Page 1

Medishield

MID-O-GAS

APPARATUS

SERVICING

INSTRUCTIONS

EOUIPMENT

Mid-O-Gas

and

TM36

SPECIAL

Test

(i)

(ii)

Inclined

Oxygen

Wright

Box

Screw

Open

Allen

Approved

TOOLS

Unit with

Vacuum

Oxygen

water

analyser

Respirometer

spanner,

driver,

ended

key,

5/32”

oxygen

PREVENTIVE

(Recommended

otherwise

specified).

Check

1

2

3

4

5

6

7

8

9

COVERED

Analgesic

Apparatus,

(obsolete).

AND

adaptor

for

measurement

analyser

tube

manometer

0-100%

4""

BSW

4’’

diameter

spanners:

3/8”

16

compatible

MAINTENANCE

every 3 to 6 months

Nature

Basic

Leak

Inspiratory

Output

Alarm

test

Emergency

Primary

Exhale

Final

of

Service

assembly

test

effort

composition

whistle

oxygen

regulator

valve

performance

Test

TEST

EQUIPMENT

(ref.

(ref.

Fig.

O2

,

.

by

4”

Α.Ε.

mm

lubricant.

inspection.

test

test

and

air

valve

servicing

TM111,

Fig.

TM114,

2)

2)

blade

length.

PROGRAMME

unless

vaive

function

performance

(annually)

Do

not

test

Always

Use only

cleaning.

DETAILED

Check

Inspect

damage.

Check

corrugated

or

Inspect

correct

thread

support

Check

master

signs

damage

wall

use

1.

apparatus

Ensure

of

gas

colour

stem,

equipment

test

apparatus

lint-free

SERVICING

Basic

Assembly

all

control

breathing

perishing.

supply

coding

and

base,

attachment

by

as

cloth

for

PROCEDURE

for

cleanliness

labelling

valve

tube

and

hoses

and

and

handwheel

effective

and

castors

security,

inhaling

internal

Inspection

is

for

through

detailed.

and

and

clear

and

positive

face

mask

connections

sealing.

for

damage.

where

it.

external

signs

of.

intact.

action,

for

dama:

for

identificatior

Examine

applicable.

Procedures

A

B

C

SERVICING

Oxygen

flammable

all

non-approved

Use

teak

soap

for

removed

reacts

components

only

approved

detector

completely

leak

detection.

at

Setting

oxygen

Dismantling

Reassembly

PRECAUTIONS

explosively

solvents,

the

When

keep

them

solvents,

solvents

solution,

dissolved

All

completion

percentage.

procedure

procedure

with

handling

free

and

foreign

and

Snoop

traces

solution,

in

water,

of

of

testing.

oil,

grease,

and

dismantling

from

oil,

grease,

materials.

lubricants.

or

may

be

deposit

must

and

CIG

pure

used

be

Check

2.1 _ Turn

.

2.2

2.

Leak

Test

on

master

Remove

unit

outlet

bubble

K a significant,

a

high

suspect.

Setting

technique.

If

an

control

the

ance

corrugated

outlet

connection.

and

bubble

leak

is

pressure

Refer

Procedure

intermittent

regulator

Dismantling

technique.

control

breathing

test

for

allowable.

continuous

in

the

control

to

the

Oxygen

for

the

delivery

seat

is

suspect.

Procedure

valve.

tube

Partially

correction

occlude

leaks. A slow

leak

occurs

regulator

Percentage

occurs a leaky

Refer

for

the

mainten-

from

then

is

to

Page 2

Check

3.1

3.2

3.

inspiratory

Connect

manometer

apparatus

gently

and

pressure

Check

of

flow.

A

indicates

valve

section

that

-1

to

high

resistance

shut-off

on

as

-2

Effort

the

Test

Unit

attachment

outlet.

cm

that

release

the

bag

an

indicated

H20

cleaning

disc

Squeeze

to

at

is

Dismantling

Test

with a water

(Fig.

2)

to

the

recoil

create a negative

attempts

initiates

the

required.

to

negative

unrestricted

start

of

of

the

demand

Refer

reform.

pressure

inspiration

Procedure.

tube

the

bag

to

the

6.2

Check

The

are

ment

Press

ensure a minimum

the

O2.

7.

Primary

primary

to

be

serviced

of

the

components.

Procedures

Regulators

Servicing

521483.

the

emergency

apparatus

Regulator

regulators,

annually.

diaphragm

7%0

to

be

followed

Instructions

oxygen

flow

at a composition

of

valve

30

Servicing

Mini-reg

and

Model

This

includes

seat/spindie

Kea

are

detailed

Publication

and

L/min

leaves

of

100%

(Annually)

518495,

replace-

combination

in

the

Mini

Check

4.1

4.2

Check

5.1

5.2

4.

Output

Attach

Analyser

outlet.

Compress

imately 7 to 9 times

note

the

analyser.

Performance

percentage

and

60%

~he

analysed

reading

tf

the

this

tolerance

carried

setting

5.

Alarm

Composition

the

Test

connection

and

the

output

readings

control

oxygen.

gas

is

0%

oxygen

out

as

procedure.

Whistle

Unit

release

percentage

Allowable

mixture

to

+5%.

content

corrective

per

the

and

Test

Turn

off

Press

the

pressure

the

warning

clear

and

oxygen

emergency

within

audible.

supply

the

device

Test

with

an

(Fig.

2)

the

recoil

over

30

are

to

lever

settings

output

reading

adjustment

oxygen

Air

Valve

only.

oxygen

apparatus

alarm

whistle

Oxygen

to

the

apparatus

bag

approx-

seconds

O2

reading

be

taken

of

30%,

variation

to

the

is

outside

is

percentage

Function

valve

to

and

ensure

sounds

and

on

at

the

40%,

of

scale

to

be

reduce

Check

8.1

8.2

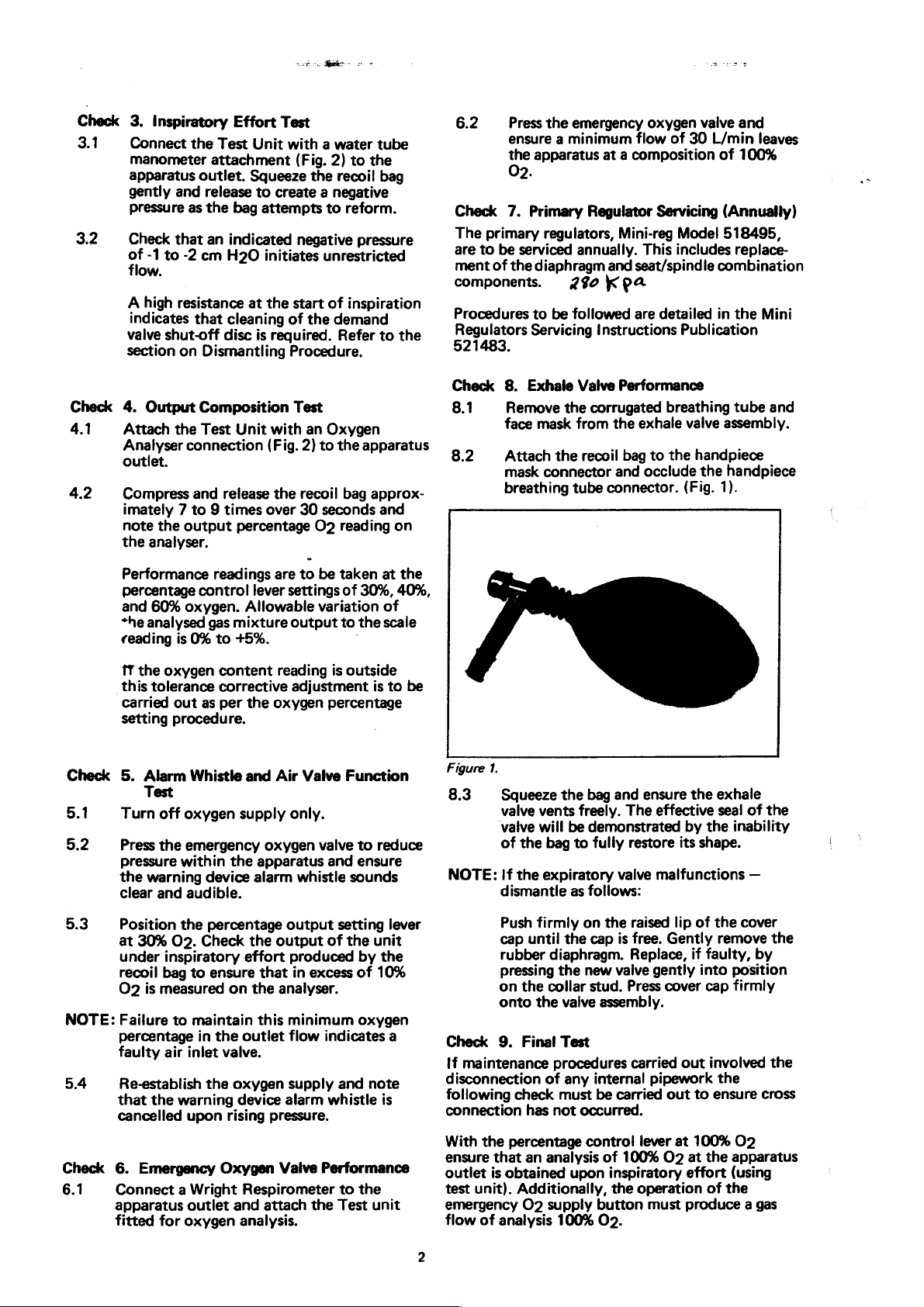

8.

Exhale

Remove

face

mask

Attach

mask

connector

the

breathing

Figure

1.

8.3

NOTE:

Squeeze

valve

vents

valve

will

of

the

bag

If

the

expiratory

dismantle

Valve

the

corrugated

from

recoil

tube

connector.

the bag

freely.

be

demonstrated

to

fully

as

follows:

Performance

breathing

the

exhale

bag

to

the

and

occlude

and

ensure

The

effective

restore

valve

malfunctions

valve

assembly.

handpiece

the

handpiece

(Fig.

1).

the

exhale

seal

by

the

its

shape.

tube

and

of

the

inability

—

5.3

NOTE:

5.4

Check

6.1

Position

at

under

recoil

O2

Faiture

percentage

faulty

Re-establish

that

cancelled

6.

Connect a Wright

apparatus

fitted

the

30%

O2.

inspiratory

bag

to

is

measured

to

maintain

air

inlet

the

warning

upon

Emergency

outlet

for

oxygen

percentage

Check

ensure

in

the

valve.

the

Oxygen

output

the

output

effort

produced

that

on

the

analyser.

this

minimum

outlet

flow

oxygen

device

rising

and

analysis.

supply

alarm

pressure.

Valve

Respirometer

attach

of

in

excess

indicates

whistle

Performance

the

setting

the

unit

by

the

of

10%

oxygen

and

note

is

to

the

Test

unit

lever

a

Push

cap

until

rubber

pressing

on

the

onto

Check

If

disconnection

following

connection

With

ensure

outlet

test

emergency

flow

9.

Final

maintenance

check

has

the

percentage

that

an

is

obtained

unit).

Additionally,

O2

of

analysis

firmly

on

the

cap

diaphragm.

the

new

collar

stud.

the

valve

Test

procedures

of

any

must

not

occurred.

control

analysis

upon

supply

100%

the

raised

is

free.

Replace,

valve

Press

assembly.

carried

interna!

be

pipework

carried

lever

of

100%

inspiratory

the

operation

button

O2.

must

lip

of

Gently

if

faulty,

gently

into

cover

cap

out

out

to

at

100%

O2

at

the

effort

of

produce a gas

the

cover

remove

by

position

firmly

involved

the

ensure

O2

apparatus

(using

the

the

the

cross

Page 3

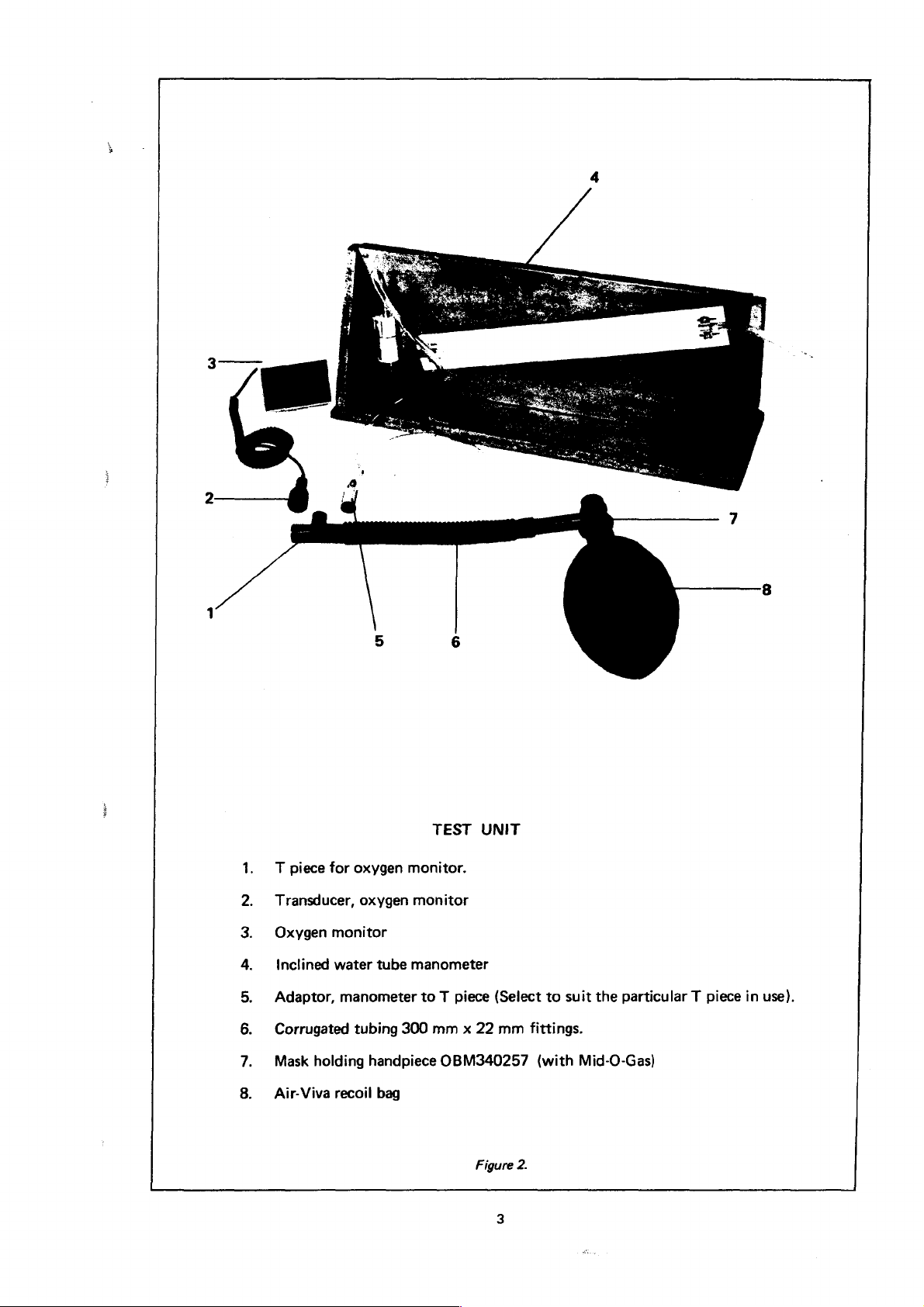

He

T

piece

Transducer,

Oxygen

WH

inclined

δ

Adaptor,

Corrugated

Mask

"on

Air-Viva

o

for

oxygen

monitor

water

manometer

tubing

holding

recoil

oxygen

tube

300

handpiece

bag

TEST

monitor.

monitor

manometer

to T piece

mm x 22

UNIT

{Select

OBM340257

mm

to

suit

fittings.

(with

Mid-O-Gas)

the

particular T piece

in

use).

Figure

2.

Page 4

『

it:

+

Ensure

further

the

Mid-O-Gas

use.

unit

is

re-assembled

ready

for

A.6

PROCEDURES

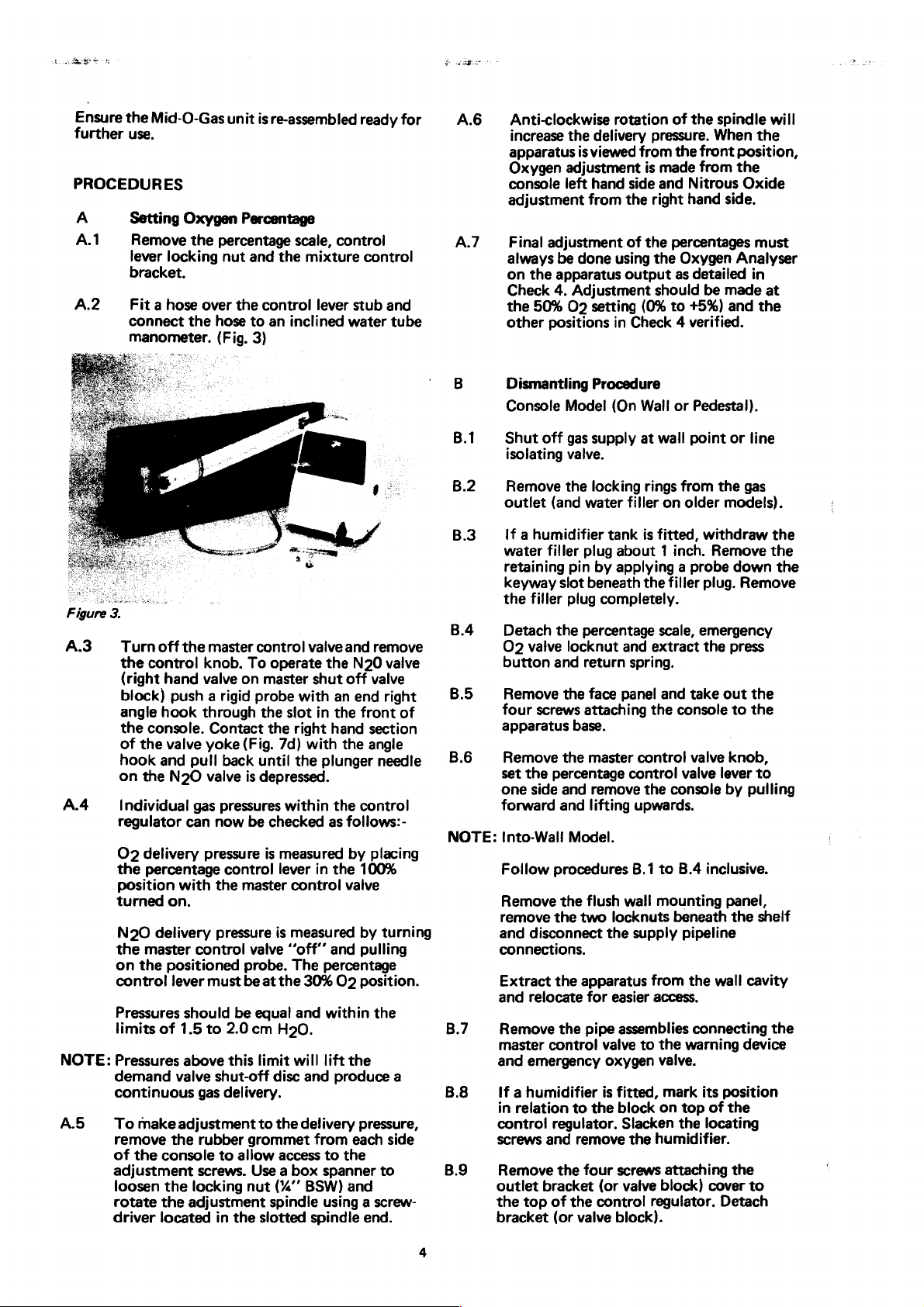

A

A.1

A.2

Setting

Remove

lever

bracket.

Fit a hose

connect

manometer.

Oxygen

the

locking

the

Percentage

percentage

nut

over

the

hose

(Fig.

and

the

control

to

an

3)

scale,

control

mixture

lever

inclined

control

stub

water

A.7

and

tube

B.1

B.2

B.3

Figure

3.

B.4

A.3

A.4

NOTE:

A.5

Turn

off

the

control

(right

hand

block)

angle

the

of

hook

on

Individual

regulator

O2

the

position

turned

N20

the

on

control

Pressures

limits

Pressures

demand

continuous

To

remove

of

adjustment

loosen

rotate

driver

push a rigid

hook

console.

the

valve

and

the

N20

delivery

percentage

on.

delivery

master

the

positioned

lever

of

valve

make

adjustment

the

the

console

the

the

located

the

master

knob.

valve on

through

Contact

yoke

pull

valve

gas

can

pressure

control

To

master

probe

the

the

(Fig.

back

until

is

depressed.

pressures

now

be

checked

is

control

with

the

master

pressure

control

should

1.5

above

gas

rubber

screws. Use a box

locking

adjustment

probe.

must

be

be

to

2.0

this

shut-off

delivery.

to

allow

nut

in

the

valve

at

equal

cm

limit

to

grommet

slotted

valve

operate

shut

with

slot

right

7d)

with

the

within

measured

lever

control

is

measured

‘’off’’

The

the

30%

and

H20.

will

disc

and

the

delivery

access

(%’’

BSW)

spindle

spindle

and

remove

the

N20

valve

off

valve

an

end

right

in

the

front

hand

section

the

angle

plunger

as

in

percentage

within

lift

from

to

spanner

the

control

follows:-

by

placing

the

100%

valve

by

and

pulling

O2

position.

the

produce

pressure,

each

the

needle

turning

the

side

to

and

using a screw-

end.

B.5

of

B.6

NOTE:

B.7

a

B.8

B.9

Anti-clockwise

increase

apparatus

Oxygen

console

adjustment

Final

always

on

Check

the

other

the

adjustment

left

adjustment

be

the

apparatus

4.

Adjustment

50%

O2

positions

is

from

done

Dismantling

Console

Shut

isolating

Remove

outlet

If a humidifier

water

retaining

keyway

the

Detach

O2

button

Remove

four

apparatus

Remove

set

one

forward

into-Wali

Follow

Remove

remove

and

connections.

Extract

and

Remove

master

and

If a humidifier

in

relation

control

screws

Remove

outlet

the

bracket

Model

off

gas

valve.

the

(and

water

filler

plug

pin

slot

beneath

filler

plug

the

percentage

valve

locknut

and

return

the

face

screws

the

side

attaching

base.

the

master

percentage

and

and

Model.

procedures

the

flush

the

two

disconnect

the

apparatus

relocate

for

the

pipe

control

emergency

to

regulator.

and

remove

the

four

bracket

top

of

the

(or

valve

rotation

delivery

viewed

hand

from

is

side

the

of

the

using

output

pressure.

made

and

right

the

should

setting

(0%

in

Check 4 verified.

Procedure

(On

Wall

supply

locking

at

wall

rings

filler

on

tank

is

fitted,

about 1 inch.

by

applying a probe

the

completely.

scale,

and

extract

spring.

panel

and

the

control

control

remove

lifting

the

upwards.

B.1

wall

locknuts

the

supply

to

mounting

from

easier

access.

assemblies

valve

to

the

oxygen

is

the

valve.

fitted,

block

on

mark

Slacken

the

humidifier.

screws

(or

control

valve

regulator.

attaching

block)

block).

of

the

spindle

When

the

front

from

the

Nitrous

hand

side.

percentages

Oxygen

as

to

or

from

older

filler

console

valve

console

B.4

Analyser

detailed

be

made

+5%)

and

Pedestal).

point

or

the

models).

withdraw

Remove

down

plug.

emergency

the

press

take

out

to

valve

knob,

lever

by

inclusive.

panel,

beneath

the

pipeline

the

wall

connecting

warning

its

position

top

of

the

the

locating

the

cover

Detach

will

the

position,

Oxide

must

in

at

the

line

gas

the

the

the

Remove

the

the

to

pulling

shelf

cavity

the

device

to

Page 5

-B.10

Remove

taking

adjusting

on

a

corresponding

ator

position

the

the

body.

same

and

care

shim(s).

side

and

position

inspect

not

of

the

This

the

the

to

damage

Note

the

mixture

mark

on

indicates

disc

must

during

sealing

or

misplace

‘’O’

scribed

control

the

control

the

resetting

be

replaced

assembly.

ring

the

mark

plate

regul-

in

and

set

between a straight

diaphragm

body

point

Adjustment

housing

“A”.

and

the

on

the

allows

(Ref.

bearing

regulator

seat

of

B14).

lever

the

the

edge

face

of

stirrup

arm.

control

setting

across

the

dual

loading

regulator

of

dimension

the

regulator

seat

B.11

B.12

NOTE:

B.13

B.14

If

the

demand

should

cloth

Remove

bonnet

control

by

block.

signs

Care

sealing

or

instrument.

Remove

lever

and

new

Access

requires

unscrewing

disconnection

control

must

spacer

housing

See

mentioned

be

cleaned

and

Methylated

the

and

detach

spring.

sliding

prise

it

Inspect

of

perishing.

must

be

faces

the

bonnet

the

pin

to

the

pin.

Remove

assemblies

to

the

removal

the

valve.

be

loosened

detached

unscrewed

Figure 6 for

items.

valve

shut-off

and

Spirits.

screws

upwards

on

screws

around

the

bonnet

The

diaphragm

towards

the

diaphragm

taken

to

avoid

each

bonnet.

free

attaching

body

and

the

seat

as

required.

control

of

The

regulator

of

the

holding

all

tubing

seat

housing

and

removed,

and

the

and

identification

disc

polished

with a soft

each

regulator

and

is

removed

the

for

damaging

Do

not

with a sharp

the

seat

extract

assembly,

seat

base

plate

locknuts

to

and

the

locknuts

the

regulator

removed.

of

above-

is

dirty

it

diaphragm

control

damage

the

by

master

seat

or

the

lever

lever

replace

assembly

inlet

NOTE:

C.3

it

is

recommended

setting

procedure.

the

diaphragm

stirrup,

It

is

recommended

diaphragm

tool

retainer

diaphragm).

is

located

when

regulator

Before

ensure

common

opposite

The

the

face

the

in

the

bonnet

body.

positioning

the

regulator

extended

peripheral

diaphragm

threaded

prior

to

bonnet

that a suitable

be

made

is

replaced

assembly

diaphragm

It

is

essential

an

even,

is

the

centre

holes

holes

in

attaching

retaining

to

aid

this

that,

when

by a complete

(including

that

unstressed

screwed

diaphragm

stirrup

line

diaphragm

must

neatly

the

regulator

the

bonnet.

screws

dimension

measurement

necessary,

regulator

plate

and

the

diaphragm

condition

to

the

dual

assembly

aligns

with

between

holes.

lie

body

Tighten

evenly.

the

two

(Fig.

over

4)

B.15

C.1

0.2

For

assembly

air

inlet

and

master

relevant

Re-Assembly

The

apparatus

order

of

cleanliness

and a re-inspection

should

The

following

attention.

Before

seat

lever

pin

is

sitting

When

re-positioning

seat

housing

dimension

drawing,

seat

lever

held

firmly

a

dimension

detail

apparatus,

shut

off

diagrams

Procedure

is

the

Dismantling

of

all

be

carried

details

tightening

pin

to

the

within

and

nominated

(Fig.

6)

pin

installed

bearing

of

18

emergency

attached.

re-assembled

components

of

out.

the

seat

must

on

mm

on

the

valve,

all

require

screws

body

its

groove

the

control

lever

“А”

be

and

the

(0.71

warning

oxygen

refer

to

the

(Figure

in

the

Procedure.

is

essential

items

for

damage

particular

holding

ensure

in

the

critical

on

sectional

that

the

regulator

achieved.

the

seat

seat

assembly

inches)

device/

valve

7).

reverse

The

the

the

body.

With

lever

is

C4

C.5

Figure

4.

if

the

mixture

eguivalent

regulator

carefully

operation

“O”

ring

may

be

required

Replace

Ensure

control

body

percentage

the

scale

are

54%

when

“’O’’

that

plate

O2

Warning:

marks

and

are

pre-set

of

the

mixture

be

conducted

mination

control

bearing

body

is

until

flat.

an

additional

in

the

top

ring

the

setting

and

aligned

control

position

the

setting

The

above

the

percentage

during

control

without

that

the

plate

face

on

the

worn

or

scratched,

Following

shim

of

the

control

to

obtain a good

if

worn

or

marks

the

control

during

lever

on

marks

assembly,

must

the

mentioned

scale

manufacture.

disc

only

accurate

control

apertures

seat

or

the

control

lap

the

lapping

beneath

the

disc

seal.

damaged.

on

the

mixture

regulator

The

be

indicating

percentage

are

aligned.

setting

location

Replacement

must

not

deter-

are

Page 6

equal

and

the

54%

in

the

when

percentage

O2.

This

field

the

setting

control

operation

situation.

marks

lever

is

not

are

aligned

indicates

recommended

Bee

C.6

Conduct

Bubble

apparatus

conditions

test

Checks

all

under

after

2,

3,

and 4 after

sealing

joints

full

supply

re-assembly.

re-assembly.

on

the

pressure

Figure

5.

.

Item

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

ITEMS

Part

No.

M1110

OBM340257

NB705

OBM372748

NB559

DM427

OR27A1

DM435

OR9A2

DM423

DM421

OR12A2

DM431

DM432

DM430

DM429

NB538

REPLACEABLE

PARTS

UNDER

Description

Facemask,

Handpiece,

Grommet,

Corrugated

Knob,

Shim,

"O"

Disc,

“O”

Seat

Housing,

“O”

Diaphragm

Lever,

Plate,

Stirrup,

Retainer,

anti-static

mask

%’’

tube,

master

control

ring

shut-off,

ring

assembly

seat

ring

seat

diaphragm

regulator

%’’

LIST

MAINTENANCE

holding

dia.

hole

one

metre,

shut-off

adjusting

demand

dia.

valve

valve

SERVICE

anti-static

Qty.

1

1

2

1

1

As

Required

1

1

2

2

2

2

2

2

2

2

2

Page 7

Fig. 6 Control

Regulator

and

Mixture

Control

6

/

;

SET

11)

POSITION

TO

OBTAIN

}

ーー-

Mixture

Control

Plate

17

16

OF

18

SEAT

mm

HERE.

ジス

o

HOUSING

ンジ

IN

M

“J

x

22

ラン

クン

の

の

A

Pi

|

'

|

-

+]

K

SS

Ñ

Ny

N

N

M s

40

N

Rİ

BN

AN

N

TON

让

4

プ

GIA,

NS

3

Г,

x

NS

>

レーン

NY

SN

クン

|

I

iF

ンク

|

TT

4

=>

7

8

7

15

14

13

518495

(301112)

|

P

4

+

—

-|

=

_

-

/

A

SY

0

à

NTFS

の

NS

NN

Si # No

NS

“

,

TR

GA

レン

、

IEA

。

VANS

ノン

~

7

~,

4

~

12

11

i

10

A

>

KN

k

A

DN

、

、

ヽ

XS

AN

、

M

AROSA

I

a

A.

s

s

N

N

>

n

、

S

BO

E

AFFATTO

S

a

>

>

、

x y i

è

M

Ba

KESK

7.

+

,

レ ェ ン

ング

^

NAAN

シン

+

i

ン

2

i

LR

ン

ルン

ØS

,

N

7

D

(Holding

J

B

(Inlet

(Seat

(Seat

.

housing

housing-adjusting

locknut

spacer)

locknut)

not

shown)

nut)

Page 8

1

TO

ALARM

TO

MACHINE

OUTLET

WHISTLE

>

AIR INLET

VALVE

:

4

>

2

(D7

Figure

7

E)

INLET

ο,

ΙΝΙΕΤ

-----

(Α)

(D) i

8

J

>

İp

9)

VA

- 3 long.

/

(10

4

Note:

(item

Jİ

AJ

13

and

spindle with

0.2

mm

with

and

seat

Cut

to

9)

Assemble

14

clearance

spindle

shut,

spring

17

on

central

0.1

fully

mm

items

to

out

Item

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

CIG

ププ

プア

ШЕЕ}

ノン

The

(Incorporated

Nedishieid

Macquarie

—

11-17

Part

No.

DM468

M537

M543

DM474

NB1284

OR1A2

7968003

AT45

NS9

NS37

DM464

OR1A2

DM453

DM454

NB493

DM462

Commonwealth

Khartoum

South

New

in

Division

Technology

Industrial

Wales)

Road,

North

Description

Washer

Filter

Collar

Gases

Centre

Ryde,

Diaphragm

safety

Cap,

safety

Disc,

Neoprene

ring

“O”

Valve,

Spring,

Seat

Screw,

“O”

Washer,

Screw,

Yoke

Schrader

air

(complete)

gland

ring

P.T.F.E.

socket,

Limited

N.S.W.

2113.

8

valve

valve

washer

valve

3/16"

BSW

x

3/16”

Lg.

Oty.

2

1

1

1

1

1

1

2

2

2

2

2

1

1

1

1

Publication

1,

ssue

521467

January

AP/500/181

1981

Page 9

AdO9

NOILVOISILNSQI

Siva

ャ

6/

|

TESTİ

80

SWIVIHAVIC

1V3S

688218

ΟΙΛΞ3Α

IN3W39V

ININGVM

Iddd

SVI-O-GIW

30

SQOUVMOI

NIVIHAVIO

30IS

HLOONS

098213

JI

TIOHINOO

YITIOH

MAN

0315

YSONNId

688313

SOJVMOL

WNIVIHAVIO

30IS

HLOOWS

ONV

(688316)

ON

|140009

vd

|

"(098C1S)

(898015)

NOTIVTIVISNI

8600464

831114

3ZNO88

{

8928213

ἀνο

MAN

ーーー

1

ヨ

TNr

|

“0

HA

AVI

WNIVIHAVIO

80*0/60*0

(658618)

40

39VH4

JO

и043

NIVIHAVIA

3ATI9

SSINADFHL

NOI1V9131.1N301

|

dais

IVIZILVW

Ol

SALON

A

1SM3SSV

CIYINDIY

SYNSVSW

IAOWIU

31

/1

OL

HSYNDS

JI0I0H

403

3YNOJIOJA

ヨ

AGBV

1Y

コ

ヨコ

d

ヨ d

AP?»

/

ㅇ

Page 10

COMWELD

MEDICAL

GROUP

PRODUCTS

Neg

em

Kit

ee

AAA

ие

INSTALLATION

I.

DESCRIPTION

Kit

TMIH

It

contains

in

fittings,

2~

GENERAL

2.1

Norgren

Norgren

and

then

2.2

Diameter

To

prevent

the

Oxygen

Nitrous

2.3

Snap

Gauge

Both

check

2.4

Thread

sealants.

For

general

For

prevent

INSTRUCTIONS - KIT

Pt.No.512467

and

INFORMATION

Regulators.

regulators

the

regulator

installing

Coding

Oxide

Testing.

Norgren

the

outlet

the

1/8

the

is a replacement

TM114.

Norgren

and a number

gas

connections

use,

BSP

fitting

regulators,

have 1 inlet

seat

ensure

of

Tubing.

cross

connections.

regulators

pressure.

Loctite

regulator

from

Pt.No.

which

of

special

port

is

visible

through

that

the

supply

connection,

and

have a connection

S20

turning

the

This

Pipe

to

snap

the

5/16

fitting

Sealant

gauge

when a snap

512467

primary

adaptors.

regulator

have

been

and 3 outlet

the port.

gas

is

connected

1/4

inch.

diameter

inch.

diameter

to

which a snap

is

normally

is

recommended.

fitting-Loctite

gauge

kit

cleaned

ports,

The

to

tubing

tubing

sealed

with a blind

271

is

attached.

for the

for

medical

inlet

the

port

and

and

gauge

or

Loctite

Mid-O-Gas

use,

port

ts

marked

marked

with

fittings

fittings

must

may

be

nipple.

277

apparatus

nylon

tubing,

with

the

arrow.

must

be

be

used

fitted

to

set

is

recommended

an

used

for

TM36,

push

arrow

for

the

and

to

3.

CONTENTS

{tem

Part

1

2

3

4

5

6

7

8

9

10

11

12

13

Number

K50

512258

512434

512443

512454

512455

512456

512460

512464

512465

512466

7966030

521982

Description

Nut

1/4ins.BSP

Regulator

Elbow

Swvl

Elbow

Swvl

Adaptor

Nipple

Elbow

Elbow

Adaptor

Tube

Tube

Circlip

Instructions

Regulator

Blank

Swvl

Swvl 1 1/4BSPT-5/16tube

ON/OFF

1/4

OD

5/16

Bowed

Norgren

OD

0-350Kp

1/8BSPT-1/4tube

1/4BSPT-1/4tube

1/8BSPT-5/16tube

control

Ext.22.2

mm

to

Quantity

elbow

ο

ved

2

2

4

2

2

2

ΕΕ

Net

EN

ΤΕ

님 | 는

dl

Lara

ken

Åen

o!

i

Page 11

4.

PROCEDURE

Notes:-

the

Mid-O-Gas

It

is

important

with

the

Part

No.

1.

Remove

2.

Remove

3.

Disconnect

emergency

4.

Tum

remove

5.

Taking

the

inlets

comers

may

6.

Fit

Elbow

other

.

Fit

Adaptor

Looking

on

regulator,

9.

Fit

the

connected

service.(see

the

swivel

IO.

Fit

Adaptor

Bend

11.

Fit

Adaptor

This

kit

should

apparatus.

that

servicing

521467

the

outer

the

pipes

the

oxygen.

the

unit

over

the

base

care

not

to

the

of

the

be

more

room

item 3 to

Norgren

item 5 to

at

the

then

regulators

for

Oxygen

Note

inlets

item 9 to

the

Adaptor

item 9 to

be

installed

this

procedure

procedures

detailed

case.

connecting

02

and

N20

and

undo

bracket.

to

move

the

secondary

base

regulator.(see

base

place

to

2.2).

to

bracket

if

the

the

inlet

the

opposite

of

the

another

the

main

service and

Position

the

secondary

regulators

when

02

regulator,

Elbow

to

clear

the

Elbow

by a person

is

carried

in

Servicing

the

inlet

pipes

at

the

the

nuts

that

secondary

and

refitted.

inlet

is

positioned

of

one

of

Note

2.1.)

ports

blank

adaptor

item 5 in

assembly:

the

the

regulators

regulators.

item 4 ¿hen

bonnet

of

item 8 then

trained

out

in

block

to

air

valve

secure

regulator

swivel

Refit

the

Norgren

of

both

off

the

making

regulator

to

connect

the

N20

connect

in

the

servicing

conjunction

Instructions,

the

primary

and

the

pull

main

regulators

off

assembly

:

seat

housings,

the

inlets

so

the

base

bracket.

towards

the

front

regulators

regulators.

port

next

clockwise

the

remaining

sure

that

the

with

the

5/16ins.

clear

the

outer

this

assembly

secondary

this

regulator

assembly

of

then

the

PVC

to

the

Slightly

that

they

point

Note:-

comer

and

Elbow

from

port,

of

both

regulator

with

is

connected

case , then

to

the

02

to

the

N20

remove

tube

that

base

bracket,

loosen

towards

In

some

of the

base

item 7 to

the

regulators.

the

for

tighten

outlet

of

outlet

the

regulators.

supplies

the

then

both

locknuts

the

rear

assemblies,

bracket.

the

inlet

inlet

of

the

1/4

ins.

fitting

Nitrous

both

lock

the

inlet

of

the

inlet

-

on

there

of

the

is

Oxide

nuts

block.

block.

on

12.

Using

regulators.

and

the

Fittings

a)

Ensure

b)

Simply

c)

To

dismantle,

13.

Reconnect,

PVC

tubing.

14.

Remove

“A".

If

15.

Fit a snap

At

280kPayLock

16.

Repeat

17.

Complete

Instructions.

Part

No.

521982

the

Nylon

Run

and

adjustment

is:

that

the

end

push

the

simply

the

02

the

secondary

necessary,

gauge

with

the

procedure

the

assembly

Issue

02

Date

198

tubing,

cut

1/4ins.

the

screws

of

the

nylon

tube

into

push

and

N20

regulator

reposition

to

the

02

Norgren

Clip item

using

of

Nylon

of

the

the

collet

the

tube

pipes

the

12.

nitrous

the

Mid-O-Gas

for

02

and

tubing

secondary

tube

is

properly

until

into

the

to

the

air

bonnets

seat

and

housing.

regulator,

Replace

oxide

5/16ins.

so

that

the

regulators.

sguared

it

locates

through

fitting,

hold

valve

and

diaphragms,

(refer

pressurise

the

snap

gauge

for

the

N20

and

check

for

N20,

connect

tubing

is

The

method

off.

the

down

reconnect

in

turn,

to

the

Mid-O-Gas

with

oxygen,

with

Norgren

it's

calibration,

the

not

strained,

of

assembly

'O'

ring.

the

collet

the

emergency

to

check

Servicing

and

Nipple

item

regulator.

in

accordance

inlet

is

then

and

the

set

6.and

block

to

clear

of

the

of

Push

pull

back.

withdraw

oxygen

critical

Instructions)

the

regulator

Nut

item

with

the

Norgren

outer

case

In

Tube

the

tube.

supply

dimension

to

the

Service

Loading...

Loading...