Page 1

6121 Baker Road,

Suite 108

Minnetonka, MN 55345

www.chtechnology.com

Phone (952) 933-6190

Fax (952) 933-6223

1-800-274-4284

Thank you for downloading this document from C&H Technology, Inc.

Please contact the C&H Technology team for the following questions -

Technical

Application

Assembly

Availability

Pricing

Phone – 1-800-274-4284

E-Mail – sales@chtechnology.com

www.chtechnology.com - SPECIALISTS IN POWER ELECTRONIC COMPONENTS AND ASSEMBLIES - www.chtechnology.com

Page 2

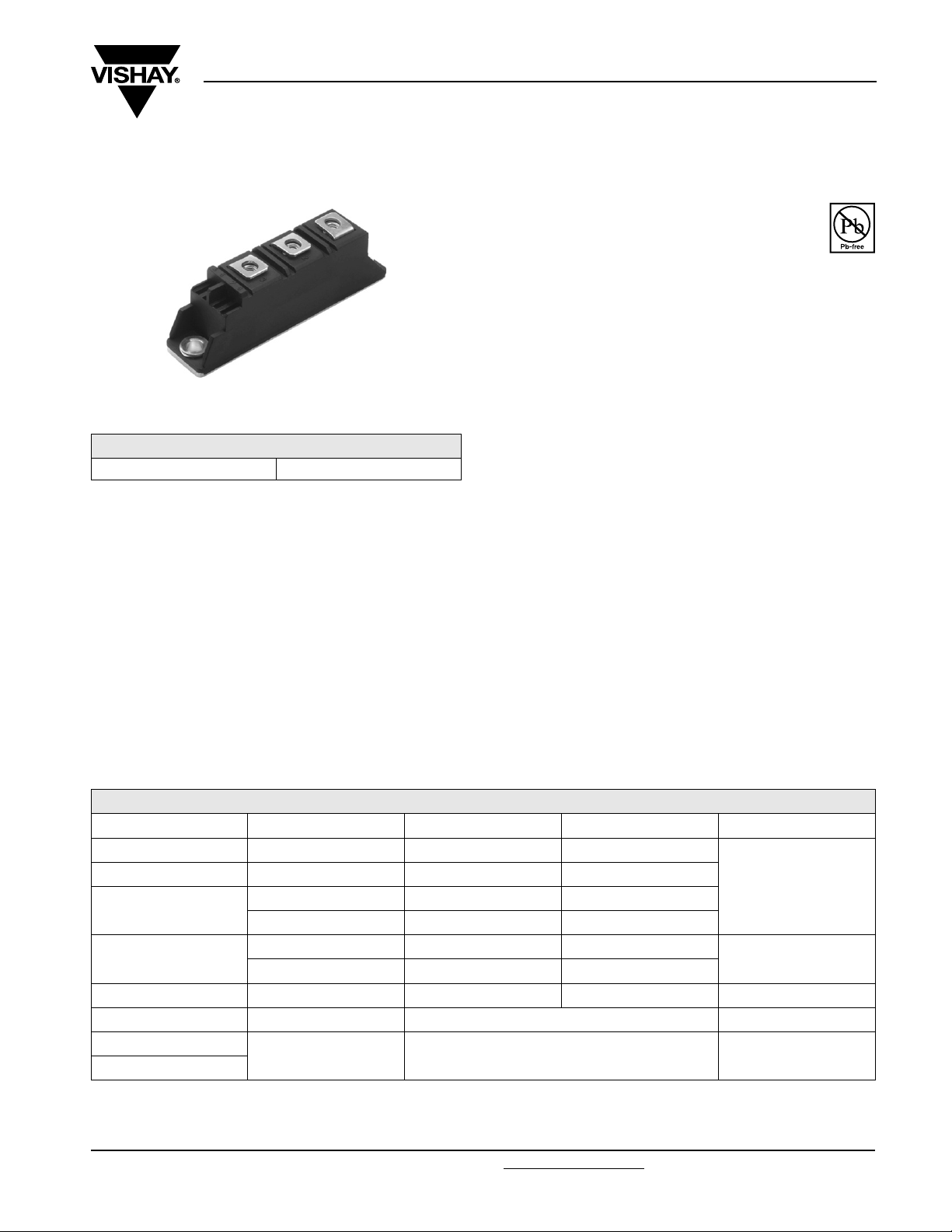

Thyristor/Diode and Thyristor/Thyristor

(ADD-A-PAK

VSK.41, .56..PbF Series

Vishay High Power Products

TM

Generation 5 Power Modules), 45/60 A

FEATURES

• High voltage

ADD-A-PAK

TM

PRODUCT SUMMARY

I

T(AV)

or I

F(AV)

45/60 A

MECHANICAL DESCRIPTION

The Generation 5 of ADD-A-PAKTM modules combine the

excellent thermal performance obtained by the usage of

Direct Bonded Copper substrate with superior mechanical

ruggedness, thanks to the insertion of a solid copper

baseplate at the bottom side of the device. The Cu baseplate

allows an easier mounting on the majority of heatsink with

increased tolerance of surface roughness and improved

thermal spread. The Generation 5 of AAP modules is

manufactured without hard mold, eliminating in this way any

possible direct stress on the leads.

The electrical terminals are secured against axial pull-out:

they are fixed to the module housing via a click-stop feature

already tested and proved as reliable on other Vishay HPP

modules.

• Industrial standard package

• Thick copper baseplate

RoHS

COMPLIANT

• UL E78996 approved

• 3500 V

isolating voltage

RMS

• Totally lead (Pb)-free

• Designed and qualified for industrial level

BENEFITS

• Up to 1600 V

• Fully compatible TO-240AA

• High surge capability

• Easy mounting on heatsink

DBC insulator

•Al

203

• Heatsink grounded

ELECTRICAL DESCRIPTION

These modules are intended for general purpose high

voltage applications such as high voltage regulated power

supplies, lighting circuits, temperature and motor speed

control circuits, UPS and battery charger.

MAJOR RATINGS AND CHARACTERISTICS

SYMBOL CHARACTERISTICS VSK.41 VSK.56 UNITS

or I

I

T(AV)

F(AV)

I

O(RMS)

I

TSM,

I

FSM

2

I

t

2

I

√t 36.1 85.0 kA2√s

V

RRM

T

Stg

T

J

Document Number: 94419 For technical questions, contact: ind-modules@vishay.com

Revision: 23-Apr-08 1

85 °C 45 60

As AC switch 100 135

50 Hz 850 1310

60 Hz 890 1370

50 Hz 3.61 8.50

60 Hz 3.30 7.82

Range 400 to 1600 V

- 40 to 125 °C

kA2s

www.vishay.com

A

Page 3

VSK.41, .56..PbF Series

Vishay High Power Products

Thyristor/Diode and Thyristor/Thyristor

(ADD-A-PAKTM Generation 5 Power Modules),

45/60 A

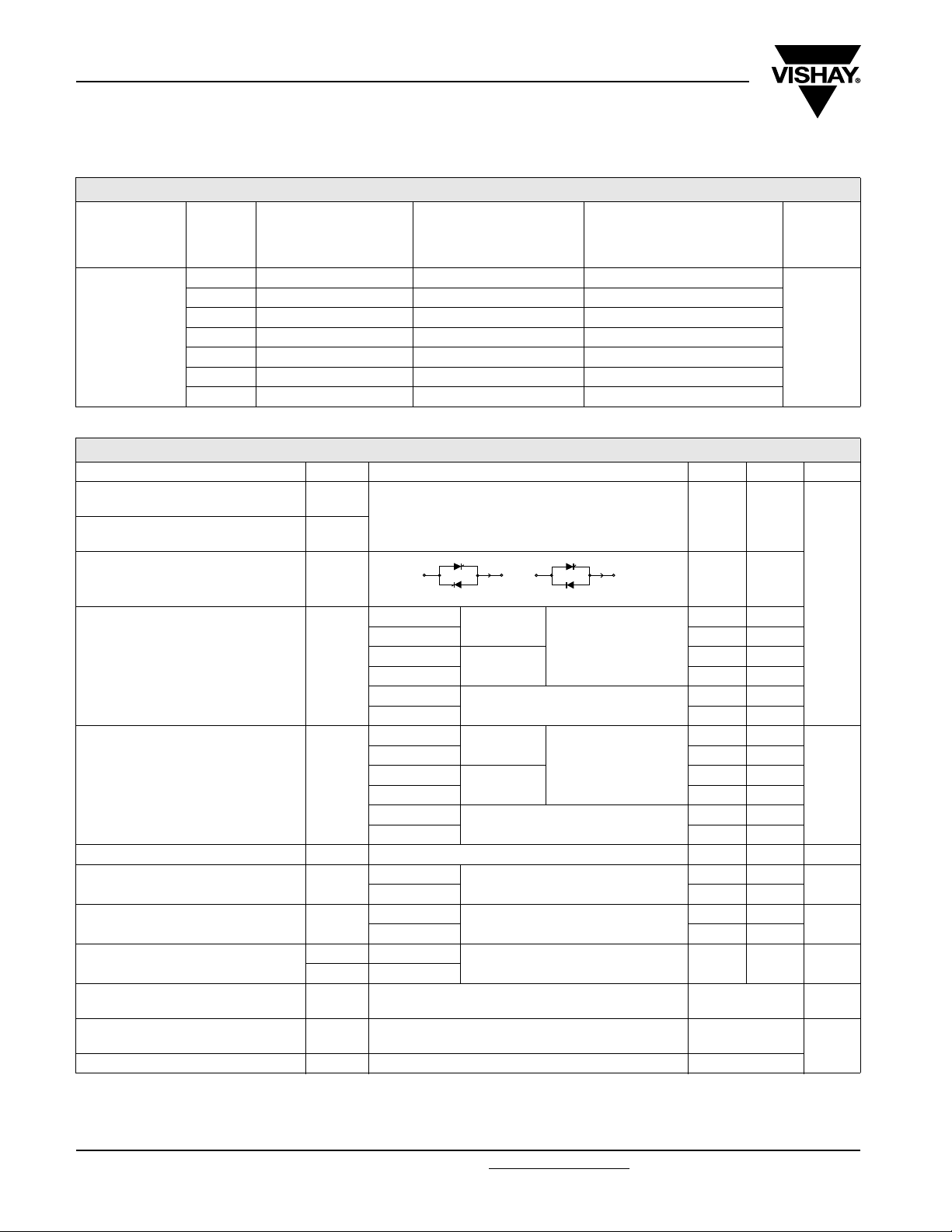

ELECTRICAL SPECIFICATIONS

VOLTAGE RATINGS

V

, MAXIMUM

RRM

REPETITIVE PEAK

REVERSE VOLTAGE

TYPE NUMBER

VOLTAGE

CODE

V

04 400 500 400

06 600 700 600

08 800 900 800

VSK.41/.56

10 1000 1100 1000

12 1200 1300 1200

14 1400 1500 1400

16 1600 1700 1600

ON-STATE CONDUCTION

PARAMETER SYMBOL TEST CONDITIONS VSK.41 VSK.56 UNITS

Maximum average on-state current

(thyristors)

Maximum average forward current

(diodes)

I

T(AV)

I

F(AV)

180° conduction, half sine wave,

T

= 85 °C

C

V

, MAXIMUM

RSM

NON-REPETITIVE PEAK

REVERSE VOLTAGE

V

V

, MAXIMUM REPETITIVE

DRM

PEAK OFF-STATE VOLTAGE,

GATE OPEN CIRCUIT

V

45 60

I

RRM,

I

DRM

AT 125 °C

mA

15

Maximum continuous RMS

on-state current, as AC switch

I

O(RMS)

Maximum peak, one-cycle

non-repetitive on-state

or forward current

Maximum I

Maximum I

Maximum value or threshold voltage V

2

t for fusing I2t

2

√t for fusing I2√t

T(TO)

Maximum value of on-state

slope resistance

Maximum peak on-state or

forward voltage

Maximum non-repetitive rate of

rise of turned on current

Maximum holding current I

Maximum latching current I

I

TSM

or

I

FSM

(2)

r

t

V

TM

V

FM

dI/dt

H

L

t = 10 ms

t = 8.3 ms 890 1370

t = 10 ms

t = 8.3 ms 750 1150

t = 10 ms

t = 8.3 ms 985 1520

t = 10 ms

t = 8.3 ms 3.30 7.82

t = 10 ms

t = 8.3 ms 2.33 5.53

t = 10 ms

t = 8.3 ms 4.03 9.60

(1)

t = 0.1 to 10 ms, no voltage reapplied 36.1 85.6 kA2√s

(2)

Low level

High level

Low level

High level

ITM = π x I

IFM = π x I

T

J

I

TM

(3)

(4)

(3)

(4)

T(AV)

F(AV)

= 25 °C, from 0.67 V

= π x I

, Ig = 500 mA, tr < 0.5 µs, tp > 6 µs

T(AV)

TJ = 25 °C, anode supply = 6 V,

resistive load, gate open circuit

TJ = 25 °C, anode supply = 6 V, resistive load 400

or

I

(RMS)

No voltage

reapplied

100 % V

reapplied

T

= 25 °C

J

RRM

Sinusoidal

half wave,

initial T

= TJ maximum

J

I

(RMS)

100 135

850 1310

715 1100

940 1450

no voltage reapplied

No voltage

reapplied

100 % V

RRM

Initial T

= TJ maximum

J

reapplied

T

= 25 °C, no voltage reapplied

J

TJ = TJ maximum

TJ = TJ maximum

3.61 8.56

2.56 6.05

4.42 10.05

0.88 0.85

0.91 0.88

5.90 3.53

5.74 3.41

kA

mΩ

TJ = 25 °C 1.81 1.54 V

,

DRM

150 A/µs

200

mA

A

2

s

V

Notes

(1)I2

t for time tx = I2√t x √t

(2)

Average power = V

T(TO)

x

x I

+ rt x (I

T(AV)

T(RMS)

2

)

(3)

16.7 % x π x IAV < I < π x I

(4)

I > π x I

AV

AV

www.vishay.com For technical questions, contact: ind-modules@vishay.com

Document Number: 94419

2 Revision: 23-Apr-08

Page 4

VSK.41, .56..PbF Series

Thyristor/Diode and Thyristor/Thyristor

Vishay High Power Products

(ADD-A-PAKTM Generation 5 Power Modules),

45/60 A

TRIGGERING

PARAMETER SYMBOL TEST CONDITIONS VSK.41 VSK.56 UNITS

Maximum peak gate power P

Maximum average gate power P

Maximum peak gate current I

Maximum peak negative gate voltage - V

GM

G(AV)

GM

GM

TJ = - 40 °C

Maximum gate voltage required to trigger V

GT

T

= 25 °C 2.5

J

= 125 °C 1.7

T

J

Anode supply = 6 V

resistive load

TJ = - 40 °C

Maximum gate current required to trigger I

Maximum gate voltage that will not trigger V

Maximum gate current that will not trigger I

GT

GD

J

T

J

TJ = 125 °C, rated V

GD

TJ = 125 °C, rated V

= 25 °C 150

= 125 °C 80

Anode supply = 6 V

resistive load

applied 0.25 V

DRM

applied 6 mA

DRM

BLOCKING

PARAMETER SYMBOL TEST CONDITIONS VSK.41 VSK.56 UNITS

Maximum peak reverse and off-state

leakage current at V

RRM

, V

DRM

RMS insulation voltage V

Maximum critical rate of rise of off-state voltage dV/dt

Note

(1)

Available with dV/dt = 1000 V/ms, to complete code add S90 i.e. VSKT41/16AS90

I

RRM,

I

DRM

TJ = 125 °C, gate open circuit 15 mA

50 Hz, circuit to base, all terminals shorted

INS

(1)

TJ = 125 °C, linear to 0.67 V

DRM

10

2.5

2.5 A

10

4.0

270

2500 (1 min)

3500 (1 s)

500 V/µs

W

V

mAT

V

THERMAL AND MECHANICAL SPECIFICATIONS

PARAMETER SYMBOL TEST CONDITIONS VSK.41 VSK.56 UNITS

Junction operating and storage

temperature range

Maximum internal thermal resistance,

junction to case per module

Typical thermal resistance, case to heatsink R

to heatsink

Mounting torque ± 10 %

busbar 3

Approximate weight

T

, T

J

Stg

R

thJC

thCS

DC operation 0.23 0.20

Mounting surface flat, smooth and greased 0.1

A mounting compound is recommended and the

torque should be rechecked after a period of 3

- 40 to 125 °C

K/W

5

Nm

hours to allow for the spread of the compound.

110 g

4oz.

Case style JEDEC TO-240AA

ΔR CONDUCTION PER JUNCTION

DEVICES

VSK.41 0.11 0.13 0.17 0.23 0.34 0.09 0.14 0.18 0.23 0.34

VSK.56 0.09 0.11 0.13 0.18 0.27 0.07 0.11 0.14 0.19 0.28

Note

• Table shows the increment of thermal resistance R

Document Number: 94419 For technical questions, contact: ind-modules@vishay.com

Revision: 23-Apr-08 3

SINE HALF WAVE CONDUCTION RECTANGULAR WAVE CONDUCTION

180° 120° 90° 60° 30° 180° 120° 90° 60° 30°

when devices operate at different conduction angles than DC

thJC

www.vishay.com

UNITS

°C/W

Page 5

VSK.41, .56..PbF Series

Vishay High Power Products

130

120

110

100

90

80

Maximum Allow able Case Tempera ture (°C)

0 1020304050

Fig. 1 - Current Ratings Characteristics

130

120

110

100

90

80

Maximum Allowable Case Temperature (°C)

020406080

VSK.41.. Seri e s

R (DC) = 0.46 K/W

thJC

Conduction Angle

30°

60°

90°

120°

180°

Average On-state Current (A)

VSK.41.. Se ries

R ( DC ) = 0.46 K/ W

thJC

Cond uct ion Period

30°

60°

90°

120°

180°

DC

Avera ge On-state Current (A)

Thyristor/Diode and Thyristor/Thyristor

(ADD-A-PAKTM Generation 5 Power Modules),

45/60 A

100

DC

180°

80

120°

90°

60°

30°

60

40

20

0

Maximum Average On-state Power Loss (W)

0 20406080

Average On-state Current (A)

Fig. 4 - On-State Power Loss Characteristics

800

At Any Rat ed Loa d Condition And With

Rated V Applied Following Surge .

RRM

700

600

500

400

VSK.41.. Serie s

Pe r J u n ct io n

300

Peak Half Sine Wave On-state Current (A)

110100

Numb er Of Equ al Am plit ude Half Cy cle Current Pulses (N)

Conduction Period

VSK.41.. Se ries

Pe r Ju nc t io n

T = 1 25 °C

J

Init ial T = 125°C

@ 60 Hz 0. 0083 s

@ 50 Hz 0. 0100 s

RM S Li m it

J

Fig. 2 - Current Ratings Characteristics

70

180°

60

120°

50

40

30

20

10

Maximum Average On-sta te Power Loss (W)

90°

60°

30°

0

01020304050

Average On-state Current (A)

RM S Li m i t

Cond uctio n Angle

VSK.41.. Se ries

Per Junction

T = 125°C

J

Fig. 3 - On-State Power Loss Characteristics

Fig. 5 - Maximum Non-Repetitive Surge Current

900

Maximum Non Repetitive Surge Current

Ve rsus Pul se Tra in Dura t io n. Co ntro l

Of Conduc tion May Not Be Maintained.

800

700

600

500

400

VSK.41.. Series

Per Junc tion

Pe a k Ha lf Si ne Wa v e On -st a t e C u r re n t ( A)

300

0.01 0.1 1

Pulse Train Duration (s)

Init ia l TJ = 125°C

No Voltage Reapplied

Ra t e d V

Re a p p l i ed

RRM

Fig. 6 - Maximum Non-Repetitive Surge Current

www.vishay.com For technical questions, contact: ind-modules@vishay.com

Document Number: 94419

4 Revision: 23-Apr-08

Page 6

VSK.41, .56..PbF Series

Thyristor/Diode and Thyristor/Thyristor

(ADD-A-PAKTM Generation 5 Power Modules),

45/60 A

140

120

100

80

60

Conduction Angle

40

20

Maximum Total On-state Power Loss (W)

0

020

To t a l R M S Outp ut Curre nt ( A)

350

300

250

200

150

100

50

Maximum Total Pow er Loss (W)

0

0 20406080100

Total Output Current (A)

180°

120°

90°

60°

30°

VSK.41.. Se rie s

Pe r M o d ule

T = 12 5° C

J

40

60

80

1

K

/

W

1

.

5

K

/

W

2

K

/

W

3

K

/

W

5

K

/

W

020406080100120140

100

0

.

0

5

.

7

K

K

/

W

/

W

Maximum Allowable Ambient Temperature (°C)

Fig. 7 - On-State Power Loss Characteristics

R

0

t

.

h

2

S

K

A

/

W

=

0

.

1

K

/

180°

(Sine)

180°

(Rec t)

2 x VSK.41.. Series

Single Phase Brid ge

0

.

3

K

/

W

0

.

5

K

/

W

0

.

7

K

/

W

1

K

/

W

1

.

5

K

/

W

Connected

T = 1 25 °C

J

020406080100120140

Maximum Allowable Ambient Temperature (°C)

Fig. 8 - On-State Power Loss Characteristics

Vishay High Power Products

0

.

3

R

K

t

/

h

W

S

A

=

0

.

1

K

/

W

D

e

l

t

a

R

W

D

e

l

t

a

R

500

450

400

350

300

250

120°

(Rec t)

200

150

100

Maximum Tota l Power Loss (W)

50

0

0 20406080100120140

3 x VSK.41.. Serie s

Three Phase Bridge

Connec t ed

T = 1 25 ° C

J

Total Output Current (A)

0

0 20406080100120140

Maximum Allowable Ambient Temperature (°C)

R

t

h

S

A

=

0.2 K/

0

.

3

K

0

.

5

K

/

.

7

K

/

1

K

/

W

0

.

1

W

/

W

W

W

K/

W

D

e

l

t

a

R

Fig. 9 - On-State Power Loss Characteristics

Document Number: 94419 For technical questions, contact: ind-modules@vishay.com

www.vishay.com

Revision: 23-Apr-08 5

Page 7

VSK.41, .56..PbF Series

Vishay High Power Products

130

120

110

100

90

80

70

Maximum Allowable Case Temperature (°C)

0 10203040506070

Fig. 10 - Current Ratings Characteristics

130

120

110

100

90

80

70

Maximum Allowable Case Temperature (°C)

020406080100

Fig. 11 - Current Ratings Characteristics

VSK.56.. Se ries

R (DC ) = 0.40 K/ W

thJC

Cond uction Angle

30°

60°

90°

120°

Average On-state Current (A)

VSK.56.. Series

R ( DC) = 0.40 K/W

thJC

Conduction Period

90°

60°

30°

Average On-state Current (A)

120°

180°

Thyristor/Diode and Thyristor/Thyristor

(ADD-A-PAKTM Generation 5 Power Modules),

45/60 A

180°

DC

120

100

80

60

40

20

Maximum Average On-sta te Power Loss (W)

Fig. 13 - On-State Power Loss Characteristics

1200

1100

1000

900

800

700

600

Peak Half Sine Wave On-stat e Current (A)

500

Numb er Of Equal Amplitude Ha lf Cycle Current Pulses (N)

Fig. 14 - Maximum Non-Repetitive Surge Current

DC

180°

120°

90°

60°

30°

RM S Li m it

0

020406080100

Average On-state Current (A)

At Any Ra ted Loa d Condition And With

Rated V Applied Following Surge.

RRM

VSK.56.. Serie s

Pe r J u n ct io n

110100

Conduc tion Period

VSK.56.. Se rie s

Pe r Ju n c t io n

T = 1 25 °C

J

Init ial T = 125° C

J

@ 6 0 H z 0 . 0 08 3 s

@ 5 0 H z 0 . 0 10 0 s

90

80

70

60

50

40

30

20

10

0

Maximum Avera ge On -st at e Power Loss ( W)

180°

120°

90°

60°

30°

RM S Li m i t

Conduc tion Ang le

VSK.56.. Se rie s

Per Junction

T = 125°C

J

0 102030405060

Average On-state Current (A)

Fig. 12 - On-State Power Loss Characteristics

1400

Maximum Non Repetitive Surge Current

Ve rsus Pul se Tra in Dura t io n. Co nt rol

Of C ond uctio n Ma y Not Be Ma int a ine d .

1200

1000

800

600

VSK.56.. Series

Peak Half Sine Wave On-state Current (A)

Pe r J un c t io n

400

0.01 0.1 1

Pulse Train Duration (s)

Initia l T = 125°C

No Voltage Reapplied

Ra t e d V

Reapplied

RRM

J

Fig. 15 - Maximum Non-Repetitive Surge Current

www.vishay.com For technical questions, contact: ind-modules@vishay.com

Document Number: 94419

6 Revision: 23-Apr-08

Page 8

VSK.41, .56..PbF Series

Thyristor/Diode and Thyristor/Thyristor

(ADD-A-PAKTM Generation 5 Power Modules),

45/60 A

200

180

160

140

180°

120°

90°

60°

30°

120

100

80

Cond uction Ang le

60

40

20

Maximum To tal On-st at e Power Loss (W)

0

0 20406080100120140

VSK.56.. Ser ie s

Pe r M o du le

T = 125°C

J

Total RMS Output Current (A)

Fig. 16 - On-State Power Loss Characteristics

450

400

350

300

250

200

180°

(Sine)

180°

(Rec t)

150

100

Maximum Total Powe r Loss (W)

50

0

0 20406080100120140

2 x VSK.56.. Serie s

Single Phase Bridge

Connected

T = 1 2 5° C

J

Total Output Current (A)

Fig. 17 - On-State Power Loss Characteristics

0

.

3

K

0

.

4

K

/

W

0

.

5

K

/

W

0

.

7

K

/

W

1

K

/

W

1

.

5

K

/

W

2

K

/

W

4

K

/

W

0 204060 80100120140

Maximum Allowable Ambient Temperature (°C)

0

.

2

K

/

W

0

.

3

K

/

W

0

.

5

K

/

W

0

.

7

K

/

W

1

K

/

W

2

K

/

W

0 20 40 60 80 100 120 140

Maximum Allowable Ambient Temperature (°C)

R

0

.

2

t

h

K

/

W

S

/

A

W

=

R

t

h

S

A

=

0

.

1

K

/

W

D

e

l

t

Vishay High Power Products

0

.

1

K

/

W

D

e

l

t

a

R

a

R

600

R

t

h

S

500

400

120°

300

200

100

Maximum Tot al Pow er Lo ss (W)

0

0 20 40 60 80 100120140160180

(Rec t)

3 x VSK.56.. Serie s

Th re e Ph ase Brid g e

Connected

T = 12 5° C

J

Total Output Current (A)

A

=

0

.

1

0

.

2

K

0

.

3

K

/W

0

.

5

K

0

.

7

K

/

1

K

/

W

K

/

W

/

W

/

W

W

D

e

l

t

a

R

0 20 40 60 80 100 120 140

Maximum Allowable Ambient Temperature (°C)

Fig. 18 - On-State Power Loss Characteristics

Document Number: 94419 For technical questions, contact: ind-modules@vishay.com

www.vishay.com

Revision: 23-Apr-08 7

Page 9

VSK.41, .56..PbF Series

Vishay High Power Products

1000

100

T = 2 5° C

J

10

Instantaneous On-state Current (A)

1

01234567

Instantaneous On-state Voltage (V)

Fig. 19 - On-State Voltage Drop Characteristics

1000

100

10

Insta ntaneous On-state Current (A)

1

0.5 1 1.5 2 2.5 3 3.5 4 4.5

Instantaneous On-state Voltage (V)

Fig. 20 - On-State Voltage Drop Characteristics

T = 1 25 ° C

J

T = 2 5° C

J

T = 1 25 ° C

J

VSK.41.. Se ries

Per Junction

VSK.56.. Se ries

Pe r Ju nc t io n

Thyristor/Diode and Thyristor/Thyristor

(ADD-A-PAKTM Generation 5 Power Modules),

45/60 A

500

VSK.41.. Se rie s

VSK.56.. Se rie s

450

T = 1 25 ° C

J

400

350

300

250

200

150

100

10 20 30 40 50 60 70 80 90 100

Maxim um Rev e rse Rec ov e ry Ch arg e - Q rr (µC )

Rate Of Fall Of On-state Current - di/dt (A/µs)

Fig. 21 - Recovery Charge Characteristics

110

100

90

80

70

60

50

40

30

Maximum Re verse Recovery Current - Irr (A)

10 20 30 40 50 60 70 80 90 100

Rate Of Fa ll Of Forward Current - di/dt (A/ µs)

Fig. 22 - Recovery Current Characteristics

I = 200 A

TM

I = 2 00 A

TM

VSK.41.. Se ries

VSK.56.. Se ries

T = 125 °C

J

100 A

50 A

20 A

10 A

100 A

50 A

20 A

10 A

1

Steady State Value:

R = 0. 46 K/ W

thJC

Tr a n si e n t Th e rm a l Im p e d a n c e Z ( K / W )

thJC

R = 0. 40 K/ W

thJC

(DC Operation)

0.1

0.0 1

0.001 0.01 0.1 1 10

Sq ua re Wa v e Pulse Du ra t io n (s)

Fig. 23 - Thermal Impedance Z

VSK.41.. Se ries

VSK.56.. Se ries

Characteristics

thJC

Pe r Ju nc t io n

www.vishay.com For technical questions, contact: ind-modules@vishay.com

Document Number: 94419

8 Revision: 23-Apr-08

Page 10

VSK.41, .56..PbF Series

Thyristor/Diode and Thyristor/Thyristor

(ADD-A-PAKTM Generation 5 Power Modules),

100

Rectangular gat e p ulse

a)Recommended load line for

rated di/ dt: 20 V, 30 ohms

tr = 0.5 µs, tp >= 6 µs

b)Rec ommended load line for

<= 30% rated di/dt: 20 V, 65 ohms

10

tr = 1 µs, tp >= 6 µs

1

Instantaneous Gate Voltage (V)

ORDERING INFORMATION TABLE

Device code

VGD

IGD

0.1

0.001 0.01 0.1 1 10 100 1000

VSK T 56 / 16 S90 P

45/60 A

(a)

(b)

TJ = - 4 0 °C

TJ = 2 5 ° C

TJ = 12 5 °C

VSK.41../ .56.. Se rie s

Inst a nt a neo us Ga t e C urre nt (A)

Fig. 24 - Gate Characteristics

Vishay High Power Products

(1) PGM = 100 W, tp = 500 µs

(2) PGM = 50 W, tp = 1 ms

(3) PGM = 20 W, tp = 25 ms

(4) PGM = 10 W, tp = 5 ms

(4)

Fr e q u e nc y Li m it e d b y PG ( AV )

(2) (1)

(3)

1 - Module type

2 - Circuit configuration (see end of datasheet)

3 - Current code

4 - Voltage code (see Voltage Ratings table)

5 - dV/dt code: S90 = dV/dt 1000 V/µs

6 - P = Lead (Pb)-free

(1)

Available with no auxiliary cathode

(for details see dimensions - link at the end of datasheet)

To specify change: 41 to 42

56 to 57

e.g.: VSKT57/16P etc.

Note

• To order the optional hardware go to www.vishay.com/doc?95172

51324

(1)

No letter = dV/dt 500 V/µs

6

Document Number: 94419 For technical questions, contact: ind-modules@vishay.com

www.vishay.com

Revision: 23-Apr-08 9

Page 11

VSK.41, .56..PbF Series

Vishay High Power Products

Thyristor/Diode and Thyristor/Thyristor

(ADD-A-PAKTM Generation 5 Power Modules),

45/60 A

CIRCUIT CONFIGURATION

VSKT

1

45 76

2

3

(1)

~

+

(2)

-

(3)

G1

(4)K1(5)K2(7)G2(6)

1

45

(1)

~

G1

(4)K1(5)

(2)

(3)

+

-

2

3

VSKLVSKH

(1)

~

1

(2)

(3)

+

-

K2

(7)G2(6)

2

3

76

LINKS TO RELATED DOCUMENTS

Dimensions http://www.vishay.com/doc?95085

VSKN

1

2

3

45

G1

(4)K1(5)

(1)

(3)

(2)

-

+

+

www.vishay.com For technical questions, contact: ind-modules@vishay.com

Document Number: 94419

10 Revision: 23-Apr-08

Page 12

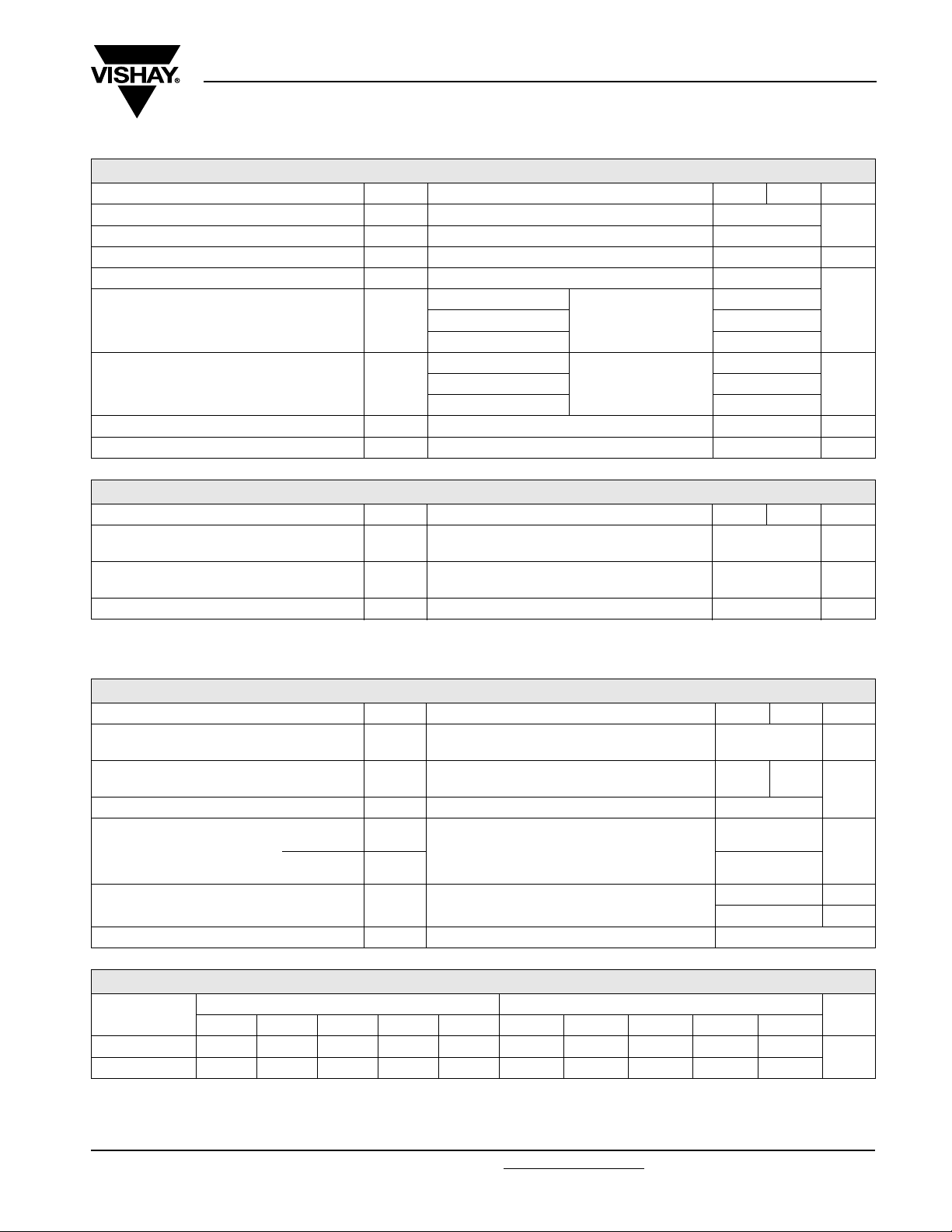

DIMENSIONS in millimeters (inches)

Outline Dimensions

Vishay High Power Products

ADD-A-PAK Thyristor

Faston tab 2.8 x 0.8 (0.110 x 0.03)

35 REF.

21 ± 0.75

Screws M5 x 0.8

30 ± 0.5

29 ± 0.5

(1 ± 0.0197)

(1.18 ± 0.0197)

(0.8 ± 0.02953)

15 ± 0.5 (0.59 ± 0.0197)

6.2 (2 x) ± 0.2 (0.2 ± 0.0079)

Viti M5 x 0.8

80 ± 0.3 (3.15 ± 0.0118)

1

20 ± 0.5 (0.79 ± 0.0197)

92 ± 0.75 (3.6 ± 0.02953)

15.6 ± 0.5

(0.6 ± 0.0197)

18 (0.7) REF.

2

20 ± 0.5 (0.79 ± 0.0197)

3

45 76

6.3 ± 0.3 (0.2 ± 0.0118)

24 ± 0.5

(1 ± 0.0197)

30 ± 1 (1.18 ± 0.039)

Detail Z

With no auxiliary cathode

46

45 76

13.8 (0.54)

4 ± 0.2

(0.2 ± 0.0079)

13.8 REF.

Document Number: 95087 For technical questions concerning discrete products, contact: diodes-tech@vishay.com

Revision: 03-Aug-07 For technical questions concerning module products, contact: ind-modules@vishay.com

5.8 ± 0.25

(0.2 ± 0.00984)

www.vishay.com

1

Loading...

Loading...