Page 1

TS2

Service

Thermocot

Manual

iN

i

|

|

ή

[

il

Eu

ag

페

1

1

EL

Ц

|

CIG

Health

e

Commonweatih

Care

Indu

С.М.

т

000

029

|

729

pi

Page 2

TS2

Thermocot

Service

Manual

Page 3

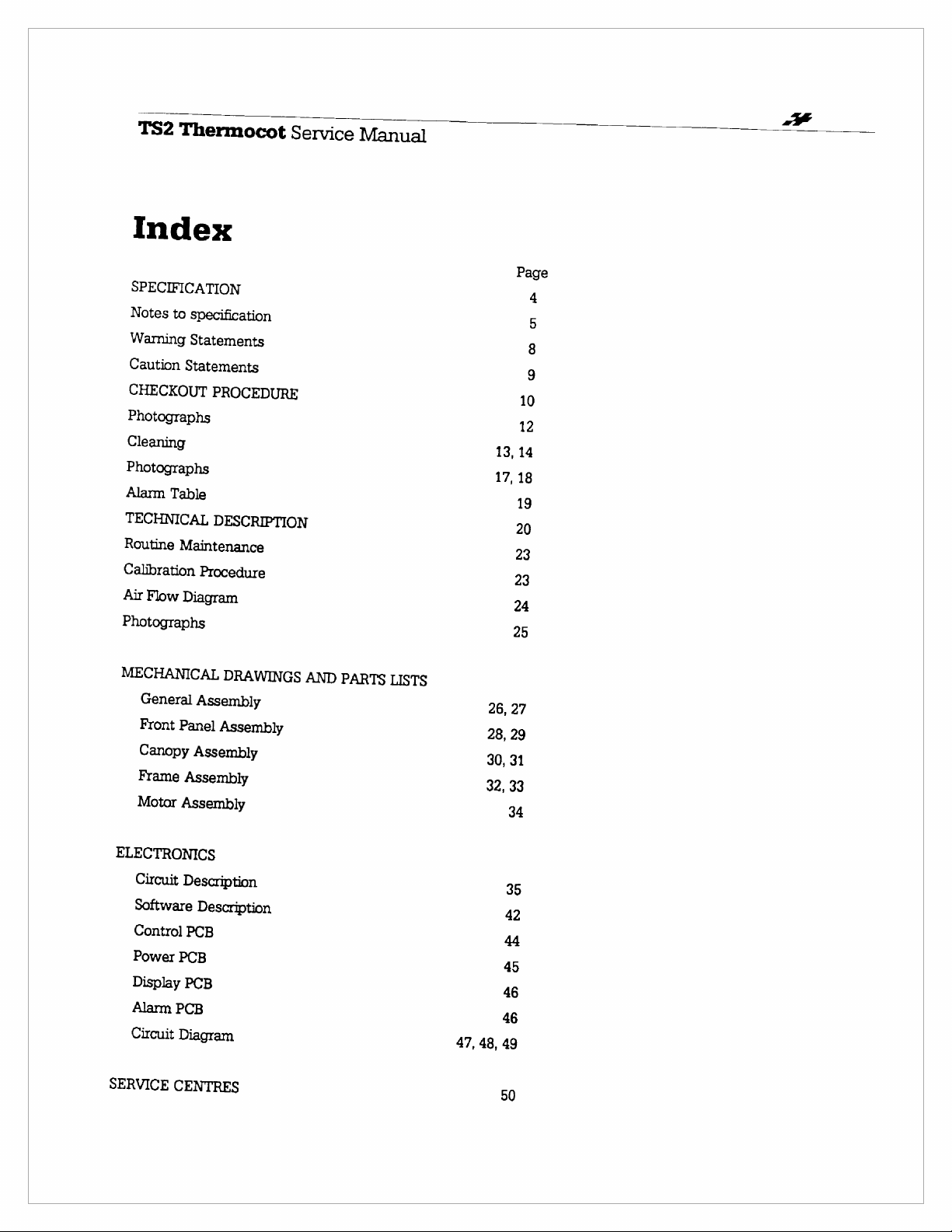

TS2

Thermocot

Index

SPECIFICATION

Notes

to

specification

Warning

Caution

CHECKOUT

Photographs

Cleaning

Photographs

Alarm

TECHNICAL

Routine

Calibration

Air

Photographs

Statements

Table

Maintenance

Flow

Diagram

Statements

PROCEDURE

DESCRIPTION

Procedure

Service

Manual

13,

17,

25

Page

4

5

8

9

10

12

14

18

19

20

23

23

24

25

MECHANICAL

General

Front

Panel

Canopy

Frame

Motor

Assembly

ELECTRONICS

Circuit

Software

Control

Power

Display

Alarm

Circuit

SERVICE

Description

PCB

PCB

Diagram

CENTRES

DRAWINGS

Assembly

Assembly

Assembly

Assembly

Description

PCB

PCB

AND

PARTS

LISTS

47,

26,

28,

30,

32,

48,

27

29

31

33

34

35

42

44

45

46

46

49

50

Page 4

TS2

Thermocot

Service

Manual

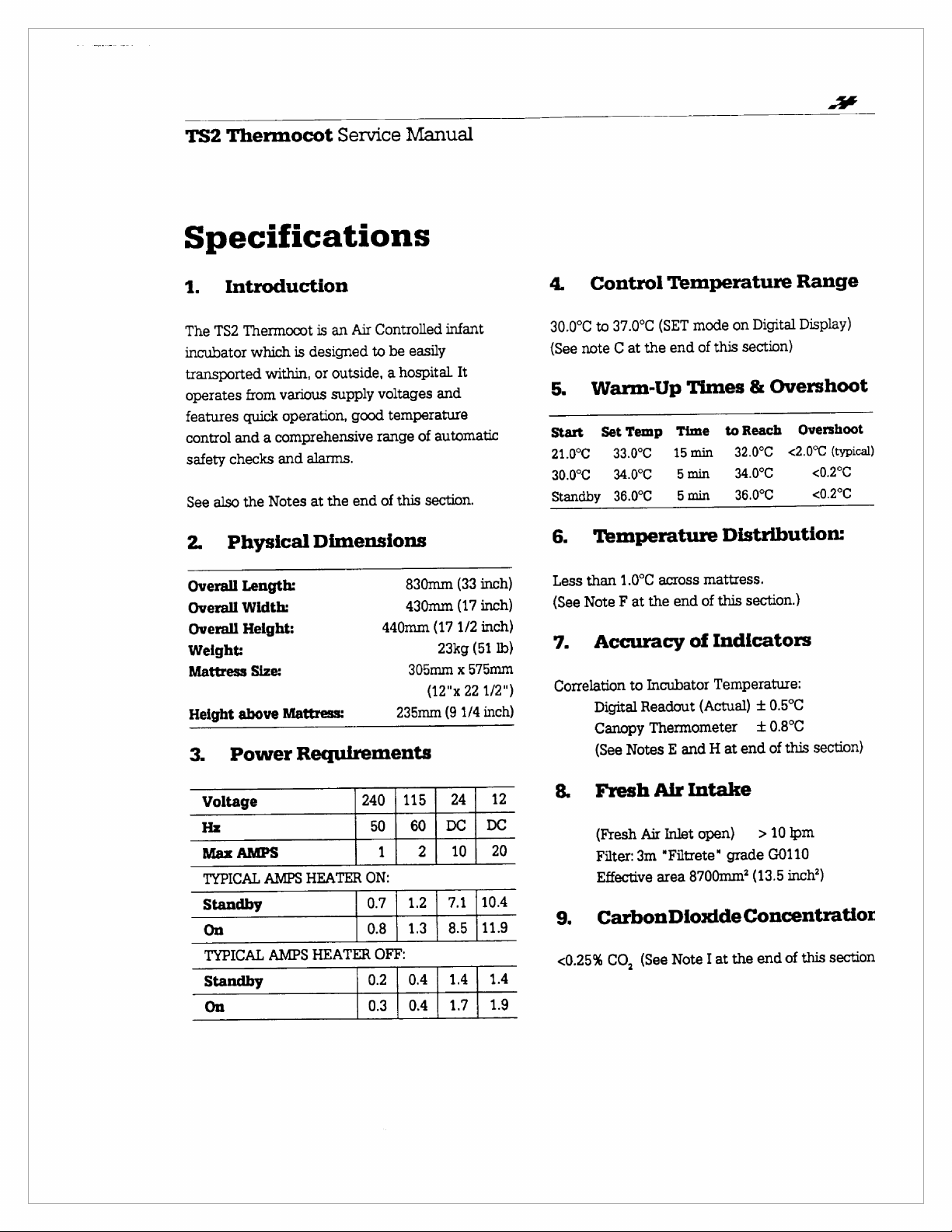

Specifications

4.

1.

Introduction

Control

Temperature

Range

The

TS2

Thermocot

incubator

transported

operates

features

control

safety

See

2.

Overall

Overall

Overall

Weight:

Mattress

Height

3.

from

quick

and a comprehensive

checks

also

the

Physical

Length:

Width:

Height:

above

Power

which

is

within,

various

operation,

and

Notes

Size:

Mattress:

Requirements

is

an

Air

Controlled

designed

or

alarms.

at

Dimensions

to

be

outside, a hospital

supply

voltages

good

temperature

range

the

end

of

this

440mm

235mm

easily

and

of

automatic

section.

830mm

430mm

(17

23kg

305mm

(12"x

infant

It

(33

inch)

(17

inch)

1/2

inch)

(51

575mm

x

22

(9

1/4

lb)

1/2")

inch)

37.0°C

to

30.0°C

(See

note

C

Warm-Up

5.

Start

21.0°C

30.0°C

Standby

6.

Less

(See

7.

Correlation

SetTemp

33.0°C

34.0°C

36.0°C

Temperature

than

Note F at

Accuracy

Digital

Canopy

(See

(SET

at

the

1.0°C

across

the

to

Incubator

Readout

Thermometer

Notes

on

mode

end

of

this

Times

Time

15min

5min

Smin

end

E

toReach

32.0°C

34.0°C

36.0°C

Distribution:

mattress.

of

this

of

Indicators

Temperature:

(Actual) + 0.5°C

end

at

H

and

Digital

section)

Overshoot

&

<2.0°C

section.)

340.80

this

of

Display)

Overshoot

(typical)

<0.2°C

<0.2°C

section)

Voltage

Hz

Max

AMPS

TYPICAL

Standby

On

TYPICAL

Standby

On

AMPS

AMPS

HEATER

240

50 | 60 | DC | DC

ON:

0.7 | 1.2 | 7.1

0.8 | 13 | 8.5

HEATER

0.2 | 04 | 14 | 14

0.3 | 0.4 | 1.7 | 19

|115 | 24|

1|

2|

OFF:

10|

12

20

|104

|119

8.

Fresh

(Fresh

Filter:

Effective

CarbonDioxideConcentratior

9.

<0.25%

CO,

Air

Air

Inlet

3m

"Filtrete“

area

Note

(See

Intake

open) > 10

grade

8700mm?

at

I

the

G0110

(13.5

end

pm

inch?)

this

of

section

Page 5

TS2

10.

1.

il.

11.

Across

12.

i,

i.

Ш.

iv.

v.

13.

(See

the

Thermocot

Oxygen

With

applied-

With

8

lpm

after

an

ambient

(See

notes

Air

Velocity

mattress

Sound

At

centre

Sameas

8

lpm

Oxygen

Same

as

10

Ipm

Same

as

Alarm

Alarm

level

in

front

(See

Note

Alarms

Alarm

Fresh

5

sounding

Concentration

Fresh

Air

Inlet

maximum

Air

Inlet

Oxygen

minutes

of

B,

J)

-

<0.1

applied,

from

21%

m/s

Levels

of

Mattress

(i)

but

with

applied

(i)

but

with

Oxygen

of

Chart,

applied

(i)

but

with

3

metres

incubator

K)

and

serviceMana

open,

5

Ipm

Oxygen

40%

O,

Closed,

O,

-

55%

O,

minimum

(typical)

52

dbA

(max)

50

dbA

(typical)

Note

52dbA

54dbA

60dbA

>65dbA

L)

(typical)

(typical)

(typical)

NOTES:

A.

This

cannot

incubator

automatic

temperature.

adjusted

requirements

B.

OXYGEN:

achievable

applying

end,

amount

atmosphere.

If

the

maximum

achieved.

cause

some

If

the

of

oxygen

Note

that

Fresh

applied

accumulation

Carbon

is

an

Air

Controlled

be

used

as

ie.

there

control

by

The

within

oxygen

is

dependent

and

Fresh

of

Note

physiological

patients.

Fresh

Air

of

The

air

the

nursing

of

the

oxygen

the

at

on

position

Air

Inlet

40%

oxygen

that

Inlet

concentration

it

is

important

Air

Inlet

when

-

otherwise

Dioxide.

of

the

there

patient's

incubator;

a

Baby

Controlled

is

no

provision

the

infant's

temperature

staff

to

suit

infant.

concentration

incubator,

the

nipple

the

flow

of

leaks

is

left

only

even

this

complications

is

closed,

can

to

oxygen

can

by

at

the

rate

to

the

open,

a

can

be

low

level

with

higher

be

obtained.

only

close

is

being

be

an

expired

ae

一

it

for

must

be

the

level

left

and

the

outside

may

levels

the

一

SOFTWARE

Auto

reset

HARDWARE

Latch,

manual

14.

Humidity

Increase

in

holders

OVERTEMP

at

in

humidity

about

36.0°C

OVERTEMP

reset

by

20%

RH.

adding

(See

water

Note

37.5°C

38.0°С

to

sponges

M)

As

a

guide,

applied,

55%

within

ambient).

will

give

Note

though,

increase

incubator.

the

if

a

flow

the

concentration

5

minutes

Higher

higher

flows,

concentrations.

that

higher

noise

level

of

8

(i.e.

inside

lpm

or

of

oxygen

will

build

34%

above

longer

times,

flows

also

the

up

is

to

Page 6

TS2

C.

D.

E.

Thermocot

Temperature

Set

The

During

to

available

will

normal

exceed

to

override

testing

of

points.

when

incubator.

Always

preparing

starting

When

overshoot.

Overtemperature

the

of

Temperature

Set

than

more

Temperature

about

after

warm-up

A

minimal

only

recommended

incubator

the

if

service

All

an

Temperatures

calibrated

centre

at

parameters

ambient

of

diameter

discs

The

the

above

points.

disc

Fach

diameter

50mm

diameter

Service

is

operation

37.0°C.

the

However,

Biomedical

a

maximum

this

Overtemperature

check

nurse

to

cold

from

inadvertent

avoid

To

this

for

and

34°C,

higher

a

to

minutes.

20

STANDBY

from

overshoot,

this

that

likely

is

notice.

short

specified

temperature

measured

are

thermocouples

black-painted

and

25mm

of

mounted

are

mattress

in

held

is

rods

plastic

base.

Manual

limited

not

is

it

facility

a

Technician

for

Temperature

Set

the

infant

an

there

alarms,

first

change

then

setting

will

it

and

mode

be

to

are

21°C.

of

attached

brass

thickness

a

horizontally

nominated

the

at

by

place

protruding

37.0°C.

to

possible

is

which

purpose

the

alarm

the

in

be

may

operation

make

warm-up

the

required

if

produce

is

employed

be

pressed

measured

using

to

having

discs

of

1mm

three

from

an

the

no

Set

into

at

the

1mm.

100mm

test

a

à

the

assess

To

Control

temperature,

this

following

Point

the

are

points

the

Temperature

the

and

5

100mm

is

A

mattress

same

the

at

the

of

mattress

CONTROL

selected

mode).

INCUBATOR

Temperature

F.

the

To

concentration

Fresh

Air

to

mattress

point

monitored

The

increases

lpm

this

applied.

at

is,

That

mattress

evaluate

Inlet

Air

administered

is

point

a

and

150mm

sound

sound

the

increases

sound

The

measured

perpendicular

3m

of

incubator.

incubator

the

the

floor.

temperature

can

difference

the

and

temperature

is

points

test

above

surface;

lines

to

TEMPERATURE:

the

100mm

the

100mm

until

level

as

level

at

Both

four

height

drawn

of

each

display

digital

TEMPERATURE:

measured

above

surface.

maximum

will

which

a

open,

at

above

CO,

the

from

apart

stability

inside

level

54dbA

to

the

of

point

the

positioned

are

flow

is

sound

oxygen

a

distribution,

any

at

set

be

between

the

of

each

at

measured.

exact

the

other

above

from

corners.

its

point

at

the

Test

centre

points

test

mid-

the

centre

the

Temperature

SET

(in

Note

in

A

centre

exact

CO,

the

with

occur,

CO,

mixture

4%

rate

a

the

concentration

this

achieved.

is

incubator

the

is

typically

when

Audible

which

the

to

of

750m1/min

of

of

centre

at

is

point

increased.

52dbA,

lpm

10

Alarm

distance

a

at

is

the

of

front

meter

level

above

1.5m

the

of

of

of

in

the

a

At8

but

is

is

and

Page 7

TS2

Thermocot

L.

There

One

and

readout

automatically

disconnected

can

However

overtemperature

be

initiated

failure

Temperature

temperature

erature

disconnected,

alarm

latch

by

the

are

two

is

in

the

monitors

goes

be

muted.

there

which

Alarm

which

so

that

incubator

Service

Overtemperature

microprocessor

its

own

readings;

over

37.5°C

cause

the

and

sound

is

also a totally

detection

if

there

is a microprocessor

causes

to

the

cannot

it

the

go

up

to

Hardware

will

cause

will

sound a steady

be

muted,

cannot

being

be

tumed

Manual

control

if

it

will

heaters

an

alarm

independent

circuit.

Incubator

38.0°C.

Overtemp-

the

heaters

and

reset

other

off.

Alarms.

system

the

to

be

which

This

At

this

to

Audible

will

than

will

be

The

added

by

sponge

factors:

+

+

e

e

*

amount

to

adding

holders

The

relative

drawn

Whether

The

temperature

the

sponges.

The

Incubator

The

length

to

build

of

moisture

the

circulating

water

is

humidity

in

through

(dry)

of

up.

which

air

in

to

the

sponges

controlled

of

the

the

Fresh

oxygen

Temperature.

time

of

the

allowed

is

being

water

will

the

by

several

air

Air

for

'

in

be

incubator

the

being

Filter.

applied.

added

to

humidity

Note

cause

that

the

both

Overtemperature

heaters

to

be

disconnected.

Alarms

Page 8

TS2

Thermocot

Service

Manual

Warning

statements

(A

is a possibility

operator.)

WARNING

of a source

or

cause

WARNING

detailed

Incubator

any

withdrawn

WARNING

should

operation

qualified

the

equipment.

WARNING

presence

possible

these

WARNING

in

patient's

minutes.

WARNING

move

When

loss.

WARNING

the

Warning

an

portion

known

the

incubator

Statement

of

Do

not

place

of

radiant

electric

the infant

Complete

All

Do

conditions.

Do

incubator

The

the

Do

radiator.

in

this

into

service.

of

the

from

personnel

be

thoroughly

and

under

medical

risks

not

use

of

flammable

explosion

not

leave

temperature

canopy

infant

it

is

raised

not

leave a patient

while

the

Manual

is

injury

to

the

incubator

heat

Such

to

overheat.

Checkout

before

If

procedure

service.

using

familiar

the

personnel

and

benefits

the

incubator

anaesthetics;

hazard

the

patient

for

long

at

should

in

or

out

there

is

the

used

when

the

patient

in

such

as

exposure

Procedure

placing

the

incubator

it

must

the

incubator

with

direction

familiar

of

using

in

exists

under

unattended

periods.

least

only

of

significant

canopy

Check

every

be

raised

the

incubator.

unattended

is

there

or

the

path

sunlight

may

the

fails

be

its

of

with

the

the

a

the

30

to

heat

raised.

the

as

in

WARNING

does

pressure

measurements

the

concentrations

environment

concentrations

retrolental

below

infants.

WARNING

measured

flowmeter.

should

infant's

WARNING

the

service

incubator

WARNING

the

WARNING

increase

incubator.

WARNING

dependent

air

openings

mattress.

proper

air

build-up.

triggered.

The

concentration

not

predictably

of

oxygen

regulation

40%

If

be

When a system

incubator

If

patient.

The

Proper

circulation.

air

temperature

of

is

fibroplasia.

can

oxygen

with a pressure

The

monitored

head.

should

and

the

to

ensure

an

alarm

administration

the

noise

temperature

upon

Do

at

the

Obstruction

circulation,

An

air

of

inspired

determine

in

the

blood;

are

extremely

inspired

when

necessary.

can

be

is

applied

concentration

infant

is

level

continuous

not

ends

control

circulation

oxygen

an

oxygen

High

increase

Even

dangerous

its

compensated

at a position

fail

alarm

be

removed

shifted

continuity

muted

closely

of

within

control

cover

and

sides

could

loss

of

and

alarm

oxygen

the

partial

blood

gas

important

enriched

oxygen

the

risk

of

concentrations

to

some

flow

should

of

oxygen

near

the

is

activated,

from

to

another

of

care.

monitor

oxygen

unobstructed

air

lead

heat,

carbon

will

the

is

circulation

of

the

to

loss

of

loss

of

dioxide

may

be

for

be

Page 9

TS2

Thermocot

Service

Manual

Caution

Statements

{A

CAUTION

CAUTION

CAUTION

caution

a

possibility

incandescent

phototherapy)

canopy.

least

ether,

scouring

incubator.

the

CAUTION

of

the

CAUTION

electricity

canopy

CAUTION

cleaning

least

to

cool.

CAUTION

for

cleaning

has

amounts

left

in

particularly

statement

of

Do

not

mount a radiant

Thoroughly

once a week

Do

not

use

alcohols,

compounds

These

surfaces

Do

To

When

10

If

been

to

not

autoclave

plastic

minimise

do

with a dry

disassembling

disconnect

minutes

flammable

make

thoroughly

of

agents

the

incubator

in

damage

light

on

or

clean

organic

ketones

compounds

which

parts

the

not

polish

for

agents

sure

the

presence

is

used

to

source

over

the

or

after

solvents

(e.g.

for

cleaning

they

the

of

the

generation

the

cloth.

the

power

the

heating

that

air

dried.

such

as

can

cause a fire

the

warmer

(including

the

incubator

each

are

mattress

incubator.

incubator

the

have

the

alcohol

of

when

there

equipment.)

or

incubator

at

patient.

including

acetone)

may

incubator

been

Small

oxygen.

or

the

damage

applied.

or

any

of

static

and

allow

elements

used

incubator

or

ether

is

for

at

CAUTION

with

this

readily

burn

on

CAUTION

automatically

the

is

period

prevent

The

every 6 months.

CAUTION

sponge

free

sponges

water

CAUTION

20Kg.

two

either

CAUTION

danger

may

in

Never

other

type

and

violently.

suitable

The

incubator

to

he

taken

the

possible

battery

When

holder

liquid

is

is

spilled

The

It

should

people

end.

The

of

produce

the

incubator.

oil

or

grease

than a substance

of

service.

in

lubricants.

voltage

battery

should

applying

that

at

Thermocot

and

use

fire.

Oils

the

presence

CIG

Health

of

the

checked

is

turned

out

of

service

should

damage

be

water

be

careful

is

not

soaked

least

5mm

mop

it

weighs

only

be

only

by

of

oxygen

Auxiliary

sparks

should

continually

on.

routinely

up

lifted

oxygen

and

internal

that

below

the

increases

equipment

equipment

approved

grease

of

oxygen

Care

can

battery

If

the

incubator

for

an

be

removed

due

to

leaking.

replaced

to

the

humidity

the

level

up

into

the

immediately.

in

excess

by

at

handles

not

be

for

oxidise

will

advise

is

when

extended

to

of

the

lip.

If

of

least

at

the

which

placed

Page 10

TS2

Thermocot

Service

Manual

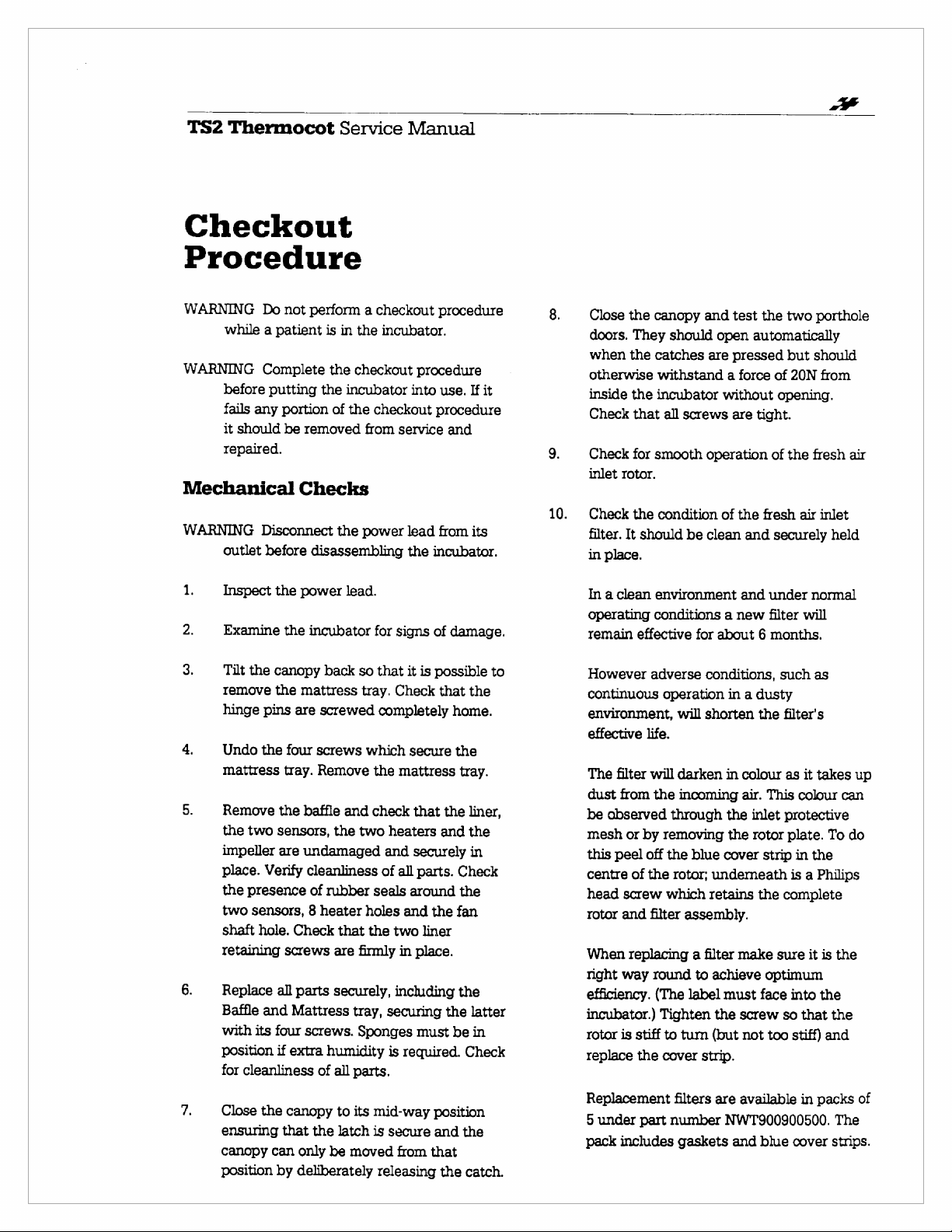

Checkout

Procedure

WARNING

while a patient

WARNING

before

fails

it

should

repaired.

Mechanical

WARNING

outlet

1.

Inspect

2.

Examine

3.

Tilt

remove

hinge

4.

Undo

mattress

5.

Remove

the

impeller

place.

the

two

shaft

retaining

6.

Replace

Baffle

with

position

for

Do

not

perform a checkout

is

Complete

putting

any

portion

Disconnect

before

the

the

canopy

the

pins

the

the

two

sensors,

are

Verify

presence

sensors, 8 heater

hole.

all

and

its

four

if

cleanliness

the

the

of

be

removed

Checks

the

disassembling

power

the

incubator

back

mattress

are

screwed

four

screws

tray.

Remove

baffle

the

undamaged

cleanliness

of

rubber

Check

that

screws

are

parts

securely,

Mattress

screws.

extra

humidity

of

all

in

the

incubator.

checkout

incubator

the

checkout

from

power

lead.

for

so

that

tray.

completely

which

the

and

check

two

heaters

and

of

seals

holes

the

two

firmly

tray,

securing

Sponges

is

parts.

procedure

procedure

into

use.

procedure

service

signs

Check

mattress

all

in

including

and

lead

from

the

incubator.

of

damage.

it

is

possible

that

home.

secure

that

the

and

securely

parts.

around

and

the fan

liner

place.

the

must

be

required.

If

it

its

the

the

tray.

liner,

the

in

Check

the

the

latter

in

Check

to

8.

9.

10.

be

mesh

this

centre

head

rotor

When

night

efficiency.

incubator.)

rotor

replace

Close

the

canopy

doors.

They

when

the

catches

otherwise

inside

Check

Check

inlet

Check

filter.

in

place.

In a clean

operating

remain

However

continuous

environment,

effective

The

dust

observed

withstand a force

the

incubator

that

all

for

smooth

rotor.

the

condition

It

should

environment

conditions a new

effective

adverse

operation

life.

filter

will

from

the

or

by

removing

peel

off

the

of

the

screw

which

and

filter

replacing a filter

way

round

(The

Tighten

is

stiff

to

the

cover

and

should

are

screws

operation

be

clean

for

conditions,

will

shorten

darken

incoming

through

blue

rotor;

underneath

retains

assembly.

to

achieve

label

turn

(but

strip.

test

the

two

open

automatically

pressed

without

are

of

the

and

about 6 months.

in a dusty

in

the

the

cover

make

must

the

screw

of

opening.

tight.

of

fresh

and

securely

under

filter

the

colour

air.

This

inlet

rotor

strip

the

sure

optimum

face

not

too

but

20N

the

air

such

filter's

as

colour

protective

plate.

in

is a Philips

complete

into

so

stiff)

porthole

should

from

fresh

inlet

held

normal

will

as

it

takes

To

the

it

is

the

the

that

the

and

air

up

can

do

7.

Close

the

canopy

ensuring

canopy

position

that

can

only

by

deliberately

the

to

latch

be

moved

its

mid-way

is

releasing

secure

from

position

and

the

that

the

catch.

Replacement

5

under

part

pack

includes

filters

number

gaskets

are

available

NWT900900500.

and

blue

in

packs

cover

of

The

strips.

Page 11

TS2

Thermocot

Service

Manual

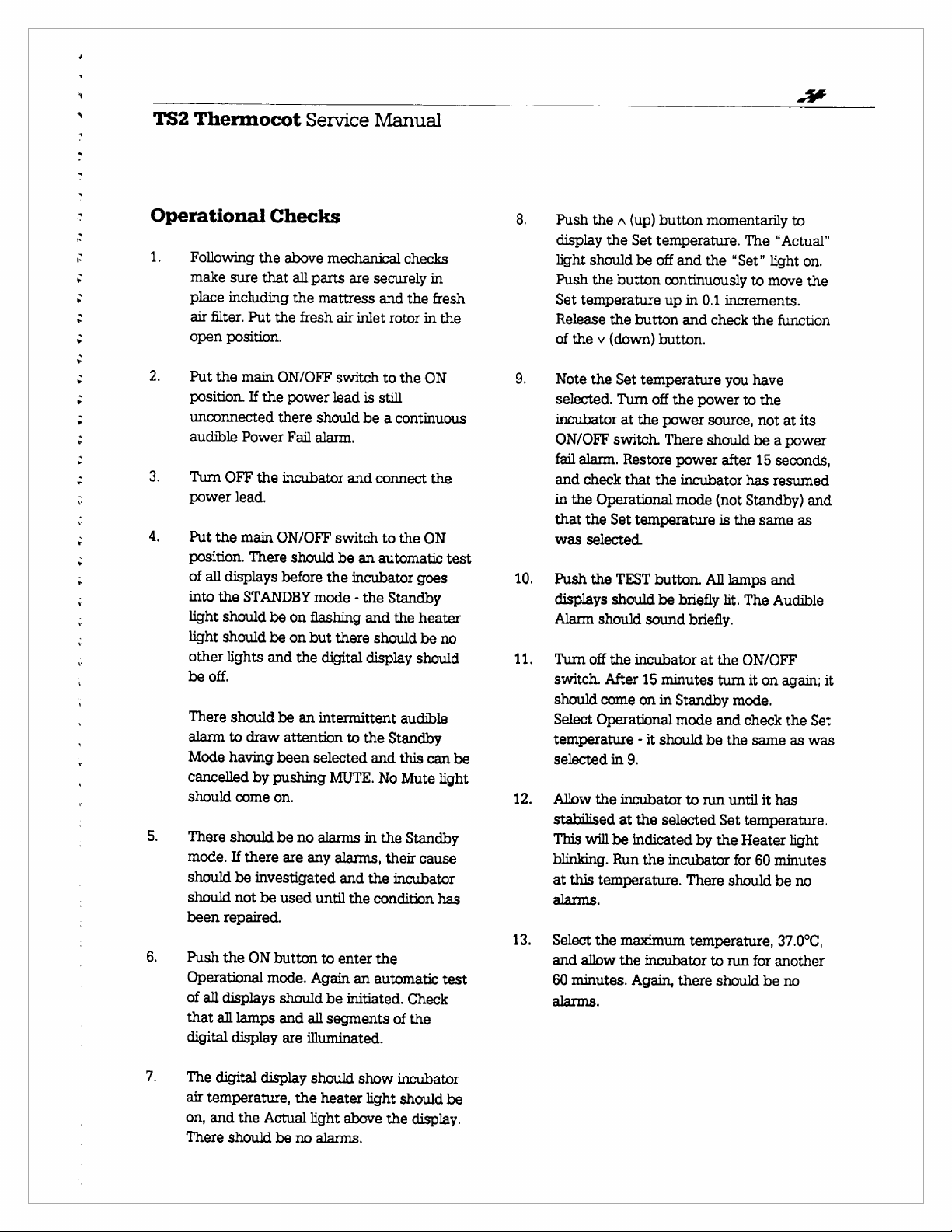

Operational

TA

Fs

Fs

Ta

т,

1.

Following

make

place

air

filter.

open

Put

the

position.

unconnected

audible

Turn

power

Put

the

position.

of

all

into

the

light

should

light

should

other

be

off.

There

alarm

Mode

cancelled

should

There

mode.

should

should

been

Push

the

Operational

of

all

displays

that

all

digital

Checks

the

sure

that

inchiding

Put

the

position.

main

ON/OFF

If

the

there

Power

OFF

the

lead.

main

ON/OFF

There

displays

STANDBY

be

be

lights

and

should

to

having

should

repaired.

be

draw

been

by

pushing

come

on.

be

If

there

be

investigated

not

be

used

ON

button

mode.

should

lamps

and

display

above

mechanical

all

parts

the

mattress

fresh

switch

power

lead

should

Fail

alarm.

incubator

switch

should

before

the

mode - the

on

flashing

on

but

there

the

digital

an

intermittent

attention

selected

MUTE.

no

alarms

are

any alarms,

until

to

Again

be

all

segments

are

illuminated.

checks

are

securely

and

the

air

inlet

rotor

to

the

is

still

be a continuous

and

connect

to

the

be

an

automatic

incubator

Standby

and

the

should

display

audible

to

the

Standby

and

this

No

Mute

in

the

Standby

their

and

the

incubator

the

condition

enter

the

an

automatic

initiated.

Check

of

the

in

fresh

in

the

ON

the

ON

test

goes

heater

be

no

should

can

light

cause

has

test

be

Push

display

light

Push

Set

Release

of

the v (down)

Note

selected.

incubator

ON/OFF

fail

and

in

the

that

was

10.

Push

displays

Alarm

11.

Tum

switch.

should

Select

temperature - it

selected

12.

Allow

stabilised

This

blinking.

at

this

alarms.

13.

Select

and

60

minutes.

alarms.

the A (up)

the

Set

should

be

the

button

temperature

the

button

the

Set

temperature

Tum

at

the

switch.

alarm.

Restore

check

that

Operational

the

Set

temperature

selected.

the

TEST

should

should

off

Operational

the

will

temperature.

the

allow

the

incubator

After

come

in

9.

incubator

at

the

be

indicated

Run

maximum

the

Again,

sound

15

on

the

incubator

button

temperature.

off

button.

off

the

button.

be

in

should

momentarily

and

the

continuously

up

in

0.1

increments.

and

check

you

the

power

power

source,

There

should

power

after

incubator

mode

(not

is

All

briefly

lit.

briefly.

at

the

minutes

selected

incubator

turn

Standby

mode

and

be

to

run

Set

by

the

There

temperature,

to

there

should

The

“Actual”

“Set”

light

to

move

the

function

have

to

the

not

at

be a power

15

seconds,

has

resumed

Standby)

the

same

lamps

and

The

Audible

ON/OFF

it

on

again;

mode.

check

the

the

same

until

it

has

temperature.

Heater

for

60

minutes

should

be

37.0°C,

run

for

another

be

no

to

on.

the

its

and

as

Set

as

was

light

no

it

The

digital

display

air

temperature,

on,

and

the

There

should

the

Actual

be

no

should

heater

light

above

alarms.

show

light

incubator

should

the

display.

be

Page 12

TS2

Thermocot

Service

Manual

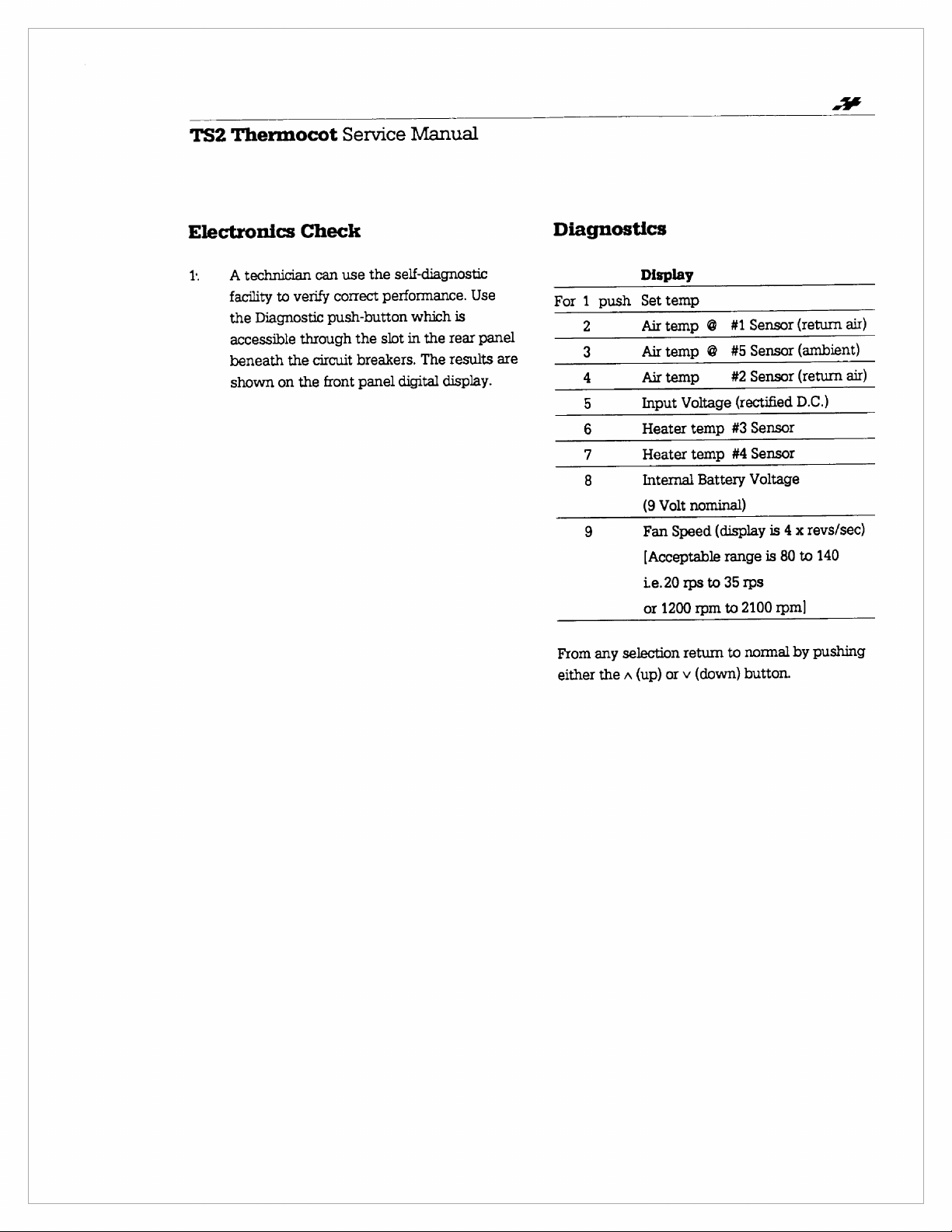

Electronics

1.

A

technician

facility

the

Diagnostic

accessible

beneath

shown

to

verify

the

on

Check

can

correct

push-button

through

circuit

the

front

use

the

performance.

the

slot

breakers.

panel

self-diagnostic

Use

which

is

in

the

rear

panel

The

results

digital

display.

are

Diagnostics

For 1 push

2

|

lola

From

any

either

Display

Set

Air

Airtemp

Air

Input

Heater

Heater

Internal

selection

the A (up)

temp

temp © #1

@

temp

Voltage

temp

temp

Battery

(9

Volt

nominal)

Fan

Speed

[Acceptable

Le.20

rps

to

or

1200

rpm

retum

or v (down)

Sensor

#5

Sensor

#2

Sensor

(rectified

#3

Sensor

#4

Sensor

Voltage

(display

range

is

35

rps

to

2100

to

normal

button.

(return

(ambient)

(return

D.C.)

is 4 x

80

rpm]

by

air)

air)

revs/sec)

to

140

pushing

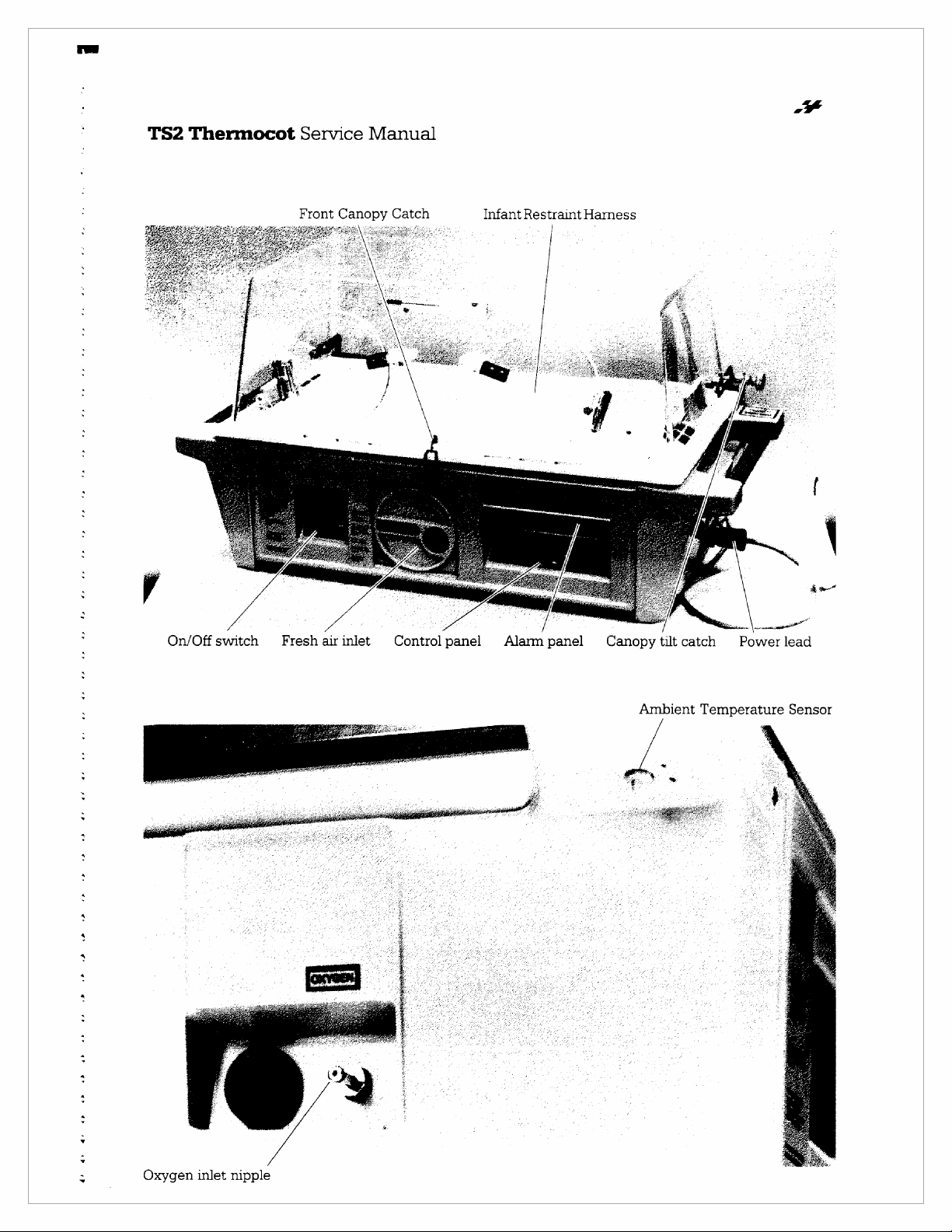

Page 13

.

TS2

Thermocot

Service

Front

Canopy

PEN:

Manual

Catch

SE

Infant

Restraint

Harness

O

On/Off

“> “>

switch

Fresh

air

mlet

Control

panel

«ad

db

Oxygen

inlet

nipple

Page 14

チン

TS2

Thermocot

Service

Manual

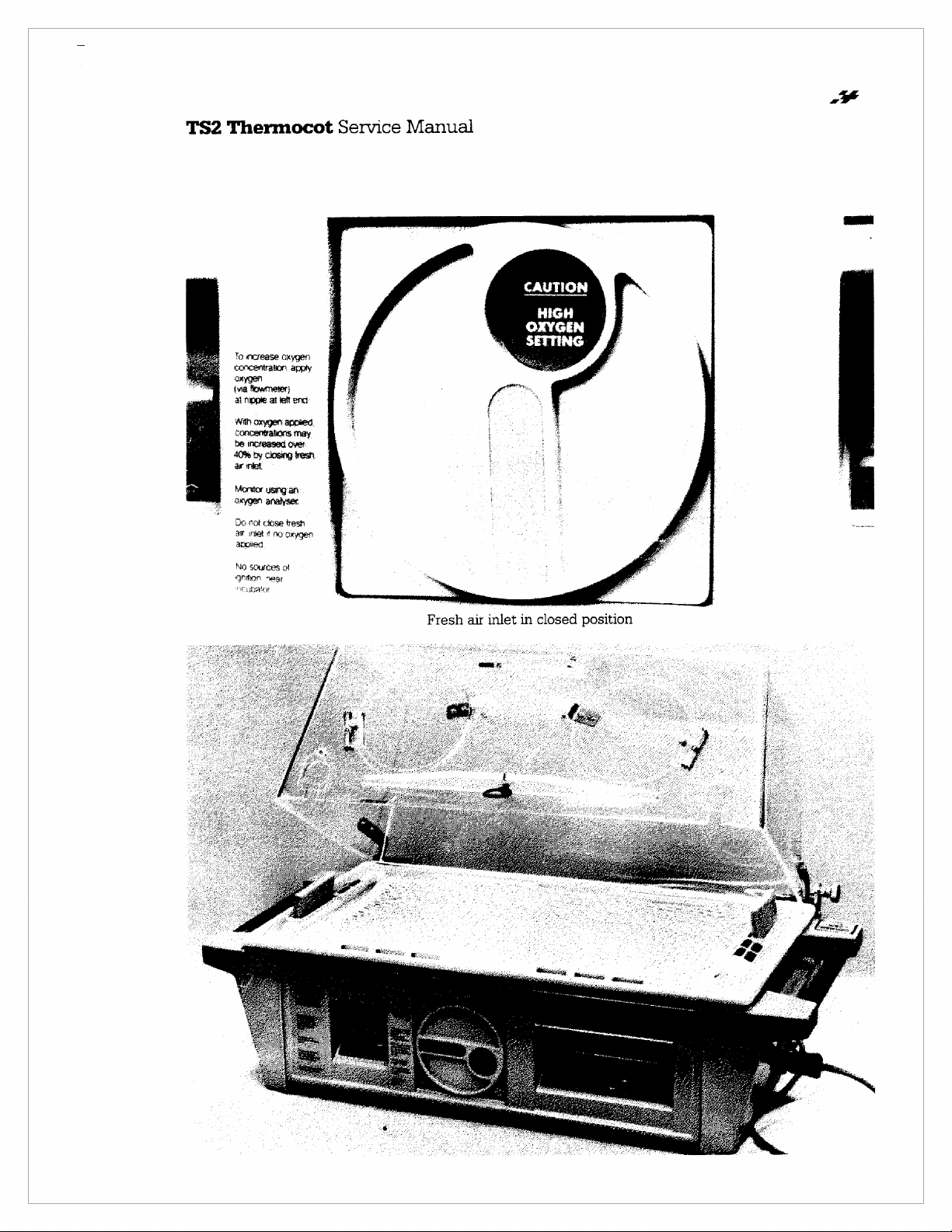

CAUTION

HIGH

OXYGEN

To

increase

corcentrator.

Oxygen

(via

40%

ar

oxygen

No

oxygen

appty

Te)

at

ripple

at

det

enc:

With

oxyger:

increased

by

closing

inlet

using

analyser

not

close

nel

no

sources

near

applied.

may.

over.

fresh,

ah

trash

oxygen

of

concentrations

be

Mondor

Do

ar

anche

Anion

neubator

Re;

ee

ее

4

」

7

a

-

RR

9

DED.

^

22

ys

の

2%

^

ЕВ:

ЕР

~

ag

ge

9

ON

Le 2 s

%

o

Е

-

~

5

42200

OE

GUS,

~

E

SINS

SØG

2

TR x eee

4

の

ASE

20

a

paro

>

DİM

22

295

ASG).

À

&

Page 15

TS2

Thermocot

Service

Manual

Cleaning

WARNING

WARNING

CAUTION

CAUTION

CAUTION

Disconnect

outlet

Allow

incubator

handling

Do

ether,

scouring

incubator.

the

surfaces

To

electricity

dry

cloth.

If

for

cleaning,

been

thoroughly

assembly.

Disassembly

1.

Make

sure

before

disassembling

at

least

has

been

the

heaters.

not

use

alcohols,

compounds

These

to

minimise

do

not

flammable

make

Procedure

the

incubator

the

10

switched

organic

ketones

compounds

which

the

polish

agents

sure

air

dried

power

for

lead

the

minutes

off

solvents

(e.g.

acetone)

cleaning

may

they

are

generation

the

canopy

have

been

that

all

before

is

turned

from

its

incubator.

after

the

before

including

or

the

damage

applied.

of

static

with

used

parts

have

re-

off.

a

Check

to

touch.

The

the

7mm

Cleaning

10.

All

removed

only

Do

not

coarse

The

clean.

The

the

two

immersed

wipe

11.

The

brush

antiseptic

Do

not

coarse

that

the

Remove

liner

may

two

retaining

Nut-driver

parts

antiseptic

use

alcohols,

polish.

mattress

Do

not

Mattress

heaters

if

necessary.

clean.

canopy

may

or

cloth

soap

use

alcohols,

polishes.

two

heaters

both

be

removed

screws

is

required.

should

soap

can

be

immerse

Tray,

the

and

be

scrubbed

and

wiped

and

warm

ether,

heaters.

for

are

be

and

warm

ether

or

scrubbed

the

mattress.

Baffle,

the

Liner

Scrub

clean.

water.

ketones

are

not

too

cleaning

removed.

cleaned

ketones,

them

with a soft

water.

and

the

Impeller,

can

all

Use

using

wiped

and

only

or

hot

if

A

or

be

an

2.

Disconnect

outlet.

3.

Open

4.

Undo

tray.

mattress.

5.

Remove

tray.

6.

Remove

7.

Remove

the

power

the

canopy

the 4 screws

Remove

the

the

the

the

sponges

baffle.

impeller

lead

to

its

retaining

tray,

the

from

from

from

fully

screws

the

the

the

back

position.

the

mattress

mattress

motor

power

and

shaft.

the

With a slightly

seals

fan

13.

Remove

and

needs

discoloured a new

Wipe

slightly

14.

With a damp

contains

or

similar

tube

on

the

shaft

to

remove

the

Air

the

filter.

replacing - if

the

rotor

damp

the

technique,

and

its

top

damp

sensors,

any

inlet

Check

it

filter

and

filter

cloth.

cloth,

wipe

filter,

and,

gasket.

cloth

wipe

the

heaters

deposits.

rotor,

the

filter

the

filter

to

is

excessively

is

required.

panel

with

the

area

using a bottle

the

air

entrainment

the

and

see

a

which

rubber

the

panel,

if

it

brush

Page 16

TS2

15.

16.

Thermocot

Before

re-assembling

make

sure

of

soap

or

Replace

that

sure

Push

screws

should

Make

clean

rotor

tum.

position;

be

all

in

which

that

on

the

which

be

sure

air

side

should

Leave

showing.

other

the

firm,

the

that

they

deposits.

parts

in

they

heaters

impeller

retain

but

the

filter

towards

be

firm,

the

rotor

red

warning

Service

the

are

quite

the

reverse

were

removed.

are

as

far

the

mattress

not

over

is

installed

the

but

not

in

the

Manual

removed

dry

and

order

Make

firmly

seated.

as

it

will

tray

tightened.

with

incubator.

too

hard

fresh

air

label

should

parts,

free

to

go.

The

the

The

to

not

17.

18.

19.

Replace

Before

incubator

make

correctly

With a damp

surfaces

control

the

being

should

sure

carried

to

panel.

mattress

declared

be

that

the

out.

cloth

remove

and

close

fit

for

service,

briefly

operated

re-assembly

wipe

all

extemal

grime.

Include

the

has

the

canopy.

the

to

been

front

Page 17

TS2

Thermocot

Service

SIRIA

PES

Е

AO

な

ES

o

LESSE

Boe

の

Manual

2.15

ος

EZIO

RE

か

か

の

の

SOLITA

o

RÁNA

κο

μα

En.

eM

NS

Heaters

des

ee

removed,

showing

sitio

SORES

2

Dro:

impeller, 2 sen

A

クン ク 244

DITS

7

И

АИ

~

SOOS

SRM

RA,

a>

ЛЯ

ジン

И

SR

ES

RO

S

577

SOIS

Rox

グン

НЕЕ

SU

Page 18

TS2

Thermocot

Alarms

Power

Failure

Low

Voltage

System

Failure

Fan

Service

Caused

Removal

when

cot

Input

Voltage

below

Fan

less

by:

of

power

switched

normal

than

Manual

12.5%

60%

on

Visible

Alarm

None

Flashing

Flashing

Audible

Alarm

Steady

Flashing

Flashing

Mute

No

15

min

15

min

Mute

Heaters

x

No

action

No

action

Digital

display

(Push

None

|

Normal

|

Normal

Test)

Heater Heater

Sensor

Internal

Battery

Control

Over

Standby

Initiated

temp

Temp

Software

Hardware

Mode

|

of

normal

temp

not

Error

in

five

sensors

Voltage

Air

temp

1°C

from

Air

Temp

Air

temp

Cot

tumed

Main

Switch

RPM

current

correct

one

of

below

more

set

temp

over

over

38°C

on

at

or

the

7.5

volt

than

37.5°C

Flashing

Flashing

None

None

(Standby

Flashing

|

Flashing

Steady

Flashing

15

|

15min

N/A

|

Continuous

min

|

No

action

Cut

off

reset

36°C

Cut

off

Manual

reset

On

at

|

Normal

Normal

N/A

None

(FAn)

(HEA)

(SEn)

(bAt)

light

flashing)

Page 19

TS2

Thermocot

Service

Technical

Description

The

TS2

Thermocot

which

supplies

air

around

nursing

CAUTION

This

Temperature

be

routinely

Underneath

heaters.

down

and

two

nursing

CAUTION

Ensure

blocked

Fresh

If

the

fresh

helping

carbon

positive

any

and

it

staff.

incubator

Return

to

the

rear

of

heaters

area

that

by

Air

fresh

filtered

to

minimise

dioxide.

pressure,

gaps

which

doors.

Oxygen

The

fresh

air

desired

patient's

concentration

flow

continuously

placing

fresh

into

dioxide

to

apply

environment

rate

of

the

air

inlet

the

incubator

build-up.

at a temperature

monitored.

the

fan

the

and

the

blankets,

air

oxygen,

sensor

is a lightweight

warmth

does

not

and

the

infant’s

mattress

air

from

through

mattress.

the

warmed

through

air

inlet

monitor

is

the

vent

holes

sheets

inlet

is

is

added

the

The

circuit

and

there

should

pure

achieved

and

near

closed

there

to

have

the

open,

some

may

oxygen

above

will

the

without

Manual

incubator

an

infant

by

which

is

Servo

Control

temperature

are a fan

the

It

then

end

and

to

accumulation

thus

be

only

time.

oxygen

the

is a danger

and

patient

or

more

the

be a factor

patient’s

vicinity

vent

holes

is

passed

air

re-enters

slots.

end

slots are

any

other

than

circulating

acquires a slight

air

escapes

around

be

closed

and

raise

40%

oxygen.

It

is

important

concentration,

oxygen

of

circulating

set

by

the

of

Skin

should

two

passes

in

the

front

over

the

not

materials.

10

Ipm

of

air,

of

expired

through

the

canopy

if it

is

the

The

of

the

input

to

head.

If

the

being

fed

carbon

the

If

oxygen

the

limited.

is

applied

concentration

Humidity

As

the

recently

area

through

humidity

wet

the

water

through

spill

any

sponges

use a syringe

sponges.

sponges

into

the

the

water.

to

the

holders

sponges.

add

to

Circulation

After

the

warmed

goes

up

along

the

attracted

mode

advantages - the

reducing

the

thus

CAUTION

It

is

the

air

Electronics

The

electronically

which

functions

to

Temperature,

audible

procedure.

down

of

air

movement

radiant

air

velocity

reducing

important

mattress - any

circulation

operation

is

operate.

evaporative

patterns.

by a microprocessor-based

relatively

it

performs,

The

turn

alarms

The

with

the

fresh

achieved

warmed

end

If

by

Either

water,

add

air

skin

into the

canopy

heat

around

to

keep

blockage

of

the

sophisticated

user

the

and

microprocessor

in

the

air

re-enters

slots,

it

passes

elevated

putting a small

and

Do

remove

or

water

passes

losses

heaters

but

is

perform a rudimentary

allowing

not

leave

to

of

the

retum

has

two

is

kept

the

infant

heat

clear

quite

able

unit

humidity

overfill

and

the

out

canopy

from

the

can

and

only

ON

air

inlet

incubator

the

nursing

over

the

is

amount

it

to

soak

the

holders

soak

the

them

in

place

holders.

of

the

end

before

air

vents.

This

significant

warm,

thereby

the

infant;

is

relatively

losses.

vent

holes

interfere

fan

is

controlled

in

the

variety

simple

for

to

adjust

and

OFF,

is

all

the

time

open,

is

required,

of

up

or

and

slots,

it

being

and

low,

around

with

the

system

of

the

user

the

Set

mute

test

Page 20

TS2

Thermocot

Service

Manual

scanning 5 temperature

sensor,

battery

operation.

microprocessor

of

calculations

heater

conditions

Alarms

Refer

causes

In

is

sounds.

light.

restoration

Most

accompanied

alarm.

minutes

indicates

When

mode

There

The

37.5°C

functioning

Over

Hardware

triggered

and

any

heater

voltage

the

information

power

to

the

and

the

event

switched

It

The

other

The

by

that

the

is

cancelled.

are

first

activates

and

Temperature

if

this

is

other

normal

power,

and

monitoring

As

it

runs

through

is

constantly

it

is

and

decisions,

and

fan

are

detected,

Alarms

effects

of a power

on,

is a steady

alarm

of

alarms

audible

pushing

alarm

two

if

correctly - this

Overtemperature

the

independent

Chart

of

fault

the

Power

tone,

can

only

power

or

come

by a similarly

alarm

the

the

Mute

condition

types

of

if

the

the

microprocessor

Alarm.

air

temperature

control

sensors, a fan

input

voltage,

its

own

its

program,

checking

receiving,

speed.

alarms

failure

be

turning

on

can

Mute. A flashing

mode

Over

air

of

circuitry.

making

and

controlling

If

any

fault

are

initiated.

for a quick

conditions.

while

Fail

audible

and

there

cancelled

off

the

as

flashing

modulated

he

cancelled

has

been

is

cleared,

Temperature

temperature

itself

is

called

the

There

is

also

Alarm

which

exceeds

the

microprocessor

speed

internal

correct

the

the

validity

the

guide

to

(Page

19)

the

incubator

alarm

is

no

alarm

by

incubator.

red

lights

audible

for

red

selected.

the

Mute

alarm.

exceeds

is

Software

a

is

38.0°C,

the

15

light

and

Whereas

will

36.0°C

Hardware

heaters,

only

Immediate

Overtemperature

A

supply

i.e.

The

air

Set

heaters

incubator's

the

be

A

failure

of

attended

be

transferred

cause

pushing

current,

could

(HEA),

(bAt).

If

there

be a continuous

the

reset

itself

and

restore

Overtemperture

gives a Steady

be

reset

attention

Low

Voltage

voltage

on a 12

temperature

temperature,

situation.

required.

System

nursing

withdrawn

volt

Control

Temp

and

fan

control

The

alarm

with

the

staff,

to

by a technician.

to

of a System

the

Test

and

reading

be

sensor

fan

failure

is a total

Software

by

However,

from

another

Overtemperature

when

the

power

audible

tuming

is

required

Alarm.

alarm

indicates

is

12.5%

below

supply,

is

continue

incubator,

which

failure

down

alarm

more

than

either

above

system

nursing

Audible

indicates

should

service,

as

alarm

button,

the

(SEn), a heater

(FAn)

or a flat

control

audible

system

alarm

incubator

to

the

Alarm

alarm

off

the

incubator.

for

that

its

to

10.5

indicates

1.0°C

or

to

run,

will

attempt

intervention

alarm

can

that

there

outside

be

The

and

the

soon

as

can

be

diagnosed

while

the

message

internal

failure,

and

alarm

cools

to

heaters,

nominal

below.

and

immediately

incubator

possible.

the

locks

out the

and

can

either

the

incoming

value

volts.

that

the

away

from

The

the

to

remedy

be

muted.

has

been

of

the

control

should

patient

The

by

alarm

is

displayed.

failure

battery

there

no

displays.

Actual

the

may

a

It

will

Page 21

TSZ

Thermocot

Service

Manual

Display

The

digital

display

shows

the

actual

infant.

Calculations

microprocessor

temperature

accurately

nursing

Set

Temperature

To

read

(A)

or

reading,

seconds

Temperature

digital

Actual

Test

Pushing

causes

operator

Alarm

alarm,

diagnostic

known

area.

the

the

Down

touch

and

display

air

temperature

the

all

the

can

is

also

pushing

message

sensors

Set

hold

Test

see

Standby

When

the

incubator

automatically

condition

temperature

operate,

air

Standby

alarm

pushing

ready

associated

is

not

the

thus

drawn

light

which

Mute.

for

immediate

with

is

on

the

air

temperature

performed

on

readings

allow

without

Temperature,

(v)

touch

the

appropriate

it

until

is

reached.

indicate

displays

tested.

the

into

heaters

regulated.

saving

flashes,

can

The

whether

or

button

to

if

any

are

When

Test

to

be

is

first

Standby

are

wear

through

and

be

permanently

incubator

use,

full

operation.

front

panel

normally

around

by

the

from

the

5

this

temperature

having a sensor

push

either

button.

the

The

the

during

be

button

activated,

the

without

To

button

desired

lights

above

the

reading

Set

temperature.

normal

activated,

faulty.

The

there

is a System

causes

displayed.

switched

mode.

In

The

fan

does

on

the

fan

inlet

filter.

there

is

an

cancelled

is

thus

the

Warm

change

Set

on

this

and

the

to

in

the

the

for

2

the

is

operation

so

that

Audible

an

alarm

it

goes

their

not

motor,

The

audible

by

kept

warm,

wear

up

time,

be

the

Up

the

the

and

through

about

mode,

is

switch

use

15%

of

push

necessary

on.

the

Memory

When

the

incubator

intentionally

is

pulled

out

Temperature

or

Operational,

temporary

time,

in

Standby

sounding,

default,

Power

The

supply

12v

disconnect

the

of

anticlockwise

Now

new

clockwise

make

Filter

The

replaced

dark,

flow.

environments,

filter

memory

restoration

mode,

and

32.0°C

Supply

TS2

Thermocot

voltages;

d.c.

To

change

the

incubator

attach

power

until

any

other

fresh

air

every

seems

or

If

the

incubator

more

frequently.

of

this

Standby

normal.

On

button.

to

switch

or

by

accident

or

there

and

the

are

automatically

for

of

power

with

the

Set

until

240v

from

power

by

the

until

power

the

supply,

it

is

adjustments.

inlet

filter

months,

6

be

to

will

it

mode,

To

go

to

To

off

the

is

switched

(e.g.

is a power

mode

of

about

will

an

audible

Temperature

reset

is

it

will

operate

a.c.,

115v

one

supply

at

cable

screwing

connector

cable

screwing

tight.

It

is

should

when

or

restricting

is

used

necessary

be

is

reduced

full

Operational

revert

to

Standby

incubator

failure),

operation,

one

set

by

the

the

designated

the

not

be

in

and

off,

either

the

power

the

Standby

stored

in

hour.

After

the

incubator

alarm

will

be,

Operator.

the

from 4 different

a.c.,

24v

d.c.,

to

another,

hand

right

retaining

away.

comes

for

retaining

necessary

routinely

noticeably

is

it

fresh

inlet

dusty

change

to

to

it

then

cord

Set

this

by

and

end

ring

the

ring

to

air

the

Page 22

TS2

Thermocot

Routine

Maintenance

Every

cleaning

Mechanical

—

2

3

4

5

Listen

6

Check

need

Six

Change

Check

the

dirty.

or

Check

for

plastic

in

Iscanopy

parts,

canopy

for

fan

no

Months

(q.v.)

the

filter.

seals-still

damage-look

split

or

doors.

latch

o.k.?

excessive

speed

(on

maintenance

Service

Manual

Technical

-

apart

in

place,

for

in

mattress,

noise.

diagnostics);

(do

chips

not

from

cracked

or

cracks

chips

motor

oil).

or

or

cracks

split,

in

should

Calibration

Procedure

There

are

are

only

two

be

made-

one

for

the

Incubator

align

with

the

digital

readout,

the

Hardware

The

Incubator

point

100mm

mattress

black-painted

1mm

thick,

Set

the

incubator

stabilized,

the

cerice

readout

Temperature.

of

37.0°C

necessary.

Overtemperature

Temperature

above

using

a

brass

aligned

adjust

of

the

is

the

same

Check

and

33.0°C

the

thermocouple

disk,

horizontally.

to

run

the

calibration

incubator)

as

the

and

calibration

Temperature

and

is

measured

exact

centre

attached

25mm

in

at

34.0°C.

pot

so

that

the

Incubator

calibration

make

adjustments

adjustments

the

other

alarm.

at

of

the

to

diameter

When

it

(closest

the

digital

at

Set

points

to

to

for

a

a

and

has

to

if

7.

Canopy

8

Self

9

Are

10

Is

11

Measure

12

Check

13

Replace

14

Carefully

incubator

fluff.

door

test.

heaters

impeller

earth

over-temp.

on-board

vacuum

to

function

secure?

secure

ieakage,

ren-ove

-

adjust

on

shaft?

operating

battery

clean

inside

accumulated

(9

volt).

if

necessary.

currents.

bottom

dust

of

and

To

set

the

overtemperature

stabilize

Then

followed

Set

will

buttons

Incubator

Temperature-

on

should

So

should

is

correct

triggered,

OFF.

re-stabilize

the

push

by

Temperature

commence

so

that

Temperature.

the

brass

have

that

this

happens.

be

at

and

the

Allow

the

at

incubator

the

Diagnostic

the

Test

of

39.0°C

to

rise.

there

as

measured

disc-

reaches

sounded;

about

37.8°C.

consistent.

circuit

can

incubator

36.0°C.

alarm

temperature

button

button

Ideally

Push

is

a

digital

When

38.0°C

adjust

Repeat

Once

only

to

once-

and

one

by

the

the

be

cool

point,

at

36.0°C.

3

times

this

selects

the

temperature

of

the

SET

display

the

Incubator

the

thermocouple

the

alarm

pot

(left

trigger

the

test

the

alarm

reset

by

before

trying

first

of

hand)

point

until

has

turning

a

it

to

Page 23

TS2

Thermocot

Service

Manual

Air

ur

AMBIENT

EMPERA

SENSOR

Flow

Г

|

Diagram

|

p

NOS

LR

&

FRESH

as

|

fr

~

SENSO

2

im,

SEND.

I

LT

>

N

1

|

FHM

m

BB

©

Page 24

‘à

3

TS2

Thermocot

Service

Manual

Circuit

Breakers

Serial

Number

Calibration

Slot

Turn

anti-clockwise

to

release

Page 25

TS2

Thermocot

Parts

Item

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

31

32

33

34

35

36

37

38

39

40

41

42

Service

List

Part

9012-002-00

9012-003-00

9012-005-00

9012-004-00

9012-006-00

9013-101-00

9027-018-00

9100-001-00

9012-010

9012-009-00

9012-001-00

9013-102-00

9027-017-00

9001-101-00

9001-102-00

9016-003-00

9015-002-00

9016-001-00

9100-002-00

9100-003-00

9006-000-00

9015-005-00

9015-003-00

9100-004-00

9015-004-00

9100-005-00

9015-001-00

9015-006-00

9020-001-00

9022-000-00

9023-001-00

9026-004-00

9024-001-00

9030-000-00

9026-002-00

9029-000-00

9100-006-00

9100-007-00

9100-008-00

9100-009-00

9016-002-00

9026-005-00

Manual

General

-

No.

-00

Assembly

Description

Hinge

Hinge

Hinge,

Hinge

Hinge

Cable

Cable

Label,

Handle

Cover,

Screw,

Screw,

Front

Label,

Nipple,

Hex

Nut,

Buzzer,

Screw,

Cover,

Sensor,

Liner,

Heater

Baffle

Screw,

Screw,

Washer,

Label,

Infant

Breaker

Breaker

Breaker

Breaker

Breaker

Circ.

Bkt.

Arm

HD.

Soc.

C/W

Circuit

Back

Bkt.

Arm

Assembly,

Assembly,

Power

Right

HD.

Phil.

Slotted

Assembly

Panel

Oxygen

Oxygen

Sonalert

Tap

Self

Hand

Left

Ambient

Screws

C/W

Assembly

Assembly

Slotted

LD.4mm

Head,

Hex

6mm

LD.

Canopy

Restraint

Circuit

Circuit

Circuit

Circuit

Label,

R.H.

R.H.

Screw,

Axle,

Cover,

Panel,

L.H.

L.H.

Sponge

Tray

Thumbscrew

Mattress

Impeller

Washer,

1.0

2.0

20.0

10.0

Assy.

Cap,

End

Breaker

Assy.

12V

240V

Lead

Hand

No.10

Pan

Supply

MC-07-1305

End

Temp.

PanHD.

M6

Release

Hamess

AMP

AMP

AMP

AMP

End

HD.

and

M6

Stops

M4

Hose

Washers

M4

Qty

1

2

1

1

1

1

1

4

1

1

1

1

1

1

1

1

2

1

2

8

1

1

1

1

1

4

1

1

1

2

1

2

1

4

1

1

2

2

4

4

1

1

Page 26

TS2

Thermocot

Service

Manual

General

Assembly

mene

En

SPONGE

&

WASHERS

SENSOR

fiNCL.

mee)

NUTS}

27}

^

LH.

END

22)

LABEL

3

LINER

ASSY.

RH,

6

)BRACKET

SSEMBLY

HINGE

INSERT

(BAFFLE)

MS

[

|

O

7

1

FRONT

ASSY.

RH.

HINGE

8 ) SCREW

PANEL

DRG.

SEE

ARM

ο

(21

an

HARNESS

UM. HINGE

BRACKET

11)

BACK

oe

/

PANEL

ASSEMBLY

—

CON

U

Page 27

TS2

Thermocot

Service