CIAT OPERA User Manual

1

OPERA

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 15.689 A

Drycoolers

Air-cooled condensers

The OPERA range, available in drycooler or air-cooled condenser versions, is particularly suited to service sector, industrial

and healthcare applications.

Drycoolers in the OPERA range are mainly designed for

cooling water or glycol/water mix for:

n Condensers for water chillers,

n Generators,

n Free cooling,

n Processes and machines (presses, compressors, etc.).

Air-cooled condensers in the OPERA range are mainly

designed for the condensation of refrigerants for water

chillers, as a "split system".

These devices are designed to be installed outdoors.

OPERA is a large modular range, which offers:

n 3 casing lengths (S, M or L module), allowing either the

dimensions, the capacity or the power consumption to be

optimised.

n A range of sizes, from 1 to 14 fans.

n 2 impeller diameters, 800 or 910 mm.

n Several rotation speeds, from 330 to 1 000 rpm.

n Several configurations: horizontal or vertical unit with forced or

induced draught for high temperatures.

Various combinations of these elements, as well as the choice

of a number of options, allow us to provide devices that are

adapted to a lange range of applications and environments.

Use

Range

Capacity: up to 1100 kW

MORE

n

More efficient

n

More flexible

n

More intelligent

for

LESS

n

Less energy

n

Less time

n

Less noise

134a

407C

410A 404A

Water

misting

Free cooling

2

heat pumps - aIR CONDItIONING - ReFRIGeRatION - aIR haNDLING - heat eXChaNGe - Na 15.689 a

Drycoolers

Air-cooled condensers

OPERA

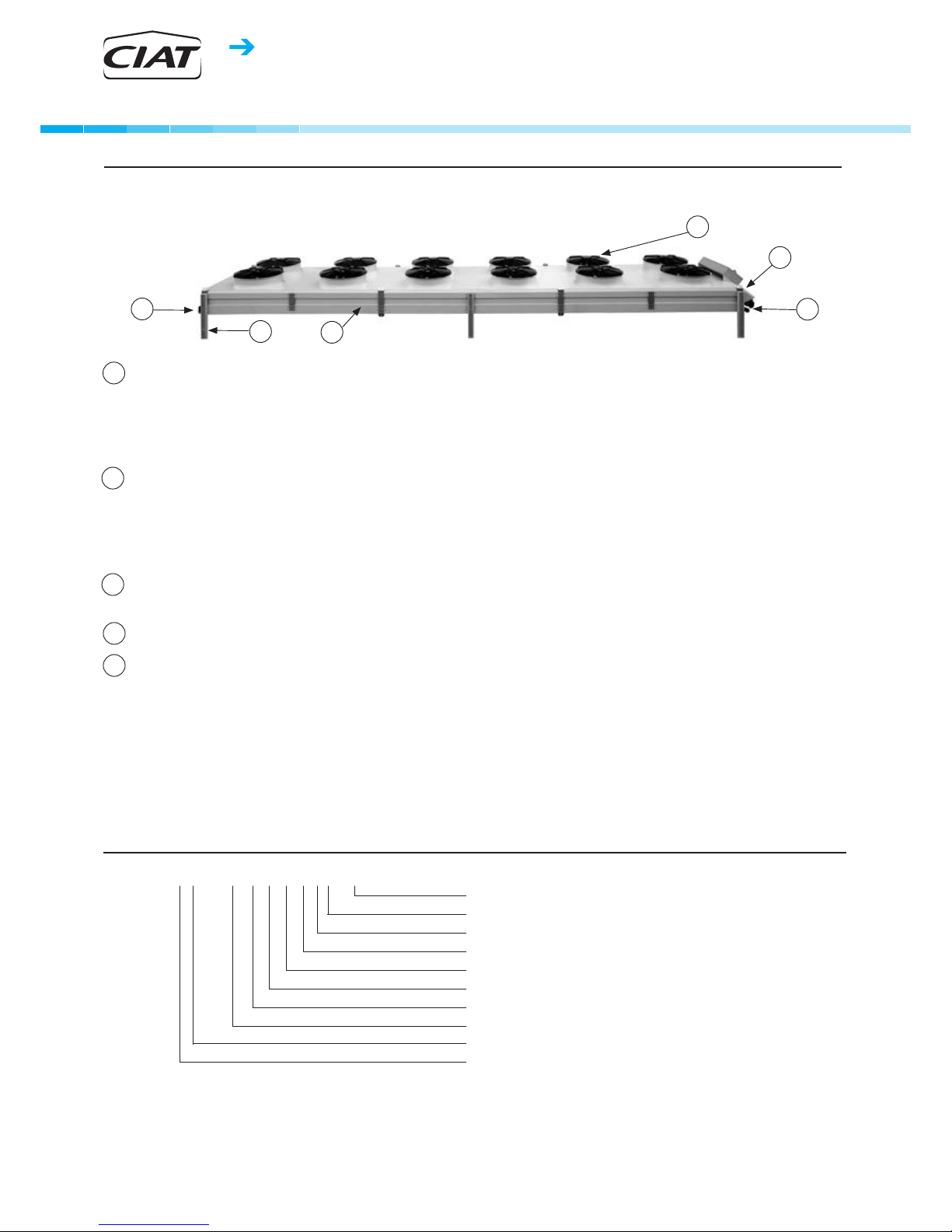

Coil

Copper tubing and manifolds, high-performance aluminium fins, resistant to fouling.

Anti-shear system for tube bundles.

Pipings for drycooler: ISO PN16 type 02A rotating flanges in line with NFEN1092 in 304L stainless steel (1 or 2 input(s)/

outputs(s) depending on the flow rate) – The tubes are sealed with plastic caps to protect the bundle.

Tubes for condenser: copper (1 input/output per refrigerating circuit for units with 1 fan line, 2 inputs/outputs for units with 2 fan

lines). Delivered pressurised with nitrogen.

Fan motor assemblies

Profiles collars with galvanised steel with polyester powder coating on the internal and external surfaces.

Aluminium and polypropylene impellers.

Class F motor - IP54 - 3PH400V +/-10% 50Hz+/-2% - Standard connection to the motor terminal boxes

Black protective grille compliant with standard BS ISO 12499.

Individual partitioning.

The motors are also available in a 60 Hz version or in other voltages.

Casing

Galvanised steel with polyester powder coating on the internal and external surfaces. Assembly using stainless rivets and

LANTHANUM nuts and bolts for the feet.

Feet

Galvanised steel with polyester powder coating on the internal and external surfaces.

Protective enclosures on the elbows and manifolds

Excellent resistance to corrosion

The casing boasts category C3 protection against corrosion,

in line with ISO standard 12944-2 – colour RAL 7035 (light grey)

DescRiption

1

1

2

2

4

4

3

3

5

5

5

Each device is tested:

n The coil sealing is subjected to an underwater airtightness

test.

n For devices with the terminal box or electrical cabinet option:

rotation tests, dielectric tests, current measurement.

The OPERA range complies with the following European

directives:

n Machinery Directive 2006/42/EC,

n EMC Directive 2004/108/EC,

n Pressure Equipment Directive (PED) 97/23 EC.

Designation (example)

OPERA DLN 9124-2 SHI 690A

Rotation speed

Draught (I = Induced, F = Forced)

Position (H = Horizontal, V = Vertical)

Coil type (S = Single, D = Double, T = Twin, Z = Drainable)

Number of fan lines (1 or 2)

Number of coil rows

Number of fans

Impeller diameter (8 = 800, 9 = 900 mm)

Module size (S = Short, M = Medium, L = Long)

D = Drycooler C = Condenser

3

OPERA

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 15.689 A

Drycoolers

Air-cooled condensers

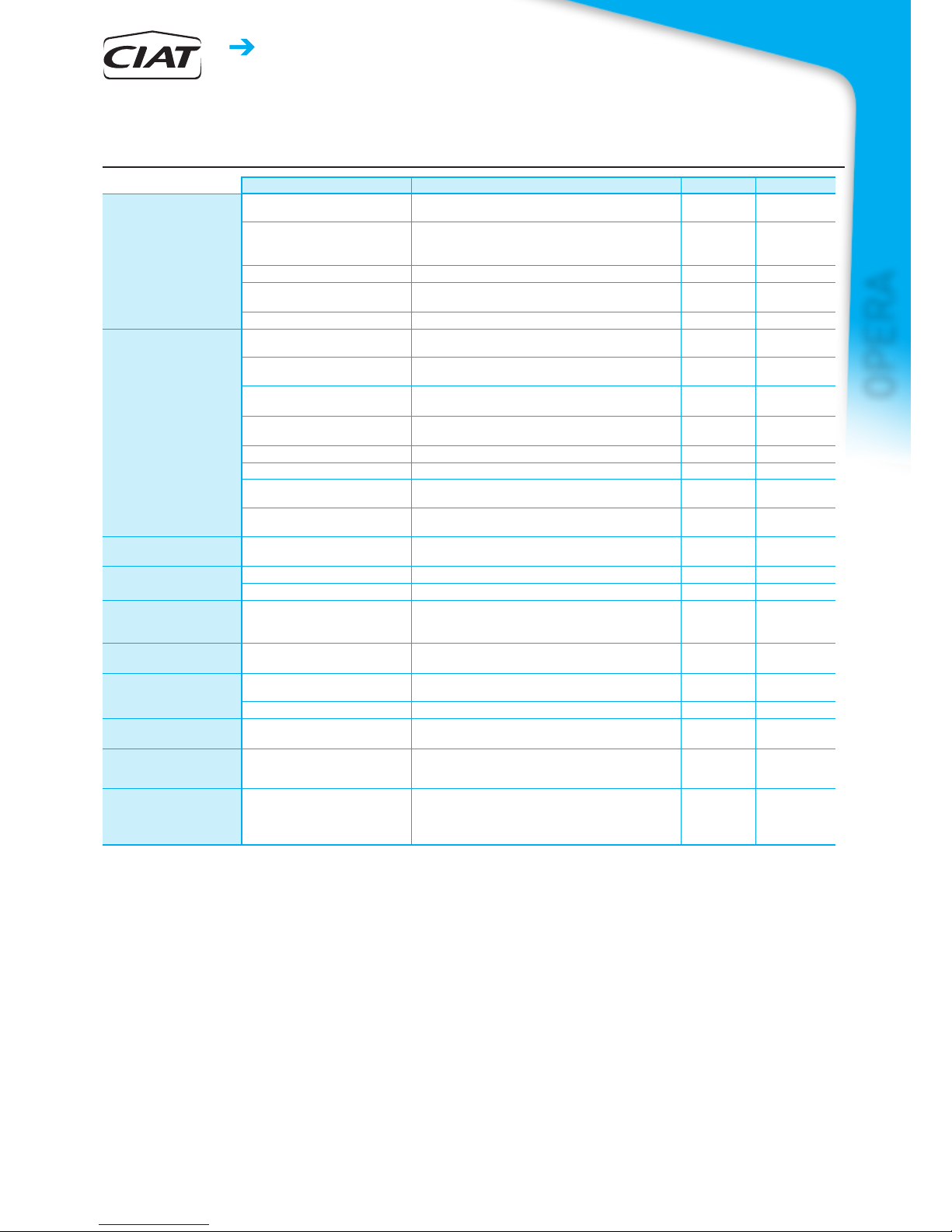

options foR each application

Options Description/Advantages DRYCOOLER CONDENSER

Protection adapted

for the environment

Pre-coated aluminium ns

Improves the resistance of the blades to corrosion.

For low corrosion environments.

● ●

High efciency coating on the

nned bundle:

ALUCOAT®507 or HERESITE

Improves the resistance of the blades to corrosion.

For corrosive environments.

● ●

Stainless steel tube bundle

For corrosive uids.

●

Corrosiveness resistance

category C5M

Casing and fan motor assemblies for corrosive environments.

● ●

ATEX II 2G/3G

For explosive atmospheres.

● ●

Quick, simple installation

Terminal box

Connection to the terminals of each motor on the front panel

of unit.

● ●

Protection cabinet

Protected by a thermal-magnetic circuit breaker on each

motor.

●

Control cabinet with

AeroCONNECT

Protection for motors and stage regulation provided by an

electronic board according to temperature or pressure.

● ●

Control cabinet with stages on

terminals

Motor protection and stages controlled by the customer

control.

●

Maintenance switch

For stopping individual motors.

● ●

Companion anges

In stainless steel, with gaskets and bolts.

●

Raised feet

To ensure a good ow of air depending on how the units are

installed: against a wall, side by side, etc.

● ●

Blade protective screen

Protection against hail, impacts, etc.

For forced draught, vertical units.

● ●

Installation surface

constraints

Vertical position

For narrow terraces.

● ●

Optimised, secure

transport

Stacking of 2 identical devices

● ●

Skid for transport by container

Secure transport and easy loading/unloading.

● ●

Optimisation

of electrical consumption

and sound levels

EC motor

(with electronic switching)

Variable speed control from 0 to 100% using a 0/10V signal.

With the control cabinet via electronic board option, the

device is self-regulating

● ●

High-temperature

uid application

Forced draught

Motors in the ow of fresh air.

●

Generator application

Double circuit drycooler

Cooling of 2 water circuits (LT – HT) in series using air from

just 1 unit.

●

Expansion vessel

Max permissible pressure: 0.5 bar eff.

●

Application for water

without glycol

Drainable coil

Device located on a slope to prevent frost - drainage by gravity

●

Free cooling application Free cooling valve kit

Valves with motor and sensor, controlled by the electronic

board. Controlled according to the operation of the drycooler

or chiller.

●

Application with

adiabatic cooling AEROFRESH (water misting

into the air ow)

Size of the unit reduced by cooling of the ambient air.

Operates completely safely due to the antibacterial

treatment applied to the water.

● ●

Loading...

Loading...