Figure 54: Selective fil tering screen.

If the unit is configured with the control 1 algorit hm (Frequency mode)

(refer to section 4.3.3.- CONFIGURATION OF PARAMETERS , select the

harmonics you wish to neutralise from the 3rd to the 25th. (3rd, 5th, 7th by

default)

If the unit is configured with the control 2 algorithm (Tempora ry mode)

(refer to section 4.3.3.- CONFIG URATION OF PARAMETERS, you can (use

this option only if recommended by your supplier):

• Leave all harmonics unselected. The AFQ-4W will automatically

filter all harmonics from the 3rd to the 50th.

• Select the harmonics NOT to be filtered. The selected harmonics

will not be filtered.

Click on the Main key to open the home screen.

Click on the Back key to return to the work mode screen.

Click on the Lock/Unlock parameters key to lock or unlock the configuration

parameters. (Refer to section 4.3.6)

52 Instruction Manual

Page 53

AFQ-4W

Disable the polarity alarm only in installations with loads temporarily

by default and it is recommended not to

4.3.2.3.- ENABLE ALARM

This screen (Figure 55) allows us to control the different alarms:

Figure 55: Alarm activation screen.

Polarity alarm:

With the polarity alarm enabled, the active filter detects the direction of the load

measuring transformer current and if it detects inverse polarity (current towards

the mains) it returns to the initial conditions and restarts with the new conditions

in measuring the current. In the case of regenerative loads temporarily injecting

current into the mains, the polarity alarm will be activated.

With the polarity alarm disabled, if the load is injecting energy into the mains,

the AFQ-4W will measure negative active power and will stop neutralising

harmonics, balancing phases and compensating reactive energy. It will only

adjust the bus to the operating voltage.

When the active power is positive again, it will reperform all of the filtering

functions.

injecting current into the mains.

This option is enabled

disable it.

Before starting the active filter with the polarity alarm disabled, check

the connection and polarity of the load measuring transformers.

Instruction Manual 53

Page 54

AFQ-4W

by default and it is recommended not to

ed not to

Before disabling the resonance alarm, it is essential to make sure

there is no resonating current between the active filter and the load.

Resonating currents can damage the active filter and other devices

Low temperature Alarm:

This alarm is activated to prevent the unit from starting when the temperature

inside the active filter is below 0ºC or when there is a problem in the connections

of the temperature probes.

This option is enabled

disable it.

Resonance A larm:

The resonance alarm protects the unit against possible resonating currents

between the AFQ-4W and the load. This alarm is tripped when the level of a

harmonic in the load current rises considerably.

This option is enabled by default and it is recommend

disable it.

connected to the installation.

54 Instruction Manual

Page 55

AFQ-4W

4.3.3.- CONFIGURATION OF PARAMETERS

This menu (Figure 56) contains the parameters that have to be configured during

the installation of the active filter. To be modify these parameters, you have to

unlock the password (refer to 4.3.6.- PASSWORD) and have the filter in “STOP”

mode.

Figure 56: Parameter configuration screen.

Transformer ratio:

The ratio between the load transformer primary and secondary.

The active filter admits the following transformation ratios: 5/5, 10/5, 15/5, 20/5,

25/5, 30/5, 40/5, 50/5, 60/5, 75/5, 100/5, 125/5, 150/5, 200/5, 250/5, 300/5,

400/5, 500/5, 600/5, 700/5, 750/5, 800/5, 1000/5, 1200/5, 1500/5, 1600/5,

2000/5, 2500/5, 3000/5, 4000/5 and 5000/5.

Minimum current:

The minimum load current to start the active filter. The AFQ-4W will stop when

the load current is below the entered value and will start when it is higher.

Control algorithm:

Control algorithm selection:

1, Frequency mode: Harmonic filtering based on the selection of the

harmonics to be neutralised from the 3rd to the 25th. (Option enabled by

default.)

2, Temporary mode: Harmonic filtering based on the total and instant

neutralisation of the 3rd to 50t h har m onic s.

When the temporary mode is active, the AFQ-4W resets all the harmonics

selected in “Selective filtering” (Section 4.3.2.2) to completely neutralise

the harmonics.

Instruction Manual 55

Page 56

AFQ-4W

Do not use the Temporary mode (2) if the supplier has not

recommended this for their installation. This method can cause

All of the AFQ-4W must use the same load transformer. Refer to the

resonance in certain installations.

Power limit

This parameter allows the maximum power of the active filter to be limited. The

value is configured as a percentage with respect to the unit's nominal power. The

minimum configurable value is 20%, and the maximum is 100%.

Parallel Modules :

Access to the configuration screen of the number of active filters set out in

parallel with the same load (Figure 57).

Figure 57: Parallel module configuration screen.

A maximum of 8 AFQ-4W units can be installed in parallel, with different power

ratings.

section 3.6.- PARALLEL CONNECTION OF 2 TO 8 ACTIVE FILTERS

to install more than one active filter in parallel.

56 Instruction Manual

Page 57

AFQ-4W

4.3.4.- FILTER DATA This menu (Figure 58) contains the featur es of the AFQ-4W.

Figure 58: Filter data screen.

This information is factory set and cannot be changed by the user.

Filter range: AFQ-4W nominal current.

Serial number: Identification of the AFQ-4W.

Setup code: An internal code used to configure the unit.

Software version: Software version in the unit.

Panel version: Screen software version.

Click on the Main key to open the home screen.

Click on the Back key to return to the general configuration screen.

Instruction Manual 57

Page 58

AFQ-4W

4.3.5.- SCREEN CONFIGURATION

This screen (Figure 59) enables all of the screen parameters to be configured.

Figure 59: Screen configur ation.

Language: Panel language selection.

Date: .Date configuration.

Time: Time configuration.

Sound: Panel beep sound enabling and disabling.

Click on the Main key to open the home screen.

Click on the Back key to return to the general configuration screen.

58 Instruction Manual

Page 59

AFQ-4W

4.3.6.- PASSWORD

All configu ra tion opti ons of the active filter can be password protected. To lock or

unlock the configuration, press on the “LOCK/UNLOCK PARAMETERS” key on

the different screens (Figure 60)

Figure 60: Parameter locking key.

When the locking function is active, the unlocking option appears;

When the locking function is inactive, the activation option appears;

To activate or deactivate the parameter locking function, the password must be

entered on the virtual keyboard on the screen after pressing the

“LOCK/UNLOCK PARAMETERS” key. ( Figure 61)

Instruction Manual 59

Page 60

AFQ-4W

configuration, the password must be reactivated to

RS-485

connector

Figure 61 : Password screen.

The defaul t password is: 1 2 3 4.

The password is confirmed by pressing Enter.

Press ESC to return to the previous screen.

After changing the

avoid accidental changes in the future.

4.4.- RS-485 COMMUNICATIONS

The active filters have a RS-485 communications port with the MODBUS RTU

communications protocol.

The RS-485 communication cable is connected to the back of the display, as

shown in Figura 62:

Figure 62: Position of the RS-485 connector in the AFQ-4W

60 Instruction Manual

Page 61

AFQ-4W

Variable

Value

Protocol

MODBUS RTU slave

Peripheral no.

2

Baud Rate

9600

Parity

No

Data bits

8

Stop bits

1

Permitted Modbus functions

(1)

Read (R)

03

Write (W)

10

The RS-485 connection is shown in Figure 63:

Figure 63: RS-485 connection.

The Modbus configuration of the AFQ-4W is shown in Table 8:

Table 8: Modbus configuration.

The permitted Modbus functions are (Table 9):

(1)

Values expressed as hexadecimals

Table 9: Permitted Modbus functions

Instruction Manual 61

Page 62

AFQ-4W

Peripheral

Modbus

Start

CRC 16

02

03

H L H L H

L

Peripheral

Modbus

No. bytes

Data

CRC 16

02

03

1 Byte

H

L H L

No. bytes

Data

02

10

H L H L 1 Byte

H L H

L

Peripheral

Modbus

Start

CRC 16

02

10

H L H L H

L

4.4.1. MODBUS FRAMES Variable reading

• Question:

number

function

• Response:

number

function

V ariable write

• Question:

Peripheral

number

Modbus

function

• Response:

number

function

address

(2 x number of logs)

Start

address

address

No. logs

No. logs

No. logs

(Modbus)

(2 x number of logs)

(2 x number of

logs)

(Modbus)

(Modbus)

(2 x number of

logs)

CRC 16

(Modbus)

Note All of the values are expressed as hexadecimals.

In Appendi x B: In Modbus Map you can see the memory map of the parameters

that can be viewed via RS-485.

4.4.2. PowerStudio SOFTWARE CIRCUTOR uses the PowerStudio energy management software for the

configuration, com mun i cati on and m oni tor i ng o f the AFQ-4W.

62 Instruction Manual

Page 63

AFQ-4W

is recommended to follow the notes described in this chapter to

Description

Interval

Standard maintenance

5,000 to 9,000 hours

Cooling turbines (for AFQ-4W-100, AFQ-4W-150 and AFQ-4W-

Cooling fans

100,000 h

DC bus capacitors

200,000 h

Follow the safety instructions given in “SAFETY PRECAUTIONS”

lure to follow these instructions may result in injury or even

Certain components in the unit can reach high temperatures.

Allow the unit to cool down before performing any maintenance

5.- MAINTENANCE

The AFQ-4W active filter requires a minimum of preventive maintenance.

It

avoid premature damage to the unit's components.

Table 10 shows the maintenance jobs with their respective time intervals.

200)

Table 10: Active filter maintenance.

40,000 h

Note: The time intervals of the maintenance operations can vary depending on

the unit's operating conditions and environmental factors.

before any maintenance operation in the AFQ-4W filters.

Fai

death.

operations.

Instruction Manual 63

Page 64

AFQ-4W

monthly intervals, depending on the

Display battery

5.1. STANDARD MAINTENANCE

Perform maintenance in 6 to 12

environmental dirt and oper ation of the unit.

The points to be followed are:

1.- Set the AFQ-4W in STOP mode and turn off the main switch

(OFF position).

2.- Wait 5 minutes for the capacitors to discha r g e.

3.- Clean the ventilation grilles, the inside of the unit and fans.

4.- Check the state and tightness of the electrical connections.

5.- Replace the display battery if necessary.

The display uses a CR2032 3V battery. The LED in the bottom left corner of the

display indicates the st ate of the battery.

Green: the battery is correct.

Red: low battery level.

Figure 64: Rear of the display.

The battery display is in its rear, as indicated in Figure 64.

When the panel battery is changed, the language, date and time of the unit have

to be reconfigured. (refer to 4.3.5.- SCREEN CONFIG URATION).

64 Instruction Manual

It is best to note the configuration of the AFQ-4W, refer to 4.3.-

CONFIGURACIÓN

.

Page 65

AFQ-4W

The cooling fans and turbines must work properly to avoid

Inductor

IGBT cooling

AFQ-4W-25 A

3 2 -

AFQ-4W-50 A

AFQ-4W-150 A

6 - 2

AFQ-4W-200 A

6 - 2

5.2. COOLING TURBINES AND FANS

overheating in the active filter components.

Table 11 gives the number of fans and/or turbines required to cool the inductors

and the semiconductors according to the active filter model.

AFQ model

AFQ-4W-100 A

Table 11 : Cooling components depending on the active filter model.

cooling fans

3 4 3 - 1

IGBT cooling fans

turbines

The following symptoms in the behaviour of the filter can indicate wear in the

fans or turbines:

Increased noise in the fan / turbine.

Increased temperature in the unit under the same environmental

conditions and load.

The AFQ-4W periodically indicates the te m p er atur e al arm.

If any sign of wear is detected, the affected fan/turbine should be replaced.

Instruction Manual 65

Page 66

AFQ-4W

5.2.1. INDUCTOR COOLING F ANS

5.2.1.1. AF Q-4W-25 A / 50 A / 100 A MODELS

Follow these instructions to replace the inductor cooling fans in the AFQ-4W25A, AFQ-4W-50A and AFQ-4W-100A models:

Figure 65: Position of the inductor fans in the AFQ-4W-25, AFQ-4W-50 and AF Q-4W-100.

1.- Set the AFQ-4W to STOP mode and turn off the main switch

(OFF position).

2.- Wait 5 minutes for the energy accumulated in the capacitors to discharge.

3.- Open the AFQ-4W cabinet and disconnect the fan's power supply. (Figure

66)

The power supply terminals are located in the lower left corner of the fan. Grasp

the terminal firmly and pull to disconnect it.

66 Instruction Manual

Page 67

AFQ-4W

Figure 66: Disconnection of the fan p o wer supply.

4.- Use a 3 mm Allen key to unscrew the 4 screws fixing the fan to the front

panel. (Figure 67)

Figure 67: Unscrew the 4 screws from the fan

5.- Replace the damaged fan, connecting the power supply terminals in the

bottom left corner.

Instruction Manual 67

Page 68

AFQ-4W

6.- Use the 3 mm Allen key to fix the fan to the front panel. (Figure 68)

Figure 68: Fix the fan to the front panel.

7.-Connect the power supply terminals.

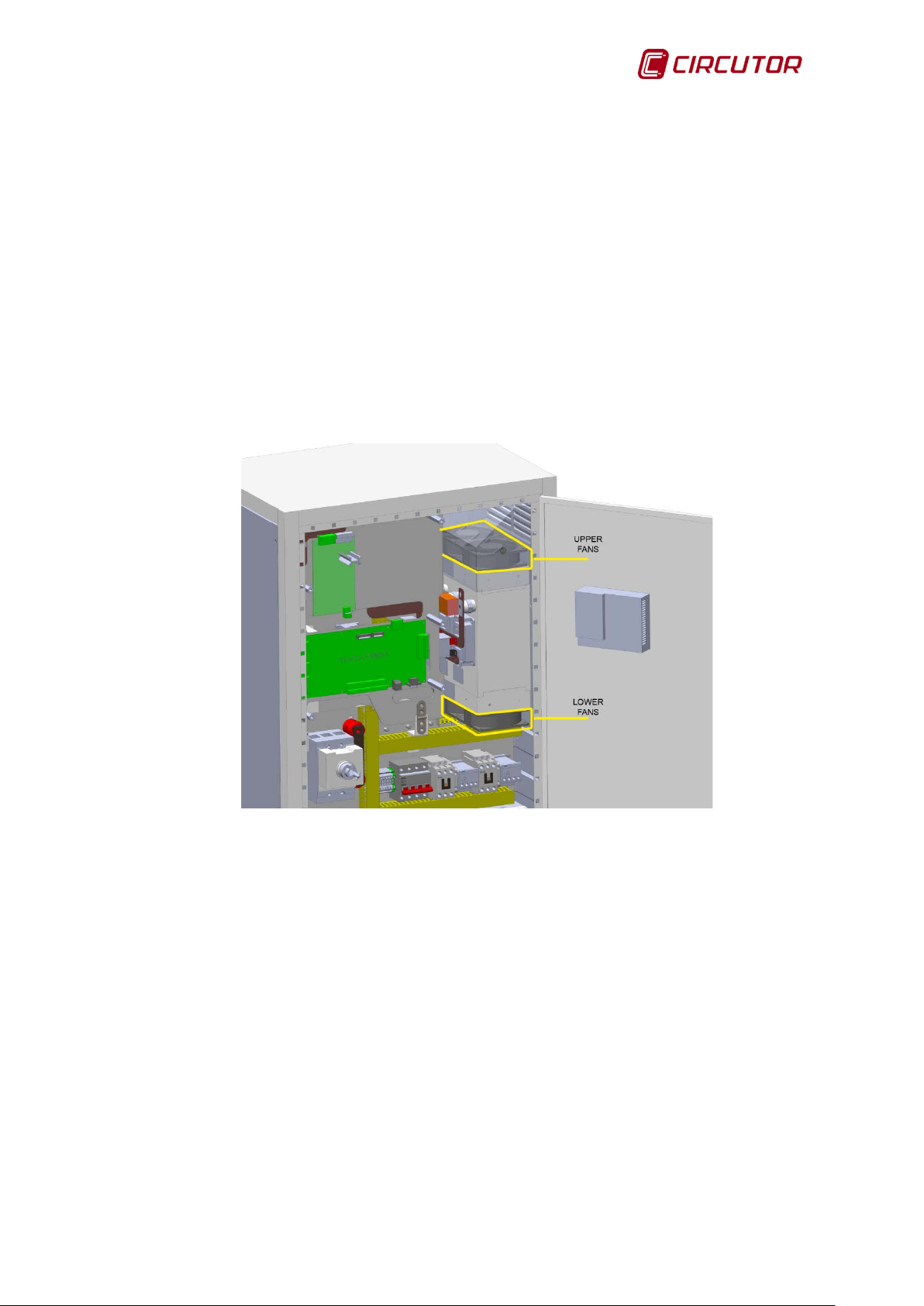

5.2.1.2. AF Q-4W-150 A / 200 A MODELS

Follow these instructions to replace the inductor cooling fans in the AFQ-4W150A, and AFQ-4W-200A models:

Figure 69: Position of the inductor fans in the AFQ-4W-150 and AFQ-4W-200 filters.

1.- Set the AFQ-4W to STOP mode and turn off the main switc h

(OFF position).

68 Instruction Manual

Page 69

AFQ-4W

2.- Wait 5 minutes for the energy accumulated in the capacitors to discharge.

3.- Remove the protection board from the inductor compartment.

(Figure 70)

Figure 70: Remove the protectio n b o ard from the inductor compartment.

4.- Take off the inductor busbars and cables. (Figure 71)

Use a 10 mm socket spanner and 5 mm Allen key to take off the cables

from the inductors' side.

Use a 13 mm socket spanner and 13 mm open-end spanner to

disconnect the cable from the mains side.

Figure 71: Take off the inductor busb ars and cables.

Instruction Manual 69

Page 70

AFQ-4W

5.- Unscrew the compartment cover fasteners with a no. 20 Torx key and remove

the cover. (Figure 72).

Figure 72: Unscrew the cover fasteners

6.- Disconnect the power supply fans by firmly grasping the terminal and pulling

to disconnect it. (Figure 73)

Figure 73: Disconnect the power suppl y from the fans.

7.-Take out the fan being changed using a socket spanner or 7 mm spanner to

hold the rear nut and a flat or Phillips screwdriver to loosen the screw. (Figure

)

74

Figure 74: Remove the fan.

70 Instruction Manual

Page 71

AFQ-4W

8.- Fix and connect the replacement fan.

9.- Fix the inductor compartment cover.

10.- Fasten the inductor cables and busbars.

11.- Fit the protection board.

5.2.2. COOLING FANS/TURBINES OF THE IGBTs

5.2.2.1. AF Q-4W-25 A / 50 A MODELS

The AFQ-4W-25 and AFQ-4W-50 active filters cool the IGBTs using fans.

The fans are fixed to the IGBT heatsink. Each unit has four fans: two on the top

and two on the bottom.

(Figure 75).

Figure 75: Position of the IGBT upper and lower fans (AFQ-4W-25 and AFQ-4W-50).

The instructions that follow must be observed in replacing the fans:

1.- Place the AFQ-4W in STOP mode and turn off the main switch

(OFF position).

2.- Wait 5 minutes for the energy accumulated in the capacitors to discharge.

3.-Remove the protection board and unfasten the front panel holding the

electronic boards. (Figure 76)

Instruction Manual 71

Page 72

AFQ-4W

Figure 76: Position of the protection board ( AFQ-4W-25 and AFQ-4W-50)

4.- Remove the right side cabinet cover.

UPPER FANS

5.- Remove the extractor hood fasteners to be able to reach the top fans. (Figure

77

)

Figure 77: Remove the fasteners from the extractor hood.

6.- Lift the extractor hood, disconnect the power supply from the fans and

remove the hood. (Figure 78)

72 Instruction Manual

Page 73

AFQ-4W

Figure 78: Disconnect the power suppl y from the fans and remove the hood.

7.-Remove the four fan screws to extract them.(Figure 79)

Figure 79: Remove the fan screws.

8.- Replace the damaged fans. Fit the fan, leaving the power supply pins on the

side of the IGBTs

9.- Pass the power supply cable through the drill hole on the hood.

10.- Connect the power supply of the two fans.

11.- Screw back on the extractor hood fasteners.

LOWER FANS

12.- Remove the power supply cable from the bottom heatsink fans. (Figure 80)

Figure 80: Remove the power supply cable

Instruction Manual 73

Page 74

AFQ-4W

1 2 3 5 4

13.- Reach into the fans from the side and remove the right fan fasteners. It is

best to follow the order of the steps shown in Figure 81.

Figure 81: Remove the fan fasteners on the right.

14.- Remove the left fan by unscrewing the four fasteners.

15.- Replace the left fan with a new one.

16.- Replace the fan on the right.

17.- Connect the fan power supply cables.

18.- Lift up and attach the front panel metal plate.

19.- Fit the protection boar d.

20.- Fit the side cover.

21.- Start up the unit and check that the fans operate correctly.

74 Instruction Manual

Page 75

AFQ-4W

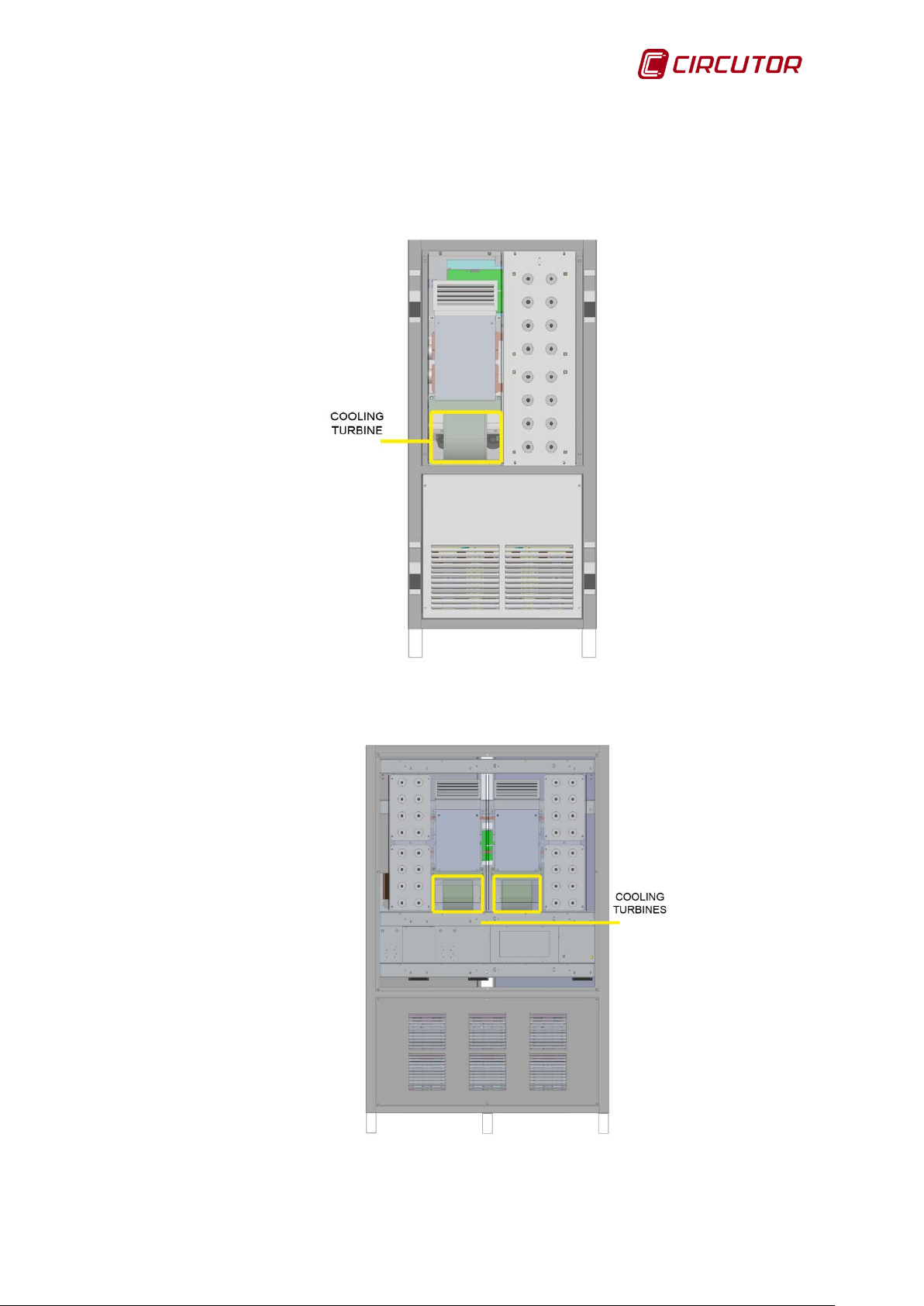

5.2.2.2. AF Q-4W-100 A / 150 A / 200 A MODELS

The AFQ-4W-100A, AFQ-4W-150A and AFQ-4W-200A active f ilters

cool the IGBTs using turbines.

Figure 82: Position of the cooling turbine in the AFQ-4W-100.

Figure 83: Position of the cooling turbines in the AFQ-4W-150 and AFQ-4W-200 filters.

Instruction Manual 75

Page 76

AFQ-4W

5 4 6 5 7

The instructions that follow must be observed:

1.- Place the AFQ-4W in STOP mode and turn off the main switch

(OFF position).

2.- Wait 5 minutes for the energy accumulated in the capacitors to discharge.

3.- Remove the front panel pr otect ion board.

4.- Drop the front panel metal plate. (Figure 84)

5.- Remove the DC bus busbar. (Figure 84)

6.- Disconnect the earth wire from the front panel metal plate. (Figure 84)

7.- Remove the top crossbar. (Figure 84)

Figure 84: Steps 4, 5, 6 and 7

8- Remove the back cabinet cover. The side cabinet covers can be removed if

more space or light is needed during these procedures.

9.- Disconnect the inverter bridge R-S-T phases. (Figure 85)

Figure 85: Disconnect the inverter bridge R-S-T phases.

76 Instruction Manual

Page 77

AFQ-4W

10.- Disconnect the IGBT connectors from the gate board. The top board must

first be removed to be able to disconnect the IGBTs from the bottom board.

11.- Disconnect the NTC connectors from the controller board

12.- Take the NTC probe cabling out of the channel.

13.-. Disconnect the turbine power supply.

The location of the power supply depends on the turbine model.

If the turbine is black, the power supply is on the front part (Figure 86).

Figure 86: Disconnect the turbine power supply (black turbine).

If the turbine has a steel finish, the power supply is on the rear part

(Figure 87).

Figure 87: Disconnect the turbine power supply (steel turbine).

Instruction Manual 77

Page 78

AFQ-4W

14.- Unscrew the extrac tor hood fas te ner s on the back met al pla te (Figure 88).

Figure 88: Unscrew the fasteners from the extractor hood.

15.- Remove the screws fastening the heatsink to the hood. (Figure 89)

Figure 89: Remove the screws fastening the heatsink to the hood.