CIAT PowerCiat LX ST, PowerCiat LX XE, PowerCiat LX HE Instruction Manual

Instruction manual

06 - 2018

10256

POWERCIAT LX

ST/HE/XE

POWERCIAT LX ST/HE/XE EN-2

CONTENTS

1 - INTRODUCTION .................................................................................................................................................................... 4

1.1 - Installation safety considerations ........................................................................................................................................ 4

1.2 - Equipment and components under pressure ...................................................................................................................... 5

1.3 - Maintenance safety considerations ..................................................................................................................................... 5

1.4 - Repair safety considerations ............................................................................................................................................... 6

2 - PRELIMINARY CHECKS .......................................................................................................................................................8

2.1 - Check equipment received .................................................................................................................................................. 8

2.2 - Moving and siting the unit....................................................................................................................................................8

3 - DIMENSIONS, CLEARANCES ............................................................................................................................................ 10

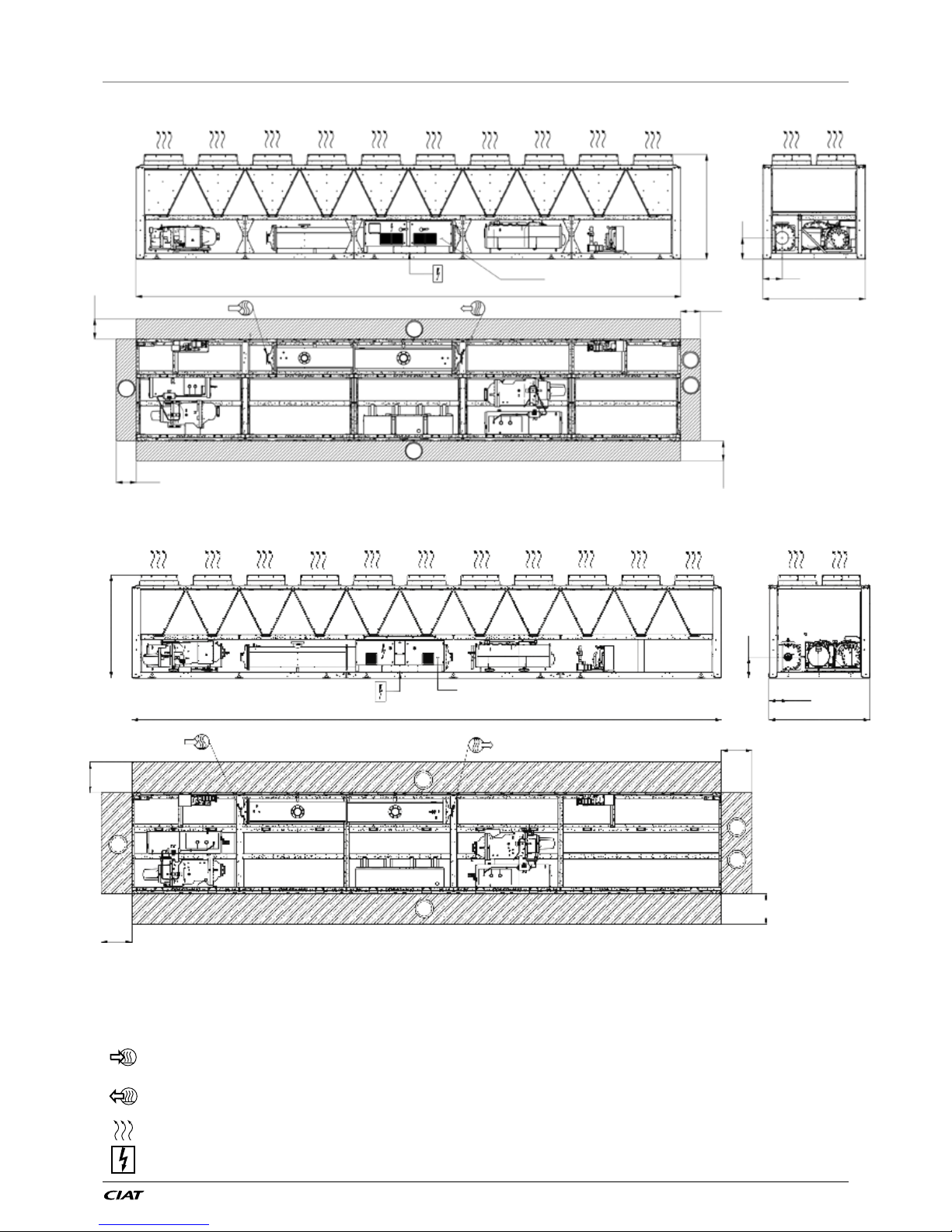

3.1 - LX 0808 to 1008 ................................................................................................................................................................ 10

3.2 - LX 1108 to 1358 ................................................................................................................................................................10

3.3 - LX 1528 ............................................................................................................................................................................. 11

3.4 - LX1858 to 2308 ................................................................................................................................................................. 11

3.5 - LX2528 to 2628 ................................................................................................................................................................. 12

3.6 - LX 3028 ............................................................................................................................................................................. 12

3.7 - LX 3428 to 4408 ................................................................................................................................................................ 13

3.8 - LX 4608 ............................................................................................................................................................................. 13

3.9 - Multiple chiller installation.................................................................................................................................................. 14

3.10 - Distance to the wall ......................................................................................................................................................... 14

4 - PHYSICAL PROPERTIES AND ELECTRICAL DATA FOR LX UNITS .............................................................................. 15

4.1 - Physical properties of LX units .......................................................................................................................................... 15

4.2 - Electrical data .................................................................................................................................................................... 19

4.3 - Compressor electrical data................................................................................................................................................23

4.4 - Compressor usage per circuit (A, B, C, D) ........................................................................................................................ 23

4.5 - Electrical data, optional hydraulic module ......................................................................................................................... 25

5 - ELECTRICAL CONNECTION .............................................................................................................................................26

5.1 - Power supply ..................................................................................................................................................................... 26

5.2 - Voltage phase imbalance (%)............................................................................................................................................26

5.3 - Power connection/disconnect switch................................................................................................................................. 26

5.4 - Recommended wire sections ............................................................................................................................................ 26

5.5 - Power cable entry..............................................................................................................................................................26

5.6 - Field control wiring ............................................................................................................................................................ 27

6 - APPLICATION DATA ........................................................................................................................................................... 28

6.1 - Operating range ................................................................................................................................................................ 28

6.2 - Minimum chilled water ow (unit without hydraulic module).............................................................................................. 28

6.3 - Maximum chilled water ow (units without hydraulic module) ........................................................................................... 29

6.4 - Variable ow evaporator ....................................................................................................................................................29

6.5 - System minimum water volume ........................................................................................................................................ 29

6.6 - Maximum system water volume ........................................................................................................................................ 29

6.7 - Evaporator water ow rate ................................................................................................................................................ 29

6.8 - Evaporator pressure drop curve ........................................................................................................................................ 30

7 - WATER CONNECTIONS ..................................................................................................................................................... 31

7.1 - Operating precautions ....................................................................................................................................................... 31

7.2 - Victaulic water connections ............................................................................................................................................... 32

7.3 - Flow control ....................................................................................................................................................................... 33

7.4 - Evaporator water box bolt tightening ................................................................................................................................. 33

7.5 - Frost protection .................................................................................................................................................................33

7.6 - Operation of two units in master/slave mode (option) ....................................................................................................... 33

7.7 - Pump characteristics ......................................................................................................................................................... 34

8 - HEAT RECLAIM CONDENSER OPTION ............................................................................................................................37

8.1 - Physical properties, LX units with heat reclaim condenser option .................................................................................... 37

8.2 - Dimensions, clearances .................................................................................................................................................... 37

8.3 - Condenser location ........................................................................................................................................................... 41

8.4 - Condenser water connections ........................................................................................................................................... 41

8.5 - Operating ranges for stable operation (no mode changeover) ......................................................................................... 41

8.6 - Operating limits for changeover between modes ............................................................................................................. 42

8.7 - Flow control ....................................................................................................................................................................... 42

8.8 - Heat reclaim operation ...................................................................................................................................................... 42

8.9 - Condenser pump selection................................................................................................................................................43

8.10 - Frost protection ...............................................................................................................................................................43

EN-3 POWERCIAT LX ST/HE/XE

This manual applies to the following two PowerCiat versions:

• LX ST units, standard efciency

• LX HE units, high seasonal efciency

• LX XE Premium units

For the operation of the control, please refer to the POWERCIAT Connect'Touch control manual.

CONTENTS

9 - FANS WITH AVAILABLE PRESSURE ................................................................................................................................ 43

10 - UNIT OPERATION WITH A FREE COOLING DRYCOOLER ........................................................................................... 43

10.1 - Unit operation option with a free cooling drycooler ......................................................................................................... 43

11 - MAJOR SYSTEM COMPONENTS AND OPERATION DATA ...........................................................................................45

11.1 - Direct-drive twin-screw compressor with variable capacity slide valve ...........................................................................45

11.2 - Pressure vessels .............................................................................................................................................................45

11.3 - High-pressure safety switch ............................................................................................................................................46

11.4 - Condensers .....................................................................................................................................................................46

11.5 - Fans .................................................................................................................................................................................46

11.6 - Electronic expansion valve (EXV) ...................................................................................................................................47

11.7 - Moisture indicator ............................................................................................................................................................47

11.8 - Filter drier ........................................................................................................................................................................47

11.9 - Sensors ...........................................................................................................................................................................47

11.10 - Service valve set (option) ..............................................................................................................................................47

11.11 - Power factor correction capacitors (option) ................................................................................................................... 47

12 - MAIN OPTIONS ................................................................................................................................................................. 49

13 - STANDARD MAINTENANCE ............................................................................................................................................51

13.1 - Level 1 maintenance ....................................................................................................................................................... 51

13.2 - Level 2 maintenance ....................................................................................................................................................... 51

13.3 - Level 3 (or higher) maintenance......................................................................................................................................51

13.4 - Tightening torques for the main electrical connections ...................................................................................................51

13.5 - Tightening torques for the main bolts and screws ...........................................................................................................52

13.6 - Condenser coil ................................................................................................................................................................52

13.7 - Evaporator maintenance ................................................................................................................................................. 53

13.8 - Compressor maintenance ............................................................................................................................................... 53

13.9 - Precaution for compressor power supply bus bar connection......................................................................................... 54

13.10 - Check of power factor correction capacitors ................................................................................................................. 54

14 - START-UP CHECKLIST FOR LX LIQUID CHILLERS

(USE FOR JOB FILE) ........................................................................................................................................................55

POWERCIAT LX ST/HE/XE EN-4

1 - INTRODUCTION

PowerCiatTM LX ST/HE/XE units are designed to cool water for

the air conditioning of buildings or for industrial processes.

Prior to the initial start-up of LX units, the persons responsible

for the on-site installation, start-up, operation, and maintenance

of this unit should be thoroughly familiar with these instructions

and the technical characteristics for the project, specic to the

installation site.

They are designed for an operating life of 15 years by assuming

a 57 % utilisation factor; that is approximately 75,000 operating

hours.

LX liquid chillers are designed to provide a very high level of

safety during installation, start-up, operation and maintenance.

They will provide safe and reliable service when operated within

their application range.

This manual provides the necessary information to familiarize

yourself with the control system before performing start-up

procedures. The procedures in this manual are arranged in the

sequence required for machine installation, start-up, operation

and maintenance.

Always ensure that all required safety measures are followed,

including those in this document, such as, wearing protective

clothing (gloves, ear defenders, safety glasses and shoes), using

appropriate tools, employing qualied and skilled technicians

(electricians, refrigeration engineers) and following local

regulations.

To nd out, if these products comply with European directives

(machine safety, low voltage, electromagnetic compatibility,

equipment under pressure etc.) check the declarations of

conformity for these products.

1.1 - Installation safety considerations

Access to the unit must be reserved to authorised personnel,

qualied and trained in monitoring and maintenance. The access

limitation device must be installed by the customer (e.g. cut-off,

enclosure).

After the unit has been received, when it is ready to be installed

or reinstalled, and before it is started up, it must be inspected for

damage. Check that the refrigerant circuit(s) is (are) intact,

especially that no components or pipes have shifted (e.g. following

a shock). If in doubt, carry out a leak tightness check and verify

with the manufacturer that the circuit integrity has not been

impaired. If damage is detected upon receipt, immediately le a

claim with the shipping company.

CIAT strongly recommends employing a specialised

company to unload the machine.

Do not remove the skid or the packaging until the unit is in

its nal position. These units can be moved with a fork lift

truck, as long as the forks are positioned in the right place

and direction on the unit.

The units can also be lifted with slings, using only the

designated lifting points marked on the unit.

These units are not designed to be lifted from above. Use

slings with the correct capacity, and always follow the lifting

instructions on the certied drawings supplied with the unit.

Safety is only guaranteed, if these instructions are carefully

followed. If this is not the case, there is a risk of material

deterioration and injuries to personnel.

DO NOT COVER ANY PROTECTION DEVICES.

This applies to fuse plugs and relief valves (if used) in the

refrigerant or heat transfer medium circuits. Check if the

original protection plugs are still present at the valve outlets.

These plugs are generally made of plastic and should not

be used. If they are still present, please remove them. Install

devices at the valve outlets or drain piping that prevent the

penetration of foreign bodies (dust, building debris, etc.)

and atmospheric agents (water can form rust or ice). These

devices, as well as the drain piping, must not impair

operation and not lead to a pressure drop that is higher than

10% of the control pressure.

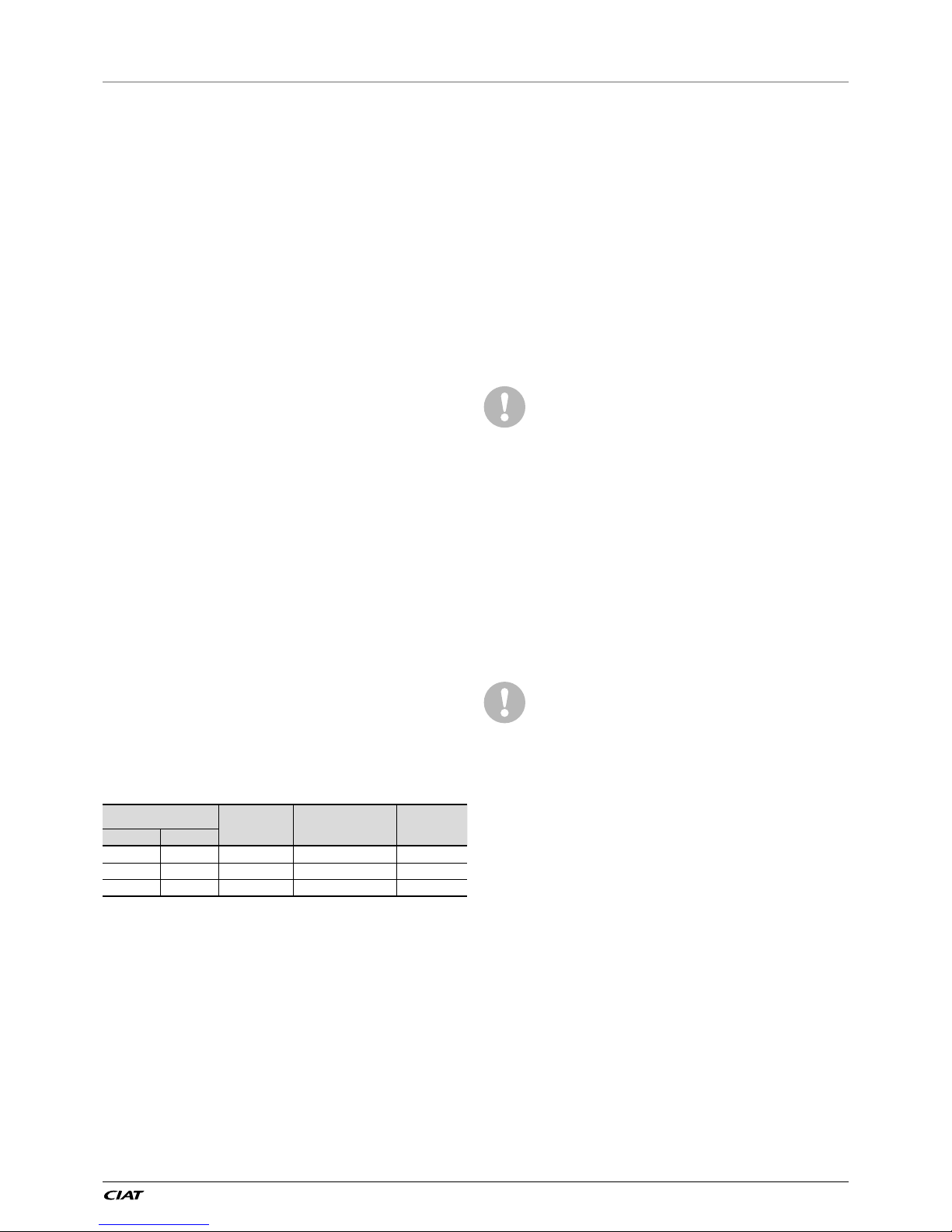

Classication and control

In accordance with the Pressure Equipment Directive and

national usage monitoring regulations in the European

Union the protection devices for these machines are

classied as follows:

Safety

accessory

(1)

Damage limitation accessory

in case of an external re

(2)

Refrigerant Side

High pressure switch x

External relief valve

(3)

x

Heat transfer uid side

External relief valve

(4) (4)

(1) Classied for protection in normal service situations.

(2) Classied for protection in abnormal service situations. These accessories

are sized for res with a thermal ow of 10kW/m². No combustible matter

should be placed within 6.5m of the unit.

(3) The instantaneous overpressure limitation of 10% of the operating pressure

does not apply to this abnormal service situation.

The control pressure can be higher than the service pressure. In this case,

either the design temperature or the high pressure switch ensures that the

service pressure is not exceeded in normal service situations.

(4) The selection of these relief valves must be made by the personnel responsible

for completing the hydraulic installation.

Do not remove these valves and fuses, even if the re risk

is under control for a particular installation. There is no

guarantee that the accessories are re-installed if the

installation is changed or for transport with a gas charge.

When the unit is subjected to re, safety devices prevent

rupture due to over-pressure by releasing the refrigerant.

The uid may then be decomposed into toxic residues when

subjected to the ame:

• Stay away from the unit.

• Set up warnings and recommendations for personnel in

charge to stop the re.

• Fire extinguishers appropriate to the system and the

refrigerant type must be easily accessible

All factory-installed relief valves are lead-sealed to prevent

any calibration change. If the relief valves are installed on

a change-over valve, this is equipped with a relief valve on

each of the two outlets. Only one of the two relief valves is

in operation, the other one is isolated. Never leave the

change-over valve in the intermediate position, i.e. with both

ways open (Bring the actuator in abutment, front or back

according to the outlet to isolate).

If a relief valve is removed for checking or replacement

please ensure that there is always an active relief valve on

each of the change-over valves installed in the unit.

The external relief valves must always be connected to drain

pipes for units installed in a closed room. Refer to the

installation regulations, for example those of European

standard EN 378 and EN 13136.

EN-5 POWERCIAT LX ST/HE/XE

These pipes must be installed in a way that ensures that

people and property are not exposed to refrigerant leaks.

As the uids can be diffused in the air, ensure that the outlet

is far away from any building air intake, or that they are

discharged in a quantity that is appropriate for a suitably

absorbing environment.

Periodic check of the relief valves: See chapter 1.3

“Maintenance safety considerations”.

Provide a drain in the drain pipe, close to each relief valve,

to avoid an accumulation of condensate or rain water.

All precautions concerning handling of refrigerant must be

observed in accordance with local regulations.

Ensure good ventilation, as accumulation of refrigerant in

an enclosed space can displace oxygen and cause

asphyxiation or explosions.

Inhalation of high concentrations of vapour is harmful and

may cause heart irregularities, unconsciousness, or death.

Vapour is heavier than air and reduces the amount of oxygen

available for breathing. These products cause eye and skin

irritation. Decomposition products are hazardous.

1.2 - Equipment and components under

pressure

These products incorporate pressure equipment or components.

We recommend that you consult your appropriate national trade

association or the owner of the equipment or components under

pressure (declaration, re-qualification, retesting, etc.).

The characteristics of this equipment/these components are

given on the nameplate or in the required documentation,

supplied with the products.

These units are intended to be stored and operated in an

environment where the ambient temperature must be not less

than the lowest allowable temperature indicated on the

nameplate.

Do not introduce signicant static or dynamic pressure with

regard to the operating pressures used during operation or for

tests in the refrigerant circuit or in the heat exchange circuits.

See section 11.2 - “Pressure vessels”.

1.3 - Maintenance safety considerations

CIAT recommends using the following maintenance logbook

template (the table below should not be considered a reference,

nor does it invoke the manufacturer's liability):

Intervention

Name of the

commissioning

engineer

Applicable national

regulations

Verication

Organism

Date Nature

(1)

(1) Maintenance, repairs, regular verications (EN 378), leakage, etc.

Engineers working on the electric or refrigeration components

must be authorized, trained and fully qualied to do so.

All refrigerant circuit repairs must be carried out by a trained

person, fully qualied to work on these units. He must have been

trained and be familiar with the equipment and the installation.

All welding operations must be carried out by qualied specialists.

Any manipulation (opening or closing) of a shut-off valve must

be carried out by a qualied and authorised engineer. These

procedures must be carried out with the unit shut-down.

NOTE: The unit must never be left shut down with the liquid

line valve closed, as liquid refrigerant can be trapped

between this valve and the expansion device and lead to

the risk of a pressure increase. This valve is situated on the

liquid line before the lter drier box.

During any handling, maintenance and service operations

the engineers working on the unit must be equipped with

safety gloves, glasses, shoes and protective clothing.

Never work on a unit that is still energized.

Never work on any of the electrical components, until the

general power supply to the unit has been cut using the

disconnect switch(es) in the control box(es).

If any maintenance operations are carried out on the unit,

lock the power supply circuit in the open position ahead of

the machine.

If the work is interrupted, always ensure that all circuits are

still deenergised before resuming the work.

Even if the unit has been switched off, the power

circuit remains energized, unless the unit or circuit

disconnect switch is open. Refer to the wiring

diagram for further details. Attach appropriate safety

labels.

Units with the Power Factor Correction option are equipped

with capacitor batteries with a discharge time of ve (5)

minutes after disconnecting the power. After disconnecting

the power to the control box, wait ve minutes before

opening the control box. Before any intervention, verify that

there is no voltage present at any accessible conducting

parts of the power circuit.

OPERATING CHECKS:

Important information regarding the refrigerant used:

This product contains uorinated greenhouse gas covered

by the Kyoto protocol.

Fluid type: R134a

Global Warming Potential (GWP): 1430

1. Any intervention on the refrigerant circuit of this

product should be performed in accordance with

the applicable legislation. In the EU,

the regulation is called F-Gas, N°517/2014

2. Ensure that the refrigerant is never released to

the atmosphere during installation, maintenance

or equipment disposal.

3. The deliberate gas release into the atmosphere

is not allowed.

4. If a refrigerant leak is detected, ensure that it is

stopped and repaired as quickly as possible.

5. Only qualified and certified personnel can

perform installation and maintenance work, run

the refrigerant circuit leak tests, prepare the

equipment for disposal, and recover the

refrigerant.

6. The gas recovery for recycling, regeneration or

destruction is at customer charge.

7. Periodic leak tests have to be carried out by the

customer or by third parties. The EU regulation

set the periodicity here after:

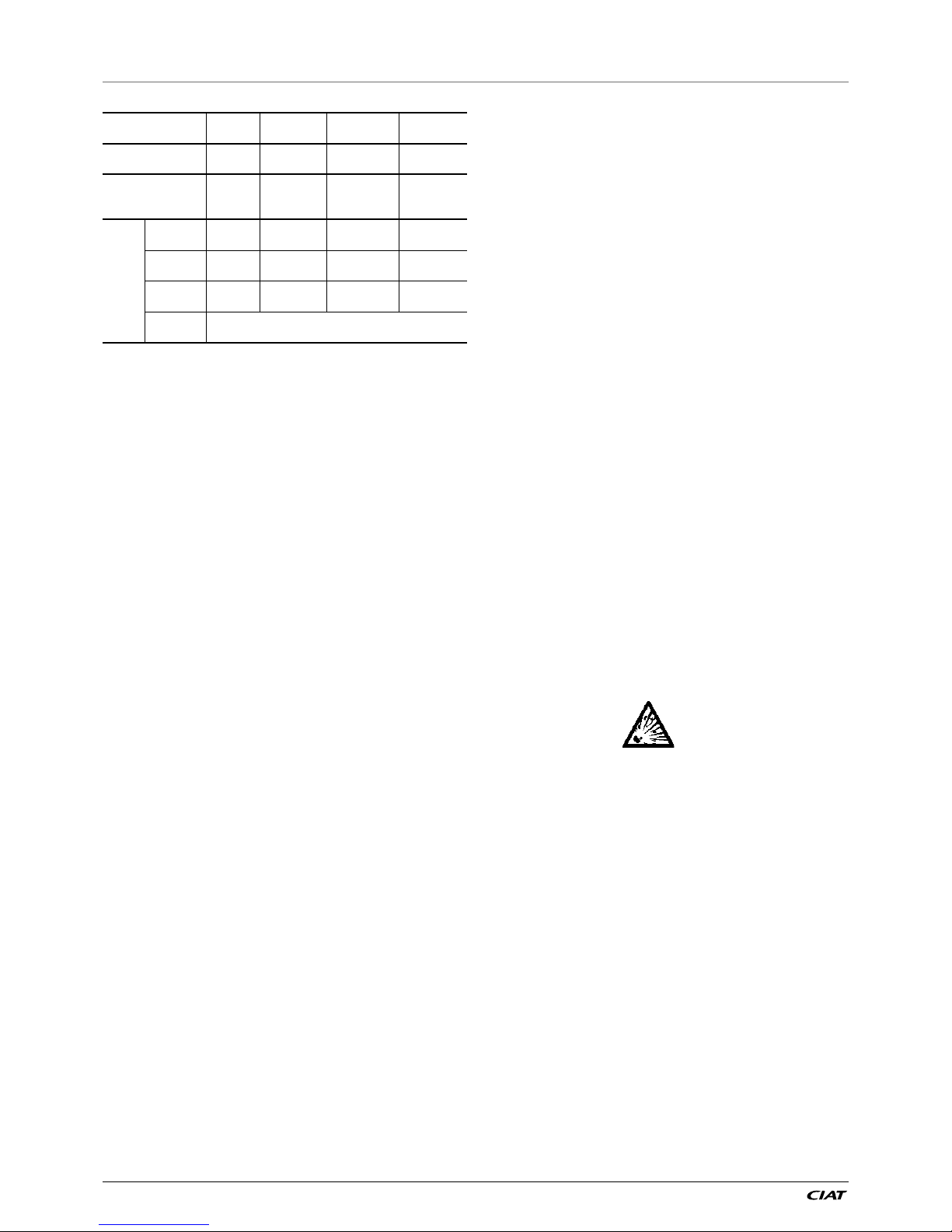

1 - INTRODUCTION

POWERCIAT LX ST/HE/XE EN-6

System WITHOUT

leakage detection

No Check 12 Months 6 Months 3 Months

System WITH leakage

detection

No Check 24 Months 12 Months 6 Months

Refrigerant

charge/circuit

(CO

2

equivalent)

< 5 Tons

5 ≤ Charge

< 50 Tons

50 ≤ Charge

< 500 Tons

Charge

> 500 Tons*

Refrigerant charge/

Circuit (kg)

R134A

(GWP 1430)

Charge

< 3.5 kg

3.5 ≤ Charge

< 34.9 kg

34.9 ≤ Charge

< 349.7 kg

Charge

> 349.7 kg

R407C

(GWP 1774)

Charge

< 2.8 kg

2.8 ≤ Charge

< 28.2 kg

28.2 ≤ Charge

< 281.9 kg

Charge

> 281.9 kg

R410A

(GWP 2088)

Charge

< 2.4 kg

2.4 ≤ Charge

< 23.9 kg

23.9 ≤ Charge

< 239.5 kg

Charge

> 239.5 kg

HFO’s:

R1234ze

No requirement

* From 01/01/2017, units must be equipped with a leak detection system.

8. A logbook must be maintained for equipment

subject to periodic leak tests. It should contain

the quantity and the type of uid present in the

installation (added and recovered), the quantity

of recycled uid, the date and result of the leak

test, the name of the operator and the name of

his/her company, etc.

9. Contact your local dealer or installer if you have any

questions.

The information on operating inspections given in annex C

of standard EN 378 can be used if no similar criteria exist

in the national regulations.

While working in the fan area, especially when grilles or

casings are removed, disconnect the fan power supply to

prevent their automatic restart.

PROTECTION DEVICE CHECKS:

If no national regulations exist, check the protection devices

on site in accordance with standard EN 378: Once a year for

the high-pressure switches, every ve years for external

relief valves.

The company or organisation that conducts a pressure switch

test must establish and implement detailed procedures for:

- Safety measures

- Measuring equipment calibration

- Validating operation of protective devices

- Test protocols

- Recommissioning of the equipment.

Consult CIAT Service for this type of test. In this document, CIAT

only outlines the principle for a test without removal of the

pressure switches:

- Check and record the nominal values for triggering the

pressure switches and external relief devices (valves,

if present).

- Be ready to switch-off the main disconnect switch of the

power supply if the pressure switch does not trigger (avoid

over-pressure or excess gas in case of valves on the

high-pressure side with the recovery condensers)

- Connect a pressure gauge protected against pulsations

(filled with oil with maximum pointer if mechanical),

preferably calibrated (the values displayed on the user

interface may be inaccurate in an instant reading because

of the scanning delay applied in the control)

- Complete an HP Test as provided by the software (refer to

the Control IOM for details).

If the machine operates in a corrosive environment, inspect

the protection devices more frequently.

Regularly carry out leak tests and immediately repair any

leaks. Ensure regularly that the vibration levels remain

acceptable and close to those at the initial unit start-up.

Before opening a refrigerant circuit, purge and consult the

pressure gauges.

Change the refrigerant after an equipment failure, following

a procedure such as the one described in NF E29-795 or

carry out a refrigerant analysis in a specialist laboratory.

If the refrigerant circuit is opened for a day or less, block all

openings; ll the circuit with a nitrogen charge if open for

longer periods.

1.4 - Repair safety considerations

All installation parts must be maintained by the personnel in charge,

in order to avoid material deterioration and injuries to people. Faults

and leaks must be repaired immediately. The authorized technician

must have the responsibility to repair the fault immediately. After

each repair of the unit, check the operation of the protection devices

and create a report of the parameter operation at 100%.

Comply with the regulations and recommendations in unit and HVAC

installation safety standards, such as: EN 378, ISO 5149, etc.

If a leak occurs or if the refrigerant becomes contaminated

(e.g. by a short circuit in a motor) remove the complete charge

using a recovery unit and store the refrigerant in mobile

containers.

Repair the leak detected and recharge the circuit with the total

R-134a charge, as indicated on the unit name plate. Certain parts

of the circuit can be isolated. Only charge liquid refrigerant

R-134a at the liquid line.

Ensure that you are using the correct refrigerant type before

recharging the unit. Charging any refrigerant other than the

original charge type (R-134a) will impair machine operation

and even destroy the compressors. The compressors

operating with this refrigerant type are lubricated with a

synthetic polyolester oil.

RISK OF EXPLOSION:

Never use air or a gas containing oxygen during leak tests

to purge lines or to pressurise a machine. Pressurised air

mixtures or gases containing oxygen can be the cause of

an explosion.

Only use dry nitrogen for leak tests, possibly with an appropriate

tracer gas.

If the recommendations above are not observed, this can have

serious or even fatal consequences and damage the installation.

Never exceed the specied maximum operating pressures.

Verify the allowable maximum high- and low-side test

pressures by checking the instructions in this manual and

the pressures given on the unit name plate.

1 - INTRODUCTION

EN-7 POWERCIAT LX ST/HE/XE

Do not unweld or amecut the refrigerant lines or any

refrigerant circuit component until all refrigerant (liquid and

vapour) as well as the oil have been removed from chiller.

Traces of vapour should be displaced with dry air nitrogen.

Refrigerant in contact with an open ame produces toxic

gases.

The necessary protection equipment must be available, and

appropriate fire extinguishers for the system and the

refrigerant type used must be within easy reach.

Do not siphon refrigerant.

Avoid spilling liquid refrigerant on skin or splashing it into

the eyes. Use safety goggles and safety gloves. Wash any

spills from the skin with soap and water. If liquid refrigerant

enters the eyes, immediately and abundantly ush the eyes

with water and consult a doctor.

The accidental releases of the refrigerant, due to small leaks

or signicant discharges following the rupture of a pipe or

an unexpected release from a safety valve, can cause

frostbites and burns to personnel exposed. Do not ignore

such injuries. Installers, owners and especially service

engineers for these units must:

• Seek medical attention before treating such injuries.

• Have access to a rst-aid kit, especially for treating eye

injuries.

We recommend to apply standard EN 378-3 Annex 3.

Never apply an open ame or live steam to a refrigerant

container. Dangerous overpressure can result. If it is

necessary to heat refrigerant, use only warm water.

During refrigerant removal and storage operations follow applicable

regulations. These regulations, permitting conditioning and recovery

of halogenated hydrocarbons under optimum quality conditions for

the products and optimum safety conditions for people, property

and the environment are described in standard NF E29-795.

Any refrigerant transfer and recovery operations must be carried

out using a transfer unit. A 3/8” SAE connector on the manual

liquid line valve is supplied with all units for connection to the

transfer station. The units must never be modied to add refrigerant

and oil charging, removal and purging devices. All these devices

are provided with the units. Please refer to the certied dimensional

drawings for the units.

Do not re-use disposable (non-returnable) cylinders or

attempt to rell them. It is dangerous and illegal. When

cylinders are empty, evacuate the remaining gas pressure,

and move the cylinders to a place designated for their

recovery. Do not incinerate them.

Only use R134a refrigerant, in accordance with AHRI

Standard 700 (published by the US Air conditioning,

Heating and Refrigeration Institute). The use of any

other refrigerant may expose users and operators

to unexpected risks.

Do not attempt to remove refrigerant circuit components or

ttings, while the machine is under pressure or while it is

running. Be sure pressure is at 0 kPa and that the unit has

been shut-down and de-energised before removing

components or opening a circuit.

Do not attempt to repair or recondition any safety devices

when corrosion or build-up of foreign material (rust, dirt,

scale, etc.) is found within the valve body or mechanism.

If necessary, replace the device. Do not install relief valves

in series or backwards.

No part of the unit must be used as a walkway, rack

or support. Periodically check and repair or if

necessary replace any component or piping that

shows signs of damage.

The refrigerant lines can break under the weight and release

refrigerant, causing personal injury.

Do not climb on a machine. Use a platform, or staging to

work at higher levels.

Use mechanical lifting equipment (crane, hoist, winch, etc.)

to lift or move heavy components. For lighter components,

use lifting equipment when there is a risk of slipping or losing

your balance.

Use only original replacement parts for any repair or

component replacement. Consult the list of replacement

parts that corresponds to the specication of the original

equipment.

Do not drain water circuits containing industrial brines,

without informing the technical service department at the

installation site or a competent body rst.

Close the entering and leaving water shutoff valves and

purge the unit water circuit, before working on the

components installed on the circuit (screen lter, pump,

water ow switch, etc.).

Do not loosen the water box bolts until the water boxes have

been completely drained.

Periodically inspect all valves, ttings and pipes of the

refrigerant and hydraulic circuits to ensure that they do not

show any corrosion or any signs of leaks.

It is recommended to wear ear defenders, when working

near the unit and the unit is in operation.

1 - INTRODUCTION

POWERCIAT LX ST/HE/XE EN-8

2 - PRELIMINARY CHECKS

2.1 - Checking the equipment received

• Check that the unit has not been damaged during transport

and that no parts are missing. If the unit has been damaged

or the shipment is incomplete, send a claim to the shipping

company.

• Compare the name plate data with the order. The name plate is

attached in two places to the unit:

- On one of the unit sides on the outside,

- On the control box door on the inside.

• The unit name plate must include the following information:

- Version number

- Model number

- CE marking

- Serial number

- Year of manufacture and test date

- Fluid being transported

- Refrigerant used and refrigerant class

- Refrigerant charge per circuit

- Containment uid to be used

- PS: Min./max. allowable pressure (high and low pressure

side)

- TS: Min./max. allowable temperature (high and low pressure

side)

- Pressure switch cut-out pressure

- Unit leak test pressure

- Voltage, frequency, number of phases

- Maximum current drawn

- Maximum power input

- Unit net weight

• Conrm that all accessories ordered for on-site installation have

been supplied, are complete and undamaged.

The unit must be checked periodically during its whole

operating life to ensure that no shocks (handling accessories,

tools etc.) have damaged it. If necessary, damaged parts

must be repaired or replaced. See also chapter 13 “Standard

maintenance”.

2.2 - Handling and positioning the unit

2.2.1 - Handling

See chapter 1.1 “Installation safety considerations”.

In some cases vertical supports are added for the transport and

handling of the unit. These supports can be removed for access

or connection, if required.

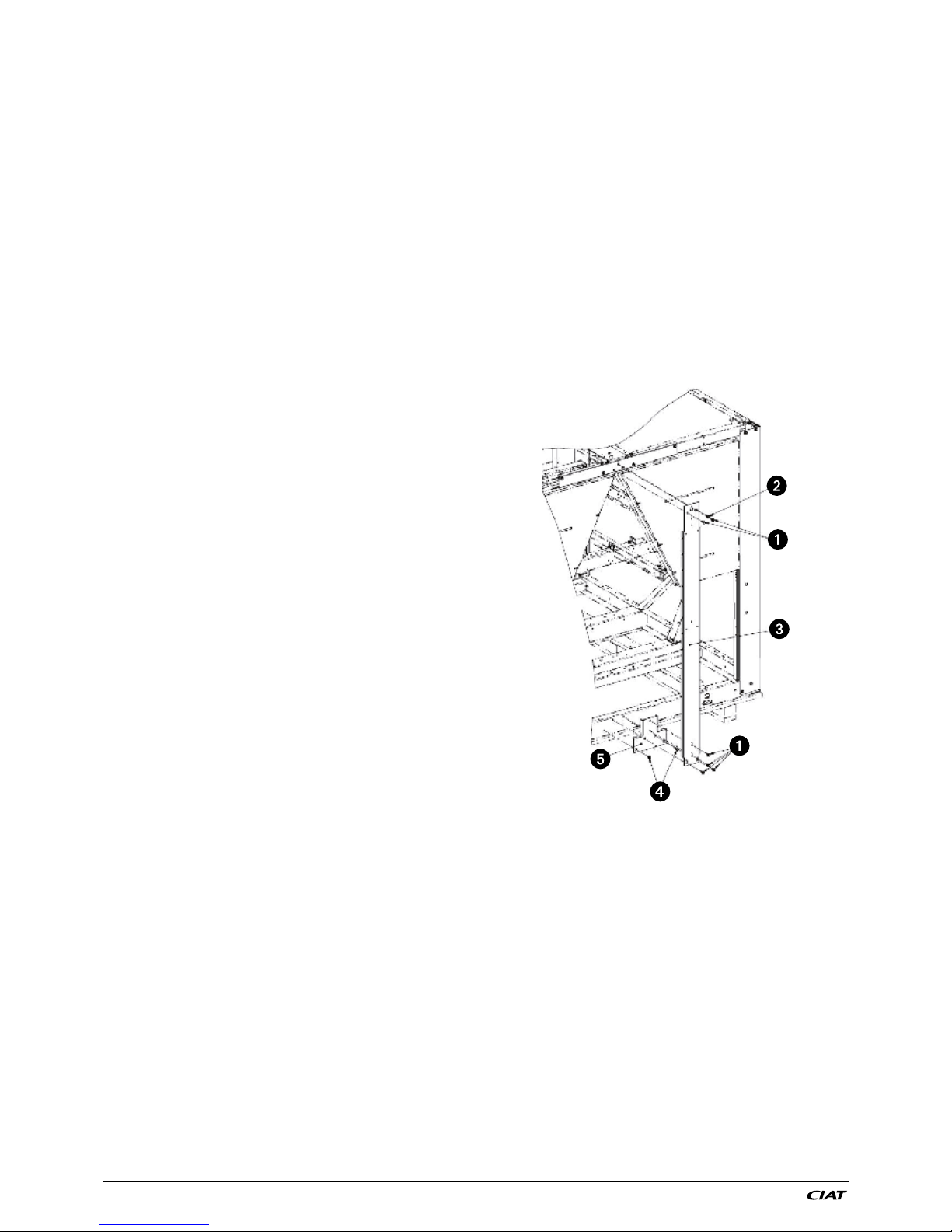

IMPORTANT: Follow the disassembly sequence shown in

the disassembly instructions.

NOTE:

• Unbolt item: 1

• Loosen screw item: 2

• Raise and remove frame post item: 3

• Screw off item: 4 and remove reinforcement plate item: 5

Keep the vertical supports after commissioning the units and

re-insert them when the unit is moved.

EN-9 POWERCIAT LX ST/HE/XE

2.2.2 - Positioning the unit

The machine must be installed in a place that is not accessible to the

public or protected against access by non-authorised persons.

In case of extra-high units the machine environment must

permit easy access for maintenance operations.

Always refer to the chapter 3 “Dimensions, clearances” to conrm

that there is adequate space for all connections and service

operations. For the centre of gravity coordinates, the position of the

unit mounting holes, and the weight distribution points, refer to the

certied dimensional drawing supplied with the unit.

The support points under the chassis must have at least the size

of the chassis opening at the lifting point (minimum 220 x 180 mm)

in order to prevent a deformation of the chassis.

These units are typically used in refrigeration systems,

and therefore do not need to be able to withstand earthquakes

or high winds. Earthquake resistance has not been veried.

Only use slings at the designated lifting points

which are marked on the unit.

Before siting the unit check that:

- The permitted loading at the site is adequate or that

appropriate strengthening measures have been taken.

- The unit is installed level on an even surface (maximum

tolerance is 5 mm in both axes).

- There is adequate space above the unit for air ow and to

ensure access to the components.

- The number of support points is adequate and that they are

in the right places.

- The location is not subject to ooding.

- For outdoor installations, where heavy snowfall is likely and

long periods of sub-zero temperatures are normal, provision

has to be made to prevent snow accumulating by raising

the unit above the height of drifts normally experienced.

- Bafes may be necessary to deect strong winds. They

must not restrict air ow into the unit.

Before lifting the unit, check that all casing panels

are securely xed in place. Lift and set down the

unit with great care. Tilting and jarring can damage

the unit and impair unit operation.

If units are hoisted with rigging, it is advisable to protect the coils

against accidental impacts. Use struts or spreader bar to spread

the slings above the unit. Do not tilt a unit more than 15°.

WARNING: Never push or lever on any of the enclosure

panels of the unit. Only the base of the unit frame is designed

to withstand such stresses.

If a unit contains a hydraulic module, the hydraulic module

and pump piping must be installed in a way that does not

submit it to any strain. The hydraulic module pipes must be

tted so that the pump does not support the weight of the

pipes.

2.2.3 - Checks before system start-up

Before the start-up of the refrigeration system, the complete

installation, including the refrigeration system must be veried

against the installation drawings, dimensional drawings, system

piping and instrumentation diagrams and the wiring diagrams.

For these checks national regulations must be followed. If the

national regulation does not specify any details, refer to standard

EN 378 as follows:

External visual installation checks:

- Ensure that the machine is charged with refrigerant. Verify

on the unit nameplate that the ‘fluid transported’ is R134A

and is not nitrogen.

- Compare the complete installation with the refrigeration

system and power circuit diagrams.

- Check that all components comply with the design

specifications.

- Check that all protection documents and equipment

provided by the manufacturer (dimensional drawings, P&ID,

declarations etc.) to comply with the regulations are present.

- Verify that the environmental safety and protection and

devices and arrangements provided by the manufacturer

to comply with the regulations are in place.

- Verify that all documents for pressure containers,

certificates, name plates, files, instruction manuals provided

by the manufacturer to comply with the regulations are

present.

- Verify the free passage of access and safety routes.

- Check that ventilation in the plant room is adequate.

- Check that refrigerant detectors are present.

- Verify the instructions and directives to prevent the

deliberate removal of refrigerant gases that are harmful to

the environment.

- Verify the installation of connections.

- Verify the supports and fixing elements (materials, routing

and connection).

- Verify the quality of welds and other joints.

- Check the protection against mechanical damage.

- Check the protection against heat.

- Check the protection of moving parts.

- Verify the accessibility for maintenance or repair and to

check the piping.

- Verify the status of the valves.

- Verify the quality of the thermal insulation and of the vapour

barriers.

2 - PRELIMINARY CHECKS

POWERCIAT LX ST/HE/XE EN-10

3 - DIMENSIONS/CLEARANCES

3.1 - LX 0808 to 1008

1

2

1

1

Power And control

electrical box

2297 HT

3604 HT

2253 HT

1500

1500

2200

1500

500

1

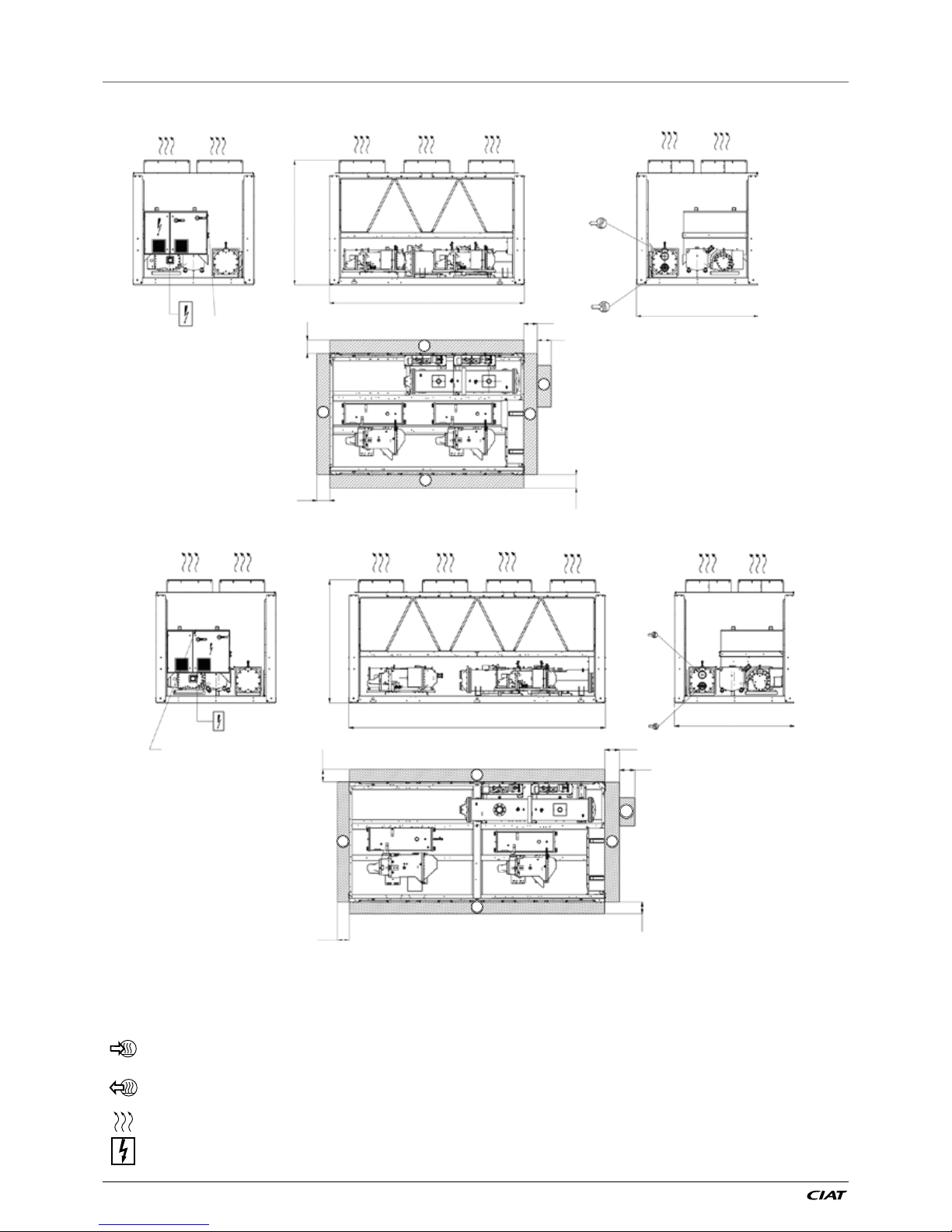

3.2 - LX 1108 to 1358

Power And control

electrical box

2297 HT

4798 HT

2253 HT

1500

500

2200

1500

1500

1

1

2

1

1

Key

NOTES:

• Drawings are not contractually binding.

• Before designing an installation, consult the certied

dimensional drawings, available on request.

• For the positioning of the xing points, weight distribution

and centre of gravity coordinates please refer to the

dimensional drawings.

• If the installation includes several units or if this (these)

is (are) close to walls, please refer to chapters 3.12

“Multiple chiller installation” and 3.13 “Distance to the

wall” of this document to determine the space required.

All dimensions are given in mm.

a

Required clearances for maintenance (see note)

b

Recommended space for evaporator tube removal

Water inlet for standard unit

For the Brine and evaporator options with one pass less or one pass

more, refer to the certied dimensional drawing.

Water outlet for standard unit

For the

Brine and evaporator options with one pass less or one pass

more

, refer to the certied dimensional drawing.

Air outlet – do not obstruct

Power supply and control connection

EN-11 POWERCIAT LX ST/HE/XE

3 - DIMENSIONS, CLEARANCES

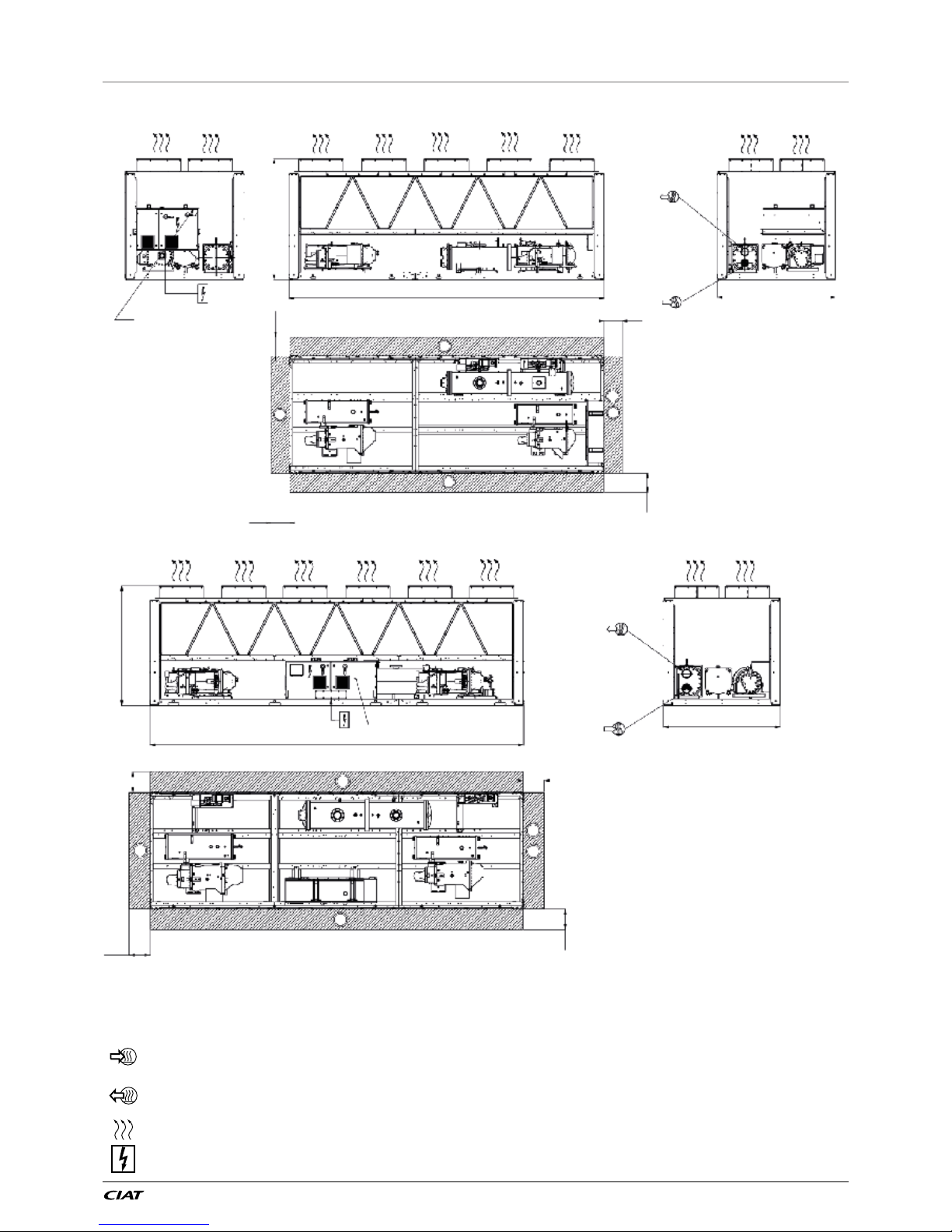

3.3 - LX 1528

2

1

1

1

1

Power And control

Electrical

box

1500

2200

1500

1500

2253 HT

5992 Ht

2297 HT

3.4 - LX1858 to 2308

Power electrical Box

1500

2200

1500

1500

2253 HT

7186 Ht

2297 HT

2

1

1

1

1

Key

NOTES:

• Drawings are not contractually binding.

• Before designing an installation, consult the certied

dimensional drawings, available on request.

• For the positioning of the xing points, weight distribution

and centre of gravity coordinates please refer to the

dimensional drawings.

• If the installation includes several units or if this (these)

is (are) close to walls, please refer to chapters 3.12

“Multiple chiller installation” and 3.13 “Distance to the

wall” of this document to determine the space required.

All dimensions are given in mm.

a

Required clearances for maintenance (see note)

b

Recommended space for evaporator tube removal

Water inlet for standard unit

For the Brine and evaporator options with one pass less or one pass

more, refer to the certied dimensional drawing.

Water outlet for standard unit

For the

Brine and evaporator options with one pass less or one pass

more

, refer to the certied dimensional drawing.

Air outlet – do not obstruct

Power supply and control connection

POWERCIAT LX ST/HE/XE EN-12

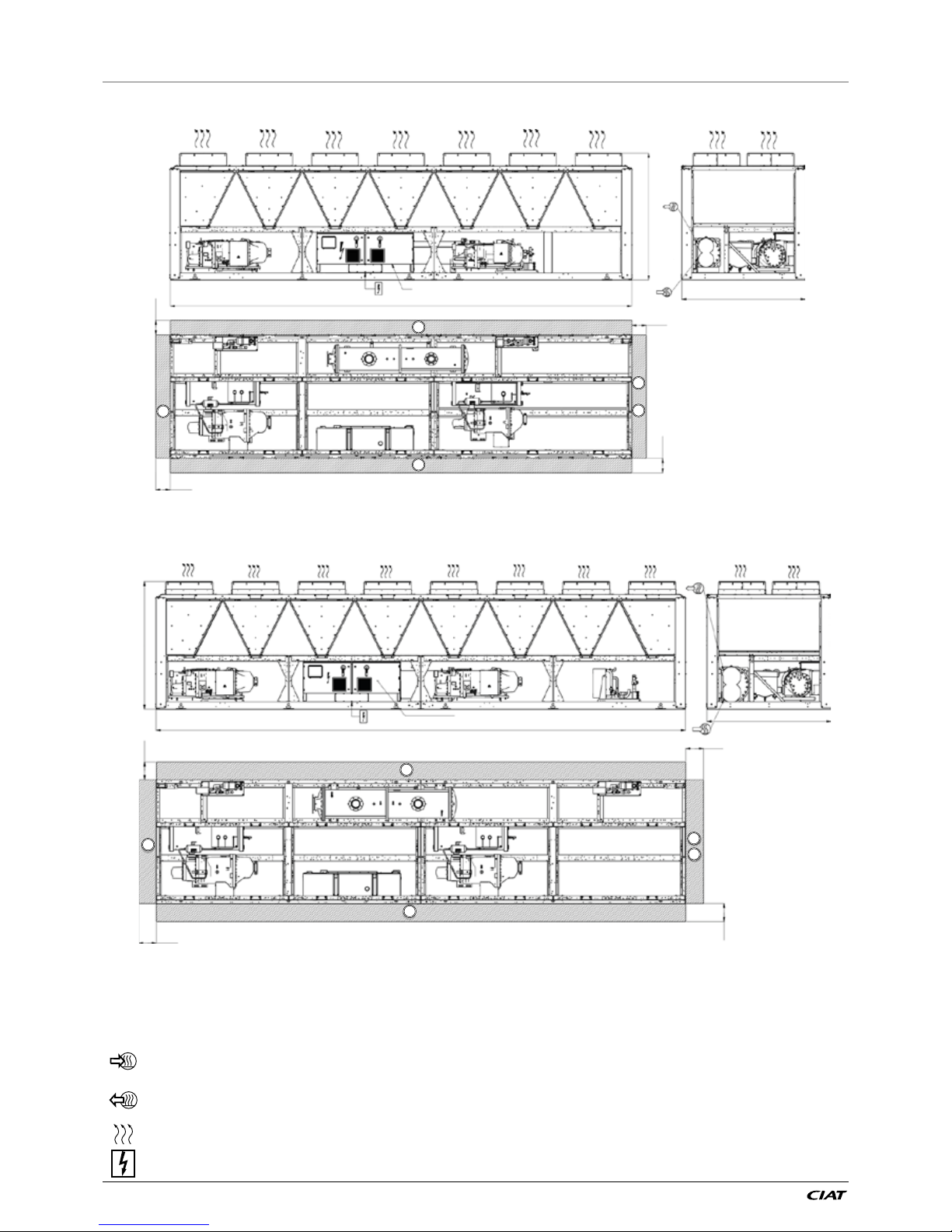

3.5 - LX2528 to 2628

Power And control electrical box

8380 HT

2253 HT

1500

1500

1500

2200

2297 HT

1

1

1

2

1

3.6 - LX 3028

Power And control electrical box

9574 HT

2253 HT

1500

1500

1500

2200

2297 HT

1

1

1

2

1

Key

NOTES:

• Drawings are not contractually binding.

• Before designing an installation, consult the certied

dimensional drawings, available on request.

• For the positioning of the xing points, weight distribution

and centre of gravity coordinates please refer to the

dimensional drawings.

• If the installation includes several units or if this (these)

is (are) close to walls, please refer to chapters 3.12

“Multiple chiller installation” and 3.13 “Distance to the

wall” of this document to determine the space required.

All dimensions are given in mm.

a

Required clearances for maintenance (see note)

b

Recommended space for evaporator tube removal

Water inlet for standard unit

For the Brine and evaporator options with one pass less or one pass

more, refer to the certied dimensional drawing.

Water outlet for standard unit

For the

Brine and evaporator options with one pass less or one pass

more

, refer to the certied dimensional drawing.

Air outlet – do not obstruct

Power supply and control connection

3 - DIMENSIONS, CLEARANCES

EN-13 POWERCIAT LX ST/HE/XE

3.7 - LX 3428 to 4408

2253 HT

419

467

2297 HT

11 962

1500

1500

1500

2200

Power and control

electrical box

2

1

1

1

1

3.8 - LX 4608

2253 HT

419

467

2297 HT

13156 HT

1500

1500

1500

2200

Power And control electrical box

1

2

1

1

1

Key

NOTES:

• Drawings are not contractually binding.

• Before designing an installation, consult the certied

dimensional drawings, available on request.

• For the positioning of the fixing points, weight

distribution and centre of gravity coordinates please

refer to the dimensional drawings.

• If the installation includes several units or if this (these)

is (are) close to walls, please refer to chapters 3.12

“Multiple chiller installation” and 3.13 “Distance to the

wall” of this document to determine the space required.

All dimensions are given in mm.

a

Required clearances for maintenance (see note)

b

Recommended space for evaporator tube removal

Water inlet for standard unit

For the Brine and evaporator options with one pass less or one pass

more, refer to the certied dimensional drawing.

Water outlet for standard unit

For the

Brine and evaporator options with one pass less or one pass

more

, refer to the certied dimensional drawing.

Air outlet – do not obstruct

Power supply and control connection

3 - DIMENSIONS, CLEARANCES

POWERCIAT LX ST/HE/XE EN-14

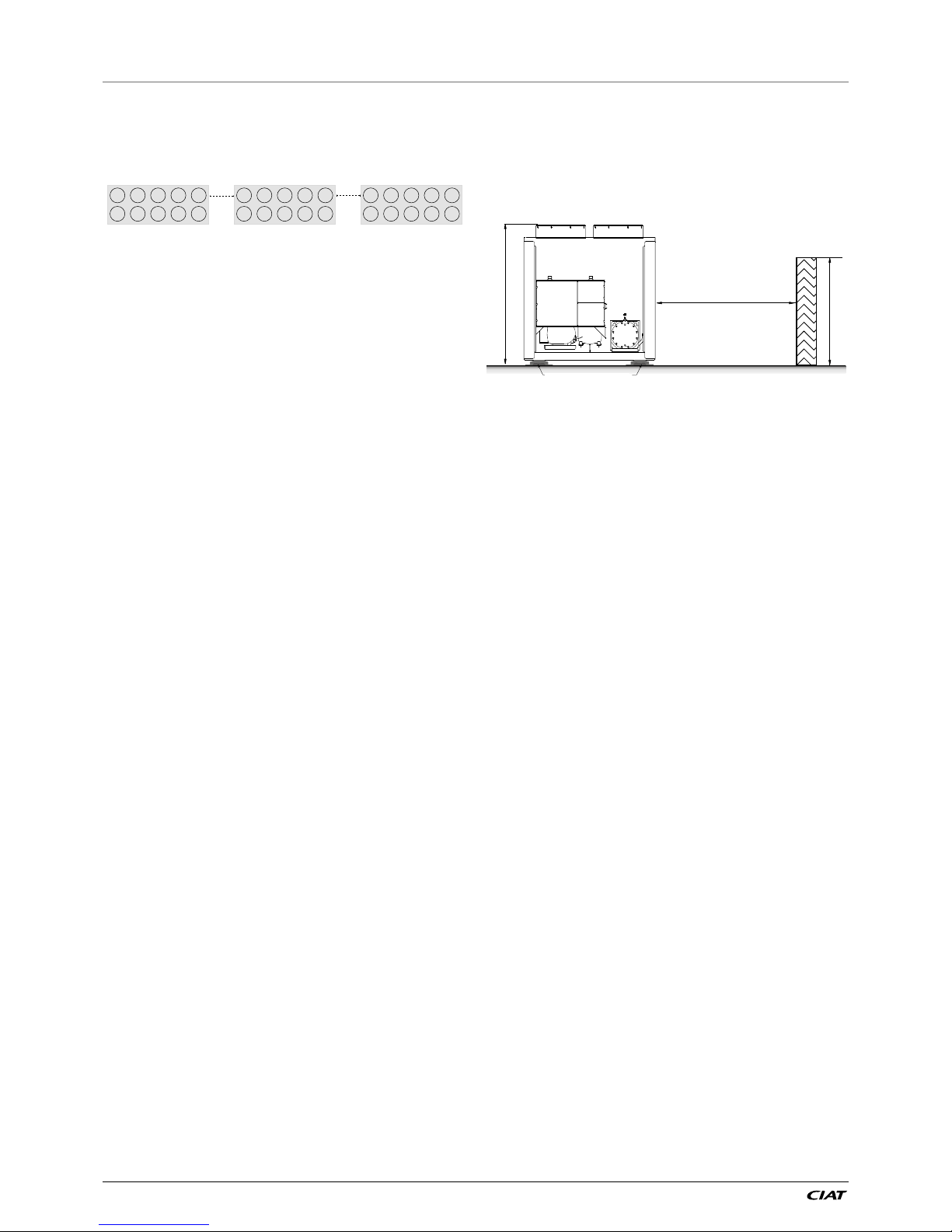

3.9 - Installation of multiple chillers

It is recommended to install multiple chillers in a single row,

arranged as shown in the example below, to avoid recycling of

warm air from one unit to another.

1.5 m

min.

1.5 m

min.

If the situation at the site does not permit this arrangement, contact

your distributor to evaluate the various possible arrangements.

In certain situations an accessory (supplied loose at the time of

purchase) can be added.

3.10 - Distance from the wall

To ensure correct operation for most cases:

If h < H (2.3 m), minimum S = 3 m

If h > H or S < 3 m, contact your CIAT distributor to evaluate the

various possible arrangements. In certain situations an accessory

(supplied loose at the time of purchase) can be added.

H

S

h

Anti-vibration mounts

3 - DIMENSIONS, CLEARANCES

EN-15 POWERCIAT LX ST/HE/XE

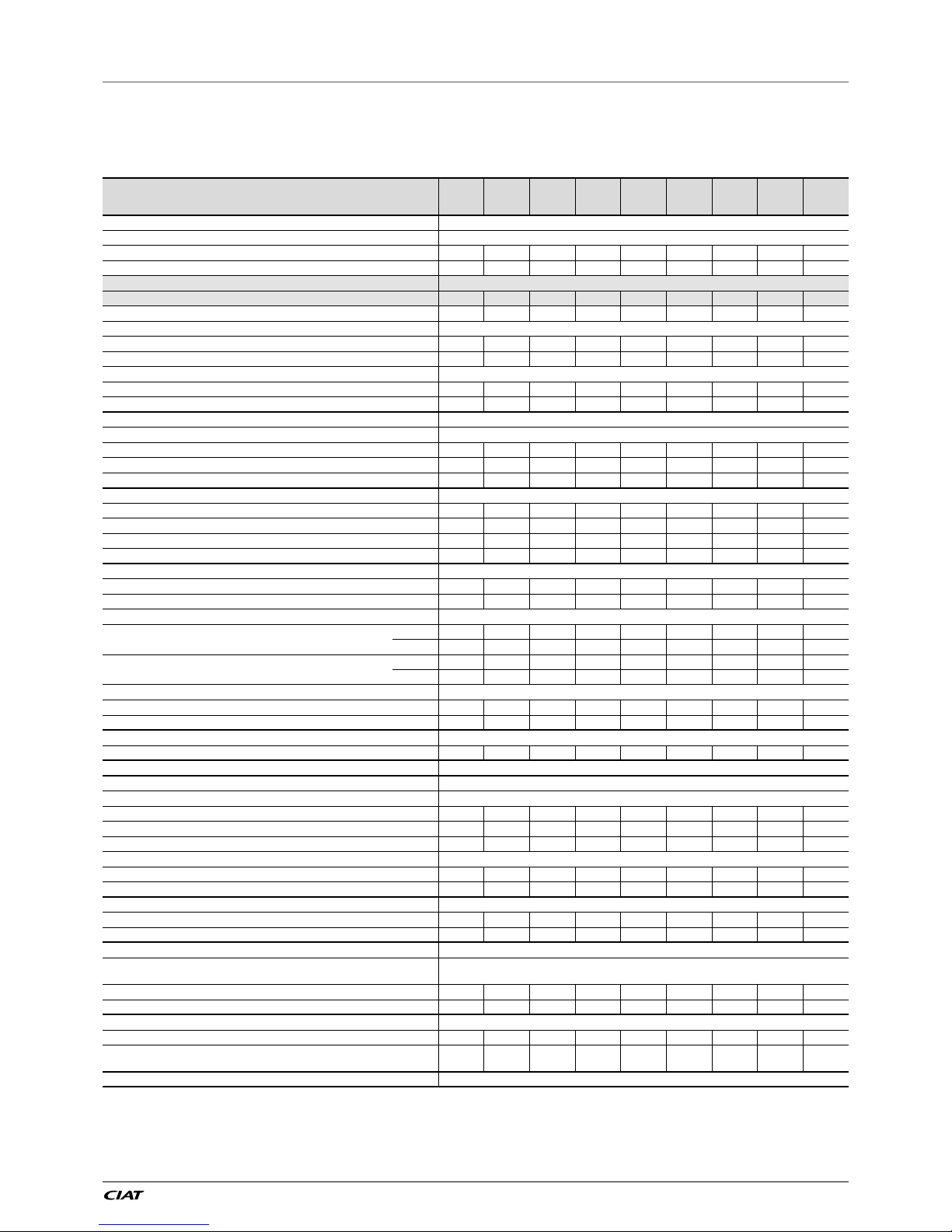

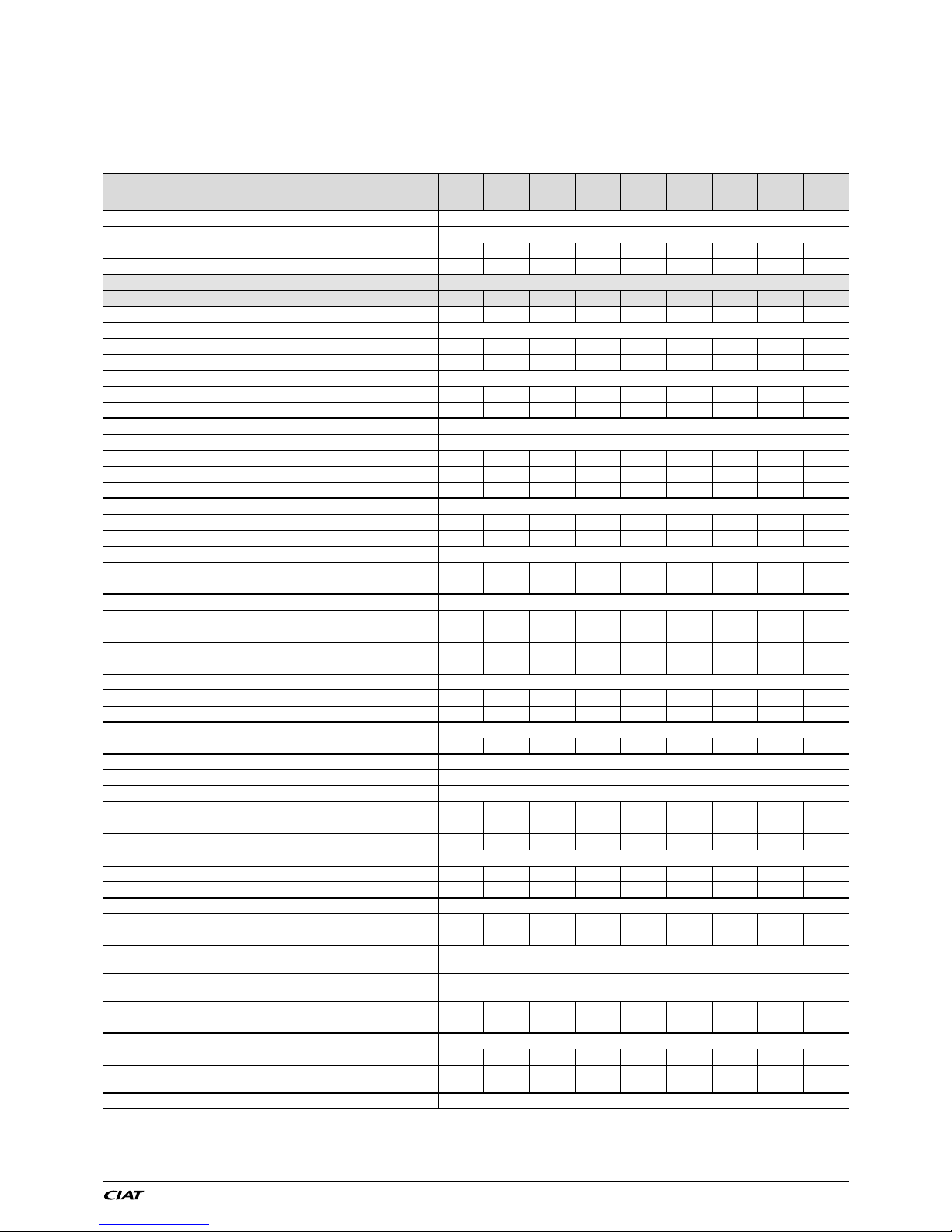

4 - PHYSICAL PROPERTIES AND ELECTRICAL DATA FOR LX UNITS

4.1 - Physical properties of LX units

LX 0808 to 2158 units

LX ST-HE 0808 0908 1008 1108 1358 1528 1858 2008 2158

Sound levels

LX ST HE

Sound power

(1)

dB(A) 100 100 100 100 102 100 102 100 103

Sound pressure at 10 m

(2)

dB(A) 68 68 68 68 70 68 69 68 71

LX ST HE + low noise option

Sound power

(1)

dB(A) 94 94 95 96 96 96 98 96 98

Sound pressure at 10 m

(2)

dB(A) 62 62 63 64 64 64 66 63 65

LX ST HE + Xtra low noise option

Sound power

(1)

dB(A) 87 87 87 90 91 91 93 92 93

Sound pressure at 10 m

(2)

dB(A) 55 55 55 58 59 59 60 59 60

LX ST HE + Super low noise option

Sound power

(1)

dB(A) - - - - 89 89 91 90 91

Sound pressure at 10 m

(2)

dB(A) - - - - 57 56 58 57 59

Dimensions

LX ST HE

Length mm 3604 3604 3604 4798 4798 5992 7186 7186 7186

Width mm 2253 2253 2253 2253 2253 2253 2253 2253 2253

Height mm 2297 2297 2297 2297 2297 2297 2297 2297 2297

Operating weight

(3)

LX ST standard kg 3190 3224 3245 3834 3899 4261 4962 5093 5376

LX ST Unit + low noise option kg 3458 3492 3513 4133 4198 4560 5293 5424 5707

LX HE standard kg 3240 3274 3295 3934 3999 4411 5112 5293 5526

LX HE Unit + low noise option kg 3508 3542 3563 4233 4298 4710 5443 5624 5857

Compressors 06T semi-hermetic screw, 50 r/s

Circuit A 1 1 1 1 1 1 1 1 1

Circuit B 1 1 1 1 1 1 1 1 1

Refrigerant

(3)

R134a

Circuit A

kg 37 35 35 51 52 54 58 58 65

tCO

2

e 52,9 50,1 50,1 72,2 74,4 76,5 82,9 82,9 93,0

Circuit B

kg 38,5 36 37 36,5 37 32,5 59 62 58

tCO

2

e 55,1 51,5 52,9 52,2 52,9 46,5 84,4 88,7 82,9

Oil

Circuit A l 20,8 20,8 20,8 23,5 23,5 23,5 23,5 23,5 27,6

Circuit B l 20,8 20,8 20,8 20,8 20,8 20,8 23,5 23,5 23,5

Capacity control Connect Touch, electronic expansion valve (EXV)

Minimum capacity % 15 15 15 15 15 15 15 15 15

Air-cooled exchanger Aluminium micro-channel coils (MCHE)

Fans

LX ST/HE Axial type, with rotating impeller

Quantity 6 6 6 8 8 9 11 12 12

Maximum total air ow l/s 27082,98 27082,98 27082,98 36110,64 36110,64 40624,47 49652,13 54165,96 54165,96

Maximum rotation speed r/s 15,7 15,7 15,7 15,7 15,7 15,7 15,7 15,7 15,7

LX ST/HE Unit + Xtra low noise option

Maximum total air ow l/s 20500 20500 20500 27333 27333 30750 37583 41000 41000

Maximum rotation speed r/s 11,7 11,7 11,7 11,7 11,7 11,7 11,7 11,7 11,7

Exchanger Flooded multi-pipe type

Water volume l 58 61 61 66 70 77 79 94 98

Max. water-side operating pressure without hydraulic module

kPa 1000 1000 1000 1000 1000 1000 1000 1000 1000

Hydraulic module (option) Pump, Victaulic screen lter, relief valve, water and air vent valve, pressure sensors

Pump

Centrifugal pump, monocell, 48.3 r/s, low- or high-pressure (as required), single or dual

(as required)

Expansion vessel volume l 50 50 50 50 50 80

Max. water-side operating pressure with hydraulic module

kPa 400 400 400 400 400 400

Water connections with or without hydraulic module Victaulic

®

type

Connections inch 5 or 4 5 or 4 5 or 4 5 or 4 5 or 4 5 or 4 5 6 6

External diameter

(4)

mm

114.3 or

141.3

114.3 or

141.3

114.3 or

141.3

114.3 or

141.3

114.3 or

141.3

114.3 or

141.3

141,3 168,3 168,3

Casing paintwork Colour code RAL 7035 & RAL 7024

(1) In dB ref=10

-12

W, 'A' weighted. Declared dual-number noise emission values in accordance with ISO 4871 with an associated uncertainty of +/-3dB(A). Measured

in accordance with ISO 9614-1 and certied by Eurovent.

(2) In dB ref 20µPa, 'A' weighted. Declared dual-number noise emission values in accordance with ISO 4871 with an associated uncertainty of +/-3dB(A). For information,

calculated from the sound power Lw(A).

(3) Values are guidelines only. Refer to the unit name plate.

(4) Depends on the number of passes on the evaporator

POWERCIAT LX ST/HE/XE EN-16

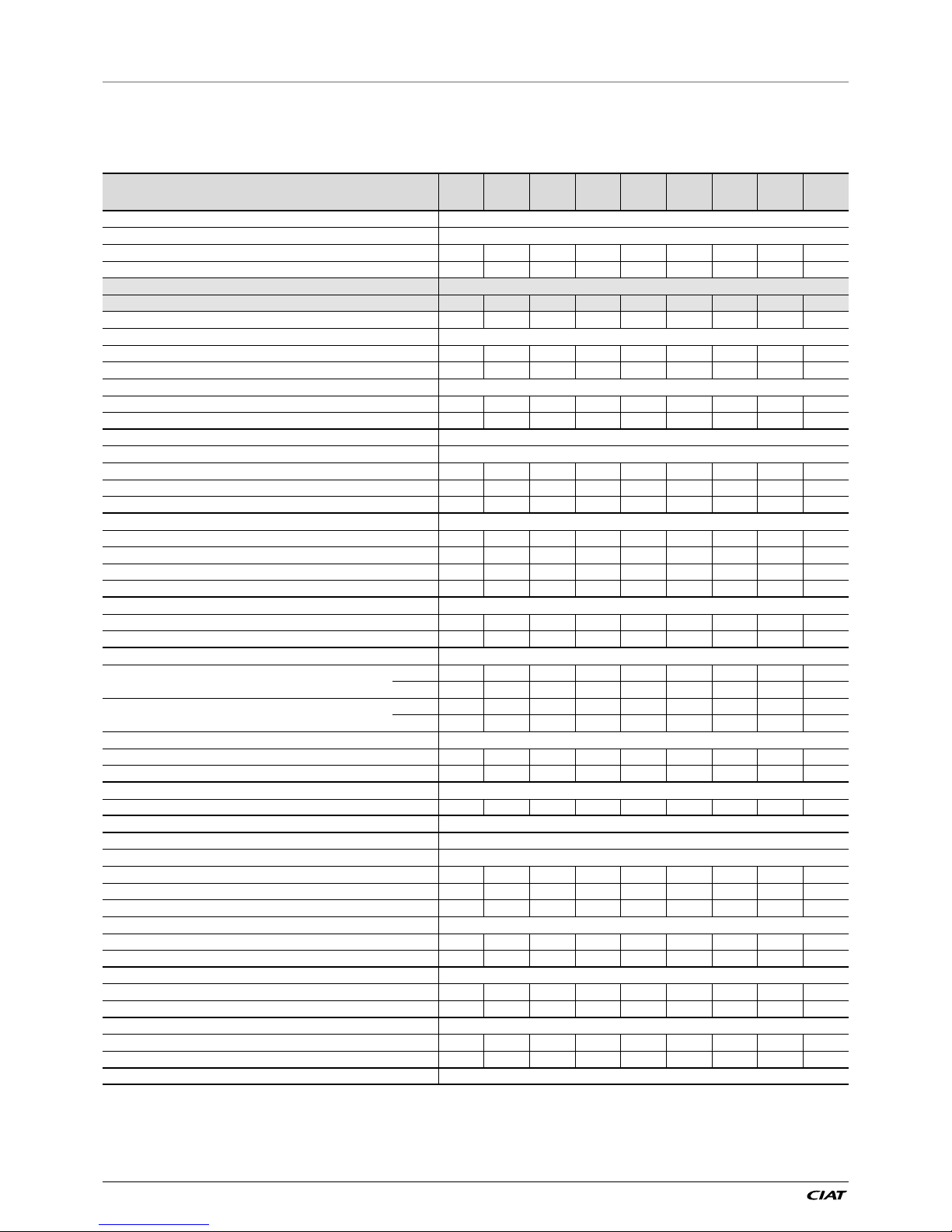

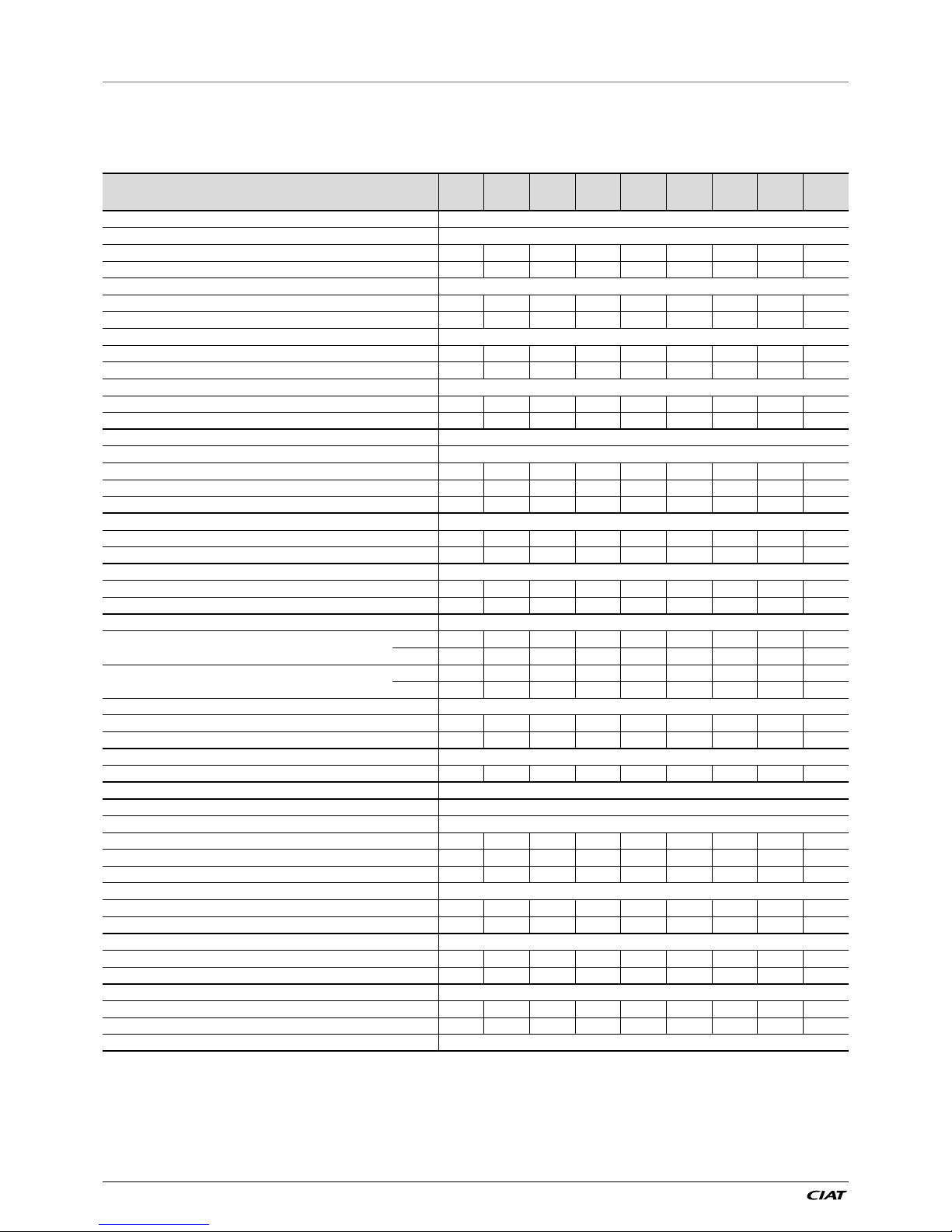

4 - PHYSICAL PROPERTIES AND ELECTRICAL DATA FOR LX UNITS

4.1 - Physical properties of LX units

LX 2308 to 4608 units

LX ST-HE 2308 2528 2628 3028 3428 3828 4008 4408 4608

Sound levels

LX ST-HE

Sound power

(1)

dB(A) 103 101 104 103 104 103 105 105 105

Sound pressure at 10 m

(2)

dB(A) 70 70 71 70 71 70 72 72 72

LX ST-HE + low noise option

Sound power

(1)

dB(A) 98 98 99 98 98 98 101 99 99

Sound pressure at 10 m

(2)

dB(A) 65 66 66 65 65 65 68 65 65

LX ST-HE + Xtra low noise option

Sound power

(1)

dB(A) 94 93 95 94 94 94 99 95 96

Sound pressure at 10 m

(2)

dB(A) 61 60 62 61 61 61 66 62 63

LX ST-HE + Super low noise option

Sound power

(1)

dB(A) 92 91 93 92 93 93 97 94 95

Sound pressure at 10 m

(2)

dB(A) 59 58 60 59 60 60 64 61 62

Dimensions

Standard unit

Length mm 7186 8380 8380 9574 11962 11962 11962 11962 13157

Width mm 2253 2253 2253 2253 2253 2253 2253 2253 2253

Height mm 2297 2297 2297 2297 2297 2297 2297 2297 2297

Operating weight

(3)

LX ST standard kg 5687 6072 6376 6827 8070 8211 8790 8867 9181

LX ST Unit + low noise option kg 6018 6403 6707 7158 8441 8582 9162 9239 9553

LX HE standard kg 5687 6072 6376 6827 8070 8211 8790 8867 9181

LX HE Unit + Low noise option kg 6018 6403 6707 7158 8441 8582 9162 9239 9553

Compressors 06T semi-hermetic screw, 50 r/s

Circuit A 1 1 1 1 1 1 1 1 1

Circuit B 1 1 1 1 1 1 1 1 1

Refrigerant

(3)

R134a

Circuit A

kg 69 72 69 75 76 76 110 116 132

tCO

2

e 98,7 103,0 98,7 107,3 108,7 108,7 157,3 165,9 188,8

Circuit B

kg 65 63 76 79 108 120 116 124 120

tCO

2

e 93,0 90,1 108,7 113,0 154,4 171,6 165,9 177,3 171,6

Oil

Circuit A l 27,6 27,6 27,6 27,6 27,6 27,6 36,0 36,0 36,0

Circuit B l 23,5 23,5 27,6 27,6 36,0 36,0 36,0 36,0 36,0

Capacity control Connect Touch, electronic expansion valve (EXV)

Minimum capacity % 15 15 15 15 15 15 15 15 15

Air-cooled exchanger Aluminium micro-channel coils (MCHE)

Fans Axial type, with rotating impeller

LX ST/HE

Quantity 12 14 14 16 20 20 20 20 22

Maximum total air ow l/s 54166 63194 63194 72221 90277 90277 90277 90277 99304

Maximum rotation speed r/s 15,7 15,7 15,7 15,7 15,7 15,7 15,7 15,7 15,7

LX ST/HE Unit + Xtra low noise option

Maximum total air ow l/s 41000 47833 47833 54667 68333 68333 68333 68333 75167

Maximum rotation speed r/s 11,7 11,7 11,7 11,7 11,7 11,7 11,7 11,7 11,7

Exchanger Flooded multi-pipe type

Water volume l 119 11 9 130 140 164 174 180 189 189

Max. water-side operating pressure without hydraulic module

kPa 1000 1000 1000 1000 1000 1000 1000 1000 1000

Water connections with or without hydraulic module Victaulic

®

type

Connections inch 6 6 6 8 6 6 6 6 6

External diameter mm

168,3 168,3 168,3 219,1 168,3 168,3 168,3 168,3 168,3

Casing paintwork Colour code RAL 7035 & RAL 7024

(1) In dB ref=10

-12

W, 'A' weighted. Declared dual-number noise emission values in accordance with ISO 4871 with an associated uncertainty of +/-3dB(A). Measured

in accordance with ISO 9614-1 and certied by Eurovent.

(2) In dB ref 20 µPa, 'A' weighted. Declared dual-number noise emission values in accordance with ISO 4871 with an associated uncertainty of +/-3dB(A).

For information, calculated from the sound power Lw(A).

(3) Values are guidelines only. Refer to the unit name plate.

EN-17 POWERCIAT LX ST/HE/XE

4.1 - Physical properties of LX units

LX 0808 to 2158 units

LX XE 0808 0908 1008 1108 1358 1528 1858 2008 2158

Sound levels

LX XE

Sound power

(1)

dB(A) 99 99 99 99 101 99 101 99 103

Sound pressure at 10 m

(2)

dB(A) 67 67 67 67 69 67 68 67 70

LX XE + low noise option

Sound power

(1)

dB(A) 93 93 94 95 95 95 97 96 97

Sound pressure at 10 m

(2)

dB(A) 61 61 62 63 63 63 65 63 64

LX XE + Xtra low noise option

Sound power

(1)

dB(A) 87 87 87 90 91 91 93 92 94

Sound pressure at 10 m

(2)

dB(A) 55 55 55 58 59 59 60 59 61

LX XE + Super low noise option not available

Sound power

(1)

dB(A) - - - - - - - - -

Sound pressure at 10 m

(2)

dB(A) - - - - - - - - -

Dimensions

Standard unit

Length mm 3604 3604 3604 4798 4798 5992 7186 7186 7186

Width mm 2253 2253 2253 2253 2253 2253 2253 2253 2253

Height mm 2297 2297 2297 2297 2297 2297 2297 2297 2297

Operating weight

(3)

LX XE standard kg 3190 3224 3245 3834 3899 4261 4962 5093 5376

LX XE + low noise option kg 3458 3492 3513 4133 4198 4560 5293 5424 5707

Compressors 06T semi-hermetic screw, 50 r/s

Circuit A 1 1 1 1 1 1 1 1 1

Circuit B 1 1 1 1 1 1 1 1 1

Refrigerant

(3)

R134a

Circuit A

kg 37 35 35 51 52 54 58 58 65

tCO

2

e 52,9 50,1 50,1 72,2 74,4 76,5 82,9 82,9 93,0

Circuit B

kg 38,5 36 37 36,5 37 32,5 59 62 58

tCO

2

e 55,1 51,5 52,9 52,2 52,9 46,5 84,4 88,7 82,9

Oil

Circuit A l 20,8 20,8 20,8 23,5 23,5 23,5 23,5 23,5 27,6

Circuit B l 20,8 20,8 20,8 20,8 20,8 20,8 23,5 23,5 23,5

Capacity control Connect Touch, electronic expansion valve (EXV)

Minimum capacity % 15 15 15 15 15 15 15 15 15

Air-cooled exchanger Aluminium micro-channel coils (MCHE)

Fans

LX XE Axial type, with rotating impeller

Quantity 6 6 6 8 8 9 11 12 12

Maximum total air ow l/s 28920 28920 28920 38560 38560 43380 53020 57840 57840

Maximum rotation speed r/s 15,7 15,7 15,7 15,7 15,7 15,7 15,7 15,7 15,7

LX XE + Xtra low noise option

Maximum total air ow l/s 23580 23580 23580 31440 31440 35370 43230 47160 47160

Maximum rotation speed r/s 11,7 11,7 11,7 11,7 11,7 11,7 11,7 11,7 11,7

Exchanger Flooded multi-pipe type

Water volume l 58 61 61 66 70 77 79 94 98

Max. water-side operating pressure without hydraulic module

kPa 1000 1000 1000 1000 1000 1000 1000 1000 1000

Hydraulic module (option)

Pump, Victaulic screen lter, relief valve, water and air vent valve,

pressure sensors

Pump

Centrifugal pump, monocell, 48,3r/s, low or high pressure (as required),

single or dual (as required)

Expansion vessel volume l 50 50 50 50 50 80

Max. water-side operating pressure with hydraulic module

kPa 400 400 400 400 400 400

Water connections with or without hydraulic module Victaulic

®

type

Connections inch 5 or 4 5 or 4 5 or 4 5 or 4 5 or 4 5 or 4 5 6 6

External diameter mm

114.3 or

141.3

114.3 or

141.3

114.3 or

141.3

114.3 or

141.3

114.3 or

141.3

114.3 or

141.3

141,3 168,3 168,3

Casing paintwork Colour code RAL 7035 & RAL 7024

(1) In dB ref=10

-12

W, 'A' weighted. Declared dual-number noise emission values in accordance with ISO 4871 with an associated uncertainty of +/-3dB(A). Measured

in accordance with ISO 9614-1 and certied by Eurovent.

(2) In dB ref 20µPa, 'A' weighted. Declared dual-number noise emission values in accordance with ISO 4871 with an associated uncertainty of +/-3dB(A). For information,

calculated from the sound power Lw(A).

(3) Values are guidelines only. Refer to the unit name plate.

4 - PHYSICAL PROPERTIES AND ELECTRICAL DATA FOR LX UNITS

POWERCIAT LX ST/HE/XE EN-18

4.1 - Physical properties of LX units

LX 2308 to 4608 units

LX XE 2308 2528 2628 3028 3428 3828 4008 4408 4608

Sound levels

LX XE

Sound power

(1)

dB(A) 103 101 104 102 103 102 104 104 104

Sound pressure at 10 m

(2)

dB(A) 70 70 71 69 70 69 71 71 71

LX XE + low noise option

Sound power

(1)

dB(A) 98 97 99 98 98 98 100 99 99

Sound pressure at 10 m

(2)

dB(A) 65 65 66 65 65 65 67 65 65

LX XE + Xtra low noise option

Sound power

(1)

dB(A) 94 94 95 94 94 94 99 95 96

Sound pressure at 10 m

(2)

dB(A) 61 61 62 61 61 61 66 62 63

LX XE + Super low noise option not available

Sound power

(1)

dB(A) - - - - - - - - -

Sound pressure at 10 m

(2)

dB(A) - - - - - - - - -

Dimensions

Standard unit

Length mm 7186 8380 8380 9574 11962 11962 11962 11962 13157

Width mm 2253 2253 2253 2253 2253 2253 2253 2253 2253

Height mm 2297 2297 2297 2297 2297 2297 2297 2297 2297

Operating weight

(3)

LX XE standard kg 5687 6072 6376 6827 8070 8211 8790 8867 9181

LX XE + low noise option kg 6018 6403 6707 7158 8441 8582 9162 9239 9553

Compressors 06T semi-hermetic screw, 50 r/s

Circuit A 1 1 1 1 1 1 1 1 1

Circuit B 1 1 1 1 1 1 1 1 1

Refrigerant

(4)

R134a

Circuit A

kg 69 72 69 75 76 76 110 116 132

tCO

2

e 98,7 103,0 98,7 107,3 108,7 108,7 157,3 165,9 188,8

Circuit B

kg 65 63 76 79 108 120 116 124 120

tCO

2

e 93,0 90,1 108,7 113,0 154,4 171,6 165,9 177,3 171,6

Oil

Circuit A l 27,6 27,6 27,6 27,6 27,6 27,6 36,0 36,0 36,0

Circuit B l 23,5 23,5 27,6 27,6 36,0 36,0 36,0 36,0 36,0

Capacity control Connect Touch, electronic expansion valve (EXV)

Minimum capacity % 15 15 15 15 15 15 15 15 15

Air-cooled exchanger Aluminium micro-channel coils (MCHE)

Fans Axial type, with rotating impeller

LX XE

Quantity 12 14 14 16 20 20 20 20 22

Maximum total air ow l/s 57840 67480 67480 77120 96400 96400 96400 96400 106040

Maximum rotation speed r/s 15,7 15,7 15,7 15,7 15,7 15,7 15,7 15,7 15,7

LX XE + Xtra low noise option

Maximum total air ow l/s 47160 55020 55020 62880 78600 78600 78600 78600 86460

Maximum rotation speed r/s 11,7 11,7 11,7 11,7 11,7 11,7 11,7 11,7 11,7

Exchanger Flooded multi-pipe type

Water volume l 119 11 9 130 140 164 174 180 189 189

Max. water-side operating pressure without hydraulic module

kPa 1000 1000 1000 1000 1000 1000 1000 1000 1000

Water connections with or without hydraulic module Victaulic

®

type

Connections inch 6 6 6 8 6 6 6 6 6

External diameter mm 168,3 168,3 168,3 219,1 168,3 168,3 168,3 168,3 168,3

Casing paintwork Colour code RAL 7035 & RAL 7024

(1) In dB ref=10

-12

W, 'A' weighted. Declared dual-number noise emission values in accordance with ISO 4871 with an associated uncertainty of +/-3dB(A). Measured

in accordance with ISO 9614-1 and certied by Eurovent.

(2) In dB ref 20µPa, 'A' weighted. Declared dual-number noise emission values in accordance with ISO 4871 with an associated uncertainty of +/-3dB(A). For information,

calculated from the sound power Lw(A).

(3) Values are guidelines only. Refer to the unit name plate.

4 - PHYSICAL PROPERTIES AND ELECTRICAL DATA FOR LX UNITS

Loading...

Loading...