CIAT ITEX NA 10.51 D Installation, Operation, Commissioning, Maintenance

Installation

Operation

Commissioning

Maintenance

ITEX

03 - 2014

NA 10.51 D

G

ASKETED PLATE

HEAT EXCHANGER

EN - 1

EN

CONTENTS PAGE

1 - GENERAL INFORMATION

2

1.1 Preface

2

1.2 Standards

2

1.3 Warranty

2

1.4 Residual risks

2

1.5 Receiving the unit

3

1.6 Handling

3

1.7 Intended use

4

1.8 Description

4

1.9 Data plate

5

2 - STORAGE

5

3 - INSTALLATION

6

3.1 Choice of installation location

6

3.2 Installation recommendations

6

3.3 Hydraulic connections

6

3.4 Insulation and protection accessories

7

4 - OPERATION

7

4.1 Commissioning

7

4.2 Post-commissioning tests

7

5 - MAINTENANCE

7

5.1 Preventive maintenance 7

5.2 Disassembly 8

5.3 Manual cleaning 8

5.4 Cleaning in place (CIP) 8

5.5 Detergents 9

5.6 Liquid penetrant testing 9

5.7 Gasket replacement 10

5.8 Reassembly 11

5.9 Plate codes 11

5.10 Arrangement examples 12

5.11 Increasing the transfer area 12

5.12 Spare plates 12

5.13 Troubleshooting 13

6 - DISPOSAL 13

EN - 2

1. GENERAL INFORMATION

1.1 - Preface

Your heat exchanger will give you full satisfaction provided you maintain it well, in full, and diligently.

- Be sure to keep the following documents in a safe place:

1) this instruction and maintenance manual (supplied with the heat exchanger);

2) the EC declaration of conformity, where necessary. Supplied upon request.

- Your plate heat exchanger has temperature and pressure limits and is highly sensitive to sudden changes in these parameters.

Therefore, all necessary precautions must be taken to avoid operating outside the limits indicated on the data plate.

1) Excessive temperatures will damage the gaskets (install the appropriate safety thermostats, etc.).

2) Excessive operating pressures or differential pressures will damage the gaskets and plates (install the appropriate safety

valves, etc.).

- Plate heat exchangers are highly sensitive to water hammers. The control must be designed accordingly and QUARTER-TURN

VALVES MUST NOT BE INSTALLED ON ANY OF THE CIRCUITS.

- Given the large number of gaskets, leaks may occasionally occur. To protect against this eventuality, install protective screens

if dangerous fluids are used or the temperatures rise to above 60°C.

- CIAT may not be held liable for any damage or injury resulting from failure to follow the instructions in this manual.

- CIAT is not liable for any consequences that may result from the accidental mixing of the fluids used in the heat exchanger.

1.2 - Standards

- Official checks: some heat exchangers must be regularly checked by official bodies. It is the operator’s responsibility to organise

these checks directly with the competent bodies. The dossier sent to our contractors must therefore be kept in a safe place.

- The heat exchanger category set out in the European Pressure Equipment Directive 97/23/EC is specified on the data plate on

the heat exchanger and on the last page of this manual.

- You must make sure that the installation complies with the directives and legislation in effect in the country of operation.

- This heat exchanger must not be used for purposes other than those stated on the order documents. In particular, do not use

fluids other than those specified at the time of ordering.

- Scrupulously comply with the operating conditions set out in the order documents. These were used to determine the equipment

category set out in the European Pressure Equipment Directive. CIAT shall not be held liable for any consequential or incidental

damages resulting from failure to do so.

- CIAT must be notified of any changes in the operating conditions and will inform you of the procedure to follow.

1.3 Warranty

- Unless otherwise indicated, our equipment is guaranteed for 12 months after commissioning and no more than 18 months after

invoicing. Our warranty is limited to the replacement of defective parts used under the intended conditions. However, it does not

cover normal wear and tear, deterioration resulting from corrosion, dirt or the use of fluids incompatible with the materials used

in the heat exchanger, or consequential damage.

- Gaskets are warranted for six months.

- Keep a maintenance log.You may be requested to provide this in order to benefit from the warranty.

- The warranty is valid only if the heat exchanger is operated under the conditions set out in the order documents. It will be applied

only if the pressures and temperatures of the fluids can be easily measured on the heat exchanger’s inlets and outlets and the

maintenance log is kept up to date.

- The plate pack is sealed by a strap (warranty seal) which serves as proof that the heat exchanger has never been disassembled.

Removing this strap will void the warranty.

- Spare parts are warranted only if the storage instructions have been followed (see the section on storage).

- CIAT must be promptly notified of any defects, in writing. If CIAT’s liability for the defect is proven, CIAT pledges to react quickly

and to remedy it within the terms of the warranty.

1.4 - Residual risks :

damage > cause (prevention)

POSSIBLE BODILY INJURY

- Unit tips over > Failure to follow the handling or anchoring instructions (the unit has a very high centre of gravity; follow the

harnessing instructions; anchor the unit to the floor).

- Burns > Direct contact with the unit while in operation or with scalding or corrosive fluids following a leak (cut off the supply to

the unit; set up barriers around it; wear PPE = Personal Protective Equipment).

EN - 3

EN

- Cuts > Handling the plates without protective gloves (wear PPE).

- Injury > Caused by pressure, affecting in particular the eyes or bare skin (wear PPE and prohibit access by unauthorised

personnel).

- Poisoning > Skin contact with, or inhalation of, a dangerous fluid (wear PPE and use safety devices).

- Poisoning > Combustion of the gaskets (never dispose of the gaskets by burning them).

- Poisoning > Accidental mixing of circulating fluids resulting in the release of hazardous vapours (make sure that resulting

mixture is not dangerous).

COMMON TYPES OF COMPONENT DAMAGE

- Gasket destruction > One fluid circulated at a high temperature (always circulate the cold fluid FIRST and then the hot fluid).

- Gasket destruction > Sudden changes in pressure or temperature (monitor the control).

- Gasket destruction > Overrun of operating conditions (check the operating parameters).

- Plate destruction > Corrosion or erosion (check the type and speed of the fluids being circulated; install filters).

- Plate destruction > Overpressure (check the pressure of the fluids; watch out for sudden or frequent changes in pressure or

temperature).

- Plate destruction > The heat exchanger has frozen (make sure that the room temperature does not drop below 0°C while the

system is not in use or drain the circuits).

- Leaks > The tightening dimension is wrong (check the tightness of the plate pack).

- Leaks > The frame or a number of plates are deformed (contact CIAT).

- Pollution > Leak of a dangerous or polluting fluid (have recovery pans on hand).

- Explosion > Accidental mixing of circulating fluids resulting in the release of explosive vapours (make sure that resulting mixture

is not dangerous).

Prohibit access to the installation by unauthorised personnel.

Make sure that servicing technicians have the proper training.

Keep this manual near the heat exchanger.

1.5 - Receiving the unit

- At delivery, check the condition of the product. Check that it has not been damaged during transport and that all accessories

are included. If any damage is found or the delivery is incomplete, make a detailed note of the non-conformity on the delivery

note and inform the carrier by registered letter within three days of delivery and forward a copy to CIAT.

- The front of each heat exchanger is fitted with a data plate listing a service number. Please state this number in all

correspondence.

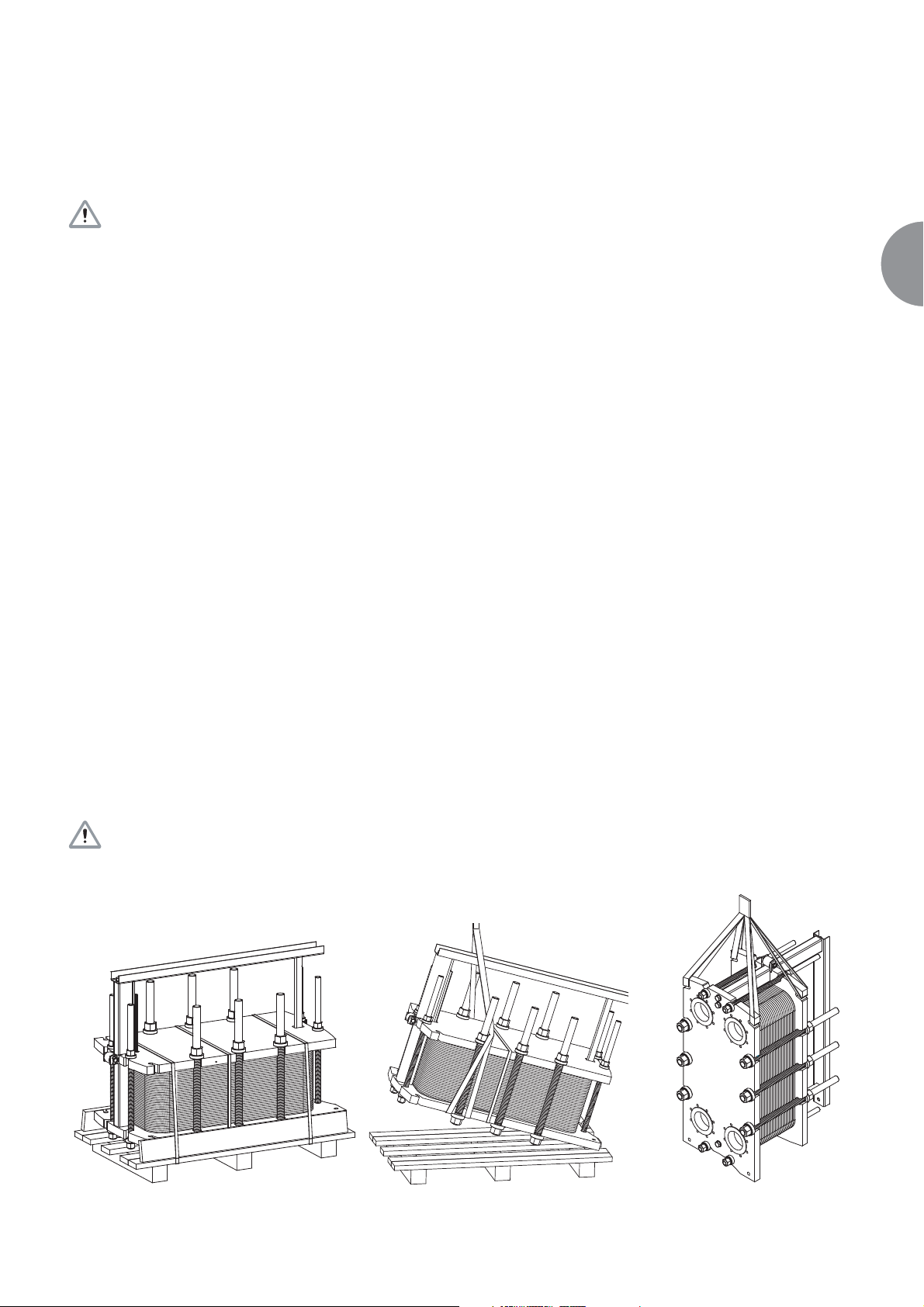

1.6 - Handling

- The handling and unloading equipment is the responsibility of the recipient.

- Follow the harnessing instructions (Figures 1a, 1b and 2).

- Use fabric belts (no metal chains). Insert them in the designated notches on the plates.

- The unit’s weight is stated on the delivery note and shipping note.

- When moving and handling the heat exchanger, make sure that it is properly supported and secured as its high centre

of gravity may cause it to tip over easily.

- Never lift the unit by its runners, threaded rods or couplings, as doing so can cause them to bend.

- Shield the plates from impacts as they could cause irreparable leaks.

Fig.1a

Fig.1b

Fig.2

Loading...

Loading...