CIAT COADIS LINE 900, CDL922, CDL924, CDL934, CDL934SP Series Manual

...

1

COADIS LINE 900

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 14.712 A

Comfort units

Coanda effect cassette

Use

Range

advantages

New generation

of water loop cassette

comfort units

360° Coanda effect

diffusion

Energy efficient

motor

and

high-efficiency filtration

ErP

READY

The active water loop comfort unit, for installation in suspended

ceilings, can be used to autonomously and individually adapt

the indoor temperature over very short periods to ensure the

comfort of occupants. Designed for offices, open plan areas,

meeting rooms, commercial premises and entrance halls.

The COADIS LINE 900 range of cassettes features 9 sizes

covering flow rates from 550 to 1400 m3/h, and meeting the

most stringent sound level requirements.

■

1 Visual 360° diffusion model:

- Coanda effect diffuser across 360°.

■

The Coadis Line is available as:

- A 2-tube system, with heating or cooling mode,

- A 2-tube, 2-wire system, with heating or

cooling/cooling + electric mode,

- A 4-tube system, with heating and cooling mode.

■

Uses an ecological and long-lasting heat-transfer fluid.

■

Individual adaptation of the indoor temperature.

■

Responsiveness of the system.

■

Extensive capacity range.

■

Diffusion by Coanda effect across 360° for comprehensive

coverage, and perfect control of thermal phenomena which

cause discomfort.

■

Acoustic comfort.

■

Optimum indoor air quality thanks to the EPURE function.

■

Energy optimisation:

- High Energy Efficiency motor,

- EPURE filter with low pressure drop,

- Optimised hydraulic coil.

■

Maintenance facilitated by access to the filter and the highly

accessible internal components.

■

Modern, elegant design to ensure perfect integration.

■

Environmentally-responsible product.

Cooling capacity: 3 to 11 kW

Heating capacity: 3 to 20 kW

2

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 14.712 A

Comfort units

Coanda effect cassette

COADIS LINE 900

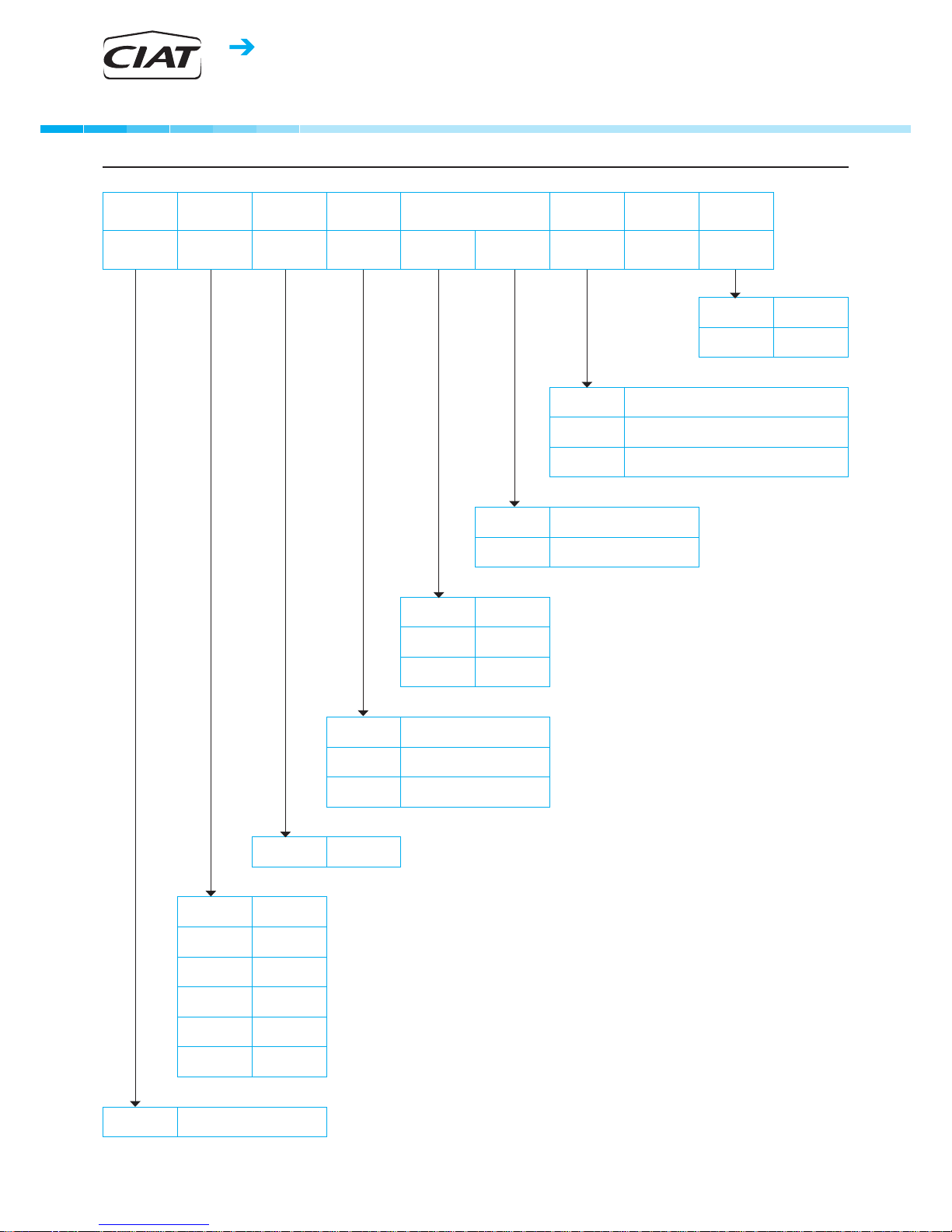

Range Size Model

Coil

type

Thermal function Motor Speeds Filter

CDL 922 V360° 2T2F F + 2000W HEE As selected G3

EP EPURE lter

G3 G3 lter

HEE 2-10V Energy efcient motor 2-10V control

HEE ON/OFF Energy efcient motor 3-speed control

AC 5-speed asynchronous motor

2000W For 922

3000W For 932 and 932SP

F Cooling

C Heating

CF Heating/cooling

2T 2 pipes

2T2F 2-tube + wiring

4T 4 pipes

V360° Visual 360°

922 2 tubes

924 4 tubes

932 2 tubes

934 4 tubes

932SP 2 tubes

934SP 4 tubes

CDL COADIS LINE

Coadis Line 900 moRpho-desCRiptive Codes

3

COADIS LINE 900

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 14.712 A

Comfort units

Coanda effect cassette

teChniCaL desCRiption

Return/supply air interface

● VISUAL 360°

Painted galvanised steel.

PSE insulation, 10 to 40 mm thick.

Uniform RAL 9010 white colour for all components. Integration

within a suspended ceiling, fitting in the centre of four tiles.

Perforated metal return air grille with filter housing with quick

opening via 2 lugs.

Interface secured by 4 screws, to be removed to gain full

access to the internal components (coil, FMA, temperature

limiters, condensate pan, condensate drain pump).

Coanda effect diffusion which allows a jet of air to follow the

ceiling, preventing cold air from dropping into the comfort area.

Coanda effect offers 360° coverage of the surface area of the

room to be treated, with no dead zone.

Narrow opening single-slot and specific internal profile.

Base

■ Ribbed galvanised steel motor support base panel.

■

High-density PSE packaged casing, ensuring the thermal

and acoustic functionalities. 18 mm thick for the base and

25 mm to 30 mm thick for the vertical walls which form the

casing. M1 fire rating.

■

Low emission of TVOCs and no halogenated compounds.

■

ABS technical plate supporting the electrics box, hydraulic

and air couplings (fresh air).

■

Reinforcing ABS angle bars fitted in the corners and

equipped with open galvanised steel mounting brackets with

check valve for fitting threaded rods.

■

Fixed frame in RAL 9010 painted (white) galvanised steel,

housing the return/supply air interface and providing rigidity

to the casing assembly.

Water coil

● 1 hot water or cold water circuit (2-tube system),

● 1 hot water + 1 cold water circuit (4-tube system),

● one-piece coupling (40 mm centre distance) with rotating

female couplings with integrated flat face and seals, for easy

fitting of control valves,

● one, two or three-row circular coil with low pressure drop,

● copper tubes, continuous aluminium fins (1.8 mm spacing),

● bleeding and draining,

● nominal pressure of 16 bar (at 20°C),

● test pressure of 24 bar,

● max. hot water inlet temperature:

- 4-tube application: 80°C,

- 2-tube application: 70°C,

- 2-tube/2-wire application: 55°C (min. air flow rate: 200m3/h)

● min. cold water inlet temperature: 6°C.

Electric heater

(2-tube + electric system)

230/1/50 single-tube electrical elements inserted into the

aluminium housing.

Two temperature limiters with manual and automatic reset,

inserted into the aluminium housing and easily accessible via

the return/supply air interface without the need to open the

suspended ceiling.

Heater power supply connected to the terminal block inside

the electrics box.

Option of deactivating a heater on site by removing a shunt

from the terminal block, to reduce the electrical power.

Condensate drain pan

One-piece main pan with all-climate insulation in high-density

PSE, with sealing treatment on the upper section.

Removable from below.

Condensate drainage (internal Ø 32 connection) provided by

an internal drain pump equipped with a safety float, check

valve and fitted on anti-vibration mounts.

Auxiliary pan available as an accessory for recovery of

condensate from the valves.

Fan motor assembly

■ HEE motor

High energy efficiency motor enabling a reduction of up to

85% in electricity consumption.

● BLAC (Brushless Alternating Current) technology offering

more linear torque progression and a lower operating sound

level than BLDC (Brushless Direct Current) technology,

● sealed, tropicalised, with protected shaft,

● 3-speed gradual operation by 0-10V or on/off control signal,

without expansion board,

● ball bearings,

● internal automatic overload protection as standard on

winding,

● "DFS" motor fault output using a photocoupler for potential

alarm feedback via a Konnex protocol communication bus

(via the V3000 controller),

● fitted on anti-vibration mounts,

● 230V/1Ph/50 Hz power supply (60Hz compatible).

Note: The minimum voltage required for start-up of the motor

is 2V.

Or

■ Asynchronous motor

5 factory-fitted cabled speeds (connected and available at the

terminal) for customised adjustment.

● sealed, tropicalised, with protected shaft,

● permanent capacitor,

● ball bearings,

● internal automatic overload protection as standard on

winding,

● resilient mounts,

● 230V/1Ph/50 Hz power supply (60Hz compatible),

● high efficiency and power factor.

■ Fan(s)

● balanced centrifugal impeller (Ø 476mm) with airfoil blades,

● polymer impeller,

● single-point mounting system with foolproofing device.

4

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 14.712 A

Comfort units

Coanda effect cassette

COADIS LINE 900

Electrics box

■ Large ABS electrics box, with a hinge to keep it open and

screw closure.

■

Protection rating: IP20.

■

Terminal block on DIN rail in accordance with EN 50022,

depth 7.5 mm.

■

Junction block located with tension clamp. Cross section 0.5

to 2.5 mm² - Max current: 24A – Shock resistance: 8 kV.

■

Cable routing for customer electrical connections.

Fresh air supply sleeve

■ Ø 100mm sleeve integrated into the casing with removable plug.

Air filter

■ EPURE function

● a protected air stream which prevents particles present in the

suspended ceilings from being drawn in,

● uniform treatment of the room thanks to optimised diffusion

(Coanda effect) and an adapted mixing rate,

● local filtration by high efficiency filter medium effective on fine

particles up to 2.5 microns,

● filter area 10 times greater than the intake grille surface,

● no discharge from the filter during replacement thanks to the

folded filter medium with heat-sealed lateral inserts to make

it more rigid,

● longer service life compared to a conventional flat filter,

thanks to its high retention capacity,

● low energy impact,

● fire rating: M1,

● no release of glass fibres,

● 100% incinerable at end of life.

Or

● flexible filter medium made of regenerative polyester fibre,

● efficiency class EN 779: G3,

● fire rating: M1,

● rigid metal frame,

● accessible via the hinged air recovery grille.

Standard wiring diagram

without control

■ 2-tube and 4-tube application: 7320074.

■

2-tubes + electric application: 7320075.

Securing the device

Open mounting brackets, factory-fitted, made from galvanised

steel, 15/10th thick, with check valve for securing the threaded

rods during fitting and levelling.

Packaging

■ Strapped cardboard crate for the casing.

■

Fitting template and direction of assembly printed on the box.

■

Visual return/supply air interface delivered separately in its

own protective cardboard packaging.

■

Delivered on a plastic-wrapped pallet.

Controls

■ RTR-E electromechanical thermostat range.

■

V30 electronic range.

■

V300 electronic range.

■

V3000 networked electronic range (KNX).

■

V-Lon networked electronic range (LON).

Optional accessories

■ Delivered separately:

● self-adjusting fresh air module kit:

- 15/30/45 m3/h flow rates,

- 60/75/90 m3/h flow rates,

● Ø100/125 mm adapter for fresh air sleeve,

● resilient mounts,

● finish frame for STAFF ceiling,

● fresh air pack:

- R1: fresh air managed via presence sensor,

- R+: fresh air management via CO2 sensor (max. air flow

90 m3/h recommended, network balancing system not

supplied by CIAT).

Option (contact us)

● Hydraulic coil with blades protected for use in harmful/

corrosive atmospheres (coastal locations, or areas close to

chemical industries).

5

COADIS LINE 900

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 14.712 A

Comfort units

Coanda effect cassette

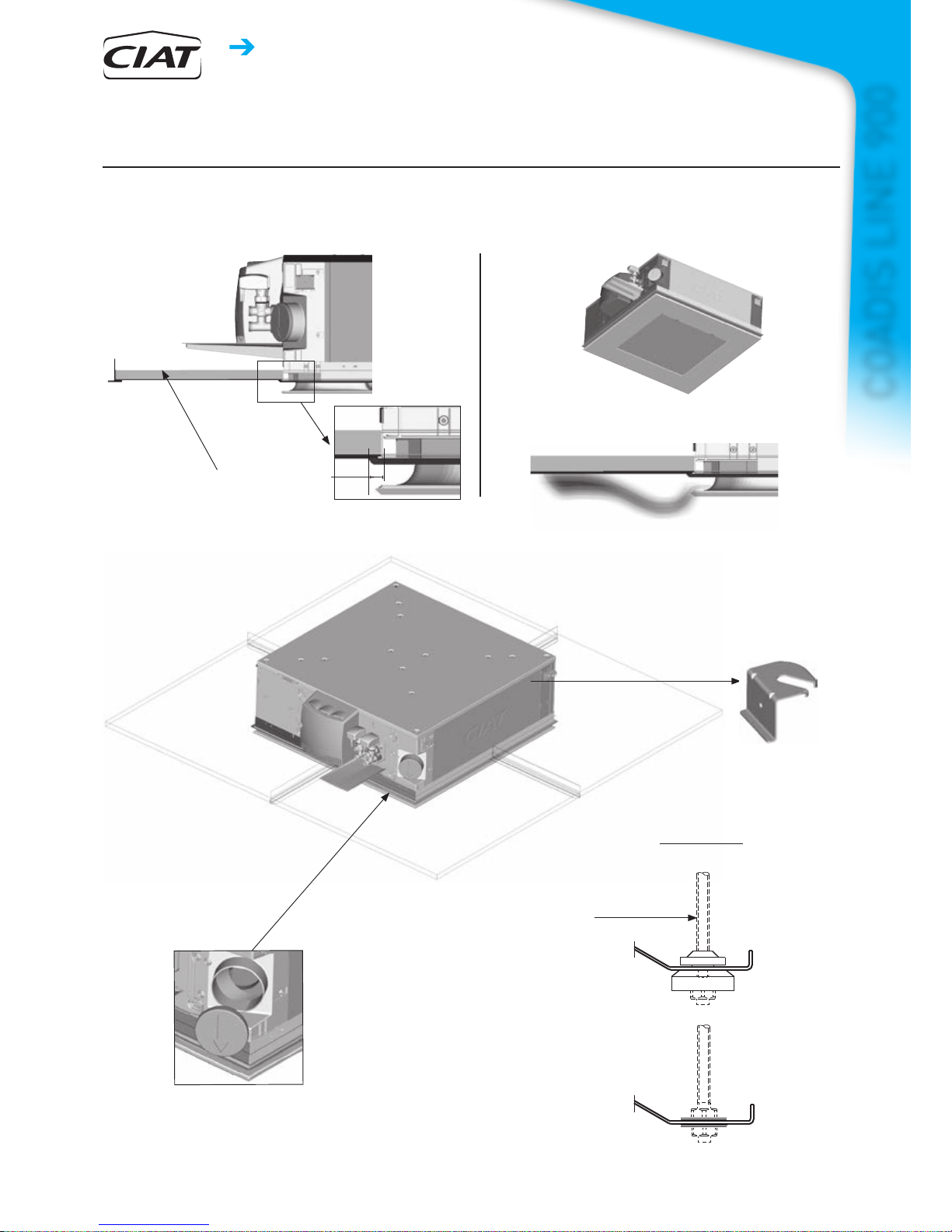

integRation in sUspended CeiLing

The air handling casing is fitted inside the suspended ceiling, in the centre of 4 tiles, to be positioned in the centre of the room.

The COADIS LINE must be suspended from the ceiling using 4 threaded rods either 6 mm or 8 mm in diameter (not supplied),

which are fixed to the unit's 4 support brackets using resilient mounts or a nut/washer assembly positioned on either side of the

mounting bracket.

Suspended ceiling tile

Support brackets (x4)

Ø 100 mm fresh air inlet collar, max.

air flow 90 m3/hr recommended.

Network balancing system

(not supplied by CIAT)

Mounting principle

2 options

Attached using 4 threaded rods

(6mm or 8mm)

Resilient

mount

Nut/washer

assembly

Positioned either

side of the

mounting

bracket

Coanda effect air diffusion

12.5

6

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 14.712 A

Comfort units

Coanda effect cassette

COADIS LINE 900

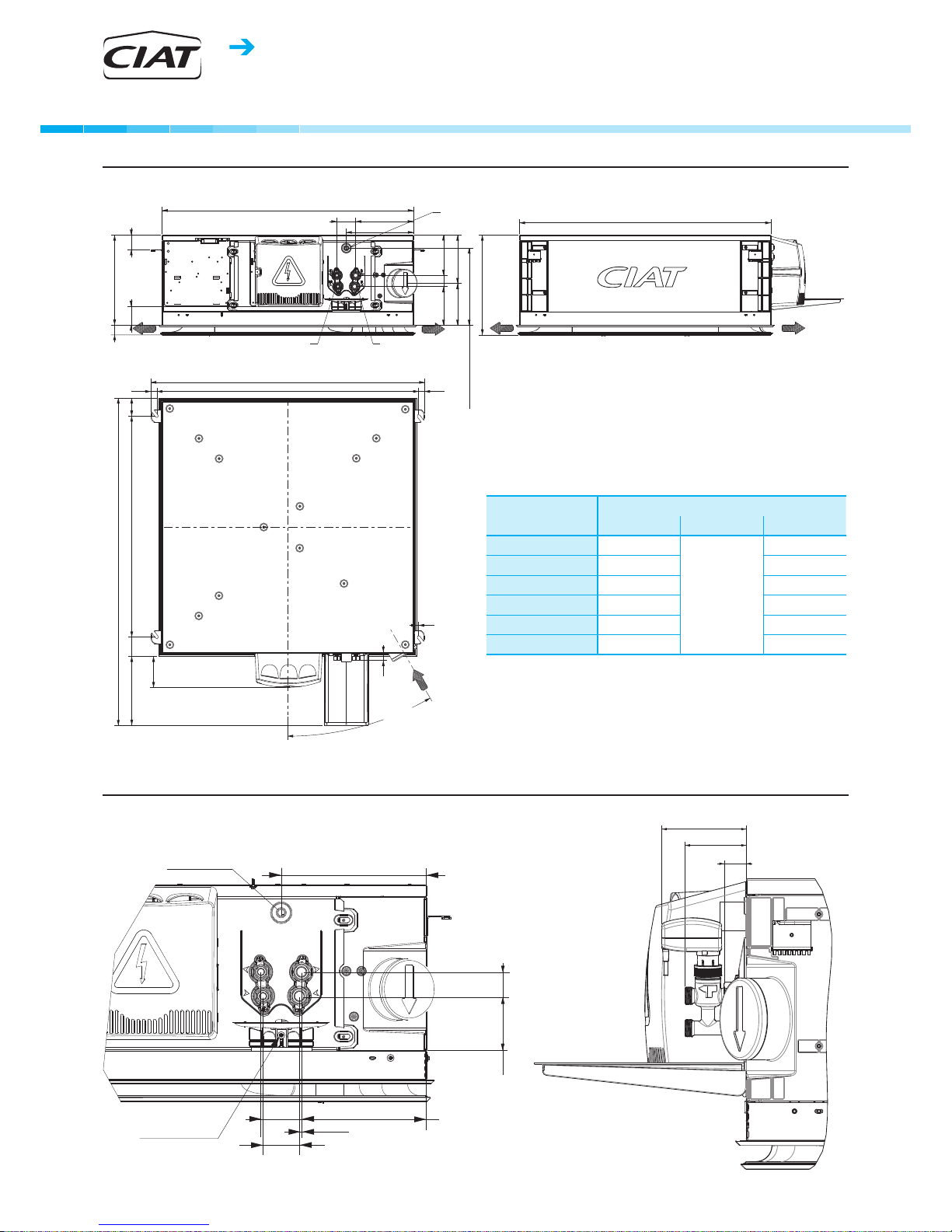

dimensions

positioning of pipes and vaLves

COADIS LINE 900

Weight (kg)

Unit Grid Total

922

35

10

45

924

35 45

932

40 50

932SP

40 50

934

40 50

934SP

40 50

900

240

103.5

75

27

205

67

60

40145

Ø 32

S1 S

E1 E

981

938

21.5

G1/2~ heating manifold

G3/4"

cooling manifold

Condensate drainage coupling

for ø32 tube

Condensate drain

height 276.5

ø100

fresh air

inlet

5.9

30°

21.5

1173.1

792

323

69

27

65

53

144

173150

357

139

40

34

67

247

111

900

67 207

240

Auxiliary pan

mounting screws

Loading...

Loading...