Page 1

6121 Baker Road,

Suite 108

Minnetonka, MN 55345

www.chtechnology.com

Phone (952) 933-6190

Fax (952) 933-6223

1-800-274-4284

Thank you for downloading this document from C&H Technology, Inc.

Please contact the C&H Technology team for the following questions -

Technical

Application

Assembly

Availability

Pricing

Phone – 1-800-274-4284

E-Mail – sales@chtechnology.com

www.chtechnology.com - SPECIALISTS IN POWER ELECTRONIC COMPONENTS AND ASSEMBLIES - www.chtechnology.com

Page 2

RWM

Vishay Sfernice

Enamelled Wirewound Power Resistors

Axial Leads

FEATURES

• High dissipation up to 30 W (25 °C)

• Fire Proof

• Excellent Endurance typical drift ± 1.5 % after

1000 h

• Conformal Vitreous Enamel

• All Welded Construction

• Low ohmic values 0.1 Ω available

• Termination: Sn/Ag/Cu

RoHS

COMPLIANT

As a result of more than 50 years of experience and

continuous improvements the RWM Series of resistors

features proven reliability in AC or DC applications.

The high quality of the RWM resides mainly in the use of a

proprietary VISHAY SFERNICE enamel fired at high

temperature and free from any compound liable to corrode

the resistive wire.

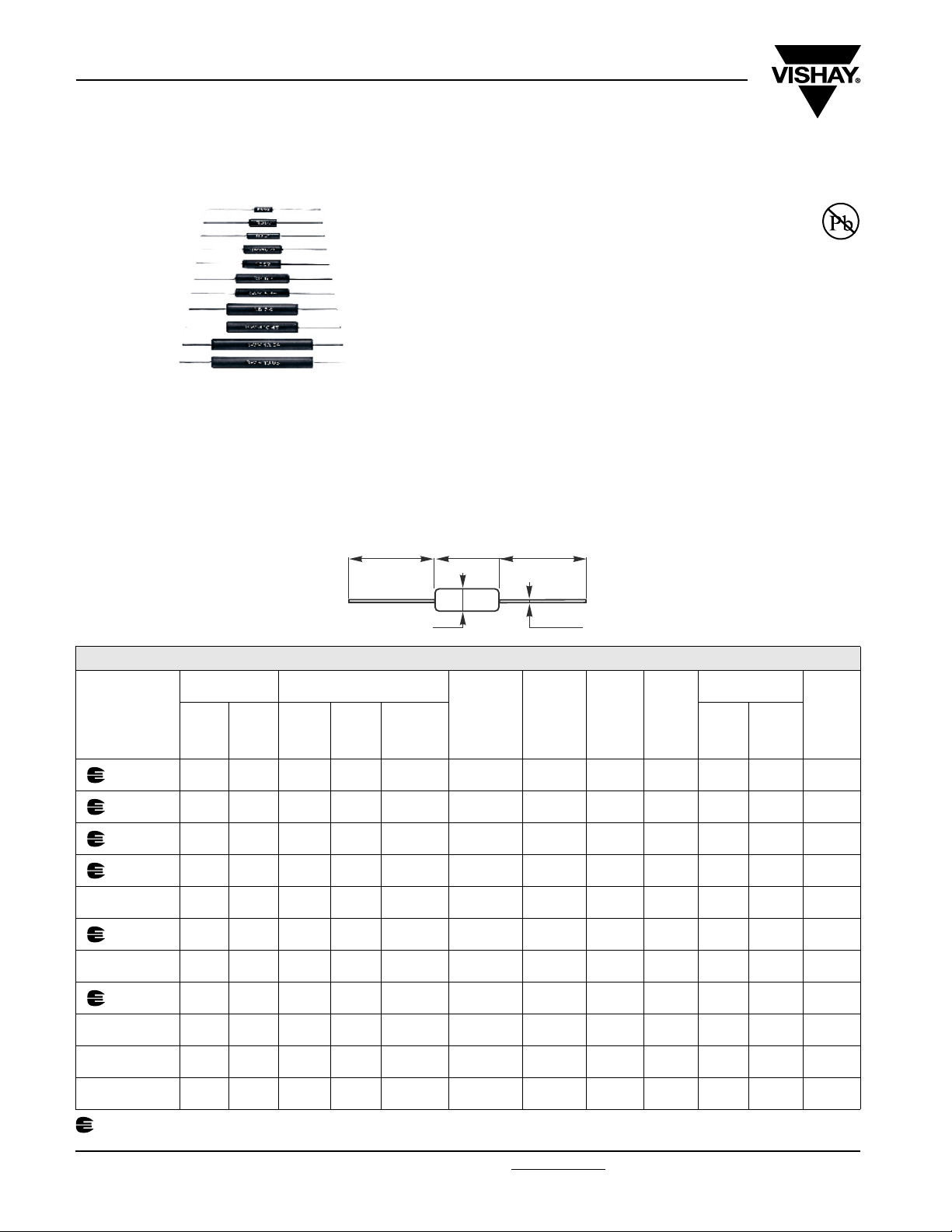

DIMENSIONS in millimeters

25 min. A 25 min.

TECHNICAL SPECIFICATIONS

DESIGNATIONS POWER RATING

VISHAY

SFERNICE

STYLES

RWM 4 x 10 RB59 JB 2.6 W 3 W 5.5 W

RWM 4 x 22 RB61 HB 4.5 W 5 W 7 W

RWM 5 x 26 RB57 - 6 W 7 W 10 W

RWM 6 x 22 RB57 KB 6 W 7 W 10 W

RWM 8 x 26 RB60 - 7 W 8 W 10 W

RWM 6 x 34 RB60 LB 7 W 8 W 12 W

RWM 8 x 34 RB58 - 9.5 W 11 W 14 W

RWM 8 x 45 RB58 MB 9.5 W 11 W 20 W

RWM 10 x 45 - - 21 W 25 W 25 W

RWM 10 x 64 - - 21 W 25 W 25 W

RWM 10 x 65 - - 25.8 W 30 W 30 W

Undergoes European Quality Insurance System (CECC)

CECC

40201

-001

CECC

40201

-002

at

+ 70 °C

at

+ 25 °C

With

Surface

Temp.

≤ + 450 °C

The performance of this series of professional resistors fully

meets the requirements of the following specifications:

– NF C 83-210-001

– CECC 40201-001

– BS - CECC 40201-002

Ø 0.8 ± 0.1 Ø B

Ohmic

Range in

Relation to

Tolerance

± 5 %

E24 Series

0.1 Ω

10 kΩ

0.1 Ω

16 kΩ

0.1 Ω

27 kΩ

0.1 Ω

39 kΩ

0.1 Ω

27 kΩ

0.33 Ω

36 kΩ

0.33 Ω

36 kΩ

0.47 Ω

62 kΩ

0.47 Ω

62 kΩ

0.68 Ω

100 kΩ

0.68 Ω

100 kΩ

Qualified

Ohmic

Range

NF C

83-210

0.1 Ω

10 kΩ

0.1 Ω

6.8 kΩ

0.15 Ω

10 kΩ

0.15 Ω

39 kΩ

0.33 Ω

15 kΩ

0.47 Ω

33 kΩ

Limiting

Element

Voltage

120 V 4.8 kΩ 12

300 V - 22.1

350 V 18.8 kΩ 24.7

350 V 17.5 kΩ 18

- 500 V - 24.7

500 V 31 kΩ 33.7

- 650 V - 33.7

650 V 38 kΩ 45.8

- 800 V 25.6 kΩ 45.8

- 800 V 25.6 kΩ 63.8

- 800 V 21.3 kΩ 63.8

Critical

Resis-

tance

DIMENSIONS

IN mm

A Ø B

± 1

5.5

± 1

5.5

± 1

7.4

± 1

6.5

± 1

7.4

± 1

7.4

± 1

7.4

± 2

9.4

± 2

9.4

± 1

9.4

± 1

9.4

± 1

± 1

± 1.5

± 1

± 1.5

± 1.5

± 1.5

± 1.5

± 1.5

± 1.5

± 1.5

WEIGH T

IN g

1

2

3

2.2

3

4

4

8

8

14

14

www.vishay.com For technical questions, contact: sfer@vishay.com Document Number: 50008

38 Revision: 11-Dec-06

Page 3

RWM

Enamelled Wirewound Power Rsistors

Vishay Sfernice

Axial Leads

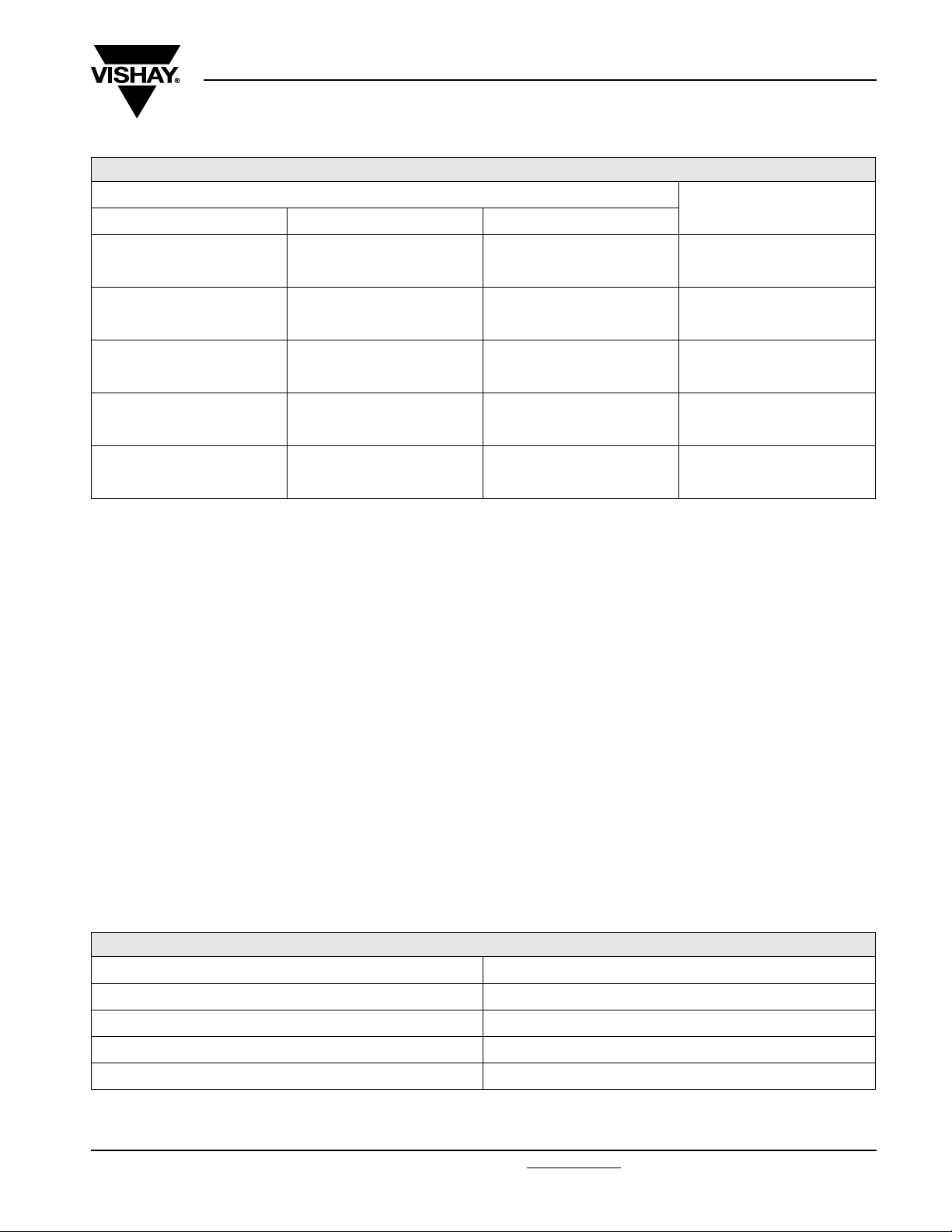

PERFORMANCE

CECC 40201 - EN 140-201

TESTS CONDITIONS REQUIREMENTS

Short Time Overload

Temperature Cycling - 55 °C + 200 °C ± (1 % + 0.05 Ω) ± (0.5 % + 0.05 Ω)

Humidity (Steady State)

Terminal Strength

Load Life

10 Pr during 10 s

25 °C ambient

56 days

40 °C Ambient - R.H. 95 %

Tensile test: 20 N

2 successive bending

2 full rotations of 180°

1000 h at Pr

90/30 Cycle

25 °C ambient

± (2 % + 0.1 Ω) ± (0.5 % + 0.05 Ω)

± (5 % + 0.1 Ω) ± (0.5 % + 0.05 Ω)

± (1 % + 0.05 Ω) ± (0.1 % + 0.05 Ω)

± (5 % + 0.1 Ω) ± (1.5 % + 0.05 Ω)

OVERLOAD

Heavy overloads can be endured in the form of short pulses < 0.1 s. Particular requirements should be submitted to Vishay

Sfernice, specifying peak voltage, cycle and environmental conditions.

TYPICAL DRIFTS

RECOMMENDATIONS FOR USE

Since these components are high dissipation power resistors, customers are advised to use a high melting point solder.

For low ohmic values, the measurement becomes critical and the connecting wires resistance is to be included. The value is

measured at 5 mm from the resistor body.

Group Mounting

In a still atmosphere, a distance between axes equal to five times the resistor’s diameter is recommended.

Cabinet Mounting

• Unventilated box: dissipation should be reduced (see dimensional drawing).

• Forced ventilation: if conditions are appropriate, dissipation may be doubled or even trebled.

• In any case: the surface temperature at the hottest point should not exceed 450 °C.

These aspects should be considered by the end user.

ELECTRICAL SPECIFICATIONS

Tolerance Standard ± 5 %

On request ± 1 % to ± 10 %

Temperature Coefficient + 75 ppm/°C typical

Dielectric Withstanding Voltage NF EN 140000 500 VRMS - 1 minute - 10 mA

Inductance non inductive (Ayrton-Perry) winding available

Document Number: 50008 For technical questions, contact: sfer@vishay.com

Revision: 11-Dec-06 39

www.vishay.com

Page 4

RWM

Vishay Sfernice

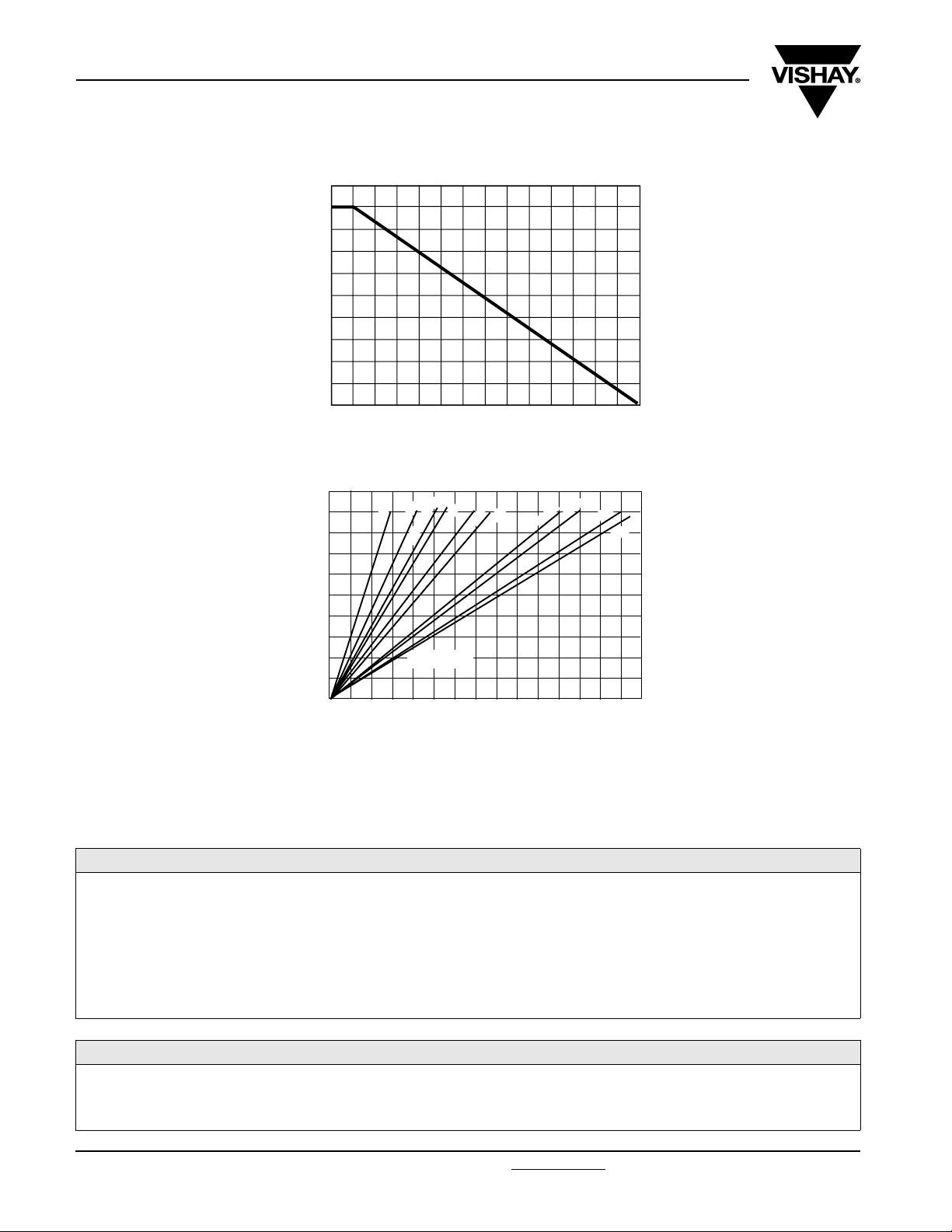

POWER RATING CHART

116

100

REWOP DETAR %

75

50

25

0

TYPICAL TEMPERATURE RISE

C ° N I E R

400

U

T

300

A R E P M E T

Enamelled Wirewound Power Resistors

Axial Leads

25 100 200 300 350

0

IENT TEMPERATURE IN °C

AMB

5 4

x

46 x

0 1

4 x 10

4 x 22

5 x 26 - 6 x 22

8 x 26

6 x 34

8 x 34

8 x 45

01

5

6 x

0 1

T O P S

200

T

O

H

100

0

0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30

Optional

RATED POWER IN WATTS

MARKING

Sfernice trademark, model and style, CECC style, if applicable (except for the smallest model due to lack of space: (4 x 10 or

RB 59), ohmic value, resistance tolerance, manufacturing date (year - month).

ORDERING INFORMATION

RWM 4 x 10 XXX 150U ± 5 % AM500 e1

MODEL STYLE NI OPTIONAL

Non Inductive

Winding

SPECIAL

DESIGN

Method N°

Optional

OHMIC VALUE

Custom items

are subject to

extra charge and

min. order.

TOLERANCE PACKAGING LEAD

(Pb)-FREE

Please see price list.

SAP PART NUMBERING GUIDELINES

RWM 0410 1500 J A20 E1

MODEL STYLE OHMIC VALUE TOLERANCE PACKAGING LEAD (Pb)-FREE

www.vishay.com For technical questions, contact: sfer@vishay.com Document Number: 50008

40 Revision: 11-Dec-06

Loading...

Loading...