CIAT Aeroconnect Installation, Operation, Commissioning, Maintenance

N 08.132 B

11 - 2008

Installation

Fonctionnement

Mise en service

Maintenance

Installation

Operation

Commissioning

Maintenance

Montage-

Betriebs-und

Wartungs-

Anweisung

AEROCONNECT

Contents

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Sections Page

General......................................................................................................................

Board functions..........................................................................................

Limits of use ...............................................................................................

Compatible equipment...............................................................................

Control console.........................................................................................................4

Description of control console .................................................................

Display ........................................................................................................

Menu tree structure....................................................................................

Menu list .......................................................................................

Structure of the menus................................................................

Navigation...................................................................................................

Board functions: description ..................................................................................

Control choices ..........................................................................................

On/Off control (stages) ................................................................

Speed control ...............................................................................

Mixed control................................................................................

Automatic operation control .....................................................................

Manual override..........................................................................................

Two setpoints .............................................................................................

Stage runtime balancing............................................................................

Spray ...........................................................................................................

Free cooling................................................................................................

Link with CIAT chiller.................................................................................

BMS link......................................................................................................

Options......................................................................................................................

Relay boards...............................................................................................

Remote control console ............................................................................

Electrical connections .............................................................................................

General........................................................................................................

Connection diagram...................................................................................

Board connections.....................................................................................

Dry cooler configuration..........................................................................................

Configurations............................................................................................

Commissioning and configuration ...........................................................

Information available while the unit is running .......................................

Factory-set parameters..............................................................................

Condenser configuration.........................................................................................

Configurations............................................................................................

Commissioning and configuration ...........................................................

Information available while the unit is running .......................................

Factory-set parameters..............................................................................

BMS communication protocol ................................................................................

Communication interface ..........................................................................

Transmission mode ...................................................................................

Remote signalling register ........................................................................

Remote alarm register ...............................................................................

Remote measurement register..................................................................

Fault memory..............................................................................................

Counters .....................................................................................................

Remote configuration register ..................................................................

Functions 1 and 2.......................................................................................

Remote alarm and operating status ...........................................

Remote control.............................................................................

Remote diagnostics.....................................................................

Event counter ...............................................................................

Glossary....................................................................................................................

3

3

3

3

4

5

5

5

5

6

7

7

7

7

8

8

8

8

8

8

9

9

9

10

10

10

10

10

11

13

16

16

16

18

19

20

20

20

21

23

24

24

24

24

25

25

26

26

27

29

29

29

29

29

30

EN - 2

General

Board functions

Limits of use

Electrical

Compatible

equipment

Integrated in an electrical panel, this board performs the following functions:

• temperature or pressure control,

• operation parameter monitoring,

• communication with CIAT chillers,

• diagnostics and fault storage,

• communication with the remote control console, ancillary boards,

and customer BMS (bus).

Ambient air:

During operation: min./max. temperatures = -25°C/40°C

Stored: min./max. temperatures = -40°C/80°C

Single-phase fluid: min./max. adjustment temperature = 5/90°C (up to 150°C

optional)

Refrigerant: min./max. set pressure: 5/45 bar

Board supply voltage: 230 V

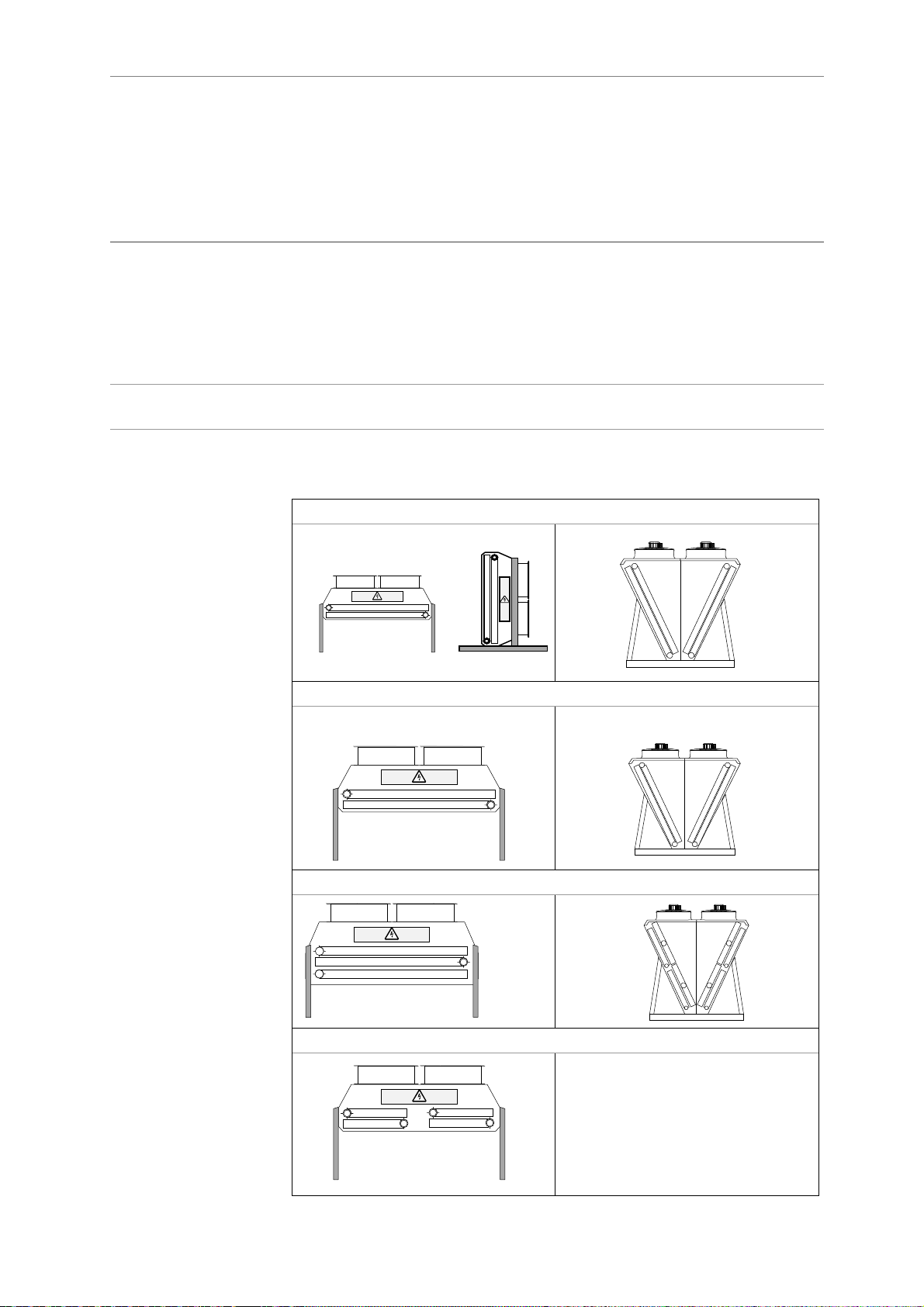

The AeroConnect board is used to control the dry coolers and air-cooled

condensers

Possible configurations and identification conventions:

Flatbed or V-type coils

Flatbed

+6%

-10%

V-type

Unit with one or two fan lines

Unit with one or two coils

Unit with one or two circuits

Line 1

Circuit 1 Circuit 2

Line 2

Coil 2

Coil 1

Coil 1

Line 1

Line 2

Coil 2

EN - 3

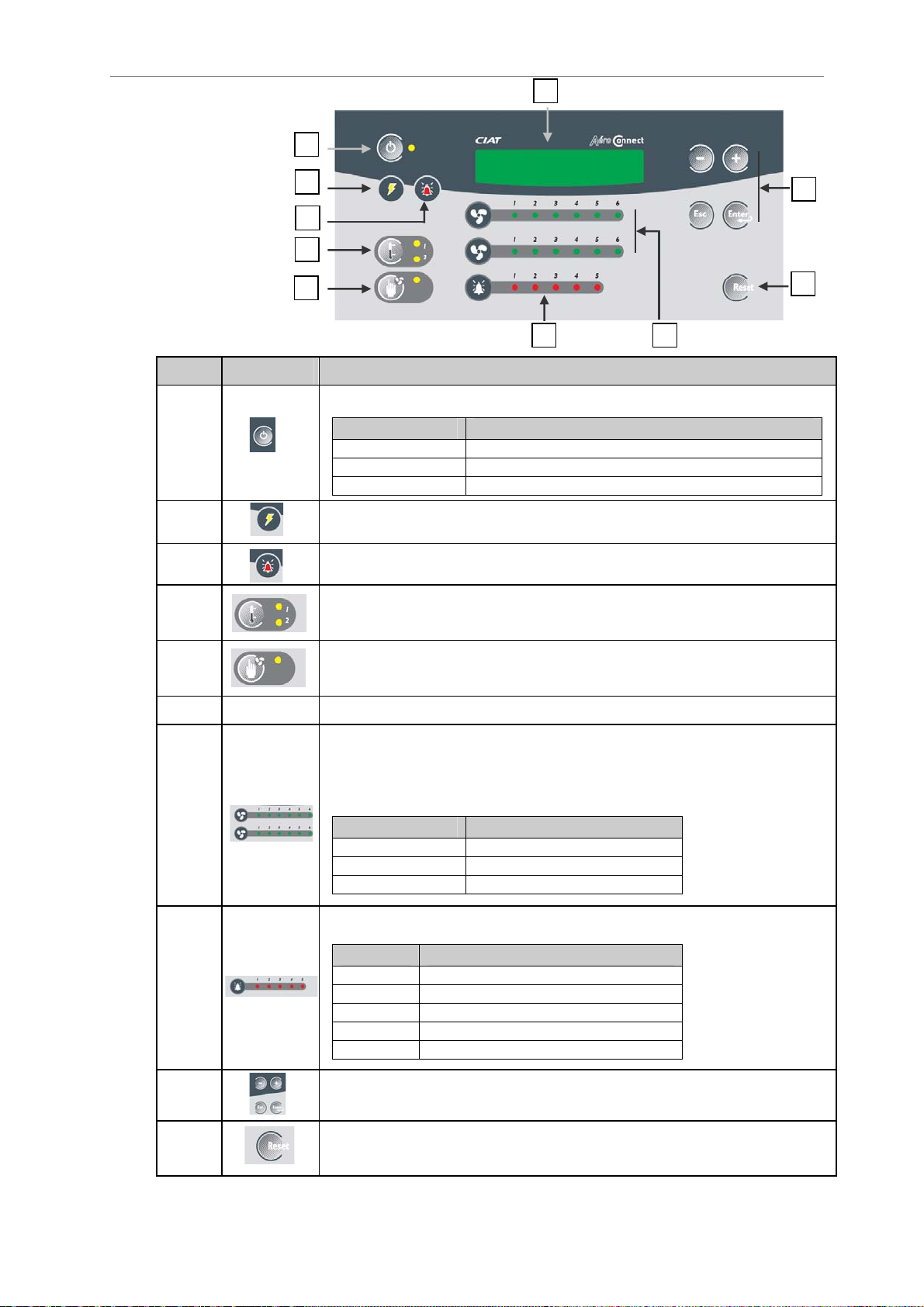

Control console

Description of

control console

(local and remote)

Letter Illustration Function

A

B

F

A

B

I

C

D

E

J

H G

Power button

LED Meaning

Off

On

Flashing

LED on = system energised.

Machine off

Machine on

Machine shut off by automatic control

C

D

E

F

G

H

I

LED flashing = fault

Press this button to select setpoint 1 or 2.

The corresponding LED lights up.

Press this button to activate or deactivate the fan manual override.

Flashing LED = manual override on.

Display screen.

Status of the fan stages:

• Top row = Fan line 1

• Bottom row = Fan line 2

LED Meaning

Off

On

Flashing

Measurement faults

LED No. Meaning

1

2

3

4

5

Menu navigation buttons: see the Navigation section.

Circuit 1 coil 1

Circuit 2 coil 1

Circuit 1 coil 2

Circuit 2 coil 2

Outdoor temperature

Stage off

Stage on

Stage fault

J

Reset button for certain faults.

Does not work with the remote control console.

EN - 4

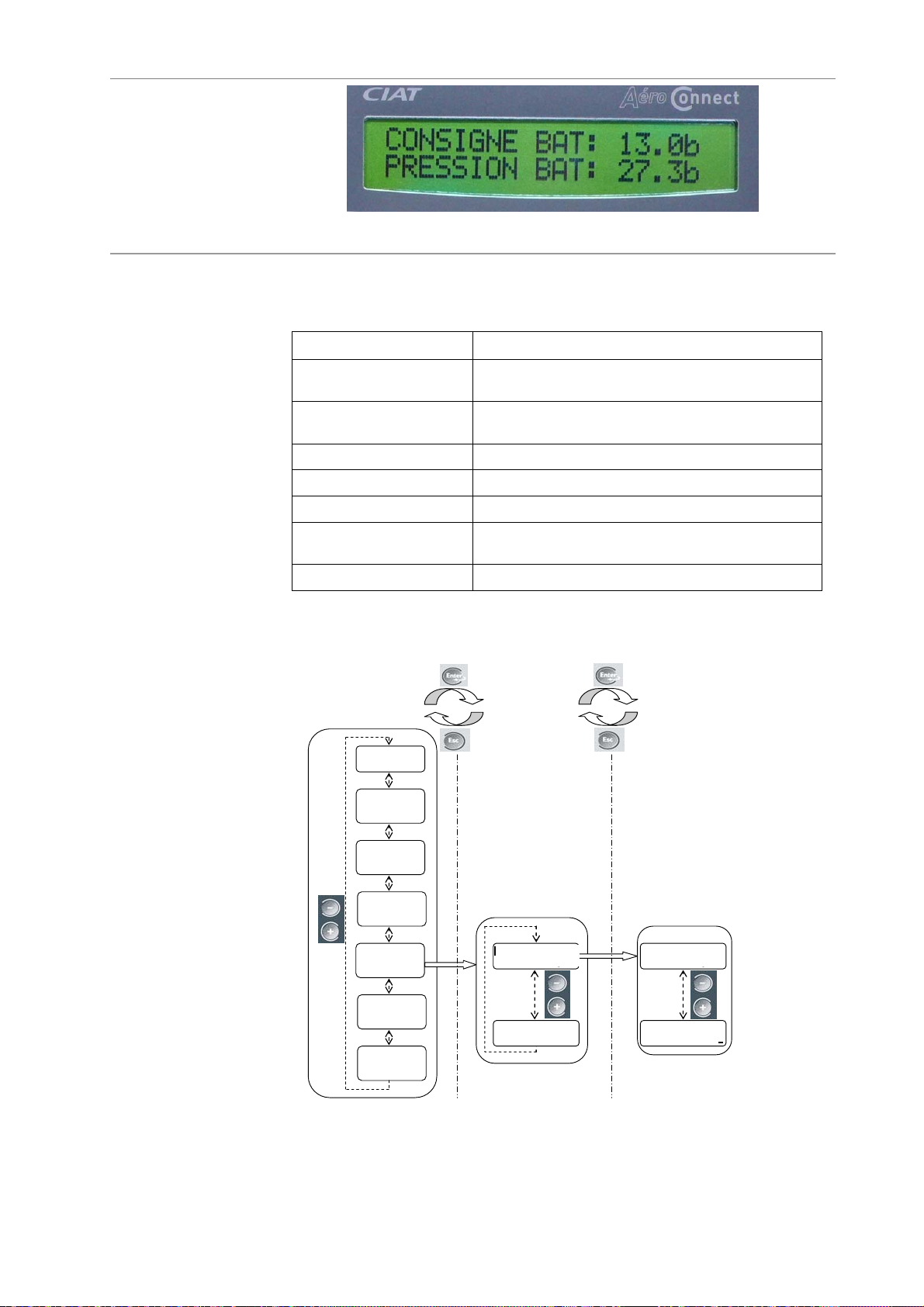

Control console (continued)

Display

Menu tree

structure

Menu list

Two-line LCD – Displays system readings and controls.

There are seven main menus for controlling the system.

Each menu contains different parameters.

MENUS Description

1-Setpoints Change setpoints - Menu not displayed if the unit is

run with a CIAT chiller.

2-Machine status Default menu. Contains read-only information on the

operation of the machine.

3-Measured values Displays read-only temperature and pressure values.

4-Machine parameters Machine configuration parameters.

5-Settings parameters Parameters set for the control and various options.

6-Reading parameters Displays the status of the inputs, outputs, counters,

etc. (read-only).

7-Fault memory Shows the nine most recent faults (read-only).

Structure

of the menus

All information in the menus is displayed in a tree structure.

This tree structure is split into three levels, as shown by the diagram below.

MENUS

MENUS

PARAMETRES

PARAMETERS

MODIFICATION DES

CHANGING OF

VALEURS

VALUES

1-Consigne

1-Setpoint

2-Machine

2-Etat

status

machine

3-Measured

3-Valeurs

values

mesurees

4-Machine

4-Param

parameters

machine

5-Settings

-Param

parameters

de réglage

6-Read

6-Param de

parameters

Lecture

7-Fault

7-Memoire

memory

defauts

P100 Language

100 Langue

P203 ---------------

English

Français

-------

P100 Language

P100 Langue

P100 Langue

P100 Language

English

Français

----------

-------------

EN - 5

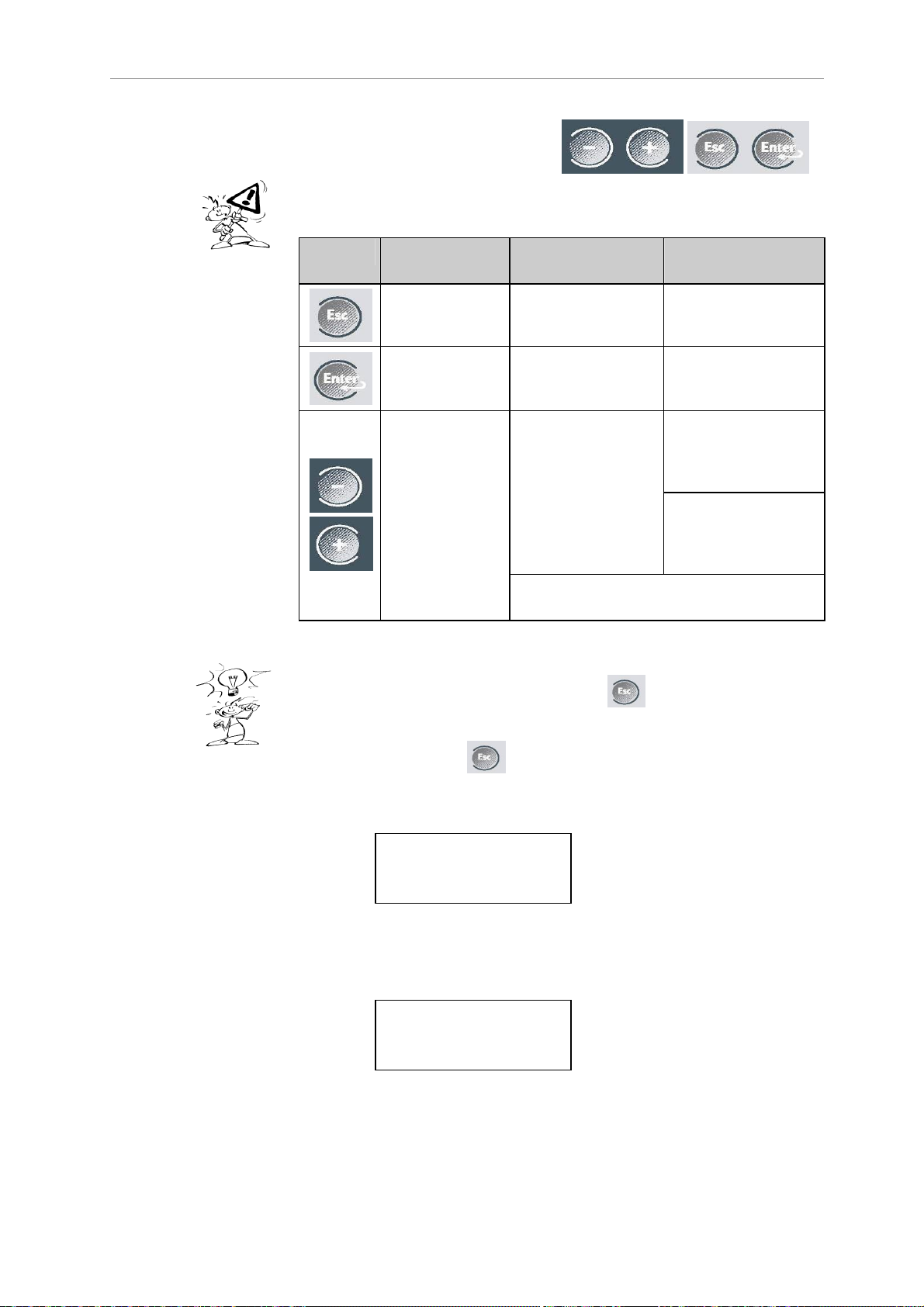

Control console (continued)

Navigation

Navigating through

the menus

Four buttons are available for

navigating through the menus:

Each button is described in the table below:

Î Press these buttons firmly!

Button Level

Menus

Select menu Select parameter

Scroll

through the

menus

Level

Parameters

Back to

Menus level

Scroll

through the

parameters

Pressing and holding the ‘+’ or ‘-‘ buttons

will cause the display to scroll faster.

Level

Values

Back to

Parameters level

Confirm value and

go back to

parameters

Lower the

parameter value or

scroll through the

values

Raise the

parameter value or

scroll through the

values

When the machine is turned on, the "machine off – on/off" menu

[2-Machine status] screen appears. Press to go back to the menu

list.

If the control console is not used for one hour, the [2-Machine status]

menu reappears. Press to go back to the menu list.

Arrows on the right of the screen indicate that additional information is

available. To see this information, press the ‘+’ or ‘-‘ buttons.

Example

The active line in a menu is shown by a flashing box to the left of the menu

number.

Example

▮100 LANGUAGE

COIL PRESSURE ↑

20.7 B↓

ENGLISH

EN - 6

Board functions: descriptions

Control

choices

On/Off control

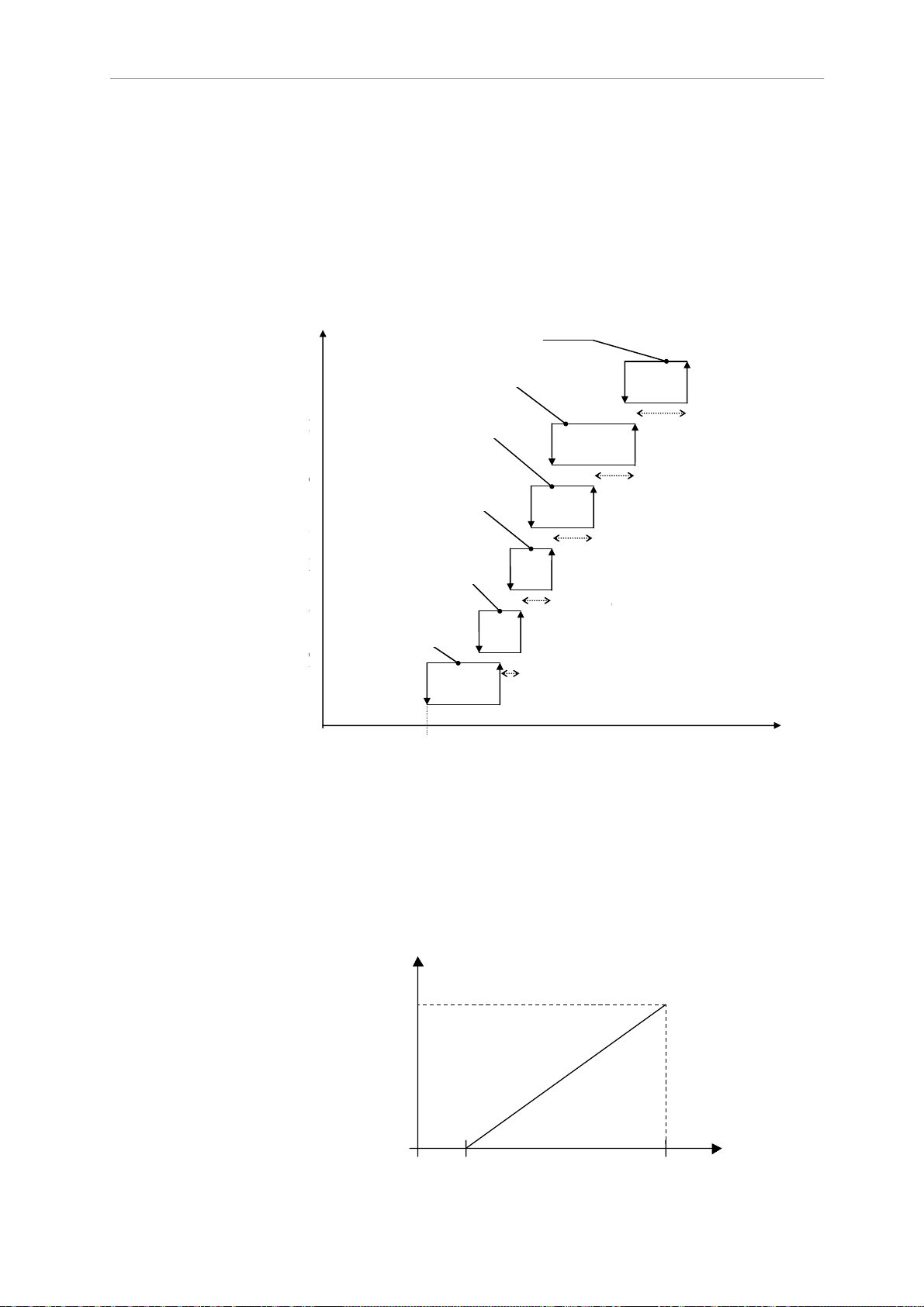

Three types of control are possible. Refer to your order acknowledgement

to see which type you have selected:

• On/Off: Cascade control by activation of fan stages.

• Speed control: Fan speed control.

• Mixed: Speed control on stage 1, cascade control for the following

stages.

Used for cascade control of fan stages:

The diagram below illustrates this type of control:

A160 : Hystérésis étage 6

A 160: Stage 6 hysteresis

EXAMPLE FOR CIRCUIT 1

EXEMPLE POUR CIRCUIT 1

A 158 : Hystérésis étage 5

A 158: Stage 5 hysteresis

C

E

O

T

N

A

A156 : Hystérésis étage 4

A 156: Stage 4 hysteresis

T

G

R

E

O

L

D

A 154: Stage 3 hysteresis

E

A154 : Hystérésis étage 3

S

T

R

A

E

G

G

A152 : Hystérésis étage 2

A 152: Stage 2 hysteresis

E

U

L

A

T

A 150: Stage 1 hysteresis

A150 : Hystérésis étage 1

I

O

N

A155 : ∆ étage 4

A153 : ∆ étage 3

A151 : ∆ étage 2

stage 3

stage 2

A159 : ∆ étage 6

A157 : ∆ étage 5

stage 5

stage 4

Stage 6

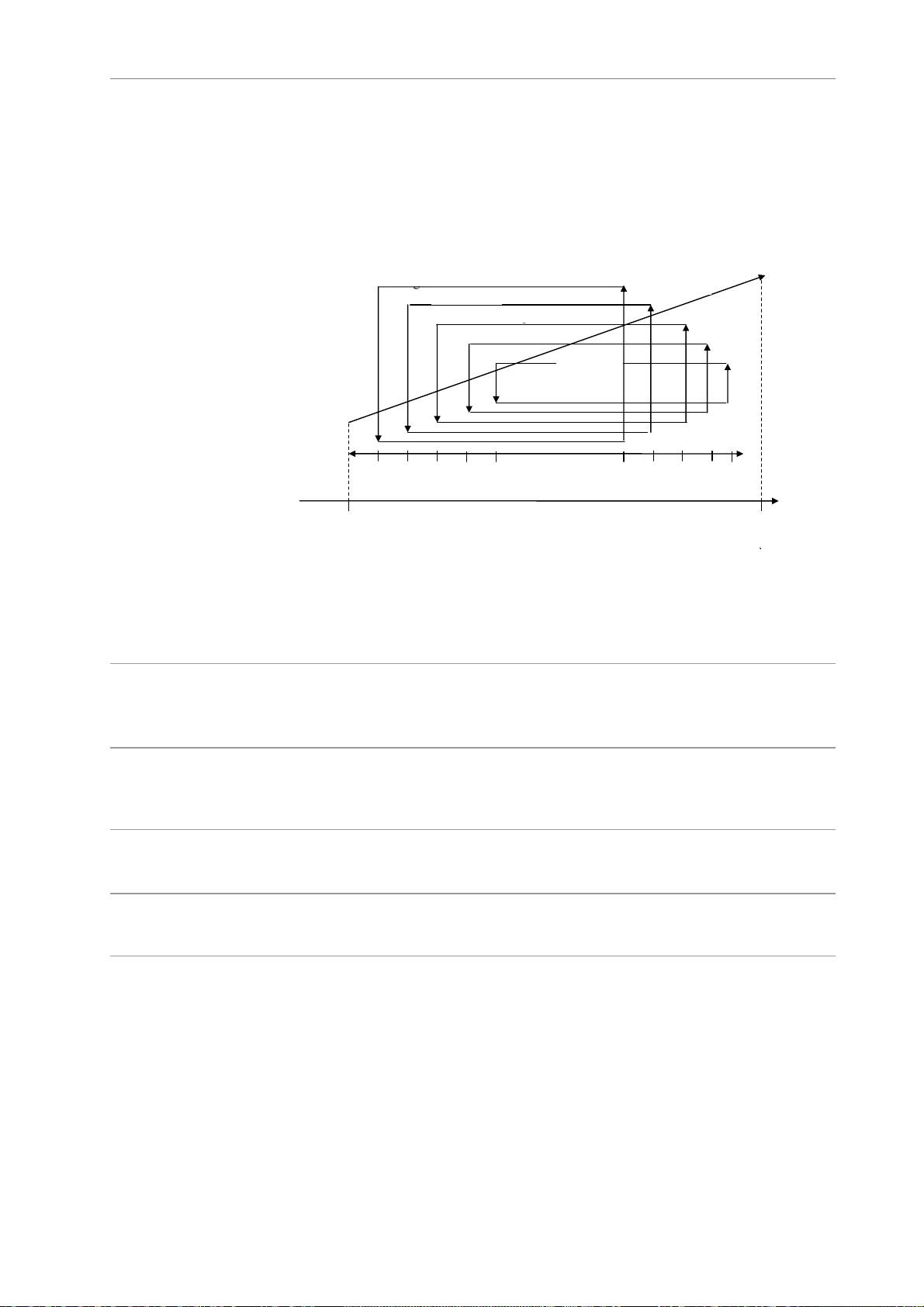

Speed control

With a speed drive

(option)

A121 or A122 Setpoint

A121 ou A122 Consigne

Used to adjust the speed of all the fans.

The diagram below illustrates this type of control:

Voltage

Tension

EXAMPLE FOR COIL 1, CIRCUIT 1,

EXEMPLE BATTERIE 1 CIRCUIT 1

SETPOINT 1

CONSIGNE 1

10V

0V

(A150=hystérésis)

(A150=hysteresis)

A121 + A150

Measurement

Mesure

Measurement

EN - 7

Board functions: descriptions (continued)

Control

choices

(continued)

Mixed control

With a speed drive

(option)

Used to adjust the speed on stage 1. Cascade control is used for the other

fan stages.

The diagram below illustrates this type of control:

2nd stage

2°étage

EXAMPLE FOR CIRCUIT 1

EXEMPLE POUR CIRCUIT 1

3°étage

3rd stage

4°étage

4th stage

5°étage

5th stage

6°étage

6th stage

1st stage

1°étage

5%

A121

Setpoint

Consigne

55% 65% 75% 85%

(A150=hysteresis)

(A150=hystérésis

95% 15% 25% 35% 45%

Measurement

A121 + A150

Automatic

machine operation

control

Manual

override

Two setpoints

Stage runtime

balancing

Spray

(units with spray

ducts)

Used to remotely authorise or prohibit the operation of the machine.

The machine is on when the contact is closed.

Used to turn on all the fans. The machine is in override mode when the

contact is closed.

Manual override can be activated and deactivated either directly on the unit or

remotely.

Used, for example, for summer/winter or day/night operation. Each circuit can

have up to two control setpoints. These setpoints can be switched via the dry

contact (On/Off), the console or over a BMS.

The running time of each fan stage is balanced by a time counter.

Used to increase the efficiency of the AeroConnect by spraying very fine

droplets of water into the ambient air to cool it through evaporation.

Two options:

- Optimised water consumption: the water spray does not start until all the

stages are on and the setpoint is exceeded.

- Optimised electricity consumption: the water spray does not come on until

the outdoor temperature reaches a preset value.

EN - 8

Board functions: descriptions (continued)

p

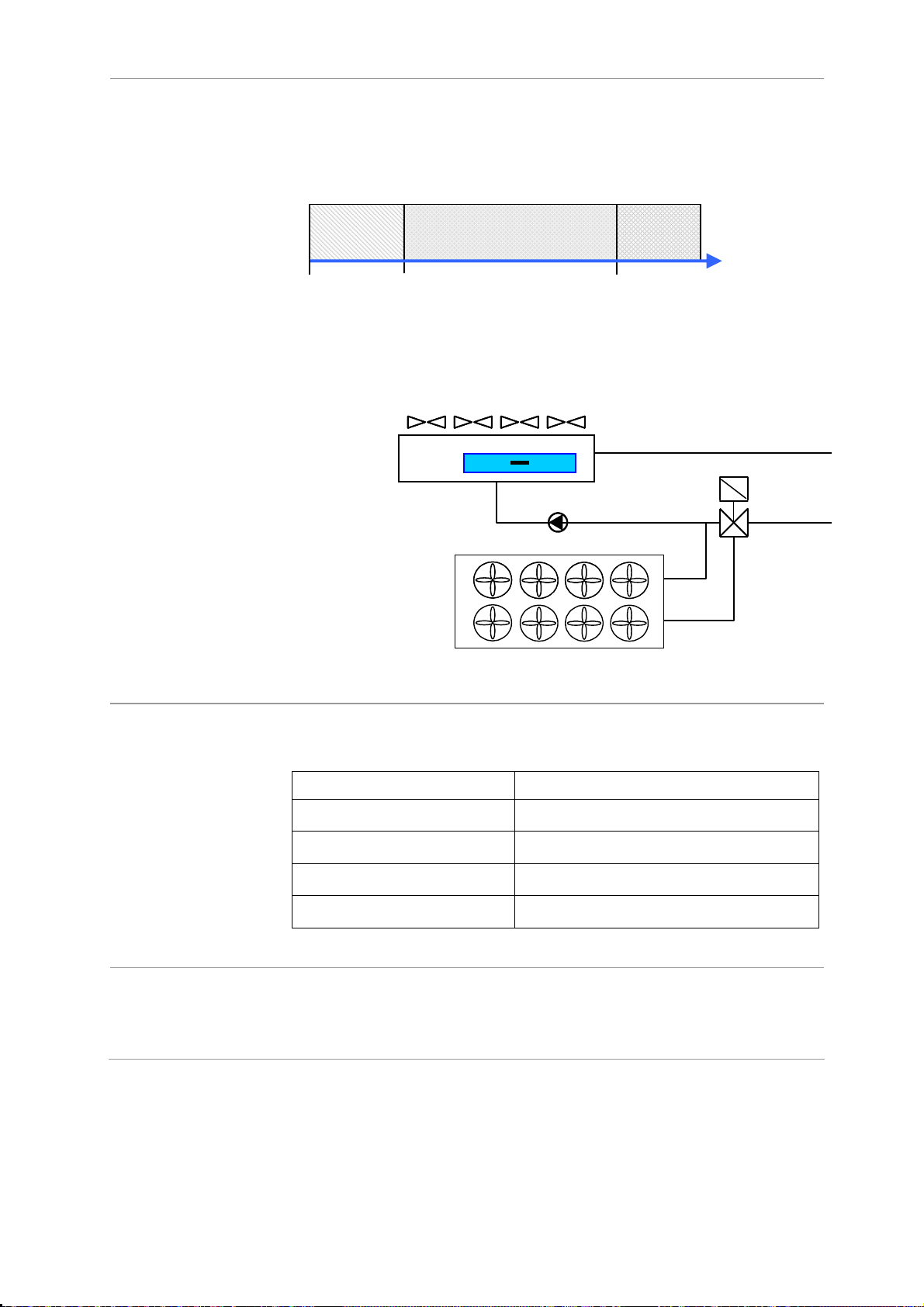

Free cooling

During free cooling, the dry cooler is run with a CIAT chiller. Both units are

controlled by the board.

The three-way valve can be controlled by the board provided the maximum

current is 3 A and the maximum voltage is 230 V. Refer to the chiller pump

curve to size the valve.

DC only

Chiller (CH)

Selection

temperature

P

CH only DRY COOLER + CHILLER

Process

return

tem

.

Text

Link with CIAT

chiller

BMS link

The following information is exchanged between the dry cooler (DC) or the

condenser (CO) and the chiller (CH):

CH > (DC / CO) (DC / CO) > CH

Dry cooler (DC)

• Chiller on/off • DC or CO on/off

• Setpoint (CO) • Free cooling

• Pressure value (CO) • Fan stage fault

With the exception of the language, control type (local, remote),

communication mode and bus number, all the parameters can be accessed

in read and write modes.

• Sensor fault

EN - 9

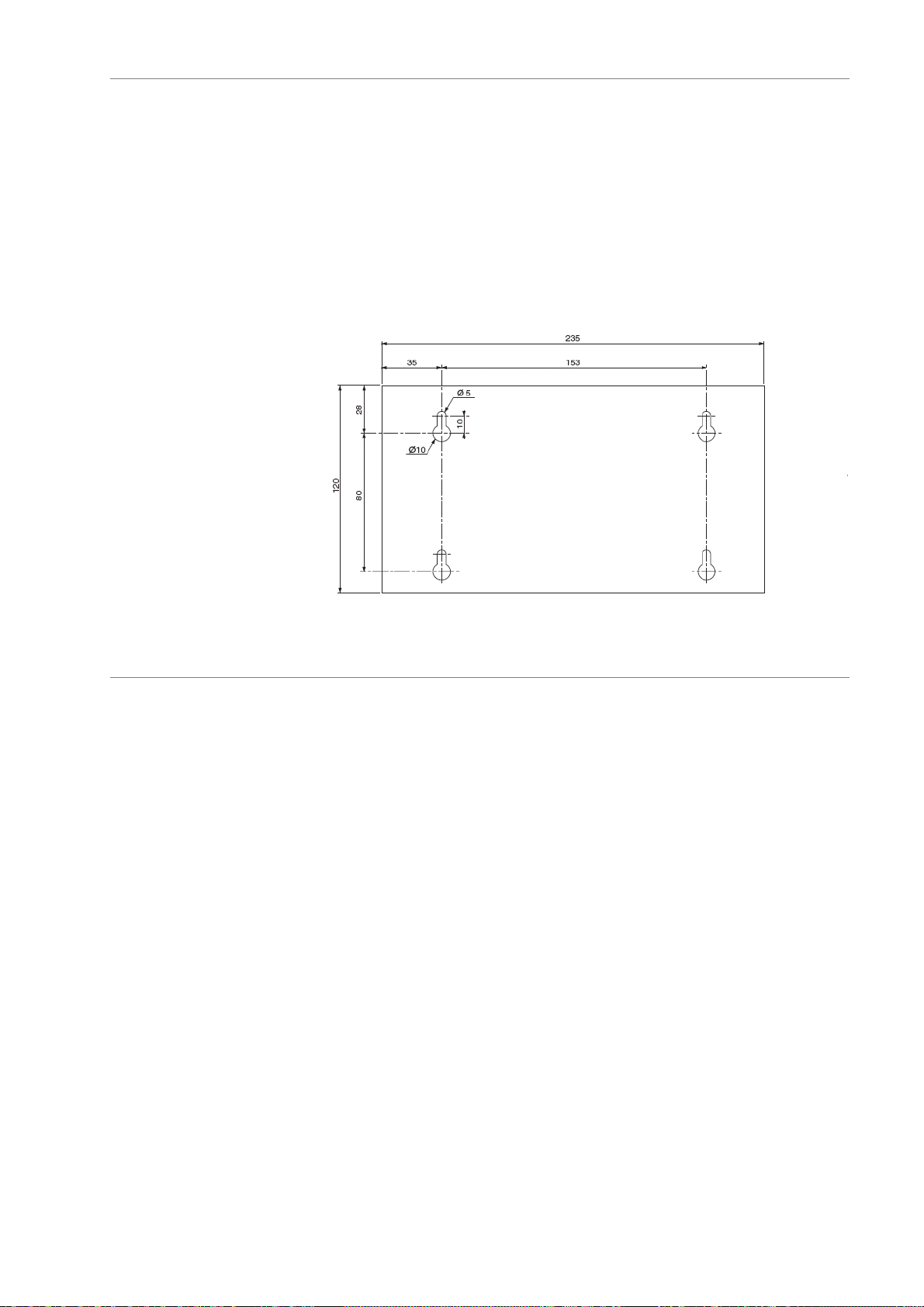

Options

Relay boards

Main board

Additional board

Remote control

console

Console mounting

dimensions (mm)

The boards must be installed in a cabinet.

It has dry contacts for displaying three parameters: unit operation, sensor faults

and fan stage faults.

For units with a motherboard and a daughterboard. It has dry contacts for

displaying two parameters: sensor faults and fan stage faults.

Used to view and control the operation of the unit from a distance.

Maximum distance of 1000 m.

Must be installed indoors.

Height = 55

Electrical connections

General

Communication bus

connection

On/Off input

connections

(automatic operation

control, manual override,

changeover of two

setpoints)

Analogue output

connections

Single-pair shielded cable required. Capacitance between wire and shield:

120 pF/m – Resistance of 56 Ω/km.

Examples: Filotex FMA 2P or Filotex IBM 7 362 211.

The shield must be connected at each end to the 0 V line (terminal 3 on J13 or

J12) on the units and the earth to the PLC end. The shielding braid must be as

short as possible (2 cm max.).

The cables must be routed at a distance of at least 30 cm from the power

cables. However, if a power cable intersects with a computer cable, they must

do so at a right angle.

For distances of less than 30 metres, use a shielded cable and keep it at least

30 cm away cm from all lines that could generate interference.

For distances of over 30 metres, install a relay for each input near the board.

Signal output of 0/10 V. Minimum VFD input impedance of 1 kΩ. Shielded cable

connections. Shield connected at both ends to earth. Minimum cross-section of

0.32 mm

2

(1.5 mm2 max.).

On/Off output

connections

(General operation signal,

general fault signal)

Potential-free dry contacts. Maximum current of 10 A (AC1 load), minimum of

5 mA. Voltage of 12 to 230 V AC. Maximum connection cross-section of

2.5 mm

2

.

EN - 10

Loading...

Loading...