Page 1

OEM SCAN MODULE

Programming Manual

International Edition, Rev. A2

Page 2

FuzzyScan OEM Scan Module

Revision History

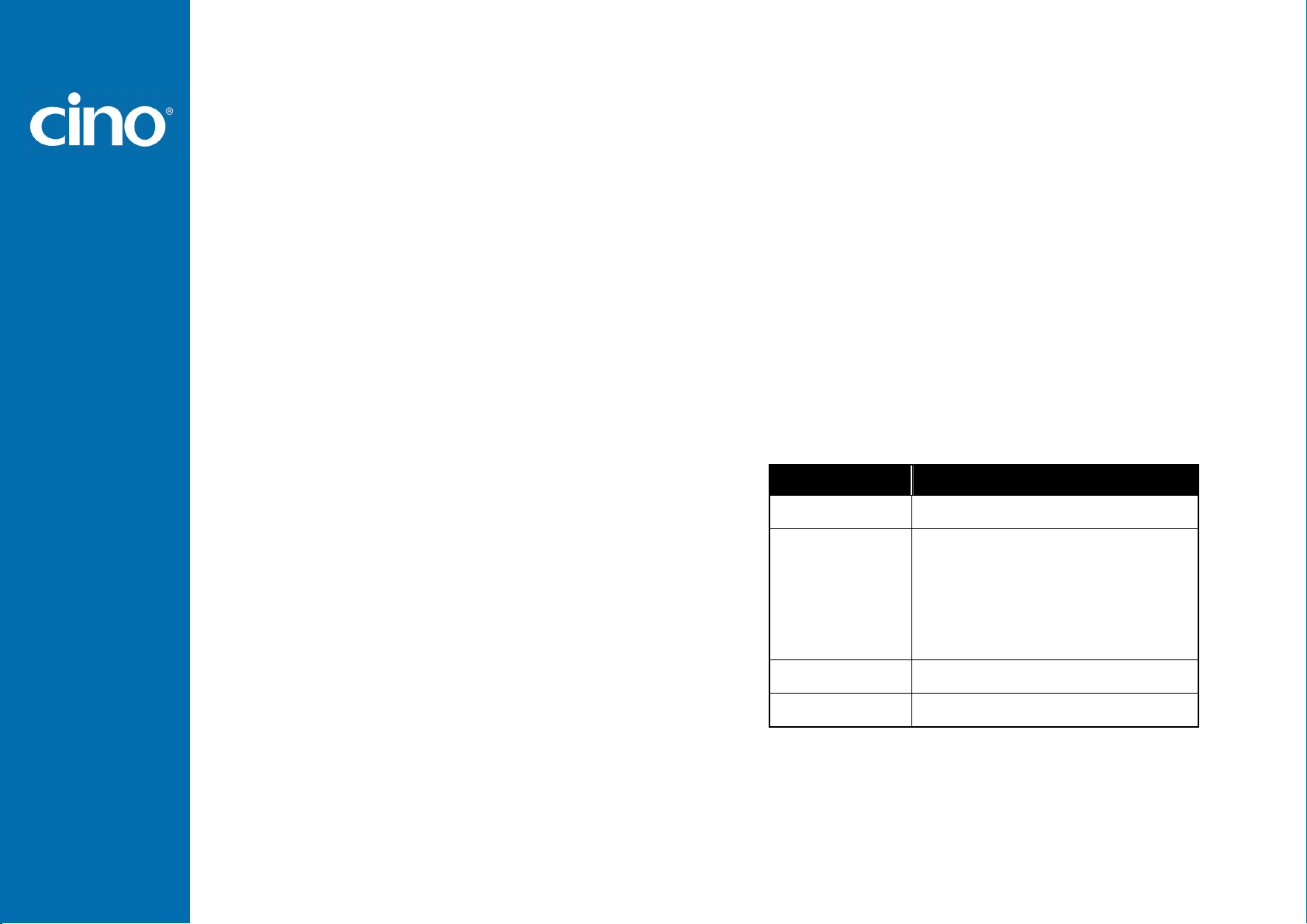

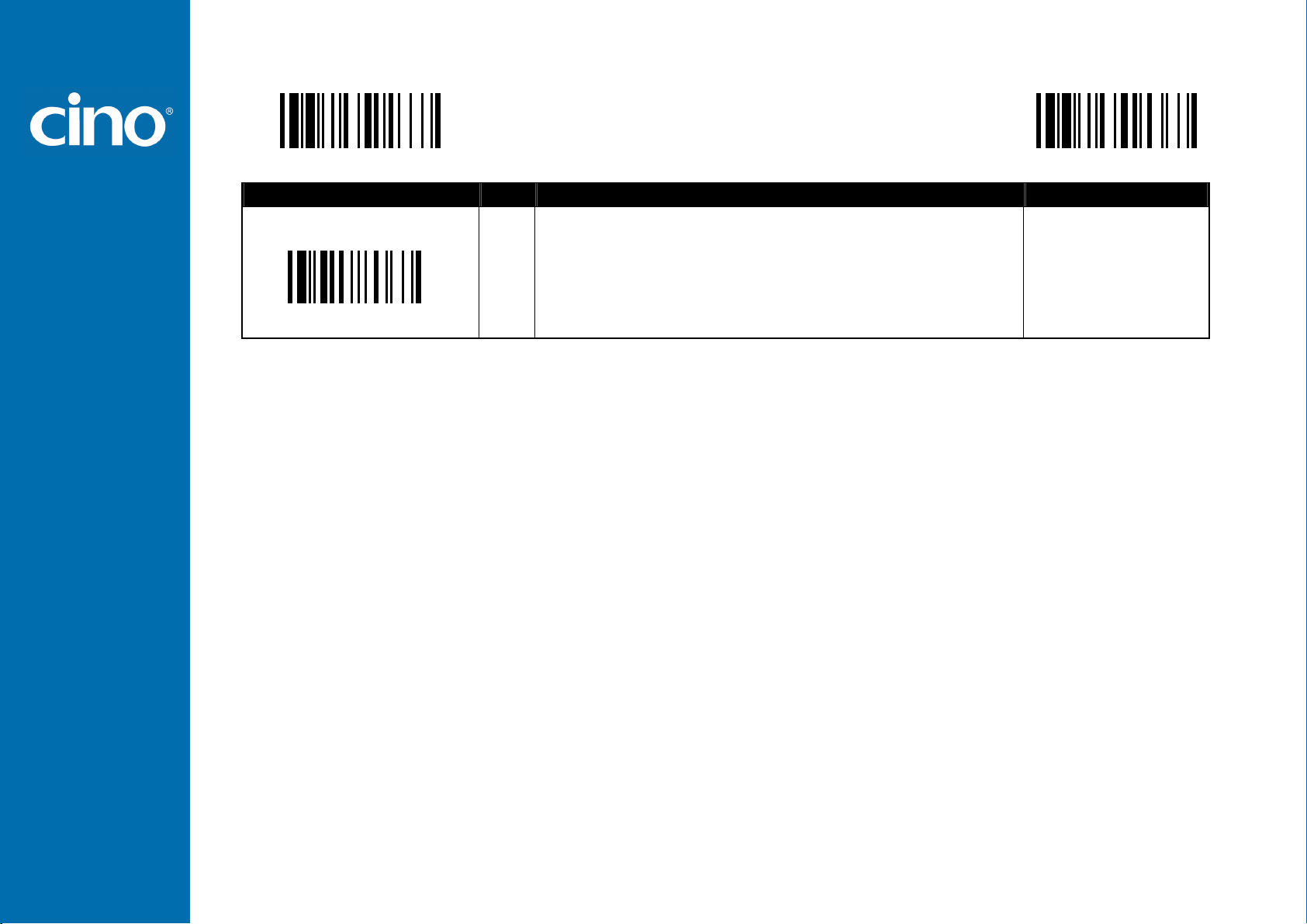

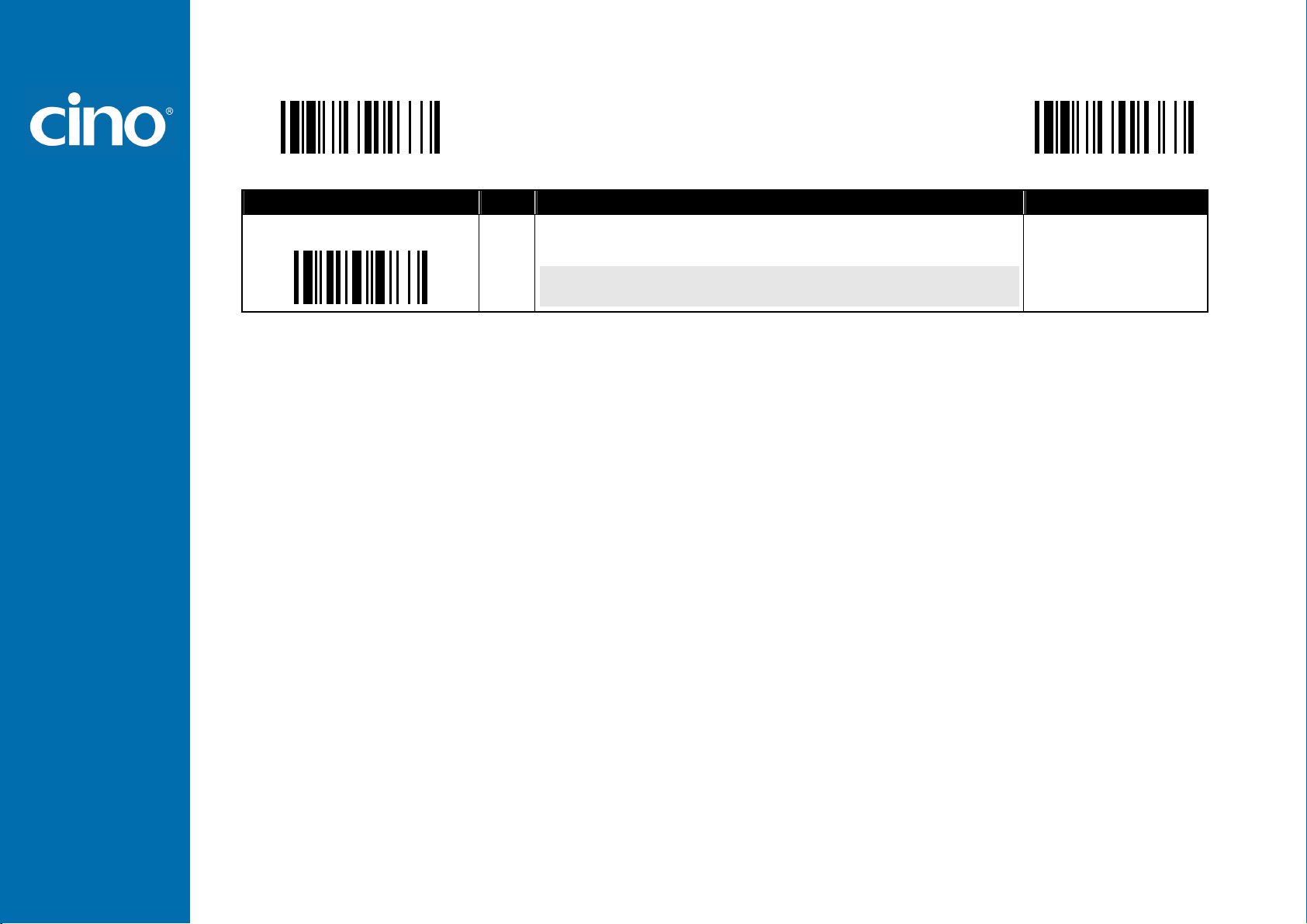

Rev. No. Released Date Description

Rev. A1 May 2, 2014 First Release

Rev. A2 Feb. 06, 2015 Page 42 Add “MaxiCode Setting”

Programming Manual

Page 3

FuzzyScan OEM Scan Module

© Copyright Cino Group

© Copyright PC Worth Int’l Co., Ltd

Cino makes no warranty of any kind with regard to this publication, including, but not limited to, the implied warranty of

merchantability and fitness for any particular purpose. Cino shall not be liable for errors contained herein or for incidental

consequential damages in connection with the furnishing, performance, or use of this publication. This publication contains

proprietary information that is protected by copyright. All rights are reserved. No part of this publication may be photocopied,

reproduced or translated into any language, in any forms, in an electronic retrieval system or otherwise, without prior written

permission of Cino. All product information and specifications shown in this document may be changed without prior notice.

Warranty

Cino warrants its products against defects in workmanship and materials from the date of shipment, provided that the

product is operated under normal and proper conditions. The warranty provisions and durations are furnished by different

warranty programs. The above warranty does not apply to any product which has been (i) misused; (ii) damaged by accident

or negligence; (iii) modified or altered by the purchaser or other party; (iv) repaired or tampered by unauthorized

representatives; (v) operated or stored beyond the specified operational and environmental parameters; (vi) applied

software, accessories or parts are not supplied by Cino; (vii) damaged by circumstances out of Cino’s control, such as, but

not limited to, lightning or fluctuation in electrical power. Any defective product must follow the warranty program and RMA

procedures to return Cino for inspection.

Programming Manual

Page 4

FuzzyScan OEM Scan Module

Regulatory

LED Eye Safety

IEC62471 Exempt group

Programming Manual

Page 5

FuzzyScan OEM Scan Module

Table of Contents

Getting Started

Getting Familiar with Your FuzzyScan 1

Connect to Your Host 3

Connecting Host Interface 4

Intelli Button 5

Use Your FuzzyScan 6

Configure Your FuzzyScan

Bar Code Programming Manual 9

Programming Procedures 10

Host Interface Selection 14

Symbology Reading Control 15

Keyboard Interface Control 46

Serial Interface Control 51

Operation Control 55

Condensed DataWizard 70

Appendix

Symbology ID Table 78

Keyboard Function Code Table 80

ASCII Input Shortcut 81

Host Interface Quick Set 82

Operation Mode Quick Set 82

Option Codes 84

System Commands 85

Indications 86

Programming Manual

Page 6

FuzzyScan OEM Scan Module

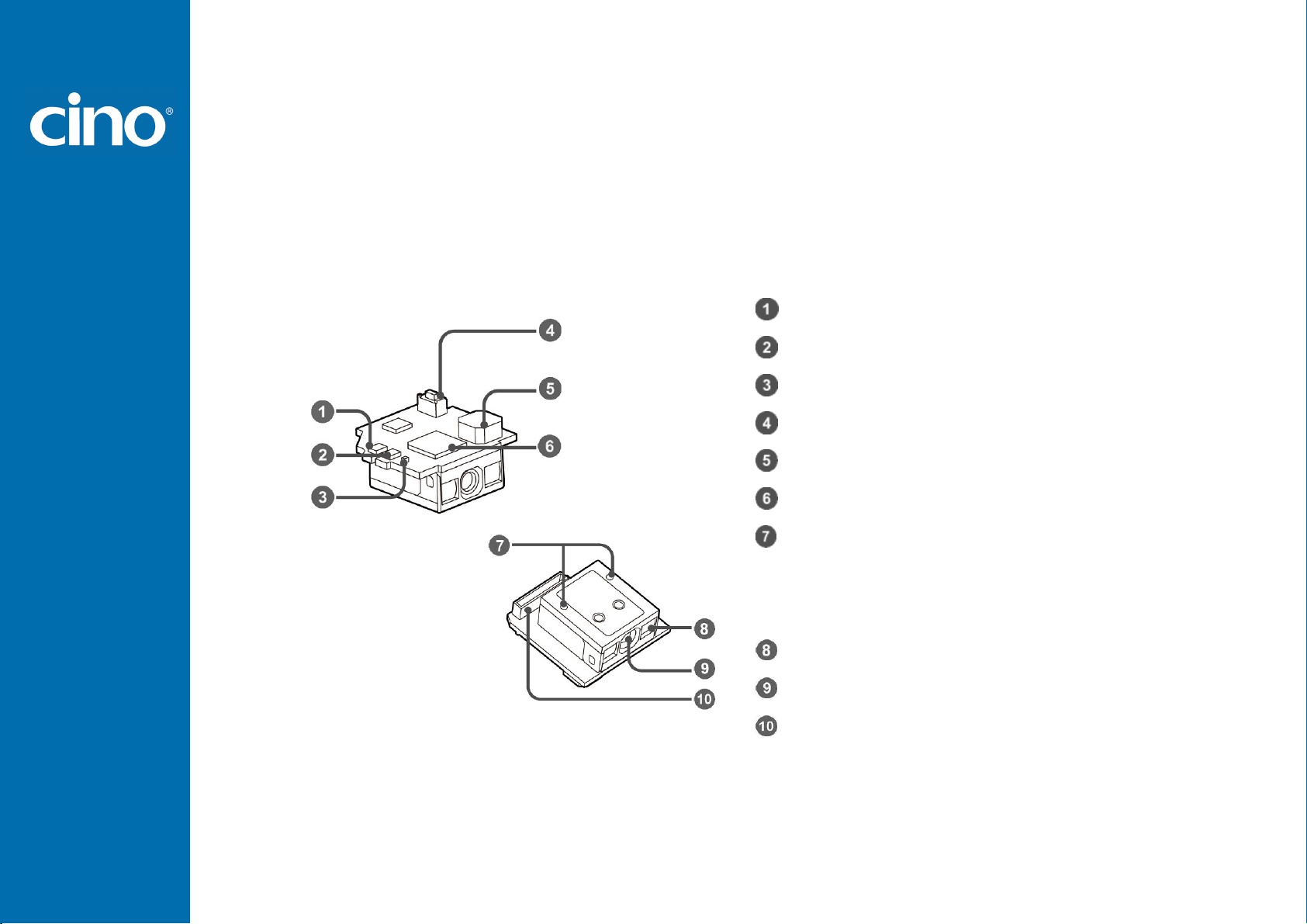

Getting Familiar with Your FuzzyScan

Thank you for choosing Cino FuzzyScan Scan Module SM380/SM5700 Series. Powered by the cutting-edge FuzzyScan 3.0

imaging technology, the compact and easy-integration scan module comes with exceptional reading capability yet versatile

functionality. Designed with system integration in mind, FuzzyScan OEM Scan Module combines all characteristics of

FuzzyScan fixed mount scanner in a small and compact package. It provides an ideal solution for embedded barcode

scanning applications.

SM380

OK/NG Indicator

Status Indicator

Power Indicator

Trigger Button

Buzzer

Main Processor

Mounting holes

(ø1.2 x 4mm depth)

TP1.7 screws suggested

Condenser

Lens

15-pin interface connector

Programming Manual

1

Page 7

FuzzyScan OEM Scan Module

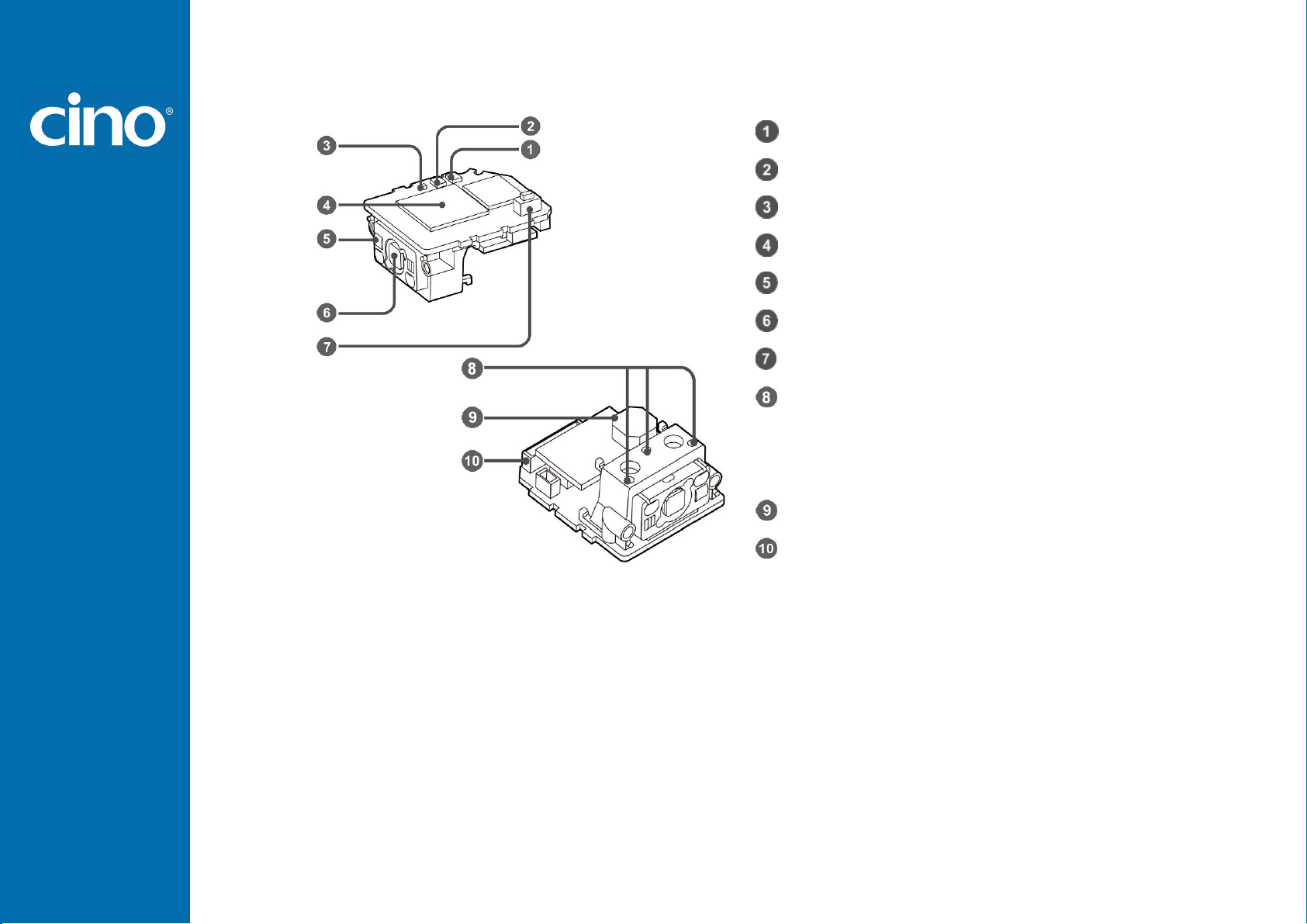

SM5700

OK/NG Indicator

Status Indicator

Power Indicator

Main Processor

Condenser

Lens

Trigger Button

Mounting holes

(ø1.7 x 3mm depth)

TP2.0 screws suggested

Buzzer

15-pin interface connector

Programming Manual

2

Page 8

FuzzyScan OEM Scan Module

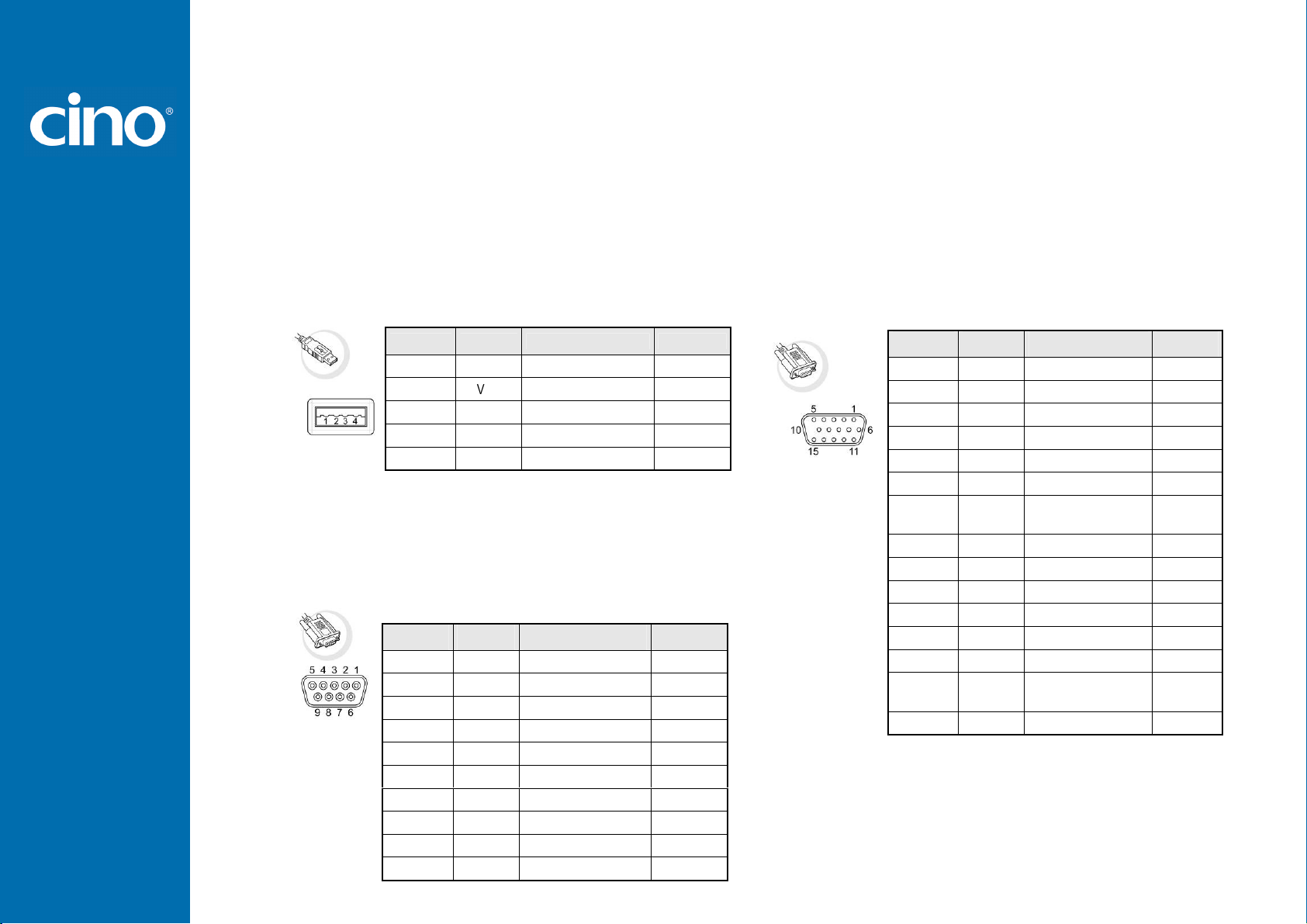

Connect to Your Host

FuzzyScan Scan Module is designed to support RS232 Serial, USB HID and USB COM Port Emulation interfaces. The

Evaluation Kit incorporates 2 scan modules, USB, RS232, Universal interface cables and power steal cable. It enables you

to make immediate evaluation once you plug in the interface cable. You may choose one of the interface cables to connect

the scan module and host device.

USB Interface

Universal Interface

Both USB HID and USB COM Port Emulation interfaces are

available for user’s choice.

4-pin Type A

Connector

Pin No. Signal Description I/O Type

Case FG Frame Ground ---

1

2 Data - USB Data - I/O

3 Data + USB Data + I/O

4 GND --- ---

VCC --- I

Standard RS232 Interface

The standard RS232 interface cable equips a 9-pin D-sub

connector with power jack for external 5Vdc power inlet.

9-pin D-sub

Female Connector

Pin No. Signal Description I/O Type

Case FG Frame Ground ---

1 --- --- ---

2 TXD Transmit Data I

3 RXD Receive Data O

4 --- --- ---

5 GND Signal Ground ---

6 --- --- ---

7 CTS Clear to Send I

8 RTS Request to Send O

9 VCC 5Vdc Power Supply I

Programming Manual

The scan module supports RS232 and USB interfaces with

OK/NG signal outputs and external trigger input.

15-pin D-sub HD

Female Connector

Pin No. Signal Description I/O Type

1 VCC 5Vdc Power Supply I

2 TXD Transmit Data O

3 RXD Receive Data I

4 GND Signal Ground ---

5 --- --- ---

6 RTS Request to Send O

7 OK

8 Data + USB Data + I/O

9 Trigger External Trigger Input I

10 CTS Clear to Send I

11 --- --- ---

12 Data - USB Data - I/O

13 Shield Frame Ground ---

14 NG

15 Reserved --- ---

OK Signal Output

(3-24Vdc)

NG Signal Output

(3-24Vdc)

3

O

O

Page 9

FuzzyScan OEM Scan Module

Connecting Host Interface

Standard RS232

Universal

USB

Programming Manual

4

Page 10

FuzzyScan OEM Scan Module

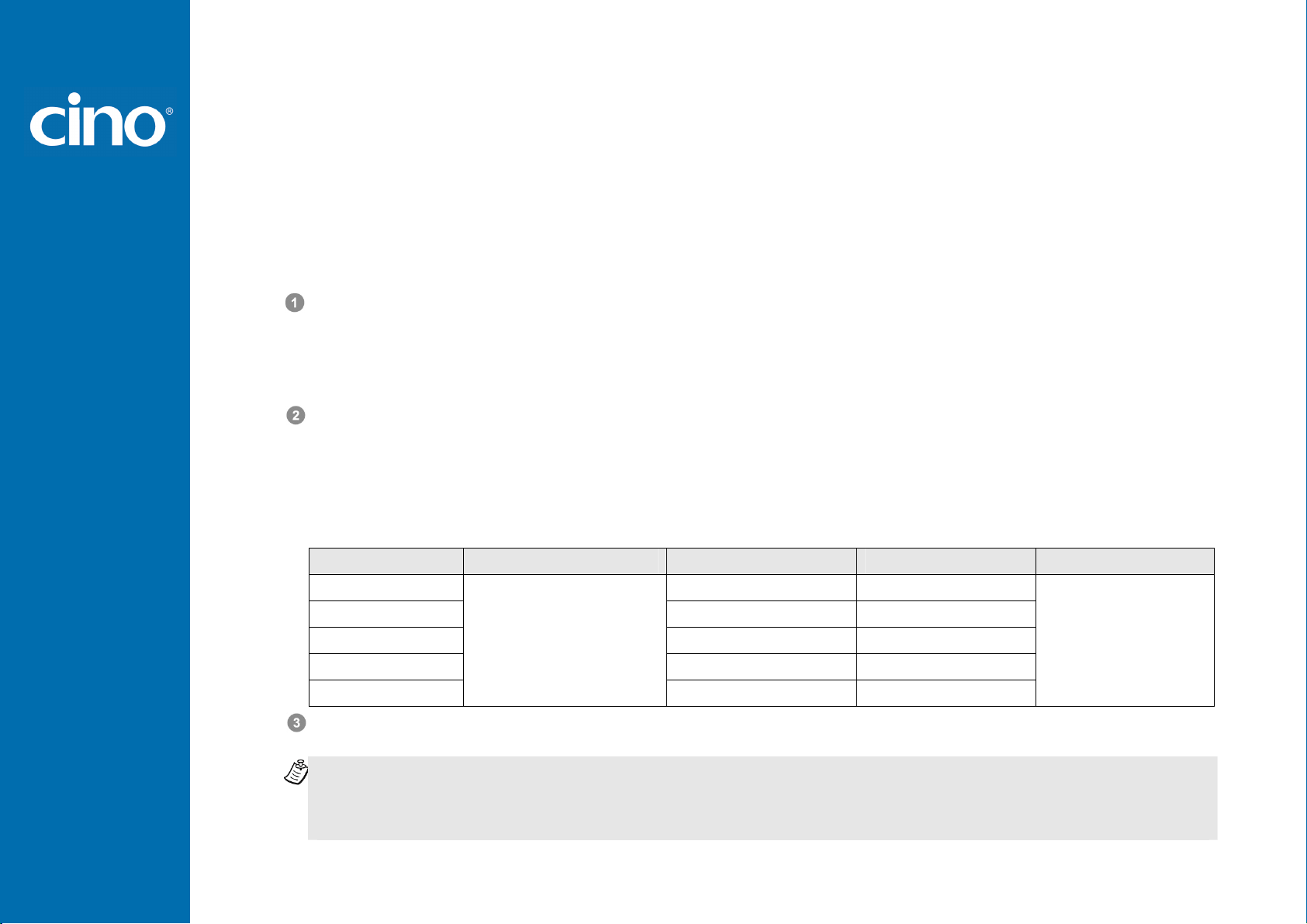

Intelli Button

For normal operation, the Intelli Button of the scan module acts as a manual Trigger Switch. You can press the Intelli Button

to scan the corresponding barcode commands to configure your scan module with ease. Moreover, the useful Intelli Button

can help you to identify the best mounting position. Please refer to following descriptions for more details.

Optimize Your Installation

Once the mounting position for the scan module is determined, you may use the Intelli Button to optimize the mounting

position with ease. Please follow below procedures to use the Intelli Button.

Press and hold the Intelli Button for more than 5 seconds until the status indicator gives one green blink, then release the

button. The scan module will emit 2 short beeps and the power indicator will flash blue blink per 1 second to indicate the

force reading process is activated. The scan module will turn on the light source to scan barcodes continuously until the

whole process completed.

Keep the scan module to read the same barcode. The scan module will count the Good Read numbers, then output the

information of reading rate and refresh LED indications every 100 scans. The format of output message is listed below.

< Readout data >

Meanwhile, both Status and OK/NG indicators provide the visible reading rate information as well. You may refer to the

table listed below for details.

Reading rate

100% Steady Green Steady Green

80 to 99% Steady Red Steady Green

50 to 79% Steady Green Steady Red

20 to 49% Steady Orange Steady Orange

0 to 19%

If the reading rate is not good enough, please adjust the reading angle and distance to get the optimum readability. If you

would like to exit the force reading process, please press the Intelli Button once again.

1.

If the scan module is unable to read any barcode during preset scan input time-out (default is 900ms), the scan module will

count it as a NG reading

2.

During force reading process, the OK/NG output signals will not be Performed.

POWER Indicator

1 blue blink per 1 sec

Programming Manual

STATUS Indicator OK/NG Indicator

:

Steady Red Steady Red

5

< Reading rate (0 to 100) >

Beeper

One short beep

Page 11

FuzzyScan OEM Scan Module

Use Your FuzzyScan

Both FuzzyScan Barcode commands and Serial commands are available to configure your scan module. The FuzzyScan

barcode commands are a series of proprietary barcodes which allow you to easily configure the scan module for most

applications. Moreover, the FuzzyScan serial commands are ideal for precise and complicated reading control in

machine-controllable environments. Please refer to the relevant documentations for details.

External Trigger and Serial Trigger

The scan module provides both external trigger and serial trigger to activate the scanning processes. Please note that the

external trigger is only available for universal models. The serial trigger is workable for all models including Standard RS232

serial and USB COM Port Emulation interfaces.

User Defined Serial Trigger Command

For user’s convenience to replace the other existing scan module, the useful user defined serial trigger command allows you

to trigger the scan module without impacting the existing application programs.

Scan Input Time-out

The scan input time-out is an adjustable value for the time period that light source turns on. It’s available for presentation,

alternative and level modes. The scan module keeps the light source on and continues to scan until the defined scan input

time-out is up. You can adjust the time-out duration from 100 milliseconds to 99 seconds to meet various demands.

OK and NG Outputs

The universal models support additional OK and NG outputs for more precise reading control. If the scan module got a good

read, a signal will be outputted through the OK pin. However, if the scan module failed to read the barcode during a reading

cycle or preset scan input time-out, a signal will be outputted through the NG pin.

The OK and NG outputs are designed as NPN signal outputs and preset to active low. You may change the active state of

OK and NG outputs to meet your applications

Operation Modes

The FuzzyScan Scan Module provides five different operation modes, including trigger, alternative, level, presentation and

force modes to meet various application demands

Both the presentation and force modes support triggerless operation, you don’t need to use either external trigger or serial

trigger to activate the scanning. But the trigger, alternative and level modes have to work with external trigger or serial

trigger to scan barcode

Programming Manual

6

Page 12

FuzzyScan OEM Scan Module

Operation Mode

The details of each operation mode supported by SM5700 area-imaging scan module are listed below.

Under trigger mode, the scan module will turn on the light source to read barcode when it receives an external trigger or a

serial trigger ON command. Once the external trigger has been released, or the scan module gets a good read or a serial

trigger OFF command, the scan module will stop reading and wait for the next trigger to activate scanning again.

When the scan module receives an external trigger or a serial trigger ON command under alternative mode, the scan

module will turn on the light source to read barcodes until the preset scan input time-out is up. The scan input time-out will

be reset after each good read. Once the light source is off, the scan module is waiting for the next trigger to activate

scanning again.

When the scan module receives an external trigger or a serial trigger ON command under level mode, the scan module will

turn on the light source to read barcodes until a good read is performed or the preset scan input time-out is up. Once the

light source goes off, the scan module is waiting for the next trigger to activate scanning again.

area-imaging scan module

Trigger Mode

Alternative Mode

Level Mode

Presentation Mode

When presentation mode is selected, the scan module is preset to turn on the background lighting to detect the bar codes.

Once the scan module detects an image similar to a bar code in the scan module field of view, it will turn on the light source

to scan until the preset scan input time-out is up. You may adjust the setting of “Presentation Sensitivity” to increase

detection sensitivity.

Force Mode

Under Force Mode, the scan module continues to read barcodes without using external trigger or serial trigger. Please note

that the scan module will not stop reading until you switch to another operation mode.

Programming Manual

7

Page 13

FuzzyScan OEM Scan Module

Trigger Mode

Alternative

Mode

Level

Mode

Presentation

Mode

Force

Mode

Operation Mode

The details of each operation mode supported by SM380 scan module are listed below.

Under trigger mode, the scan module will turn on the light source to read barcode when it receives an external trigger or a

serial trigger ON command. Once the external trigger has been released, or the scan module gets a good read or a serial

trigger OFF command, the scan module will stop reading and wait for the next trigger to activate scanning again.

When the scan module receives an external trigger or a serial trigger ON command under alternative mode, the scan

module will turn on the light source to read barcodes until the preset scan input time-out is up. The scan input time-out will

be reset after each good read. Once the light source goes off, the scan module is waiting for the next trigger to activate

scanning again.

When the scan module receives an external trigger or a serial trigger ON command under level mode, the scan module will

turn on the light source to read barcodes until a good read is performed or the preset scan input time-out is up. Once the

light source goes off, the scan module is waiting for the next trigger to activate scanning again.

linear imaging scan module

Under presentation mode, the scan module will automatically detect the object movement in the scanning field of view. Once

the scan module detects an image similar to a barcode, it will turn on the light source to scan until the preset scan input

time-out is up. You may adjust the setting of “Presentation Sensitivity” to increase the detection sensitivity.

Under force mode, the scan module continues to read barcodes without using external trigger or serial trigger. Please note

that the scan module will not stop reading until you switch to another operation mode

Programming Manual

8

.

Page 14

FuzzyScan OEM Scan Module

Bar Code Programming Menu

The FuzzyScan bar code commands are specially designed

Proprietary bar code labels which allow you to set the

FuzzyScan internal programming parameters. There are

System Command, Family Code and Option Code for

programming purpose.

Each programmable family and bar code command label is

listed on the same page with major system commands. The

detailed explanations and special programming flowchart are

printed on facing or following pages. You can read the

explanation and set the FuzzyScan concurrently.

A supplemental bar code command menu incorporates the

bar code command labels of System Command and Option

Code. As you set the FuzzyScan, open the bar code

command menu to find the option code page. You may scan

the desired family code and option code to set FuzzyScan. If

you want to change the programming family for multiple

settings, you need only turn over the programming page to

find next desired programming family.

System Command

System Command

System CommandSystem Command

The System Command is the highest level bar code

command which directs FuzzyScan to perform immediate

operations, such as entering programming mode

(PROGRAM), exiting programming mode (EXIT), listing

system information (SYSLIST), recovering to factory

preset configurations (M_DEFAULT), and so on. Please

note that all system commands will take a few seconds to

complete the operations. User must wait for the

completion beeps before scanning another bar code.

Family Code

Family Code

Family CodeFamily Code

The Family Code is scanned to select the user desired

programming family. FuzzyScan has already provided

more than one hundred programming families to meet any

specific requirements.

Option Code

Option Code

Option CodeOption Code

The Option Codes is a set of bar code commands

represented by “0–9”, “A–F” and finishing selection (FIN).

For most setting, you must select at least one option code

following the family code selection to set the desired

parameter for the selected programming family.

Programming Manual

9

Page 15

FuzzyScan OEM Scan Module

Programming Procedures

Programming Procedures

Programming ProceduresProgramming Procedures

As you scan the bar code command to select the desired

parameters, information about the final selected parameters

represented by the bar code commands are stored in the

FuzzyScan’s internal Flash Memory ASIC or non-volatile

memory. If you turn off the unit, the Flash Memory ASIC or

non-volatile memory retains all programming options. You

need not re-program the FuzzyScan if you want to keep the

existing configurations in the next power on.

The programming procedures of FuzzyScan are designed

as simple as possible for ease of setting. Most

programming families take the Single Scan Selection

programming procedure. But several programming families

have more complex and flexible programmable options,

and you must take Multiple Scans Selection, Cycling

Scan Selection or Dual Level Selection to complete their

programming procedures. Each kind of programming

procedure is listed in the following pages for your reference.

Please give careful attention to become familiar with each

programming procedure.

If the programming family must take multiple scans

selection, cycling scan selection, or dual level selection

procedures, the family of the programming menu will be

marked with the matched representing symbol of

Programming Category (P.C.) in bold font listed in the

following table. You can easily find the bold mark in the

programming menu, and refer to their flowcharts for details.

Before setting the FuzzyScan, please also refer to the

“Beeping Indications” listed in Appendix to understand the

details of programming beeping indications. It will be very

helpful for you to know the existing status while you are

programming the FuzzyScan.

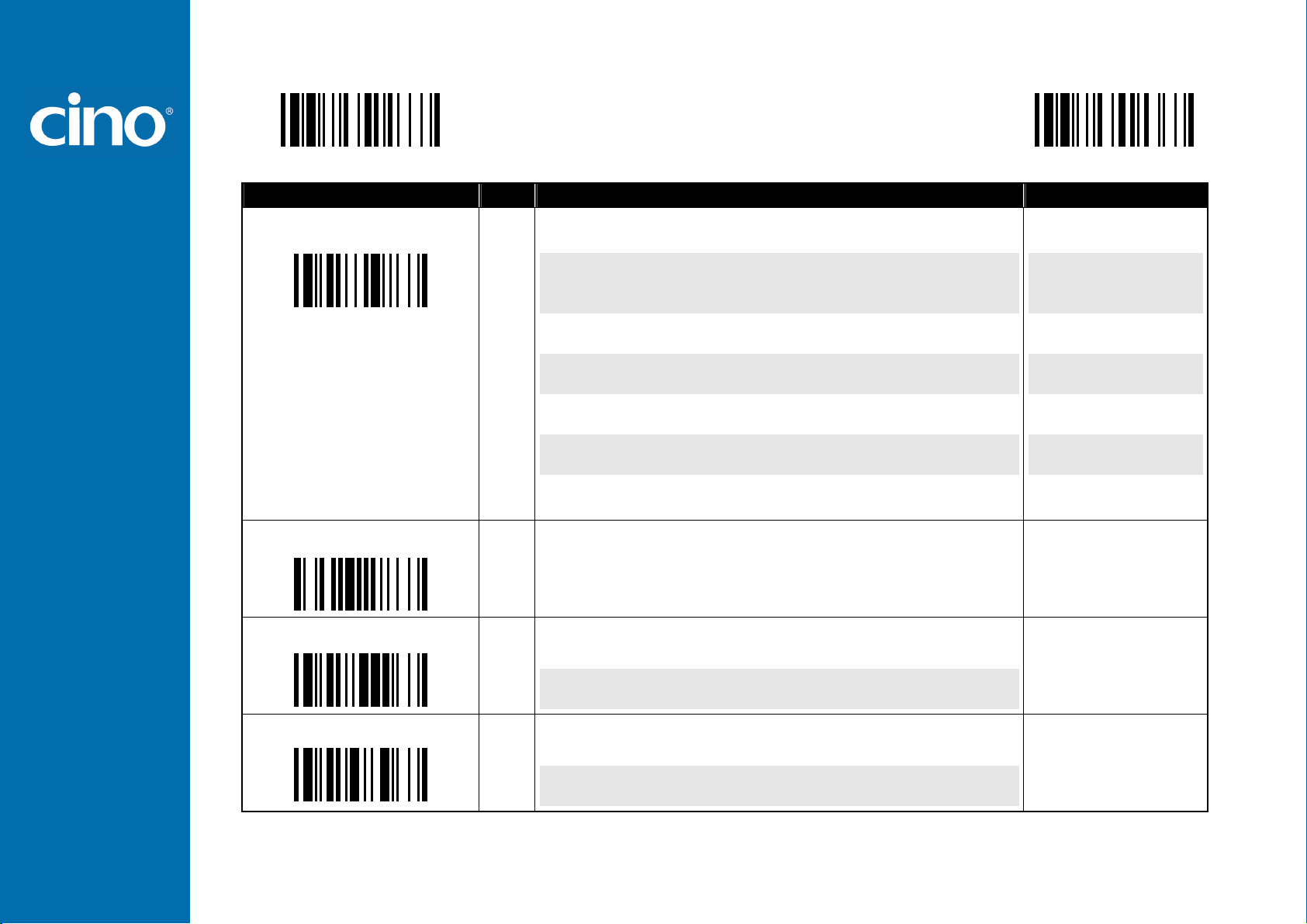

Conventions of Programming Menu

Conventions of Programming Menu

Conventions of Programming MenuConventions of Programming Menu

Conventions Descriptions

P.C. Programming Category

( ) Necessary Option Code

[ ] Selectable Option Code

Factory Default Value

: Signle scan selection

SS

MS : Multiple scans selection

CS : Cycling scan selection

DS : Dual level scan selection

Programming Manual

10

Page 16

FuzzyScan OEM Scan Module

Program & End

Program & End

Program & EndProgram & End

parameters in Flash Memory ASIC or non-volatile memory,

FuzzyScan will enter programming mode,

and inhibit all non-programming functions.

FuzzyScan will exit programming mode, and store all

then issue the completion beeping.

Please note that the FuzzyScan will take 3-4 seconds to

store parameters in internal Flash Memory ASIC or

non-volatile memory after you scan the “END”. Please

don’t turn off the power before the completion beeping. It

may destroy all configured parameters.

Scan

“

PROGRAM”

Scan

“

”

END

System List, Group & Master Default

System List, Group & Master Default

System List, Group & Master DefaultSystem List, Group & Master Default

FuzzyScan will list the product information and

revision number to host via selected host interface,

then issue the completion beeping.

FuzzyScan will recover all programmable

parameters into factory preset configurations,

then issue the completion beeping.

Scan

“

SYSLIST”

Scan

“

M_DEFAULT

”

Programming Manual

11

Page 17

FuzzyScan OEM Scan Module

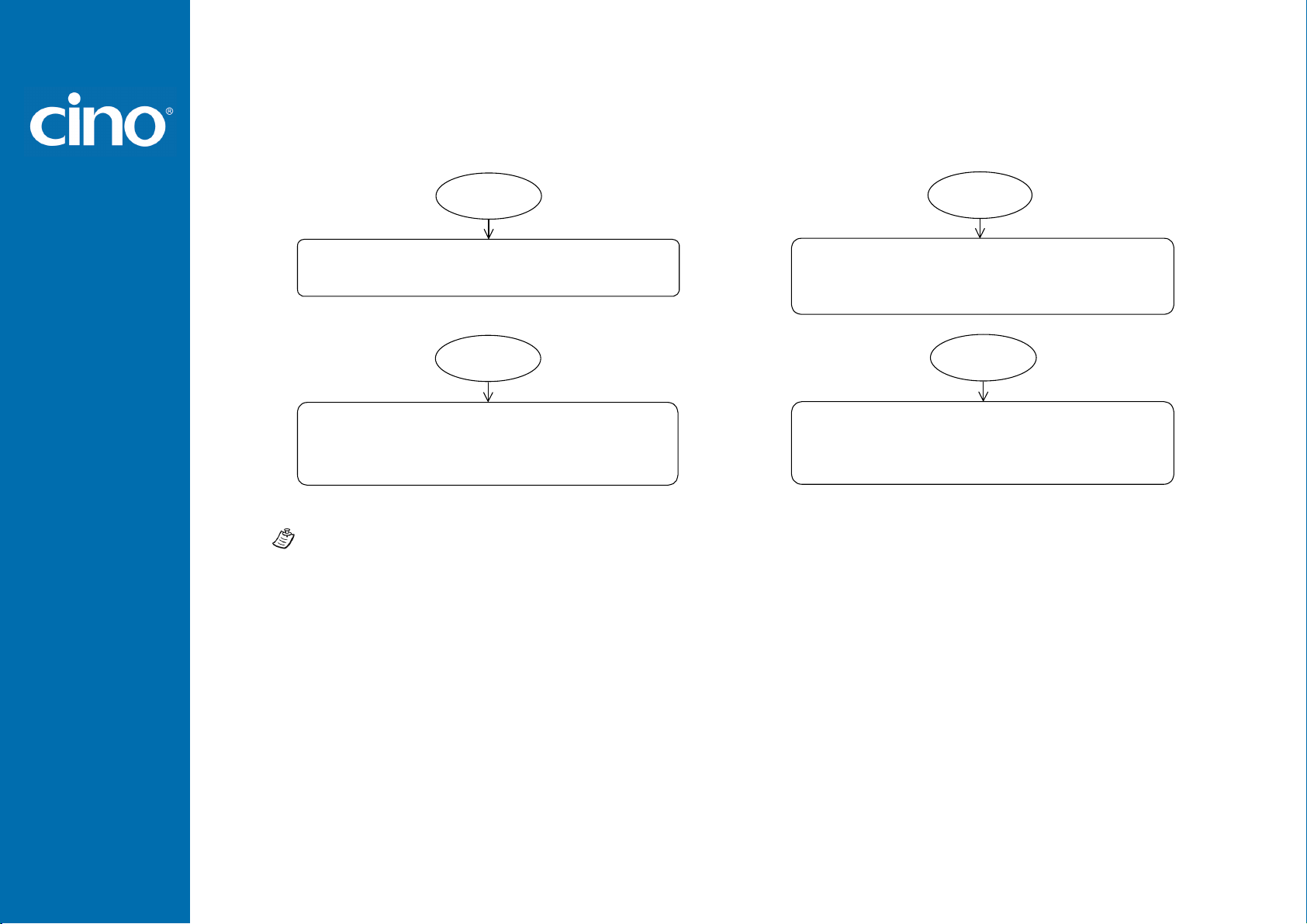

Single scan selection

Single scan selection

Single scan selectionSingle scan selection

One of

One of

Yes

Scan

“

PROGRAM

Scan

Family

Scan

Option

Repeat

Selection

Scan

“

END

”

Codes

Codes

No

”

Enter programming mode.

Select one of desired

programming families.

Select one option code of

desired parameter.

Want to select another

programming family?

Exit programming mode.

Multiple scans selection

Multiple scans selection

Multiple scans selectionMultiple scans selection

Yes

One of

Several

Scan

“

PROGRAM”

Scan

Family

Codes

Scan One or

Option

Codes

Repeat

Selection

No

Scan

“

”

END

Enter programming mode.

Select one of desired

programming families.

1. Select one or several

option codes to select

desired parameters.

2. If it’s necessary, scan

“FIN” to terminate

option code selection.

Want to select another

programming family?

Exit programming mode.

Programming Manual

12

Page 18

FuzzyScan OEM Scan Module

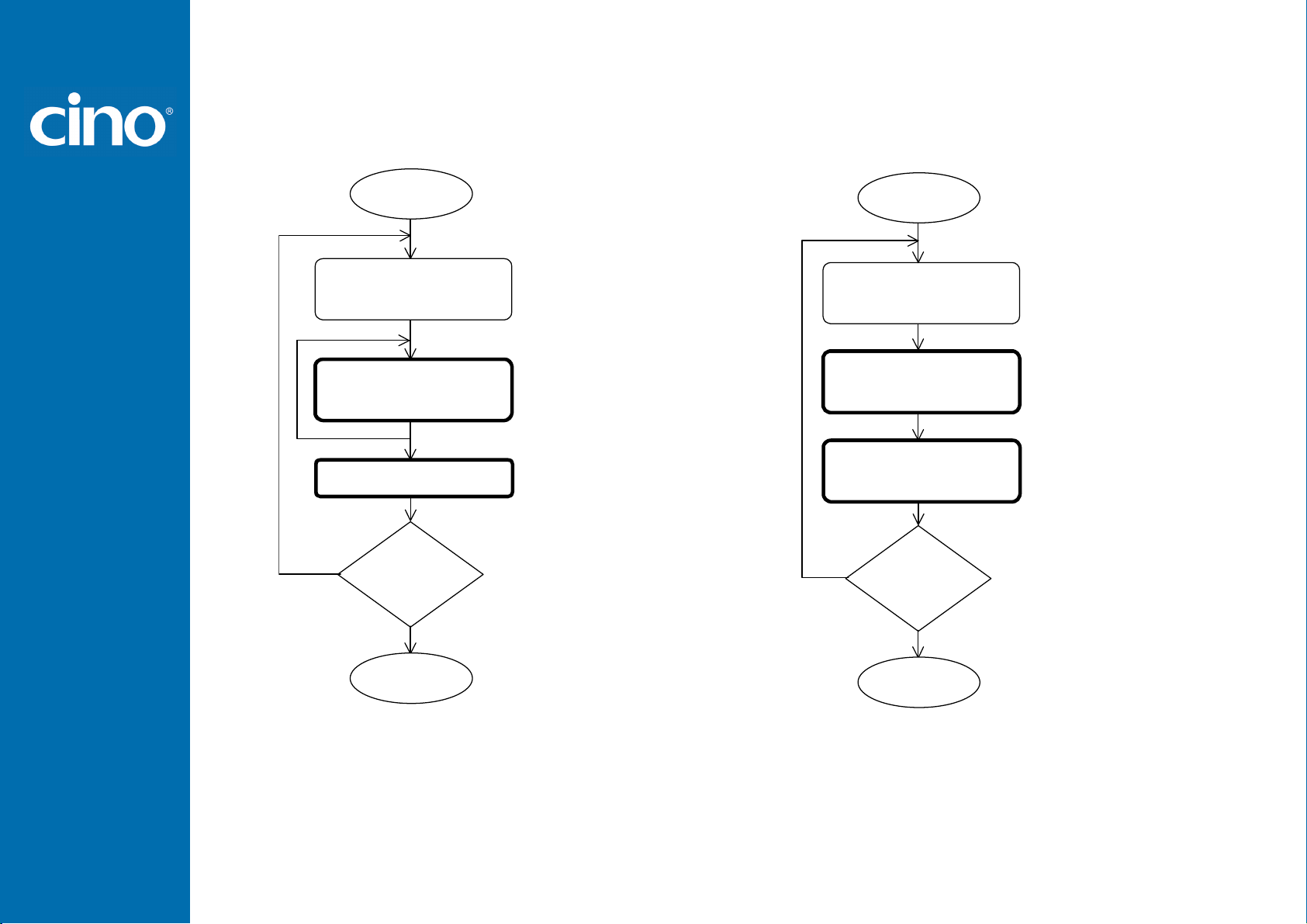

Cycling scan selection

Cycling scan selection

Cycling scan selectionCycling scan selection

Yes

One of

One of

Scan

“PROGRAM”

Scan

Family

Codes

Scan

Option

Scan “

Codes

FIN

”

Repeat

Selection

No

Scan

“

”

END

Enter programming mode.

Select one of desired

programming families.

Cycling select one or

several option codes of

desired parameters as

“Single” or “Multiple”

scans selection.

Finish cycling selection.

(If necessary)

Want to select another

programming family?

Exit programming mode.

Dual level selection

Dual level selection

Dual level selectionDual level selection

One of

Several

Several

Yes

Scan

“

PROGRAM”

Scan

Family

(

) Scan

1st

Option

(

) Scan One or

2nd

Option

Repeat

Selection

Scan

“

END”

Codes

No

Codes

Codes

Enter programming mode.

Select one of desired

programming families.

Select several option codes

of desired parameters.

1. Select one or several

option codes of desired

parameters.

2. If it’s necessary, scan

“FIN” to terminate

option code selection.

Want to select another

programming family?

Exit programming mode.

Programming Manual

13

Page 19

FuzzyScan OEM Scan Module

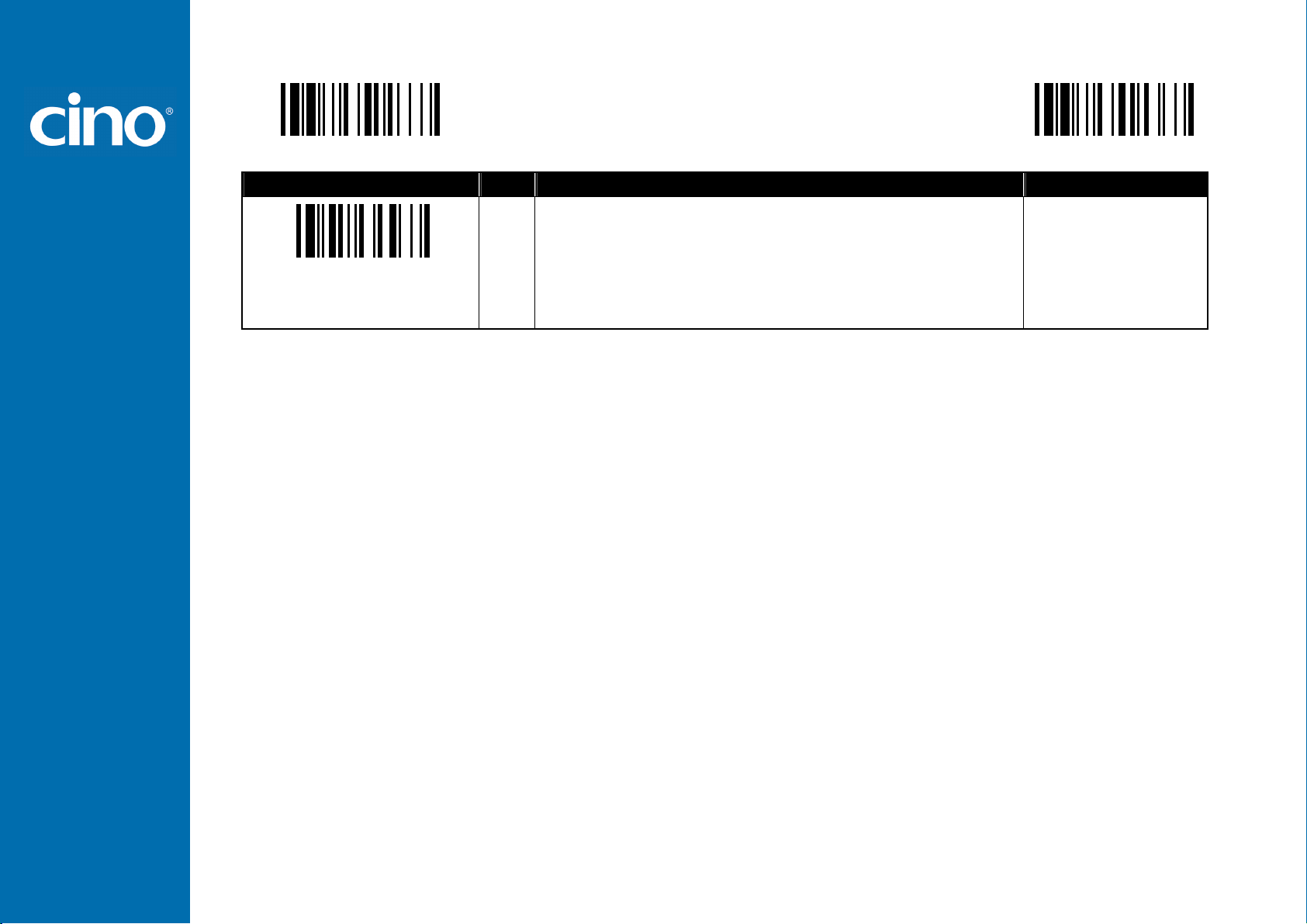

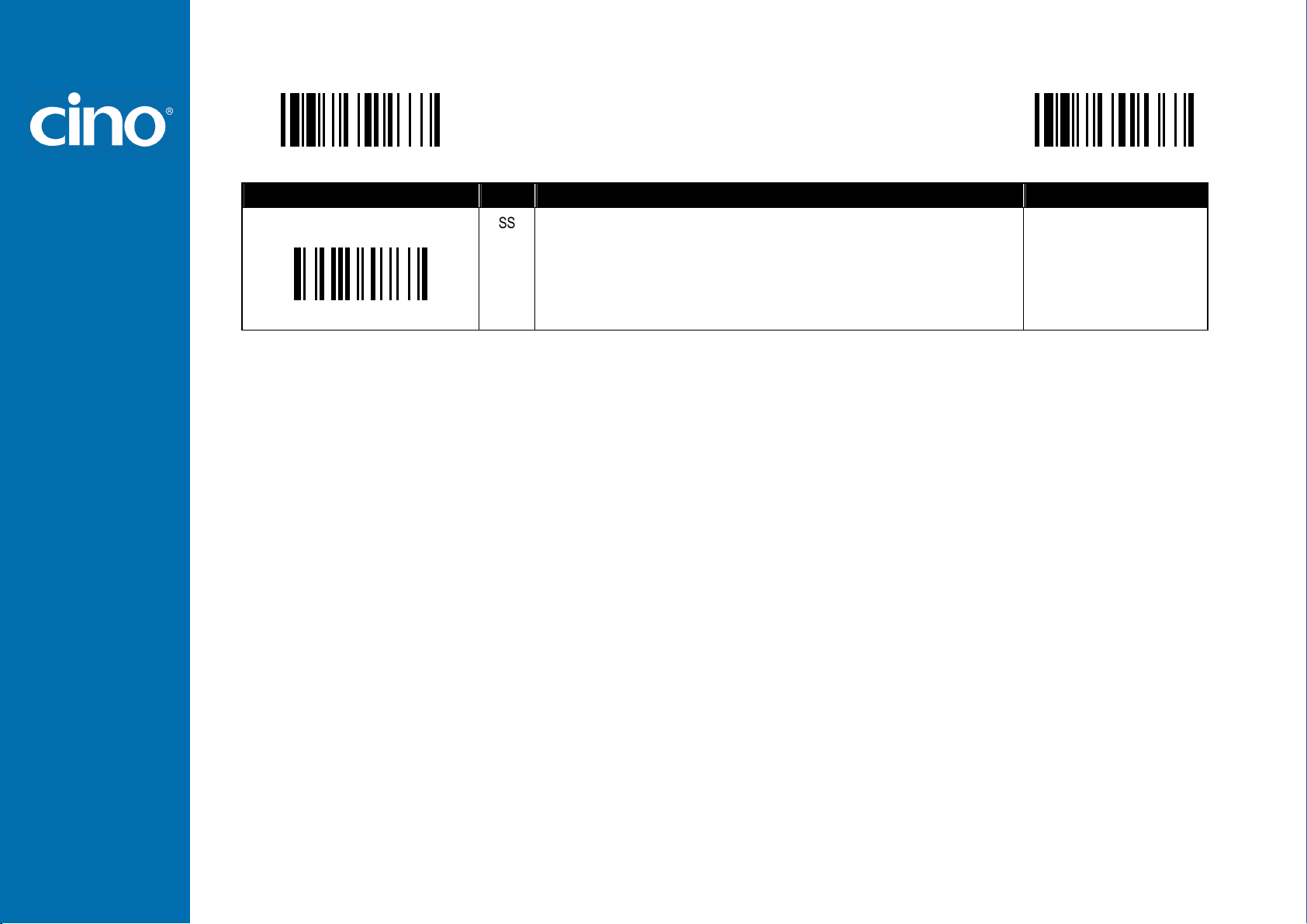

Host Interface Selection

PROGRAM

Family Code Selection P.C

Host Interface Selection

MS

Standard/TTL RS-232 peer-to-peer serial

MS

USB Com Port Emulation

MS

USB HID standard mode

MS

USB HID turbo mode

MS

USB HID Legacy

F_DEFAULT

Parameter Selection Option Code

06

09

18

19

20

Programming Manual

14

Page 20

FuzzyScan OEM Scan Module

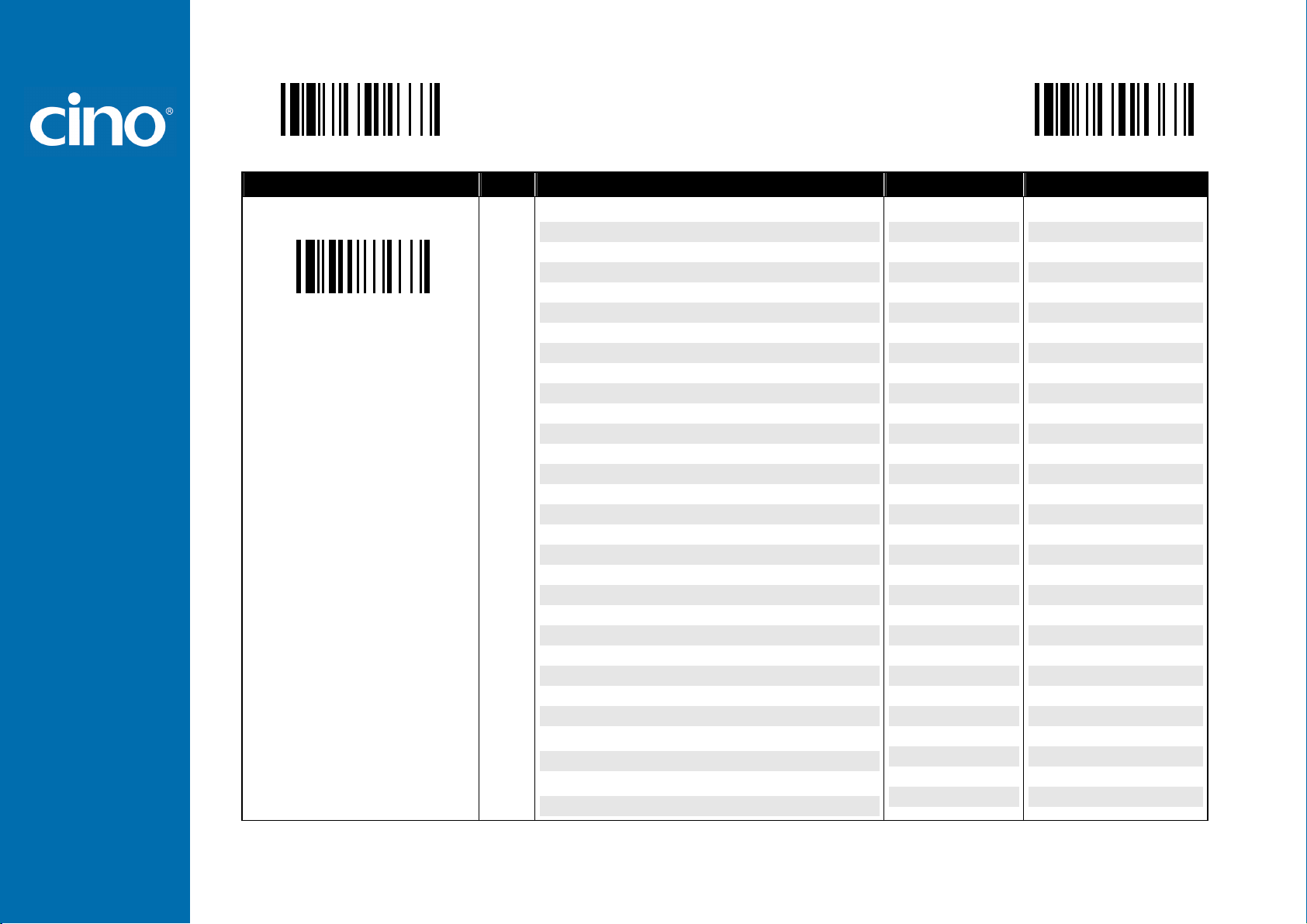

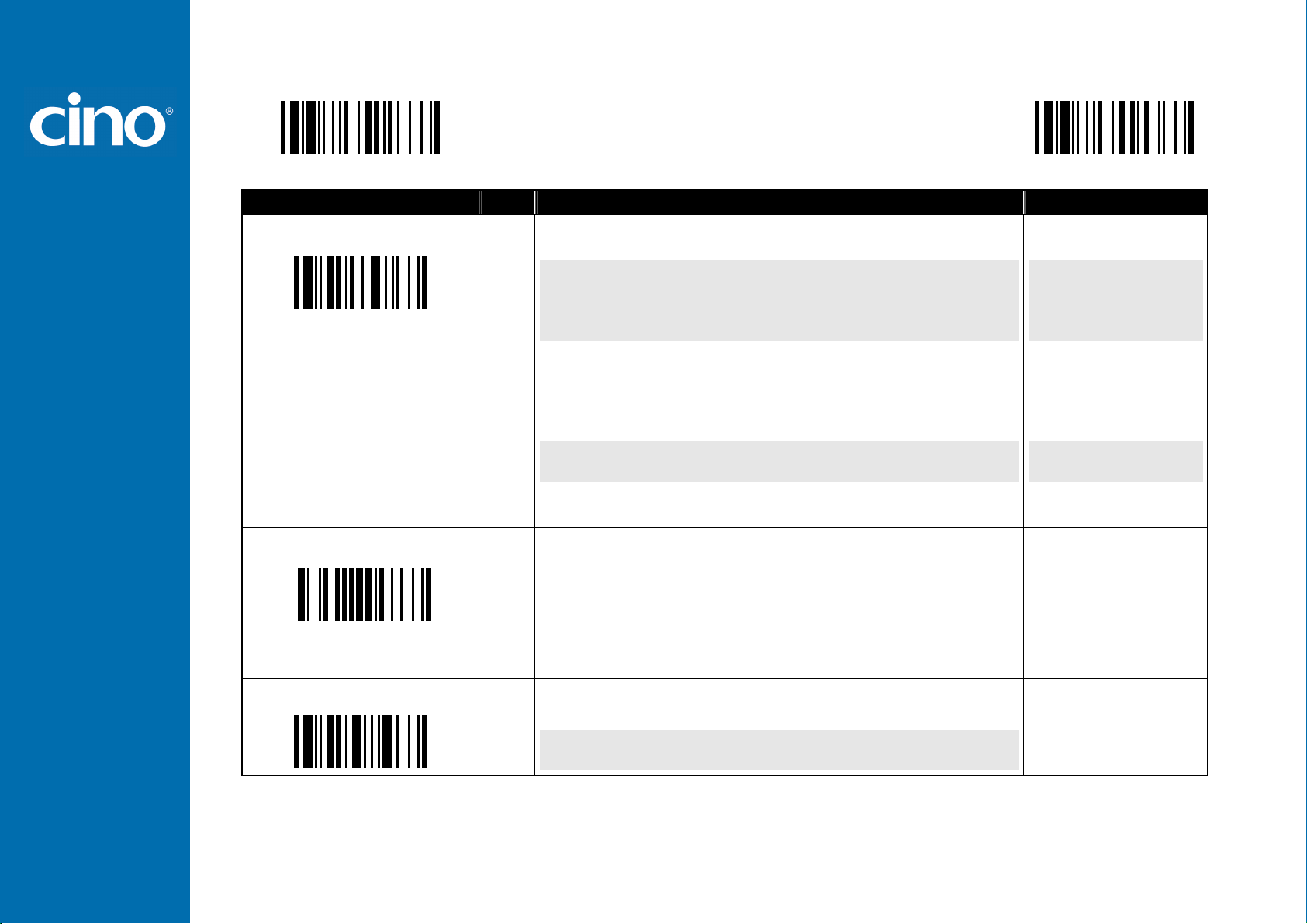

Symbology Reading Control

PROGRAM

Family Code Selection P.C

Symbol ID : 1 character

DS Code 128 (default=B)

♦♦♦♦ User Defined Symbol ID ♦♦♦♦

Parameter Selection Option Code 2nd Option Code

GS1-128 (default=C)

UPC-A (default=A)

EAN-13 (default=F)

Codabar/NW-7 (default=D)

Code 39/Code 32 (default=G)

Code 93 (default=H)

Standard/Industrial 2 of 5 (default=I)

Interleaved 2 of 5 (default=J)

Matrix 2 of 5 (default=K)

China Postal Code (default=L)

German Postal Code (default=M)

IATA (default=O)

Code 11 (default=P)

MSI/Plessey (default=R)

UK/Plessey (default=S)

Telepen (default=T)

GS1 DataBar (default=X)

UPC-E (default=E)

EAN-8 (default=N)

Trioptic Code 39 (Default=W)

UCC Coupon Extended Code (Default=Z)

PDF417/Micro PDF417 (default=V)

Codablock F (default=Y)

Code 16K (default=Q)

Code 49 (default=U)

Korea Post Code (default=a)

QR & Micro QR Code (default=b)

Data Matrix (default=c)

Maxi Code (default=d)

00

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

28

29

30

F_DEFAULT

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

Programming Manual

15

Page 21

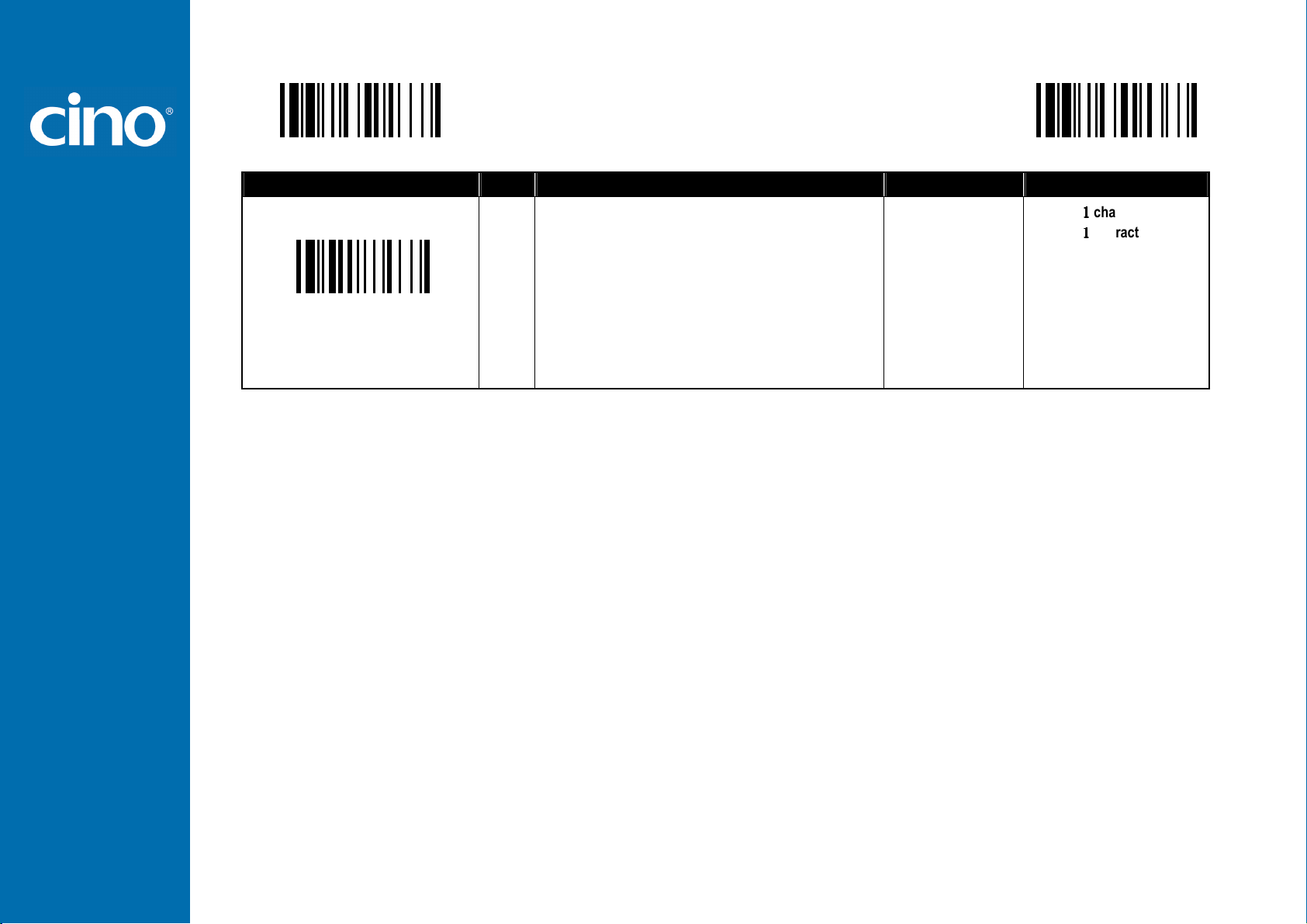

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

Symbol ID : 1 character

DS Aztec Code (default=e)

♦♦♦♦ User Defined Symbol ID ♦♦♦♦

Parameter Selection Option Code 2nd Option Code

Chinese Sensible (default=f)

Australian Post (default=g)

British Post (default=h)

Intelligent Mail (USPS 4CB/One Code) (default=j)

Japan Post (default=k)

Netherlands KIX Post (default=l)

US Planet (default=m)

US Postnet (default=o)

31

32

33

34

36

37

38

39

41

F_DEFAULT

(

1111

character)

(

1111

character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

(1 character)

Programming Manual

16

Page 22

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

Symbology ID Transmission

♦♦♦♦ Symbology ID Transmission ♦♦♦♦

Parameter Selection Option Code

SS

Disable symbology ID transmission

SS

Enable prefix CINO symbology ID transmission

SS

Enable suffix CINO symbology ID transmission

SS

Enable both prefix and suffix CINO symbology ID transmission

SS

Enable prefix AIM symbology ID transmission

SS

Enable suffix AIM symbology ID transmission

SS

Enable both prefix and suffix AIM symbology ID transmission

F_DEFAULT

0

1

2

3

4

5

6

Programming Manual

17

Page 23

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

Readable Symbology Setting

Remember to scan “FIN” to terminate

this selection. But if you select the

“Auto”, FuzzyScan will terminate this

selection automatically.

SS

CS

CS

CS

CS

CS

CS

CS

CS

CS

CS

CS

CS

CS

CS

CS

CS

CS

CS

CS

CS

CS

CS

CS

CS

CS

CS

CS

CS

CS

CS

CS

♦♦♦♦ Readable Bar Code Setting ♦♦♦♦

Parameter Selection Option Code

Auto

Code 128 *

GS1-128 *

UPC-A *

UPC-E *

EAN-13 *

EAN-8 *

Codabar/NW-7 *

Code 39 *

Trioptic Code 39

Standard/Industrial 2 of 5

Matrix 2 of 5

Interleaved 2 of 5 *

China Postal Code

Germany Postal Code

Code 93 *

Code 11

MSI/Plessey

UK/Plessey

Telepen

GS1 DataBar (RSS-14) *

IATA

PDF417 * /Micro PDF417

Codablock F

Code 16K

Code 49

Korea Post Code

QR Code */ Micro QR Code *

Data Matrix *

MaxiCode

Aztec Code *

Chinese Sensible (Han Xin) Code

F_DEFAULT

00

01

31

02

03

04

05

06

07

47

08

38

48

58

68

09

10

11

12

13

14

15

17

18

19

20

21

A0

A1

A2

A3

A4

Programming Manual

18

Page 24

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

CS

Readable Symbology Setting

If your application is known, you may select those known symbologies only to increase the reading speed and decrease the possibility of reading error. Furthermore, to add

the “Symbology ID” into the transmitted data is also helpful to identify the specific symbology.

Above symbologies marketed with * are enabled as default. When you select “Auto”, the scan module only reads those symbologies marked with *.

When you set the minimum and maximum length of each symbology, please note the data length of scanned bar code doesn’t include start/stop characters.

Australian Post

CS

British Post

CS

Intelligent Mail barcode

CS

Japanese Post

CS

KIX Post

CS

Planet Code

CS

Postnet

♦♦♦♦ Readable Bar Code Setting ♦♦♦♦

F_DEFAULT

Parameter Selection Option Code

B0

B1

B3

B4

B5

B6

B8

Programming Manual

19

Page 25

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

Code 39 Family Setting

Trioptic Code 39 Setting

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

♦

♦ Code 39/Code 32 Setting ♦

♦♦

♦♦♦

Parameter Selection Option Code

Disable Code 39

Enable Code 39

Select Standard Code 39 as primary format

Select Full ASCII Code 39 as primary format

Select Code 32 (PARAF, Italian Pharmaceutical) as primary format

Disable start/stop symbol transmission

Enable start/stop symbol transmission

Disable Code 32 leading A transmission

Enable Code 32 leading A transmission

Disable MOD 43 check digit verification

Enable MOD 43 check digit verification

Disable check digit transmission

Enable check digit transmission

Disable Code 39 buffering

Enable Code 39 buffering

Disable Trioptic Code 39

Enable Trioptic Code 39

F_DEFAULT

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

0

1

SS

Code 39 Min. Length

Code 39 Max. Length

Trioptic Code 39 and Code 39 Full ASCII cannot be enabled simultaneously.

Default (01)

MS

01-Maximum

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

SS

Default (98)

MS

98-Minimum

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

Programming Manual

FIN

(2 digits)

FIN

(2 digits)

20

Page 26

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

SS

SS

SS

SS

Level 0

Level 1

Level 2

Level 3

Code 39 Security Level

Code 39 Security Level

The scan module offers four levels of decode security for Code39 bar codes:

Level 0: If you are experiencing misread of poorly-printed or serious out-of-spec. bar codes in level 1, please select level 0.

Level 1: If you are experiencing misread of poorly-printed or out-of-spec. bar codes in level 2, please select level 1.

Level 2: This is the default setting which allows the scan module to operate fastest, while providing sufficient security in decoding “in-spec” Code39 bar codes.

Level 3: If you failed to read poorly-printed or out-of-spec. bar codes in level 2, please select level 3. This is the most aggressive setting and may increase the misread.

♦

♦ Code 39 Setting♦

♦♦

Parameter Selection Option Code

♦♦♦

F_DEFAULT

0

1

2

3

Programming Manual

21

Page 27

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

Codabar Setting

Codabar Check Digit Settings

♦♦♦♦ Codabar/NW-7 Setting ♦♦♦♦

Parameter Selection Option Code

SS

Disable Codabar

SS

Enable Codabar

SS

Select Codabar standard format

SS

Select Codabar ABC format

SS

Select Codabar CLSI format

SS

Select Codabar CX format

SS

Disable start/stop symbol transmission

SS

Enable ABCD/ABCD start/stop symbol transmission

SS

Enable abcd/abcd start/stop symbol transmission

SS

Enable ABCD/TN*E start/stop symbol transmission

SS

Enable abcd/tn*e start/stop symbol transmission

SS

Disable check digit verification

SS

Enable check digit verification

SS

Disable check digit transmission

SS

Enable check digit transmission

SS

Modulus 16

SS

Modulus 10/weight 3

SS

Modulus 11

SS

Modulus 10/weight 2

SS

7 check DR

SS

Weight Modulus 11

SS

Runes (Modulus 10/weight 2)

F_DEFAULT

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

0

1

2

3

4

5

6

SS

Codabar Min. Length

Default (04)

MS

01-Maximum

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

Programming Manual

FIN

(2 digits)

22

Page 28

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

Codabar Max. Length

SS

MS

♦♦♦♦ Codabar/NW-7 Setting ♦♦♦♦

Parameter Selection Option Code

Default (98)

98-Minimum

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

F_DEFAULT

FIN

(2 digits)

Programming Manual

23

Page 29

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

SS

UPC Family Setting

When enable UPC-E expansion, the UPC-E decoded data will be converted to UPC-A format and affected by related setting, such as UPC standardization, UPC numeric

system, UPC-A check digit transmission.

UPC-E & EAN-8 Expansion : Expand the 8-digit UPC-E and 8-digit ENA-8 to 12-digit UPC-A and 13-digit EAN-13.

UPC-A Standardization : Expand the 12-digit UPC-A to 13-digit EAN-13 with 1 zero insertion.

UPC Lead 1 Numeric System : Enable to read UPC leading with the 1 numeric system, you must enable this option.

WPC Selection

(UPC/EAN/CAN)

UPC-A 12 - 1 - 1 + 2 + 5 + 1 0

UPC-E 8 - 1 - 1 + 2 + 5 + 1 + 4

EAN-13 13 - 1 NC + 2 + 5 NC 0

EAN-8 8 - 1 NC + 2 + 5 NC + 5

Basic Length

Disable UPC-A

SS

Enable UPC-A

SS

Disable UPC-E

SS

Enable UPC-E

SS

Disable UPC-E expansion

SS

Enable UPC-E expansion

SS

Disable UPC standardization

SS

Enable UPC standardization

SS

Disable UPC numeric system

SS

Enable UPC numeric system

SS

Disable UPC-A check digit transmission

SS

Enable UPC-A check digit transmission

SS

Disable UPC-E check digit transmission

SS

Enable UPC-E check digit transmission

SS

Disable UPC “leading 1” portion

SS

Enable UPC “leading 1” portion

Disable

Check Digit

♦♦♦♦ UPC-A & UPC-E Setting ♦♦♦♦

Parameter Selection Option Code

Disable

Numeric System

With 2-digit

Addendum

With 5-digit

Addendum

Enable

Standardization

F_DEFAULT

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

Enable

Expansion

Programming Manual

24

Page 30

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

UPC Supplement Setting

UPC/EAN Security Level

Supplement Scan Voting

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

♦♦♦♦ UPC-A & UPC-E Setting , Supplement Scan Voting♦♦♦♦

Parameter Selection Option Code

Select UPC without supplement digits

Select UPC with only 2 supplement digits

Select UPC with only 5 supplement digits

Select UPC with 2/5 supplement digits

Disable force supplement digits output

Enable force supplement digits output

UPC Family Addenda Separator Off

UPC Family Addenda Separator On

Level 0

Level 1

Level 2

Only available for UPC-A & EAN-13

None

Level 1

Level 2

Level 3

Level 4

Level 5

Level 6

Level 7

Level 8

Level 9

Level 10

Level 11

Level 12

Level 13

F_DEFAULT

0

1

2

3

4

5

6

7

0

1

2

0

1

2

3

4

5

6

7

8

9

A

B

C

D

UPC/EAN Security Level

The scan module offers three levels of decode security for UPC/EAN bar codes:

Level 0: If you are experiencing misread of poorly-printed or out-of-spec. bar codes, especially in characters 1, 2, 7, and 8 in level 1, please select level 0. Selection of this

Level 1: This is the default setting which allows the scan module to operate fastest, while providing sufficient security in decoding “in-spec” UPC/EAN bar codes.

Level 2: If you are experiencing misread of poorly-printed, soiled or damage bar codes in level 1, please select level 2. This is the most aggressive setting and may

The Supplement Scan Voting is the number of times the same UPC/EAN with 2/5 supplement digits has to be decoded before it is transmitted. It is helpful when decoding

a mix of UPC/EAN symbols with and without supplement digits. This function is effective when you select UPC/EAN with only 2 supplement digits, UPC/EAN with only 5

supplement digits or UPC/EAN with 2/5 supplement digits. The default value is Level 3. When you select higher level, it may impact the reading speed on poorly-printed,

low contrast or damage barcode labels.

Programming Manual

security level may significantly impair the decoding ability of the scan module..

increase the misread.

25

Page 31

FuzzyScan OEM Scan Module

Symbology Reading Control

♦♦♦♦ EAN Setting , Supplement , Supplement Scan Voting♦♦♦♦

PROGRAM

Family Code Selection P.C

EAN Setting

EAN Supplement Setting

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

Parameter Selection Option Code

Disable EAN-13

Enable EAN-13

Disable EAN-8

Enable EAN-8

Disable EAN-8 expansion

Enable EAN-8 expansion

Disable EAN-13 check digit transmission

Enable EAN-13 check digit transmission

Disable EAN-8 check digit transmission

Enable EAN-8 check digit transmission

Disable ISBN/ISSN Conversion reading check

Enable ISBN/ISSN Conversion reading check

Select EAN without supplement digits

Select EAN with only 2 supplement digits

Select EAN with only 5 supplement digits

Select EAN with 2/5 supplement digits

Disable force supplement digits output

Enable force supplement digits output

EAN Addenda Separator Off

EAN Addenda Separator On

F_DEFAULT

0

1

2

3

4

5

6

7

8

9

A

B

0

1

2

3

4

5

6

7

SS

SS

SS

SS

SS

SS

SS

None

Level 1

Level 2

Level 3

Level 4

Level 5

Level 6

Supplement Scan Voting

The Supplement Scan Voting is the number of times the same UPC/EAN with 2/5 supplement digits has to be decoded before it is transmitted. It is helpful when decoding

a mix of UPC/EAN symbols with and without supplement digits. This function is effective when you select UPC/EAN with only 2 supplement digits, UPC/EAN with only 5

supplement digits or UPC/EAN with 2/5 supplement digits. The default value is Level 3. When you select higher level, it may impact the reading speed on poorly-printed,

low contrast or damage barcode labels.

Programming Manual

26

Level 7

Level 8

Level 9

Level 10

Level 11

Level 12

Level 13

0

1

2

3

4

5

6

7

8

9

A

B

C

D

Page 32

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

SS

UPC/EAN Security Level

EAN Supplement Control

UPC/EAN Security Level

The scan module offers three levels of decode security for UPC/EAN bar codes:

Level 0: If you are experiencing misread of poorly-printed or out-of-spec. bar codes, especially in characters 1, 2, 7, and 8 in level 1, please select level 0. Selection of this

Level 1: This is the default setting which allows the scan module to operate fastest, while providing sufficient security in decoding “in-spec” UPC/EAN bar codes.

Level 2: If you are experiencing misread of poorly-printed, soiled or damage bar codes in level 1, please select level 2. This is the most aggressive setting and may

EAN Supplement Control

If you select EAN with only 2, or 5 or 2/5 supplement digits and enable 491 prefix supplement digit output, the scan module will transmit EAN with 2, or 5 or 2/5 supplement

digits bar codes starting with 491 prefix. The EAN without supplement digit will not be transmitted.

If you select EAN with only 2, or 5 or 2/5 supplement digits and enable the other except 491 prefix supplement digit output, the scan module will transmit EAN with 2, or 5,

or 2/5 supplement digits bar codes starting with specific prefix. The EAN without supplement digit will be transmitted.

security level may significantly impair the decoding ability of the scan module..

increase the misread.

Level 0

SS

Level 1

Level 2

SS

Only available for UPC-A & EAN-13

SS

Disable all specific prefix supplement digital output

SS

Enable all specific prefix supplement digital output

SS

Enable 491 Supplement Digit Output

SS

Enable 978/979 Supplement Digit Output

SS

Enable 977 Supplement Digit Output

SS

Enable 378/379 Supplement Digit Output

SS

Enable 414/419 Supplement Digit Output

SS

Enable 434/439 Supplement Digit Output

♦♦♦♦ UPC/EAN Security Level Setting ,

EAN Supplement Control♦♦♦♦

Parameter Selection Option Code

F_DEFAULT

0

1

2

0

1

2

3

4

5

6

7

Programming Manual

27

Page 33

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

UCC Coupon Extended Code

UCC Coupon Extended Code

When UCC coupon extended code function is enabled, scan module decodes UPC-A barcodes starting with digit “5”, EAN-13 barcodes starting with digit “99” and GS1-128

Coupon Codes. UPC-A, EAN-13 and EAN-128 must be enabled to scan all types of Coupon Codes.

SS

SS

♦♦♦♦ UCC Coupon Extended Code Setting ♦♦♦♦

Parameter Selection Option Code

Disable UCC Coupon Extended Code

Enable UCC Coupon Extended Code

F_DEFAULT

0

1

Programming Manual

28

Page 34

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

IATA Setting

Interleaved 2 of 5 Setting

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

♦♦♦♦ IATA & Interleaved 2 of 5 Setting ♦♦♦♦

Parameter Selection Option Code

Disable IATA

Enable IATA

Select 15-digit fixed length IATA checking

Select variable length IATA

Disable check digit verification

Enable check digit automatic verification

Enable S/N checking digit verification only

Enable CPN checking digit verification only

Enable CPN, Airline and S/N check digit verification

Disable check digit transmission

Enable check digit transmission

Disable start/stop symbol transmission

Enable start/stop symbol transmission

Disable Interleaved 2 of 5

Enable Interleaved 2 of 5

Select Interleaved 2 of 5 as primary format

Select German Postal Code as primary format

No check character

Validate USS check digit

Validate OPCC check digit

Disable check digit transmission

Enable check digit transmission

F_DEFAULT

0

1

2

3

4

5

6

7

8

9

A

B

C

0

1

2

3

4

5

6

7

8

Programming Manual

29

Page 35

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

Code 25 Setting

Code 25 Family Min. Length

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

MS

Code 25 Family Max. Length

SS

MS

♦♦♦♦ Code 25 Family Setting ♦♦♦♦

Parameter Selection Option Code

Disable Standard/Industrial 2 of 5

Enable Standard/Industrial 2 of 5

Disable Matrix 2 of 5

Enable Matrix 2 of 5

Disable China Postal Code

Enable China Postal Code

Disable check digit verification

Enable check digit verification

Disable check digit transmission

Enable check digit transmission

Default (04)

01-Maximum

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

Default (98)

98-Minimum

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

F_DEFAULT

0

1

2

3

4

5

6

7

8

9

FIN

(2 digits)

FIN

(2 digits)

For Code25 setting, we recommend you to select only one type of Code 25 or set the maximum/minimum bar code length. To decode all types of Code 25 or to variable

length of Code 25 will increase the possibility of reading error.

Programming Manual

30

Page 36

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

Code 11 Setting

Code 11 Min. Length

SS

SS

SS

SS

SS

SS

SS

SS

MS

Code 11 Max. Length

SS

MS

Code 93 Setting

SS

SS

SS

SS

♦♦♦♦ Code 11 & Code 93 Setting ♦♦♦♦

Parameter Selection Option Code

Disable Code 11

Enable Code 11

Disable check digit verification

Select 1-check digit verification

Select 2-check digit verification

Disable check digit transmission

Enable check digit transmission

Default (04)

01-Maximum

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

Default (98)

98-Minimum

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

Disable Code 93

Enable Code 93

Disable check digit transmission

Enable check digit transmission

F_DEFAULT

0

1

2

3

4

5

6

FIN

(2 digits)

FIN

(2 digits)

0

1

2

3

SS

Code 93 Min. Length

Code 93 Max. Length

Default (01)

MS

01-Maximum

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

SS

Default (98)

MS

98-Minimum

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

Programming Manual

FIN

(2 digits)

FIN

(2 digits)

31

Page 37

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

MSI/Plessey Setting

MSI/Plessey Min. Length

MSI/Plessey Max. Length

SS

SS

SS

SS

SS

SS

SS

SS

MS

SS

MS

♦♦♦♦ MSI/Plessey Setting ♦♦♦♦

Parameter Selection Option Code

Disable MSI/Plessy

Enable MSI/Plessy

Select MOD 10 check digit

Select MOD 10-10 check digit

Select MOD 11-10 check digit

Disable check digit transmission

Enable check digit transmission

Default (04)

01-Maximum

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

Default (98)

98-Minimum

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

F_DEFAULT

0

1

2

3

4

5

6

FIN

(2 digits)

FIN

(2 digits)

Programming Manual

32

Page 38

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

Code 128 Setting

Code 128 Min. Length

Code 128 Max. Length

Code 128 Security Level

SS

SS

SS

SS

SS

MS

SS

MS

SS

SS

♦♦♦♦ Code 128 Setting ♦♦♦♦

Parameter Selection Option Code

Disable Code 128

Enable Code 128

ISBT Concatenation Off

ISBT Concatenation On

Default (01)

01-Maximum

Scan 2 digits from the option code chart in Appendix; then FuzzyScan will terminate

this selection automatically.

Default (98)

98-Minimum

Scan 2 digits from the option code chart in Appendix; then FuzzyScan will terminate

this selection automatically.

Level 0

Level 1

F_DEFAULT

0

1

2

3

FIN

(2 digits)

FIN

(2 digits)

0

1

Code 128 Security Level

The scan module offers two levels of decode security for Code128 bar codes:

Level 0: If you are experiencing misread of poor-printed or out-of-spec. bar code in level1, please select level 0.

Level 1: This is the default setting which allows the scan module to operate fastest, while providing sufficient security in decoding "in-spec." Code128 bar codes.

Programming Manual

33

Page 39

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

GS1-128 Setting

GS1-128 Min. Length

GS1-128 Max. Length

SS

SS

SS

MS

SS

MS

♦♦♦♦ GS1-128 Setting ♦♦♦♦

Parameter Selection Option Code

Disable GS1-128

Enable GS1-128

Default (01)

01-Maximum

Scan 2 digits from the option code chart in Appendix; then FuzzyScan will terminate

this selection automatically.

Default (98)

98-Minimum

Scan 2 digits from the option code chart in Appendix; then FuzzyScan will terminate

this selection automatically.

F_DEFAULT

0

1

FIN

(2 digits)

FIN

(2 digits)

Programming Manual

34

Page 40

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

UK/Plessey Setting

UK/Plessey Min. Length

SS

SS

SS

SS

SS

SS

SS

SS

SS

MS

UK/Plessey Max. Length

SS

MS

♦♦♦♦ UK/Plessey Setting ♦♦♦♦

Parameter Selection Option Code

Disable UK/Plessey

Enable UK/Plessey

Select UK/Plessey Standard Format

Select UK/Plessey CLSI Format

Disable Convert X to A-F

Enable Convert X to A-F

Disable check digit transmission

Enable check digit transmission

Default (04)

01-Maximum

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

Default (98)

98-Minimum

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

F_DEFAULT

0

1

2

3

4

5

6

7

FIN

(2 digits)

FIN

(2 digits)

Programming Manual

35

Page 41

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

Telepen Setting

Telepen Min. Length

Telepen Max. Length

SS

SS

SS

SS

SS

SS

SS

MS

SS

MS

♦♦♦♦ Telepen Setting ♦♦♦♦

Parameter Selection Option Code

Disable Telepen

Enable Telepen

Select Telepen Numeric mode

Select Telepen Full ASCII mode

Disable check digit transmission

Enable check digit transmission

Default (04)

01-Maximum

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

Default (98)

98-Minimum

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

F_DEFAULT

0

1

2

3

4

5

FIN

(2 digits)

FIN

(2 digits)

Programming Manual

36

Page 42

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

GS1 DataBar Setting

GS1 DataBar Min. Length

GS1 DataBar Max. Length

SS

SS

SS

SS

SS

SS

SS

MS

SS

MS

♦♦♦♦ GS1 DataBar Setting ♦♦♦♦

Parameter Selection Option Code

Disable GS1 DataBar (RSS-14)

Enable GS1 DataBar (RSS-14)

Disable GS1 DataBar Limited

Enable GS1 DataBar Limited

Disable GS1 DataBar Expanded

Enable GS1 DataBar Expanded

Default (04)

01-Maximum

Only available for GS1 Databar Expanded.

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

Default (74)

74-Minimum

Only available for GS1 Databar Expanded.

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

F_DEFAULT

0

1

2

3

4

5

FIN

(2 digits)

FIN

(2 digits)

Programming Manual

37

Page 43

FuzzyScan OEM Scan Module

r not.

Symbology Reading Control

PROGRAM

Family Code Selection P.C

Composite Codes Setting

PDF417/MicroPDF417 Setting

Codablock F Setting

♦♦♦♦ Composite Codes, PDF417/microPDF417,

Codablock F Setting ♦♦♦♦

Parameter Selection Option Code

SS

Disable composite codes

SS

Enable composite codes

SS

UPC Composite Mode: UPC never linked

SS

UPC Composite Mode: UPC always linked

If UPC Composite Mode: UPC never linked is selected, UPC barcodes are

transmitted whether MicroPDF417 symbol is detected o

If UPC Composite Mode: UPC always linked is selected, UPC barcodes are only

transmitted when the MicroPDF417 is detected.

SS

Disable PDF417

SS

Enable PDF417

SS

Disable MicroPDF417

SS

Enable MicroPDF417

SS

Disable

SS

Enable

F_DEFAULT

0

1

2

3

0

1

2

3

0

1

Programming Manual

38

Page 44

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

Code 16K Setting

SS

SS

Code 16K Min. Length

SS

MS

Code 16K Max. Length

SS

MS

Code 49 Setting

SS

SS

♦♦♦♦ Code 16K & Code 49 Setting ♦♦♦♦

Parameter Selection Option Code

Disable Code 16K

Enable Code 16K

Default (01)

01-Maximum

Scan 3 digits from the option code chart in Appendix; then FuzzyScan will terminate

this selection automatically.

Default (160)

160-Minimum

Scan 3 digits from the option code chart in Appendix; then FuzzyScan will terminate

this selection automatically.

Disable Code 49

Enable Code 49

F_DEFAULT

0

1

FIN

(3 digits)

FIN

(3 digits)

0

1

Code 49 Min. Length

Code 49 Max. Length

SS

Default (01)

MS

01-Maximum

Scan 2 digits from the option code chart in Appendix; then FuzzyScan will terminate

this selection automatically.

SS

Default (81)

MS

81-Minimum

Scan 2 digits from the option code chart in Appendix; then FuzzyScan will terminate

this selection automatically.

FIN

(2 digits)

FIN

(2 digits)

Programming Manual

39

Page 45

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

QR Code Setting

QR Code Min. Length

QR Code Max. Length

SS

SS

SS

MS

SS

MS

♦♦♦♦ QR Code Setting ♦♦♦♦

Parameter Selection Option Code

Disable QR Code

Enable QR Code

Disable MicroQR Code

Enable MicroQR Code

Disable QR Code Append

Enable QR Code Append

Disable QR Code Inverse Reading

Enable QR Code Inverse Reading

Auto detect QR Code Inverse Reading

Default (01)

01-Maximum

Scan 4 digits from the option code chart in Appendix; then FuzzyScan will terminate

this selection automatically.

Default (7089)

7089-Minimum

Scan 4 digits from the option code chart in Appendix; then FuzzyScan will terminate

this selection automatically.

F_DEFAULT

0

1

2

3

4

5

6

7

8

FIN

(4 digits)

FIN

(4 digits)

Programming Manual

40

Page 46

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

11Family Code Selection P.C

Data Matrix Setting

Data Matrix Min. Length

Data Matrix Max. Length

SS

SS

SS

SS

SS

SS

SS

SS

SS

MS

SS

MS

♦♦♦♦ Data Matrix Setting ♦♦♦♦

Parameter Selection Option Code

Disable Data Matrix

Enable Data Matrix

Disable Data Matrix Inverse Reading

Enable Data Matrix Inverse Reading

Auto Detect Data Matrix Inverse Reading

Disable Data Matrix Mirror Images

Enable Data Matrix Mirror Images

Auto Detect Data Matrix Mirror Images

Default (01)

01-Maximum

Scan 4 digits from the option code chart in Appendix; then FuzzyScan will terminate

this selection automatically.

Default (3116)

3116-Minimum

Scan 4 digits from the option code chart in Appendix; then FuzzyScan will terminate

this selection automatically.

F_DEFAULT

0

1

4

5

6

7

8

9

FIN

(4 digits)

FIN

(4 digits)

Programming Manual

41

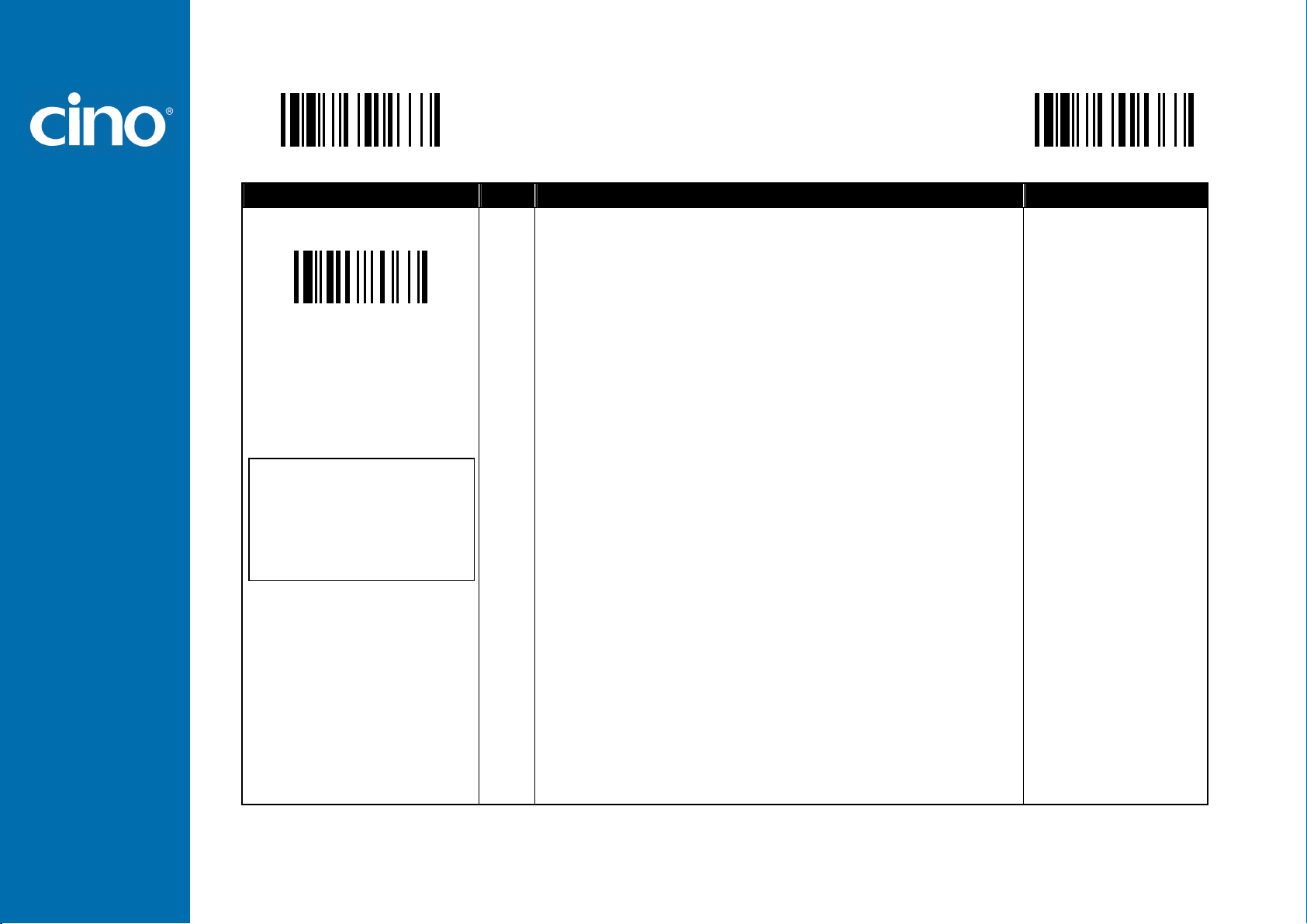

Page 47

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

MaxiCode Setting

MaxiCode Min. Length

MaxiCode Max. Length

♦♦♦♦MaxiCode Setting ♦♦♦♦

Parameter Selection Option Code

SS

Disable MaxiCode

SS

Enable MaxiCode

SS

Default (01)

MS

01-Maximum

Scan 3 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

SS

Default (150)

MS

150-Minimum

Scan 3 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

F_DEFAULT

0

1

FIN

(3 digits)

FIN

(3 digits)

Programming Manual

42

Page 48

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

Aztec Code Setting

Aztec Code Min. Length

Aztec Code Max. Length

SS

SS

SS

MS

SS

MS

♦♦♦♦ Aztec Code Setting ♦♦♦♦

Parameter Selection Option Code

Disable Aztec Code

Enable Aztec Code

Default (01)

01-Maximum

Scan 4 digits from the option code chart in Appendix; then FuzzyScan will terminate

this selection automatically.

Default (3832)

3832-Minimum

Scan 4 digits from the option code chart in Appendix; then FuzzyScan will terminate

this selection automatically.

F_DEFAULT

0

1

FIN

(4 digits)

FIN

(4 digits)

Programming Manual

43

Page 49

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

Australian Post Setting

US Planet Setting

US Postnet Setting

British Post Setting

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

♦♦♦♦ Australian Post, US Planet, US Postnet,

British Post & Japan Post Setting ♦♦♦♦

Parameter Selection Option Code

Disable Australian Post

Enable Australian Post

Raw format Output

Numeric Encoding Output (N Encoding Table)

Alphanumeric Encoding Output (C Encoding Table)

Auto-discriminate Output (Combination C & N Encoding Table)

Disable US Planet

Enable US Planet

Disable Check Digit Transmission

Enable Check Digit Transmission

Disable US Postnet

Enable US Postnet

Disable Check Digit Transmission

Enable Check Digit Transmission

Disable British Post

Enable British Post

Disable Check Digit Transmission

Enable Check Digit Transmission

F_DEFAULT

0

1

2

3

4

5

0

1

2

3

0

1

2

3

0

1

2

3

SS

Japan Post Setting

Australian Post Setting: Auto-discriminate output option increase the risk of misread because the encoded data format does not specify the Encoding Table used for

encoding.

Programming Manual

Disable Japan Post

SS

Enable Japan Post

44

0

1

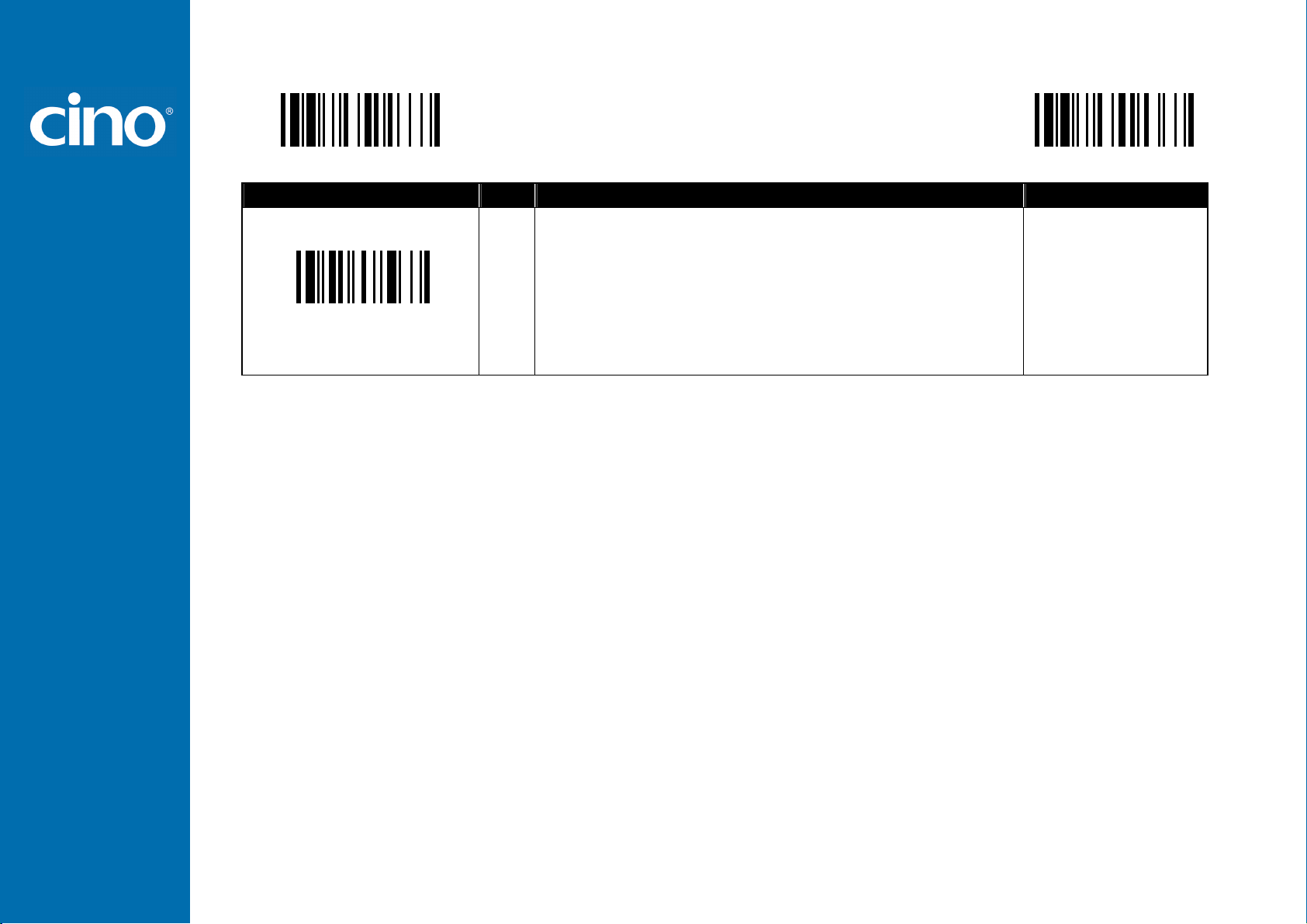

Page 50

FuzzyScan OEM Scan Module

Symbology Reading Control

PROGRAM

Family Code Selection P.C

Netherlands KIX Code Setting

Intelligent Mail Setting

(USPS 4CB/One Code)

Korea Post Code Setting

♦♦♦♦ Netherlands KIX Code, Intelligent Mail

& Korea Post Code Setting ♦♦♦♦

SS

Disable Netherlands KIX Code

SS

Enable Netherlands KIX Code

SS

Disable Intelligent Mail

SS

Enable Intelligent Mail

SS

Disable

SS

Enable

Length fixed in 6 characters.

F_DEFAULT

Parameter Selection Option Code

0

1

0

1

0

1

Programming Manual

45

Page 51

FuzzyScan OEM Scan Module

Keyboard Interface Control

PROGRAM

Family Code Selection P.C

Keyboard Layout

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

SS

♦♦♦♦ Keyboard Layout (Language) Setting ♦♦♦♦

Parameter Selection Option Code

USA (QWERTY)

France (AZERTY)

Germany (QWERTZ)

United Kingdom - UK (QWERTY)

Canadian French (QWERTY)

Spain (Spanish, QWERTY)

Sweden/Finland (QWERTY)

Portugal (QWERTY)

Norway (QWERTY)

Spain (Latin America, QWERTY)

Italy (QWERTY)

Netherlands (QWERTY)

Denmark (QWERTY)

Belgium (AZERTY)

Switzerland-Germany (QWERTY)

Iceland (QWERTY)

Japan (DOS/V)

Czech (QWERTY)

F_DEFAULT

00

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

Please refer to the ASCII/HEX Table listed in the Appendix to determine HEX codes for characters, symbols, and functions to be used as preamble or postamble.

To set preamble or postamble as function key output, you must enable the “Function Key Emulation” feature as listed in page 3-25 first.

Keyboard Interface Message String :

Preamble Data Length Prefix Symbol ID Scanned Data Suffix Symbol ID Postamble Record Suffix

1-15 characters 2-4 digits 1 or 3 characters Variable length 1 or 3 characters 1-15 characters 1 character

Programming Manual

46

Page 52

FuzzyScan OEM Scan Module

Keyboard Interface Control

PROGRAM

Family Code Selection P.C

Record Suffix

Preamble

MS

Postamble

MS

FNC1 Symbol Char. Transmit

♦♦♦♦ Record Suffix, Preamble, Postamble

FNC1 Transmit & Caps Lock ♦♦♦♦

Parameter Selection Option Code

SS

None

SS

RETURN

SS

TAB

SS

SPACE

SS

ENTER (Numeric Key Pad)

SS

User defined character (1 character)

SS

None

1-15 characters

Maximum 15-character input; scan “FIN” to terminate this selection.

SS

None

1-15 characters

Maximum 15-character input; scan “FIN” to terminate this selection.

SS

Disable

SS

Enable

F_DEFAULT

0

1

2

3

4

5, (00-7F)

FIN

[00-7F], [FIN]

FIN

[00-7F], [FIN]

0

1

Caps Lock Control

Caps Lock Release Control

SS

“Caps Lock Off” State

SS

“Caps Lock On” State

SS

Auto Detect (PC/AT, PS/2, Keyboard Replacement and DOS/V Machines only)

SS

“Caps Lock On, Caps Off”

SS

“Caps Lock On, Shift Off”

0

1

2

0

1

Programming Manual

47

Page 53

FuzzyScan OEM Scan Module

FNC1 Symbol Char. Transmit: When this function is enabled and the FNC1 is contained in scanned data, the scan module transmits the FNC1 to the host. Chart of

theFNC1 is provided in Appendix- Keyboard Function Code Table. When the scan module interface is set to keyboard, the scan code is converted to corresponding key

function before it is transmitted.

The function of “Caps Lock Control” and “Key Pad Emulation” are only available for IBM PC/AT, PS/VP, PS/2 series personal computers and compatible machines.

While selecting the other host interfaces, these selections don’t perform the above functions for you.

Please check the actual Caps Lock state in use while software application is running. If the Caps Lock state is off, select “Caps Lock Off” state, then FuzzyScan will

perform normal data transmission. If the Caps Lock state is on, select “Caps Lock On” state. Select “Auto Detect”, FuzzyScan will perform special transmission

handshaking without changing the status of Caps Lock switch.

Programming Manual

48

Page 54

FuzzyScan OEM Scan Module

Keyboard Interface Control

PROGRAM

Family Code Selection P.C

Intermessage Delay

Intercharacter Delay

Interfunction Delay

Intermessage Delay is a time delay between messages output by FuzzyScan. Increasing this delay will help host applications process the incoming data on time.

Intercharacter Delay is a time delay between data characters output by FuzzyScan. These two parameters are used to synchronize data communication when : 1) the data

transmission speed is too fast, characters may be skipped; 2) multitasking operation system or host computers in a network may slow down the keyboard handling; 3)

various notebook or desktop PC systems require different timing parameter settings. Please always add one extra unit as safety margin when adjusting these two

parameters.

Interfunction Delay is a time delay between the transmissions of each segment of the message string.

SS

MS

SS

MS

SS

MS

None

1-99 (x5) msec.

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

None

1-99 (x5) msec.

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

None

1-99 (x5) msec.

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

♦♦♦♦ Delay Setting ♦♦♦♦

F_DEFAULT

Parameter Selection Option Code

FIN

(2 digits)

FIN

(2 digits)

FIN

(2 digits)

Programming Manual

49

Page 55

FuzzyScan OEM Scan Module

Keyboard Interface Control

PROGRAM

Family Code Selection P.C

Function Key Emulation

Key Pad Emulation

Upper/Lower Case

SS

SS

SS

SS

SS

SS

SS

SS

♦♦♦♦ Emulation Setting & Upper/Lower Case Setting ♦♦♦♦

Parameter Selection Option Code

Enable ASCII 00-31 code as keyboard function code output

Ctrl-Output

Refer to Appendix – Keyboard Function Code Table for details.

Disable key pad emulation

Enable numeric output as key pad (Num Lock On) output

Normal case (neglect the upper/lower case control)

Inverse case (change all characters output to inverse case)

Upper case (force all characters output as upper case)

Lower case (force all characters output as lower case)

F_DEFAULT

0

1

0

1

0

1

2

3

Programming Manual

50

Page 56

FuzzyScan OEM Scan Module

interface is set to keyboard,

Serial Interface Control

PROGRAM

Family Code Selection P.C

STX/ETX Control

SS

SS

Record Suffix

Preamble

SS

SS

SS

SS

SS

SS

MS

SS

MS

Postamble

SS

MS

♦♦♦♦ Record Suffix, Preamble, Postamble Setting ♦♦♦♦

Parameter Selection Option Code

Disable STX/ETX transmission

Enable STX/ETX transmission

STX/ETX are two characters used to indicate the starting and ending of the total

data frame transmitted via serial interface.

None

CR (0DH)

LF (0AH)

CRLF (0D0AH)

TAB (09H)

SPACE (20H)

User defined character (1 character)

None

1-15 characters

Maximum 15-character input; scan “FIN” to terminate this selection.

None

1-15 characters

Maximum 15-character input; scan “FIN” to terminate this selection.

F_DEFAULT

0

1

0

1

2

3

4

5

6, (00-7F)

FIN

[00-7F], [FIN]

FIN

[00-7F], [FIN]

Programming Manual

FNC1 Symbol Char. Transmit

SS

SS

Serial Interface Message String (RS232, USB COM) :

STX Preamble Data Length Prefix Symbol ID Scanned Data Suffix Symbol ID

1 character

1-15 characters

2-4 digits 1 or 3 characters Variable length 1 or 3 characters 1-15 characters

Disable

Enable

When this function is enabled and the FNC1 is contained in scanned data, the scan

module transmits the FNC1 to the host. Chart of the FNC1 is provided in Appendix –

Keyboard Function Code Table. When the scan module

the scan code is converted to corresponding key function before it is transmitted

Postamble ETX Record Suffix

1 character 1 character

51

0

1

Page 57

FuzzyScan OEM Scan Module

Serial Interface Control

PROGRAM

Family Code Selection P.C

Intermessage Delay

Intercharacter Delay

Interfunction Delay

Intermessage Delay is a time delay between messages output by FuzzyScan. Increasing this delay will help host applications process the incoming data on time.

Intercharacter Delay is a time delay between data characters output by FuzzyScan. These two parameters are used to synchronize data communication when : 1) the data

transmission speed is too fast, characters may be skipped; 2) multitasking operation system or host computers in a network may slow down the keyboard handling; 3)

various notebook or desktop PC systems require different timing parameter settings. Please always add one extra unit as safety margin when adjusting these two

parameters.

Interfunction Delay is a time delay between the transmission of each segment of the message string.

SS

MS

SS

MS

SS

MS

None

1-99 (x5) msec.

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

None

1-99 (x5) msec.

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

None

1-99 (x5) msec.

Scan 2 digits from the option code chart in Appendix, then FuzzyScan will terminate

this selection automatically.

♦♦♦♦ Delay Setting ♦♦♦♦

F_DEFAULT

Parameter Selection Option Code

FIN

(2 digits)

FIN

(2 digits)

FIN

(2 digits)

Programming Manual

52

Page 58

FuzzyScan OEM Scan Module

Serial Interface Control

PROGRAM

Family Code Selection P.C

Handshaking Protocol

NAK Retry Count

SS

SS

SS

SS

SS

SS

None (free running mode)

RTS/CTS (hardware handshaking)