CIAT Yuna II 5H, Yuna II 9H, Yuna II 11H, Yuna II 12HT, Yuna II 15HT User Manual

...

1

Yuna II

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 15.739 A

air-to-water heat pump

Heating nominal capacity : 4 to 15kW

Cooling nominal capacity : 14 to 16kW

The YUNA II air-to-water split heat pump is designed for

heating applications in new, existing individual homes and

small businesses.

When installed alone, YUNA II is compatible with low to

medium temperature emitters (underfloor heating, fan coil

units, water cassettes, radiators, mixed installations, etc.).

YUNA II is also compatible with high temperature emitters for

boiler backup operation.

Each device is tested in the factory and delivered ready for

operation.

YUNA II's range is composed by 6 single-phase and threephase models.

Operation in cooling mode with an outdoor temperature of

0°C to 46°C (only three-phase units).

Operation in heating mode with an outdoor temperature of

-20°C to +30°C.

If the heat pump is the only source of heat:

Below this temperature, heating must be provided by a

separate heating source or an additional electrical supply.

If the heat pump is used for backup operation:

Operates down to the equilibrium point (temperature below

which the heat pump can no longer keep up with heating

needs). Below this point, the heat pump and boiler run

alternately (heat pump OR boiler).

Low Voltage Directive 2006/95/EC

EMC: ElectroMagnectic Compatibility 2004/108/EC

PED: Pressure Equipment Directive 97/23/EC

WEEE: Waste Electrical & Electronic Equipment 2012/19/EU

RoHS: Restriction of Hazardous Substances Directive 2011/65/UE

Use

Range

ConfoRmity

Simple, reliable

,

efficient split heat pump!

Equipped with

CS controller

*Reversible mode only with three-phase models

410A

60

Cooling or

heating

** except three-phase models

***

2

heat pumps - aIR CONDItIONING - ReFRIGeRatION - aIR haNDLING - heat eXChaNGe - Na 15.739 a

air-to-water heat pump

Yuna II

Yuna II air-to-water split system heat pumps with built-in

inverter technology are designed for residential and light

commercial applications. They offer excellent energy efficiency

values, exceptionally quiet operation and meet the most

stringent operating temperature demands.

The units integrate the latest technological innovations: Non-

ozone depleting refrigerant R410A, DC inverter twin-rotary

compressors, low-noise fan and microprocessor control.

With exceptional energy efficiency values, the inverter air-towater split-system heat pumps qualify for local tax reductions

and incentive plans in all the EU countries.

Ecodesign is the European Directive that sets mandatory requirements for Energy related Products (ErP) to improve

their energy efficiency. CIAT supports initiatives to reduce the environmental impact of its products.

Features

■ Wide operating range in both heating and cooling mode

offers high performance in a wide temperature range.

■ DC inverter twin-rotary compressors with Pulse Amplitude

Modulation (PAM) and Pulse Width Modulation (PWM)

provide enhanced reliability, low energy consumption

and smooth vibration-free operation under all operating

conditions.

■ Variable-speed fans with an innovative patented fan blade

shape ensure improved air distribution at exceptionally low

noise levels.

■ Pre-set or customised selection of the appropriate climate

curve for stable output capacity to match the heat load.

■ Output to link and integrate the unit with the existing heat

sources offers a dual-energy approach, increased savings

and optimum comfort in all weather conditions.

■ Able to control two independent comfort zones with a

two-zone kit added to the main comfort module.

■ Leaving water temperature up to 60 °C for radiator and

domestic hot water applications, making hot water readily

available.

Adapted to your needs

■ Heating only or reversible comfort module

■ Backup heating, either electrical (single-energy applications)

or gas boiler (dual-energy applications)

■ Comfort is ensured via the user interface and the possibility

of integrating two leaving water temperature zones.

Advanced technology

■ Electronic system management: Several sensors placed in

key positions in the refrigerant circuit electronically detect

the operational system status. Two micro-controllers receive

the input from the sensors, manage them using advanced

control algorithms and optimise the refrigerant flow and the

functioning of all the core components - the compressor, fan

motors and the pulse modulation valve.

■ The pulse modulation valve, a bi-flow electronic expansion

device, optimises the refrigerant amount in the circuit and the

superheat, and prevents the refrigerant migration back into

the compressor. This device further enhances high system

performance and reliability.

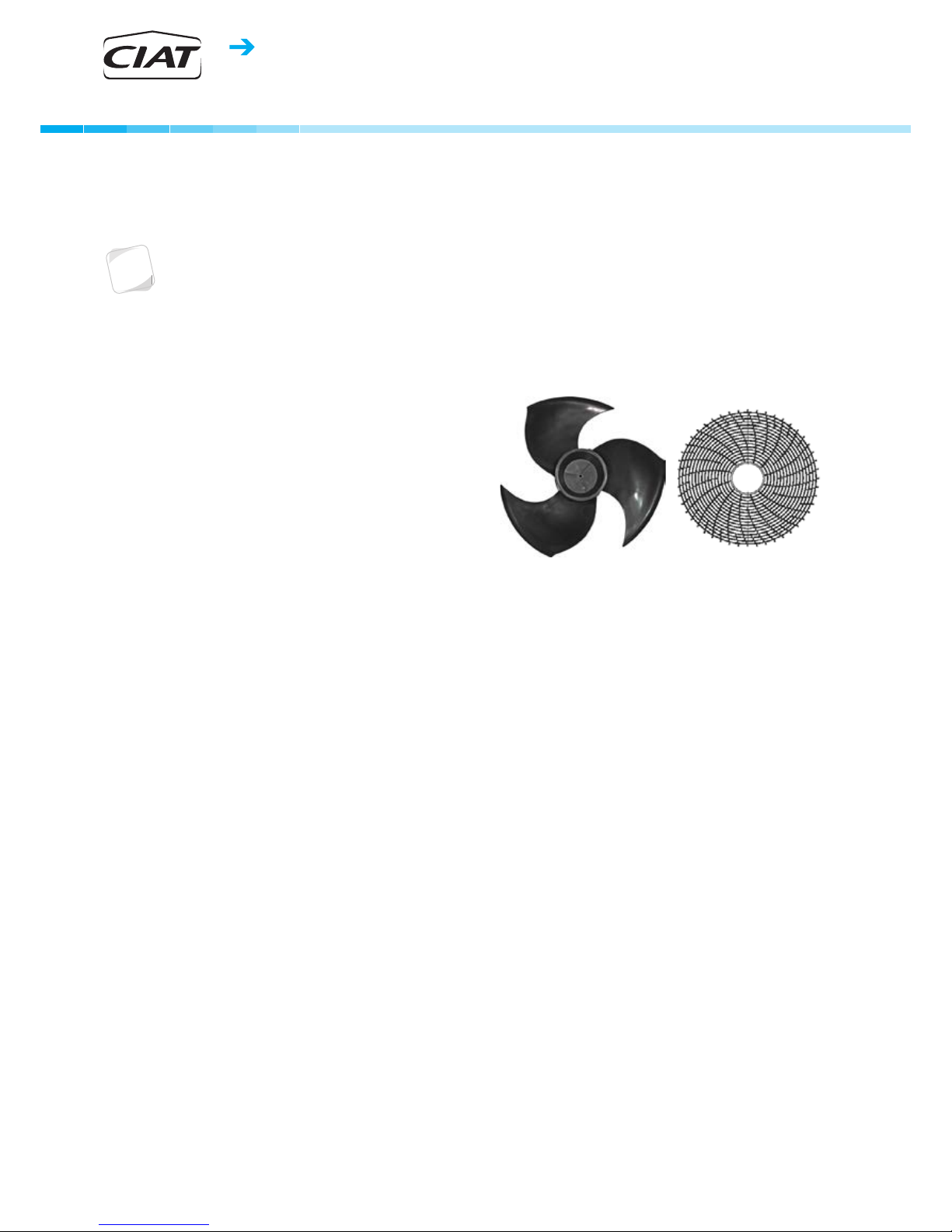

■ The air management system, which consists of a propeller

fan, orifice and an air discharge grille, guarantees minimised

noise levels.

New patented fan blade shape and grille prole with low

pressure drop

Advanced performance

■ Yuna II have an extremely high energy efficiency ratio

in both cooling and heating mode, ensuring significant

energy savings. Large and efficient coils and optimised

circuiting feature ensure that all the combinations meet the

European tax rebate efficiency targets. Efficiency at part-load

conditions (seasonal energy efficiency) reaches the highest

level in the industry.

■ Year-round comfort: The advanced technology used in

Yuna II provides optimised comfort levels for the end

users, both in terms of water temperature control and silent

operation. The desired temperature is quickly reached and

effectively maintained without fluctuations. Yuna II offers

optimised individual comfort levels - both in winter and in

summer.

■ Wide temperature operating range: Yuna II can operate

efficiently in extreme temperature conditions. For end user

comfort the units operate down to -20 °C outdoor temperature

in heating mode, and in the summer, they produce hot water

up to 60 °C at up to 30 °C outside temperature for domestic

hot water applications.

ErP

READY

3

Yuna II

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 15.739 A

air-to-water heat pump

Environmental care

■ Non-ozone depleting refrigerant R410A:

- Chlorine-free refrigerant of the HFC group with zero ozone

depletion potential

- High-density refrigerant, therefore less refrigerant required

- Very efficient, therefore gives an increased energy

efficiency ratio (EER)

■ The new packaging ensures high protection during transport

and handling and is 100% recyclable.

Fast and simple installation and service

■ Easy access to all internal components: Unscrew only three

screws to remove the complete front panel to access the

refrigerant piping connections, control box and electrical

connections, as well as the compressor and other key parts.

■ Advanced circuit design and component selection has

resulted in a compact unit with an exceptionally small footprint that is easy to transport through narrow doors.

■ Reduced weight and a handle on the unit panels to facilitate

transport.

■ No additional buffer tank required. This simplies and speeds

up the installation process.

■ 3-bar pressure relief valve as standard

■ 8-litre internal expansion tank

■ High-temperature refrigerant protection

■ Water flow switch to ensure that the circuits contain enough

water to operate correctly.

■ Various power cable outlet options: Pre-punched holes in

the cabinet panels permit cable exit on the side, front or rear.

■ Dealer service tool connection kit includes the software

and connections to monitor the operating parameters from

a personal computer, giving an easy-to-read display with

visual graphs and statistics indicators.

■ Yuna II units are equipped with 1 inch gas MPT water

connections.

■ Yuna II internal module reduces space requirements and

simplifies the installation. Only the power and the water

supply and return piping need to be connected.

■ Condensate drain piping connection

■ Specially shaped anchorage feet ensure correct and safe

fixing of the unit.

■ The programmable thermostat periodically runs system

checks to monitor and assess the unit operating parameters.

If a problem occurs, troubleshooting fault codes and

messages help the service technician to identify the fault.

DC inverter twin-rotary compressor

■ Advanced technology provides maximum energy-efficiency

with high capacity available at peak conditions and optimised

efficiency at low and mid compressor speeds. Yuna II DC

inverter uses Intelligent Power Drive Unit (IPDU) hybrid

inverter technology, combining two electronic management

logics: Pulse Amplitude Modulation (PAM) and Pulse Width

Modulation (PWM) for optimised compressor operation

in all conditions, minimised temperature fluctuations, and

provides perfect individual comfort control with significantly

reduced energy consumption:

- PAM: Pulse Amplitude Modulation of the direct current

controls the compressor at maximum load conditions

(start-up and peak load), and increases the voltage at fixed

frequency. The compressor works at high speed to rapidly

achieve the desired temperature.

- PWM: Pulse Width Modulation of the direct current controls

the compressor at partial load conditions, and adjusts

the frequency at fixed voltage. The compressor speed is

fine-tuned and the system provides high-level comfort (no

temperature fluctuations) at exceptionally efficient working

conditions.

■ Compressor frequency is increased continuously up to

the maximum level. This ensures that there are no current

draw peaks in the start-up phase and safe connection to a

single-phase power supply even in large-capacity systems.

The maximum operating current of Yuna II is below 12 A

(systems up to 6.5 kW) and below 23 A for larger systems

(up to 11.5 kW). Inverter ramp-up speed makes soft starts

unnecessary and ensures immediate maximum power.

■ The two rotary compression cylinders, offset from each

other by 180°, and the DC brushless motor with the shaft in

perfect balance ensure reduced vibration and noise, even

at very low operating speeds. This results in an extremely

wide range between minimum and maximum capacity

with continuous operation, guaranteeing that the system

is always optimised and provides maximum comfort at

exceptionally high efficiency levels.

■ Twin-rotary cylinders, low vibrations and low load to the

shaft ensure highest compressor reliability and a long

trouble-free operating life.

■ All DC brushless twin-rotary compressors are equipped with

crankcase heaters as standard.

■ A double compressor shield for acoustic insulation further

reduces noise levels.

Superior reliability

■ Exceptional endurance tests:

- All the units are tested at various stages on the production

line for circuit leakage, electrical compliance, water and

refrigerant pressures.

- End-of-line test of all unit operating parameters

- Corrosion resistance test

- Accelerated ageing test on critical components and complete

assembled units, simulating thousands of hours of continuous

operation.

- Packaging crash test to ensure that the units are adequately

protected against accidental shocks

- Extensive field and site testing.

Corrosion-resistant casing

4

heat pumps - aIR CONDItIONING - ReFRIGeRatION - aIR haNDLING - heat eXChaNGe - Na 15.739 a

air-to-water heat pump

Yuna II

Economical operation

■ Increased energy efficiency at part load:

- The exceptionally high energy efficiency of the Yuna II is the

result of a long qualification and optimisation process.

- Use of ambient air as primary source of energy in domestic

heating applications significantly reduces the overall energy

consumption and minimises CO2 emissions.

- Night mode operation at reduced compressor speed, results

in low-noise operation and a significant reduction in energy

consumption.

- Easy-to-set and economical silent mode, reduces the

compressor speed.

- R-410A refrigerant is easier to use than other refrigerant

blends.

GMC board

■ The new GMC controller is specifically developed for

Yuna II, and incorporates new control algorithms. It features

customised or pre-defined climate curves, domestic hot

water control, a night-time noise reduction function, a

defrost/alarm output signal, an external heat source, a pump

block prevention function, freeze protection and compressor

operation management.

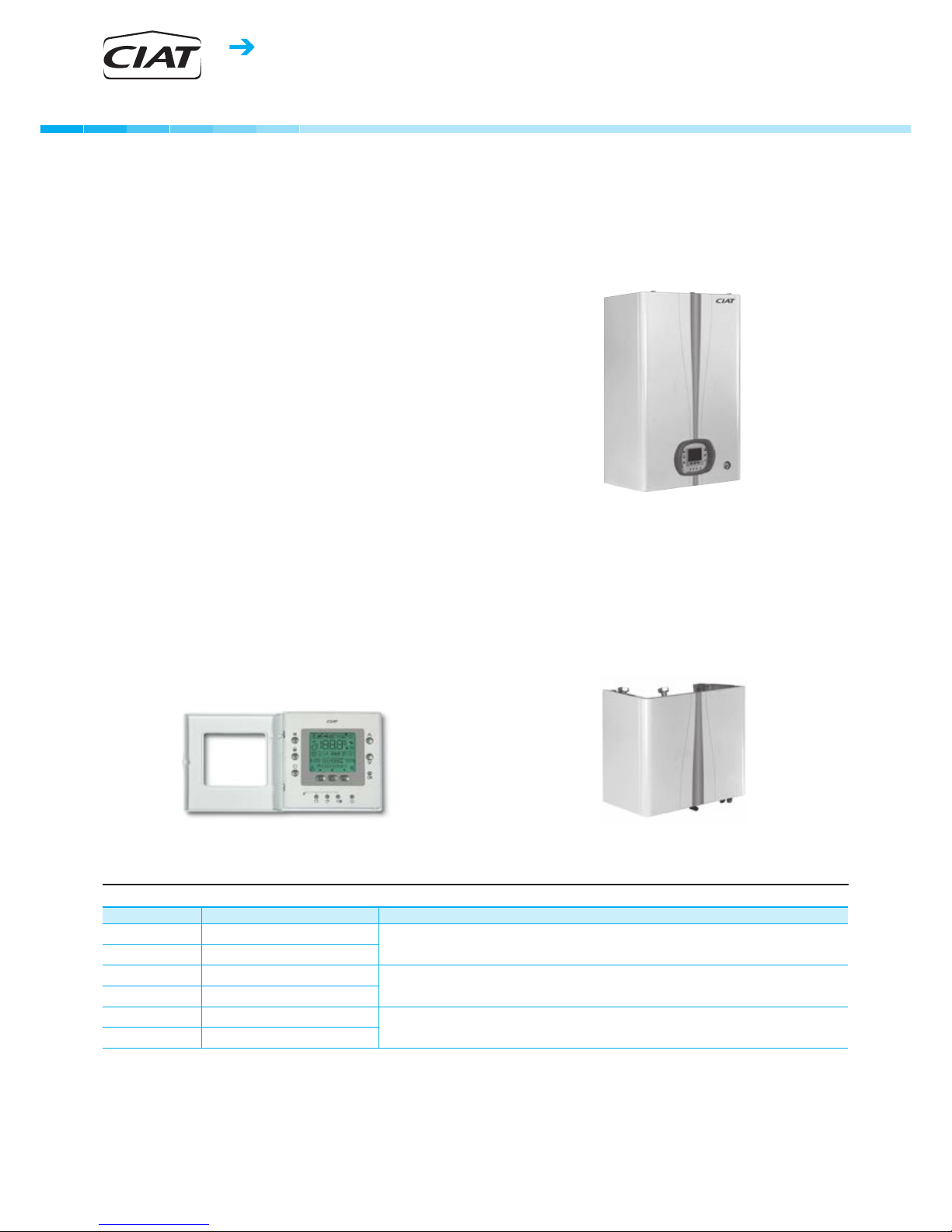

New user interface

■ Yuna II has an easy-to-use user interface with easy-to-

read LCD screen. It provides enhanced control capability

for maximised performance, reliability and indoor comfort

and has extended programming features such as weekly

scheduling. The sleek contemporary design blends in with

any room decor.

New comfort module

■ With its enhanced aesthetics and compactness, combined

with features and options, Yuna II sets new standards in

energy savings and comfort. Using the two-zone kit, two

separate terminal units or two independent comfort zones

can be closely monitored. Domestic hot water production is

made easy and can be interfaced with solar thermal panels.

Two-zone kit

■ The new design facilitates the installation process and makes

two independent comfort zones, which are easy to control.

This kit includes a hydronic disconnection collector, the

necessary circulating pumps and modulating valve. Installed

together with the domestic hot water tank, the two-zone kit

can integrate all accessories, such as the diverting valve and

T-connection.

DesCRiption oUtDooR anD inDooR Units

Outdoor unit Indoor unit

Yuna II 5H 5 kW nominal capacity

Heating only, 1 zone, max. heating capacity 6.5 kW with 3 kW 1-ph electric heater backup

Yuna II 6H 6.5 kW nominal capacity

Yuna II 9H 9 kW nominal capacity

Heating only, 1 zone, max. heating capacity 11.5 kW with 3 kW 1-ph electric heater backup

Yuna II 11H 11.5 kW nominal capacity

Yuna II 12HT 12 kW nominal capacity

Heating and cooling, 1 zone, max. heating capacity 15 kW with 6 kW 3-ph electric heater backup

Yuna II 15HT 15 kW nominal capacity

5

Yuna II

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 15.739 A

air-to-water heat pump

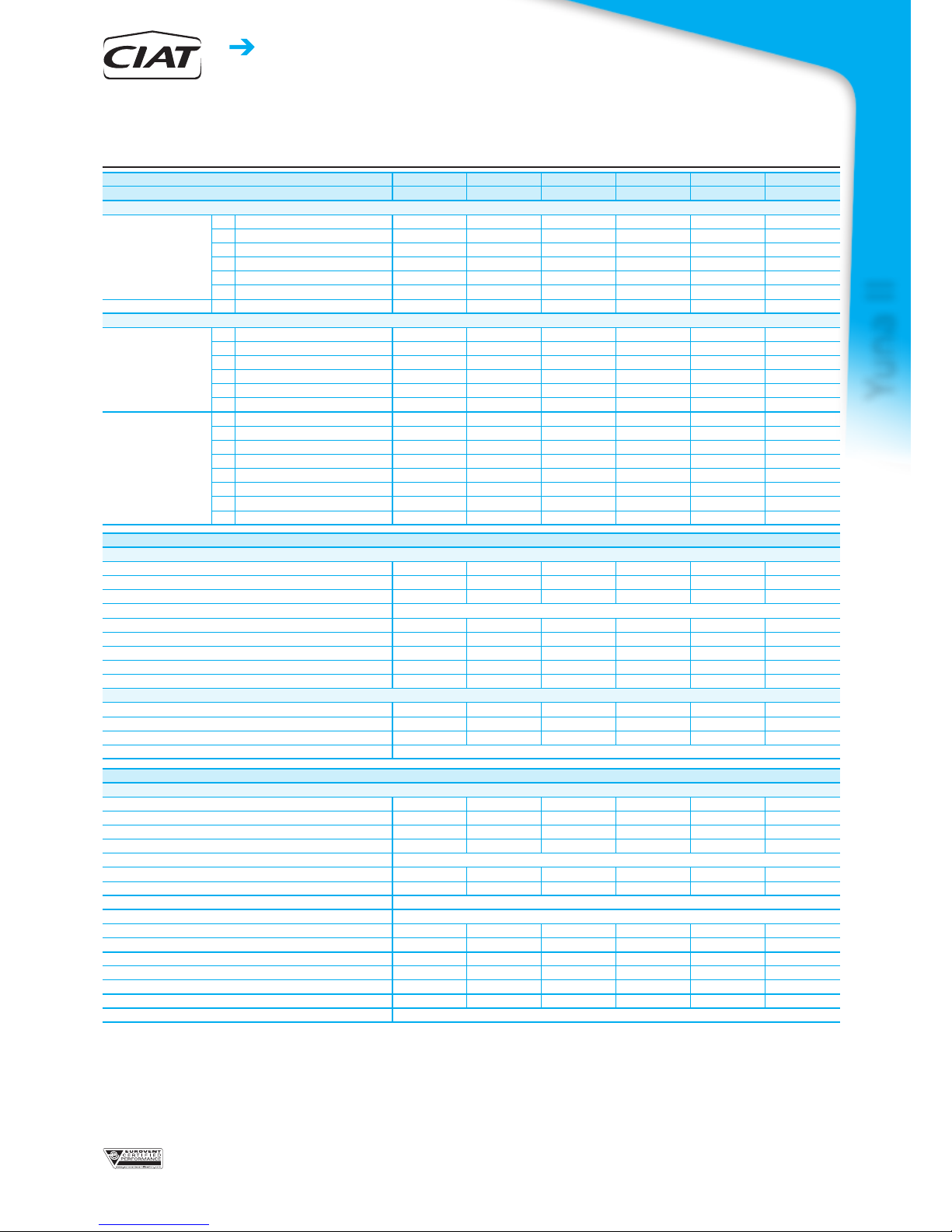

physiCal Data, oUtDooR anD inDooR Units

Outdoor unit (heat pump) 5HK 6HK 9HK 11HK 12HTK 15HTK

Indoor unit (confort module) 5-63D 5-63D 9-113D 9-113D 12-156D 12-156D

Cooling

Full load performances*

C1 Nominal capacity kW 3.57 4.73 5.95 6.8 10.3 12.6

C1 EER kW / kW 2.6 2.6 3.07 2.88 3.41 3.17

C1 Eurovent class cooling D D B C A A

C2 Nominal capacity kW 5.1 6.55 7.88 9 13.5 15.79

C2 EER kW / kW 3.4 3.4 4.05 3.8 4.74 4.24

C2 Eurovent class cooling - - - - - -

Seasonal efciency** ESEER kW / kW

3.71 3.71 4.45 4.37 4.56 4.79

Heating

Full load performances*

H1 Nominal capacity kW 5.01 6.55 9.27 11.5 12 15.01

H1 COP 4.15 4.15 4.48 4.1 4.65 4.3

H2 Nominal capacity kW 4.37 5.7 8.7 11.3 11.2 14.02

H2 COP 3.42 3.34 3.45 3.32 3.7 3.4

H3 Nominal capacity kW 4.25 5.52 7.86 10.95 11.48 11.91

H3 COP

2.65 2.86 2.9 2.79 3.12 3.1

Seasonal efciency**

H1 SCOP

3.1 3 3.2 3.19 3.82 3.67

H1 ŋ

s

% 121 117 125 125 150 144

H1 P

rated

kW 2.34 2.52 8.83 10.09 9.89 11.00

H1 Energy efciency class A A+ A+ A+ A++ A+

H3 SCOP 3 2.98 2.99 2.94 3.45 3.29

H3 ŋ

s

% 117 11 6 11 7 115 135 128

H3 P

rated

kW 1.90 2.16 7.60 8.75 8.37 9.38

H3 Energy efciency class

A+ A+ A+ A+ A++ A++

Indoor unit

Sound levels

Sound power level

(*)

(H3) dB(A) 49 49 49 49 49 49

Dimension, H x L x D mm 800 x 450 x 320 800 x 450 x 320 800 x 450 x 320 800 x 450 x 320 800 x 450 x 320 800 x 450 x 320

Operating weight

(3)

kg 48 48 50 50 52 52

Pump Variable speed circulator

Expansion tank volume l 8 8 8 8 8 8

Availabale static pressure (C1) kPa 70 68 68 65 55 41

Availabale static pressure (H1) kPa 66 60 54 40 45 25

Availabale static pressure (H2) kPa 68 64 57 41 50 31

Max. water-side operating pressure kPa 300 300 300 300 300 300

Water connections

Diameter inch 1 M 1 M 1 M 1 M 1 M 1 M

Outside tube diameter mm 25.4 M 25.4 M 25.4 M 25.4 M 25.4 M 25.4 M

Connections, Liquid / Gas side inch 3/8 - 5/8 3/8 - 5/8 3/8 - 5/8 3/8 - 5/8 3/8 - 5/8 3/8 - 5/8

Chassis paint colour White

Outdoor unit

Sound levels

Sound power level

(*)

(H3) dB(A) 64 67 68 69 69 69

Sound power level

(1)

(C1) dB(A) 68 68

Dimension, H x L x D mm 690 x 900 x 320 820 x 900 x 320 1360 x 900 x 3201360 x 900 x 3201360 x 900 x 320 1360 x 900 x 320

Operating weight

(3)

kg 49 51 88 88 100 100

Refrigerant R410A

Circuit charge

(3)

kg 1.17 1.36 2.1 2.1 3.9 3.9

CO

2

eq. 2.4 2.8 4.4 4.4 8.1 8.1

Compressors DC Inverter Twin-Rotary

Fans Variable speed 3 blades fan

Quantity 1 1 2 2 2 2

Air ow m3/h 2620 2820 5970 6360 5770 5770

Maximum connection pipe length m 50 30 70 70 70 70

Maximum height difference Out/In - In/Out m 30 - 15 30 - 15 30 - 15 30 - 15 30 - 15 30 - 15

Precharged length m 20 20 20 30 30 30

Connections, Liquid / Gas side inch 1/4 - 1/2 3/8 - 5/8 3/8 - 5/8 3/8 - 5/8 3/8 - 5/8 3/8 - 5/8

Chassis paint colour Beige

* In accordance with standard EN14511-3:2013

** In accordance with standard EN14825:2013, average climate

C1 Cooling mode conditions: evaporator water entering/leaving temperature

12°C/7°C, outside air temperature 35°C, evaporator fooling factor 0 m² K/W

C2 Cooling mode conditions: evaporator water entering/leaving temperature

23°C/18°C, outside air temperature 35°C, evaporator fooling factor 0 m² K/W

H1 Heating mode conditions: Water heat exchanger water entering/leaving

temperature 30°C/35°C, fouling factor 0 m2 K/W. Outside air temperature 7°C

db/6°C wb,

H2 Heating mode conditions: Water heat exchanger water entering/leaving

temperature 40°C/45°C, fouling factor 0 m2 K/W. Outside air temperature 7°C

db/6°C wb,

H3 Heating mode conditions: Water heat exchanger water entering/leaving

temperature 47°C/55°C, fouling factor 0 m2 K/W. Outside air temperature 7°C

db/6°C wb,

(1) In dB ref=10-12 W, (A) weighting. Declared dualnumber noise emission values in

accordance with ISO 4871 (with an associated uncertainty of +/-3dB(A)).

Measured in accordance with ISO 9614-1.

(3) Weights are guideline only. Refer to the unit nameplate.

Eurovent certified values

6

heat pumps - aIR CONDItIONING - ReFRIGeRatION - aIR haNDLING - heat eXChaNGe - Na 15.739 a

air-to-water heat pump

Yuna II

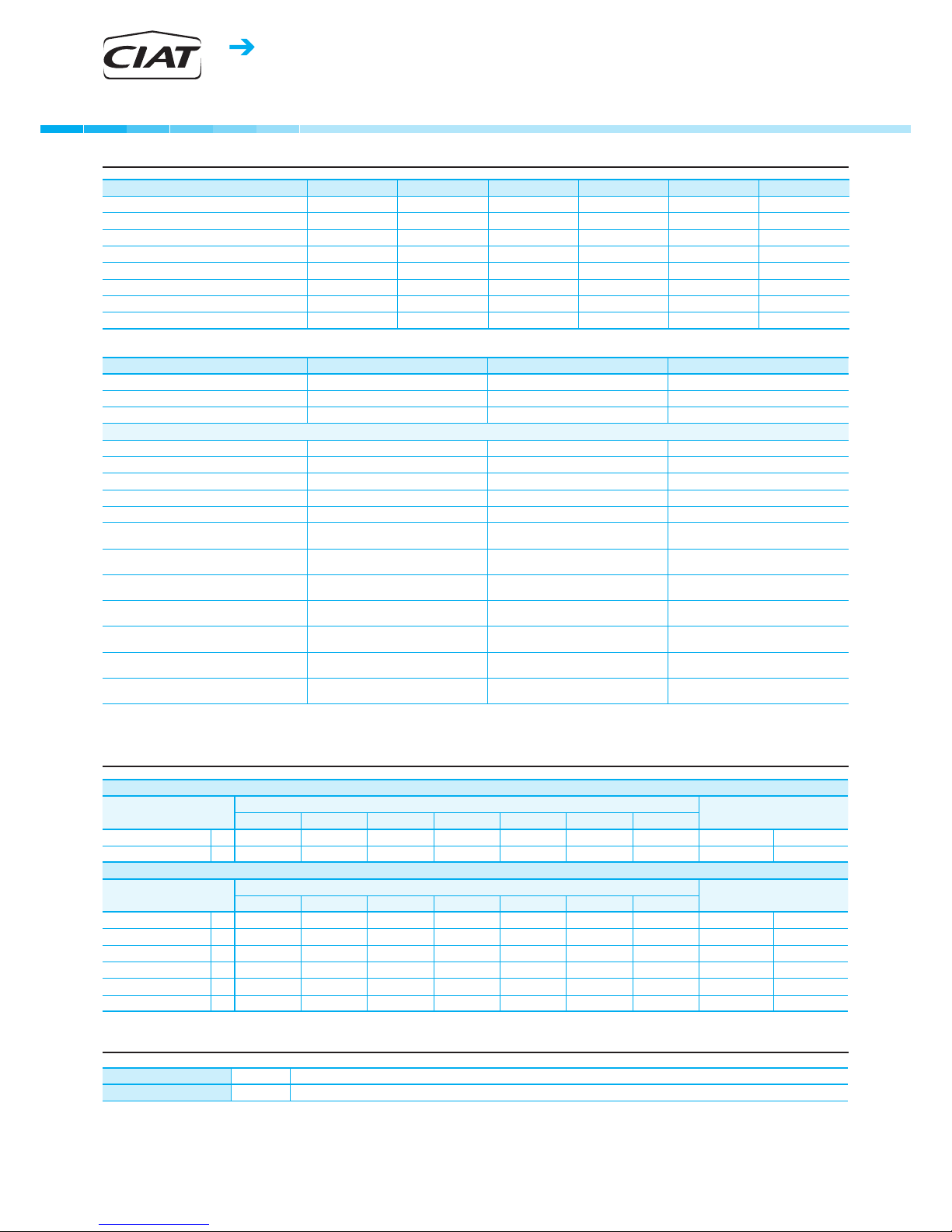

eleCtRiCal Data, oUtDooR anD inDooR Units

soUnD levels, oUtDooR Units

soUnD levels, inDooR Units

Outdoor unit 5HK 6HK 9HK 11HK 12HTK 15HTK

Power supply V-ph-Hz

230-1-50 230-1-50 230-1-50 230-1-50 400-3+N-50 400-3+N-50

Voltage range V-ph-Hz 198-264 198-264 198-264 198-264 400-3N-50 400-3N-50

Full load current A 12 12 23 23 15.4 15.4

Fuse rating* A 16 16 25 25 16 16

Operating current A 5.3 6.91 9.43 12.22 6.45 8.72

Power consumption W 1220 1590 2170 2810 2580 3490

Main power wire size mm² 2.5 2.5 4 4 2.5 2.5

Power factor %

0.95 0.95 0.95 0.95 0.95 0.95

Indoor unit 5-63D 9-113D 12-156D

Power supply V-ph-Hz 230-1-50 230-1-50 400-3+N-50

Voltage range V-ph-Hz 207-253 207-253 376-424

Power input kW 3 3 6

Operating current

L1 A 13.0 13.0 8.7

L2 A - - 8.7

L3 A - - 8.7

N A 13.0 13.0 -

Power factor % 1 1 1

Indoor unit power supply and

communication cable - H07 RN-F

mm

2

2G x 1 2G x 1 2G x 1

Backup heater power supply cable

- H07 RN-F

mm

2

3G x 4 3G x 4 5G x 2.5

User interface cable (additional or

remote) - FROH2R

mm

2

4 x 0.75 4 x 0.75 4 x 0.75

Booster heater power supply cable

- H05VV-F

mm

2

3G x 2.5 3G x 2.5 3G x 2.5

DHW booster heater activation

cable - FROH2R

mm

2

2 x 1 2 x 1 2 x 1

DHW hot water sensor cable FROH2R

mm

2

2 x 0.5 2 x 0.5 2 x 0.5

Remote outdoor sensor cable FROH2R

mm

2

2 x 0.5 2 x 0.5 2 x 0.5

* Time delay fuse

* Measured at 2 m distance, in accordance with UNI EN ISO 3741.

Cooling mode

Outdoor unit

Octave bands, Hz

Sound power levels

125 250 500 1000 2000 4000 8000

12HTK dB 71 69 66 63 59 56 49 dB(A) 68

15HTK dB 72 68 66 63 60 54 50 dB(A) 68

Heating mode

Outdoor unit

Octave bands, Hz

Sound power levels

125 250 500 1000 2000 4000 8000

5HK dB 68 62 61 60 54 54 46 dB(A) 64

6HK dB 73 67 67 63 56 56 51 dB(A) 68

9HK dB 73 66 68 63 57 56 51 dB(A) 69

11HK dB

70

68 69 64 60 57 51 dB(A) 70

12HTK dB

72

69 66 63 59 56 50 dB(A) 68

15HTK dB 72 68 67 63 59 56 50 dB(A) 68

Sound power level

dB(A) 41

Sound pressure level* dB(A) 27

Loading...

Loading...