Cineversum BarcoGraphics 6300 User Manual

BARCO PROJECTION SYSTEMS

Date: 09/02/2000

UNI-TCR

G6300

R9001440/9

ADJUSTMENT MANUAL

Rev:00

Order No. R5976123

Due to constant research, the information in this manual is subject to change without notice.

Produced by BARCO NV, May 1999.

Trademarks are the rights of their respective owners.

All rights reserved.

BARCO n.v./Projection Systems

Noordlaan 5

B-8520 Kuurne

Belgium

Tel.: +32/56/368211

Fax: +32/56/351651

E-mail: sales.bps@barco.com

Visit Barco on the web: http://www.barco.com

Printed in Belgium

GRAPHICS

6300

R9001440/9

Contents Page

Contents

Panel Adjustments ...............................................................................................................5

Recommendation ................................................................................................................................................ 5

Caution ................................................................................................................................................................ 5

Reasons for Adjustment ...................................................................................................................................... 5

Projector settings ................................................................................................................................................. 5

Set Up ................................................................................................................................................................. 5

Starting up the Service Mode ............................................................................................................................... 5

Connection of the TCR tracker unit ..................................................................................................................... 6

Change Baudrate PC .......................................................................................................................................... 6

Change Projector Address................................................................................................................................... 6

Starting the Panel adjustment .............................................................................................................................. 7

Uniformity Adjustment ......................................................................................................... 9

Software Validity .................................................................................................................................................. 9

Reason For Uniformity Correction ....................................................................................................................... 9

Preparation .......................................................................................................................................................... 9

Color Meter........................................................................................................................................................ 10

Line-up of the measurement apparatus ............................................................................................................. 10

RS232 Connection to color meter ...................................................................................................................... 10

Signal connection for Uniformity adjustment ....................................................................................................... 11

Setting Noise Reduction level at 0 ..................................................................................................................... 12

Running the Program ........................................................................................................................................ 12

Step 1 : Input projector data ............................................................................................................................... 12

Automatict Adjustment Procedure: A ................................................................................................................ 14

Manual top-bottom-left-right Adjustment Procedure: M .................................................................................... 16

Overview of Commands .................................................................................................................................... 17

TCR Adjustment ................................................................................................................. 18

Related Item ...................................................................................................................................................... 18

Reason for TCR ................................................................................................................................................ 18

Line-up of the measurement apparatus ............................................................................................................. 19

Color Meter........................................................................................................................................................ 19

Running the Program ........................................................................................................................................ 19

Step 1: Input projector data ................................................................................................................................ 19

Step 2: Green reduction..................................................................................................................................... 22

Step 3: LCD transmission curves....................................................................................................................... 24

Step 4: adj. different color temperatures ............................................................................................................ 26

Step 4: adj. different color temperatures - preset input balance ......................................................................... 26

Automatic Adjustment (Color meter connected!!) ........................................................................................... 29

Manual Adjustment ......................................................................................................................................... 30

Step 5: checking color tracking .......................................................................................................................... 32

Step 7: exit - save settings................................................................................................................................. 33

Important

All described procedures refer to a projector configuration Front/Table

3

Contents

Date: 10/02/2000

GRAPHICS

6300

R9001440/9

Panel Adjustments

NOTES

DATE:__/__/__

Notes

4

Date:10/02/2000

Caution

GRAPHICS

R9001440/9

6300

Panel Adjustments

Panel Adjustment

PANEL ADJUSTMENT TO BE PERFORMED BY

QUALIFIED BARCO PERSONNEL ONLY

The adjustment procedure must be performed with great care. Panel settings

have a dramatic influence on the light output, contrast ratio and color tracking

of the projector.

Reasons for Adjustment

Recommendation

Set Up

Projector settings

Have the adjustment procedure performed after the following occurrences;

1) Replacement of an LCD Panel.

2) Replacement of the LCD Driver Module.

- Before starting any adjustment procedure, first, clean the not replaced panels and

analyzers (see the respective cleaning kit: Art. No R5976057)

- In case of a Software update (see procedure Info T 331), execute first the update

before starting the panel, uniformity and TCR adjustments.

1) The projector must be set up in a table mounted configuration.

2) The room where the procedure is to be performed must be darkened.

Before starting any adjustment procedure, first, set for the projector the Baudrate on

9600 and the address on 001, as follows,

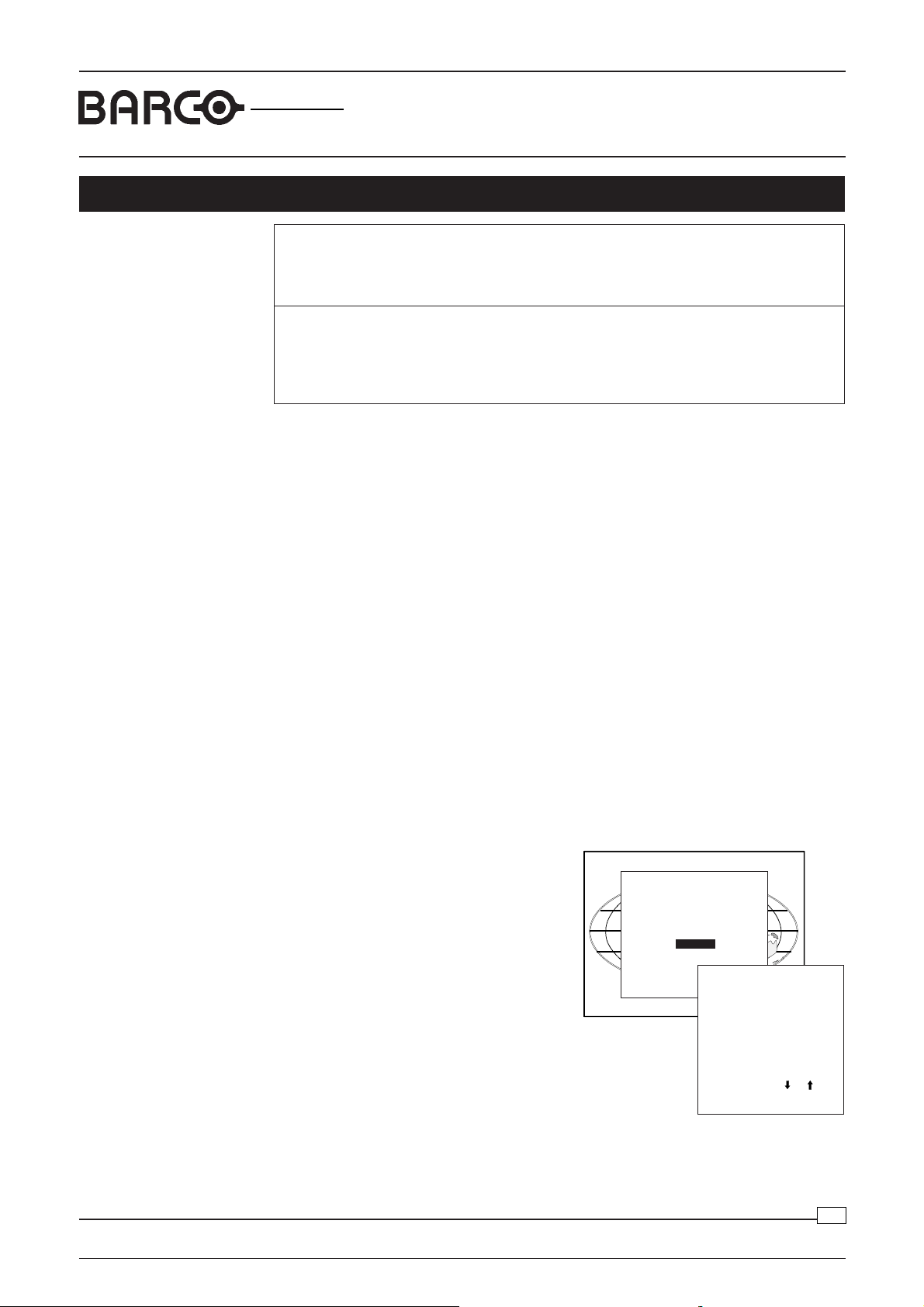

Starting up the Service Mode

Push the cursor key é or ê to highlight

ADJUSTMENT MODE

Select a path from below :

'Service' and then press ENTER.

RANDOM ACCESS

INSTALLATION

Some items in the Service mode are password protected (when the password function

is active). Enter the password to continue.

All other password protected items are now

available if you stay in the adjustment mode.

The service menu is built-up in two parts

which are connected together with the 'more'

item.

If the desired item is not in the list of the

SERVICE

Select with or

then <ENTER>

<EXIT> to return.

SERVICE

IDENTIFICATION

CHANGE PASSWORD

CHANGE LANGUAGE

CHANGE PROJ. ADDRESS

CHANGE BAUDRATE PC

RESET LAMP RUNTIME

LAMP RUNTIME HISTORY

DIMMING

MORE...

Select with or

then <ENTER>

<EXIT> to return.

displayed menu, select 'more' with the cursor key and push ENTER to display the other

items in the service menu.

Panel Adjustments

5

Date:10/02/2000

GRAPHICS

6300

R9001440/9

Panel Adjustments

Change Baudrate PC

The communication speed between projector

and computer, e.g. PC or MAC, has 8 possible

speeds. The baud rate speed can be software

set. Handle as follow:

1 Push the cursor key é or ê to highlight

'Change Baudrate PC''.

2 Press ENTER to display the Change

SERVICE

IDENTIFICATION

CHANGE PASSWORD

CHANGE LANGUAGE

CHANGE PROJ. ADDRESS

CHANGE BAUDRATE PC

RESET LAMP RUNTIME

LAMP RUNTIME HISTORY

DIMMING

MORE...

Select with or

CHANGE BAUDRATE PC

then <ENTER>

<EXIT> to return.

Baudrate PC menu. The actual baudrate

will be highligted.

The following baud rates are available :

230400/115200/57600/38400/19200/9600/

4800/1200

Select with or

<ENTER> to accept

<EXIT> to return.

3 Push the cursor key é or ê to highlight the

baudrate 9600 and press ENTER to select.

Change Projector Address

Every projector requires an individual address

between 0 and 255. This address can be

software installed.

To change that address:

1 Push the cursor key é or ê to highlight

SERVICE

IDENTIFICATION

CHANGE PASSWORD

CHANGE LANGUAGE

CHANGE PROJ. ADDRESS

CHANGE BAUDRATE PC

RESET LAMP RUNTIME

LAMP RUNTIME HISTORY

DIMMING

MORE ...

Select with or

then <ENTER>

CHANGE PROJ. ADDRESS

<EXIT> to return.

Enter new address

'Change Projector Address''.

2 Press ENTER to display the Change

Projector Address menu. The actual

address will be filled in.

Select with or

Reprogram with or

<ENTER> to confirm

Set the projector address on 001 as follows:

The first digit is highlighted. Enter the new projector address with :

- the digit keys on the RCU or the local keypad or

- push the cursor key ç or è to select a digit and change the value by pushing

the cursor key é or ê until the new value is reached. Continue with the other

digits on the same way.

230400

115200

57600

38400

19200

9600

4800

1200

001

or numeric keys

<EXIT> to return

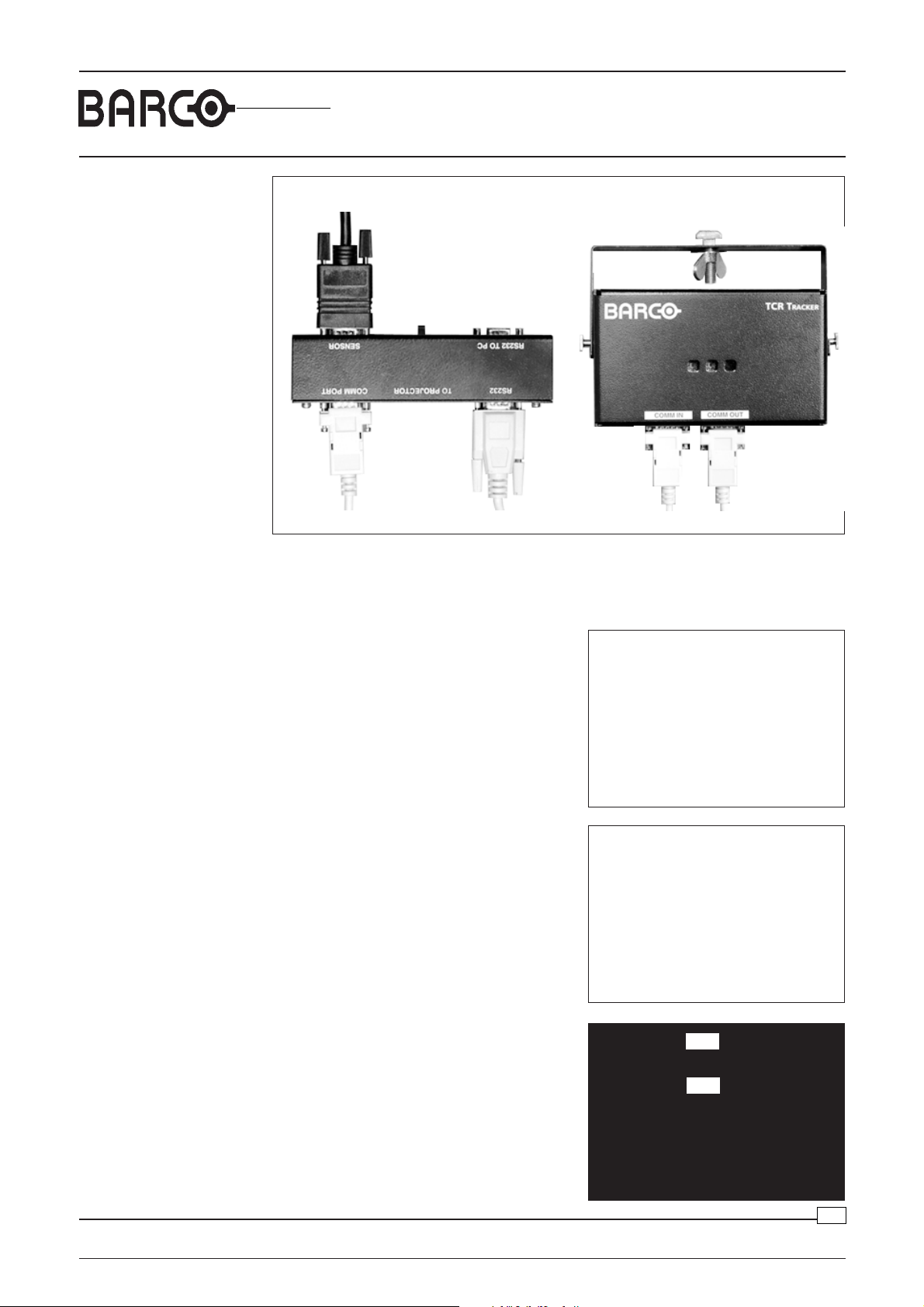

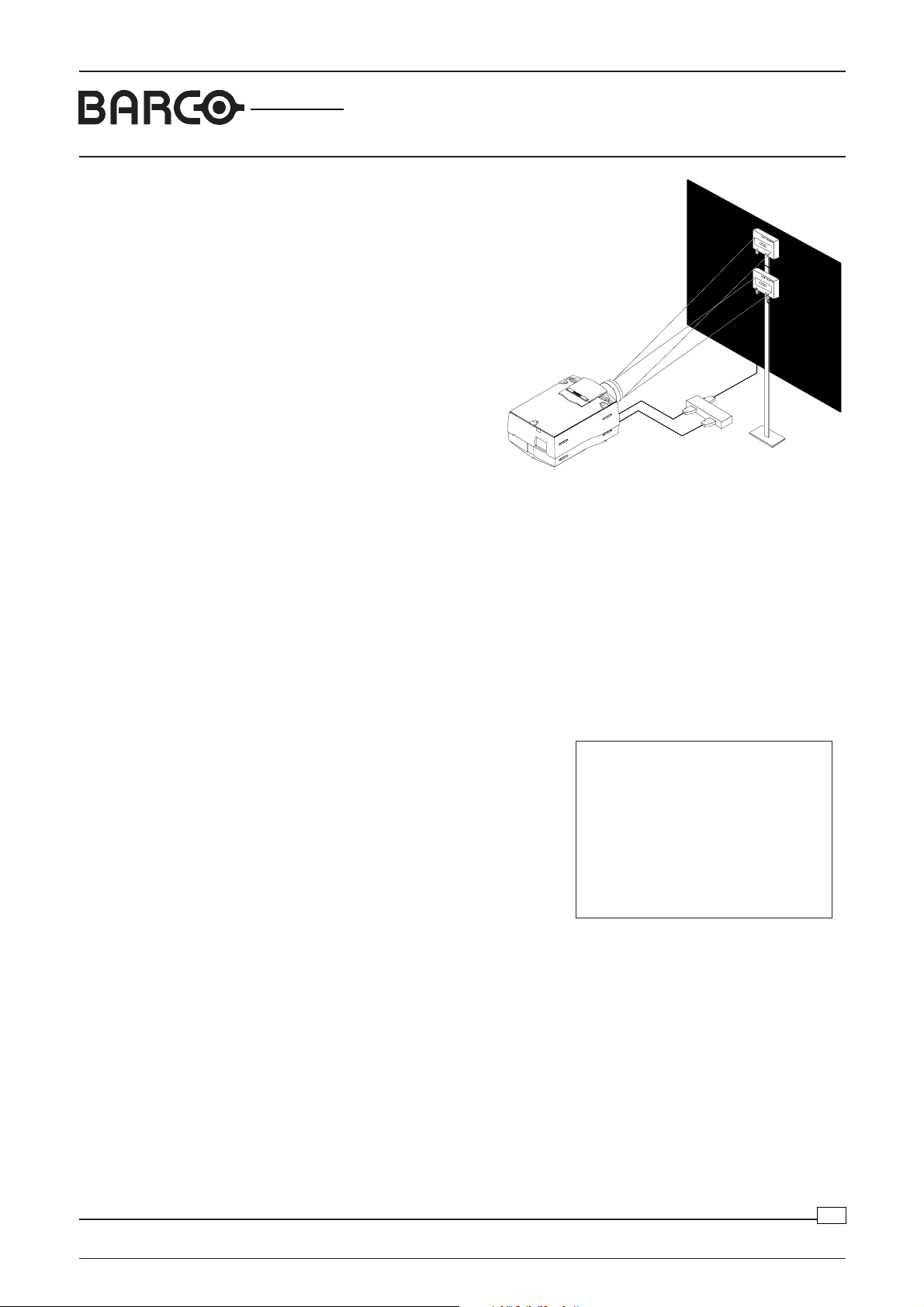

Connection of the TCR

tracker unit

Panel Adjustments

Install the TCR Tracker unit, as illustrated in

drawing below. Make sure that the switch on

the TCR Interface is put in the position OFF

and that the projector is switched to Standby.

Detailed view of the TCR Tracker

and interface, see next page

Projector

TCR Tracker

TCR Interface

to COMM PORT

projector

to RS232 IN

projector

Screen

from Sensor

6

Date:10/02/2000

GRAPHICS

6300

from

Sensors

to COMM PORT

projector

(Order No. CAS LCD TCR R9829970)

ON/OFF

Switch

to RS232 IN

projector

R9001440/9

Contents Page

TCR Tracker Sensor (R763228)TCR Tracker Interface (R763229)

Starting the Panel

adjustment

To start the adjustment procedure, put the ON/OFF switch on the TCR Tracker interface

in the position ON. The MAIN menu will be displayed on the screen.

Selection of item User Guided

MAIN MENU

Push the cursor key é or ê on the RCU or

local key board to highlight 'User Guided'' or

type in number 2 on the numeric keyboard.

1. Automatic

2. User Guided

3. Service

0. EXIT

Press a key

The USER GUIDED menu is displayed on

the screen.

USER GUIDED

1. Panel Settings

2. User Guided

3. Service

4. Save to Default

0. EXIT

Press a key

Panel Adjustments

Selection of item Panel Settings

Push the cursor key é or ê on the RCU or

local key board to highlight 'Panel Settings''

or type in number 1 on the numeric keyboard.

A testpattern, containing two 100% white

rectangles, is generated and projected on

the screen.

Press ENTER to continue

Press EXIT to leave

7

Date: 10/02/2000

GRAPHICS

6300

R9001440/9

Panel Adjustments

Lining up the white rectangles with the

TCR Tracker modules.

Loosen the wing nut on each TCR Tracker

unit and move the unit along the stand until

the two generated white rectangles match

the sensors on the respective TCR Tracker.

When the white rectangles match the respective sensors, Press ENTER on

the local key board or on the RCU to start the panel adjustment procedure.

The automatic panel adjustment process adjusts consecutively the following items:

- Field Flicker adjustment for Red, Green and Blue.

- GAIN adjustment for for Red, Green and Blue.

- Blacklevel adjustment for Red, Green and Blue.

At the end of the adjustment process, duration of about a few minutes, the following

message appears on the screen: SAVE TO DEFAULT. Press ENTER to store the

default values in the projector.

USER GUIDED

1. Panel Settings

2. User Guided

3. Service

4. Save to Default

0. EXIT

Press a key

Panel Adjustments

8

Date:10/02/2000

GRAPHICS

6300

R9001440/9

Uniformity Adjustments

Uniformity Adjustment

Program version

Software Validity

Reason For Uniformity

Correction

Program version 1.02

List of projectors where this adjustment can be used.

Type Art. number

BG6300 TCR+ (DLC)

Soft 1.02 and higher R900144X

BR6300 TCR+ (DLC) R900155X

BG6400 TCR+ (DLC)

BR6400 TCR+ (DLC) R900176X

Color non-uniformities on a LCD projector can have two fundamentally different origins:

- the optical components and

- the LCDs.

An optical non-uniformity is present in the white as well as in the grey as in black and

can be caused by :

- poorly matched mirrors

- vignetting

- birefringence effects in the field lenses, etc

A non-uniformity caused by the LCD becomes more visible in the darker grey and

black levels. It is caused by the fact that the LCD transmission curve is not equal for

the whole LCD area. This can be a result of thickness variations or temperature

variations on the LCD which mainly cause a horizontal shift of the transmission curve.

In this case the effect will be most pronounced for the steepest part of the transmission

curve, this is the mid grey levels.

Other effects, like the stress on the glass induced by the drivers, or the variation of the

average incident angle of the light in different areas of the LCD, have a more complex

influence on the transmission curve, and therefore they are more difficult to

compensate.

With the current compensation program we can compensate the horizontal shift of

the transmission curves on different areas of the screen, so that the first order effect

of thickness and temperature variations can be compensated. As a result the

compensation will give the best results for the grey levels, but will have a very small

effect on the full (projector) white and on the black (there is some effect on e.g. the

6500K white because in that case green is already reduced).

The uniformity compensation can be modified independently on 17x13 points on the

screen. Because it is not feasible to adjust these points one by one, the program

contains an automatic adjustment in which 16 or 25 points are measured and adjusted

with the aid a color meter, and the other points are interpolated.

Preparation The Uniformity Compensation Program requires

- A PC (486, or higher) with 2 COMM ports and DOS.

- The UNI.EXE program.

- A color meter: LMT (C1210 or higher) , Thoma (TMF6 or TMF6 II) or a Minolta

CS1000 color meter.

Uniformity Correction Adjustments

9

Date:10/02/2000

GRAPHICS

6300

R9001440/9

Uniformity Adjustments

- RS232 connection from the PC to the projector and to the color meter. Allow the

projector to warm up during 10 minutes. Put the lamp into the highest power mode.

Close the hoods on the projector. Put the projector in FRONT TABLE configuration.

Darken the room before the evaluation or the measurements start.

For this adjustment the projector white panel settings have to be adjusted properly.

The uniformity adjustment is completely independent from the TCR adjustment, so it

can be done before or after TCR.

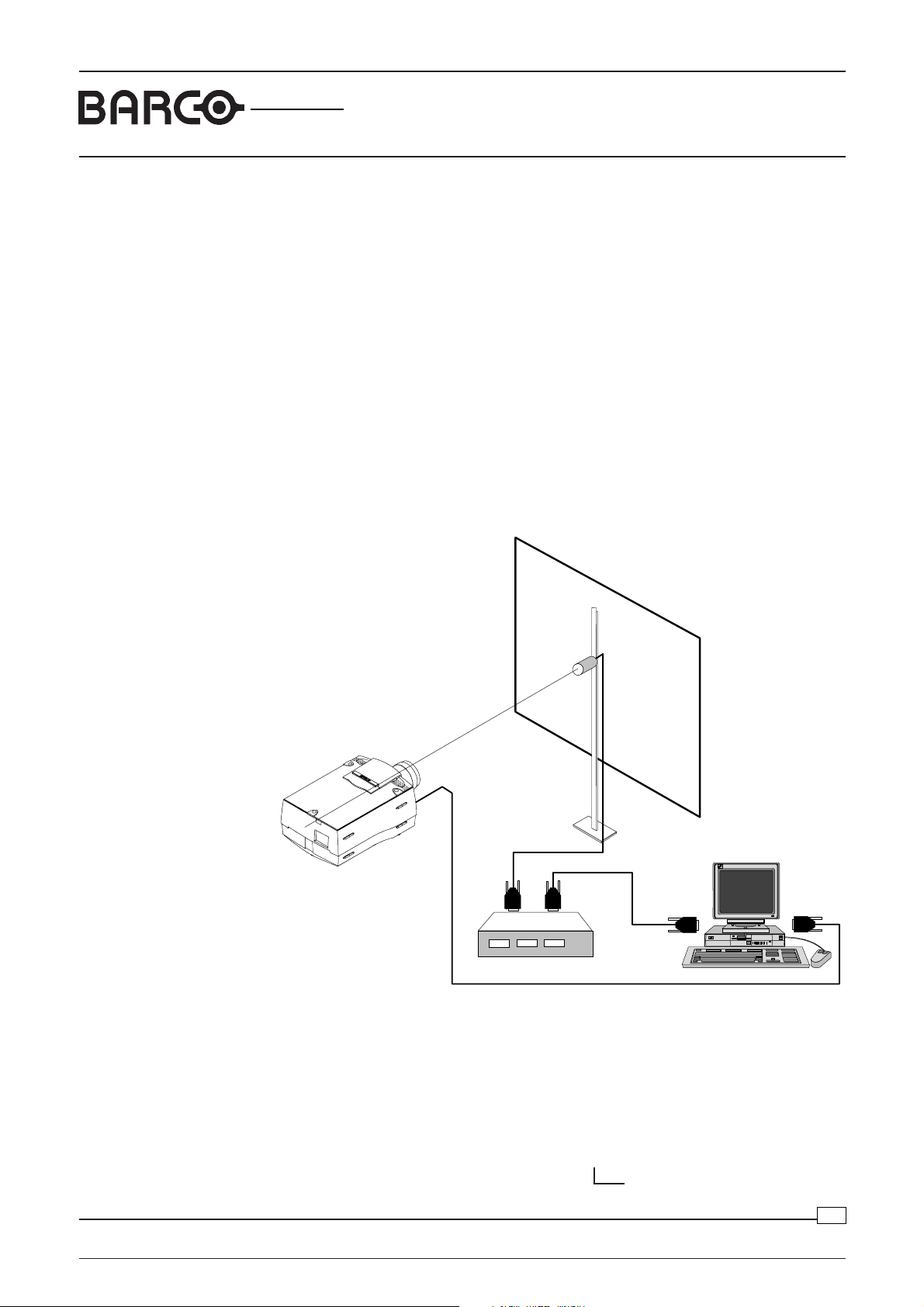

Color Meter

Line-up of the

measurement apparatus

Put the color meter at the center of the image.

In case of the Thoma TMF use a diaphragm to avoid overranging of the meter. In that

case make sure that the light through the diaphragm hits the center spot on the back

of the white integration sphere.

The Minolta CS1000 is used in a reflective measurement mode. Use a perfect white

projection screen. Use the manual measurement mode with an integration time of

0.2s or more.

Check the RS232 to color meter section for the correct RS232 connections to the

color meter.

Screen

Projector

to RS232 IN

projector

RS232 Connection to

color meter

Thoma TMF 6 or TMF 6/II Color Meter

For the RS232 connection between the PC and the Thoma color meter a serial

communication cable with the following connections must be made:

PC PC Thoma

(D9 female connector) (D25 female connector) (D15 male connector)

Pin 2 (RxD) _______________ Pin 3 (RxD) ______________ Pin 3 (DATA OUT)

Pin 3 (TxD) _______________ Pin 2 (TxD) _______________ Pin 2 (DATA IN)

Pin 5 (GND) ______________ Pin 7 (GND) ______________ Pin 1 (MASS)

Uniformity Correction Adjustments

Color meter

PC

to COMM 1

PC

Pin 7 (0 VOLT, DATAGROUND)

from COMM 2

PC

Date:10/02/2000

10

GRAPHICS

6300

R9001440/9

Uniformity Adjustments

LMT C1210I Color Meter

For the RS232 connection between the PC and the LMT C1210 color meter a serial

communication cable with the following connections must be made:

PC PC LMT

(D9 female connector) (D25 female connector) (D25 male connector)

Pin 2 (RxD) __________ Pin 3 (RxD)______________ Pin 3 (TxD)

Pin 3 (TxD) __________ Pin 2 (TxD) ______________ Pin 2 (RxD)

Pin 4 (DTR) __________ Pin 20 (DTR) ____________ Pin 20 (CTS)

Pin 5 (GND)__________ Pin 7 (GND) _____________ Pin 7 (GROUND)

Pin 8 (CTS) __________ Pin 5 (CTS)______________ Pin 5 (RTS)

Minolta CS1000 Color Meter

For the RS232 connection between the PC and the Minolta CS1000 color meter a

serial communication cable with the following connections must be made:

PC PC Minolta CS1000

(D9 female connector) (D25 female connector) (D9 male connector)

Pin 2 (RxD) __________ Pin 2 (TxD) _______________ Pin 3 (TxD)

Pin 3 (TxD) __________ Pin 3 (RxD) _______________ Pin 2 (RxD)

Pin 4 (DTR) __________ Pin 4 (RTS)_______________ Pin 6 (DSR)

Pin 5 (GND)__________ Pin 5 (CTS) _______________ Pin 5 (SG)

Pin 6 (DSR) __________ Pin 6 (DSR) ______________ Pin 4 (DTR)

Pin 7 (RTS) __________ Pin 7 (GND) ______________ Pin 8 (CTS)

Pin 8 (CTS) __________ Pin 20 (DTR) _____________ Pin 7 (RTS)

NOTE: The configurations above do not seem to work in all cases. It is possible that

they will only work if the communication to the Minolta has been initialized by the

accompanying PC-software. The configuration below seems to work without this

initialization:

Minolta alternative configuration:

PC Minolta CS1000

(D9 female connector) (D9 male connector)

Pin 2 (RxD) Pin 3 (TxD)

Pin 3 (TxD) Pin 2 (RxD)

Pin 4 (DTR) Pin 6 (DSR)

Pin 6 (DSR) Pin 4 (DTR)

Pin 5 (GND) Pin 5 (SG)

Pin 7 (RTS) Pin 8 (CTS)

Pin 8 (CTS) Pin 7 (RTS)

Signal connection for

Uniformity adjustment

Connect to the Component Video inputs, the signal Y and the separate Sync signal,

from a reliable multitestpattern generator.

Select on the generator the full white testpattern.

Uniformity Correction Adjustments

11

Date:10/02/2000

Loading...

Loading...