C&H Technology VS230DM16CCB User Manual

6121 Baker Road,

Suite 108

Minnetonka, MN 55345

www.chtechnology.com

Phone (952) 933-6190

Fax (952) 933-6223

1-800-274-4284

Thank you for downloading this document from C&H Technology, Inc.

Please contact the C&H Technology team for the following questions -

Technical

Application

Assembly

Availability

Pricing

Phone – 1-800-274-4284

E-Mail – sales@chtechnology.com

www.chtechnology.com - SPECIALISTS IN POWER ELECTRONIC COMPONENTS AND ASSEMBLIES - www.chtechnology.com

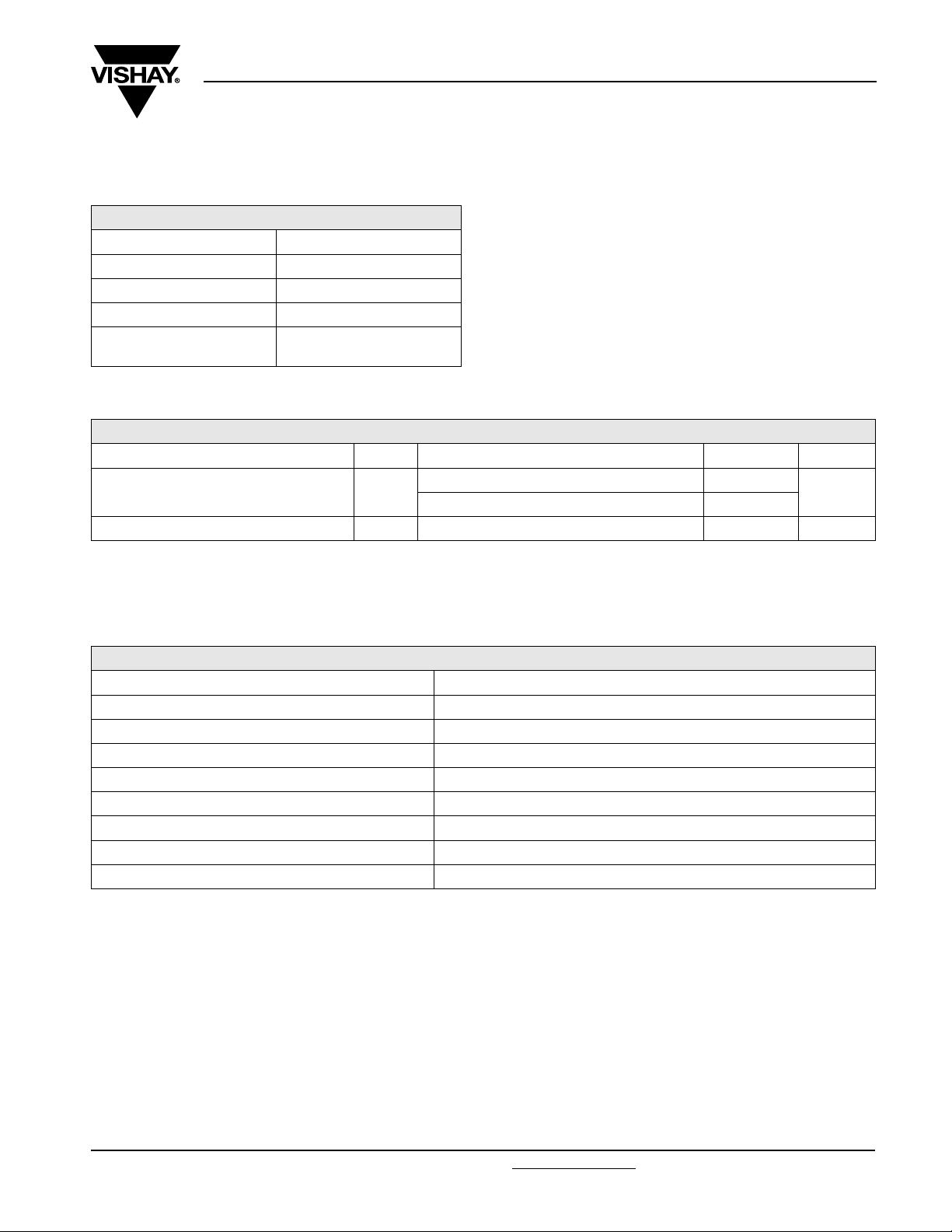

Vishay High Power Products

Standard Recovery Diodes

VS230DM16CCB

PRODUCT SUMMARY

Junction size Square 230 mils

Wafer size 4"

class 1600 V

V

RRM

Passivation process Glassivated MOAT

Reference Vishay HPP

packaged part

40EPS Series

FEATURES

• 100 % tested at probe

• Bondable top metal

• Wafer in box, and die in chip carrier

MAJOR RATINGS AND CHARACTERISTICS

PARAMETER SYMBOL TEST CONDITIONS VALUES UNITS

Maximum forward voltage V

Maximum repetitive reverse voltage V

Notes

(1)

Nitrogen flow on die edge

(2)

Wafer and die probe test clamped at 1200 V to limit arcing. 1600 V BV testable only in encapsulated packages

RRM

TJ = 25 °C, IF = 20 A 1.05

FM

T

= 25 °C, IF = 40 A 1.20

J

(1)

TJ = 25 °C, I

= 100 µA 1600

RRM

(2)

RoHS

COMPLIANT

V

V

MECHANICAL DATA

Nominal back metal composition (thickness) Cr-Ni-Ag (1 kÅ - 4 kÅ - 6 kÅ)

Nominal front metal composition (thickness) 100 % Al (20 µm)

Chip dimensions 230 x 230 mils - see dimensions (link at the end of datasheet)

Wafer diameter 100 mm, with standard < 110 > flat

Wafer thickness 330 µm ± 10 µm

Maximum width of sawing line 45 µm

Reject ink dot size Ø 0.25 mm minimum

Ink dot location See dimensions (link at the end of datasheet)

Recommended storage environment Storage in original container, in desiccated nitrogen, with no contamination

Document Number: 93833 For technical questions, contact: die-wafer@vishay.com

Revision: 31-Mar-08 1

www.vishay.com

Loading...

Loading...