Page 1

FIXED MOUNT SCANNER

Fixed Mount Scanner

FUZZYSCAN FAMILY

Quick Start Guide

Page 2

Getting Familiar with Your FuzzyScan

Thank you for choosing Cino FuzzyScan Fixed Mount Scanner. Built with

FuzzyScan 3.0 Imaging Technology, durable ultra-compact design and rich

functionality, it provides an ideal barcode scanning solution for both industrial

and general purpose applications. This document provides a quick reference

for installation and operation. The complete documentation is available at

www.cino.com.tw.

FM480 Series (Front-view Model)

Power Indicator

Status Indicator

FM480 Series (Side-view Model)

FA470 Series (Front-view Model)

OK/NG Indicator

Intelli Button

Scan Window

Mounting Hole

Power Indicator

Status Indicator

OK/NG Indicator

FA470 Series (Side-view Model)

1

Intelli Button

Scan Window

Mounting Hole

Page 3

Connect to Your Host

Both standard RS232 and USB interfaces are available in different models.

Each model is equipped with corresponding connector to meet various

application demands.

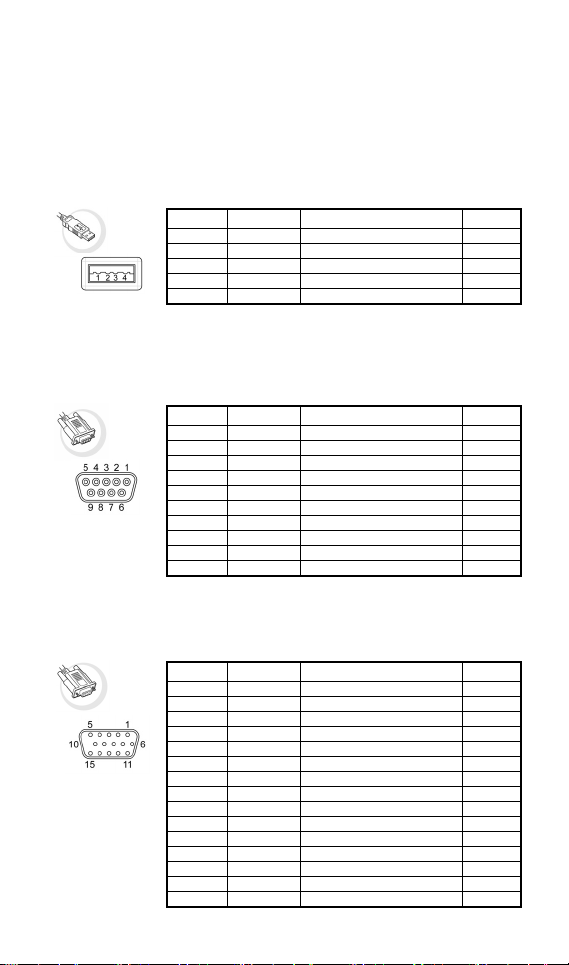

USB Models (FM4xx-11x/FA4xx-11x)

The USB models provide a plug-and-play solution. Both USB HID and USB

COM Port Emulation interfaces are available for user’s choice.

4-pin Type A

Connector

RS232 Models (FM4xx-00x/FA4xx- 00x)

The RS232 models support the standard RS232 interface equipped with a

9-pin D-sub connector with power jack for external 5VDC power inlet.

9-pin D-sub

Female Connecto

Universal Models (FM4xx-98x/FA4xx-98x)

The universal models support both standard RS232 and USB interfaces with

OK/NG signal outputs and external trigger input.

15-pin D-sub HD

Female Connector

Pin No. Signal Description I/O Type

Case FG Frame Ground ---

1 VCC --- I

2 Data - USB Data - I/O

3 Data + USB Data + I/O

4 GND --- ---

Pin No. Signal Description I/O Type

Case FG Frame Ground ---

1 --- --- --2 TXD Transmit Data O

3 RXD Receive Data I

4 --- --- --5 GND Signal Ground --6 --- --- --7 CTS Clear to Send I

r

8 RTS Request to Send O

9 VCC 5Vdc Power Supply I

Pin No. Signal Description I/O Type

1 VCC 5Vdc Power Supply I

2 TXD Transmit Data O

3 RXD Receive Data I

4 GND Signal Ground --5 --- --- --6 RTS Request to Send O

7 OK OK Signal Output (3-24Vdc) O

8 Data + USB Data + I/O

9 Trigger External Trigger Input I

10 CTS Clear to Send I

11 --- --- --12 Data - USB Data - I/O

13 Shield Frame Ground --14 NG NG Signal Output (3-24Vdc) O

15 Reserved --- ---

2

Page 4

Install Your FuzzyScan

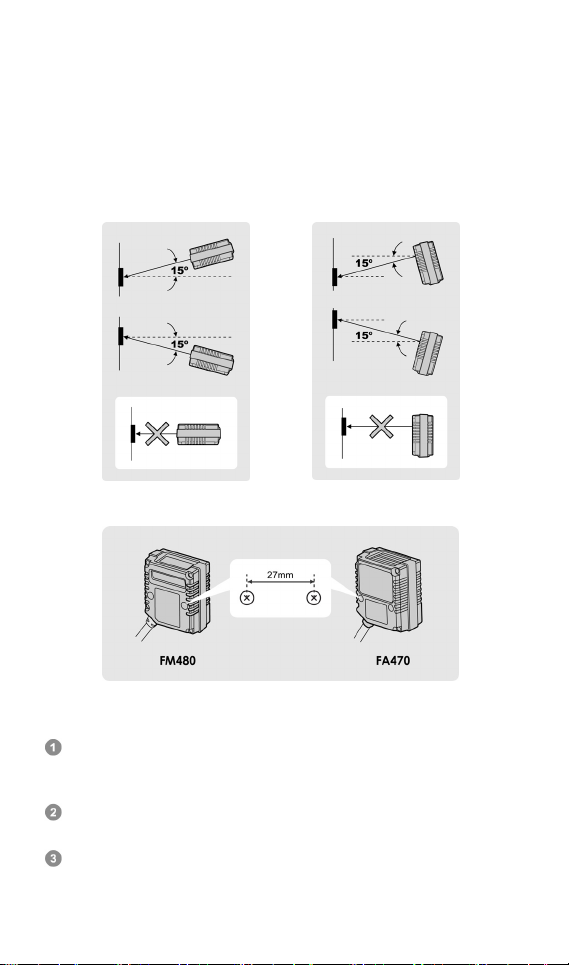

Adjust Reading Angle

The readability may be impacted by the specular reflection caused by the

perpendicular reading angle. To get the most optimal reading performance, it

is recommended to install the scanner at an approximate 15° angle to the

perpendicular line of the target barcode. However, the reading angle and

distance may vary depending on the size and printing quality of barcodes.

Mount Your FuzzyScan

There are two M3 mounting holes on the bottom of the chassis. Please follow

below procedures to mount your scanner.

Prepare two appropriate M3 screws (minimal 4mm in depth) and decide

your desired mounting location. Then adjust the two screws to

accommodate 27mm center width.

Optimize the mounting position by adjusting reading angle and distance.

Ensure the illumination envelop is not blocked by any external object.

Use the Intelli Button to verify the actual reading rate. If the reading rate

is not good enough, please adjust the reading angle and distance to get

the optimum readability.

Front-view Side-view

3

Page 5

Intelli Button

For normal operation, the Intelli Button of the scanner acts as a manual

Trigger Switch. You can press the Intelli Button to scan the corresponding

barcode commands to configure your scanner with ease. Moreover, the

useful Intelli Button can help you to identify the best mounting position.

Please refer to following descriptions for more details.

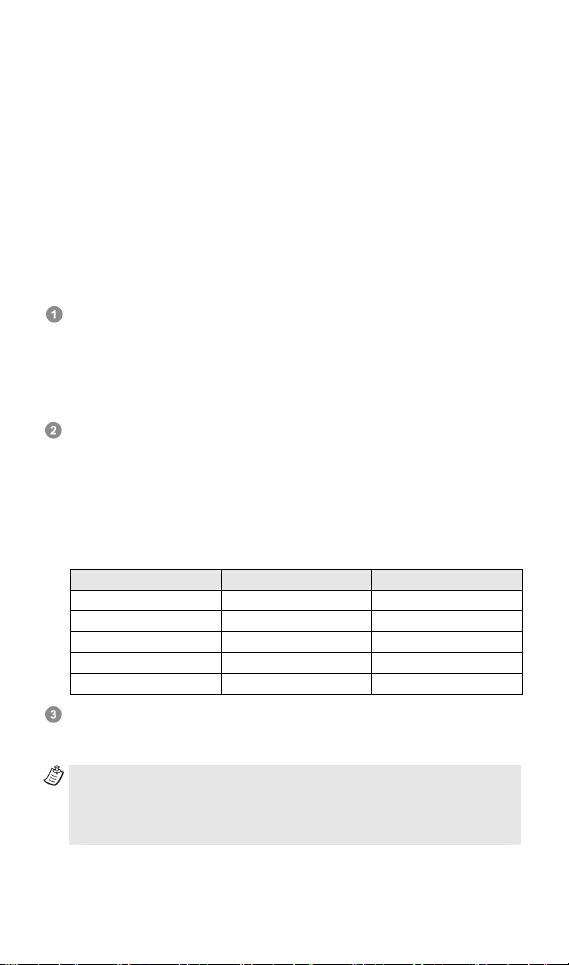

Optimize Your Installation

Once the mounting position for the scanner is determined, you may use the

Intelli Button to optimize the mounting position with ease. Please follow below

procedures to use the Intelli Button.

Press and hold the Intelli Button for more than 5 seconds until the status

indicator gives one green blink, then release the button. The scanner will

emit 2 short beeps and the power indicator will flash blue blink per 1

second to indicate the force reading process is activated. The scanner

will turn on the light source to scan barcodes continuously until the whole

process completed.

Keep the scanner to read the same barcode. The scanner will count the

Good Read numbers, then output the information of reading rate and

refresh LED indications every 100 scans. The format of output message

is listed below.

< Readout data > : < Reading rate (0 to 100) >

Meanwhile, both Status and OK/NG indicators provide the visible reading

rate information as well. You may refer to the table listed below for details.

Reading Rate Status Indicator OK/NG Indicator

100% Steady Green Steady Green

80 to 99% Steady Red Steady Green

50 to 79% Steady Green Steady Red

20 to 49% Steady Orange Steady Orange

0 to 19% Steady Red Steady Red

If the reading rate is not good enough, please adjust the reading angle

and distance to get the optimum readability. If you would like to exit the

force reading process, please press the Intelli Button once again.

1. If the scanner is unable to read any barcode after time-out duration

(default is 900ms), the scanner will count it as a NG reading.

2. During force reading process, the OK/NG output signals will not be

performed.

4

Page 6

Use Your FuzzyScan

Both FuzzyScan Barcode commands and Serial commands are available

to configure your scanner. The FuzzyScan barcode commands are a series

of proprietary barcodes which allow you to easily configure the scanner for

most applications. Moreover, the FuzzyScan serial commands are ideal for

precise and complicated reading control in machine-controllable

environments. Please refer to the relevant documentations for details.

External Trigger and Serial Trigger

The scanner provides both external trigger and serial trigger to activate the

scanning processes. Please note that the external trigger is only available for

universal models. The serial trigger is workable for all models including

RS232 serial and USB COM Port Emulation interfaces.

User Defined Serial Trigger Command

For user’s convenience to replace the other existing fixed mount scanner, the

useful user defined serial trigger command allows you to trigger the scanner

without impacting the existing application programs.

Scan Input Time-out

The scan input time-out is an adjustable value for the time period that light

source turns on. It’s available for presentation, alternative and level modes.

The scanner keeps the light source on and continues to scan until the defined

scan input time-out is up. You can adjust the time-out duration from 100

milliseconds to 99 seconds to meet various application demands.

OK and NG Outputs

The universal models support additional OK and NG outputs for more precise

reading control. If the scanner got a good read, a signal will be outputted

through the OK pin. However, if the scanner failed to read the barcode during

a reading cycle or preset scan input time-out, a signal will be outputted

through the NG pin.

The OK and NG outputs are designed as NPN signal outputs and preset to

active low. If necessary, you can change the active state of OK and NG

outputs to meet your applications.

Operation Modes

The FuzzyScan Fixed Mount Scanner provides five different operation modes,

including trigger, alternative, level, presentation and force modes to meet

various application demands.

Both the presentation and force modes support triggerless operation, you

don’t need to use either external trigger or serial trigger to activate the

scanning. But the trigger, alternative and level modes have to work with

external trigger or serial trigger to scan barcode.

5

Page 7

Operation Mode area-imaging fixed mount scanner

The details

mount scanner are listed below.

Under trigger mode, the scanner will turn on the light source to read barcode

when it receives an external trigger or a serial trigger ON command. Once the

external trigger has been released, or the scanner gets a good read or a

serial trigger OFF command, the scanner will stop reading and wait for the

next trigger to activate scanning again.

When the scanner receives an external trigger or a serial trigger ON

command under alternative mode, the scanner will turn on the light source to

read barcodes until the preset scan input time-out is up. The scan input

time-out will be reset after each good read. Once the light source goes off,

the scanner is waiting for the next trigger to activate scanning again.

When the scanner receives an external trigger or a serial trigger ON

command under level mode, the scanner will turn on the light source to read

barcodes until a good read is performed or the preset scan input time-out

is up. Once the light source goes off, the scanner is waiting for the next

trigger to activate scanning again

of each operation mode supported by FA470 area-imaging fixed

Trigger Mode

Alternative Mode

Level Mode

Presentation Mode

When presentation mode is selected, the scanner is preset to turn on the

background lighting to detect the bar codes. Once the scanner detects an

image similar to a bar code in the scanner field of view, it will turn on the light

source to scan until the preset scan input time-out is up. You may adjust

the setting of “Presentation Sensitivity” to increase the detection sensitivity.

Force Mode

Under force mode, the scanner continues to read barcodes without using

external trigger or serial trigger. Please note that the scanner will not stop

reading until you switch to another operation mode.

6

Page 8

Operation Mode linear fixed mount scanner

The details

scanner are listed below.

Under trigger mode, the scanner will turn on the light source to read barcode

when it receives an external trigger or a serial trigger ON command. Once the

external trigger has been released, or the scanner gets a good read or a

serial trigger OFF command, the scanner will stop reading and wait for the

next trigger to activate scanning again.

When the scanner receives an external trigger or a serial trigger ON

command under alternative mode, the scanner will turn on the light source to

read barcodes until the preset scan input time-out is up. The scan input

time-out will be reset after each good read. Once the light source goes off,

the scanner is waiting for the next trigger to activate scanning again.

When the scanner receives an external trigger or a serial trigger ON

command under level mode, the scanner will turn on the light source to read

barcodes until a good read is performed or the preset scan input time-out

is up. Once the light source goes off, the scanner is waiting for the next

trigger to activate scanning again.

Under presentation mode, the scanner will automatically detect the object

movement in the scanner field of view. Once the scanner detects an image

similar to a barcode, it will turn on the light source to scan until the preset

scan input time-out is up. For dark environments, you may adjust the setting

of “Presentation Sensitivity” to increase the detection sensitivity.

Under force mode, the scanner continues to read barcodes without using

external trigger or serial trigger. Please note that the scanner will not stop

reading until you switch to another operation mode.

of each operation mode supported by FM480 fixed mount

Trigger Mode

Alternative Mode

Level Mode

Presentation Mode

Force Mode

7

Page 9

Host Interface Quick Set

USB HID Turbo Mode

RS232 Serial

USB HID Standard Mode

USB Com Port Emulation

USB HID Interface Quick Set

- Record Suffix -

None

RETURN ◆

TAB

SPACE

ENTER

- Keyboard Layout -

USA ◆

France

Germany

United Kingdom-UK

Canadian French

Spain

Latin America

Nertherlands

Japan

8

Page 10

Serial Interface Quick Set

- Record Suffix -

None TAB

LF

CR ◆ SPACE

CRLF

- Baud Rate -

38.4K BPS 1200 BPS

4800 BPS

19.2K BPS 600 BPS

2400 BPS

9600 BPS ◆ 300 BPS

- Data Frame -

8, None, 1 ◆ 7, None, 2

8, None, 2

8, Odd, 1 7, Odd, 2

7, Odd, 1

8, Even, 1 7, Even, 2

7, Even, 1

8, Space, 1 7, Space, 2

7, Space, 1

8, Mark, 1 7, Mark, 2

7, Mark, 1

9

Page 11

USB HID Interface Control

Command Parameter Selection Option Code

Keyboard Layout

Record Suffix

Preamble None ◆

USA ◆

France

Germany

United Kingdom-UK

Canadian French

Spain

Sweden/Finland

Portugal

Norway

None

RETURN ◆

TAB

SPACE

1-15 characters

Latin America

Italy

Netherlands

Denmark

Belgium

Switzerland-Germany

Iceland

Japan

Universal

ENTER

User define character

00

01

02

03

04

05

06

07

08

0

1

2

3

FIN

[00-7F], [FIN]

09

10

11

12

13

14

15

16

99

4

5

Postamble None ◆

Intermessage Delay None ◆

Intercharacter Delay None ◆

Interfunction Delay None ◆

1-15 characters

1-99 (x5) msec.

1-99 (x5) msec.

1-99 (x5) msec.

Caps Lock Control “Caps Lock Off” State ◆

Caps Lock Release Control “Caps Lock On, Caps Off’’ ◆

Function Key Emulation Enable ASCII 00-31 as KB function code output ◆

Key Pad Emulation Disable key pad emulation ◆

Upper/Lower Case Normal case ◆

“Caps Lock On” State

Auto Detect

“Caps Lock On, Shift Off’’

Enable ASCII 00-31 as Ctrl-xx output

Enable numeric output as key pad output

Inverse case

Upper case

Lower case

10

FIN

[00-7F], [FIN]

FIN

(2 digits)

FIN

(2 digits)

FIN

(2 digits)

0

1

2

0

1

0

1

0

1

0

1

2

3

Page 12

Serial Interface Control

Command Parameter Selection Option Code

STX/ETX Control

Disable STX/ETX transmission ◆

Enable STX/ETX transmission

0

1

Record Suffix

Preamble

Postamble

Handshaking Protocol

Intermessage Delay

Intercharacter Delay

Interfunction Delay

Serial Response Time-out None

None

CR ◆

LF

CRLF

None ◆

1-15 characters

None ◆

1-15 characters

None ◆

RTS/CTS

ACK/ NAK

Xon/Xoff

None ◆

1-99 (x5) msec.

None ◆

1-99 (x5) msec.

None ◆

1-99 (x5) msec.

200 msec.

500 msec. ◆

800 msec.

1 sec.

2 sec

TAB

SPACE

User define character

3 sec.

4 sec

5 sec.

8 sec.

10 sec.

15 sec.

0

1

2

3

[00-7F], [FIN]

[00-7F], [FIN]

(2 digits)

(2 digits)

(2 digits)

0

1

2

3

4

5

Message String Breakdown

USB HID interface output (DOS/V, USB HID)

Preamble Data Length Prefix ID Scanned Data Suffix ID Postamble Record Suffix

1-15 char. 2-4 digits 1 or 3 char. Variable 1 or 3 char. 1-15 char. 1 char.

Serial interface output (RS-232, USB COM Port Emulation)

STX Preamble Data Length Prefix ID

1 char. 1-15 char. 2-4 digits 1 or 3 char. Variable 1 or 3 char. 1-15 char. 1 char. 1 char.

Scanned Data

Suffix ID Postamble ETX

FIN

FIN

FIN

FIN

FIN

0

1

2

3

Record

Suffix

4

5

6

6

7

8

9

A

B

11

Page 13

Operation Control

Command Parameter Selection Option Code

Redundancy

Power On Indicator

Buzzer Tone Control

Good Read Duration

Presentation Sensitivity

Scan Rate Control

None

Level 1 ◆

Level 2

Level 3

Level 4

Level 5

Scan Voting

Disable (LED off)

LED steady on ◆

LED flash

Buzzer tone – mute

Buzzer tone – low

Buzzer tone – medium ◆

Buzzer tone – high

Buzzer tone – extremely high

Power–on beep ◆

No Power–on beep

Short

Medium ◆

Long

Extremely long

Extremely short

Level 1

Level 2

Level 3

Level 4

Level 5 ◆

Level 6

Level 7

Dynamic ◆

Fixed

0

1

2

3

4

5

0

1

2

0

1

2

3

4

5

6

0

1

2

3

4

0

1

2

3

4

5

6

0

1

Hands Free Time-out

Scan Input Time-out

Short ◆

Medium

Long

Extremely long

Disable

100 msec.

200 msec.

300 msec.

400 msec.

500 msec.

600 msec.

700 msec.

800 msec.

900 msec. ◆

User define: 1-99 sec.

0

1

2

3

4

0

1

2

3

4

5

6

7

8

9, (2 digits)

12

Page 14

Output Control

Command Parameter Selection Option Code

Dollar Sign Output

Good Read Delay

Reread Delay

OK/NG Signal Active States

OK/NG Signal Output Control

OK/NG Signal Duration

OK/NG Beeping Control

Symbology ID Transmission

Dollar sign output as “ $ “ ◆

Dollar sign output as “¥“

Dollar sign output as “ € “

Dollar sign output as “ £ “

Dollar sign output as “¢ “

None ◆

200 msec.

500 msec.

1 sec.

1.5 sec.

2 sec.

3 sec.

Disable

Immediate time out ◆

Short time out

Medium time out

Long time out

Force verification

Double Scan Verification

OK low/NG low ◆

OK low/NG high

OK high/NG low

OK high/NG high

Disable OK/NG output

Enable NG output

Enable OK output

Enable OK/NG output ◆

10 msec.

20 msec.

30 msec.

40 msec.

50 msec.

60 msec.

70 msec.

80 msec.

90 msec.

100 msec. ◆

User define: 1-99 (x50) msec.

Disable OK and NG beep

Enable OK and NG beep ◆

Enable OK beep and disable NG beep

Enable NG beep and disable OK beep

Disable symbology ID transmission ◆

Enable prefix CINO symbology ID transmission

Enable suffix CINO symbology ID transmission

Enable prefix and suffix CINO symbology ID transmission

Enable prefix AIM symbology ID transmission

Enable suffix AIM symbology ID transmission

Enable prefix and suffix AIM symbology ID transmission

0

1

2

3

4

0

1

2

3

4

5

6

0

1

2

3

4

5

0

1

2

3

0

1

2

3

0

1

2

3

4

5

6

7

8

9

A, (2 digits)

0

1

2

3

0

1

2

3

4

5

6

13

Page 15

System Commands

PROGRAM

(Enter Programming Mode)

System Information

(Exit Programming Mode)

END

Master Default

Save User Default

PowerTool Host Link

Factory Default User Default

Option Codes

0 8

1 9

2 A

3 B

7 F

4 C

5 D

6 E

FIN (Finish) END (Exit)

14

Page 16

www.cino.com.tw

FuzzyScan Fixed Mount Scanner Quick Start Guide

International Edition, Rev. B1

P/N: YMAUB70010010R0

Disclaimer

Cino makes no warranty of any kind with regard to this publication, including, but not limited to, the

implied warranty of merchantability and fitness for any particular purpose. Cino shall not be liable for

errors contained herein or for incidental consequential damages in connection with the furnishing,

performance, or use of this publication. This publication contains proprietary information that is protected

by copyright. All rights are reserved. No part of this publication may be photocopied, reproduced or

translated into any language, in any forms, in an electronic retrieval system or otherwise, without prior

written permission of Cino. All product information and specifications shown in this document may be

changed without prior notice.

© COPYRIGHT CINO GROUP • PC WORTH INT’L CO., LTD. ALL RIGHT RESERVED.

Warranty

Cino warrants its products against defects in workmanship and materials from the date of shipment,

provided that the product is operated under normal and proper conditions. The warranty provisions and

durations are furnished by different warranty programs. The above warranty does not apply to any

product which has been (i) misused; (ii) damaged by accident or negligence; (iii) modified or altered by the

purchaser or other party; (iv) repaired or tampered by unauthorized representatives; (v) operated or stored

beyond the specified operational and environmental parameters; (vi) applied software, accessories or

parts are not supplied by Cino; (vii) damaged by circumstances out of Cino’s control, such as, but not

limited to, lightning or fluctuation in electr ical power. Any defective product must follow the warranty

program and RMA procedures to return Cino for inspection.

Regulatory

FCC part 15B

EN55022, EN55024,

EN61000-3-2, EN61000-3-3

Clause 3, Article 58-2 of Radio Waves Act.

V-3/2011.04, TECHNICAL REQUIREMENTS,

Class B ITE

LED Eye Safety

Industry Canada ICES-003

CNS13438

IEC62471 Exempt group

Loading...

Loading...