225, 255

TRANSMIG

POWER SOURCE

Operating

Manual

Version No:5 Issue Date: September 2008 Manual No: 719557

Operating Features

1

PHASE

DCCV

240

V

ii Jan 24, 2008

LEADER IN ARC WELDING TECHNOLOGY

We appreciate your business!

Congratulations on your new CIGWELD product. We are proud to have you

as our customer and will strive to provide you with the best service and

reliability in the industry. This product is backed by our extensive warranty

and world-wide service network. To locate your nearest distributor or

service agency call 1300-654-674, or visit us on the web at

www.cigweld.com.au.

This Operating Manual has been designed to instruct you on the correct

use and operation of your CIGWELD product. Your satisfaction with this

product and its safe operation is our ultimate concern. Therefore please

take the time to read the entire manual, especially the Safety Precautions.

They will help you to avoid potential hazards that may exist when working

with this product.

YOU ARE IN GOOD COMPANY

The Brand of Choice for Contractors and Fabricators. CIGWELD is the

Market Leading Brand of Arc Welding Products for Thermadyne Industries

Inc.

We are a mainline supplier to major welding industry sectors in the Asia

Pacific and emerging global markets including; Manufacturing,

Construction, Mining, Automotive, Engineering, Rural and DIY.

We distinguish ourselves from our competition through market leading

dependable brands that have stood the test of time, technical innovation,

competitive prices, excellent delivery, superior customer service and

technical support, together with excellence in sales and marketing

expertise.

We are committed to develop technologically advanced products to

achieve a safer working environment for industry operators.

Jan 24, 2008 iii

WARNING 1

Read and understand this entire Manual and your employer’s safety practices before installing, operating, or servicing the equipment.

While the information contained in this Manual represents the Manufacturer's best judgement, the Manufacturer assumes no liability for its use.

Welding Power Supply

Instruction Manual Number 719557 for:

TRANSMIG 225 Power Source (Compact) Spec Number 710001

TRANSMIG 255 Power Source (Compact) Spec Number 710007

TRANSMIG 255 Power Source (Remote) Spec Number 710002

TRANSMIG 255 2R Wire Feeder (Remote) Spec Number 707593

Published by:

CIGWELD Pty Ltd

71 Gower Street

Preston, Victoria, Australia, 3072

www.cigweld.com.au

Copyright 2008 by

CIGWELD

All rights reserved.

A reproduction of this work, in whole or in part, without written permission of the publisher is prohibited.

The publisher does not assume and hereby disclaims any liability to any party for any loss or damage caused by any error or omission in

this Manual, whether such error results from negligence, accident, or any other cause.

Publication Date: September 4th, 2008

Record the following information for Warranty purposes:

Where Purchased: ___________________________________________

Purchase Date: ___________________________________________

Equipment Serial #: ___________________________________________

TRANSMIG 225, 255 MIG Power Source, 255 2R MIG Wirefeeder

4 Sep 16, 2008

TABLE OF CONTENTS

SECTION 1: Arc Welding Safety Instructions and Warnings ........................................................ 5

SECTION 2: Introduction ................................................................................................................ 10

SECTION 3: Electromagnetic Compatibility ................................................................................. 10

SECTION 4: General Information ................................................................................................... 12

SECTION 5: Safe Practices For The Use Of Welding Equipment ................................................ 12

SECTION 6: Resuscitation For Electric Shock Victims................................................................ 14

SECTION 7: Specifications ............................................................................................................ 15

SECTION 8: Installation Recommendations ................................................................................. 16

SECTION 9: Set up for the TRANSMIG 225, 255 MIG Power Source ........................................... 18

SECTION 10: Power Source and Wirefeeder Controls, Indicators and Features ......................... 20

SECTION 11: 250A TWECO MIG Torch OTWX212/3035 (where supplied).................................... 22

SECTION 12: Basic Welding Technique ......................................................................................... 24

SECTION 13: Routine Maintenance & Inspection .......................................................................... 25

SECTION 14: Basic Troubleshooting .............................................................................................. 26

SECTION 15: Key Spare Parts ......................................................................................................... 30

SECTION 16: Volt / Amp Curves ...................................................................................................... 31

SECTION 17: Circuit Diagram .......................................................................................................... 32

SECTION 18: Weld Settings Guide TRANSMIG 225 ....................................................................... 33

SECTION 19: Weld Settings Guide TRANSMIG 255 ....................................................................... 34

TABLES

Table 1 - Filter lens size verses welding current/electrode size ........................................................................................ 13

Table 2 – Power Source Specifications ................................................................................................................... 15

Table 3 – Optional Accessories ............................................................................................................................ 16

Table 4 – Supply Requirements ........................................................................................................................... 17

Table 5 – Wire Spool parts ................................................................................................................................. 19

Table 6 – Interconnection Control Plug configuration ................................................................................................... 21

Table 7 – MIG Torch Components ........................................................................................................................ 22

Table 8 – MIG Torch Contact Tips ........................................................................................................................ 23

Table 9 – MIG Torch Conduits ............................................................................................................................. 23

Table 10 – Electrode Wire Deposition Rate .............................................................................................................. 24

Table 11 – Key Spare Parts ................................................................................................................................ 30

TRANSMIG 225, 255 MIG Power Source, 255 2R MIG Wirefeeder

Sep 16, 2008 5

SECTION 1: Arc Welding Safety Instructions and Warnings

WARNING 2

ARC WELDING can be hazardous.

Protect yourself and others from possible serious injury or death. Keep children away. Pace maker wearers keep away until

consulting your doctor. Do not lose these instructions. Read operating / instruction manual before installing, operating or

servicing this equipment.

Welding products and welding processes can cause serious injury or death, or damage to other equipment or property, if the operator does not strictly

observe all safety rules and take precautionary actions.

Safe practices have developed from past experience in the use of welding and cutting. These practices must be learned through study and training before

using this equipment. Anyone not having extensive training in welding and cutting practices should not attempt to weld. Certain practices apply to equipment

connected to power lines; other practices apply to engine driven equipment.

Safe practices are out lined in the American National Standard Z49.1 entitled: SAFETY IN WELDING AND CUTTING. This publication and other guides to

what you should learn before operating this equipment are listed at the end of these safety precautions.

HAVE ALL INSTALLATION, OPERATION, MAINTENANCE, AND REPAIR WORK PERFORMED ONLY BY QUALIFIED PEOPLE.

ELECTRIC SHOCK can kill.

Touching live electrical parts can cause fatal shocks

or severe burns. The electrode and work circuit is

electrically live whenever the output is on. The input

power circuit and machine terminal circuits are also

live when power is on. In semiautomatic or automatic

wire welding, the wire, wire reel, drive roll housing,

and all metal parts touching the welding wire are electrically live. Incorrectly

installed or improperly grounded equipment is a hazard.

1. Do not touch live electrical parts.

2. Wear dry, hole-free insulating gloves and body protection.

3. Insulate yourself from work and ground using dry insulating mats or

covers.

4. Disconnect input power or stop engine before installing or servicing

this equipment. Lock input power disconnect switch open, or remove

line fuses so power cannot be turned on accidentally.

5. Properly install and ground this equipment according to its Owner's

Manual and national, state, and 10 cal codes.

6. Turn off all equipment when not in use. Disconnect power to equipment

if it will be left unattended or out of service.

7. Use fully insulated electrode holders. Never dip holder in water to cool

it or lay it down on the ground or the work surface. Do not touch

holders connected to two welding machines at the same time or touch

other people with the holder or electrode.

8. Do not use worn, damaged, under sized or poorly spliced cables.

9. Do not wrap cables around your body.

10. Ground the workpiece to a good electrical (earth) ground.

11. Do not touch electrode while in contact with the work (ground) circuit.

12. Use only well-maintained equipment. Repair or replace damaged parts

at once.

13. In confined spaces or damp locations, do not use a welder with AC

output unless it is equipped with a voltage reducer. Use equipment with

DC output.

14. Wear a safety harness to prevent falling if working above floor level.

15. Keep all panels and covers securely in place.

ARC RAYS can burn eyes and skin;

NOISE can damage hearing.

Arc rays from the welding process produce intense heat

and strong ultraviolet rays that can burn eyes and skin.

Noise from some processes can damage hearing.

1. Wear a welding helmet fitted with a proper shade of filter (see ANSI

249.1 listed in Safety Standards) to protect your face and eyes when

welding or watching.

2. Wear approved safety glasses. Side shields recommended.

3. Use protective screens or barriers to protect others from flash and

glare; warn others not to watch the arc.

4. Wear protective clothing made from durable, flame-resistant material

(wool and leather) and foot protection.

5. Use approved earplugs or earmuffs if noise level is high.

Eye protection filter shade selector for welding or cutting (goggles or helmet), from AWS A 8.2-73

Welding or Cutting

operation

Electrode size Metal Thickness or

Welding Current

Filter

shade

no.

Welding or Cutting operation

Electrode size Metal

Thickness or Welding

Current

Filter

shade no.

Torch soldering

All

2

Gas metal arc welding

Torch brazing

All

2 or 3

Non Ferrous base metal

All

11

Oxygen cutting

Ferrous base metal

All

12

Light

Under 1 in., 25 mm

3 or 4

Gas tungsten arc welding (TIG)

All

12

Medium

1 – 6 in., 25 – 150 mm

4 or 5

Atomic Hydrogen welding

All

12

Heavy

Over 6 in., 150 mm

5 or 6

Carbon Arc welding

All

12

Gas welding

Plasma arc Welding

All

12

Light

Under 1/8 in., 3 mm

4 or 5

Carbon Arc Gouging

Medium

1/8 – 1/2 in., 3 – 12 mm

5 or 6

Light 12

Heavy

Over 1/2 in., 12 mm

6 or 8

Heavy 14

Shielded metal-arc welding (stick) electrodes

Plasma arc cutting

Under 5/32 in., 4 mm

10

Light

Under 300 Amp

9 Under 5/32 to ¼ in., 4 to 6.4mm

12

Medium

300 to 400 Amp

12 Over ¼ in., 6.4 mm

14

Heavy

Over 400 Amp

14

TRANSMIG 225, 255 MIG Power Source, 255 2R MIG Wirefeeder

6 Sep 16, 2008

FUMES AND GASES can be hazardous

to your health.

Welding produces fumes and gases. Breathing these

fumes and gases can be hazardous to your health.

1. Keep your head out of the fumes. Do not breathe

the fumes.

2. If inside, ventilate the area and/or use exhaust at the arc to remove

welding fumes and gases.

3. If ventilation is poor, use an approved air-supplied respirator.

4. Read the Material Safety Data Sheets (MSDS) and the manufacturer's

instruction for metals, consumables, coatings, and cleaners.

5. Work in a confined space only if it is well ventilated, or while wearing an

air-supplied respirator. Shielding gases used for welding can displace

air causing injury or death. Be sure the breathing air is safe.

6. Do not weld in locations near degreasing, cleaning, or spraying

operations. The heat and rays of the arc can react with vapours to form

highly toxic and irritating gases.

7. Do not weld on coated metals, such as galvanized lead, or cadmium

plated steel, unless the coating is re moved from the weld area, the

area is well ventilated, and if necessary, while wearing an air supplied

respirator. The coatings and any metals containing these elements can

give off toxic fumes if welded.

WELDING can cause fire or explosion.

Sparks and spatter fly off from the welding arc. The

flying sparks and hot metal, weld spatter, hot work

piece, and hot equipment can cause fires and burns.

Accidental contact of electrode or welding wire to

metal objects can cause sparks, over heating, or fire.

1. Protect yourself and others from flying sparks and hot metal.

2. Do not weld where flying sparks can strike flammable material

Remove all flammables within 35ft (10.7 m) of the welding arc. If this is

not possible, tightly cover them with approved covers.

3. Be alert that welding sparks and hot materials from welding can easily

go through small cracks and openings to adjacent areas.

4. Watch for fire, and keep a fire extinguisher nearby.

5. Be aware that welding on a ceiling, floor, bulkhead, or partition can

cause fire on the hidden side.

6. Do not weld on closed containers such as tanks or drums.

7. Connect work cable to the work as close to the welding area as practical

to prevent welding current from travelling long, possibly unknown paths

and causing electric shock and fire hazards.

8. Do not use welder to thaw frozen pipes.

9. Remove stick electrode from holder or cut off welding wire at contact tip

when not in use.

Flying sparks and hot metal can

cause Injury

Chipping and grinding cause flying metal. As welds

cool, they can throw off slag.

1. Wear approved face shield or safety goggles. Side shields

recommended.

2. Wear proper body protection to protect skin.

CYLINDERS can explode if damaged.

Shielding gas cylinders contain gas under high

pressure. If damaged, a cylinder can explode. Since

gas cylinders are normally part of the welding process,

be sure to treat them carefuIIy.

1. Protect compressed gas cylinders from excessive heat, mechanical

shocks, and arcs.

2. Install and secure cylinders in an upright position by chaining them to a

stationary support or equipment cylinder rack to prevent falling or tipping.

3. Keep cylinders away from any welding or other electrical circuits.

4. Never allow a welding electrode to touch any cylinder.

5. Use only correct shielding gas cylinders, regulators, hoses and fittings

designed for the specific application; maintain them and associated

parts in good condition.

6. Turn face away from valve outlet when opening cylinder valve.

7. Keep protective cap in place over valve except when cylinder is in use

or connected for use.

8. Read and follow instructions on compressed gas cylinders, associated

equipment, and CGA publication P-1 listed in Safety Standards.

WARNING 3

ENGINES can be dangerous.

ENGINE EXHAUST GASES can kill.

Engines produce harmful exhaust gases

1. Use equipment outside in open, well-ventilated areas.

2. If used in a closed area, vent engine exhaust outside and away from any

building air intakes.

ENGINE FUEL can cause fire or

explosion.

Engine fuel is highly flammable

1. Stop engine before checking or adding fuel.

2. Do not add fuel while smoking or if unit is near any

sparks or open flames.

3. Allow engine to cool before fuelling. If possible, check and add fuel to

cold engine before beginning job.

4. Do not overfill tank - allow room for fuel to expand away from any building

air intakes.

TRANSMIG 225, 255 MIG Power Source, 255 2R MIG Wirefeeder

Sep 16, 2008 7

MOVING PARTS can cause injury.

Moving parts, such as fans, rotors, and belts can cut

fingers and hands and catch loose clothing.

1. Keep all doors, panels, covers, and guards

closed and securely in place.

2. Stop engine before installing or connecting unit.

3. Have only qualified people remove guards or covers for maintenance

and troubleshooting as necessary.

4. To prevent accidental starting during servicing, disconnect negative (-)

battery cable from battery.

5. Keep hands, hair, loose clothing, and tools away from moving parts.

6. Re-install panels or guards and close doors when servicing is finished

and before starting engine.

SPARKS can cause BATTERY GASES

TO EXPLODE; BATTERY ACID can burn

eyes and skin.

Batteries contain acid and generate explosive gases

1. Always wear a face shield when working on a battery.

2. Stop engine before disconnecting or connecting battery cables.

3. Do not allow tools to cause sparks when working on a battery.

4. Do not use welder to charge batteries or jump start vehicles.

STEAM AND PRESSURIZED HOT

COOLANT can burn face, eyes, and

skin.

The coolant in the radiator can be very hot and under

pressure

1. Do not remove radiator cap when engine is hot. Allow engine to cool.

2. Wear gloves and put a rag over cap area when removing cap.

3. Allow pressure to escape before completely removing cap.

WARNING: This product, when used for welding or cutting, produces fumes or gases which contain chemicals known to the State of

California to cause birth defects and, in some cases, cancer. (California Health & Safety Code Sec. 25249.5 et seq.)

NOTE: Considerations About Welding And The Effects Of Low Frequency Electric And Magnetic Fields

The following is a quotation from the General Conclusions Section of the U.S. Congress, Office of Technology Assessment, Biological Effects of Power

Frequency Electric & Magnetic Fields Background Paper OTA-BP-E-63 (Washington, DC: U.S. Government Printing Office, May 1989): "... there is now a

very large volume of scientific findings based on experiments at the cellular level and from studies with animals and people which clearly establish that low

frequency magnetic fields can interact with, and produce changes in, biological systems. While most of this work is of very high quality, the results are

complex. Current scientific understanding does not yet allow us to interpret the evidence in a single coherent framework. Even more frustrating, it does not

yet allow us to draw definite conclusions about questions of possible risk or to offer clear science based advice on strategies to minimize or avoid potential

risks."

To reduce magnetic fields in the work place, use the following procedures:

1. Keep cables close together by twisting or taping them.

2. Do not coil or drape cables around the body.

3. Arrange cables to one side and away from the operator.

4. Keep welding power source and cables as far away from body as

practical.

About Pacemakers: The above procedures are among those also normally recommended for pacemaker wearers. Consult your doctor for complete

information.

1.01 Publications

Refer to the following standards or their latest revisions for more information:

1. OSHA, SAFETY AND HEALTH STANDARDS, 29CFR 1910, obtainable from the Superintendent of Documents, U.S.

Government Printing Office, Washington, D.C. 20402

2. ANSI Standard Z49.1, SAFETY IN WELDING AND CUTTING, obtainable from the American Welding Society, 550 N.W.

LeJeune Rd, Miami, FL 33126

3. NIOSH, SAFETY AND HEALTH IN ARC WELDING AND GAS WELDING AND CUTTING, obtainable from the Superintendent of

Documents, U.S. Government Printing Office, Washington, D.C. 20402

4. ANSI Standard Z87.1, SAFE PRACTICES FOR OCCUPATION AND EDUCATIONAL EYE AND FACE PROTECTION,

obtainable from American National Standards Institute, 1430 Broadway, New York, NY 10018

5. ANSI Standard Z41.1, STANDARD FOR MEN‟S SAFETY-TOE FOOTWEAR, obtainable from the American National Standards

Institute, 1430 Broadway, New York, NY 10018

6. ANSI Standard Z49.2, FIRE PREVENTION IN THE USE OF CUTTING AND WELDING PROCESSES, obtainable from American

National Standards Institute, 1430 Broadway, New York, NY 10018

7. AWS Standard A6.0, WELDING AND CUTTING CONTAINERS WHICH HAVE HELD COMBUSTIBLES, obtainable from

American Welding Society, 550 N.W. LeJeune Rd, Miami, FL 33126

TRANSMIG 225, 255 MIG Power Source, 255 2R MIG Wirefeeder

8 Sep 16, 2008

8. NFPA Standard 51, OXYGEN-FUEL GAS SYSTEMS FOR WELDING, CUTTING AND ALLIED PROCESSES, obtainable from

the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269

9. NFPA Standard 70, NATIONAL ELECTRICAL CODE, obtainable from the National Fire Protection Association, Batterymarch

Park, Quincy, MA 02269

10. NFPA Standard 51B, CUTTING AND WELDING PROCESSES, obtainable from the National Fire Protection Association,

Batterymarch Park, Quincy, MA 02269

11. CGA Pamphlet P-1, SAFE HANDLING OF COMPRESSED GASES IN CYLINDERS, obtainable from the Compressed Gas

Association, 1235 Jefferson Davis Highway, Suite 501, Arlington, VA 22202

12. CSA Standard W117.2, CODE FOR SAFETY IN WELDING AND CUTTING, obtainable from the Canadian Standards

Association, Standards Sales, 178 Rexdale Boulevard, Rexdale, Ontario, Canada M9W 1R3

13. NWSA booklet, WELDING SAFETY BIBLIOGRAPHY obtainable from the National Welding Supply Association, 1900 Arch

Street, Philadelphia, PA 19103

14. American Welding Society Standard AWSF4.1, RECOMMENDED SAFE PRACTICES FOR THE PREPARATION FOR

WELDING AND CUTTING OF CONTAINERS AND PIPING THAT HAVE HELD HAZARDOUS SUBSTANCES, obtainable from

the American Welding Society, 550 N.W. LeJeune Rd, Miami, FL 33126

15. 15. ANSI Standard Z88.2, PRACTICE FOR RESPIRATORY PROTECTION, obtainable from American National Standards

Institute, 1430 Broadway, New York, NY 10018

1.02 Declaration of Conformity

Manufacturer and Merchandiser of Quality Consumables and Equipment: CIGWELD

Address: 71 Gower St, Preston

Victoria 3072

Australia

Description of equipment: Welding Equipment (GMAW). TRANSMIG 225, 255 MIG Power Source TRANSMIG 255 2R Wirefeeder and

associated accessories.

* Serial numbers are unique with each individual piece of equipment and details description, parts used to manufacture a unit and date

of manufacture.

* The equipment conforms to all applicable aspects and regulations of the „Low Voltage Directive‟ (Directive 73/23/EU, as recently

changed in Directive 93/68/EU and to the National legislation for the enforcement of the Directive.

National Standard and Technical Specifications

The product is designed and manufactured to a number of standards and technical requirements among them are:

* AS/NZS 3652-(EMC Directive EN50199) applicable to arc welding equipment - generic emissions and regulations.

* AS60974-1 2006 applicable to welding equipment and associated accessories.

* UL-94V0 flammability rating for all Printed Circuit Boards used.

* 92/31/EEC – EMC directive EN50199 applicable to Arc Welding Equipment – generic emissions and regulations.

* Extensive product design verification is conducted at the manufacturing facility as part of the routine design and manufacturing

process, to ensure the product is safe and performs as specified. Rigorous testing is incorporated into the manufacturing process to

ensure the manufactured product meets or exceeds all design specifications.

CIGWELD has been manufacturing and merchandising an extensive equipment range with superior performance, ultra safe operation

and world class quality for more than 30 years and will continue to achieve excellence.

TRANSMIG 225, 255 MIG Power Source, 255 2R MIG Wirefeeder

Sep 16, 2008 9

1.03 Limited Warranty

LIMITED WARRANTY: CIGWELD, A Thermadyne Company, hereafter, “CIGWELD” warrants to customers of its authorized distributors hereafter “Purchaser” that its

products will be free of defects in workmanship or material. Should any failure to conform to this warranty appear within the time period applicable to the CIGWELD products

as stated below, CIGWELD shall, upon notification thereof and substantiation that the product has been stored, installed, operated, and maintained in accordance with

CIGWELD‟s specifications, instructions, recommendations and recognized standard industry practice, and not subject to misuse, repair, neglect, alteration, or accident,

correct such defects by suitable repair or replacement, at CIGWELD‟s sole option, of any components or parts of the product determined by CIGWELD to be defective.

CIGWELD MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED. THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHERS, INCLUDING, BUT NOT

LIMITED TO ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

LIMITATION OF LIABILITY: CIGWELD SHALL NOT UNDER ANY CIRCUMSTANCES BE LIABLE FOR SPECIAL, INDIRECT OR CONSEQUENTIAL DAMAGES, SUCH

AS, BUT NOT LIMITED TO, LOST PROFITS AND BUSINESS INTERRUPTION. The remedies of the Purchaser set forth herein are exclusive and the liability of CIGWELD

with respect to any contract, or anything done in connection therewith such as the performance or breach thereof, or from the manufacture, sale, delivery, resale, or use of

any goods covered by or furnished by CIGWELD whether arising out of contract, negligence, strict tort, or under any warranty, or otherwise, shall not, except as expressly

provided herein, exceed the price of the goods upon which such liability is based. No employee, agent, or representative of C IGWELD is authorized to change this warranty

in any way or grant any other warranty.

PURCHASER‟S RIGHTS UNDER THIS WARRANTY ARE VOID IF REPLACEMENT PARTS OR ACCESSORIES ARE USED WHICH IN CIGWELD‟S SOLE

JUDGEMENT MAY IMPAIR THE SAFETY OR PERFORMANCE OF ANY CIGWELD PRODUCT. PURCHASER‟S RIGHTS UNDER THIS WARRANTY ARE VOID IF THE

PRODUCT IS SOLD TO PURCHASER BY NON -AUTHORIZED PERSONS.

The warranty is effective for the time stated below beginning on the date that the authorized distributor delivers the products to the Purchaser. Notwithstanding the

foregoing, in no event shall the warranty period extend more than the time stated plus one year from the date CIGWELD delivered the product to the authorized distributor.

Terms of Warranty – July 2007

1. The Trade Practices Act 1974 (Commonwealth) and similar State Territory legislation relating to the supply of goods and services, protects consumers' interests by

ensuring that consumers are entitled in certain situations to the benefit of various conditions, warranties, guarantees, righ ts and remedies (including warranties as to

merchantability and fitness for purpose) associated with the supply of goods and services. A consumer should seek legal advice as to the nature and extent of these

protected interests. In some circumstances, the supplier of goods and services may legally stipulate that the said conditions, warranties, guarantees, rights and

remedies are limited or entirely excluded. The warranties set out in Clause 2 shall be additional to any non-excludable warranties to which the Customer may be

entitled pursuant to any statute.

2. Subject to Clause 3. CIGWELD gives the following warranties to the Customer:

Insofar as they are manufactured or imported by CIGWELD, goods will upon delivery be of merchantable quality and reasonably fit for the purpose for which they are

supplied by CIGWELD.

CIGWELD will repair or, at its option, replace those of the goods which, upon examination, are found by CIGWELD to be defective in workmanship and/or materials.

CIGWELD reserves the right to request documented evidence of date of purchase.

3. The Warranty in Clause 2;

Is conditional upon:

The Customer notifying CIGWELD or our Accredited Distributor in writing of its claim within seven (7) days of becoming aware of the basis thereof, and at its own

expense returning the goods which are the subject of the claim to CIGWELD or nominated Accredited Distributor/Accredited Service Provider.

The goods being used in accordance with the Manufacturer's Operating Manuals, and under competent supervision.

Does not apply to:

Obsolete goods sold at auction, second-hand goods and prototype goods.

Breakdown or malfunction caused by accident, misuse or normal wear and tear.

Repairs or replacement made other than by CIGWELD or Accredited Service Providers, unless by prior arrangement with CIGWELD.

Replacement parts or accessories which may affect product safety or performance and which are not manufactured, distributed or approved by CIGWELD.

4. CIGWELD declares that, to the extent permitted by law, it hereby limits its liability in respect of the supply of goods which are not of a kind ordinarily acquired for

personal, domestic or household use or consumption to any one or more of the following (the choice of which shall be at the option of CIGWELD).

The replacement of the goods or the supply of equivalent goods.

The repair of goods.

The payment of cost of replacing the goods or acquiring equivalent goods.

The payment of the cost of having goods repaired.

5. Except as provided in Clauses 2 to 4 above, to the extent permitted by statute, CIGWELD hereby excludes all liability for any loss, damage, death or injury of any kind

whatsoever occasioned to the Customer in respect of the supply of goods including direct, indirect, consequential or incidental loss, damage or injury of any kind.

Warranty Schedule – January 2007

These warranty periods relate to the warranty conditions in clause 2. All warranty periods are from date of sale from the Accredited Distributor of the equipment.

Notwithstanding the foregoing, in no event shall the warranty period extend more than the time stated plus one year from the date CIGWELD delivered the product to the

Accredited Distributor. Unless otherwise stated the warranty period includes parts and labour.

CIGWELD reserves the right to request documented evidence of date of purchase.

CIGWELD MIG WELDING EQUIPMENT

WARRANTY PERIOD

TRANSMIG 225, 255 MIG Power Source, 255 2R Wirefeeder

Original Main Power Rectifier, Main Power Magnetics, Control Printed Circuit Boards .................................................................................

All other circuits and components including, but not limited to, relays, switches, contactors, solenoids, fans, power switch semi-

conductors........................................................................................................................................................................................................

ACCESSORIES

MIG torch (where fitted) ...................................................................................................................................................................................

MIG torch consumable items ...........................................................................................................................................................................

Please note that the information detailed in this statement supersedes any prior published data produced by CIGWELD.

TRANSMIG 225, 255 MIG Power Source, 255 2R MIG Wirefeeder

10 Sep 16, 2008

WARNING 4

For the purpose of safety and performance and to protect your CIGWELD Equipment Warranty always use genuine CIGWELD

replacement parts and accessories.

SECTION 2: Introduction

2.01 How to Use This Manual

This Owner‟s Manual usually applies to just the underlined

specification or part numbers listed on the page 3. If none are

underlined, they are all covered by this manual.

To ensure safe operation, read the entire manual, including the

chapter on safety instructions and warnings.

Throughout this manual, the word WARNING,

CAUTION and NOTE may appear. Pay particular attention to the

in formation provided under these headings. These special

annotations are easily recognized as follows:

WARNING

Gives information regarding possible personal injury.

Warnings will be enclosed in a box such as this.

CAUTION

Refers to possible equipment damage. Cautions will be

shown in bold type.

NOTE

Offers helpful information concerning certain operating

procedures. Notes will be shown in italics.

2.02 Equipment Identification

The unit‟s identification number (specification or part number),

model, and serial number usually appear on a nameplate attached

to the machine.

Equipment which does not have a nameplate attached to the

machine is identified only by the specification or part number

printed on the shipping container. Record these numbers for future

reference.

2.03 Receipt of Equipment

When you receive the equipment, check it against the invoice to

make sure it is complete and inspect the equipment for possible

damage due to shipping. If there is any damage, notify the carrier

immediately to file a claim. Furnish complete information

concerning damage claims or shipping errors to:

CIGWELD, Customer Care Department, 71 Gower St, Preston,

Victoria, Australia, 3072.

Include all equipment identification numbers as described above

along with a full description of the parts in error.

Additional copies of this manual may be purchased by contacting

CIGWELD, Customer Care Department, at the address given

above. Include the Owner‟s Manual number and equipment

identification numbers.

SECTION 3: Electromagnetic Compatibility

WARNING 5

Extra precautions for Electromagnetic Compatibility may be required when this Welding Power Source is used in a

domestic situation.

3.01 Installation and use - Users Responsibility

The user is responsible for installing and using the welding equipment according to the manufacturer‟s instructions. If

electromagnetic disturbances are detected then it shall be the responsibility of the user of the welding equipment to resolve the

situation with the technical assistance of the manufacturer. In some cases this remedial action may be as simple as earthing the

welding circuit, see NOTE 1. In other cases it could involve constructing an electromagnetic screen enclosing the Welding Power

Source and the work, complete with associated input filters. In all cases, electromagnetic disturbances shall be reduced to the

point where they are no longer troublesome.

NOTE 1

The welding circuit may or may nor be earthed for safety reasons. Changing the earthing arrangements should only be

authorised by a person who is competent to assess whether the changes will increase the risk of injury, e.g. by allowing

parallel welding current return paths which may damage the earth circuits of other equipment. Further guidance is given

in IEC 974-13 Arc Welding Equipment - Installation and use (under preparation).

TRANSMIG 225, 255 MIG Power Source, 255 2R MIG Wirefeeder

Sep 16, 2008 11

3.02 Assessment of Area

Before installing welding equipment, the user shall make an assessment of potential electromagnetic problems in the

surrounding area. The following shall be taken into account

i) Other supply cables, control cables, signalling and telephone cables; above, below and adjacent to the welding

equipment.

ii) Radio and television transmitters and receivers.

iii) Computer and other control equipment.

iv) Safety critical equipment, e.g. guarding of industrial equipment.

v) The health of people around, e.g. the use of pacemakers and hearing aids.

vi) Equipment used for calibration and measurement.

vii) The time of day that welding or other activities are to be carried out.

viii) The immunity of other equipment in the environment: the user shall ensure that other equipment being used in

the environment is compatible: this may require additional protection measures.

The size of the surrounding area to be considered will depend on the structure of the building and other activities that are taking

place. The surrounding area may extend beyond the boundaries of the premises.

3.03 Methods of Reducing Electromagnetic Emissions

a) Mains Supply

Welding equipment should be connected to the mains supply according to the manufacturer‟s recommendations. If

interference occurs, it may be necessary to take additional precautions such as filtering of the mains supply.

Consideration should be given to shielding the supply cable of permanently installed welding equipment in metallic conduit

or equivalent.

Shielding should be electrically continuous throughout it‟s length. The shielding should be connected to the Welding Power

Source so that good electrical contact is maintained between the conduit and the Welding Power Source enclosure.

b) Maintenance of Welding Equipment

The welding equipment should be routinely maintained according to the manufacturer‟s recommendations. All access and

service doors and covers should be closed and properly fastened when the welding equipment is in operation. The

welding equipment should not be modified in any way except for those changes and adjustments covered in the

manufacturer‟s instructions. In particular, the spark gaps of arc striking and stabilising devices should be adjusted and

maintained according to the manufacturer‟s recommendations.

c) Welding Cables

The welding cables should be kept as short as possible and should be positioned close together, running at or close to the

floor level.

d) Equipotential Bonding

Bonding of all metallic components in the welding installation and adjacent to it should be considered. However. Metallic

components bonded to the work piece will increase the risk that the operator could receive a shock by touching the

metallic components and the electrode at the same time. The operator should be insulated from all such bonded metallic

components.

e) Earthing of the Workpiece

Where the workpiece is not bonded to earth for electrical safety, nor connected to earth because of it‟s size and position,

e.g. ship‟s hull or building steelwork, a connection bonding the workpiece to earth may reduce emissions in some, but not

all instances. Care should be taken to prevent the earthing of the workpiece increasing the risk of injury to users, or

damage to other electrical equipment. Where necessary, the connection of the workpiece to earth should be made by

direct connection to the workpiece, but in some countries where direct connection is not permitted, the bonding should be

achieved by suitable capacitance, selected according to national regulations.

f) Screening and Shielding

Selective screening and shielding of other cables and equipment in the surrounding area may alleviate problems of

interference. Screening the entire welding installation may be considered for special applications.

TRANSMIG 225, 255 MIG Power Source, 255 2R MIG Wirefeeder

12 Sep 16, 2008

SECTION 4: General Information

4.01 TRANSMIG 225, 255 MIG Power Source, 255 2R Wirefeeder

The TRANSMIG 225, 255 MIG Power Source is a semi-automatic Gas Metal Arc Welder (GMAW-commonly MIG) with either an

integrated or a separate wire feed unit. The Power Source is designed to meet the broad operating needs of the metal

fabrication industry where production efficiency is vital. They are designed to meet the requirements of international standard

EN60974-1 and Australian Standard AS60974-1.

The TRANSMIG 225, 255 MIG Power Source gives excellent performance on mild steel, stainless steel, aluminium, silicon

bronze and some hard facing wires with Argon based shielding gases. The Power Source also gives excellent results on mild

steel using Carbon Dioxide shielding gas.

The TRANSMIG 225, 255 MIG Power Source is supplied as a complete package ready to weld (apart from shielding gas,

electrode wire and Hiderok TM welding helmet). The following instructions detail how to correctly set up the machine and give

guidelines on gaining the best production efficiency from the Power Source. Please read these instructions thoroughly before

using your welder.

4.02 User Responsibility

This equipment will perform as per the information contained herein when installed, operated, maintained and repaired in

accordance with the instructions provided. This equipment must be checked periodically. Defective equipment (including

welding leads) should not be used. Parts that are broken, missing, plainly worn, distorted or contaminated, should be replaced

immediately. Should such repairs or replacements become necessary, it is recommended that such repairs be carried out by

appropriately qualified persons approved by CIGWELD. Advice in this regard can be obtained by contacting accredited

CIGWELD Distributor.

This equipment or any of its parts should not be altered from standard specification without prior written approval of CIGWELD.

The user of this equipment shall have the sole responsibility for any malfunction which results from improper use or unauthorised

modification from standard specification, faulty maintenance, damage or improper repair by anyone other than appropriately

qualified persons approved by CIGWELD.

4.03 Duty Cycle

The rated duty cycle of a Welding Power Source, is a statement of the time it may be operated at its rated welding current output

without exceeding the temperature limits of the insulation of the component parts. To explain the 10 minute duty cycle period the

following example is used. Suppose a Welding Power Source is designed to operate at a 30% duty cycle, 255 amperes at 26.5

volts. This means that it has been designed and built to provide the rated amperage (255A) for 3 minutes, i.e. arc welding time,

out of every 10 minute period (30% of 10 minutes is 3 minutes). During the other 7 minutes of the 10 minute period the Welding

Power Source must idle and allowed to cool. The thermal cutout will operate if the duty cycle is exceeded.

SECTION 5: Safe Practices For The Use Of Welding Equipment

In many situations the “striking” voltage can be hazardous. Any person touching simultaneously the electrode lead/terminal and the work

lead/terminal may receive a serious electrical shock. Additional precautions must be exercised where two Welding Power Sources are

being used close to each other because, under certain conditions, the voltages between the welding terminals of the two Welding Power

Sources could be two times the specified open circuit voltage.

It is essential that the Welding Power Source is correctly installed, if necessary, by a qualified electrician and maintained in sound

mechanical and electrical condition. It is also important that the Welding Power Source be switched off when not in use.

0

20

40

60

80

100

0 20 40 60 80 100 120 140 160 180 200 220 240 260 280

Welding Current (Amps)

Duty Cycle (%)

Safe Operating

ZONE

225

255

TRANSMIG 225, 255 MIG Power Source, 255 2R MIG Wirefeeder

Sep 16, 2008 13

5.01 Precautions to be Taken by Operators

Whenever practicable, all parts of the welding circuit should be isolated from earth and other conducting material and under

no circumstances should any earthing conductor of the electrical installation be used in place of the work lead.

The Mains supply voltage should be switched off before connecting or disconnecting welding leads. Welding lead

connections must have clean contact surfaces and must be securely tightened. Poor connections will result in overheating

and loss of welding current. All parts of the welding circuit, including the return paths, are to be considered electrically alive,

so the operator must ensure that no part of the body is placed in such a position that it will provide a path for an electric

current.

Welding operators should avoid direct contact with the work to be welded or against any metal in contact with the work.

When this cannot be avoided the operator must not touch any exposed portion of the electrode holder with any part of the

body. Should this occur, the operator will risk completing the electrical circuit through the body.

When welding in confined spaces, where reasonable movement is restricted, particular care must be taken to ensure that the

area is well ventilated and the operator is under constant observation by a person who can immediately switch off the power

and give assistance in an emergency.

The flux covering of an electrode cannot be assumed to provide effective insulation, consequently an insulating glove must

be worn when placing an electrode into its holder, or should it be necessary to handle an electrode once it is in contact with

its holder.

During pauses between welding runs, electrode holders, TIG torches and MIG torches should be so placed that they cannot

make electrical contact with persons or conductive objects.

The welding leads, both the electrode lead, TIG torch lead or MIG torch lead and the work lead, must be protected from

damage. Damaged leads must not be used.

Keep combustible materials away from the welding area. Have a suitable fire extinguisher handy.

Do not stand on damp ground when welding.

5.02 Personal Protection

The radiation from an electric arc during the welding process can seriously harm eyes and skin. It is essential that the following

precautions be taken:

Gloves should be flameproof gauntlet type to protect hands and wrists from heat burns and harmful radiations. They should

be kept dry and in good repair.

Protective clothing must protect the operator from burns, spatter and harmful radiation. Woollen clothing is preferable to

cotton because of its greater flame resistance. Clothing should be free from oil or grease. Wear leggings and spats to

protect the lower portion of the legs and to prevent slag and molten metal from falling into boots or shoes.

Welding Faceshield

It is a requirement to use a welding Faceshield, complying to a relevant standard, when electric arc welding. Use a welding

Faceshield in serviceable condition and fitted with an eye filter lens to safely reduce harmful radiation from the arc as per

Table 1.

Welding Process

Welding current range

Suggested Filter Lens

GMAW

40 – 150A

Shade 10

GMAW

150 – 250A

Shade 11

GMAW

250 – 300A

Shade 12

GMAW

300 – 400A

Shade 13

GMAW

Over 400A

Shade 14

Table 1 - Filter lens size verses welding current/electrode size

Protective filter lenses are provided to reduce the intensity of radiation entering the eye thus filtering out harmful infra-red,

ultra-violet radiation and a percentage of the visible light. Such filter lenses are incorporated within welding handshields. To

prevent damage to the filter lenses from molten or hard particles an additional hard clear glass or special plastic external

cover lens is provided. This cover lens should always be kept in place and replaced before the damage impairs your vision

while welding.

Notes:

Recognised standards for recommended practices for occupational eye protection include AS/ANZ 1336 and EN 175.

For maximum possible protection, the use of full helmet equipment is recommended.

The indicated filter lens shade numbers are minimum. If any discomfort is felt, higher shade numbers (i.e. darker filters)

should be used.

TRANSMIG 225, 255 MIG Power Source, 255 2R MIG Wirefeeder

14 Sep 16, 2008

SECTION 6: Resuscitation For Electric Shock Victims

Electric shock may kill immediately. Early resuscitation is required if a life is to be saved. Every Second Counts! Electrical currents may:

Stop the heart;

Cause contraction of the muscles of the body;

Paralyse breathing due to paralysis of the centre of respiration in the brain;

Cause burns.

The victims often cannot free themselves from the current and may not be able to breathe due to fixation of the chest.

6.01 Resuscitation

Efficient resuscitation requires training which is available from the St John‟s Ambulance Association, Red Cross and other

sources.

1 Don‟t become a victim. Switch off power if possible. If

not, remove victim from contact, using some insulating

material.

2 If unconscious, place victim on their side and clear vomit

and other foreign matter from mouth. Check for breathing

by look, listen and feel. If not breathing, commence

expired air resuscitation (E.A.R.). This should take no

longer than 3 or 4 seconds.

3 Place victim flat on their back on a hard surface, open

airway - using head tilt and jaw support as shown.

4 Begin artificial breathing - 5 full breaths in 10 seconds,

sealing nostrils with cheek or holding nose closed.

5 Check carotid pulse in neck. If pulse is present,

continue E.A.R.

15 breaths per minute for adults.

20 breaths per minute for children.

7 Check for return of pulse and breathing after 1 minute

and at least every 2 minutes. Continue uninterrupted

until trained assistance is available. When breathing

and pulse return, turn on side and continue

observation.

6 If pulse is absent and you have been trained, begin cardio

pulmonary resuscitation (C.P.R).

Cardiac Compression - depress lower end of breast bone

(sternum) 4cm to 5cm, less for small children.

One rescuer - 2 breaths, 15 compressions in 15 seconds,

i.e. 4 cycles per minute.

Two rescuers - 1 breath, 5 compressions in 5 seconds, i.e.

12 cycles per minute.

TRANSMIG 225, 255 MIG Power Source, 255 2R MIG Wirefeeder

Sep 16, 2008 15

SECTION 7: Specifications

7.01 TRANSMIG 225, 255 MIG Power Source Specifications

Description (Refer NOTE 2)

TRANSMIG 225

Compact

TRANSMIG 255

Compact

TRANSMIG 255

Remote

Plant Assembly

710001

710007

710002

Plant Mass

84 kg

88 kg

104 kg

Plant Dimensions (including cylinder carrier

& excluding wheels)

H 1000mm x W 430mm x D 880mm

Power Source Part Number

707564

707565

707566

Power Source Mass

80 kg

83kg

80 kg

Maximum Inlet Gas Pressure

1.2 MPa (gas hose)

1.2 MPa (gas hose)

1.2 MPa (gas hose)

Suitable Gas Types

Argon based mixed gases &

C02

Argon based mixed gases &

C02

Argon based mixed gases &

C02

Description (Refer NOTE 2)

TRANSMIG 225 MIG Power Source

TRANSMIG 255 MIG Power Source

Supply Input Voltage

220 VAC

240 VAC

220 VAC

240 VAC

Number of Phases & Frequency

1 phase 50 / 60 Hz

1 phase 50 / 60 Hz

Rated Input Current @ 100% Duty Cycle

22.4A

20.5A

31A

28A

Rated kVA @ 100% Duty Cycle

4.0 kVA

4.0 kVA

5.5 kVA

5.5 kVA

Maximum Input Current

48.0A

44A

54A

50A

Generator Requirements

10.5 kVA

10.5 kVA

12 kVA

12 kVA

Supply VA @ no load

970 VA

1120 VA

970 VA

1120 VA

Supply VA @ max. output

9.8 kVA

9.8 kVA

12.2 kVA

11.7 kVA

Power Factor @ max. output

0.85

0.85

0.85

0.85

Open Circuit Voltage Range

19 to 41V

19 to 41V

18 to 41V

18 to 41V

Output Current Range

30 – 225A

30 – 225A

30 – 255A

30 – 255A

Rated Outlet Maximum Duty Cycle

30A

30A A 35A

Recommended Fuse Size

30A

30A

35A

35A

Rated Output Duty Cycle

225A@ 25%

225A@ 25%

255A@ 30%

255A@ 30%

100% Duty Cycle Output Rating

110A

110A

137A

137A

Operating Temperature Range

0ºC - 40ºC

0ºC - 40ºC

0ºC - 40ºC

0ºC - 40ºC

Duty Cycle Period

10 minutes

10 minutes

10 minutes

10 minutes

Number of Output Voltage Switch Settings

16

16

16

16

Wire Size Range

Hard Wire: 0.6mm – 0.9mm

Soft Wire: 0.8mm - 1.2mm

Fluxcored Wire: 0.6mm – 1.2mm

Hard Wire: 0.6mm – 0.9mm

Soft Wire: 0.8mm – 1.2mm

Fluxcored Wire: 0.6mm – 1.2mm

Table 2 – Power Source Specifications

The Rated Input Current should be used for the determination of cable size & supply requirements.

Motor start fuses or thermal circuit breakers are recommended for this application. Check local requirements for your situation in

this regard.

Generator Requirements at the Maximum Output Duty Cycle.

Reduced output ratings apply with the supplied 15A supply cable. To achieve these ratings the 15A supply cable and plug must be

replaced with a larger plug and cable as specified in section 8.04. This must be carried out be a qualified electrical tradesperson.

NOTE 2

Due to variations that can occur in manufactured products, claimed performance, voltages, ratings, all capacities,

measurements, dimensions and weights quoted are approximate only. Achievable capacities and ratings in use and operation

will depend upon correct installation, use, applications, maintenance and service.

TRANSMIG 225, 255 MIG Power Source, 255 2R MIG Wirefeeder

16 Sep 16, 2008

Description (Refer NOTE 2)

For Fitted 15A supply cable

TRANSMIG 225 MIG Power Source

TRANSMIG 255 MIG Power Source

Supply Input Voltage

220 VAC

240 VAC

220 VAC

240 VAC

Rated Outlet Maximum Duty Cycle

20A A 25A

A

Recommended Fuse Size

20A

20A

25A

25A

Rated Output Duty Cycle

160A@ 40%

160A@ 40%

190A@ 23%

190A@ 23%

100% Duty Cycle Output Rating

105A

105A

110A

110A

7.02 Optional Accessories

Part Number

Description

OTWX212/3035

TWECO 2, 250A MIG torch, 3.6 metre EURO

OTWX412/3545

TWECO 4, 400A MIG torch, 3.6 metre EURO

7977036

Feed Roll 0.6 / 0.8 HARD

7977660

Feed Roll 0.9 / 1.2 HARD

7977731

Feed Roll 0.8 / 0.9 SOFT

7977264

Feed Roll 1.0 / 1.2 SOFT

7977732

Feed Roll 0.8 / 0.9 CORED

704277

Feed Roll 1.2 / 1.6 CORED

210254

Regulator 600 Argon – 55lpm 2G

705000

MIG pliers (size No 1)

705001

MIG pliers (size No 2)

Table 3 – Optional Accessories

NOTE 3

Two feedrolls are required for each electrode wire size used

SECTION 8: Installation Recommendations

8.01 Environment

These units are not designed for use in environments with increased hazard of electric shock.

a) Examples of environments with increased hazard of electric shock are -

i) In locations in which freedom of movement is restricted, so that the operator is forced to perform the work in a

cramped (kneeling, sitting or lying) position with physical contact with conductive parts;

ii) In locations which are fully or partially limited by conductive elements, and in which there is a high risk of

unavoidable or accidental contact by the operator, or

iii) In wet or damp hot locations where humidity or perspiration considerable reduces the skin resistance of the

human body and the insulation properties of accessories.

b) Environments with increased hazard of electric shock do not include places where electrically conductive parts in the

near vicinity of the operator, which can cause increased hazard, have been insulated.

8.02 Location

Be sure to locate the welder according to the following guidelines:

a) In areas, free from moisture and dust.

b) Ambient temperature between 0

o

C to 400 C.

c) In areas, free from oil, steam and corrosive gases.

d) In areas, not subjected to abnormal vibration or shock.

e) In areas, not exposed to direct sunlight or rain.

f) Place at a distance of 300mm or more from walls or similar that could restrict natural air flow for cooling.

TRANSMIG 225, 255 MIG Power Source, 255 2R MIG Wirefeeder

Sep 16, 2008 17

8.03 Ventilation

Since the inhalation of welding fumes can be harmful, ensure that the welding area is effectively ventilated.

8.04 Mains Supply Voltage Requirements

The Mains supply voltage should be within 10% of the rated Mains supply voltage. Too low a voltage may cause poor welding

performance. Too high a supply voltage will cause components to overheat and possibly fail.

The Welding Power Source must be:

Correctly installed, if necessary, by a qualified electrician.

Correctly earthed (electrically) in accordance with local regulations.

Connected to the correct size power point and fuse for each Power Source as per the Specifications on page 15.

The TRANSMIG 225, 255 MIG Power Source is supplied with a 15 Amp input lead.

The TRANSMIG 225, 255 MIG Power Source is factory connected for 240 VAC supply voltage:

The TRANSMIG 225, 255 MIG Power Source is suitable for the following Mains supply voltages:

The following Mains Current Circuit recommendations are required to obtain the maximum welding current and duty cycle from

these welding products:

Model

Mains Supply

Voltage Setting

Mains Supply

Lead Size

Minimum Mains

Current Circuit Size

Fuse Size

Machines Duty

Cycle

TRANSMIG 225

220V

2.5 mm2

30 Amp

30Amp

225A @ 25%

TRANSMIG 225

240V

2.5 mm2

30 Amp

30Amp

225A @ 25%

TRANSMIG 255

220V

6 mm2

35 Amp

35Amp

255A @ 30%

TRANSMIG 255

240V

6 mm2

35 Amp

35Amp

255A @ 30%

Table 4 – Supply Requirements

8.05 Mains Supply Voltage Requirements

The TRANSMIG 225, 255 can be rewired to operate from a 220VAC mains supply voltage.

WARNING 6

CIGWELD ADVISES THAT A QUALIFIED ELECTRICAL TRADESPERSON REWIRE YOUR TRANSMIG 225, 255

FOR 220VAC OPERATION

Disconnect the TRANSMIG 225, 255 from the mains supply

Disconnect NEUTRAL (Blue) from terminal 2 and reconnect it to terminal 3 on the supply cable terminal block

The TRANSMIG 225, 255 is now ready for operation at 220VAC mains supply voltage

SUPPLY LEAD CONNECTION

TRANSMIG 225, 255 MIG Power Source, 255 2R MIG Wirefeeder

18 Sep 16, 2008

SECTION 9: Set up for the TRANSMIG 225, 255 MIG Power Source

9.01 Power Source Connections

a) Remove all packaging materials.

b) Connect the work lead to the negative welding terminal (-) [positive welding terminal (+) for flux cored electrode wire]. If in

doubt, consult the electrode wire manufacturer.

c) Position a gas cylinder on the rear tray of the Power Source and lock securely to the Power Source cylinder bracket with

the chain provided. If this arrangement is not used or the Power Source is not fitted with a gas cylinder tray then ensure

that the gas cylinder is secured to a building pillar, wall bracket or otherwise securely fixed in an upright position.

9.02 Wirefeeder Connections (Remote models only)

a) Connect the welding power cable from the Wirefeeder's interconnection cables to the positive welding terminal (+)

[negative welding terminal (-) for flux cored electrode wire]. If in doubt, consult the electrode wire manufacturer.

b) Connect the control cable from the Wirefeeder to the socket on the Power Source.

c) Fit the gas regulator and flowmeter to the gas cylinder then connect the gas hose from the rear of the Wirefeeder to the

Flowmeter outlet.

d) Dual groove feed rollers are supplied as standard. They can

accommodate 0.9 / 1.2 diameter hard wires. Select the roller required with

the chosen wire size marking facing outwards.

e) Fit the electrode wire spool to the wire reel hub. Ensure that the drive

dog-pin engages the mating hole in the wire spool. Push the 'R' clip into place to retain the wire spool securely. The

electrode wire should feed from the bottom of the spool.

f) MIG Torch, EURO MIG Torch Connection

Fit the MIG Torch to the Wirefeeder by pushing the torch connector into the brass torch adaptor and screwing the plastic

torch nut clockwise to secure the torch to the torch adaptor. Remove the contact tip from the torch handset.

9.03 Wirefeeder Connections (Compact models only)

a) Connect the TORCH power cable to the positive welding terminal (+) [negative welding terminal (-) for flux cored electrode

wire]. If in doubt, consult the electrode wire manufacturer.

b) Fit the gas regulator and flowmeter to the gas cylinder then connect the gas hose from the rear of the Power Source to the

Flowmeter outlet.

c) Dual groove feed rollers are supplied as standard. They can

accommodate 0.6 / 0.8 diameter hard wires. Select the roller required with

the chosen wire size marking facing outwards.

d) Fit the electrode wire spool to the wire reel hub. Ensure that the drive

dog-pin engages the mating hole in the wire spool. Push the 'R' clip into place to retain the wire spool securely. The

electrode wire should feed from the bottom of the spool.

e) MIG Torch, EURO MIG Torch Connection

Fit the MIG Torch to the Power Source by pushing the torch connector into the brass torch adaptor and screwing the plastic

torch nut clockwise to secure the torch to the torch adaptor. Remove the contact tip from the torch handset.

9.04 Common Connections

a) Lift up the wire feeder pressure levers and pass the electrode wire through the inlet guide, between the rollers, through the

centre guide, between the rollers, through the outlet guide and into the MIG torch.

GROOVE “B”GROOVE “A”

GROOVE “A” SIZE

GROOVE “B” SIZE

GROOVE “B”GROOVE “A”

GROOVE “A” SIZE

GROOVE “B” SIZE

TRANSMIG 225, 255 MIG Power Source, 255 2R MIG Wirefeeder

Sep 16, 2008 19

b) Lift up the wire feeder pressure levers and pass the electrode wire through the inlet guide, between the rollers, through the

centre guide, between the rollers, through the outlet guide and into the MIG torch.

WARNING 7

DO NOT WEAR GLOVES WHILE THREADING THE WIRE OR CHANGING THE WIRE SPOOL.

c) Lower the pressure levers and with the torch lead reasonably straight, feed the electrode wire through the torch. Fit the

appropriate contact tip, eg a 0.8mm tip for 0.8mm wire.

d) Press the Torch switch to feed the wire through the torch.

WARNING 8

The electrode wire will be at welding voltage potential whilst it is being fed through the wirefeeder system if the wire is

fed by using the TORCH SWITCH

9.05 Drive Roller Pressure Adjustment

The moveable rollers apply pressure to the grooved feed rollers via a scaled adjustable tension screw. These devices should be

adjusted to a minimum pressure that will provide satisfactory WIREFEED without slippage. If slipping occurs, and inspection of

the wire contact tip reveals no wear, distortion or burn back jam, the conduit liner should be checked for kinks and clogging by

metal flakes and swarf. If it is not the cause of slipping, the feedroll pressures can be increased by rotating the scaled tension

screws clockwise. The use of excessive pressure may cause rapid wear of the feed rollers, shafts and bearing.

9.06 Wire Reel Brake

The wire reel hub incorporates a friction brake which is adjusted during manufacture for optimum breaking. If it is considered

necessary, adjustment can be made by turning the large nut inside the open end of the hub clockwise to tighten the brake.

Correct adjustment will result in the wire reel circumference continuing no further than 20mm after release of the trigger. The

electrode wire should be slack without becoming dislodged from wire spool

CAUTION 1

Overtension of brake will cause rapid wear of mechanical WIREFEED parts, overheating of electrical componentry and

possibly an increased incidence of electrode wire Burnback into contact tip

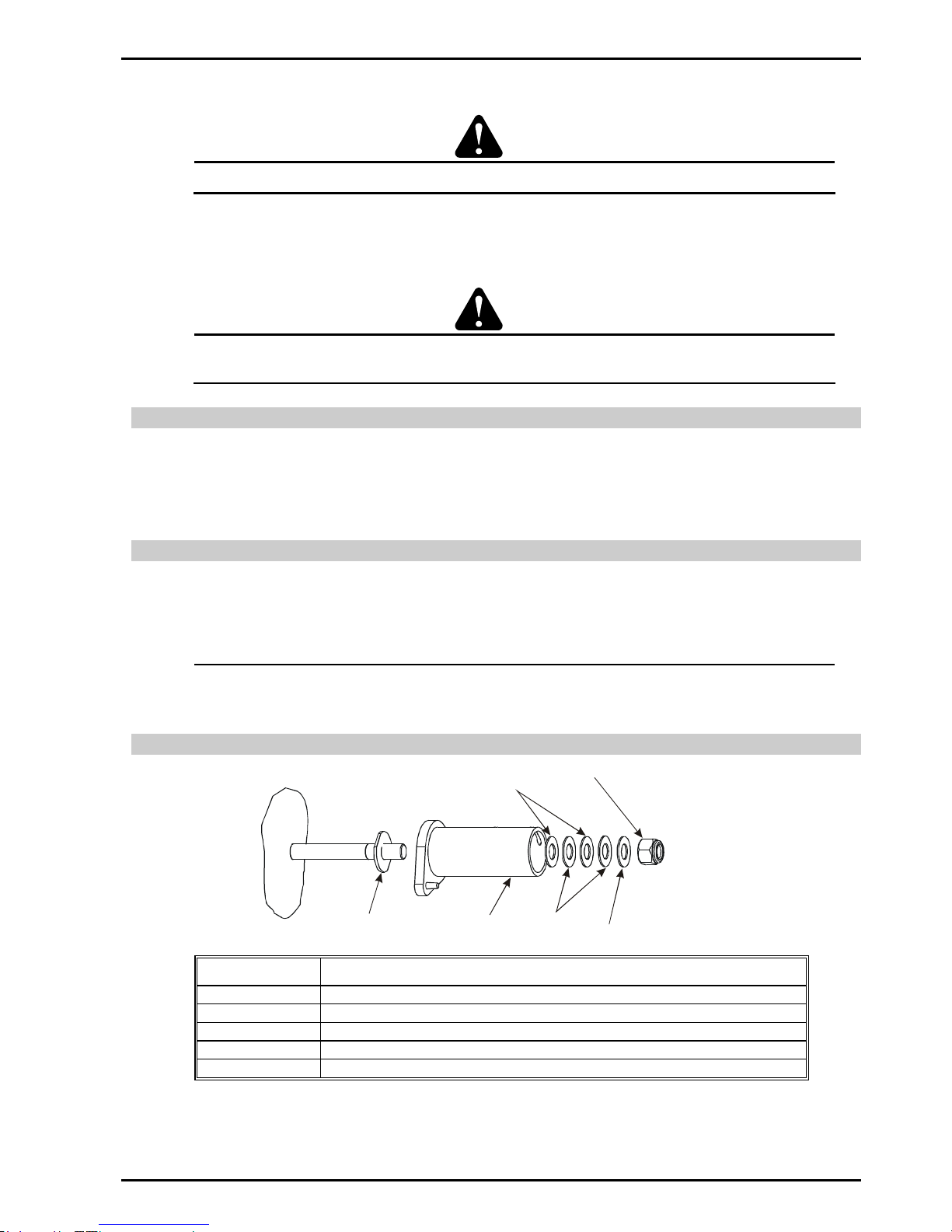

9.07 Wire Reel Hub Assembly

Item Number

Part Number / Description

1

7976411 / friction Washer

2

NB1245 / washer flat M16

3

7977187 / washer wave M16

4

7958040 / nut nyloc 5/8 BSW

--

702337 / Hub

Table 5 – Wire Spool parts

friction washer

(7976411)

Wire spool hub

(702337)

Steel flat washer 16mm ID

(NB1245)

Wave washer

(7977187)

Steel flat washer 16mm ID

(NB1245)

Nut 5/8” BSW

(7958040)

TRANSMIG 225, 255 MIG Power Source, 255 2R MIG Wirefeeder

20 Sep 16, 2008

SECTION 10: Power Source and Wirefeeder Controls, Indicators and Features

10.01 Standby switch with in-built Indicator Light

The indicator light is provided to indicate when the TRANSMIG 225, 255 MIG Power Source is connected to the Mains Supply voltage.

With the switch in the STANDBY position, the auxiliary power and the fan are turned off.

WARNING 9

When the light is lit, the machine is connected to the Mains supply voltage and the internal electrical components are at

Mains voltage potential.

10.02 Wirespeed Control

The Wirespeed Control knob controls the welding current via the electrode wirefeed rate. ie the speed of the wirefeed motor.

10.03 Output Voltage Control Switch (Coarse)

The Coarse Voltage Control switch increases the voltage (in larger increments than the Fine switch) as it is rotated in the clockwise

direction.

10.04 Output Voltage Control Switch (Fine)

The Fine Voltage Control switch increases the voltage (in smaller increments than the Coarse switch) as it is rotated in the clockwise

direction.

CAUTION 2

The Coarse and Fine Voltage Control switches MUST NOT BE SWITCHED during the welding process

2

5

8

11

14

17

20

2

1

3

4

TORCH

2

1

3

4

1

4

5

0

32

2

1

3

4

2

1

3

4

FEEDER OUTPUT

7

11

4

3

4

3

1

12

6

7

1

2

10

5

6

7

8

9

2

5

8

11

14

17

20

1 4

5

0

32

11

2

10

9

TRANSMIG 225, 255 MIG Power Source, 255 2R MIG Wirefeeder

Sep 16, 2008 21

10.05 Torch Polarity Lead (Compact models only)

This lead selects the welding voltage polarity of the electrode wire. Plug it into the positive welding terminal (+) when using steel,

stainless steel or aluminium electrode wire. Plug the Torch Polarity Lead into the negative welding terminal (-) when using gasless

electrode wire. If in doubt, consult the manufacturer of the electrode wire for the correct polarity.

10.06 Positive Welding Terminal

Positive Welding Terminal. Welding current flows from the Power Source via heavy duty bayonet type terminals. It is essential, however,

that the male plug is inserted and turned securely to achieve a sound electrical connection.

10.07 Negative Welding Terminal

Negative Welding Terminal. Welding current flows from the Power Source via heavy duty bayonet type terminals. It is essential,

however, that the male plug is inserted and turned securely to achieve a sound electrical connection.

CAUTION 3

Loose welding terminal connections can cause overheating and result in the male plug being fused in the terminal.

10.08 Torch Connector (Compact models only)

The MIG torch connects to this outlet.

10.09 Thermal Overload

The critical component for thermal protection is the rectifier stack, which is fitted with a thermal overload cut out device. If the overload

operates then the machine should be left to cool for approximately 15 minutes before resuming welding. The thermal overload will not

operate and there will be no danger of transformer damage if the Power Source is operated within its duty cycle.

The TRANSMIG 225, 255 Compact Power Source has a front panel indication of Thermal Overload.

The TRANSMIG 255 Remote Power Source has a front panel indication of Thermal Overload on the 255 2R Wirefeeder.

10.10 Spot Selector Switch

The SPOT SELECTOR switch selects Spot welding mode.

This mode of welding is used to weld two plates together at a desired location by melting the top & bottom plates together to form a

nugget between them. The spot time period is set by the SPOT TIME control knob.

10.11 Spot Timer

With the SPOT SELECTOR switch in the SPOT position, the SPOT TIME knob controls the duration of a single spot weld.

10.12 Wirefeeder Control Socket (Remote model only)

The WIREFEEDER 7 pin receptacle is used to connect a Wirefeeder to the welding Power Source circuitry:

To make connections, align keyway, insert plug, and rotate threaded collar fully clockwise. The socket information is included in the event

the supplied cable is not suitable and it is necessary to wire a plug or cable to interface with the WIREFEEDER 7-pin receptacle.

Socket Pin

Part Number / Description

1

Output to energise the power supply contactor

(Contact closure is provided between socket pins 1 and 2 to energise the

contactor)

2

24 VAC Active

3

Power Source Thermostats

4

Power Source Thermostats

5

24 VAC Neutral

6

Power source welding voltage - Negative

7

Power source welding voltage - Positive

Table 6 – Interconnection Control Plug configuration

7

4 35

2 1

7 6

TRANSMIG 225, 255 MIG Power Source, 255 2R MIG Wirefeeder

22 Sep 16, 2008

10.13 Burnback

Burnback time is the difference between the wirefeed motor stopping and switching off of the welding current. The Burnback time allows

the electrode wire to burn out of the molten metal weld pool. The Burnback time is factory set for optimum performance.

Clockwise adjustment increases Burnback time.

The Burnback adjustment is located within the wiredrive compartment of the power source for TRANSMIG 225 and TRANSMIG 255

Compact, and is located within the wiredrive compartment of the wirefeeder for TRANSMIG 255 Remote (255 2R wirefeeder).

SECTION 11: 250A TWECO MIG Torch OTWX212/3035 (where supplied)

11.01 MIG Torch Components

Item

Part No.

Description

Qty

1

OTW22

Nozzle

1

2 Contact tip (refer to Table 8)

1

3

OTW52

Gas diffuser

1 4 OTW32

Insulator

1 5 OTW64A/45

Conductor Tube

1 6 OTW102

Power Connector

1 7 OTW83

Handle Kit

1 8 OTW92

Trigger Assembly

1 9 OTW152

Gun Hanger

1

10

OTW142/6

Front Cable Support

1

11

OTW132/12

Front Cable Clamp

1

19

OTW134/14

Front Cable Clamp

1

20

OTW350R23010

Rear Support

1

21

OTW174X/2

Connector Nut

1

22

OTW174EX/1C

Conduit Cap

1

23

OTW174EX/1G

O-Ring

1

24

OTW4M/S

Screw

1

25

OTW174EX/1

Rear Connector

1

26

OTW174X/M

Power Connection

1

27

OTWX6RC

Rear Case

1

28 Conduit (refer to Table 9)

1

Table 7 – MIG Torch Components

13

TRANSMIG 225, 255 MIG Power Source, 255 2R MIG Wirefeeder

Sep 16, 2008 23

11.02 MIG Torch Contact Tips

STANDARD & TAPERED

HEAVY DUTY

Wire Size

Part No.

Wire Size

Part No.

0.6mm (.024”)

OTW14/23

0.9mm (.035”)

OTW14H/35

0.8mm (.030”)

OTW14/30

1.0mm (.040”)

OTW14H/40

0.9mm (.035”)

OTW14/35

1.2mm (.045”)

OTW14H/45

1.0mm (.040”)

OTW14/40

1.2mm (.045”) ALUM

717256

1.2mm (.045”)

OTW14/45

0.8mm (.030”) Taper

OTW14T/30

0.9mm (.035”) Taper

OTW14T/35

1.2mm (.045”) Taper

OTW14T/45

Table 8 – MIG Torch Contact Tips

11.03 MIG Torch Conduits

HARD ELECTRODE WIRE

SOFT ELECTRODE WIRE

Wire Size

Part No.

Wire Size

Part No.

0.8-0.9mm

(.030”-.035”)

OTW42/3035

0.9-1.2mm NYLON

(.035”-.045”)

OTW42N/3545

1.0-1.2mm

(.040”-.045”)

OTW42/4045

Table 9 – MIG Torch Conduits

11.04 Installing a new Wire Conduit

a) Be sure the MIG Torch cable is arranged in a straight line, free from twists, when installing or removing a wire conduit.

Remove the old conduit by first removing the conduit retaining nut, MIG Torches nozzle, contact tip and gas diffuser. Pull the

old wire conduit out of the cable assembly from the connector plug end.

b) To install a new wire conduit, first inspect the o-ring gas seal on the conduit for cuts or damage. Start from the connector plug

end of the assembly and begin pushing the conduit through the connector plug, cable assembly and into the torch. If the

conduit should lodge along the way, gently whip or work the cable assembly to aid forward movement.

c) When the wire conduit stop meets the end of the connector plug and the new raw end extends through the end of the

conductor tube, secure the conduit retaining nut at the plug to prevent its backward movement.

NOTE 4

When the conduit is fully inserted into the cable assembly and the conduit stop is firmly against the Connector Plug, the "raw

end" of the conduit will protrude out of the open end of the torch conductor tube. Trim the conduit to 34mm. The trimmed end

which seats in the Gas Diffuser must be filed and reamed smooth on the inside and outside radii so wire feed will not be

obstructed.

d) Replace Gas Diffuser, Contact Tip, and Nozzle.

e) Tighten the Allen screw in the conductor tube.

11.05 MIG Torch Maintenance

Remove dust and metallic particles from the torch conduit by forcing clean, dry compressed air into the conduit once a week.