Page 1

6121 Baker Road,

Suite 108

Minnetonka, MN 55345

www.chtechnology.com

Phone (952) 933-6190

Fax (952) 933-6223

1-800-274-4284

Thank you for downloading this document from C&H Technology, Inc.

Please contact the C&H Technology team for the following questions -

Technical

Application

Assembly

Availability

Pricing

Phone – 1-800-274-4284

E-Mail – sales@chtechnology.com

www.chtechnology.com - SPECIALISTS IN POWER ELECTRONIC COMPONENTS AND ASSEMBLIES - www.chtechnology.com

Page 2

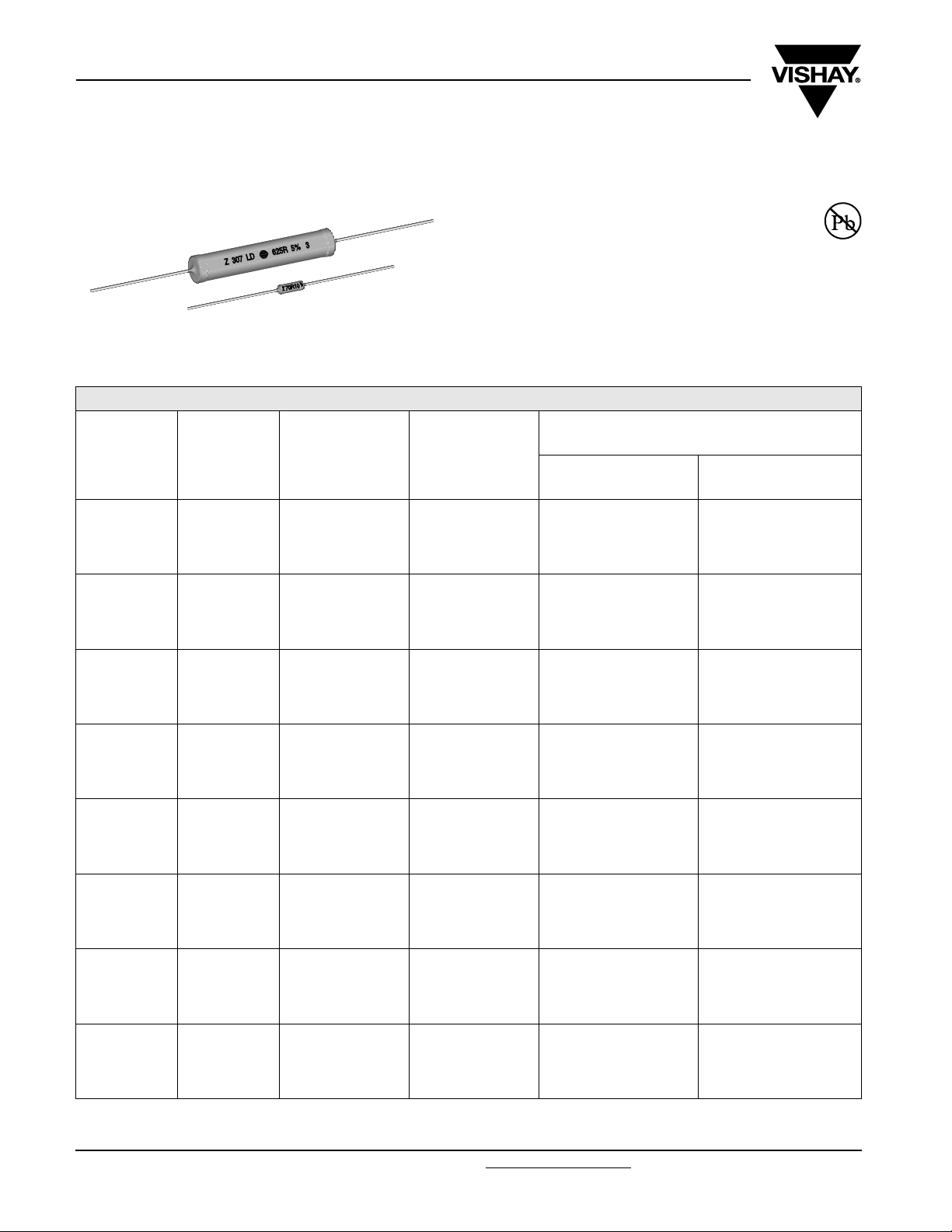

Z300

Vishay Draloric

Axial Cemented Wirewound Resistors

STANDARD ELECTRICAL SPECIFICATIONS

GLOBAL

MODEL

Z310309 Z301 1

ZDA0411 ZDA0411 2

ZDV0411 ZDV0411 2

Z320414 Z302 3

Z330617 Z303 4

Z350922 Z305 6

Z360933 Z306 8

Z370947 Z307 10

1)

Lower TCR or other power range on request

HISTORICAL

MODEL

POWER RATING

P

40 °C

W

FEATURES

• All welded construction

• Non flammable cement coating

• Ceramic core

• Various kinds of lead forming available

• Lead (Pb)-free

TOLERANCE

± %

10

5

2

1

10

5

2

1

10

5

2

1

10

5

2

1

10

5

2

1

10

5

2

1

10

5

2

1

10

5

2

1

RESISTANCE RANGE E12/E24

WM 50 (Class 1)

TCR -10...-80 ppm/K

R30 - 270R

R30 - 270R

-

-

R47 - 560R

R47 - 560R

on request

on request

R47 - 560R

R47 - 560R

on request

on request

R10 - 510R

R10 - 510R

R22 - 510R

1R0 - 510R

R10 - 1K0

R10 - 1K0

R10 - 1K0

1R0 - 1K0

R10 - 2K4

R10 - 2K4

R62 - 2K4

R62 - 2K4

R13 - 4K7

R13 - 4K7

1R0 - 4K7

2R2 - 4K7

R20 - 8K2

R20 - 8K2

1R8 - 8K2

3R3 - 8K2

1)

Ω

WM 110 (Class 3)

TCR 100...180 ppm/K

R68 - 2K0

R68 - 2K0

-

-

1R5 - 4K3

1R5 - 4K3

-

-

1R5 - 4K3

1R5 - 4K3

-

-

1R8 - 3K3

24R - 3K3

-

-

1R8 - 3K9

12R - 3K9

-

-

3R9 - 10K

10R - 10K

-

-

6R8 - 16K

6R8 - 16K

-

-

12R - 30K

12R - 30K

-

-

www.vishay.com For technical questions, contact: ww1resistors@vishay.com

106 Revision: 17-Apr-07

Document Number: 21007

Page 3

Z300

Axial Cemented Wirewound Resistors

Vishay Draloric

GLOBAL PART NUMBER INFORMATION

New Global Part Numbering: Z32041411509K2C000 (preferred part numbering format)

Z3 204141 1509K2C000

MODEL PACKAGINGTOLERANCE CODE

(see Standard

Electrical

Specifications table)

Historical Part Number example: Z32041411509K2C000 15 Ω 10 % WM50, ammo 53 mm, 500 pc (will continue to be accepted)

Z302

HISTORICAL MODEL TC / MATERIAL VALUE TOLERANCE CODE PACKAGING

TC/MATERIAL

1 =

-10...- 80 ppm/K

WM50

Class 1

3 =

100...180 ppm/K

WM110

Class 3

4 = SWI

(special

winding)

VALUE

3 digit value

1 digit multiplier

Multiplier:

F = *10

7 = *10

8 = *10

9 = *10

0 = *10

1 = *10

2 = *10

3

F = ± 1.0 %

G = ± 2.0 %

-4

-3

-2

-1

0

1

2

J = ± 5.0 %

K = ± 10.0 %

15 Ω 10 % AC

(see Packaging table)

The 5 digit BV number will

SPECIAL

be encoded using a 36

character code. This code

contains numbers 0...9

and letters A...Z (36

characters total and allows

to encode at least 46.655

five digit BV numbers.

000 = standard

PACKAGING TABLE

SAP

DRALORIC

LEGACY

21 A1 G53 Ammo pack tape 53 mm, 1000 pcs. Z301

DS RS G53 Reel pack tape 53 mm, 7500 pcs. Z301, Z302

D2 R2 G53 Reel pack tape 53 mm, 2000 pcs. Z301, Z302

6C AC G83 Ammo pack tape 83 mm, 500 pcs. Z302, Z303

H1 R1 G83 Reel pack tape 83 mm, 1000 pcs. Z302, Z303

2C AC G53 Ammo pack tape 53 mm, 500 pcs. Z302, Z303

JS RS 108 Reel pack tape 108 mm, 7500 pcs. Z302

HS RS G83 Reel pack tape 83 mm, 7500 pcs. Z302

4C AC G73 Ammo pack tape 73 mm, 500 pcs. Z302

D1 R1 G53 Reel pack tape 53 mm, 1000 pcs. Z303

6B AB G83 Ammo pack tape 83 mm, 250 pcs. Z305, Z306

41 A1 G73 Ammo pack tape 73 mm, 1000 pcs. ZDA0411

F2 R2 G73 Reel pack tape 73 mm, 2000 pcs. ZDA0411

40 A2 G73 Ammo pack tape 73 mm, 2000 pcs. ZDV0411

HC RC G83 Reel pack tape 83 mm, 500 pcs. Z305, Z306

LC LC loose PKG, 500 pcs. Z302, Z303

LJ LJ loose PKG, 200 pcs. Z307

L1 L1 loose PKG, 1000 pcs. ZL302

24 A4 G53 Ammo pack tape 53 mm, 4000 pcs. Z302

6A A4 G83 Ammo pack tape 83 mm, 100 pcs. Z305

25 A4 G63 Ammo pack tape 63 mm, 4000 pcs. Z302

Document Number: 21007 For technical questions, contact: ww1resistors@vishay.com

Revision: 17-Apr-07 107

PACKAGING

2 digits

www.vishay.com

Page 4

Z300

Vishay Draloric

Axial Cemented Wirewound Resistors

DIMENSIONS

G

B

For packaging dimensions see appropriate catalog or web page.

MODEL

A

max

B

max

Z301 8.5 [0.355] 3 [0.118] 0.7 [0.027] 53 ± 1 [2.087 ± 0.039] 0.5

ZDA0411 11 [0.433] 4 [0.157] 0.7 [0.027] 53 ± 1 [2.087 ± 0.039 0.8

Z302 13 [0.512] 4.8 [0.189] 0.8 [0.031] 53 ± 1 [2.087 ± 0.039] 1.1

Z303 15.8 [0.622] 5.5 [0.217] 0.8 [0.031] 53 ± 1 [2.087 ± 0.039] 1.4

Z305 22.3 [0.878] 8.7 [0.343] 0.8 [0.031] 83 ± 1 [3.268 ± 0.039] 3.7

Z306 32.3 [1.272] 8.7 [0.343] 0.8 [0.031] 83 ± 1 [3.268 ± 0.039] 5

Z307 49.8 [1.961 9 [0.354] 0.8 [0.031] 120 ± 2 [4.724 ± 0.079] 7

A

C

DIMENSIONS in millimeters [inches]

C

max

GWeight (g)

DIMENSIONS ZDV0411

Δh

P

P

2

Ø 4 max.

“Z”

1 max.

H

1

H

0

H

L

P

1

d

F

P

0

W

2

W

W

0

1

D

0

t

For body dimensions, see dimensions table above, model ZDA0411.

Area “Z”

a

1

R

d

d

1

2

R

R

a

2

R

d1 / d2 = 35 ... 45°

/ a2 = < 1.25

a

1

1) Test over 10 holes - 9 intervals P0 12 × 9 = 114.3 ± 0.5

2) Parallelism, < 0.5 mm

3) Thickness of carrier tape: 0.55 mm ± 0.1

1

W

DIMENSIONS (in millimeters) TOL.

Lead Ø d 0.6

Pitch of components P 12.7 ± 1.0

Pitch of sprocket holes

Distance between hole

center and resistor center

Distance between hole

center and lead center

1)

P

0

P

1

P

2

12.7 ± 0.3

3.85 ± 0.7

6.35 ± 0.7

Lead spacing F 5 + 0.6, - 0.1

Angle of Insertion Δh1 2 max. -

Width of carrier tape W 18.0 + 1, - 0.5

Width of adhesive tape

Position of holes

Position of adhesive tape

W

0

W

1

W

2

12.0 ± 0.5

9 + 0.75, - 0.5

0.5 + 0, - 0.5

Body to hole center H 16.0 ± 0.5

Lead crimp to hole center

Hole Ø

Thickness of tape

3)

H

0

D

0

t 0.9 max. -

19.5 ± 1.0

4.0 ± 0.2

2)

Height of cutting L 11 max. -

Height of insertion

H

32.3 max. -

1

www.vishay.com For technical questions, contact: ww1resistors@vishay.com Document Number: 21007

108 Revision: 17-Apr-07

Page 5

Z300

120

100

80

60

40

RATED POWER IN %

20

0

- 55

Derating

300

200

Axial Cemented Wirewound Resistors

300

200

100

TEMPERATURE RISE IN °C

50

40

150 250 350

AMBIENT TEMPERATURE IN °C

0

0

0.4

Vishay Draloric

ZDA 1041

Z301

0.8 1.2

1.6

POWER IN W

2.0

Temperature Rise

300

Z302

Z303

Z305

200

Z306

Z307

100

TEMPERATURE RISE IN °C

0

0 1 2 3 4 5

POWER IN W

Temperature Rise

100

TEMPERATURE RISE IN °C

0

0

2

Temperature Rise

4

PERFORMANCE

TEST TEST RESULTS

Damp Heat, Steady State 56 days ± 3 % ΔR

Climatic Sequence ± 3 % ΔR

Load Life 5000 h ± 3 % ΔR

Short Time Overload, 5 x rated power x 5 sec ± 1 % ΔR

Vibration ± 1 % ΔR

Shock ± 1 % ΔR

Resistance to Soldering Heat ± 1 % ΔR

6 8

POWER IN W

10

Document Number: 21007 For technical questions, contact: ww1resistors@vishay.com

www.vishay.com

Revision: 17-Apr-07 109

Loading...

Loading...