Page 1

1000 / 1090+ / 1100 / 1105 Barcode

Scanner

Setup barcodes included.

Version 3.02

Page 2

Copyright © 2005~2014 CIPHERLAB CO., LTD.

All rights reserved

The software contains proprietary information of CIPHERLAB CO., LTD.; it is provided

under a license agreement containing restrictions on use and disclosure and is also

protected by copyright law. Reverse engineering of the software is prohibited.

Due to continued product development this information may change without notice. The

information and intellectual property cont ained herein is confident ial between CIPHER LAB

and the client and remains the exclusive property of CIPHERLAB CO., LTD. If you find

any problems in the documentation, please report them to us in writing. CIPHERLAB

does not warrant that this document is error-free.

No part of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic, mechanical, photocopying,

recording or otherwise without the prior written permission of CIPHERLAB CO., LTD.

For product consultancy and technical support, please contact your local sales

representative. Also, you may visit our web site for more information.

The CipherLab logo is a registered trademark of CIPHERLAB CO., LTD.

All brand, product and service, and trademark names are the property of their registered

owners.

The editorial use of these names is for identification as well as to the benefit of the

owners, with no intention of infringement.

CIPHERLAB CO., LTD.

Website:

http://www.cipherlab.com

Page 3

IMPORTANT NOTICES

FOR USA

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

Reorient or relocate t he receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

This device complies with Part 15 of the FCC Rules. Operation is subject to th e following

two conditions: (1) This device may not cause harmful int erference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

FOR CANADA

This digital apparatus does not exceed the Class B limits for radio noise emissions from

digital apparatus as set out in the interference-causing equipment standard entitled

"Digital Apparatus," ICES-003 of Industry Canada.

This device complies with Part 15 of the FCC Rules. Operation is subject to th e following

two conditions: (1) This device may not cause harmful int erference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

Cet appareil numerique respecte les limites de bruits radioelectriques applicables aux

appareils numeriques de Classe B prescrites dans la norme sur le material brouilleur:

"Appareils Numeriques," NMB-003 edictee par l'Industrie.

Page 4

FOR PRODUCT WITH LASER

CAUTION

This laser component emits FDA / IEC Class 2 laser light at the exit port. Do not

stare into beam.

SAFETY PRECAUTIONS

DO NOT expose the scanner to any flammable sources.

Under no circumstances, internal components are self-serviceable.

For AC power adaptor, a socket outlet shall be installed near the equipment and shall

be easily accessible. Make sure there is stable power supply for the scanner or its

peripherals to operate properly.

CARE & MAINTENANCE

Use a clean cloth to wipe dust off the scanning window and the body of the scanner.

DO NOT use/mix any bleach or cleaner.

If you shall find the scanner malfunctioning, write down the specific scenario and

consult your local sales representative.

Page 5

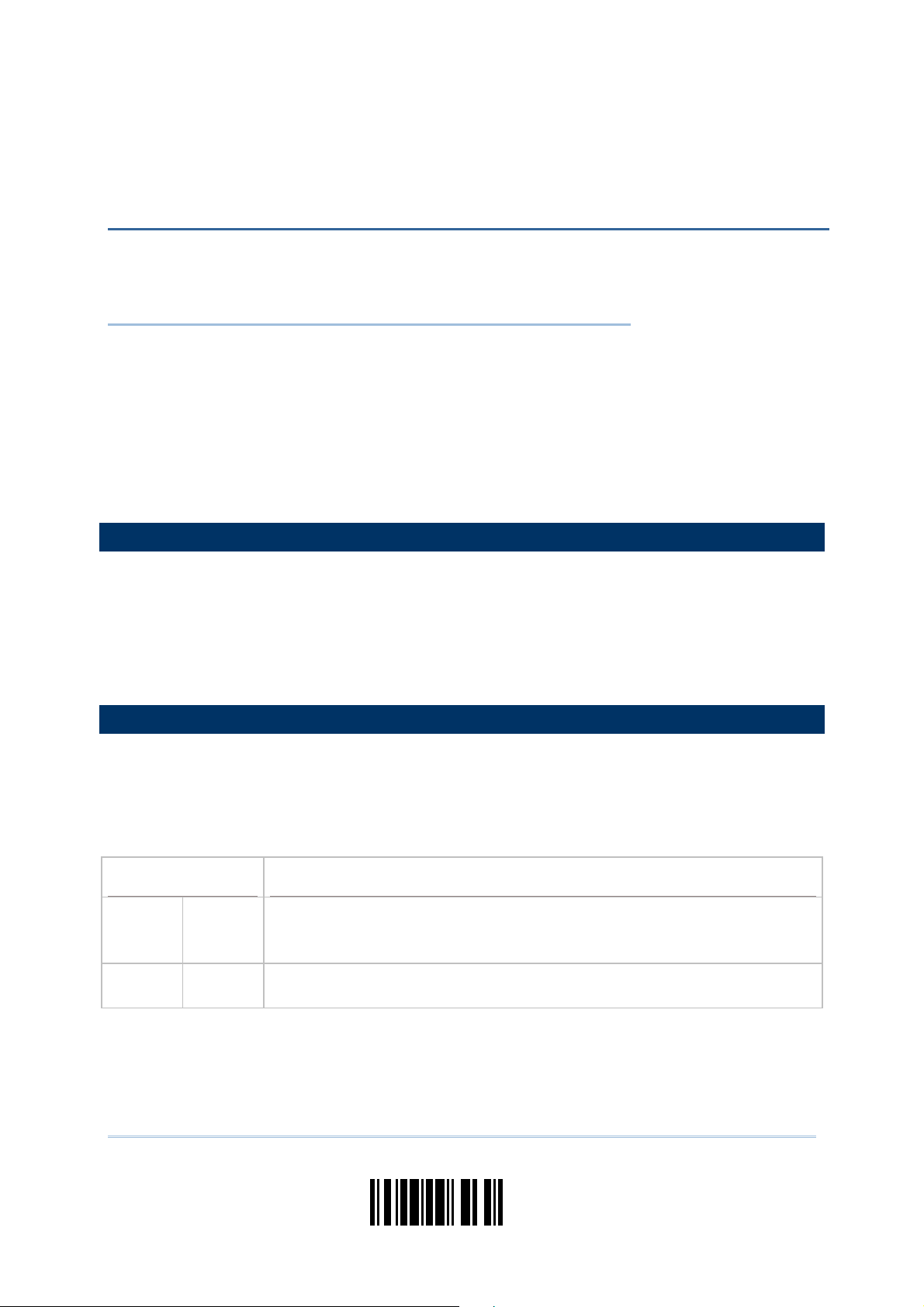

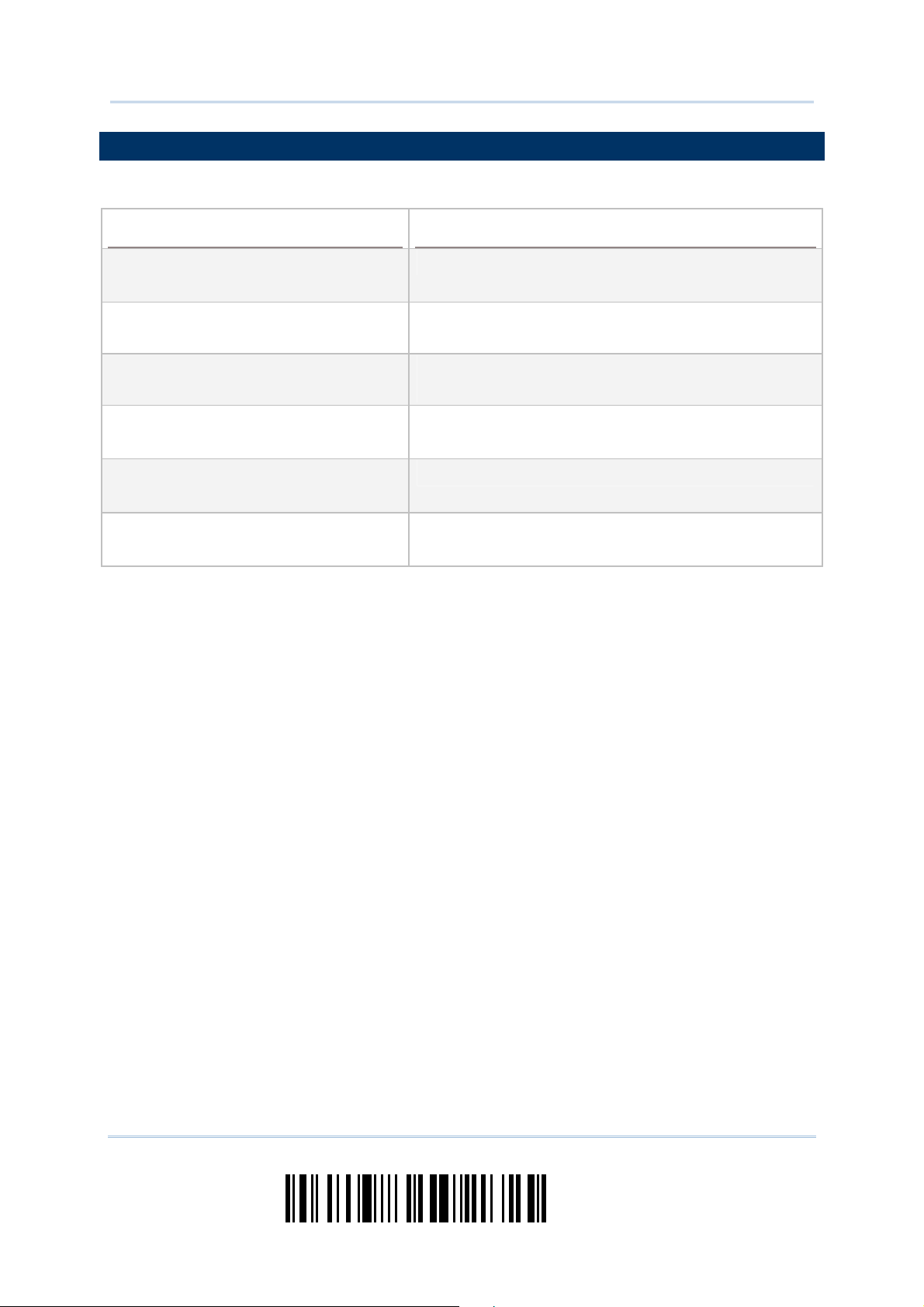

RELEASE NOTES

Version Date Notes

3.02 Jan. 29, 2014

3.01 Jan. 04, 2011

3.00 Nov. 08, 2010 New Layout

Modified: remove 120 0 model (phased out)

Modified: Introducti on – Inside the Package: add notes for CD-ROM

accompanying models that need USB Virtual COM driver

Modified: 2.2.2 Baud Rate – remove barcode (600 bps) for 1200

model

Modified: Specifications — remove max. power consumption

Modified: Introduction, Symbologies Supported — add support of

more RSS symbologies

Modified: 3. 15 GS1 DataBar (RSS Family)

Modified: 3. 15.2 GS1 DataBar Omnidirectional (RSS-14)

Modified: 3. 15.3 GS1 DataBar Expanded (RSS Expanded)

Page 6

Page 7

CONTENTS

IMPORTANT NOTICES ...................................................................................................................... - 3 -

For USA .......................................................................................................................................... - 3 -

For Canada .................................................................................................................................... - 3 -

For Product with Laser .................................................................................................................. - 4 -

Safety Precautions ........................................................................................................................ - 4 -

Care & Maintenance ..................................................................................................................... - 4 -

RELEASE NOTES.............................................................................................................................. - 5 -

INTRODUCTION.................................................................................................................................... 1

Inside the Package............................................................................................................................ 2

Accessories & Interface Options ...................................................................................................... 2

Product Highlights ............................................................................................................................. 3

Symbologies Supported .................................................................................................................... 4

QUICK START ....................................................................................................................................... 7

Enter Configuration Mode................................................................................................................. 8

Exit Configuration Mode.................................................................................................................... 8

Default Settings................................................................................................................................. 9

Restore System Defaults ............................................................................................................. 9

Read a Setup Barcode.................................................................................................................... 10

Configure Parameters................................................................................................................ 10

List the Current Settings............................................................................................................ 14

UNDERSTANDING THE BARCODE SCANNER.................................................................................... 15

1.1 Power......................................................................................................................................... 15

1.2 LED Indicator ............................................................................................................................15

1.3 Beeper....................................................................................................................................... 16

1.3.1 Good Read Beep .............................................................................................................. 17

1.3.2 Frequency .........................................................................................................................17

1.4 Scan Modes .............................................................................................................................. 18

1.4.1 Continuous Mode............................................................................................................. 19

1.4.2 Test Mode......................................................................................................................... 19

1.4.3 Laser Mode....................................................................................................................... 19

1.4.4 Auto Off Mode...................................................................................................................20

1.4.5 Auto Power Off Mode ....................................................................................................... 20

1.4.6 Alternate Mode.................................................................................................................20

1.4.7 Repeat Mode .................................................................................................................... 21

1.4.8 Momentary Mode............................................................................................................. 21

1.5 Scanning Timeout.....................................................................................................................22

1.6 Delay between Re-read ............................................................................................................ 23

1.7 Read Redundancy for All Symblogies...................................................................................... 24

1.8 Auto-Sense Mode (1100 Only).................................................................................................25

Page 8

1000/1090+/1100/1105 Barcode Scanner User Guide

1.9 Negative Barcodes ...................................................................................................................

25

SELECTING OUTPUT INTERFACE .......................................................................................................27

2.1 Keyboard Wedge ......................................................................................................................28

2.1.1 Activate Keyboard Wedge & Select Keyboard Type....................................................... 28

2.1.2 Keyboard Settings............................................................................................................ 30

2.1.3 Inter-Character Delay ....................................................................................................... 38

2.2 RS-232 ......................................................................................................................................39

2.2.1 Activate RS-232 Interface ...............................................................................................39

2.2.2 Baud Rate......................................................................................................................... 39

2.2.3 Data Bits ........................................................................................................................... 40

2.2.4 Parity ................................................................................................................................. 40

2.2.5 Flow Control......................................................................................................................41

2.2.6 Inter-Character Delay ....................................................................................................... 41

2.3 Wand Emulation .......................................................................................................................42

2.3.1 Activate Wand Emulation.................................................................................................42

2.3.2 Normal State ....................................................................................................................42

2.3.3 Bar State...........................................................................................................................43

2.3.4 Module Time.....................................................................................................................43

2.3.5 Margin Time...................................................................................................................... 44

CHANGING SYMBOLOGY SETTINGS.................................................................................................. 45

3.1 Codabar.....................................................................................................................................46

3.1.1 Start/Stop Characters Selection .....................................................................................46

3.1.2 Start/Stop Transmission..................................................................................................47

3.1.3 CLSI Conversion ...............................................................................................................47

3.2 Code 25 – Industrial 25........................................................................................................... 48

3.2.1 Select Start/Stop Pattern ................................................................................................ 48

3.2.2 Verify Check Digit .............................................................................................................49

3.2.3 Transmit Check Digit........................................................................................................49

3.2.4 Code Length Qualification ...............................................................................................50

3.3 Code 25 – Interleaved 25........................................................................................................51

3.3.1 Select Start/Stop Pattern ................................................................................................ 51

3.3.2 Verify Check Digit .............................................................................................................52

3.3.3 Transmit Check Digit........................................................................................................52

3.3.4 Code Length Qualification ...............................................................................................53

3.4 Code 25 – Matrix 25 ................................................................................................................ 54

3.4.1 Select Start/Stop Pattern ................................................................................................ 54

3.4.2 Verify Check Digit .............................................................................................................55

3.4.3 Transmit Check Digit........................................................................................................55

3.4.4 Code Length Qualification ...............................................................................................56

3.5 Code 39..................................................................................................................................... 57

3.5.1 Transmit Start/Stop Characters...................................................................................... 57

3.5.2 Verify Check Digit .............................................................................................................58

3.5.3 Transmit Check Digit........................................................................................................58

3.5.4 Standard/Full ASCII Code 39 ..........................................................................................58

3.6 Code 93..................................................................................................................................... 59

3.7 Code 128 ..................................................................................................................................59

3.8 EAN-8......................................................................................................................................... 60

3.8.1 Convert to EAN-13............................................................................................................ 61

Page 9

1000/1090+/1100/1105 Barcode Scanner User Guide

3.8.2 Transmit Check Digit........................................................................................................61

3.9 EAN-13 ......................................................................................................................................62

3.9.1 Convert to ISBN ................................................................................................................63

3.9.2 Convert to ISSN ................................................................................................................ 63

3.9.3 Transmit Check Digit........................................................................................................63

3.10 GS1-128 (EAN-128) ............................................................................................................... 64

3.10.1 Transmit Code ID ...........................................................................................................64

3.10.2 Field Separator (GS Character)..................................................................................... 64

3.11 MSI .......................................................................................................................................... 65

3.11.1 Verify Check Digit........................................................................................................... 65

3.11.2 Transmit Check Digit .....................................................................................................65

3.11.3 Code Length Qualification .............................................................................................66

3.12 French Pharmacode...............................................................................................................67

3.12.1 Transmit Check Digit .....................................................................................................67

3.13 Italian Pharmacode ................................................................................................................68

3.13.1 Transmit Check Digit .....................................................................................................68

3.14 Plessey ....................................................................................................................................69

3.14.1 Convert to UK Plessey ...................................................................................................69

3.14.2 Transmit Check Digit .....................................................................................................69

3.15 GS1 DataBar (RSS Family) ....................................................................................................70

3.15.1 Select Code ID................................................................................................................70

3.15.2 GS1 DataBar Omnidirectional (RSS-14)....................................................................... 71

3.15.3 GS1 DataBar Expanded (RSS Expanded)..................................................................... 73

3.15.4 GS1 DataBar Limited (RSS Limited) ............................................................................. 74

3.16 Telepen ...................................................................................................................................75

3.16.1 Telepen Output – Full ASCII/Numeric ..........................................................................75

3.16.2 Apply All 3 Editing Formats to Telepen ......................................................................... 75

3.17 UPC-A....................................................................................................................................... 76

3.17.1 Convert to EAN-13 .........................................................................................................77

3.17.2 Transmit System Number.............................................................................................. 77

3.17.3 Transmit Check Digit .....................................................................................................77

3.18 UPC-E.......................................................................................................................................78

3.18.1 Select System Number.................................................................................................. 79

3.18.2 Convert to UPC-A............................................................................................................ 79

3.18.3 Transmit System Number.............................................................................................. 80

3.18.4 Transmit Check Digit .....................................................................................................80

DEFINING OUTPUT FORMAT.............................................................................................................. 81

4.1 Character Substitution ............................................................................................................. 81

4.1.1 Select a Set for Character Substitution .......................................................................... 82

4.2 Prefix/Suffix Code.....................................................................................................................83

4.3 Code ID......................................................................................................................................84

4.3.1 Select Pre-defined Code ID.............................................................................................. 84

4.3.2 Change Code ID................................................................................................................86

4.3.3 Clear Code ID Settings..................................................................................................... 87

4.4 Length Code.............................................................................................................................. 88

APPLYING FORMATS FOR DATA EDITING.......................................................................................... 93

5.1 Activating Editing Formats .......................................................................................................94

Page 10

1000/1090+/1100/1105 Barcode Scanner User Guide

5.1.1 Activate Editing Formats..................................................................................................

94

5.1.2 Exclusive Data Editing...................................................................................................... 95

5.2 How to Configure Editing Formats........................................................................................... 96

5.2.1 Select Format to Configure.............................................................................................. 97

5.2.2 Restore Default Format ................................................................................................... 98

5.3 Configuring Format — Define Data Criteria ............................................................................. 99

5.3.1 Applicable Code Type....................................................................................................... 99

5.3.2 Data Length ....................................................................................................................103

5.3.3 Matching String & Location ...........................................................................................104

5.4 Configuring Format — Define Data Field ...............................................................................105

5.4.1 Total Number of Fields...................................................................................................105

5.4.2 Field Settings..................................................................................................................106

5.5 Configuring Format — Define Transmission Sequence ........................................................112

5.6 Programming Examples .........................................................................................................114

5.6.1 Example I ........................................................................................................................114

5.6.2 Example II .......................................................................................................................115

SPECIFICATIONS..............................................................................................................................117

1000, 1090+.................................................................................................................................117

1100, 1105 ...................................................................................................................................119

HOST SERIAL COMMANDS..............................................................................................................121

Serial Commands..........................................................................................................................121

Example .........................................................................................................................................122

KEYBOARD WEDGE TABLE..............................................................................................................123

Key Type & Status .........................................................................................................................124

Key Type....................................................................................................................................124

Key Status ................................................................................................................................124

Example .........................................................................................................................................125

NUMERAL SYSTEMS........................................................................................................................127

Decimal System.............................................................................................................................127

Hexadecimal System.....................................................................................................................128

ASCII Table.....................................................................................................................................129

Page 11

INTRODUCTION

CipherLab Barcode Scanners provide convenient and versatile solutions to meet your

business needs. The tethered handheld scanners are designed to help accelerate

productivity while lowering the total cost of ownership. Intensive data collection jobs are

made easier with fast, accurate barcode scanning in retail, industrial, manufacturing, and

enterprise environments.

Owing to the compact design, extremely low power consumption, and powerful decoding

capability, CipherLab Barcode Scanners are the best choice for the following

applications –

Receiving in Retail

Product labeling & Tracking

Shelf Product Replenishment

Mobile Poin t of Sale (POS)

Mobile Inventory Management

Order Picking & Staging

Work-In-Process Tracking

Material Flow Control

Transportation & Distribution

Warehousing

Asset Management

This manual contains information on operating the scanner and using its features. We

recommend you to keep one copy of the manual at hand for quick reference or

maintenance purposes. To avoid any improper disposal or operation, please read the

manual thoroughly before use.

Thank you for choosing CipherLab products!

1

Update

Page 12

1000/1090+/1100/1105 Barcode Scanner User Guide

INSIDE THE PACKAGE

The items included in the package may be different, depending on your order. Rich

choices of output interfaces are available for you to enhance the total performance of the

scanner. Refer to product specifications.

Save the box and packaging material for future use in case you need to store or ship the

scanner.

Barcode Scanner: 1000, 1090+, 1100, or 1105

Product CD (only for models that need USB Virtual COM driver)

Note: (1) You may purchase one or more interface cable separately. For USB Virtual

COM (Part #308), find the associated driver on the CD.

(2) The CD-ROM includes this manual and Windows-based ScanManager software

for configuration, as well as the 308 driver.

(3) For model designation, please see the label on the scanner.

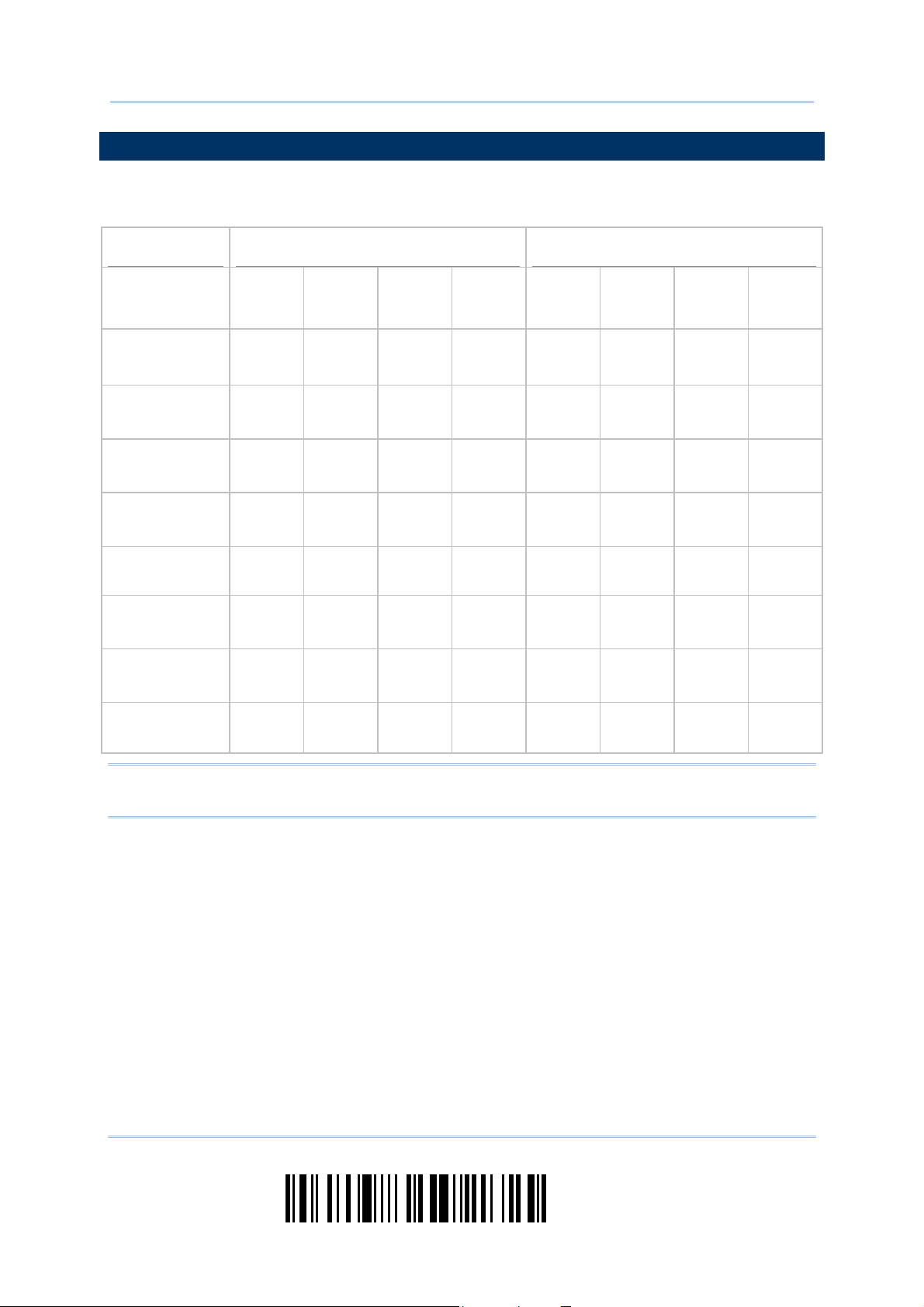

ACCESSORIES & INTERFACE OPTIONS

Rich choices of output interface are available to enhance the total performance of the

scanner.

Accessories

Keyboard Wedge Cable

RS-232 Cable

Wand Emulation Cable

USB HID Cable (307)

USB Virtual COM Cable (308)

IBM 4683/4694 Cable (346)

Auto-Sense Stand

Holder

1000 1090+ 1100 1105

√ √ √

√ √ √

√ √ √

√ √ √

√ √ √

√ √ √

√

√ √

Assembly Options 1000 1090+ 1100 1105

Keyboard Wedge

RS-232

USB HID (307)

USB Virtual COM (308)

√

√

√

√

IBM 4683/4694 (346)

√

2

Enter Setup

Page 13

Introduction

PRODUCT HIGHLIGHTS

Ergonomic design and built tough to survive drop test.

Extremely low power consumption

Supports most popular barcode symbologies, including GS1-128 (EAN-128), GS1

DataBar (RSS), etc.

Supports negative barcodes

Supports eight different scan modes

User feedback includes dual-color LED indicator and beeper

Beeping tone programmable for Good Read

Choices of output interfaces, including RS-232, Keyboard Wedge, Wand Emulation,

USB HID, USB Virtual COM, IBM 4683/4694, etc.

Programmable parameters include data output format, editing format, symbologies,

etc.

3

Update

Page 14

1000/1090+/1100/1105 Barcode Scanner User Guide

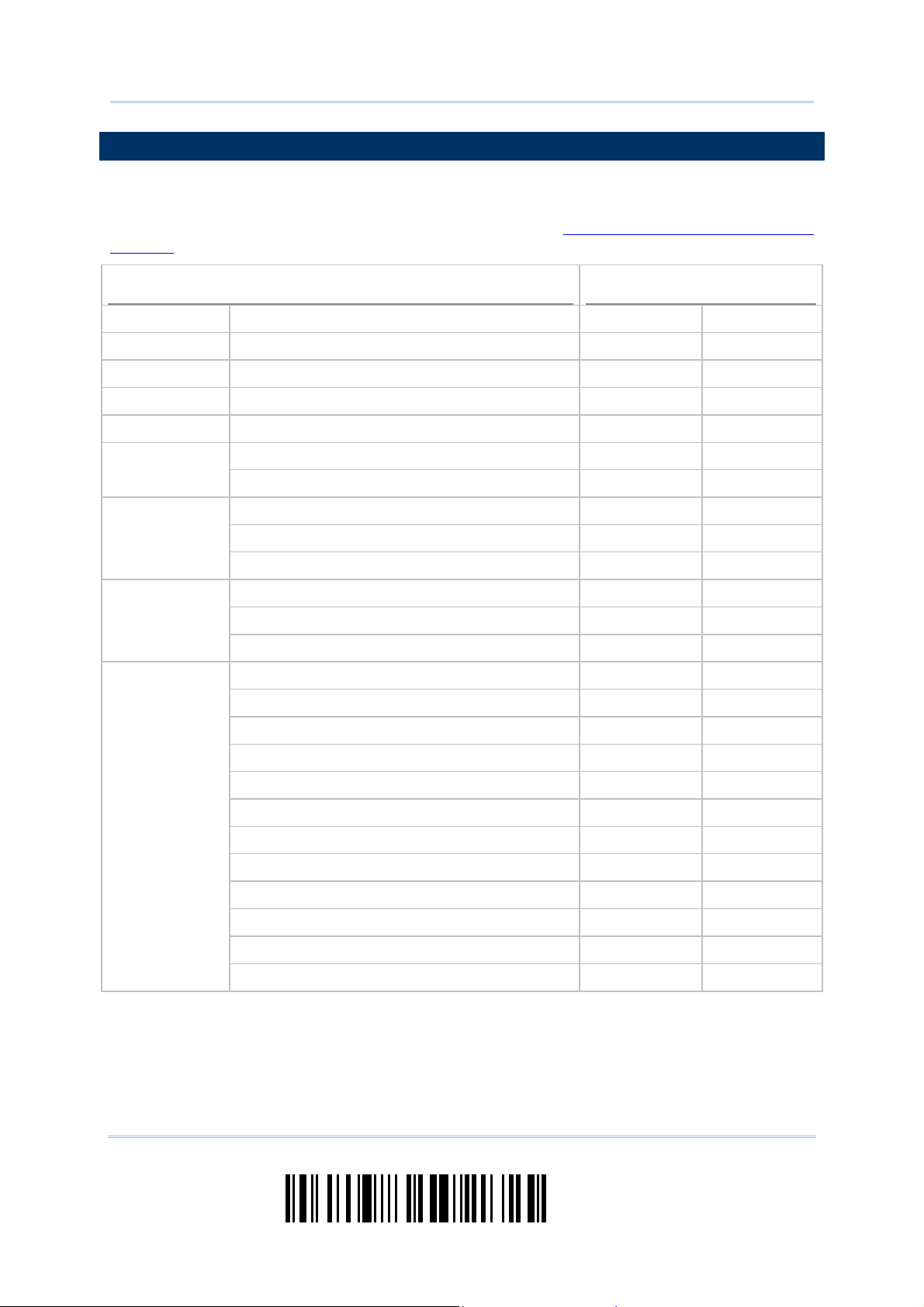

SYMBOLOGIES SUPPORTED

Most of the popular barcode symbologies are supported, as listed below. Each can be

individually enabled or disabled. The scanner will automatically discriminate and

recognize all the symbologies that are enabled. Refer to

Settings for details of each symbology.

Chapter 3 Changing Symbology

Symbologies Supported: Enable/Disable

Codabar Enabled

Code 93 Enabled

MSI Disabled

Plessey Disabled

Telepen Disabled

Code 128 Enabled Code 128

GS1-128 (EAN-128) Disabled

Code 2 of 5

Code 3 of 9

EAN/UPC

Industrial 25 Enabled

Interleaved 25 Enabled

Matrix 25 Disabled

Code 39 Enabled

Italian Pharmacode Disabled

French Pharmacode Disabled

EAN-8 Enabled

EAN-8 Addon 2 Disabled

EAN-8 Addon 5 Disabled

Default

4

EAN-13 Enabled

EAN-13 & UPC-A Addon 2 Disabled

EAN-13 & UPC-A Addon 5 Disabled

ISBN Disabled

UPC-E0 Enabled

UPC-E1 Disabled

UPC-E Addon 2 Disabled

UPC-E Addon 5 Disabled

UPC-A Enabled

Enter Setup

Page 15

Introduction

GS1 DataBar

(RSS)

GS1 DataBar Omnidirectional (RSS-14) Disabled

GS1 DataBar Truncated Disabled

GS1 DataBar Stacked Disabled

GS1 DataBar Stacked Omnidirectional Disabled

GS1 DataBar Limited (RSS Limited) Disabled

GS1 DataBar Expanded (RSS Expanded) Disabled

GS1 DataBar Expanded Stacked Disabled

5

Update

Page 16

1000/1090+/1100/1105 Barcode Scanner User Guide

6

Enter Setup

Page 17

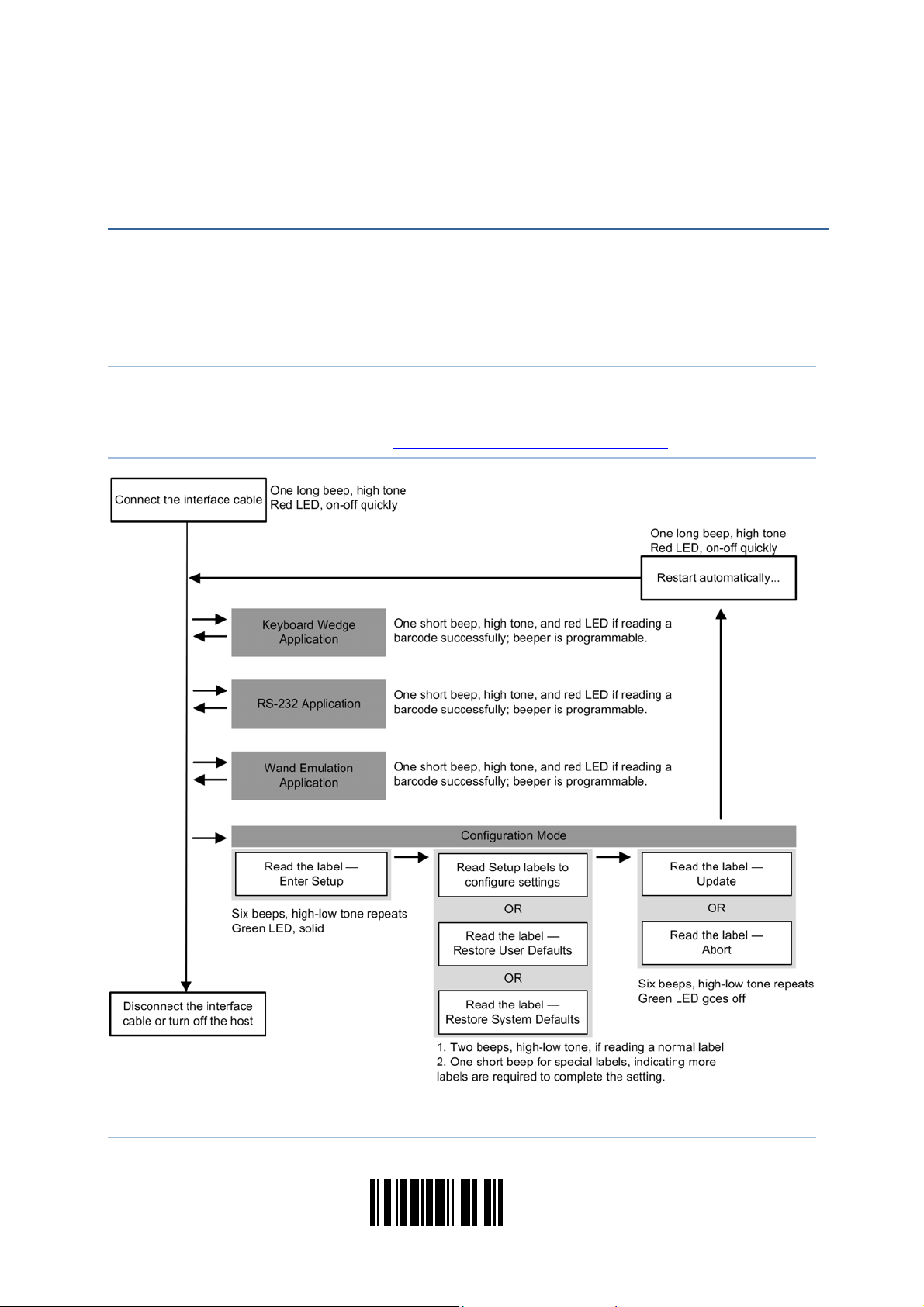

QUICK START

The configuration of the scanner can be done by reading the setup barcodes contained in

this manual or via the ScanManager software.

This section describes the procedure of configuring the scanner by reading the setup

barcodes and provides some examples for demonstration.

Note: If RS-232 is selected for output interface, the host can directly send serial

commands to configure the scanner.

For example, run HyperTerminal.exe and type the 4-digit command located under

each setup barcode. Refer to

Appendix II Host Serial Commands.

7

Update

Page 18

1000/1090+/1100/1105 Barcode Scanner User Guide

ENTER CONFIGURATION MODE

For the scanner to enter the configuration mode, you must have it read the "Enter Setup"

barcode, which can be located at the bottom of almost every even page of this manual.

The scanner will respon d with six beeps and its LED indicator will become solid green

after reading the barcode.

Enter Setup

For configuring scanner parameters, see “Read a Setup Barcode” below.

EXIT CONFIGURATION MODE

For the scanner to save settings and exit the configuration mode, you must have it read

the “Update” barcode, which can be located at the bottom of almost every odd page of

this manual. If you want to exit the configuration mode without saving any changes,

have the scanner read the “Abort” barcode instead.

Just like readin g the “Enter Setup” barcode, the scanner will respond with six beeps

and its LED indicator will go off after reading the barcode. Wait for a few seconds for

the scanner to restart itself.

Update

Abort

8

Enter Setup

Page 19

Quick Start

DEFAULT SETTINGS

RESTORE SYSTEM DEFAULTS

For the scanner to restore the factory defaults, you must have it read the “Restore

System Defaults” barcode. This is a normal setup barcode, and the scann er will respond

with two beeps (high-low tone).

After reading t he “Update” barcode, all the parameters of the scanner will return to

their default values.

Restore System

Defaults

Note: The system default value (if there is) for each setting is indicated by an asterisk

“*”.

9

Update

Page 20

1000/1090+/1100/1105 Barcode Scanner User Guide

READ A SETUP BARCODE

CONFIGURE PARAMETERS

For most of the scanner parameters, only one read is required to set them to new values.

The scanner will respond with two beeps (high-low tone) when each parameter is set

successfully.

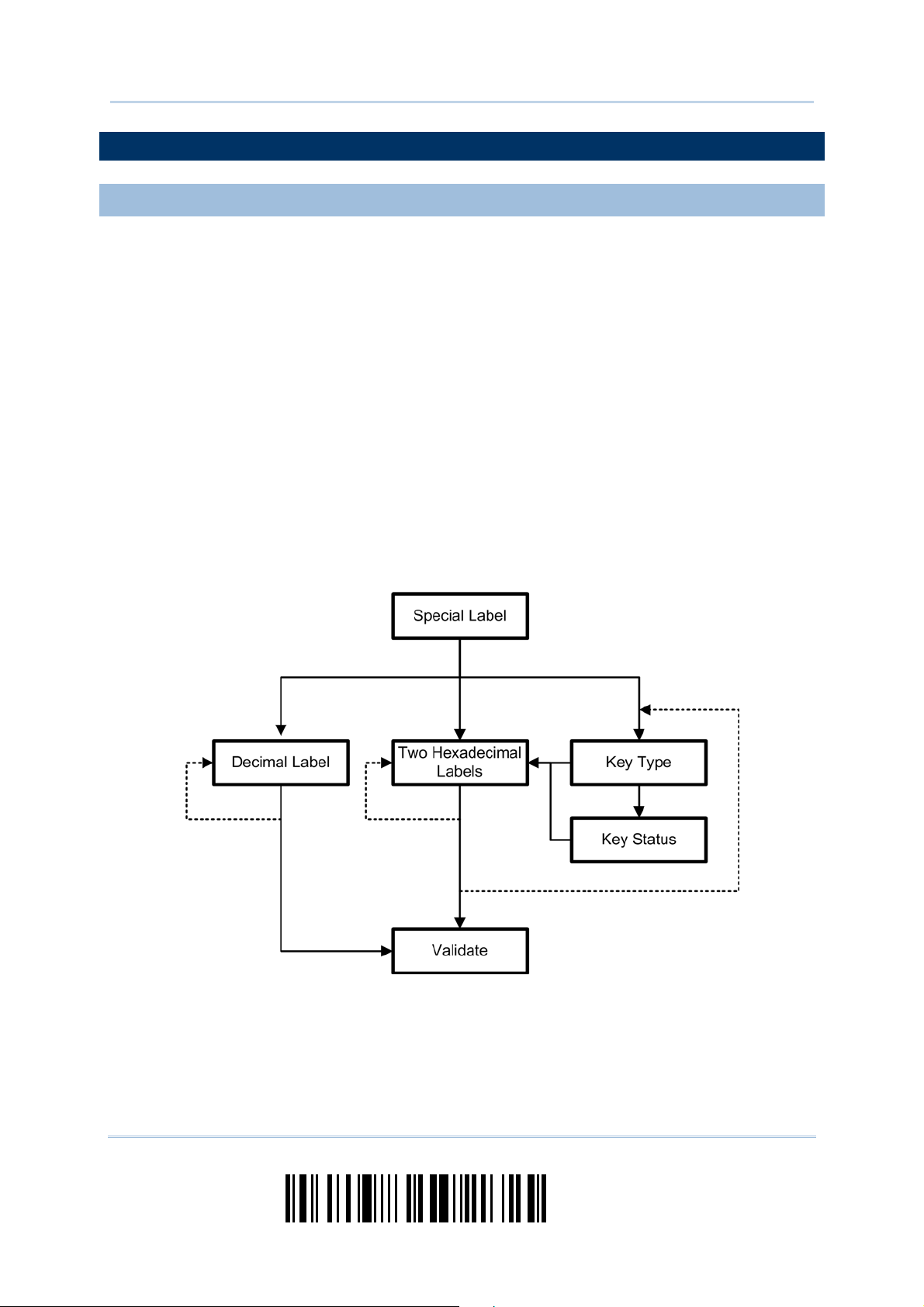

But for a number of special parameters, multiple reads are required to complete the

setting. In this case, the scanner will respond with a short beep to indicat e it needs to

read more setup barcodes. These special parameters may require reading one or more

setup barcodes, such as

Numeric barcodes, say, f or k eyboard type, inter-character delay, length qualification

Hexadecimal barcodes, say, for character strings as prefix, suffix, etc.

When “Keyboard Wedge” is configured for interface, Key Type and Key Status will

then become applicable. You may decide whether or not to change key status when

“Normal Key” is selected for Key Type.

To complete the configuration of these special parameters, it requires reading the

“Validate” barcode, and the scanner will respond with two beeps (high-low tone) to

indicate the input values are validated.

10

Enter Setup

Page 21

Quick Start

T

T

T

The example below shows how to enable a specific symbology, say, Interleaved 25:

Steps

1 Power on the scanner…

Action User Feedback if Successful

he scanner will respond with a long beep

(high tone)

and its LED indicator will

become solid red and go off quickly.

2 Enter the Configuration Mode…

Enter Setup

The scanner

will respond with six beeps

(high-low tone repeats three times), and

its LED indicator will become solid green.

3 Read a Setup barcode…

For example,

he scanner will respond with two beeps

(high-low tone) if reading a normal setup

barcode.

Enable Interleaved 25

4 Exit the Configuration Mode…

Same as for Enter the Configuration Mode.

Update OR Abort

5 The scanner will automatically restart itself… Same as for Power on the scanner.

* When any configuration error occurs...

he scanner will respond with one long

beep (low tone).

11

Update

Page 22

1000/1090+/1100/1105 Barcode Scanner User Guide

T

T

T

T

T

N

N

The example below shows how to set numeric parameters:

Steps

1 Power on the scanner...

2 Enter the Configuration Mode…

3

ormal setup

barcode

ormal setup

barcode

Special setup

barcode

Decimal barcodes

4 Exit the Configuration Mode…

Action User Feedback if Successful

Enter Setup

Read a Setup barcode...

For example,

Enable Interleaved 25

Select Max./Min. Length

Qualification

Max. Length

Validate

1

5

he scanner will respond with a long beep

(high tone) and its LED indicator will

become solid red and go off quickly.

he scanner will respond with six beeps

(high-low tone repeats three times), and

its LED indicator will become solid green.

he scanner will respond with two beeps

(high-low tone) if reading a normal setup

barcode.

he scanner will respond with one short

beep if reading a special setup barcode

such as “Max. Length”, indicating the

setup requires reading more barcodes.

Read the “Decimal Value” barcode(s).

Refer to Appendix IV “Decimal

System”

he scanner will respond with two beeps

(high-low tone) when the input values are

validated.

Same as for Enter the Configuration Mode.

Update OR Abort

5 The scanner will automatically restart itself… Same as for Power on the scanner.

12

Enter Setup

Page 23

Quick Start

T

T

T

The example below shows how to set string parameters:

Steps

1 Power on the scanner...

2 Enter the Configuration Mode…

3

Special setup

Hexadecimal

4 Exit the Configuration Mode…

Action User Feedback if Successful

Enter Setup

Read a Setup barcode...

For example,

barcodes

barcodes

Prefix Code

<Normal>

Add Left Alt

2

B

Validate

he scanner will respond with a long beep

(high tone)

become solid red and go off quickly.

he scanner will respond with six beeps

(high-low tone repeats three times), and

its LED indicator will become solid green.

he scanner will respond with one short

beep if reading a special setup barcode

such as “Prefix Code”, indicating the setup

requires reading more barcodes.

When “Keyboard Wedge” is configured for

interface, Key Type and Key Status will

then become applicable. You may decide

whether or not to change key status

“Normal Key” is selected for Key Type.

Refer to Appendix III

Read the “Hexadecimal Value” barcodes

for the desired character string. For

example, read “2” and “B” for the scanner

to prefix the character “+”.

Refer to Appendix IV “Hexadecimal

System”

The scanner will respond with two beeps

(high-low tone) when the input values are

validated.

Same as for Enter the Configuration Mode.

and its LED indicator will

when

Update OR Abort

5 The scanner will automatically restart itself… Same as for Power on the scanner.

13

Update

Page 24

1000/1090+/1100/1105 Barcode Scanner User Guide

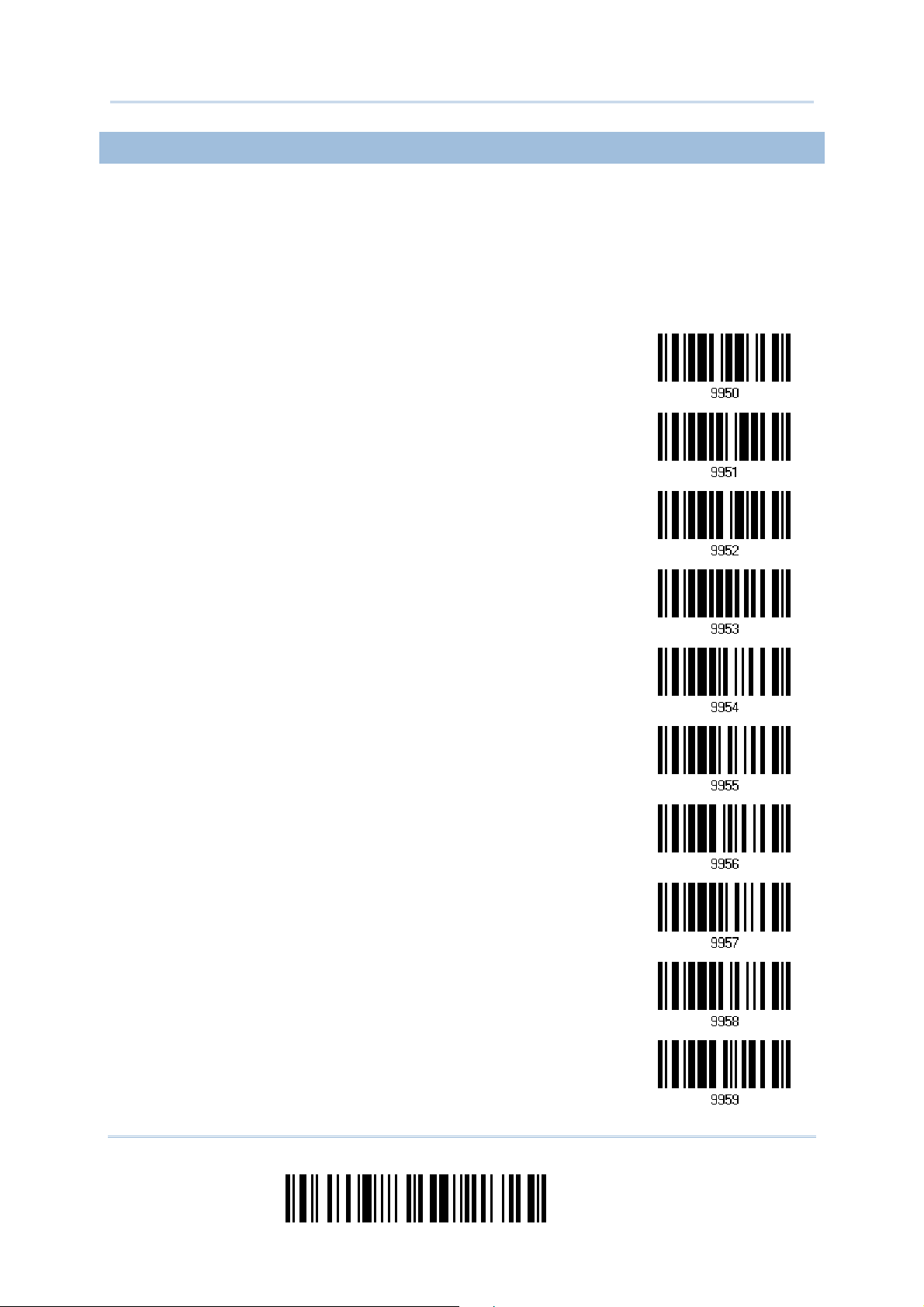

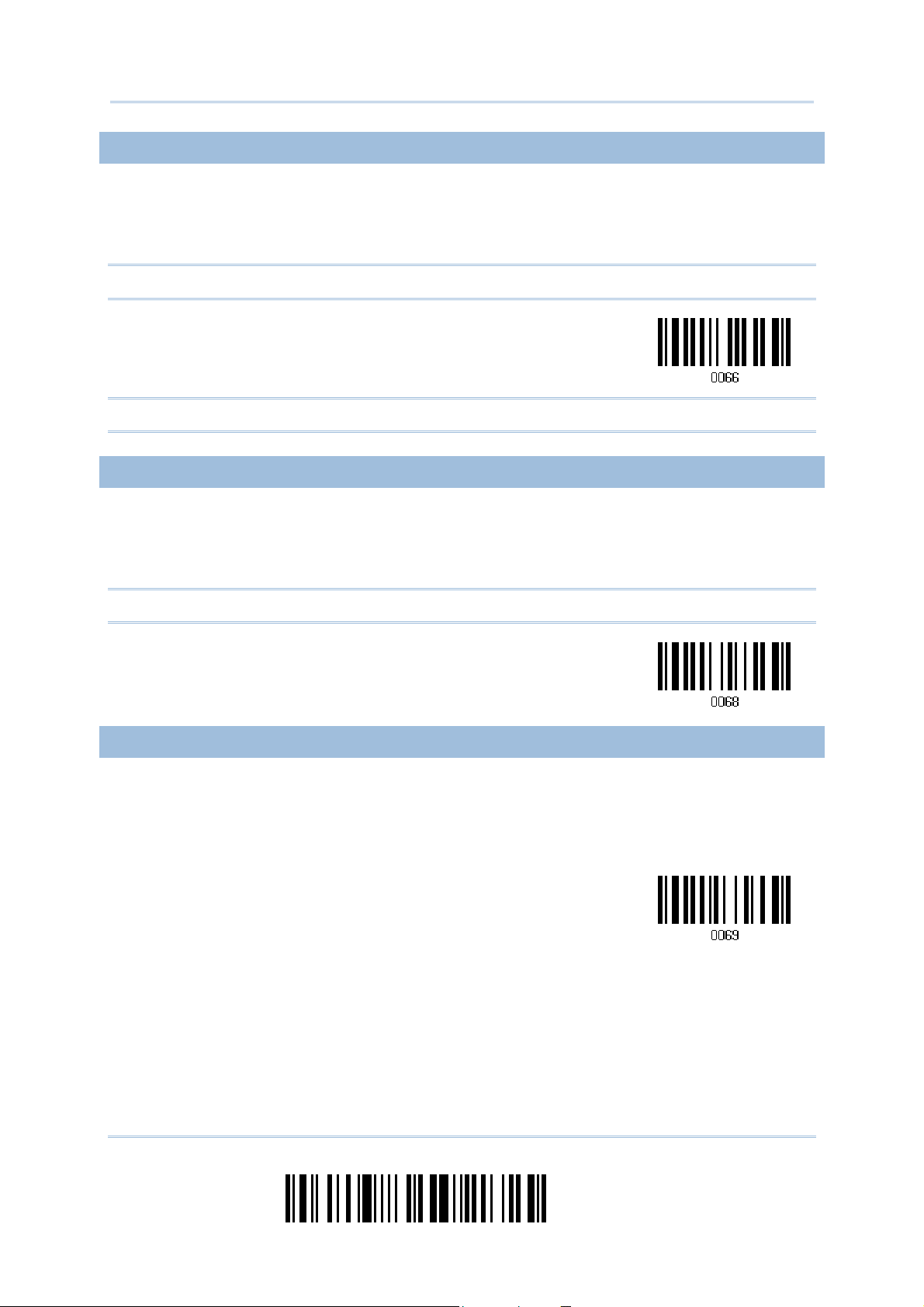

LIST THE CURRENT SETTINGS

The current settings of all scanner parameters can be sent, via Keyboard Wedge, RS-232,

USB HID or Virtual COM, to the host computer for user inspection. The listing includes

pages as shown below. You can select the page of interest by having the scanner read

the “List Page x” barcode. The scanner will respond with two beeps (high-low t one) and

send the selected page to the host immediately.

List settings regarding Interface, Buzzer, and

Other Scanner Parameters

List settings regarding Prefix, Suffix, and Length

Code Setting

List settings regarding Code ID

List Page 1

List Page 2

List Page 3

List settings regarding: Readable Symbologies

List settings regarding Symbology Parameters

(1/3)

List settings regarding Symbology Parameters

(2/3)

List settings regarding Symbology Parameters

(3/3)

List settings regarding Editing Format 1

List settings regarding Editing Format 2

List Page 4

List Page 5

List Page 6

List Page 7

List Page 8

List Page 9

List settings regarding Editing Format 3

List Page 10

14

Enter Setup

Page 25

UNDERSTANDING THE BARCODE SCANNER

This chapter explains the features and usage of the barcode scanner.

IN THIS CHAPTER

1.1 Power ...................................................................... 15

1.2 LED Indicator............................................................ 15

1.3 Beeper..................................................................... 16

1.4 Scan Modes .............................................................. 18

1.5 Scanning Timeout...................................................... 22

1.6 Delay between Re-read............................................... 23

1.7 Read Redundancy for All Symblogies ............................ 24

1.8 Auto-Sense Mode (1100 Only)..................................... 25

1.9 Negative Barcodes ..................................................... 25

Chapter 1

1.1 POWER

Connect the interface cable between the scanner and your computer.

If using the RS-232 cable, you must join the power supply cord to power up the

scanner.

The scanner will respond with one long beep (high tone) and its LED indicator will

become solid red and go off quickly.

1.2 LED INDICATOR

The dual-color LED on top of the scanner is used to provide user feedback. For example,

the LED becomes solid red and goes off quickly upon powering on or reading a barcode

successfully. You may tell the difference by the beeps – you will hear a long beep when

powering on the scanner, and a short beep (pitch programmable) when it reads a

barcode successfully.

Scanner LED

Red,

on-off

--- Green,

---

solid

Meaning

Power on, with one long beep (high tone, LED on for 1 second)

Good Read, with one short beep (high tone) and beeper pitch

programmable

Configuration Mode

15

Update

Page 26

1000/1090+/1100/1105 Barcode Scanner User Guide

1.3 BEEPER

The scanner has a buzzer to provide user feedback in various operating conditions.

Beeping

One long beep, high tone

One short beep, high tone

Programmable, default to 4 KHz

Six short beeps

High-low tone repeats three times

Two beeps, high-low tone

One short beep, high tone

One long beep, low tone

Meaning

Power on, with red LED on (1 second) and off quickly

Good Read, with red LED on and off quickly

Enter Configuration Mode, with green LED on

Exit Configuration Mode

Setup barcode read successfully

More setup barcode required

Configuration error (Wrong barcode…)

16

Enter Setup

Page 27

Chapter 1 Understanding the Barcode Scanner

1.3.1 GOOD READ BEEP

*Enable Buzzer

Disable Buzzer

1.3.2 FREQUENCY

8 kHz

*4 kHz

2 kHz

1 kHz

17

Update

Page 28

1000/1090+/1100/1105 Barcode Scanner User Guide

1.4 SCAN MODES

Different scan modes are supported – select the scan mode that best suits the

requirements of a specific application. Refer to the comparison table below.

Scan Mode

Always Press

Continuous

mode

Test mode

Laser mode

Auto Off mode

Auto Power Off

mode

Alternate mode

Repeat mode

Momentary

mode

Start to Scan Stop Scanning

trigger

once

Hold

trigger

Press

trigger

twice

Release

trigger

Press

trigger

once

Barcode

being

read

Timeout

Note: (1) 1000, 1090+: By default, the scan mode is set to Auto Off mode.

(2) 1100, 1105: By default, the scan mode is set to Laser mode.

18

Enter Setup

Page 29

Chapter 1 Understanding the Barcode Scanner

1.4.1 CONTINUOUS MODE

The scanner is always scanning.

After a successf ul decoding, the removal of barcode is required. It is not allowed to

proceed to decode until the preset decoding delay time has passed.

To decode the same barcode repeatedly, move away the barcode and put it back

again and again for scanning.

Note: Refer to “Delay between Re-read”.

Continuous Mode

1.4.2 TEST MODE

The scanner is always scanning.

Capable of decoding the same barcode repeatedly without removing it, for testing

purpose.

Test Mode

1.4.3 LASER MODE

The scanner will start scanning once the trigger is held down.

The scanning won't stop until (1) a barcode is decoded, (2) the pre-set timeout

expires, or (3) you release the trigger.

Note: Refer to “Scanning Timeout”.

*Laser Mode

Note: By default, the scan mode of 1100/1105 is set to Laser mode.

19

Update

Page 30

1000/1090+/1100/1105 Barcode Scanner User Guide

1.4.4 AUTO OFF MODE

The scanner will start scanning once the trigger is pressed.

The scanning won't stop until (1) a barcode is decoded, and (2) the pre-set timeout

expires.

Note: Refer to “Scanning Timeout”.

Auto Off Mode

Note: By default, the scan mode of 1000 and 1090+ is set to Auto Off mode.

1.4.5 AUTO POWER OFF MODE

The scanner will start scanning once the trigger is pressed.

The scanning won't stop until the pre-set timeout expires, and, the pre-set timeout

period re-counts after each successful decoding.

Note: Refer to “Delay between Re-read” and “Scanning Timeout”.

Auto Power Off Mode

1.4.6 ALTERNATE MODE

The scanner will start scanning once the trigger is pressed

The scanning won't stop until you press the trigger again.

Alternate Mode

20

Enter Setup

Page 31

Chapter 1 Understanding the Barcode Scanner

1.4.7 REPEAT MODE

Like the Continuous Mode, the scanner is always scanning. But now the scan trigger acts

like a “re-transmission” button when being pressed within one second after a successful

reading, which will re-transmit the same data without actually readin g the barcode again.

This scan mode is most useful when the same barcode is to be read many times.

Capable of re-transmitting barcode data if triggering within one second after a

successful decoding.

Such re-transmission can be activated as many times as needed, as long as the time

interval between each triggering does not exceed one second.

Repeat Mode

1.4.8 MOMENTARY MODE

The scanner will be scanning as long as the trigger is hold down.

The scanning won't stop until you release the trigger.

Momentary Mode

21

Update

Page 32

1000/1090+/1100/1105 Barcode Scanner User Guide

1.5 SCANNING TIMEOUT

Specify the scanning time interval (1~255 sec.; 0= Disable) when the scan mode is set

to any of the following –

Laser mode

Auto Off mode

Auto Power Off mode

Scanner Time-out

after 0~255 sec.

(*10)

1) Read the barcode above to specify the time interval before the scan engine times out.

2) Read the “

scanner to automatically shut down after being idle for 15 seconds.

3) Read the “Validate” barcode on the same page to complete this setting.

Decimal Value” barcode on page 127. For example, read “1” and “5” for the

22

Enter Setup

Page 33

Chapter 1 Understanding the Barcode Scanner

1.6 DELAY BETWEEN RE-READ

This is also referred to as the “Blocking Time”, which is used to prev ent the scanner f rom

accidentally reading the same barcode twice when the scan mode is set to any of the

following –

Continuous mode

Auto Power Off mode

Alternate mode

Momentary mode

100 ms

200 ms

*400 ms

800 ms

1 sec

2 sec

3 sec

5 sec

23

Update

Page 34

1000/1090+/1100/1105 Barcode Scanner User Guide

1.7 READ REDUNDANCY FOR ALL SYMBLOGIES

Select the level of reading security. For example,

If "No Redundancy " is selected, one successful decoding will make the reading valid

and induce the "READER Event".

If "Three Times" is selected, it will take a total of four consecutive successful

decoding of the same barcode to make the reading valid. The higher the reading

security is (that is, the more redundancy the user selects), the slower the reading

speed gets.

It is obvious that the more redundancy you select, the higher the reading security is, and

thus, the slower the reading speed becomes. You will have to compromise between

reading security and decoding speed.

*No Redundancy

One Time

Two Times

Three Times

24

Enter Setup

Page 35

Chapter 1 Understanding the Barcode Scanner

1.8 AUTO-SENSE MODE (1100 ONLY)

This mode is only available when you want to seat the scanner in the Auto-Sense Stand.

When you enable this mode, it will force the scanner to apply Laser mode as the scan

mode. However, it works slightly different from the original L aser mode. Now the scann er

will be scanning as long as it is seated in the stand. Whenever a barcode is brought

within range, the scanner will be able to decode it.

Note: Auto-sense can only be enabled for CCD scanner and will force it to Laser mode.

Enable

*Disable

Warning: When you disable this mode later, the scan mode remains unchanged. If

Laser mode is not desired, proceed to select a scan mode best suits your

application.

1.9 NEGATIVE BARCODES

Normally, barcodes are printed with the color of the bars darker than that of the spaces.

But for negative barcodes, they are printed in the opposite sense just like negative films.

The spaces of negative barcodes are printed with a color darker than that of the bars.

You can configure the scanner to be able to read negative barcodes.

Enable

*Disable

25

Update

Page 36

1000/1090+/1100/1105 Barcode Scanner User Guide

26

Enter Setup

Page 37

Chapter 2

SELECTING OUTPUT INTERFACE

In order to establish a proper connection between your computer and the scanner, we

suggest that you follow these instructions –

1) Connect the interface cable to your computer.

If using the RS-232 cable, join the power supply cord.

2) Have the scanner read the “Enter Setup” barcode to enter the configuration mode.

3) Have the scanner read the associated barcodes to activate the desired interface.

See the following sections for output interfaces supported.

If you are connecting the scanner to the USB port of the host computer via USB

HID cable (part # 307), refer to

If you are connecting the scanner to the USB port of the host computer via USB

Virtual COM cable (part # 308), refer to

2.1 Keyboard Wedge for related settings.

2.2 RS-232 related settings.

If you are connecting the scanner to the IBM POS 4683/4694 via the converter

cable (part # 346), refer to

4) Have the scanner read the barcodes for related settings.

5) Have the scanner read the “Update” barcode to exit the configuration mode.

Note: By default, the output interface is set to “Keyboard Wedge”.

2.1 Keyboard Wedge for related settings.

IN THIS CHAPTER

2.1 Keyboard Wedge ....................................................... 28

2.2 RS-232 .................................................................... 39

2.3 Wand Emulation ........................................................ 42

27

Update

Page 38

1000/1090+/1100/1105 Barcode Scanner User Guide

2.1 KEYBOARD WEDGE

The Y cable allows you to connect the scanner via 3666 to the keyboard input port of PC

and you may join the keyboard as well. Th e scanned data will be transmitted to the ho st

keyboard port as if it is manually entered via the keyboard. For example, run a text

editor on your computer to receive the data.

Keyboard Wedge Settings

Keyboard Type PCAT (US)

Alphabets Layout Normal

Digits Layout Normal

Capital Lock Type Normal

Capital Lock State Off

Alphabets Transmission Case-sensitive

Digits Transmission Alphanumeric keypad

Alternate Composing No

Inter-Character Delay 0 (ms)

Laptop Support Disable

Defaults

2.1.1 ACTIVATE KEYBOARD WEDGE & SELECT KEYBOARD TYPE

When Keyboard Wedge interface is activated, you will have to select a keyboard type to

complete this setting. By default, Keyboard Wedge is activated on the scanner, and the

keyboard type is set to PCAT (US).

Activate Keyboard

Wedge & Select

Keyboard Type…

1) Read this barcode above to activate Keyboard Wedge and select a keyboard type.

2) Read the “

Decimal Value” barcode on page 127. Refer to the table below for the

number of desired keyboard type.

3) Read the “Validate” barcode on the same page to complete this setting.

28

Enter Setup

Page 39

Chapter 2 Selecting Output Interface

Keyboard Wedge

By default, the keyboard type is set to PCAT (US). The following keyboard types are supported —

No. Keyboard Type No. Keyboard Type

1 PCAT (US) 15 PS55 001-81

2 PCAT (French) 16 PS55 001-2

3 PCAT (German) 17 PS55 001-82

4 PCAT (Italian) 18 PS55 001-3

5 PCAT (Swedish) 19 PS55 001-8A

6 PCAT (Norwegian) 20 PS55 002-1, 003-1

7 PCAT (UK) 21 PS55 002-81, 003-81

8 PCAT (Belgium) 22 PS55 002-2, 003-2

9 PCAT (Spanish) 23 PS55 002-82, 003-82

10 PCAT (Portuguese) 24 PS55 002-3, 003-3

11 PS55 A01-1 25 PS55 002-8A, 003-8A

12 PS55 A01-2 (Japanese) 26 IBM 3477 Type 4 (Japanese)

13 PS55 A01-3 27 PS2-30

14 PS55 001-1 28 IBM 34XX/319X, Memorex Telex 122 Keys

29

Update

Page 40

1000/1090+/1100/1105 Barcode Scanner User Guide

2.1.2 KEYBOARD SETTINGS

Alphabets Layout

By default, the alphabets layout is set to normal mode, also known as the standard English layout.

Select French or German keyboard layout if necessary. The scanner will make adjustments when

sending the "A", "Q", "W", "Z", "Y", and "M" characters according to this setting.

*Normal

AZERTY

QWERTZ

Note: This setting only works when the keyb oard type selected is US keyboard, such as

PCAT (US). The Alphabets Layout and Digits Layout setting must match your

keyboard.

30

Enter Setup

Page 41

Chapter 2 Selecting Output Interface

US Keyboard Style – Normal

QWERTY layout, which is normally used in western countries.

Select “Lower Row” for the “Digits Layout” setting for the upper row is for special characters.

French Keyboard Style – AZERTY

French layout; see below for French Keyboard Style.

Select “Upper Row” for the “Digits Layout” setting for the lower row is for special characters.

German Keyboard Layout – QWERTZ

German layout; see below for German Keyboard Style.

Select “Lower Row” for the “Digits Layout” setting for the upper row is for special characters.

31

Update

Page 42

1000/1090+/1100/1105 Barcode Scanner User Guide

Digits Layout

Select a proper layout that matches the alphabets layout. The scanner will make adjustments

according to this setting.

Options Description

Normal Depends on the [Shift] key or [Shift Lock] setting

Lower Row For QWERTY or QWERTZ keyboard

Upper Row For AZERTY keyboard

*Normal

Upper Row

Lower Row

Note: This setting is meant to be used with the Alphabets Layout; and perhaps with the

Character Substitution setting when support to certain keyboard types (languages)

is unavailable but required.

32

Enter Setup

Page 43

Chapter 2 Selecting Output Interface

T

Capital Lock Type & Setting

In order to send the alphabets with correct case, the scanner needs to know the status of Caps

Lock on the keyboard. Incorrect settings may result in reversed case of the alphabets being

transmitted.

Cap Lock Type Description

Normal Normal type

Capital Lock When enabled, the keys of alphabetic characters will be interpreted as

capital letters. However, this does not affect the number or punctuation

keys.

Shift Lock When enabled, the keys of alphabetic characters will be interpreted as

capital letters. In addition, this affects the number or punctuation keys.

*Normal

Shift Lock

Capital Lock

Capital Lock State Description

Capital Lock OFF Assuming that the status of Caps Lock on the keyboard is OFF,

transmitted characters are exactly the same as in the barcode (when

"case-sensitive" is selected for Alphabets Transmission).

Capital Lock ON Assuming that the status of Caps Lock on the keyboard is ON, transmitted

characters are exactly the same as in the barcode (when "case-sensitive"

is selected for Alphabets Transmission).

Refer to the Capital Lock Type abov e.

Auto Detection

he scanner will automatically detect the status of Caps Lock on the

keyboard before data is transmitted; transmitted characters are exactly

the same as in the barcode (when "case-sensitive" is selected for

Alphabets Transmission).

Auto Detect

Capital Lock ON

33

Update

Page 44

1000/1090+/1100/1105 Barcode Scanner User Guide

*Capital Lock OFF

34

Enter Setup

Page 45

Chapter 2 Selecting Output Interface

Alphabets Transmission

By default, the alphabets transmission is case-sensitive, meaning that the alphabets will be

transmitted according to their original case, the status of Caps Lock on the keyboard, as well as the

Capital Lock setting. Select [Ignore Case] to have alphabets transmitted according to the status of

Caps Lock on the keyboard only.

Ignore Case

*Case-sensitive

35

Update

Page 46

1000/1090+/1100/1105 Barcode Scanner User Guide

Digits Transmission

By default, the alphanumeric keypad is used for transmitting digits. Select “Numeric Keypad” if you

wish to use the keys on the numeric keypad.

Numeric Key

*Alphanumeric Key

Note: If you select “Numeric Keypad”, the Num Lock status of the physical keyboard

should be "ON".

36

Enter Setup

Page 47

Chapter 2 Selecting Output Interface

ALT Composing

By default, Alternate key composing is disabled. Select [Yes] to allow emul ating Alternate key code

of a specific keyboard character. For example, [Alt] + [065] will be sent to host for the character

“A” regardless the keyboard type you are using.

*No

Yes

Laptop Support

By default, laptop support is disabled. It is suggested to enable this feature if you connect the

wedge cable to a laptop without an external keyboard being inter-connected.

*Disable

Enable

37

Update

Page 48

1000/1090+/1100/1105 Barcode Scanner User Guide

2.1.3 INTER-CHARACTER DELAY

By default, the inter-character delay is set to zero. Specify a value, ranging from 0 to

255 in units of millisecond, to match the computer response time of the keyboard

interface. Such delay time is inserted between every character being transmitted. The

longer the delay time is, the slower the transmission speed will be.

Inter-Character

Delay… (*0~255)

1) Read the barcode above to specify the inter-character delay.

2) Read the “

Decimal Value” barcode on page 127 for the desired inter-character delay

(millisecond).

3) Read the “Validate” barcode on the same page to complete this setting.

38

Enter Setup

Page 49

Chapter 2 Selecting Output Interface

2.2 RS-232

Use the RS-232 cable to cconnect the scanner to the serial port of PC and join the power

adaptor to the RS-232 connector. The associated RS-232 parameters must match those

configured on the computer. The scanned data will be transmitted t o the serial port.

RS-232 Settings

Baud Rate, Data Bit, Parity, Stop Bit 9600 bps, 8 bits, No parity

Flow Control None

Inter-Character Delay 0 (ms)

Defaults

2.2.1 ACTIVATE RS-232 INTERFACE

Activate RS-232

Interface

2.2.2 BAUD RATE

115200 bps

38400 bps

19200 bps

*9600 bps

4800 bps

2400 bps

1200 bps

39

Update

Page 50

1000/1090+/1100/1105 Barcode Scanner User Guide

2.2.3 DATA BITS

2.2.4 PARITY

*8 bits

7 bits

*No parity

Even

Odd

40

Enter Setup

Page 51

Chapter 2 Selecting Output Interface

2.2.5 FLOW CONTROL

By default, there is no flow control in use. Select the flow control (handshake) method.

Options

No No flow control

Scanner Ready The scanner will activate the RTS signal upon powering on. After each good

Data Ready The RTS signal will be activated after each good read. The scanner will

Inverted Data Ready It works the same as the Data Ready flow control except that the RTS

Description

read, the scanner will then wait for the CTS signal to become active. Data

will not be sent until the CTS signal becomes active.

then wait for the CTS signal to become active. Data will not be sent until

the CTS signal becomes active.

signal level is inverted.

*None

Scanner Ready

Data Ready

Invert Data Ready

2.2.6 INTER-CHARACTER DELAY

By default, the inter-character delay is zero. Specify a value, ranging from 0 to 255 in

units of millisecond, to match the computer response time. Su ch delay time is inserted

between every character being transmitted. The longer the delay time is, the slower the

transmission speed will be.

Inter-Character

Delay… (*0~255)

1) Read the barcode above to specify the inter-character delay.

2) Read the “

(millisecond).

3) Read the “Validate” barcode on the same page to complete this setting.

Decimal Value” barcode on page 127 for the desired inter-character delay

41

Update

Page 52

1000/1090+/1100/1105 Barcode Scanner User Guide

2.3 WAND EMULATION

Wand Emulation is supported on many of our batch scanners, except for 1000.

1090+

1100

1105

The wand emulation cable allows you to connect the scanner to a data terminal that is

expecting input from a wand scanner.

Wand Emulation Settings

Normal State Low

Bar State High

Module Time 1 (ms)

Margin Time 20 (ms)

Defaults

2.3.1 ACTIVATE WAND EMULATION

Activate Wand

Emulation

2.3.2 NORMAL STATE

By default, the signal level is set "Low" for the normal state when not transmitting any

barcode image (= white spaces in a barcode).

High

42

*Low

Enter Setup

Page 53

Chapter 2 Selecting Output Interface

2.3.3 BAR STATE

By default, the signal level is set "High" for a bar when transmitting a barcode image (=

dark bars in a barcode).

*High

Low

2.3.4 MODULE TIME

By default, it is set 1 millisecond as the time span for bar and space modules. Select

other value for the module time, in units of micro-second or millisecond.

250 µs

500 µs

*1 ms

1.5 ms

2 ms

3 ms

4 ms

43

Update

Page 54

1000/1090+/1100/1105 Barcode Scanner User Guide

5 ms

2.3.5 MARGIN TIME

By default, it is set 20 milliseconds as the time span for the change in state for bar and

space modules. Select other value for the margin time.

5 ms

10 ms

*20 ms

30 ms

40 ms

60 ms

80 ms

100 ms

Note: Margin Time is applied only when the signal level for N ormal Stat e and Bar St ate is

the same.

44

Enter Setup

Page 55

Chapter 3

CHANGING SYMBOLOGY SETTINGS

In this chapter, a brief on the symbology settings is provided for your reference.

IN THIS CHAPTER

3.1 Codabar ................................................................... 46

3.2 Code 25 – Industrial 25.............................................. 48

3.3 Code 25 – Interleaved 25............................................ 51

3.4 Code 25 – Matrix 25................................................... 54

3.5 Code 39 ................................................................... 57

3.6 Code 93 ................................................................... 59

3.7 Code 128.................................................................. 59

3.8 EAN-8...................................................................... 60

3.9 EAN-13 .................................................................... 62

3.10 GS1-128 (EAN-128) ................................................. 64

3.11 MSI........................................................................ 65

3.12 French Pharmacode.................................................. 67

3.13 Italian Pharmacode .................................................. 68

3.14 Plessey................................................................... 69

3.15 GS1 DataBar (RSS Family)........................................ 70

3.16 Telepen .................................................................. 75

3.17 UPC-A .................................................................... 76

3.18 UPC-E .................................................................... 78

45

Update

Page 56

1000/1090+/1100/1105 Barcode Scanner User Guide

3.1 CODABAR

*Enable

Disable

3.1.1 START/STOP CHARACTERS SELECTION

Select one of the four different start/stop character pairs –

* abcd/abcd

abcd/tn*e

ABCD/ABCD

ABCD/TN*E

46

Enter Setup

Page 57

Chapter 3 Changing Symbology Settings

3.1.2 START/STOP TRANSMISSION

Decide whether to include the start/stop characters in the data being transmitted.

Transmit Start/Stop

Characters

*Do Not Transmit

3.1.3 CLSI CONVERSION

When enabled, the CLSI editing strips the start/stop characters and inserts a space after

the first, fifth, and tenth characters of a 14-character Codabar barcode.

Apply CLSI Editing

*Do Not Apply

Note: The 14-character barcode length does not include start/stop characters.

47

Update

Page 58

1000/1090+/1100/1105 Barcode Scanner User Guide

3.2 CODE 25 – INDUSTRIAL 25

*Enable

Disable

3.2.1 SELECT START/STOP PATTERN

This decides the readability of all 2 of 5 symbology variants. For ex ample, flight tickets

actually use an Industrial 2 of 5 barcode but with Interleaved 2 of 5 start/stop pattern. In

order to read this barcode, the start/stop pattern selection parameter of Industrial 2 of 5

should set to "Interleaved 25".

*Industrial 25

Start/Stop Pattern

Interleaved 25

Start/Stop Pattern

Matrix 25

Start/Stop Pattern

48

Enter Setup

Page 59

Chapter 3 Changing Symbology Settings

I

3.2.2 VERIFY CHECK DIGIT

Decide whether to verify the check digit. If incorrect, t he barcode will not be accepted.

Verify Industrial 25

Check Digit

*Do Not Verify

3.2.3 TRANSMIT CHECK DIGIT

Decide whether to include the check digit in the data being transmitted.

*Transmit

ndustrial 25

Check Digit

Do Not Transmit

49

Update

Page 60

1000/1090+/1100/1105 Barcode Scanner User Guide

3.2.4 CODE LENGTH QUALIFICATION

To prevent the "short scan" error, define the "Length Qualification" settings to ensure

that the correct barcode is read by qualifying the allowable code length.

If "Max/M in Length" is selected, the maximum length and the minimum length must

be specified. It only accepts those barcodes with lengths that fall between max/min

lengths specified.

If “Fixed L ength ” is selected, up to 2 fixed lengths can be specified.

1) Read the barcode to enable either Max. /Min. Length qualification or Fix ed Length(s)

qualification.

*Enable Max./Min.

Length (0~127)…

Enable Fixed

Length(s)…

2) Read the barcode for Max. Length or Fixed Length 1, and follow steps 3~4.

Repeat steps 2~4 for Min. Length or Fixed Length 2.

Max. Length (*127) or

Fixed Length 1

Min. Length (*0) or

Fixed Length 2

3) Read the “

Decimal Value” barcode on page 127 for the desired length.

4) Read the “Validate” barcode on the same page to complete this setting.

50

Enter Setup

Page 61

Chapter 3 Changing Symbology Settings

3.3 CODE 25 – INTERLEAVED 25

*Enable

Disable

3.3.1 SELECT START/STOP PATTERN

This decides the readability of all 2 of 5 symbology variants. For ex ample, flight tickets

actually use an Industrial 2 of 5 barcode but with Interleaved 2 of 5 start/stop pattern. In

order to read this barcode, the start/stop pattern selection parameter of Industrial 2 of 5

should set to "Interleaved 25".

Industrial 25

Start/Stop Pattern

*Interleaved 25

Start/Stop Pattern

Matrix 25

Start/Stop Pattern

51

Update

Page 62

1000/1090+/1100/1105 Barcode Scanner User Guide

I

I

3.3.2 VERIFY CHECK DIGIT

Decide whether to verify the check digit. If incorrect, t he barcode will not be accepted.

Verify

nterleaved 25

Check Digit

*Do Not Verify

3.3.3 TRANSMIT CHECK DIGIT

Decide whether to include the check digit in the data being transmitted.

*Transmit

nterleaved 25

Check Digit

Do Not Transmit

52

Enter Setup

Page 63

Chapter 3 Changing Symbology Settings

3.3.4 CODE LENGTH QUALIFICATION

To prevent the "short scan" error, define the "Length Qualification" settings to ensure

that the correct barcode is read by qualifying the allowable code length.

If "Max/M in Length" is selected, the maximum length and the minimum length must

be specified. It only accepts those barcodes with lengths that fall between max/min

lengths specified.

If “Fixed L ength ” is selected, up to 2 fixed lengths can be specified.

1) Read the barcode to enable either Max. /Min. Length qualification or Fix ed Length(s)

qualification.

*Enable Max./Min.

Length (0~127)…

Enable Fixed

Length(s)…

2) Read the barcode for Max. Length or Fixed Length 1, and follow steps 3~4.

Repeat steps 2~4 for Min. Length or Fixed Length 2.

Max. Length (*127) or

Fixed Length 1

Min. Length (*0) or

Fixed Length 2

3) Read the “

Decimal Value” barcode on page 127 for the desired length.

4) Read the “Validate” barcode on the same page to complete this setting.

53

Update

Page 64

1000/1090+/1100/1105 Barcode Scanner User Guide

*

3.4 CODE 25 – MATRIX 25

Enable

*Disable

3.4.1 SELECT START/STOP PATTERN

This decides the readability of all 2 of 5 symbology variants. For ex ample, flight tickets

actually use an Industrial 2 of 5 barcode but with Interleaved 2 of 5 start/stop pattern. In

order to read this barcode, the start/stop pattern selection parameter of Industrial 2 of 5

should set to "Interleaved 25".

Industrial 25

Start/Stop Pattern

Interleaved 25

Start/Stop Pattern

Matrix 25

Start/Stop Pattern

54

Enter Setup

Page 65

Chapter 3 Changing Symbology Settings

3.4.2 VERIFY CHECK DIGIT

Decide whether to verify the check digit. If incorrect, t he barcode will not be accepted.

Verify Matrix 25

Check Digit

*Do Not Verify

3.4.3 TRANSMIT CHECK DIGIT

Decide whether to include the check digit in the data being transmitted.

*Transmit Matrix 25

Check Digit

Do Not Transmit

55

Update

Page 66

1000/1090+/1100/1105 Barcode Scanner User Guide

3.4.4 CODE LENGTH QUALIFICATION

To prevent the "short scan" error, define the "Length Qualification" settings to ensure

that the correct barcode is read by qualifying the allowable code length.

If "Max/M in Length" is selected, the maximum length and the minimum length must

be specified. It only accepts those barcodes with lengths that fall between max/min

lengths specified.

If “Fixed L ength ” is selected, up to 2 fixed lengths can be specified.

1) Read the barcode to enable either Max. /Min. Length qualification or Fix ed Length(s)

qualification.

*Enable Max./Min.

Length (0~127)…

Enable Fixed

Length(s)…

2) Read the barcode for Max. Length or Fixed Length 1, and follow steps 3~4.

Repeat steps 2~4 for Min. Length or Fixed Length 2.

Max. Length (*127) or

Fixed Length 1

Min. Length (*0) or

Fixed Length 2

3) Read the “

Decimal Value” barcode on page 127 for the desired length.

4) Read the “Validate” barcode on the same page to complete this setting.

56

Enter Setup

Page 67

Chapter 3 Changing Symbology Settings

3.5 CODE 39

*Enable

Disable

3.5.1 TRANSMIT START/STOP CHARACTERS

Decide whether to include the start/stop characters in the data being transmitted.

Transmit Code 39

Start/Stop

Characters

*Do Not Transmit

57

Update

Page 68

1000/1090+/1100/1105 Barcode Scanner User Guide

3.5.2 VERIFY CHECK DIGIT

Decide whether to verify the check digit. If incorrect, t he barcode will not be accepted.

Verify Code 39

Check Digit

*Do Not Verify

3.5.3 TRANSMIT CHECK DIGIT

Decide whether to include the check digit in the data being transmitted.

*Transmit Code 39

Check Digit

Do Not Transmit

3.5.4 STANDARD/FULL ASCII CODE 39

Decide whether to support Code 39 Full ASCII that includes all the alphanumeric and

special characters.

Code 39 Full ASCII

*Standard Code 39

58

Enter Setup

Page 69

Chapter 3 Changing Symbology Settings

3.6 CODE 93