CIAT Connect 2 Installation, Operation, Commissioning, Maintenance

Microchip and LCD display

electronic regulation and

signaling electronic module

for liquid coolers

and heat pumps

NA 09.13 H

09 - 2011

Installation

Operation

Commissioning

Maintenance

1

CONTENTS

PAGE

1 IMPORTANT RECOMMENDATIONS

3

2 GENERAL

3

3 Composition

4

3.1 Main control board for machines with one refrigerating circuit

4

3.2 Additional board 1

5

3.3 Additional board 2

6

3.4 Control and display console

7

3.5 Connection via RS485 serial port for BMS or control console and Multiconnect with 500 kW module

8

3.6 Relay boards

9

4 DESCRIPTION

9

4.1 Main board

9

4.2 Expansion (additional) boards 1 and 2

9

4.3 Man-Machine Communication

10

5 ACCESS LEVELS

10

5.1 Selecting an authorised access level

10

5.2 Accessing the various access levels

10

5.3 Configuring access levels on the controller

12

5.4 Management of the numeric codes for accessing levels 2 and 3

12

5.5 Classification of the menus and their functions

12

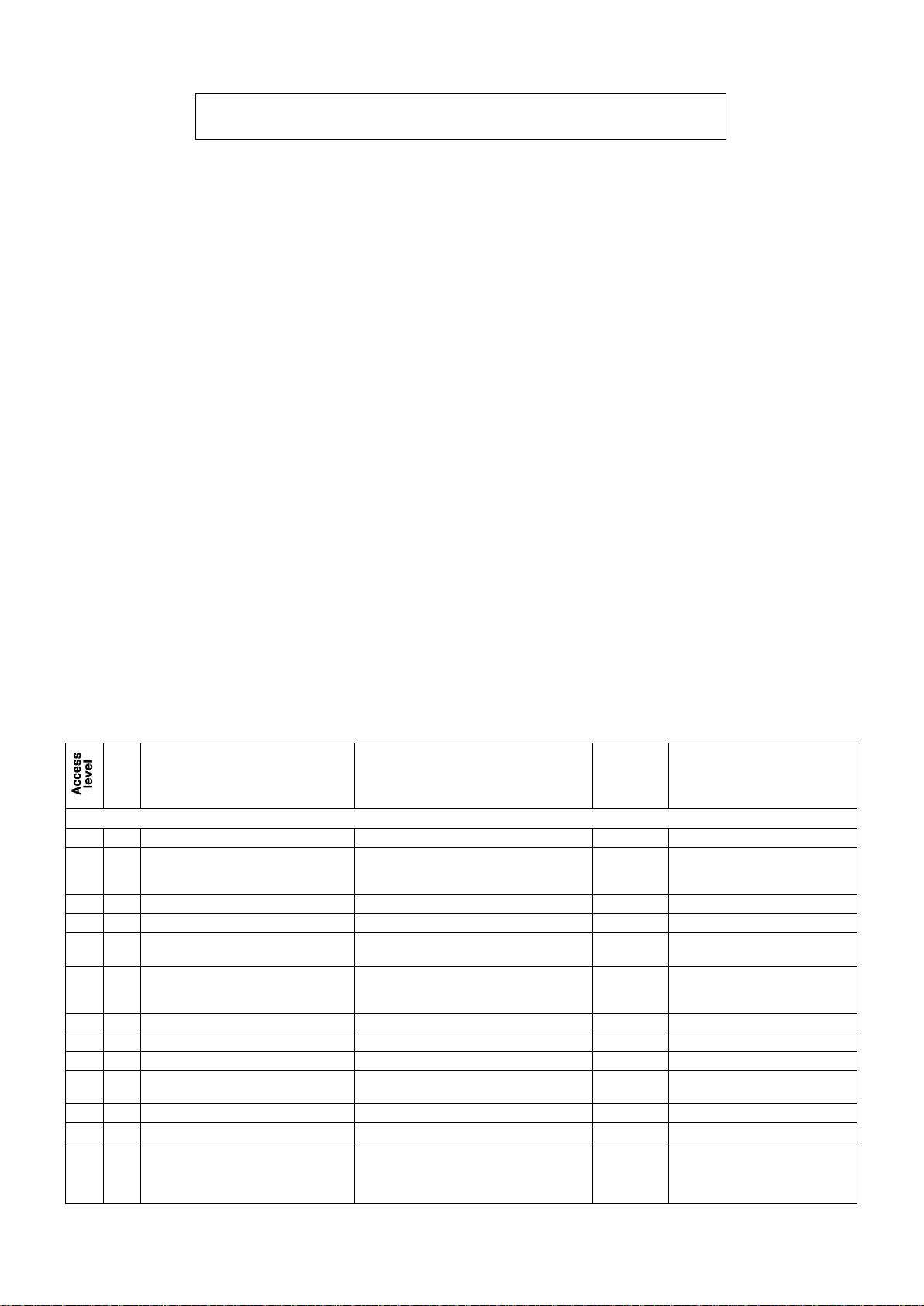

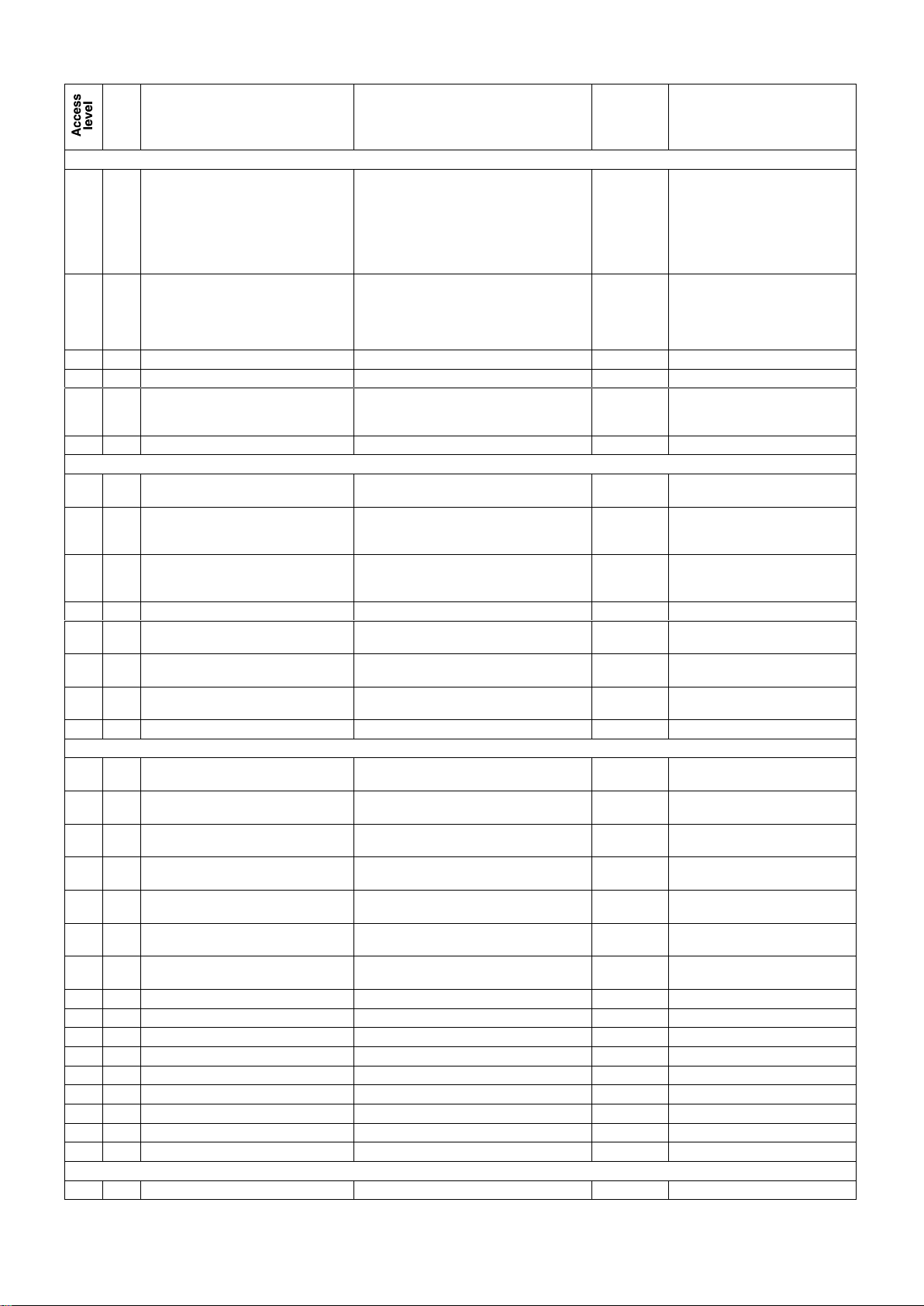

6 LIST OF PARAMETERS PER ACCESS LEVEL

12

7 MANAGEMENT OF AERO-CONNECT PARAMETERS

20

8 CONTENTS OF THE MENUS

21

8.1 MAIN menu

21

8.2 SETPOINTS menu

21

8.3 MACHINE STATUS menu

22

8.4 MEASURED VALUES menu

26

8.5 MACHINE PARAMETERS menu

26

8.6 ADJUSTMENT PARAMETERS menu

31

8.7 OPERATION PARAMETERS menu

39

8.8 FAULT MEMORY menu

50

8.9 TEST MODE menu

51

9 MANAGEMENT OF THE ON/OFF INPUTS

52

9.1 Automatic machine operation control

52

9.2 Load shedding control

52

9.3 Water flow switch

52

9.4 Fan fault (circuits 1 and 2)

53

9.5 Expansion valve fault

53

9.6 Phase controller fault

54

9.7 Pump fault

54

9.8 Compressor protection

55

9.9 Manual HP pressure switch fault on circuit 1 or 2

55

9.10 Setpoint selection via on/off input

56

9.11 Variable setpoint via 4-20 mA input

56

9.12 Operating mode selection

57

10 MANAGEMENT OF THE ANALOGUE INPUTS

57

10.1 Temperature sensor

57

10.2 Pressure sensor

60

11 MANAGEMENT OF THE WATER PUMPS

61

11.1 Pump 1

61

11.2 Pump 2

61

11.3 Pump management if P2 = 3 (reversible air-to-water) + heating mode + P111 = boiler

61

11.4 Unseizing and switching the pumps

61

12 WINTER PROTECTION

61

12.1 Frost protection of pumps and heat exchangers while unit is off:

61

12.2 Water loop winter protection

62

1

CONTENTS

PAGE

13 MANAGEMENT OF THE FUNCTIONS

62

13.1 Management of the compressor protections

62

13.2 Management of the time counters

63

13.3 Management of compressor start-up

63

13.4 Management of the reversing valves

64

13.5 Management of configurable output P111:

64

14 SELF-ADJUSTING FUNCTIONS

64

14.1 Self-adjusting function: water frost limit

64

14.2 Self-adjusting function: refrigerant frost limit

64

14.3 Self-adjusting function: HP pressure limit

65

14.4 Self-adjusting function: discharge protection, circuit 1 or 2

65

14.5 Self-adjusting function: minimum HP, circuit 1 or 2

65

14.6 Self-adjusting function for high water return temperatures

65

15 FAULT FUNCTIONS

65

15.1 Water frost limit fault on circuits 1 and 2

65

15.2 Refrigerant frost limit fault on circuits 1 and 2

66

15.3 HP pressure fault, circuits 1 and 2

66

15.4 Discharge temperature fault, circuit 1 or 2

67

15.5 LP fault on circuit 1 or 2

67

15.6 Management of superheat faults

68

16 CONTROLS

69

16.1 Main control in cooling and heating modes (Operating mode based on P119)

69

16.2 Water temperature setpoint adjustment

70

16.3 Adjustment of water temperature setpoint if P7 ≠ INVERTER

70

16.4 Adjustment of setpoint for the water supply and return temperatures (P141 = 1 or 2) if P7 =

73

16.5 Storage control

74

16.6 Control setpoint (P251) management

74

16.7 Automated self-regulating control

75

16.8 Control with AÉROCONNECT link in FREE COOLING mode

75

17 CONTROL OF CONDENSING PRESSURE FOR AIR-COOLED UNITS

75

17.1 Control during normal operation or on/off control

75

17.2 Forced and self-adjusting control for A, B and C

76

17.3 Fan speed control

77

17.4 Low Noise control (single-fan units only – Aquaciat2)

80

17.5 Total recovery control

80

17.6 Management of the air blades if P10 = Centrifugal

81

18 CONTROL OF CONDENSING PRESSURE FOR WATER-TO-WATER UNITS

82

19 RESTRICTION OF OPERATION OF THE MACHINES BASED ON THE OUTDOOR

TEMPERATURE

82

19.1 Restriction to the minimum air temperature in heating mode

82

19.2 Restriction to the maximum air temperature in cooling mode

82

19.3 Restriction to the maximum air temperature in heating mode

83

19.4 Restriction to the minimum air temperature in cooling mode

83

20 MANAGEMENT OF THE AUXILIARY HEATER BOARD AND THE ELECTRIC AUXILIARY

84

21 MANAGEMENT OF THE BACK-UP BOILER

85

22 MASTER/SLAVE CONTROL

85

22.1 Case of two parallel-connected machines

85

23 ACTUATION OF THE ELECTRONIC EXPANSION VALVE

89

23.1 With Alco driver and display

89

23.2 With CIAT driver

89

24 IMPORTANT INFORMATION REGARDING THE CONTROL OF AN INVERTER COMPRESSOR

91

25 DEFROSTING OF THE EVAPORATOR COILS

92

26 HOURLY PROGRAMMING

92

26.1 Presentation

92

26.2 Definition of the programming stages

93

26.3 Definition of holiday zones

93

26.4 Operation

93

27 COMMUNICATION PROTOCOL

95

27.1 Registers accessible by customer

95

27.2 Customer access bit

96

2

MACHINE

N°1

MACHINE

N°2

MACHINE

N°3

MACHINE

N°4

1 IMPORTANT RECOMMENDATIONS

Your unit is equipped with a microprocessor-controlled electronic circuit board. To ensure the correct operation of your machine,

you must follow the rules listed below.

Electrical power supply

Remote control: 230 V AC/50 Hz.

If the machine‟s remote control is powered separately

(transformer not supplied), provide the following:

1 - A power supply line running directly from a distribution point

(this line must be used only to supply power to the machine‟s

remote control).

2 - This power supply line must be at least 1 metre away from all

power lines (400 V).

Specifications of the CONNECT 2 board

Board power input: 35 Watts.

Maximum allowable voltage and current per input/output:

253 V AC -3.15 A.

The board is powered by an onboard screw-on three-pin

connector. The terminals are identified as follows:

1 - Live,

2 - Neutral,

3 - Earth.

Board fuse specifications:

Schurter UMT 250 V AC/3.15 A. Time lag: 10 × 3.

Product code: 34031 0171.

Environmental conditions:

- In storage → -40/+80°C, 5/85% humidity without condensation.

- In use → -20/+70°C, 5/85% humidity without condensation.

Degree of pollution: 3.

Warning

Read the instructions in the manual before attempting to service

the product.

Before attempting to service the board, disconnect its power

source and make sure that no voltage is present.

To prevent the risk of electric shock, access to the board

should be impossible while it is energised.

Certain parts of the board (USB and Ethernet connectors) may be

hot. Based on the ambient temperature, they could cause burns.

As a result, avoid touching these connectors while they are

connected.

Warning:

There is a risk of explosion if the battery is replaced by an

incorrect type.

Dispose of used batteries in accordance with local regulations.

Earthing

Compulsory (good earth quality in compliance with French

standard NF C 15-100).

Connection of sensors

Keep connection cables away from power lines (400 V) or a

remote control line (230 V). In the case of distances of over 6 m,

use a shielded cable connected to the earth on the unit.

Maximum distance: 25 m.

Connection of communication buses and of

the remote console

4-1 Connection cable specifications

- Flexible cable – RS 485 connection

- Two shielded wires

- Capacitance between cables and shield: 120 pF/m

- Resistance: 56 Ω/km

4-2 Connection of the shield

- Connect the shield on the BMS or micro-computer end to earth.

- Ensure bonding all the way to the last unit

(the shield on the communication cable must be

connected between each unit).

- Do not connect the shield to the earth connection on the units.

- The wires exiting the shield must be as short as possible (2 cm)

on each unit.

4-3 Cable routing

- The cable must be at least 30 cm away from all 230 V or 400 V

cables along its entire length.

- If a 230 V or 400 V cable must be crossed with a computer

cable, they must cross each other at a right angle.

Connection of on/off inputs

Distances of less than 30 metres:

- Use a shielded cable. Keep the cable at least 30 cm away from

all lines that could generate interference. Connect the shield to

the earth on the unit. If several shielded cables are used, connect

each shield separately (if the risk of interference persists, install a

relay for each input).

Distances of greater than 30 metres:

- Install a relay for each input near the electronic circuit board

(cable cross-section: 0.5 mm2)

Example connection diagram:

K: Auxiliary relay (fit near the electronic circuit board)

CA: Automatic operation control (on each machine)

2 GENERAL

The CONNECT 2 control module is fitted as standard on water chillers (or water heaters) equipped one or two refrigerating circuits and scroll

compressors. It is fitted on water-to-water, air-to-water and reversible air-to-water units.

Depending on the configuration, the board provides the following functions:

► Control of chilled water or hot water temperatures.

► Continuous monitoring of operating parameters.

► Diagnostics and fault storage.

► Setpoint drift based on the outdoor temperature (in heating and cooling modes).

► Communication with the console (remote or local) and the additional boards (fault reporting, BMS communication, Ethernet link for PC).

3

3 COMPOSITION

The CONNECT 2 control module consists of:

► One control and display panel fitted on the unit.

► One non-reversible circuit = one main board.

► One reversible circuit = one main board + one additional board (No. 1) → rotary switch in position 1.

► Two non-reversible circuits = one main board + one additional board (No. 2) two circuits → Rotary switch in position 1.

► Two reversible circuits = one main board + one additional board (No. 2) two circuits → Rotary switch in position 1.

+ one additional board (No. 2), two circuit changeover → Rotary switch in position 2.

► One auxiliary electric heater control board = additional board 1 → Rotary switch in position 2 (optional, ILD range).

► One remote console (optional).

► One relay board for operating states and faults (optional).

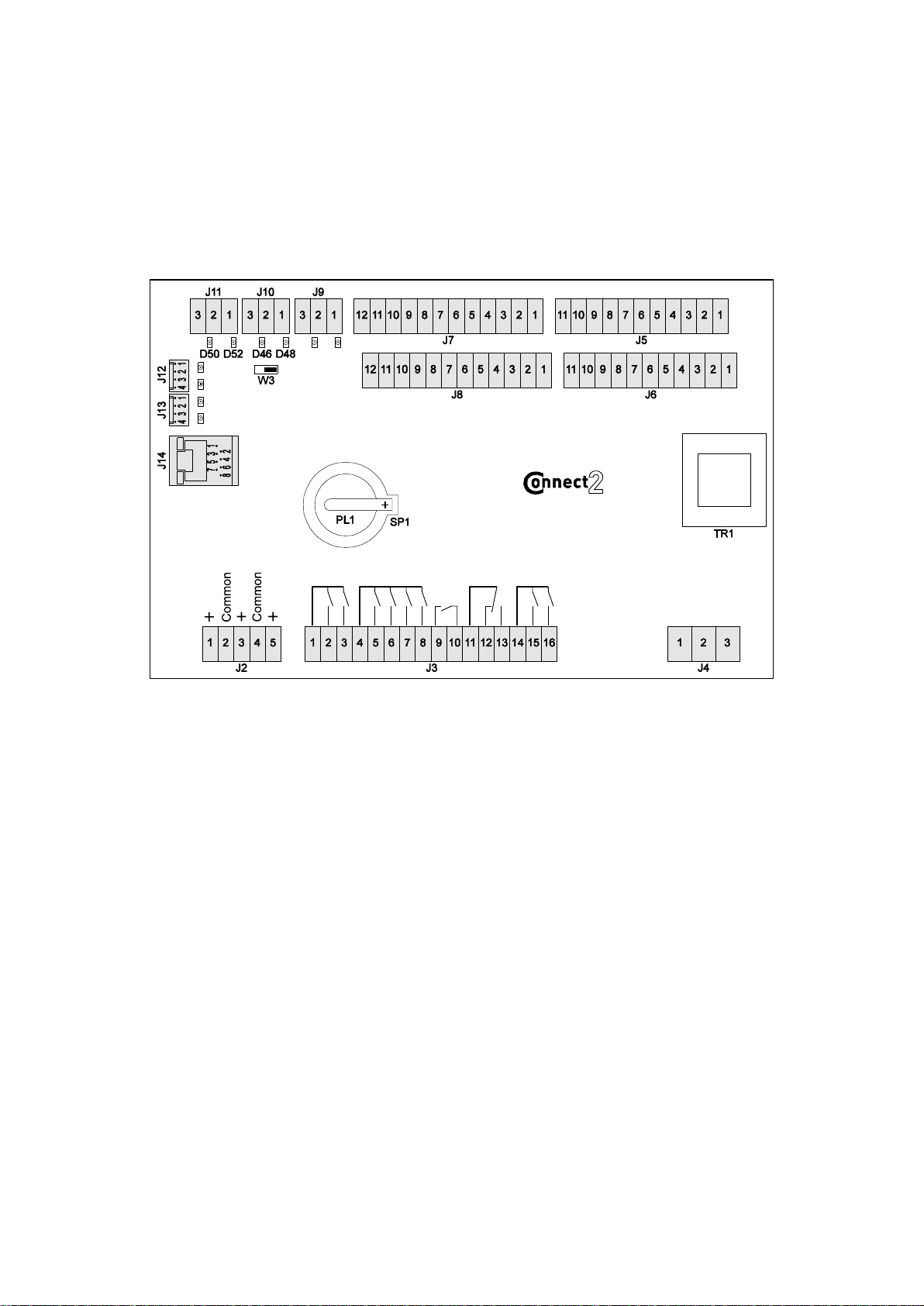

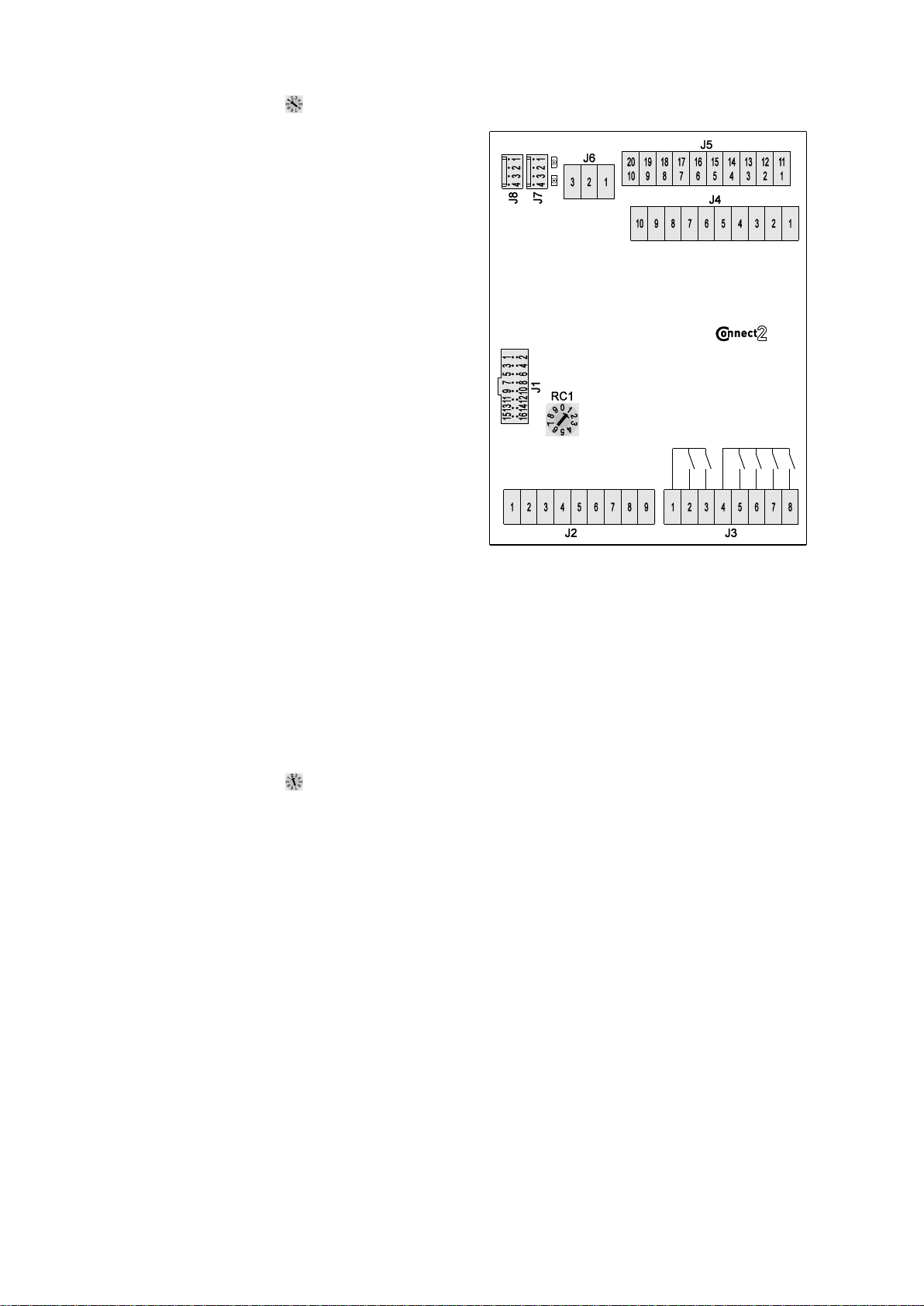

3.1 Main control board for machines with one non-reversible refrigerating circuit

SWITCH W3

End-of-line resistance for two-wire RS-485 link. The switch must

be turned to the left for the last unit on the loop and to the right for

the others.

TERMINAL BLOCK J2 (analogue outputs)

1-2 0-10 V output 1 two-way valve or three-way valve if unit type

(P2) = water-to-water.

or circuit 1 fan speed if unit type (P2) = air-to-water

or reversible air-to-water when P10 = centrifugal.

or air damper control if unit type (P2) = air-to-water

or reversible air-to-water when P10 = centrifugal and P20 = yes.

3-4 0-10 V output 2 (Compressor INVERTER if P7 = INVERTER)

4-5 0-10 V output 3 (variable speed pumps).

TERMINAL BLOCK J3 (on/off inputs)

1 Stage control common

2 Stage 1, circuit 1 control

3 Stage 2, circuit 1 control

or if P7 = INVERTER (compressor shut off order to driver)

4 Common for fans, heater and heat trace cable

5 Circuit 1, fan 1 control (and circuit 2 if intertwined coil)

6 Circuit 1, fan 2 control (and circuit 2 if intertwined coil)

7 Heater control

8 Heat trace cable control

9-10 Configurable control based on P111:

- Max. power

- Boiler

- Cooling/Heating

11 Fault output common

12 NC contact for fault output

13 NO contact for fault output

14 Common for pumps

15 Pump 1 control

16 Pump 2 or reversing valve control, circuit 1

TERMINAL BLOCK J4 (power supply)

1 230 V board power supply - Line

2 230 V board power supply - Neutral

3 Earth

TERMINAL BLOCK J5 (on/off inputs)

1-2 Motor fault, stage 1, circuit 1

2-3 Motor fault, stage 2, circuit 1

4-5 Manual reset fault, HP, circuit 1

5-6 Expansion valve fault, circuit 1

7-8 Phase controller fault

8-9 Water flow fault

10-11 Pump 1 fault

TERMINAL BLOCK J6 (on/off inputs)

1-3 Pump 2 fault

2-3 Automatic operation control

4-6 Setpoint 1/setpoint 2 selection

5-6 Heating/cooling selection if unit type (P2) = water-to-water

or fan fault if unit type (P2) = air-to-water

or reversible air-to-water

7-9 Stage 1, circuit 1 load shedding control

8-9 Stage 2, circuit 1 load shedding control

10-11 Recovery control

TERMINAL BLOCK J7 (analogue inputs)

1-2 10 K outdoor temperature sensor

2-3 10 K water inlet temperature sensor, heat exchanger 1

4-5 10 K water outlet temperature sensor, heat exchanger 1

5-6 10 K hot water temperature sensor if unit type (P2) = water-to-water

or exchanger amb. temp. if unit type (P2) = air-to-water

or reversible air-to-water

7 +24 V power supply for pressure sensors

8 0-10 V input for water inlet sensor on circuit 1

9 0-10 V input for water outlet sensor on circuit 1

10 Common for pressure sensors

11 4-20 mA remote setpoint

12 Setpoint common

4

TERMINAL BLOCK J8 (analogue inputs)

1-2 Refrigerant temperature sensor, circuit 1

2-3 10 K suction temperature sensor, circuit 1

4-5 10 K liquid temperature sensor, circuit 1

6-7 50 K discharge temperature sensor, stage 1, circuit 1

7-8 50 K discharge temperature sensor, stage 2, circuit 1

9 +5 V power supply for pressure sensor

10 0-5 V input - HP sensor

11 0-5 V input - LP sensor

12 Common for pressure sensors

TERMINAL BLOCK J9

Link for chiller or MULTICONNECT

TERMINAL BLOCK J10

Remote control console, relay board link - AEROCONNECT

TERMINAL BLOCK J11

BMS link

TERMINAL BLOCK J12

Local console link

TERMINAL BLOCK J13

Link for additional boards

TERMINAL BLOCK J14

Ethernet link for PC

On/off input specifications: 24 V - 15 mA

On/off output specifications: 250 V - 2 mA

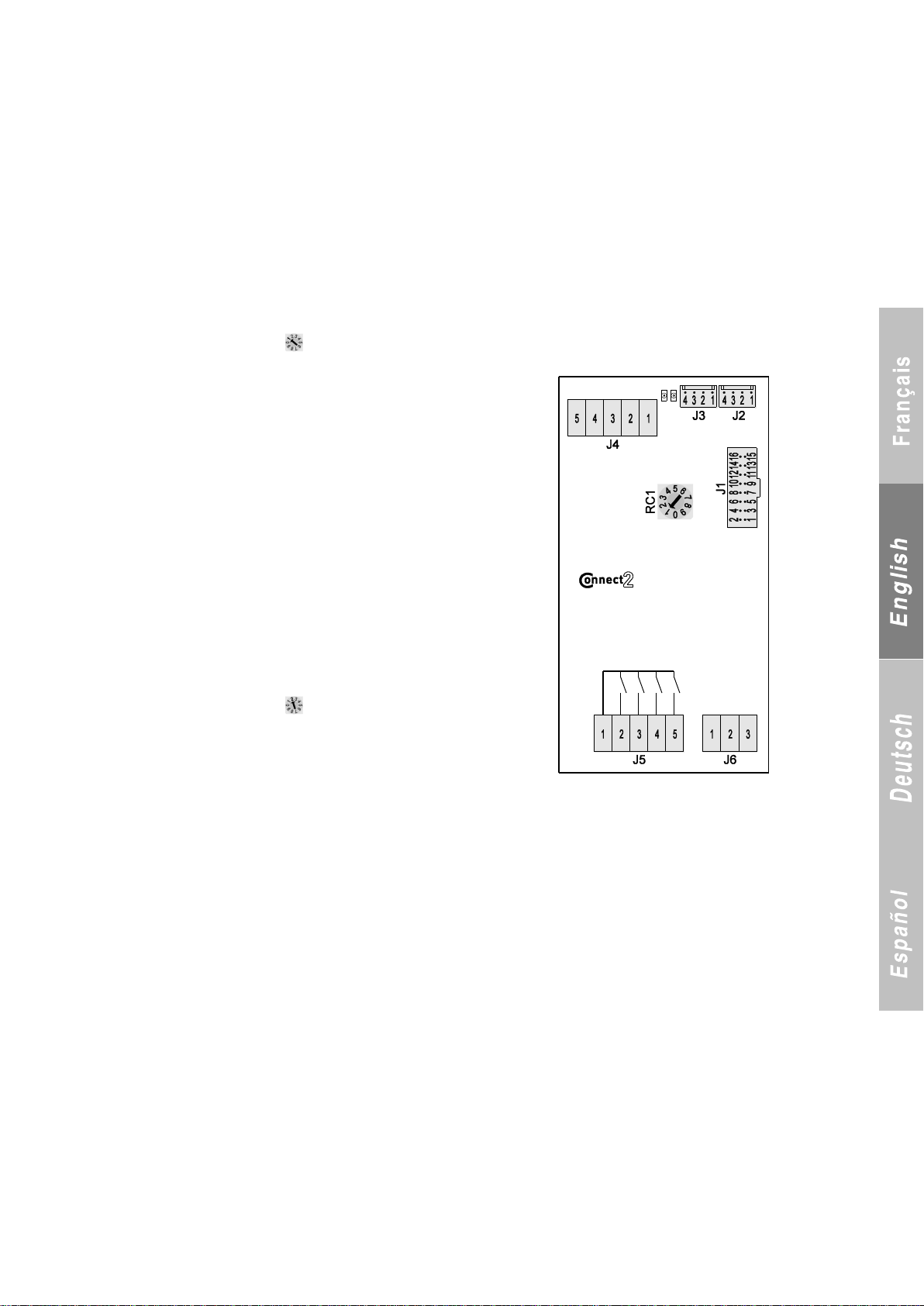

3.2 Additional board 1

3.2.1 Rotary switch set to position 1 - One circuit reversal use or recovery frost protection

TERMINAL BLOCK J1

Flash Memory connector

TERMINAL BLOCK J2

Link with motherboard or another additional board

TERMINAL BLOCK J3

Link with another additional board

TERMINAL BLOCK J4 (on/off inputs)

1-2 Heating/cooling selection input if unit type (P2) = reversible air-to-water

and number of circuits (P3) = 1

2-3 Available

4-5 Available

TERMINAL BLOCK J5 (on/off inputs)

1 Common to all outputs

2 Circuit 1 reversing valve control

3 Circuit 1 pressure balance valve control

4 Recovery frost protection heat trace cable

5 Reverse rotation control for fans

TERMINAL BLOCK J6 (analogue inputs)

1-2 Temperature sensor, coil A, circuit 1

2-3 Temperature sensor, coil B, circuit 1

3.2.2 Rotary switch set to position 2 - Use of electric auxiliary heaters

TERMINAL BLOCK J1

Flash Memory connector

TERMINAL BLOCK J2

Link with motherboard or another additional board

TERMINAL BLOCK J3

Link with another additional board

TERMINAL BLOCK J4 (on/off inputs)

1-2 Programmable input (P113)

2-3 Fault 1, electric stages

4-5 Fault 2, electric stages

TERMINAL BLOCK J5 (on/off inputs)

1 Common to all outputs

2 Electric stage 1 output

3 Electric stage 2 output

4 Electric stage 3 output

5 Electric stage 4 output

TERMINAL BLOCK J6 (analogue inputs)

1-2 Available

2-3 Available

5

3.3 Additional board 2

3.3.1 Rotary switch set to position 1 - Two circuit use

TERMINAL BLOCK J1

Flash Memory connector

TERMINAL BLOCK J2 (on/off inputs)

1-2 Motor fault, stage 1, circuit 2

2-3 Motor fault, stage 2, circuit 2

4-5 Manual reset fault, HP, circuit 2

5-6 Expansion valve fault, circuit 2

7-8 Load shedding input, stage 1, circuit 2

8-9 Load shedding input, stage 2, circuit 2

TERMINAL BLOCK J3 (on/off inputs)

1 Common for stages 1 and 2, circuit 2

2 Stage 1, circuit 2 control

3 Stage 2, circuit 2 control

4 Common for fan stages

5 Stage 1, circuit 2 fan control

6 Stage 2, circuit 2 fan control

7 Stage 3, circuit 1 fan control if coil type

(P11) = split

or stage 1, common fan if coil type

(P11) = mixed

8 Stage 3, circuit 2 fan control if coil type (P11) = split

or stage 3, common fan if coil type

(P11) = mixed

TERMINAL BLOCK J4 (analogue inputs)

1-2 10 K water outlet temperature sensor, heat exchanger 2

2-3 10 K manifold water outlet temperature sensor

4-5 10 k refrigerant temperature sensor, circuit 2

5-6 50 K Discharge temperature 3 or 2 if

2 circuits and 1 stage per circuit (P3 =1) (stage 1, circuit 2)

7-8 50 K sensor, discharge temperature 4 (stage 2, circuit 2)

8-9 Circuit 2 suction temperature

J4-10, J5-1 Circuit 2 liquid temperature

TERMINAL BLOCK J5 (analogue inputs)

1 Common

2 Available

3 +5 V power supply for pressure sensors

4 0-5 V input for HP sensor on circuit 2

5 0-5 V input for LP sensor on circuit 2

6 0 V power supply, HP-LP pressure sensors

7 +24 V power supply for water pressure sensors

8 0-10 V input for water inlet circuit on exchanger 2

9 0-10 V input for water outlet circuit on exchanger 2

10 0 V power supply for water pressure sensors

TERMINAL BLOCK J6 (analogue outputs)

1 0-10 V output for circuit 2 fan

2 Common for outputs

3 0-10 V output for common fan, circuits 1 and 2

TERMINAL BLOCK J7

Link with motherboard or another additional board

TERMINAL BLOCK J8

Link with another additional board

3.3.2 Rotary switch set to position 2 - Two circuit reversal use

TERMINAL BLOCK J1

Flash Memory connector

TERMINAL BLOCK J2 (on/off inputs)

1-2 Heating/cooling selection input if unit type (P2) = reversible

air-to-water and number of circuits (P3) = 2

2-3 Available

4-5 Available

5-6 Available

7-8 Available

8-9 Available

TERMINAL BLOCK J3 (on/off inputs)

1 Common for reversing valves

2 Circuit 1 reversing valve control

3 Circuit 2 reversing valve control

4 Common for balance valves

5 Circuit 1 balance valve control

6 Circuit 2 balance valve control

7 Reverse rotation control for circuit 1 fans

8 Reverse rotation control for circuit 2 fans

TERMINAL BLOCK J4 (analogue inputs)

1-2 Temperature sensor, coil A, circuit 1

2-3 Temperature sensor, coil B, circuit 1

4-5 Temperature sensor, coil C, circuit 1

5-6 Temperature sensor, coil D, circuit 1

7-8 Temperature sensor, coil A, circuit 2

8-9 Temperature sensor, coil B, circuit 2

8-10 Temperature sensor, coil C, circuit 2

TERMINAL BLOCK J5 (analogue inputs)

1-2 Temperature sensor, coil D, circuit 2

3 +5 V power supply - Available

4 0-5 V input - Available

5 0-5 V input - Available

6 0 V power supply - Available

7 +24 V power supply - Available

8 0-10 V input - Available

9 0-10 V input - Available

10 0 V power supply - Available

TERMINAL BLOCK J6 (analogue outputs)

1 0-10 V output - Available

2 Common for 0-10 V output - Available

3 0-10 V output - Available

TERMINAL BLOCK J7

Link with motherboard or another additional board

TERMINAL BLOCK J8

Link with another additional board

6

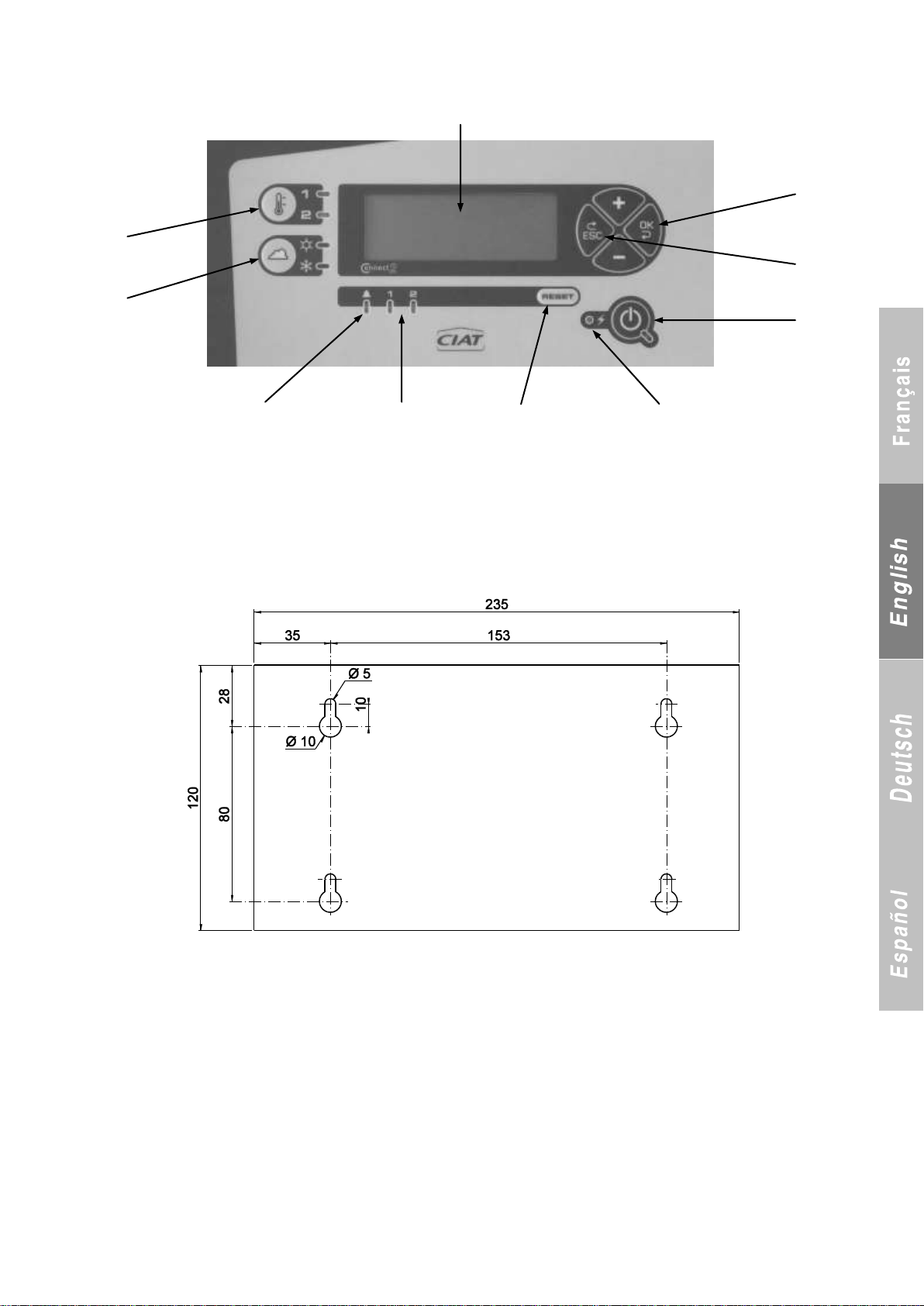

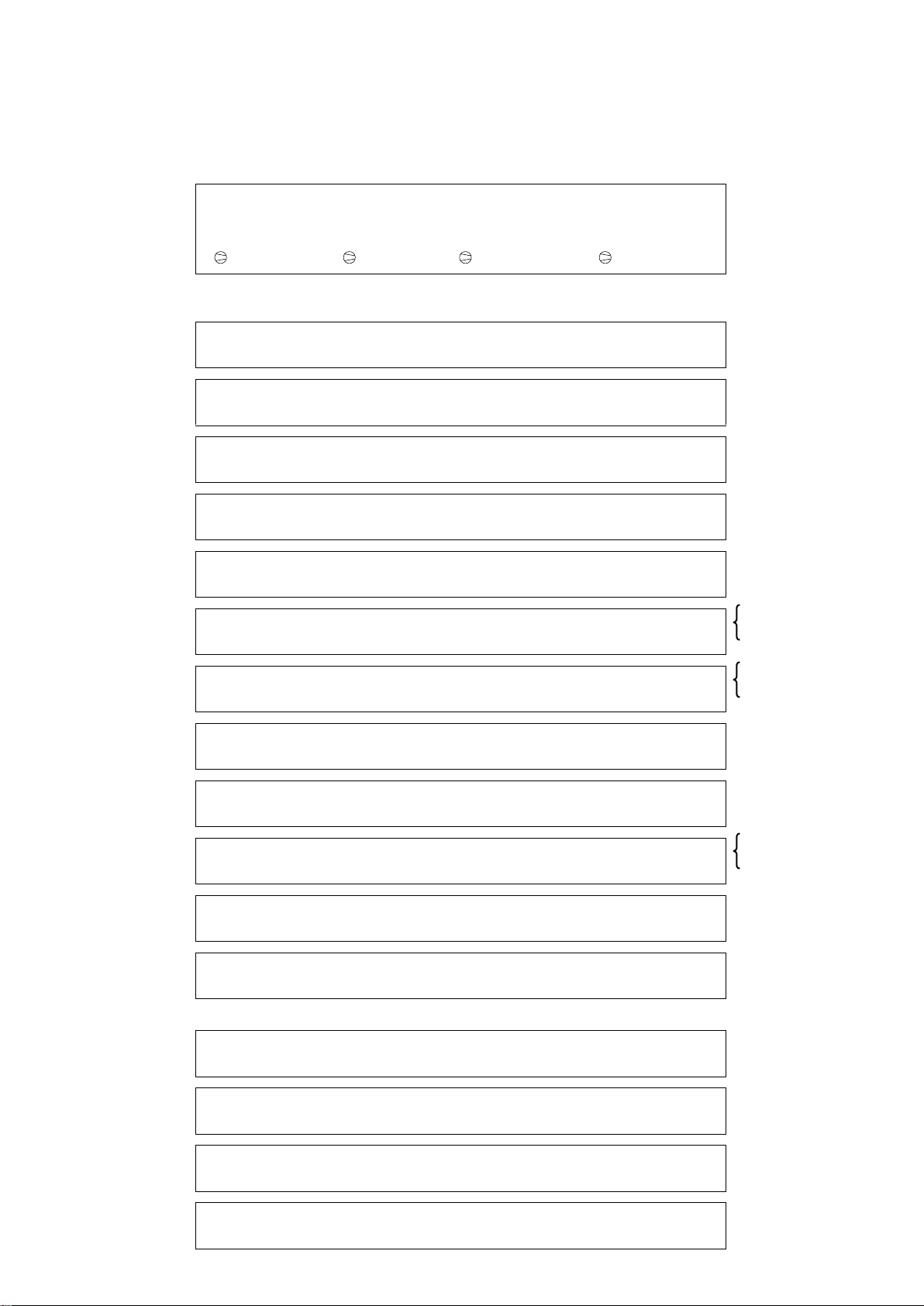

3.4 Control and display console

LCD

Setpoint 1/

Setpoint 2 button

Heating/

Cooling selection

button

Power LED

Reset

Confirm

button

Cancel

button

On/Off

button

Circuit fault

LED

General fault LED

The local console and the remote control console have the same front.

Mounting dimensions (in mm) of remote control console

Thickness: 55 mm

7

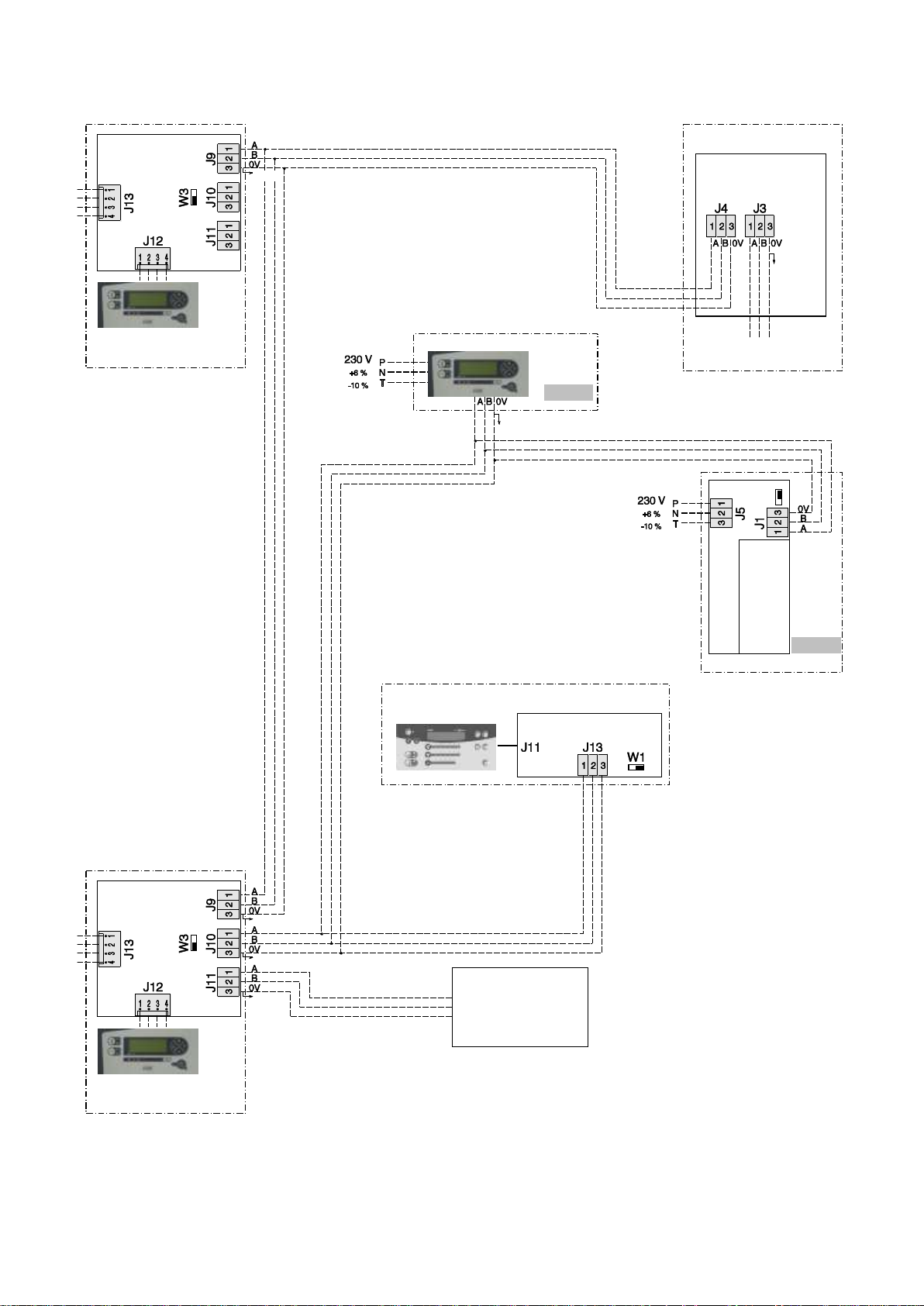

3.5 Connection via RS485 serial port for BMS or control console and Multiconnect with 500 kW module

Detail B

End of line

resistance switch

The switch is set to the right by default.

On the last machine in the loop, it must

be set to the left.

Detail A

End of line

resistance switch

Position of switch when only one

option is connected to the RS-485

output on the main board

Position of switch when several options

are connected to the RS-485 output on

the main board

RS-485 PLC

BMS

2-wire RS-485

Max. length:

1000 m

Main relay

board

Additional

relay board 1

See detail A

Optional

Installed on unit

Shield

To

additional

board

CONNECT 2 main board

Unit 2

Local console

See detail B

Shield

Shield

Installed on unit

Shield

To

additional

board

CONNECT 2 main board

Unit 1

Local console

See detail B

Remote control console

Shield

Optional

MULTICONNECT

main board

Shield

RS-485 link to BMS

(Modbus protocol)

AEROCONNECT board

UNIT

Local console

For connection to a CMS, refer to document 3991049.

Identification of Modbus connection terminals

1 →A or +

2 →B or –

3 →Earth (shield)

8

3.6 Relay boards

Main

board

Additional

board

Dimensions of boards

Main board

Width: 105 mm

Length: 208 mm

Thickness: 65 mm

Mounting centre distance:

Additional board

Width: 60 mm

Length: 157 mm

Thickness: 40 mm

Mounting centre distance:

50 × 147 mm

The dry contacts on the relay boards make it possible to remotely view the states of the stages that are on and all the fault states on the unit.

A 230 V +6% -10% power supply must be provided for each relay board.

Connect terminal block J1 (1-2) on each relay board to terminal block J10 on the main board.

If the link between the motherboard and the relay board is defective, contact 1-2 on the relay board will chatter at a rate of one change in

state per second.

These are NO dry contacts.

Terminal block layout:

1-2 Permanent fault, water flow rate

3-4 Permanent fault, frost protection (liquid or water), circuit 1

5-6 Permanent fault, HP 1 (sensor or manual)

Main 7-8 Permanent fault, LP 1

relay board: 9-10 Permanent fault, discharge temperature 1 or 2

1 circuit 11-12 Stage 1 status, contact closed, stage ON

13-14 Stage 2 status, contact closed, stage ON

15-16 Motor fault, stage 1, contact closed motor fault

17-18 Motor fault, stage 2, contact closed motor fault

19-20 Fan fault

21-22 Permanent fault, frost protection (refrigerant or water), circuit 2

Additional 23-24 Permanent fault, HP 2 (software or manual)

relay board 1 25-26 Permanent fault, LP 2

2 circuits 27-28 Permanent fault, discharge temperature 3 or 4

If P3 = 2 29-30 Stage 3 status, contact closed, stage ON

31-32 Stage 4 status, contact closed, stage ON

33-34 Motor fault, stage 3

35-36 Motor fault, stage 4

19-20 Fan fault

21-22 Fault, 1 or 2 electric stages

Or 23-24 Operation of auxiliary heaters, stage 3 or 4

Additional 25-26 Operation of auxiliary heaters, stage 1 or 2

relay board 1 27-28

circuit with aux. heaters 29-30

if P3 = 1 when P22 = Yes 31-32

33-34

35-36

4 DESCRIPTION

4.1 Main board

Main board for units with one non-reversible refrigerating circuit:

Analogue inputs:

Acquire signals measured by temperature sensors.

Acquire signals measured by pressure by sensors.

On/Off inputs:

Acquire operating state signals from surrounding

electromechanical components.

Actions:

Comparison of setpoint and water temperature to calculate which

stages are to be turned on or off.

Management of the protections for the machine‟s self-adjusting

operation.

4.2 Expansion (additional) boards 1 and 2

These boards are used for units with two reversible refrigerating circuits.

They manage the inputs/outputs on the second circuit or required for reversing the circuits.

Analogue inputs:

Acquire signals measured by temperature sensors.

Acquire signals measured by pressure by sensors.

On/Off inputs:

Acquire operating state signals from surrounding

electromechanical components.

Outputs:

Control stage control.

Pump control.

General fault.

The board also features:

- An “end-of-line resistance” switch.

Outputs:

Control stage control.

9

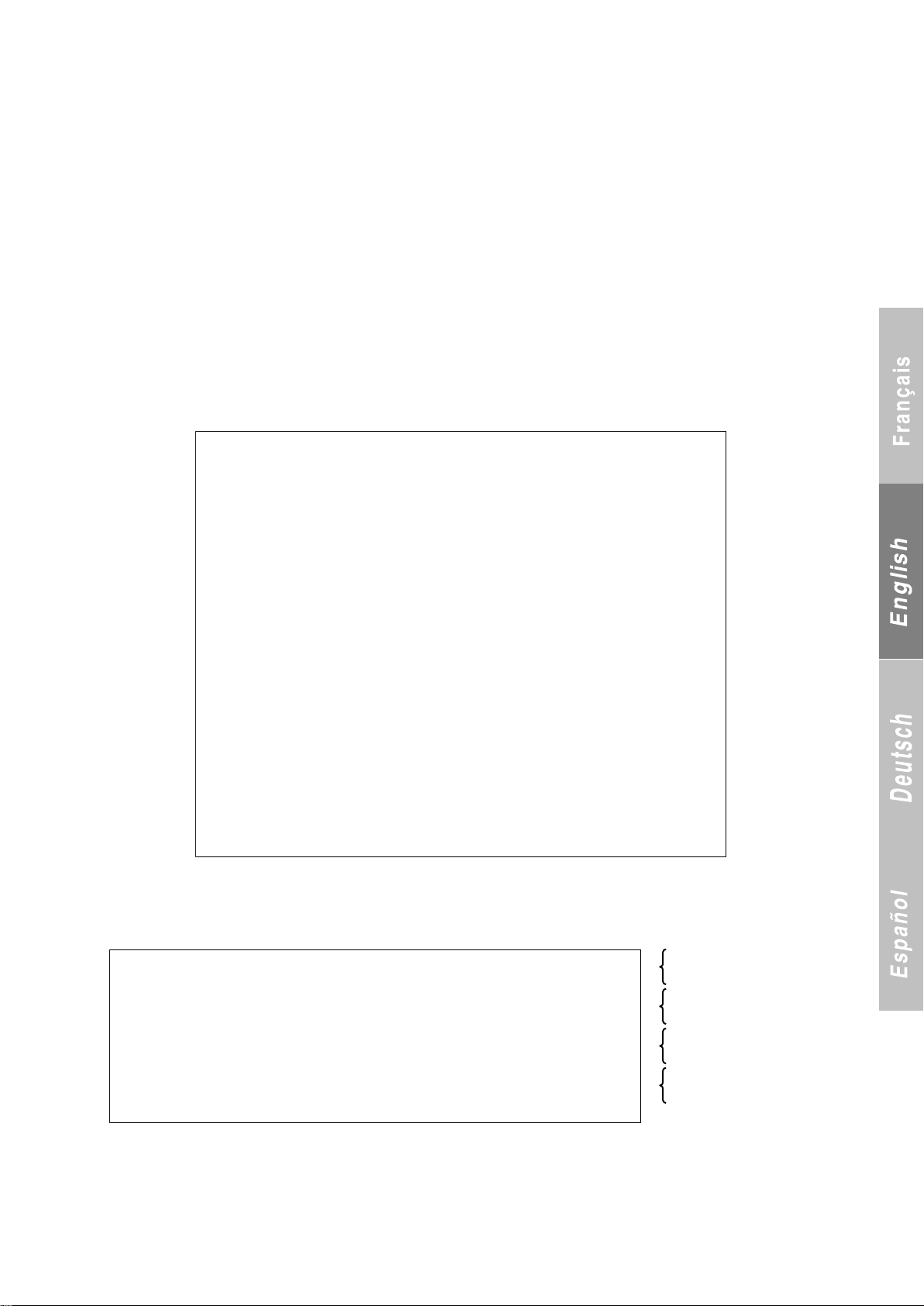

4.3 Man-Machine Communication

C O N S O L E

L O C K E D

C O N S O L E

U N L O C K E D

C O N T R O L L E R I N L E V E L x

14- 1 ACC E S S T O L E V E L 2

14- 2 ACC E S S T O L E V E L 3

Local console:

- The controls on the local console are enabled regardless of the value of P103.

- Acknowledgment of faults is possible.

Remote control console:

- All parameters may be read depending on the authorised access level.

- All unit controls are enabled if P103 = remote or BMS.

- In this case, the following parameters may be accessed for modification:

- On/Off.

- Cooling/Heating.

- All adjustment parameters are locked, depending on the authorised access level, except for the first 11 if P103 = local.

- Acknowledgment of faults is not possible.

- Test mode is possible.

BMS:

- All parameters (except P100, P103, P104 and P105) are accessible in read mode..

- All parameters (except P1 to P99, P100, P103, P104 and P105) are accessible in write mode. However, access to parameters P1 to P99 is

possible when P99 is unlocked on the machine‟s local console.

- Acknowledgment of faults is not possible.

NOTE: All the registers (see communication protocol) appear regardless of the value of P103.

To enable write mode, P103 must be set to „remote or BMS‟.

To be able to switch between heating and cooling, P199 must be set to „cooling/heating‟ via the console.

To be able to switch between setpoints 1 and 2, P120 must be set to „2‟ via the console.

Locking the console:

Available only on the local console on the unit.

The factory setting for the console is „unlocked‟.

The lock status is saved in the event of a mains power failure.

If lock mode is enabled while modifying a parameter, any

modifications made are aborted and the controller is reset to its

All modifications from the local console are then inhibited.

Any attempts to make modifications will cause the above message to appear for 3 seconds.

To unlock the console, simultaneously hold down the + and - buttons for 5 seconds. The following message appears on the screen for

3 seconds:

initial value.

To lock the console, simultaneously hold down the + and –

buttons for 5 seconds (possible in any menu on the console).

The following message appears on the screen for 5 seconds then

machine state reappears.

5 ACCESS LEVELS

CONNECT 2 features three parameter access levels:

- Level 1: Users

- Level 2: Technicians/Maintenance

- Level 3: CIAT Technicians (full access)

5.1 Selecting an authorised access level

Authorised access levels are selected in menu 14 (ACC. LEVEL SELECT.). The following screen appears:

- Level 3 provides automatic access to all levels (CIAT technicians).

- Level 2 provides access to levels 1 and 2 only (Technicians/Maintenance and CIAT technicians).

- Level 1 provides access to level 1 only (all users).

5.2 Accessing the various access levels

5.2.1 Restricting access to level 1 only

- Access level 2 is the default access level.

- If you are in a higher level and you want to restrict access to level 1 only, simultaneously hold down the ESC and OK buttons for 10 seconds.

10

- No password is needed to access level 1. The setpoint adjustment range is + or – 5 K lower than in the higher access levels.

L E V E L 2

ACC E S S C O D E

* * * *

L E V E L 2

NEW ACC E S S C O D E

* * * *

L E V E L 2

N E W C O D E S A V E D

L E V E L 3

ACC E S S C O D E

* * * *

14- 1 ACC E S S T O L E V E L 2

ACC E S S T O L E V E L 2

O N L Y

Y E S / N O

W R O N G C O D E

- The restriction messages remain displayed in access level 1. Operating messages in optimised mode are visible only in access levels 2 and 3.

- Restriction of access to level 1 only is stored in memory in the event of a mains power failure.

5.2.2 Access to level 2:

- A numeric code must be entered to access level 2:

- The following menu for entering this code appears when LEVEL 2 is selected:

- Using the + and –buttons, replace this first symbol (*) by the first character in the code and press Enter . Do the same for the second, third

and fourth symbols. When the last character is entered and Enter is pressed, the following menu appears:

- To select a new access code, proceed as described above. When the last character is entered and Enter is pressed, the screen displays the

menu below followed by the main menu.

- If you do not want to change the level 2 access code, press ESC to exit the new access code menu and go back to the main menu.

- If you have changed your access code but have forgotten it, you can reset it to the original code by entering the LEVEL 2 ACCESS CODE

menu and simultaneously holding down the + and Reset buttons for 10 seconds.

5.2.3 Access to level 3

A non-modifiable numeric code must be entered to access level 3:

- The following menu for entering this code appears when LEVEL 3 is selected:

- Using the + and –buttons, replace this first symbol (*) by the first character in the code and press Enter. Do the same for the second, third

and fourth symbols. When the last character is entered and Enter is pressed, the main menu appears.

5.2.4 Restricting access from level 3 to level 2

To restrict access from level 3 to level 2 only, go to the following menu:

Press Enter. The following menu appears:

To restrict the controller to access level 2, select „Yes‟ and press Enter.

5.2.5 Displaying the access codes on the controller after incorrectly entering the access codes:

- The digits in the access codes are replaced by the* symbol. When the + or - buttons are pressed, this symbol is replaced by the digit 0. The

digits in the code can then be selected using the + or - buttons.

The * symbol appears when the digit is confirmed by pressing Enter.

- The following message appears for 5 seconds if the access code is not entered correctly:

11

- When an access level is changed, the following message is displayed for 5 seconds:

ACC E S S L E V E L x

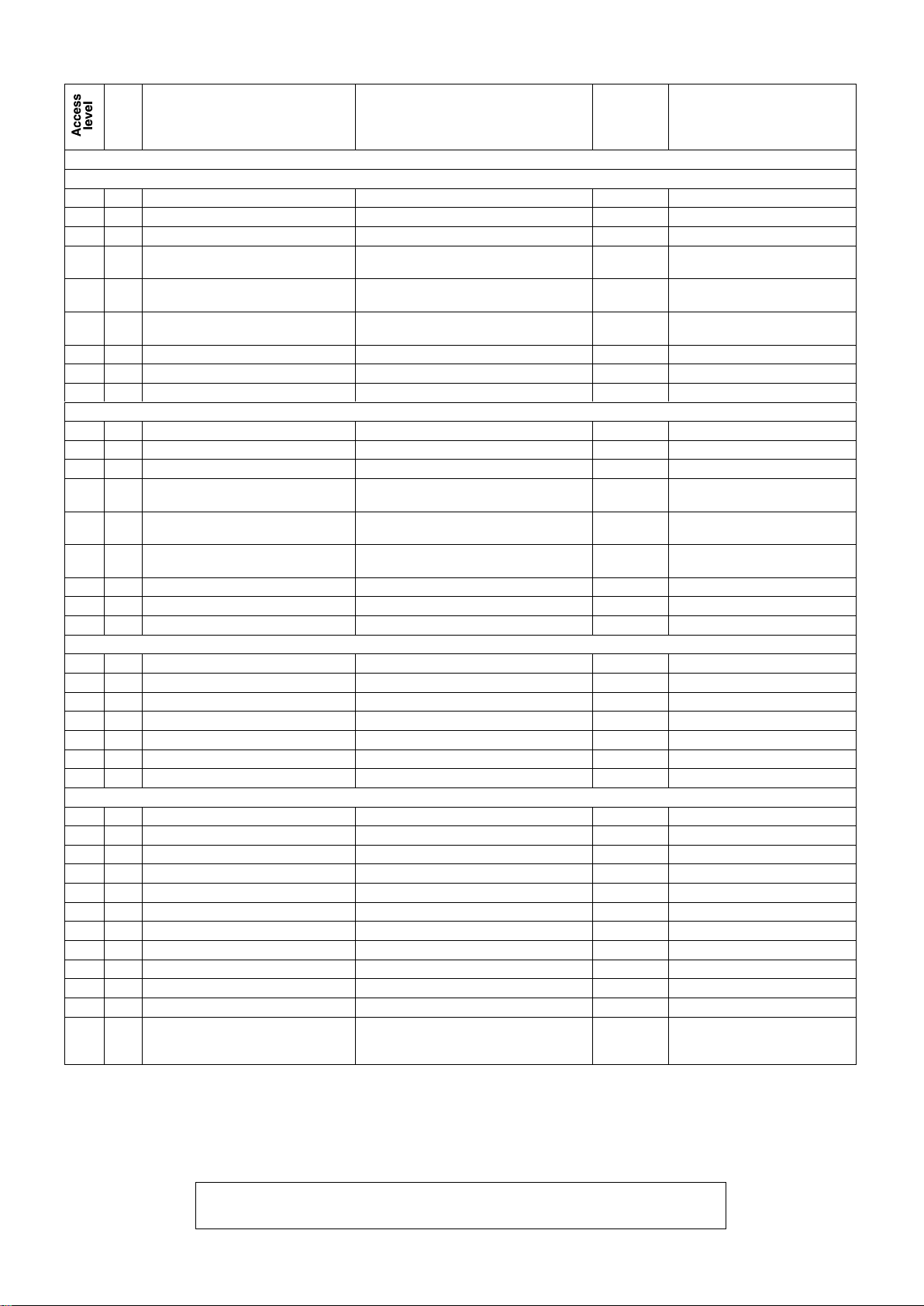

No.

Description

Setting

Default

Display conditions

CONFIGURATION OF THE MACHINE

3

1

Refrigerant type

R407C, R134a, R404a, R22, R410A

R410 A

3

2

Unit type

1-Water-to-Water

2-Air-to-Water

3-Reversible air-to-water

2

3

3

Number of circuits

1-2 1

3

4

Number of stages on circuit 1

1 or 2 1

3

5

Number of stages on circuit 2

0, 1, 2

0 if P3 = 1

1 if P3 = 2

Hidden if P3 = 1

3

6

Number of evaporators

1 if P3 = 1,

1 if P3 = 1 and P2 = air-to-water

2 if P3 = 2

1 if P3 = 1

2 if P3 = 2

3

7

Compressor supplier

Maneurop - Copeland - Inverter

Copeland

3

8

Heat exchanger suppliers

CIAT - Swep - Swep double - Alfa laval

CIAT

3

10

Fan type

Centrifugal - Propeller – Available pressure

Propeller

If P2 = 2, 3

3

11

Coil type

Intertwined - Split - Mixed

Intertwined

If P3 = 2, P10 = pressure ,

P2 = 2, 3

3

12

Pressure balance solenoid valve

No - Yes

No

If P2 = reversible air-to-water

3

13

Tandem type

Balanced Yes/No

Yes

3

14

Number of coil sensors per circuit

1.2 or 4

1 if P3

(No. of

circuits) = 1

2 if P3 = 2.

5.3 Configuring access levels on the controller

- All three access levels on all the boards are accessible for a

total of 20 hours of „on‟ time after the controller is first turned on.

During this period any defective boards may be removed and their

replacement boards configured and checked to ensure correct

operation of machine.

This time period will be automatically cancelled if a user switches

to level 1 or level 2 before it ends.

When the time period ends, level 2 will be authorised unless the

person commissioning the system chooses to restrict access by

the end user to level 1.

- If access level 3 is authorised in order to adjust the machine

parameters and, for indeterminate reasons, it is left accessible to

all users, only level 2 access will be possible after a period of 4

hours.

- Commissioning of the machine can be prohibited simply by

setting parameter P99 to „No‟ in level 2.

Only those with the level 2 access code may re-enable

commissioning of the machine.

5.4 Management of the numeric codes for accessing levels 2 and 3

- Access to level 3 is direct for anyone with a PC running the program needed to communicate with CONNECT 2 and who connects to

the board.

- Access to levels 2 and 3 is restricted to CIAT Service technicians. Please contact your local CIAT Service office.

5.5 Classification of the menus and their functions

Level 1:

Menu:

Setpoint, machine status, measured values, control parameters,

operation parameters, fault memory, hourly scheduling,

communication and access level selection.

Function:

all functions accessible via the console: On/Off, Reset,

Heating/Cooling selection; Setpoint 1/2 selection

Level 2:

Menu: all level 1 menus + test mode and master/slave

operation

Level 3:

Menu: all level 2 menus + electronic expansion valve

6 LIST OF PARAMETERS

Access levels: 1 = Access to User parameters (level 1 parameters only)

2 = Access to visible and editable parameters (level 1 and 2 parameters). EDITABLE numeric code.

3 = Access to CIAT technician parameters (level 1, 2 and 3 parameters). UNEDITABLE numeric code

12

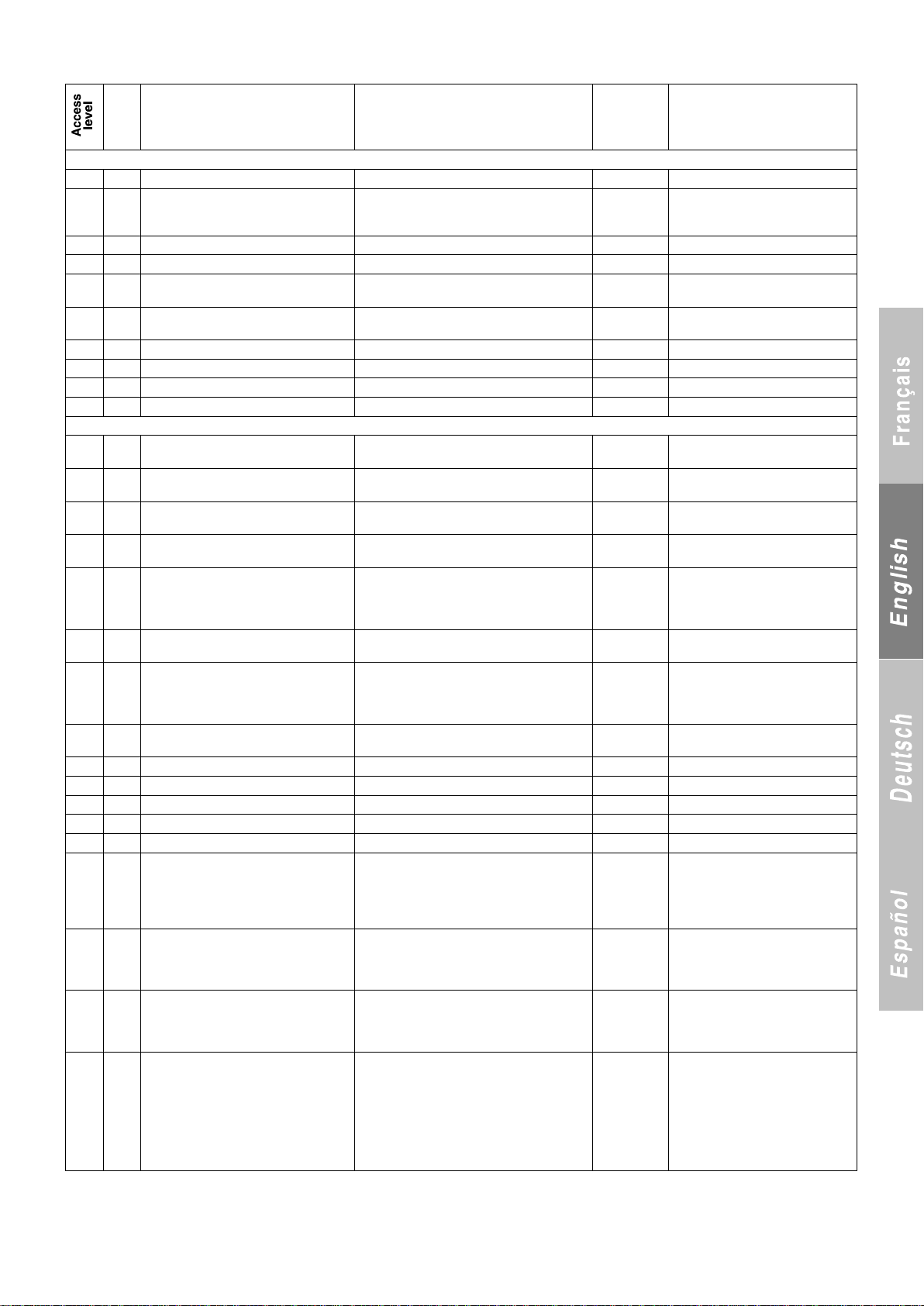

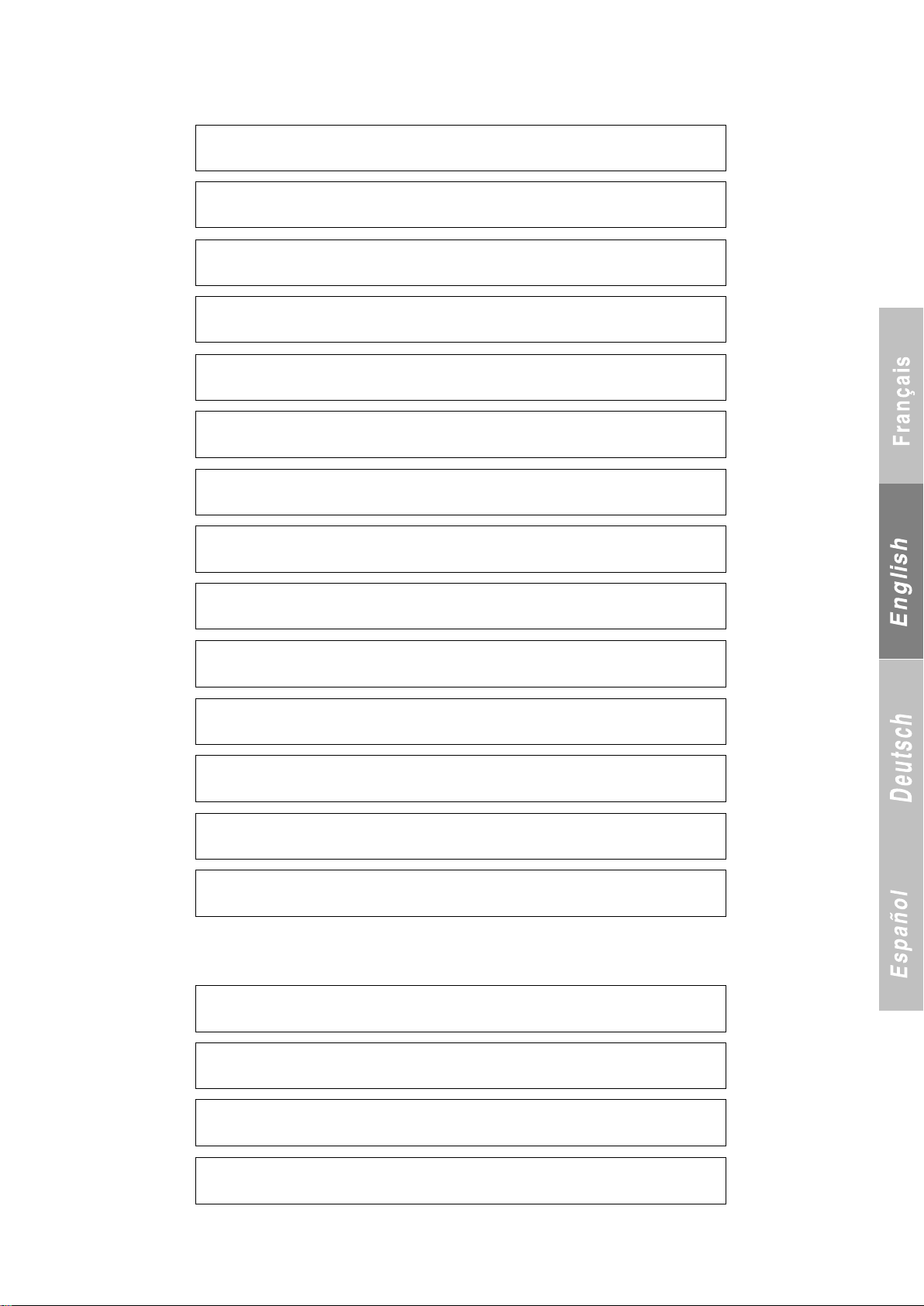

No.

Description

Setting

Default

Display conditions

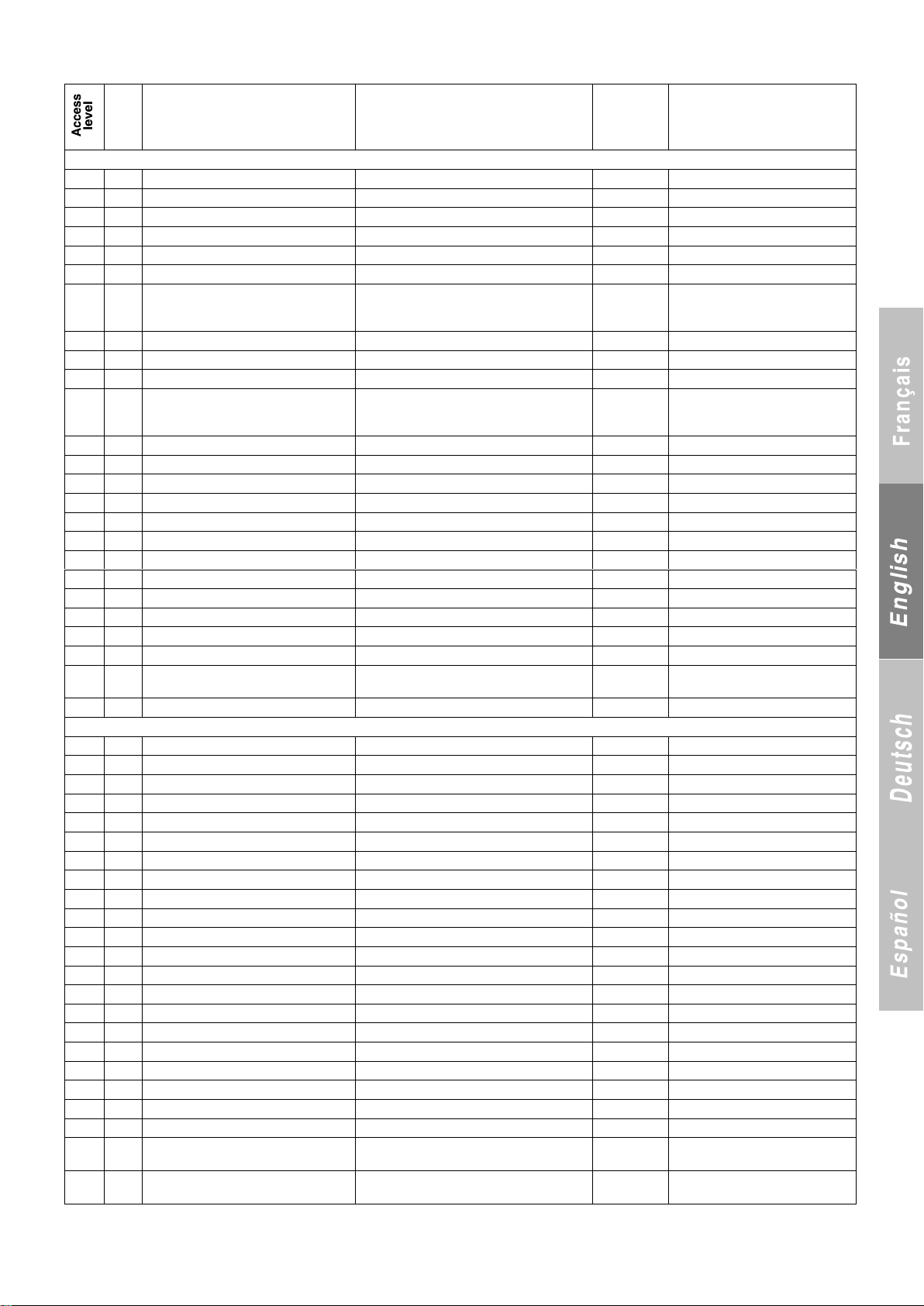

OPTION

2

20

All-season operation

No - Yes

Yes

If P2 = 2, 3

2

21

Variable speed drive

1 - Without

2 - With acoustic optimisation

3 - With energy optimisation

Without

If P2 = 2, 3 P10 = Propeller

Value 3 accessible only

if P42 = CIAT

2

22

Electric auxiliary heaters

No - Yes

No

If P2 = 1 or 3

2

25

Number of pumps delivered by CIAT

0-1-2 if P2 = 2 and 0-1 if P2 = 3

0

Visible if P2 = 2 or 3

2

26

0-10 V configurable output

2WV - 3WV

2WV

2WV, Visible if P2 = water/water and P3 = 1

3WV, Visible if P2 = water/water

2

27

Pump controlled by operation of boiler

Yes/No

No

Visible if P2 = 3

and P111 = Boiler

2

28

Master/slave control of two machines

Yes/No

No 2

29

Total recovery

Yes/No

No

If P2 = 2

2

29.1

Frost protection during heat recovery

Yes/No

No

Breakdown

3

30

High pressure, HP 1 sensor

10 to 50 b (resolution: 0.1)

34

45 with R410A

3

31

Low pressure, HP 1 sensor

-1 to 10 b (resolution: 0.1)

-0.5

0 with R410A

3 32

High pressure, HP 2 sensor

10 to 50 b (resolution: 0.1)

34

45 with R410A

If P3 = 2

3

33

Low pressure, HP 2 sensor

-1 to 10 b (resolution: 0.1)

-0.5

0 with R410A

If P3 = 2

3

36

High pressure, LP 1 sensor

10 to 50 b (resolution: 0.1)

34

45 with R410A

17.3 b if

P42 = CIAT

3

37

Low pressure, LP 1 sensor

-1 to 10 b (resolution: 0.1)

-0.5

0 with R410A

3

38

High pressure, LP 2 sensor

10 to 50 b (resolution: 0.1)

34

45 with R410A

17.3 b if

P42 = CIAT

If P3 = 2

33

39

Low pressure, LP 2 sensor

-1 to 10 b (resolution: 0.1)

-0.5

0 with R410A

If P3 = 2

3

42

Electronic expansion valve

No/ALCO/CIAT

No

3 43

Superheat protection

Yes/No

No

3

44

Minimum superheat

0 to 5 K (resolution: 0.1)

0.5 K

If P43 = Yes

3

45

Maximum overheating

10 to 20 K (resolution: 0.1)

15.0 K

If P43 = Yes

3

50

SCP (runtime + off)

3 to 10 min. (resolution: 1)

5

3

51

Discharge temperature limit

60 to 145°C (resolution: 1)

145°C if Cop.**

135°C if Man.**

125°C if

R410A and

P7 = Cop**

3

52

Water line frost protection limit

-25 to 6°C (resolution: 0.1)

2 if P1 = R22,

4 if P1 = 407C,

R134a, R404

and 3 if R410A

P52 2°C if P22 = Yes

3

53

Δ for refrigerant frost protection

limit/P52

2 to 15 K (resolution: 0.1)

10

5 with R410A

7 if P7 =

INVERTER

Refrigerant frost protection limit =

P52 - P53

3

54

HP fault threshold

15 to 45 b (resolution: 0.1)

27.5 if P1 =

R407C or R22

19 if P1 =

R134a

24 if P1 =

R404a

40.2 b if

R410A

**Cop. = Copeland; Man. = Maneurop

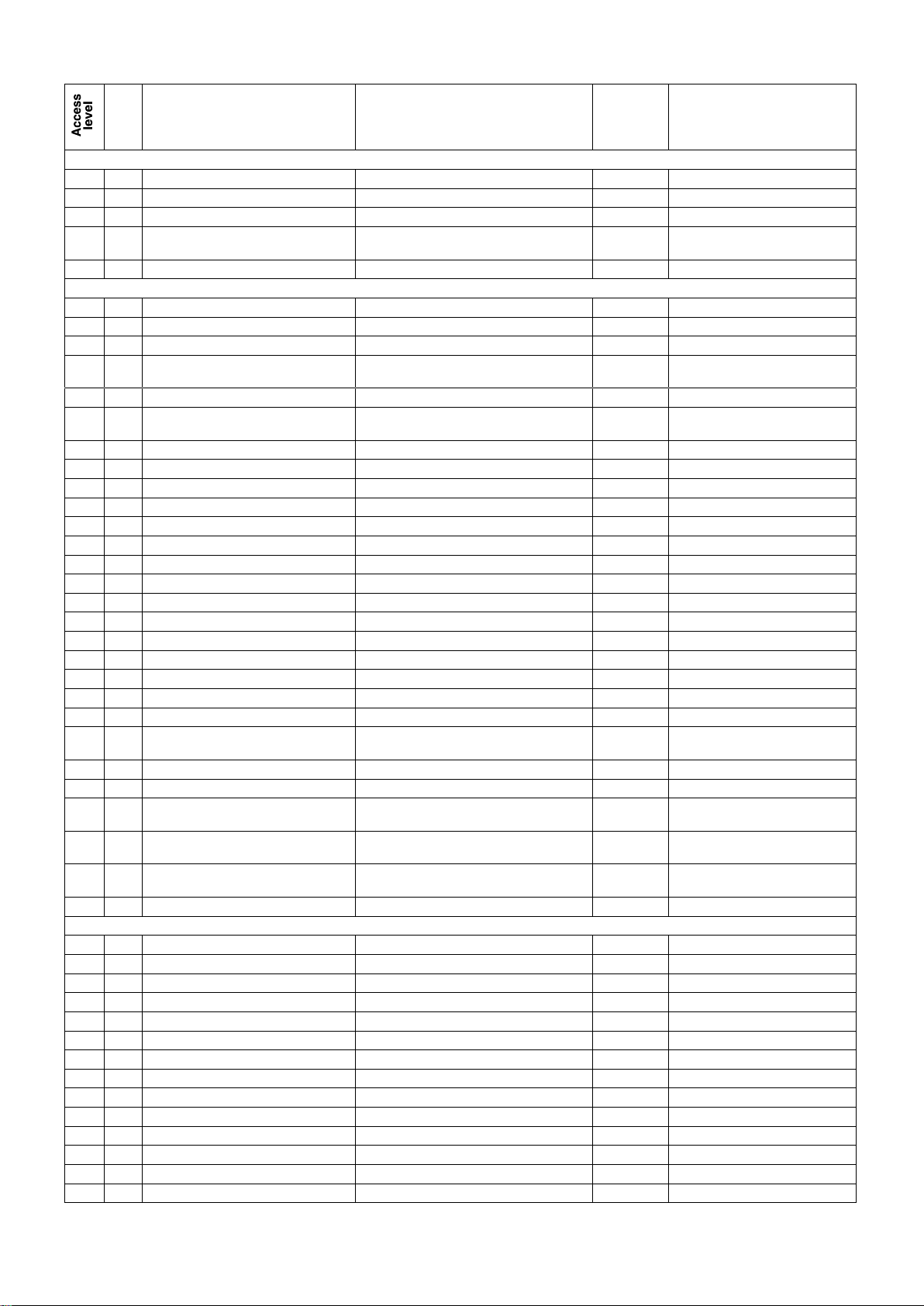

13

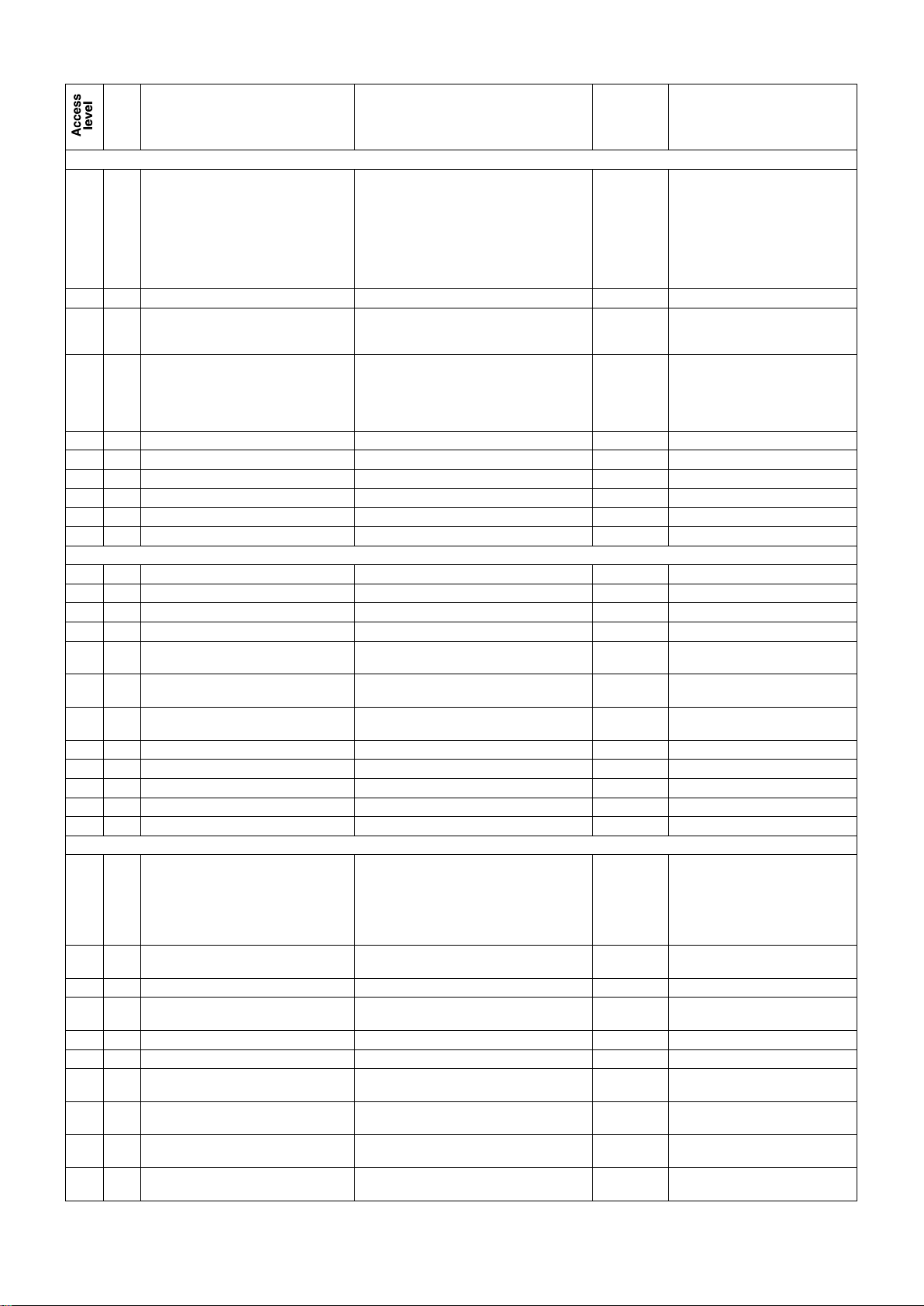

No.

Description

Setting

Default

Display conditions

Breakdown (continued)

3

55

LP fault threshold

0.1 to 5 b (resolution: 0.1)

If P2 = 3: 0.5 b

If P2 ≠ 3:

(1.5 b if P1 =

R22, R407C,

R404a) and

(0.5 b if P1 =

R134a)

2.5 b with R410A

3

58

LP slope factor

0 to 5 b (resolution: 0.5)

1

If P2 = 1, 2 or 3

3

59

Water outlet temperature slope factor

0 to 1 (resolution: 0.1)

0 if P2 = 1

0.5

if P2 = 2 and 3

If P2 = 1, 2, 3

3

63

Minimum HP limit

5 to 25 b (resolution: 0.1)

13 if

R22-R407C

8b with R134a

15 b with R404a

18 b with R410A

If P2 = water-to-water

3

64

Optimised frost protection

Yes - No

Yes

If P1 = R410A, P2 = 2 or 3

3

65

Delta T/Heat exchanger type

0 - 10 0 If P64 = Yes: confirm

3

66

Start-up time delay

0 to 300 seconds

120s

If P7 = INVERTER

3

67

Oil warming time delay

Yes - No

Yes

If P7 = INVERTER

3

99

Parameter locking

No - Yes

No

CUSTOMER CONFIGURATION

2

100

Language

F - GB - D - SP - I

F

2 101

Date

DAy/MOnth/YEar

2 102

Time

HOurs/MInutes

1

103

Control type

Local - remote (BMS)

Local

2

108

Pump 2 control

Depending on control mode

Depending on On/Off if P2 = 1

Depending on

On/Off

Visible if P2 = 1

2

109

Pump 2 ‘on’ time delay

15 to 90 seconds (resolution: 5 seconds)

15

Visible if P2 = 1

and P108 = f (Control)

2

111

Configurable output

Max. power/Boiler/Cooling-heating / Helping on

all faults on air-to-water only

P max

2

112

Number of electric stages

1 to 4 2 Visible if P22 = Yes

2

113

Configurable input

Disabled/Load shedding/Override

Disabled

Visible if P22 = Yes

3

115

Exchanger frost detection enabled

Yes - No

Yes

Visible if P2 = 1, 2, 3

3

116

AEROCONNECT LINK

Yes - No

No

Setpoint Management

1

119

Operating mode

1 - Cooling

2 - Heating

3 - Cooling/heating via console

4 - Cooling/heating via on/off input

5 - Automatic cooling/heating based on outdoor

temperature

Cooling

If P2 = 1 or 3 = All

If P2 = 2 = Cooling only

1

120

Number of setpoints

1 - 2 via console - 2 via on/off input -

3 Setpoint managed by 4-20 mA signal

1

1

121

Cooling setpoint 1

P52 + 1 K at 30°C (resolution: 0.1)

10

If P2 = 1, 2 or 3 P119 ≠ Heating

1

122

Cooling setpoint 2

P52 + 1 K at 30°C (resolution: 0.1)

12

If P120 = 2, P2 = 1, 2 or 3,

P119 ≠ Heating

1

123

Heating setpoint 1

20 to 60°C (resolution: 0.1)

40

P119 ≠ Cooling

1

124

Heating setpoint 2

20 to 60°C (resolution: 0.1)

35

P119 ≠ Cooling, P120 = 2

1

125.1

Low setpoint (4-20 mA) during cooling:

P52 + 3 K at 30°C

P52 + 3

Displayed if P120 = 3 and in cooling

mode

1

125.2

Low setpoint (4-20 mA) during heating:

10 to 60°C

20

Displayed if P120 = 3 and in heating

mode

1

126.1

High setpoint (4-20 mA) in cooling mode:

P125.1 ± 5 K at 30°C with minimum value of

P52 + 3

20

Displayed if P120 = 3 and in cooling

mode

1

126.2

High setpoint (4-20 mA) in heating mode:

P125.2 ± 5 K at 60°C with minimum value of 10°C.

40

Displayed if P120 = 3 and in heating

mode

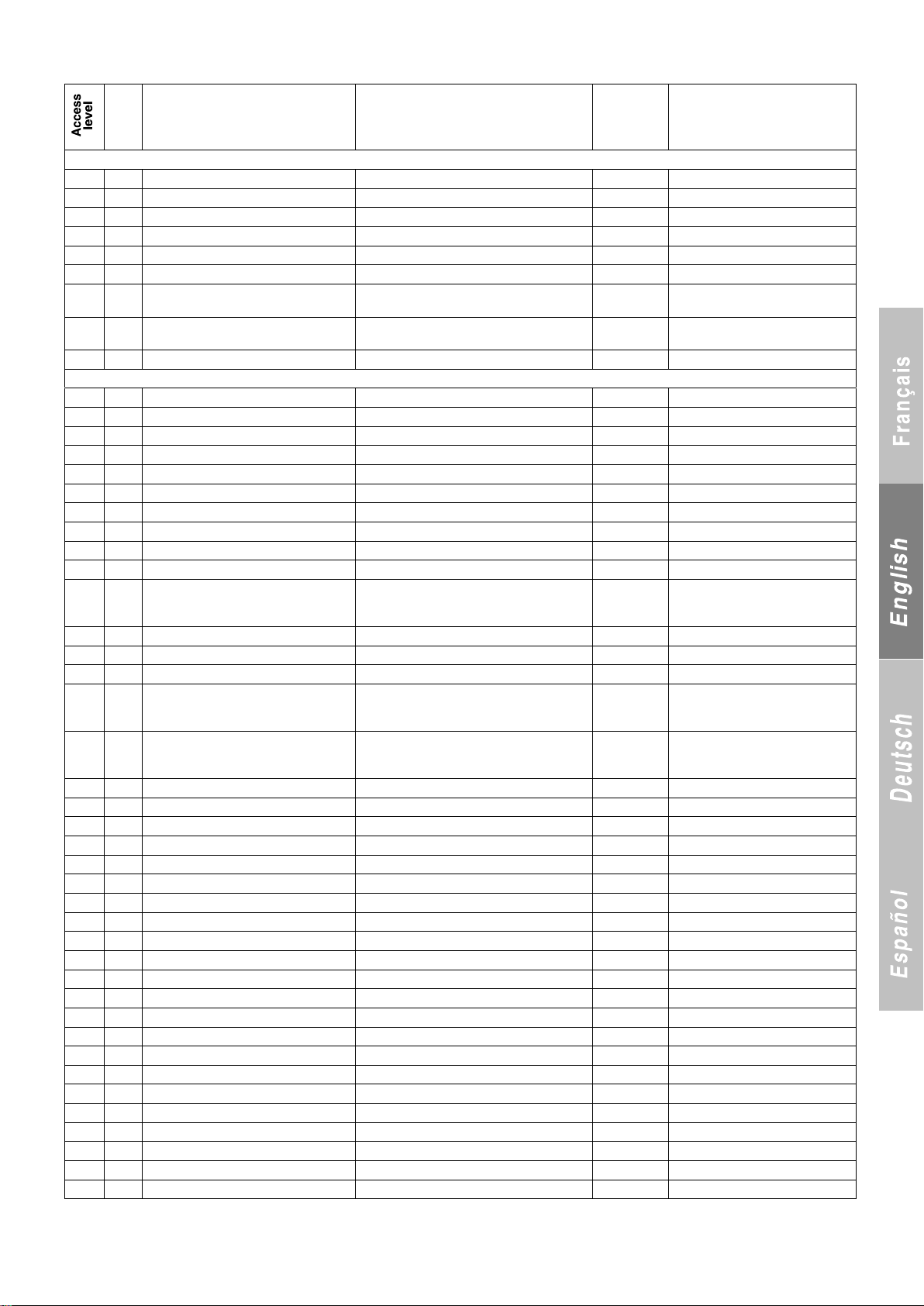

14

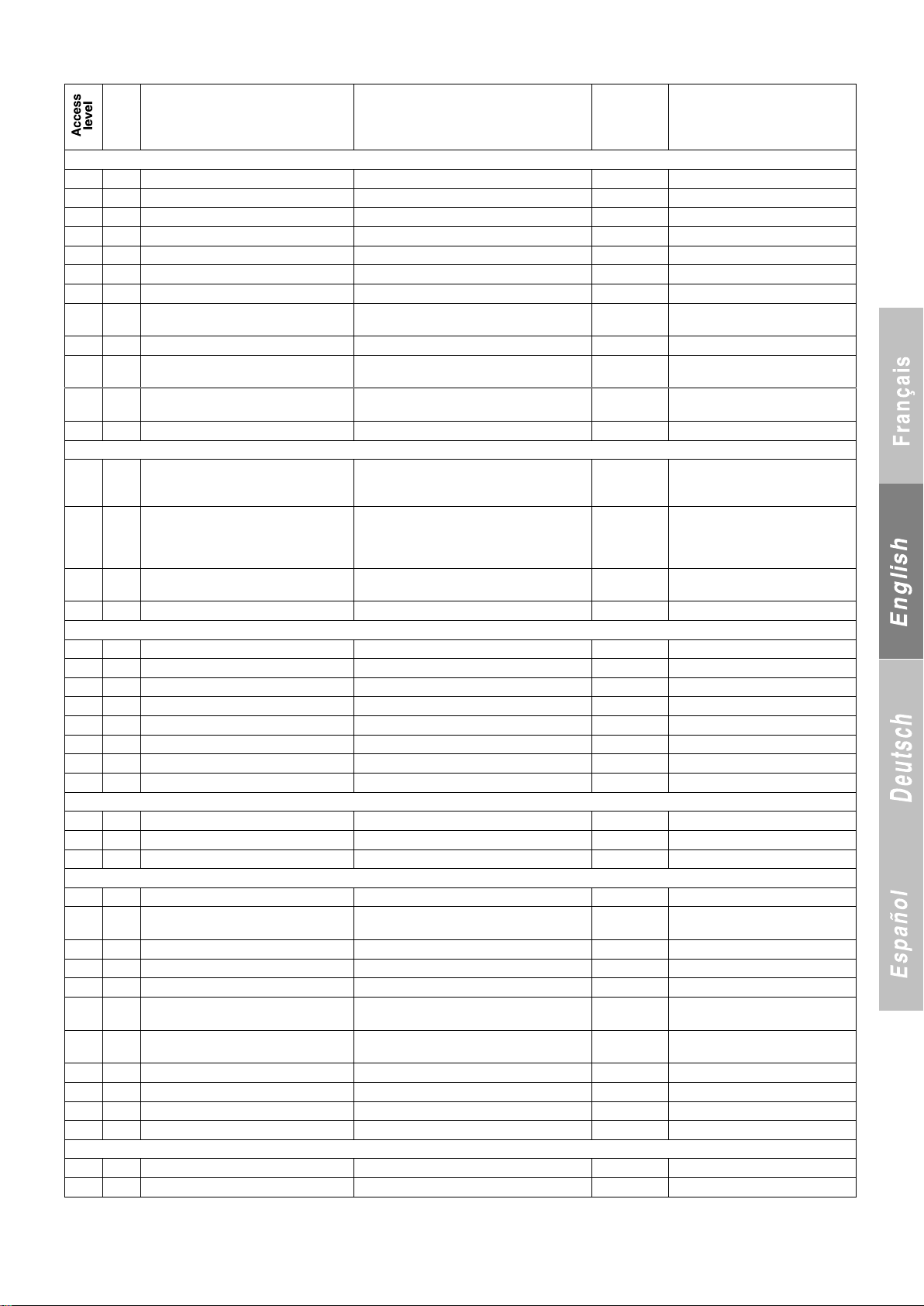

No.

Description

Setting

Default

Display conditions

Setpoint Management (CONTINUED)

1

127

Cooling setpoint adjustment = f (out. temp.)

No - Yes

No

If P2 = 1, 2 or 3 and P119 ≠ Heating

1

128

Drift start

-20 to 55°C (resolution: 1)

25

If P127 = Yes

1

129

Drift end

P128 + 5 K at 60°C (resolution: 1)

35

If P127 = Yes

1

130

Maximum setpoint at end of drift

P52 + 1 K at 30°C (resolution: 0.1)

15

If P127 = Yes

1

131

Heating setpoint adjustment = f (out. temp.)

No - Yes

No

If P2 = 1 or 3 and P119 ≠ Cooling

1

132

Drift start

-20 to 55°C (resolution: 1)

15

If P131 = Yes

1

133

Drift end

-25 to P132 - 5 K (resolution: 1)

5

If P131 = Yes

1

134

Maximum setpoint at end of drift

Highest setpoint if P120 ≠ 1 or setpoint if P120 =

1 at 60°C (resolution: 0.1)

P123

If P131 = Yes

1

135

Minimum boiler drift setpoint

30 to 55°C

50°C

If P111 = Boiler

1

136

Maximum air temperature in automatic

heating mode

- 5 to 25°C (resolution 1)

16

If P119 = 5

1

137

Minimum air temperature in automatic

cooling mode

P136 + 2 to 40°C (resolution: 1)

20

If P119 = 5

2

141

Control mode

1- Return

3- Water supply

4- Supply with compensation

1

2

142

Water loop winter protection

No - Yes

No

Visible if P2 = 1 and P141 = 1 and

heating mode

Visible if P2 = 1 and cooling mode

Visible if P2 = 2 or 3

2

143

Stage differential

0.5 to 5 K (resolution: 0.5)

2

1.5

If P141 = 1, 2

if P7 = INVERTER

2

144

Interstage differential

0.5 to 5 K (resolution: 0.5)

1.5

Supply with compensation by return

2

145

P coefficient

0.3 to 2 (resolution: 0.1)

1

If P141 = 3, 4 and P7 ≠ INVERTER

2

146

I coefficient

0 to 1 (resolution: 0.1)

0

If P141 = 3, 4 and P7 ≠ INVERTER

2

147

D coefficient

0 to 1 (resolution: 0.1)

0

If P141 = 3, 4 and P7 ≠ INVERTER

2

148

T coefficient

10 to 240 seconds (resolution: 10)

60

If P141 = 3, 4 and P7 ≠ INVERTER

2 150

Compensation of coefficient

0.1 to 1 (resolution: 0.1)

0.5

If P141 = 4

2

151

Compensation of time

5 to P148-2 (resolution: 1)

10

If P141 = 4

For storage control (CRISTOPIA)

3

154

Storage

Yes/No

No

If P119 ≠ 2, P120 ≠ 1 and P120 ≠ 4

3

155

ΔT of control

0.5 to 10°C (resolution: 0.5)

5

If P154 = Yes

Defrosting

3

157

Temperature at start of defrosting

-5 to 0°C (resolution: 0.5)

-2

If P2 = 3

3

158

Temperature at end of defrosting

10 to 30°C (resolution: 1)

15 if R407C

otherwise 25

If P2 = 3

3

159

Frosting time calculation

Fixed time Optimised

Optimised

If P2 = 3

3

160

Fixed time

30-45-60

45

If P2 = 3

3

161

Coil frosting factor

0 to 2 (resolution: 0.01)

0.3

If P159 = Optimised

3

162

DTD correction based on outdoor

temperature

0 to 1 (resolution: 0.01)

0.2

If P159 = Optimised

3

163

CP off time delay for defrosting cycle

0 to 5 min.

60s

P2 = 3

if P7 ≠ INVERTER

3

164

ΔP interlocking ventilo HP

1 to 20 b (resolution: 0.5)

2

If P2 = 3, (P HPR = P54 - P164)

3

165

DHP differential

1 to 5 b (resolution: 0.5)

2

If P2 = 3

3

166

Defrosting HP control coefficient

1 to 5 b (resolution:1)

3

If P21 ≠ 1

Charge limit

2

171

Maximum return temperature, stage 2

20 to 50°C (resolution: 1)

35

If P4 + P5 ≥ 2 and P119 ≠ Heating

15

No.

Description

Setting

Default

Display conditions

FAN MANAGEMENT

2

180

Number of HP control stages per circuit

1 to 2 if P3 = 1

2 to 4 if P3 = 2 and P11 = intertwined

2 or 3 if P3 = 2 and P11 = split

3 if P3 = 2 and P11 = mixed

1 if P3 = 1

2 if P3 = 2 and

P11 = intertwined

2 if P3 = 2 and

P11 = split

3 if P3 = 2 and

P11 = mixed

Visible if P2 = 2 or 3 +

P10 = propeller

2

181

HP control setpoint

12 to 17 b (resolution: 0.5) if P1 = R407C or R22

14 to 20 b (resolution: 0.5) if P1 = R404a

7 to 13 b (resolution: 0.5) if P1 = R134a

19 to 27 b (resolution: 0.5) if P1 = R410A

13.4 to 27 b if P7 = INVERTER

12

14

7

19

Visible if P2 = 3 or P2 = 2 +

P10 = propeller

2

182

Outdoor air temperature, forced HP

10 to 40 (resolution: 1)

25

Visible if P2 = 3 or 2 + P10 = propeller

2

183

Stage differential, HP control

2 to 8 b (resolution: 0.5)

4

Visible if P2 = 3 or 2 + P10 = propeller

2

184

Interstage differential, HP control

0.5 to 3 (resolution: 0.5)

2 to 4 (resolution: 0.5)

1

3

Visible if P2 = 3 or 2 +

P10 = propeller

If P180 = 1 (Low noise function)

HIGH PRESSURE CONTROL

3

191

Low Noise operation

Yes - No

No

If P1 = R410A and P2 = 2, 3 or 4 and

P180 = 1

2

192

Max. fan speed threshold

5 to 10 V

8.0

5.6 V if P7 =

INVERTER

- If P7 ≠ Inverter and P10 = Pressure

(P21 = 2 or 3, P180 = 1 and hidden)

If P7 = Inverter and P21 = Yes

3

193

Shifting of HP setpoint during total recovery

5 to 14 (resolution: 0.5)

8 if P21 = 1

12 if P21 = 2

or 3

If P29 = Yes

3

195

ΔP

0.1 to 1 b (resolution: 0.1)

0.3

If P4 = P5 ≠ 1

3

196

ΔP

0.1 to 2 b (resolution: 0.1)

1

1.5 with R410A

Visible if P2 = 3 or 2 +

P10 = propeller

2

197

Value at 0 V

19 to 28 if P26 = 2WV

10 to 25°C if P26 = 3WV

19b

20°C

Visible if P2 = Water-to-Water and P3 = 1

Visible if P2 = Water-to-Water

2

198

Value at 10 V

28 to 39 if P26 = 2WV

25 at 40°C if P26 = 3WV

28b

30°C

Visible if P2 = Water-to-Water and P3 = 1

Visible if P2 = Water-to-Water

Limits

3

220

Outdoor temperature, unit winter protection

2 to 10°C (resolution: 1)

2

If cooling and P142 = Yes

If P2 = Air-to-water

3

222

Outdoor temperature differential, unit winter

protection

1 to 10 K (resolution: 1)

2

If cooling and P142 = Yes

If P2 = Air-to-water

3

225

Minimum outdoor air temperature in HEATING

mode

-25 to 5°C (resolution: 1)

-10

-20

If P119 ≠ cooling and P2 = 3

If P7= INVERTER

3

225.1

Maximum outdoor air temperature in

COOLING mode

35 to 50°C (resolution: 1)

DISABLED

3

225.2

Maximum outdoor air temperature in

HEATING mode

-5 to +25°C (resolution: 1)

DISABLED

if P2 = water-to-water and reversible

air-to-water when P119 ≠ 1

3

225.3

Minimum outdoor air temperature in

COOLING mode

-20 to +25°C (resolution: 1)

DISABLED

if P2 = water-to-water and reversible

air-to-water when P119 ≠ 2

3

226

Outdoor temperature

Boiler operation authorisation

P225 at 25°C if P2 = 3 and P119 ≠ cooling

-20 to 25°C if P2 = 1 and P119 ≠ cooling

5

(resolution: 1)

2

230

On authorisation, stage 1 circuit 1

No - Yes

Yes

2 231

On authorisation, stage 2 circuit 1

No - Yes

Yes

If P4 = 2

2

232

On authorisation, stage 1 circuit 2

No - Yes

Yes

If P3 = 2

2

233

On authorisation, stage 2 circuit 2

No - Yes

Yes

If P5 = 2, P3 = 2

2

235

On authorisation, electric stage 1

No - Yes

Yes

If P22 = Yes

2

236

On authorisation, electric stage 2

No - Yes

Yes

If P22 = Yes

2

237

On authorisation, electric stage 3

No - Yes

Yes

If P22 = Yes

2

238

On authorisation, electric stage 4

No - Yes

Yes

If P22 = Yes and P112 = 4

Read-only

1

250

LED test

16

No.

Description

Setting

Default

Display conditions

Read-only (CONTINUED)

1

251

Control setpoint

If P141 ≠ 5 and ≠ 6

1

252

Outdoor air temperature

1 255

Water inlet temperature, heat exchanger 1

1

256

Water outlet temperature, heat exchanger 1

1

257

Hot water inlet temp., condenser

If P2 = 1 and P141 = 1

1

258

Hot water outlet temp., condenser

If P2 = 1 and P141 = 3

1

259

Refrigerant temperature, circuit 1 coils

A-B

C-D

If P2 = 3

If P2 = 3 and P14 = 2

If P2 = 3 and P14 = 4

1

260

Refrigerant temperature, heat exchanger 1

If P2 = 1 or 2

1

261

Manifold water outlet temperature

If P6 = 2 - P2 = 1, 2 or 3

1

262

Water outlet temperature, heat exchanger 2

If P6 = 2

1

263

Refrigerant temperature, circuit 2 coils

A-B

C-D

If P2 = 3 and P3 = 2

If P2 = 3 and P3 = 2 and P14 = 2

If P2 = 3 and P3 = 2 and P14 = 4

1

264

Refrigerant temperature, heat exchanger 2

If P2 = 1 or 2 and if P6 = 2

1

265

Exchanger ambient temperature

If P2 = Air-to-water

1

266

Calculated frosting time, circuit 1

If P2 = 3,

1

267

Calculated frosting time, circuit 2

If P2 = 3 and P3 = 2

1

268

Value of reference ΔT for defrosting of circuit 1

If P159 = Optimised

1

269

Value of reference ΔT for defrosting of circuit 2

If P159 = Optimised and P3 = 2

1

285

Runtime in heating mode

If P119 ≠ Cooling

1

286

Runtime in cooling mode

If P119 ≠ Heating

1

287

Pump 1 runtime (in hours)

1

288

Pump 2 runtime (in hours)

If (P2 = 1) or P25 = 2

1

289

No. of times P99 set to "No"

1

290

No. of water flow cut-offs in 1 hour

Visible if (cooling and P2 = 1) or

if P2 = 3 or if P2 = 2 and P25 ≠ 2

Circuit 1

1

300

Circuit 1 HP

1 300.1

Circuit 1 HP control setpoint

If P3 = 1 or 2 and P11 = Intertwined

1

301

Circuit 1 condensation temperature

See appendix

1

302.1

Discharge temperature 1

1 302.2

Discharge temperature 2

If P4 = 2

1

303.1

Desuperheat on discharge 1

P302.1 - P301

1

303.2

Desuperheat on discharge 2

P302.2 - P301

If P4 = 2

1

304

Circuit 1 LP

1

305

Circuit 1 evaporation temperature

See appendix

1

306

Circuit 1 suction temperature

°C 1 307

Circuit 1 superheat

°C 1 308

Number of HP1 cut-offs in 24 hours

1 309

Number of LP1 cut-offs in 24 hours

1 310

Number of starts, stage 1, circuit 1

1 311

Runtime (in hours), stage 1, circuit 1

1 312

SCP, stage 1, circuit 1

1 313

Number of starts, stage 2, circuit 1

If P4 = 2

1

314

Runtime (in hours), stage 2, circuit 1

If P4 = 2

1

315

SCP, stage 2, circuit 1

If P4 = 2

1

322

No. of water line frost protection cut-offs, circuit 1

1 323

No. of refrigerant line frost protection cut-offs, circuit 1

If P2 ≠ 3

1

324.1

No. of cut-offs caused by discharge

temperature 1 in 24 hours

1 324.2

No. of cut-offs caused by discharge

temperature 2 in 24 hours

If P4 = 2

17

No.

Description

Setting

Default

Display conditions

Circuit 1 (CONTINUED)

1

325

Opening of circuit 1 expansion valve

% If P42 = CIAT and P3 = 1

1

326

Circuit 1 liquid temperature

°C If P2 = 1 or 2 or (3 + cooling mode)

1

327

Circuit 1 subcooling

°C If P2 = 1 or 2 or (3 + cooling mode)

1

328

No. of cut-offs caused by C1 electronic

expansion valve fault in 24 hours

If P42 = ALCO

Circuit 2

1

330

Circuit 2 HP

If P3 = 2

1

330.1

Circuit 2 HP control setpoint

If P3 = 2 and ≠ Intertwined

1

331

Circuit 2 condensation temperature

See appendix

If P3 = 2

1

332.1

Discharge temperature 3

Discharge temperature 2

°C

If P3 = 2 and P4 = 2

If P3 = 2 and P4 = 1

1

332.2

Discharge temperature 4

°C

If P3 = 2 and P5 = 2

1

333.1

Desuperheat on discharge 3

Desuperheat on discharge 2

P332.1 - P331

If P3 = 2 and P4 = 2

If P3 = 2 and P4 = 1

1

333.2

Desuperheat on discharge 4

P332.2 - P331

If P3 = 2 and P5 = 2

1

334

Circuit 2 LP

If P3 = 2

1

335

Circuit 2 evaporation temperature

See appendix

If P3 = 2

1

336

Circuit 2 suction temperature

°C If P3 = 2

1

337

Circuit 2 superheat

°C If P3 = 2

1

338

Number of HP2 cut-offs in 24 hours

If P3 = 2

1

339

Number of LP2 cut-offs in 24 hours

If P3 = 2

1

340

Number of starts, stage 1, circuit 2

If P3 = 2

1

341

Runtime (in hours), stage 1, circuit 2

If P3 = 2

1

342

SCP, stage 1, circuit 2

If P3 = 2

1

343

Number of starts, stage 2, circuit 2

If P3 = 2, P5 = 2

1

344

Runtime (in hours), stage 2, circuit 2

If P3 = 2, P5 = 2

1

345

SCP, stage 2, circuit 2

If P3 = 2, P5 = 2

1

352

No. of water line frost protection cut-offs, circuit 2

If P3 = 2 and P2 ≠ 4, 5

1

353

No. of refrigerant line frost protection cut-offs, circuit 2

1

354.1

No. of cut-offs caused by discharge T° 2 in 24 hours

No. of cut-offs caused by discharge T° 3 in 24 hours

If P3 = 2 and P4 = 1

If P3 = 2 and P4 = 2

1

354.2

No. of cut-offs caused by discharge T° 4 in 24 hours

If P3 = 2 and P5 = 2

1

355

Opening of circuit 2 expansion valve

% P42 = CIAT and P3 = 2

1

356

Circuit 2 liquid temperature

°C

If [P2 = 1 or 2 or (3 + cooling mode)]

and P3 = 2

1

357

Circuit 2 subcooling

°C

If [P2 = 1 or 2 or (3 + cooling mode)]

and P3 = 2

1

358

No. of cut-offs caused by C1 electronic

expansion valve fault in 24 hours

If P42 = ALCO

INPUTS

1

400

Automatic machine operation control

Open/Closed

1 402

Setpoint 1/Setpoint 2 selection

Open/Closed

If P120 = 2 via On/Off control

1

403

Water flow check

Open/Closed

1 404

Fan fault check

Open/Closed

If P2 ≠ 1 or 5

1

405

Cooling/Heating input check

Open/Closed

If P119 = Cooling/Heating via On/Off control

1

406

Phase controller

Open/Closed

1 407

Recovery operating mode selection

Open/Closed

If P29 = Yes

1

408

Check of fault input for auxiliary electric heater 1

Open/Closed

If P22 = Yes

1

409

Check of fault input for auxiliary electric heater 2

Open/Closed

If P22 = Yes

1

410

Check of configurable auxiliary electric heater input

Open/Closed

If P22 = Yes

1

414

Check of override/load shedding input 1

Open/Closed

1

415

Check of override/load shedding input 2

Open/Closed

If P4 = 2

1

416

Check of override/load shedding input 3

Open/Closed

If P3 = 2

1

417

Check of override/load shedding input 4

Open/Closed

If P5 = 2

18

No.

Description

Setting

Default

Display conditions

INPUTS (CONTINUED)

1

418

Check of manual HP1 pressure switch input

Open/Closed

1

419

Check of stage 1, circuit 1 fault input

Open/Closed

1 420

Check of stage 2, circuit 1 fault input

Open/Closed

If P4 = 2

1

422

Check of manual HP2 pressure switch input

Open/Closed

If P3 = 2

1

423

Check of stage 1, circuit 2 fault input

Open/Closed

If P3 = 2

1

424

Check of stage 2, circuit 2 fault input

Open/Closed

If P5 = 2

1

425

Check of fault input for circuit 1 electronic

expansion valve

Open/Closed

If P42 = ALCO

1

426

Check of fault input for circuit 2 electronic

expansion valve

Open/Closed

If P42 = ALCO

OUTPUTS

1

430

Pump 1 control state

On/Off

1 431

Pump 2 control state

On/Off

If (P2 = 1) or P25 = 2

1

432

State of circuit 1 Y/C control output

On/Off

If P2 = 3

1

433

State of circuit 2 Y/C control output

On/Off

If P2 = 3 and P3 = 2

1

435

State of heat trace cable control output

On/Off

If P2 ≠ 1 (water-to-water)

1

436

State of heater control output

On/Off

If P2 ≠ 1 (water-to-water)

1

437

State of recovery heat trace cable control output

On/Off

If P2 ≠ 1 (water-to-water) and P29.1 = Yes

1

438

State of maximum power output

On/Off

If P111 = Max. power

1

439

State of boiler output

On/Off

If P111 = Boiler

1

440

State of cooling/heating output

On/Off

If P111 = Cooling/Heating

1

441

State of HP control output, stage 1, circuit 1

On/Off if P21 = without

High Temperature mode/Low Noise mode/Off if

P191 = acoustic

If P21 = without, P2 = 2, 3

1

442

State of HP control output, stage 2, circuit 1

On/Off

If P180 = 2 and P3 = 1, P2 = 2, 3

1

443

State of HP control output, stage 1, circuit 2

On/Off

If P180 = 1 and P3 = 2, P2 = 2, 3

1

444

State of HP control output, stage 2, circuit 2

On/Off

If P180 = 2 and P3 = 2, P2 = 2, 3

1

445

State of HP control output, stage 3, circuit 1

or

State of HP control output, common stage 1

On/Off

If P180 = 3 and P3 = 2

P11 = split P2 = 2, 3 or If P180 = 3 and

P3 = 2 P11 = mixed

1

446

State of HP control output, stage 3, circuit 2

or

State of HP control output, common stage 3

On/Off

If P180 = 3 and P3 = 2

P11 = split P2 = 2, 3 or If P180 = 3 and

P3 = 2, P11 = mixed

1

447

Driving voltage, stage 1, HP control

0-10 V

If P21 = 2 or 3 and P11 = Intertwined

1

448

Driving voltage, stage 1, circuit 1, HP control

0-10 V

If P21 = 2 or 3 and P11 = split or mixed

1

449

Driving voltage, stage 1, circuit 2, HP control

0-10 V

If P21 = 2 or 3 and P11 = split or mixed

1

450

Driving voltage, common stage 1, HP control

0-10 V

If P21 = 2 or 3 and P11 = Mixed

1

451

State of circuit 1 balance valve output

On/Off

If P12 = Yes

1

452

State of circuit 2 balance valve output

On/Off

If P12 = Yes

1

530

State of electric stage 1

On/Off

If P22 = Yes

1

531

State of electric stage 2

On/Off

If P22 = Yes

1

532

State of electric stage 3

On/Off

If P22 = Yes

1

533

State of electric stage 4

On/Off

If P22 = Yes and P112 = 4

1

535

Air blade percentage information

0-100%

If P20 =Yes and P10 = Centrifugal

1

555

CPU version number

1 556

Console version number

*

1

557

Version number of circuit 2 board

If P3 = 2

1

558

Version number of changeover board

If P2 = reversible air-to-water

1

559

Version number of auxiliary heater board

If P22 = Yes

1

560

Version number of circuit 1 expansion valve

XX.YY VCM XX.YY

If P42 = CIAT and P3 = 1

1

561

Version number of circuit 2 expansion valve

XX.YY VCM XX.YY

If P42 = CIAT and P3 = 2

1

570

"SO" order number"

To be entered via a PC

1

571

MO number

To be entered via a PC

1

572

Machine identification name

To be entered via a PC

1

573

Machine identification number

To be entered via a PC

19

No.

Description

Setting

Default

Display conditions

ELECTRONIC EXPANSION VALVE

Circuit 1

3

601

Circuit 1 valve type

EX4 - EX5 - EX6 - EX7 - EX8

EX4

If P42 = CIAT and P3 = 2

3

602

Circuit 1 superheat setpoint

0.5 to 30°C

6

If P42 = CIAT and P3 = 1

3

603

Circuit 1 MOP point

Yes - No

No

If P42 = CIAT and P3 = 1

3

604

Circuit 1 MOP value

+ 5 to 25°C

15

If P42 = CIAT and P603 = Yes

and P3 = 1

3

605

Opening of C1 valve when air conditioning

started

10 to 100%

50

If P42 = CIAT and P3 = 1

3

606

Opening of C1 valve when heat pump

started

10 to 100 %

20

If P42 = CIAT and P3 = 1

and P2 = reversible air-to-water

3

607

Opening time at start-up, C1

1 to 60 seconds

5

If P42 = CIAT and P3 = 1

3

608

Circuit 1 slow mode

Yes/No

No

If P42 = CIAT and P3 = 1

Circuit 2

3

611

Circuit 2 valve type

EX4 - EX5 - EX6 - EX7 - EX8

EX4

If P42 = CIAT and P3 = 2

3

612

Circuit 2 superheat setpoint

0.5 to 30°C

6

If P42 = CIAT and P3 = 2

3

613

Circuit 2 MOP point

Yes - No

No

If P42 = CIAT and P3 = 2

3

614

Circuit 2 MOP value

+ 5 to 25°C

15

If P42 = CIAT and P609 = Yes

and P3 = 2

3

615

Opening of C2 valve when air conditioning

started

10 to 100 %

50

If P42 = CIAT and P3 = 2

3

616

Opening of C2 valve when heat pump

started

10 to 100 %

20

If P42 = CIAT and P3 = 2

and P2 = reversible air-to-water

3

617

Opening time at start-up, C2

1 to 60 seconds

5

If P42 = CIAT and P3 = 2

3

618

Circuit 2 slow mode

If P42 = CIAT and P3 = 2

COMMUNICATION

1

700

Communication protocol

BUS MODE

BUS MODE

1 701

Transmission speed

Adjustable: 4800, 9600 baud or 9600 jbus

9600 baud

1

702

Parity

Without, even or odd

without

1

703

Number of stop bits

1 or 2 1 1 704

Swapped real number format

Yes or No

Yes

1

705

Bus number

0 to 255

1

MASTER/SLAVE (2 MACHINES)If P28 = Yes

2

800

Master machine on loop

Yes/No

No

If P28 = Yes

2

801

Backup machine

Yes/No

No

If P28 = Yes

2

802

Switch backup machine

Yes/No

No

If P28 = Yes

2

803

Name of backup machine

Master/Slave

Slave

If P28 = Yes

2

804

Loop control type

CASCADE or PARALLEL or PROGRESSIVE

CASCADE

If P28 = Yes

2

805

Machine differential

0.5 to 5°C

1.5

If P28 = Yes

2

806

Differential between machines

1 to 10°C

4.0

If P28 = Yes

2

807

Maximum differential, additional machine

1 to 10°C

0.0

if P801 = Yes

2

808

Time delay between machines

0 to 60 min.

1

If P28 = Yes

2

809

Machine 1 ‘on’ authorisation

Yes/No

Yes

If P28 = Yes

2

810

Machine 2 ‘on’ authorisation

Yes/No

Yes

If P28 = Yes

2

811

Pump turned off by control

No

Yes, except for one

Yes, machine off

13- A E R O - C O N N E C T

7 MANAGEMENT OF AERO-CONNECT PARAMETERS

To access all AERO-CONNECT parameters in read/write mode, set parameter P116 (AERO-CONNECT link) to „Yes‟.

20

- Menu 13 allows all information about AEROCONNECT to be displayed on the CONNECT 2 console without having to use the AEROCONNECT

1 - S E T P O I N T S

2 - S T A T U S O F M A C H I N E S

3 - M E A S U R E D V A L U E S

4 - M A C H I N E . P A R A M E T E R S

5 - A D J U S T M E N T . P A R A M E T E R S

6 - R E A D I N G . P A R A M E T E R S

7 - F A U L T M E M O R Y

8 - T E S T M O D E

9 - P R O G R A M M I N G

10- E L E C T R O E X P A N S I O N V AL

11- COM M U N I C A T I ON

12- M A S T E R / S L A V E

13- A E R O - C O N N E C T

14- ACC E S S L E V E L S E L E C T .

P x x x S T P 1 C O O L I N G

- x x . x °

P x x x S T P 2 C O O L I N G

- x x . x °

P x x x : S T P 1 H E A T I N G

- x x . x °

P x x x : S T P 2 H E A T I N G

- x x . x °

If P119 ≠ heating

If P120 = 2 and if P119 ≠ heating

If P119 ≠ cooling

If P120 = 2 and P119 ≠ cooling

console.

- The AERO-CONNECT parameters are preceded by the letter A to differentiate them from the CONNECT 2 parameters.

- If a dry cooler equipped with its AERO-CONNECT console is connected to CONNECT 2 and P116 is set to „Yes‟, neither console has priority over the other.

- If menu 13 remains open for 1 hour and no buttons are pressed during this time, the screen switches to the CONNECT 2 display.

- Parameter A99 (lock parameters) cannot be set to „No‟ via the CONNECT 2 console.

- Parameter A116 (CIAT CW unit link) is not accessible via the CONNECT 2 console because setting A116 to „No‟ will delete the link with the console.

- Parameter A250 is not accessible because the LED test on the CONNECT 2 console is performed via parameter P250 on CONNECT 2.

- The forced fan operation function on the console is not accessible via the CONNECT 2 console.

8 CONTENTS OF THE MENUS

The ° symbol stands for °C in the electronic programming system.

Analogue values are displayed with one decimal place. The hundreds digit may be replaced by a negative sign when appropriate.

A selection symbol flashes at the left of the display.

Holding down the + or - buttons will cause increasingly faster scrolling (and change the units) in the list of parameters or when modifying

parameter values.

8.1 MAIN menu

Scrolling through menus occurs line by line.

The + button is used to increment values and the - button is used to decrement values.

The first square at the top left flashes.

8.2 SETPOINTS menu

This menu gives quick access to settings for the control setpoints depending on the control mode and the selected operating mode.

To move from parameter to parameter, press the + or – buttons. The letter P flashes when a parameter is selected.

To change the value of a selected parameter, press OK. The value can be changed when the cursor flashes at the bottom right. Use the +

button to raise the value, and the - button to lower it. When finished, press OK to confirm or ESC to cancel the changes.

When returning to menu 1 the last parameter consulted is displayed.

21

8.3 MACHINE STATUS menu

C O N N E C T 2 h h / m n

R E T U R N T E M P . : - x x . x °

S E T P O I N T : - x x . x ° ↓

1 O F F 2ON 3 S C P 4 S C P

M A C H I N E O F F

W A T E R F L O W F A U L T

W A T E R F L O W F A U L T

X C U T ( S ) I N 1 H

M A C H I N E O F F

O U T T E M P . T O O L O W

M A C H I N E O F F

O U T T E M P . T O O H I G H

M A C H I N E O F F

P H A S E C T R L L R F A U L T

C O M P R E S S O R

DRI V E R F A U L T

O U T . T E M P . S E N S O R F A U L T

J 7 / 1 - 2

C O N D E N S E R I N L E T

S E N S O R F A U L T J 7 / 5 - 6

C O N D E N S E R O U T L E T

S E N S O R F A U L T J 7 / 5 - 6

M A N I F . W A T E R O U T L E T

S E N S O R F A U L T A D D 2 J 4 / 2 - 3

E X C H . 1 W A T E R O U T L E T

S E N S O R F A U L T J 7 / 2 - 3

M A C H I N E O F F

O P E R A T I N G M O D E C H A N G E

M A I N T A I N W A T E R L O O P

T E M P E R A T U R E A T 3 0 °

W A T E R C I R C U L A T I O N

P U M P F O R C E D O N

U N I T STOP BY

R E M O T E C O N T A C T

M A C H I N E O F F

O N / O F F

If machine off

If machine off

If P7 = INVERTER

To enter the MACHINE STATUS menu, use the + or - buttons to position the cursor on 2 then press OK.

8.3.1 Main table

This screen reappears automatically after one hour if

No general faults occur, no controls are activated (via the console, modem, etc.), no general faults are reported and no automatic controls are

closed:

The ↓arrow appears if there is another message.

- If a general fault occurs on the main machine, the messages are displayed on lines 2 and 3 in the following order of importance:

If an automatic operation control is activated → the On/Off LED flashes:

22

8.3.2 MACHINE STATUS table

M A C H I N E S T A T U S

F A N F A U L T

P U M P 1 O N

x xs

P U M P 2 O N

x x s

W A T E R R E T U R N T . L I M I T

P O W E R R E D U C .

E X C H A N G E R A M B . T E M P .

D U R I N G F R O S T P R O T E C .

N O . S T A G E S T O B E

S H U T O F F : X

U N I T D I S C H . T . L I M I T

O P T I M I S E D O P E R A T I O N

E L E C A U X C T R L

O U T T E M P . T O O L O W

W A T E R T E M P . R I S I N G

F O R D E F R O S T I N G

O U T . T E M P . S E N S O R F A U L T

J 7 / 1 - 2

M A N I F . W A T E R O U T L E T

S E N S O R F A U L T A D D 2 J 4 / 2 - 3

E X C H A N G E R A M B I E N T T E M P .

S E N S O R F A U L T J 7 / 5 - 6

H P P R E S S U R E C O N T R O L

S T A G E 1 O N L Y

S E L F - A D J U S T I N G

C O N T R O L M O D E

C I R C U I T 2 O F F

L I N K F A U L T

M O T O R F A U L T

S T A G E x C I R C U I T x

C I R C U I T X O F F

W A T E R F R O S T F A U L T

C I R C X H 2 O F R O S T F A U L T

X C U T ( S ) I N 2 4 H

This table appears only if any of the following messages must be displayed using the ↑and ↓buttons.

The messages are displayed in the following order of priority:

8.3.3 Table of “MACHINE STATUS circuit x fault” messages:

This table appears only if any of the following messages must be displayed using the ↑ and ↓ buttons.

The messages are displayed in the following order of priority:

23

C I R C U I T x O F F