CIAT Ereba He Series Instruction Manual

10195

05 - 2019

Instruction manual

EREBA He

Heat Pumps

Inverter Reversible Air-to-Water

CONTENTS

ACRONYMS AND LEGEND .................................................................................5

Acronyms .......................................................................................................................5

Control Configuration Legend ..........................................................................................5

Standard installation Legend ...........................................................................................6

1 - INTRODUCTION ..............................................................................................7

1.1 - Introduction ..............................................................................................................7

1.2 - Safety.......................................................................................................................7

1.3 - Preliminary checks ..................................................................................................13

1.4 - Dimensions and clearance for EREBA He units ......................................................14

1.5 - Physical data and electrical data of EREBA He units ..............................................16

1.6 - Accessories ............................................................................................................18

2 - INSTALLATION OF UNIT ...............................................................................19

2.1 - General ...................................................................................................................19

2.2 - Moving and placing the unit ....................................................................................19

2.3 - Water connections ..................................................................................................21

2.4 - Electrical connections .............................................................................................26

2.5 - Water flow rate control ............................................................................................28

2.6 - Commissioning modes ...........................................................................................32

2.7 - Check before start the unit ......................................................................................32

3 - INSTALLATION OF SYSTEM .........................................................................33

3.1 - General customer electrical connection on terminal block ......................................33

3.2 - First step of configuration: Setting the time and day ................................................34

3.3 - Second step of configuration: Parameter menu ......................................................35

3.4 - Installation with electrical booster heaters ..............................................................36

3.5 - Installation with DHW production ............................................................................39

3.6 - Installation with boiler ..............................................................................................43

3.7 - Installation with DHW and pool heating production, boiler and buffer tank ..............46

3.8 - Master / Slave installation .......................................................................................49

3.9 - Unit with remote user interface................................................................................54

3.10 - Additional OAT sensor ..........................................................................................56

3.11 - IAT sensor .............................................................................................................56

4 - OPERATION ...................................................................................................58

4.1 - Unit range - EREBA He ...........................................................................................58

4.2 - Operating modes ...................................................................................................58

4.3 - Major system components ......................................................................................72

EREBA He

EN-2

CONTENTS

5 - MAINTENANCE ..............................................................................................75

5.1 - Standard maintenance ............................................................................................75

5.2 - Tightening torques for the main electrical connections ...........................................77

5.3 - Air heat exchanger ..................................................................................................77

5.4 - Water heat exchanger maintenance ........................................................................77

5.5 - Unit maintenance ....................................................................................................77

5.6 - Refrigerant volume ..................................................................................................77

5.7 - Characteristics of R-410A .......................................................................................78

6 - ALARM DESCRIPTION ..................................................................................79

6.1 - Inverter board alarm codes (only for 11-15 kW 1Ph or 3Ph units) ...........................79

6.2 - Alarm listing ............................................................................................................80

7 - PARAMETERS OVERVIEW ............................................................................83

7.1 - Parameters list ........................................................................................................83

7.2 - Description of customized DI/DO configurations .....................................................90

8 - START-UP CHECKLIST FOR EREBA He HEAT PUMPS (USE FOR JOB FILE) .. 91

8.1 - General information ................................................................................................91

8.2 - Available options and accessories ..........................................................................91

8.3 - Checks before start of unit ......................................................................................92

8.4 - Checks during operation of unit ..............................................................................92

8.5 - Maintenance checks ...............................................................................................93

TABLES CONTENT

Table 1: Minimum and maximum wire section (per phase) for connection to EREBA He

units ..................................................................................................................27

Table 2: Steps to clean, purge, and define a flow rate for hydraulic circuit .......................29

Table 3:

Table 4: Different operating modes .................................................................................59

Table 5: Possible switches to install on system ...............................................................60

Table 6: Different configurations of pump .......................................................................68

Table 7: Different control logic for main pump .................................................................69

Table 8: Different control logic for additional pump ..........................................................69

Table 9: Alarms listing .....................................................................................................80

Actions in WUI parameter menu or Service tools to activate the cleaning purge and

control of flow rate for hydraulic circuit ...................................................................... 29

GRAPHICS CONTENT

Graphic 1: Available static pressure for 5 to 15 kW units with hydraulic module ..............31

EN-3

EREBA He

FIGURES CONTENT

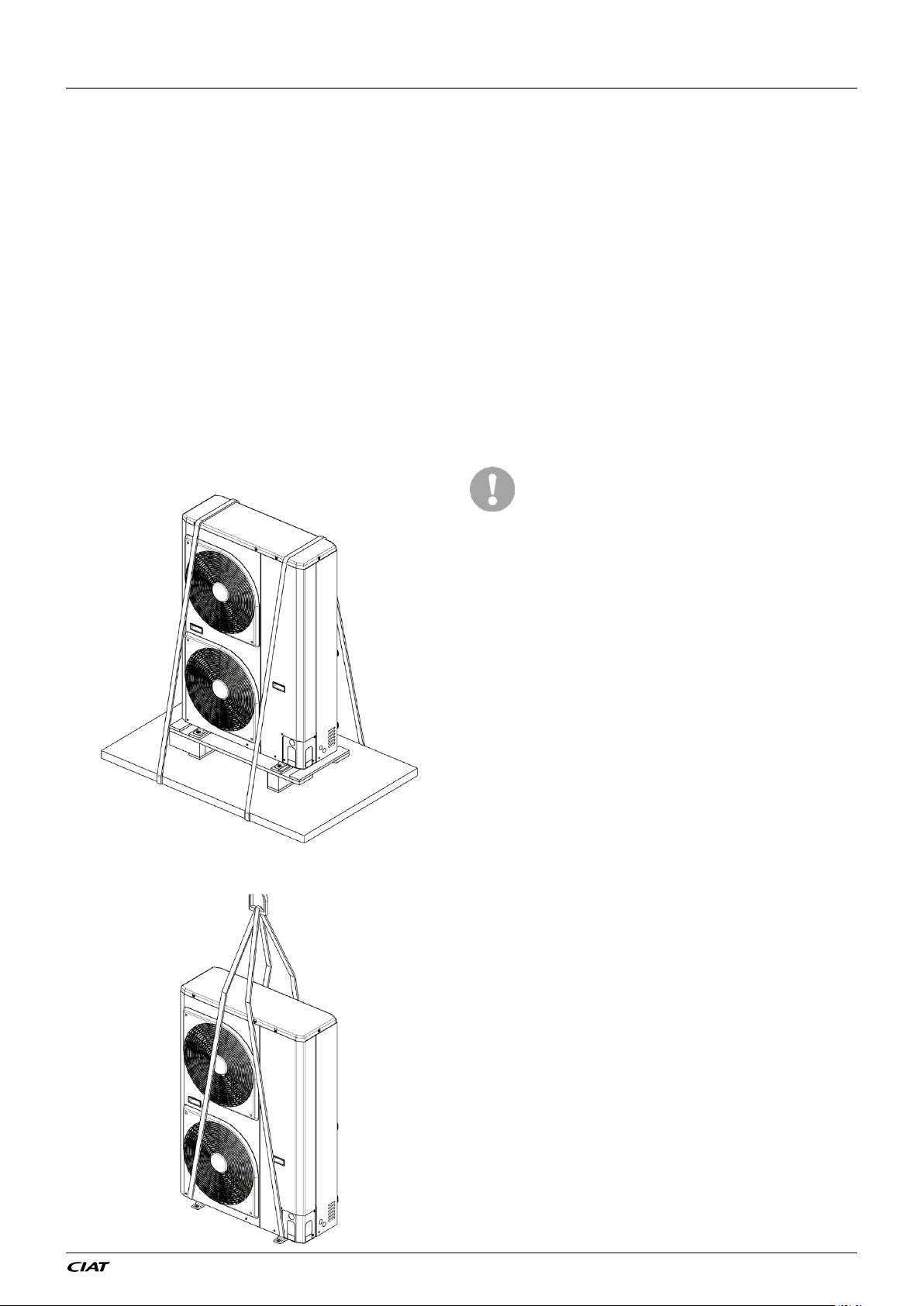

Figure 1: Transport configuration .....................................................................................19

Figure 2: Offloading configuration ...................................................................................19

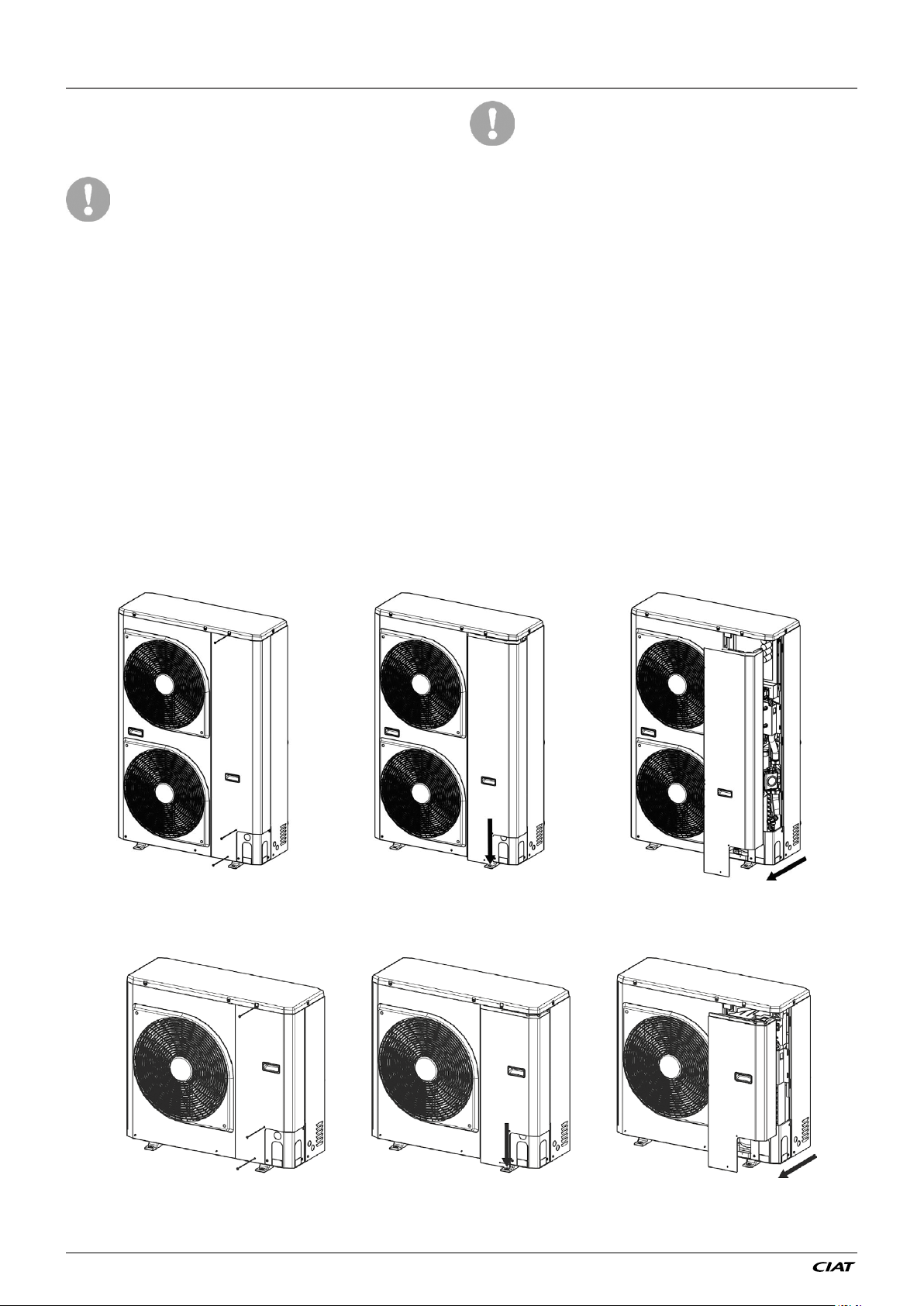

Figure 3 : How to remove front panel for 11 & 15 kW units ..............................................20

Figure 4 : How to remove front panel for 5 & 7 kW units ..................................................20

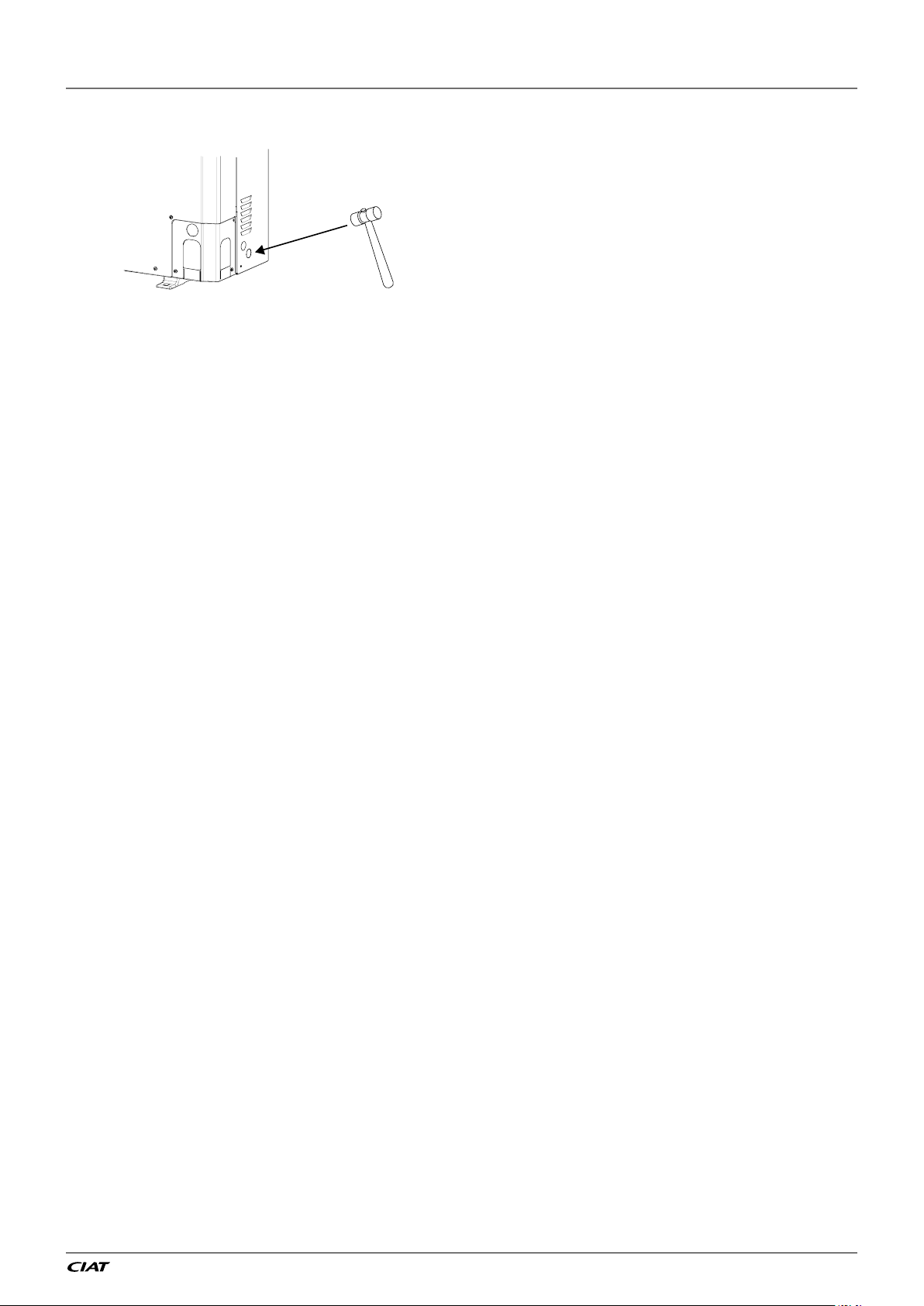

Figure 5 : Opening cable knockouts ................................................................................21

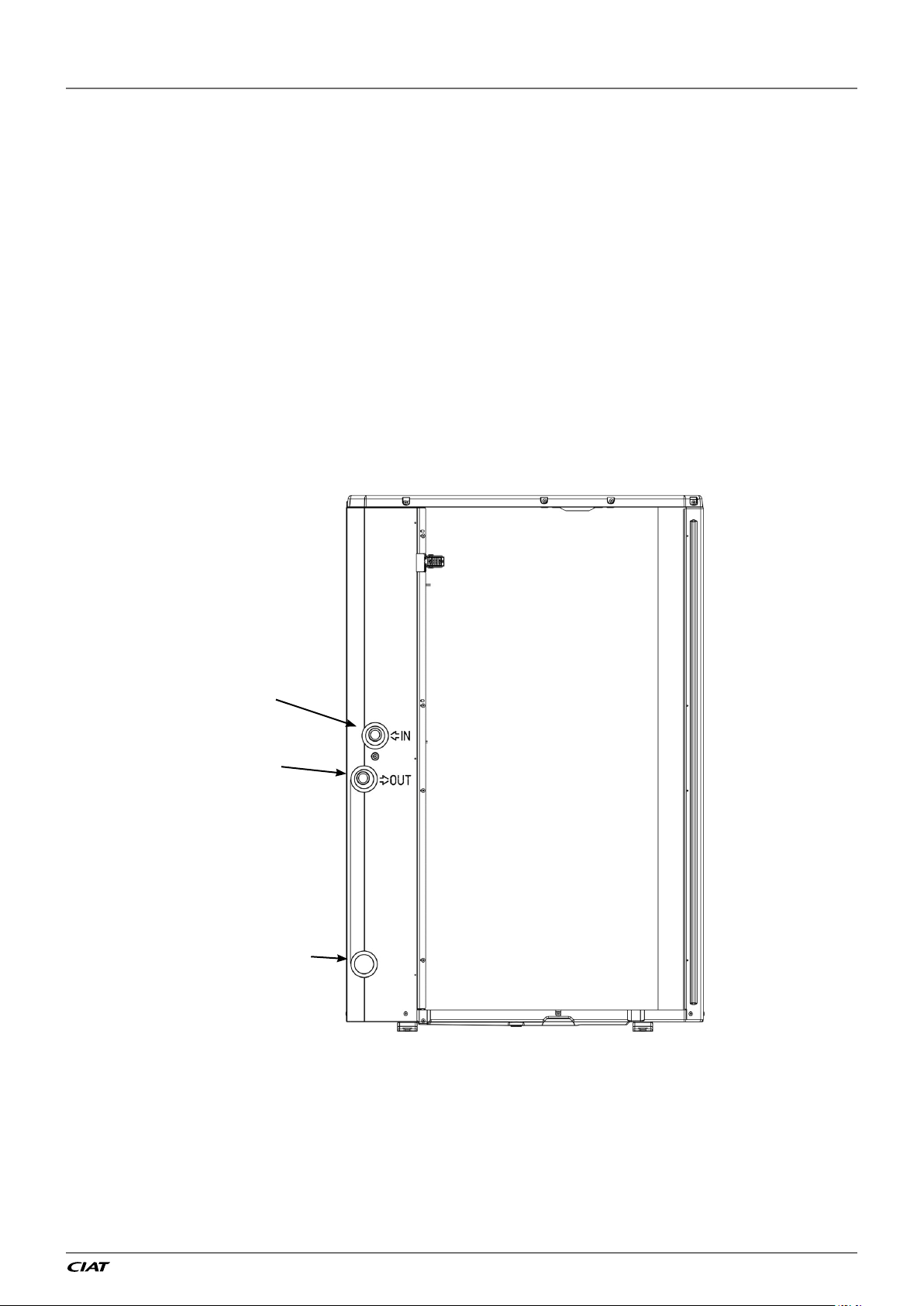

Figure 6: Water connection on unit ..................................................................................23

Figure 7: Typical diagram of the hydraulic circuit with the hydraulic module ....................24

Figure 8: Hydraulic module equipped with variable speed single pump low available pressure

with expansion tank ........................................................................................25

Figure 9: Power connection with Main Switch .................................................................26

Figure 10: Customer electrical connection on terminal block .........................................33

Figure 11: Password screen ............................................................................................35

Figure 12: Standard installation with electrical booster heaters.......................................37

Figure 13: Electrical connection on terminal block for electrical booster heaters ............38

Figure 14: Standard installation with DHW production ....................................................40

Figure 15: Electrical connection on terminal block for DHW production ..........................41

Figure 16: Standard installation with boiler ......................................................................44

Figure 17: Electrical connection on terminal block for boiler............................................45

Figure 18: Standard installation with DHW production, pool heating production ans space

heating (floor heating or radiator/fan coils) .....................................................47

Figure 19: Electrical connection on terminal block for DHW, speace heating, pool heating

production and boiler ......................................................................................48

Figure 20: Standard installation with Master / Slave (example with 3 slaves) ..................50

Figure 21: Electrical connection on terminal block for Master / Slave installation ............51

Figure 22: WUI screen for Slave 1 ...................................................................................54

Figure 23: Electrical connection of remote interface .......................................................54

Figure 24: Electrical connection of additional OAT sensor and IAT sensor ......................56

Figure 25: Winter position for unit with hydraulic module .................................................65

Figure 26: Operation of booster and backup ...................................................................69

Figure 27: Activation and configuration for drying mode .................................................71

EREBA He

EN-4

ACRONYMS AND LEGEND

Acronyms

IAT

BPHE

CHWS

DHW

EHS

EWT

FCU

LWT

NHC

OAT

PMV

SHC

TR

UFC

UFH

WUI

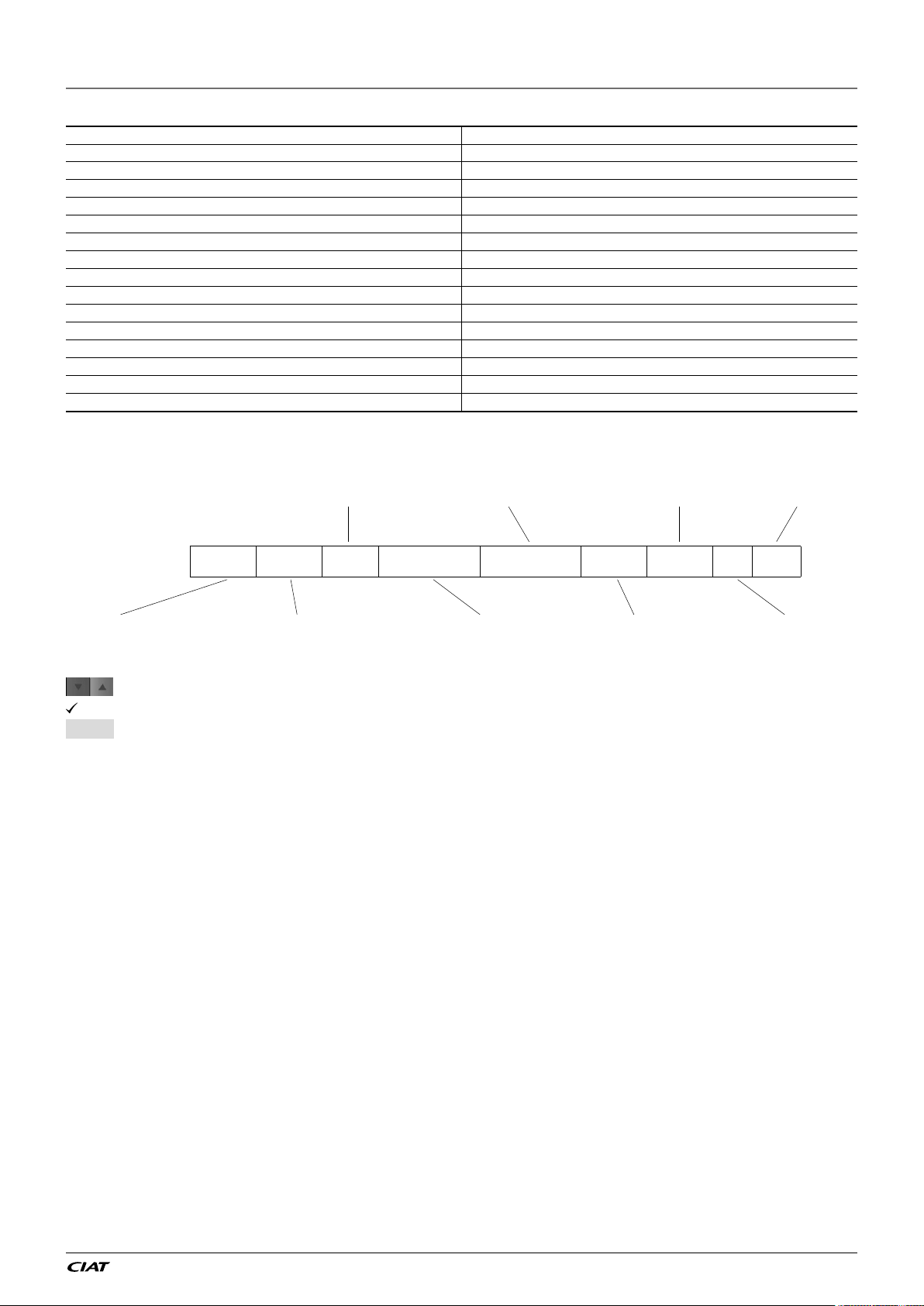

Control Configuration Legend

Indoor Air Temperature

Brazed Plate Heat Exchanger

Chiller Water System

Domestic Hot Water

Electric Heater Stage

Entering Water Temperature

Fan Coil Unit

Leaving Water Temperature

New Hydraulic Control (refer to wiring diagram 'Main control card')

Outdoor Air Temperature

Pulse Modulating Valve

Space Heating / Cooling Control

Refrigerant Temperature

Underfloor Cooling

Underfloor Heating

User Interface (Wall-mounted User Interface)

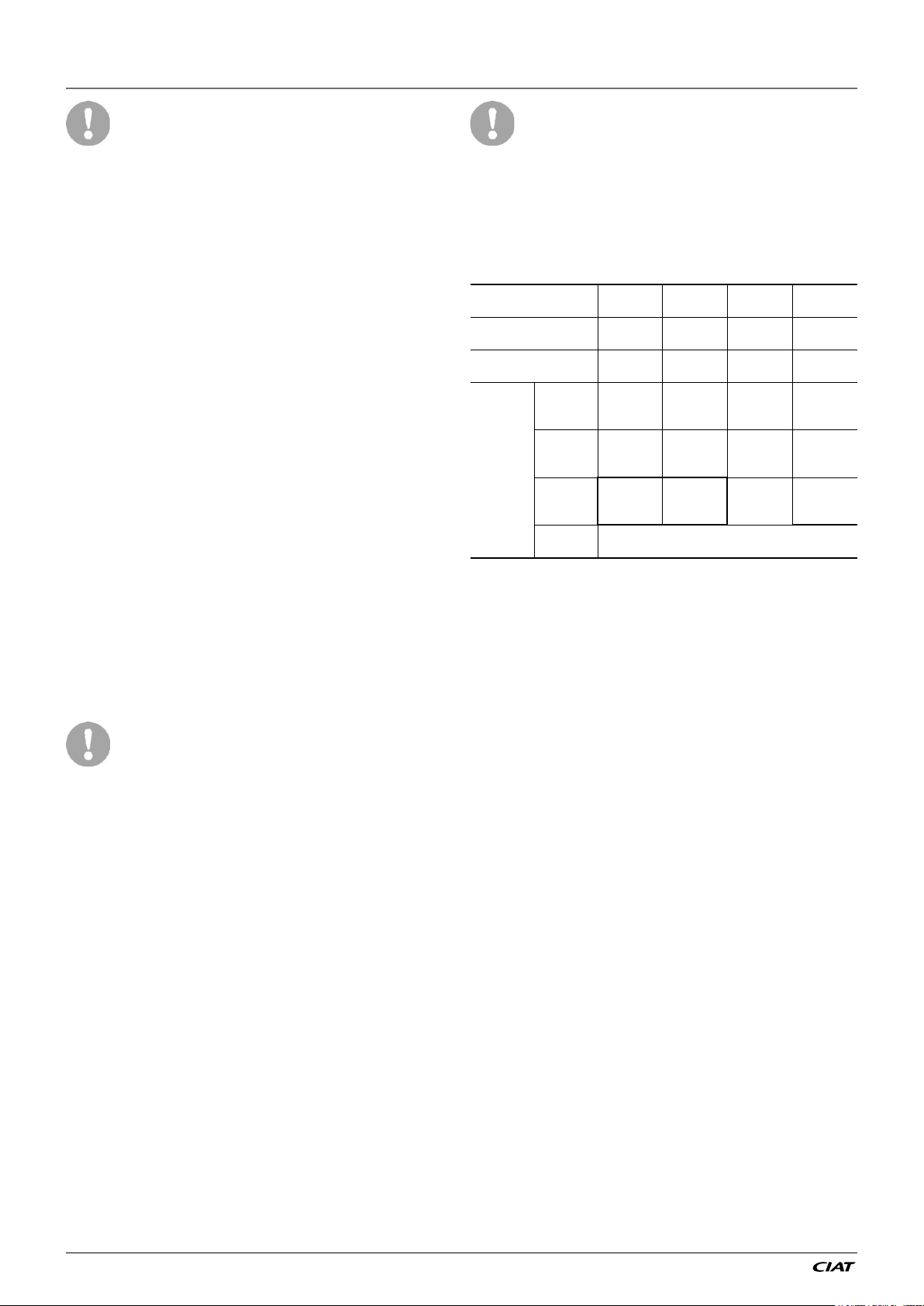

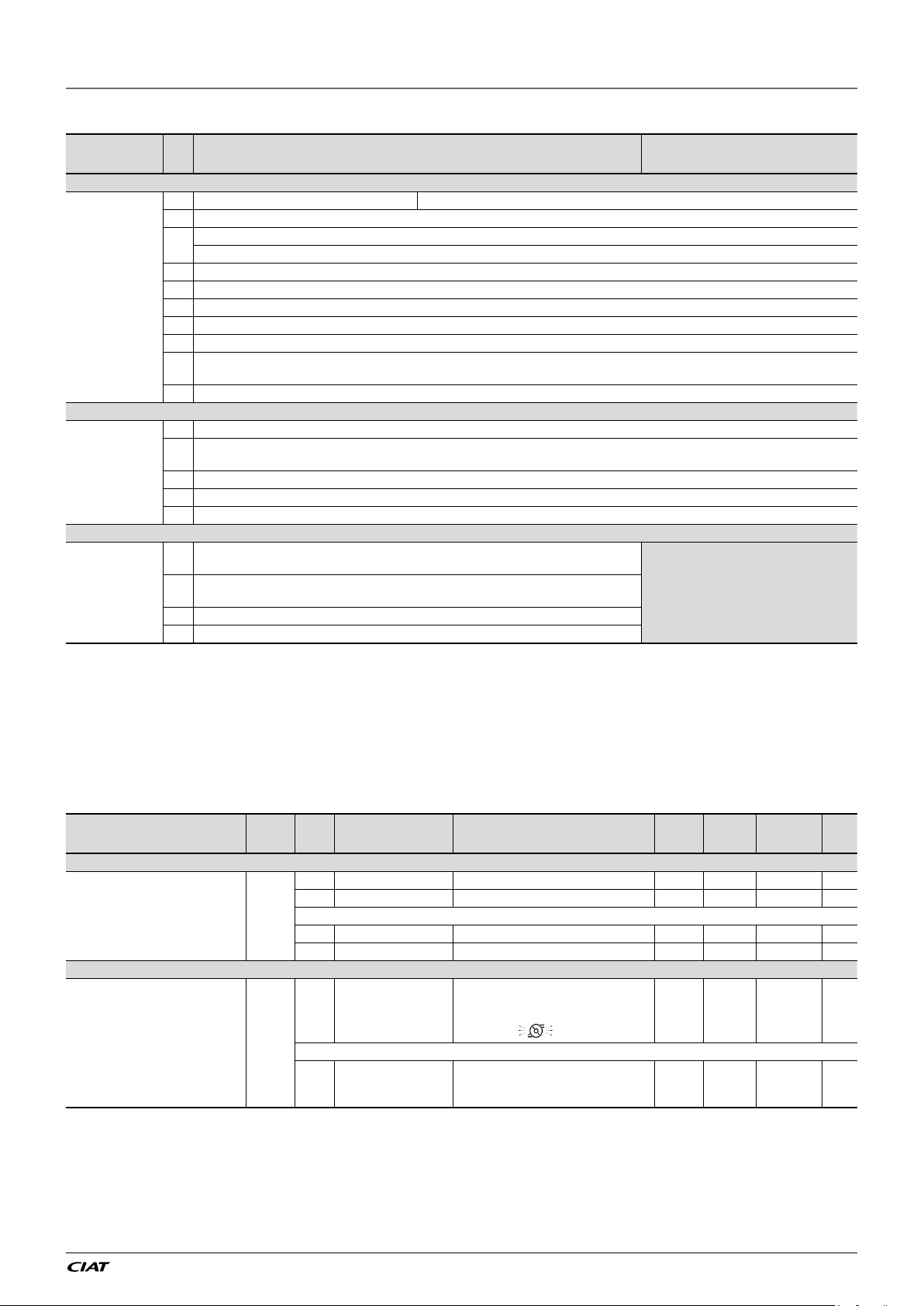

Number of

parameter

Steps Table Par. Designation Description Range Default Ex. Unit

Different steps to be done

to configure the unit

Possible to configure by direct access on WUI. Refer to WUI end user Manual.

Check to be done

Advanced Configuration Level (for basic operation no need to modify the setting)

Name of the table to be

used in Customer Com. Bus

Name of parameter to be

used in Customer Com. Bus

Description of different value

which can take the parameter

Range of

parameter

Value by Default

of parameter

Value given in example and

adapted at the described case

Unit of parameter

EN-5

EREBA He

ACRONYMS AND LEGEND

Standard installation Legend

Label Symbol Designation Notes

-

-

-

-

-

-

Acc

Acc

Add EXP-T

- Boiler Boiler used to boost or backup the heat pump for comfort

EH1 & EH2

EH3

EH3

Device Field supplied

Accessory Field mounted

Option Factory mounted

Balancing valve

Stop valve Field supplied

Automatic Air vent

Additional expansion tank

Electrical Heater (1 or 2)

DHW-Electrical Heater Backup (1 stage)

Field supplied

Balancing to adjust the water flow rate

Field supplied

Automatic air vent(s) on highest position in the loop

Field supplied

Additional expansion tank depending the total water in the

loop contend - taking in account the expansion tank (XXL)

embedded in hydraulic module

Electrical heaters up to two with a max. stages up to 3

Used to boost or backup the heat pump for comfort

Domestic Hot Water Electrical Heater - one stage used

to backup DHW (when condtions are out of heat pump

map)

DHW-T

DHW-S

DHW-V

add_pmp

De-Coupling

Tank

Backup-EH

-

HTSS

B

AB

EH1 EH2

HTSS

T>Tmax

Domestic Hot Water - Tank Field supplied

Domestic Hot Water - Sensor

A

Domestic Hot Water - Valve or Diverting valve

Additional Water Pump

De-Coupling Tank

Backup electrical heater

Flexible

High Temperature Safety Switch

Accessory to mount on top of the DHW-Tank

Measure DHW-Temperature

Accessory to be field mounted, it will position the valve

to send either to comfort loop or DHW-T, the processed

water

Field Supplied, it is used for comfort loop as a secondary

loop

Field Supplied, it is used to connect different water loop

rates as well as to receive the boiler loop

Field Supplied, it is used for comfort loop as a Booster

Heater (HP+EH) or Backup (EH only) when HP is out of

the map.

Field supply, it is used to lower vibrations transmissions

if necessary

Field supplied, use to stop system when UFH max, water

temperature is triggered

EREBA He

EN-6

1 - INTRODUCTION

1.1 - Introduction

Prior to the initial start-up of the EREBA

He units, the people involved should be

thoroughly familiar with these instructions

and technical data for the installation.

This appliance can be used by children

aged from 8 years and above and

persons with reduced physical, sensory or

mental capabilities or lack of experience

and knowledge if they have been given

supervision or instruction concerning use of

The EREBA He outdoor systems are

designed to provide a very high level of

the appliance in a safe way and understand

the hazards involved.

safety and reliability making installation,

start-up, operation and maintenance easier

and more secure. They will provide safe and

reliable service when operated within their

application range.

They are designed for an operating life of 15

years by assuming a 75% utilisation factor;

that is approximately 100,000 operating

hours.

The procedures in this manual are

arranged in the sequence required for

machine installation, start-up, operation and

maintenance.

Children shall not play with the appliance.

Cleaning and user maintenance shall not be

made by children without supervision.

Do not remove the pallet or the packaging

until the unit is in its nal position. These

units can be moved with a fork lift truck, as

long as the forks are positioned in the right

place and direction on the unit.

The units can also be lifted with slings (refer

to Figure 1 and 2).

Use slings with the correct capacity, and

always follow the lifting instructions on the

certied drawings supplied for the unit.

Be sure you understand and follow the

procedures and safety precautions contained

in the instructions supplied with the machine,

as well as those listed in this guide, such as:

protective clothing such as gloves, safety

glasses, safety shoes and appropriate tools,

and suitable qualifications (electrical, air

conditioning, local legislation).

To find out, if these products comply with

European directives (machine safety, low

voltage, electromagnetic compatibility,

equipment under pressure, etc.) check the

declarations of conformity for these products.

Safety is only guaranteed, if these

instructions are carefully followed. If this

is not the case, there is a risk of material

deterioration and injuries to personnel.

DO NOT COVER ANY PROTECTION

DEVICES.

This applies to fuse plugs and relief valves

(if used) in the refrigerant or heat transfer

medium circuits. Check if the original

protection plugs are still present at the

valve outlets. These plugs are generally

made of plastic and should not be used.

If they are still present, please remove

them. Install devices at the valve outlets or

1.2 - Safety

1.2.1 - Installation safety considerations

After the unit has been received, and before it

is started up, it must be inspected for damage.

Check that the refrigerant circuits are intact,

especially that no components or pipes have

shifted or been damaged (e.g. following a

drain piping that prevent the penetration of

foreign bodies (dust, building debris, etc.)

and atmospheric agents (water can form

rust or ice). These devices, as well as the

drain piping, must not impair operation and

not lead to a pressure drop that is higher

than 10% of the control pressure.

shock). If in doubt, carry out a leak tightness

check. If damage is detected upon receipt

and before signature, immediately file a claim

with the shipping company.

EN-7

EREBA He

1 - INTRODUCTION

Control:

When the unit is subjected to re, the

uid may then be decomposed into toxic

residues when subjected to the ame :

- Stay away from the unit.

- Set up warnings and

recommendations for personnel in

charge to stop the fire.

components are given on the nameplate or

in the required documentation, supplied with

the products.

The units are intended to be stored and

operate in an environment where the

ambient temperature must not be less than

the lowest allowable temperature indicated

on the nameplate.

- Fire extinguishers appropriate to

the system and the refrigerant type

must be easily accessible.

Do not introduce signicant static or

dynamic pressure with regard to the

operating pressures used during operation

All precautions concerning handling of

refrigerant must be observed in accordance

or for tests in the refrigerant circuit or in the

heat exchange circuits.

with local regulations.

NOTES:

Accumulation of refrigerant in an enclosed

space can displace oxygen and cause

asphyxiation or explosions.

Monitoring during operation, re-

qualication, re-testing, exemption from

retesting:

Inhalation of high concentrations of

vapour is harmful and may cause heart

irregularities, unconsciousness, or death.

Vapour is heavier than air and reduces the

amount of oxygen available for breathing.

These products cause eye and skin

irritation. Decomposition products can be

hazardous.

Short-circuit power

This equipment complies with EN 610003-12 provided that the short-circuit power

Ssc is greater than or equal to 1,6 MVA

at the interface point between the user’s

supply and the public system. It is the

responsibility of the installer or user of

the equipment to ensure, by consultation

with the distribution network operator if

necessary, that the equipment is connected

only to a supply with a short-circuit power

Ssc greater than or equal to 1,6 MVA.

1.2.2 - Equipment and components

under pressure

These products incorporate equipment or

components under pressure, produced by

manufacturers. We recommend that you

consult your appropriate national trade

association or the owner of the equipment

or components under pressure (declaration,

re-qualification, retesting, etc.). The

characteristics of this equipment/these

● Follow local regulations on the monitoring

of pressure-containing equipment.

● The user or the operator is usually

requested to create and maintain a

monitoring and maintenance register.

● In absence of regulation or in addition to

the regulations, follow the guidance in

ISO 5149.

● Follow the local professional

recommendations, whenever they exist.

● Regularly monitor the surface of the

components to detect cavernous

corrosion. To do this check an uninsulated

part of the pressure vessel or at a joint in

the insulation.

● Regularly check for possible presence of

impurities (e.g. silicon grains) in the heat

exchange fluids. These impurities can

cause wear and/or pitting corrosion.

● Filter the heat exchange fluid.

● The reports of the periodical checks by

the user or the operator must be included

in the monitoring and maintenance

register.

EREBA He

EN-8

1 - INTRODUCTION

Repair:

Any repair or modication of a pressure

vessel is prohibited.

Only the replacement of the vessel by

an original part from the manufacturer is

allowed. In this case, the replacement must

be carried out by a qualied technician. The

replacement of the vessel must be entered

in the monitoring and maintenance register.

Recycling:

The pressure equipment can be recycled in

whole or in part. After use they may contain

protective clothing.

Never work on a unit that is still energized.

Never work on any of the electrical

components, until the general power supply

to the unit has been cut.

If any maintenance operations are carried

out on the unit, lock the power supply

circuit in the open position and secure the

machine upstream with a padlock.

If the work is interrupted, always ensure

that all circuits are still de-energized before

resuming the work.

refrigerant vapours and oil residue. Some

parts are painted.

1.2.3 - Maintenance safety

considerations

Professional technicians working on the

electric or refrigeration components must be

authorized, trained and fully qualified to do

so.

All refrigerant circuit work must be carried out

by a trained person, fully qualified to work

on these units. He must have been trained

and be familiar with the equipment and the

installation. All welding operations must be

carried out by qualified specialists.

The units use high-pressure R-410A

refrigerant (the unit operating pressure

is above 40 bar, the pressure at 35°C air

temperature is 50% higher than for R-22).

Special equipment must be used when

working on the refrigerant circuit (pressure

gauge, charge transfer, etc.).

Do not clean the unit with hot water or

steam. This may cause a pressure increase

of the refrigerant.

Any manipulation (opening or closing)

of a shut-off valve must be carried out

by a qualied and authorised technician,

observing applicable standards (e.g. during

draining operations). The unit must be

switched off while this is done.

Even if the unit has been switched off,

the power circuit remains energized,

unless the unit or customer circuit

disconnect switch is open. Refer

to the wiring diagram for further

details. Attach appropriate safety

labels. When working in a fan area,

specically if the grilles have to be

removed, isolate the power supply to

the fans to prevent their operation.

The variable frequency drives

(VFD) tted to the units have circuit

capacitors whose discharge time is

ve (5) minutes after disconnecting

the power supply.

Therefore, after disconnecting the

power supply of the control box, wait

for 5 minutes before access it.

Before any intervention, verify that

there is no voltage present at any

accessible conducting parts of the

power circuit.

Moreover be careful of contact with

zones at hot temperature inside

the unit, which can exist after the

operation of unit (refrigerant and

electronic parts).

During any handling, maintenance and

service operations the qualied technician

working on the unit must be equipped with

safety gloves, safety glasses, shoes and

EN-9

EREBA He

1 - INTRODUCTION

It is recommended to install an

indicating device to show if part of the

refrigerant has leaked from the valve.

The presence of oil at the outlet orice

is a useful indicator that refrigerant

has leaked. Keep this orice clean to

ensure that any leaks are obvious. The

calibration of a valve that has leaked

is generally lower than its original

calibration. The new calibration may

affect the operating range. To avoid

nuisance tripping or leaks, replace or

re-calibrate the valve.

OPERATING CHECKS:

● IMPORTANT INFORMATION

REGARDING THE REFRIGERANT USED:

This product contains uorinated

greenhouse gas covered by the Kyoto

protocol.

Refrigerant type: R-410A

6. The gas recovery for recycling,

regeneration or destruction is at

customer charge.

7. Periodic leak tests have to be

carried out by the customer or by

third parties. The EU regulation

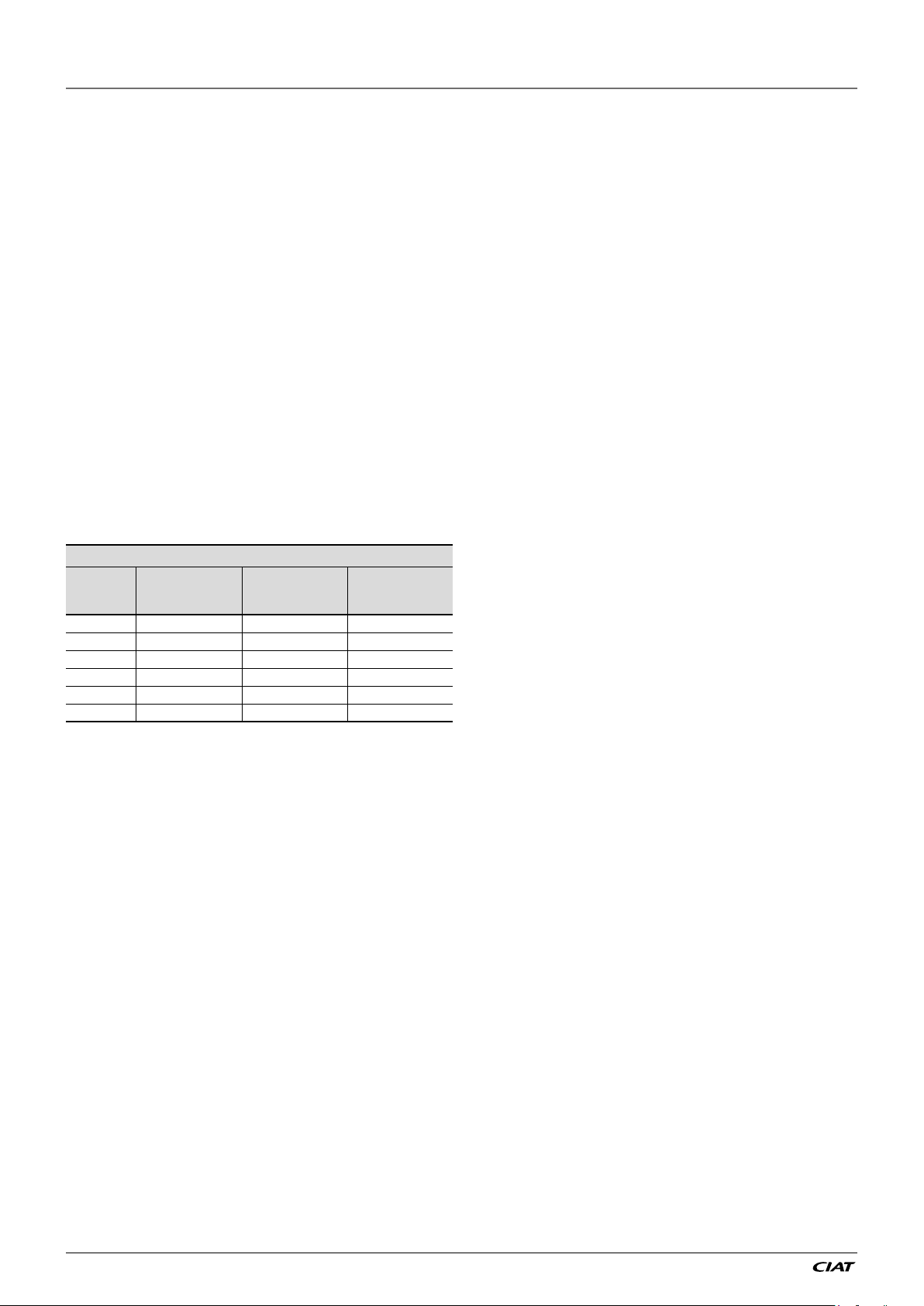

set the periodicity here after:

System WITHOUT

leakage detection

System WITH leakage

detection

Refrigerant charge/circuit

(CO

equivalent)

2

R134A

(GWP 1430)

R407C

(GWP 1774)

R410A

(GWP 2088)

HFO’s:

R1234ze

Refrigerant charge/

Circuit (kg)

(1) From 01/01/2017, units must be equipped with a leakage detection system

No Check 12 Months 6 Months 3 Months

No Check 24 Months 12 Months 6 Months

< 5 Tons

Charge <

3.5 kg

Charge <

2.8 kg

Charge <

2.4 kg

No requirement

5 ≤ Charge

< 50 Tons

3.5 ≤

Charge <

34.9 kg

2.8 ≤

Charge <

28.2 kg

2.4 ≤

Charge <

23.9 kg

50 ≤ Charge

< 500 Tons

34.9 ≤

Charge <

349.7 kg

28.2 ≤

Charge <

281.9 kg

23.9 ≤

Charge <

239.5 kg

Charge >

500 Tons(1)

Charge >

349.7 kg

Charge >

281.9 kg

Charge >

239.5 kg

Global Warming Potential (GWP): 2088

Periodic inspections for refrigerant leaks

may be required depending on European or

local legislation. Please contact your local

dealer for more information.

1. Any intervention on the refrigerant

circuit of this product should be

performed in accordance with the

applicable legislation. In the EU,

the regulation is called F-Gas,

N°517/2014.

2. Ensure that the refrigerant is

never released to the atmosphere

during installation, maintenance

or equipment disposal.

3. The deliberate gas release into the

atmosphere is not allowed.

4. If a refrigerant leak is detected,

ensure that it is stopped and

repaired as quickly as possible.

5. Only a qualified and certified

personnel can perform installation

operations, maintenance,

refrigerant circuit leak test as well

as the equipment disposal and the

refrigerant recovering.

8. A logbook must be established for

equipments subject to periodic leak

tests. It should contain the quantity

and the type of fluid present within the

installation (added and recovered), the

quantity of recycled fluid, regenerated

or destroyed, the date and output of the

leak test, the designation of the operator

and its belonging company, etc.

9. Contact your local dealer or installer if

you have any questions.

Protection device checks:

● If no national regulations exist, check the

protection devices on site in accordance

with standard ISO 5149: every five years

for external relief valves.

NOTE: The following statements are only

indicated if a pressure switch is available

on the unit.

The company or organisation that conducts

a pressure switch test shall establish and

implement a detailed procedure to fix:

- Safety measures

- Measuring equipment calibration

- Validating operation of protective

devices

EREBA He

EN-10

1 - INTRODUCTION

- Test protocols

- Recommissioning of the equipment.

Consult Service for this type of test. The

manufacturer mentions here only the principle

of a test without removing the pressure switch:

- Verify and record the setpoints of

pressure switches and relief devices

(valves and possible rupture discs)

- Be ready to switch-off the main

disconnect switch (on the unit or on the

installation) of the power supply if the

pressure switch does not trigger (avoid

over-pressure)

- Connect a calibrated pressure gauge

(with Schrader female port of ½ UNF)

Inspect the protection devices such

as valves.

If the machine operates in a corrosive

environment, inspect the protection

devices more frequently.

Check regularly for leaks and repair

immediately. Ensure regularly that

the vibration levels remain acceptable

and close to those at the initial unit

start-up.

Before opening a refrigerant circuit,

transfer the refrigerant to bottles

specically provided for this purpose

and consult the pressure gauges.

Change the refrigerant after an

equipment failure, following a

procedure such as the one described

in NF E29-795 or carry out a refrigerant

analysis in a specialist laboratory.

If the refrigerant circuit remains

open after an intervention (such as a

component replacement, etc.):

● Seal the openings if the duration is

less than a day

● If more than 1 day, charge the

circuit with oxygen free nitrogen

(inertia principle).

The objective is to prevent penetration

of atmospheric humidity and the

resulting corrosion.

1.2.4 - Repair safety considerations

All installation parts must be maintained by

the personnel in charge to avoid deterioration

and injury. Faults and leaks must be repaired

immediately. The authorized technician must

have the responsibility to repair the fault

immediately. After each unit repair check

the operation of the protection devices and

create a 100% parameter operation report.

Comply with the regulations and

recommendations in unit and HVAC

installation safety standards, such as: ISO

5149.

If the supply cord is damaged, it must be

replaced by the manufacturer, its service

agent or similarly qualied persons in order

to avoid a hazard.

RISK OF EXPLOSION

Never use air or a gas containing oxygen

during leak tests to purge lines or to

pressurise a machine. Pressurised air

mixtures or gases containing oxygen can

be the cause of an explosion. Oxygen reacts

violently with oil and grease.

Only use dry nitrogen for leak tests, possibly

with an appropriate tracer gas.

If the recommendations above are not

observed, this can have serious or even fatal

consequences and damage the installation.

Never exceed the specied maximum

operating pressures. Verify the allowable

maximum high- and low-side test pressures

by checking the instructions in this manual

and the pressures given on the unit name

plate.

Do not unweld or amecut the refrigerant

lines or any refrigerant circuit component

until all refrigerant (liquid and vapour) as well

as the oil have been removed from the heat

pump. Traces of vapour should be displaced

with dry nitrogen. Refrigerant in contact with

an open ame can produce toxic gases.

The necessary protection equipment

must be available, and appropriate re

extinguishers for the system and the

refrigerant type used must be within easy

reach.

EN-11

EREBA He

1 - INTRODUCTION

Do not siphon refrigerant.

Avoid spilling liquid refrigerant on skin

or splashing it into the eyes. Use safety

goggles and safety gloves. Wash any spills

from the skin with soap and water. If liquid

refrigerant enters the eyes, immediately

and abundantly ush the eyes with water

and consult a doctor.

The accidental releases of the refrigerant,

due to small leaks or signicant discharges

following the rupture of a pipe or an unexpected

release from a relief valve, can cause frostbites

and burns to personnel exposed. Do not

ignore such injuries. Installers, owners and

especially service technicians for these units

must:

- Seek medical attention before

treating such injuries.

- Have access to a first-aid kit,

especially for treating eye injuries.

We recommend to apply standard ISO 5149.

Never apply an open ame or live steam to a

refrigerant circuit. Dangerous overpressure

can result.

During refrigerant removal and storage

operations follow applicable regulations.

These regulations, permitting conditioning

and recovery of halogenated hydrocarbons

under optimum quality conditions for the

products and optimum safety conditions

for people, property and the environment

are described in standard NF E29-795.

The units must never be modied to add

refrigerant and oil charging, removal and

purging devices. All these devices are

provided with the units.

Be sure pressure is at 0 kPa and that the

unit has been shut-down and de-energised

before removing components or opening a

circuit.

Do not attempt to repair or recondition any

safety devices when corrosion or build-up

of foreign material (rust, dirt, scale, etc.) is

found within the valve body or mechanism.

If necessary, replace the device. Do not

install safety valves in series or backwards.

No part of the unit must be used

as a walkway, rack or support.

Periodically check and repair or if

necessary replace any component or

piping that shows signs of damage.

Do not step on refrigerant lines. The

lines can break under the weight and

release refrigerant, causing personal

injury.

Do not climb on a machine. Use a

platform, or staging to work at higher

levels.

Use mechanical lifting equipment

(crane, hoist, winch, etc.) to lift or

move heavy components. For lighter

components, use lifting equipment

when there is a risk of slipping or

losing your balance.

Refer to the certied dimensional drawings

for the units.

It is dangerous and illegal to re-use

disposable (non-returnable) cylinders or

attempt to rell them. When cylinders are

empty, evacuate the remaining gas pressure,

and move them to a designated place for

recovery. Do not incinerate.

Do not attempt to remove refrigerant circuit

components or ttings, while the machine

is under pressure or while it is running.

EREBA He

EN-12

1 - INTRODUCTION

Use only original replacement

parts for any repair or component

replacement. Consult the list of

replacement parts that corresponds

to the specication of the original

equipment.

Do not drain water circuits containing

industrial brines, without informing

the technical service department at

the installation site or a competent

body rst.

Close the entering and leaving water

shut-off valves and purge the unit

hydraulic circuit, before working

on the components installed on the

circuit (screen lter, pump, water

ow switch, etc.).

Periodically inspect all valves,

ttings and pipes of the refrigerant

and hydraulic circuits to ensure that

they do not show any corrosion or

any signs of leaks.

It is recommended to wear ear

defenders, when working near the

unit and the unit is in operation.

Always ensure you are using the

correct refrigerant type before

recharging the unit.

Charging any refrigerant other than

the original charge type (R-410A)

will impair machine operation and

can even lead to a destruction of

the compressors. The compressors

operate with R-410A and are charged

with asyntheticpolyol-ester oil.

Before any intervention on the

refrigerant circuit, the complete

refrigerant charge must be recovered.

1.3 - Preliminary checks

Check equipment received:

● Inspect the unit for damage or missing

parts. If damage is detected, or if shipment

is incomplete, immediately file a claim

with the shipping company.

● Confirm that the unit received is the one

ordered. Compare the name plate data

with the order.

● The name plate is attached to the unit in

two locations:

- on the outside on one of the unit sides

- on the inside.

● The unit name plate must include the

following information:

- Model number - size

- CE marking

- Serial number

- Year of manufacture, pressure and

leaktightness test date

- Fluid being transported

- Refrigerant used

- Refrigerant charge per circuit

- PS: Min./max. allowable pressure

(high and low pressure side)

- TS: Min./max. allowable temperature

(high and low pressure side)

- Unit leak test pressure

- Voltage, frequency, number of phases

- Maximum power input

- Unit net weight

● Confirm that all options ordered for on-site

installation have been delivered, and are

complete and undamaged.

The unit must be checked periodically, if

necessary removing the insulation (thermal,

acoustic), during its whole operating

life to ensure that no shocks (handling

accessories, tools, etc.) have damaged it.

If necessary, the damaged parts must be

repaired or replaced. See also chapter §5.

Maintenance.

EN-13

EREBA He

1 - INTRODUCTION

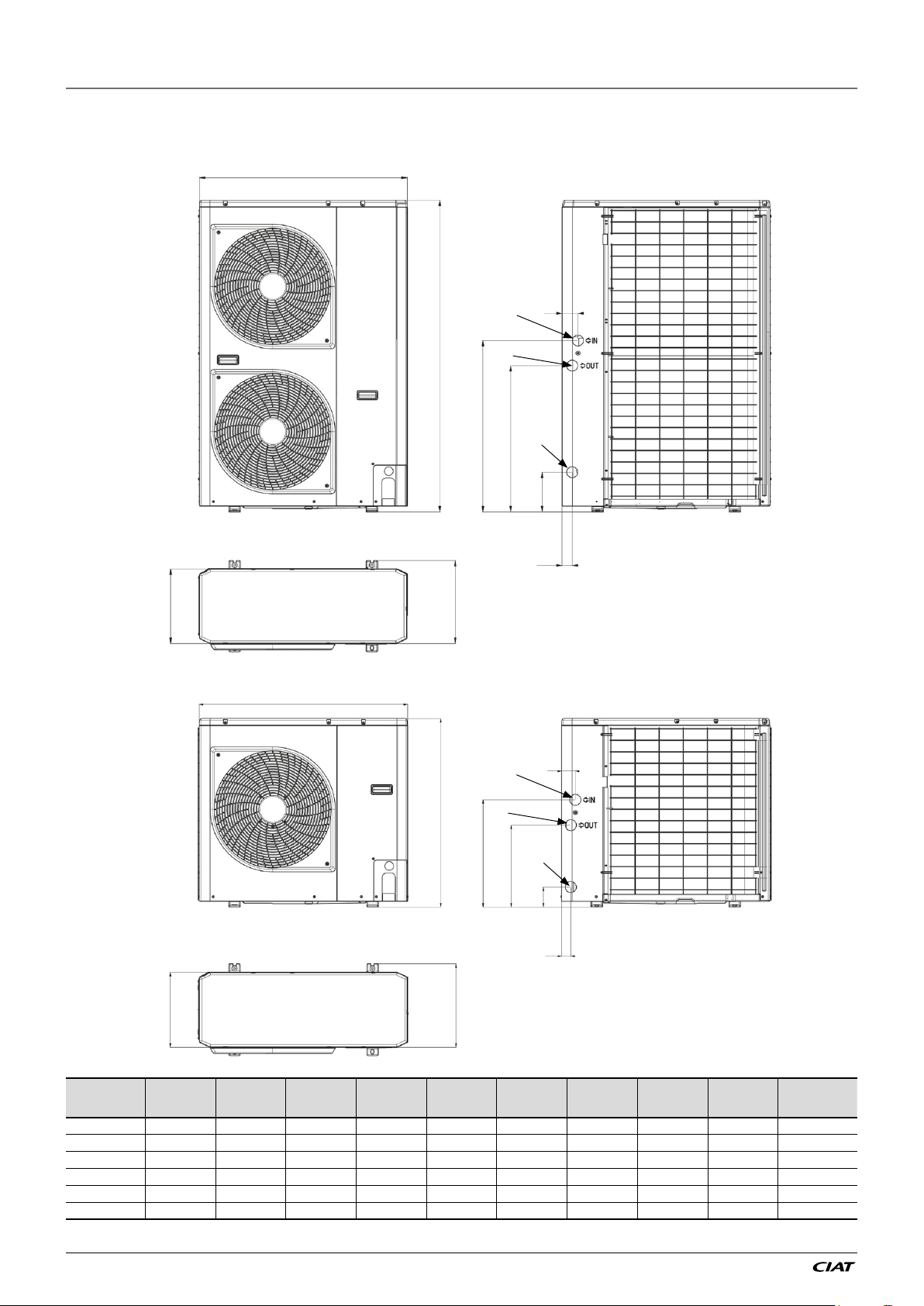

1.4 - Dimensions and clearance for EREBA He units

1.4.1 - Dimensions and location of hydraulic connections

A

L

a

B

C

A

D

b

G

F

c

E

H

L

a

B

C

EREBA He A B C D E F G H L masse (kg)

5_1Ph 908 821 326 350 87 356 466 40 60 57

7_1Ph 908 821 326 350 87 356 466 40 60 69

11_1Ph 908 1363 326 350 169 645 744 43 73 115

15_1Ph 908 1363 326 350 169 645 744 43 73 115

11_3Ph 908 1363 326 350 169 645 744 43 73 121

15_3Ph 908 1363 326 350 169 645 744 43 73 121

NOTE : Dimensions are given in mm

b

G

D

c

F

E

H

EREBA He

EN-14

1 - INTRODUCTION

1.4.2 - Clearances to ensure the correct air flow

The picture presents the minimal distances of the wall to ensure the correct air flow on air

(1)

heat exchanger

.

200

500

150

150

003051

150

1000

1000

500

1000

150150

300300

300

200

1000

200

300

(1) Anticipate different maintenance actions before to place the unit (access of different parts / opening of panel/ part replacement…)

300

1000

300

000200510001

200

EN-15

EREBA He

1 - INTRODUCTION

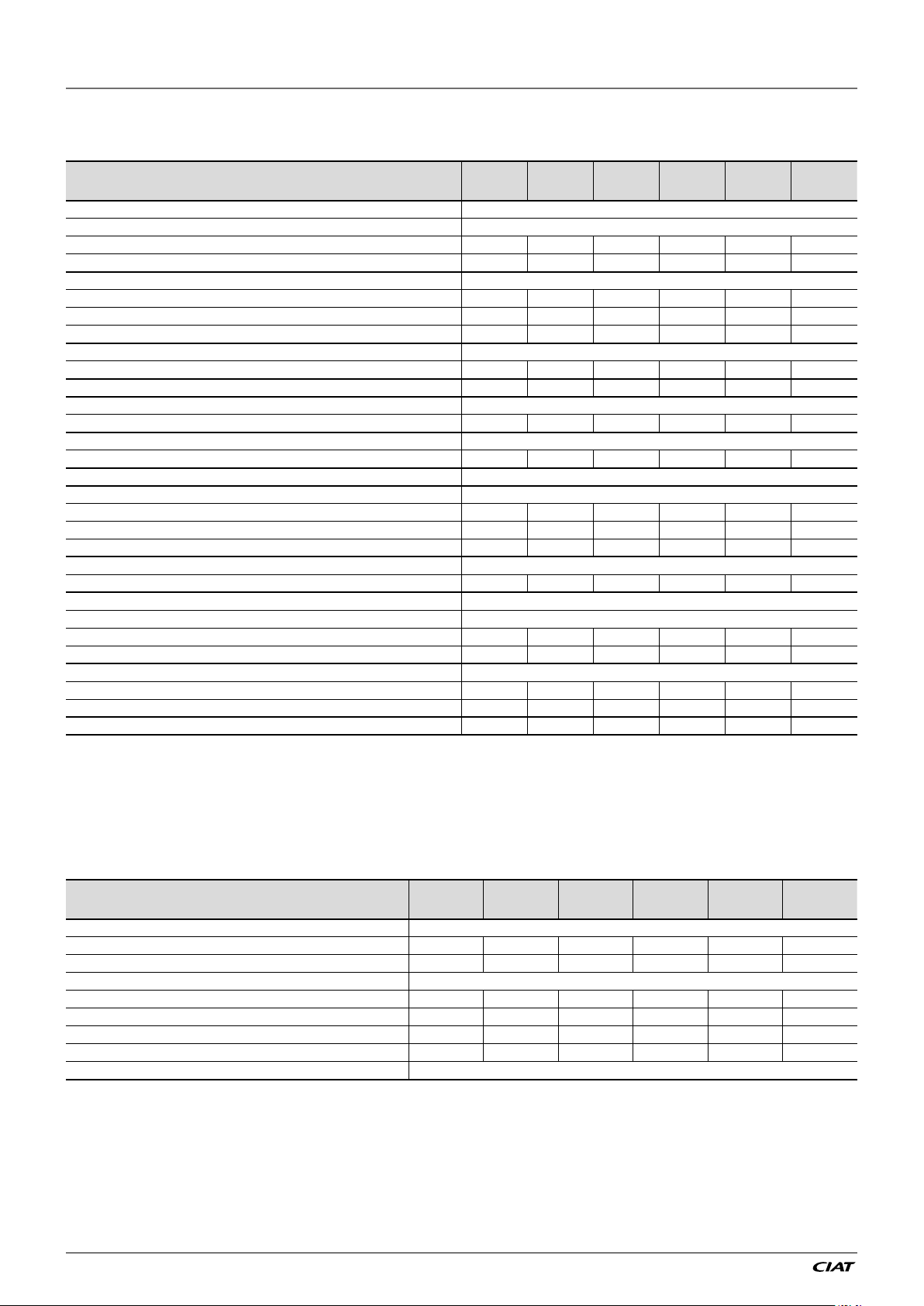

1.5 - Physical data and electrical data of EREBA He units

1.5.1 - Physical data EREBA He

EREBA He 5 (1Ph) 7 (1Ph) 11 (1Ph) 15 (1Ph) 11 (3Ph) 15 (3Ph)

Sound levels

Standard unit

Sound power level

Sound pressure level at 10 m

Dimensions

Length mm 908 908 908 908 908 908

Width mm 350 350 350 350 350 350

Height mm 821 821 1363 1363 1363 1363

Operating Weight

Standard unit kg 57 69 107 115 121 121

Compressors Rotary compressor 1 1 1 1 1 1

Refrigerant R410A

(1)

Charge

Capacity control

Minimum capacity

Condenser Grooved copper tubes, aluminium ns

Fans Axial type

Quantity 1 1 2 2 2 2

Maximum total air flow l/s 800 800 1800 1800 1800 1800

Maximum rotational speed rpm 560 660 820 820 820 820

Evaporator Brazed plate heat exchanger

Water volume l 1,7 2,3 4,4 4,4 4,4 4,4

Hydraulic module Circulator, relief valve, paddle ow switch, expansion tank

Circulator Centrifugal pump (variable speed)

Expansion tank volume l 2 2 3 3 3 3

Max. water-side operating pressure with hydraulic module

Water connections

Inlet diameter (BSP GAS) inch 1 1 1 1 1 1

Outlet diameter (BSP GAS) inch 1 1 1 1 1 1

Chassis paint colour Colour code: RAL 7035 RAL 7035 RAL 7035 RAL 7035 RAL 7035 RAL 7035

(1) Values are guidelines only. Refer to the unit nameplate.

(2) In dB ref=10

in accordance with ISO 9614-1 and certified by Eurovent.

(3) In dB ref 20 μPa, (A) weighting. Declared dualnumber noise emission values in accordance with ISO 4871 (with an associated uncertainty of +/-3dB(A)). For information,

calculated from the sound power level Lw(A).

(4) Min. water-side operating pressure with variable speed hydraulic module is 40 kPa.

(5) Cooling Eurovent condition

(2)

(3)

(1)

dB(A) 64 65 68 69 69 69

dB(A) 33 34 37 38 38 38

kg 1,1 1,6 2,8 2,8 3 3

(5)

(4)

-12

W, (A) weighting. Declared dualnumber noise emission values in accordance with ISO 4871 (with an associated uncertainty of +/-3dB(A)). Measured

% 23% 20% 20% 17% 20% 17%

kPa 300 300 300 300 300 300

1.5.2 - Electrical data EREBA He

EREBA He 5 (1Ph) 7 (1Ph) 11 (1Ph) 15 (1Ph) 11 (3Ph) 15 (3Ph)

Power circuit

Nominal power supply V-ph-Hz 230-1+N-50 230-1+N-50 230-1+N-50 230-1+N-50 400-3+N-50 400-3+N-50

Voltage range V 220-240 220-240 220-240 220-240 380-415 380-415

Control circuit supply 24V AC via internal transformer

Maximum unit power input (Un)

Cos Phi unit at maximum power

Maximum unit current drawn (Un-10%)

Maximum unit current drawn (Un)

Maximum Start-up current, standard unit

(1) Power input, compressors and fans, at the unit operating limits (saturated suction temperature 15 °C, saturated condensing temperature 68.3 °C) and nominal voltage

of 400 V (data given on the unit nameplate).

(2) Maximum unit operating current at maximum unit power input and at 360 V.

(3) Maximum unit operating current at maximum unit power input and at 400 V (values given on the unit nameplate).

(4) Maximum instantaneous start-up current at operating limits (maximum operating current of the smallest compressor(s) + fan current + locked rotor current of the

largest compressor).

EREBA He

(1)

(1)

(2)

(3)

(4)

kW 1,80 3,38 4,73 5,18 10,32 10,32

0,98 0,98 0,98 0,98 0,98 0,98

A 8,9 16,7 23,3 25,6 16,8 16,8

A 8 15 21 23 15,2 15,2

A Not Applicable (less than the operating current)

EN-16

1 - INTRODUCTION

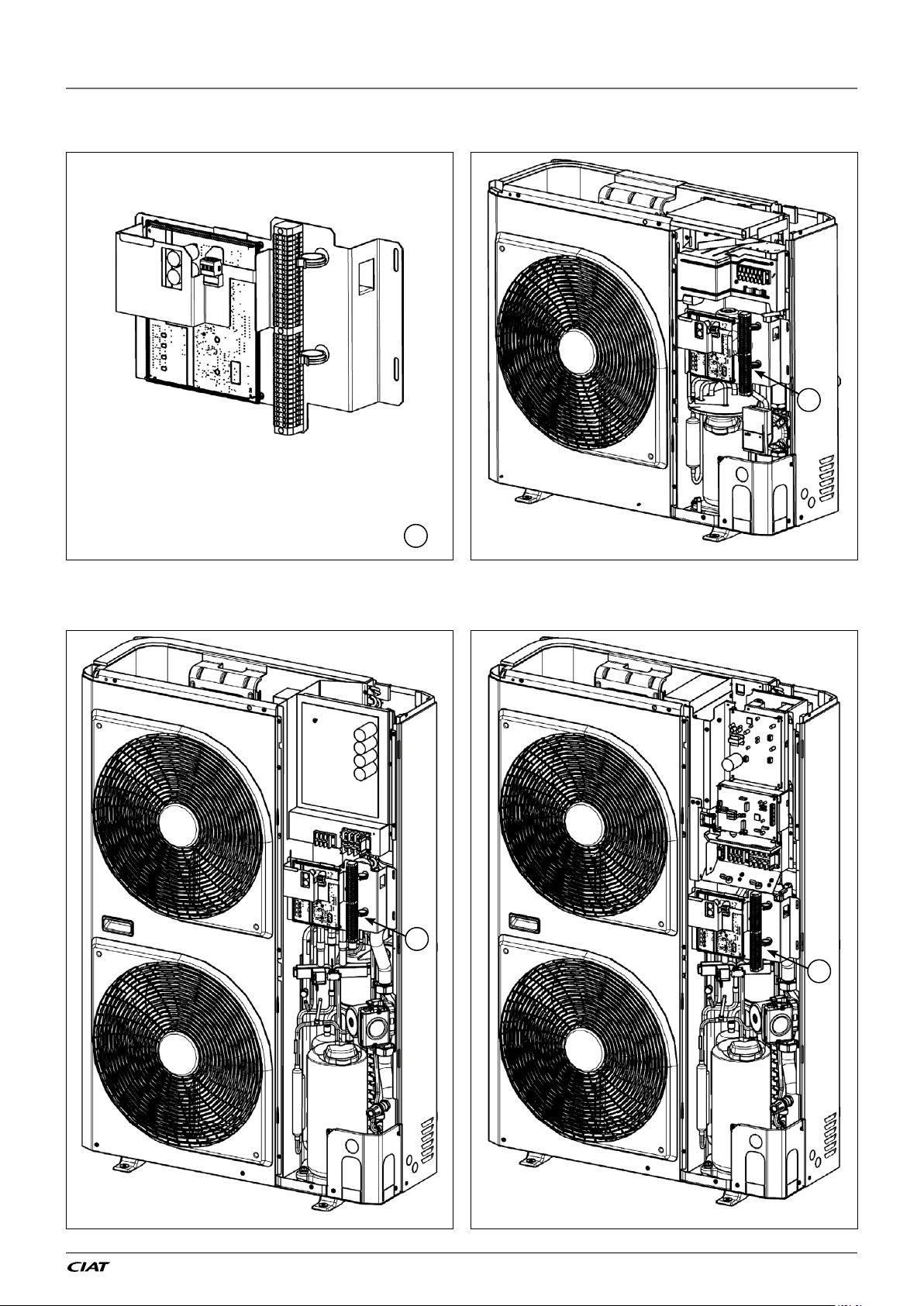

1.5.3 - Inside view

Electrical box 5 - 7 kW unit (1 Ph)

1

1

11 - 15 kW unit (1 Ph) 11 - 15 kW unit (3 Ph)

1

1

EN-17

EREBA He

1 - INTRODUCTION

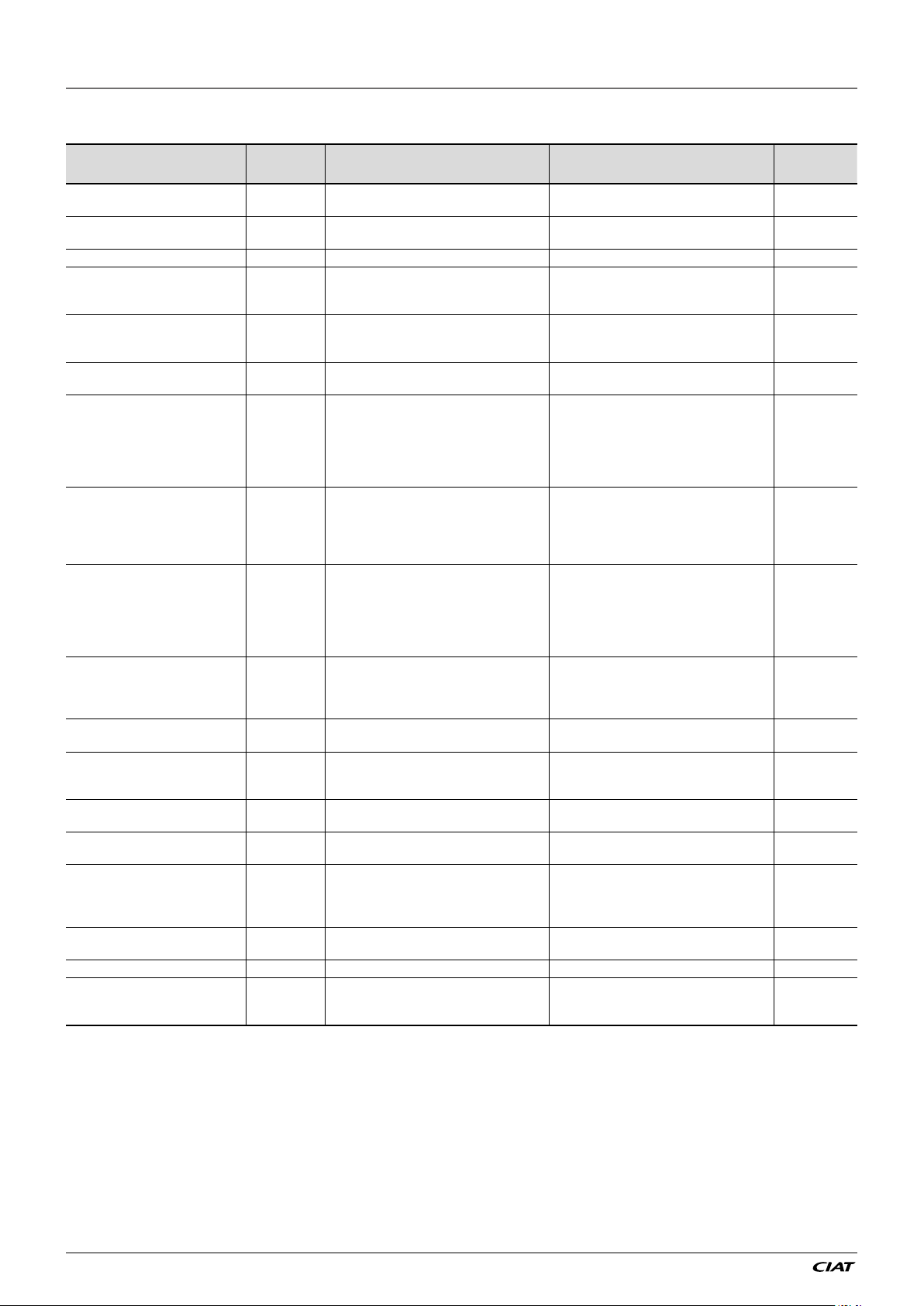

1.6 - Accessories

Accessories Reference Description Advantages Utilisation

Hydraulic tubes 7187601

Rubber cushion 7447060

Floor heating thermal cut off 7274278 Floor heating protection Reduces risk of floor heating dammage EREBA He

Backup heater 5kW 7148641 Electrical backup system

Backup heater 9kW 7148642 Electrical backup system

Backup heater for 9 kW for buffer tank

(100L & 200L)

Buffer tank 50L 7328746

Buffer tank 100L 7328744

Buffer tank 200L 7328747

Master / Slave sensor 7484985

Domestic hot water tank 300 L 7385910

Domestic hot water management

sensor and 3 way valve

"Pool heating management sensor

and 3 way valve"

Pool heating heat exchanger

(ITEX POOL +)

Remote human interface Standard Remotely installed user interface

Additional outdoor ambient

temperature sensor

Water filling kit 7013876 System enabling to fill the hydraulic circuit Hydraulic circuit easy filling EREBA He

DUO hydraulic module (for floor

heating < 11kW)

7221389 Electrical backup system Easy and fast installation inside the buffer tank EREBA He

7411357

71111 22

7268480

7484983 Additional outdoor ambient temperature sensor Better reading of outdoor air temperature EREBA He

3911008

Tubes are used to decoupling hydraulic circuits

and the units

Cushion installed under the unit to avoid

vibration trasmission

Buffer tank available to resolve installions

constraints

Buffer tank available to resolve installation

constraints

Buffer tank available to resolve installation

constraints

Unit equipped with supplementary water outlet

temperature sensor kit to be field-installed

allowing master/slave operation of two to four

units connected in parallel

Tank designed to satisfy sanitary hot water

productions

Sensor enabling to manage the water setpoint

inside the tank used for domestic hot water

production

Sensor enabling to manage the water setpoint

used for pool heating

Essential parts to ensure good working of pool

heating

This hydraulic module allows to manage two

differents heat emitters (Ex: floor heating and

radiators)

Reduces vibration transmission to hydraulic

installation

Reduces vibration transmission EREBA He

Easy and fast installation, stepped power,

hydraulic securities integrated (water relief

valve, automatic purge)

Easy and fast installation, stepped power,

hydraulic securities integrated (water relief

valve, automatic purge)

Reduce unit cycling increasing reliability, play

the roule of hydraulic separation to improve

the control of water flow rate and water

temperature in the system and finally, increase

thermal inertia during defrost and options mode

operation

Reduce unit cycling increasing reliability, play

the roule of hydraulic separation to improve the

control of water flow rate and water temperature

in the system and increase thermal inertia

during defrost and options mode operation

Reduce unit cycling increasing reliability, play

the roule of hydraulic separation to improve

the control of water flow rate and water

temperature in the system and finally, increase

thermal inertia during defrost and options mode

operation

Optimised operation of chillers connected in

parallel with operating time equalisation

Easy and fast installation, isolated tank to

reduce heat loss

Useful for domestic hot water production EREBA He

Useful for pool heating production EREBA He

Titanium exchangers plates, removable, easy

maintenance

Remote heat pump control with room

temperature sensor used to offset the water

control point.

Possibility to configure the unit on field.

Easy and fast installation, independant control

integrated

EREBA He

EREBA He

EREBA He

EREBA He

EREBA He

EREBA He

EREBA He

EREBA He

EREBA He

EREBA He

EREBA He

EREBA He

EN-18

2 - INSTALLATION OF UNIT

2.1 - General

To install an unit EREBA He the following

steps are requested

1. Place the unit

2. Make hydraulic connections to filling the

system with water or brine fluid

3. Make electrical connections

4. Check for water leaks and the water flow

rate control

5. Finally, make commissioning of the unit

2.2 - Moving and placing the unit

2.2.1 - Moving

See §1.2.1 Installation safety considerations.

Figure 1: Transport configuration

2.2.2 - Placing the unit

In case of extra-high units the machine

environment must permit easy access for

maintenance operations.

Always refer to § 1.4. Dimensions and

clearances to conrm that there is

adequate space for all connections and

service operations. For the centre of

gravity coordinates, the position of the unit

mounting holes, and the weight distribution

points, refer to the certied dimensional

drawing supplied with the unit.

Typical applications of these units do not

require earthquake resistance. Earthquake

resistance has not been veried.

Only use slings at the designated

lifting points (refer to Figure 2 to

ofoad the unit).

Before siting the unit check that:

Figure 2: Offloading configuration

● the permitted loading at the site is

adequate or that appropriate strengthening

measures have been taken.

● if the unit has to operate as a heat pump

in temperatures below 0°C it must be

raised at least 300 mm from the ground.

This is necessary to avoid ice build-up

on the unit chassis and also to permit

correct unit operation in locations where

the snow level may reach this height.

● the unit is installed level on an even

surface (maximum tolerance is 5 mm in

both axes).

● there is adequate space above the unit

for air flow and to ensure access to the

components (see dimensional drawings).

● the number of support points is adequate

and that they are in the right places.

● the location is not subject to flooding.

● for outdoor installations, where heavy

snowfall is likely and long periods of

sub-zero temperatures are normal,

provision has to be made to prevent snow

accumulating by raising the unit above

the height of drifts normally experienced.

Baffles may be necessary to deflect

strong winds. They must not restrict air

flow into the unit.

EN-19

EREBA He

2 - INSTALLATION OF UNIT

● OAT sensor, located on the coil, should

not be exposed to the sun or other heat

sources.

Before lifting the unit, check that

all casing panels are securely xed

in place. Lift and set down the unit

with great care. Tilting and jarring

can damage the unit and impair unit

operation.

Never push or lever on any of the

enclosure panels of the unit. Only

the base of the unit frame is designed

to withstand such stresses. If a unit

includes a hydraulic module, the

hydraulic module and pump piping

must be installed in a way that

does not submit it to any strain.

The hydraulic module pipes must

be tted so that the pump does not

If EREBA He units are hoisted with rigging, it

support the weight of the pipes.

is advisable to protect coils against crushing

while a unit is being moved. Use struts or a

lifting beam to spread the slings above the

unit. Do not tilt a unit more than 15°.

2.2.3 - Removing the unit panel

To access at the inside of the unit (refrigerant parts / electrical parts), the panel can be

removed. This operation must be carried out by a qualified technician.

Figure 3 : How to remove front panel for 11 & 15 kW units

Figure 4 : How to remove front panel for 5 & 7 kW units

EREBA He

EN-20

2 - INSTALLATION OF UNIT

Figure 5 : Opening cable knockouts

2.2.4 - Checks before system start-up

Before the start-up of the refrigeration

system, the complete installation, including

the refrigeration system must be verified

against the installation drawings, dimensional

drawings, system piping and instrumentation

diagrams, and wiring diagrams.

For these checks national regulations must

be followed. If the national regulation does

not specify any details, refer to standard ISO

5149 as follows:

External visual installation checks:

2.3 - Water connections

For size and position of the unit water inlet

and outlet connections refer to the certified

dimensional drawings supplied with the unit.

The water pipes must not transmit any radial

● Ensure that the machine is charged with

refrigerant. Verify on the unit nameplate

or axial force to the heat exchangers nor any

vibration.

that the ‘fluid being transported’ is R-410A

and is not nitrogen.

● Compare the complete installation with

the refrigeration system and power circuit

diag rams.

● Check that all components comply with

the design specifications.

● Check that all protection documents

and equipment provided by the

manufacturer (dimensional drawings,

P&ID, declarations etc.) to comply with

The water supply must be analysed and

appropriate filtering, treatment, control

devices, shut-off and bleed valves and

circuits built in, to prevent corrosion (example:

damage to the protection of the tube surface if

the fluid is polluted), fouling and deterioration

of the pump fittings.

Before any start-up verify that the heat

exchange fluid is compatible with the

materials and the water circuit coating.

the regulations are present.

● Verify that the environmental safety and

protection and devices and arrangements

provided by the manufacturer to comply

with the regulations are in place.

● Verify that all documents for pressure

In case additives or other fluids than those

recommended by the manufacturer are used,

ensure that the fluids are not considered as

a gas.

Recommendations on heat exchange uids:

containers, certificates, name plates,

files, instruction manuals provided by

the manufacturer to comply with the

regulations are present.

● Verify the free passage of access and

safety routes.

● Verify the instructions and directives

to prevent the deliberate removal of

refrigerant gases.

● Verify the installation of connections.

● Verify the supports and fixing elements

(materials, routing and connection).

● Verify the quality of welds and other

joints.

● Check the protection against mechanical

damage.

● Check the protection against heat.

● Check the protection of moving parts.

● Verify the accessibility for maintenance

or repair and to check the piping.

● Verify the status of the valves.

● Verify the quality of the thermal insulation

and of the vapour barriers.

● No NH4+ ammonium ions in the water, they

are very detrimental for copper. This is

one of the most important factors for the

operating life of copper piping. A content of

several tenths of mg/l will badly corrode the

copper over time.

EN-21

EREBA He

2 - INSTALLATION OF UNIT

● Cl- Chloride ions are detrimental for

copper with a risk of perforations by

corrosion by puncture. If possible keep

below 10 mg/l.

2-

● SO

sulphate ions can cause perforating

4

corrosion, if their content is above 30

mg/l.

● No fluoride ions (<0.1 mg/l).

● No Fe2+ and Fe3+ ions with non negligible

levels of dissolved oxygen must be

present. Dissolved iron < 5 mg/l with

dissolved oxygen < 5 mg/l.

● Dissolved silicon: silicon is an acid

element of water and can also lead to

corrosion risks. Content < 1mg/l.

● Water hardness: >0.5 mmol/l. Values

between 1 and 2.5 mmol/l can be

recommended. This will facilitate scale

deposit that can limit corrosion of copper.

Values that are too high can cause piping

blockage over time. A total alkalimetric

title (TAC) below 100 mg/l is desirable.

● Dissolved oxygen: Any sudden change

in water oxygenation conditions must be

avoided. It is as detrimental to deoxygenate

the water by mixing it with inert gas as

it is to over-oxygenate it by mixing it

with pure oxygen. The disturbance of

the oxygenation conditions encourages

destabilisation of copper hydroxides and

enlargement of particles.

● Electric conductivity: 0.001-0.06 S/m (10-

600 µS/cm).

● pH: Ideal case pH neutral at 20-25°C (7 <

pH < 8).

Charging, adding or draining uid

from the water circuit must be done

by qualied personnel, using air

vents and materials suitable for the

products. Water circuit charging

devices are eld-supplied.

The use of units in an open loop is

forbidden.

2.3.1 - Operating precautions and

recommendations

The water circuit should be designed to have

the least number of elbows and horizontal

pipe runs at different levels. Below the main

points to be checked for the connection:

● Comply with the water inlet and outlet

connections shown on the unit.

● Install manual or automatic air purge

valves at all high points in the circuit.

● Use a pressure reducer to maintain

pressure in the circuit(s) and install a

relief valve as well as an expansion tank.

Units with the hydraulic module include a

relief valve and an expansion tank.

● Install drain connections at all low points

to allow the whole circuit to be drained.

● Install stop valves, close to the entering

and leaving water connections.

● Use flexible connections to reduce

vibration transmission.

● Insulate all pipework, after testing for

leaks, both to reduce thermal leaks and

to prevent condensation.

● Use thermal tape to seal joints and to

seam the insulation.

● If the external unit water pipes are in an area

where the ambient temperature is likely

to fall below 0°C, they must be protected

against frost (frost protection solution or

trace heating).

● The use of different metals on hydraulic

piping could generate electrolytic pairs

and consequently corrosion. Verify then,

the need to install sacrificial anodes.

EREBA He

Charging and removing heat

exchange uids should be done with

devices that must be included on the

water circuit by the installer. Never

use the unit heat exchangers to add

heat exchange uid.

EN-22

2 - INSTALLATION OF UNIT

The plate heat exchanger can foul up quickly

at the initial unit start-up, as it complements

the lter function, and the unit operation will

be impaired (reduced water ow rate due to

increased pressure drop).

Units with hydraulic module are equipped

with a screen lter.

Do not introduce any signicant static or

pressures).

The products that may be added for thermal

insulation of the containers during the

water piping connection procedure must be

chemically neutral in relation to the materials

and coatings to which they are applied. This

is also the case for the products originally

supplied by the manufacturer.

dynamic pressure into the heat exchange

circuit (with regard to the design operating

2.3.2 - General

For details on connection diameters, refer to §1.5.1 Physical data EREBA He.

Figure 6: Water connection on unit

Water inlet

Water outlet

Draining water pipe

EN-23

EREBA He

2 - INSTALLATION OF UNIT

3

2.3.3 - Minimum water loop volume

The minimum water loop volume, in litres, is

given by the following formula:

Volume (l) = CAP (kW) x N

Where CAP is the nominal cooling capacity

at nominal operating conditions.

Application N

Air conditioning 3,5

Heating or domestic hot water application 6

Industrial process cooling See note below

Note: For industrial process cooling applications, where high stability of

water temperature levels must be achieved, the values above must be

increased.We recommend consulting the factory for these particular

applications.

This volume is required to obtain temperature

stability and precision. To achieve this volume,

it may be necessary to add a storage tank to

the circuit. This tank should be equipped with

baffles to allow mixing of the fluid (water or

brine). Please refer to the examples below.

2.3.4 - Maximum water loop volume

Units with hydraulic module incorporate an

expansion tank that limits the water loop

volume. The table below gives the maximum

loop volume for pure water or ethylene glycol

with various concentrations.

If the total system volume is higher than the

values given above, the installer must add

another expansion tank, suitable for the

additional volume.

Water maximum volume (L)

EREBA He

Static pressure (bar) 1,5 3

Fresh water 200 50

Ethylen glycol 10% 150 38

Ethylen glycol 20% 110 28

Ethylen glycol 30% 90 23

Ethylen glycol 40% 76 19

Bad Good

GoodBad

2.3.5 - Hydraulic circuit

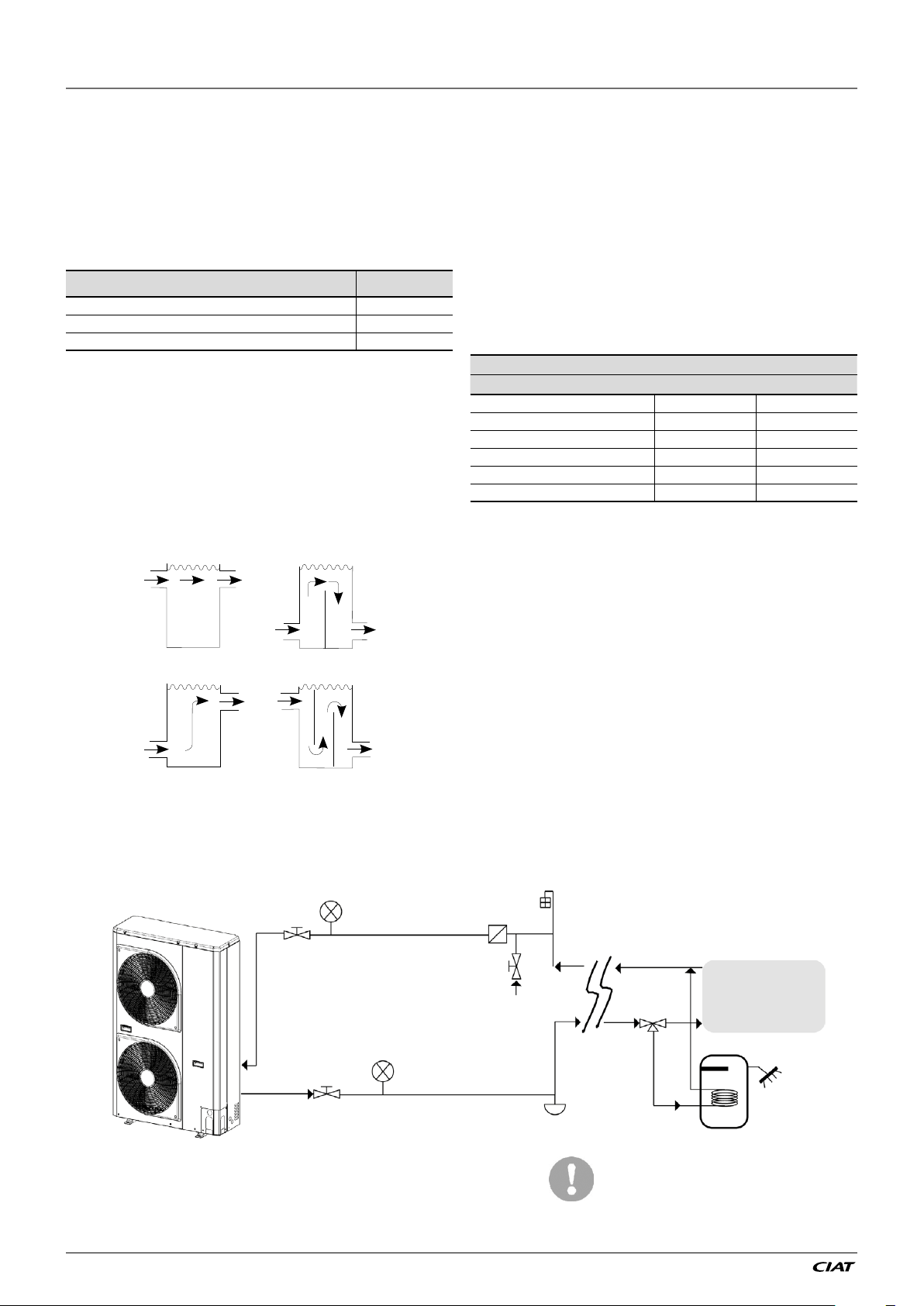

Figure 7: Typical diagram of the hydraulic circuit with the hydraulic module

1

3

1

2

6

4

7

8

5

9

Legend:

1 Shut-off valves 2 Line filter for water 3 Pressure gauges

4 Filling valve 5 System drain valve 6 Air flushing valve

7 3-way valve 8 Sanitary water accumulation tank 9 Inside system

EREBA He

EN-24

The use of the hydraulic

module on open loop is

prohibited.

2 - INSTALLATION OF UNIT

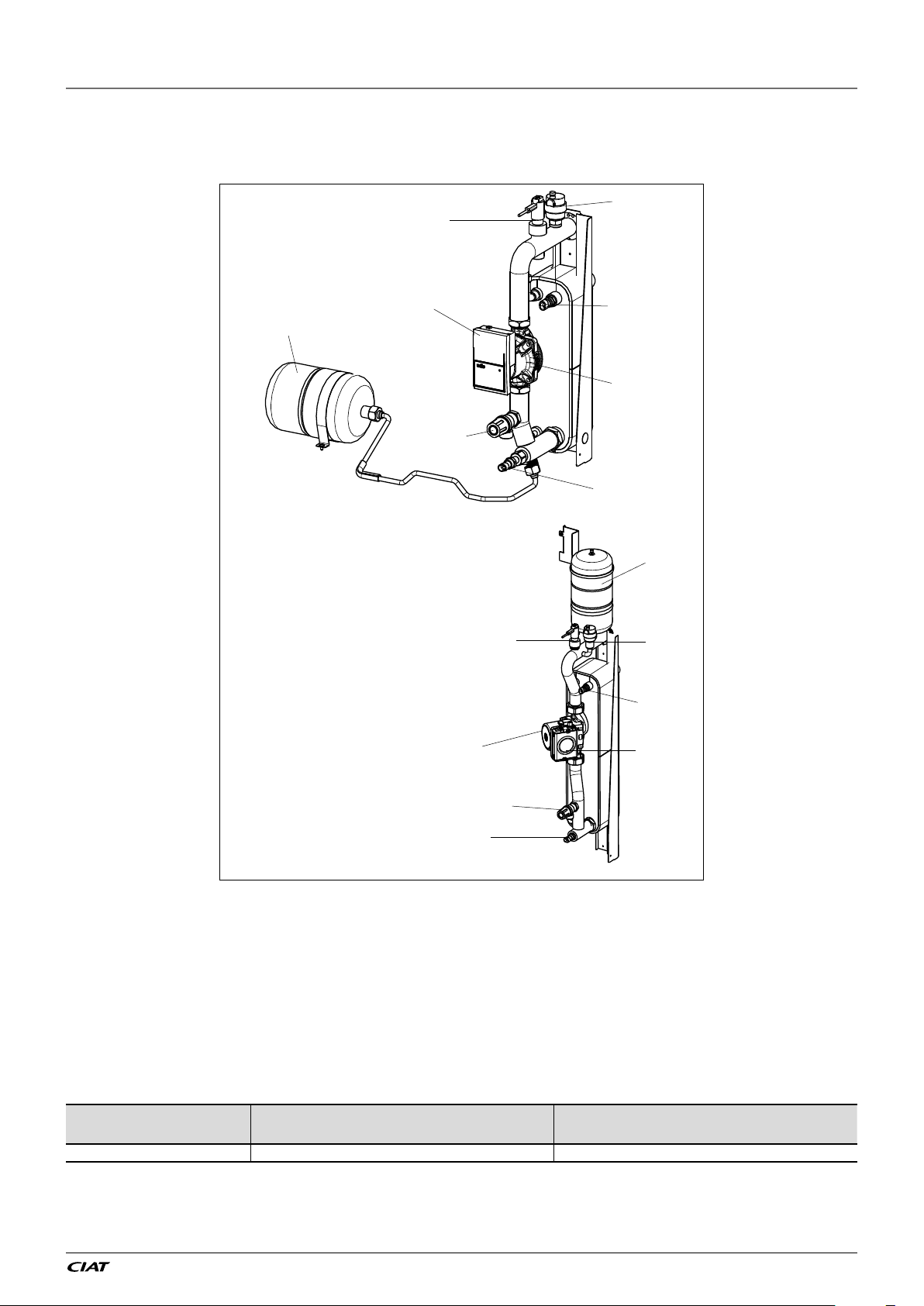

Figure 8: Hydraulic module equipped with variable speed single pump low

available pressure with expansion tank

Hydraulic module

a

b

5 & 7 kW units

g

e

c

f

b

d

f

h

g

a

d

e

11 & 15 kW units

c

h

Legend:

a Automatic purge valve

b Flow switch

c Safety valve outlet

d Leaving water temperature probe

e Circulation pump

f Plug to unblock the seizing pump

g Expansion vessel

h Entering water temperature probe

Minimum and maximum pressures necessary in the hydraulic circuit for correct operation of

the units.

Hydraulic circuit

Variable speed hydraulic module 40 kPa (0.4 bar) 300 kPa(3 bar).

Minimum pressure at the suction of the pump

to avoid the cavitation phenomena.

Maximum pressure at the suction of the pump

before the opening of the water relief valve

(1)

EN-25

EREBA He

2 - INSTALLATION OF UNIT

2.4 - Electrical connections

Please refer to the certified wiring drawings,

supplied with the unit.

2.4.1 - Power supply

The power supply must conform to the

specification on heat pump nameplate. The

supply voltage must be within the range

specified in the electrical data table. For

connections refer to the wiring diagrams and

the certified dimensional drawings.

After the unit has been commissioned,

the power supply must only be

disconnected for quick maintenance

operations (one day maximum). For

longer maintenance operations or

when the unit is taken out of service

and stored (e.g. during the winter or

if the unit does not need to generate

cooling) the power supply must be

maintained to ensure supply to the

electric heaters (compressor coil

heater, unit frost protection).

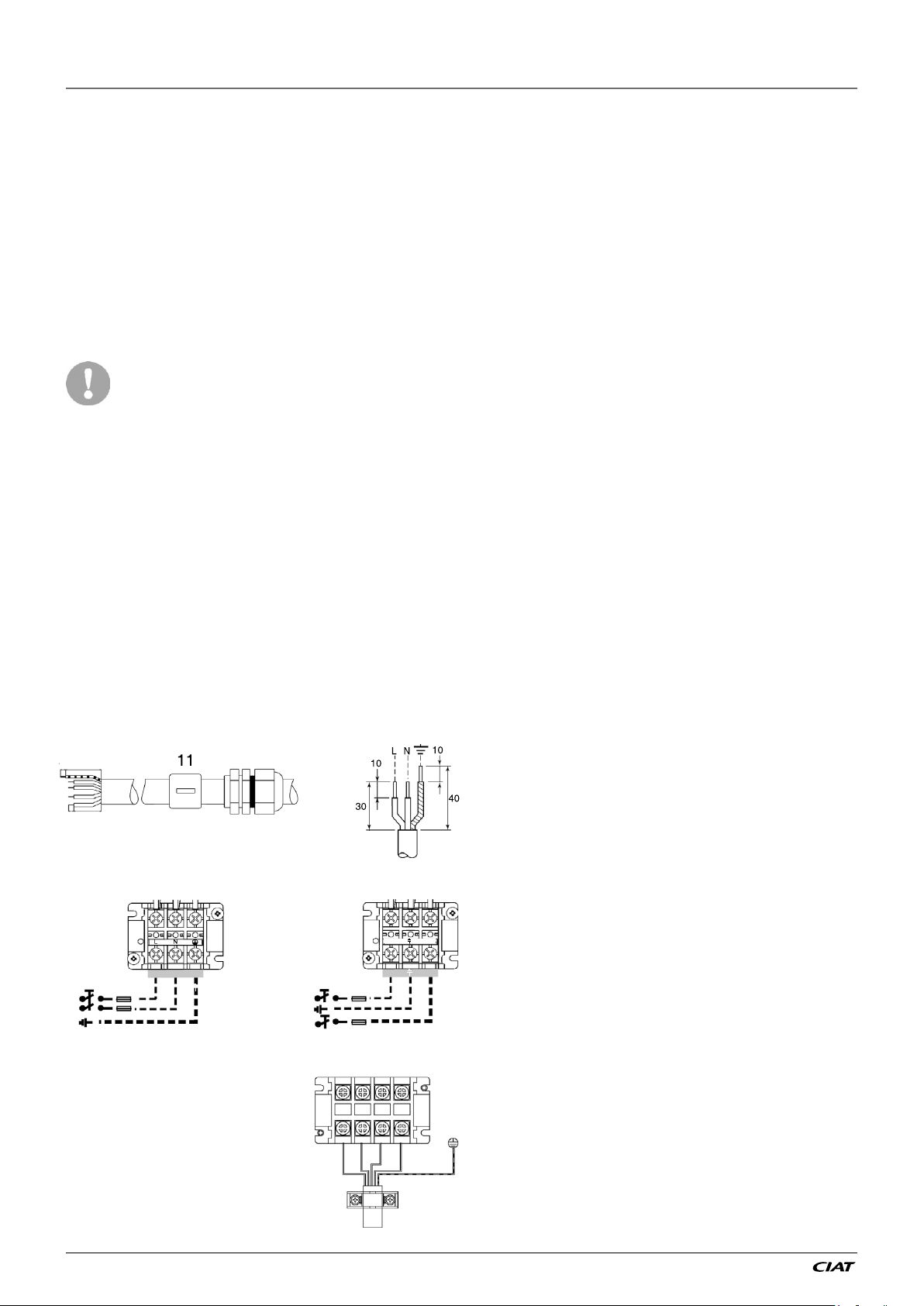

Figure 9: Power connection with Main

Switch

3Ph 1Ph

2.4.2 - Recommended wire sections

Wire sizing is the responsibility of the installer,

and depends on the characteristics and

regulations applicable to each installation

site. The following is only to be used as a

guideline, and does not make Manufacturer

in any way liable. After wire sizing has been

completed, using the certified dimensional

drawing, the installer must ensure easy

connection and define any modifications

necessary on site.

The connections provided as standard for

the field-supplied power entry cables are

designed for the number and type of wires,

listed in the table below.

The calculations of favourable and

unfavourable cases are performed by using

the maximum current possible of each unit

fitted with a hydraulic kit (see the tables of

electrical data for the unit and the hydraulic

module).

The calculation is based on PVC or XLPE

insulated cables with copper core. A

maximum ambient temperature of 46°C has

been taken into consideration. The given

wire length limits the voltage drop to < 5%

(length L in metres - see table below).

5-7 1Ph+N

L N

11-15 1Ph+N

L

L N

11-15 3Ph+N

L1 L2 L3

N

IMPORTANT:

Before connection of the main power cables

(L1 - L2 - L3 - N - PE or L1 - N - PE) on the

terminal block, it is imperative to check

the correct order of the 3 phases before

proceeding to the connection and the good

connection of the neutral wire (if the neutral

N

conductor is not connected correctly, the

unit can be damaged permanently).

EREBA He

EN-26

2 - INSTALLATION OF UNIT

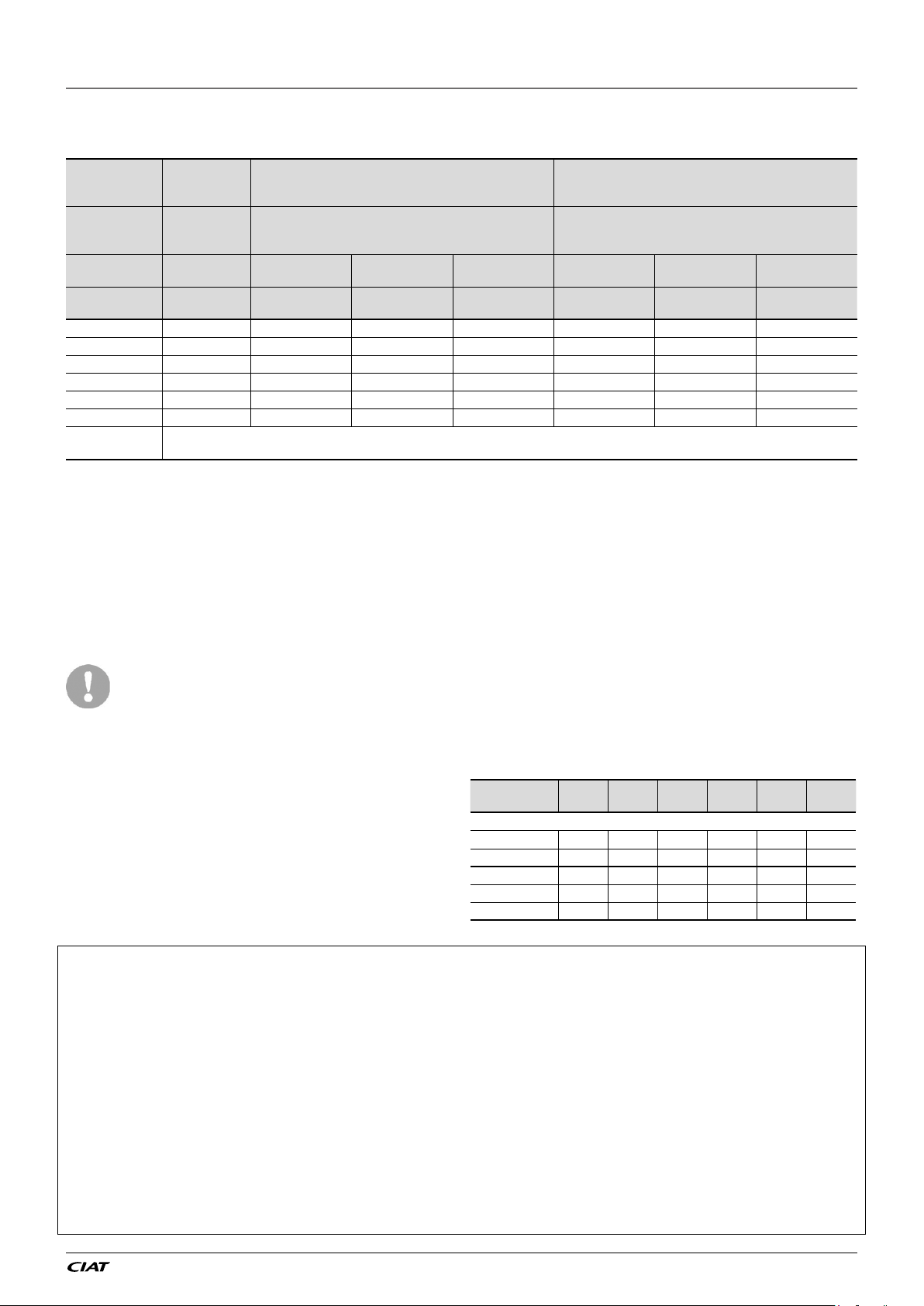

Table 1: Minimum and maximum wire section (per phase) for connection to

EREBA He units

Max.

connectable

EREBA He Section Section

(per phase)

5 (1Ph) 3G4² 3G2,5² 100 H07RNF 3G2,5² 80 H07RNF

7 (1Ph) 3G4² 3G2,5² 100 H07RNF 3G2,5² 80 H07RNF

11 (1Ph) 3G4² 3G4² 100 H07RNF 3G4² 80 H07RNF

15 (1Ph) 3G4² 3G4² 100 H07RNF 3G4² 80 H07RNF

11 (3Ph) 5G4² 5G2,5² 100 H07RNF 5G2,5² 80 H07RNF

15 (3Ph) 5G4² 5G2,5² 100 H07RNF 5G2,5² 80 H07RNF

Accessory

Remote WUI

Notes:

(1) Connection capacities actually available for each machine, defined according to the connection terminal size, the control box access opening size and the available

space inside the control box.

(2) Selection simultation result considering the hypothesis indicated.

(3) If the maximum calculated section is for an XLPE cable type, this means that a selection based on a PVC cable type can exceed the connection capacity actually

available. Special attention must be given to the selection.

Use cables H07RN-F 4x0.75 mm² up to 50m to connect the user interface WUI (not supplied with accessory)

CAUTION: Use the grey ferrite which is supplied in accessory to clamp around the WUI cable. Please clamp it directly after the customer's terminal block

section

mm²

(1)

- Suspended aerial lines (standardised routing No. 17)

- XLPE insulated cable

(per phase)

Calculation favourable case: Calculation unfavourable case:

- Conductors in conduits or multi-conductor cables

in closed conduit (standardised routing No. 41)

- PVC insulated cable, if possible

mm²

Max. length for

(2)

voltage drop <5%

Cable type Section

m -

mm²

(per phase)

Max. length for

(2)

voltage drop <5%

m -

Cable type

(3)

Power cable entry

The power cables must be entered through

the cable gland from the rear of the unit.

Use a black ferrite which is supplied

in accessory to clamp around the

supply cable. Please clamp it directly

after the customer’s terminal block.

Please clamp the second one close

to the cable gland.

The power cable should not be in

contact with hot parts of the system.

Electrical data and operating conditions notes:

• EREBA He units have a single power connection point located immediately

upstream of the field power connections.

• The control box includes the following standard features:

- Variable frequency drive for compressor, fans and pump (option)

- The control devices.

• Field connections:

All connections to the system and the electrical installations must be in full accordance

with all applicable local codes.

• The ERE BA He units are designed and built in compliance with EN 60335-1 and 2

NOTES:

• The operating environment for the EREBA He units is specified below:

1. Physical environment

EN 60364:

- outdoor installation: protection level IP44

- operating temperature range: -20°C to +46°C

- storage temperature range: -20°C to +48°C

- altitude: ≤ 2000 m (see note for table 1.5.4 - Electrical data, hydraulic module)

- presence of hard solids, class AE3 (no significant dust present)

- presence of corrosive and polluting substances, class AF1 (negligible)

(2)

. The classification of environment is specified in standard

(2)

(1)

.

2.4.3 - Recommended customer

electrical protection

Electrical protection is the responsibility of the

installer, and depends on the characteristics

and regulations applicable to each installation

site. The following is only to be used as a

guideline, and does not make manufacturer

in any way liable.

5

EREBA He

Circuit breaker:

Type C C C C C C

Current A 10 16 25 25 16 16

Fuses:

Type gG gG gG gG gG gG

Current A 16 20 32 32 20 20

2. Power supply frequency variation: ± 2 %.

3. The neutral (N) conductor must be always connected to the unit

4. Overcurrent protection of the power supply conductors is not provided with the

unit.

5. The units are designed for simplified connection on TT networks (IEC 60364).

Caution: If particular aspects of an actual installation do not conform to the

conditions described above, or if there are other conditions which should be

considered, always contact your local representative.

(1) The absence of main power disconnect switch is an exception that must be

taken into account at field installation level.

(2) The required protection level for this class is IP43BW (according to reference

document IEC 60529). All EREBA He units fulfil this protection condition:

- Closed electrical box is IP44

- When accessing to interface, the level is IPxxB

(1Ph)

7

(1Ph)

11

(1Ph)

15

(1Ph)

11

(3Ph)

15

(3Ph)

EN-27

EREBA He

2 - INSTALLATION OF UNIT

2.5 - Water flow rate control

2.5.1 - Water leakage

Check that the water-side connections are

clean and show no sign of leakage.

2.5.2 - Minimum water flow rate

If the installation flow rate is below the

minimum flow rate, there is a risk of excessive

fouling.

2.5.3 - Maximum water flow rate

This is limited by the permitted water heat

exchanger pressure drop.

2.5.4 - Water heat exchanger flow rate

Data applicable for:

- Fresh water 20°C

- In case of use of the glycol, the

maximum water flow is reduced.

EREBA He units

Minimum water

flow rate

m3/h

5 (1Ph) 0,18 0,9 4,3

7 (1Ph) 0,42 1,2 4,3

11 (1Ph) 0,6 1,9 7,0

15 (1Ph) 0,6 2,6 7,0

11 (3Ph) 0,6 1,9 7,0

15 (3Ph) 0,6 2,6 7,0

(1) Eurovent heating conditions

Nominal water

flow rate

m3/h

Maximum water

(1)

flow rate

m3/h

2.5.5 - Nominal system water flow

control

The water circulation pumps of the EREBA He

units have been sized to allow the hydraulic

modules to cover all possible configurations

based on the specific installation conditions,

i.e. for various temperature differences

between the entering and the leaving water

(∆T) at full load, which can vary between 3

and 10 K.

This required difference between the entering

and leaving water temperature determines

the nominal system flow rate. Use this

specification for the unit selection to find the

system operating conditions.

In particular, collect the data to be used for

the control of the system flow rate:

● Units with variable speed pump-control

on adjustable constant speed: nominal

flow rate,

● Units with variable speed pump -

control on temperature difference: heat

exchanger ΔT (variable flow).

If the information is not available at the

system start-up, contact the technical service

department responsible for the installation to

get it. These characteristics can be obtained

from the technical literature using the unit

performance tables for a ∆T of 5 K at the

water heat exchanger.

EREBA He

EN-28

2 - INSTALLATION OF UNIT

Table 2: Steps to clean, purge, and define a flow rate for hydraulic circuit

Cleaning

procedure

Purge

procedure

Water flow

control

procedure

N°

1 Open the manual control valve fully. No manual control valve required with Variable Speed Hydraulic module

2 Set the system pump

Read the BPHE pressure drop...

3

… by taking the difference of the readings of the pressure gauge connected to the unit inlet and outlet.

4 Let the pump run for two consecutive hours to flush the hydraulic circuit of the system (presence of solid contaminants).

5 Take another reading.

6 Compare this value to the initial value.

7 If the pressure drop…

… has decreased, this indicates that the screen filter must be removed and cleaned, as the hydraulic circuit contains solid particles.

In this case stop the pump

8

section of the unit.

9 Repeat, if necessary, to ensure that the filter is not contaminated.

1 After filling with water, wait about 24h before activating the purge procedure.

Activate the purge mode

2

switch value

3 The air purge is field-supplied.

If the purge is automatic, air will vent from circuit automatically.

If the purge is manual, open the valve to vent air from the circuit

When the circuit is cleaned and purged, activate the pump in quick test mode

1

pressures at the pressure gauges (entering water pressure - leaving water pressure), …

Compare this value to the graph of available external static pressure using the appropriate speed

3

curve (Graphic 1).

4 If the flow rate corresponding is higher, decrease pump speed

5 Proceed by successively adjusting the pump speed until the expected water flow rate is achieved.

(2)

With Variable Speed Hydraulic module

Adjustable constant speed

(1)

.

(1)

and close the shut-off valves at the water inlet and outlet and remove the screen filter after emptying the hydraulic